Page 1

Low Cost Field Programmable Microcontroller Peripherals

FEATURES SUMMARY

■ Single Supply Voltage:

– 5 V±10% for PSD211R and ZPSD211R

– 2.7 to 5.5 V for ZPSD211RV

■ Up to 256 Kbit of EPROM

■ Input Latches

■ Programmable I/O ports

■ Programmable Security

PSD211R

ZPSD211R, ZPSD211RV

Figure 1. Packages

PLDCC44 (J)

CLDCC44 (L)

PQFP44 (M)

1/3January 2002

Page 2

i

PSD211R Family

PSD211R ZPSD211R ZPSD211RV

Low Cost Microcontroller Peripherals

Table of Contents

1 Introduction...........................................................................................................................................................1

2 Notation ................................................................................................................................................................2

3 Key Features ........................................................................................................................................................4

4 PSD211R Family Feature Summary ....................................................................................................................5

5 Partial Listing of Microcontrollers Supported ........................................................................................................5

6 Applications ..........................................................................................................................................................5

7 ZPSD Background................................................................................................................................................5

7.1 Integrated Power ManagementTMOperation.............................................................................................6

8 Operating Mode....................................................................................................................................................9

9 Programmable Address Decoder (PAD)...............................................................................................................9

10 I/O Port Functions...............................................................................................................................................12

10.1 CSIOPORT Registers..............................................................................................................................12

10.2 Port A (PA0-PA7).....................................................................................................................................12

10.3 Port B (PB0-PB7).....................................................................................................................................14

10.4 Port C (PC0-PC2)....................................................................................................................................15

11 PSD Memory ......................................................................................................................................................16

11.1 EPROM....................................................................................................................................................16

11.2 Programming and Erasure.......................................................................................................................16

12 Control Signals ...................................................................................................................................................16

12.1 ALE or AS................................................................................................................................................17

12.2 WR or R/W...............................................................................................................................................17

12.3 RD/E........................................................................................................................................................17

12.4 PSEN.......................................................................................................................................................17

12.5 A19/CSI ...................................................................................................................................................17

12.6 Reset Input ..............................................................................................................................................18

13 Program/Data Space and the 8031....................................................................................................................20

14 Systems Applications..........................................................................................................................................21

15 Security Mode.....................................................................................................................................................23

16 Power Management............................................................................................................................................23

16.1 CSI Input..................................................................................................................................................23

16.2 CMiser Bit................................................................................................................................................23

16.3 Turbo Bit (ZPSD Only).............................................................................................................................24

16.4 Number of Product Terms in the PAD Logic............................................................................................24

16.5 Composite Frequency of the Input Signals to the PAD Logic..................................................................25

16.6 Loading on I/O Pins.................................................................................................................................26

17 Calculating Power...............................................................................................................................................27

18 Specifications......................................................................................................................................................30

18.1 Absolute Maximum Ratings.....................................................................................................................30

18.2 Operating RAnge.....................................................................................................................................30

18.3 Recommended Operating Conditions......................................................................................................30

18.4 Pin Capacitance.......................................................................................................................................30

18.5 AC/DC Characteristics – PSD211R/ZPSD211R (All 5 V devices)...........................................................31

18.6 AC/DC Characteristics – PSD211RV (3 V devices only).........................................................................32

18.7 Timing Parameters – PSD211R/ZPSD211R (All 5 V devices)................................................................33

18.8 Timing Parameters – ZPSD211RV (3 V devices only)............................................................................34

18.9 Timing Diagrams for PSD211R Parts.....................................................................................................36

18.10 AC Testing...............................................................................................................................................39

Page 3

ii

PSD211R Family

PSD211R ZPSD211R ZPSD211RV

Low Cost Microcontroller Peripherals

Table of Contents

(cont.)

19 Pin Assignments.................................................................................................................................................40

20 Package Information...........................................................................................................................................41

21 Package Drawings..............................................................................................................................................42

22 PSD211R Ordering Information..........................................................................................................................45

22.1 Selector Guide.........................................................................................................................................45

22.2 Part Number Construction.......................................................................................................................46

22.3 Ordering Information................................................................................................................................46

23 Data Sheet Revision History...............................................................................................................................47

Sales Reps .........................................................................................................................................................48

Page 4

1

1.0

Introduction

Programmable Peripheral

PSD211R

Field-Programmable Microcontroller Peripheral

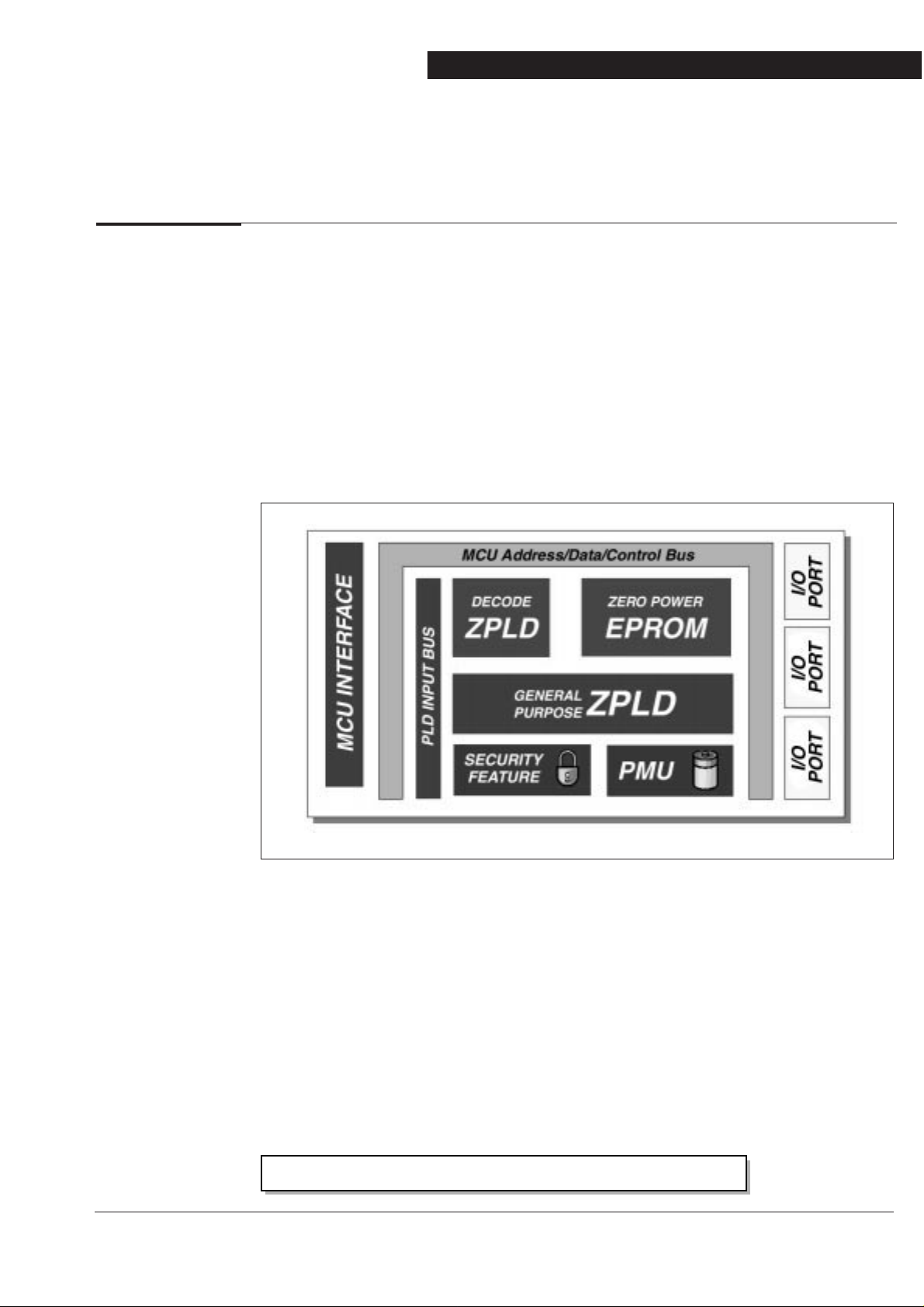

The low cost PSD211R family integrates high-performance and user-configurable blocks of

EPROM and programmable logic into one part. The PSD211R products also provide a

powerful microcontroller interface that eliminates the need for external “glue logic”. The

part’s integration, small form factor, low power consumption, and ease of use make it the

ideal part for interfacing to virtually any microcontroller.

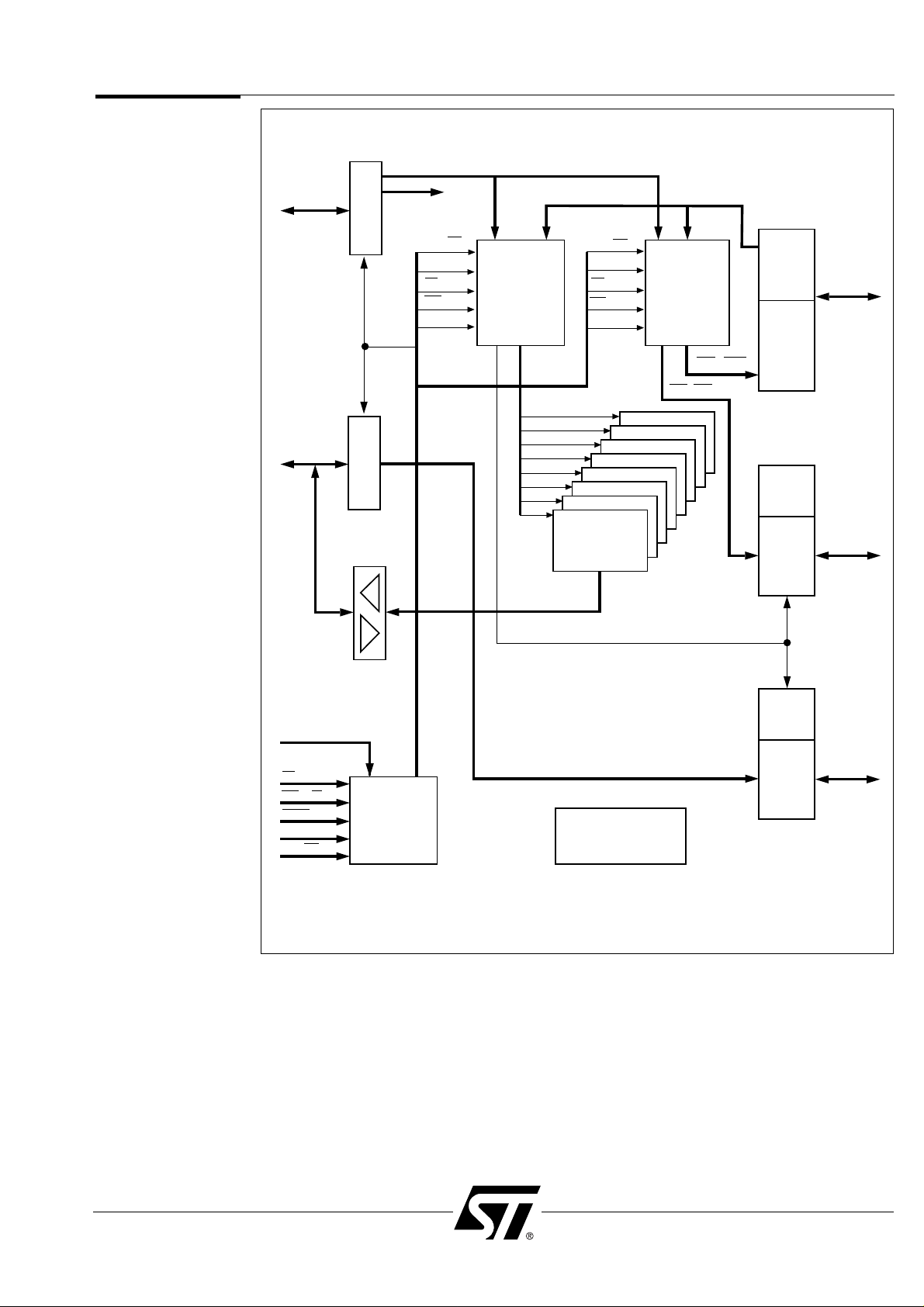

The major functional blocks of the PSD211R include:

