Page 1

Preliminary

9.Jun.99

12345

I2C-Bus Real-Time Clock ICs

with Voltage Monitoring Function

RV5C386A

1. OUTLINE

The RV5C386A is a CMOS real-time clock IC connected to the CPU by two signal lines, SCL and SDA, and

configured to perform serial transmission of time and calendar data to the CPU. The periodic interrupt circuit

is configured to generate interrupt signals with six selectable interrupts ranging from 0.5 seconds to 1 month.

The 2 alarm interrupt circuits generate interrupt signals at preset times. As the oscillation circuit is driven

under constant voltage, fluctuation of the oscillator frequency due to supply voltage is small, and the time

keeping current is small (TYP. 0. 35 µA at 3 volts). The oscillation halt sensing circuit can be used to judge

the validity of internal data in such events as power-on; The supply voltage monitoring circuit is configured to

record a drop in supply voltage below two selectable supply voltage monitoring threshold settings. The 32kHz clock output function (CMOS output) is intended to output sub-clock pulses for the external

microcomputer. The 32-kHz clock output can be disabled by certain input pin. The oscillation adjustment

circuit is intended to adjust time counts with high precision by correcting deviations in the oscillation frequency

of the crystal oscillator. This model comes in an ultra-compact SSOP10G (Pin Pitch 0.5mm, Height1.2mm,

4.0mm×2.9mm).

2. FEATURES

• Timekeeping supply voltage ranging from 1.45 to 5.5V

• Low power consumption 0.35µA TYP (0.8µA MAX) at VDD=3V

• Only two signal lines (SCL and SDA) required for connection to the CPU.

( I2C-Bus Interface, 400kHz at VDD≥2.5V, address 7bits)

• Time counters (counting hours, minutes, and seconds) and calendar counters (counting years, months, days,

and weeks) (in BCD format)

• 1900/2000 identification bit for Year 2000 compliance

• Interrupt circuit configured to generate interrupt signals (with interrupts ranging from 0.5 seconds to 1 month)

to the CPU and provided with an interrupt flag and an interrupt halt

• 2 alarm interrupt circuits (Alarm_W for week, hour, and minute alarm settings and Alarm_D for hour and

minute alarm settings)

• 32-kHz clock circuit (CMOS output, equipped with a control pin)

• Oscillation halt sensing circuit which can be used to judge the validity of internal data

• Supply voltage monitoring circuit with two supply voltage monitoring threshold settings

• Automatic identification of leap years up to the year 2099

• Selectable 12-hour and 24-hour mode settings • Built-in oscillation stabilization capacitors (CG and CD)

• High precision oscillation adjustment circuit

• CMOS process • Ultra-compact SSOP10G

*) I2C-Bus is a trademark of PHILIPS N.V.

Purchase of I2C-Bus components of Ricoh Company, LTD. conveys a license under the Philips I2C Patent

Rights to use these components in an I2C system, provided that the system comforms to the I2C standard

Specification as definded by Philips.

12345

- 1 -

Page 2

RV5C386A PRELIMINARY

SDA

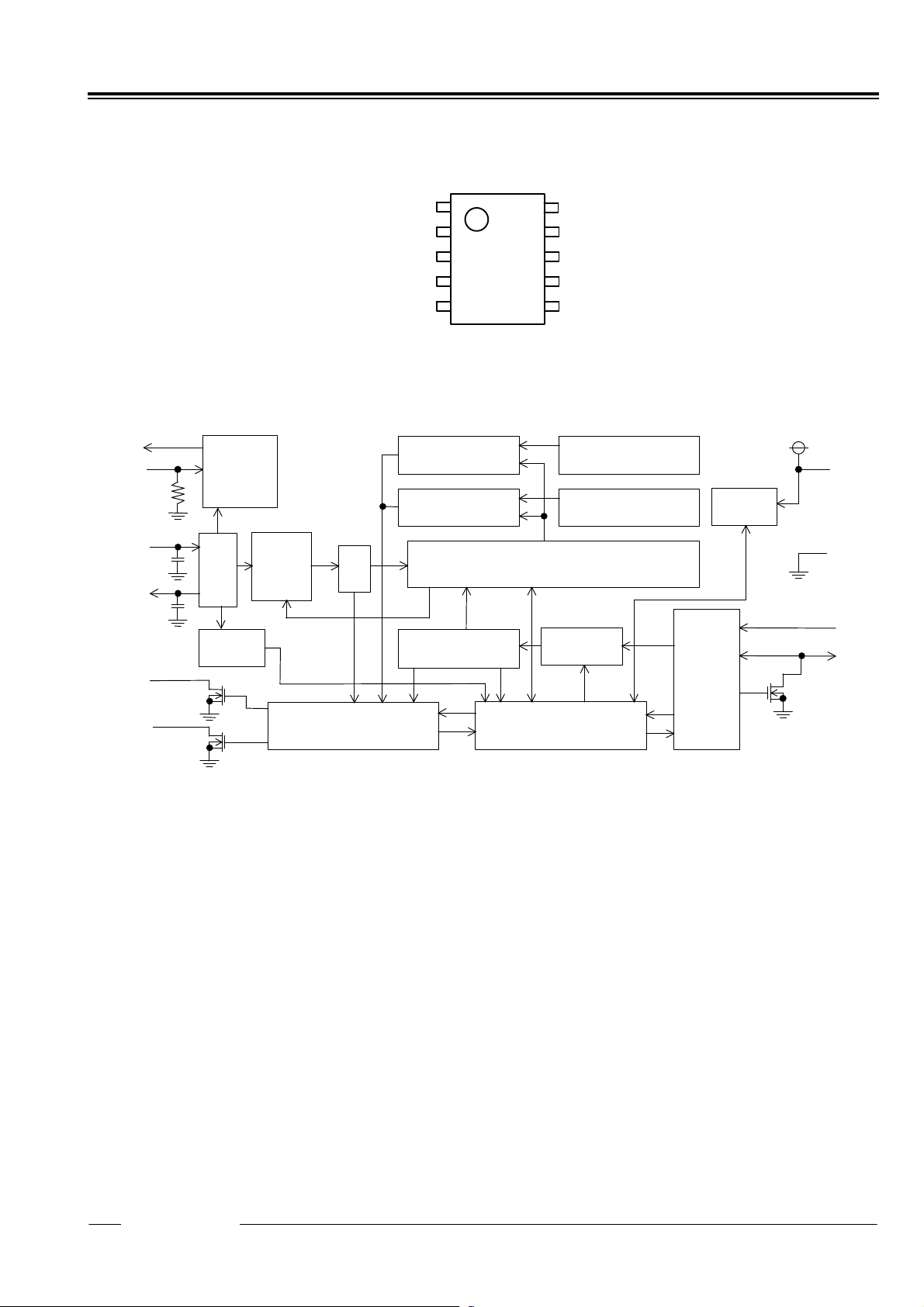

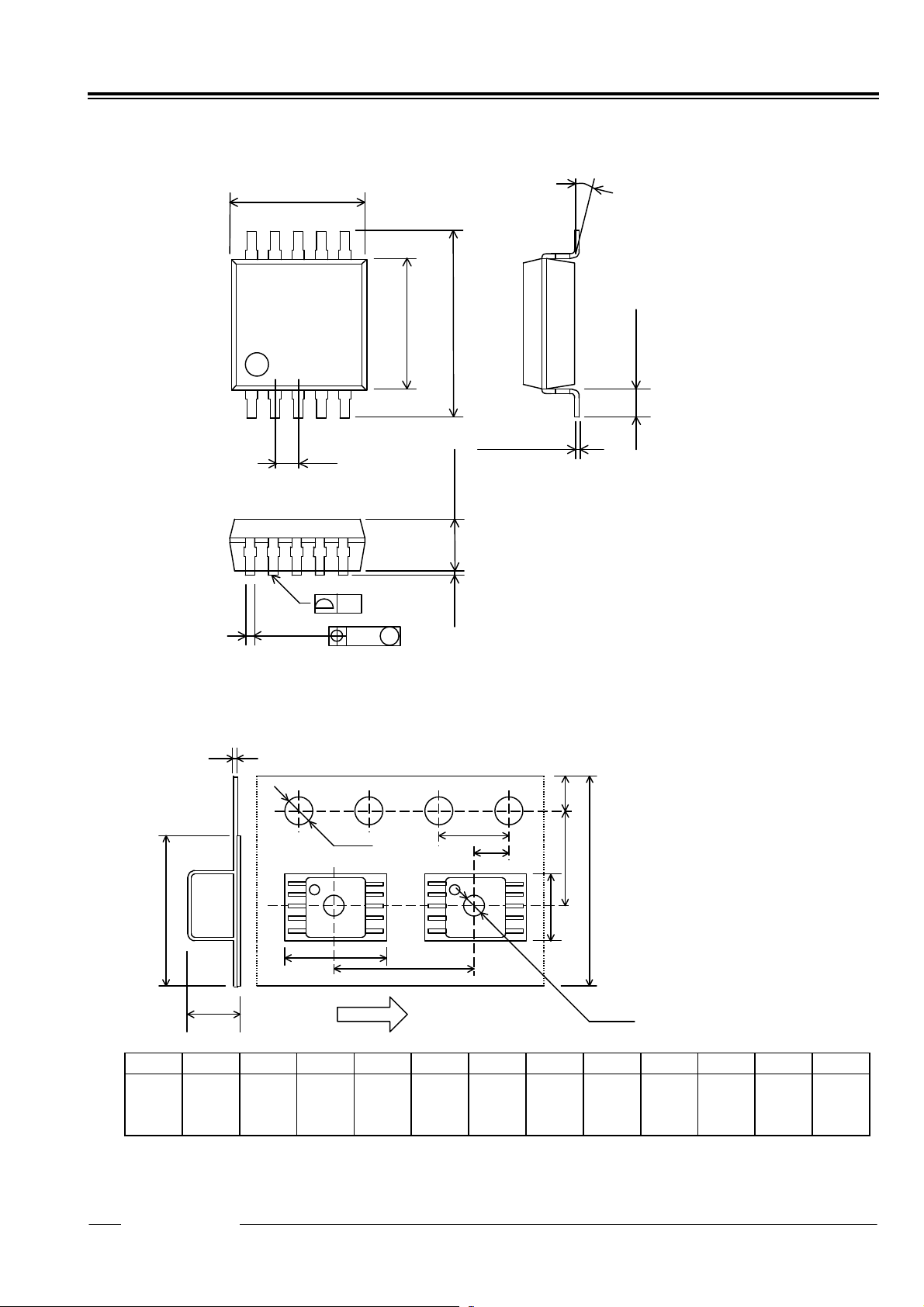

3. PIN CONFIGURATION

RV5C386A (SSOP10G)

VDD

32KOUT

SCL

SDA

/INTRB

1

2

3

4

5 6

10

9

8

7

OSCIN

OSCOUT

CLKC

/INTRAVSS

4. BLOCK DIAGRAM

32KOUT

CLKC

OSCIN

OSCOUT

/INTRA

/INTRB

32kHz

OUTPUT

CONTROL

OSC

OSC

DETECT

DIVIDER

CORREC

-TION

INTERRUPT CONTROL

DIV

TOP VIEW

COMPARATOR_W

COMPARATOR_D

TIME COUNTER

(SEC,MIN,HOUR,WEEK,DAY,MONTH,YEAR)

ADDRESS

DECODER

SHIFT REGISTER

ALARM_W REGISTER

(MIN,HOUR, WEEK)

ALARM_D REGISTER

(MIN,HOUR)

ADDRESS

REGISTER

VDD

VOLTAGE

DETECT

VSS

SCL

I/O

CONTROL

12345

- 2 -

Page 3

PRELIMINARY RV5C386A

5. PIN DESCRIPTION

Symbol Item Description

SCL Serial

Clock Line

SDA Serial

Data Line

/INTRA Interrupt

Output A

/INTRB Interrupt

Output B

32KOUT 32kHz Clock

Output

CLKC Clock control

input

OSCIN

OSCOUT

VDD

VSS

Oscillation

Circuit

Input / Output

Positive Power

Supply Input

Negative Power

Supply Input

The SCL pin is used to input clock pulses synchronizing the input and output

of data to and from the SDA pin. Allows a maximum input voltage of 5.5

volts regardless of supply voltage.

The SDA pin is used to input or output data intended for writing or reading in

synchronization with the SCL pin. Up to 5.5v beyond VDD may be input.

This pin functions as an Nch open drain output.

The /INTRA pin is used to output periodic interrupt signals to the CPU and

alarm interrupt (Alarm_D) signals. Disabled at power-on from 0 volts. Nch.

open drain output.

The /INTRB pin is used to output alarm interrupt (Alarrm_W) signals to the

CPU. Disabled at power-on from 0 volts. Nch. open drain output.

The 32KOUT pin is used to output 32.768-kHz clock pulses. Enabled at

power-on from 0 volts. CMOS output. The output is disabled if the CLKC pin

is set to Low or open.

