PIC10F200/202/204/206

Data Sheet

6-Pin, 8-Bit Flash Microcontrollers

2004 Microchip Technology Inc. Preliminary DS41239A

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical

components in life support systems is not authorized except

with express written approval by Microchip. No licenses are

conveyed, implicitly or otherwise, under any intellectual

property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, MXDEV, MXLAB, PICMASTER, SEEVAL,

SmartSensor and The Embedded Control Solutions Company

are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Migra table Memory, MPASM,

MPLIB, MPLINK, MPSIM, PICkit, PICDEM, PICDEM.net,

PICLAB, PICtail, PowerCal, PowerInfo, PowerMate,

PowerTool, rfLAB, rfPICD EM, Select Mode, Smart Serial,

SmartTel and Total Endurance are trademarks of Micro chip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2004, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

DS41239A-page ii Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

6-Pin, 8-Bit Flash Microcontrollers

Devices Included In This Data Sheet:

•PIC10F200

•PIC10F202

•PIC10F204

•PIC10F206

High-Performance RISC CPU:

• Only 33 single-word instructions to learn

• All single- cycle instructions except for program

branches, which are two-cycle

• 12-bit wide instructions

• 2-level deep hardware stack

• Direct, Indirect and Relative Addressing modes

for data and instructions

• 8-bit wide data path

• 8 Special Function Hardware registers

• Operating speed:

- 4 MHz internal clock

-1µs instruction cycle

Special Microcontroller Features:

• 4 MHz precision internal oscillator:

- Factory calibrated to ±1%

• In-Circuit Serial Programming™ (ICSP™)

• In-Circuit Debugging (ICD) support

• Power-on Reset (PO R)

• Device Reset Tim er (DRT)

• Watchdog Timer (WDT) with dedicated on-chip

RC oscillator for reliable operation

• Programmable code protection

• Multiplexed MCLR

• Internal weak pull-ups on I/O pins

• Power-saving Sleep mode

• Wake-up from Sleep on pin change

input pin

Low-Power Features/CMOS Technology:

• Operating Current:

- < 350 µA @ 2V, 4 MHz

• Standby Current:

- 100 nA @ 2V, typical

• Low-power, high-speed Flash technology:

- 100,000 Flash endurance

- > 40 year retention

• Fully static design

• Wide operating voltage range: 2.0V to 5.5V

• Wide temperature range:

- Industrial: -40°C to +85°C

- Extended: -40°C to +125°C

Peripheral Features (PIC10F200/202):

• 4 I/O pins:

- 3 I/O pins with individual direction control

- 1 input only pin

- High current sink/source for direct LED drive

- Wake-on-change

- Weak pull-ups

• 8-bit real-time cloc k/counter (TMR0) with 8-bit

programmable prescaler

Peripheral Features (PIC10F204/206):

• 4 I/O pins:

