Page 1

DATA SHEET

PHOTOCOUPLER

PS2511-1,-2,-4, PS2511L-1,-2,-4

HIGH ISOLATION VOLTAGE

STANDARD MULTI PHOTOCOUPLER SERIES

SINGLE TRANSISTOR TYPE

DESCRIPTION

The PS2511-1, -2, -4 and PS2511L-1, -2, -4 are optically coupled isolators containing a GaAs light emitting diode

and an NPN silicon phototransistor.

The PS2511-1, -2, -4 are in a plastic DIP (Dual In-line Package) and the PS2511L-1, -2, -4 are lead bending type

(Gull-wing) for surface mount.

FEATURES

• High isolation voltage (BV = 5 000 Vr.m.s.)

• High current transfer ratio (CTR = 200 % TYP.)

• High-speed switching (tr = 3 µs TYP., tf = 5 µs TYP.)

• Taping Product number : PS2511L-1-E3, E4, F3, F4, PS2511L-2-E3, E4

• UL approved : File No. E72422 (S)

−NEPOCTM Series−

APPLICATIONS

• Power supply

• Telephone/FAX.

• FA/OA equipment

• Programmable logic controller

The information in this document is subject to change without notice.

Document No. P12975EJ1V0DS00 (1st edition)

Date Published October 1998 NS CP(K)

