PIC18F2423/2523/4423/4523

Data Sheet

28/40/44-Pin, Enhanced Flash

Microcontrollers with 12-Bit A/D

and nanoWatt Technology

© 2009 Microchip Technology Inc. DS39755C

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

rfPIC and UNI/O are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, HI-TIDE, In-Circuit Serial

Programming, ICSP, Mindi, MiWi, MPASM, MPLAB Certified

logo, MPLIB, MPLINK, mTouch, Octopus, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, PIC

32

logo, REAL ICE, rfLAB, Select Mode, Total

Endurance, TSHARC, UniWinDriver, WiperLock and ZENA

are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2009, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS39755C-page 2 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

28/40/44-Pin, Enhanced Flash Microcontrollers with

12-Bit A/D and nanoWatt Technology

Power Management Features:

• Run: CPU on, Peripherals on

• Idle: CPU off, Peripherals on

• Sleep: CPU off, Peripherals off

• Ultra Low 50 nA Input Leakage

• Run mode Currents Down to 11 μA Typical

• Idle mode Currents Down to 2.5 μA Typical

• Sleep mode Current Down to 100 μA Typical

• Timer1 Oscillator: 900 nA, 32 kHz, 2V

• Watchdog Timer: 1.4 μA, 2V Typical

• Two-Speed Oscillator Start-up

Flexible Oscillator Structure:

• Four Crystal modes, up to 40 MHz

• 4x Phase Lock Loop (PLL) – Available for Crystal

and Internal Oscillators

• Two External RC modes, up to 4 MHz

• Two External Clock modes, up to 40 MHz

• Internal Oscillator Block:

- Fast wake from Sleep and Idle, 1 μs typical

- 8 user-selectable frequencies, from 31 kHz to 8 MHz

- Provides a complete range of clock speeds,

from 31 kHz to 32 MHz, when used with PLL

- User-tunable to Compensate for Frequency Drift

• Secondary Oscillator using Timer1 @ 32 kHz

• Fail-Safe Clock Monitor:

- Allows for safe shutdown if peripheral clock stops

Peripheral Highlights:

• 12-Bit, Up to 13-Channel Analog-to-Digital Converter

module (A/D):

- Auto-acquisition capability

- Conversion available during Sleep mode

• Dual Analog Comparators with Input Multiplexing

• High-Current Sink/Source 25 mA/25 mA

• Three Programmable External Interrupts

• Four Input Change Interrupts

• Up to Two Capture/Compare/PWM (CCP)

modules, One with Auto-Shutdown (28-pin devices)

• Enhanced Capture/Compare/PWM (ECCP) module

(40/44-pin devices only):

- One, two or four PWM outputs

- Selectable polarity

- Programmable dead time

- Auto-shutdown and auto-restart

Peripheral Highlights (Continued):

• Master Synchronous Serial Port (MSSP) module

Supporting 3-Wire SPI (all four modes) and I

Master and Slave modes

• Enhanced USART module:

- Support for RS-485, RS-232 and LIN/J2602

- RS-232 operation using internal oscillator

block (no external crystal required)

- Auto-wake-up on Start bit

- Auto-Baud Detect (ABD)

2

C™

Special Microcontroller Features:

• C Compiler Optimized Architecture: Optional

Extended Instruction Set Designed to Optimize

Re-Entrant Code

• 100,000 Erase/Write Cycle, Enhanced Flash

Program Memory Typical

• 1,000,000 Erase/Write Cycle, Data EEPROM

Memory Typical

• Flash/Data EEPROM Retention: 100 Years Typical

• Self-Programmable under Software Control

• Priority Levels for Interrupts

• 8 x 8 Single-Cycle Hardware Multiplier

• Extended Watchdog Timer (WDT): Programmable

Period, from 4 ms to 131s

• Single-Supply In-Circuit Serial Programming™

(ICSP™) via Two Pins

• In-Circuit Debug (ICD) via Two Pins

• Operating Voltage Range: 2.0V to 5.5V

• Programmable, 16-Level High/Low-Voltage

Detection (HLVD) module: Supports Interrupt on

High/Low-Voltage Detection

• Programmable Brown-out Reset (BOR): With

Software-Enable Option

Note: This document is supplemented by the

“PIC18F2420/2520/4420/4520 Data Sheet”

(DS39631). See Section 1.0 “Device

Overview”.

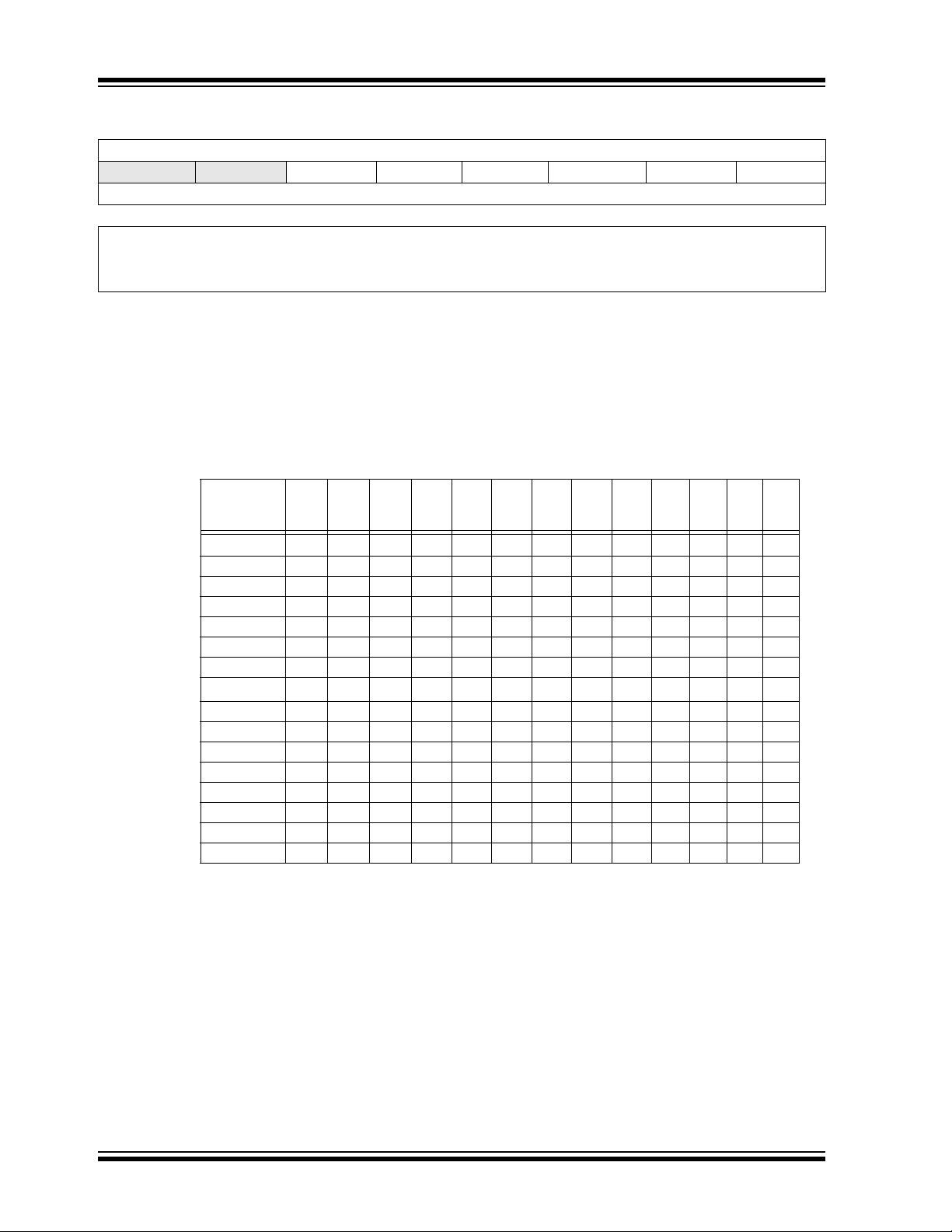

Program Memory Data Memory

Device

PIC18F2423 16K 8192 768 256 25 10 2/0 Y Y 1 2 1/3

PIC18F2523 32K 16384 1536 256 25 10 2/0 Y Y 1 2 1/3

PIC18F4423 16K 8192 768 256 36 13 1/1 Y Y 1 2 1/3

PIC18F4523 32K 16384 1536 256 36 13 1/1 Y Y 1 2 1/3

© 2009 Microchip Technology Inc. DS39755C-page 3

Flash

(bytes)

# Single-Word

Instructions

SRAM

(bytes)

EEPROM

(bytes)

I/O

12-Bit

A/D (ch)

CCP/

ECCP

(PWM)

SPI

MSSP

Master

2

C™

I

Comp.

