Page 1

PT4181

White LED Step-Up Converter

GENERAL DESCRIPTION

The PT4181 is a step-up DC/DC converter designed for

driving up to 8 white LEDs in series from a single cell

Lithium Ion battery with constant current. Because it

directly regulates output current, the PT4181 is ideal for

driving light emitting diodes (LEDs) whose light

intensity is proportional to the current passing through

them, not the voltage across their terminals. A single

external resistor sets LED current between 5mA and

20mA, which can then be easily adjusted using either a

DC voltage or a pulse width modulated (PWM) signal.

Its low 104mV feedback voltage reduces power loss

and improves efficiency. The OV pin monitors the

output voltage and turns off the converter if an

over-voltage condition is present due to an open circuit

condition. The PT4181 is available in SOT23-6

packages.

ORDERING INFORMATION

PACKAGE

TEMPERATURE

RANGE

ORDERING PART

NUMBER

FEATURES

z Drives Up to 5 Series White LEDs from 2.5V

z Drives Up to 8 Series White LEDs from 3.6V

z Up to 87% Efficiency

z 1.2MHz Fixed Switching Frequency

z Low 104mV Feedback Voltage

z Open Load Shutdown

z Soft Start/PWM Dimming

z SOT23-6 Packages

APPLICATIONS

z Cell Phones

z Handheld Computers and PDAs

z Digital Cameras

z Small LCD Displays

TRANSPORT

MEDIA

MARKING

SOT23-6 -40 oC to 85 oC PT4181E23F

Tape and Reel

3000 units

4181

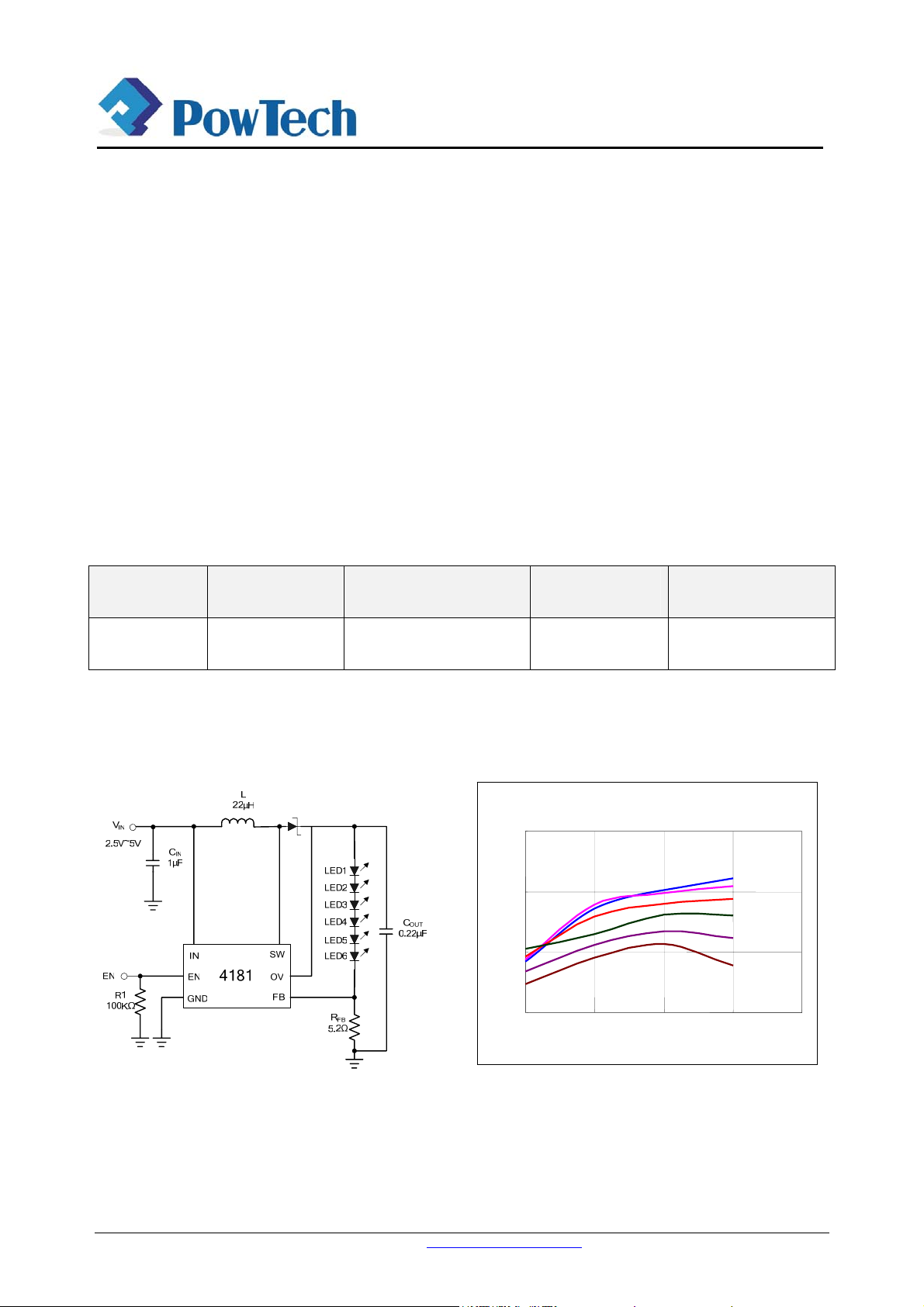

TYPICAL APPLICATIONS KEY PERFORMANCE CHART

Efficiency vs n(LED)

