Page 1

RV4140A

Low Power Two-Wire Ground Fault

Interrupter Controller

www.fairchildsemi.com

Features

• Powered from the AC line

• Built-in bridge rectifier

• Direct interface to SCR

• 350 mA quiescent current

• Adjustable trip current

• Adjustable time delay

• Minimum external components

• Meets UL 943 requirements

• Specifically for two-wire systems

• For use with 110V or 220V systems

Description

The RV4140A is a low power controller for AC outlet

appliance leakage circuit interrupters. These devices detect

hazardous current paths to ground such as an appliance

falling into water. The interrupter then open circuits the line

before a harmful or lethal shock occurs.

Internally, the RV4140A has a diode bridge rectifier, zener

shunt regulator, op amp, current reference, time delay circuit,

latch and SCR driver.

An external sense transformer, SCR, relay, two resistors

and three capacitors complete the design of the circuit

interrupter. The simple layout and minimum component

count ensure ease of application and long term reliability.

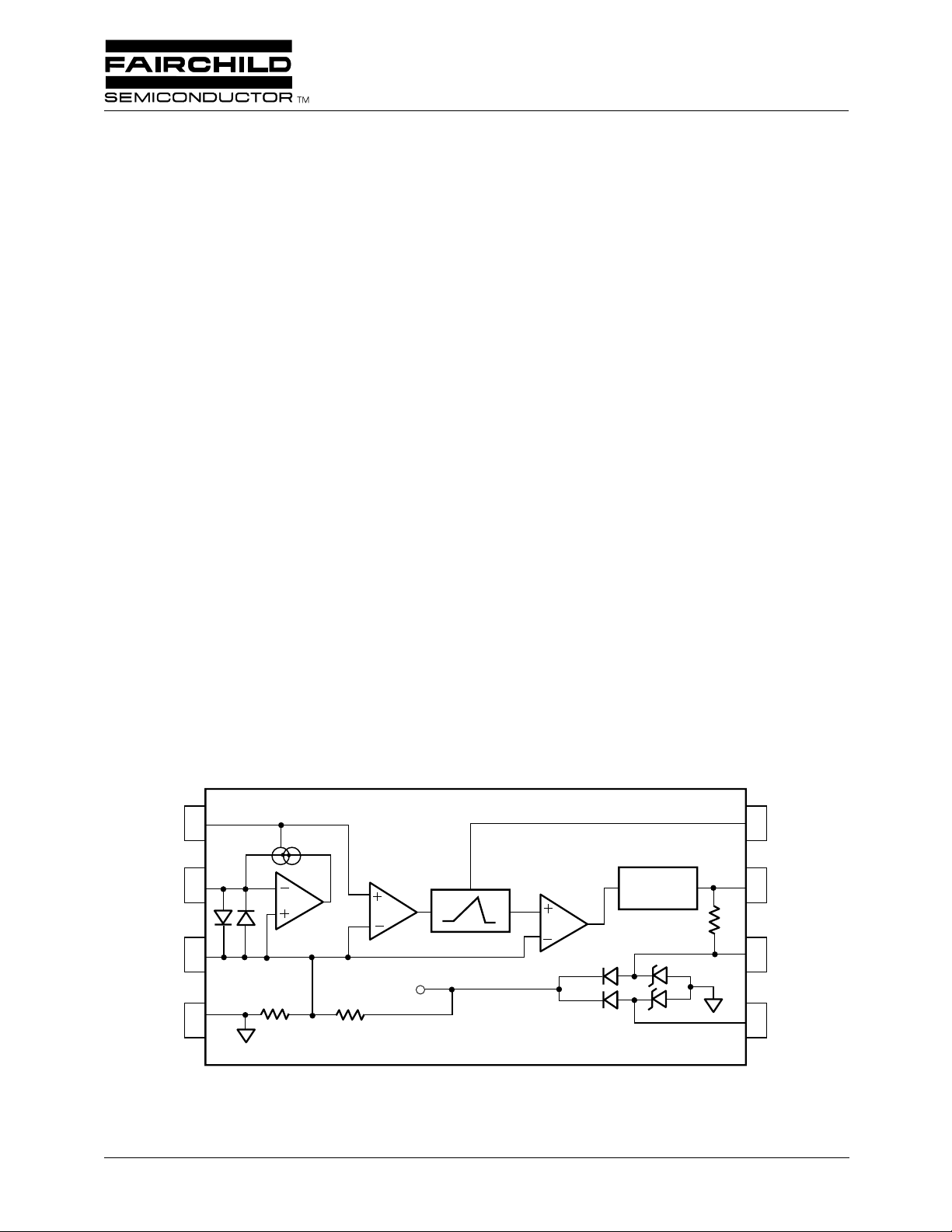

Block Diagram

1

2

3

4

RV4140A

8

Latch

4.7K

Delay

V

cc

7

6

5

65-4140A-01

Rev. 1.0.0

Page 2

RV4140A PRODUCT SPECIFICATION

Functional Description

(Refer to Block Diagram and Figure 1 )

The shunt regulator generated by a 6.5V zener diode is

built into the internal bridge rectifier. It is divided to create

an internal reference voltage of 2.9V connected to pin 3.

The secondary of the sense transformer is AC coupled to the

inverting input of the sense amplifier at pin 2; the non-inverting input is referenced to pin 3. A current feedback loop

around the sense amplifier ensures a virtual ground will be

presented to the secondary of the sense transformer. In this

manner it acts as a current transformer instead of a voltage

transformer. In this mode, the transformer’s characteristics

are very predictable and circuit adjustments are not necessary in production.

The sense transformer has a toroidal core made of laminated

steel rings or solid ferrite material. The secondary of the

transformer is 500 to 1000 turns of #40 wire wound through

the toroid. The primary’s one turn made by passing the

AC hot and neutral wires through the center of the toroid.

When a ground fault exists, a difference exists between the

current flowing in hot and neutral wires. The difference

primary current, divided by the number of secondary turns,