The CLKC pin is used to control output of the 32KOUT pin. The clock output

is disabled and held low when the pin is set to low or open. Incorporates a

pull-down resistor.

The OSCIN and OSCOUT pins are used to connect the 32.768-kHz crystal

oscillator (with all other oscillation circuit components built into the

RV5C386A).

The VDD pin is connected to the power supply.

The VSS pin is grounded.

6. ABSOLUTE MAXIMUM RATINGS

Symbol Item Pin Name Description Unit

VDD Supply Voltage -0.3 to +6.5 V

VI Input Voltage SCL, SDA, CLKC -0.3 to +6.5 V

Output Voltage 1 SDA, /INTRA, /INTRB -0.3 to +6.5 V VO

Output Voltage 1 32KOUT -0.3 to VDD+0.3 V

PD Power Dissipation

Topt Operating Temperature -40 to +85

Tstg Storage Temperature -55 to +125

7. RECOMMENDED OPERATING CONDITIONS

Symbol Item Pin Name Min, Typ. Max. Unit

VDD Supply Voltage 2.0 5.5 V

VCLK Timekeeping Voltage 1.45 5.5 V

fXT Oscillation Frequency 32.768 kHz

VPUP Pull-up Voltage SCL, SDA, /INTRA,

Topt = 25°C

/INTRB

(VSS=0V)

300 mW

°C

°C

(VSS=0V, Topt=-40 to +85°C)

5.5 V

- 3 -

12345

Page 4

RV5C386A PRELIMINARY

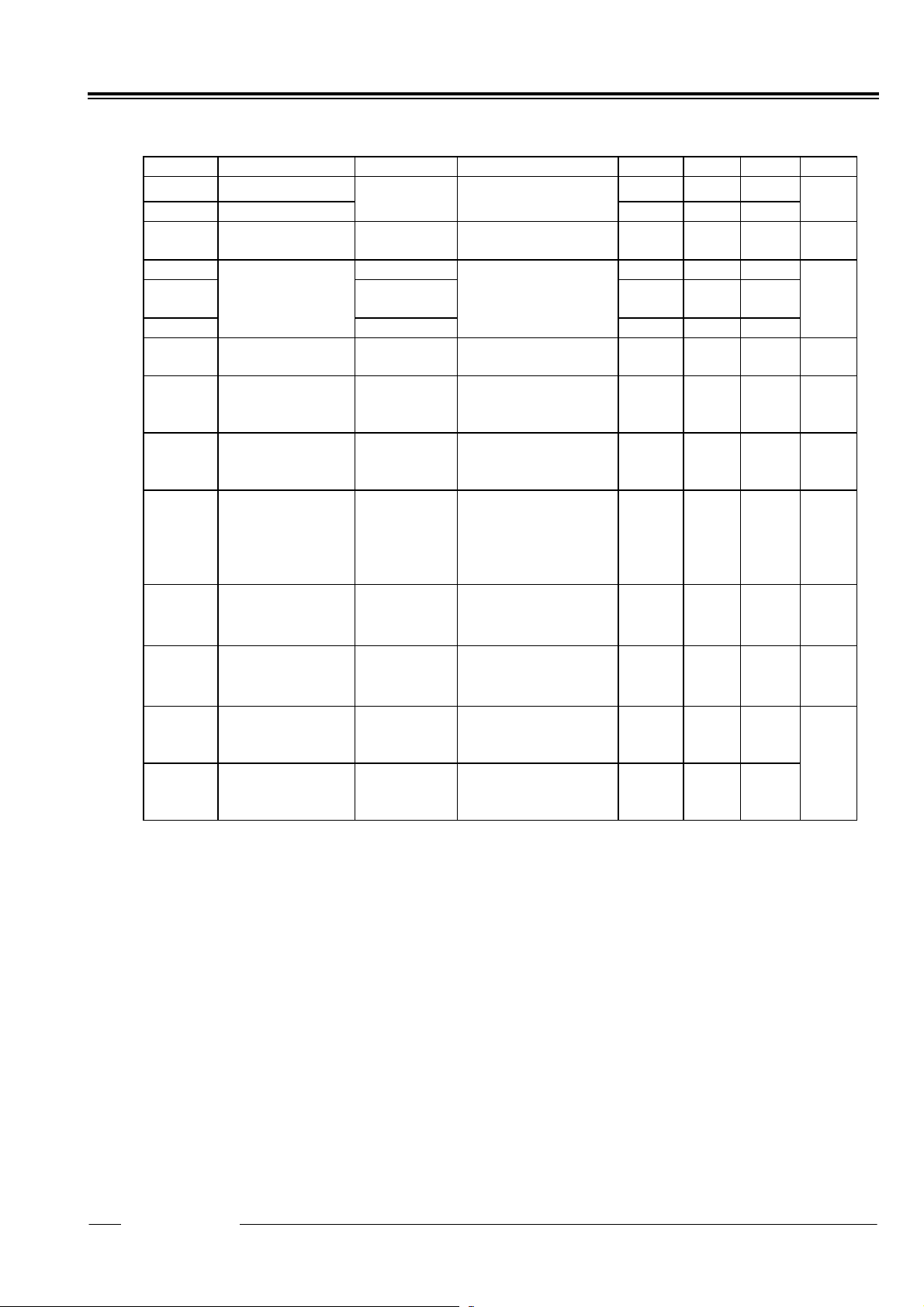

8. DC ELECTRICAL CHARACTERISTICS

(Unless otherwise specified : VSS=0V,VDD=3V,Topt=-40 to +85°C)

Symbol Item Pin Name Conditions Min. Typ. Max. Unit

VIH “H” Input Voltage 0.8VDD 5.5

VIL “L” Input Voltage

IOH “H” Output

Current

IOL1 32KOUT 0.5

IOL2 /INTRA,

IOL3

IIL Input Leakage

ICLKC Pull Down

IOZ Output Off-state

IDD Time Keeping

VDETH

VDETL

CG Internal

CD Internal

*1) For Standby Current for outputting 32.768kHz clock pulses from the 32KOUT pin, see, “14.7 Typical

Characteristics”.

“L” Output

Current

Current

Resistance Input

Current

Current

Current

Supply Voltage

Monitoring

Voltage “H”

Supply Voltage

Monitoring

Voltage “L”

Oscillation

Capacitance 1

Oscillation

Capacitance 2

SCL,SDA,

CLKC

32KOUT VOH=VDD-0.5V -0.5mA mA

/INTRB

SDA

SCL VI=5.5V or VSS

CLKC VI=5.5V 0.35 1.0

SDA,

/INTRA,

/INTRB

VDD

VDD

VDD

OSCIN 12

OSCOUT 12

VDD=2.0 to 5.5V

-0.3 0.2VDD

VOL=0.4V

VDD=5.5V

VO=5.5V or VSS

VDD=5.5V -1 1

VDD=3V,

SCL=SDA=3V,

CLKC=VSS

Output = OPEN

*1)