- 3 I/O pins with individual direction control

- 1 input only pin

- High current sink/source for direct LED drive

- Wake-on-change

- Weak pull-ups

• 8-bit real-time cloc k/counter (TMR0) with 8-bit

programmable prescaler

• 1 Comparator

- Internal absolute voltage refere nc e

- Both comparator inputs visible externally

- Comparator output visible externally

2004 Microchip Technology Inc. Preliminary DS41239A-page 1

PIC10F200/202/204/206

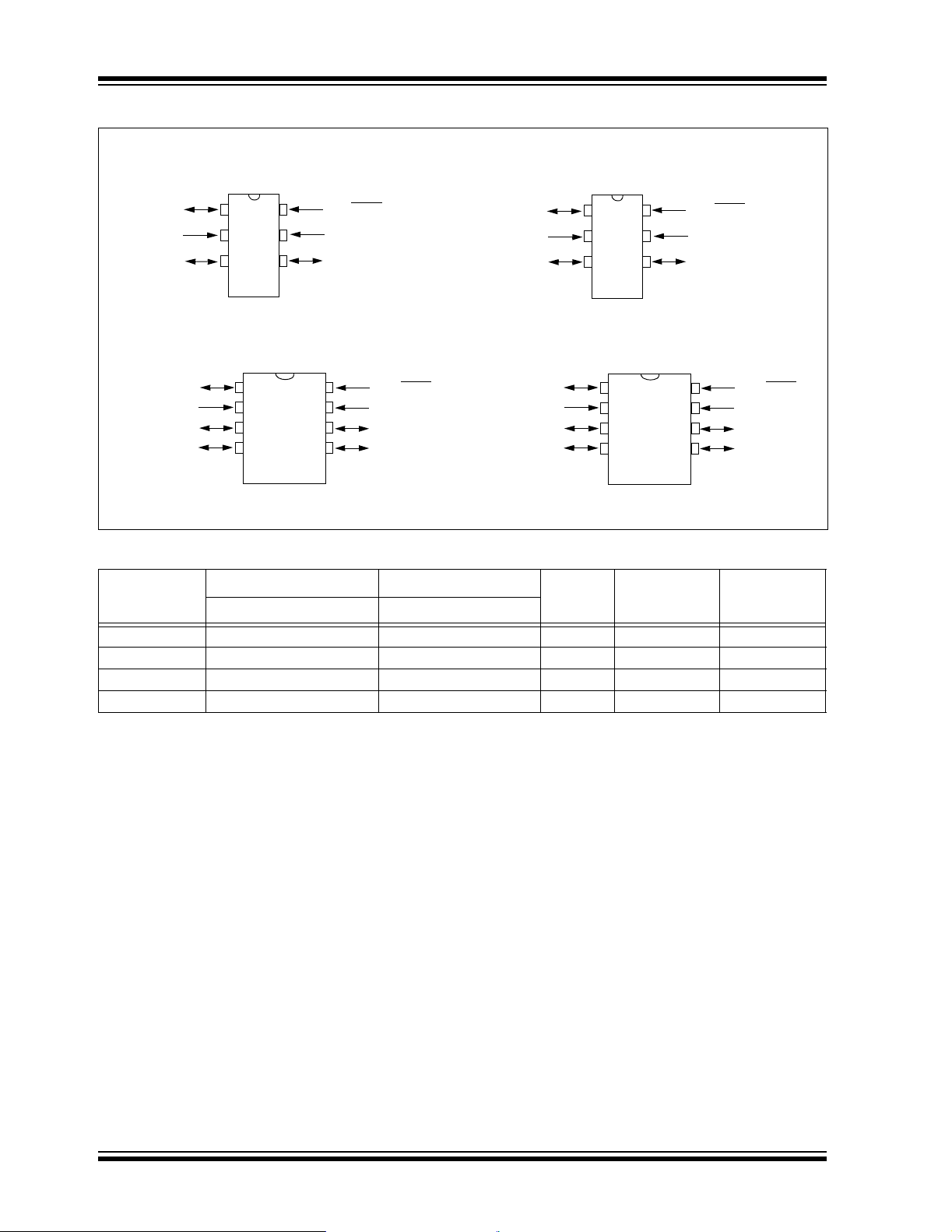

Pin Diagrams

SOT-23

GP0/ICSPDAT

SS

V

GP1/ICSPCLK

PDIP

N/C

VDD

GP2/T0CKI/FOSC4

GP1/ICSPCLK

PIC10F200/202

1

6

2

5

3

4

1

2

3

4

PIC10F200/202

8

7

6

5

GP3/MCLR

VDD

GP2/T0CKI/FOSC4

/VPP

GP3/MCLR/VPP

VSS

N/C

GP0/ICSPDAT

GP0/ICSPDAT/CIN+

GP1/ICSPCLK/CIN-

GP2/T0CKI/COUT/FOSC4

SOT-23

SS

V

PDIP

N/C

VDD

GP1/ICSPCLK/CIN-

PIC10F204/206

1

6

2

5

3

4

1

2

3

4

GP3/MCLR

VDD

GP2/T0CKI/COUT/FOSC4

PIC10F204/206

8

7

6

5

/VPP

GP3/MCLR/VPP

VSS

N/C

GP0/CIN+

TABLE 1-1: PIC10F2XX MEMORY AND FEATURES

Device

I/O

Flash (words) SRAM (bytes)

PIC10F200 256 16 4 1 0

PIC10F202 512 24 4 1 0

PIC10F204 256 16 4 1 1

PIC10F206 512 24 4 1 1

Program Memory Data Memory

Timers

8-bit

Comparator

DS41239A-page 2 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

Table of Contents

1.0 General Description............................................................................ ....... .... .. .... .. .... ................................................................... 5

2.0 PIC10F200/202/204/206 Device Varieties ............... .. .... ..... .... .. .. .... .. .. ....... .. .... .. .. .... ..... .... .. .. .... .. .. ..............................................7

3.0 Architectural Ov erview .................................................................................................................................................................9

4.0 Memory Organization................................................................................................................................................................. 15

5.0 I/O Port.......................................................................................................................................................................................25

6.0 Timer0 Module and TMR0 Register (PIC10F200/202)............................................................................................................... 29

7.0 Timer0 Module and TMR0 Register (PIC10F204/206)............................................................................................................... 33

8.0 Comparator Module................................................................................................... ....... .......................................................... 37

9.0 Special Feature s of th e CPU.......... ....................................................................... .....................................................................41

10.0 Instruction Set Summary............................................................................................................................................................ 51

11.0 Development Support............................................................................................. .................................................................... 59

12.0 Electrical Characteristics............................................................................................................................................................ 65

13.0 DC and AC Characteristics Graphs and Charts......................................................................................................................... 75

14.0 Packaging Information. ............................................................................................................................................................... 77

Index ................................................ . ................................................................................................................................................... 81

On-Line Support................................................................................................................................................................................... 83

Systems Information and Upgrade Hot Line........................................................................................................................................ 83

Reader Response................................................................................................................................................................................ 84

Product Identification System .............................................................................................................................................................. 85

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with t he best docume ntation possible to ensure successf ul use of your Mic rochip products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined

and enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@mail.microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150.

We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

• The Microchip Corporate Literature Center; U.S. FAX: (480) 792-7277

When contacting a sales office or the literature center, please specify which device, revision of silicon and data sheet (include lit-

erature number) you are using.

Customer Notification System

Register on our web site at www.microchip.com/cn to receive the most current information on all of our products.

2004 Microchip Technology Inc. Preliminary DS41239A-page 3

PIC10F200/202/204/206

NOTES:

DS41239A-page 4 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

1.0 GENERAL DESCRIPTION

The PIC10F200/202/204/206 devices from Microchip

T ec hnology are lo w-cost, hig h-performance , 8-bit, fullystatic, Flash-based CMOS microcontrollers. They

employ a RISC architecture with only 33 single-word/

single-cycle instructions. All instructions are single

cycle (1 µs) except for program branches, which take

two cycles. The PIC10F200/202/204/206 devices

deliver performance in an order of magnitude higher

than their competitors in the same price category. The

12-bit wide instructions are highly symmetrical, resulting in a typ ical 2:1 co de compre ssion over o ther 8-bi t

microcontrollers in its class. The easy to use and easy

to remember instruction set reduces development time

significantly.

The PIC10F200/202/204/206 products are equipped

with special features that reduce system cost and

power requirements. The Power-on Reset (POR) and

Device Reset Timer (DRT) eliminate the need for

external Reset circuitry. INTRC Internal Oscillator

mode is provided, thereby preserving the limited

number of I/O available. Power-saving Sleep mode,

Watchdog Timer and code protection features improve

system cost, power and reliabil ity.

The PIC10F200/202/204/206 devices are available in

cost-effective Flash, which is suitable for production in

any volume. The customer can take full advantage of

Microchip’s price leadership in Flash programmable

microcontrollers, while benefiting from the Flash

programmable flexibility.

The PIC10F200/202/204/206 products are supported

by a full-featured macro assembler, a software simulator, an in-circuit debugger, a ‘C’ compiler, a low-cost

development programmer and a full featured programmer. All the tools are supported on IBM

compatible machines.

