Page 1

RH37C

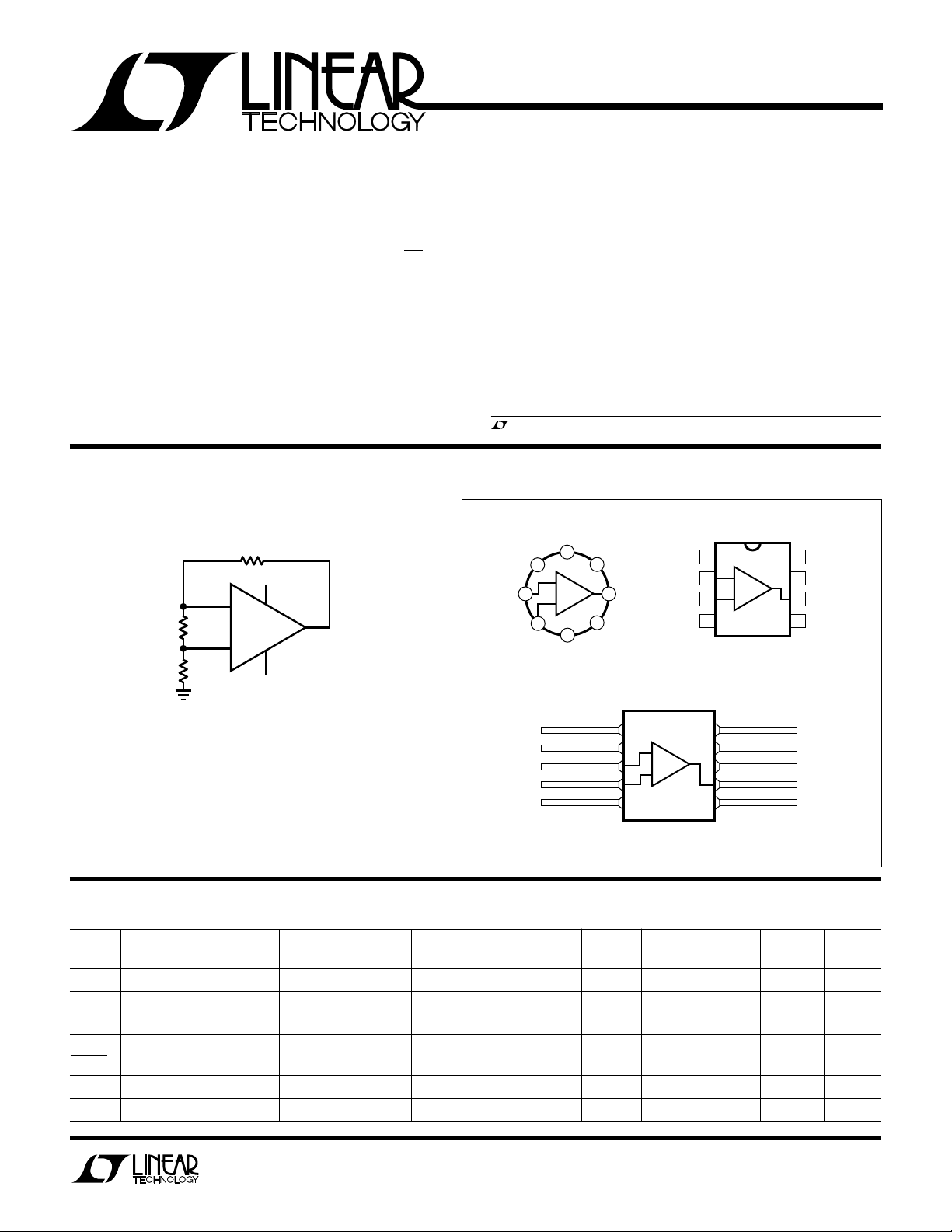

WU

U

PACKAGE

/

O

RDER I FOR ATIO

1

2

3

4

8

7

6

5

TOP VIEW

V

OS

TRIM

–IN

+IN

V

–

VOS TRIM

V

+

OUT

NC

J8 PACKAGE

8-LEAD CERDIP

–

+

Precision Operational Amplifier

DUESCRIPTIO

The RH37C combines very low noise with excellent precision and high speed specifications. The low 1/f noise

corner frequency of 2.7Hz combined with 3.5nV√Hz 10Hz

noise and low offset voltage make the RH37C an excellent

choice for low frequency military instrumentation applications. The wafer lots are processed to LTC’s in-house

Class S flow to yield circuits usable in stringent military

applications.

For complete electrical specifications and performance

curves see the OP-27/OP-37 data sheet.