Topt=-30 to +70°C

Topt=-30 to +70°C

1.0

4.0

-1 1

0.35 0.8

1.90 2.10 2.30 V

1.45 1.60 1.80 V

µA

V

mA

µA

µA

µA

pF

12345

- 4 -

Page 5

PRELIMINARY RV5C386A

t

PZ;DAT

HIGH

SU;DAT

HD;STA

SP

SU;STO

LOW

SU;STA

HD;STA

t

PL;DAT

HD;DAT

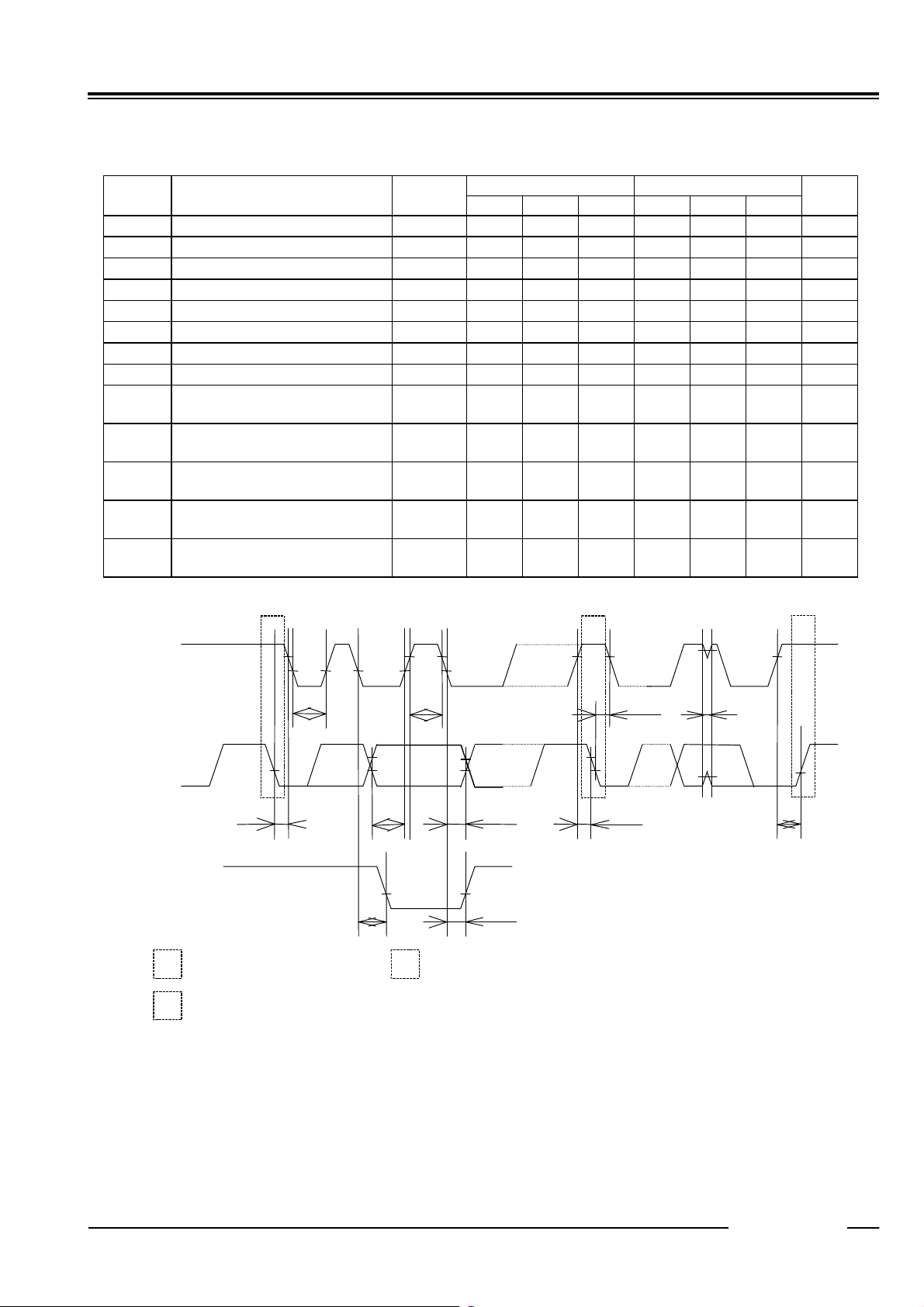

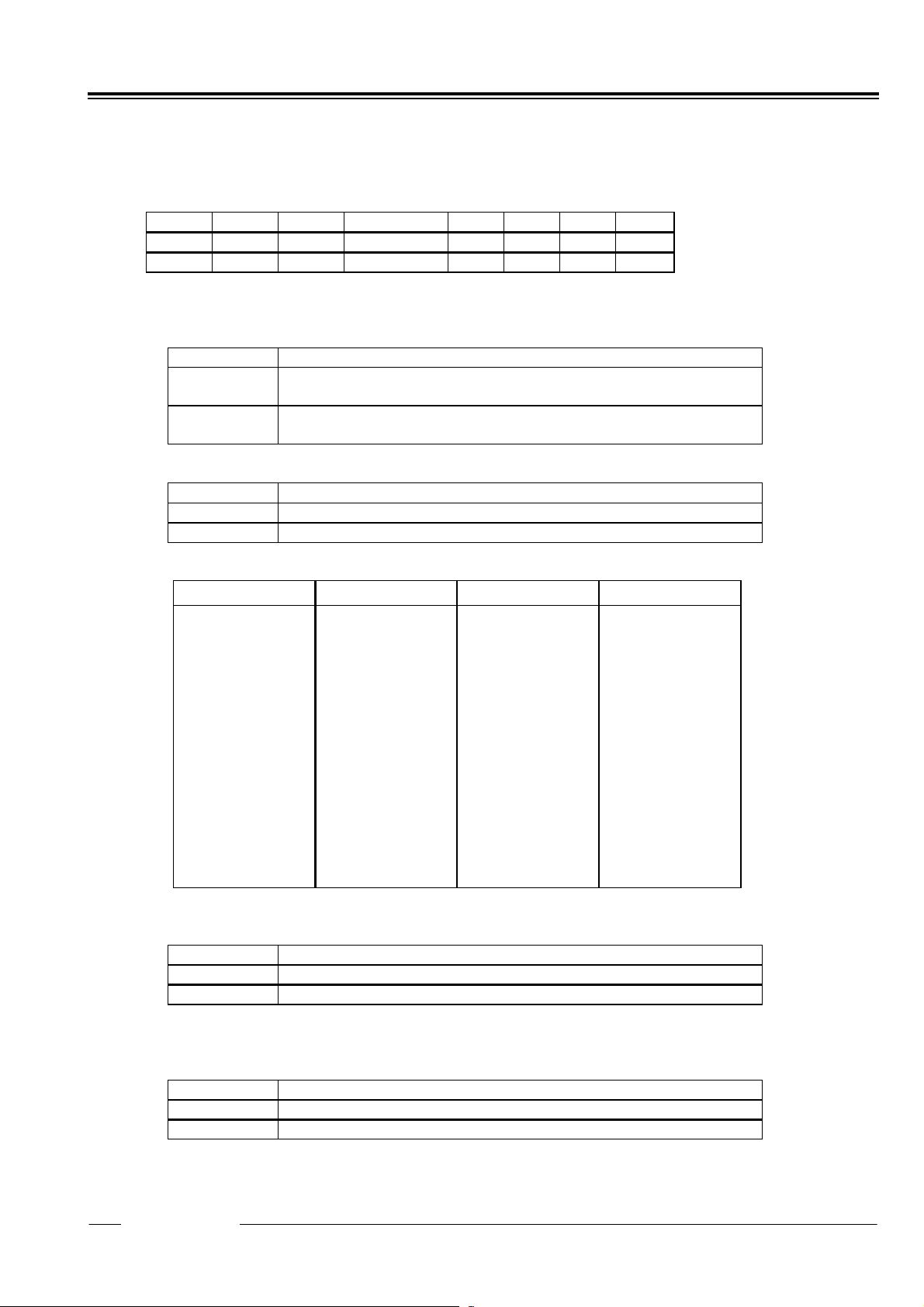

9. AC ELECTRICAL CHARACTERISTICS

Unless otherwise specified : VSS=0V,Topt=-40 to +85°C

Input and Output Conditions : VIH=0.8×VDD,VIL=0.2×VDD,VOH=0.8×VDD,VOL=0.2×VDD,CL=50pF

Symbol Item Condi-

tions

f

SCL

t

LOW

t

HIGH

t

HD;STA

t

SU;STO

t

SU;STA

t

SU;DAT

t

HD;DAT

t

PL;DAT

SCL Clock Frequency 100 400 KHz

SCL Clock Low Time 4.7 1.3

SCL Clock High Time 4.0 0.6

Start Condition Hold Time 4.0 0.6

Stop Condition Set Up Time 4.0 0.6

Start Condition Set Up Time 4.7 0.6

Data Set Up Time 250 200 ns

Data Hold Time 0 0 ns

SDA “L” Stable Time

After Falling of SCL

t

PZ;DAT

SDA off Stable Time

After Falling of SCL

t

R

Rising Time of SCL and

SDA (input)

t

F

Falling Time of SCL and

SDA (input)

t

SP

Spike Width that can be

removed with Input Filter

VDD≥2.0V VDD≥2.5V

Min. Typ. Max. Min. Typ. Max.

2.0 0.9

2.0 0.9

1000 300 ns

300 300 ns

50 50 ns

Unit

µs

µs

µs

µs

µs

µs

µs

SCL

SDA(IN)

SDA(OUT)

S

Sr

S

t

t

Start Condition

Repeated Start Condition

t

Stop Condition

P

Sr P

t

t

t

t

t

t

12345

- 5 -

Page 6

RV5C386A PRELIMINARY

M

-0.1

+0.3

0.15

-0.05

0.1

+0.1

φ

φ

10. PACKAGE DIMENSIONS (Unit : mm)

RV5C386A (SSOP10G)

0 to 10

2.9

°

10

1

0.2±0.1

0.5

6

0.2

0.3

±

±

2.8

4.0

0.2

±

0.55

5

0.127

0.1

±

1.1

+0.1

-0.05

0.1

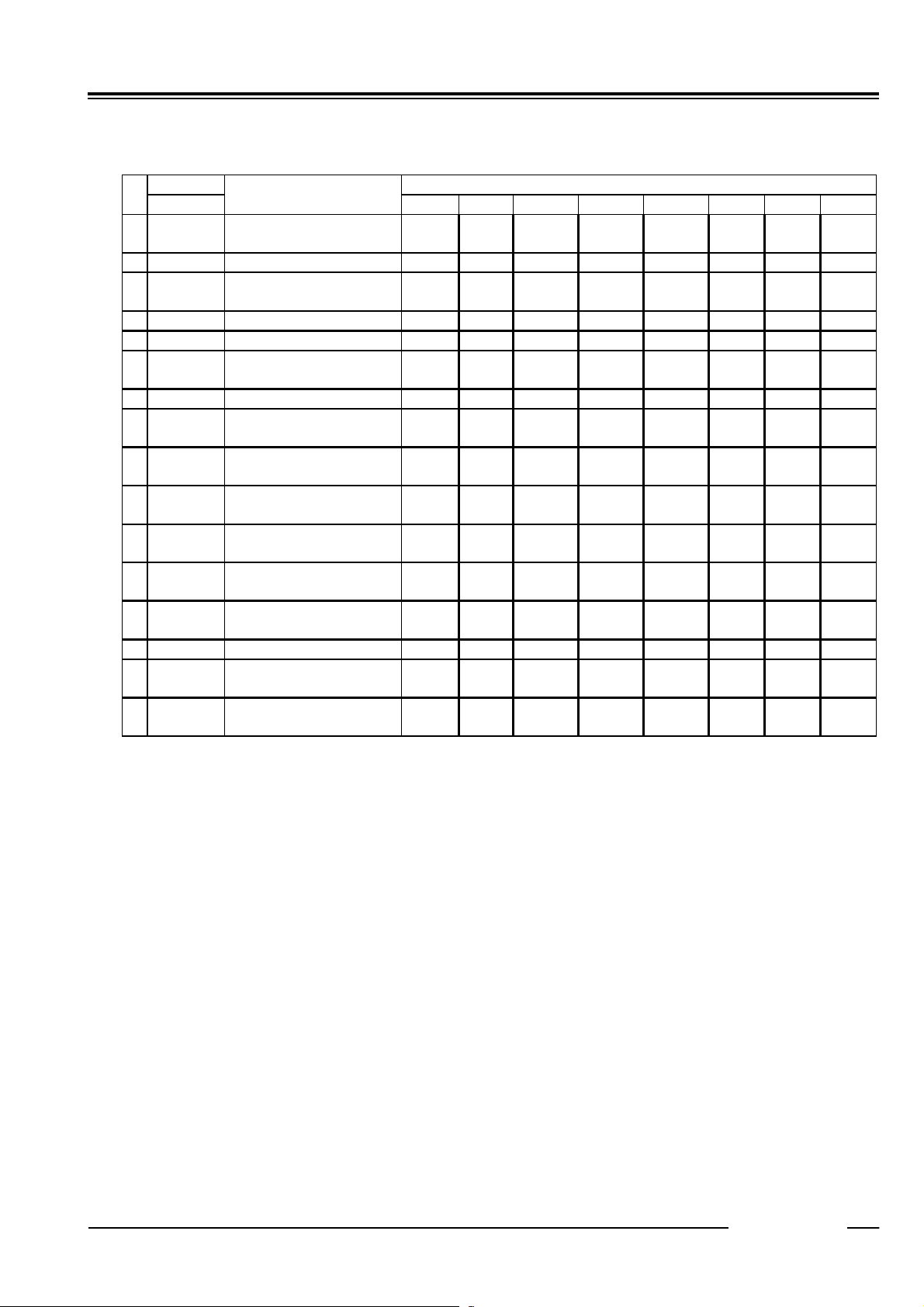

11. TAPING SPECIFICATION

The RV5C386A has one designated taping direction. The product designation for the taping components is

"RV5C386A-E2".

T

W

1

T

2

A B D

4.4

±0.1

3.2

±0.1

0

1.5

+0.1

-0

1.5

+0.1

-0

E

P

5.5

0

±0.1

P

4.0

2

0

B

P

1

8.0

±0.1

F

W

D

1

P

2

2.0

±0.05

Unit:mm

T T

0.3

±0.05

2

2.0

(MAX)

W W

12.0

±0.3

1

9.5

D

0

A

P

1

Pull-Out Directions

D

1

E F P

1.75

±0.1

±0.05

12345

- 6 -

Page 7

PRELIMINARY RV5C386A

12. GENERAL DESCRIPTION

(1) Interface with CPU

The RV5C386A is connected to the CPU by two signal lines SCL and SDA, through which it reads and writes

data from and to the CPU. Since the output of the I/O pin of SDA is open drain, data interfacing with a CPU

different supply voltage is possible by applying pull-up resistors on the circuit board. The maximum clock

frequency of 400kHz (at VDD≥2.5V) of SCL enables data transfer in I2C-Bus fast mode.

(2) Clock and Calendar Function

The RV5C386A reads and writes time data from and to the CPU in units ranging from seconds to the last two

digits of the calendar year. The calendar year will automatically be identified as a leap year when its last two

digits are a multiple of 4. Also available is the 1900 / 2000 identification bit for Year 2000 compliance.

Consequently, leap years up to the year 2099 can automatically be identified as such.

*) The year 2000 is a leap year while the year 2100 is not a leap year.

(3) Alarm Function

The RV5C386A incorporates the alarm interrupt circuit configured to generate interrupt signals to the CPU at

preset times. The alarm interrupt circuit allows two types of alarm settings specified by the Alarm_W

registers and the Alarm_D registers. The Alarm_W registers allow week, hour, and minute alarm settings

including combinations of multiple day-of-week settings such as "Monday, Wednesday, and Friday" and

"Saturday and Sunday". The Alarm_D registers allow hour and minute alarm settings. The Alarm_W

outputs from /INTRB pin, and the Alarm_D outputs from /INTRA pin. The current /INTRA or /INTRB

conditions specified by the flag bits for each alarm function can be checked from the CPU by using a polling

function.

(4) High-precision Oscillation Adjustment Function

The RV5C386A has built-in oscillation stabilization capacitors (CG and CD), which can be connected to an

external crystal oscillator to configure an oscillation circuit. To correct deviations in the oscillation frequency

of the crystal oscillator, the oscillation adjustment circuit is configured to allow correction of a time count gain

or loss (up to ±1.5 ppm at 25°C) from the CPU within a maximum range of approximately + 189 ppm in

increments of approximately 3 ppm. Such oscillation frequency adjustment in each system has the following

advantages:

* Allows timekeeping with much higher precision than conventional RTCs while using a crystal oscillator with

a wide range of precision variations.

* Corrects seasonal frequency deviations through seasonal oscillation adjustment.

* Allows timekeeping with higher precision particularly with a temperature sensing function out of RTC,

through oscillation adjustment in tune with temperature fluctuations.

(5) Oscillation Halt Sensing Function and Supply Voltage Monitoring Function

The RV5C386A incorporates an oscillation halt sensing circuit equipped with internal registers configured to

record any past oscillation halt, thereby identifying whether they are powered on from 0 volts or battery

backed-up. As such, the oscillation halt sensing circuit is useful for judging the validity of time data.

The RV5C386A also incorporates a supply voltage monitoring circuit equipped with internal registers

configured to record any drop in supply voltage below a certain threshold value. Supply voltage monitoring

threshold settings can be selected between 2.1 and 1.6 volts through internal register settings. The

oscillation halt sensing circuit is configured to confirm the established invalidation of time data in contrast to

the supply voltage monitoring circuit intended to confirm the potential invalidation of time data. Further, the

supply voltage monitoring circuit can be applied to battery supply voltage monitoring.

- 7 -

12345

Page 8

RV5C386A PRELIMINARY

(6) Periodic Interrupt Function

The RV5C386A incorporates the periodic interrupt circuit configured to generate periodic interrupt signals

aside from interrupt signals generated by the alarm interrupt circuit for output from the /INTRA pin. Periodic

interrupt signals have five selectable frequency settings of 2 Hz (once per 0.5 seconds), 1 Hz (once per 1

second), 1/60 Hz (once per 1 minute), 1/3600 Hz (once per 1 hour), and monthly (the first day of every month).

Further, periodic interrupt signals also have two selectable waveforms, a normal pulse form (with a frequency

of 2 Hz or 1 Hz) and special form adapted to interruption from the CPU in the level mode (with second,

minute, hour, and month interrupts). The condition of periodic interrupt signals can be monitored by using a

polling function.

(7) 32kHz Clock Output

The RV5C386A incorporates a 32-kHz clock circuit configured to generate clock pulses with the oscillation

frequency of a 32.768kHz crystal oscillator for output from the 32KOUT pin (CMOS push-pull output). The

32-kHz clock output is enabled and disabled when the CLKC pin is held high, and low or open, respectively.