®

PC and

1.1 Applications

The PIC10F200/202/204/20 6 devices fit in applicati ons

ranging from personal care appliances and security

systems to low-power remote transmitters/receivers.

The Flash technology makes customizing application

programs (transmitter codes, appliance settings,

receiver frequencies, etc.) extremely fast and convenient. The small footpri nt p ackag es, for t hrough h ole or

surface mounting, make these microcontrollers well

suited for application s with sp ac e limit atio ns. Low cos t,

low power, high performance, ease of use and I/O

flexibility make the PIC10F200/202/204/206 devices

very versatile even in areas where no microcontroller

use has been considered before (e.g., timer functions,

logic and PLDs in larger systems and coprocessor

applications).

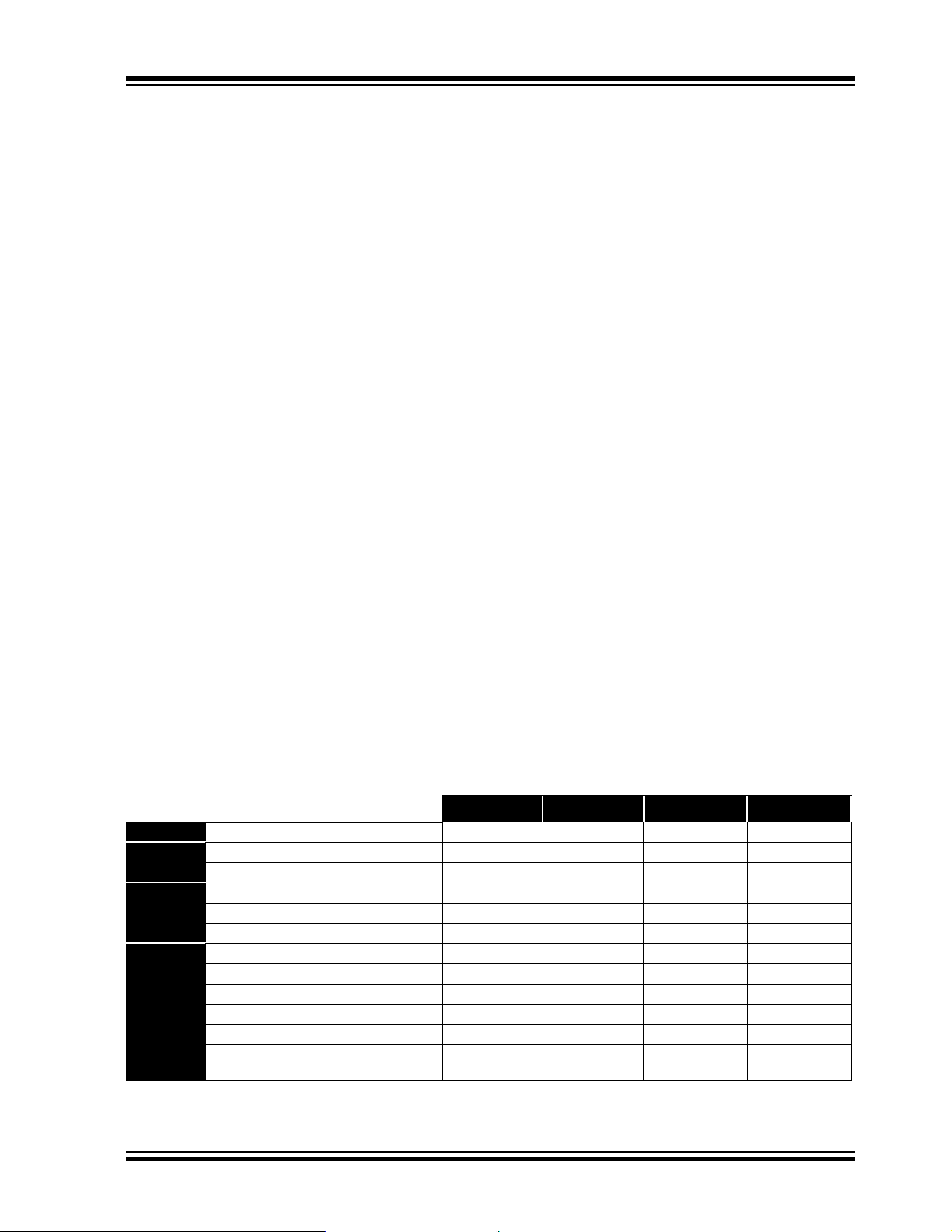

T ABLE 1-1: PIC10F200/202/204/206 DEVICES

PIC10F200 PIC10F202 PIC10F204 PIC10F206

Clock Maximum Frequency of Operation (MHz) 4 4 4 4

Memory Flash Program Memory 256 512 256 512

Data Memory (bytes) 16 24 16 24

Peripherals Timer Module(s) TMR0 TMR0 TMR0 TMR0

Wake-up from Sleep on Pin Change Yes Yes Yes Yes

Comparators 0 0 1 1

Features I/O Pins 3 3 3 3

Input Only Pins 1 1 1 1

Internal Pull-ups Yes Yes Yes Yes

In-Circuit Serial Programming Yes Yes Yes Yes

Number of Instructions 33 33 33 33

Packages 6-pin SOT-23

8-pin PDIP

The PIC10F200/202/204/206 devices have Power-on Reset, selectable Watchdog Timer, selectable code-protect, high I/O current

capability and precision internal oscillator.

The PIC10F200/202/204/206 device uses serial programming with data pin GP0 and clock pin GP1.

2004 Microchip Technology Inc. Preliminary DS41239A-page 5

6-pin SOT-23

8-pin PDIP

6-pin SOT-23

8-pin PDIP

6-pin SOT-23

8-pin PDIP

PIC10F200/202/204/206

NOTES:

DS41239A-page 6 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

2.0 PIC10F200/202/204/206 DEVICE VARIETIES

A variety of packaging options are available. Depending on application and production requirements, the

proper device option can be selected using the

information in th is section. Wh en placing orde rs, please

use the PIC10F200/202 /204 /20 6 Prod uc t Ide ntif ic atio n

System at the back of this data sheet to specify the

correct part number.

