Page 1

RD5

®

TOPSwitch-II

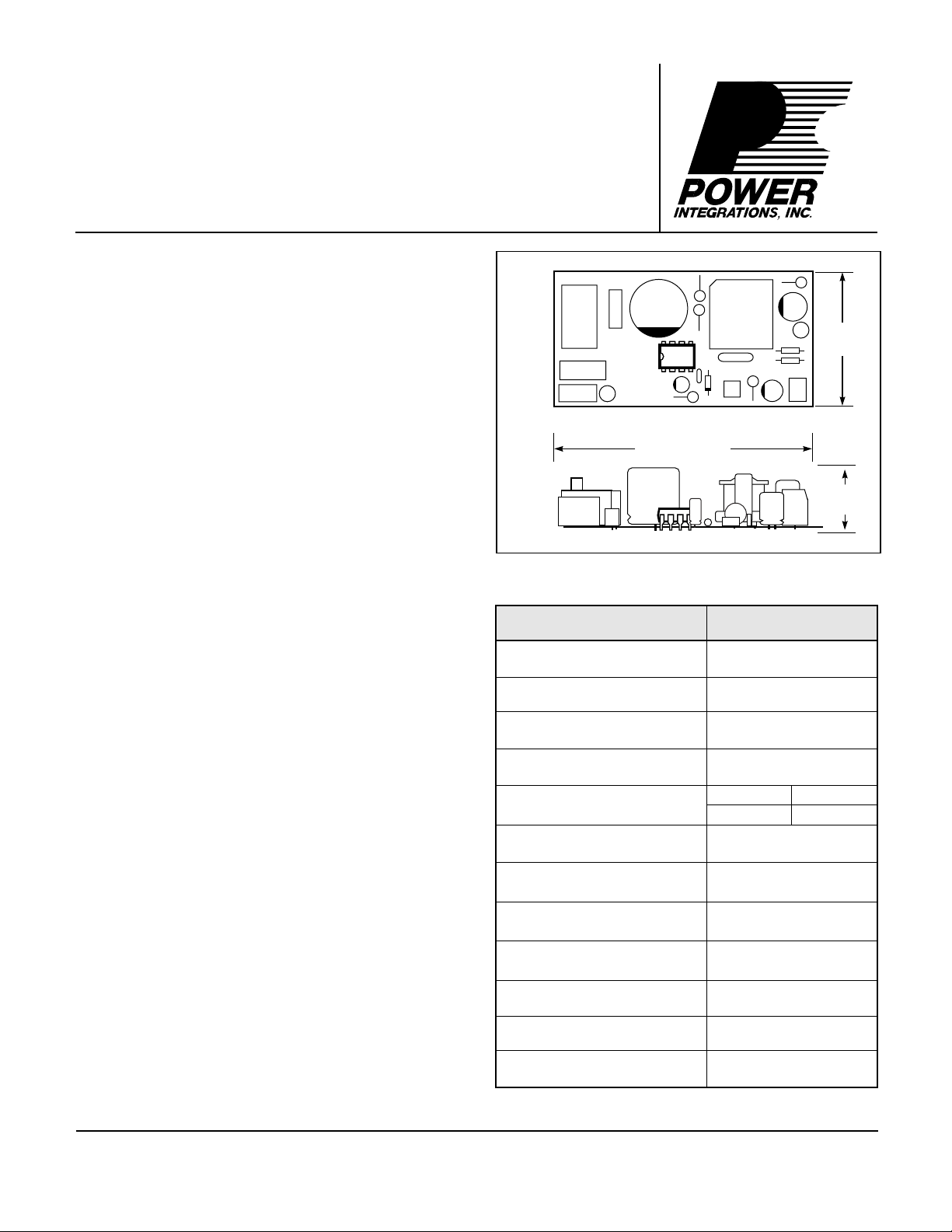

Reference Design Board

85 to 265 VAC Input, 20W (30W Peak) Output

Product Highlights

Low Cost Production Worthy Reference Design

• Only 22 components!

• Single sided board

• Low cost thru-hole components

• Fully assembled and tested

• Easy to evaluate and modify

• Extensive performance data

• Up to 80% efficiency

• Light weight – no heat sink required for TOPSwitch-II

®

1.69 in.

(43 mm)

3.57 in. (91 mm)

Fully Protected by

• Primary safety current limit

• Output short circuit protection

• Thermal shutdown protects entire power supply

Designed for World Wide Operation

• Designed for IEC/UL safety requirements

• Meets VDE Class B EMI specifications

TOPSwitch-II

Description

The RD5 reference design board is an example of a very low

cost production worthy power supply design using the

TOPSwitch family of Three-terminal Off-line PWM Switchers

from Power Integrations. It is intended to help TOPSwitch

users to develop their products quickly by providing a basic

design that can be easily modified to fit a particular application.