flows through the secondary wire of the transformer.

The AC coupled transformer secondary current then flows

through the sense amplifier’s feedback loop, creating a full

wave rectified version of the secondary fault current. This

current passes through R

equal to R

sense transformer turns ratio. This voltage is compared with

the reference voltage at pin 3.

If the voltage at pin 1 is greater than pin 3, a comparator will

charge C2 through a 29 mA current source at pin 8. If the

voltage at pin 1 exceeds pin 3 for longer than the delay time,

a 400 mA current will pulse between pins 7 and 6 which will

trigger the gate of the SCR.

If the voltage at pin 1 exceeds pin 3 for less than the delay

time, the SCR will not trigger.

The fault current at which the controller triggers the SCR

is dependent on the value of R

determined by C2.

times the peak fault current divided by the

SET

at pin 1, generating a voltage

SET

and the time delay

SET

Supply Current Requirements

The RV4140A has a built-in diode bridge rectifier that

provides power to the chip independent of the polarity of

the A C line. This eliminates the external rectifier required for

previous GFCI controllers.

R

limits the shunt regulator current to 2 mA. The rec-

LlNE

ommended value is 47K to 91K for 110V systems and 91K

to 150K for 220V systems. The recommended maximum

peak line current through R

DO NOT connect a filter capacitor between pins 5 and 6 in

an attempt to filter the supply voltage at the RV4140A.

Proper operaton of the R V4140A requires the internal supply

voltage to be unfiltered.

LlNE

is 7 mA.

SCR Driver

The SCR must have a high dV/dt rating to ensure that line

noise (generated by electrically noisy appliances) does not

falsely trigger the SCR. Also, the SCR must ha ve a gate dri ve

requirement less than 200 mA. C3 is a noise filter that

prevents high frequency line pulses from triggering the SCR.

The relay solenoid used should have a 3 ms or less response

time to meet the UL 943 timing requirement.

Supplier of Sense Transformers and Cores

Magnetic Metals Corporation, Camden, NJ 08101,

(609) 964-7842, supplies a full line of ring cores and transformers designed specifically for GFCI and related applications.

Determining the Values of RSET and C2

Determine the ground fault trip current requirement. This

will be typically 5 mA in North America (117 VAC) and

10 mA in the UK and Europe.

