PIC16F627A/628A/648A

Data Sheet

Flash-Based, 8-Bit CMOS

Microcontrollers with nanoWatt Technology

© 2007 Microchip Technology Inc. DS40044F

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, PowerSmart, rfPIC, an d

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MX DEV, MXLAB, PS logo, SEEVAL, SmartSensor

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartT el, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC® DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

DS40044F-page ii © 2007 Microchip Technology Inc.

®

PIC16F627A/628A/648A

18-pin Flash-Based, 8-Bit CMOS Microcontrollers

with nanoWatt Technology

High-Performance RISC CPU:

• Operating speeds from DC – 20 MHz

• Interrupt capability

• 8-level deep hardware stack

• Direct, Indirect and Relative Addressing modes

• 35 single-word instructions:

- All instructions single cycle except branches

Special Microcontroller Features:

• Internal and external oscilla tor opti ons :

- Precision internal 4MHz oscillator factory

calibrated to ±1%

- Low-power internal 48kHz oscillator

- External Oscillator support for crystals and

resonators

• Power-saving Sleep mode

• Programmable weak pull-u p s on PORTB

• Multiplexed Master Clear/In put -pin

• Watchdog Timer with independent osc illator for

reliable operation

• Low-voltage program mi ng

• In-Circuit Serial Programming™ (via two pins)

• Programmable code protection

• Brown-out Reset

• Power-on R eset

• Power-up Timer and Oscillator Start-up Timer

• Wide operating voltage range (2.0-5.5V)

• Industrial and extended temperature range

• High-Endurance Flash/EEPROM cell:

- 100,000 write Flash endurance

- 1,000,000 write EEPROM endurance

- 40 year data retention

Low-Power Features:

• Standby Current:

- 100 nA @ 2.0V, typical

• Operating Current:

-12μA @ 32 kHz, 2.0V, typical

-120μA @ 1 MHz, 2.0V, typical

• Watchdog Timer Current:

-1μA @ 2.0V, typical

• Timer1 Oscillator Current:

-1.2μA @ 32 kHz, 2.0V, typical

• Dual-speed Internal Oscillator:

- Run-time selectable betwe en 4MHz and

48 kHz

-4μs wake-up from Sleep, 3.0V, typical

Peripheral Features:

• 16 I/O pins with indiv idual direction control

• High current sink/source for direct LED drive

• Analog comparator module with:

- Two analog compara tors

- Programmable on-chip voltage reference

(V

REF) module

- Selectable internal or external reference

- Comparator outputs are externally accessible

• Timer0: 8-bit timer/counter with 8-bit

programmable prescaler

• Timer1: 16-bit timer/counter with external crystal/

clock capability

• Timer2: 8-bit timer/counter with 8-bit period

register, prescaler and postscaler

• Capture, Compare, PWM mo dul e:

- 16-bit Capture/Compare

-10-bit PWM

• Addressable Universal Synchronous/Asynchronous

Receiver/T ra nsmitt er USAR T/SCI

Program

Device

PIC16F627A 1024 224 128 16 1 Y 2 2/1

PIC16F628A 2048 224 128 16 1 Y 2 2/1

PIC16F648A 4096 256 256 16 1 Y 2 2/1

© 2007 Microchip Technology Inc. DS40044F-page 1

Memory

Flash

(words)

Data Memory

SRAM

(bytes)

EEPROM

(bytes)

I/O

CCP

(PWM)

USART Comparators

Timers

8/16-bit

PIC16F627A/628A/648A

Pin Diagrams

PDIP, SOIC

SSOP

RA2/AN2/V

RA3/AN3/CMP1

RA4/T0CKI/CMP2

RA5/MCLR

RA6/OSC2/CLKOUT

RA7/OSC1/CLKIN

VDD

RA1/AN1

RA0/AN0

19181615141312

20

PIC16F627A/628A/648A

2 3 4 5 6 7 8 910

1

REF

RA2/AN2/V

RA3/AN3/CMP1

VDD

RB6/T1OSO/T1CKI/PGC

RB7/T1OSI/PGD

17

SS

VSS

V

/VPP

RB0/INT

RB1/RX/DT

RA5/MCLR

RA4/T0CKI/CMP2

RB0/INT

RB1/RX/DT

RB2/TX/CK

RB3/CCP1

RB4/PGM

RB5

11

RB3/CCP1

RB2/TX/CK

REF

/VPP

VSS

118

27A/628A/648A

PIC16F627A/628A/648A

28-Pin

RB0/INT

17

16

15

14

13

12

11

10

QFN

VSS

VSS

2

3

4

5

6

7

8

9

RA5/MCLR/VPP

RA1/AN1

RA0/AN0

RA7/OSC1/CLKIN

RA6/OSC2/CLKOUT

DD

V

RB7/T1OSI/PGD

RB6/T1OSO/T1CKI/PGC

RB5

RB4/PGM

RA2/AN2/VREF

RA3/AN3/CMP1

RA4/T0CKI/CMP2

2827262524

1

NC

2

3

PIC16F627A/628A

NC

4

PIC16F648A

5

NC

6

7

8

9

10

RB3/CCP1

RB2/TX/CK

RB1/RX/DT

NC

11

NC

RA1/AN1

12

RB4/PGM

RA0/AN0

23

13

RB5

NC

22

21

20

19

18

17

16

15

14

NC

RA7/OSC1/CLKIN

RA6/OSC2/CLKOUT

V

DD

NC

VDD

RB7/T1OSI/PGD

RB6/T1OSO/T1CKI/PGC

DS40044F-page 2 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

Table of Contents

1.0 General Description............................................................................ ....... .... .. .... .. .... .................................................................. 5

2.0 PIC16F627A/628A/648A Device Varieties.................................................................................................................................. 7

3.0 Architectural Overview................................................................................................................................................................ 9

4.0 Memory Organization................................................................................................................................................................ 15

5.0 I/O Ports................ .................................................................................................................................................................... 31

6.0 Timer0 Module .......................................................................................................................................................................... 45

7.0 Timer1 Module .......................................................................................................................................................................... 48

8.0 Timer2 Module .......................................................................................................................................................................... 52

9.0 Capture/Compare/PWM (CCP) Module .................................................................................................................................... 55

10.0 Comparator Module................................................................................................................................................................... 61

11.0 Voltage Reference Module........................................................................ .. .. .... .. .. .. .. ....... .. .. ..................................................... 67

12.0 Universal Synchronous Asynchronous Receiver Transmitter (USART) Module....................................................................... 7 1

13.0 Data EEPROM Memory................... ......................................................................................................................................... 89

14.0 Special Features of the CPU..................................... ................................................................................................................ 95

15.0 Instruction Set Summary......................................................................................................................................................... 115

16.0 Development Support.............................................................................................................................................................. 129

17.0 Electrical Specifications........................................................................................................................................................... 133

18.0 DC and AC Characteristics Graphs and Tables...................................................................................................................... 149

19.0 Packaging Information. .......................................................................................... .................................................................. 161

Appendix A: Revision History............................................................................................................................................................ 167

Appendix B: Device Differences ....................................................................................................................................................... 167

Appendix C: Device Migrations - PIC16C63/65A/73A/74A —> PIC16C63A/65B/73B/74B.............................................................. 168

Appendix D: Migration from Baseline to Mid-Range Devices ........................................................................................................... 168

The Microchip Web Site.................................................................................................................................................................... 169

Customer Change Notification Service ............................................................................................................................................. 169

Customer Support............................................................................................................................................................................. 169

Reader Response............................................................................................................................................................................. 170

Product Identification System........................................................................................................................................................... 175

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with t he best docume ntation possible to ensure successf ul use of your Mic rochip products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined

and enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

© 2007 Microchip Technology Inc. DS40044F-page 3

PIC16F627A/628A/648A

NOTES:

DS40044F-page 4 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

1.0 GENERAL DESCRIPTION

The PIC16F627A/628A/648A are 18-pin Flash-based

members of the versatile PIC16F627A/628A/648A

family of low-cost, high-performance, CMOS, fullystatic, 8-bit microcontrollers.

®

All PIC

architecture. The PIC16F627A/628A/648A have

enhanced core f eatures, a n eight-le vel dee p stac k, and

multiple internal and external interrupt sources. The

separate instruction and data buses of the Harvard

architecture allow a 14-bit wide instruction word with

the separate 8-bit wide data. The two-stage instruction

pipeline allows all instructions to execute in a singlecycle, except for program branche s (which require two

cycles). A to tal of 35 instruction s (reduced instr uction

set) are available, complemented by a large register

set.

PIC16F627A/628A/648A microcontrollers typically

achieve a 2:1 code compression and a 4:1 speed

improvement over other 8-bit microcontrollers in their

class.

PIC16F627A/628A/648A devices have integrated

features to reduce ex ternal com ponent s, th us redu cing

system cost, enha ncing system reliability an d re ducing

power consumption.

The PIC16F627A/628A/648A has 8 oscillator

configurations. The single-pin RC oscillator provides a

low-cost solution. The LP oscillator minimizes power

consumption, XT is a standard crystal, and INTOSC is

a self-contain ed precis ion two-spee d internal o scillator.

microcontrollers employ an advanced RISC

The HS mode is for High-Speed cryst als. The EC mode

is for an external clock source.

The Sleep (Power-down) mode offers power savings.

Users can wake-up the chip from Sleep through several

external interrupts, internal interrupts and Resets.

A highly reliable Watchdog Timer with its own on-chip

RC oscillator prov ides protection against softw are lockup.

Table 1-1 shows the features of the PIC16F627A/628A/

648A mid-range mi c r oc o n t ro l l e r f a m ily.

A simplified block diagram of the PIC16F627A/628A/

648A is shown in Figure 3-1.

The PIC16F627A/628A/648A se rie s fit s in app lic ati on s

ranging from battery chargers to low power remote

sensors. The Flash technology makes customizing

application programs (detection levels, pulse generation, timers, etc.) extremely fast and convenient. The

small footprint packages makes this microcontroller

series ideal for all applications with space limitations.

Low cost, low power, high performance, ease of use

and I/O flexibility make the PIC16F627A/628A/648A

very versatile.

1.1 Development Support

The PIC16F627A/628A/648A family is supported by a

full-featured macr o assemble r , a software simulato r , an

in-circuit emul ator, a l ow c os t i n-c irc ui t d ebu gger, a l ow

cost development programmer and a full-featured

programmer. A Third Party “C” compiler support tool is

also available.

