Page 1

6-pin DIP Type SSR for Low

S11MA01/S21MA01

Power Control

S11MA01/S21MA01

■ Features

1. Low operating current type

(MAX 60mA

)

rms

2. Compact 5-pin dual-in-line package type

3. Recognized by UL file No. E94758

■ Applications

1. Electrical dampers for refrigerator

2. Turntable controllers for microwave oven

3. Ignitions circuit for oil fan heater

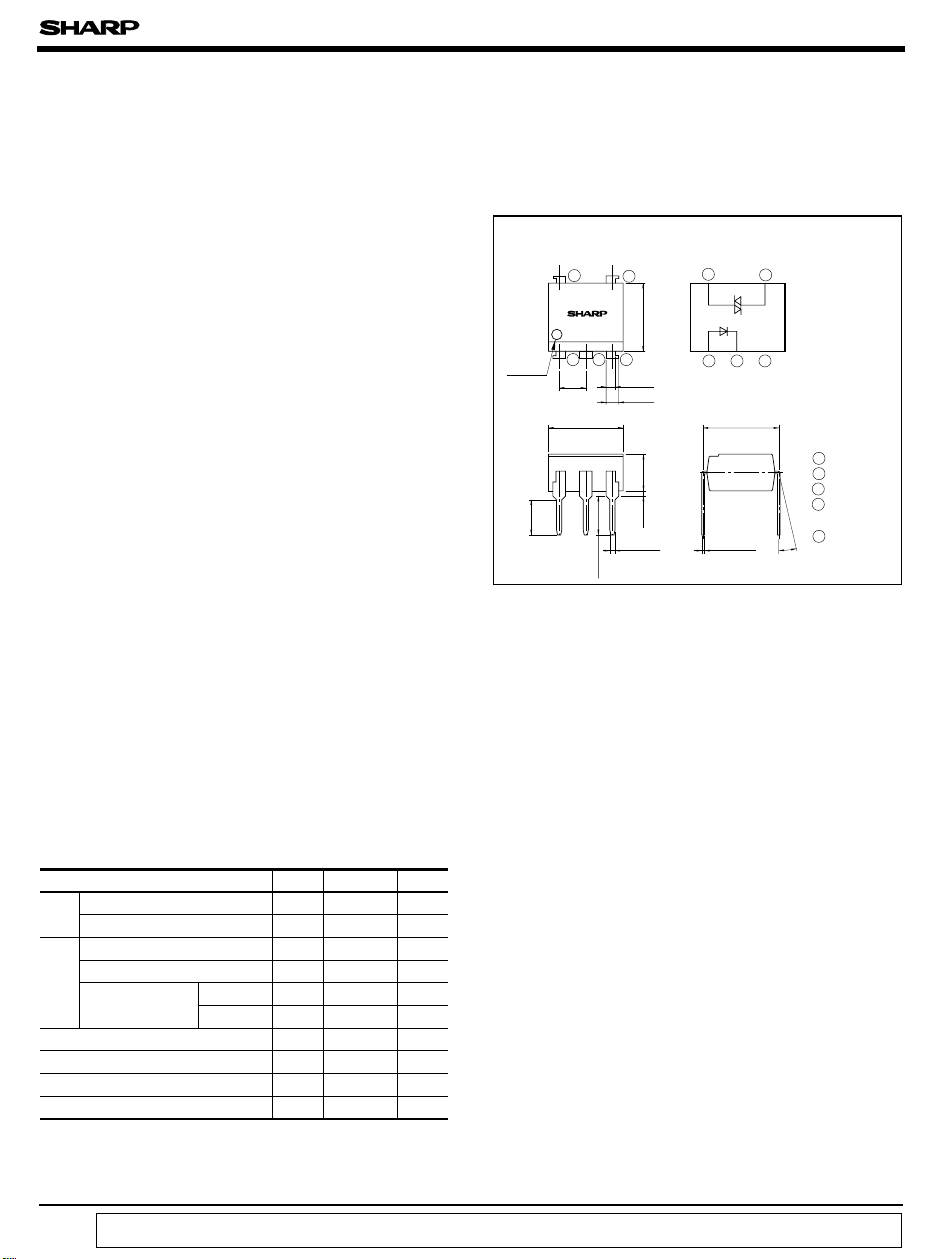

■ Outline Dimensions

S11MA01

Internal conection diagram

6

4

Anode

mark

0.5

±

3.35

S11MA01

12

±

0.25

2.54

7.12

±

0.5

±

3.7

0.5

±

6.5

3

±

0.2

0.9

±

0.3

1.2

0.5

0.5

±

3.5

TYP.