In most cases, a minor change to the transformer for a different

output voltage is all that is needed. Multiple output voltages are

obtained just as easily. A constant current or constant power

output may be implemented with the addition of a few low cost

components.

Typical applications include AC-DC adapters for laptops,

notebooks and PDAs, battery chargers for cellular telephones,

power tools and camcorders, VTR/VCR, video game, appliance

and satellite decoder power supplies.

Figure 1. RD5 Board Overall Physical Dimensions.

PARAMETER LIMITS

Input Voltage Range 85 to 265 VAC

Input Frequency Range 47 to 440 Hz

Temperature Range 0 to 50°C

Output Voltage (I = 1.0A) 12 V ± 5%

Output Power (continuous)

Output Power (peak) 30W

Line Regulation (85-265 VAC) ± 1%

Load Regulation (10%-100%) ± 1%

Efficiency 78%

o

25˚C 20W

50˚C 15W

1.06 in.

(27 mm)

PI-2058-041698

Output Ripple Voltage ± 60 mV MAX

Safety IEC 950 / UL1950

EMI

Figure 2. Table of Key Electrical Parameters.

VDE B (VFG243 B)

CISPR22

July 1997

Page 2

RD5

VR1

P6KE200

19 mH

C6

0.1 µF

250 VAC

J1

L

N

L2

F1

3.15 A

BR1

600 V

C1

47 µF

400 V

D

S

D1

UF4005

TOPSwitch-II

CONTROL

TOP224P

C

U1

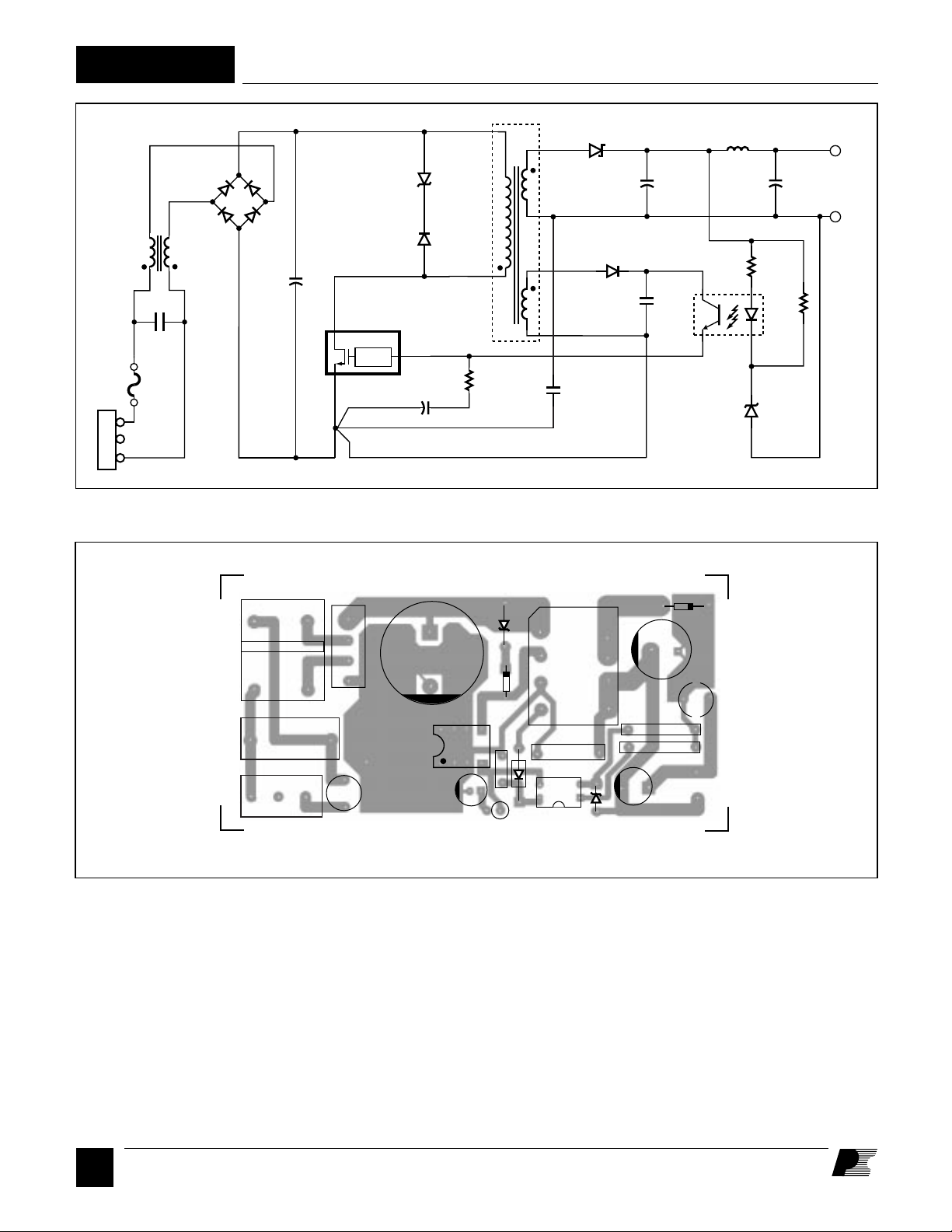

Figure 3. Schematic Diagram of the 12V RD5 Power Supply.

C5

47 µF

1

2

R3

6.8 Ω

T1

7, 8

5, 6

4

3

D2

50SQ100

1N4148

C7

1 nF

250 VAC

Y1

C2

560 µF

35 V

D3

C4

0.1 µF

L1

3.3 µH

+12V

C3

220 µF

35 V

RTN

R1

39 Ω

R2

150 Ω

U2

PC817A

VR2

1N5241B

11 V

PI-2053-041698

BR1

C1

L2

C6

POWER

INTEGRATIONS

INC.

J1

F1

RD5 Rev. A

S/N

COMPONENT SIDE SHOWN

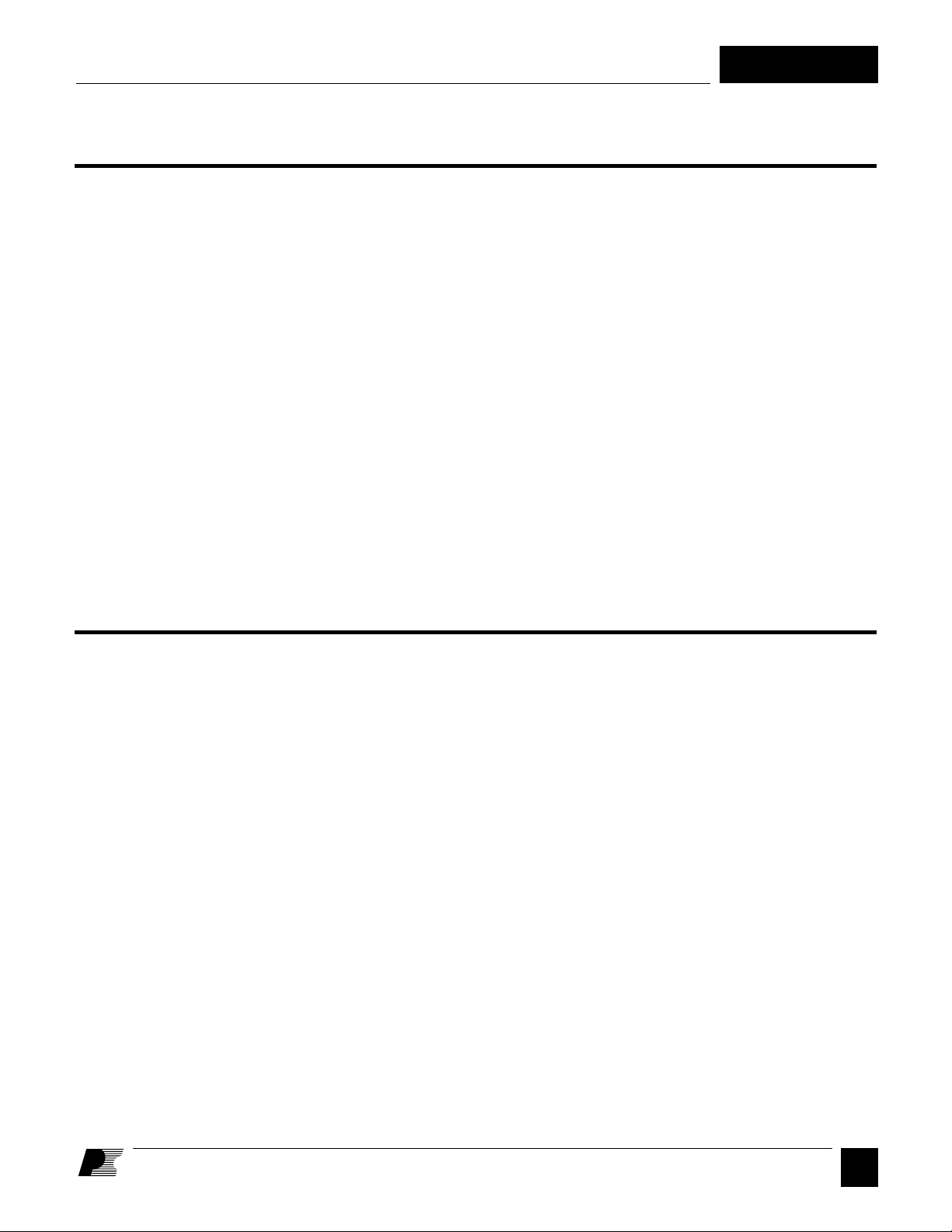

Figure 4. Component Legend of the RD5.