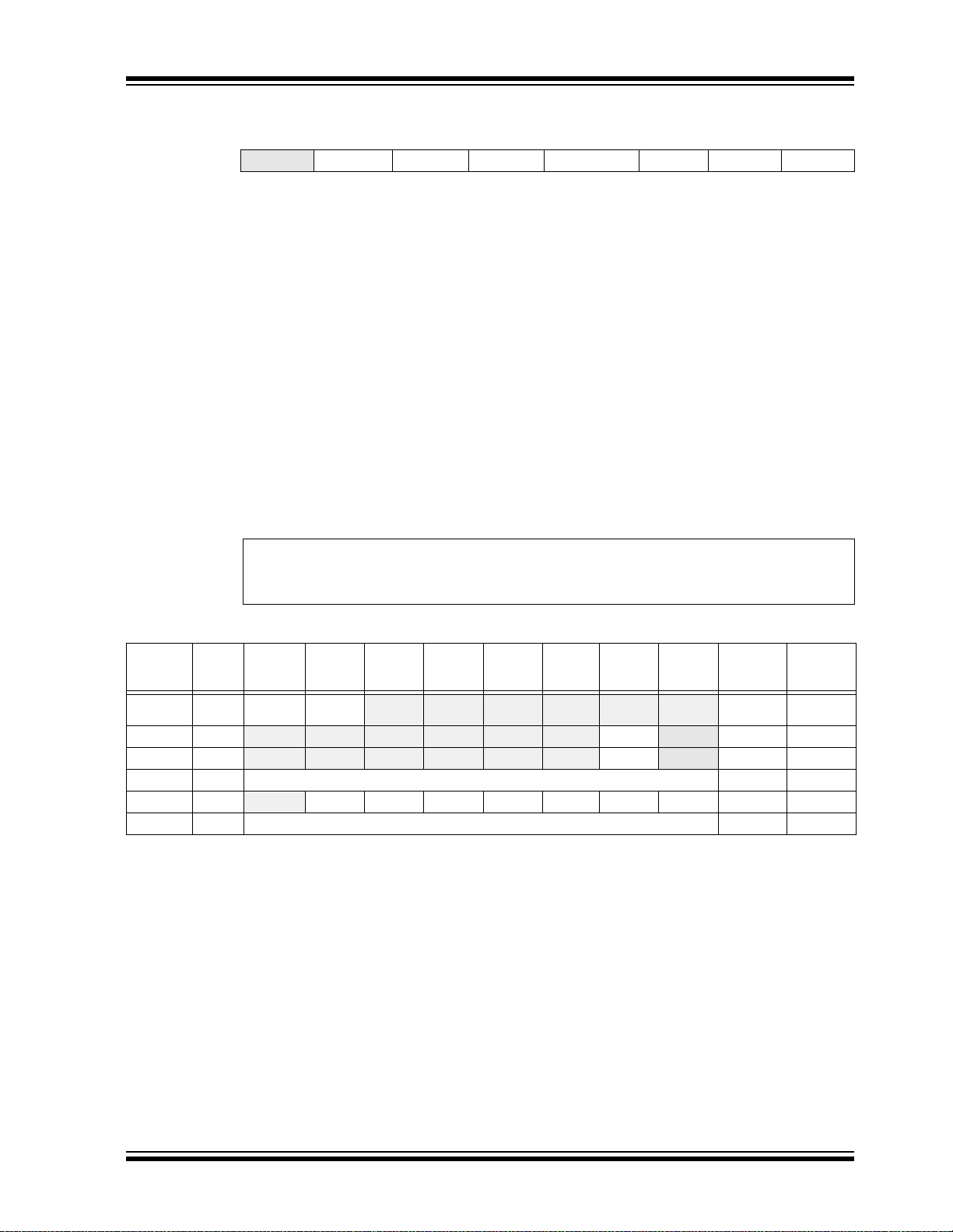

T ABLE 1-1: PIC16F627A/628A/648A FAMILY OF DEVICES

PIC16F627A PIC16F628A PIC16F648A PIC16LF627A PIC16LF628A PIC16LF648A

Clock Maximum Frequency

Memory RAM Data Memory

Peripherals Capture/Compare/

Features Voltage Range (Volts) 3.0-5.5 3.0-5.5 3.0-5.5 2.0-5.5 2.0-5.5 2.0-5.5

All PIC

All PIC16F627A/628A/648A family devices use serial programming with clock pin RB6 and data pin RB7.

of Operation (MHz)

Flash Program

Memory (words)

(bytes)

EEPROM Data

Memory (bytes)

Timer module(s) TMR0, TMR1,

Comparator(s) 222222

PWM modules

Serial Communications USART USART USART USART USART USART

Internal Voltage

Reference

Interrupt Sources101010101010

I/O Pins 16 16 16 16 16 16

Brown-out Reset Yes Yes Yes Yes Yes Yes

Packages 18-pin DIP,

®

family devices have Power-on Reset, selectable Watchdog Timer, selectable code-protect and high I/O current capability.

20 20 20 20 20 20

1024 2048 4096 1024 2048 4096

224 224 256 224 224 256

128 128 256 128 128 256

TMR2

111111

Yes Yes Yes Yes Yes Yes

SOIC, 20-pin

SSOP,

28-pin QFN

TMR0, TMR1,

TMR2

18-pin DIP,

SOIC, 20-pin

SSOP,

28-pin QFN

TMR0, TMR1,

TMR2

18-pin DIP,

SOIC, 20-pin

SSOP,

28-pin QFN

TMR0, TMR1,

TMR2

18-pin DIP,

SOIC, 20-pin

SSOP,

28-pin QFN

TMR0, TMR1,

TMR2

18-pin DIP,

SOIC, 20-pin

SSOP,

28-pin QFN

TMR0, TMR1,

TMR2

18-pin DIP,

SOIC, 20-pin

SSOP,

28-pin QFN

© 2007 Microchip Technology Inc. DS40044F-page 5

PIC16F627A/628A/648A

NOTES:

DS40044F-page 6 © 2007 Microchip Technology Inc.

2.0 PIC16F627A/628A/648A DEVICE VARIETIES

A variety of frequency ranges and packaging options

are available. Depen ding on applicati on and production

requirements, t he proper devic e option can be s elected

using the information in the PIC16F627A/628A/648A

Product Identification System, at the end of this data

sheet. When placing orders, please use this page of

the data sheet to specify the correct part number.

2.1 Flash Devices

Flash devices can be erased and re-programmed

electrically. This allows the same devi ce to be used for

prototype develo pment, pil ot prog rams and prod uction.

A further advantage of t he electri cally erasab le Flash i s

that it can be erased a nd reprogrammed in-c ircuit, or by

device program mers, such as Mi crochip’s PIC START

Plus or PRO MATE® II programmers.

2.2 Quick-Turnaround-Production (QTP) Devices

PIC16F627A/628A/648A

®

Microchip offers a QTP Programming Service for

factory production orders. This service is made

available for users who chose not to program a medium

to high quantity o f un its and whose code patterns have

stabilized. T he devic es are st andard Flash dev ices, but

with all program locations and configuration options

already programmed by the factory. Certain code and

prototype verification procedures apply before

production shipments are available. Please contact

your Microchip Technology sales office for more

details.

2.3 Serialized Quick-TurnaroundProduction (SQTP

Microchip offers a unique programming service where

a few user-defined locations in each device are

programmed with different serial numbers. The serial

numbers may be random, pseudo-random or

sequential.

Serial programming allows each device to have a

unique number, which can serve as an entry-code,

password or ID number.

SM

) Devices

© 2007 Microchip Technology Inc. DS40044F-page 7

PIC16F627A/628A/648A

NOTES:

DS40044F-page 8 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

3.0 ARCHITECTURAL OVERVIEW

The high performance of the PIC16F627A/628A/648A

family can be attributed to a number of architectural

features commonly fo und in RISC mic roproc esso rs. To

begin with, the PIC16F627A/628A/648A uses a

Harvard architecture in which program and data are

accessed from separate memories using separate

busses. This improves bandwidth over traditional Von

Neumann architecture where program and data are

fetched from the same memory. Separating program

and data memor y further allow s instructions to be sized

differently than 8-bit wide data word. Instruction

opcodes are 14-bits wide makin g it pos si ble to have all

single-word instructions. A 14-bit wide program memory access bus fetches a 14-bit instruction in a single

cycle. A two-stage pipeline overlaps fetch and execution of instructions. Consequently, all instructions (35)

execute in a single-cycle (200 ns @ 20 MHz) except for

program branches.

Table 3-1 lists device me mory sizes (Flash , Data and

EEPROM).

TABLE 3-1: DEVICE MEMORY LIST

Memory

Device

PIC16F627A 1024 x 14 224 x 8 128 x 8

PIC16F628A 2048 x 14 224 x 8 128 x 8

PIC16F648A 4096 x 14 256 x 8 256 x 8

PIC16LF627A 1024 x 14 224 x 8 128 x 8

PIC16LF628A 2048 x 14 224 x 8 128 x 8

PIC16LF648A 4096 x 14 256 x 8 256 x 8

Flash

Program

RAM

Data

EEPROM

Data

The PIC16F627A/628A/648A can directly or indirectly

address its register files or data memory. All Special

Function Registers (SFR), including the program

counter, are mapped in the data memory. The

PIC16F627A/628A/648A ha ve an orthogona l (symmetrical) instruction set that makes it possible to carry out

any operation, on any register, using any addressing

mode. This symmetrical nature and lack of ‘special

optimal situations’ makes programming with the

PIC16F627A/628A/648A simple yet efficient. In

addition, the learning curve is reduced significantly.

The PIC16F627A/628A/648A devices contain an 8-bit

ALU and working register. The ALU is a general

purpose arithmetic unit. It performs arithmetic and

Boolean functions be tween dat a in the work ing regist er

and any register file.

The ALU is 8-bits wide and capable of addition,

subtraction, shift and logical operations. Unless

otherwise me ntioned, arithmetic operations are two’s

complement in nature. In two-operand instructions,

typically one operand is the working register

(W register). The other operand is a file register or an

immediate const ant. In singl e operan d instru ction s, the

operand is either the W register or a file register.

The W register is an 8-bit workin g register used for ALU

operations. It is not an addressable register.

Depending on the instruction executed, the ALU may

affect the values of the Carry (C), Digit Carry (DC), and

Zero (Z) bits in the Status Register. The C and DC bits

operate as Borrow

respectively, in sub tractio n. See th e SUBLW and SUBWF

instructions for examples.