0.5

±

0.1

0.5

6

12

±

0.3

7.62

±

0.1

0.26

θ : 0 to 13 ˚

4

3

θ

(

Unit : mm

1 Anode

2 Cathode

3 NC

4 Anode,

Cathode

6 Anode,

Cathode

)

■ Absolute Maximum Ratings

Parameter

Forward current I

Input

Reverse voltage V

RMS ON-state current I

*1

Peak one cycle surge current

Output

Repetitive peak

OFF-state voltage

*2

Isolation voltage V

Operating temperature T

Storage temperature T

*3

Soldering temperature T

S11MA01

S21MA01

Symbol

F

R

T

I

surge

V

DRM

V

DRM

iso

opr

stg

sol

(

Ta= 25˚C

Rating Unit

50 mA

6V

100

1.2 A

400 V

600 V

5 000

- 25 to + 80

- 55 to + 125

260 ˚C

mA

V

)

rms

rms

˚C

˚C

*1 50Hz sine wave

*2 AC for 1 minute, 40 to 60%RH, f= 60Hz

*3 For 10 seconds

“ In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in equipment using any of SHARP's devices, shown in catalogs,

data books, etc. Contact SHARP in order to obtain the latest version of the device specification sheets before using any SHARP's device.”

Page 2

S11MA01/S21MA01

■ Electro-optical Characteristics

Parameter

Input

Output

Transfer

charac-

teristics

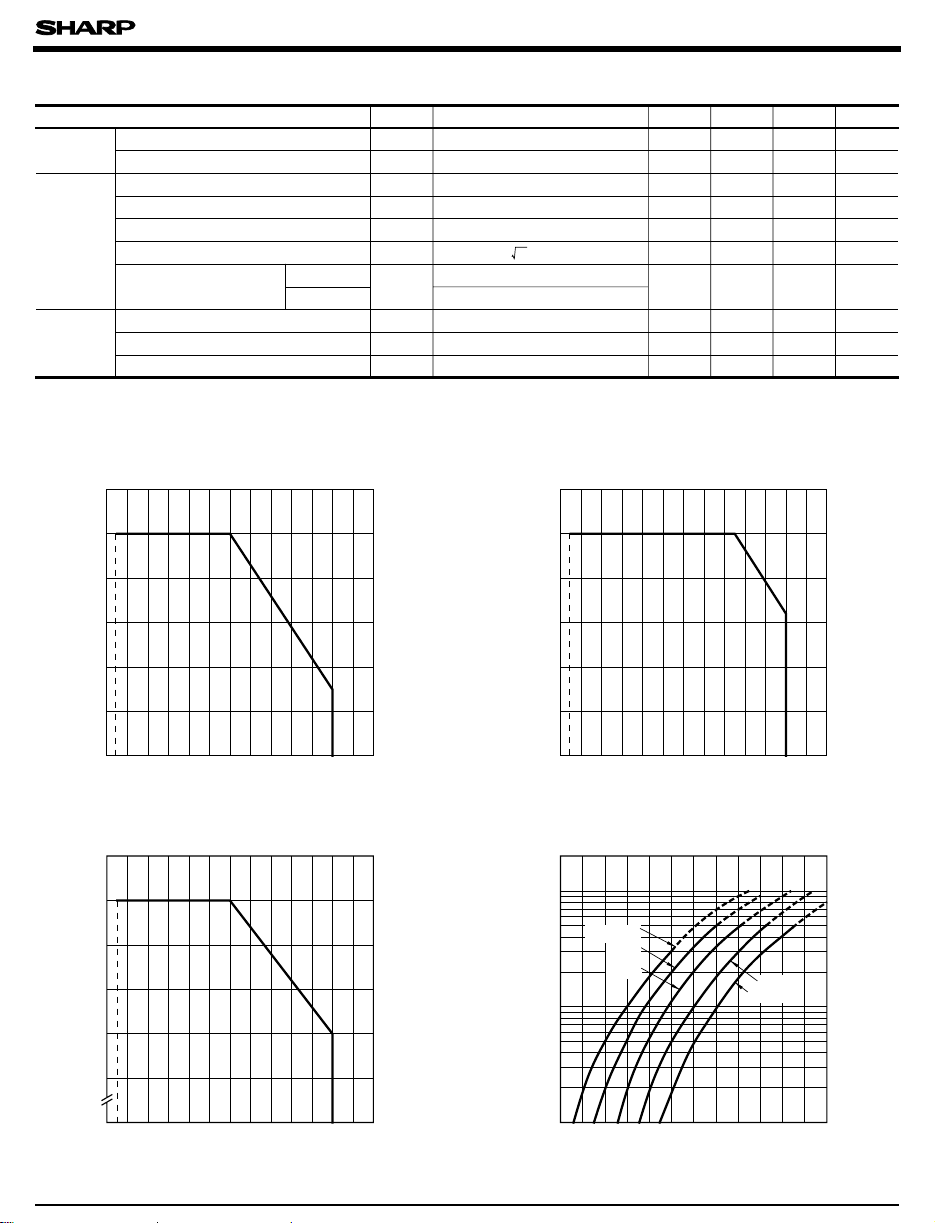

Fig. 1 RMS ON-state Current vs.

Forward voltage

Reverse current

Repetitive peak OFF-state voltage

ON-state voltage

Holding current

