Page 1

SUMMIT MICROELECTRONICS, Inc. • 300 Orchard City Drive, Suite 131 • Campbell, CA 95008 • Telephone 408-378-6461 • Fax 408-378-6586 • www.summitmicro.com

1

© SUMMIT MICROELECTRONICS, Inc. 2000

2011 2.0 5/2/00

Characteristics subject to change without notice

SUMMIT

MICROELECTRONICS, Inc.

FEATURES

• Precision Supply Voltage Monitor

— Dual reset outputs for complex

microcontroller systems

— Integrated memory write lockout

• Guaranteed RESET (RESET#) assertion

to VCC=1V

• Power-Fail Accuracy Guaranteed

• No External Components

• 3 and 5 Volt system versions

• Low Power CMOS

— Active current less than 3mA

— Standby current less than 25µA

• Memory Internally Organized 512 X 8

— Two Wire Serial Interface (I2C™)

– Bidirectional data transfer protocol

– Standard 100KHz and Fast 400KHz

Precision RESET Controller and 4K I2C Memory

With Both RESET and

RESETRESET

RESETRESET

RESET Outputs

S24042/S24043

• High Reliability

— Endurance: 100,000 erase/write cycles

— Data retention: 100 years

• 8-Pin PDIP or SOIC Packages

OVERVIEW

The S24042 and S24043 are power supervisory devices

with 4,096 bits of serial E

2

PROM. They are fabricated

using SUMMIT’s advanced CMOS E2PROM technology

and are suitable for both 3 and 5 volt systems.

The memory is internally organized as 512 x 8. It features

the I2C serial interface and software protocol allowing

operation on a simple two-wire bus.

The S24042 provides a precision VCC sense circuit and

two open drain outputs: one (RESET) drives high and the

other (RESET#) drives low whenever VCC falls below

V

TRIP

. The S24043 is identical to the S24042 with the

exception being RESET is not bonded out on pin 7.

BLOCK DIAGRAM

3 and 5 Volt Systems

+

–

GND

V

CC

RESET#

V

TRIP

RESET

PULSE

GENERATOR

5kHz

OSCILLATOR

RESET

CONTROL

MODE

DECODE

ADDRESS

DECODER

WRITE

CONTROL

DATA I/O

E2PROM

MEMORY

ARRAY

RESET

1.26V

SCL

6

SDA

5

2

7

22

2011 T-BD 1.0

4

Page 2

2

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

RESET #- RESET# is an active low open drain output.

It is driven low whenever VCC is below V

TRIP

. It is also

an input and can be used to debounce a switch input or

perform signal conditioning. The pin has an internal pullup and should be left unconnected if the signal is not used

in the system. However, when the pin is tied to a system

RESET# line an external pull-up resistor should be

employed.

RESET - RESET is an active high open drain output. It is

driven high whenever VCC is below V

TRIP

. RESET is also

an input and can be used to debounce a switch input or

perform signal conditioning. The RESET pin does have

an internal pull-down and should be left unconnected if

the signal is not used in the system. However, when the

pin is tied to a system reset line an external pull-down

resistor should be employed.

ENDURANCE AND DATA RETENTION

The S24042/43 is designed for applications requiring

100,000 erase/write cycles and unlimited read cycles. It

provides 100 years of secure data retention, with or

without power applied, after the execution of 100,000

erase/write cycles.

APPLICATIONS

Reset Controller Description

The S24042/43 provides a precision RESET controller

that ensures correct system operation during brown-out

and power-up/-down conditions. It is configured with two

open drain RESET outputs; pin 7 is an active high output

and pin 2 is an active low output.

During power-up, the RESET outputs remain active until

VCC reaches the V

TRIP

threshold and will continue driving

the outputs for approximately 200ms after reaching

V

TRIP

. The RESET outputs will be valid so long as VCC is

> 1.0V. During power-down, the RESET outputs will

begin driving active when VCC falls below V

TRIP

.

The RESET pins are I/Os; therefore, the S24042/43 can

act as a signal conditioning circuit for an externally

applied reset. The inputs are edge triggered; that is, the

RESET input will initiate a reset timeout after detecting a

low to high transition and the RESET# input will initiate a

reset timeout after detecting a high to low transition. Refer

to the applications Information section for more details on

device operation as a reset conditioning circuit.

PIN DESCRIPTIONS

Serial Clock (SCL) - The SCL input is used to clock data

into and out of the device. In the WRITE mode, data must

remain stable while SCL is HIGH. In the READ mode, data

is clocked out on the falling edge of SCL.

Serial Data (SDA) - The SDA pin is a bidirectional pin

used to transfer data into and out of the device. Data may

change only when SCL is LOW, except START and STOP

conditions. It is an open-drain output and may be wireORed with any number of open-drain or open-collector

outputs.

No Connects (NC) the no connect pins may be left

floating or tied to ground. They cannot be tied high.