90.00%

85.00%

80.00%

75.00%

51015

20 25

Iout (mA) Vin=3.6V

3LED

4LED

5LED

6LED

7LED

8LED

Figure1. Li-Ion Driver for Six White LEDs Figure2. Efficiency vs Number of LEDs

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 1

PT4181_DS Rev EN_2.1

Page 2

PT4181

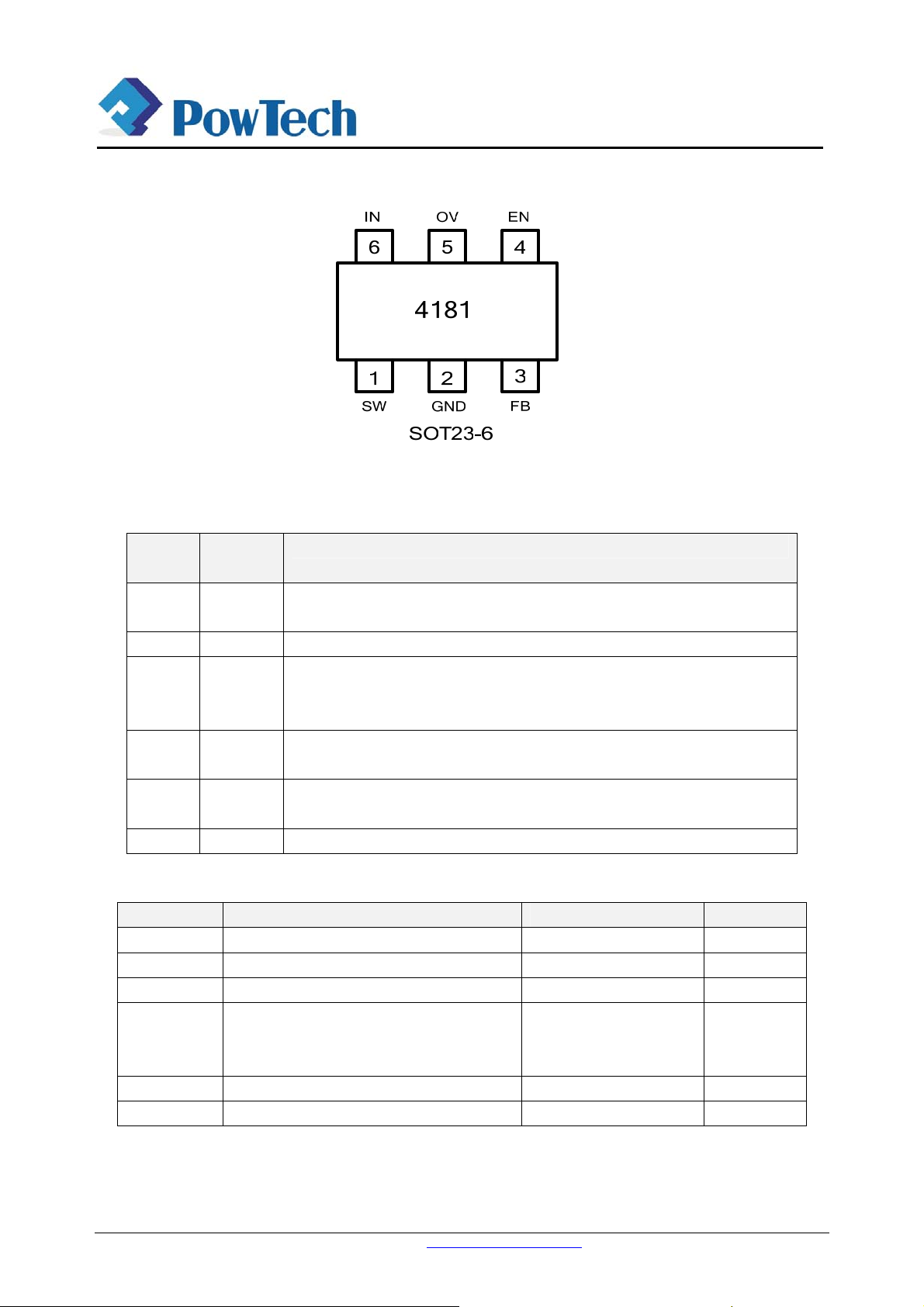

PIN ASSIGNMENT

PIN DESCRIPTIONS

SOT

PIN No.

1 SW Power Switch Output. Connect the inductor and the blocking Schottky diode to

2 GND Ground

3 FB Feedback input pin. The reference voltage at this pin is 104mV. Connect the

4 EN Enable pin. A high input at EN enables the device and a low input disables the

5 OV Over Voltage Input. OV measures the output voltage for open circuit protection.

6 IN Input Supply Pin. Must be locally bypassed.

PIN

Names

White LED Step-Up Converter

DESCRIPTION

SW.

cathode of the lowest LED to FB and a current sense resistor between FB and

GND.

devices. When not used, connect EN to the input source for automatic startup.

Connect OV to the output at the top of the LED string.

ABSOLUTE MAXIMUM RATINGS (Note 1)