Determine the minimum amount of time delay required to

prevent nuisance tripping. This will typically be 1 to 2 ms.

The value of C2 required to provide the desired delay time

is:

C2 = 10 x T

where C2 is in nF, and T is the desired delay time in ms.

UL 943 requires the circuit interrupter trip when the ground

fault exceeds 6 mA and not trip when the fault current is less

than 4 mA.

2

Page 3

PRODUCT SPECIFICATION RV4140A

The value of R

to meet nominal ground fault tip current

SET

specification is:

R

SET

---------------------------------------------------------------=

I

FAULT

2.05 N´

COS 180´ TP¤()

Where:

•R

SET

is in kW

• T is the time delay in ms

• P is the period of the line frequency in ms

•I

is the desired ground fault trip current in mA

FAULT

RMS.

• N is the number of sense transformer secondary turns.

Sense Transformer

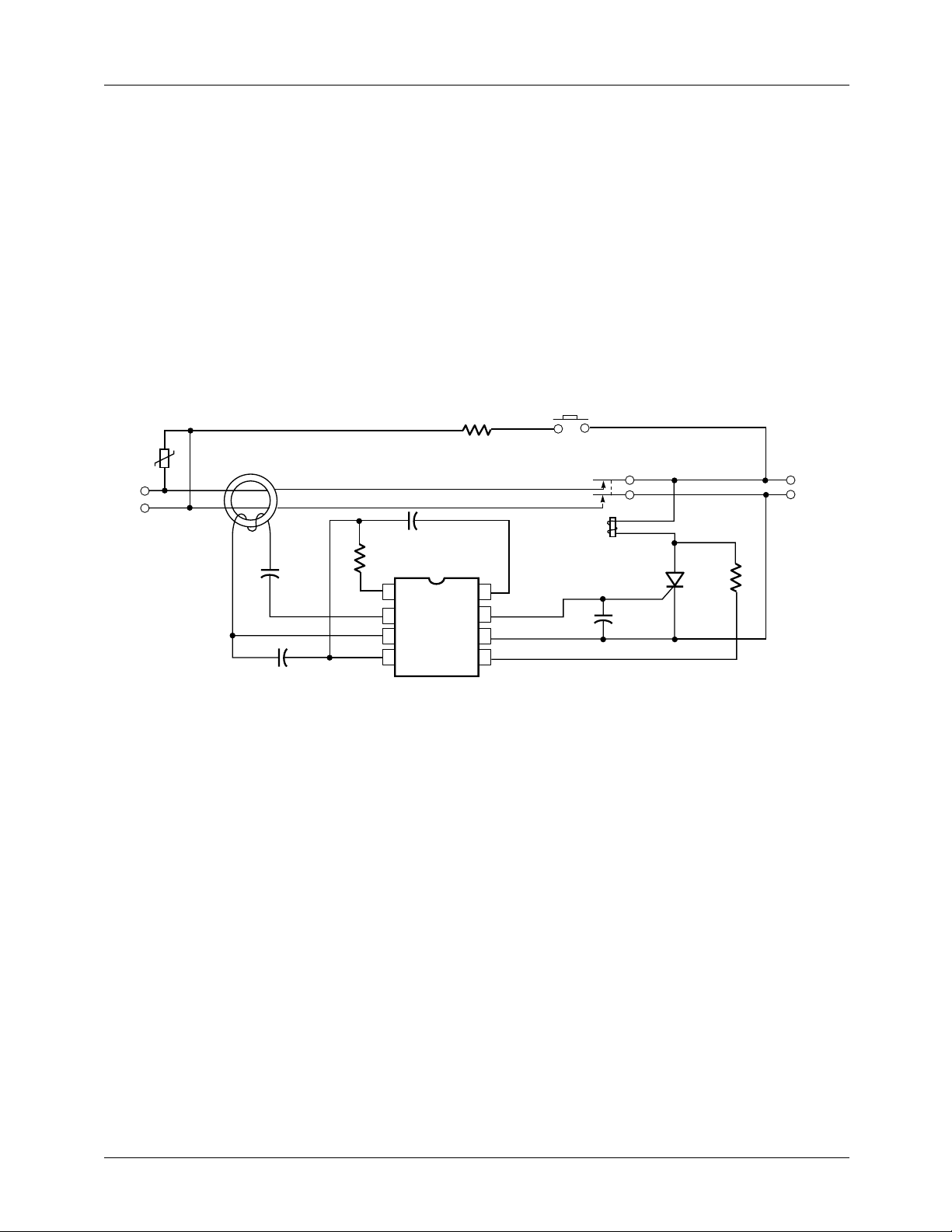

Mov

Line

1:500 Turns Ratio

3 Ring Steel Core

10 F

C1

m

C4

m

0.1 F

Hot

Neutral

R

SET

191K

1

2

3

4

C2

0.02 F

RV4140A

This formula assumes an ideal sense transformer is used.

The calculated value of R

may have to be changed up to

SET

30% when using a non-ideal transformer.