PIN NAMES

SD A Serial Data I/O

S C L Serial Clock Input

RESET & RESET# Reset Output

V

SS

Ground

V

CC

Supply Voltage

N C No Connect

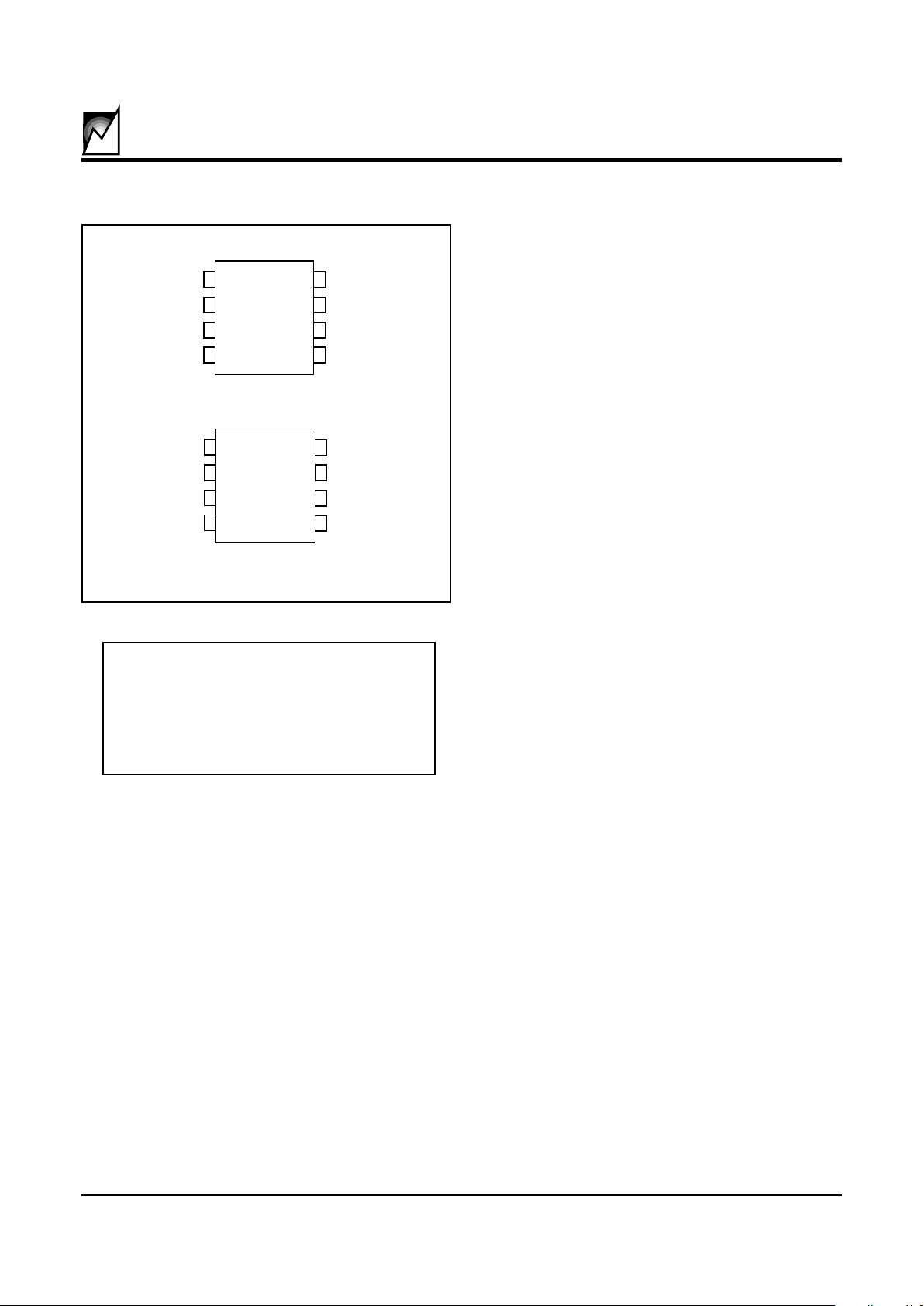

PIN CONFIGURATIONS

8

7

6

5

1

2

3

4

NC

RESET#

NC

V

SS

V

CC

NC

SCL

SDA

NC

RESET#

NC

V

SS

V

CC

RESET

SCL

SDA

8

7

6

5

1

2

3

4

S24043

S24042

2011 PCon 2.0

Page 3

S24042/S24043

3

2011 2.0 5/2/00

SUMMIT MICROELECTRONICS, Inc.