• Two programmable logic arrays

• 256 Kb of EPROM

• Input latches

• Programmable I/O ports

• Programmable security

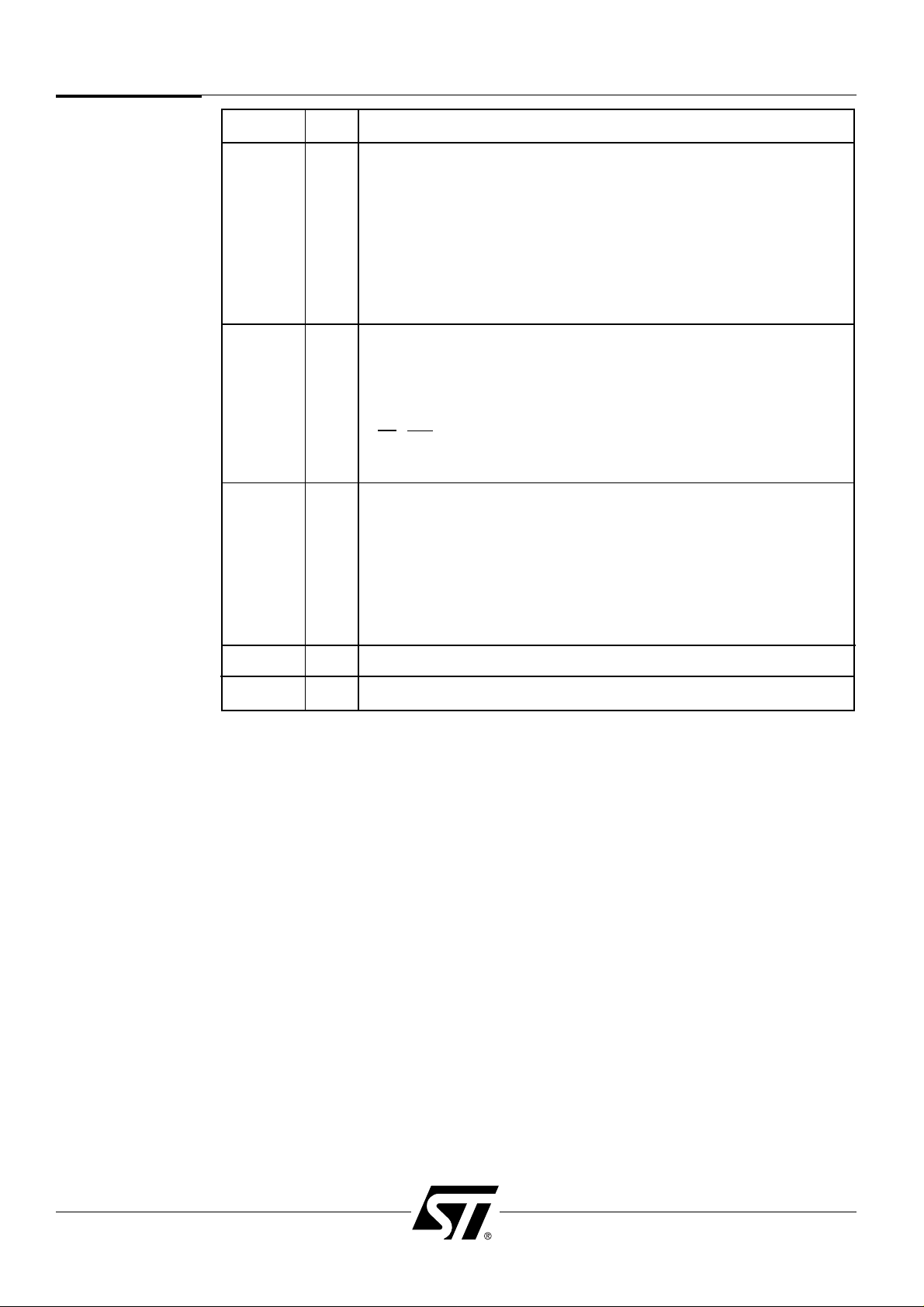

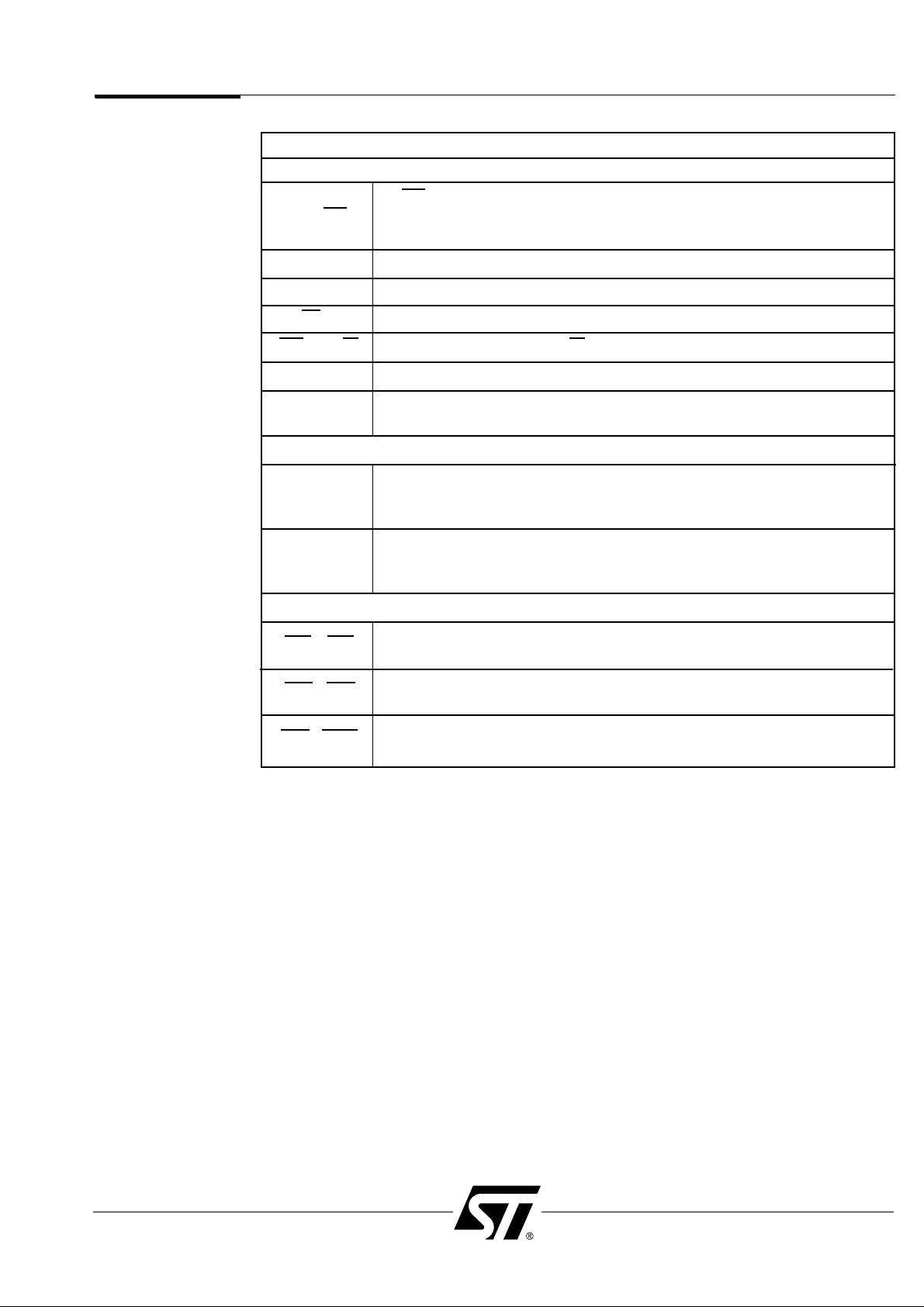

The PSD211R family architecture (Figure 1) can efficiently interface with, and enhance,

almost any 8-bit multiplexed microcontroller system. This solution provides microcontrollers

the following:

• Chip-select logic, control logic, and latched address signals that are otherwise

implemented discretely

• Port expansion (reconstructs lost microcontroller I/O)

• An EPROM (with security)

• Compatible with 8031-type architectures that use separate Program and Data Space.

Updated March 1, 1999. See page 47.

Page 5

PSD211R Family

2

2.0

Notation

1.0

Introduction

(Cont.)

The PSD211R I/O ports can be used for:

• Standard I/O ports

• Programmable chip select outputs

• Address inputs

• Demultiplexed address outputs.

Implementing your design has never been easier than with PSDsoft—WSI’s software

development suite. Using PSDsoft, you can do the following:

• Configure your PSD211R to work with virtually any 8-bit microcontroller

• Specify what you want implemented in the programmable logic using a high-level

Hardware Description Language (HDL)

• Simulate your design

• Download your design to the part using a programmer.

Throughout this data sheet, references are made to the PSD211R. In most cases, these

references also cover the ZPSD211R and ZPSD211RV products. Exceptions will be noted.

Also, references to the ZPSD211R will also cover the low-voltage ZPSD211RV. (Again,

exceptions will be noted.) Use the following table to determine what references cover which

product versions:

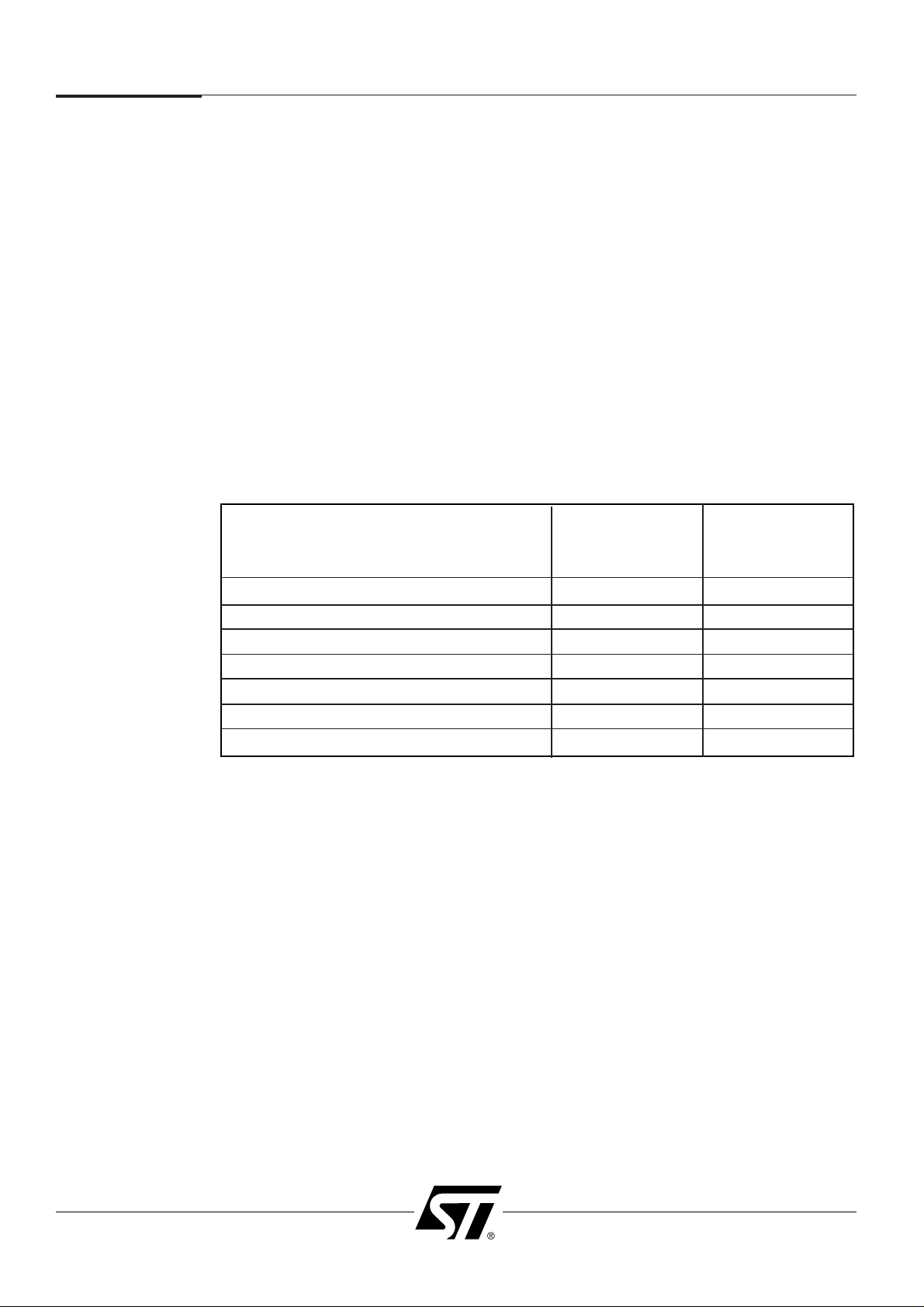

Reference PSD211R ZPSD211R ZPSD211RV

PSD211R or PSD X X X

PSD211R only X

Non-ZPSD X

ZPSD versions only X X

Non-V versions X X

V versions only or 3 V part only or

ZPSD211RV only

X

Page 6

PSD211R Family

3

PROG.

PORT

EXP.

PORT

C

PC0–PC2

ES0

ES1

ES2

ES3

ES4

ES5

ES6

ES7

PROG.