SYMBOL ITEMS VALUE UNIT

VIN Input Voltage

VSW Voltage at SW Pin

VIO All Other I/O Pins GND-0.3 to VDD+0.3 V

Thermal Resistance,SOT-23-6

P

TR1

Tstg Storage Temperature -55 to 150

Tsolder Package Lead Soldering Temperature 260 , 10s℃

θ

θ

JA

JC

-0.3~6

-0.5~35

220

110

V

V

℃/W

℃

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 2

PT4181_DS Rev EN_2.1

Page 3

PT4181

White LED Step-Up Converter

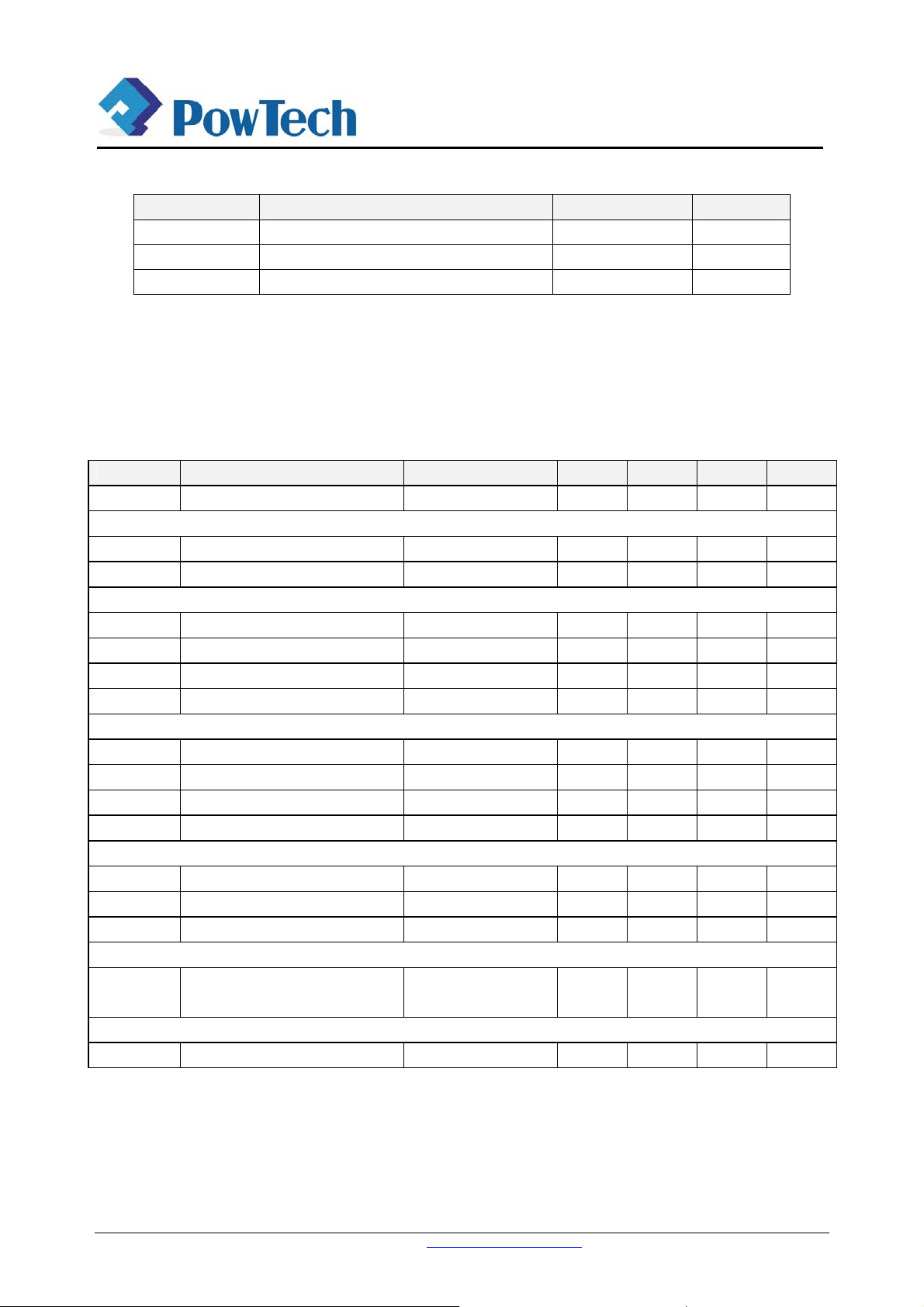

RECOMMENDED OPERATING RANGE (Note 2)

SYMBOL ITEMS VALUE UNIT

VIN VIN Supply Voltage 2.5 to +6 V

VSW Output Voltage VIN to 28 V

T

Operating Temperature -40 to +85

OPT

℃

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Recommended operating Range indicates conditions for which the device is functional, but does not guarantee specific

performance limits.

ELECTRICAL CHARACTERISTICS (Note 3,4,5)

V

SYMBOL ITEMS CONDITIONS Min. Typ. Max. UNIT

Feedback

Operating Current

Chip Enable

Output Switch

Open Circuit Protection

Soft Start

=3V, Topt=25℃ unless specified otherwise.

IN=VEN

VIN Input Voltage 2.5 6 V