2.1 Quick Turn Programming (QTP)

Devices

Microchip offers a QTP programming service for

factory production orders. This service is made

available for users who choose not to program

medium-to-high quantity units and whose code

patterns have stabilized. The devices are identical to

the Flash devices but with all Flash locations and fuse

options already programmed by the factory. Certain

code and prototype verification procedures do apply

before production shipments are available. Please

contact your loc al Microchi p Technology sales of fice for

more details.

2.2 Serialized Quick Turn

Programming

Microchip offers a unique programming service, where

a few user-defined locations in each device are

programmed with different serial numbers. The serial

numbers may be random, pseudo-random or

sequential.

Serial programming allows each device to have a

unique number, which can serve as an entry code,

password or ID number.

SM

(SQTPSM) Devices

2004 Microchip Technology Inc. Preliminary DS41239A-page 7

PIC10F200/202/204/206

NOTES:

DS41239A-page 8 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

3.0 ARCHITECTURAL OVERVIEW

The high performance of the PIC10F200/202/204/206

devices can be attributed to a number of architectural

features commonly found in RISC microprocessors. To

begin with, the PIC10F200/202/204/206 devices use a

Harvard architecture in which program and data are

accessed on separate buses. This improves bandwidth over traditional von Neumann architectures

where program and data are fetched on the same bus.

Separating program and data memory further allows

instructions to be sized differently than the 8-bit wide

data word. Instruction opcodes are 12 bits wide,

making it possible to have all single-word instructions.

A 12-bit wide program memory access bus fetches a

12-bit instruction in a single cycle. A two-stage pipeline

overlaps fetch and execution of instructions.

Consequently, all instructions (33) execute in a single

cycle (1 µs @ 4 MHz) except for program branches.

The table belo w lists p rogram me mory (Flash) and data

memory (RAM) for the PIC10F200/202/204/206

devices.

TABLE 3-1: PIC10F2XX MEMORY

Memory

Device

Program Data

PIC10F200 256 x 12 16 x 8

PIC10F202 512 x 12 24 x 8

PIC10F204 256 x 12 16 x 8

PIC10F206 512 x 12 24 x 8

The PIC10F200/202/204/206 devices contain an 8-bit

ALU and working register. The ALU is a general

purpose arithmetic unit. It performs arithmetic and

Boolean functions be tween dat a in the work ing regist er

and any register file.

The ALU is 8 bits wide and capable of addition, subtraction, shift and logical operations. Unless otherwise

mentioned, arithmetic operations are two’s complement in nature. In two-operand instructions, one operand is typically the W (working) register. The other

operand is either a file register or an immediate

constant. In sing le ope ran d inst ruction s, the operan d is

either the W register or a file register.

The W register is an 8-bit workin g register used for ALU

operations. It is not an addressable register.

Depending on the instruction executed, the ALU may

affect the values of the Carry (C), Digit Carry (DC) and

Zero (Z) bits in the Status register. The C and DC bits

operate as a borrow

tively, in subtraction. See the SUBWF and ADDWF

instructions for examples.

A simplified block diagram is shown in Figure 3-1 and

Figure 3-2, with the corresponding device pins

described in Table 3-2.

and digit borrow out bit, respec-

The PIC10F200/202/204/206 devices can directly or

indirectly address its reg ister file s and dat a mem ory. All

Special Function Registers (SFR), including the PC,

are mapped in the data memory. The PIC10F200/202/

204/206 devices have a highly orthogonal

(symmetrica l) instruct ion set that m akes it possib le to

carry out any operation, on any register, using any

addressing mode. This symmetrical nature and lack of

“special optimal situ ations” make programm ing with the

PIC10F200/202/204/206 devices simple, yet efficient.

In addition, the learning curve is reduced significantly.