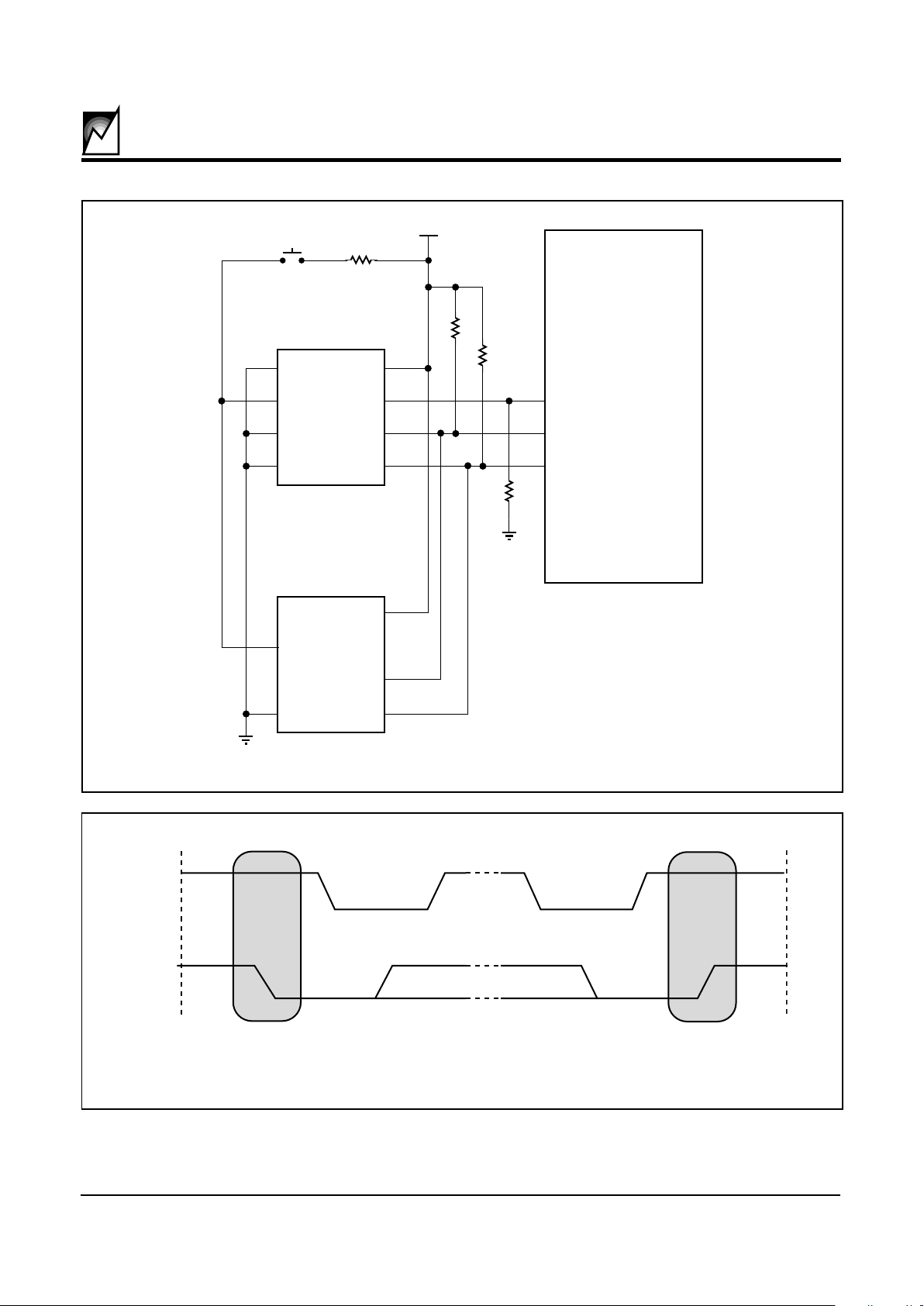

FIGURE 1. TYPICAL SYSTEM CONFIGURATION FOR DUAL RESET

FIGURE 2. START AND STOP CONDITIONS

SCL

SDA In

START

Condition

STOP

Condition

2011 ILL5 1.0

RESET

SCL

SDA

SCL

Vss

VCC = 3.0 0r 5.0

8051 Type MCU

S24042

I C

Peripheral

2

2

1

3

4

7

8

6

5

2011 T fig01 2.0

Vcc

RESET

SDA

SCL

SDA

RESET#

RESET#

Page 4

4

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

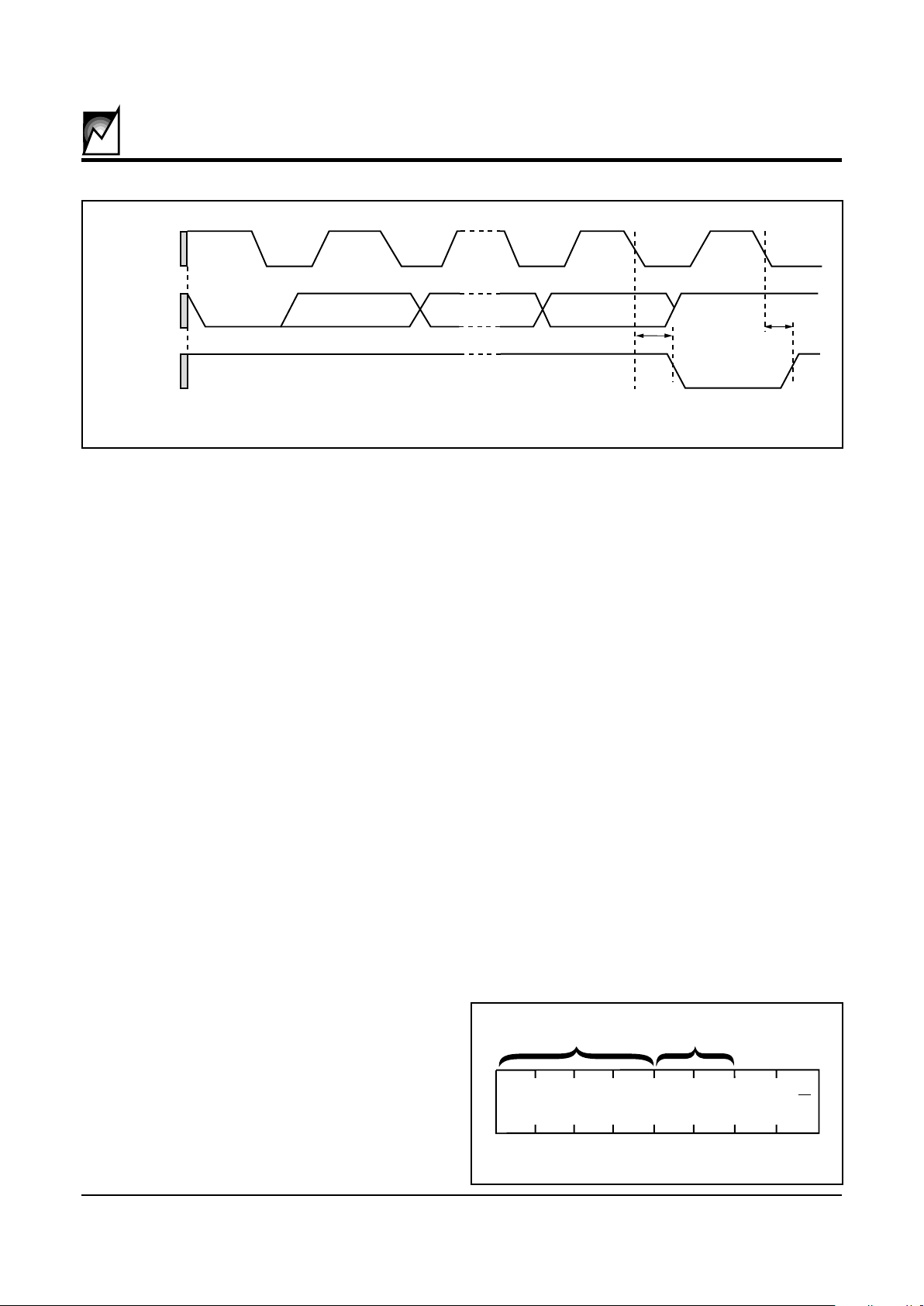

FIGURE 3. ACKNOWLEDGE RESPONSE FROM RECEIVER

CHARACTERISTICS OF THE I2C BUS

General Description

The I2C bus was designed for two-way, two-line serial

communication between different integrated circuits. The

two lines are: a serial data line (SDA), and a serial clock

line (SCL). The SDA line must be connected to a positive

supply by a pull-up resistor, located somewhere on the

bus (See Figure 1). Data transfer between devices may

be initiated with a START condition only when SCL and

SDA are HIGH (bus is not busy).