General Circuit Description

The RD5 is a low-cost, flyback switching power supply using

the TOP224P integrated circuit. The circuit shown in Figure 3

produces a 12 V, 20 W power supply that operates from 85 to

265 VAC input voltage. The 12 V output is directly sensed by

optocoupler U2 and Zener diode VR2. The output voltage is

determined by the Zener diode (VR2) voltage and the voltage

drops across the optocoupler (U2) LED and resistor R1. Other

output voltages are also possible by adjusting the transformer

VR1

D2

L1

J2

+

C5

U1

D1

C4

R3

C2

T1

C7

U2

D3

R2

R1

VR2

C3

turns ratios and value of Zener diode VR2.

AC power is rectified and filtered by BR1 and C1 to create the

high voltage DC bus applied to the primary winding of T1. The

other side of the transformer primary is driven by the integrated

high-voltage MOSFET within the TOP224. D1 and VR1

clamp the leading-edge voltage spike caused by transformer

leakage inductance to a safe value and reduce ringing. The

PI-2059-062697

34

A

7/97

Page 3

Component Listing

Reference Value Part Number Manufacturer

BR1 600 V, 2 A 2KBPC06M General Instrument

C1 47 µF, 400 V 381LX470M400H012 Cornell-Dubilier

C2 560 µF, 35 V ECA-1VFQ561 Panasonic

C3 220 µF, 35 V ECE-A1VGE221 Panasonic

C4 0.1 µF, 50 V RPE131R104M50 Murata

C5 47 µF, 10 V ECE-A1AG470 Panasonic

C6 0.1 µF, 250 VAC, X F1772-410-2000 Roederstein

C7* 1.0 nF, 400 VAC, Y1* DE1110E102M ACT4K-KD Murata

D1 600 V, 1A, UFR UF4005 General Instrument

D2 100 V, 5A, Schottky 50SQ100 International Rectifier

D3 75 V, Switching 1N4148 National Semiconductor

L1 3.3 µH, 6.5 A 622LY-3R3M Toko

L2 19 mH, 400 mA ELF15N005A Panasonic

R1 39 Ω, 1/4 W 5043CX39R00J Philips

R2 150 Ω, 1/4 W 5043CX150R0J Philips

R3 6.8 Ω, 1/4 W 5043CX6R800J Philips

T1** TRD5 Custom

U1 TOP224P Power Integrations

U2 PC817A Sharp

VR1 200 V Zener TVS P6KE200 General Instrument

VR2 11 V Zener 1N5241B Motorola

F1 3.15 A, 250 VAC 19372K, 3.15A Wickman

RD5

(or WKP102MCPE.OK Roederstein)

(or PME294RB4100M Rifa)

Figure 5. Parts List for the RD5 (* Two Series Connected, 2.2 nF, Y2-Capacitors Such as Murata DE7100F222MVA1-KC can replace C7).

** T1 is available from Premier Magnetics (714) 362-4211 as P/N POL-12017, and from Coiltronics (561) 241-7876 as P/N CTX00-13742.

power secondary winding is rectified and filtered by D2, C2,

L1, and C3 to create the 12 V output voltage. R2 and VR2

provide a slight pre-load on the 12 V output to improve load

regulation at light loads. R2 also provides bias current for Zener

VR2 to improve regulation. The bias winding is rectified and

filtered by D3 and C4 to create a bias voltage to the TOP224P.

L2 and Y1-capacitor C7 attenuate common-mode emission

currents caused by high-voltage switching waveforms on the

DRAIN side of the primary winding and the primary to secondary

capacitance. L2 and C6 attenuate differential-mode emission

currents caused by the fundamental and harmonics of the

primary current waveform. C5 filters internal MOSFET gate

drive charge current spikes on the CONTROL pin, determines

the auto-restart frequency, and together with R1 and R3,

compensates the control loop.