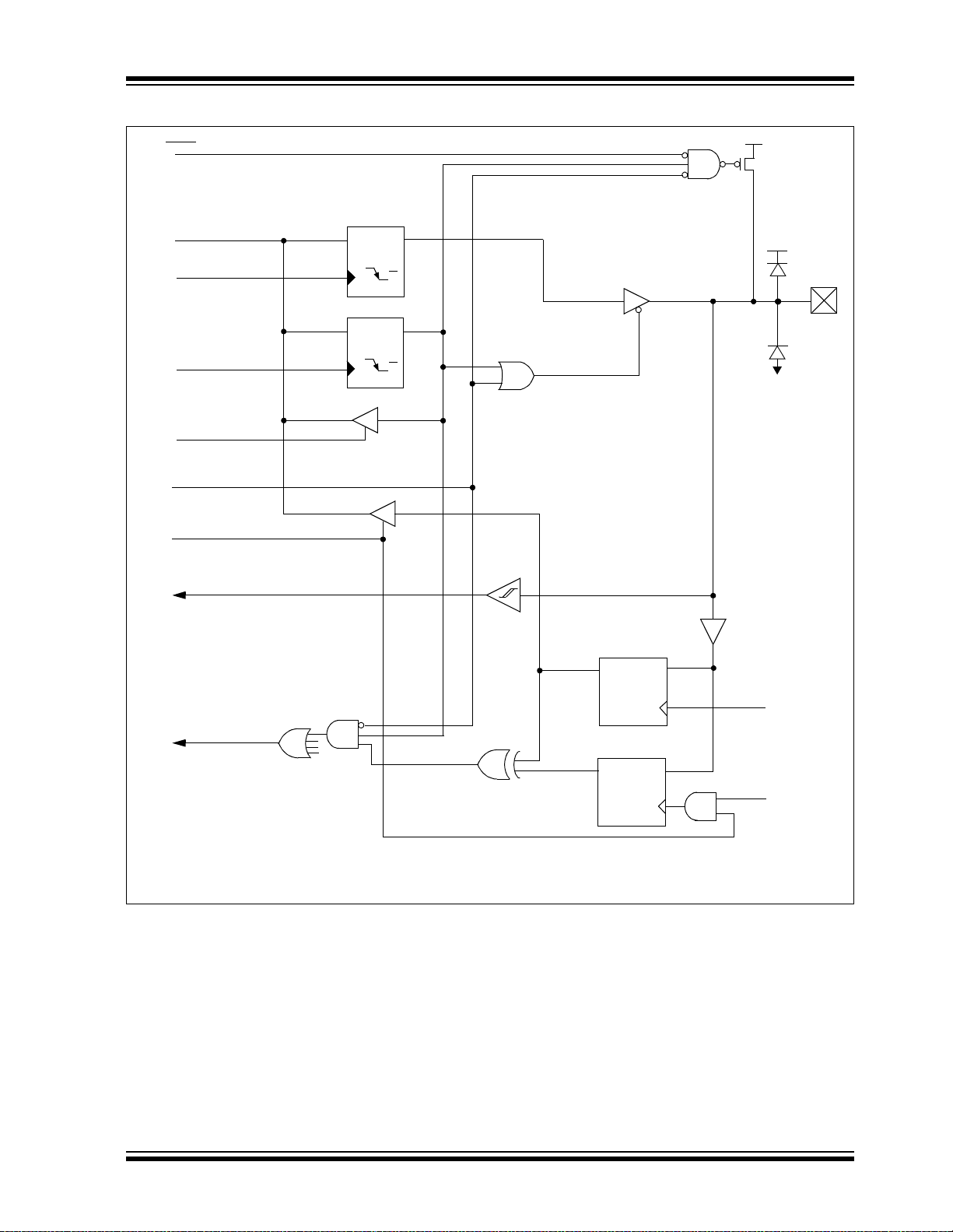

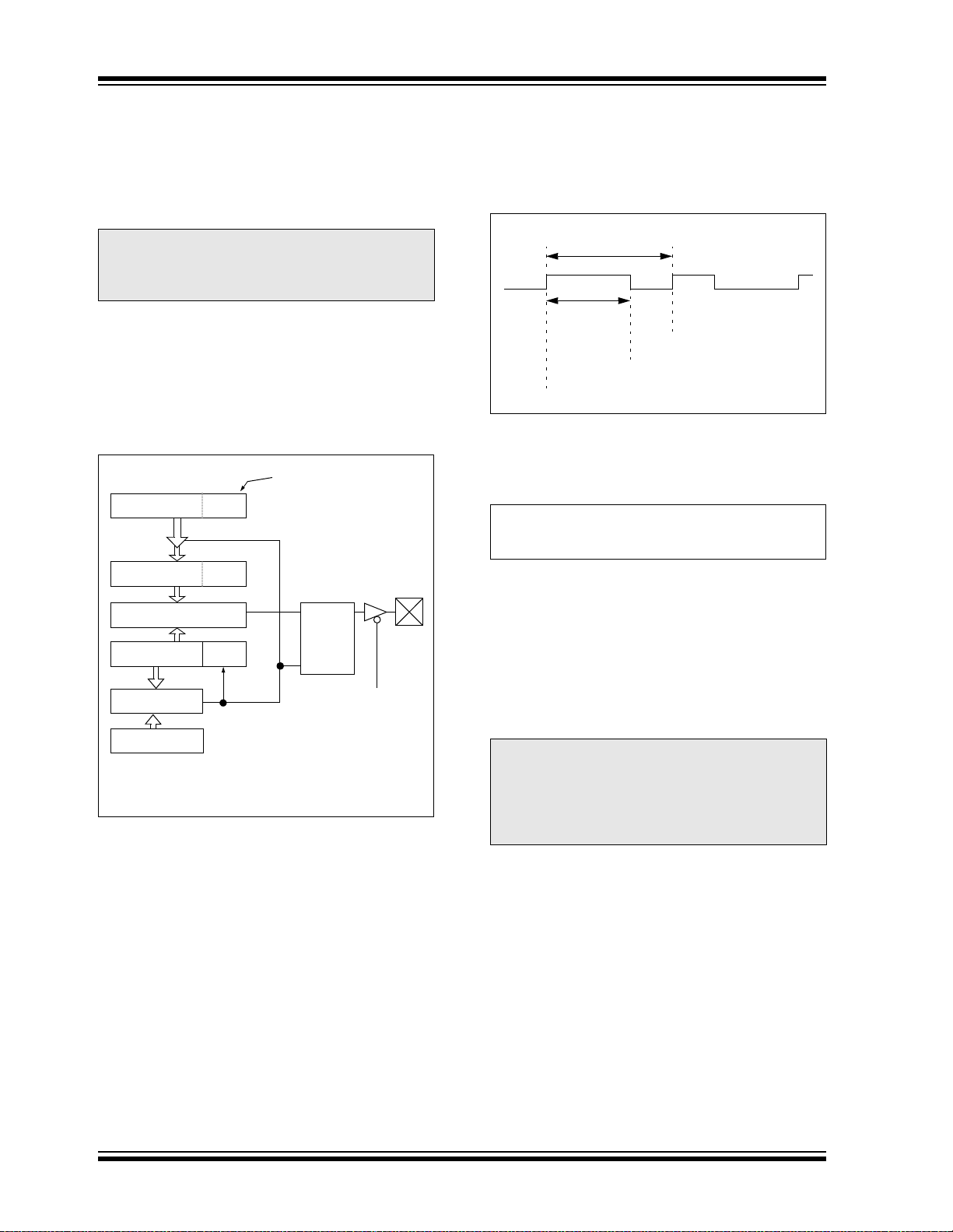

A simplified block diagram is shown in Figure 3-1, and

a description of the device pins in Table 3-2.

Two types of data memory are provided on the

PIC16F627A/628A/648A devices. Nonvolatile

EEPROM data memory is provided for long term

storage of data, such as calibration values, look-up

table data, and any other data which may require

periodic updating in the field. These data types are not

lost when power is removed. The other data memory

provided is regular RAM data memory. Regular RAM

data memory is provi de d for tempo r ary sto rage of data

during normal operation. Data is lost when power is

removed.

and Digit Borrow out bits,

© 2007 Microchip Technology Inc. DS40044F-page 9

PIC16F627A/628A/648A

FIGURE 3-1: BLOCK DIAGRAM

Program

Bus

OSC1/CLKIN

OSC2/CLKOUT

Flash

Program

Memory

14

Instruction Reg

Instruction

Decode &

Control

Timing

Generation

13

Program Counter

8-Level Stack

Direct Addr

8

Power-up

Oscillator

Start-up Timer

Power-on

Watchdog

Brown-out

Low-Voltage

Programming

(13-bit)

Timer

Reset

Timer

Reset

RAM Addr (1)

7

8

Data Bus

3

RAM

File

Registers

9

Addr MUX

8

FSR Reg

Status Re g

MUX

ALU

W Reg

8

Indirect

Addr

PORTA

PORTB

RA0/AN0

RA1/AN1

RA2/AN2/VREF

RA3/AN3/CMP1

RA4/T0CK1/CMP2

RA5/MCLR

RA6/OSC2/CLKOUT

RA7/OSC1/CLKIN

RB0/INT

RB1/RX/DT

RB2/TX/CK

RB3/CCP1

RB4/PGM

RB5

RB6/T1OSO/T1CKI/PGC

RB7/T1OSI/PGD

/VPP

MCLR

VDD, VSS

Comparator

VREF

Note 1: Higher order bits are from the Status register.

Timer0 Timer1 Timer2

CCP1

USART

Data EEPROM

DS40044F-page 10 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

T ABLE 3-2: PIC16F627A/628A/648A PINOUT DESCRIPTION

Name Function Input Type Output Type Description

RA0/AN0 RA0 ST CMOS Bidirectional I/O port

AN0 AN — Analog comparator input

RA1/AN1 RA1 ST CMOS Bidirectional I/O port

AN1 AN — Analog comparator input

RA2/AN2/VREF RA2 ST CMOS Bidirectional I/O port

AN2 AN — Analog comparator input

REF —ANVREF output

V

RA3/AN3/CMP1 RA3 ST CMOS Bidirectional I/O port

AN3 AN — Analog comparator input

CMP1 — CMOS Comparator 1 output

RA4/T0CKI/CMP2 RA4 ST OD Bidirectional I/O port

T0CKI ST — Timer0 clock input

CMP2 — OD Comparator 2 output

RA5/MCLR

RA6/OSC2/CLKOUT RA6 ST CMOS Bidirectional I/O port

RA7/OSC1/CLKIN RA7 ST CMOS Bidirectional I/O port

RB0/INT RB0 TTL CMOS Bidirectional I/O port. Can be software

RB1/RX/DT RB1 TTL CMOS Bidirectional I/O port. Can be software

RB2/TX/CK RB2 TTL CMOS Bidirectional I/O port. Can be software

RB3/CCP1 RB3 TTL CMOS Bidirectional I/O port. Can be software

Legend: O = Output CMOS = CMOS Output P = Power

/VPP RA5 ST — Input port

MCLR

V

PP — — Programming voltage input

OSC2 — XTAL Oscillator crystal output. Connects to crystal

CLKOUT — CMOS In RC/INTOSC mode, OSC2 pin can output

OSC1 XTAL — Oscillator crystal input

CLKIN ST — External clock source input. RC biasing pin.

INT ST — External interrupt

RX ST — USART receive pin

DT ST CMOS Synchronous data I/O

TX — CMOS USART transmit pin

CK ST CMOS Synchronous clock I/O

CCP1 ST CMOS Capture/Compare/PWM I/O

— = Not used I = Input ST = Schmitt Trigger Input

TTL = TTL Input OD = Open Drain Output AN = Analog

ST — Master clear. When configu red as MCL R, this

pin is an active low Reset to the device.

Voltage on MCLR

during normal device operation.

or resonator in Crystal Oscillator mode.

CLKOUT, which has 1/4 the frequency of

OSC1.

programmed for internal weak pull-up.

programmed for internal weak pull-up.

programmed for internal weak pull-up.

programmed for internal weak pull-up.

/VPP must not exceed VDD

© 2007 Microchip Technology Inc. DS40044F-page 11

PIC16F627A/628A/648A

TABLE 3-2: PIC16F627A/628A/648A PINOUT DESCRIPTION (CONTINUED)

Name Function Input Type Output Type Description

RB4/PGM RB4 TTL CMOS Bidirectional I/O port. Interrupt-on-pin change.

Can be software programmed for internal

weak pull-up.

PGM ST — Low-voltage programming inp ut pin. When

low-voltage prog ram ming is enabl ed, the

interrupt-on-pin change and weak pull-up

resistor ar e disabled.

RB5 RB5 TTL CMOS Bidirectional I/O port. Interrupt-on-pin change.

Can be software programmed for internal

weak pull-up.

RB6/T1OSO/T1CKI/PGC RB6 TTL CMOS

T1OSO — XTAL Timer1 oscillator output

T1CKI ST — Timer1 clock input

PGC ST — ICSP™ programming clock

RB7/T1OSI/PGD RB7 TTL CMOS Bidirectional I/O port. Interrupt-on-pin change.

T1OSI XTAL — Timer1 oscillator input

PGD ST CMOS ICSP data I/O

SS VSS Power — Ground reference for logic and I/O pins

V

VDD VDD Power — Positive supply for logic and I/O pins

Legend: O = Output CMOS = CMOS Output P = Power

— = Not used I = Input ST = Schmitt Trigger Input

TTL = TTL Input OD = Open Drain Output AN = Analog

Bidirectional I/O port. Interrupt-on -pin change.

Can be software programmed for internal

weak pull-up.

Can be software programmed for internal

weak pull-up.