EUSART

Timers

8/16-Bit

PIC18F2423/2523/4423/4523

PIC18F2523

10

11

2

3

4

5

6

1

8

7

9

12

13

14

15

16

17

18

19

20

23

24

25

26

27

28

22

21

MCLR/VPP/RE3

RA0/AN0

RA1/AN1

RA2/AN2/V

REF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

RA5/AN4/SS

/HLVDIN/C2OUT

V

SS

OSC1/CLKI

(3)

/RA7

OSC2/CLKO

(3)

/RA6

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

(2)

RC2/CCP1

RC3/SCK/SCL

RB7/KBI3/PGD

RB6//KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0/AN11

RB3/AN9/CCP2

(2)

RB2/INT2/AN8

RB1/INT1/AN10

RB0/INT0/FLT0/AN12

V

DD

VSS

RC7/RX/DT

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

28-Pin PDIP, SOIC

PIC18F2423

Note 1: It is recommended to connect the bottom pad of QFN package parts to VSS.

2: RB3 is the alternate pin for CCP2 multiplexing.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not

being used as digital I/O. For additional information, see Section 2.0 “Oscillator Configurations” of the

“PIC18F2420/2520/4420/4520 Data Sheet” (DS39631).

10 11

2

3

6

1

18

19

20

21

22

12 13 14

15

8

7

16

17

232425262728

9

PIC18F2423

RC0/T1OSO/T13CKI

5

4

RB7/KBI3/PGD

RB6/KBI2/PGC

RB5/KBI1/PGM

RB4KBI0/AN11

RB3/AN9/CCP2

(2)

RB2/INT2/AN8

RB1/INT1/AN10

RB0/INT0/FLT0/AN12

V

DD

VSS

RC7/RX/DT

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

MCLR

/VPP/RE3

RA0/AN0

RA1/AN1

RA2/AN2/VREF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

RA5/AN4/SS

/HLVDIN/C2OUT

V

SS

OSC1/CLKI

(3)

/RA7

OSC2/CLKO

(3)

/RA6

RC1/T1OSI/CCP2

(2)

RC2/CCP1

RC3/SCK/SCL

PIC18F2523

28-Pin QFN

(1)

Pin Diagrams

DS39755C-page 4 © 2009 Microchip Technology Inc.

RB7/KBI3/PGD

RB6/KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0/AN11

RB3/AN9/CCP2

(1)

RB2/INT2/AN8

RB1/INT1/AN10

RB0/INT0/FLT0/AN12

V

DD

VSS

RD7/PSP7/P1D

RD6/PSP6/P1C

RD5/PSP5/P1B

RD4/PSP4

RC7/RX/DT

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

RD3/PSP3

RD2/PSP2

MCLR/VPP/RE3

RA0/AN0

RA1/AN1

RA2/AN2/V

REF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

RA5/AN4/SS

/HLVDIN/C2OUT

RE0/RD

/AN5

RE1/WR

/AN6

RE2/CS

/AN7

V

DD

VSS

OSC1/CLKI

(2)

/RA7

OSC2/CLKO

(2)

/RA6

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

(1)

RC2/CCP1/P1A

RC3/SCK/SCL

RD0/PSP0

RD1/PSP1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

PIC18F4523

40-Pin PDIP

PIC18F4423

10

11

2

3

4

5

6

1

1819202122

121314

15

38

8

7

4443424140

39

16

17

29

30

31

32

33

23

24

25

26

27

28

363435

9

PIC18F4423

37

RA3/AN3/VREF+

RA2/AN2/V

REF-/CVREF

RA1/AN1

RA0/AN0

MCLR

/VPP/RE3

NC

RB7/KBI3/PGD

RB6/KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0/AN11

NC

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

RD3/PSP3

RD2/PSP2

RD1/PSP1

RD0/PSP0

RC3/SCK/SCL

RC2/CCP1/P1A

RC1/T1OSI/CCP2

(1)

NC

NC

RC0/T1OSO/T13CKI

OSC2/CLKO

(2)

/RA6

OSC1/CLKI

(2)

/RA7

V

SS

VDD

RE2/CS/AN7

RE1/WR

/AN6

RE0/RD

/AN5

RA5/AN4/SS

/HLVDIN/C2OUT

RA4/T0CKI/C1OUT

RC7/RX/DT

RD4/PSP4

RD5/PSP5/P1B

RD6/PSP6/P1C

RD7/PSP7/P1D

V

SS

VDD

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

RB3/AN9/CCP2

(1)

44-Pin TQFP

PIC18F4523

Note 1: RB3 is the alternate pin for CCP2 multiplexing.

2: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not

being used as digital I/O. For additional information, see Section 2.0 “Oscillator Configurations” of the

“PIC18F2420/2520/4420/4520 Data Sheet” (DS39631).

PIC18F2423/2523/4423/4523

Pin Diagrams (Continued)

© 2009 Microchip Technology Inc. DS39755C-page 5

PIC18F2423/2523/4423/4523

10

11

2

3

4

5

6

1

1819202122

121314

15

38

8

7

4443424140

39

16

17

29

30

31

32

33

23

24

25

26

27

28

363435

9

PIC18F4423

37

RA3/AN3/V

REF+

RA2/AN2/V

REF-/CVREF

RA1/AN1

RA0/AN0

MCLR

/VPP/RE3

RB3/AN9/CCP2

(2)

RB7/KBI3/PGD

RB6/KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0/AN11

NC

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

RD3/PSP3

RD2/PSP2

RD1/PSP1

RD0/PSP0

RC3/SCK/SCL

RC2/CCP1/P1A

RC1/T1OSI/CCP2

(2)

RC0/T1OSO/T13CKI

OSC2/CLKO

(3)

/RA6

OSC1/CLKI

(3)

/RA7

V

SS

VSS

VDD

VDD

RE2/CS/AN7

RE1/WR

/AN6

RE0/RD

/AN5

RA5/AN4/SS

/HLVDIN/C2OUT

RA4/T0CKI/C1OUT

RC7/RX/DT

RD4/PSP4

RD5/PSP5/P1B

RD6/PSP6/P1C

RD7/PSP7/P1D

V

SS

VDD

VDD

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

44-Pin QFN

(1)

PIC18F4523

Note 1: It is recommended to connect the bottom pad of QFN package parts to VSS.

2: RB3 is the alternate pin for CCP2 multiplexing.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not

being used as digital I/O. For additional information, see Section 2.0 “Oscillator Configurations” of the

“PIC18F2420/2520/4420/4520 Data Sheet” (DS39631).

Pin Diagrams (Continued)

DS39755C-page 6 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

Table of Contents

1.0 Device Overview .......................................................................................................................................................................... 9

2.0 12-Bit Analog-to-Digital Converter (A/D) Module ....................................................................................................................... 25

3.0 Special Features of the CPU...................................................................................................................................................... 35

4.0 Electrical Characteristics............................................................................................................................................................ 37

5.0 Packaging Information................................................................................................................................................................ 43

Appendix A: Revision History............................................................................................................................................................... 45

Appendix B: Device Differences .......................................................................................................................................................... 45

Appendix C: Conversion Considerations ............................................................................................................................................. 46

Appendix D: Migration from Baseline to Enhanced Devices................................................................................................................ 46

Appendix E: Migration from Mid-Range to Enhanced Devices ............................................................................................................ 47

Appendix F: Migration from High-End to Enhanced Devices ............................................................................................................... 47

Index ................................................................................................................................................................................................... 49

The Microchip Web Site....................................................................................................................................................................... 51

Customer Change Notification Service ................................................................................................................................................ 51

Customer Support ................................................................................................................................................................................ 51

Reader Response ................................................................................................................................................................................ 52

Product Identification System .............................................................................................................................................................. 53

© 2009 Microchip Technology Inc. DS39755C-page 7

PIC18F2423/2523/4423/4523

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS39755C-page 8 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

1.0 DEVICE OVERVIEW

This document contains device-specific information for

the following devices:

• PIC18F2423 • PIC18LF2423

• PIC18F2523 • PIC18LF2523

• PIC18F4423 • PIC18LF4423

• PIC18F4523 • PIC18LF4523

Note: This data sheet documents only the devices’

features and specifications that are in addition

to, or different from, the features and specifications of the PIC18F2420/2520/4420/4520

devices. For information on the features and

specifications shared by the PIC18F2423/

2523/4423/4523 and PIC18F2420/2520/

4420/4520 devices, see the “PIC18F2420/

2520/4420/4520 Data Sheet” (DS39631).

This family offers the advantages of all PIC18

microcontrollers – namely, high computational performance at an economical price – with the addition of

high-endurance, Enhanced Flash program memory.