VFB FB Pin Voltage 89 104 119 mV

Ibias FB Pin Input Bias Current 0.05 1 µA

Ioff

Isby

Operating Current(Shutdown)

Operating Current(Quiescent)

V

=0V 0.1 1 µA

SW-ON

VFB=0.3V 100 350 µA

Fsw Switching Frequency 1.0 1.25 1.5 MHz

Dmax Maximum Duty Cycle VFB=0V 85 90 %

V

EN Minimum High Level 1.5 V

EN_H

V

EN Maximum Low Level 0.4 V

EN_L

V

EN Hysteresis 90 mV

HYS

EN Input Bias Current V

=0V, 5V 1 µA

SW-ON

RON SW On Resistance (Note 3) 0.5 Ω

I

SW Current Limit 400 mA

LIMIT

I

SW Leakage Current

LEAK

VOV Open Circuit Shutdown

Vsw=5V

VOV Rising 30 V

0.01 1 µA

Threshold

tss Soft Start Time (Note 3) V

Power On 160 µS

IN

Note 3: Electrical Characteristics state DC and AC electrical specifications under particular test conditions which

guarantee specific performance limits. This assumes that the device is within the recommended operating Range.

Specifications are not guaranteed for parameters where no limit is given, however, the typical value is a good

indication of device performance.

Note 4: Typicals are measured at 25˚C and represent the parametric norm.