CONTROL

SIGNALS

A19/CSI

RESET

WR/R/W

RD/E

ALE/AS

PSEN

PAD A

RESET

WR

ALE/AS

RD

PAD B

A11–A15

PROG.

PORT

EXP.

PORT

B

PB0–PB7

PROG.

PORT

EXP.

PORT

A

PA0–PA7

A19/CSI

RESET

ALE/AS

A19/CSI

A8–A10

WR

RD

ALE/AS

L

A

T

C

H

L

A

T

C

H

A8–A15

AD0–AD7

D0–D7

13 P.T.

27 P.T.

LOGIC

IN

EPROM

256Kb

A16–A18

CS8–CS10

CS0–CS7

A0–A7

CSIOPORT

PROG. CHIP

CONFIGURATION

Figure 1.

PSD211R Family

Architecture

Page 7

PSD211R Family

4

3.0

Key Features

❏ Low cost programmable microcontroller peripheral

❏ 256Kb of UV EPROM with the following features:

• Configurable as 32 K x 8

• Divided into eight equally-sized mappable blocks for optimized address mapping

• As fast as 70 ns access time, which includes address decoding

❏ 19 I/O pins that can be individually configured for :

• Microcontroller I/O port expansion

• Programmable Address decoder (PAD) I/O

• Latched address output

❏ Two Programmable Arrays (PAD A and PAD B) replace your discrete PLD or decoder

and have the following features:

• Up to 13 Inputs and 24 outputs

• 36 Product terms (9 for PAD A and 27 for PAD B)

• Ability to decode up to 1 MB of address

❏ Microcontroller logic that eliminates the need for external “glue logic” has the following

features:

• Ability to interface to multiplexed buses

• Built-in address latches for multiplexed address/data bus

• ALE and Reset polarity are programmable (Reset polarity not programmable

on V-versions)

• Multiple configurations are possible for interface to many different microcontrollers

❏ Programmable power management with standby current as low as 1µA

(V versions only)

• CMiser bit—programmable option to reduce AC power consumption in memory

• Turbo Bit (ZPSD only)—programmable bit to reduce AC and DC power consumption

in the PADs

❏ Built-in security locks the device and PAD decoding configuration

❏ Wide Operating Voltage Range

• V-versions: 2.7 to 5.5 volts

• Others: 4.5 to 5.5 volts

❏ Available in a variety of packaging (44-pin PLDCC, CLDCC, and PQFP)

❏ Simple, menu-driven software (PSDsoft) allows configuration and design entry on a PC.

Page 8

PSD211R Family

5

4.0

PSD211R Family

Feature

Summary

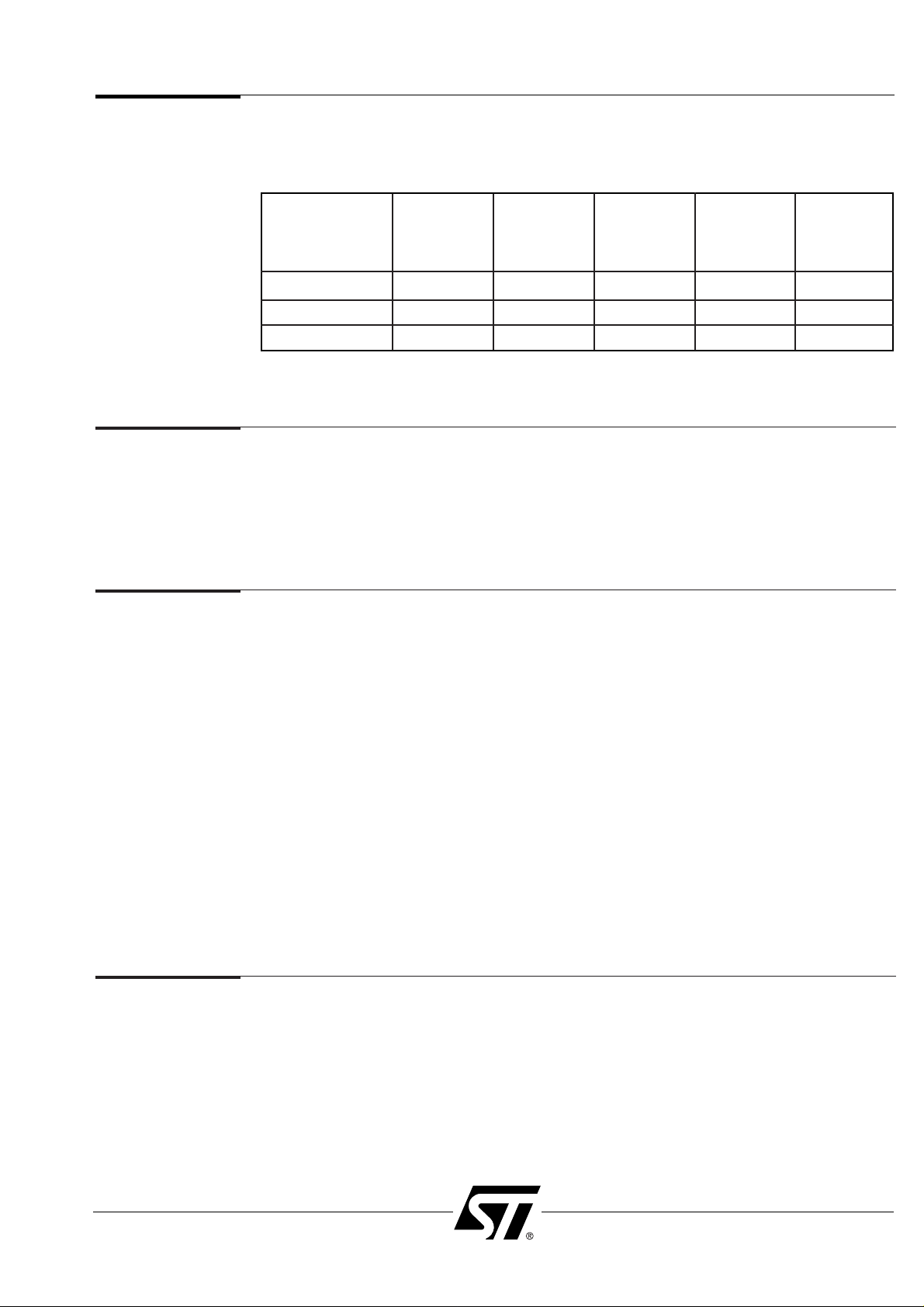

Use the following table to determine which PSD product will fit your needs. Refer back to

this page whenever there is confusion as to which part has what features.

❏ Motorola family: 68HC11, 68HC05C0

❏ Intel family: 80C31, 80C51, 80C188, 80C198

❏ Philips family: 80C31 and 80C51 based MCUs

❏ Zilog: Z8

Typical

# PLD EPROM Turbo Standby

Part Inputs Size Voltage Bit Current

PSD211R 13 256 Kb 5 V 50 µA

ZPSD211R 13 256 Kb 5 V X 10 µA

ZPSD211RV 13 256 Kb 3 V/5 V X 1 µA

Table 1. PSD211R Product Summary

5.0

Partial Listing

of

Microcontrollers

Supported

❏ Telecommunications:

• Cellular phone

• Digital PBX

• Digital speech

• FAX

• Digital Signal Processing (DSP)

❏ Portable Industrial Equipment:

• Industrial Control

• Measurement meters

• Data recorders

• Security and access control

❏ Medical Instrumentation:

• Hearing aids

• Monitoring equipment

• Diagnostic tools

6.0

Applications

NOTE: The low power version of the ZPSD211R (the ZPSD211RV) can only accept an active-low level Reset

input.

Portable and battery-powered systems have recently become major embedded control

application segments. As a result, the demand for electronic components having extremely

low power consumption has increased dramatically. Recognizing this trend, WSI, Inc.

developed a new lower power PSD part, denoted ZPSD211R. The Z stands for Zero-power

because ZPSD products virtually eliminate the DC component of power consumption,

reducing it to standby levels. Virtual elimination of the DC component is the basis for the

words “Zero-power” in the ZPSD name. ZPSD products also minimize the AC power

component when the chip is changing states. The result is a programmable microcontroller

peripheral family that replaces discrete circuit components, while drawing less power.

7.0

ZPSD

Background

Page 9

PSD211R Family

6

7.0

ZPSD

Background

(Cont.)

7.1 Integrated Power ManagementTMOperation

Upon each address or logic input change to the ZPSD, the device powers up from low

power standby for a short time. Then the ZPSD consumes only the necessary power to

deliver new logic or memory data to its outputs as a response to the input change. After the

new outputs are stable, the ZPSD latches them and automatically reverts back to standby

mode. The ICCcurrent flowing during standby mode and during DC operation is identical

and is only a few microamperes.

The ZPSD automatically reduces its DC current drain to these low levels and does not

require controlling by the CSI (Chip Select Input). Disabling the CSI pin unconditionally

forces the ZPSD to standby mode independent of other input transitions. The only

significant power consumption in the ZPSD occurs during AC operation. The ZPSD

contains the first architecture to apply Zero-power techniques to memory and logic blocks.

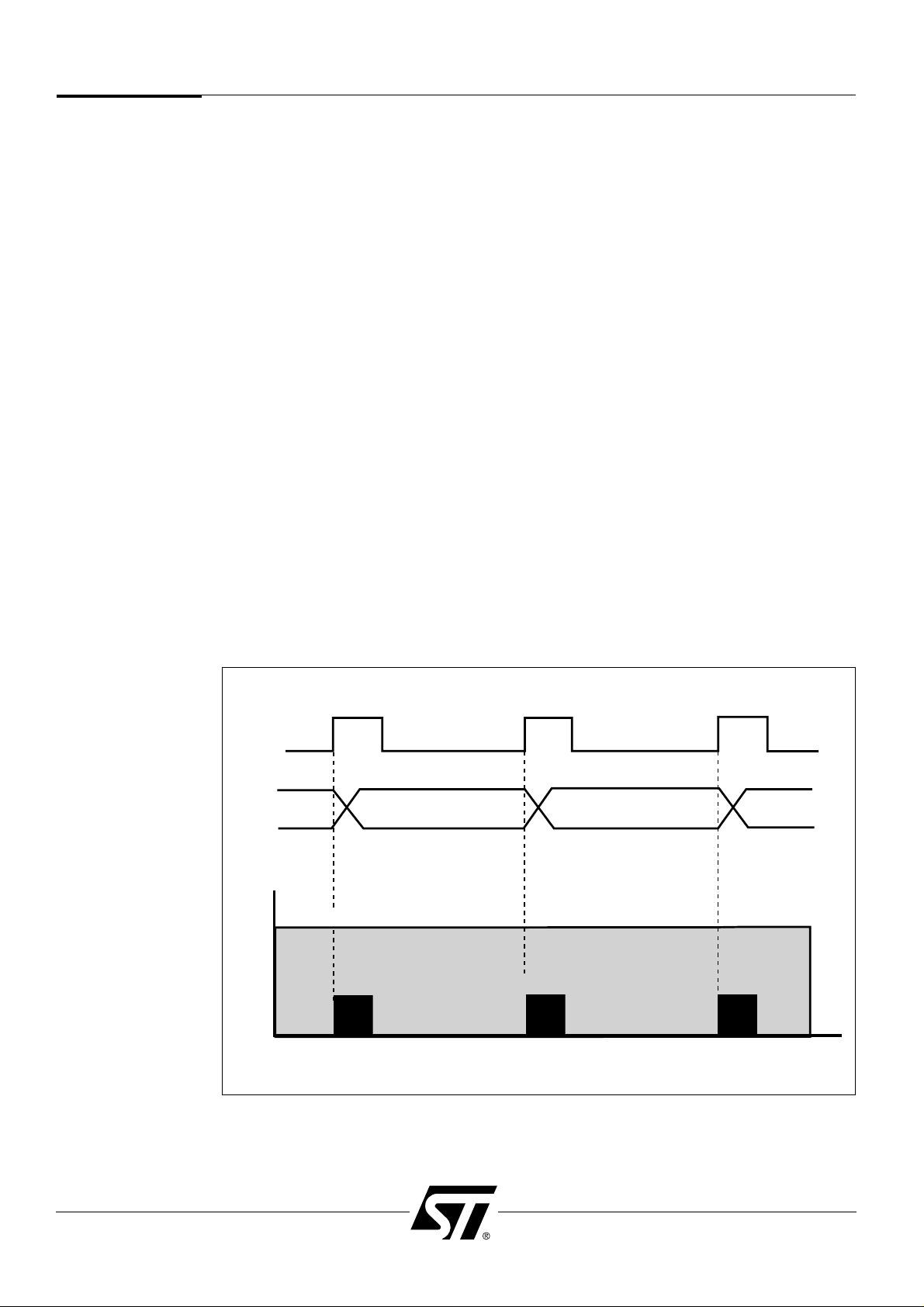

Figure 2 compares ZPSD zero power operation to the operation of a discrete solution.