On top of these features, the PIC18F2423/2523/4423/

4523 family introduces design enhancements that

make these microcontrollers a logical choice for many

high-performance, power-sensitive applications.

1.1 New Core Features

1.1.1 nanoWatt TECHNOLOGY

All of the devices in the PIC18F2423/2523/4423/4523

family incorporate a range of features that can significantly reduce power consumption during operation.

Key items include:

• Alternate Run Modes: By clocking the controller

from the Timer1 source or the internal oscillator

block, power consumption during code execution

can be reduced by as much as 90%.

• Multiple Idle Modes: The controller also can run

with its CPU core disabled and the peripherals still

active. In these states, power consumption can be

reduced even further, to as little as 4% of normal

operation requirements.

• On-the-Fly Mode Switching: The power-managed

modes are invoked by user code during operation,

allowing the user to incorporate power-saving ideas

into their application’s software design.

• Low Consumption in Key Modules: The power

requirements for both Timer1 and the Watchdog

Timer are minimized. See Section 4.0 “Electrical

Characteristics” for values.

1.1.2 MULTIPLE OSCILLATOR OPTIONS AND FEATURES

All of the devices in the PIC18F2423/2523/4423/4523

family offer ten different oscillator options, allowing

users a wide range of choices in developing application

hardware. These include:

• Four Crystal modes, using crystals or ceramic

resonators.

• Two External Clock modes, offering the option of

using two pins (oscillator input and a divide-by-4

clock output) or one pin (oscillator input, with the

second pin reassigned as general I/O).

• Two External RC Oscillator modes with the same

pin options as the External Clock modes.

• An internal oscillator block that offers eight clock

frequencies: an 8 MHz clock and an INTRC source

(approximately 31 kHz), as well as a range of six

user-selectable clock frequencies, between

125 kHz to 4 MHz. This option frees the two

oscillator pins for use as additional general

purpose I/O.

• A Phase Lock Loop (PLL) frequency multiplier,

available to both the High-Speed Crystal and

Internal Oscillator modes, allowing clock speeds

of up to 40 MHz from the HS clock source. Used

with the internal oscillator, the PLL gives users a

complete selection of clock speeds, from 31 kHz

to 32 MHz, all without using an external crystal or

clock circuit.

Besides its availability as a clock source, the internal

oscillator block provides a stable reference source that

gives the family additional features for robust

operation:

• Fail-Safe Clock Monitor: Constantly monitors

the main clock source against a reference signal

provided by the internal oscillator. If a clock failure

occurs, the controller is switched to the internal

oscillator block, allowing for continued operation

or a safe application shutdown.

• Two-Speed Start-up: Allows the internal oscillator

to serve as the clock source from Power-on Reset,

or wake-up from Sleep mode, until the primary clock

source is available.

© 2009 Microchip Technology Inc. DS39755C-page 9

PIC18F2423/2523/4423/4523

1.2 Other Special Features

• 12-Bit A/D Converter: This module incorporates

programmable acquisition time, allowing for a

channel to be selected and a conversion to be

initiated without waiting for a sampling period,

thereby reducing code overhead.

• Memory Endurance: The Enhanced Flash cells

for both program memory and data EEPROM are

rated to last for many thousands of erase/write

cycles – up to 100,000 for program memory and

1,000,000 for EEPROM. Data retention without

refresh is conservatively estimated to be greater

than 40 years.

• Self-Programmability: These devices can write

to their own program memory spaces under internal software control. By using a bootloader routine

located in the protected Boot Block at the top of

program memory, it is possible to create an

application that can update itself in the field.

• Extended Instruction Set: The PIC18F2423/

2523/4423/4523 family introduces an optional

extension to the PIC18 instruction set that adds

eight new instructions and an Indexed Addressing

mode. This extension, enabled as a device configuration option, has been specifically designed

to optimize re-entrant application code originally

developed in high-level languages, such as C.

• Enhanced CCP module: In PWM mode, this

module provides one, two or four modulated

outputs for controlling half-bridge and full-bridge

drivers. Other features include auto-shutdown, for

disabling PWM outputs on interrupt or other select

conditions, and auto-restart, to reactivate outputs

once the condition has cleared.

• Enhanced Addressable USART: This serial

communication module is capable of standard

RS-232 operation and provides support for the

LIN/J2602 bus protocol. Other enhancements

include automatic baud rate detection and a 16-bit

Baud Rate Generator for improved resolution.

When the microcontroller is using the internal

oscillator block, the EUSART provides stable

operation for applications that talk to the outside

world without using an external crystal (or its

accompanying power requirement).

• Extended Watchdog Timer (WDT): This

Enhanced version incorporates a 16-bit prescaler,

allowing an extended time-out range that is stable

across operating voltage and temperature. See

Section 4.0 “Electrical Characteristics” for

time-out periods.

1.3 Details on Individual Family Members

Devices in the PIC18F2423/2523/4423/4523 family are

available in 28-pin and 40/44-pin packages. Block

diagrams for the two groups are shown in Figure 1-1

and Figure 1-2.

The devices are differentiated from each other in these

ways:

• Flash Program Memory:

- PIC18F2423/4423 devices – 16 Kbytes

- PIC18F2523/4523 devices – 32 Kbytes

• A/D Channels:

- PIC18F2423/2523 devices – 10

- PIC18F4423/4523 devices – 13

• I/O Ports:

- PIC18F2423/2523 devices – Three bidirectional

ports

- PIC18F4423/4523 devices – Five bidirectional

ports

• CCP and Enhanced CCP Implementation:

- PIC18F2423/2523 devices – Two standard

CCP modules

- PIC18F4423/4523 devices – One standard

CCP module and one ECCP module

• Parallel Slave Port – Present only on

PIC18F4423/4523 devices

All other features for devices in this family are identical.

These are summarized in Table 1-1.

The pinouts for all devices are listed in Table 1-2 and

Table 1-3.

Members of the PIC18F2423/2523/4423/4523 family

are available only as low-voltage devices, designated

by “LF” (such as PIC18LF2423), and function over an

extended V

DD range of 2.0V to 5.5V.

DS39755C-page 10 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TABLE 1-1: DEVICE FEATURES

Features PIC18F2423 PIC18F2523 PIC18F4423 PIC18F4523

Operating Frequency DC – 40 MHz DC – 40 MHz DC – 40 MHz DC – 40 MHz

Program Memory (Bytes) 16,384 32,768 16,384 32,768

Program Memory (Instructions) 8,192 16,384 8,192 16,384

Data Memory (Bytes) 768 1,536 768 1,536

Data EEPROM Memory (Bytes) 256 256 256 256

Interrupt Sources 19 19 20 20

I/O Ports Ports A, B, C, (E) Ports A, B, C, (E) Ports A, B, C, D, E Ports A, B, C, D, E

Timers 4 4 4 4

Capture/Compare/PWM Modules 2 2 1 1

Enhanced

Capture/Compare/PWM Modules

Serial Communications MSSP,

Parallel Communications (PSP) No No Yes Yes

12-Bit Analog-to-Digital Module 10 Input Channels 10 Input Channels 13 Input Channels 13 Input Channels

Resets (and Delays) POR, BOR,

Underflow (PWRT, OST),

MCLR

Programmable

High/Low-Voltage Detect

Programmable Brown-out Reset Yes Yes Yes Yes

Instruction Set 75 Instructions;

Instruction Set enabled

Packages 28-Pin PDIP

0011

Enhanced USART

RESET Instruction,

Stack Full, Stack

(optional), WDT

Ye s Ye s Ye s Ye s

83 with Extended

28-Pin SOIC

28-Pin QFN

MSSP,

Enhanced USART

POR, BOR,

RESET Instruction,

Stack Full, Stack

Underflow (PWRT, OST),

MCLR (optional), WDT

75 Instructions;

83 with Extended

Instruction Set enabled

28-Pin PDIP

28-Pin SOIC

28-Pin QFN

MSSP,

Enhanced USART

POR, BOR,

RESET Instruction,

Stack Full, Stack

Underflow (PWRT, OST),

MCLR (optional), WDT

75 Instructions;

83 with Extended

Instruction Set enabled

40-Pin PDIP

44-Pin QFN

44-Pin TQFP

MSSP,

Enhanced USART

POR, BOR,

RESET Instruction,

Stack Full, Stack

Underflow (PWRT, OST),

MCLR (optional), WDT

75 Instructions;

83 with Extended

Instruction Set enabled

40-Pin PDIP

44-Pin QFN

44-Pin TQFP

© 2009 Microchip Technology Inc. DS39755C-page 11

PIC18F2423/2523/4423/4523

Instruction

Decode and

Control

PORTA

PORTB

PORTC

RA4/T0CKI/C1OUT

RA5/AN4/SS

/HLVDIN/C2OUT

RB0/INT0/FLT0/AN12

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

(1)