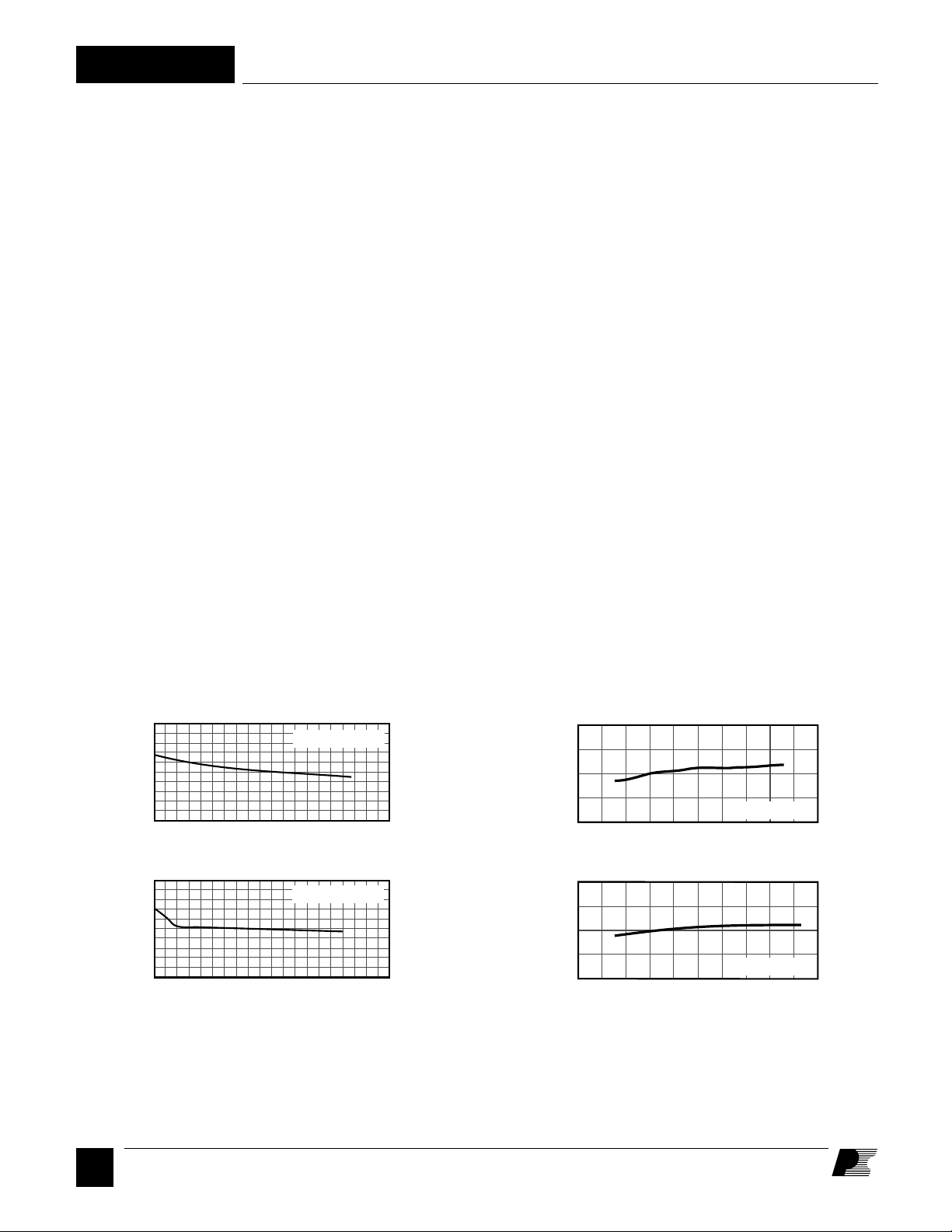

The circuit performance data shown in Figures 6-18 were

measured with AC voltage applied to the RD5.

Load Regulation (Figure 6) – The amount of change in the DC

output voltage for a given change in output current is referred

to as load regulation. The 12 V output stays within ±1% from

10% to 100% of rated load current. The TOPSwitch on–chip

overtemperature protection circuit will safely shut down the

power supply under persisting overload conditions. Below

minimum load, the 12 V output rises slightly due to the

TOPSwitch minimum duty cycle.

Line Regulation (Figure 7) - The amount of change in the DC

output voltage for a given change in the AC input voltage is

called line regulation. The maximum change in output voltage

is within ± 1%.

Efficiency (Line Dependent) – Efficiency is the ratio of the

output power to the input power. The curves in Figures 8 and 9

show how the efficiency changes with input voltage.

Efficiency (Load Dependent) – The curves in Figures 10 and 11

show how the efficiency changes with output power for 115

VAC and 230 VAC inputs.

Power Supply Turn On Sequence – The internal switched, highvoltage current source provides the initial bias current for

TOPSwitch when power is first applied. The waveforms shown

7/97

A

35

Page 4

RD5

General Circuit Description (cont.)

in Figure 12 illustrate the relationship between the high-voltage

DC bus and the 12 V output voltage. Capacitor C1 charges to

the peak of the AC input voltage before TOPSwitch turns on.