Printed in Japan

©

1997

Page 2

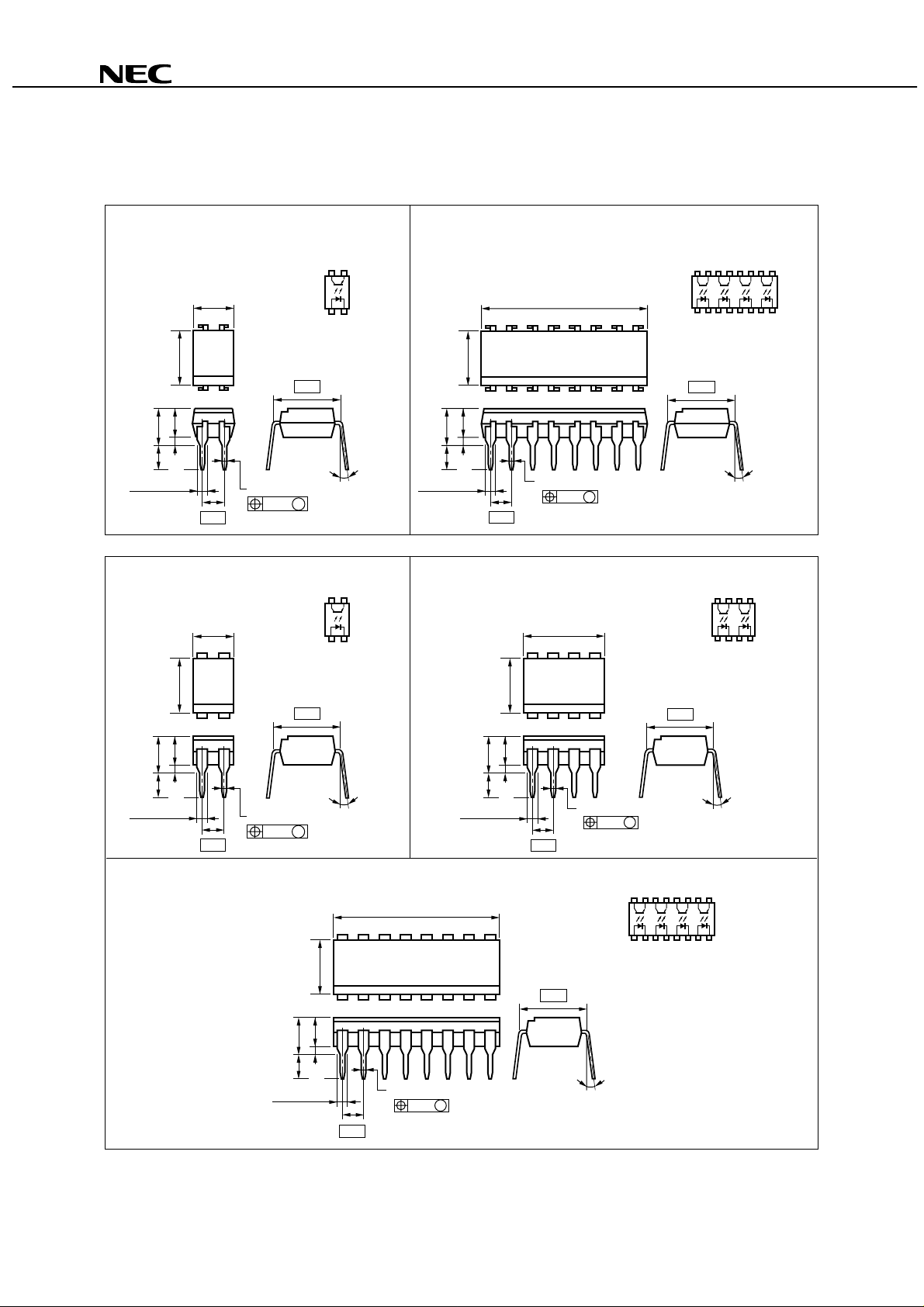

PACKAGE DIMENSIONS (in millimeters)

DIP (Dual In-line Package)

PS2511-1,-2,-4, PS2511L-1,-2,-4

3.8

4.55

MAX.

2.8

MIN.

1.25±0.15

6.5

4.6 ± 0.35

6.5

MAX.

0.65

5.1 MAX.

PS2511-1

2.54

PS2511-1

7.62

0.50 ± 0.10

0.25

M

7.62

TOP VIEW

3

4

2

1

1. Anode

2. Cathode

3. Emitter

4. Collector

0 to 15˚

TOP VIEW

3

4

2

1

1. Anode

2. Cathode

3. Emitter

4. Collector

4.55

MAX.

2.8

MIN.

1.25±0.15

6.5

3.8

MAX.

0.65

2.54

6.5

PS2511-4

20.3 MAX.

0.50 ± 0.10

0.25

PS2511-2

10.2 MAX.

TOP VIEW

13

12

11

14

34

56

10 9

78

16 15

2

1

1, 3, 5, 7. Anode

2, 4, 6, 8. Cathode

9,11,13,15. Emitter

10,12,14,16. Collector

7.62

M

0 to 15˚

TOP VIEW

7

65

8

1

34

2

1, 3. Anode

2, 4. Cathode

5, 7. Emitter

6, 8. Collector

7.62

3.8

4.55

MAX.

2.8

MIN.

1.25±0.15

MAX.

0.65

2.54

0.50 ± 0.10

M

0.25

4.55

MAX.

2.8

MIN.

1.25±0.15

6.5

3.8

0.65

0 to 15˚

MAX.

2.54

PS2511-4

20.3 MAX.

0.50 ± 0.10

0.25

M

4.55

MAX.

2.8

MIN.

1.25±0.15

3.8

MAX.