R

TEST

15K

m

8

7

6

5

Press to Test

Normally

Latching

Solinoid

Closed

Contacts

Q1

Tag

X0103DA

C3

10 nF

R

LINE

91K

Load

65-4140A-02

Figure 1. Appliance Leakage Detector Circuit Application

3

Page 4

RV4140A PRODUCT SPECIFICATION

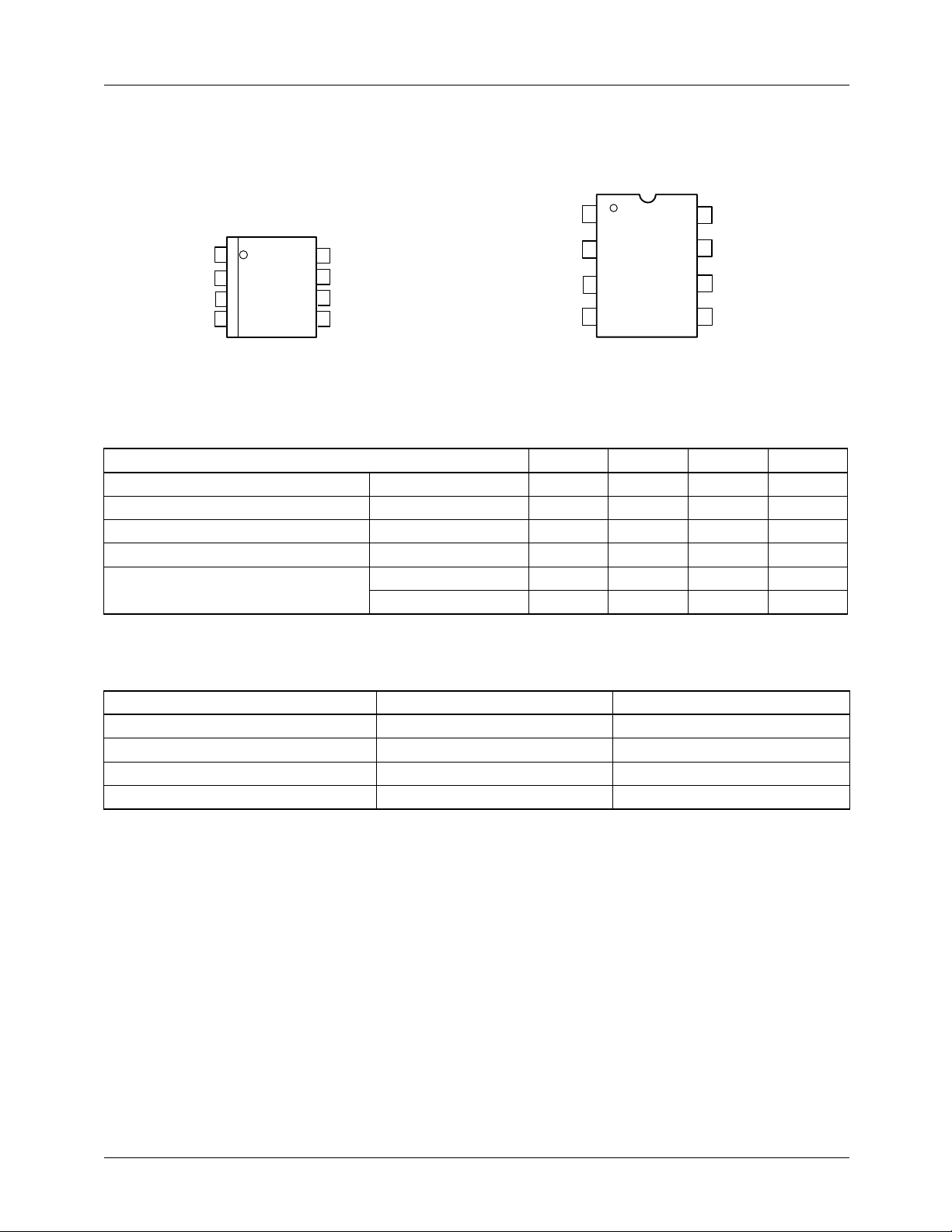

Pin Assignments

PDIP

(Top View)

SOIC

(Top View)

1

R

SET

VFB

2

2.9V

3

Ground 5

4

8

C Delay

7

SCR Trigger

6

Neutral

Line

R

1

SET

2

VFB

3

2.9V

Ground 5

4

65-4140A-03

8

C Delay

7

SCR Trigger

6

Neutral

Line

Absolute Maximum Ratings

Parameter Min. Typ. Max. Units

Supply Current 7mA

Internal Power Dissipation 500 mW

Storage Temperature Range -65 +150 °C

Operating Temperature Range -35 +80 °C

Lead Soldering Temperature 60 Seconds, DIP +300 °C

10 Seconds, SOIC +260 °C

Thermal Characteristics

Parameter 8 Lead Plastic SOIC 8 Lead Plastic DIP

Maximum Junction Temperature +125°C +125°C

Maximum P

Thermal Resistance, q

For TA > 50°C Derate at 4.1 mW/°C 6.25 mW/°C

<50°C 300 mW 468 mW

DTA

JA

240°C/W 160°C/W

4

Page 5

PRODUCT SPECIFICATION RV4140A

Electrical Characteristics

I

= 1.2mA and TA = +25°C, R

LINE