2004 Microchip Technology Inc. Preliminary DS41239A-page 9

PIC10F200/202/204/206

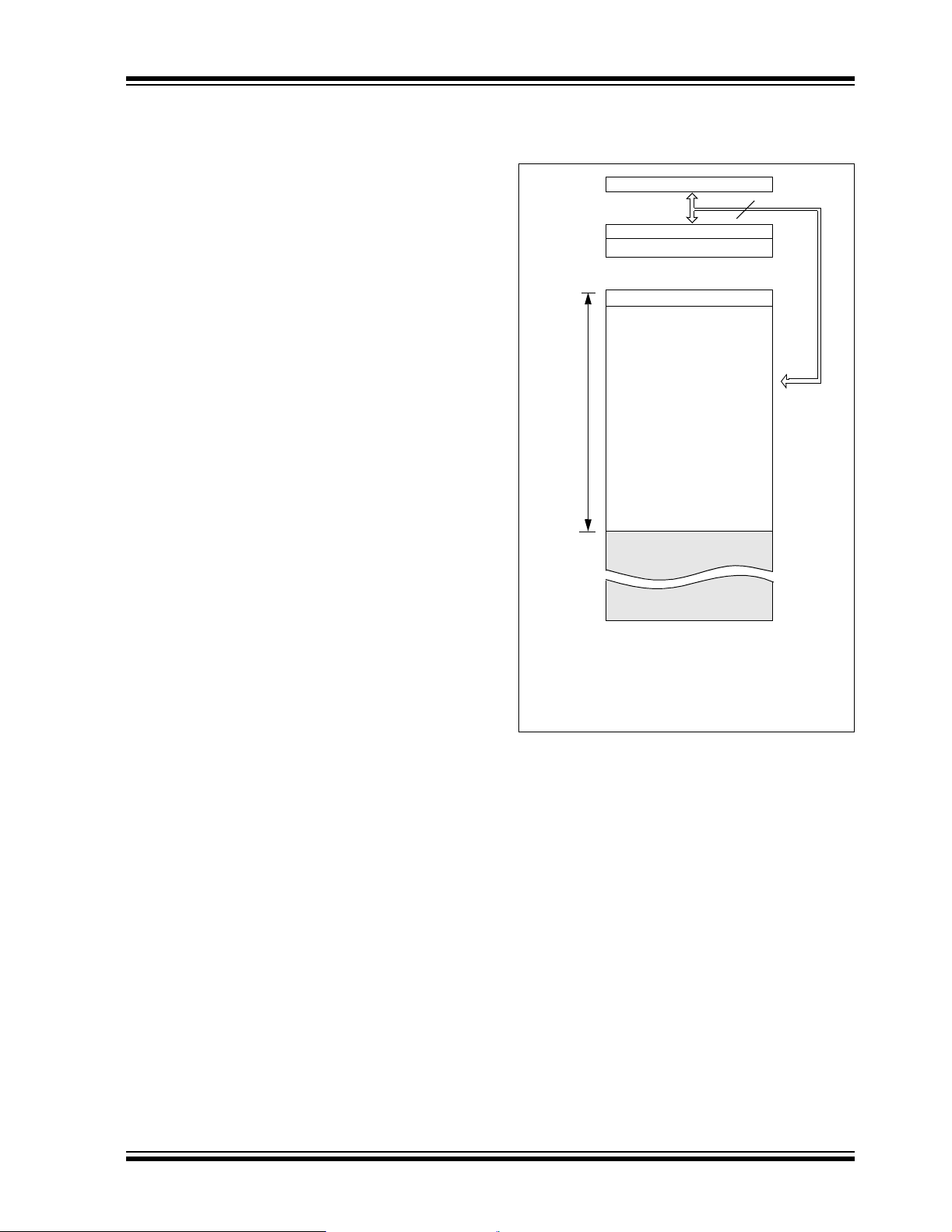

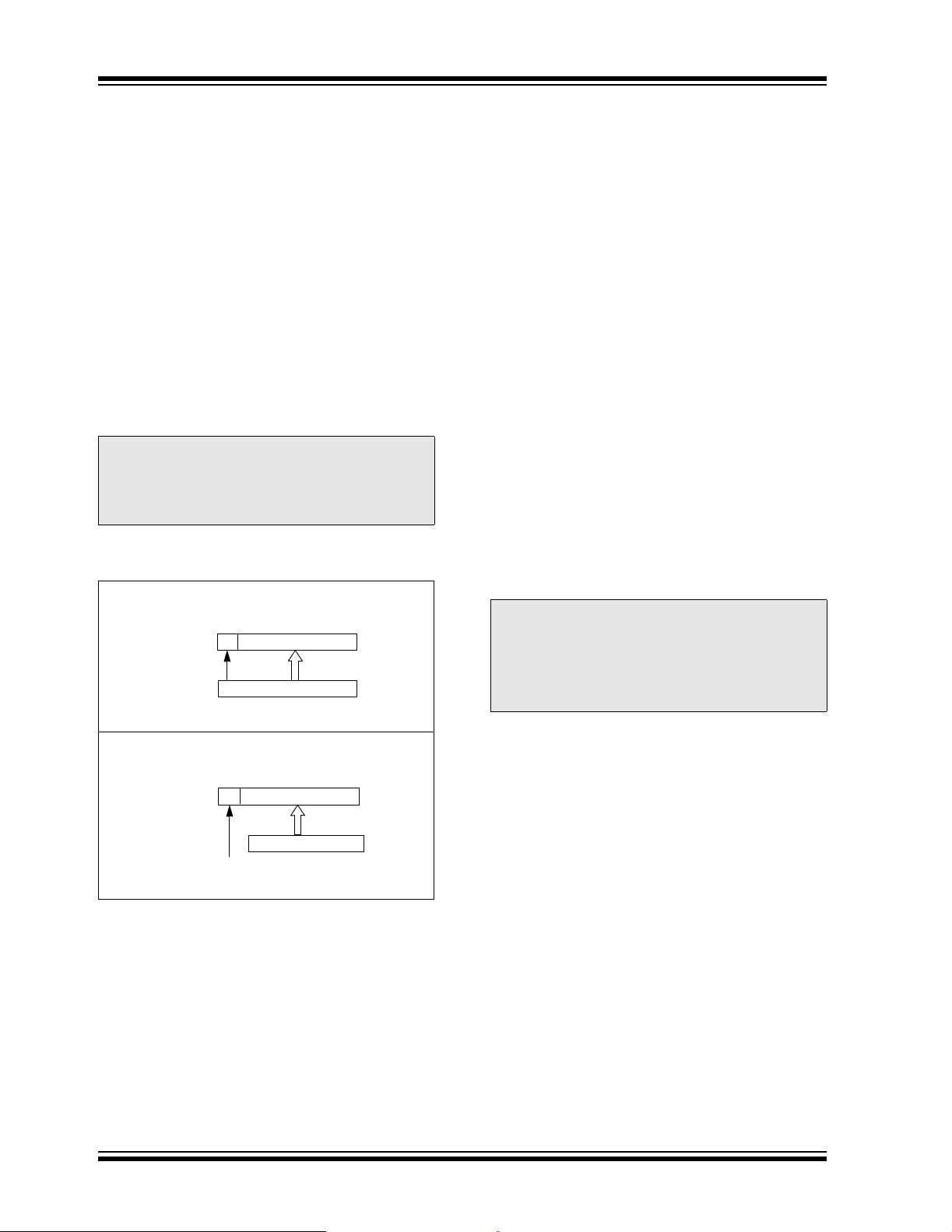

FIGURE 3-1: PIC10F200/202 BLOCK DIAGRAM

Program

Bus

Flash

512 x12 or

256 x12

Program

Memory

12

Instruction reg

Instruction

Decode &

Control

Timing

Generation

9-10

Program Counter

Direct Addr

8

Device Reset

Power-on

Watchdog

Internal RC

MCLR

Stack 1

Stack 2

Timer

Reset

Timer

Clock

VDD, VSS

RAM Addr

5

Data Bus

RAM

24 or 16

bytes

File

Registers

(1)

Addr MUX

3

ALU

8

W reg

9

Indirect

5-7

FSR reg

Status re g

MUX

Timer0

Addr

8

GPIO

GP0/ICSPDAT

GP1/ICSPCLK

GP2/T0CKI/FOSC4

GP3/MCLR/VPP

DS41239A-page 10 Preliminary 2004 Microchip Technology Inc.