RC2/CCP1

RC3/SCK/SCL

RC4/SDI/SDA

RC5/SDO

RC6/TX/CK

RC7/RX/DT

RA3/AN3/VREF+

RA2/AN2/VREF-/CVREF

RA1/AN1

RA0/AN0

RB1/INT1/AN10

Data Latch

Data Memory

( 3.9 Kbytes )

Address Latch

Data Address<12>

12

Access

BSR

FSR0

FSR1

FSR2

inc/dec

logic

Address

4

12

4

PCH PCL

PCLATH

8

31 Level Stack

Program Counter

PRODLPRODH

8 x 8 Multiply

8

BITOP

8

8

ALU<8>

Address Latch

Program Memory

(16/32 Kbytes)

Data Latch

20

8

8

Table Pointer<21>

inc/dec logic

21

8

Data Bus<8>

Table Latch

8

IR

12

3

ROM Latch

RB2/INT2/AN8

RB3/AN9/CCP2

(1)

PCLATU

PCU

OSC2/CLKO

(3)

/RA6

Note 1: CCP2 is multiplexed with RC1 when Configuration bit, CCP2MX, is set or RB3 when CCP2MX is not set.

2: RE3 is only available when MCLR

functionality is disabled.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not being used as digital I/O.

For additional information, see Section 2.0 “Oscillator Configurations” of the “PIC18F2420/2520/4420/4520 Data Sheet” (DS39631).

RB4/KBI0/AN11

RB5/KBI1/PGM

RB6/KBI2/PGC

RB7/KBI3/PGD

EUSARTComparator

MSSP

12-Bit

ADC

Timer2Timer1 Tim er3Timer0

CCP2

HLVD

CCP1

BOR

Data

EEPROM

W

Instruction Bus <16>

STKPTR

Bank

8

State Machine

Control Signals

Decode

8

8

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

OSC1

(3)

OSC2

(3)

VDD,

Brown-out

Reset

Internal

Oscillator

Fail-Safe

Clock Monitor

Precision

Reference

Band Gap

V

SS

MCLR

(2)

Block

INTRC

Oscillator

8 MHz

Oscillator

Single-Supply

Programming

In-Circuit

Debugger

T1OSO

OSC1/CLKI

(3)

/RA7

T1OSI

PORTE

MCLR/VPP/RE3

(2)

FIGURE 1-1: PIC18F2423/2523 (28-PIN) BLOCK DIAGRAM

DS39755C-page 12 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

Instruction

Decode and

Control

Data Latch

Data Memory

( 3.9 Kbytes )

Address Latch

Data Address<12>

12

Access

BSR

FSR0

FSR1

FSR2

inc/dec

logic

Address

4

12

4

PCH PCL

PCLATH

8

31 Level Stack

Program Counter

PRODLPRODH

8 x 8 Multiply

8

BITOP

8

8

ALU<8>

Address Latch

Program Memory

(16/32 Kbytes)

Data Latch

20

8

8

Table Pointer<21>

inc/dec logic

21

8

Data Bus<8>

Table Latch

8

IR

12

3

ROM Latch

PORTD

RD0/PSP0

PCLATU

PCU

PORTE

MCLR/VPP/RE3

(2)

RE2/CS/AN7

RE0/RD/AN5

RE1/WR/AN6

Note 1: CCP2 is multiplexed with RC1 when Configuration bit, CCP2MX, is set or RB3 when CCP2MX is not set.

2: RE3 is only available when MCLR

functionality is disabled.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not being used as digital I/O.

For additional information, see Section 2.0 “Oscillator Configurations” of the “PIC18F2420/2520/4420/4520 Data Sheet” (DS39631).

:RD4/PSP4

EUSARTComparator

MSSP

12-Bit

ADC

Timer2Timer1 Timer3Timer0

CCP2

HLVD

ECCP1

BOR

Data

EEPROM

W

Instruction Bus <16>

STKPTR

Bank

8

State Machine

Control Signals

Decode

8

8

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

OSC1

(3)

OSC2

(3)

VDD,

Brown-out

Reset

Internal

Oscillator

Fail-Safe

Clock Monitor

Precision

Reference

Band Gap

V

SS

MCLR

(2)

Block

INTRC

Oscillator

8 MHz

Oscillator

Single-Supply

Programming

In-Circuit

Debugger

T1OSI

T1OSO

RD5/PSP5/P1B

RD6/PSP6/P1C

RD7/PSP7/P1D

PORTA

PORTB

PORTC

RA4/T0CKI/C1OUT

RA5/AN4/SS

/HLVDIN/C2OUT

RB0/INT0/FLT0/AN12

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

(1)

RC2/CCP1/P1A

RC3/SCK/SCL

RC4/SDI/SDA

RC5/SDO

RC6/TX/CK

RC7/RX/DT

RA3/AN3/VREF+

RA2/AN2/VREF-/CVREF

RA1/AN1

RA0/AN0

RB1/INT1/AN10

RB2/INT2/AN8

RB3/AN9/CCP2

(1)

OSC2/CLKO

(3)

/RA6

RB4/KBI0/AN11

RB5/KBI1/PGM

RB6/KBI2/PGC

RB7/KBI3/PGD

OSC1/CLKI

(3)

/RA7

FIGURE 1-2: PIC18F4423/4523 (40/44-PIN) BLOCK DIAGRAM

© 2009 Microchip Technology Inc. DS39755C-page 13

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS

Pin Number

Pin Name

/VPP/RE3

MCLR

MCLR

VPP

RE3

OSC1/CLKI/RA7

OSC1

CLKI

RA7

OSC2/CLKO/RA6

OSC2

CLKO

RA6

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

PDIP,

SOIC

QFN

126

96

10 7

Pin

Typ e

I

P

I

I

I

I/O

O

O

I/O

Buffer

Type

ST

ST

ST

CMOS

TTL

—

—

TTL

Description

Master Clear (input) or programming voltage (input).

Master Clear (Reset) input. This pin is an active-low

Reset to the device.

Programming voltage input.

Digital input.

Oscillator crystal or external clock input.

Oscillator crystal input or external clock source input.

ST buffer when configured in RC mode; CMOS otherwise.

External clock source input. Always associated with pin

function, OSC1. (See related OSC1/CLKI, OSC2/CLKO

pins.)

General purpose I/O pin.

Oscillator crystal or clock output.

Oscillator crystal output. Connects to crystal or

resonator in Crystal Oscillator mode.

In RC mode, OSC2 pin outputs CLKO, which has 1/4 the

frequency of OSC1 and denotes the instruction cycle rate.

General purpose I/O pin.

DS39755C-page 14 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Number

Pin Name

RA0/AN0

RA0

AN0

RA1/AN1

RA1

AN1

RA2/AN2/VREF-/CVREF

RA2

AN2

VREF-

REF

CV

RA3/AN3/V

RA3

AN3

V

RA4/T0CKI/C1OUT

RA4

T0CKI

C1OUT

RA5/AN4/SS

C2OUT

RA5

AN4

SS

HLVDIN

C2OUT

RA6 See the OSC2/CLKO/RA6 pin.

RA7 See the OSC1/CLKI/RA7 pin.

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

REF+

REF+

/HLVDIN/

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

2

C=I2C™/SMBus

I

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

PDIP,

SOIC

227

328

41

52

63

74

QFN

Pin

Buffer

Typ e

Type

I/OITTL

Analog

I/OITTL

Analog

I/O

TTL

I

Analog

I

Analog

O

Analog

I/O

TTL

I

Analog

I

Analog

I/O

I

O

I/O

TTL

I

Analog

I

TTL

I

Analog

O

PORTA is a bidirectional I/O port.

Digital I/O.

Analog Input 0.

Digital I/O.

Analog Input 1.

Digital I/O.

Analog Input 2.

A/D reference voltage (low) input.

Comparator reference voltage output.

Digital I/O.

Analog Input 3.

A/D reference voltage (high) input.

ST

ST

—

—

Digital I/O.

Timer0 external clock input.

Comparator 1 output.

Digital I/O.

Analog Input 4.

SPI slave select input.

High/Low-Voltage Detect input.

Comparator 2 output.