A standard microcontroller (MCU) bus cycle usually starts with an ALE (or AS) pulse and

the generation of an address. The ZPSD detects the address transition and powers up for a

short time. The ZPSD then latches the outputs of the PAD and EPROM to the new values.

After finishing these operations, the ZPSD shuts off its internal power, entering standby

mode. The time taken for the entire cycle is less than the ZPSD’s “access time.”

The ZPSD will stay in standby mode while its inputs are not changing between bus

cycles. In an alternate system implementation using discrete EPROM, and other discrete

components, the system will consume operating power during the entire bus cycle.

This is because the chip select inputs on the memory devices are usually active throughout

the entire cycle. The AC power consumption of the ZPSD may be calculated using the

composite frequency of the MCU address and control signals, as well as any other logic

inputs to the ZPSD.

ALE

DISCRETE EPROM & LOGIC

ADDRESS

EPROM

ACCESS

EPROM

ACCESS

EPROM

ACCESS

I

CC

ZPSD ZPSD

ZPSD

TIME

Figure 2. ZPSD Power Operation vs. Discrete Implementation

Page 10

PSD211R Family

7

Name Type Description

This pin is for 8031 or compatible MCUs that use PSEN to

separate program space from data space. In this case, PSEN is

used for reads from the EPROM.

PSEN I Notes:

1) If your MCU does not output a PSEN signal, pull up this pin to

VCC.

2) In programming mode, this pin is pulsed between VPPand 0 V.

The following control signals can be connected to this port, based on

WR/V

PP

your MCU (and the way you configure the PSD in PSDsoft):

or I 1. WR—active-low write pulse.

R/W/V

PP

2. R/W—active-high read/active-low write input.

Note: in programming mode, this pin must be tied to VPP.

The following control signals can be connected to this port, based on

RD/E I

your MCU (and the way you configure the PSD in PSDsoft):

1. RD—active-low read input.

2. E—E clock input.

The following control signals can be connected to this port:

1. CSI-Active-low chip select input. If your MCU supports a chip

select output, and you want the PSD to save power when not

A19/CSI I selected, use this pin as a chip select input.

2. If you don’t wish to use the CSI feature, you may use this pin as

an additional input (logic or address) to the PAD. A19 can be

latched with ALE/AS, or be a transparent logic input.

PSD211R/ZPSD211R:

This pin is user-programmable and can be configured to reset on a

high- or low-level input. Reset must be applied for at least 100 ns.

Reset I

ZPSD211RV:

This pin is not configurable, and the chip will only reset on an

active-low level input. Reset must be applied for at least 500 ns,

and no operations may take place for an additional 500 ns minimum.

(See Figure 8.)

ALE/AS I

Connect ALE or AS to this pin. The polarity of this pin is configurable.

The trailing edge of ALE/AS latches all multiplexed address inputs.

PA0

PA1

PA2

These pins make up Port A. These port pins are configurable, and

PA3

I/O

can have the following functions: (see Figure 5)

PA4

1. MCU I/O—in this mode, the direction of the pin is defined by its

PA5

direction bit, which resides in the direction register.

PA6

2. Latched address output.

PA7

PB0

These pins make up Port B. These port pins are configurable, and

PB1

can have the following functions: (see Figure 6)

PB2

1. MCU I/O—in this mode, the direction of the pin is defined by its

PB3

I/O direction bit, which resides in the direction register.

PB4

2. Chip select output—each of PB0-3 has four product terms

PB5

available per pin, while PB4-7 have 2 product terms each.

PB6

See Figure 4.

PB7

Legend:

The Type column abbreviations are: I = input only; I/O = input/output; P = power.

Table 2.

PSD211R Pin

Descriptions

Page 11

Table 1.

PSD211R Pin

Descriptions

(cont.)

PSD211R Family

8

Name Type Description

These pins make up Port C. These port pins are configurable, and

can have the following functions (see Figure 7):

1. PAD input—when configured as an input, a bit individually

PC0 becomes an address or a logic input, depending on your PSDsoft

PC1 I/O design file. When declared as an address, the bits are latched

PC2 with ALE/AS.

2. PAD output—when configured as an output (i.e. there is an

equation written for it in your PSDsoft design file), there is one

product term available to it.

AD0

AD1

AD2

These pins are the multiplexed, low-order address/data byte

AD3

I/O

(AD0-AD7). As inputs, address information is latched by the ALE/AS

AD4

signal and used internally by the PSD. The pins also serve as MCU

AD5

data bus inputs or outputs, depending on the MCU control signals

AD6

(RD, WR, etc.).

AD7

A8

A9

A10

A11

I/O These pins are the high-order address inputs (A8-A15).

A12

A13

A14

A15

GND P Ground Pin

V

CC

P Supply voltage input.

Legend:

The Type column abbreviations are: I = input only; I/O = input/output; P = power.

Page 12

Port Configurations

A I/O or low-order (latched) address lines

B I/O and/or CS0–CS7

C A16-A18 or CS8-CS10

PSD211R Family

9

The PSD211R operates in 8-bit address/data mode, enabling it to interface directly to a

variety of 8-bit multiplexed microcontrollers. It works as follows: the address/data bus

(AD0-AD7) is bi-directional and permits the latching of the address when the ALE/AS signal

is active. On the same pins, the data is read from or written to the device, depending on the

state of the control signals (WR, RD, etc.). You should connect your MCU according to the

following figure. Ports A through C can be configured according to Table 3, below.

Your

8-bit

MCU

PSD211R

PA

PB

PC

AD0-AD7

I/O or A0-A7A8-A15

ALE/AS

PSEN

R/W or WR

RD/E

A19/CSI

RESET

A16-A18

1

I/O or CS0-CS7

CS8-CS10

OR

Figure 3. Connecting a PSD211R to an 8-Bit Multiplexed-Bus MCU

8.0

Operating Mode

Table 3. Bus and Port Configuration Options

9.0

Programmable

Address

Decoder (PAD)

NOTE: 1. Connect A16-A18 to Port C if your MCU outputs more than 16 bits of address.

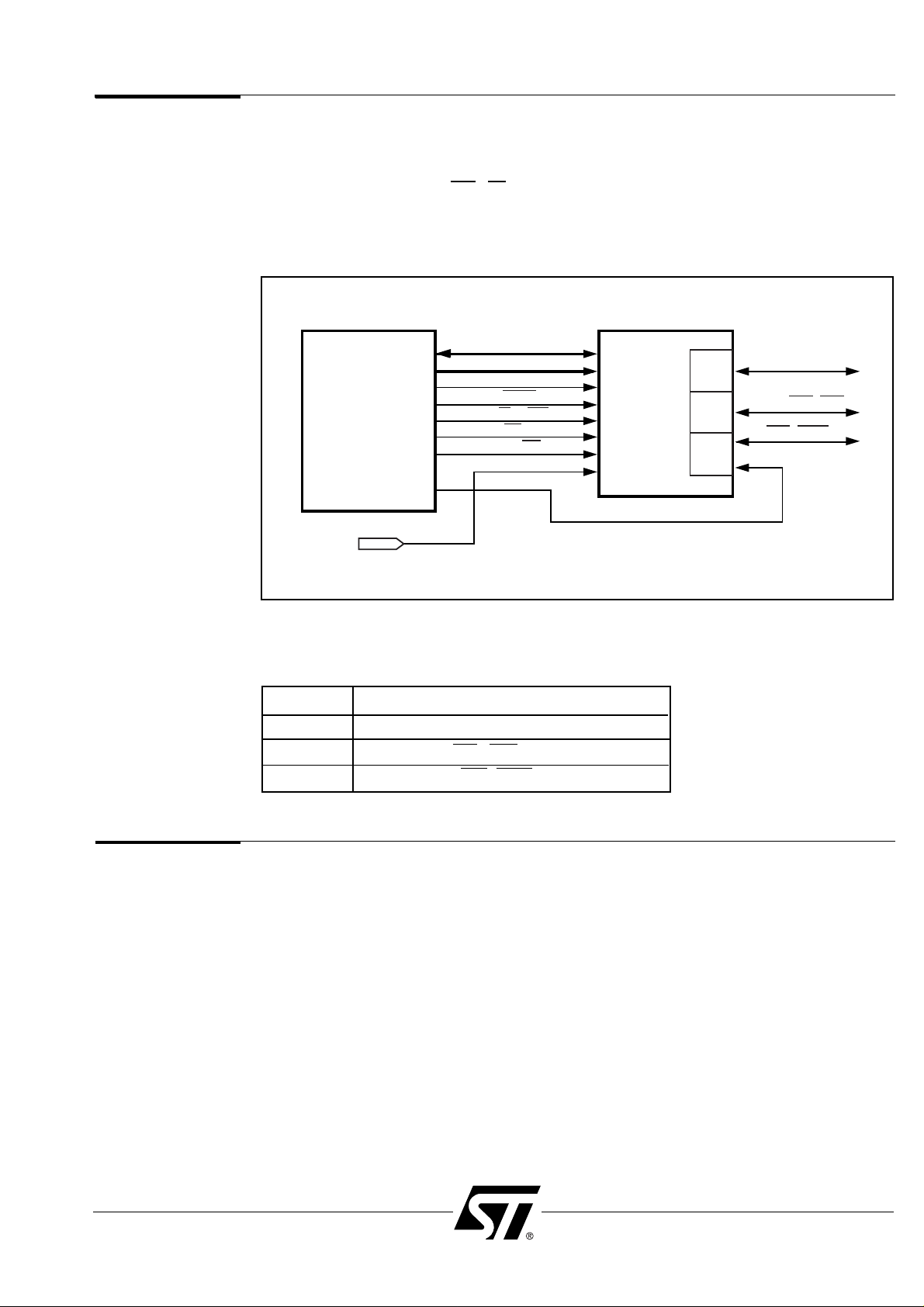

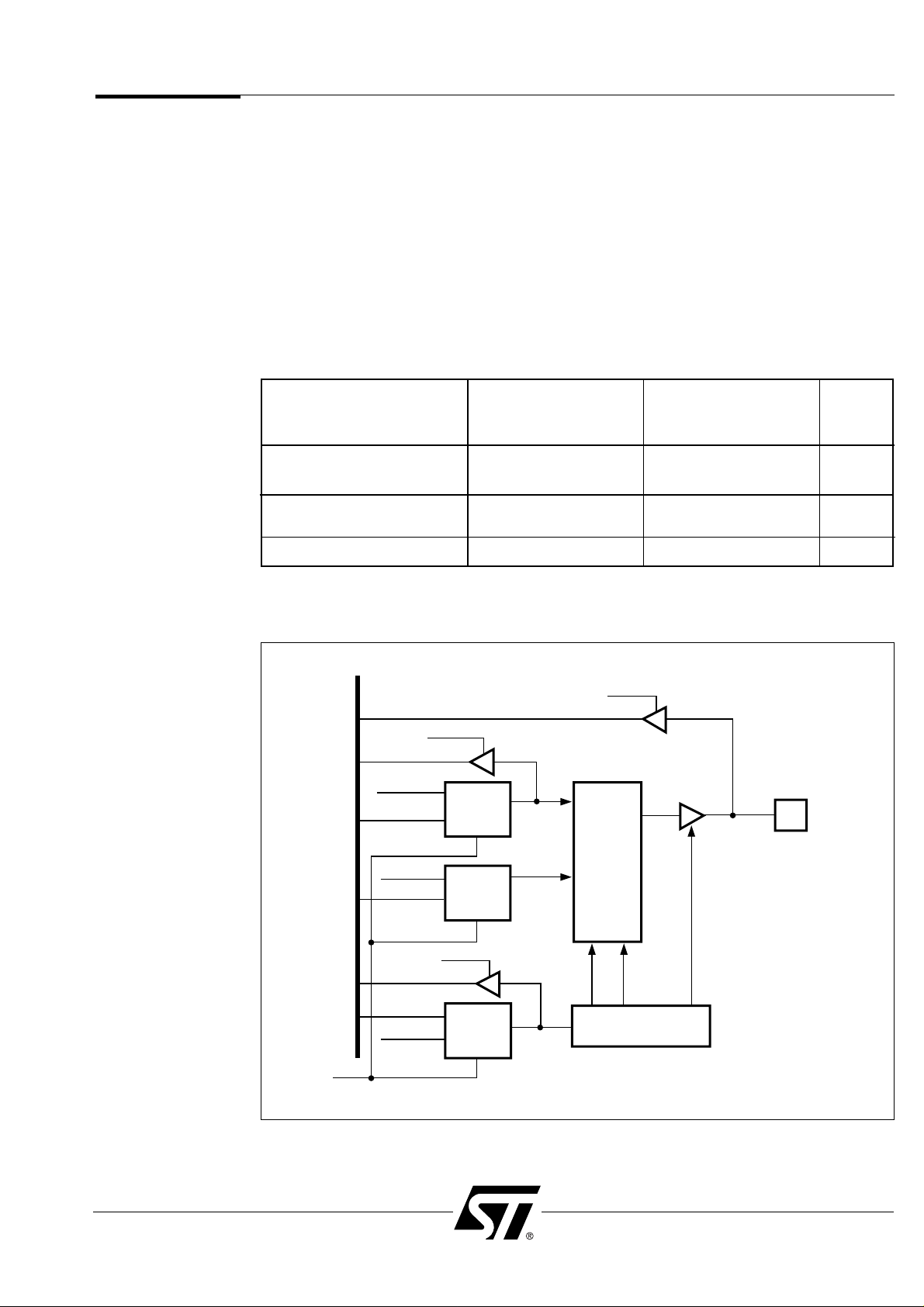

The PSD211R contains two programmable arrays, referred to as PAD A and PAD B

(Figure 4). PAD A is used to generate chip select signals derived from the input address to

the internal EPROM blocks and I/O ports.