0.65

2.54

7.62

0.50 ± 0.10

0.25

0 to 15˚

M

0 to 15˚

TOP VIEW

12

15

14

10

11

13

16

3

6

1

2

1, 3, 5, 7. Anode

2, 4, 6, 8. Cathode

9,11,13,15. Emitter

10,12,14,16. Collector

78

4

5

9

2

Page 3

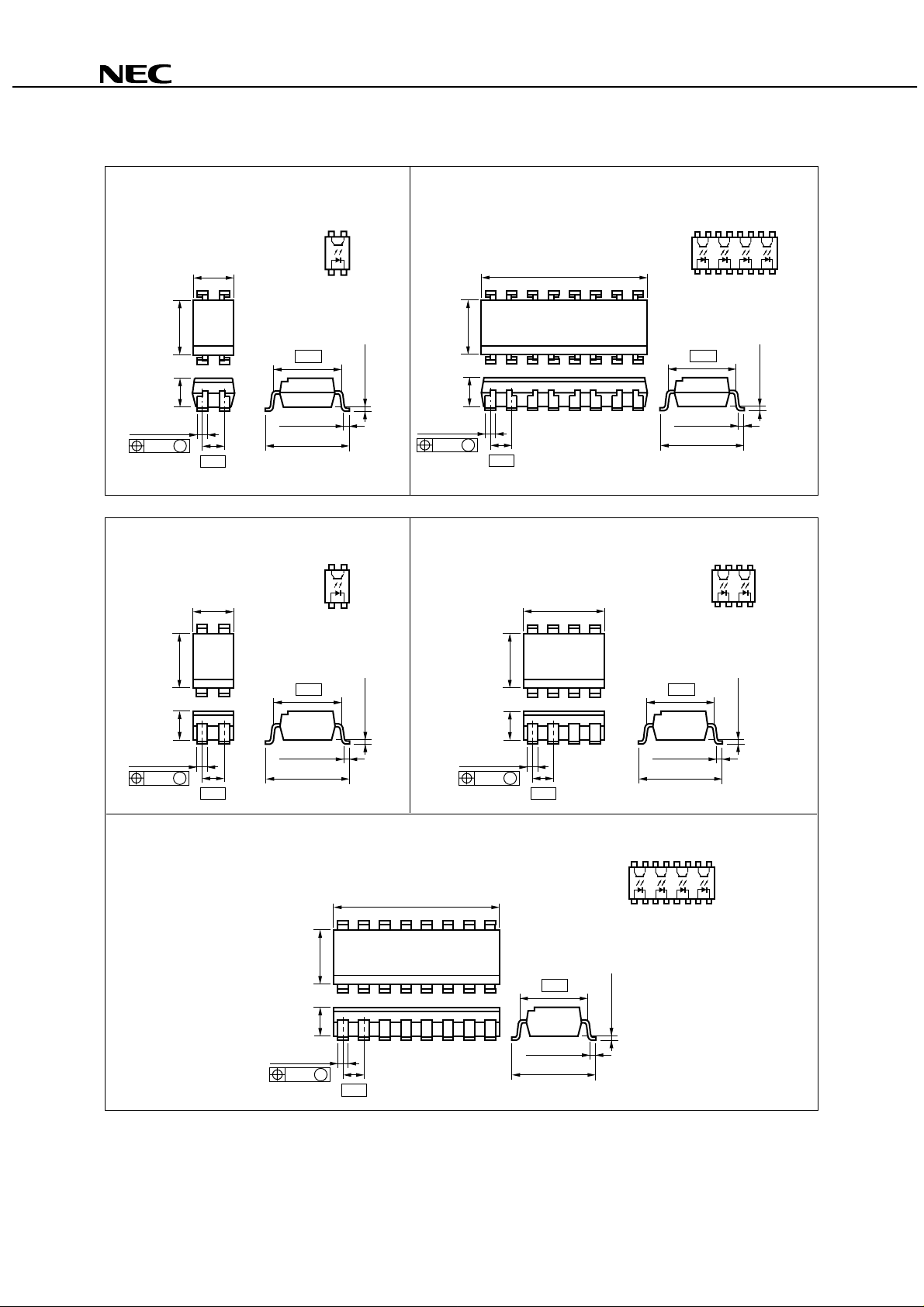

Lead Bending Type (Gull-wing)

PS2511-1,-2,-4, PS2511L-1,-2,-4

3.8

MAX.

1.25±0.15

0.25

4.6 ± 0.35

6.5

M

5.1 MAX.

6.5

PS2511L-1

2.54

PS2511L-1

TOP VIEW

1. Anode

2. Cathode

3. Emitter

4. Collector

7.62

0.90 ± 0.25

9.60 ± 0.4

TOP VIEW

1. Anode

2. Cathode

3. Emitter

4. Collector

7.62

4

1

4

1

3

2

0.05 to 0.2

3

2

3.8

1.25±0.15

0.25

6.5

MAX.