The delay of 160 ms (typical) is caused by the time required to

charge the auto-restart capacitor C5 to 5.8 V. At this point the

power supply turns on as shown.

Figure 13 shows the output voltage turn on transient as well as

a family of curves associated with an additional soft-start

capacitor. The soft-start capacitor is placed across VR2 and can

range in value from 4.7 uF to 47 uF as shown.

Line frequency ripple voltage is shown in Figure 14 for 115

VAC input and 20 W output. Switching frequency ripple

voltage is shown in Figure 15 for the same test condition.

The power supply transient response to a step load change from

1.25 to 1.67 A (75% to 100%) is shown in Figure 16. Note that

the response is quick and well damped.

The RD5 is designed to meet worldwide safety and EMI (VDE

B) specifications. Measured conduction emissions are shown

in Figure 17 for 115 VAC and Figure 18 for 230 VAC.

Thermal Considerations

The RD5 utilizes the printed circuit copper for TOPSwitch

heatsinking. For 20 W output, the heatsink area is approximately

1.25 in2 (8 cm2). The copper area required for heatsinking at

15 W output is outlined on the non-component side of the board,

and is approximately 0.56 in2 (3.6 cm2). The RD5 printed circuit

board utilizes 2 oz. copper cladding. Printed circuit boards with

lighter cladding will require apertures in the solder mask to

build-up effective trace thickness.

Transformer Specification

The electrical specifications and construction details for

transformer TRD5 are shown in Figures 19 and 20. Transformer

TRD5 is supplied with the RD5 reference design board. This

design utilizes an EI25 core and a triple insulated wire secondary

winding. The use of triple insulated wire allows the transformer

to be constructed using a smaller core and bobbin than a

conventional magnet wire design due to the elimination of the

margins required for safety spacing in a conventional design.

If a conventional margin wound transformer is desired, the

design of Figures 21-22 can be used. This design (TRD5-1)

uses a EEL22 core and bobbin to accommodate the 3 mm

margins required to meet international safety standards when

using magnet wire rather than triple insulated wire, and has the

same pinout and printed circuit foot print as TRD5. The

transformer is approximately 50% taller than the triple insulated

wire design due to the inclusion of creepage margins required

to meet international safety standards.

110

100

90

VIN = 115 VAC

PI-2062-070297

0

0.5

1 1.5

2

110

100

90

50 100 150 200 250 300

Load Current (A)

110

100

Output Voltage (% of Nominal)

90

0 0.5 1 1.5

VIN = 230 VAC

2

110

100

Output Voltage (% of Nominal)

90

50 100 150 200 250 300

Load Current (A)

Figure 6. Load Regulation Figure 7. Line Regulation

A

7/97

36

PI-2063-070297

IL = 1.67 A

Input Voltage (VAC)

IL = 0.33 A

Input Voltage (VAC)

Page 5

RD5

PI-2069-070297

0

10 20

Time (ms)

0

6

4

8

10

2

0 µF

4.7 µF

10 µF

22 µF 47 µF

Output Voltage (V)

100

Po = 20 W

80

60

40

20

Output Efficiency (%)

0

0 100 300200

Input Voltage (VAC)

PI-2064-070297

100

Po = 4 W

80

60

40

Output Efficiency (%)

20

0

0 100 300200

Input Voltage (VAC)

Figure 8. Efficiency vs. Input Voltage, 20 W Output Figure 9. Efficiency vs. Input Voltage, 4 W Output

100

80

60

VIN = 115 VAC

PI-2066-070297

100

VIN = 230 VAC

80

60

PI-2065-070297

PI-2067-070297

150

100

50

0

15

10

5

0

40

Output Efficiency (%)

20

0

01020155

Output Power (W)

Figure 10. Efficiency vs. Output Power, 115 VAC Input

40

Output Efficiency (%)

20

0

01020155

Output Power (W)

Figure 11. Efficiency vs. Output Power, 230 VAC Input

DC BUS VOLTAGE

PI-2068-070297

0

100 200

OUTPUT

VOLTAGE

Time (ms)

Figure 12. Turn On Delay Figure 13. Output Voltage Turn On Transient vs. Soft Start Capacitor

A

37

7/97

Page 6

RD5

80

60

40

20

0

-20

Output Voltage (mV)

-40

-60

-80

0

25 50

Time (ms)

Figure 14. Line Frequency Ripple, 115 VAC In, 20 W Output

100

0

80

60

PI-2070-070297

40

20

0

-20

Output Voltage (mV)

-40

-60

-80

0

25 50

Time (µs)

Figure 15. Switching Frequency Ripple, 115 VAC In, 20 W Output

PI-2072-070297

PI-2071-070297

100

80

60

40

Amplitude (dBmV)

20

-100

Output Voltage (mV)

2.0

1.5

1.0

0.5

0

Output Current (A)

01020

Time (ms)

Figure 16. Transient Load Response (75% to 100% of load)

VDE B Limit

(VFG243A)

100

PI-2061-040197

80

60

40

VDE B Limit

(VFG243A)

Amplitude (dBmV)

20

PI-2060-040197

0

0.01 0.1

1

10

Frequency (MHz)

Figure 17. EMI Characteristics at 115 VAC Input.