PAD B outputs to Ports B and C for off-chip usage. PAD B can also be used to extend the

decoding to select external devices or as a random logic replacement.

PAD A and PAD B receive the same inputs. The PAD logic is configured by PSDsoft based

on the designer’s input. The PAD’s non-volatile configuration is stored in a re-programmable

CMOS EPROM. Windowed packages are available for erasure by the user. See Table 4 for

a list of PAD A and PAD B functions.

Page 13

NOTES: 1. CSI is a power-down signal. When high, the PAD is in stand-by mode and all its outputs

become non-active. See Tables 7A and 7B.

2. RESET deselects all PAD output signals. See Tables 8A and 8B.

3. A18, A17, and A16 are internally multiplexed with CS10, CS9, and CS8, respectively.

Either A18 or CS10, A17 or CS9, and A16 or CS8 can be routed to the external pins of

Port C. Port C can be configured as either input or output.

ALE or AS

WR or R/W

A19

A18

A17

A16

A15

A14

A13

A12

A11

ES0

ES1

ES2

ES3

ES4

ES5

ES6

ES7

CSIOPORT

CS0/PB0

CS1/PB1

CS2/PB2

CS3/PB3

CS4/PB4

CS5/PB5

CS6/PB6

CS7/PB7

CS8/PC0

CS9/PC1

CS10/PC2

RD/E

8 EPROM BLOCK

SELECT LINES

CSI

RESET

I/O BASE ADDRESS

PAD

B

PAD

A

PSD211R Family

10

Figure 4. PAD Description

Programmable

Address

Decoder (PAD)

Page 14

PSD211R Family

11

Function

PAD A and PAD B Inputs

In CSI mode (when high), PAD deselects all of its outputs and enters a

A19/CSI power-down mode (see Tables 7A and 7B). In A19 mode, it is another

input to the PAD.

A16–A18 These are general purpose inputs from Port C. See Figure 4, Note 3.

A11–A15 These are address inputs.

RD/E This is the read pulse or enable strobe input.

WR or R/W This is the write pulse or R/W select signal.

ALE/AS This is the ALE or AS input to the chip.

RESET

This deselects all outputs from the PAD; it can not be used in product

term equations.See Tables 8A and 8B.

PAD A Outputs

These are internal chip-selects to the 8 EPROM banks. Each bank can

ES0–ES7 be located on any boundary that is a function of one product term of the

PAD address inputs.

This internal chip-select selects the I/O ports. It can be placed on any

CSIOPORT boundary that is a function of one product term of the PAD inputs. See

Table 5.

PAD B Outputs

CS0–CS3

These chip-select outputs can be routed through Port B. Each of them is

a function of up to four product terms of the PAD inputs.

CS4–CS7

These chip-select outputs can be routed through Port B. Each of them is

a function of up to two product terms of the PAD inputs.

CS8–CS10

These chip-select outputs can be routed through Port C. See Figure 4,

Note 3. Each of them is a function of one product term of the PAD inputs.

Table 4. PSD211R PAD A and PAD B Functions

Programmable

Address

Decoder (PAD)

(cont.)

Page 15

PSD211R Family

12

10.0

I/O Port

Functions

The PSD211R has three I/O ports (Ports A, B, and C) that are configurable at the bit level.

This permits great flexibility and a high degree of customization for specific applications.

The next section describes the control registers for the ports. Following that are sections

that describe each port. Figures 5 through 7 show the structure of Ports A through C,

respectively.

Note: any unused inputs should be connected directly to ground or pulled up to VCC(using

a 10KΩ to 100KΩ resistor).

10.1 CSIOPORT Registers

Control of the ports is primarily handled through the CSIOPORT registers. There are 24

bytes in the address space, starting at the base address labeled CSIOPORT. Since the

PSD211R uses internal address lines A15-A11 for decoding, the CSIOPORT space

will occupy 2 Kbytes of memory, on a 2 Kbyte boundary. This resolution can be improved

to reduce wasted address space by connecting lower order address lines (A10 and below)

to Port C. Using this method, resolution down to 256 Kbytes may be achieved. The

CSIOPORT space must be defined in your PSDsoft design file. The following tables list

the registers located in the CSIOPORT space.

Table 5. CSIOPORT Registers for 8-Bit Data Busses

NOTE: 1. ZPSD only.

Offset (in hex) Type of

from CSIOPORT Access

Register Name Base Address Allowed

Port A Pin Register +2 Read

Port A Direction Register +4 Read/Write

Port A Data Register +6 Read/Write

Port B Pin Register +3 Read

Port B Direction Register +5 Read/Write

Port B Data Register +7 Read/Write

Power Management Register (Note 1) +10 Read/Write

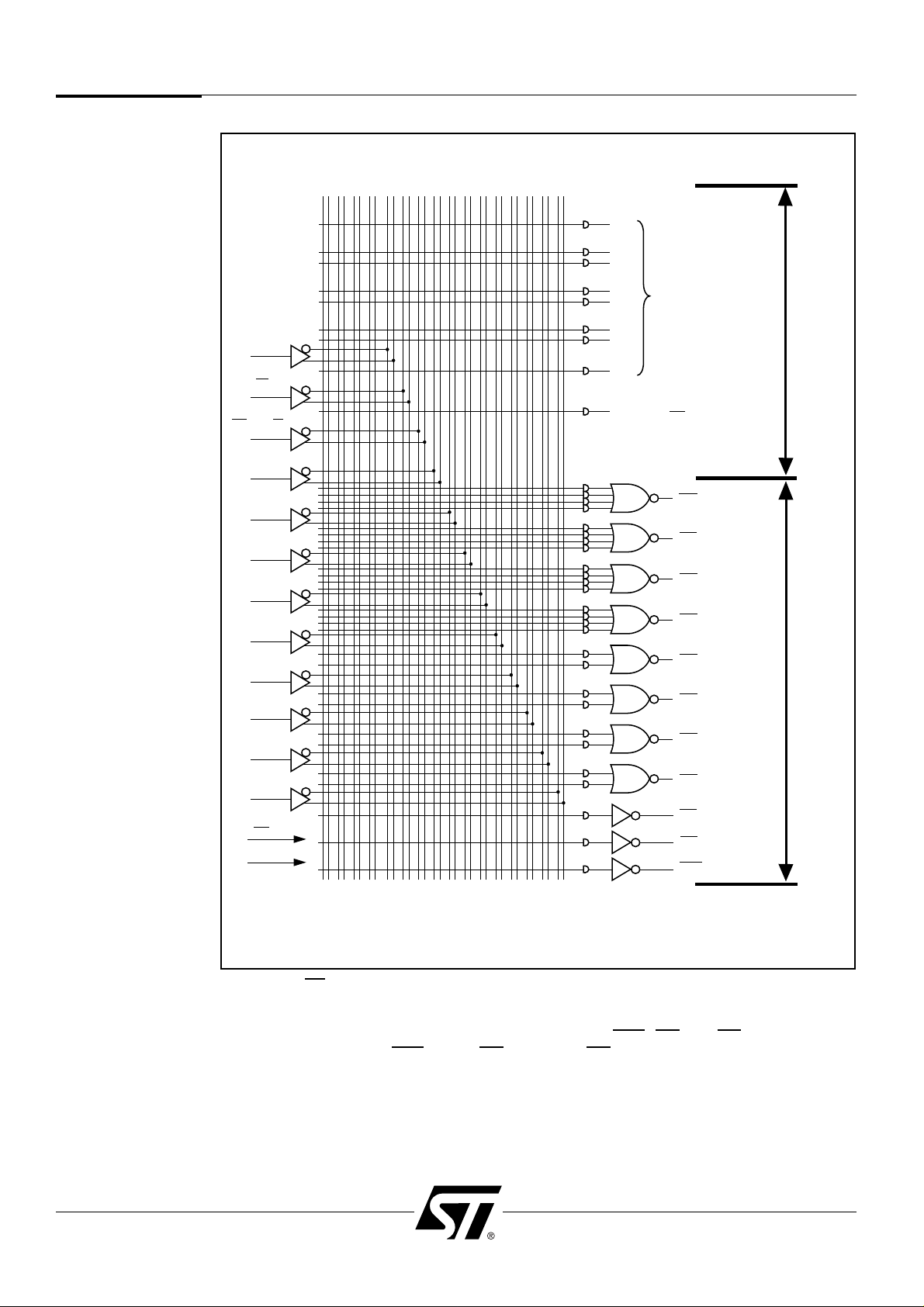

10.2 Port A (PA0-PA7)

MCU I/O Mode

The default configuration of Port A is MCU I/O. In this mode, every pin can be set

(at run-time) as an input or output by writing to the respective pin’s direction flip-flop

(DIR FF, Figure 5). As an output, the pin level can be controlled by writing to the respective

pin’s data flip-flop (DFF, Figure 5A). The Pin Register can be read to determine logic level

of the pin. The contents of the pin register indicate the true state of the PSD driving the pin

through the DFF or an external source driving the pin.

Page 16

13

PSD211R

10.0

I/O Port

Functions

(Cont.)

10.2 Port A (PA0-PA7)

(Cont.)

Latched Address Output Mode

Alternatively, any bit(s) of Port A can be configured to output a low-order demultiplexed

address bus bit. The address is provided by the internal PSD address latch, which latches

the address on the trailing edge of ALE/AS. Port A then outputs the desired demultiplexed

address bits. This feature can eliminate the need for an external latch (for example:

74LS373) if you have devices that require low-order latched address bits. Although any pin

of Port A may output an address signal, the pin is position-dependent. In other words, pin

PA0 of Port A may only pass A0, PA1 only A1, and so on.

The control registers of Port A are located in CSIOPORT space; see Table 5. Each pin of

Port A can be individually configured. The following table summarizes what the control

registers (in CSIOPORT space) for Port A do:

NOTE: 1. Default value is the value after reset.

Default

Value

Register Name 0 Value 1 Value

(Note 1)

Port A Pin Register

Sampled logic level Sampled logic level

X

at pin = ‘0’ at pin = ‘1’

Port A Direction Register

Pin is configured Pin is configured

0

as input as output

Port A Data Register Data in DFF = ‘0’ Data in DFF = ‘1’ 0

Figure 5. Port A Pin Structure

READ PIN

PORT A PIN

ENABLE

LATCHED

ADDR

OUT

MCU

I/O

OUT

READ DATA

WRITE DATA

ALE

READ DIR

WRITE DIR

RESET

CK

D

R

G

D

R

D

CK

R

I

N

T

E

R

N

A

L

A

D

D

R

/

D

A

T

A

B

U

S

A

D

0

/

A

D

7

DFF

LATCH

DIR

FF

CONTROL

MUX

Page 17

PSD211R Family

14

Figure 6. Port B Pin Structure

READ PIN

READ DATA

PORT B PIN

MCU

I/O

OUT

WRITE DATA

CK

D

R

DFF

ENABLE

MUX

CSn

CONTROL

DIR

FF

D

CK

R

WRITE DIR

RESET

READ DIR

I

N

T

E

R

N

A

L

I

N

T

E

R

N

A

L

C

S

O

U

T

D

A

T

A

B

U

S

B

U

S

C

S

0

•

•

•

7

D

8

•

•

•

D

1

5

10.0

I/O Port

Functions

(Cont.)

10.3 Port B (PB0-PB7)

MCU I/O Mode

The default configuration of Port B is MCU I/O. In this mode, every pin can be set

(at run-time) as an input or output by writing to the respective pin’s direction flip-flop (DIR

FF, Figure 6). As an output, the pin level can be controlled by writing to the respective pin’s

data flip-flop (DFF, Figure 6). The Pin Register can be read to determine logic level of the

pin. The contents of the Pin Register indicate the true state of the PSD driving the pin

through the DFF or an external source driving the pin.