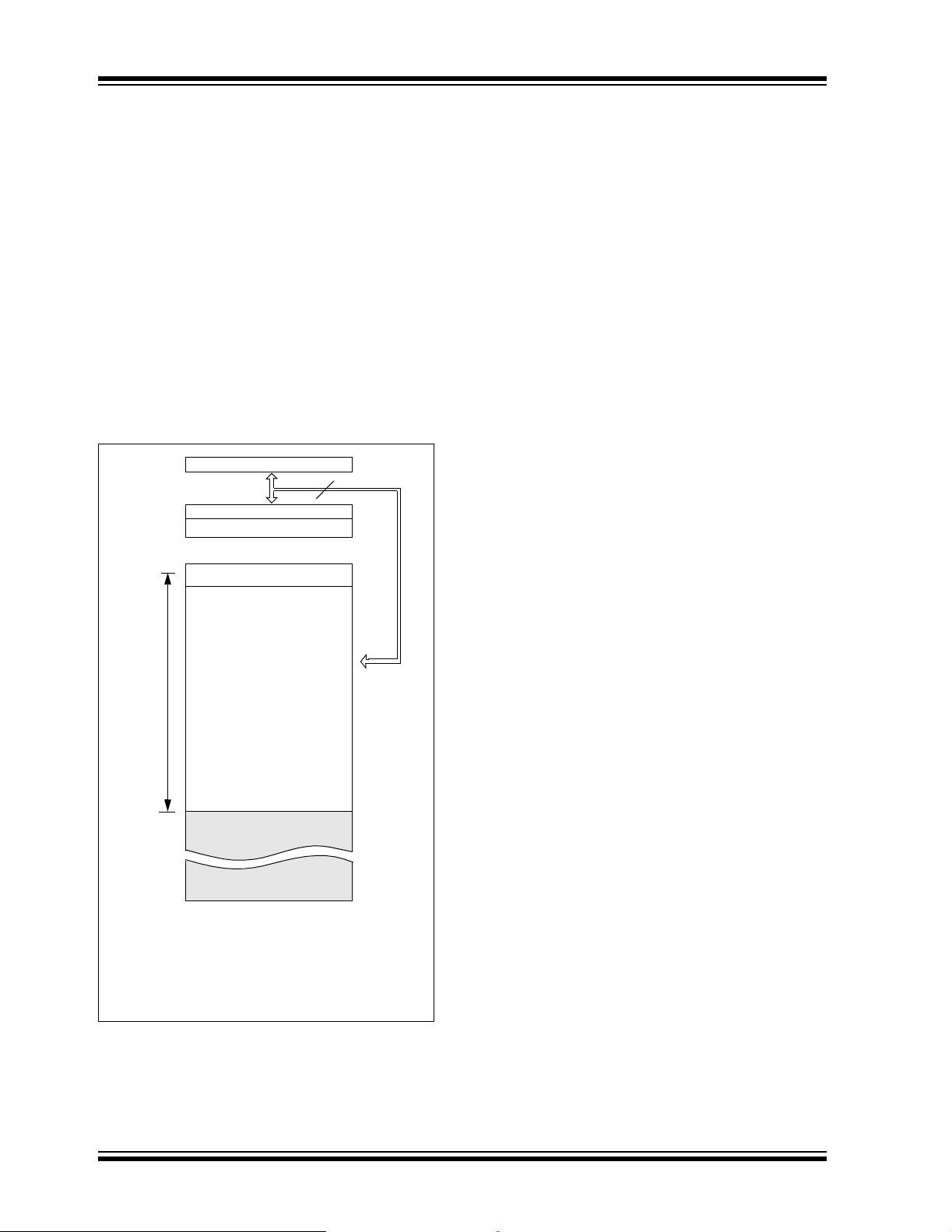

PIC10F200/202/204/206

FIGURE 3-2: PIC10F204/206 BLOCK DIAGRAM

Program

Bus

Flash

512 x12 or

256 x12

Program

Memory

12

Instruction reg

Instruction

Decode &

Control

Timing

Generation

9-10

Program Counter

Direct Addr

8

Device Reset

Power-on

Watchdog

Internal RC

MCLR

Stack 1

Stack 2

Timer

Reset

Timer

Clock

VDD, VSS

RAM Addr

5

Data Bus

RAM

24 or 16

bytes

File

Registers

(1)

Addr MUX

3

ALU

8

W reg

9

Indirect

5-7

FSR reg

Status re g

MUX

Timer0

Addr

8

GPIO

Comparator

GP0/ICSPDAT

GP1/ICSPCLK

GP2/T0CKI/FOSC4

GP3/MCLR/VPP

CIN+

CINCOUT

2004 Microchip Technology Inc. Preliminary DS41239A-page 11

PIC10F200/202/204/206

TABLE 3-2: PIC10F200/202/204/206 PINOUT DESCRIPTION

Name Function

GP0/ICSPDA T/ CIN+ GP0 TTL CMOS Bidirectional I/O pin. Can be software programmed for i nternal

ICSPDAT ST CMOS In -Circu it Serial Programming

CIN+ AN — Comparator input (PIC10F204/206 only).

GP1/ICSPCLK/CIN- GP1 TTL CMOS Bidirectional I/O pin. Can be software programmed for i nternal

ICSPCLK ST CMOS In-Circuit Serial Programming clock pin.

CIN- AN — Comparator input (PIC10F204/206 only).

GP2/T0CKI/COUT/

FOSC4

GP3/MCLR

DD VDD P — Positive supply for logic and I/O pins.

V

VSS VSS P — Ground reference for logic and I/O pins.

Legend: I = Input, O = Output, I/O = Input/Output, P = Power, — = Not used, TTL = TTL input,

/VPP GP3 TTL — Input pin. Can be software programmed for internal weak

ST = Schmitt Trigger input, AN = Analog input

GP2 TTL CMOS Bidirectional I/O pin.