Description

© 2009 Microchip Technology Inc. DS39755C-page 15

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Number

Pin Name

RB0/INT0/FLT0/AN12

RB0

INT0

FLT0

AN12

RB1/INT1/AN10

RB1

INT1

AN10

RB2/INT2/AN8

RB2

INT2

AN8

RB3/AN9/CCP2

RB3

AN9

(1)

CCP2

RB4/KBI0/AN11

RB4

KBI0

AN11

RB5/KBI1/PGM

RB5

KBI1

PGM

RB6/KBI2/PGC

RB6

KBI2

PGC

RB7/KBI3/PGD

RB7

KBI3

PGD

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

PDIP,

SOIC

21 18

22 19

23 20

24 21

25 22

26 23

27 24

28 25

QFN

Pin

Typ e

I/O

I

I

I

I/O

I

I

I/O

I

I

I/O

I

I/O

I/O

I

I

I/O

I

I/O

I/O

I

I/O

I/O

I

I/O

Buffer

Type

TTL

ST

ST

Analog

TTL

ST

Analog

TTL

ST

Analog

TTL

Analog

ST

TTL

TTL

Analog

TTL

TTL

ST

TTL

TTL

ST

TTL

TTL

ST

Description

PORTB is a bidirectional I/O port. PORTB can be software

programmed for internal weak pull-ups on all inputs.

Digital I/O.

External Interrupt 0.

PWM Fault input for CCP1.

Analog Input 12.

Digital I/O.

External Interrupt 1.

Analog Input 10.

Digital I/O.

External Interrupt 2.

Analog Input 8.

Digital I/O.

Analog Input 9.

Capture 2 input/Compare 2 output/PWM2 output.

Digital I/O.

Interrupt-on-change pin.

Analog Input 11.

Digital I/O.

Interrupt-on-change pin.

Low-Voltage ICSP™ Programming enable pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming clock pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming data pin.

DS39755C-page 16 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Number

Pin Name

RC0/T1OSO/T13CKI

RC0

T1OSO

T13CKI

RC1/T1OSI/CCP2

RC1

T1OSI

(2)

CCP2

RC2/CCP1

RC2

CCP1

RC3/SCK/SCL

RC3

SCK

SCL

RC4/SDI/SDA

RC4

SDI

SDA

RC5/SDO

RC5

SDO

RC6/TX/CK

RC6

TX

CK

RC7/RX/DT

RC7

RX

DT

RE3 — — — — See MCLR

SS 8, 19 5, 16 P — Ground reference for logic and I/O pins.

V

V

DD 20 17 P — Positive supply for logic and I/O pins.

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

PDIP,

SOIC

11 8

12 9

13 10

14 11

15 12

16 13

17 14

18 15

QFN

Pin

Buffer

Typ e

Type

I/O

O

I

I/O

I

Analog

I/O

I/O

I/OSTST

I/O

I/O

I/O

I/O

I

I/O

I/OOST

I/O

O

I/O

I/O

I

I/O

PORTC is a bidirectional I/O port.

ST

—

ST

ST

ST

ST

ST

I

ST

ST

I

—

ST

—

ST

ST

ST

ST

2

2

Digital I/O.

Timer1 oscillator output.

Timer1/Timer3 external clock input.

Digital I/O.

Timer1 oscillator input.

Capture 2 input/Compare 2 output/PWM2 output.

Digital I/O.

Capture 1 input/Compare 1 output/PWM1 output.

Digital I/O.

Synchronous serial clock input/output for SPI mode.

C

C

Synchronous serial clock input/output for I2C™ mode.

Digital I/O.

SPI data in.

I2C data I/O.

Digital I/O.

SPI data out.

Digital I/O.

EUSART asynchronous transmit.

EUSART synchronous clock (see related RX/DT).

Digital I/O.

EUSART asynchronous receive.

EUSART synchronous data (see related TX/CK).

/VPP/RE3 pin.

Description

© 2009 Microchip Technology Inc. DS39755C-page 17

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS

Pin Name

/VPP/RE3

MCLR

MCLR

VPP

RE3

OSC1/CLKI/RA7

OSC1

CLKI

RA7

OSC2/CLKO/RA6

OSC2

CLKO

RA6

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

Pin Number

PDIP QFN TQFP

11818

13 32 30

14 33 31

Pin

Type

I

P

I

I

I

I/O

O

O

I/O

Buffer

Typ e

ST

ST

ST

CMOS

TTL

—

—

TTL

Description

Master Clear (input) or programming voltage (input).

Master Clear (Reset) input. This pin is an active-low

Reset to the device.

Programming voltage input.

Digital input.

Oscillator crystal or external clock input.

Oscillator crystal input or external clock source input.

ST buffer when configured in RC mode;

analog otherwise.

External clock source input. Always associated with

pin function, OSC1. (See related OSC1/CLKI,

OSC2/CLKO pins.)

General purpose I/O pin.

Oscillator crystal or clock output.

Oscillator crystal output. Connects to crystal

or resonator in Crystal Oscillator mode.

In RC mode, OSC2 pin outputs CLKO, which

has 1/4 the frequency of OSC1 and denotes

the instruction cycle rate.

General purpose I/O pin.

DS39755C-page 18 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RA0/AN0

RA0

AN0

RA1/AN1

RA1

AN1

RA2/AN2/V

RA3/AN3/V

RA4/T0CKI/C1OUT

RA5/AN4/SS

C2OUT

RA6 See the OSC2/CLKO/RA6 pin.

RA7 See the OSC1/CLKI/RA7 pin.

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

REF-/CVREF

RA2

AN2

VREF-

REF

CV

REF+

RA3

AN3

REF+

V

RA4

T0CKI

C1OUT

/HLVDIN/

RA5

AN4

SS

HLVDIN

C2OUT

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2

C=I2C™/SMBus

I

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

Pin Number

PDIP QFN TQFP

21919

32020

42121

52222

62323

72424

Pin

Buffer

Type

Typ e

I/OITTL

Analog

I/OITTL

Analog

I/O

I

Analog

I

Analog

O

Analog

I/O

I

Analog

I

Analog

I/O

I

O

I/O

I

Analog

I

I

Analog

O

PORTA is a bidirectional I/O port.

Digital I/O.

Analog Input 0.

Digital I/O.

Analog Input 1.

TTL

TTL

ST

ST

—

TTL

TTL

—

Digital I/O.

Analog Input 2.

A/D reference voltage (low) input.

Comparator reference voltage output.

Digital I/O.

Analog Input 3.

A/D reference voltage (high) input.

Digital I/O.

Timer0 external clock input.

Comparator 1 output.

Digital I/O.

Analog Input 4.

SPI slave select input.

High/Low-Voltage Detect input.

Comparator 2 output.

Description

© 2009 Microchip Technology Inc. DS39755C-page 19

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RB0/INT0/FLT0/AN12

RB0

INT0

FLT0

AN12

RB1/INT1/AN10

RB1

INT1

AN10

RB2/INT2/AN8

RB2

INT2

AN8

RB3/AN9/CCP2

RB3

AN9

(1)

CCP2

RB4/KBI0/AN11

RB4

KBI0

AN11

RB5/KBI1/PGM

RB5

KBI1

PGM

RB6/KBI2/PGC

RB6

KBI2

PGC

RB7/KBI3/PGD

RB7

KBI3

PGD

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

Pin Number

PDIP QFN TQFP

33 9 8

34 10 9

35 11 10

36 12 11

37 14 14

38 15 15

39 16 16

40 17 17

Pin

Type

I/O

I

I

I

I/O

I

I

I/O

I

I

I/O

I

I/O

I/O

I

I

I/O

I

I/O

I/O

I

I/O

I/O

I

I/O

Buffer

Typ e

TTL

ST

ST

Analog

TTL

ST

Analog

TTL

ST

Analog

TTL

Analog

ST

TTL

TTL

Analog

TTL

TTL

ST

TTL

TTL

ST

TTL

TTL

ST

Description

PORTB is a bidirectional I/O port. PORTB can be

software programmed for internal weak pull-ups on all

inputs.

Digital I/O.

External Interrupt 0.

PWM Fault input for Enhanced CCP1.

Analog Input 12.

Digital I/O.

External Interrupt 1.

Analog Input 10.

Digital I/O.

External Interrupt 2.

Analog Input 8.

Digital I/O.

Analog Input 9.

Capture 2 input/Compare 2 output/PWM2 output.

Digital I/O.

Interrupt-on-change pin.

Analog Input 11.

Digital I/O.

Interrupt-on-change pin.

Low-Voltage ICSP™ Programming enable pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming

clock pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming

data pin.