M

2.54

6.5

PS2511L-4

20.3 MAX.

PS2511L-2

10.2 MAX.

TOP VIEW

13

12

16 15

14

2

34

56

1

1, 3, 5, 7. Anode

2, 4, 6, 8. Cathode

9,11,13,15. Emitter

10,12,14,16. Collector

7.62

0.90 ± 0.25

9.60 ± 0.4

TOP VIEW

65

7

8

34

1

2

1, 3. Anode

2, 4. Cathode

5, 7. Emitter

6, 8. Collector

7.62

11

10 9

78

0.05 to 0.2

3.8

MAX.

1.25±0.15

0.25

0.05 to 0.2

0.90 ± 0.25

M

9.60 ± 0.4

2.54

PS2511L-4

3.8

MAX.

1.25±0.15

0.25

0.90 ± 0.25

M

9.60 ± 0.4

2.54

TOP VIEW

12

15

14

11

13

16

10

0.05 to 0.2

9

20.3 MAX.

3

6

78

4

5

6.5

1

2

1, 3, 5, 7. Anode

2, 4, 6, 8. Cathode

9,11,13,15. Emitter

10,12,14,16. Collector

7.62

3.8

MAX.

1.25±0.15

0.25

0.90 ± 0.25

M

9.60 ± 0.4

0.05 to 0.2

2.54

3

Page 4

PS2511-1,-2,-4, PS2511L-1,-2,-4

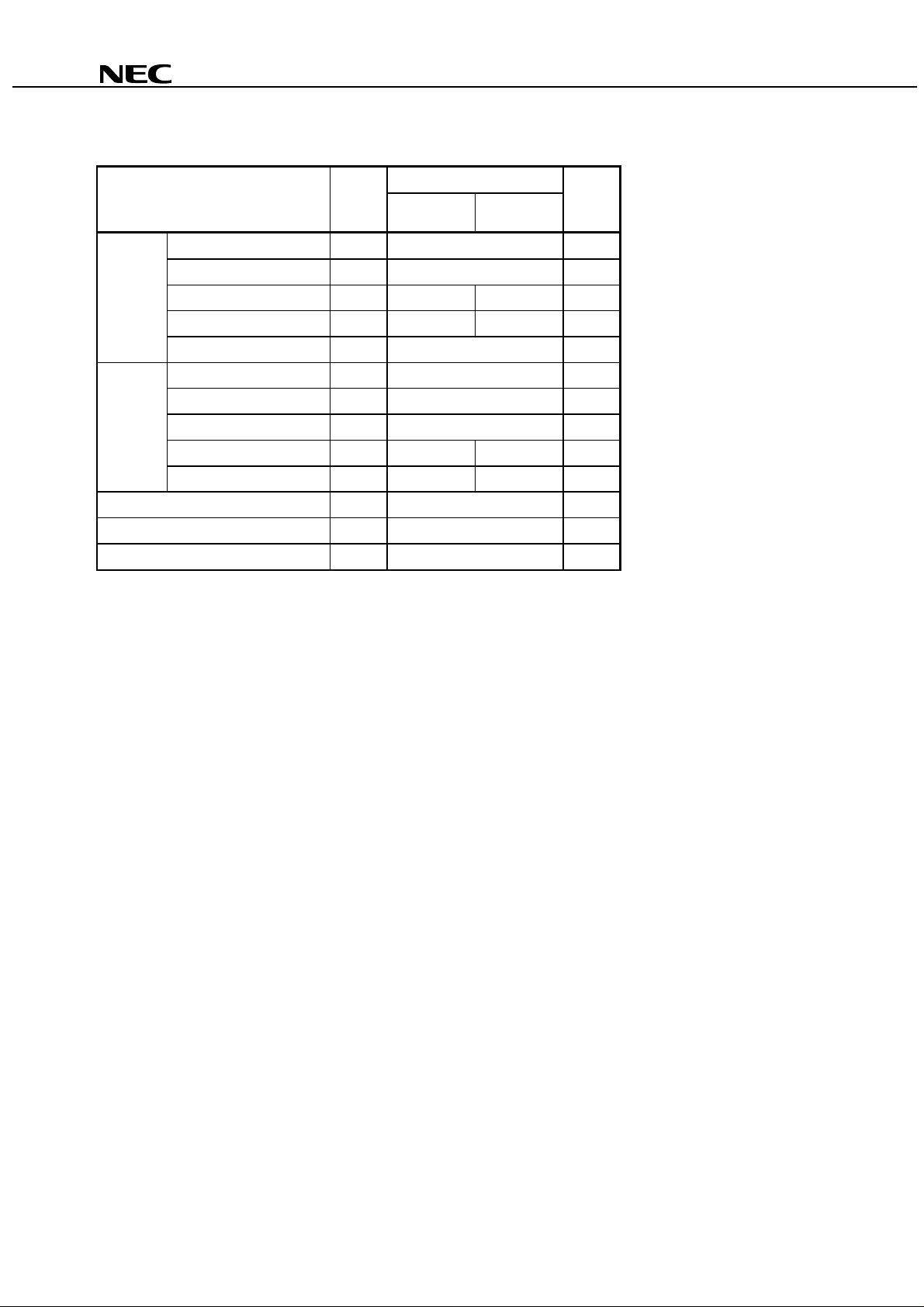

ABSOLUTE MAXIMUM RATINGS (TA = 25 °°°°C, unless otherwise specified)

Parameter Symbol Ratings Unit

PS2511-1,

PS2511L-1

PS2511-2,-4

PS2511L-2,-4

Diode Reverse Voltage V

Forward Current (DC) I

R

F

6V

50 mA

Power Dissipation Derating∆PD/°C 0.7 0.55 mW/°C

I

CEO

ECO

D

FP

70 55 mW/ch

1A

40 V

5V

C

40 mA

Power Dissipation P

Peak Forward Current

*1

Transistor Collector to Emitter Voltage V

Emitter to Collector Vo lta g e V

Collector Current I

Power Dissipation Derating∆PC/°C 1.5 1.2 mW/°C

Power Dissipation P