T0CKI ST — Clock input to TMR0.

COUT — CMOS Comparator output (PIC10F204/206 only).

FOSC4 — CMOS Oscillator/4 output.

MCLR

VPP HV — Programming voltage input.

Input

Type

Output

Type

weak pull-up and wake-up from Sleep on pin change.

weak pull-up and wake-up from Sleep on pin change.

pull-up and wake-up from Sleep on pin change.

ST — Master Clear (Reset). When configured as MCLR, this pin is

an active-low Rese t to the de vice. Voltage on GP3/M

must not exceed V

device will enter Programming mode. Weak pull-up alway s on

if configured as MCLR.

Description

™

data pin.

CLR/VPP

DD during normal device operation or the

DS41239A-page 12 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

3.1 Clocking Scheme/Instruction

Cycle

The clock is internally divided by four to generate four

non-overlapping quadrature clocks, namely Q1, Q2,

Q3 and Q4. Internal ly, the PC is incremented ev ery Q1

and the instruction is fetched from program memory

and latched into the instruction register in Q4. It is

decoded and execute d during the followin g Q1 throug h

Q4. The clocks and instruction execution flow is shown

in Figure 3-3 and Example 3-1.

FIGURE 3-3: CLOCK/INSTRUCTION CYCLE

Q2 Q3 Q4

OSC1

Q1

Q2

Q3

Q4

PC

Q1

PC PC+1 PC+2

Q1

3.2 Instruction Flow/Pipelining

An instruction cycle consists of four Q cycles (Q1, Q2,

Q3 and Q4). The instruction fetch and execute are

pipelined such that fetch takes one instruction cycle,

while decode and execute take another instruction

cycle. However, due to the pipelining, each instruction

effectively executes in one cycle. If an instruction

causes the PC to change (e.g ., GOTO), t hen two c yc le s

are required to complete the ins tructi on (Exampl e 3-1).

A fetch cycle begins with the PC incrementing in Q1.

In the execution cy cle, the fetch ed instruction i s latched

into the Instruction Register (IR) in cycle Q1. This

instruction is then decoded and executed during the

Q2, Q3 and Q4 c ycles. Dat a m emory is read during Q2

(operand read) and written during Q4 (destination

write).

Q2 Q3 Q4

Q1

Q2 Q3 Q4

Internal

phase

clock

Fetch INST (PC)

Execute INST (PC – 1)

Fetch INST (PC + 1)

Execute INST (PC)

Fetch INST (PC + 2)

Execute INST (PC + 1)

EXAMPLE 3-1: INSTRUCTION PIPELINE FLOW

1. MOVLW 03H

2. MOVWF GPIO

3. CALL SUB_1

4. BSF GPIO, BIT1

All instructions are si ngle cycle, except for any program bra nches. These tak e two cycles, since th e fetch instruction

is “flushed” from the pipeline, while the new instruction is being fetched and then executed.

Fetch 1 Execute 1

Fetch 2 Execute 2

Fetch 3 Execute 3

Fetch 4 Flush

Fetch SUB_1 Execute SUB_1

2004 Microchip Technology Inc. Preliminary DS41239A-page 13

PIC10F200/202/204/206

NOTES:

DS41239A-page 14 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

4.0 MEMORY ORGANIZATION

The PIC10F200/202/204/206 memories are organized

into program memory and data memory. Data memory

banks are accessed using the File Select Register

(FSR).

4.1 Program Memory Organization for

the PIC10F200/204

The PIC10F200/204 devices have a 9-bit Program

Counter (PC) capable of addressing a 512 x 12

program memory space.

Only the first 256 x 12 (0000h-00FFh) for the

PIC10F200/204 are physically implemented (see

Figure 4-1). Accessing a location above these

boundaries will cause a wraparound within the first

256 x 12 space (PIC10F200/204). The effective

Reset vector is at 0000h (see Figure 4-1). Location

00FFh (PIC10F200/204) contains the interna l clock

oscillator calibration value. This value should never

be overwritten.

FIGURE 4-1: PROGRAM MEMORY MAP

AND STACK FOR THE

PIC10F200/204

PC<7:0>

CALL, RETLW

Stack Level 1

Stack Level 2

Reset Vector

On-chip Program

Memory

Space

User Memory

256 Word

9

(1)

0000h

00FFh

0100h

Note 1: Address 0000h becomes the

effective Reset vector. Location

00FFh contains the MOVLW XX

internal oscillator calibration value.

01FFh

2004 Microchip Technology Inc. Preliminary DS41239A-page 15

PIC10F200/202/204/206

4.2 Program Memory Organization for

the PIC10F202/206

The PIC10F202/206 devices have a 10-bit Program

Counter (PC) capable of addressing a 1024 x 12

program memory space.

Only the first 512 x 12 (0000h-01FFh) for the

PIC10F202/206 are physically implemented (see

Figure 4-2). Accessing a location above these

boundaries will cause a wraparound within the first

512 x 12 space (PIC10F202/206). The effective

Reset vector is at 0000h (see Figure 4-2). Location

01FFh (PIC10F202/206) contains the interna l clock

oscillator calibration value. This value should never

be overwritten.

FIGURE 4-2: PROGRAM MEMORY MAP

AND STACK FOR TH E

PIC10F202/206

PC<8:0>

CALL, RETLW

Stack Level 1

Stack Level 2

Reset Vector

On-chip Program

Memory

10

(1)

0000h

4.3 Data Memory Organization

Data memory is composed of registers or bytes of

RAM. Therefore, da ta memory for a device is sp eci fie d

by its register file. The register file is divided into two

functional groups: Special Function Registers (SFR)

and General Purpose Registers (GPR).

The Special Function Regi st ers in cl ude the TMR0 register, the Program Counter (PCL), the Status register,

the I/O register (GPIO) and the File Select Register

(FSR). In addition, Special Func tion Registers are use d

to control the I/O port configuration and prescaler

options.

The General Purpose Registers are used for data and

control informatio n u nd er com ma nd of the instructions.