A

7/97

38

0

0.01 0.1

1

10

Frequency (MHz)

Figure 18. EMI Characteristics at 230 VAC Input.

Page 7

RD5

1

67 T

#30 AWG

2

3

8 T

2x #30 AWG

4

7, 8

8 T

2x #24 AWG

Triple-insulated

5, 6

PIN FUNCTION

5, 6

7, 8

CORE# - PC40 EI25-Z (TDK)

GAP FOR AL OF 145 nH/T

2

BOBBIN# - BE-25-118CP (TDK)

ELECTRICAL SPECIFICATIONS

Electrical Strength

Creepage

Primary Inductance

Between Pins 1-2 (All other windings open)

1

HIGH-VOLTAGE DC BUS

2

TOPSwitch DRAIN

3

PRIMARY-SIDE COMMON

4

V

BIAS

RETURN

OUTPUT

60 Hz, 1 minute,

from pins 1-4 to pins 5-8

Between pins 1-4 and pins 5-8

8

1

5

4

3000 VAC

6.0 mm (min)

650 µH, ±10%

Resonant Frequency

Between Pins 1-2 (All other windings open)

Primary Leakage Inductance

NOTE: All inductance measurements should be made at 100 kHz

Figure 19. Electrical specification of transformer TRD5

Between Pins 1-2 (Pins 5-8 shorted)

700 KHz (min)

35 µH (max)

PI-2054-050798

7/97

A

39

Page 8

RD5

TAPE

WINDING INSTRUCTIONS

5

6

8

7

3

4

SECONDARY

BIAS

1

2

PRIMARY

Primary (2 layers)

Basic Insulation

Bifilar Bias Winding

Basic Insulation

24 V Double Bifilar

Secondary Winding

Outer Insulation

Final Assembly

* Triple insulated wire sources.

P/N: T28A01TXXX-3

Rubudue Wire Company

5150 E. La Palma Avenue

Suite 108

Anaheim Hills, CA 92807

(714) 693-5512

(714) 693-5515 FAX

Start at pin 2. Wind 67 turns of #30 AWG heavy nyleze

magnet wire in two layers. Finish on Pin 1

1 layer of 10.8 mm wide polyester tape for basic insulation.

Start at Pin 4. Wind 8 turns of 2 parallel strands of

#30 AWG heavy nyleze magnet wire. Space turns evenly

across bobbin to form a single layer. Finish on Pin 3.

1 layer of 10.8 mm wide polyester tape for basic insulation.

Start at Pins 7 and 8. Wind 8 bifilar turns of #24 AWG

Triple Insulated Wire. Finish on Pins 5 and 6.

3 layers of 10.8 mm wide polyester tape for insulation.

Assemble and secure core halves. Impregnate

uniformly using varnish.

P/N: order by description

Furukawa Electric America, Inc.

200 Westpark Drive

Suite 190

Peachtree City, GA 30269

(770) 487-1234

P/N: order by description

The Furukawa Electric Co., Ltd

6-1, Marunouchi 2-chome,

Chiyoda-ku, Tokyo 100, Japan

81-3-3286-3226

81-3-3286-3747 FAX

(770) 487-9910 FAX

Figure 20. Construction details of transformer TRD5.

A

7/97

40

PI-2055-050798

Page 9

RD5

1

67 T

#30 AWG

2

3

8 T

2x #30 AWG

4

CORE# - PC40 EE22/29/6-Z (TDK)

GAP FOR AL OF 145 nH/T

7, 8

8 T

2x #24 AWG

5, 6

2

BOBBIN# - YC 2204 (Ying Chin)

ELECTRICAL SPECIFICATIONS

Electrical Strength

Creepage

Primary Inductance

Between Pins 1-2 (All other windings open)

PIN FUNCTION

1

HIGH-VOLTAGE DC BUS

2

TOPSwitch DRAIN

3

PRIMARY-SIDE COMMON

4

V

5, 6

7, 8

BIAS

RETURN

OUTPUT

60 Hz, 1 minute,

from pins 1-4 to pins 5-8

Between pins 1-4 and pins 5-8

8

1

5

4

3000 VAC

6.0 mm (min)

650 µH, ±10%

Resonant Frequency

Primary Leakage Inductance

Between Pins 1-2 (All other windings open)

Between Pins 1-2 (Pins 5-8 shorted)

NOTE: All inductance measurements should be made at 100 kHz

Figure 21. Electrical specification of transformer TRD5-1.