Critical rate of rise of OFF-state voltage

Operating current

Mininum trigger current

Isolation resistance

Turn-on time

Ambient Temperature

120

)

100

mArms

(

80

T

60

40

20

RMS ON-state current I

S11MA01

S21MA01

Symbol

I

V

F

F

I

V

R

I

V

DRM

V

I

T

T

I

V

H

V

dV/dt

AC100Vrms, 60Hz, Resistance load

AC200Vrms, 60Hz, Resistance load

V

I

FT

R

DC = 500V, 40 to 60% RH

ISO

t

VD= 6V, RL= 100Ω, IF= 20mA

on

Conditions

= 20mA

=3V

R

= Rated

DRM

= 0.06A

=6V

D

=(1/ )• Rated

DRM

D

2

= 6V, RL= 100 Ω

Fig. 2 Forward Current vs.

Ambient Temperature

)

mA

(

F

Forward current I

(

Ta= 25˚C

MIN.

500

5x10

60

50

40

30

20

10

TYP. MAX. Unit

1.2 1.4 V

-

-

-

-

0.1

-10

-10

- 2.5 V

1.0 3.5 mA

--V/µs

-

-

-

-60

-10mA

10

11

10

- 100 µs

-5

-6

- Ω

mA

)

A

A

rms

0

-30 -30

0 50 100

Ambient temperature Ta (˚C

)

Fig. 3 Operating Current vs.

Ambient Temperature

70

60

)

50

rms

mA

(

40

30

Operating current

20

0

-30

0 50 100

Ambient temperature T

a

(˚C

)

0

0 50 100

Ambient temperature T

Fig. 4 Forward Current vs.

Forward Voltage

100

)

50

T

= 75˚C

mA

(

F

Forward current I

a

50˚C

20

10

5

2

1

0.9 1.0 1.1 1.2 1.3 1.4 1.5

25˚C

Forward voltage V

F

(V

(˚C

a

)

0˚C

- 25˚C

)