Input Data Protocol

One data bit is transferred during each clock pulse. The

data on the SDA line must remain stable during clock

HIGH time, because changes on the data line while SCL

is HIGH will be interpreted as start or stop condition, refer

to Figure 10.

START and STOP Conditions

When both the data and clock lines are HIGH, the bus is

said to be not busy. A HIGH-to-LOW transition on the data

line, while the clock is HIGH, is defined as the “START”

condition. A LOW-to-HIGH transition on the data line,

while the clock is HIGH, is defined as the “STOP” condition (See Figure 2).

DEVICE OPERATION

The S24042/43 is a 4,096-bit serial E2PROM. The device

supports the I2C bidirectional data transmission protocol.

The protocol defines any device that sends data onto the

bus as a “transmitter” and any device which receives data

as a “receiver.” The device controlling data transmission

is called the “master” and the controlled device is called

the “slave.” In all cases, the S24042/43 will be a “slave”

device, since it never initiates any data transfers.

FIGURE 4. SLAVE ADDRESS BYTE

Acknowledge (ACK)

Acknowledge is a software convention used to indicate

successful data transfers. The transmitting device, either

the master or the slave, will release the bus after transmitting eight bits. During the ninth clock cycle, the receiver

will pull the SDA line LOW to ACKnowledge that it received the eight bits of data (See Figure 3).

The S24042/43 will respond with an ACKnowledge after

recognition of a START condition and its slave address

byte. If both the device and a write operation are selected,

the S24042/43 will respond with an ACKnowledge after

the receipt of each subsequent 8-bit word.

In the READ mode, the S24042/43 transmits eight bits of

data, then releases the SDA line, and monitors the line for

an ACKnowledge signal. If an ACKnowledge is detected,

and no STOP condition is generated by the master, the

S24042/43 will continue to transmit data. If an

ACKnowledge is not detected, the S24042/43 will terminate further data transmissions and awaits a STOP condition before returning to the standby power mode.

Device Addressing

Following a start condition the master must output the

address of the slave it is accessing. The most significant

four bits of the slave address are the device type identifier

(see figure 4). For the S24042/43 this is fixed as 1010[B].

The next two bits are don’t care. The next bit is the high

order address bit A8.

SCL from

Master

Data Output

from

Transmitter

Data Output

from

Receiver

Start

Condition

ACKnowledge

t

AA

t

AA

1

8

9

2011 ILL6 1.0

1 0 1 0

X X R/W

DEVICE

IDENTIFIER

DON’T CARE

2011 ILL7 1.1

A

8

Page 5

S24042/S24043

5

2011 2.0 5/2/00

SUMMIT MICROELECTRONICS, Inc.

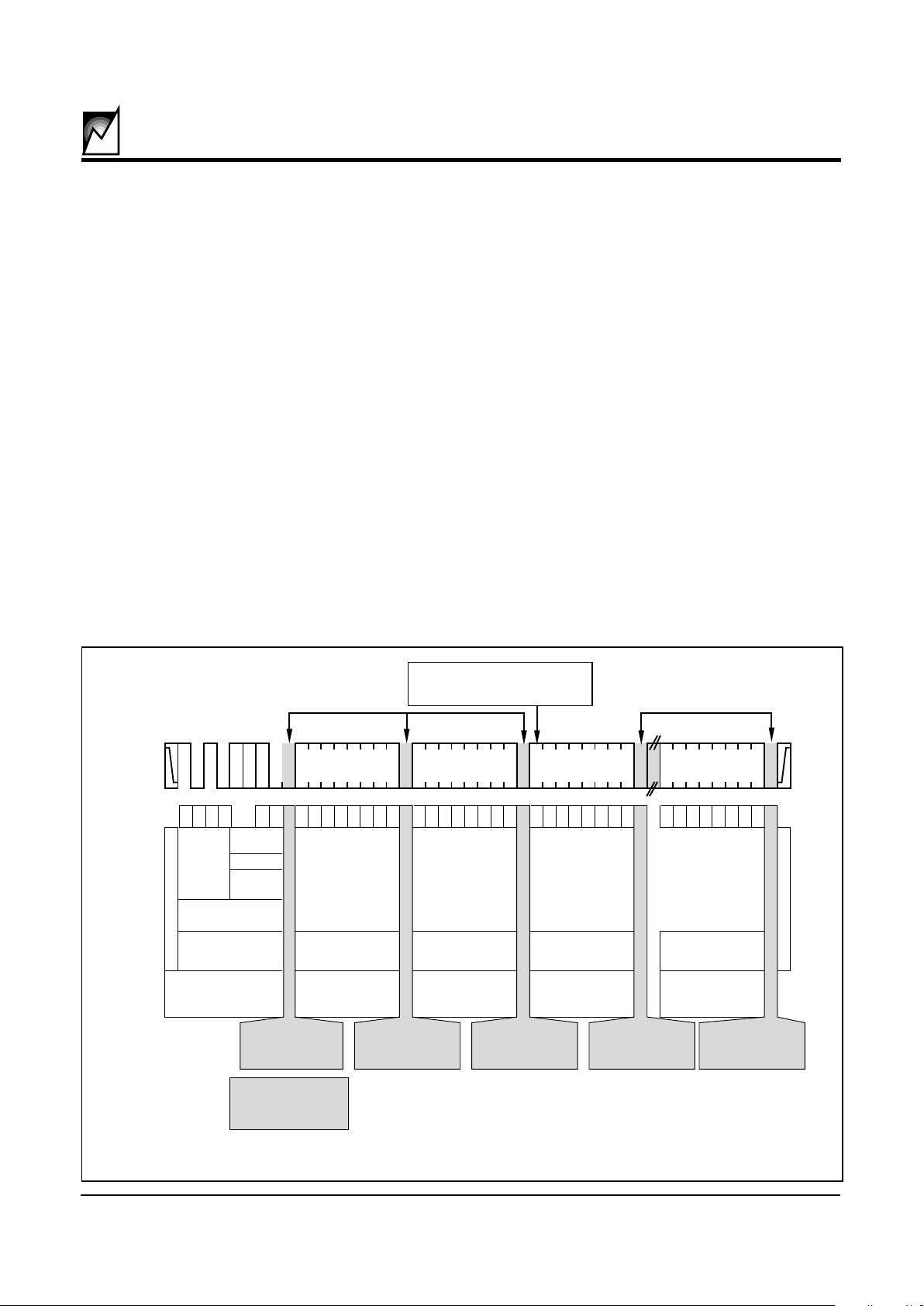

FIGURE 5. PAGE/BYTE WRITE MODE

WRITE OPERATIONS

The S24042/43 allows two types of write operations: byte

write and page write. The byte write operation writes a

single byte during the nonvolatile write period (tWR). The

page write operation allows up to 16 bytes in the same

page to be written during tWR.