DS39755C-page 20 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RC0/T1OSO/T13CKI

RC0

T1OSO

T13CKI

RC1/T1OSI/CCP2

RC1

T1OSI

(2)

CCP2

RC2/CCP1/P1A

RC2

CCP1

P1A

RC3/SCK/SCL

RC3

SCK

SCL

RC4/SDI/SDA

RC4

SDI

SDA

RC5/SDO

RC5

SDO

RC6/TX/CK

RC6

TX

CK

RC7/RX/DT

RC7

RX

DT

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

Pin Number

PDIP QFN TQFP

15 34 32

16 35 35

17 36 36

18 37 37

23 42 42

24 43 43

25 44 44

26 1 1

Pin

Buffer

Type

I/O

O

I

I/O

I

CMOS

I/O

I/O

I/O

O

I/O

I/O

I/O

I/O

I

I/O

I/OOST

I/O

O

I/O

I/O

I

I/O

Typ e

PORTC is a bidirectional I/O port.

ST

ST

ST

ST

ST

ST

ST

ST

I

ST

ST

I

ST

ST

ST

ST

ST

—

—

2

2

—

—

Digital I/O.

Timer1 oscillator output.

Timer1/Timer3 external clock input.

Digital I/O.

Timer1 oscillator input.

Capture 2 input/Compare 2 output/PWM2 output.

Digital I/O.

Capture 1 input/Compare 1 output/PWM1 output.

Enhanced CCP1 output.

Digital I/O.

Synchronous serial clock input/output for

SPI mode.

C

Synchronous serial clock input/output for I2C™ mode.

Digital I/O.

SPI data in.

C

2

C data I/O.

I

Digital I/O.

SPI data out.

Digital I/O.

EUSART asynchronous transmit.

EUSART synchronous clock (see related RX/DT).

Digital I/O.

EUSART asynchronous receive.

EUSART synchronous data (see related TX/CK).

Description

© 2009 Microchip Technology Inc. DS39755C-page 21

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RD0/PSP0

RD0

PSP0

RD1/PSP1

RD1

PSP1

RD2/PSP2

RD2

PSP2

RD3/PSP3

RD3

PSP3

RD4/PSP4

RD4

PSP4

RD5/PSP5/P1B

RD5

PSP5

P1B

RD6/PSP6/P1C

RD6

PSP6

P1C

RD7/PSP7/P1D

RD7

PSP7

P1D

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2

C=I2C™/SMBus

I

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

Pin Number

PDIP QFN TQFP

19 38 38

20 39 39

21 40 40

22 41 41

27 2 2

28 3 3

29 4 4

30 5 5

Pin

Buffer

Type

Typ e

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/O

TTL

O

I/O

I/O

TTL

O

I/O

I/O

TTL

O

Description

PORTD is a bidirectional I/O port or a Parallel Slave

Port (PSP) for interfacing to a microprocessor port.

These pins have TTL input buffers when the PSP

module is enabled.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

ST

—

ST

—

ST

—

Digital I/O.

Parallel Slave Port data.

Enhanced CCP1 output.

Digital I/O.

Parallel Slave Port data.

Enhanced CCP1 output.

Digital I/O.

Parallel Slave Port data.

Enhanced CCP1 output.

DS39755C-page 22 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RE0/RD

RE1/WR/AN6

RE2/CS

RE3 — — — — — See MCLR

V

V

NC — 13 12, 13,

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

Note 1: Default assignment for CCP2 when Configuration bit, CCP2MX, is set.

/AN5

RE0

RD

AN5

RE1

WR

AN6

/AN7

RE2

CS

AN7

SS 12, 31 6, 30,

DD 11, 32 7, 8,

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2

C=I2C™/SMBus

I

2: Alternate assignment for CCP2 when Configuration bit, CCP2MX, is cleared.

Pin Number

PDIP QFN TQFP

82525

92626

10 27 27

6, 29 P — Ground reference for logic and I/O pins.

31

7, 28 P — Positive supply for logic and I/O pins.

28, 29

33, 34

Pin

Buffer

Type

Typ e

PORTE is a bidirectional I/O port.

I/O

I/O

I/O

— — No connect.

I

I

I

I

I

I

ST

TTL

Analog

ST

TTL

Analog

ST

TTL

Analog

Digital I/O.

Read control for Parallel Slave Port

(see also WR

Analog Input 5.

Digital I/O.

Write control for Parallel Slave Port

(see CS

Analog Input 6.

Digital I/O.

Chip select control for Parallel Slave Port

(see related RD

Analog Input 7.

Description

and CS pins).

and RD pins).

and WR).

/VPP/RE3 pin.

© 2009 Microchip Technology Inc. DS39755C-page 23

PIC18F2423/2523/4423/4523

NOTES:

DS39755C-page 24 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

2.0 12-BIT ANALOG-TO-DIGITAL CONVERTER (A/D) MODULE

The Analog-to-Digital (A/D) Converter module has

10 inputs for the PIC18F2423/2523 devices and 13 for

the PIC18F4423/4523 devices. This module allows

conversion of an analog input signal to a corresponding

12-bit digital number.

The module has five registers:

• A/D Result High Register (ADRESH)

• A/D Result Low Register (ADRESL)

• A/D Control Register 0 (ADCON0)

• A/D Control Register 1 (ADCON1)

• A/D Control Register 2 (ADCON2)

Of the ADCONx registers:

• ADCON0 (shown in Register 2-1) – Controls the

module’s operation

• ADCON1 (Register 2-2) – Configures the

functions of the port pins

• ADCON2 (Register 2-3) – Configures the A/D

clock source, programmed acquisition time and

justification

REGISTER 2-1: ADCON0: A/D CONTROL REGISTER 0

U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— — CHS3 CHS2 CHS1 CHS0 GO/DONE ADON

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-6 Unimplemented: Read as ‘0’

bit 5-2 CHS<3:0>: Analog Channel Select bits

0000 = Channel 0 (AN0)

0001 = Channel 1 (AN1)

0010 = Channel 2 (AN2)

0011 = Channel 3 (AN3)

0100 = Channel 4 (AN4)

0101 = Channel 5 (AN5)

0110 = Channel 6 (AN6)

0111 = Channel 7 (AN7)

1000 = Channel 8 (AN8)

1001 = Channel 9 (AN9)

1010 = Channel 10 (AN10)

1011 = Channel 11 (AN11)

1100 = Channel 12 (AN12

1101 = Unimplemented

1110 = Unimplemented

1111 = Unimplemented

bit 1 GO/DONE

When ADON =

1 = A/D conversion in progress

0 = A/D Idle

bit 0 ADON: A/D On bit

1 = A/D Converter module is enabled

0 = A/D Converter module is disabled

: A/D Conversion Status bit

1:

(2)

(2)

(2)

(1,2)

(1,2)

(1,2)

Note 1: These channels are not implemented on PIC18F2423/2523 devices.

2: Performing a conversion on unimplemented channels will return a floating input measurement.

© 2009 Microchip Technology Inc. DS39755C-page 25

PIC18F2423/2523/4423/4523

A = Analog input D = Digital I/O

PCFG<3:0>

AN12

AN11

AN10

AN9

AN8

AN7

(2)

AN6

(2)

AN5

(2)

AN4

AN3

AN2

AN1

AN0

0000

(1)

A A AAAAAAAAAAA

0001 AA A AAAAAAAAAA

0010 AA A AAAAAAAAAA

0011 D A AAAAAAAAAAA

0100 DDAAAAAAAAAAA

0101 DDDAAAAAAAAAA

0110 DDDDAAAAAAAAA

0111

(1)

DDDDDAAAAAAAA

1000 D D DDDDAAAAAAA

1001 D D DDDDDAAAAAA

1010 D D DDDDDDAAAAA

1011 D D DDDDDDDAAAA

1100 D D DDDDDDDDAAA

1101 D D DDDDDDDDDAA

1110 D D DDDDDDDDDDA

1111 D D DDDDDDDDDDD

REGISTER 2-2: ADCON1: A/D CONTROL REGISTER 1

U-0 U-0 R/W-0 R/W-0 R/W-0

(1)

— — VCFG1 VCFG0 PCFG3 PCFG2 PCFG1 PCFG0

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-6 Unimplemented: Read as ‘0’

bit 5 VCFG1: Voltage Reference Configuration bit (V

1 = V

REF- (AN2)

0 = V

SS

REF- source)

bit 4 VCFG0: Voltage Reference Configuration bit (VREF+ source)

REF+ (AN3)

1 = V

DD

0 = V

bit 3-0 PCFG<3:0>: A/D Port Configuration Control bits:

R/W

(1)

R/W

(1)

R/W

(1)

Note 1: The POR value of the PCFG bits depends on the value of the PBADEN Configuration bit. When

PBADEN = 1, PCFG<3:0> = 0000; when PBADEN = 0, PCFG<3:0> = 0111.

2: AN5 through AN7 are only available on PIC18F4423/4523 devices.