DS40044F-page 12 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

l

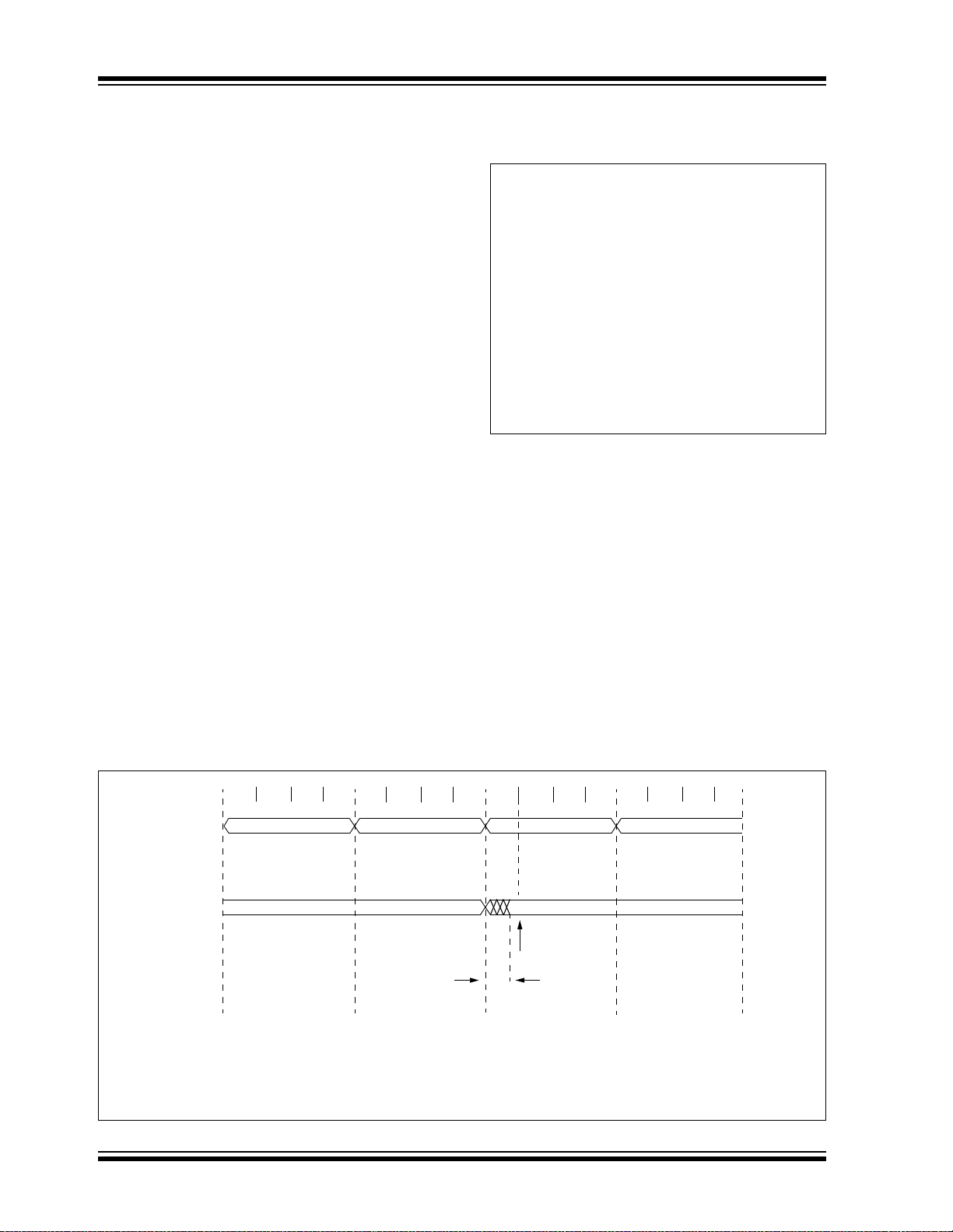

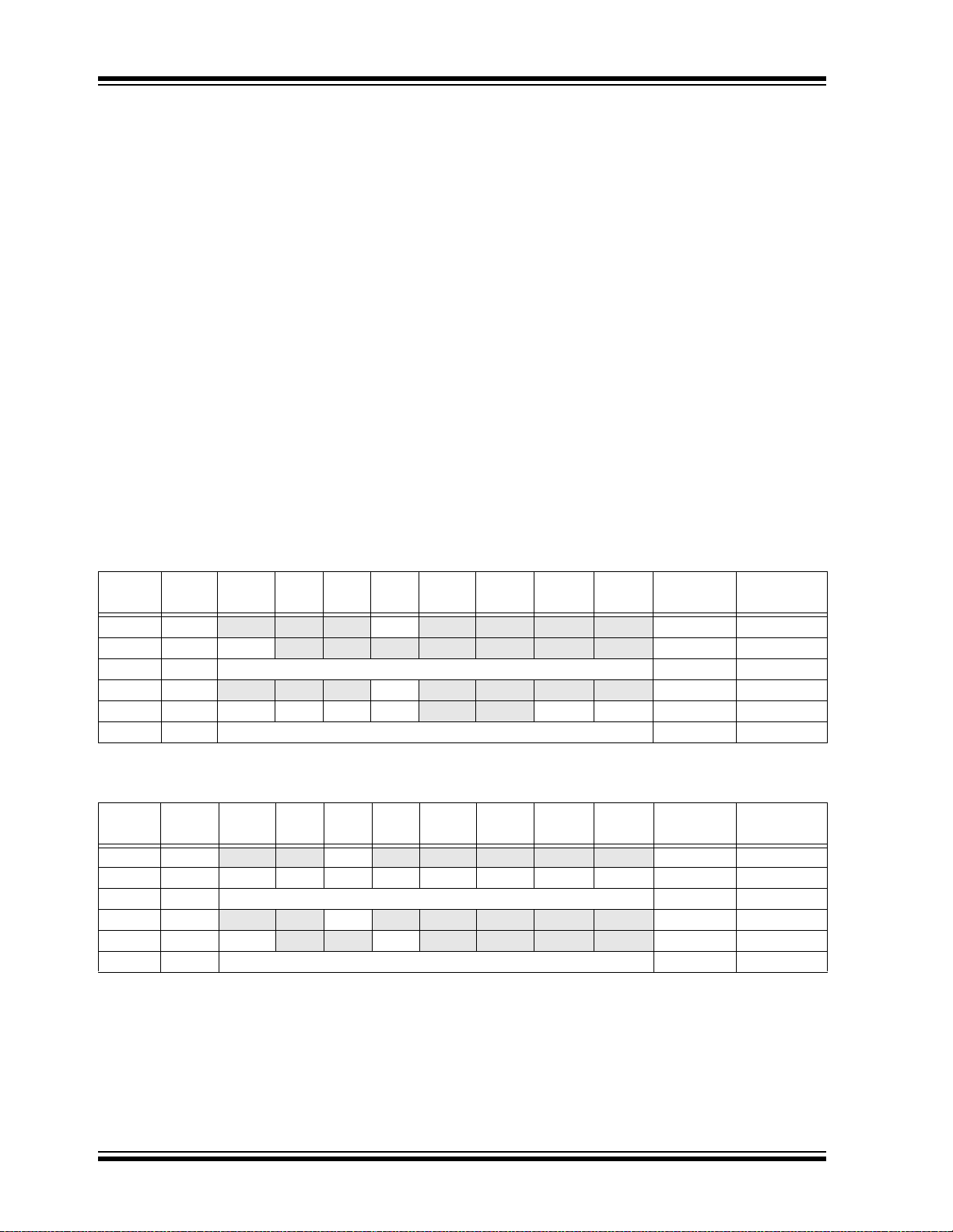

3.1 Clocking Scheme/Instruction Cycle

The clock input (RA7/OSC1/CLKIN pin) is internally

divided by four to generate four non-overlapping

quadrature clocks namely Q1, Q2, Q3 and Q4.

Internally, the Program Counter (PC) is incremented

every Q1, the instruction is fetched from the program

memory and latched into the instruction register in Q4.

The instruction is decoded and executed during the

following Q1 through Q4. The clocks and instruction

execution flow is shown in Figure 3-2.

FIGURE 3-2: CLOCK/INSTRUCTION CYCLE

OSC1

Q1

Q2

Q3

Q4

PC

CLKOUT

Q1

Q2 Q3 Q4

PC PC + 1 PC + 2

Fetch INST (P C )

Execute INST (PC - 1) Fetch INST (PC + 1)

Q1

Q2 Q3 Q4

Execute INST (PC) Fetch INST (PC + 2)

3.2 Instruction Flow/Pipelining

An instruction cycle consists of four Q cycles (Q1, Q2,

Q3 and Q4). The instruction fetch and execute are

pipelined such that fetch takes one instruction cycle

while decode and execute takes another instruction

cycle. However, due to the pipelining, each instruction

effectively executes in one cycle. If an instruction

causes the program counter to change (e.g., GOTO)

then two cycles are req uired to c omplete the ins truction

(Example 3-1).

A fetch cycle begins with the program counter

incrementing in Q1.

In the execution cy cle, the fetch ed instruction i s latched

into the Instruction Register (IR) in cycle Q1. This

instruction is then decoded and executed during the

Q2, Q3 and Q4 c ycles. Dat a m emory is read during Q2

(operand read) and written during Q4 (destination

write).

Q1

Q2 Q3 Q4

Execute INST (PC + 1)

Interna

phase

clock

EXAMPLE 3-1: INSTRUCTION PIPELINE FLOW

1. MOVLW 55h Fetch 1 Execute 1

2. MOVWF PORTB Fetch 2 Execute 2

3. CALL SUB_1 Fetch 3 Execute 3

4. BSF PORTA, 3 Fetch 4

Note: All instructions are single cycle except for an y program branches. The se take two cycles since the fetch

instruction is “flushed” from th e pi peline while the new instruct io n is bei ng fetched and then execu t ed.

© 2007 Microchip Technology Inc. DS40044F-page 13

Flush

Fetch SUB_1 Execute SUB_1

PIC16F627A/628A/648A

NOTES:

DS40044F-page 14 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

4.0 MEMORY ORGANIZATION

4.1 Program Memory Organization

The PIC16F627A/628A/648A has a 13-bit program

counter capable of addressing an 8K x 14 program

memory space. Only the first 1K x 14 (0000h-03FFh)

for the PIC16F627A, 2K x 14 (0000h-07FFh) for the

PIC16F628A and 4Kx 14 (0000h-0FFFh) for the

PIC16F648A are physically implemented. Accessing a

location above these boundaries will cause a wraparound within the first 1K x 14 space (PIC16F627A),

2K x 14 space (PIC16F628A) or 4K x 14 space

(PIC16F648A). The Reset vector is at 0000h and the

interrupt vector is at 0004h (Figure 4-1).