Byte WRITE

Upon receipt of the slave address and word address, the

S24042/43 responds with an ACKnowledge. After receiving the next byte of data, it again responds with an

ACKnowledge. The master then terminates the transfer

by generating a STOP condition, at which time the

S24042/43 begins the internal write cycle.

While the internal write cycle is in progress, the S24042/

43 inputs are disabled, and the device will not respond to

any requests from the master. Refer to Figure 5 for the

address, ACKnowledge and data transfer sequence.

Page WRITE

The S24042/43 is capable of a 16-byte page write operation. It is initiated in the same manner as the byte-write

operation, but instead of terminating the write cycle after

the first data word, the master can transmit up to 15 more

bytes of data. After the receipt of each byte, the S24042/

43 will respond with an ACKnowledge.

The S24042/43 automatically increments the address for

subsequent data words. After the receipt of each word,

the low order address bits are internally incremented by

one. The high order five bits of the address byte remain

constant. Should the master transmit more than 16 bytes,

prior to generating the STOP condition, the address

counter will “roll over,” and the previously written data will

be overwritten. As with the byte-write operation, all inputs

are disabled during the internal write cycle. Refer to

Figure 5 for the address, ACKnowledge and data transfer

sequence.

Read/Write Bit

The last bit of the data stream defines the operation to be

performed. When set to “1,” a read operation is selected;

when set to “0,” a write operation is selected.

D7D6D5D4D3D2D1D

0

D7D6D5D4D3D2D1D

0

A

7

A

8

A

8

A6A5A4A3A2A1A0D7D5D6D

4

D

0

D3D2D

1

S

T

A

R

T

Word Address Data Byte n Data Byte n+15

S

T

O

P

A

C

K

Acknowledges Transmitted from

24042/43 to Master Receiver

Slave Address

Device

Type

Address

Read/Write

0= Write

SDA

Bus

Activity

A

C

K

A

C

K

Master Sends Read

Request to Slave

Master Writes Word

Address to Slave

1 0 1 0

0

Data Byte n+1

A

C

K

Master Writes

Data to Slave

Master Transmitter

to

Slave Receiver

Slave Transmitter

to

Master Receiver

Slave Transmitter

to

Master Receiver

Master Transmitter

to

Slave Receiver

Master Transmitter

to

Slave Receiver

Shading Denotes

24042/43

SDA Output Active

Master Transmitter

to

Slave Receiver

Slave Transmitter

to

Master Receiver

Slave Transmitter

to

Master Receiver

Master Transmitter

to

Slave Receiver

Slave Transmitter

to

Master Receiver

Master Writes

Data to Slave

Master Writes

Data to Slave

Acknowledges Transmitted from

24042/43 to Master Receiver

If single byte-write only,

Stop bit issued here.

XX

R

W

A

C

K

2011 ILL8 1.0

Page 6

6

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

FIGURE 7. CURRENT ADDRESS BYTE READ MODE

FIGURE 6. ACKNOWLEDGE POLLING

Acknowledge Polling

When the S24042/43 is performing an internal WRITE

operation, it will ignore any new START conditions. Since

the device will only return an acknowledge after it accepts

the START, the part can be continuously queried until an

acknowledge is issued, indicating that the internal WRITE

cycle is complete.

To poll the device, give it a START condition, followed by

a slave address for a WRITE operation (See Figure 6).

READ OPERATIONS

Read operations are initiated with the R/W bit of the

identification field set to “1.” There are four different read

options:

1. Current Address Byte Read

2. Random Address Byte Read

3. Current Address Sequential Read

4. Random Address Sequential Read

Current Address Byte Read

The S24042/43 contains an internal address counter

which maintains the address of the last word accessed,

incremented by one. If the last address accessed (either

a read or write) was to address location n, the next read

operation would access data from address location n+1

and increment the current address pointer. When the

S24042/43 receives the slave address field with the R/W

bit set to “1,” it issues an acknowledge and transmits the

8-bit word stored at address location n+1.

The current address byte read operation only accesses a

single byte of data. The master does not acknowledge the

transfer, but does generate a stop condition. At this point,

the S24042/43 discontinues data transmission. See Figure 7 for the address acknowledge and data transfer

sequence.

Issue Start

Internal WRITE Cycle

In Progress;

Begin ACK Polling

Issue Slave

Address and

R/W = 0

ACK

Returned?

Next

operation a

WRITE?

Issue Byte

Address

Proceed with

WRITE

Issue Stop

Await Next

Command

Issue Stop

No

No

Yes (Internal WRITE Cycle is completed)

Yes

2011 ILL9 1.0

S

T

A

R

T

S

T

O

P

Slave Address

Device

Type

Address

Read/Write

1= Read

SDA Bus Activity

D7D6D5D4D3D2D1D

0

Master sends Read

request to Slave

Slave sends

Data to Master

Master Transmitter

to

Slave Receiver

Slave Transmitter

to

Master Receiver

11100 1

Lack of ACK (low)

from Master

determines last

data byte to be read

1

Shading Denotes

24042/43

SDA Output Active

XX

R

W

A

C

K

X

Data Byte

2011 ILL 10 1.0

Page 7

S24042/S24043

7

2011 2.0 5/2/00

SUMMIT MICROELECTRONICS, Inc.

FIGURE 8. RANDOM ADDRESS BYTE READ MODE

Random Address Byte Read

Random address read operations allow the master to

access any memory location in a random fashion. This

operation involves a two-step process. First, the master

issues a write command which includes the start condition and the slave address field (with the R/W bit set to

WRITE) followed by the address of the word it is to read.