Page 3

S11MA01/S21MA01

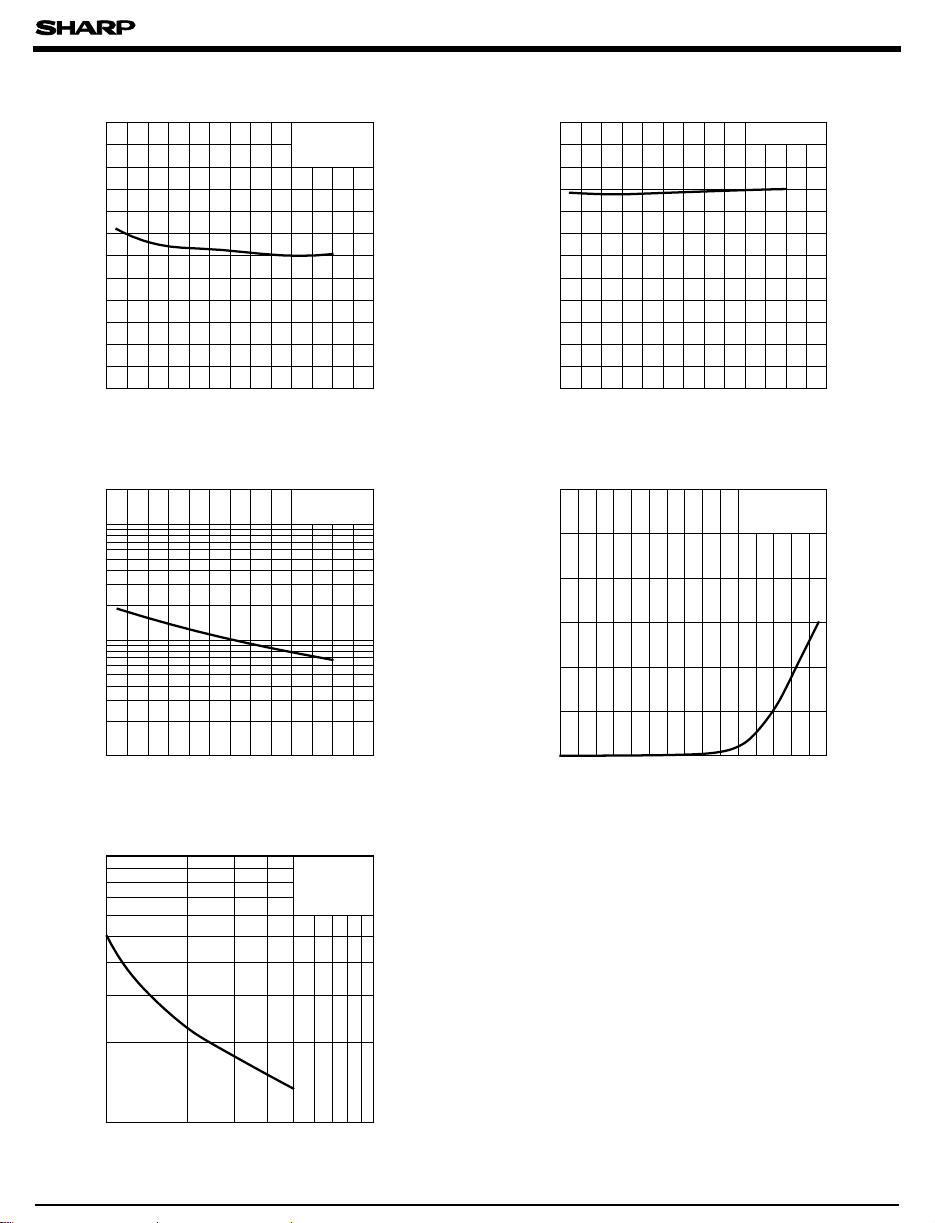

Fig. 5 Minimum Trigger Current vs.

Ambient Temperature

)

mA

(

FT

12

10

8

V

D

R

L

=6V

= 100Ω

6

4

Minimum trigger current I

2

0

- 30 0 20 40 60 80 100

Ambient temperature Ta (˚C

)

Fig. 7 Relative Holding Current vs.

Ambient Temperature

V

a

(˚C

D

)

100%

3

x

10

)

25˚C

(

H

/I

)

t˚C

(

H

2

10

Relative holding current I

1

10

- 30 0 20 40 60 80 100

Ambient temperature T

=6V

Fig. 6 ON-state Voltage vs.

Ambient Temperature

1.6

1.5

)

V

(

1.4

T

1.3

1.2

ON-state voltage V

1.1

1.0

- 30 0 20 40 60 80 100

Ambient temperature T

a

Fig. 8 ON-state Current vs.

ON-state Voltage

120

100

)

mA

80

(

T

60

40

ON-state current I

20

0

0 0.5 1.0 1.5

ON-state voltage V

(V

T

(˚C

I

T

= 0.06A

I

T

)

= 20mA

F

= 25˚C

a

)

Fig. 9 Turn-on Time vs. Forward Current

100

)

50

µ s

(

40

on

30

20

Turn-on time t

10

10

20 30 40 50 100

Forward current I

(mA

F

VD=6V

= 100Ω

R

L

= 20mA

I

F

)