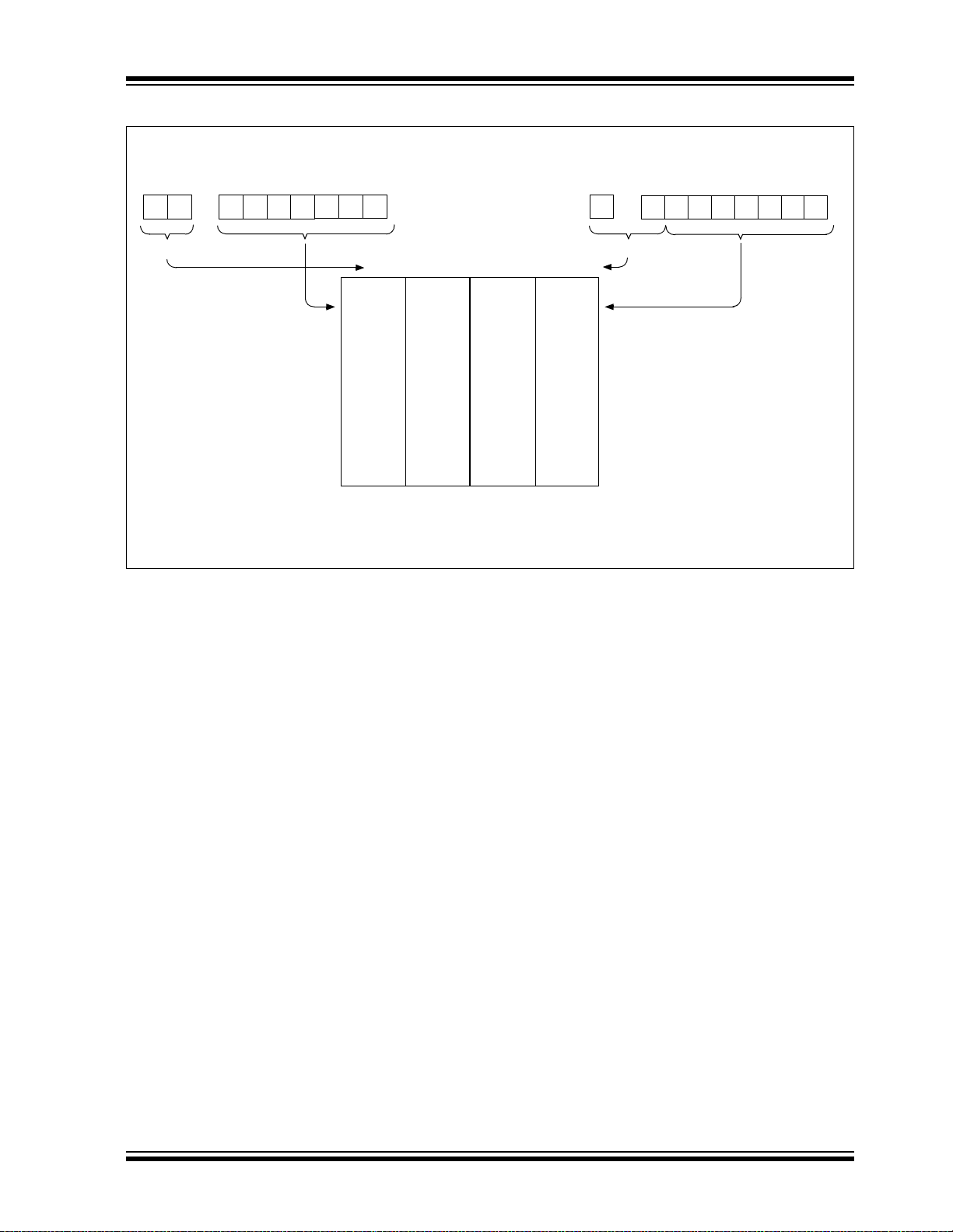

FIGURE 4-1: PROGRAM MEMORY MAP

AND STACK

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 2

13

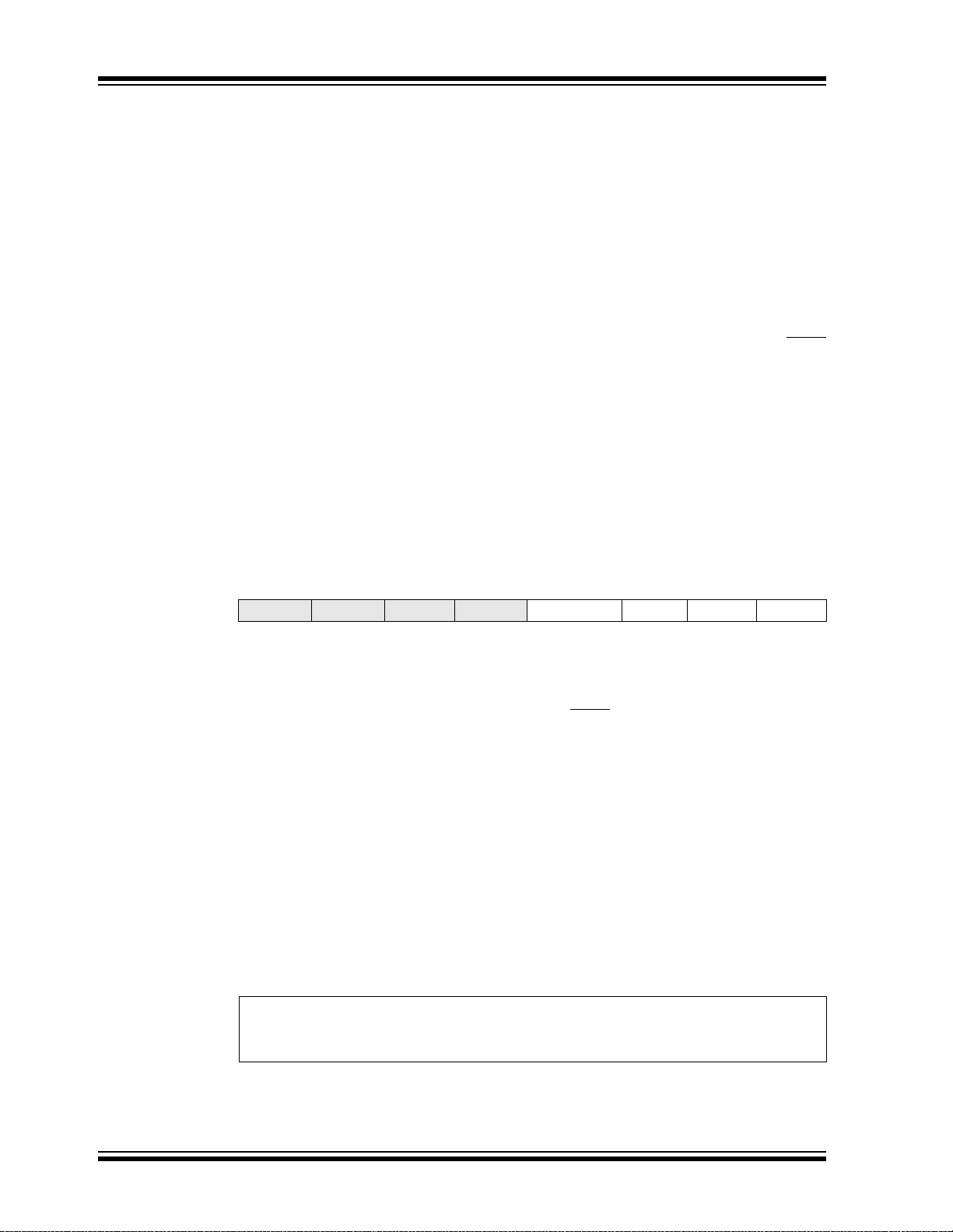

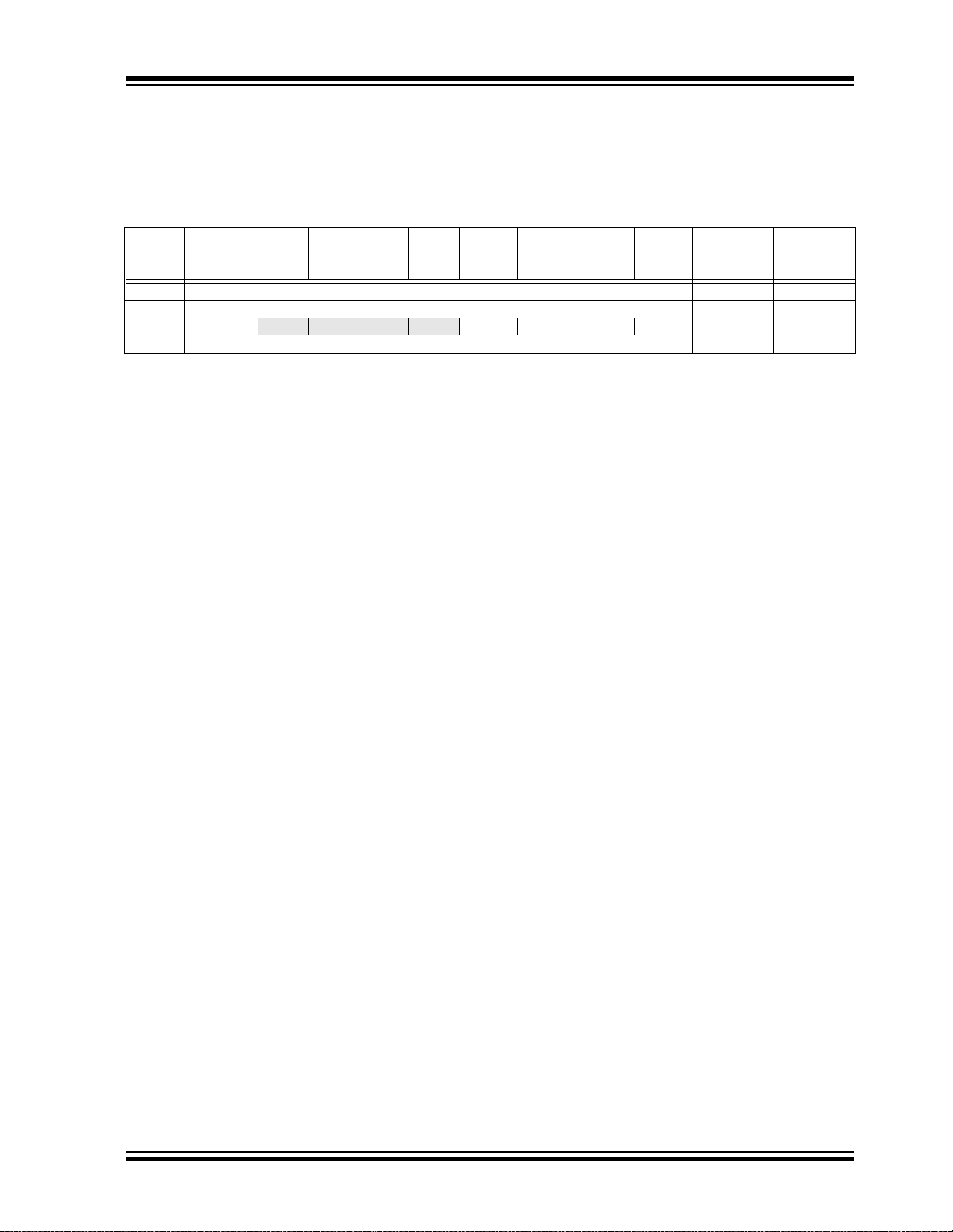

4.2 Data Memory Organization

The data memory (Figure 4-2 and Figure 4-3) is

partitioned into four banks, which contain the General

Purpose Registers (GPRs) and the Special Function

Registers (SFRs). The SFRs are located in the first 32

locations of each bank. There are General Purpose

Registers implemented as static RAM in each bank.

Table 4-1 lists the General Purpose Register available

in each of the four banks.

TABLE 4-1: GENERAL PURPOSE STATIC

RAM REGISTERS

PIC16F627A/628A PIC16F648A

Bank0 20-7Fh 20-7Fh

Bank1 A0h-FF A0h-FF

Bank2 120h-14Fh, 170h-17Fh 120h-17Fh

Bank3 1F0h-1FFh 1F0h-1FFh

Addresses F0h-FFh, 170h-17Fh and 1F0h-1FFh are

implemented as common RAM and mapped back to

addresses 70h-7Fh.

T abl e 4-2 lists how to acces s the four banks of regis ters

via the Status register bits RP1 and RP0.

Stack Level 8

Reset Vector

Interru pt Vector

On-chip Program

Memory

PIC16F627A,

PIC16F628A and

PIC16F648A

On-chip Program

Memory

PIC16F628A and

PIC16F648A

On-chip Program

Memory

PIC16F648A only

000h

0004

0005

03FFh

07FFh

0FFFh

TABLE 4-2: ACCESS TO BANKS OF

REGISTERS

Bank RP1 RP0

0 00

1 01

2 10

3 11

4.2.1 GENERAL PURPOSE REGISTER FILE

The register file is organized as 224 x 8 in the

PIC16F627A/628A and 256 x 8 in the PIC16F648A.

Each is accessed either directly or indirectly through

the File Select Register (FSR), See Section 4.4

“Indirect Addressing, INDF and FSR Registers”.

1FFFh

© 2007 Microchip Technology Inc. DS40044F-page 15

PIC16F627A/628A/648A

FIGURE 4-2: DATA MEMORY MAP OF THE PIC16F627A AND PIC16F628A

File

Address

Indirect addr.