This procedure sets the internal address counter of the

S24042/43 to the desired address.

After the word address acknowledge is received by the

master, the master immediately reissues a start condition

followed by another slave address field with the R/W bit

set to READ. The S24042/43 will respond with an acknowledge and then transmit the 8-data bits stored at the

addressed location. At this point, the master does not

acknowledge the transmission but does generate the stop

condition. The S24042/43 discontinues data transmission and reverts to its standby power mode. See Figure 8

for the address, acknowledge and data transfer sequence.

D7D6D5D4D3D2D1D

0

A

7

A

8

A

8

A6A5A4A3A2A1A

0

S

T

A

R

T

Word Address

S

T

O

P

A

C

K

Slave Address

Slave Address

Device

Type

Address

Read/Write

0= Write

Device

Type

Address

SDA Bus

Activity

S

T

A

R

T

Read/Write

1= Read

A

C

K

A

C

K

Master sends Read

request to Slave

Master Writes Word

Address to Slave

Master Requests

Data from Slave

Slave sends

Data to Master

1010 1010 10

XX

R

W

X

R

W

XX

Lack of ACK (low)

from Master

determines last

data byte to be read

1

Slave Transmitter

to

Master Receiver

Slave Transmitter

to

Master Receiver

Shading Denotes

24042/43

SDA Output Active

Slave Transmitter

to

Master Receiver

Master Transmitter

to

Slave Receiver

Master Transmitter

to

Slave Receiver

Master Transmitter

to

Slave Receiver

Slave Transmitter

to

Master Receiver

Data Byte

2011 ILL11 1.0

Page 8

8

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

Sequential READ

Sequential READs can be initiated as either a current

address READ or random access READ. The first word is

transmitted as with the other byte read modes (current

address byte READ or random address byte READ);

however, the master now responds with an ACKnowledge,

indicating that it requires additional data from the

S24042/43. The S24042/43 continues to output data for

each ACKnowledge received. The master terminates the

sequential READ operation by not responding with an

ACKnowledge, and issues a STOP conditions.

During a sequential read operation, the internal address

counter is automatically incremented with each acknowledge signal. For read operations, all address bits are

incremented, allowing the entire array to be read using a

single read command. After a count of the last memory

address, the address counter will ‘roll-over’ and the

memory will continue to output data. See Figure 9 for the

address, acknowledge and data transfer sequence.

FIGURE 9. SEQUENTIAL READ OPERATION (starting with a Random Address READ)

D7D6D5D4D3D2D1D

0

D7D6D5D4D3D2D1D

0

A

7

A

8

A

8

A6A5A4A3A2A1A

0

Shading Denotes

24042/43

SDA Output Active

S

T

A

R

T

Word Address

S

T

O

P

A

C

K

Acknowledges from 24042/43

Slave AddressSlave Address

Device

Type

Address

Read/Write

0= Write

Device

Type

Address

SDA Bus

Activity

S

T

A

R

T

Read/Write

1= Read

X

R

W

X

Acknowledge from

Master Receiver

A

C

K

A

C

K

A

C

K

Master sends Read

request to Slave

Master Writes Word

Address to Slave

Master Requests

Data from Slave

Slave sends

Data to Master

Slave Transmitter

to

Master Receiver

Slave Transmitter

to

Master Receiver

Master Transmitter

to

Slave Receiver

1010 1010 10

Slave sends

Data to Master

XX

R

W

Lack of ACK (low)

determines last

data byte to be read

1

Lack of

Acknowledge from

Master Receiver

Slave Transmitter

to

Master Receiver

Master Transmitter

to

Slave Receiver

Master Transmitter

to

Slave Receiver

Master Transmitter

to

Slave Receiver

Slave Transmitter

to

Master Receiver

Slave Transmitter

to

Master Receiver

Last Data Byte

First Data Byte

2011 T fig09 2.0

A

8

Page 9

S24042/S24043

9

2011 2.0 5/2/00

SUMMIT MICROELECTRONICS, Inc.

ABSOLUTE MAXIMUM RATINGS

Temperature Under Bias ............................................................................................................................... -40°C to +85°C

Storage Temperature ..................................................................................................................................... -65°C to +125°C

Soldering Temperature (less than 10 seconds) ...................................................................................................................300°C

Supply Voltage ............................................................................................................................................................. 0 to 6.5V

Voltage on Any Pin ....................................................................................................................................... -0.3V to V

CC

+0.3V

ESD Voltage (JEDEC method) .......................................................................................................................................... 2,000V

NOTE: These are STRESS ratings only. Appropriate conditions for operating these devices are given elsewhere in this specification. Stresses

beyond those listed here may permanently damage the part. Prolonged exposure to maximum ratings may affect device reliability.

2.7V to 4.5V 4.5V to 5.5V

Symbol Parameter Conditions Min Max Min Max Units

fSCL SCL Clock Frequency 0 100 400 KHz

tLOW Clock Low Period 4.7 1.3 µs

tHIGH Clock High Period 4.0 0.6 µs

tBUF Bus Free Time Before New Transmission 4.7 1.3 µs

tSU:STA Start Condition Setup Time 4.7 0.6 µs

tHD:STA Start Condition Hold Time 4.0 0.6 µs

tSU:STO Stop Condition Setup Time 4.7 0.6 µs

tAA Clock to Output SCL Low to SDA Data Out Valid 0.3 3.5 0.2 0.9 µs

tDH Data Out Hold Time SCL Low to SDA Data Out Change 0.3 0.2 µs

tR SCL and SDA Rise Time 1000 300 ns

tF SCL and SDA Fall Time 300 300 ns

tSU:DAT Data In Setup Time 250 100 ns

tHD:DAT Data In Hold Time 0 0 ns

TI Noise Spike Width Noise Suppression Time Constant 100 100 ns

@ SCL, SDA Inputs

tWR Write Cycle Time 10 10 ms

AC ELECTRICAL CHARACTERISTICS

(over recommended operating conditions unless otherwise specified)