Isolation Voltage

*2

Operating Ambient Temperature T

Storage Temperature T

PW = 100

*1

AC voltage for 1 minute at TA = 25 °C, RH = 60 % between input and output

*2

µ

s, Duty Cycle = 1 %

C

150 120 mW/ch

BV 5 000 Vr.m.s.

A

stg

−

55 to +100

−

55 to +150

°

C

°

C

4

Page 5

ELECTRICAL CHARACTERISTICS (TA = 25 °°°°C)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

PS2511-1,-2,-4, PS2511L-1,-2,-4

Diode Forward Voltage V

Reverse Current I

Terminal Capacitance C

Transistor

Collector to Emitter

Dark Current

Coupled Current Transfer Ratio

*1

C/IF

)

(I

CTR IF = 5 mA, VCE = 5 V 80 200 400 %

Collector Saturation Voltage V

Isolation Resistance R

Isolation Capacitance C

Rise Time

Fall Time

CTR rank (PS2511-1,PS2511L-1 only)

*1

*2

*2

D : 100 to 300 %

F

IF = 10 mA 1.2 1.4 V

R

VR = 5 V 5

t

V = 0 V, f = 1.0 MHz 50 pF

CEO

I

VCE = 40 V, IF = 0 mA 100 nA

CE(sat)IF

= 10 mA, IC = 2 mA 0.3 V

I-O

I-O

V

= 1.0 kV

I-O

V = 0 V, f = 1.0 MHz 0.5 pF

r

t

VCC = 10 V, IC = 2 mA, RL = 100

f

t

DC

Ω

Test Circuit for Switching Time

*2

Pulse Input

PW = 100 s

µ

10

I

11

3

5

F

Duty Cycle = 1/10

In monitor

50 Ω

V

V

RL = 100 Ω

CC

OUT

µ

A

Ω

µ

s

5

Page 6

PS2511-1,-2,-4, PS2511L-1,-2,-4

TYPICAL CHARACTERISTICS (TA = 25 °°°°C, unless otherwise specified)

DIODE POWER DISSIPATION vs.