TMR0

PCL

STATUS

FSR

PORTA

PORTB

PCLATH

INTCON

PIR1

TMR1L

TMR1H

T1CON

TMR2

T2CON

CCPR1L

CCPR1H

CCP1CON

RCSTA

TXREG

RCREG

CMCON

General

Purpose

Register

80 Bytes

16 Bytes

Bank 0

(1)

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

6Fh

70h

7Fh FFh

Indirect addr.

OPTION

PCL

STATUS

FSR

TRISA

TRISB

PCLATH

INTCON

PIE1

PCON

PR2

TXSTA

SPBRG

EEDATA

EEADR

EECON1

EECON2

VRCON

General

Purpose

Register

80 Bytes

accesses

70h-7Fh

Bank 1

PCL

FSR

TRISB

(1)

180h

181h

182h

183h

184h

185h

186h

187h

188h

189h

18Ah

18Bh

18Ch

18Dh

18Eh

18Fh

1EFh

1F0h

TMR0

PCL

FSR

(1)

100h

101h

102h

103h

104h

105h

106h

107h

108h

109h

10Ah

10Bh

10Ch

10Dh

10Eh

10Fh

11Fh

120h

14Fh

150h

16Fh

170h

17Fh 1FFh

Indirect addr.

OPTION

STATUS

PCLATH

INTCON

accesses

70h-7Fh

Bank 3

(1)

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

(1)

9Dh

9Eh

9Fh

A0h

EFh

F0h

Indirect addr.

STATUS

PORTB

PCLATH

INTCON

General

Purpose

Register

48 Bytes

accesses

70h-7Fh

Bank 2

Note 1: Not a physical register.

DS40044F-page 16 © 2007 Microchip Technology Inc.

Unimplemented data memory locations, read as ‘0’.

PIC16F627A/628A/648A

FIGURE 4-3: DATA MEMORY MAP OF THE PIC16F648A

File

Address

Indirect addr.

TMR0

PCL

STATUS

FSR

PORTA

PORTB

PCLATH

INTCON

PIR1

TMR1L

TMR1H

T1CON

TMR2

T2CON

CCPR1L

CCPR1H

CCP1CON

RCSTA

TXREG

RCREG

CMCON

General

Purpose

Register

80 Bytes

16 Bytes

Bank 0

(1)

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

6Fh

70h

7Fh FFh

Indirect addr.

OPTION

PCL

STATUS

FSR

TRISA

TRISB

PCLATH

INTCON

PIE1

PCON

PR2

TXSTA

SPBRG

EEDATA

EEADR

EECON1

EECON2

VRCON

General

Purpose

Register

80 Bytes

accesses

70h-7Fh

Bank 1

PCL

FSR

TRISB

(1)

180h

181h

182h

183h

184h

185h

186h

187h

188h

189h

18Ah

18Bh

18Ch

18Dh

18Eh

18Fh

1EFh

1F0h

TMR0

PCL

FSR

(1)

100h

101h

102h

103h

104h

105h

106h

107h

108h

109h

10Ah

10Bh

10Ch

10Dh

10Eh

10Fh

11Fh

120h

16Fh

170h

17Fh 1FFh

Indirect addr.

OPTION

STATUS

PCLATH

INTCON

accesses

70h-7Fh

Bank 3

(1)

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

(1)

9Dh

9Eh

9Fh

A0h

EFh

F0h

Indirect addr.

STATUS

PORTB

PCLATH

INTCON

General

Purpose

Register

80 Bytes

accesses

70h-7Fh

Bank 2

Note 1: Not a physical register.

© 2007 Microchip Technology Inc. DS40044F-page 17

Unimplemented data memory locations, read as ‘0’.

PIC16F627A/628A/648A

4.2.2 SPECIAL FUNCTION REGISTERS

The SFRs are registers used by the CPU and Peripheral functions for controlling the desired operation of

the device (Table4-3). These registers are st a tic RAM.

The special registers can be classified into two sets

(core and peripheral). The SFRs associated with the

“core” functions are described in this section. Those

related to the operation of the peripheral features are

described in the section of that peripheral feature.

TABLE 4-3: SPECIAL REGISTERS SUMMARY BANK0

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0

00h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 28

01h TMR0 Timer0 Module’s Register xxxx xxxx 45

02h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 28

03h STATUS IRP RP1 RP0 TO

04h F SR Indirect Data Memory Ad dr ess Pointer xxxx xxxx 28

05h PORTA

06h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0 xxxx xxxx 36

07h — Unimplemented — —

08h — Unimplemented — —

09h — Unimplemented — —

0Ah PCLATH — — — Write Buffer for upper 5 bits of Program Counter ---0 0000 28

0Bh INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 24

0Ch PIR1

0Dh — Unimplemented — —

0Eh TMR1L Holding Register for the Least Significant Byte of the 16-bit TMR1 Register xxxx xxxx 48

0Fh TMR1H Holding Register for the Most Significant Byte of the 16-bit TMR1 Register xxxx xxxx 48

10h T1CON

11h TMR2 TMR2 Module’s Register 0000 0000 52

12h T2CON

13h — Unimplemented — —

14h — Unimplemented — —

15h CCPR1L Capture/Compare/PWM Register (LSB) xxxx xxxx 55

16h CCPR1H Capture/Compare/PWM Register (MSB) xxxx xxxx 55

17h CCP1CON

18h RCSTA SPEN RX9 SREN CREN ADEN FERR OERR RX9D 0000 000x 72

19h TXREG USART Transmit Data Register 0000 0000 77

1Ah RCREG USART Receive Data Register 0000 0000 80

1Bh — Unimplemented — —

1Ch — Unimplemented — —

1Dh — Unimplemented — —

1Eh — Unimplemented — —

1Fh CMCON C2OUT C1OUT

Legend: - = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: For the initialization condition for registers tables, refer to Table 14-6 and Table 14-7.

RA7 RA6 RA5 RA4 RA3 RA2 RA1 RA0 xxxx 0000 31

EEIF CMIF RCI F TXIF — CCP1IF TMR2IF TMR1IF 0000 -000 26

— — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON --00 0000 48

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 -000 0000 52

— — CCP1X CCP1Y CCP1M3 CCP1M2 CCP1M1 CCP1M0 --00 0000 55

C2INV C1INV CIS CM2 CM1 CM0 0000 0000 61

PD ZDCC0001 1xxx 22

Value on

POR

Reset

Details

on Page

(1)

DS40044F-page 18 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

TABLE 4-4: SPECIAL FUNCTION REGISTERS SUMMARY BANK1

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 1

80h INDF Addressing this location uses contents of FSR to address data memory (not a physical

81h OPTION RBPU

82h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 28

83h STATUS IRP RP1 RP0 TO

84h FSR Indirect Data Memory Address Pointer xxxx xxxx 28

85h TRISA TRISA7 TRISA6 TRISA5 TRISA4 TRISA3 TRISA2 TRISA1 TRISA0 1111 1111 31

86h TRISB TRISB7 TRISB6 TRISB5 TRISB4 TRISB3 TRISB2 TRISB1 TRISB0 1111 1111 36

87h — Unimplemented — —

88h — Unimplemented — —

89h — Unimplemented — —

8Ah PCLATH

8Bh INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 24

8Ch PIE1 EEIE CMIE RCIE TXIE

8Dh — Unimplemented — —

8Eh PCON

8Fh — Unimplemented — —

90h — Unimplemented — —

91h — Unimplemented — —

92h PR2 Timer2 Period Register 1111 1111 52

93h — Unimplemented — —

94h — Unimplemented — —

95h — Unimplemented — —

96h — Unimplemented — —

97h — Unimplemented — —

98h TXSTA CSRC TX9 TXEN SYNC

99h SPBRG Baud Rate Generator Register 0000 0000 73

9Ah EEDATA EEPROM Data Register xxxx xxxx 89

9Bh EEADR EEPROM Address Register xxxx xxxx 90

9Ch EECON1

9Dh EECON2 EEPROM Control Register 2 (not a physical register) ---- ---- 90

9Eh — Unimplemented — —

9Fh VRCON VREN VROE VRR

Legend: - = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: For the initialization condition for registers tables, refer to Table 14-6 and Table 14-7.

register)

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 23

PD ZDCC0001 1xxx 22

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 28

— CCP1IE TMR2IE TMR1IE 0000 -000 25

— — — — OSCF —PORBOR ---- 1-0x 27

— BRGH TRMT TX9D 0000 -010 71

— — — — WRERR WREN WR RD ---- x000 90

— VR3 VR2 VR1 VR0 000- 0000 67

Value on

POR

Reset

xxxx xxxx 28

Details

on Page

(1)

© 2007 Microchip Technology Inc. DS40044F-page 19

PIC16F627A/628A/648A

TABLE 4-5: SPECIAL FUNCTION REGISTERS SUMMARY BANK2

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 2

100h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 28

101h TMR0

102h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 28

103h STATUS IRP RP1 RP0 TO

104h FSR Indirect Data Memory Address Pointer xxxx xxxx 28

105h — Unimplemented — —

106h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0 xxxx xxxx 36

107h — Unimplemented — —

108h — Unimplemented — —

109h — Unimplemented — —

10Ah PCLATH

10Bh INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 24

10Ch — Unimplemented — —

10Dh — Unimplemented — —

10Eh — Unimplemented — —

10Fh — Unimplemented — —

110h — Unimplemented — —

111h — Unimplemented — —

112h — Unimplemented — —

113h — Unimplemented — —

114h — Unimplemented — —

115h — Unimplemented — —

116h — Unimplemented — —

117h — Unimplemented — —

118h — Unimplemented — —

119h — Unimplemented — —

11Ah — Unimplemented — —

11Bh — Unimplemented — —

11Ch — Unimplemented — —

11Dh — Unimplemented — —

11Eh — Unimplemented — —

11Fh — Unimplemented — —

Legend: - = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented.

Note 1: For the initialization condition for registers tables, refer to Table 14-6 and Table 14-7.

Timer0 Module’s Register xxxx xxxx

PD ZDCC0001 1xxx 22

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 28

Value on

POR

Reset

Details

on Page

(1)

45

DS40044F-page 20 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

TABLE 4-6: SPECIAL FUNCTION REGISTERS SUMMARY BANK3

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 3

180h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 28

181h OPTION RBPU

182h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 28

183h STATUS IRP RP1 RP0 TO

184h FSR Indirect Data Memory Address Pointer xxxx xxxx 28

185h — Unimplemented — —

186h TRISB TRISB7 TRISB6 TRISB5 TRISB4 TRISB3 TRISB2 TRISB1 TRISB0 1111 1111 36

187h — Unimplemented — —

188h — Unimplemented — —

189h — Unimplemented — —

18Ah PCLATH

18Bh INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 24

18Ch — Unimplemented — —

18Dh — Unimplemented — —

18Eh — Unimplemented — —

18Fh — Unimplemented — —

190h — Unimplemented — —

191h — Unimplemented — —

192h — Unimplemented — —

193h — Unimplemented — —

194h — Unimplemented — —

195h — Unimplemented — —

196h — Unimplemented — —

197h — Unimplemented — —

198h — Unimplemented — —

199h — Unimplemented — —

19Ah — Unimplemented — —

19Bh — Unimplemented — —

19Ch — Unimplemented — —

19Dh — Unimplemented — —

19Eh — Unimplemented — —

19Fh — Unimplemented — —

Legend: - = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: For the initialization condition for registers tables, refer to Table 14-6 and Table 14-7.

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 23

PD ZDCC0001 1xxx 22

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 28

Value on

POR

Reset

Details

on Page

(1)

© 2007 Microchip Technology Inc. DS40044F-page 21

PIC16F627A/628A/648A

4.2.2.1 Status Register

The St atus register , s hown in Register4-1, contains th e

arithmeti c statu s of th e ALU; the Re set sta tus an d the

bank select bits for data memory (SRAM).