U U

BUR -I CIRCUIT

10k

20V

–

200Ω

10k

2

3

7

6

+

4

–20V

RH37C BI

A

W

O

LUTEXI T

S

A

WUW

ARB

U

G

I

S

Supply Voltage ..................................................... ±22V

Internal Power Dissipation................................ 500mW

Input Voltage ........................... Equal to Supply Voltage

Output Short-Circuit Duration ......................... Indefinite

Differential Input Current (Note 8) ..................... ±25mA

Operating Temperature Range ............. – 55°C to 125°C

Junction Temperature Range............... –55°C to 150°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

, LTC and LT are registered trademarks of Linear Technology Corporation.

TOP VIEW

VOS TRIM

V

OS

1

TRIM

2

–IN

3

+IN

V

H PACKAGE

8-LEAD TO-5 METAL CAN

8

–

+

4

–

(CASE)

+

V

7

6

OUT

5

NC

TOP VIEW

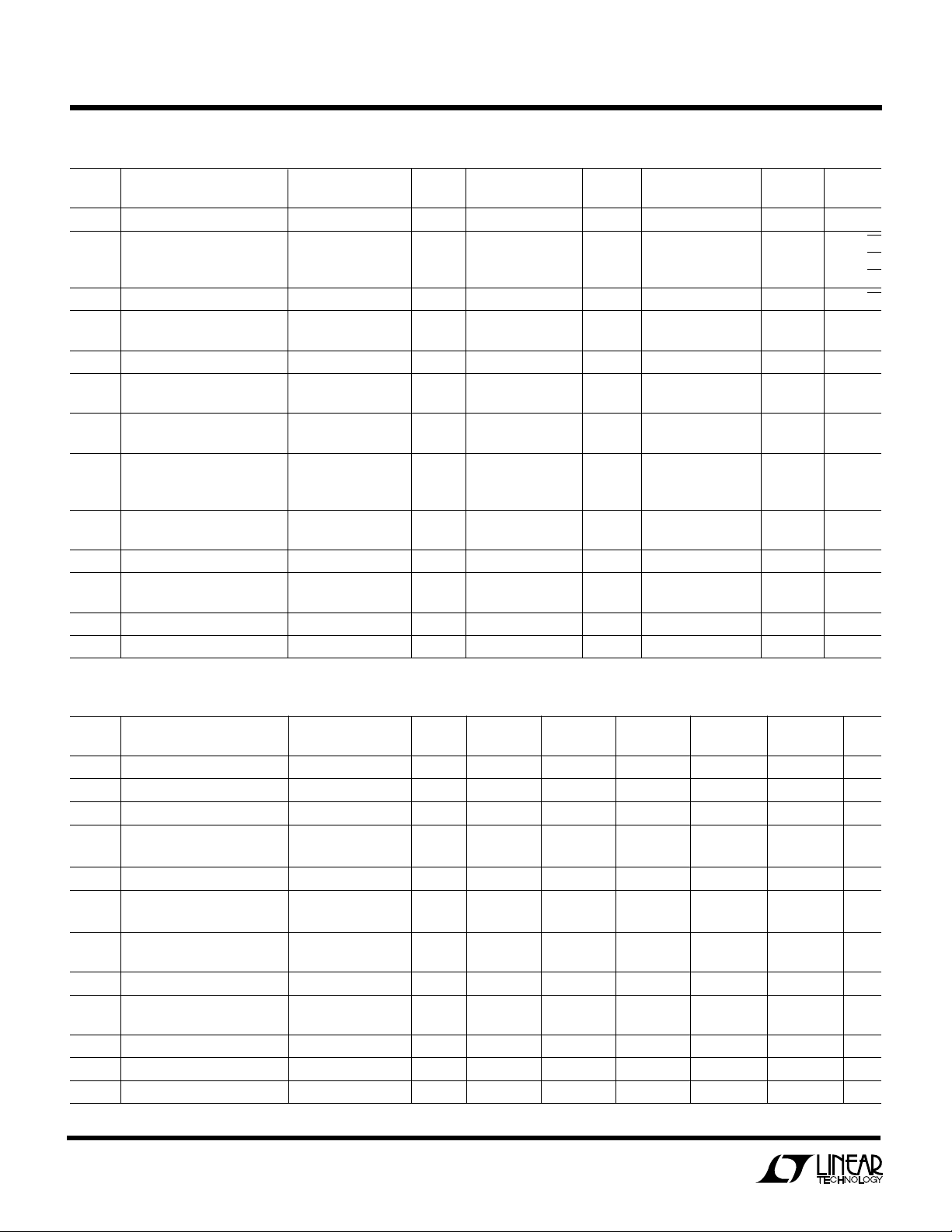

TABLE 1: ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS NOTES MIN TYP MAX GROUP MIN TYP MAX GROUP UNITS

V

OS

∆V

∆Temp

∆V

∆Time Voltage Stability

I

OS

I

B

NC

1

V

TRIM

2

OS

–IN

3

4

+IN

–

5

V

–

+

W PACKAGE

10-LEAD CERPAC

(Preirradiation) (Note 9)