Parameters Test Conditions Min. Typ. Max. Units

Shunt Regulator (Pins 5 to 4)

Regulated Voltage I

Regulated Voltage I

Sense Amplifier (Pins 2 to 3)

Offset Voltage Design Value -3.0 0 3.0 mV

Gain Bandwidth Design Value 2.0 MHz

Input Bias Current Design Value 30 100 nA

SCR Trigger (Pins 7 to 6)

Output Resistance V

Output Voltage I

Output Voltage I

Output Current V

Reference Voltage (Pins 3 to 4)

Reference Voltage I

Delay Timer (Pins 8 to 4)

Delay Time

1

Delay Current I

Note:

1. Delay time is defined as starting when the instantaneous sense current (I

trigger voltage V

goes high.

7-6

SET

= 290kW

C

= 11mA 6.8 7.2 7.6 V

2-3

= 700 mA, I

LINE

= open, I

5-6

= 9mA 0 0.1 10 mV

2-3

= 11mA 1.4 2.0 2.6 V

2-3

= 0V, I

7-6

LINE

8-4

= 11mA 232935mA

2-3

2-3

= 700 mA 2.6 2.9 3.2 V

= 20nF — 2.0 — ms

= 9mA 6.8 7.2 7.6 V

2-3

= 0mA 4.0 4.7 5.4 kW

2-3

= 11mA 300 420 600 mA

) exceeds 2.9V/R

2-3

and ending when the SCR

SET

5

Page 6

RV4140A PRODUCT SPECIFICATION

Schematic Diagram

(6)

Neutral

Q38

Q25

R10

Q32

Q24

SCR

Q26

4.7K

Q39

(7)

(8)

Cap

Q50

Q49

Q41

R9

83K

Sub

Sub

Q42

Q40

Q31

Q30

Q29

Q28

65-4653

Sub

(5)