12345

- 8 -

Page 9

PRELIMINARY RV5C386A

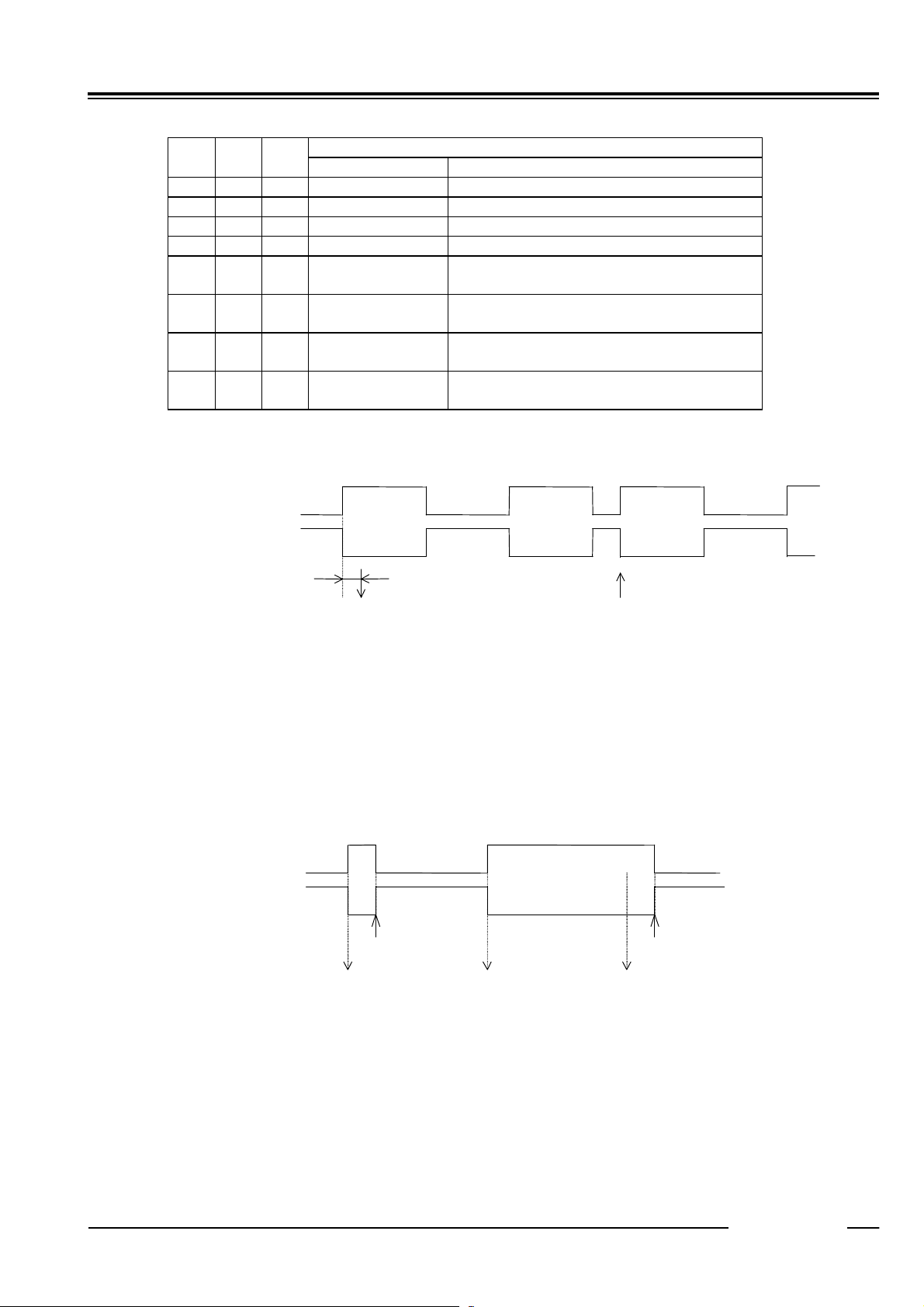

13. FUNCTION DESCRIPTIONS

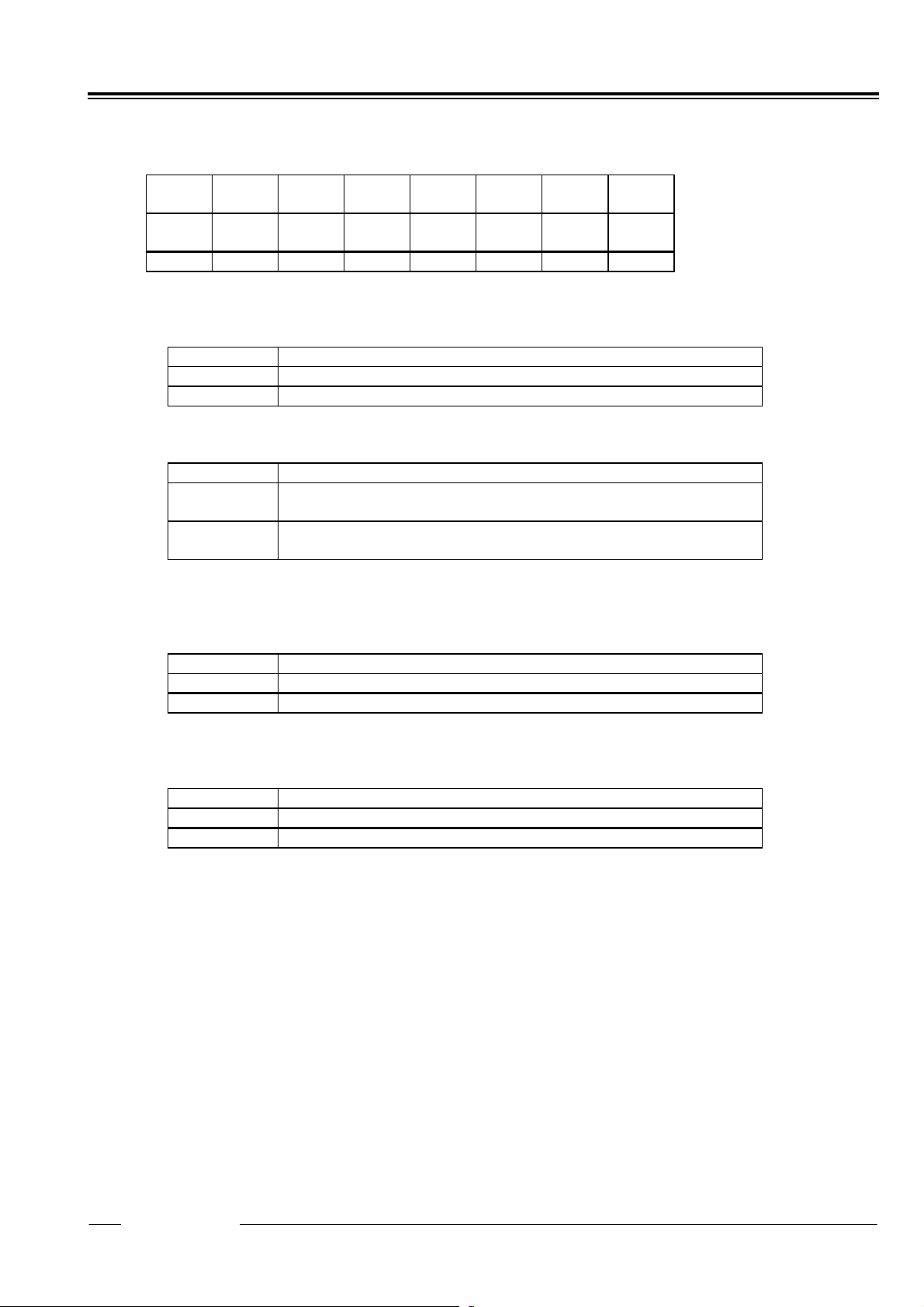

13.1. Address Mapping

Address Register Name D a t a

A3A2A1A0 D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 Second Counter -

*2)

1 0 0 0 1 Minute Counter - M40 M20 M10 M8 M4 M2 M1

2 0 0 1 0 Hour Counter - - H20

3 0 0 1 1 Day-of-week Counter - - - - - W4 W2 W1

4 0 1 0 0 Day-of-month Counter - - D20 D10 D8 D4 D2 D1

5 0 1 0 1 Month Counter and

Century Bit

6 0 1 1 0 Year Counter Y80 Y40 Y20 Y10 Y8 Y4 Y2 Y1

7 0 1 1 1 Oscillation Adjustment

Register *3)

8 1 0 0 0 Alarm_W

(Minute Register)

9 1 0 0 1 Alarm_W

(Hour Register)

A 1 0 1 0 Alarm_W

(Day-of-week Register)

B 1 0 1 1 Alarm_D

(Minute Register)

C 1 1 0 0 Alarm_D

(Hour Register)

D 1 1 0 1 - - - - - - - E 1 1 1 0 Control Register 1 *3) WALE DALE

F 1 1 1 1 Control Register 2 *3) VDSL VDET SCRA-

Notes:

* 1) All the data listed above accept both reading and writing.

* 2) The data marked with "-" is invalid for writing and reset to 0 for reading.

* 3) When the XSTP bit is set to 1 in Control Register 2, all the bits are reset to 0 in Oscillation Adjustment

Register, Control Register 1 and Control Register 2 excluding the XSTP bit.

/19⋅20

S40 S20 S10 S8 S4 S2 S1

H10 H8 H4 H2 H1

P⋅/A

- - MO10 MO8 MO4 MO2 MO1

- F6 F5 F4 F3 F2 F1 F0

- WM40 WM20 WM10 WM8 WM4 WM2 WM1

- - WH20

WP⋅/A

- WW6 WW5 WW4 WW3 WW2 WW1 WW0

- DM40 DM20 DM10 DM8 DM4 DM2 DM1

- - DH20

DP⋅/A

/12⋅24

TCH1

WH10 WH8 WH4 W H2 WH1

DH10 DH8 DH4 DH2 DH1

SCRA-

TCH3

XSTP SCRA-

TEST CT2 CT1 CT0

CTFG WAFG DAFG

TCH2

- 9 -

12345

Page 10

RV5C386A PRELIMINARY

13.2. Register Settings

13.2.1. Control Register 1 (ADDRESS Eh)

D7 D6 D5 D4 D3 D2 D1 D0

WALE DALE

WALE DALE

0 0 0 0 0 0 0 0 Default Settings *)

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

(1) WALE, DALE Alarm_W Enable Bit, Alarm_D Enable Bit

WALE,DALE Description

0 Disabling the alarm interrupt circuit (under the control of the settings

1 Enabling the alarm interrupt circuit (under the control of the settings

(2) /12⋅24 12-/24-hour Mode Selection Bit

/12⋅24

0 Selecting the 12-hour mode with a.m. and p.m. indications. (Default)

1 Selecting the 24-hour mode

Setting the /12 ⋅ 24 bit to 0 and 1 specifies the 12-hour mode and the 24-hour mode, respectively.

/12⋅24

/12⋅24

of the Alarm_W registers and the Alarm_D registers).

of the Alarm_W registers and the Alarm_D registers)

SCRATCH3 TEST CT2 CT1 CT0 (For Writing)

SCRATCH3 TEST CT2 CT1 CT0 (For Reading)

(Default)

Description

24-hour mode 12-hour mode 24-hour mode 12-hour mode

00 12 (AM12) 12 32 (PM12)

01 01 (AM 1) 13 21 (PM 1)

02 02 (AM 2) 14 22 (PM 2)

03 03 (AM 3) 15 23 (PM 3)

04 04 (AM 4) 16 24 (PM 4)

05 05 (AM 5) 17 25 (PM 5)

06 06 (AM 6) 18 26 (PM 6)

07 07 (AM 7) 19 27 (PM 7)

08 08 (AM 8) 20 28 (PM 8)

09 09 (AM 9) 21 29 (PM 9)

10 10 (AM10) 22 30 (PM10)

11 11 (AM11) 23 31 (PM11)

Setting the /12⋅24 bit should precede writing time data

(3) SCRATCH3 Scratch Bit 3

SCRATCH3 Description

0 (Default)

1

The SCRATCH3 bit is intended for scratching and accepts the reading and writing of 0 and 1. The SCRATCH3

bit will be set to 0 when the XSTP bit is set to 1 in the Control Register 2.

(4) TEST Test Bit

TEST Description

0 Normal operation mode. (Default)

1 Test mode.

The TEST bit is used only for testing in the factory and should normally be set to 0.