TA = 25°C SUB- SUB-

Input Offset Voltage 1 100 4 300 2, 3 µV

Average Offset Drift 4, 7 1.8 µV/°C

OS

Long-Term Input Offset 2, 4 2 µV/Month

OS

Input Offset Current 75 1 135 2, 3 nA

Input Bias Current ±80 1 ±150 2, 3 nA

–55°C ≤ TA ≤ 125°C

10

NC

V

TRIM

9

OS

+

V

8

7

OUT

6

NC

1

Page 2

RH37C

TABLE 1: ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS NOTES MIN TYP MAX GROUP MIN TYP MAX GROUP UNITS

e

n

i

n

CMRR Common Mode VCM = ±11V 100 1 dB

PSRR Power Supply VS = ±4V to ±18V 94 1 dB

A

VOL

V

OUT

SR Slew Rate RL = 2k, A

GBW Gain-Bandwidth Product fO = 10kHz (A

Z

O

P

D

Input Noise Voltage 0.1Hz to 10Hz 4, 5 0.25 µV

Input Noise Voltage Density fO = 10Hz 3 8.0 nV/√Hz

= 30Hz 4 5.6 nV/√Hz

f

O

= 1000Hz 4 4.5 nV/√Hz

f

O

Input Noise Current Density fO = 1000Hz 4, 6 0.6 pV/√Hz

Input Resistance 2 GΩ

Common Mode

Input Voltage Range 4 ±11 ±10.2 V

Rejection Ratio VCM = ±10V 94 2, 3 dB

Rejection Ratio VS = ±4.5V to ±18V 86 2, 3 dB

Large-Signal Voltage Gain RL ≥ 2k, VO = ±10V 700 4 300 5, 6 V/mV

≥ 600Ω, VO = ±1V 4 200 V/mV

R

L

= ±4V

V

S

Maximum Output RL = 2k ±11.5 4 ±10.5 5, 6 V

Voltage Swing R

Open-Loop Output Resistance VO = 0, IO = 0 470 Ω

Power Dissipation 170 1 mW

= 600Ω±10.0 4 V

L

≥ 511 7 V/µs

VCL

≥ 5) 4 45 MHz

= 1MHz (A

f

O

VCL

≥ 5) 40 MHz

VCL

(Preirradiation) (Note 9)

TA = 25°C SUB- SUB-

–55°C ≤ TA ≤ 125°C

P-P

TABLE 1A: ELECTRICAL CHARACTERISTICS

10KRAD(Si)

SYMBOL PARAMETER CONDITIONS NOTES MIN MAX MIN MAX MIN MAX MIN MAX MIN MAX UNITS

V

OS

I

OS

I

B

CMRR Common Mode VCM = ±11V 100 100 97 94 90 dB

PSRR Power Supply VS = ±4V to ±18V 94 94 92 90 86 dB

A

VOL

V

OUT

SR Slew Rate RL ≥ 2k 1.7 1.7 1.7 1.5 1 V/µs

Z

O

P

D

Input Offset Voltage 1 100 130 180 280 400 µV

Input Offset Current 75 75 90 120 180 nA

Input Bias Current ±80 ±80 ±125 ±200 ±400 nA

Input Resistance 2 (Typ) 2 (Typ) 2 (Typ) 2 (Typ) 2 (Typ) GΩ

Common Mode

Input Voltage Range 4 ±11 ±11 ±11 ±11 ±11 V

Rejection Ratio

Rejection Ratio

Large-Signal Voltage Gain RL ≥ 2k, VO = ±10V 700 700 700 700 400 V/mV

Maximum Output RL ≥ 10k ±11.5 ±11.5 ±11.5 ±11.5 ±11.5 V

Voltage Swing RL ≥ 600Ω±10.0 ±10.0 ±10.0 ±10.0 ±10.0 V

Open-Loop Output Resistance VO = 0, IO = 0 70 (Typ) 70 (Typ) 70 (Typ) 70 (Typ) 70 (Typ) Ω

Power Dissipation 170 170 170 170 170 mW

(Postirradiation) (Note 10)

100KRAD(Si)50KRAD(Si)20KRAD(Si)

200KRAD(Si)

2

Page 3

TABLE 1A: ELECTRICAL CHARACTERISTICS

RH37C

Note 1: Input offset voltage measurements are performed by automatic

test equipment approximately 0.5 seconds after application of power.