Line

Q48

Q47

Q46

Q45

Q44

Q43

Q37

Q36

Q34

Q33

Q27

Q35

Sub

Q22

Q15

Q14Q12

Q13

Q23

Q21

Q18

R7

23K

Q16

R3

8.5K

Q5

V

Q3

FB

Q44

Q17

C1

R2

10K

CC

V

R1

10K

Q2

(2)

(3)

Common

Q19

6.5 pF

Q20

Q9

Q7

Q11

R8

23K

(1)

SET

2.5K

50K

(4)

Ground

R

Q8

Q6

Q10

R6

R5

50K

R4

6

Page 7

PRODUCT SPECIFICATION RV4140A

Notes:

7

Page 8

RV4140A PRODUCT SPECIFICATION

Notes:

8

Page 9

PRODUCT SPECIFICATION RV4140A

Notes:

9

Page 10

RV4140A PRODUCT SPECIFICATION

Mechanical Dimensions

8-Lead Plastic DIP Package

Symbol

A — .210 — 5.33

A1 .015 — .38 —

A2 .115 .195 2.93 4.95

B .014 .36

B1 .045 .070 1.14 1.78

C .008 .015 .20 .38

D .348 .430 8.84 10.92

D1

E

E1

e

eB

L

N

E1

Inches

Min. Max. Min. Max.

.022 .56

.005 — .13 —

.300 .325 7.62 8.26

.240 .280 6.10 7.11

.100 BSC 2.54 BSC

— .430 — 10.92

.115 .160 2.92 4.06

8¡ 8¡ 5

D

4

1

Millimeters

Notes

4

2

2

Notes:

1.

Dimensioning and tolerancing per ANSI Y14.5M-1982.

2.

"D" and "E1" do not include mold flashing. Mold flash or protrusions

shall not exceed .010 inch (0.25mm).

3.

Terminal numbers are for reference only.

4.

"C" dimension does not include solder finish thickness.

5.

Symbol "N" is the maximum number of terminals.

5

D1

A

A1

B1

8

e

A2

L

B

E

C

eB

10

Page 11

PRODUCT SPECIFICATION RV4140A

Mechanical Dimensions (continued)

8-Lead SOIC Package

Symbol

A .053 .069 1.35 1.75

A1 .004 .010 0.10 0.25

B .013 0.33

C .008 .010 0.20 0.25

D .189 .197 4.80 5.00

E .150 .158 3.81 4.01

e

H

h

L .016 .050 0.40 1.27

N8 8

a

ccc .004 0.10——

85

14

Inches

Min. Max. Min. Max.

.020 0.51

.050 BSC 1.27 BSC

.228 .244 5.79 6.20

.010 .020 0.25 0.50

0¡ 8¡ 0¡ 8¡

EH

Millimeters

Notes

Notes:

1.

Dimensioning and tolerancing per ANSI Y14.5M-1982.

2.

"D" and "E" do not include mold flash. Mold flash or

protrusions shall not exceed .010 inch (0.25mm).

3.

"L" is the length of terminal for soldering to a substrate.

4.

5

2

2

3

6

Terminal numbers are shown for reference only.

5.

"C" dimension does not include solder finish thickness.

6.

Symbol "N" is the maximum number of terminals.

D

A

e

B

A1

SEATING

PLANE

– C –

LEAD COPLANARITY

ccc C

a

h x 45¡

C

L

11

Page 12

RV4140A PRODUCT SPECIFICATION

Ordering Information

Part Number Package Operating Temperature Range

RV4140AN 8-Lead Plastic DIP -35°C to +80°C

RV4140AM 8-Lead Plastic SOIC -35°C to +80°C

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body,

or (b) support or sustain life, and (c) whose failure to

perform when properly used in accordance with

instructions for use provided in the labeling, can be

reasonably expected to result in a significant injury of the

user.

2. A critical component in any component of a life support

device or system whose failure to perform can be

reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

www.fairchildsemi.com

7/27/98 0.0m 002

Ó 1998 Fairchild Semiconductor Corporation

Stock#DS20004140A

Loading...

Loading...