2011 PGM T2 1.0

2011 PGM T1 1.0

DC ELECTRICAL CHARACTERISTICS (over recommended operating conditions unless otherwise specified)

Symbol Parameter Conditions Min Max Units

SCL = CMOS Levels @ 100KHz V

CC

=5.5V 3 mA

I

CC

Supply Current (CMOS) SDA = Open

All other inputs = GND or V

CC

V

CC

=3.3V 2 mA

I

SB

Standby Current (CMOS) SCL = SDA = V

CC

V

CC

=5.5V 50 µA

All other inputs = GND

I

LI

Input Leakage VIN = 0 To V

CC

10 µA

I

LO

Output Leakage V

OUT

= 0 To V

CC

10 µA

V

IL

Input Low Voltage SCL, SDA, RESET 0.3xV

CC

V

V

IH

Input High Voltage SCL, SDA 0.7xV

CC

V

V

OL

Output Low Voltage IOL = 3mA SDA 0.4 V

V

CC

=3.3V 25 µA

Characteristic Min Max

V

CC

2.7V 5.5V

Operating Temperature Range –40°C85°C

RECOMMENDED OPERATING CONDITIONS

2011 PGM T6 1.0

Page 10

10

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

FIGURE 10. BUS TIMING

CAPACITANCE

TA = 25°C, f = 100KHz

Symbol Parameter Max Units

C

IN

Input Capacitance 5 pF

C

OUT

Output Capacitance 8 pF

2011 PGM T3 1.0

SCL

SDA In

SDA Out

t

AA

t

R

t

H IGHtLOW

t

SU:STO

t

BUF

t

SU:DAT

t

HD:DAT

t

HD:SDA

t

SU:SDA

t

DH

2011 ILL 13 1.0

t

F

Page 11

S24042/S24043

11

2011 2.0 5/2/00

SUMMIT MICROELECTRONICS, Inc.

FIGURE 11. RESET OUTPUT TIMING

S24042/43-2.7 S24042/43–A S24042/43–B

Symbol Parameter Min Max Min Max Min Max Unit

V

TRIP

Reset Trip Point 2.55 2.7 4.25 4.5 4.5 4.75 V

t

PURST

Power-Up Reset Timeout 130 270 130 270 130 270 ms

t

RPD

V

TRIP

to RESET Output Delay 5 5 5 µs

V

RVALID

RESET# Output Valid 1 1 1 V

t

GLITCH

Glitch Reject Pulse Width 30 30 30 ns

V

OLRS

RESET# Output Low Voltage IOL= 1mA 0.4 0.4 0.4 V

V

OHRS

RESET Output High Voltage IOH = 800 µA VCC-.75 VCC-.75 VCC-.75 V

RESET CIRCUIT AC and DC ELECTRICAL CHARACTERISTICS

TA = -40°C to +85°C

2011 PGM T6 1.1

V

CC

V

RVALID

V

TRIP

t

PURST

RESET#

RESET

2011 T fig11 2.0

t

GLITCH

t

RPD

t

PURST

t

RPD

S24042 only

Page 12

12

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

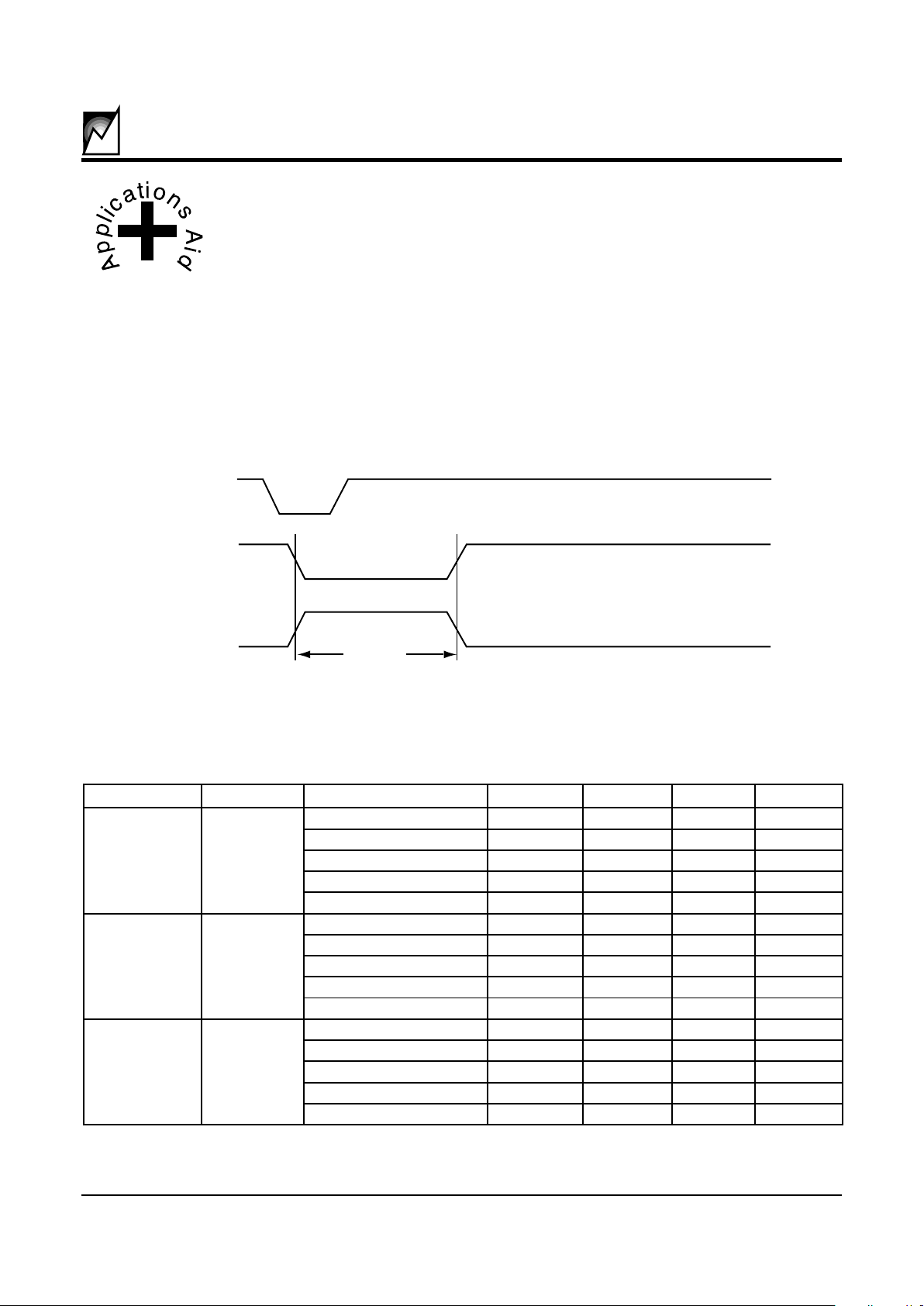

Frequently the reset controller will be deployed on a PC board that provides a peripheral function to a system.