Note 5:

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 3

PT4181_DS Rev EN_2.1

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Page 4

PT4181

White LED Step-Up Converter

SIMPLIFIED BLOCK DIAGRAM

Figure 3. Simplified Block Diagram of the PT4181

OPERATION DESCRIPTION

The PT4181 uses a constant frequency, peak current

mode boost regulator architecture to regulate the series

string of white LEDs. The operation of the PT4181 can

be understood by referring to the simplified block

diagram shown above. At the start of each oscillator

cycle, the control logic turns on the power switch M1.

The signal at the non-inverting input of the PWM

comparator is proportional to the switch current,

summed together with a portion of the oscillator ramp.

When this signal reaches the level set by the output of

error amplifier, the PWM comparator resets the latch in

the control logic and turns off the power switch. In this

manner, error amplifier sets the correct peak current

level to keep the LED current in regulation. If the

feedback voltage starts to drop, the output of the error

amplifier increases. This results in more current to flow

through M1, hence increasing the power delivered to

the output.

TYPICAL PERFORMANCE CHARACTERISTICS

Driving Capability

100.00%

95.00%

90.00%

85.00%

80.00%

75.00%

70.00%

Efficiency vs Vin and I

Efficiency vs. Vin

3

3.13.23.3

3.43.53.63.7 3.83.9

Vin I

2.5V

3.0V

3.6V

LED

20mA

15mA

10mA

5mA

4

4.14.24.34.44.5

Vin (V)

=15mA I

LED

5 x LED 4 x LED

6 x LED 5 x LED

8 x LED 8 x LED

Efficiency

90.00%

89.00%

88.00%

87.00%

86.00%

85.00%

84.00%

83.00%

82.00%

81.00%

80.00%

-50 0 50 100 150

=20mA

LED

Efficiency vs Temperature

Efficiency vs. Temperature

20mA

15mA

10mA

Temp (C)

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 4

PT4181_DS Rev EN_2.1

Page 5

PT4181

White LED Step-Up Converter

TYPICAL PERFORMANCE CHARACTERISTICS

Quiescent Current vs VIN and Temperature

Iq VS Temperature

250

200

150

100

Iq(uA)

50

0

2.5 3 3.5 4 4.5 5 5.5 6

Vin(V)

Temp=-40℃

Temp=25℃

Temp=100℃

APPLICATION INFORMATION

Inductor Selections

For most of the applications of the PT4181, it is

recommended to use an inductor of 22uH. Although

small size is one of the major factors in selecting an

inductor, the smaller and thinner inductors give higher

core losses at 1.25MHz and DRC, resulting in lower

efficiencies. The following tab le provides a list of

recommended inductors:

Part

Number

LQH3C220 0.71 250 MURATA

CDRH3D16-220 0.53 350 SUMIDA

LB2012B220M 1.7 75 TAIYO YUDEN

LEM2520-220 5.5 125 TAIYO YUDEN

EJPC220KF 4.0 160 PANASONIC

DCR

(Ω)

Capacitor Selection

The small size of ceramic capacitors makes them ideal

for PT4181 applications. X5R and X7R types are

recommended because they retain their capacitance

over wider voltage and temperature ranges than other

types such as Y5V or Z5U. A 1μF input capacitor and a

0.22 μF output capacitor are sufficient for most PT4181

applications.

Diodes Selection

Schottky diodes, with their low forward voltage drop

and fast reverse recovery, are the ideal choices for

PT4181 applications. The forward voltage drop of a

Schottky diode represents the conduction losses in the

Current

Rating

(mA)

Manufacture

diode, while the diode capacitance (C

represents the switching losses. For diode selection,

both forward voltage drop and diode capacitance need

to be considered. Schottky diodes with higher current

ratings usually have lower forward voltage drop and

larger diode capacitance, which can cause significant

switching losses at the 1.25MHz switching frequency

of the PT4181. A Schottky diode rated at 100mA to

200mA is sufficient for most PT4181 applications.

Some recommended Schottky diodes are listed in the

following table:

CMDSH-3 100 0.58@100mA 7.0@10V Central

CMDSH2-3 200 0.49@200mA 15@10v Central

BAT54 200 0.53@100mA 10@25v Zetex

LED Current Control

The LED current is controlled by the feedback resistor.

The feedback reference is 104mV. The LED current is

104mV/Rfb. In order to have accurate LED current,

precision resistors are preferred (1% is recommended).