AMBIENT TEMPERATURE

75

(mW)

D

50

PS2511-2

PS2511L-2

PS2511-4

PS2511L-4

25

Diode Power Dissipation P

0255075

Ambient Temperature TA (˚C)

PS2511-1

PS2511L-1

0.55 mW/˚C

0.7 mW/˚C

100

FORWARD CURRENT vs.

FORWARD VOLTAGE

100

10

T

A

(mA)

F

1

0.1

Forward Current I

0.01

= +100 ˚C

+60 ˚C

+25 ˚C

–25 ˚C

–50 ˚C

0.0 0.5 1.0 1.5 2.0

Forward Voltage VF (V)

125 150

0 ˚C

TRANSISTOR POWER DISSIPATION

vs. AMBIENT TEMPERATURE

150

(mW)

C

100

PS2511-2

PS2511L-2

PS2511-4

PS2511L-4

50

Transistor Power Dissipation P

25 50 75 100 125 1500

Ambient Temperature TA (˚C)

PS2511-1

PS2511L-1

1.2 mW/˚C

1.5 mW/˚C

COLLECTOR CURRENT vs.

COLLECTOR TO EMITTER VOLTAGE

50

40

(mA)

C

30

20

10

Collector Current I

50 mA

20 mA

10 mA

5 mA

IF = 1 mA

6108420

Collector to Emitter Voltage VCE (V)

COLLECTOR TO EMITTER DARK

CURRENT vs. AMBIENT TEMPERATURE

10 000

(nA)

CEO

1 000

100

10

1

0.1

0.01

Collector to Emitter Dark Current I

–50 –25 0 25 50 75 100

VCE = 80 V

40 V

25 V

10 V

5 V

Ambient Temperature TA (˚C)

6

COLLECTOR CURRENT vs.

COLLECTOR SATURATION VOLTAGE

100

(mA)

C

10

1

Collector Current I

0.1

.0

0 0.2 0.4 0.6 0.8 1.0

Collector Saturation Voltage V

50 mA

20 mA

10 mA

5 mA

I

F

= 1 mA

CE(sat)

2 mA

(V)

Page 7

PS2511-1,-2,-4, PS2511L-1,-2,-4

NORMALIZED CURRENT TRANSFER

RATIO vs. AMBIENT TEMPERATURE

1.2

1.0

0.8

0.6

0.4

Normalized to 1.0

A

= 25 ˚C,

0.2

Normalized Current Transfer Ratio CTR

0.0

–50

–25 0 25 50 75 100

Ambient Temperature T

at T

F

= 5 mA, VCE = 5 V

I

A

(˚C)

SWITCHING TIME vs.

LOAD RESISTANCE

100

I

C

= 2 mA,

V

CC

= 10 V,

CTR = 220 %

µ

10

CURRENT TRANSFER RATIO vs.

FORWARD CURRENT

300

VCE = 5 V

250

200

150

100

50

Current Transfer Ratio CTR (%)

0

0.01 0.1 1 10 100

Forward Current I

F

(mA)

SWITCHING TIME vs.

LOAD RESISTANCE

1 000

IF = 5 mA,

V

CC

= 5 V,

t

f

t

r

100

µ

CTR = 220 %

t

f

t

s

1

Switching Time t ( s)

0.1

10010

Load Resistance R

1 k

L

(Ω)

FREQUENCY RESPONSE

0

V

–5

–10

–15

Normalized Gain G

–20

0.5 1 2 5 10 20 50 100200 500

Frequency f (kHz)

RL = 1 kΩ

t

d

t

s

I

C

= 1 mA,

CC

= 5 V

V

300 Ω

100 Ω

10 k

10

1

Switching Time t ( s)

0.1

10 100 1 k 10 k 100 k

Load Resistance RL (Ω)

LONG TERM CTR DEGRADATION

1.2

I

F

= 5 mA (TYP.)