Examples might be modem or network cards in a PC or a PCMCIA card in a laptop. In instances like this the peripheral

card may have a requirement for a clean reset function to insure proper operation. The system may or may not provide

a reset pulse of sufficient duration to clear the peripheral or to protect data stored in a nonvolatile memory.

The I/O capability of the RESET pins can provide a solution. The system’s reset signal to the peripheral can be fed

into the S24042/43 and it in turn can clean up the signal and provide a known entity to the peripheral’s circuits. The

figure below shows the basic timing characteristics under the assumption the reset input is shorter in duration than

t

PURST

. The same reset output affect can be attained by using the active high reset input.

When planning your resistor pull-up and pull-down values, use the following chart to help determine min. resistances.

Condition Min Typ Max Units

VCC = 1.0V, IOL=100µA 0.3 V

VCC = 1.2V, IOL=100µA 0.3 V

VCC = 3.0V, IOL=500µA 0.3 V

VCC = 3.6V, IOL=500µA 0.3 V

VCC = 4.5V, IOL=750µA 0.3 V

VCC = 1.0V, IOL=100µA 0.4 V

VCC = 1.2V, IOL=150µA 0.4 V

VCC = 3.0V, IOL=750µA 0.4 V

VCC = 3.6V, IOL=1mA 0.4 V

VCC = 4.5V, IOL=1mA 0.4 V

VCC = 1.0V, IOH=400µA VCC-0.75 V

VCC = 1.2V, IOH=800µA VCC-0.75 V

VCC = 3.0V, IOH=800µA VCC-0.5 V

VCC = 3.6V, IOH=800µA VCC-0.5 V

VCC = 4.5V, IOH=800µA VCC-0.5 V

Worst Case RESET Sink/Source Capabilities at Various VCC Levels

Parameter Symbol

RESET# Output V

OL

Voltage

RESET# Output V

OL

Voltage

RESET Output V

OH

Voltage

2011 PGM T5 1.0

RESET#

Input

RESET#

Output

RESET

Output

2011 T fig12 2.0

t

PURST

Page 13

S24042/S24043

13

2011 2.0 5/2/00

SUMMIT MICROELECTRONICS, Inc.

.228 (5.80)

.244 (6.20)

.016 (.40)

.035 (.90)

.020 (.50)

.010 (.25)

x45°

.0192 (.49)

.0138 (.35)

.061 (1.75)

.053 (1.35)

.0098 (.25)

.004 (.127)

.05 (1.27) TYP.

.275 (6.99) TYP.

.030 (.762) TYP.

8 Places

.050 (1.27) TYP.

.050 (1.270) TYP.

8 Places

.157 (4.00)

.150 (3.80)

.196 (5.00)

1

.189 (4.80)

FOOTPRINT

8pn JEDEC SOIC ILL.2

8 Pin SOIC (Type S) Package JEDEC (150 mil body width)

8 Pin PDIP (Type P) Package

.375

(9.525)

PIN 1 INDICATOR

.015 (.381) Min.

.130 (3.302)

.100 (2.54)

TYP.

.018 (.457)

TYP.

.060 ± .005

(1.524) ± .127

TYP.

.130 (3.302)

SEATING PLANE

.070 (1.778)

.0375 (0.952)

.300 (7.620)

5°-7°TYP.

(4 PLCS)

.350 (8.89)

.009 ± .002

(.229 ± .051)

0°-15°

.250

(6.350)

8pn PDIP/P ILL.3

Page 14

14

S24042/S24043

2011 2.0 5/2/00 SUMMIT MICROELECTRONICS, Inc.

ORDERING INFORMATION

NOTICE

SUMMIT Microelectronics, Inc. reserves the right to make changes to the products contained in this publication in order to improve

design, performance or reliability. SUMMIT Microelectronics, Inc. assumes no responsibility for the use of any circuits described

herein, conveys no license under any patent or other right, and makes no representation that the circuits are free of patent

infringement. Charts and schedules contained herein reflect representative operating parameters, and may vary depending upon

a user’s specific application. While the information in this publication has been carefully checked, SUMMIT Microelectronics, Inc.

shall not be liable for any damages arising as a result of any error or omission.

SUMMIT Microelectronics, Inc. does not recommend the use of any of its products in life support applications where the failure or

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly affect its safety

or effectiveness. Products are not authorized for use in such applications unless SUMMIT Microelectronics, Inc. receives written

assurances, to its satisfaction, that: (a) the risk of injury or damage has been minimized; (b) the user assumes all such risks; and

(c) potential liability of SUMMIT Microelectronics, Inc. is adequately protected under the circumstances.

I2C is a trademark of Philips Corporation.

© Copyright 2000 SUMMIT Microelectronics, Inc.

S24022

P

A

T

Base Part Number

Tape & Reel Option

Operating V oltage Range

Package

P = 8 Lead PDIP

S = 8 Lead 150mil SOIC

Blank = Tube

T = Tape & Reel

A = 4.5V to 5.5V V

TRIP

min. @ 4.25V

B = 4.5V to 5.5V V

TRIP

min. @ 4.50V

2.7 = 2.7V to 5.5V V

TRIP

min. @ 2.55V

S24022 = Reset Active High & Low

S24023 = Reset Active Low

2011 Tree 2.0

Loading...

Loading...