12345

- 10 -

Page 11

PRELIMINARY RV5C386A

(5) CT2,CT1, and CT0 Periodic Interrupt Selection Bits

DescriptionCT2 CT1 CT0

Wave form mode Interrupt Cycle and Falling Timing

0 0 0 - OFF(H) (Default)

0 0 1 - Fixed at “L”

0 1 0 Pulse Mode *1) 2Hz(Duty50%)

0 1 1 Pulse Mode *1) 1Hz(Duty50%)

1 0 0 Level Mode *2) Once per 1 second (Synchronized with

second counter increment)

1 0 1 Level Mode *2) Once per 1 minute (at 00 seconds of every

minute)

1 1 0 Level Mode *2) Once per hour (at 00 minutes and 00

seconds of every hour)

1 1 1 Level Mode *2) Once per month (at 00 hours, 00 minutes,

and 00 seconds of first day of every month)

*1) Pulse Mode: 2-Hz and 1-Hz clock pulses are output in synchronization with the increment of the second

counter as illustrated in the timing chart below.

CTFG Bit

/INTRA Pin

Approx. 92µs

(Increment of second counter)

Rewriting of the second counter

In the pulse mode, the increment of the second counter is delayed by approximately 92 µs from the falling edge of

clock pulses. Consequently, time readings immediately after the falling edge of clock pulses may appear to lag

behind the time counts of the real-time clocks by approximately 1 second. Rewriting the second counter will

reset the other time counters of less than 1 second, driving the /INTRA pin low.

*2) Level Mode: Periodic interrupt signals are output with selectable interrupt cycle settings of 1 second, 1

minute, 1 hour, and 1 month. The increment of the second counter is synchronized with the

falling edge of periodic interrupt signals. For example, periodic interrupt signals with an

interrupt cycle setting of 1 second are output in synchronization with the increment of the second

counter as illustrated in the timing chart below.

CTFG Bit

/INTRA Pin

Setting CTFG bit to 0

(Increment of

second counter)

(Increment of

second counter)

Setting CTFG bit to 0

(Increment of

second counter)

*1), *2) When the oscillation adjustment circuit is used, the interrupt cycle will fluctuate once per 20sec. as follows:

Pulse Mode: The “L” period of output pulses will increment or decrement by a maximum of ±3.784 ms. For

example, 1-Hz clock pulses will have a duty cycle of 50 ±0.3784%.

Level Mode: A periodic interrupt cycle of 1 second will increment or decrement by a maximum of ±3.784 ms.

- 11 -

12345

Page 12

RV5C386A PRELIMINARY

SCRA-

TCH1

XSTP

SCRA-

TCH1

SCRA-

13.2.2. Control Register 2 (Address Fh)

D7 D6 D5 D4 D3 D2 D1 D0

VDSL

TCH2

VDSL

0 0 0 1 0 0 0 0 Default Settings *)

(1) VDSL Supply Voltage Monitoring Threshold Selection Bit

(2) VDET Supply Voltage Monitoring Result Indication Bit

(3) SCRATCH1 Scratch Bit 1

(4) XSTP Oscillation Halt Sensing Bit

VDET

*) Default settings: Default value means read / written values when the XSTP bit is reset due to power-on from

0 volts or supply voltage drop.

VDSL Description

0 Selecting the supply voltage monitoring threshold setting of 2.1v. (Default)

1 Selecting the supply voltage monitoring threshold setting of 1.6v.

The VDSL bit is intended to select the supply voltage monitoring threshold settings.

VDET Description

0 Indicating supply voltage above the supply voltage monitoring

threshold settings.

1 Indicating supply voltage below the supply voltage monitoring

threshold settings.

Once the VDET bit is set to 1, the supply voltage monitoring circuit will be disabled while the VDET bit will hold the

setting of 1. The VDET bit accepts only the writing of 0, which restarts the supply voltage monitoring circuit.

Conversely, setting the VDET bit to 1 causes no event.

SCRATCH1 Description

0 (Default)

1

The SCRATCH1 bit is intended for scratching and accepts the reading and writing of 0 and 1. The SCRATCH1

bit will be set to 0 when the XSTP bit is set to 1 in the Control Register 2.

XSTP Description

0 Sensing a normal condition of oscillation

1 Sensing a halt of oscillation (Default)

The XSTP bit is for sensing a halt in the oscillation of the crystal oscillator.

* The XSTP bit will be set to 1 once a halt in the oscillation of the crystal oscillator is caused by such events as

power-on from 0 volts and a drop in supply voltage. The XSTP bit will hold the setting of 1 even after the

restart of oscillation. As such, the XSTP bit can be applied to judge the validity of clock and calendar data

after power-on or a drop in supply voltage.

* When the XSTP bit is set to 1, all bits will be reset to 0 in the Oscillation Adjustment Register, Control Register

1, and Control Register 2, stopping the output from /INTRA and /INTRB pins and starting the output of

32.768-kHz clock pulses from the 32KOUT pin.

* The XSTP bit accepts only the writing of 0, which restarts the oscillation halt sensing circuit. Conversely,

setting the XSTP bit to 1 causes no event.

* It is recommendable to frequently check the XSTP bit for setting errors or data garbles, which may seriously

affect the operation of the RV5C386A.

XSTP

TCH2

CTFG

CTFG

WAFG

WAFG

DAFG (For Writing)

DAFG (For Reading)

(Default)

12345

- 12 -

Page 13

PRELIMINARY RV5C386A

(5) SCRATCH2 Scratch Bit 2

SCRATCH2 Description

0 (Default)

1

The SCRATCH2 bit is intended for scratching and accepts the reading and writing of 0 and 1. The SCRATCH2

bit will be set to 0 when the XSTP bit is set to 1 in the Control Register 2.

(6) CTFG Periodic Interrupt Flag Bit

CTFG Description

0 Periodic interrupt output = “H” (Default)

1 Periodic interrupt output = “L”

The CTFG bit is set to 1 when the periodic interrupt signals are output from the /INTRA pin (“L”). The CTFG bit

accepts only the writing of 0 in the level mode, which disables (“H”) the /INTRA pin until it is enabled (“L”) again in

the next interrupt cycle. Conversely, setting the CTFG bit to 1 causes no event.

(7) WAFG,DAFG Alarm_W Flag Bit and Alarm_D Flag Bit

WAFG,DAFG Description

0 Indicating a mismatch between current time and preset alarm time (Default)

1 Indicating a match between current time and preset alarm time

The WAFG and DAFG bits are valid only when the WALE and DALE have the setting of 1, which is caused

approximately 61µs after any match between current time and preset alarm time specified by the Alarm_W

registers and the Alarm_D registers. The WAFG (DAFG) bit accepts only the writing of 0. /INTRB (/INTRA) pin

outputs off (“H”) when this bit is set to 0. And /INTRB (/INTRA) pin outputs “L” again at the next preset alarm

time. Conversely, setting the WAFG and DAFG bits to 1 causes no event. The WAFG and DAFG bits will have

the reading of 0 when the alarm interrupt circuit is disabled with the WALE and DALE bits set to 0. The settings

of the WAFG and DAFG bits are synchronized with the output of the /INTRB (/INTRA) pin as shown in the timing

chart below.

Approx. 61µs Approx. 61µs

WAFG(DAFG) Bit

/INTRB(/INTRA) Pin

(Match between

current time and

preset alarm time)

Writing of 0 to

WAFG(DAFG) bit

(Match between

current time and

preset alarm time)

Writing of 0 to

WAFG(DAFG) bit

(Match between

current time and

preset alarm time)

- 13 -

12345

Page 14

RV5C386A PRELIMINARY

13.2.3. Time Counter (Address 0-2h)

• Second Counter (Address 0h)

D7 D6 D5 D4 D3 D2 D1 D0

- S40 S20 S10 S8 S4 S2 S1

0 S40 S20 S10 S8 S4 S2 S1

0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

• Minute Counter (Address 1h)

D7 D6 D5 D4 D3 D2 D1 D0

- M40 M20 M10 M8 M4 M2 M1

0 M40 M20 M10 M8 M4 M2 M1

0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

• Hour Counter (Address 2h)

D7 D6 D5 D4 D3 D2 D1 D0

- -

0 0

0 0

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

* Time digit display (BCD format) as follows:

The second digits range from 00 to 59 and are carried to the minute digit in transition from 59 to 00.

The minute digits range from 00 to 59 and are carried to the hour digits in transition from 59 to 00.

The hour digits range as shown in "13.2.1. – (2). /12⋅24: 12-/24-hour Mode Selection Bit" and are carried to

the day-of-month and day-of-week digits in transition from PM11 to AM12 or from 23 to 00.

* Any writing to the second counter resets divider units of less than 1 second.

* Any carry from lower digits with the writing of non-existent time may cause the time counters to malfunction.

Therefore, such incorrect writing should be replaced with the writing of existent time data.

13.2.4. Day-of-week Counter (Address 3h)

P⋅/A

or H20

P⋅/A

or H20

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

H10 H8 H4 H2 H1 (For Writing)

H10 H8 H4 H2 H1 (For Reading)

(For Writing)

(For Reading)

Default Settings *)

(For Writing)

(For Reading)

Default Settings *)

Default Settings *)

D7 D6 D5 D4 D3 D2 D1 D0

- - - - - W4 W2 W1

0 0 0 0 0 W4 W2 W1

0 0 0 0 0

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

* The day-of-week counter is incremented by 1 when the day-of-week digits are carried to the day-of-

month digits.

* Day-of-week display (incremented in septimal notation):

(W4, W2, W1) = (0, 0, 0) → (0, 0, 1)→…→(1, 1, 0) → (0, 0, 0)

* Correspondences between days of the week and the day-of-week digits are user-definable

(e.g. Sunday = 0, 0, 0)

* The writing of (1, 1, 1) to (W4, W2, W1) is prohibited except when days of the week are unused.

12345

Indefinite Indefinite Indefinite

- 14 -

(For Writing)

(For Reading)

Default Settings *)

Page 15

PRELIMINARY RV5C386A

13.2.5. Calendar Counter (Address 4-6h)

• Day-of-month Counter (Address 4h)

D7 D6 D5 D4 D3 D2 D1 D0

- - D20 D10 D8 D4 D2 D1

0 0 D20 D10 D8 D4 D2 D1

0 0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

• Month Counter + Century Bit (Address 5h)

D7 D6 D5 D4 D3 D2 D1 D0

/19⋅20 - - MO10 MO8 MO4 MO2 MO1

/19⋅20 0 0 MO10 MO8 MO4 MO2 MO1

Indefinite

0 0

Indefinite Indefinite Indefinite Indefinite Indefinite

• Year Counter (Address 6h)

D7 D6 D5 D4 D3 D2 D1 D0

Y80 Y40 Y20 Y10 Y8 Y4 Y2 Y1

Y80 Y40 Y20 Y10 Y8 Y4 Y2 Y1

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

* The calendar counters are configured to display the calendar digits in BCD format by using the automatic

calendar function as follows:

The day-of-month digits (D20 to D1) range from 1 to 31 for January, March, May, July, August, October, and

December; from 1 to 30 for April, June, September, and November; from 1 to 29 for February in leap years;

from 1 to 28 for February in ordinary years. The day-of-month digits are carried to the month digits in

reversion from the last day of the month to 1. The month digits (MO10 to MO1) range from 1 to 12 and are

carried to the year digits in reversion from 12 to 1.

The year digits (Y80 to Y1) range from 00 to 99 (00, 04, 08, …, 92, and 96 in leap years) and are carried to the

/19⋅20 digits in reversion from 99 to 00.

The /19⋅20 digits cycle between 0 and 1 in reversion from 99 to 00 in the year digits.

* Any carry from lower digits with the writing of non-existent calendar data may cause the calendar counters to

malfunction. Therefore, such incorrect writing should be replaced with the writing of existent calendar data.

(For Writing)

(For Reading)

Default Settings *)

(For Writing)

(For Reading)

Default Settings *)

(For Writing)

(For Reading)

Default Settings *)

13.2.6. Oscillation Adjustment Register (Address 7h)

D7 D6 D5 D4 D3 D2 D1 D0

- F6 F5 F4 F3 F2 F1 F0

0 F6 F5 F4 F3 F2 F1 F0

0 0 0 0 0 0 0 0 Default Settings *)

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

(For Writing)

(For Reading)

12345

- 15 -

Page 16

RV5C386A PRELIMINARY

F6 to F0 bits

The Oscillation Adjustment Circuit is configured to change time counts of 1 second on the basis of the settings

of

the Oscillation Adjustment Register when the second digits read 00, 20, or 40 seconds. Normally, the Second

Counter is incremented once per 32768 32.768-kHz clock pulses generated by the crystal oscillator. Writing to

the F6 to F0 bits activates the oscillation adjustment circuit.

* The Oscillation Adjustment Circuit will not operate with the same timing (00, 20, or 40 seconds)

as the timing of writing to the Oscillation Adjustment Register.

* The F6 bit setting of 0 causes an increment of time counts by ((F5, F4, F3, F2, F1, F0) - 1) x 2.

The F6 bit setting of 1 causes a decrement of time counts by ((/F5, /F4, /F3, /F2, /F1, /F0) + 1) x 2.