DS39755C-page 26 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

REGISTER 2-3: ADCON2: A/D CONTROL REGISTER 2

R/W-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

ADFM — ACQT2 ACQT1 ACQT0 ADCS2 ADCS1 ADCS0

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 ADFM: A/D Result Format Select bit

1 = Right justified

0 = Left justified

bit 6 Unimplemented: Read as ‘0’

bit 5-3 ACQT<2:0>: A/D Acquisition Time Select bits

111 = 20 T

110 = 16 TAD

101 = 12 TAD

100 = 8 TAD

011 = 6 TAD

010 = 4 TAD

001 = 2 TAD

000 = 0 TAD

bit 2-0 ADCS<2:0>: A/D Conversion Clock Select bits

111 = FRC (clock derived from A/D RC oscillator)

110 = F

101 = F

100 = F

011 = F

010 = F

001 = F

000 = F

AD

(1)

OSC/64

OSC/16

OSC/4

RC (clock derived from A/D RC oscillator)

OSC/32

OSC/8

OSC/2

(1)

(1)

Note 1: If the A/D F

RC clock source is selected, a delay of one TCY (instruction cycle) is added before the A/D

clock starts. This allows the SLEEP instruction to be executed before starting a conversion.

© 2009 Microchip Technology Inc. DS39755C-page 27

PIC18F2423/2523/4423/4523

(Input Voltage)

V

AIN

VREF+

Reference

Voltage

V

DD

(2)

VCFG<1:0>

CHS<3:0>

AN7

(1)

AN6

(1)

AN5

(1)

AN4

AN3

AN2

AN1

AN0

0111

0110

0101

0100

0011

0010

0001

0000

12-Bit

A/D

VREF-

VSS

(2)

Converter

AN12

AN11

AN10

AN9

AN8

1100

1011

1010

1001

1000

Note 1: Channels, AN5 through AN7, are not available on PIC18F2423/2523 devices.

2: I/O pins have diode protection to VDD and VSS.

0X

1X

X

1

X0

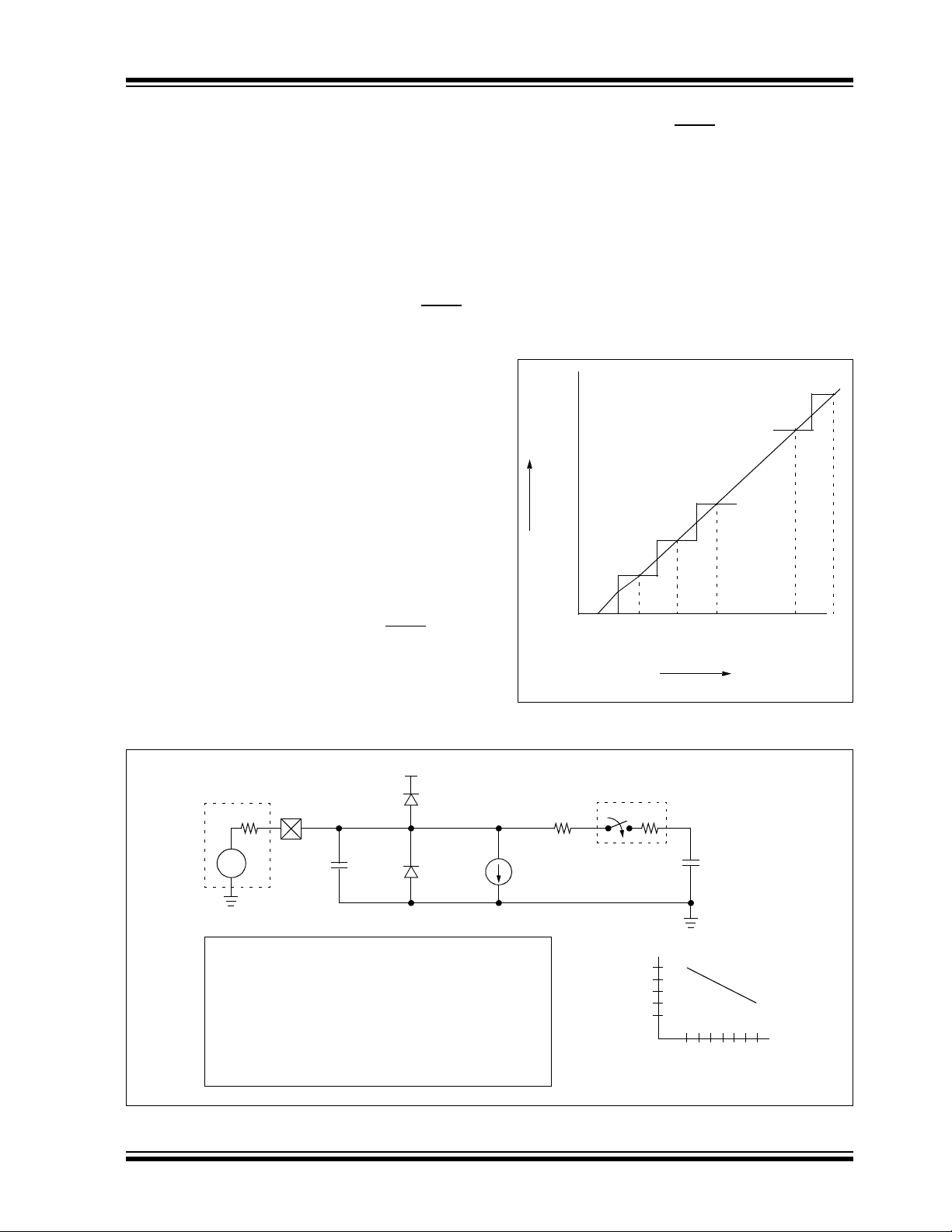

The analog reference voltage is software selectable to

either the device’s positive and negative supply voltage

(VDD and VSS), or the voltage level on the RA3/AN3/

REF+ and RA2/AN2/VREF-/CVREF pins.

V

The A/D Converter has a unique feature of being able

to operate while the device is in Sleep mode. To operate in Sleep, the A/D conversion clock must be derived

from the A/D’s internal RC oscillator.

The output of the sample and hold is the input into the

converter, which generates the result via successive

approximation.

FIGURE 2-1: A/D BLOCK DIAGRAM

A device Reset forces all registers to their Reset state.

This forces the A/D module to be turned off and any

conversion in progress is aborted.

Each port pin associated with the A/D Converter can be

configured as an analog input or as a digital I/O. The

ADRESH and ADRESL registers contain the result of

the A/D conversion. When the A/D conversion is complete, the result is loaded into the ADRESH:ADRESL

register pair, the GO/DONE

bit (ADCON0<1>) is cleared

and A/D Interrupt Flag bit, ADIF, is set.

The block diagram of the A/D module is shown in

Figure 2-1.

DS39755C-page 28 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

Digital Code Output

FFEh

003h

002h

001h

000h

0.5 LSB

1 LSB

1.5 LSB

2 LSB

2.5 LSB

4094 LSB

4094.5 LSB

3 LSB

Analog Input Voltage

FFFh

4095 LSB

4095.5 LSB

VAIN

CPIN

Rs

ANx

5 pF

V

T = 0.6V

V

T = 0.6V

I

LEAKAGE

RIC ≤ 1k

Sampling

Switch

SS

R

SS

CHOLD = 25 pF

V

SS

VDD

±100 nA

Legend: CPIN

VT

ILEAKAGE

RIC

SS

C

HOLD

= Input Capacitance

= Threshold Voltage

= Leakage Current at the pin due to

= Interconnect Resistance

= Sampling Switch

= Sample/Hold Capacitance (from DAC)

various junctions

= Sampling Switch ResistanceRSS

VDD

6V

Sampling Switch

5V

4V

3V

2V

1234

(kΩ)

The value in the ADRESH:ADRESL registers is

unknown following POR and BOR Resets and is not

affected by any other Reset.

After the A/D module has been configured as desired,

the selected channel must be acquired before the

conversion is started. The analog input channels must

have their corresponding TRIS bits selected as inputs.

To determine acquisition time, see Section 2.1 “A/D

Acquisition Requirements”.

After this acquisition time has elapsed, the A/D conversion can be started. An acquisition time can be

programmed to occur between setting the GO/DONE

bit and the actual start of the conversion.

The following steps should be followed to perform an A/D

conversion:

1. Configure the A/D module:

• Configure analog pins, voltage reference and

digital I/O (ADCON1)

• Select A/D input channel (ADCON0)

• Select A/D acquisition time (ADCON2)

• Select A/D conversion clock (ADCON2)

• Turn on the A/D module (ADCON0)

2. Configure the A/D interrupt (if desired):

• Clear ADIF bit

• Set ADIE bit

• Set GIE bit

3. Wait the required acquisition time (if required).

4. Start conversion by setting the GO/DONE

bit

(ADCON0<1>).