Chip Select Output

Alternatively, each bit of Port B can be configured to provide a chip-select output signal

from PAD B. PB0-PB7 can provide CS0-CS7, respectively. The functionality of these pins

is not limited to chip selects only; they can be used for generic combinatorial logic as well.

Each of the CS0-CS3 signals is comprised of four product terms, and each of the CS4-CS7

signals is comprised of two product terms.

The control registers of Port B are located in CSIOPORT space; see Table 5. Each pin of

Port B can be individually configured. The following table summarizes what the control

registers (in CSIOPORT space) for Port B do:

NOTE: 1. Default value is the value after reset.

Default

Value

Register Name 0 Value 1 Value

(Note 1)

Port B Pin Register

Sampled logic level Sampled logic level

X

at pin = ‘0’ at pin = ‘1’

Port B Direction Register

Pin is configured Pin is configured

0

as input as output

Port B Data Register Data in DFF = ‘0’ Data in DFF = ‘1’ 0

Page 18

PSD211R Family

15

10.0

I/O Port

Functions

(Cont.)

10.4 Port C (PC0-PC2)

Each pin of Port C (Figure 7) can be configured as an input to PAD A and PAD B, or as an

output from PAD B. As inputs, the pins are referenced as A16-A18. Although the pins are

given this reference, they can be used for any address or logic input. [For example, A8-A10

could be connected to those pins to improve the resolution (boundaries) of CS0-CS7 to

256 bytes.] How they are defined in the PSDsoft design file determines:

• Whether they are address or logic inputs

• Whether the input is transparent or latched by the trailing edge of ALE/AS.

Notes:

1) If the inputs are addresses, they are routed to PAD A and B, and can be used in any or

all PAD equations.

2) If the inputs are logic, they are routed to PAD B and can be used for Boolean equations

that are implemented in any or all of the CS0-CS10 PAD B outputs.

3) If Port C pins are configured as inputs, they can not be individually configured as

address or logic and latched or transparent. They must be configured as a group to be

address or logic and latched or transparent.

Alternately, PC0-PC2 can become CS8-CS10 outputs, respectively, providing the user with

more external chip-select PAD outputs. Each of the signals (CS8-CS10) is comprised of

one product term.

Figure 7. Port C (PC0-PC2) Pin Structure

CS8/CS9/CS10

From PAD

To PAD

A16/A17/A18

Latched Address

Input

QD

En

Logic Input

D

E

M

U

X

Address In or

Chip Select Out

Input or Output

Set by PSDsoft

2

PSDsoft

2

Port C I/O

1

(PC0/PC1/PC2)

ALE

NOTES: 1. Port C pins can be individually configured as inputs or outputs, but not both.

2. PSDsoft sets this configuration prior to run-time based on your PSDsoft design file.

Page 19

PSD211R Family

16

11.0

PSD Memory

The following sections explain the EPROM memory block and how to program and erase

the PSD211R.

11.1 EPROM

For all PSD211R devices, the EPROM is built using Zero-power technology. This means

that the EPROM powers up only when the address changes. It consumes power for the

necessary time to latch data on its outputs. After this, it powers down and remains in

standby mode until the next address change. This happens automatically, and the designer

has to do nothing special.

The 32K x 8 EPROM is divided into eight equal-sized banks. Each bank can be placed in

any address location by programming the PAD. Bank0-Bank7 are selected by PAD A

outputs ES0-ES7, respectively. There is one product term for each bank select (ESi).

11.2 Programming and Erasure

Programming the device can be done using the following methods:

• WSI’s main programmer—PSDpro—which is accessible through a parallel port.

• WSI’s programmer used specifically with the PSD211R—PEP300.

• WSI’s discontinued programmer—Magic Pro.

• A 3rd party programmer, such as Data I/O.

Information for programming the device is available directly from WSI. Please contact your

local sales representative. Also, check our web site (waferscale.com) for information related

to 3rd party programmers.

Upon delivery from WSI, or after each erasure (using windowed part), the PSD211R device

has all bits in the PAD and EPROM in the HI state (logic 1). The configuration bits are in the

LO state (logic 0).

To clear all locations of their programmed contents (assuming you have a windowed

version), expose the windowed device to an Ultra-Violet (UV) light source. A dosage of

30 W second/cm2is required for PSD211R devices, and 40 W second/cm2for low-voltage

(V suffix) devices. This dosage can be obtained with exposure to a wavelength of

2537 Å and intensity of 12000 µW/cm2for 40 to 45 minutes for the PSD211R and 55 to 60

minutes for the low-voltage (V suffix) devices. The device should be approximately 1 inch

(2.54 cm) from the source, and all filters should be removed from the UV light source prior

to erasure.

The PSD211R devices will erase with light sources having wavelengths shorter than

4000 Å. However, the erasure times will be much longer than when using the

recommended 2537 Å wavelength. Note: exposure to sunlight will eventually erase the

device. If used in such an environment, the package window should be covered with an

opaque substance.

12.0

Control Signals

Consult your MCU data sheet to determine which control signals your MCU generates, and

how they operate. This section is intended to show which control signals should be

connected to what pins on the PSD211R. You will then use PSDsoft to configure the

PSD211R, based on the combination of control signals that your MCU outputs, for example

RD, WR, and PSEN.

The PSD211R is compatible with the following control signals:

• ALE or AS (polarity is programmable)

• WR or R/W

• RD/E

• PSEN

• A19/CSI

• RESET (polarity is programmable except on low voltage versions with the V suffix).

Page 20

PSD211R Family

17

12.0

Control Signals

(Cont.)

12.1 ALE or AS

Connect the ALE or AS signal from your MCU to this pin where applicable, and program

the polarity using PSDsoft. The trailing edge (when the signal goes inactive) of ALE or AS

latches the address on the appropriate address pins.

12.2 WR or R/W

Your MCU should output a stand-alone write signal (WR) or a multiplexed read/write signal

(R/W). In either case, the signal should be connected to this pin.

12.3 RD/E

Your MCU should output either RD or E (clock). In either case, connect the appropriate

signal to this pin. Note: if you have an MCU that outputs DS, it will not be compatible with

the PSD211R, and you must use a PSD3XX family device.

12.4 PSEN

❏ If your MCU does not output PSEN (or some program select enable equivalent signal),

tie this pin to Vcc (through a series resistor), and skip to the next signal.

❏ If you use an 8-bit 8031 compatible MCU that outputs a separate signal when

accessing program space, such as PSEN, connect it to this pin. You would then use

PSDsoft to configure the EPROM in the PSD211R to respond to PSEN only or PSEN

and RD. If you have an 8031 compatible MCU, refer to the “Program/Data Space and

the 8031” section for further information.

12.5 A19/CSI

This pin is configured using PSDsoft to be either a chip select for the entire PSD device or

an additional PAD input. If your MCU can generate a chip-select signal, and you wish to

save power, use the PSD chip select feature. Otherwise, use this pin as an address or logic

input.

❏ When configured as CSI (active-low PSD chip select): a low on this pin keeps the

PSD in normal operation. However, when a high is detected on the pin, the PSD

enters Power-down Mode. See Tables 7A and 7B for information on signal states

during Power-down Mode. See section 16 for details about the reduction of power

consumption.

❏ When configured as A19, the pin can be used as an additional input to the PADs.

It can be used for address or logic. It can also be ALE/AS dependent or a transparent

input, which is determined by your PSDsoft design file. In A19 mode, the PSD is

always enabled.

Port Configuration Mode(s) State

AD0–AD15 All Input (Hi-Z)

Port Pins PA0–PA7

MCU I/O Unchanged

Latched Address Out Logic 1

MCU I/O Unchanged

Port Pins PB0–PB7 Chip Select Outputs, CS0–CS7, CMOS Logic 1

Chip Select Outputs, CS0–CS7, Open Drain Hi-Z

Port Pins PC0–PC2

Address or Logic Inputs, A16-A18 Input (Hi-Z)

Chip Select Outputs, CS8–CS10, CMOS only Logic 1

Table 7A. Signal States During Power-down Mode

Page 21

PSD211R Family

18

12.0

Control Signals

(Cont.)

Internal Signal State

Component Internal Signal During Power-Down

PAD A and PAD B

CS0–CS10 Logic 1 (inactive)

CSIOPORT, ES0–ES7 Logic 0 (inactive)

All registers in CSIOPORT address N/A

space, including:

✓ Direction

✓ Data All unchanged

✓ PMR (turbo bit, ZPSD only)

Table 7B. Internal States During Power-down

NOTE: N/A = Not Applicable

12.6 Reset Input

This is an asynchronous input to initialize the PSD device.

Refer to tables 8A and 8B for information on device status during and after reset.

The standard-voltage PSD211R and ZPSD211R (non-V) devices require a reset input. In

this case, the reset input must be asserted for at least 100 nsec. The PSD will be functional

immediately after reset is de-asserted. For these standard-voltage devices, the polarity of

the reset input signal is programmable using PSDsoft (active-high or active-low), to match

the functionality of your MCU reset.

Note: It is not recommended to drive the reset input of the MCU and the reset input of the

PSD with a simple RC circuit between power on ground. The input threshold of the MCU

and the PSD devices may differ, causing the devices to enter and exit reset at different

times because of slow ramping of the signal. This may result in the PSD not being operational when accessed by the MCU. It is recommended to drive both devices actively. A

supervisory device or a gate with hysteresis is recommended.

For low-voltage ZPSD211RV devices only, the reset input must be asserted for at least

500 nsec. The ZPSD211RV will not be functional for an additional 500 nsec after reset is

de-asserted (see Figure 8). These low voltage ZPSD211RV devices require an active-low

polarity signal for reset. Unlike the PSD211R, the polarity of the reset input is not

programmable for the ZPSD211RV. If your MCU operates with an active high reset, you

must invert this signal before driving the ZPSD211RV reset input.

You must design your system to ensure that the PSD comes out of reset and the PSD

is active before the MCU makes its first access to PSD memory. Depending on the

characteristics and speed of your MCU, a delay between the PSD reset and the MCU reset

may be needed.

Page 22

PSD211R Family

19

12.

Control Signals

(Cont.)

Signal State Just

Signal State After Reset

Port Configured Mode of Operation During Reset

(Note 1)

AD0/A0-

All Input (Hi-Z)

MCU address

AD15/A15 and/or data

MCU I/O Input (Hi-Z) Input (Hi-Z)

Port Pins PSD211R,

Logic 0 MCU address

PA0-PA7 Latched Address Out ZPSD211R

ZPSD211RV Hi-Z MCU address

MCU I/O Input (Hi-Z Input (Hi-Z)

Chip Select Outputs,

PSD211R,

Logic 1 Per CS equations

Port Pins

CS0-CS7, CMOS

ZPSD211R

PB0-PB7

ZPSD211RV Hi-Z Per CS equations

Chip Select Outputs,

PSD211R,

Hi-Z Per CS equations

CS0-CS7, Open Drain

ZPSD211R

ZPSD211RV Hi-Z Per CS equations

Address or Logic Inputs, A16-A18 Input (Hi-Z) Input (Hi-Z)

Port Pins

Chip Select Outputs,

PSD211R,

Logic 1 Per CS equations

PC0-PC2

CS8-CS10, CMOS

ZPSD211R

ZPSD211RV Hi-Z Per CS equations

Table 8A. External PSD Signal States During and Just After Reset

NOTE: 1. Signal is valid immediately after reset for non-V devices. ZPSD211RV devices need an additional

500 nsec after reset before signal is valid.

Internal

Internal Signal Signal State

State During During

Component Internal Signal Reset Power-Down

CS0-CS10 Logic 1 (inactive) Per CS Equations

PAD A and PAD B

CSIOPORT,

Per equations

ES0-ES7

Logic 0 (inactive) for each

internal signal

All registers in CSIOPORT N/A

address space, including:

✓ Direction Logic 0 in all bit of Logic 0 until

✓ Data all registers changed by MCU

✓ PMR (turbo bit, ZPSD only)

Table 8B. Internal PSD Signal States During and Just After Reset

NOTE: N/A = Not Applicable

RESET LOW

V

IH

RESET HIGH ZPSD211R(V)

IS OPERATIONAL

500 ns 500 ns

V

IL

Figure 8. The Required Reset Cycle for ZPSD211RV Devices Only.

Page 23

PSD211R Family

20

13.0

Program/Data

Space and the

8031

Figure 9. Combined Address Space

INTERNAL

OE

OE

CS

CS

RD

ADDRESS

PSEN

I/O PORTS

PAD

EPROM

Figure 10. 8031-Compatible Separate Code and Data Address Spaces

INTERNAL

OE

OE

CS

CS

RD

ADDRESS

PSEN

I/O PORTS

PAD

EPROM

This section only applies to users who have an 8031 or compatible MCU that outputs a

signal such as PSEN when accessing program space. If this applies to you, be aware of the

following: the PSD211R can be configured using PSDsoft such that the EPROM is either 1)

accessed by PSEN only (Figure 10); or 2) accessed by PSEN or RD (Figure 9). The default

is PSEN only unless changed in PSDsoft.