The settings of "*, 0, 0, 0, 0, 0, *" ("*" representing either "0" or "1") in the F6, F5, F4, F3, F2, F1, and F0

bits cause neither an increment nor decrement of time counts.

Example:

When the second digits read 00, 20, or 40, the settings of "0, 0, 0, 0, 1, 1, 1" in the F6, F5, F4, F3, F2, F1, and F0

bits cause an increment of the current time counts of 32768 by (7 - 1) x 2 to 32780 (a current time count loss).

When the second digits read 00, 20, or 40, the settings of "0, 0, 0, 0, 0, 0, 1" in the F6, F5, F4, F3, F2, F1, and F0

bits cause neither an increment nor a decrement of the current time counts of 32768.

When the second digits read 00, 20, or 40, the settings of "1, 1, 1, 1, 1, 1, 0" in the F6, F5, F4, F3, F2, F1, and F0

bits cause a decrement of the current time counts of 32768 by (- 2) x 2 to 32764 (a current time count gain).

An increase of two clock pulses once per 20 seconds causes a time count loss of approximately 3 ppm (2 / (32768

x 20 = 3.051 ppm). Conversely, a decrease of two clock pulses once per 20 seconds causes a time count gain of

3 ppm. Consequently, deviations in time counts can be corrected with a precision of ±1.5 ppm. Note that the

oscillation adjustment circuit is configured to correct deviations in time counts and not the oscillation frequency of

the 32.768-kHz clock pulses. For further details, see "14. 2. 4. Oscillation Adjustment Circuit".

13.2.7. Alarm_W Registers (Address 8-Ah)

• Alarm_W Minute Register (Address 8h)

D7 D6 D5 D4 D3 D2 D1 D0

- WM40 WM20 WM10 WM8 WM4 WM2 WM1

0 WM40 WM20 WM10 WM8 WM4 WM2 WM1

0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

• Alarm_W Hour Register (Address 9h)

D7 D6 D5 D4 D3 D2 D1 D0

- - WH20

WH10 WH8 WH4 WH2 WH1

WP⋅/A

0 0 WH20

WH10 WH8 WH4 WH2 WH1

WP⋅/A

0 0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

• Alarm_W Day-of-week Register (Address Ah)

D7 D6 D5 D4 D3 D2 D1 D0

- WW6 WW5 WW4 WW3 WW2 WW1 WW0

0 WW6 WW5 WW4 WW3 WW2 WW1 WW0

0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

* The D5 bit of the Alarm_W Hour Register represents WP/A when the 12-hour mode is selected (0 for a.m. and

1 for p.m.) and W H20 when the 24-hour mode is selected (tens in the hour digits).

* The Alarm_W Registers should not have any non-existent alarm time settings.

(For Writing)

(For Reading)

Default Settings *)

(For Writing)

(For Reading)

Default Settings *)

(For Writing)

(For Reading)

Default Settings *)

12345

- 16 -

Page 17

PRELIMINARY RV5C386A

(Note that any mismatch between current time and preset alarm time specified by the Alarm_W registers may

disable the alarm interrupt circuit.)

* When the 12-hour mode is selected, the hour digits read 12 and 32 for 0 a.m. and 0 p.m., respectively.

(See "13.2. 1. – (2). /12 * 24: 12-/24-hour Mode Selection Bit").

* WW0 to WW6 correspond to W4, W2, and W1 of the day-of-week counter with settings ranging from (0, 0, 0)

to (1, 1, 0).

* WW0 to WW6 with respective settings of 0 disable the outputs of the Alarm_W Registers.

Example of Alarm Time Setting

Alarm Day-of-week 12-hour mode 24-hour mode

Preset alarm time

00:00 a.m. on all days 1 1 1 1 1 1 1 1 2 0 0 0 0 0 0

01:30 a.m. on all days 1 1 1 1 1 1 1 0 1 3 0 0 1 3 0

11:59 a.m. on all days 1 1 1 1 1 1 1 1 1 5 9 1 1 5 9

00:00 p.m. on Mon. to Fri. 0 1 1 1 1 1 0 3 2 0 0 1 2 0 0

01:30 p.m. on Sun. 1 0 0 0 0 0 0 2 1 3 0 1 3 3 0

11:59 p.m.

on Mon. ,Wed., and Fri.

Note that the correspondence between WW0 to WW6 and the days of the week shown in the above table is only

an example and not mandatory.

Sun. Mon. Tue. Wed. Th. Fri. Sat. 10

hr.1hr.10min.1min.10hr.1hr.10min.1min.

WW0 WW1 WW2 WW3 WW4 WW5 WW6

0 1 0 1 0 1 0 3 1 5 9 2 3 5 9

13.2.8. Alarm_D Register (Address B-Ch)

• Alarm_D Minute Register (Address Bh)

D7 D6 D5 D4 D3 D2 D1 D0

- DM40 DM20 DM10 DM8 DM4 DM2 DM1

0 DM40 DM20 DM10 DM8 DM4 DM2 DM1

0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

• Alarm_D Hour Register (Address Ch)

D7 D6 D5 D4 D3 D2 D1 D0

- - DH20

DH10 DH8 DH4 DH2 DH1

DP⋅/A

0 0 DH20

DH10 DH8 DH4 DH2 DH1

DP⋅/A

0 0

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

*) Default settings: Default value means read/written values when the XSTP bit is set to “1” due to power-on

from 0 volts or supply voltage drop.

* The D5 bit represents DP/A when the 12-hour mode is selected (0 for a.m. and 1 for p.m.) and DH20 when the

24-hour mode is selected (tens in the hour digits).

* The Alarm_D registers should not have any non-existent alarm time settings.

(Note that any mismatch between current time and preset alarm time specified by the Alarm_D registers may

disable the alarm interrupt circuit.)

* When the 12-hour mode is selected, the hour digits read 12 and 32 for 0a.m. and 0p.m., respectively.

(see "13.2.1. (2) /12 * 24: 12-/24-hour Mode Selection Bit").

(For Writing)

(For Reading)

Default Settings *)

(For Writing)

(For Reading)

Default Settings *)

- 17 -

12345

Page 18

RV5C386A PRELIMINARY

For data interface, the following conditions

* When the master is one, the micro-

14. USAGE

14.1. Interfacing with the CPU

The RV5C386A employs the I2C-Bus system to be connected to the CPU via 2-wires. Connection and

system of I2C-Bus are described in the following sections.

14.1.1. Connection of I2C-Bus

2-wires, SCL and SDA pins that are connected to I2C-Bus are used for transmit clock pulses and data

respectively. All ICs that are connected to these lines are designed that will not be clamped when a voltage

beyond supply voltage is applied to input or output pins. Open drain pins are used for output. This

construction allows communication of signals between ICs with different supply voltages by adding a pull-up

resistor to each signal line as shown in the figure below. Each IC is designed not to affect SCL and SDA

signal lines when power to each of these is turned off separately.

VDD1

VDD2

VDD3

VDD4

SCL

SDA

Micro-

Controller

Rp Rp

RV5C386A

Other

Peripheral

Device

*

must be met:

VDD4≥VDD1

VDD4≥VDD2

VDD4≥VDD3

controller is ready for driving SCL to “H” and

Rp of SCL may not be required.

Cautions on determining Rp resistance,

(1) Dropping voltage at Rp due to sum of input current or output current at off conditions on each IC pin

connected to the I2C-Bus shall be adequately small.

(2) Rising time of each signal be kept short even when all capacity of the bus is driven.

(3) Current consumed in I2C-Bus is small compared to the consumption current permitted for the entire

system.

When all ICs connected to I2C-Bus are CMOS type, condition (1) may usually be ignored since input current

and off-state output current is extremely small for the many CMOS type ICs. Thus the maximum resistance

of Rp may be determined based on (2), while the minimum on (3) in most cases.

In actual cases a resistor may be place between the bus and input/output pins of each IC to improve noise

margins in which case the Rp minimum value may be determined by the resistance.

Consumption current in the bus to review (3) above may be expressed by the formula below:

Bus consumption current ≈

(Sum of input current and off state output current of all devices in standby mode ) × Bus standby duration

+ Supply voltage × Bus operation duration × 2

Rp resistance × 2 × (Bus stand-by duration + bus operation duration)

+ Supply voltage × Bus capacity × Charging/Discharging times per unit time

Operation of “× 2” in the second member denominator in the above formula is derived from assumption that

“L” duration of SDA and SCL pins are the half of bus operation duration. “× 2” in the numerator of the same

member is because there are two pins of SDA and SCL. The third member, (charging/discharging times per

unit time) means number of transition from “H” to “L” of the signal line.

12345

Bus stand-by duration + the Bus operation duration

- 18 -

Page 19

PRELIMINARY RV5C386A

;STA

Calculation example is shown below:

Pull-up resistor (Rp) = 10kΩ, Bus capacity = 50pF(both for SCL, SDA), Vdd=3v,

In a system with sum of input current and off-state output current of each pin = 0.1µA,

I2C-Bus is used for 10ms every second while the rest of 990ms in the stand-by mode,

In this mode, number of transitions of the SCL pin from “H” to “L” state is 100 while SDA 50, every second.

Bus consumption current ≈ 0.1µA×990msec

990msec + 10msec

+ 3V × 10msec × 2

10KΩ × 2 × (990msec + 10msec)

+ 3V × 50pF × (100 + 50)

≈ 0.099µA + 3.0µA + 0.0225µA ≈ 3.12µA

Generally, the second member of the above formula is larger enough than the first and the third members,

bus consumption current may be determined by the second member is many cases.

14.1.2. Transmission System of I2C-Bus

(1) Start Condition and Stop Condition

In I2C-Bus, SDA must be kept at a certain state while SCL is at the “H” state during data transmission as

shown below.

SCL

SDA

tSU;DAT

tHD;DAT

The SCL and SDA pins are at the “H” level when no data transmission is made. Changing the SDA from “H” to

“L” when the SCL and the SDA are “H” activates the Start Condition and access is started. Changing the SDA

from “L” to “H” when the SCL is “H” activates Stop Condition and accessing stopped. Generation of Start and

Stop Conditions are always made by the master (see the figure below).

Start Condition Stop Condition

SCL

SDA

tHD

(2) Data transmission and its acknowledge

After Start condition is entered, data is transmitted by 1byte (8bits). Any bytes of data may be serially

transmitted. The receiving side will send an acknowledge signal to the transmission side each time 8bit data

is transmitted. The acknowledge signal is sent immediately after falling to “L” of SCL 8bit clock pulses of

data is transmitted, by releasing the SDA by the transmission side that has asserted the bus at that time and

by turning SDA to “L” by receiving side. When transmission of 1byte data next to preceding 1byte of data is

received the receiving side releases the SDA pin at falling edge of the SCL 9bit of clock pulses or when the

receiving side switches to the transmission side it starts data transmission. When the master is receiving

side, it generates no acknowledge signal after last 1byte of data from the slave to tell the transmitter that data

tSU;STO

12345

- 19 -

Page 20

RV5C386A PRELIMINARY

transmission has completed. The slave side (transmission side) continues to release the SDA pin so that

the master will be able to generate Stop Condition, after falling edge of the SCL 9bit of clock pulses.

SCL

from the master

SDA from

the transmission side

SDA from

the receiving side

Start

Condition

(3) Data Transmission Format in I2C-Bus

I2C-Bus has no chip enable signal line. In place of it, each device has a 7bit Slave Address allocated. The

first 1byte is allocated to this 7bit address and to the command (R/W) for which data transmission direction is

designated by the data transmission thereafter. 7bit address is sequentially transmitted from the MSB and 2

and after bytes are read, when 8bit is “H” and when write “L”.

The Slave Address of the RV5C386A is specified at (0110010).

At the end of data transmission / receiving, Stop Condition is generated to complete transmission. However,

if start condition is generated without generating Stop Condition, Repeated Start Condition is met and

transmission / receiving data may be continue by setting the Slave Address again. Use this procedure when

the transmission direction needs to be change during one transmission.

Data is written to the slave

from the master

Slave Address Data

S 0 A

1 2 8 9

Acknowledge

signal

A A P

Data

When data is read from the

slave immediately after 7bit

addressing from the master

When the transmission

direction is to be changed

during transmission.

Master to slave Slave to master

Start Condition

S

R/W=0(Write)(0110010)

Slave Address

S 1 A /A P

(0110010)

Slave Address Salve Address

S

(0110010)

Data

P

A

R/W=1(Read)

R/W=0(Write)

AA

Inform read has been completed by not generate

an acknowledge signal to the slave side.

Stop Condition

Data

Data

Data

Data

Inform read has been completed by not generate

an acknowledge signal to the slave side.