1.0

0.8

0.6

0.4

CTR (Relative Value)

0.2

0

10

2

TA = 25 ˚C

A

= 60 ˚C

T

3

10

Time (Hr)

10

4

10

t

r

t

d

5

Remark

The graphs indicate nominal characteristics.

7

Page 8

TAPING SPECIFICATIONS (in millimeters)

Outline and Dimensions (Tape)

2.0±0.1

4.0±0.1

1.55±0.1

8.0±0.1

Tape Direction

1.55±0.1

5.6±0.1

PS2511-1,-2,-4, PS2511L-1,-2,-4

1.75±0.1

7.5±0.1

16.0±0.3

4.3±0.2

10.3±0.1

0.3

PS2511L-1-E3

PS2511L-1-F3

Outline and Dimensions (Reel)

R 1.0

2.0±0.5

φ

13.0±0.5

21.0±0.8

φ

PS2511L-1-E4

PS2511L-1-F4

φ

PS2511L-1-E3, E4: 250

φ

80.0±5.0

φ

PS2511L-1-F3, F4: 330

+2.0

16.4

–0.0

Packing: PS2511L-1-E3, E4 1 000 pcs/reel

PS2511L-1-F3, F4 2 000 pcs/reel

8

Page 9

Outline and Dimensions (Tape)

2.0±0.1

4.0±0.1

1.55±0.1

12.0±0.1

Tape Direction

1.55±0.1

10.4±0.1

PS2511-1,-2,-4, PS2511L-1,-2,-4

1.75±0.1

7.5±0.1

16.0±0.3

4.3±0.2

10.3±0.1

0.3

PS2511L-2-E3 PS2511L-2-E4

Outline and Dimensions (Reel)

R 1.0

2.0±0.5

13.0±0.5

φ

21.0±0.8

φ

330

φ

80.0±5.0

φ

Packing: 1 000 pcs/reel

16.4

+2.0

–0.0

9

Page 10

PS2511-1,-2,-4, PS2511L-1,-2,-4

RECOMMENDED SOLDERING CONDITIONS

(1) Infrared reflow soldering

• Peak reflow temperature 235 °C (package surface temperature)

• Time of temperature higher than 210 °C 30 seconds or less

• Number of reflows Three

• Flux Rosin flux containing small amount of chlorine (The flux with a

maximum chlorine content of 0.2 Wt % is recommended.)

Recommended Temperature Profile of Infrared Reflow

(heating)

to 10 s

235 ˚C (peak temperature)

210 ˚C

to 30 s

120 to 160 ˚C

60 to 90 s

(preheating)

Package Surface Temperature T (˚C)

Time (s)

Peak temperature 235 ˚C or below

(2) Dip soldering

• Temperature 260 °C or below (molten solder temperature)

• Time 10 seconds or less

• Number of times One

• Flux Rosin flux containing small amount of chlorine (The flux with a maximum chlorine content of

0.2 Wt % is recommended.)

(3) Cautions

•Fluxes

Avoid removing the residual flux with freon-based and chlorine-based cleaning solvent.

10

Page 11

[MEMO]

PS2511-1,-2,-4, PS2511L-1,-2,-4

11

Page 12

PS2511-1,-2,-4, PS2511L-1,-2,-4

CAUTION

Within this device there exists GaAs (Gallium Arsenide) material which is a

harmful substance if ingested. Please do not under any circumstances break the

hermetic seal.

NEPOC is a trademark of NEC Corporation.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on

a customer designated "quality assurance program" for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

M4 96. 5

Loading...

Loading...