Page 24

PSD211R Family

21

14.0

System

Applications

In Figure 11, the PSD211R is configured to interface with Intel’s 80C31, which is a 16-bit

address/8-bit data bus microcontroller. Its data bus is multiplexed with the low-order

address byte. The 80C31 uses signals RD to read from data memory and PSEN to read

from code memory. It uses WR to write into the data memory. It also uses active high reset

and ALE signals. Only the necessary connections are shown.

Figure 11. Interface With Intel’s 80C31

MICROCONTROLLER

31

19

18

9

12

13

14

15

1

2

3

4

5

6

7

8

23

24

25

26

27

28

29

30

31

32

33

35

36

37

38

39

22

2

1

13

3

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

P2.0

P2.1

P2.2

P2.3

P2.4

P2.5

P2.6

P2.7

RD

WR

PSEN

ALE

TXD

RXD

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC0

PC1

PC2

A19/CSI

39

38

37

36

35

34

33

32

21

22

23

24

25

26

27

28

17

16

29

30

11

10

21

20

19

18

17

16

15

14

11

10

9

8

7

6

5

4

40

41

42

43

EA/VP

X1

X2

RESET

INT0

INT1

T0

T1

P1.0

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

AD0/A0

AD1/A1

AD2/A2

AD3/A3

AD4/A4

AD5/A5

AD6/A6

AD7/A7

AD8/A8

AD9/A9

AD10/A10

AD11/A11

AD12/A12

AD13/A13

AD14/A14

AD15/A15

RD

WR/V

PP

PSEN

ALE

RESET

GND

PSD211R

80C31

Reset

34 12

V

CC

44

0.1µF

NOTE: RESET to the PSD211R must be the output of a RESET chip or buffer.

If RESET to the 80C31 is the output of an RC circuit, a separate buffered RC RESET to the

PSD211R (shorter than the 80C31 RC RESET) must be provided to avoid a race condition.

Page 25

PSD211R Family

22

In Figure 12, the PSD211R is configured to interface with Motorola’s 68HC11, which

is a 16-bit address/8-bit data bus microcontroller. Its data bus is multiplexed with the

low-order address byte. The 68HC11 uses E and R/W signals to derive the read and write

strobes. It uses the term AS (address strobe) for the address latch pulse. RESET is an

active low signal. Only the necessary connections are shown.

Figure 12. Interface With Motorola’s 68HC11

MICROCONTROLLER

20

21

22

23

24

25

43

45

47

49

44

46

48

50

34

33

32

31

30

29

28

27

52

51

23

24

25

26

27

28

29

30

31

32

33

35

36

37

38

39

22

2

13

3

1

PC0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

E

R/W

AS

RESET

XIRQ

IRQ

MODB

MODA

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC0

PC1

PC2

A19/CSI

9

10

11

12

13

14

15

16

42

41

40

39

38

37

36

35

5

6

4

17

18

19

2

3

21

20

19

18

17

16

15

14

11

10

9

8

7

6

5

4

40

41

42

43

PD0

PD1

PD2

PD3

PD4

PD5

PE0

PE1

PE2

PE3

PD4

PE5

PE6

PE7

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

VRH

VRL

AD0/A0

AD1/A1

AD2/A2

AD3/A3

AD4/A4

AD5/A5

AD6/A6

AD7/A7

AD8/A8

AD9/A9

AD10/A10

AD11/A11

AD12/A12

AD13/A13

AD14/A14

AD15/A15

E

R/W/V

PP

AS

RESET

PSEN

GND

PSD211R

34

12

V

CC

V

CC

68HC11

XTAL

EXTAL

44

0.1µF

Reset

14.0

System

Applications

(cont.)

Page 26

PSD211R Family

23

15.0

Security Mode

Security Mode in the PSD211R locks the contents of PAD A, PAD B, and all the

configuration bits. The EPROM and I/O contents can be accessed only through the PAD.

The Security Mode must be set by PSDsoft prior to run-time. The Security Bit can only be

erased on the UV parts using a full-chip erase. If Security Mode is enabled, the contents of

the PSD211R can not be uploaded (copied) on a device programmer.

16.0

Power

Management

PSDs from all 211R families use zero-power memory techniques that place memory into

Standby Mode between MCU accesses. The memory becomes active briefly after an

address transition, then delivers new data to the outputs, latches the outputs, and returns to

Standby. This is done automatically and the designer has to do nothing special to benefit

from this feature.

In addition to the benefits of Zero-power memory technology, there are ways to gain

additional savings. The following factors determine how much current the entire PSD device

uses:

• Use of CSI (Chip Select Input)

• Setting of the CMiser bit

• Setting of the Turbo Bit (ZPSD only)

• The number of product terms used in the PAD

• The composite frequency of the input signals to the PAD

• The loading on I/O pins.

The total current consumption for the PSD is calculated by summing the currents from

memory, PAD logic, and I/O pins, based on your design parameters and the power

management options used.

16.1 CSI Input

Driving the CSI pin inactive (logic 1) disables the inputs of the PSD and forces the entire

PSD to enter Power-down Mode, independent of any transition on the MCU bus (address

and control) or other PSD inputs. During this time, the PSD device draws only standby

current (micro-amps). Alternately, driving a logic 0 on the CSI pin returns the PSD to normal

operation. See Tables 7A and 7B for information on signal states during Power-down Mode.

The CSI pin feature is available only if enabled in the PSDsoft Configuration utility.

16.2 CMiser bit

In addition to power savings resulting from the Zero-power technology used in the memory,

the CMiser feature saves even more power under certain conditions. Savings are

significant when the PSD is configured for an 8-bit data path because the CMiser feature

turns off half of the array when memory is being accessed (the memory is divided internally

into odd and even arrays). See the DC characteristics table for current usage related to the

CMiser bit.

You should keep the following in mind when using this bit:

• Setting of this bit is accomplished with PSDsoft at the design stage, prior to run-time.

• Memory access times are extended by 10 nsec for standard voltage (non-V) devices,

and 20 nsec for low voltage (V) devices.

Page 27

PSD211R Family

24

16.

Power

Management

(cont.)

16.3 Turbo Bit (ZPSD only)

The turbo bit is controlled by the MCU at run-time and is accessed through bit zero of the

Power Management Register (PMR). The PMR is located in CSIOPORT space at offset 10h.

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

*******

Turbo bit

1=OFF 1=OFF 1=OFF 1=OFF 1=OFF 1=OFF 1=OFF 1=OFF

Power Management Register (PMR)

*Future Configuration bits are reserved and should be set to one when writing to this register.

The default value at reset of all bits in the PMR is logic 0, which means the Turbo feature is

enabled. The PAD logic (PAD A and PAD B) of the PSD will operate at full speed and full

power. When the Turbo bit is set to logic 1, the Turbo feature is disabled. When disabled,

the PAD logic will draw only standby current (micro-amps) while no PAD inputs change.

Whenever there is a transition on any PAD input (including MCU address and control

signals), the PAD logic will power up and will generate new outputs, latch those outputs,

then go back to Standby Mode. Keep in mind that the signal propagation delay through

the PAD logic increases by 10 nsec for non-V devices, and 20 nsec for V devices while in

non-turbo mode. Use of the Turbo bit does not affect the operation or power consumption of

memory.

Tremendous power savings are possible by setting the Turbo bit and going into non-turbo

mode. This essentially reduces the DC power consumption of the PAD logic to zero. It also

reduces the AC power consumption of PAD logic when the composite frequency of all PAD

inputs change at a rate less than 40 MHz for non-V devices, and less than 20 MHz for V

devices. Use figures 13 and 14 to calculate AC and DC current usage in the PAD with the

Turbo bit on and off. You will need to know the number of product terms that are used in

your design and you will have to calculate the composite frequency of all signals entering

the PAD logic.

16.4 Number of Product Terms in the PAD Logic

The number of product terms used in your design relates directly to how much current the

PADs will draw. Therefore, minimizing this number will be in your best interest if power is a

concern for you. Basically, the amount of product terms your design will use is based on the

following (see Figure 4):

• Each of the EPROM block selects, ES0-ES7 uses one product term (for a total of 8).

• The CSIOPORT select uses one product term.

• Port B, pins PB0-PB3 are allocated four product terms each if used as outputs.

• Port B, pins PB4-PB7 are allocated two product terms each if used as outputs.

• Port C, pins PC0-PC2 are allocated one product term each if used as outputs.

Given the above product term allocation, keep the following three points in mind when

calculating the total number of product terms your design will require:

1) The EPROM block selects and CSIOPORT select will use a product term whether you

use these blocks or not. This means you start out with 9 product terms, and go up from

there.

2) For Port B, if you use a pin as an output and your logic equation requires only one

product term, you still have to include all the available product terms for that pin for

power consumption, even though only one product term is specified. For example, if the

output equation for pin PB0 uses just one product term, you will have to count PB0 as

contributing four product terms to the overall count. With this in mind, you should use

Port C for the outputs that only require one product term and PB4-7 for outputs that

require two product terms. Use pins PB0-3 if you need outputs requiring more than two

product terms or you have run out of outputs.

3) The following PSD functions do not consume product terms: MCU I/O mode, Latched

Address Output, and PAD inputs (logic or address).

Page 28

PSD211R Family

25

16.0

Power

Management

(cont.)

16.5 Composite Frequency of the Input Signals to the PAD Logic

The composite frequency of the input signals to the PADs is calculated by considering all

transitions on any PAD input signal (including the MCU address and control inputs). Once

you have calculated the composite frequency and know the number of product terms used,

you can determine the total AC current consumption of the PAD by using Figure 13 or

Figure 14. From the figures, notice that the DC component (f = 0 MHz) of PAD current is

essentially zero when the turbo feature is disabled, and that the AC component increases

as frequency increases.

When the turbo feature is disabled, the PAD logic can achieve low power consumption by

becoming active briefly, only when inputs change. For standard voltage (non-V) devices, the

PAD logic will stay active for 25 nsec after it detects a transition on any input. If there are

more transitions on any PAD input within the 25 nsec period, these transitions will not add

to power consumption because the PAD logic is already active. This effect helps reduce the

overall composite frequency value. In other words, narrowly spaced groups of transitions on

input signals may count as just one transition when estimating the composite frequency.

Note that the “knee” frequency in Figure 13 is 40 MHz, which means that the PAD will

consume less power only if the composite frequency of all PAD inputs is less than 40 MHz.

When the composite frequency is above 40 MHz, the PAD logic never gets a chance to shut

down (inputs are spaced less than 25 nsec) and no power savings can be achieved.

Figure 14 is for low-voltage devices in which the “knee” frequency is 20 MHz.

Take the following steps to calculate the composite frequency:

1) Determine your highest frequency input for either PAD A or PAD B.

2) Calculate the period of this input and use this period as a basis for determining the

composite frequency.

3) Examine the remaining PAD input signals within this base period to determine the

number of distinct transitions.

4) Signal transitions that are spaced further than 25 nsec apart count as a distinct transition

(50 nsec for low-voltage V devices). Signal transitions spaced closer than 25 nsec count

as the same transition.

5) Count up the number of distinct transitions and divide that into the value of the base

period.

6) The result is the period of the composite frequency. Divide into one to get the composite

frequency value.

Unfortunately, this procedure is complicated and usually not deterministic since different

inputs may be changing in various cycles. Therefore, we recommend you think of the

situation that has the most activity on the inputs to the PLD and use this to calculate the

composite frequency. Then you will have a number that represents your best estimate at

the worst case scenario.

Since this is a complicated process, the following example should help.

Example Composite Frequency Calculation

Suppose you had the following circuit:

80C31

(12 MHz

Crystal)

ZPSD211R

PA

PB

PC

AD0-AD7

Latched Address

Output (LA0-LA7)

A8-A16

ALE

RD

WR

PSEN

CSI

3 Inputs: Int, Sel, Rdy

6 MCU I/O Outputs

3 Chip-Select Outputs

Page 29

PSD211R Family

26

16.0

Power

Management

(cont.)

All the inputs shown, except CSI, go to the PAD logic. These signals must be taken into

consideration when calculating the composite frequency. Before we make the calculation,

let’s establish the following conditions:

• The input with the highest frequency is ALE, which is 2 MHz. So our base period is

500 nsec for this example.

• Only the address information from the multiplexed signals AD0-AD7 reach the PAD

logic because of the internal address latch. Signal transitions from data on AD0-AD7

do not reach the PADs.

• The three inputs (Int, Sel, or Rdy) change state very infrequently relative to the 80C31

bus signals.

Now, lets assume the following is a snapshot in time of all the input signals during a typical

80C31 bus cycle. We’ll use a code fetch as an example since that happens most often.