Sr 10 AA

R/W=1(Read)(0110010)

/A P

A A /A

Repeated Start Condition

Sr

Acknowledge Signal

12345

- 20 -

Page 21

PRELIMINARY RV5C386A

0h

14.1.3. Data Transmission Write Format in the RV5C386A

Although the I2C-Bus standard defines a transmission format for the slave allocated for each IC, transmission

method of address information in IC is not defined. The RV5C386A transmits data the internal address

pointer (4bit) and the Transmission Format Register (4bit) at the 1byte next to one which transmitted a Slave

Address and a write command. For write operation only one transmission format is available and (0000) is

set to the Transmission Format Register. The 3byte transmits data to the address specified by the internal

address pointer written to the 2byte. Internal address pointer setting are automatically incremented for

4byte and after. Note that when the internal address pointer is Fh, it will change to 0h on transmitting the

next byte.

Example of data writing (When writing to internal address Eh to Fh)

R/W=0(Write)

1 AS 0 A

Slave Address

←(0110010)

S

A A /A

A

110 0 00 0 0 0 00 1 11

Address

Pointer

←Eh

Master to slave Slave to master

Start Condition

Acknowledge signal

Transmission

Format

Register

Data

Writing of data to the

internal address Eh

←

Stop Condition

P

Data

Writing of data to the

internal address Fh

A P

12345

- 21 -

Page 22

RV5C386A PRELIMINARY

Reading of data from

Reading of data from

14.1.4. Data transmission read format of the RV5C386A

The RV5C386A allows the following three readout method of data an internal register.

1) The first method to reading data from the internal register is to specify an internal address by setting the

internal address pointer and the transmission format register described 14.1.3, generate the Repeated

Start Condition (See section 14.1.2-(3)) to change the data transmission direction to perform reading.

The internal address pointer is set to Fh when the Stop Condition is met. Therefore, this method of

reading allows no insertion of Stop Condition before the Repeated Start Condition. Set 0h to the

Transmission Format Register when this method used.

Example 1 of Data Read (when data is read from 2h to 4h)

Slave Address

← (0110010)

Reading of data from

the internal address 2h

Master to slave Slave to master

Start Condition

S

A A /A

10 0 00 1

0 10 00 11 0 0 0 00 0 1

Pointer←2h

Data

Acknowledge signal

Address

Repeated Start Condition

Sr1 0 A

Transmission

Format

Register←0h

A

the internal address 3h

Data

Repeated Start

Sr

Condition

R/W=1(Read)R/W=0(Write)

1S 0A A

Slave Address

← (0110010)

A

the internal address 4h

Data

P

/A P

Stop Condition

12345

- 22 -

Page 23

PRELIMINARY RV5C386A

Reading of data from

2) The second method to reading data from the internal register is to start reading immediately after writing

to the Internal Address Pointer and the Transmission Format Register. Although this method is not based

on I2C-Bus standard in a strict sense it still effective to shorten read time to ease load to the master. Set

4h to the transmission format register when this method used.

Example 2 of data read (when data is read from internal addresses Eh to 1h)

R/W=0(Write)

1 0 A

Slave Address

← (0110010)

S

A A /A

10 0 00 1

the internal address Fh

Master to slave Slave to Master

Start Condition

1S A A

Address

Pointer

←

Data

Acknowledge Signal

Transmission

Eh

Register←4h

A

Reading of data from

the internal address 0h

0 11 0 001

Format

Data

Reading of data from

the internal address Eh

Data

Stop Condition

P

A

Data

Reading of data from

the internal address 1h

/A P

12345

- 23 -

Page 24

RV5C386A PRELIMINARY

3) The third method to reading data from the internal register is to start reading immediately after writing to

the Slave Address and R/W bit. Since the Internal Address Pointer is set to Fh by default as described

in 1), this method is only effective when reading is started from the Internal Address Fh.

Example 3 of data read (when data is read from internal addresses Fh to 3h)

R/W=1(Read)

S A A

1 0 A

Slave Address

← (0110010)

S

A A /A

10 0 10 1

Reading of data from

the Internal Address Fh

Data

Reading of data from

the Internal Address 1h

Master to slave Slave to master

Start Condition

Acknowledge Signal

Data

Reading of data from

the Internal Address 0h

A

Reading of data from

the Internal Address 2h

Data

Stop Condition

P

Data

A

Reading of data from

the Internal Address 3h

Data

/A P

12345

- 24 -

Page 25

PRELIMINARY RV5C386A

14.1.5. Data Transmission under Special Condition

The RV5C386A holds the clock tentatively for duration from Start Condition to avoid invalid read or write

clock on carrying clock. When clock carried during this period, which will be adjusted within approx. 61µs

from Stop Condition. To prevent invalid read or write, clock shall be made during one transmission

operation (from Start Condition to Stop Condition). When 0.5 to 1.0 second elapses after Start Condition,

any access to the RV5C386A is automatically released to release tentative hold of the clock, and access from

the CPU is forced to be terminated (The same action as made Stop Condition is received: automatic resume

function from I2C-Bus interface). Therefore, one access must be complete within 0.5 seconds. The

automatic resume function prevents delay in clock even if SCL is stopped from sudden failure of the system

during clock read operation.

Also a second Start Condition after the first Start Condition and before the Stop Condition is regarded

“Repeated Start Condition”. Therefore, when 0.5 to 1.0 seconds passed after the first Start Condition, an

access to the RV5C386A is automatically released.

If access is tried after automatic resume function is activated, no acknowledge signal will be output for writing

while FFh will be output for reading.

The user shall always be able to access the real-time clock as long as three conditions are met.

(1) No Stop Condition shall be generated until clock read/write is started and completed.

(2) One cycle read/write operation shall be complete within 0.5 seconds.

(3) Do not make Start Condition within 61µs from Stop Condition. When clock is carried during the access,

which will be adjusted within approx. 61µs from Stop Condition.

Bad example of reading from seconds to hours (invalid read)

(Start Condition) → (Read of seconds) → (read of minutes) → (Stop Condition) → (Start Condition) → (Read

of hour) → (Stop Condition)

Assuming read was started at 05:59:59 P.M. and while reading seconds and minutes the time advanced to

06:00:00 P.M. At this time second digit is hold so read the read as 05:59:59. Then the RV5C386A confirms

(Stop Condition) and carries second digit being hold and the time change to 06:00:00 P.M. Then, when the

hour digit is read, it changes to 6. The wrong results of 06:59:59 will be read.

- 25 -

12345

Page 26

RV5C386A PRELIMINARY

14.2. Configuration of Oscillation Circuit and Correction of Time Count Deviations

14.2.1. Configuration of Oscillation Circuit

VDD

OSCIN

RF

The oscillation circuit is driven at a constant voltage of approximately 1.2 volts relative to the level of the VSS

pin input. As such, it is configured to generate an oscillating waveform with a peak-to-peak voltage on the

order of 1.2 volts on the positive side of the VSS pin input.

< Considerations in Handling Crystal Oscillators >

Generally, crystal oscillators have basic characteristics including an equivalent series resistance (R1)

indicating the ease of their oscillation and a load capacitance (CL) indicating the degree of their center

frequency. Particularly, crystal oscillators intended for use in the RV5C386A are recommended to have a

typical R1 value of 30kΩ and a typical CL value of 6 to 8pF. To confirm these recommended values,

contact the manufacturers of crystal oscillators intended for use in these particular models.

< Considerations in Installing Components around the Oscillation Circuit >

1) Install the crystal oscillator in the closest possible vicinity to the real-time clock ICs.

2) Avoid laying any signal lines or power lines in the vicinity of the oscillation circuit (particularly in the area

marked "A" in the above figure).

3) Apply the highest possible insulation resistance between the OSCIN and OSCOUT pins and the printed

circuit board.

4) Avoid using any long parallel lines to wire the OSCIN and OSCOUT pins.

5) Take extreme care not to cause condensation, which leads to various problems such as oscillation halt.

CG

RD

CD

32kHz

OSCOUT

A

VDD

Typical externally-equipped element

X’tal : 32.768kHz

(R1=30kΩ typ)

(CL=6pF to 8pF)

Standard values of internal elements

RF 15MΩ typ

RD 120kΩ typ

CG,CD 12pF typ

< Other Relevant Considerations >

1) For external input of 32.768-kHz clock pulses to the OSCIN pin:

DC coupling: Prohibited due to an input level mismatch.

AC coupling: Permissible except that the oscillation halt sensing circuit does not guarantee perfect

operation because it may cause sensing errors due to such factors as noise.

2) To maintain stable characteristics of the crystal oscillator, avoid driving any other IC through 32.768-kHz

clock pulses output from the OSCOUT pin.

12345

- 26 -

Page 27

PRELIMINARY RV5C386A

OSCIN

OSCOUT

VSS

14.2.2. Measurement of Oscillation Frequency

VDD

32768Hz

CLKC

32KOUT

* 1) The RV5C386A is configured to generate 32.768-kHz clock pulses for output from the 32KOUT pin.

* 2) A frequency counter with 6 (more preferably 7) or more digits on the order of 1ppm is recommended for

use in the measurement of the oscillation frequency of the oscillation circuit.

* 3) The CLKC pin should be connected to the VDD pin as a pull-up resistor.

14.2.3. Adjustment of Oscillation frequency

The oscillation frequency of the oscillation circuit can be adjusted by varying procedures depending on the

usage of Model RV5C386A in the system into which they are to be built and on the allowable degree of time

count errors. The flow chart below serves as a guide to selecting an optimum oscillation frequency

adjustment procedure for the relevant system.

Frequency

Counter

Start

Use 32-kHz

clock output?

YES

Use 32-kHz clock output without regard

to its frequency precision

NO

Allowable time count precision on order of oscillation

frequency variations of crystal oscillator (*1) plus

frequency variations of RTC (*2)? (*3)

Allowable time count precision on order of oscillation

NO

frequency variations of crystal oscillator (*1) plus

frequency variations of RTC (*2)? (*3)

YES

* 1) Generally, crystal oscillators for commercial use are classified in terms of their center frequency depending

on their load capacitance (CL) and further divided into ranks on the order of ±10, ±20, and ±50ppm

depending on the degree of their oscillation frequency variations.

* 2) Basically, Model RV5C386A is configured to cause frequency variations on the order of ±5 to ±10ppm at

normal temperature.

* 3) Time count precision as referred to in the above flow chart is applicable to normal temperature and actually

affected by the temperature characteristics and other properties of crystal oscillators.

YES

NO

YES

NO

Course (A)

Course (B)

Course (C)

Course (D)

12345

- 27 -

Page 28

RV5C386A PRELIMINARY

Course (A)

When the time count precision of each RTC is not to be adjusted, the crystal oscillator intended for use in that

RTC may have any CL value requiring no presetting. The crystal oscillator may be subject to frequency

variations which are selectable within the allowable range of time count precision. Several crystal oscillators

and RTCs should be used to find the center frequency of the crystal oscillators by the method described in

"14.2. 2. Measurement of Oscillation Frequency" and then calculate an appropriate oscillation adjustment

value by the method described in "14.2. 4. Oscillation Adjustment Circuit" for writing this value to the

RV5C386A.

Course (B)

When the time count precision of each RTC is to be adjusted within the oscillation frequency variations of the

crystal oscillator plus the frequency variations of the real-time clock ICs, it becomes necessary to correct

deviations in the time count of each RTC by the method described in "14.2.4. Oscillation Adjustment

Circuit". Such oscillation adjustment provides crystal oscillators with a wider range of allowable settings of

their oscillation frequency variations and their CL values. The real-time clock IC and the crystal oscillator

intended for use in that real-time clock IC should be used to find the center frequency of the crystal oscillator

by the method described in "14.2.2. Measurement of Oscillation Frequency" and then confirm the center

frequency thus found to fall within the range adjustable by the oscillation adjustment circuit before adjusting

the oscillation frequency of the oscillation circuit. At normal temperature, the oscillation frequency of the

oscillator circuit can be adjusted by up to approximately ±1.5ppm.

Course (C)

Course (C) together with Course (D) requires adjusting the time count precision of each RTC as well as the

frequency of 32.768-kHz clock pulses output from the 32KOUT pin. Normally, the oscillation frequency of

the crystal oscillator intended for use in the RTCs should be adjusted by adjusting the oscillation stabilizing

capacitors CG and CD connected to both ends of the crystal oscillator. The RV5C386A, which incorporate

the CG and the CD, require adjusting the oscillation frequency of the crystal oscillator through its CL value.

Generally, the relationship between the CL value and the CG and CD values can be represented by the

following equation:

CL = (CG × CD)/(CG + CD) + CS where "CS" represents the floating capacity of the printed circuit board.

The crystal oscillator intended for use in the RV5C386A is recommended to have the CL value on the order of

6 to 8pF. Its oscillation frequency should be measured by the method described in "14.2.2. Measurement

of Oscillation Frequency". Any crystal oscillator found to have an excessively high or low oscillation

frequency (causing a time count gain or loss, respectively) should be replaced with another one having a

smaller and greater CL value, respectively until another one having an optimum CL value is selected. In

this case, the bit settings disabling the oscillation adjustment circuit (see "14.2.4. Oscillation Adjustment

Circuit") should be written to the oscillation adjustment register.

Incidentally, the high oscillation frequency of the crystal oscillator can also be adjusted by adding an external

oscillation stabilization capacitor CGOUT as illustrated in the diagram below.