5. Wait for the A/D conversion to complete by either:

• Polling for the GO/DONE

bit to be cleared

OR

• Waiting for the A/D interrupt

6. Read the A/D Result registers (ADRESH:ADRESL)

and clear the ADIF bit, if required.

7. For the next conversion, go to step 1 or step 2,

as required.

The A/D conversion time per bit is defined as

AD. A minimum wait of 2 TAD is required before

T

the next acquisition starts.

FIGURE 2-2: A/D TRANSFER FUNCTION

FIGURE 2-3: ANALOG INPUT MODEL

© 2009 Microchip Technology Inc. DS39755C-page 29

PIC18F2423/2523/4423/4523

2.1 A/D Acquisition Requirements

For the A/D Converter to meet its specified accuracy,

the charge holding capacitor (C

to fully charge to the input channel voltage level. The

analog input model is shown in Figure 2-3.

The source impedance (R

switch (R

SS) impedance directly affect the time

required to charge the capacitor, C

switch (R

(V

SS) impedance varies over the device voltage

DD). The source impedance affects the offset voltage

at the analog input (due to pin leakage current). The

maximum recommended impedance for analog

sources is 2.5 kΩ.

After the analog input channel is selected (changed),

the channel must be sampled for at least the minimum

acquisition time before starting a conversion.

HOLD) must be allowed

S) and the internal sampling

HOLD. The sampling

To calculate the minimum acquisition time, Equation 2-1

may be used. This equation assumes that 1/2 LSb error

is used (4,096 steps for the A/D). The 1/2 LSb error is the

maximum error allowed for the A/D to meet its specified

resolution.

Example 2-3 shows the calculation of the minimum

required acquisition time, T

based on the application system assumptions shown in

Table 2-1:

TABLE 2-1: TACQ ASSUMPTIONS

CHOLD = 25 pF

Rs = 2.5 kΩ

Conversion Error ≤ 1/2 LSb

DD =3V → Rss = 4 kΩ

V

Temperature = 85°C (system maximum)

Note: When the conversion is started, the

holding capacitor is disconnected from the

input pin.

EQUATION 2-1: ACQUISITION TIME

TACQ = Amplifier Settling Time + Holding Capacitor Charging Time + Temperature Coefficient

AMP + TC + TCOFF

=T

ACQ. This calculation is

EQUATION 2-2: A/D MINIMUM CHARGING TIME

VHOLD = (VREF – (VREF/4096)) • (1 – e

or

C = -(CHOLD)(RIC + RSS + RS) ln(1/4096)

T

(-TC/CHOLD(RIC + RSS + RS))

)

EQUATION 2-3: CALCULATING THE MINIMUM REQUIRED ACQUISITION TIME

T

ACQ =TAMP + TC + TCOFF

TAMP =0.2 μs

COFF = (Temp – 25°C)(0.02 μs/°C)

T

(85°C – 25°C)(0.02 μs/°C)

1.2 μs

Temperature coefficient is only required for temperatures > 25°C. Below 25°C, T

C = -(CHOLD)(RIC + RSS + RS) ln(1/4095) μs

T

-(25 pF) (1 kΩ + 4 kΩ + 2.5 kΩ) ln(0.0004883) μs

1.56 μs

ACQ =0.2 μs + 1.56 μs + 1.2 μs

T

2.96 μs

COFF = 0 ms.

DS39755C-page 30 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

2.2 Selecting and Configuring Acquisition Time

The ADCON2 register allows the user to select an

acquisition time that occurs each time the GO/DONE

bit is set. It also gives users the option of having an

automatically determined acquisition time.

Acquisition time may be set with the ACQT<2:0> bits

(ADCON2<5:3>), which provide a range of 2 to 20 T

When the GO/DONE

bit is set, the A/D module continues to sample the input for the selected acquisition

time, then automatically begins a conversion. Since the

acquisition time is programmed, there may be no need

to wait for an acquisition time between selecting a

channel and setting the GO/DONE

bit.

Manual acquisition time is selected when

ACQT<2:0> = 000. When the GO/DONE

bit is set,

sampling is stopped and a conversion begins. The user

is responsible for ensuring the required acquisition time

has passed between selecting the desired input

channel and setting the GO/DONE

bit. This option is

also the default Reset state of the ACQT<2:0> bits and

is compatible with devices that do not offer

programmable acquisition times.

In either case, when the conversion is completed, the

GO/DONE

bit is cleared, the ADIF flag is set and the

A/D begins sampling the currently selected channel

again. If an acquisition time is programmed, there is

nothing to indicate if the acquisition time has ended or

if the conversion has begun.

AD.

2.3 Selecting the A/D Conversion Clock

The A/D conversion time per bit is defined as TAD. The

A/D conversion requires 13 T

The source of the A/D conversion clock is software

selectable.

There are seven possible options for T

•2 TOSC • 32 TOSC

•4 TOSC • 64 TOSC

•8 TOSC • Internal RC Oscillator

OSC

•16 T

For correct A/D conversions, the A/D conversion clock

(T

AD) must be as short as possible, but greater than the

minimum T

AD. (For more information, see parameter 130

on page 41.)

Table 2-2 shows the resultant T

the device operating frequencies and the A/D clock

source selected.

AD per 12-bit conversion.

AD:

AD times derived from

TABLE 2-2: TAD vs. DEVICE OPERATING FREQUENCIES

A/D Clock Source (TAD)

Operation ADCS<2:0> Maximum F

2 TOSC 000 2.50 MHz

4 TOSC 100 5.00 MHz

OSC 001 10.00 MHz

8 T

16 TOSC 101 20.00 MHz

32 T

OSC 010 40.00 MHz

OSC 110 40.00 MHz

64 T

(2)

RC

x11 1.00 MHz

Note 1: The RC source has a typical TAD time of 2.5 μs.

2: For device frequencies above 1 MHz, the device must be in Sleep for the entire conversion or a F

divider should be used instead; otherwise, the A/D accuracy specification may not be met.

Assumes T

AD Min. = 0.8 μs

OSC

(1)

OSC

© 2009 Microchip Technology Inc. DS39755C-page 31

PIC18F2423/2523/4423/4523

2.4 Operation in Power-Managed Modes

The selection of the automatic acquisition time and A/D

conversion clock is determined in part by the clock

source and frequency while in a power-managed mode.

If the A/D is expected to operate while the device is in

a power-managed mode, the ADCS<2:0> bits in

ADCON2 should be updated in accordance with the

clock source to be used. The ACQT<2:0> bits do not

need to be adjusted as the ADCS<2:0> bits adjust the

AD time for the new clock speed. After entering the

T

mode, an A/D acquisition or conversion may be started.

Once started, the device should continue to be clocked

by the same clock source until the conversion has been

completed.

If desired, the device may be placed into the

corresponding Idle mode during the conversion. If the

device clock frequency is less than 1 MHz, the A/D RC

clock source should be selected.

Operation in Sleep mode requires the A/D F

be selected. If bits, ACQT<2:0>, are set to ‘000’ and a

conversion is started, the conversion will be delayed

one instruction cycle to allow execution of the SLEEP

instruction and entry to Sleep mode. The IDLEN bit

(OSCCON<7>) must have already been cleared prior

to starting the conversion.

RC clock to

2.5 Configuring Analog Port Pins

The ADCON1, TRISA, TRISB and TRISE registers all

configure the A/D port pins. The port pins needed as

analog inputs must have their corresponding TRIS bits

set (input). If the TRIS bit is cleared (output), the digital

output level (V

The A/D operation is independent of the state of the

CHS<3:0> bits and the TRIS bits.

Note 1: When reading the PORT register, all pins

OH or VOL) will be converted.

configured as analog input channels will

read as cleared (a low level). Analog conversion on pins configured as digital pins

can be performed. The voltage on the pin

will be accurately converted.

2: Analog levels on any pin defined as a

digital input may cause the digital input

buffer to consume current out of the

device’s specification limits.

3: The PBADEN bit in Configuration

Register 3H configures PORTB pins to

reset as analog or digital pins by controlling

how the PCFG<3:0> bits in ADCON1 are

reset.

DS39755C-page 32 © 2009 Microchip Technology Inc.

PIC18F2423/2523/4423/4523

TAD1 TAD2 TAD3 TAD4 TAD5 TAD6 TAD7 TAD8 TAD11

Set GO/DONE bit

Holding capacitor is disconnected from analog input (typically 100 ns)

TAD9 TAD10TCY – TAD

ADRESH:ADRESL are loaded, GO/DONE bit is cleared,

ADIF bit is set, holding capacitor is connected to analog input.

Conversion starts

b2

b11

b8

b7