The Status register can be the destination for any

instruction, like any other register. If the Status register

is the destination for an instruction that affects the Z,

DC or C bits, then the write to these three bits is

disabled. These bit s are set or cleared ac cording to the

device logic. Further more, the T O

writable. Therefore, the result of an instruction with the

Status register as destination may be different than

intended.

and PD bits are non-

For example, CLRF STATUS will clear the upper-three

bits and set the Z bit. This leaves the Status register

as “000uu1uu” (where u = unchanged).

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions are used to alter the

Stat us register be cause the se instruct ions do not af fect

any Status bit. For other instructions, not affecting any

Status bits, see the “Instruction Set Summary”.

Note: The C and DC bits operate as a Borrow

and Digit Borrow out bit, respectively, in

subtraction. See the SUBLW and SUBWF

instructions for examples.

REGISTER 4-1: STATUS – STATUS REGISTER (ADDRESS: 03h, 83h, 103h, 183h)

R/W-0 R/W-0 R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 TO

bit 7 bit 0

bit 7 IRP: Register Bank Select bit (used for indirect addressing)

1 = Bank 2, 3 (100h-1FFh)

0 = Bank 0, 1 (00h-FFh)

bit 6-5 RP<1:0>: Register Bank Select bits (used for direct addressing)

00 = Bank 0 (00h-7Fh)

01 = Bank 1 (80h-FFh)

10 = Bank 2 (100h-17Fh)

11 = Bank 3 (180h-1FFh)

bit 4 TO

bit 3 PD

bit 2 Z: Zero bit

bit 1 DC: Digit Carry/Bo

bit 0 C: Carry/Bo

: Time Out bit

1 = After power-up, CLRWDT instruction or SLEEP instruction

0 = A WDT time out occurred

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

rrow bit (ADDWF, ADDLW,SUBLW,SUBWF instructions) (for Borrow the polarity

is reversed)

1 = A carry-out from the 4th low order bit of the result occurred

0 = No carry-out from the 4th low order bit of the result

rrow bit (ADDWF, ADDLW,SUBLW,SUBWF instructions)

1 = A carry-out from the Most Significant bit of the result occurred

0 = No carry-out from the Most Significant bit of the result occurred

Note: For Bo

rrow, the polarity is reversed. A subtraction is executed by adding the two’s

complement of the second operand. For rotate (RRF, RLF) instructions, this bit is

loaded with either the high or low order bit of the source register.

PD ZDCC

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS40044F-page 22 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

4.2.2.2 OPTION Register

The Option register is a readable and writable register,

which contains various control bits to configure the

TMR0/WDT prescaler, the external RB0/INT interrupt,

TMR0 and the weak pull-ups on PORTB.

REGISTER 4-2: OPTION_REG – OPTION REGISTER (ADDRESS: 81h, 181h)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

RBPU

bit 7 bit 0

INTEDG T0CS T0SE PSA PS2 PS1 PS0

Note: To achieve a 1:1 prescaler assignment for

TMR0, assign the prescaler to the WDT

(PSA = 1). See Section 6.3.1 “Switching

Prescaler Assignment”.

bit 7 RBPU

bit 6 INTEDG: Interrupt Edge Select bit

bit 5 T0CS: TMR0 Clock Source Select bit

bit 4 T0SE: TMR0 Source Edge Select bit

bit 3 PSA: Prescaler Assignment bit

bit 2-0 PS<2:0>: Prescaler Rate Select bits

: PORTB Pull-up Enable bit

1 = PORTB pull-ups are disabled

0 = PORTB pull-ups are enabled by individual port latch values

1 = Interrupt on rising edge of RB0/INT pin

0 = Interrupt on falling edge of RB0/INT pin

1 = Transition on RA4/T0CKI/CMP2 pin

0 = Internal instruction cycle clock (CLKOUT)

1 = Increment on high-to-low transition on RA4/T0CKI/CMP2 pin

0 = Increment on low-to-high transition on RA4/T0CKI/CMP2 pin

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

Bit Value TMR0 Rate WDT Rate

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

© 2007 Microchip Technology Inc. DS40044F-page 23

PIC16F627A/628A/648A

4.2.2.3 INTCON Register

The INTCON register is a readable and writable

register , which c ontains the various en able and fl ag bit s

for all interrupt so urces excep t th e comp arator mo dule.

See Section 4.2.2.4 “PIE1 Register” and

Section 4.2.2.5 “PIR1 Register” for a description of

the comparator enable and flag bits.

Note: Interrupt flag bits get set when an interrupt

condition occurs regard less of the sta te of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>).

REGISTER 4-3: INTCON – INTERRUPT CONTROL REGISTER (ADDRESS: 0Bh, 8Bh, 10Bh, 18Bh)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-x

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF

bit 7 bit 0

bit 7 GIE: Global Interrupt Enable bit

1 = Enables all un-masked interrupts

0 = Disables all interrupts

bit 6 PEIE: Peripheral Interrupt Enable bit

1 = Enables all un-masked peripheral interrupts

0 = Disables all peripheral interrupts

bit 5 T0IE: TMR0 Overflow Inter rupt Enable bit

1 = Enables the TMR0 interrupt

0 = Disables the TMR0 interrupt

bit 4 INTE: RB0/INT External Interrupt Enable bit

1 = Enables the RB0/INT external interrupt

0 = Disables the RB0/INT external interrupt

bit 3 RBIE: RB Port Change Interrupt Enable bit

1 = Enables the RB port change interrupt

0 = Disables the RB port change interrupt

bit 2 T0IF: TMR0 Overflow Interrupt Flag bit

1 = TMR0 regis ter has overflowed (must be cleared in software)

0 = TMR0 register did not overflow

bit 1 INTF: RB0/INT External Interrupt Flag bit

1 = The RB0/INT external interrupt occurred (must be cleared in so ftware)

0 = The RB0/INT external interrupt did not occur

bit 0 RBIF: RB Port Change Interrupt Flag bit

1 = When at least one of the RB<7:4> pins changes state (must be cleared in software)

0 = None of the RB<7:4> pins have changed state

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS40044F-page 24 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

4.2.2.4 PIE1 Register

This register contains interrupt enable bits.

REGISTER 4-4: PIE1 – PERIPHERAL INTERRUPT ENABLE REGISTER 1 (ADDRESS: 8Ch)

R/W-0 R/W-0 R/W-0 R/W-0 U-0 R/W-0 R/W-0 R/W-0

EEIE CMIE RCIE TXIE — CCP1IE TMR2IE TMR1IE

bit 7 bit 0

bit 7 EEIE: EE Write Complete Interrupt Enable Bit

1 = Enables the EE write complete interrupt

0 = Disables the EE write complete interrupt

bit 6 CMIE: Comparator Interrupt Enable bit

1 = Enables the comparator interrupt

0 = Disables the comparator interrupt

bit 5 RCIE: USART Receive Interrupt Enable bit

1 = Enables the USART receive interrupt

0 = Disables the USART receive interrupt

bit 4 TXIE: USART Transmit Interrupt Enable bit

1 = Enables the USART transmit interrupt

0 = Disables the USART transmit interrupt

bit 3 Unimplemented: Read as ‘0’

bit 2 CCP1IE: CCP1 Interrupt Enable bit

1 = Enables the CCP1 interrupt

0 = Disables the CCP1 interrupt

bit 1 TMR2IE: TMR2 to PR2 Match Interrupt Enable bit

1 = Enables the TMR2 to PR2 match interrupt

0 = Disables the TMR2 to PR2 match interrupt

bit 0 TMR1IE: T MR1 Overflow Interrupt Enable bit

1 = Enables the TMR1 overflow interrupt

0 = Disables the TMR1 overflow interrupt

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

© 2007 Microchip Technology Inc. DS40044F-page 25

PIC16F627A/628A/648A

4.2.2.5 PIR1 Register

This register contains interrupt flag bits.

Note: Interrupt flag bits get set when an interrupt

condition occurs regardle ss of the sta te of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User

software should ensure the appropriate

interrupt flag bits are clear prior to

enabling an interrupt.

REGISTER 4-5: PIR1 – PERIPHERAL INTERRUPT REGISTER 1 (ADDRESS: 0Ch)

R/W-0 R/W-0 R-0 R-0 U-0 R/W-0 R/W-0 R/W-0

EEIF CMIF RCIF TXIF

bit 7 bit 0

bit 7 EEIF: EEPROM Write Operation Interrupt Flag bit

1 = The write operation completed (must be cleared in software)

0 = The write operation has not completed or has not been started

bit 6 CMIF: Comparator Interrupt Flag bit

1 = Comparator output has changed

0 = Comparator output has not changed

bit 5 RCIF: USART Receive Interrupt Flag bit

1 = The USART receive buffer is full

0 = The USART receive buffer is empty

bit 4 TXIF: USART Transmit Interrupt Flag bit

1 = The USART transmit buffer is empty

0 = The USART transmit buffer is full

bit 3 Unimplemented: Read as ‘0’

bit 2 CCP1IF: CCP1 Interrupt Flag bit

Capture Mode

1 = A TMR1 register capture occurred (must be cleared in software)

0 = No TMR1 register capture occurred

Compare Mode

1 = A TMR1 register compare match occurred (must be cleared in software)

0 = No TMR1 register compare match occurred

PWM Mode

Unused in this mode

bit 1 TMR2IF: TMR2 to PR2 Match Interrupt Flag bit

1 = TMR2 to PR2 match occurred (must be cleared in software)

0 = No TMR2 to PR2 match occurred

bit 0 TMR1IF: TMR1 Overflow Interrupt Flag bit

1 = TMR1 register overflowed (must be cleared in software)

0 = TMR1 register did not overflow

— CCP1IF TMR2IF TMR1IF

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS40044F-page 26 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

4.2.2.6 PCON Register

The PCON register contains flag bits to differentiate

between a Power-on Reset, an external MCLR

WDT Reset or a Brown-out Reset.

Reset,

Note: BOR is unknown on Power-on Reset. It

must then be set by the us er an d c hec ke d

on subsequent Resets to see if BOR is

cleared, indicating a brown-out has

occurred. T he BOR Status bit is a “don’t

care” and is not necessarily predictable if

the brown-out circuit is disabled (by

clearing the BOREN bit in the

Configuration Word).

REGISTER 4-6: PCON – POWER CONTROL REGISTER (ADDRESS: 8Eh)

U-0 U-0 U-0 U-0 R/W-1 U-0 R/W-0 R/W-x

— — — — OSCF —PORBOR

bit 7 bit 0

bit 7-4 Unimplemented: Read as ‘0’

bit 3 OSCF: INTOSC Oscillator Frequency bit

1 = 4 MHz typical

0 = 48 kHz typical

bit 2 Unimplemented: Read as ‘0’

bit 1 POR

bit 0 BOR

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

: Brown-out Reset Status bit

1 = No Brown-out Reset occurred

0 = A Brown-out Reset occurred (must be set in software after a Brown-out Reset occurs)

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

© 2007 Microchip Technology Inc. DS40044F-page 27

PIC16F627A/628A/648A

4.3 PCL and PCLATH

The Program Counter (PC) is 13-bits wide. The low

byte comes from the PCL register, which is a readable

and writable register. The high byte (PC<12:8>) is not

directly readable or wri table and comes from PCLATH.

On any Reset, the PC is c leared. Figure 4-4 shows the

two situations for loading the PC. The upper example

in Figure 4-4 shows how the PC is loaded o n a w rite to

PCL (PCLATH<4:0> → PCH). The lower example in

Figure 4-4 shows how the PC is loaded during a CALL

or GOTO instruction (PCLATH<4:3> → PCH).

FIGURE 4-4: LOADING OF PC IN

DIFFERENT SITUATIONS

PCH PCL

12 8 7 0

PC

PCLATH<4:0>

5

PCLATH

PCH PCL

12 11 10 0

PC

2

87

PCLATH<4:3>

PCLATH

11

8

Instruction with

PCL as

Destination

ALU result

GOTO, CALL

Opcode <10:0>

The stack operat es as a circular buf fer . This means th at

after the stack has been PUSHed eight times, the ninth

PUSH overwrites the value that was stored from the

first PUSH. The tenth PUSH overwrites the second

PUSH (and so on).