The formula and table for R

below:

Switching Frequency vs Temperature

1.6

1.4

1.2

1

0.8

0.6

Fosc(MHz)

0.4

0.2

0

Part

Number

I

LED

Fosc VS Temp.

-40 25 100

Temp(℃)

or CD)

T

Forward

Current

(mA)

RFB = 104mV/I

Voltage

Drop

(V)

selection are shown

FB

LED

Diode

CAP

(Pf)

Manu

facture

(mA) RFB Valu e (Ω)

5 20.8

10 10.4

15 6.93

20 5.2

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 5

PT4181_DS Rev EN_2.1

Page 6

PT4181

White LED Step-Up Converter

Open Circuit Protection

Open circuit protection will shut off the PT4181 if the

output voltage goes too high when the OV pin is tied to

the output. In some cases an LED may fail, which will

result in the feedback voltage always being zero. The

PT4181 will then switch at its maximum duty cycle

boosting the output voltage higher and higher. By

connecting the OV pin to the top of the LED string the

PT4181 checks this condition and if the output ever

exceeds 30V, the PT4181will shut down. The part will

not switch again until the power is recycled.

Dimming Control

There are three different types of dimming control

circuits:

1. Using a DC Voltage

For some applications, the preferred method of

brightness control is a variable DC voltage to adjust the

LED current. The dimming control using a DC voltage

is shown in Figure 3. As the DC voltage increases, the

voltage drop on R2 increases and the voltage drop on

R1 decreases. Thus, the LED current decreases. The

selection of R2 and R3 will make the current from the

variable DC source much smaller than the LED current

and much larger than the FB pin bias current.

Figure4. Dimming Control Using a PWM Signal

3. Using a Filtered PWM Signal

The filtered PWM signal can be considered as an

adjustable DC voltage. It can be used to replace the

variable DC voltage source in dimming control. The

circuit is shown in Figure 5.

Figure3. Dimming Control Using a DC Voltage

2. Using a PWM Signal to EN Pin

With the PWM signal applied to the EN pin, the PT410

is turned on or off by the PWM signal. The LEDs

operate at either zero or full current. The average LED

current increases proportionally with the duty cycle of

the PWM signal. A 0% duty cycle will turn off the

PT4181 and corresponds to zero LED current. A 100%

duty cycle corresponds to full current. The typical

frequency range of the PWM signal should be 1kHz or

less due to the soft start function.

Figure5. Dimming Control Using a Filtered PWM Signal

Start-up and Inrush Current

The PT4181has internal soft start to limit the amount of

current through VIN at startup and to also limit the

amount of overshoot on the output. The soft start is

realized by gradually increasing the current limit during

start-up. The current limit is increased by a third every

60μS giving a total soft start time of around 180μS.

Board Layout Consideration

As with all switching regulators, careful attention must

be paid to the PCB board layout and component

placement. To maximize efficiency, switch rise and fall

times are made as short as possible. To prevent

electromagnetic interference (EMI) problems, proper

layout of the high frequency switching path is essential.

The voltage signal of the SW pin has sharp rise and fall

edges. Minimize the length and area of all traces

connected to the SW pin and always use a ground plane

under the switching regulator to minimize interplane

coupling. In addition, the ground connection for the

feedback resistor R1 should be tied directly to the GND

pin and not shared with any other component, ensuring

a clean, noise-free connection.

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 6

PT4181_DS Rev EN_2.1

Page 7

PT4181

PACKAGE INFORMATION

E1

White LED Step-Up Converter

SOT23-6

D

b

E

e

e1

θ

0.2

L1

L

c

A1

A

A2

SYMBOL

A 1.050 1.250 0.041 0.049

A1 0.000 0.100 0.000 0.004

A2 1.050 1.150 0.041 0.045

b 0.300 0.400 0.012 0.016

c 0.100 0.200 0.004 0.008

D 2.820 3.020 0.111 0.119

E 1.500 1.700 0.059 0.067

E1 2.650 2.950 0.104 0.116

e 0.950TYP 0.037TYP

e1 1.800 2.000 0.071 0.079

L 0.700REF 0.028REF

L1 0.300 0.600 0.012 0.024

θ 0° 8° 0° 8°

MILLIMETERS INCHES

MIN MAX MIN MAX

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 7

PT4181_DS Rev EN_2.1

Page 8

Loading...

Loading...