700 KHz (min)

35 µH (max)

PI-2057-050798

7/97

A

41

Page 10

RD5

TAPE

5, 6

7, 8

SECONDARY

4

3

BIAS

SLEEVING

WINDING INSTRUCTIONS

Primary Margins

Primary Windings

Basic Insulation

Bias Winding

Reinforced Insulation

Secondary Windings

Tape margins with 3 mm wide polyester tape. Match height with primary

and bias windings.

Start at pin 2. Wind one layer (approximately 40 turns) of 30 AWG

heavy nyleze magnet wire from bottom (pin side) to top. Use one layer

of 12.2 mm wide polyester tape over first primary layer for basic

insulation. Continue winding remaining primary turns from top to bottom.

Finish on Pin 1. Sleeve start and finish with 24 AWG Teflon sleeving.

Use 1 layer of 12.2 mm wide tape for basic insulation.

Start at Pin 4. Wind 8 bifilar turns 30 AWG heavy nyleze magnet wire

from bottom to top. Spread turns evenly across bobbin. Finish on Pin 3.

Sleeve start and finish leads with 24 AWG Teflon sleeving.

Use 3 layers of 18.2 mm wide polyester tape for reinforced insulation.

Tape margins with 3 mm wide polyester tape. Match height with

secondary winding.

1

2

TAPE MARGINS

PRIMARY

12V Secondary Winding

Start at Pins 7 and 8. Wind 8 bifilar turns of 24 AWG heavy nyleze

magnet wire from bottom to top. Spread turns evenly across bobbin.

Finish on Pins 5 and 6. Sleeve start and finish leads with 24 AWG

Teflon sleeving.

Outer Insulation

Final Assembly

Figure 22. Construction details of transformer TRD5-1.

A

7/97

42

Apply 3 layers of 18.2 mm wide polyester tape for outer insulation.

Assemble and secure core halves. Impregnate uniformly with varnish.

PI-2056-050798

Page 11

RD5

7/97

A

43

Page 12

RD5

Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability.

Power Integrations does not assume any liability arising from the use of any device or circuit described herein, nor does it

convey any license under its patent rights or the rights of others.

PI Logo and

TOPSwitch

are registered trademarks of Power Integrations, Inc.

©Copyright 1998, Power Integrations, Inc. 477 N. Mathilda Avenue, Sunnyvale, CA 94086 http://www.powerint.com

WORLD HEADQUARTERS

NORTH AMERICA - WEST

Power Integrations, Inc.

477 N. Mathilda Avenue

Sunnyvale, CA 94086 USA

Main: +1•408•523•9200

Customer Service:

Phone: +1•408•523•9265

Fax: +1•408•523•9365

KOREA

Power Integrations International

Holdings, Inc.

Rm# 402, Handuk Building,

649-4 Yeoksam-Dong, Kangnam-Gu,

Seoul, Korea

Phone: +82•2•568•7520

Fax: +82•2•568•7474

A

7/97

44

NORTH AMERICA - EAST

& SOUTH AMERICA

Power Integrations, Inc.

Eastern Area Sales Office

1343 Canton Road, Suite C1

Marietta, GA 30066 USA

Phone: +1•770•424•5152

Fax: +1•770•424•6567

JAPAN

Power Integrations, K.K.

Keihin-Tatemono 1st Bldg.

12-20 Shin-Yokohama 2-Chome,

Kohoku-ku, Yokohama-shi,

Kanagawa 222, Japan

Phone: +81•(0)•45•471•1021

Fax: +81•(0)•45•471•3717

EUROPE & AFRICA

Power Integrations (Europe) Ltd.

Mountbatten House

Fair Acres Windsor

Berkshire SL4 4LE,

United Kingdom

Phone: +44•(0)•1753•622•208

Fax: +44•(0)•1753•622•209

INDIA (Technical Support)

Innovatech

#1, 8th Main Road

Vasanthnagar

Bangalore 560052, India

Phone: +91•80•226•6023

Fax: +91•80•228•2191

TAIWAN

Power Integrations International

Holdings, Inc.

2F, #508, Chung Hsiao E. Rd., Sec. 5,

Taipei 105, Taiwan

Phone: +886•2•2727•1221

Fax: +886•2•2727•1223

APPLICATIONS HOTLINE

World Wide +1•408•523•9260

APPLICATIONS FAX

World Wide +1•408•523•9361

Loading...

Loading...