Note 1: There are no Status bits to indicate stack

overflow or stack underflow conditions.

2: There are no instructions/mnemonics

called PUSH or POP. These are actions

that occur from the execution of the

CALL, RETURN, RETLW and RETFIE

instructions, or the vectoring to an

interrupt address.

4.4 Indirect Addressing, INDF and FSR Registers

The INDF register is not a physica l register . Addr essing

the INDF register will cause indirect addressing.

Indirect addressing is possible by using the INDF

register. Any instruction using the INDF register

actually accesses data pointed to by the File Select

Register (FSR). Reading INDF itself indirectly will

produce 00h. Writing to the INDF register indirectly

results in a no-operation (although Status bits may be

affected). An effective 9-bit address is obtained by

concatenating the 8-bit FSR register and the IRP bit

(STATUS<7>), as shown in Figure 4-5.

A simple program to clear RAM location 20h-2Fh using

indirect addressing is shown in Example 4-1.

4.3.1 COMPUTED GOTO

A computed GOTO is accomplish ed by adding an offs et

to the progr am counter (ADDWF PCL). When doing a

table read using a computed GOTO method, care

should be exercise d i f the t able loca tio n cros ses a PCL

memory boundary (each 256-byte block). Refer to the

Application Note AN556 “Implementing a Table Read”

(DS00556).

4.3.2 STACK

The PIC16F627A/628A/648A family has an 8-level

deep x 13-bit wide hardware stack (Figure 4-1). The

stack space i s no t p art o f eith er pro gram or da t a space

and the Stack Pointer is not readabl e or writable . The

PC is PUSHed onto the stack when a CALL instruction

is executed or an interrupt causes a b ranch. The stack

is POPed in the event of a RETURN, RETLW or a

RETFIE instruction exec uti on. PCLATH is not affect ed

by a PUSH or POP operation.

EXAMPLE 4-1: INDIR ECT ADDRESSING

MOVLW 0x20 ;initialize pointer

MOVWF FSR ;to RAM

NEXT CLRF INDF ;clear INDF register

INCF FSR ;inc pointer

BTFSS FSR,4 ;all done?

GOTO NEXT ;no clear next

;yes continue

DS40044F-page 28 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

FIGURE 4-5: DIRECT/INDIRECT ADDRESSING PIC16F627A/628A/648A

Status

Register

RP1 RP0 6

bank select location select

Note: For memory map detail see Figure 4-3, Figure 4-2 and Figure 4-1.

from opcode

RAM

File

Registers

0

00 01 10 11

00h

7Fh

Bank 0 Bank 1 Bank 2 Bank 3

Status

Register

IRP FSR Register

bank select

180h

Indirect AddressingDirect Addressing

7

location select

1FFh

0

© 2007 Microchip Technology Inc. DS40044F-page 29

PIC16F627A/628A/648A

NOTES:

DS40044F-page 30 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

n

5.0 I/O PORTS

The PIC16F627A/628A/648A have two ports, PORTA

and PORTB. Some pins for these I/O ports are

multiplexed with alternate functions for the peripheral

features on the device. In general, when a peripheral i s

enabled, that pin may not be used as a general

purpose I/ O pin.

5.1 PORTA and TRISA Registers

PORTA is an 8-bit wide latch. RA4 is a Schmitt Trigger

input and an open drain output. Port R A4 is multi plexed

with the T0CKI clock input. RA5

input only and has no output drivers. All other RA port

pins have Schmitt Trigger input levels and full CMOS

output drivers. All pins have data direction bits (TRIS

registers) which can configure these pins as input or

output.

A ‘1’ in the TRISA register puts the corresponding

output driver in a High-impedance mode. A ‘0’ in the

TRISA register puts the contents of the output latch on

the selected pin(s).

Reading the PORTA register reads the status of the

pins whereas writing to it will write to the port latch. All

write operations are re ad-modify-write operations. So a

write to a port implies that the port pins are first read,

then this value is modified and written to the port data

latch.

The PORTA pins are multiplexed with comparator and

voltage reference functions. The operation of these

pins are selected by control bits in the CMCON

(Comparator Control register) re gister a nd the VRCON

(Voltage Reference Control register) register. When

selected as a comparator input, these pins will read

as ‘0’s.

Note 1: RA5 shares function with VPP. When VPP

voltage levels are applied to RA5, the

device will enter Progra mming mode.

2: On Reset, the TRISA register is set to all

inputs. The digital inputs (RA<3:0>) are

disabled and the comparator inputs are

forced to ground to reduce current

consumption.

3: TRISA<6:7> is overridden by oscillator

configuration. When PORTA<6:7> is

overridden, the data reads ‘0’ and the

TRISA<6: 7> bits are ignored.

TRISA controls the direction of the RA pins, even when

they are being used as comparator inputs. The user

must make sure to keep the pins configured as inputs

when using them as comparator inputs.

The RA2 pin will also function as the output for the

voltage referen ce. When in this mo de, the V

very high-impedance output. The user must configure

TRISA<2> bit as an input and use high-impedance

loads.

(1)

is a Schmitt Trigger

REF pin is a

In one of the comparator modes defined by the

CMCON register, pins RA3 and RA4 become outputs

of the comparators. The TRISA<4:3> bits must be

cleared to enable outputs to use this function.

EXAMPLE 5-1: INITIALIZING PORTA

CLRF PORTA ;Initialize PORTA by

MOVLW 0x07 ;Turn comparators off and

MOVWF CMCON ;enable pins for I/O

BCF STATUS, RP1

BSF STATUS, RP0 ;Select Bank1

MOVLW 0x1F ;Value used to initialize

MOVWF TRISA ;Set RA<4:0> as inputs

;setting

;output data latches

;functions

;data direction

;TRISA<5> always

;read as ‘1’.

;TRISA<7:6>

;depend on oscillator

;mode

FIGURE 5-1: BLOCK DIAGRAM OF

RA0/AN0:RA1/AN1 PINS

Data

Bus

WR

PORTA

Data Latch

WR

TRISA

TRIS Latch

RD

TRISA

RD PORTA

To Comparator

CK

CK

QD

Q

QD

Q

Input Mode

(CMCON Reg.)

Analog

Schmitt Trigger

Input Buffer

EN

VDD

I/O Pi

VSS

DQ

© 2007 Microchip Technology Inc. DS40044F-page 31

PIC16F627A/628A/648A

in

FIGURE 5-2: BLOCK DIAGRAM OF

Data

Bus

WR

PORTA

WR

TRISA

RD

TRISA

RD PORTA

CK

Data Latch

CK

TRIS Latch

RA2/AN2/V

QD

Q

QD

Q

Input Mode

(CMCON Reg.)

Schmitt Trigger

Analog

Input Buffer

REF PIN

VDD

RA2 P

VSS

DQ

EN

To Comparator

VROE

V

REF

FIGURE 5-3: BLOCK DIAGRAM OF THE RA3/AN3/CMP1 PIN

Data

Bus

WR

PORTA

WR

TRISA

RD

TRISA

CK

Data Latch

CK

TRIS Latch

QD

Comparator Mode = 110

Comparator Output

Q

QD

Q

(CMCON Reg.)

1

0

Analog

Input Mode

(CMCON Reg.)

Schmitt Trigger

Input Buffer

DQ

EN

VDD

RA3 Pin

VSS

RD PORTA

To Comparator

DS40044F-page 32 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

.

r

FIGURE 5-4: BLOCK DIAGRAM OF RA4/T0CKI/CMP2 PIN

Data

Bus

WR

PORTA

WR

TRISA

RD PORTA

CK

Data Latch

CK

TRIS Latch

RD TRISA

QD

Q

QD

Q

Comparator Mode = 110

Comparator Output

(CMCON Reg.)

1

0

Schmitt Trigger

Input Buffer

DQ

EN

N

Vss

RA4 Pin

Vss

TMR0 Clock Input

FIGURE 5-5: BLOCK DIAGRAM OF THE

MCLR

circuit

Program

mode

Data

Bus

RD

TRISA

RD

PORTA

MCLRE

MCLR

HV Detect

RA5/MCLR

(Configuration Bit)

Filter

Schmitt Trigger

Input Buffer

VSS

Q

D

EN

/VPP PIN

RA5/MCLR/VPP

VSS

FIGURE 5-6: BLOCK DIAGRAM OF

RA6/OSC2/CLKOUT PIN

From OSC1

CLKOUT(FOSC/4)

DCKQ

Data Latch

(2)

DCKQ

TRIS Latch

(1)

WR

PORTA

FOSC =

101, 111

WR

TRISA

RD

TRISA

OSC =

F

011, 100, 110

RD PORTA

1

0

Q

Q

QD

EN

OSC

Circuit

VDD

VSS

Schmitt

Trigger

Input Buffe

© 2007 Microchip Technology Inc. DS40044F-page 33

Note 1: INTOSC with RA6 = I/O or RC with RA6 = I/O

2: INTOSC with RA6 = CLKOUT or RC with

RA6 = CLKOUT.

PIC16F627A/628A/648A

FIGURE 5-7: BLOCK DIAGRAM OF RA7/OSC1/CLKIN PIN

Data Bus

WR PORTA

WR TRISA

RD TRISA

F

OSC = 100, 101

RD PORTA

To Clock Circuits

QD

CK

Data Latch

D

CK

TRIS Latch

Q

Q

Q

(1)

EN

VDD

RA7/OSC1/CLKIN Pin

VSS

DQ

Schmitt Trigger

Input Buffer

Note 1: INTOSC with CLKOUT and INTOSC with I/O.

DS40044F-page 34 © 2007 Microchip Technology Inc.

PIC16F627A/628A/648A

TABLE 5-1: PORTA FUNCTIONS

Name Function

Input

Type

RA0/AN0 RA0 ST CMOS Bidirectional I/O port

AN0 AN — Analog comparator input

RA1/AN1 RA1 ST CMOS Bidirectional I/O port

AN1 AN — Analog comparator input

RA2/AN2/V

REF RA2 ST CMOS Bidirectional I/O port

AN2 AN — Analog comparator input

VREF —ANVREF output

RA3/AN3/CMP1 RA3 ST CMOS Bidirectional I/O port

AN3 AN — Analog comparator input

CMP1 — CMOS Comparator 1 output

RA4/T0CKI/CMP2 RA4 ST OD Bidirectional I/O port. Output is open drain type.

T0CKI ST — External clock input for TMR0 or comparator output

CMP2 — OD Comparator 2 output

RA5/MCLR

/VPP RA5 ST — Input port

MCLR

V

PP HV —

ST — Master clear. When configured as MCLR, this pin is an

RA6/OSC2/CLKOUT RA6 ST CMOS Bidirectional I/O port

OSC2 — XTAL Oscillator crystal output. Connects to crystal resonator in

CLKOUT — CMOS In RC or INTOSC mode. OSC2 pin can output CLKOUT,

RA7/OSC1/CLKIN RA7 ST CMOS Bidirectional I/O port

OSC1 XTAL — Oscillator crystal input. Connects to crystal resonator in

CLKIN ST — External clock source input. RC biasing pin.

Legend: O = Output CMOS = CMOS Output P = Power

— = Not used I = Input ST = Schmitt Trigger Input

TTL = TTL Input OD = Open Drain Output AN = Analog

Output

Type

Description

active low Reset to the device. Volt age on MCLR

not exceed V

DD during normal device operation.

Programming voltage input

Crystal Oscillator mode.

which has 1/4 the frequency of OSC1.

Crystal Oscillator mode.

/VPP must

TABLE 5-2: SUMMARY OF REGISTERS ASSOCIATED WITH PORTA