Note 2: Long-term input offset voltage stability refers to the average trend

line of offset voltage vs time over the first 30 days of operation. Excluding

the initial hour of operation, changes in V

during the first 30 days are

OS

typically 2.5µV. Refer to the typical performance curves.

Note 3: Sample tested to an LTPD of 15 on every lot. Contact factory for

100% testing of 10Hz voltage density noise.

Note 4: Parameter is guaranteed by design, characterization, or correlation

to other tested parameters.

Note 5: See test circuit and frequency response curve for 0.1Hz to 10Hz

tester on OP-27/OP-37 data sheet.

TOTAL DOSE BIAS CIRCUIT

10k

15V

–

Note 6: See test circuit for current noise measurement on OP-27/OP-37

data sheet.

Note 7: The average input offset drift performance is within the specifications unnulled or when nulled with a pot having a range 8kΩ to 20kΩ.

Note 8: The RH37C’s inputs are protected by back-to-back diodes. Current

limiting resistors are not used in order to achieve low noise. If differential

input voltage exceeds ±0.7V, the input current should be limited to 25mA.

Note 9: V

Note 10: T

= ±15V, VCM = 0V unless otherwise noted.

S

= 25°C, VS = ±15V, VCM = 0V, unless otherwise noted.

A

10k

8V

+

–15V

WU

TYPICAL PERFOR A CE CHARACTERISTICS

Positive Slew Rate

25

VS = ±15V

= 2k

R

L

≥ 5

A

VCL

20

15

10

POSITIVE SLEW RATE (V/µs)

5

0

1

10

TOTAL DOSE KRAD (Si)

100 1000

RH37C G01

25

20

15

10

NEGATIVE SLEW RATE (V/µs)

0

Negative Slew Rate

V

= ±15V

S

= 2k

R

L

≥ 5

A

VCL

1

10

TOTAL DOSE KRAD (Si)

100 1000

RH37C G02

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3

Page 4

RH37C

TOTAL DOSE KRAD (Si)

1

110

120

140

100

RH37C G08

100

90

10 1000

80

70

130

POWER SUPPLY REJECTION RATIO (dB)

VS = ±4V TO ±18V

WU

TYPICAL PERFOR A CE CHARACTERISTICS

Input Offset Voltage Input Bias Current

150

VS = ±15V

= 0V

V

CM

100

50

0

–50

–100

INPUT OFFSET VOLTAGE (µV)

–150

–200

1

10 1000

TOTAL DOSE KRAD (Si)

100

RH37C G03

Common Mode Rejection Ratio Input Offset Current

170

VS = ±15V

= ±11V

V

CM

160

150

140

130

120

110

COMMON MODE REJECTION RATIO (dB)

100

1

10 1000

TOTAL DOSE KRAD (Si)

100

RH37C G06

Open-Loop Gain

170

160

150

140

130

120

OPEN-LOOP GAIN (dB)

110

100

1

75

VS = ±15V

V

CM

50

25

0

INPUT OFFSET CURRENT (nA)

–25

–50

1

10 1000

TOTAL DOSE KRAD (Si)

= 0V

10

TOTAL DOSE KRAD (Si)

VS = ±15V

R

L

V

OUT

100

100

= 2k

= ±10V

RH37C G04

RH37C G07

1000

350

VS = ±15V

V

CM

300

250

200

150

100

INPUT BIAS CURRENT (nA)

50

0

1

Power Supply Rejection Ratio

= 0V

10 1000

TOTAL DOSE KRAD (Si)

100

RH37C G05

TABLE 2: ELECTRICAL TEST REQUIRE E TS

MIL-STD-883 TEST REQUIREMENTS SUBGROUP

Final Electrical Test Requirements (Method 5004) 1*,2,3,4,5,6,7

Group A Test Requirements (Method 5005) 1,2,3,4,5,6,7

Group B and D for Class S, and 1

Group C and D for Class B

End Point Electrical Parameters (Method 5005)

* PDA applies to subgroup 1. See PDA Test Notes.

4

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417 ● (408) 432-1900

FAX: (408) 434-0507

●

TELEX: 499-3977 ● www.linear-tech.com

U

W

PDA Test Notes

The PDA is specified as 5% based on failures from group A, subgroup 1,

tests after cooldown as the final electrical test in accordance with method

5004 of MIL-STD-883 Class B. The verified failures of group A, subgroup

1, after burn-in divided by the total number of devices submitted for burnin in that lot shall be used to determine the percent for the lot.

Linear Technology Corporation reserves the right to test to tighter limits

than those given.

I.D. No. 66-10-0172 Rev. B 0398

rh37cb LT/HP 0398 100 REV B • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1993

Loading...

Loading...