ONE TYPICAL 80C31 BUS CYCLE (2 MHz, 500 nsec)

ALE

PSEN

AD0-AD7

A8-A15

INT

SEL

RDY

FOUR DISTINCT

TRANSITIONS

<

25 nsec

ADDR DATA

1

2

3

The calculation of the composite frequency is as follows:

• There are four distinct transitions (first four dotted lines) within the base period of

500 nsec. These first four transitions all count toward the final composite frequency.

• The transition at (1) in the diagram does not count as a distinct transition because it is

within 25 nsec of a neighboring transition (use 50 nsec for a ZPSD211RV device).

• Transition (2) above does not add to the composite frequency because only the

internally latched address signals reach the PADs, the data signal transitions do not.

• The transition at (3) just happens to appear in this snapshot, but its frequency is so

low that it is not a significant contributor to the overall composite frequency, and will

not be used.

• Divide the 500 nsec base period by the four (distinct transitions), yielding 125 nsec.

1/125 nsec = 8 MHz.

• Use 8 MHz as the composite frequency of PAD inputs when calculating current

consumption. (See the next section for a sample current calculation.)

16.6 Loading on I/O pins

A final consideration when calculating the current usage for the entire PSD device is the

loading on I/O pins. All specifications for PSD current consumption in this document

assume zero current flowing through PSD I/O pins (including ADIO). I/O current is dictated

by the individual design implementation, and must be calculated by the designer. Be aware

that I/O current is a function of loading on the pins and the frequency at which the signals

toggle.

Page 30

PSD211R Family

27

17.0

Calculating

Power

Conditions

Part Used = ZPSD211R (VCC= 5.0 V)

MCU ALE Clock Frequency = 2.0 MHz

Composite ZPLD input Frequency = 8.0 MHz (see example in above section)

% EPROM Access = 80%

% I/O access = 20%

% Time CSI is high (standby mode) = 90%

% Time CSI is low (normal operation mode) = 10%

# Product terms used (see previous section) = 10

Turbo bit = OFF (Turbo Mode disabled)

CMiser bit = ON

MCU Bus Configuration = 8-bit multiplexed bus mode

Calculation (Based on Typical AC and DC Currents)

I

CC

total = Istandby x % time CSI is high + [ICC(AC) + ICC(DC)] x % time CSI is low.

= Istandby x % time CSI is high +

[%EPROM Access x 0.8 mA/MHz x Freq. ALE

+ ZPLD AC current (Figure 13: 10 PTs, 8 MHz, Non-Turbo)]

x % time CSI is low.

= 10 µA x 0.9 + (0.8 x 0.8 mA/MHz x 2 MHz + 5.0 mA) x 0.1

= 9.0 µA + (1.28 mA + 5.0 mA) x 0.1

= 637 µA, based on the system operating in standby 90% of the time

Once you have read the “Power Management” section, you should be able to calculate

power. The following is a sample power calculation:

NOTES: 1. Calculation is based on the assumption that Iout = 0 mA (no I/O pin loading).

2. I

CC

(DC) is zero for all ZPSD devices operating in non-turbo mode.

3. 10 product terms: 8 for EPROM, 1 for CSIOPORT, 1 for CS8

4. The 5% I/O access in the conditions section is when the MCU accesses CSIOPORT space.

5. Standby Mode can also be achieved without using the CSI pin. The ZPSD device will automatically

go into Standby while no inputs are changing on any pin, and Turbo Mode is disabled.

Page 31

PSD211R Family

28

17.0

Calculating

Power

(cont.)

0

0 5 10 15 20 25 30 35 40 45 50

5

10

15

20

25

30

35

40

45

I

CC

(mA)

Composite Frequency at PAD Inputs (MHz)

36 PT Turbo

36 PT Non-Turbo

10 PT Turbo

10 PT Non-Turbo

Figure 13. Typical ICCvs. Frequency for the PAD (VCC= 5 V)

0

0 5 10 15 20 25

2

4

6

8

10

12

14

I

CC

(mA)

Composite Frequency at PAD Inputs (MHz)

36 PT Turbo

36 PT Non-Turbo

10 PT Turbo

10 PT Non-Turbo

Figure 14. Typical ICCvs. Frequency for the PAD (VCC= 3 V)

Page 32

PSD211R Family

29

Figure 17. Normalized ICC(AC)

(VCC= 3.0 V)

Figure 18. Normalized Access Time (T6)

(VCC= 3.0 V)

Figure 15. IOLvs. V

OL

(5 V± 10%)

Figure 16. Normalized ICC(DC vs. VCC)

(VCC= 3.0 V)

40

35

30

25

20

15

10

5

0

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

VOL (V)

I

OL

(mA)

Temp. = 125°C

Temp. = 25°C

3.5

3.0

2.5

2.0

1.5

1.0

0.5

I

CC

2.5

3.0 3.5 4.0 4.5 5.0

5.5 6.0

V

CC

(V

)

2.7

2.7

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

I

CC

(AC)

2.5

3.0 3.5 4.0 4.5 5.0

5.5 6.0

V

CC

(V

)

2.7

1.1

1.05

1.0

0.95

0.9

0.85

0.8

0.75

0.7

0.65

2.5

3.0 3.5 4.0 4.5 5.0

5.5 6.0

ACCESS TIME

VCC (V

)

ZPSD211R(V)

ZPSD211R(V) ZPSD211R(V)

ZPSD211R(V)

Page 33

PSD211R Family

30

Symbol Parameter Condition Min Max Unit

T

STG

Storage Temperature

CERDIP – 65 + 150 °C

PLASTIC – 65 + 125 °C

Voltage on any Pin With Respect to GND – 0.6 + 7 V

V

PP

Programming

Supply Voltage

With Respect to GND – 0.6 + 14 V

V

CC

Supply Voltage With Respect to GND – 0.6 + 7 V

ESD Protection >2000 V

Range Temperature V

CC

VCCTolerance

Commercial 0° C to +70°C + 3 V1, + 5 V ± 10%

Industrial –40° C to +85°C + 3 V1, + 5 V ± 10%

Symbol Parameter Conditions Min Typ Max Unit

V

CC

Supply Voltage PSD Versions, All Speeds 4.5 5 5.5 V

V

CC

Supply Voltage

ZPSD V Versions Only,

2.7 3.0 5.5 V

All Speeds

18.0

Specifications

18.3 Recommended Operating Conditions

NOTE: 1. Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at these or any other

conditions above those indicated in the operational sections of this specification is not implied.

Exposure to Absolute Maximum Rating conditions for extended periods of time may affect device

reliability.

18.1 Absolute Maximum Ratings

1

NOTE: 1.3 V available on ZPSD211RV only.

18.2 Operating Range

Symbol Parameter Conditions Typical2Max Unit

C

IN

Capacitance (for input pins only) VIN= 0 V 4 6 pF

C

OUT

Capacitance (for input/output pins) V

OUT

= 0 V 8 12 pF

C

VPP

Capacitance (for WR/VPPor R/W/VPP)VPP= 0 V 18 25 pF

NOTES: 1. This parameter is only sampled and is not 100% tested.

2. Typical values are for TA= 25°C and nominal supply voltages.

18.4 Pin Capacitance

1

Page 34

PSD211R Family

31

NOTES: 1. CMOS inputs: GND ± 0.3 V or VCC± 0.3V.

2. TTL inputs: VIL≤ 0.8 V, VIH≥ 2.0 V.

3. I

OUT

= 0 mA.

4. CSI/A19 is high and the part is in a power-down configuration mode.

Symbol Parameter Conditions Min Typ Max Unit

V

CC

Supply Voltage All Speeds 4.5 5 5.5 V

V

IH

High-Level Input Voltage 4.5 V < VCC> 5.5 V 2 V

CC

+.1 V

V

IL

Low-Level Input Voltage 4.5 V < VCC> 5.5 V –0.5 0.8 V

IOH= –20 µA, VCC= 4.5 V 4.4 4.49 V

V

OH

Output High Voltage

IOH= –2 mA, VCC= 4.5 V 2.4 3.9 V

Output Low Voltage

IOL= 20 µA, VCC= 4.5 V 0.01 0.1 V

V

OL

(See Figure 14)

IOL= 8 mA, VCC= 4.5 V 0.15 0.45 V

ZPSD211R

10 20 µA

I

SB

Standby Supply Current

(Notes 1,4)

PSD211R

Standby Supply Current

50 100 µA

I

LI

Input Leakage Current VSS< VIN> V

CC

–1 ±.1 1 µA

I

LO

Output Leakage Current .45 < VIN> V

CC

–10 ±5 10 µA

ZPLD Turbo Mode = Off, f = 0 MHz See I

SB

µA

ZPSD211R

ZPLD Turbo Mode = On, f = 0 MHz 0.5 1 mA/PT

Operating Suppy Current

EPROM, f = 0 MHz 0 0 µA

I

CC

(DC)

SRAM, f = 0 MHz 0 0 µA

(Note 3)

PLD, f = 0 MHz 0.5 1 mA/PT

PSD211R

EPROM, f = 0 MHz 0 0 µA

Operating Supply Current

SRAM, f = 0 MHz 0 0 µA

ZPLD AC Base (See Figure 13) Fig. 13 1 mA/MHz

I

CC

(AC)

EPROM Access CMiser = On and 8-Bit Bus Mode 0.8 2.0 mA/MHz

(Note 3)

AC Adder CMiser = Off 1.8 4.0 mA/MHz

18.5 AC/DC Characteristics – PSD211R/ZPSD211R (All 5 V devices)

Page 35

PSD211R Family

32

Symbol Parameter Conditions Min Typ Max Unit

V

CC

Supply Voltage All Speeds 2.7 3 5.5 V

V

IH

High-Level Input Voltage 2.7 V < VCC> 5.5 V .7 V

CC

V

CC

+.5 V

V

IL

Low-Level Input Voltage 2.7 V < VCC> 5.5 V –0.5 .3 V

CC

V

IOH= –20 µA, VCC= 2.7 V 2.6 2.69 V

V

OH

Output High Voltage

IOH= –1 mA, VCC= 2.7 V 2.3 2.4 V

IOL= 20 µA, VCC= 2.7 V 0.01 0.1 V

V

OL

Output Low Voltage

IOL= 4 mA, VCC= 2.7 V 0.15 0.45 V

I

SB

Standby Supply Current VCC= 3.0 V 1 5 µA

(Notes 1,4)

I

LI

Input Leakage Current VIN= VCCor GND –1 ±.1 1 µA

I

LO

Output Leakage Current V

OUT

= VCCor GND –1 .1 1 µA

ZPLD Turbo Mode= Off,

f = 0 MHz, VCC= 3.0 V

See I

SB

µA

I

CC

(DC)

Operating Supply Current

ZPLD Turbo Mode= On,

(Note 3) f = 0 MHz, V

CC

= 3.0 V

0.17 0.35 mA/PT

EPROM, f = 0 MHz,

VCC= 3.0 V

00µA

ZPLD AC Base See Figure 14 (VCC= 3.0 V) Fig. 14 0.5 mA/MHz

CMiser = On and 8-Bit Bus

I

CC

(AC)

EPROM Access

Mode (VCC= 3.0 V)

0.4 1 mA/MHz

(Note 3)

AC Adder

CMiser = Off

(VCC= 3.0 V)

0.9 1.7 mA/MHz

18.6 AC/DC DC Characteristics ZPSD211RV (3 V devices only)

NOTES: 1. CMOS inputs: GND ± 0.3 V or VCC± 0.3V.

2. TTL inputs: VIL≤ 0.8 V, VIH≥ 2.0 V.

3. I

OUT

= 0 mA.

4. CSI/A19 is high and the part is in a power-down configuration mode.

Page 36

PSD211R Family

33

-70 -90 -15 CMiser

Symbol Parameter

On =

Unit

Min Max Min Max Min Max Add

T1 ALE or AS Pulse Width 18 20 40 0 ns

T2 Address Set-up Time 5 5 12 0 ns

T3 Address Hold Time 7 8 10 0 ns

T4 Leading Edge of Read to Data Active 0 0 0 0 ns

T5 ALE Valid to Data Valid 80 100 160 10 ns

T6 Address Valid to Data Valid 70 90 150 10 ns

T7 CSI Active to Data Valid 80 100 160 10 ns

T8 Leading Edge of Read to Data Valid 20 32 55 0 ns

Leading Edge of Read to Data Valid in

T8A 8031-Based Architecture Operating with PSEN 32 32 55 0 ns

and RD in Separate Mode

T9 Read Data Hold Time 0 0 0 0 ns

T10 Trailing Edge of Read to Data High-Z 20 35 35 0 ns

Trailing Edge of ALE or AS to Leading Edge

T11

of Write

000 0ns

T12 RD, E, PSEN Pulse Width 35 45 60 0 ns

T12A WR Pulse Width 18 25 35 0 ns

Trailing Edge of Write or Read to Leading Edge

T13

of ALE or AS

555 0ns