VDD

OSCIN

RF

Course (D)

It is necessary to select the crystal oscillator in the same manner as in Course (C) as well as correct errors in

the time count of each RTC in the same manner as in Course (B) by the method described in "14.2.4.

Oscillation Adjustment Circuit".

CG

RD

CD

32kHz

OSCOUT

VDD

CGout

*1)

*1) The CGOUT should have a capacitance ranging

from 0 to 15 pF.

12345

- 28 -

Page 29

PRELIMINARY RV5C386A

14.2.4. Oscillation Adjustment Circuit

The oscillation adjustment circuit can be used to correct a time count gain or loss with high precision by

varying the number of 1-second clock pulses once per 20 seconds. When such oscillation adjustment is not

to be made, the oscillation adjustment circuit can be disabled by writing the settings of "*, 0, 0, 0, 0, 0, *" ("*"

representing "0" or "1") to the F6, F5, F4, F3, F2, F1, and F0 bits in the oscillation adjustment circuit.

Conversely, when such oscillation adjustment is to be made, an appropriate oscillation adjustment value can

be calculated by the equation below for writing to the oscillation adjustment circuit.

(1) When Oscillation Frequency (* 1) Is Higher Than Target Frequency (* 2) (Causing Time Count Gain)

Oscillation adjustment value (*3) = (Oscillation frequency - Target Frequency + 0.1)

Oscillation frequency × 3.051 × 10

≈ (Oscillation Frequency – Target Frequency) × 10 + 1

* 1) Oscillation frequency:

Frequency of clock pulse output from the 32KOUT pin at normal temperature in the manner described in

"14.2.2. Measurement of Oscillation Frequency".

* 2) Target frequency:

Desired frequency to be set. Generally, a 32.768-kHz crystal oscillator has such temperature

characteristics as to have the highest oscillation frequency at normal temperature. Consequently, the

crystal oscillator is recommended to have target frequency settings on the order of 32.768 to 32.76810 kHz

(+3.05ppm relative to 32.768 kHz). Note that the target frequency differs depending on the environment or

location where the equipment incorporating the RTC is expected to be operated.

* 3) Oscillation adjustment value:

Value that is to be finally written to the F0 to F6 bits in the Oscillation Adjustment Register and is represented

in 7-bit coded decimal notation.

(2) When Oscillation Frequency Is Equal To Target Frequency (Causing Time Count neither Gain nor Loss)

Oscillation adjustment value = 0, +1, -64, or –63

-6

(3) When Oscillation Frequency Is Lower Than Target Frequency (Causing Time Count Loss)

Oscillation adjustment value = (Oscillation frequency - Target Frequency)

Oscillation frequency × 3.051 × 10

≈ (Oscillation Frequency – Target Frequency) × 10

Oscillation adjustment value calculations are exemplified below

(A) For an oscillation frequency = 32768.85Hz and a target frequency = 32768.05Hz

Oscillation adjustment value = (32768.85 - 32768.05 + 0.1) / (32768.85 × 3.051 × 10-6)

≈ (32768.85 - 32768.05) × 10 + 1

= 9.001 ≈ 9

In this instance, write the settings (F6,F5,F4,F3,F2,F1,F0)=(0,0,0,1,0,0,1) in the oscillation adjustment

register. Thus, an appropriate oscillation adjustment value in the presence of any time count gain

represents a distance from 01h.

(B) For an oscillation frequency = 32763.95Hz and a target frequency = 32768.05Hz

Oscillation adjustment value = (32763.95 - 32768.05) / (32763.95 × 3.051 × 10-6)

≈ (32763.95 - 32768.05) × 10

= -41.015 ≈ -41

To represent an oscillation adjustment value of - 41 in 7-bit coded decimal notation, subtract 41 (29h)

from 128 (80h) to obtain 57h. In this instance, write the settings of (F6,F5,F4,F3,F2,F1,F0) =

(1,0,1,0,1,1,1) in the oscillation adjustment register. Thus, an appropriate oscillation adjustment value

in the presence of any time count loss represents a distance from 80h.

Oscillation adjustment involves an adjustment differential of approximately ±1.5ppm from the target

frequency at normal temperature.

-6

- 29 -

12345

Page 30

RV5C386A PRELIMINARY

(1 to 2 sec.)

Notes:

1) Oscillation adjustment does not affect the frequency of 32.768-kHz clock pulses output from the 32KOUT pin.

2) Oscillation adjustment value range: When the oscillation frequency is higher than the target frequency

(causing a time count gain), an appropriate time count gain ranges from -3.05ppm to -189.2ppm with the

settings of "0, 0, 0, 0, 0, 1, 0" to "0, 1, 1, 1, 1, 1, 1" written to the F6, F5, F4, F3, F2, F1, and F0 bits in the

oscillation adjustment register, thus allowing correction of a time count gain of up to +189.2ppm. Conversely,

when the oscillation frequency is lower than the target frequency (causing a time count loss), an appropriate

time count gain ranges from +3.05ppm to +189.2ppm with the settings of "1, 1, 1, 1, 1, 1, 1" to "1, 0, 0, 0, 0, 1,

0" written to the F6, F5, F4, F3, F2, F1, and F0 bits in the oscillation adjustment register, thus allowing

correction of a time count loss of up to -189.2ppm.

14.3. Oscillation Halt Sensing and Supply Voltage Monitoring

The oscillation halt sensing circuit is configured to record a halt on oscillation by 32.768-kHz clock pulses.

The supply voltage monitoring circuit is configured to record a drop in supply voltage below a threshold

voltage of 2.1 or 1.6v. Both the flag bits of these circuits (i.e. the XSTP bit for the former and the VDET bit

for the latter) in the control register 2, are maintained “1” until they are reset by the setting of 0 in the same

bits.

When the XSTP bit is set to 1 for the oscillation halt sensing circuit, the VDET bit is reset to 0 for the supply

voltage monitoring circuit. The relationship between the XSTP and VDET bits is shown in the table below.

XSTP VDET Conditions of supply voltage and oscillation

0 0 No drop in supply voltage below threshold voltage and no halt in oscillation

0 1 Drop in supply voltage below threshold voltage and no halt in oscillation

1 * Halt on oscillation

Threshold voltage (2.1V or 1.6V)

Supply voltage

32768Hz Oscillation

Normal voltage detector

Supply voltage monitoring

(VDET)

Oscillation halt sensing

(XSTP)

Internal initialization period

XSTP,VDET←0

VDET←0

XSTP,VDET←0

When the XSTP bit is set to 1 in the control register 2, the F6 to F0, WALE, DALE, /12⋅24, SCRATCH3, TEST,

CT2, CT1, CT0, VDSL, VDET, SCRATCH1, SCRATCH2, CTFG, WAFG, and DAFG bits are reset to 0 in the

oscillation adjustment register, the control register 1, and the control register 2. The XSTP bit is also set to 1

at power-on from 0 volts. Note that the XSTP bit may be locked upon instantaneous power-down.

12345

- 30 -

Page 31

PRELIMINARY RV5C386A

(1 to 2 sec.)

< Considerations in Using Oscillation Halt Sensing Circuit >

Be sure to prevent the oscillation halt sensing circuit from malfunctioning by preventing the following:

1) Instantaneous power-down on the VDD

2) Condensation on the crystal oscillator

3) On-board noise to the crystal oscillator

4) Applying to individual pins voltage exceeding their respective maximum ratings

In particular, note that the XSTP bit may fail to be set to 1 in the presence of any applied supply voltage as

illustrated below in such events as backup battery installation. Further, give special considerations to prevent

excessive chattering in the oscillation halt sensing circuit.

VDD

< Supply Voltage Sensing Circuit >

The Supply voltage monitoring circuit is configured to conduct a sampling operation during an interval of 7.8ms per

second to check for a drop in supply voltage below a threshold voltage of 2.1 or 1.6v for the VDSL bit setting of 0 (the

default setting) or 1, respectively, in the Control Register 2, thus minimizing supply current requirements as illustrated in

the timing chart below. This circuit suspends a sampling operation once the VDET bit is set to 1 in the Control Register

2.

VDD

XSTP

Sampling operation by supply

voltage monitoring circuit

VDET

(D6 at Address Fh)

Internal initialization period

XSTP, VDET←0

Threshold voltage of 2.1 or 1.6v

7.8ms

1s

VDET←0

12345

- 31 -

Page 32

RV5C386A PRELIMINARY

14.4. Alarm and Periodic Interrupt

The RV5C386A incorporates the alarm interrupt circuit and the periodic interrupt circuit that are configured to

generate alarm signals and periodic interrupt signals, respectively, for output from the /INTRA or /INTRB pins

as described below.

(1) Alarm Interrupt Circuit

The alarm interrupt circuit is configured to generate alarm signals for output from the /INTRA or /INTRB,

which is driven low (enabled) upon the occurrence of a match between current time read by the time counters

(the day-of-week, hour, and minute counters) and alarm time preset by the alarm registers (the Alarm_W

registers intended for the day-of-week, hour, and minute digit settings and the Alarm_D registers intended for

the hour and minute digit settings). The Alarm_W is output from the /INTRB, and the Alarm_D is output

from /INTRA.

(2) Periodic Interrupt Circuit

The periodic interrupt circuit is configured to generate either clock pulses in the pulse mode or interrupt

signals in the level mode for output from the /INTRA pin depending on the CT2, CT1, and CT0 bit settings in

the control register 1.

The above two types of interrupt signals are monitored by the flag bits (i.e. the WAFG, DAFG, and CTFG bits

in the Control Register 2) and enabled or disabled by the enable bits (i.e. the WALE, DALE, CT2, CT1, and

CT0 bits in the Control Register 1) as listed in the table below.

Alarm_W WAFG

(D1 at Address Fh)

Alarm_D DAFG

(D0 at Address Fh)

Peridic

Interrupt

14.4.1. Alarm Interrupt

The alarm interrupt circuit is controlled by the enable bits (i.e. the WALE and DALE bits in the Control

Register 1) and the flag bits (i.e. the WAFG and DAFG bits in the Control Register 2). The enable bits can

be used to enable this circuit when set to 1 and to disable it when set to 0. When intended for reading, the

flag bits can be used to monitor alarm interrupt signals. When intended for writing, the flag bits will cause no

event when set to 1 and will drive high (disable) the alarm interrupt circuit when set to 0.

The enable bits will not be affected even when the flag bits are set to 0. In this event, therefore, the alarm

interrupt circuit will continue to function until it is driven low (enabled) upon the next occurrence of a match

between current time and preset alarm time.

CTFG

(D2 at Address Fh)

* At power-on, when the WALE, DALE, CT2, CT1, and CT0 bits are set to 0 in the Control Register 1, the

/INTRA and /INTRB pins are driven high (disabled).

* When two types of interrupt signals are output simultaneously from the /INTRA pin, the output from the

/INTRA pin becomes an OR waveform of their negative logic.

In this event, which type of interrupt signal is output from the /INTRA pin can be confirmed by reading the DAFG,

and CTFG bit settings in the Control Register 2.

Flag bits Enable bits Output Pin

WALE

(D7 at Address Eh)

DALE

(D6 at Address Eh)

CT2=CT1=CT0=0

(These bit setting of “0” disable the Periodic Interrupt)

(D2 to D0 at Address Eh)

Example: Combined Output to /INTRA Pin Under Control of

/ALARM_D and Periodic Interrupt

/Alarm_D

Periodic Interrupt

/INTRA

/INTRB

/INTRA

/INTRA

12345

- 32 -

Page 33

PRELIMINARY RV5C386A

between current time and preset alarm time

The alarm function can be set by presetting desired alarm time in the alarm registers (the Alarm_W Registers

for the day-of-week digit settings and both the Alarm_W Registers and the Alarm_D Registers for the hour

and minute digit settings) with the WALE and DALE bits once set to 0 and then to 1 in the Control Register 1.

Note that the WALE and DALE bits should be once set to 0 in order to disable the alarm interrupt circuit upon

the coincidental occurrence of a match between current time and preset alarm time in the process of setting

the alarm function.

Interval (1min.) during which a match

occurs

Max.61.1µs

/INTRB

(/INTRA)

WALE←1

(DALE)

/INTRB

(/INTRA)

WALE←1

(DALE)

14.4.2. Periodic Interrupt

Setting of the periodic selection bits (CT2 to CT0) enables periodic interrupt to the CPU. There are two

waveform modes: pulse mode and level mode. In the pulse mode, the output has a waveform duty cycle of

around 50%. In the level mode, the output is cyclically driven low and, when the CTFG bit is set to 0, the

output is return to High (OFF).

0 0 0 - OFF(H) (Default)

0 0 1 - Fixed at “L”

0 1 0 Pulse Mode *1) 2Hz(Duty50%)

0 1 1 Pulse Mode *1) 1Hz(Duty50%)

1 0 0 Level Mode *2) Once per 1 second (Synchronized with