Page 4

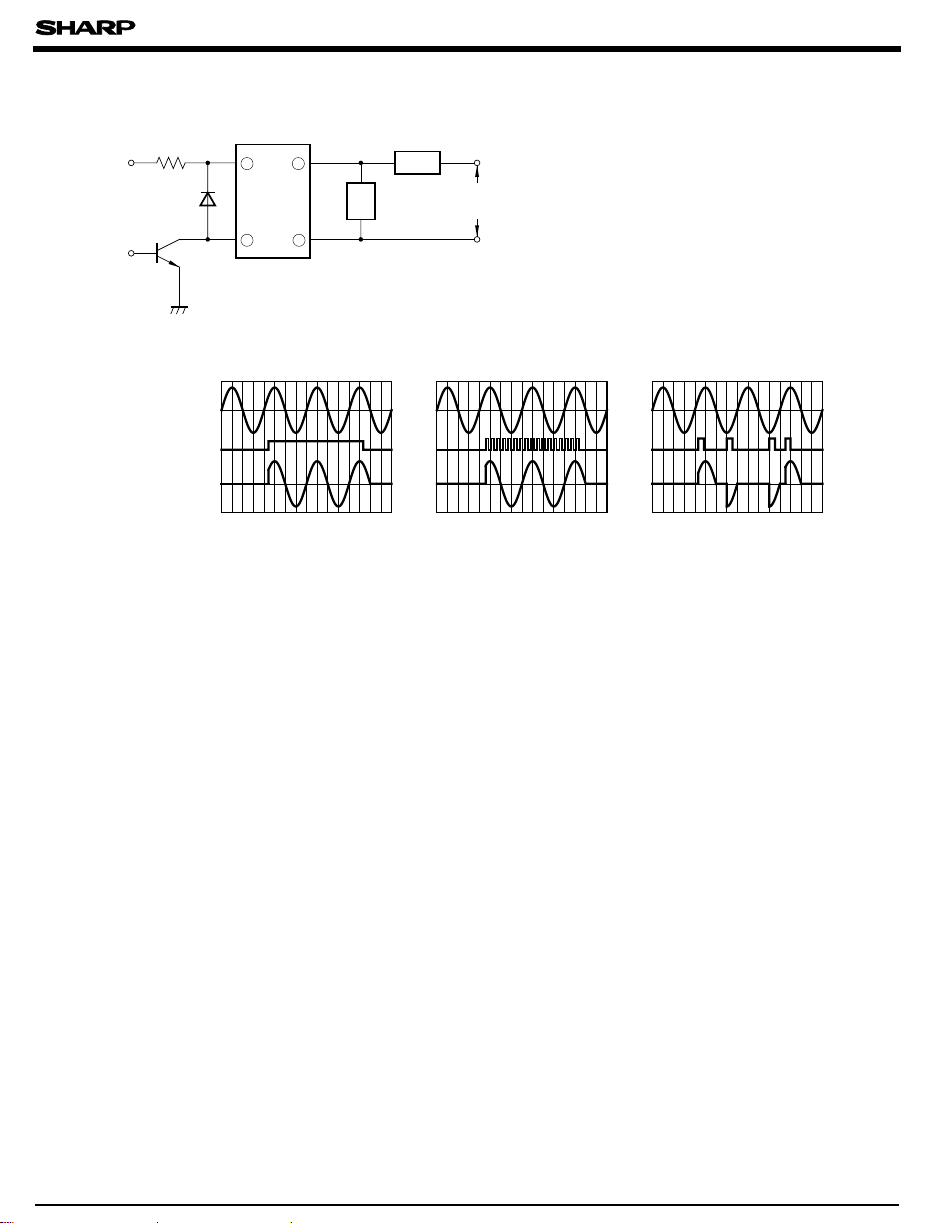

■ Basic Operation Circuit

R

+ V

CC

V

I

1

D

Tr1

1

1

SSR

2

6

4

ZS: Surge absorption circuit

Load

Z

S

AC 100V

AC 200V

S11MA01/S21MA01

(1)

DC Drive

AC supply voltage

Input signal

Load current

(

for resistance load

)

Notes 1) If large amount of surge is loaded onto V

or the driver circuit, add a diode D1 between terminals 1

CC

(2)

Pulse Drive

and 2 to prevent reverse bias from being applied to the infrared LED.

2) Be sure to install a surge absorption circuit.

An appropriate circuit must be chosen according to the load (for CR, choose its constant). This must be

carefully done especially for an inductive load.

3) For phase control, adjust such that the load current immediately after the input signal is applied will

be more than 10mA.

● Please refer to the chapter“ Precautions for Use”

(3)

Phase Control

Loading...

Loading...