For the PIC10F200/204, the register file is composed of

7 Special Function Registers and 16 General Purpose

Registers (see Figure 4-3 and Figure 4-4).

For the PIC10F202/206, the register file is composed of

8 Special Function Registers and 24 General Purpose

Registers (see Figure 4-4).

4.3.1 GENERAL PURPOSE REGISTER

FILE

The General Purpose Register file is accessed, either

directly or indirectly, through the File Select Register

(FSR). See Section 4.9 “Indirect Data Addressing:

INDF and FSR Registers”.

Space

User Memory

512 Words

Note 1: Address 0000h becomes the

effective Reset vector. Location

01FFh contains the MOVLW XX

internal oscillator calibration value.

01FFh

0200h

02FFh

DS41239A-page 16 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

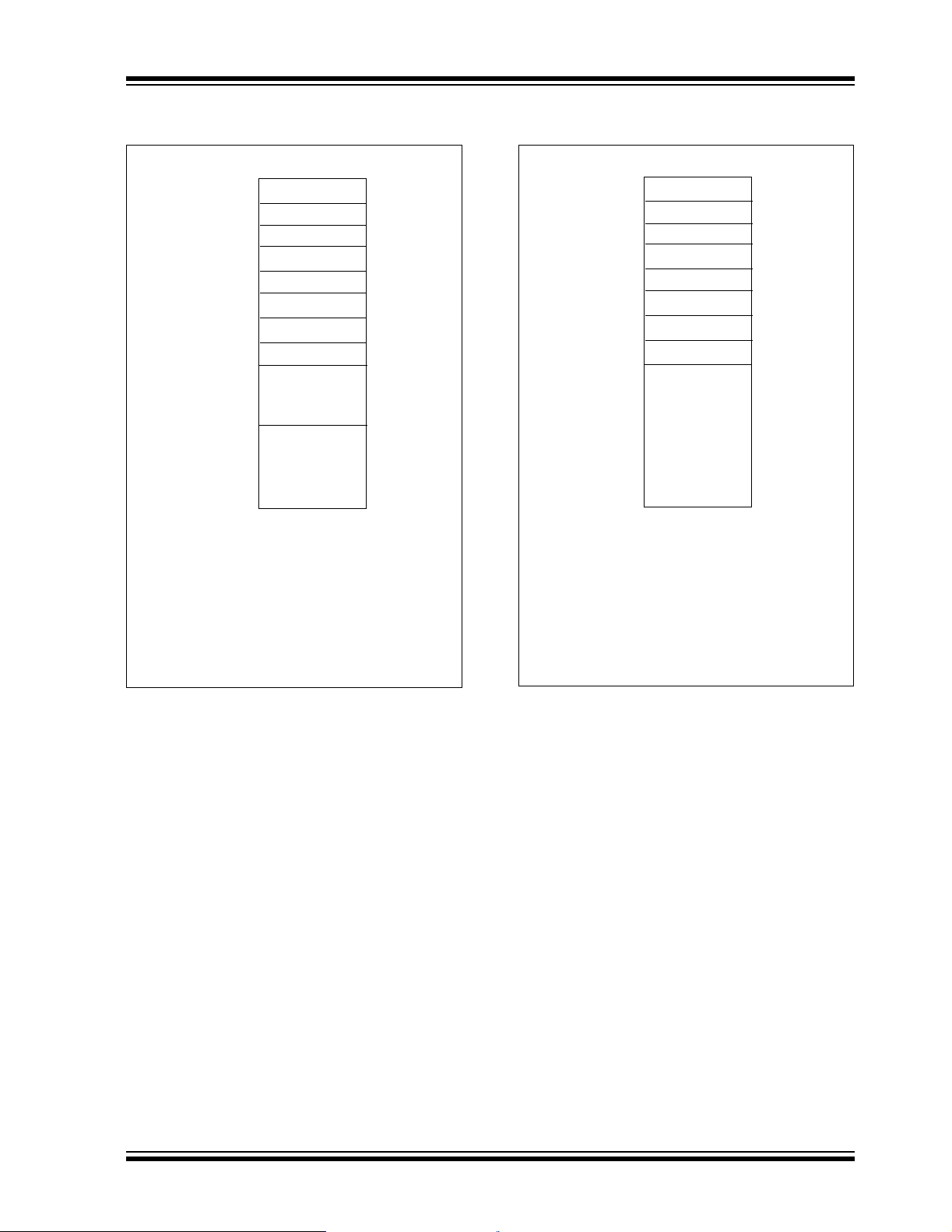

FIGURE 4-3: PIC10F200/204 REGISTER

FILE MAP

File Address

(1)

00h

01h

02h

03h

04h

05h

06h

07h

08h

0Fh

10h

1Fh

Note 1: Not a physical register. See Section 4.9

“Indirect Data Addressing: INDF and

FSR Registers”.

2: PIC10F204 only. Unimplemented on the

PIC10F200 and reads as 00h.

3: Unimplemented, read as 00h.

INDF

TMR0

PCL

STATUS

FSR

OSCCAL

GPIO

General

Purpose

Registers

(2)

CMCON0

Unimplemented

(3)

FIGURE 4-4: PIC10F202/206 REGISTER

FILE MAP

File Address

(1)

00h

01h

02h

03h

04h

05h

06h

07h

08h

18h

Note 1: Not a physical register. See Section 4.9

“Indirect Data Addressing: INDF and

FSR Registers”.

2: PIC10F206 only. Unimplemented on the

PIC10F202 and reads as 00h.

INDF

TMR0

PCL

STATUS

FSR

OSCCAL

GPIO

CMCON0

General

Purpose

Registers

(2)

2004 Microchip Technology Inc. Preliminary DS41239A-page 17

PIC10F200/202/204/206

4.3.2 SPECIAL FUNCTION REGISTERS

The Special Function Registers (SFRs) are registers

used by the CPU and per ipheral functio ns to con trol the

operation of the device (Table 4-1).

The Special Function Registers can be classified into

two sets. The Special Function Registers associated

with the “core” functions are described in this section.

Those related to the operation of the peripheral

features are described in the section for each

peripheral feature.

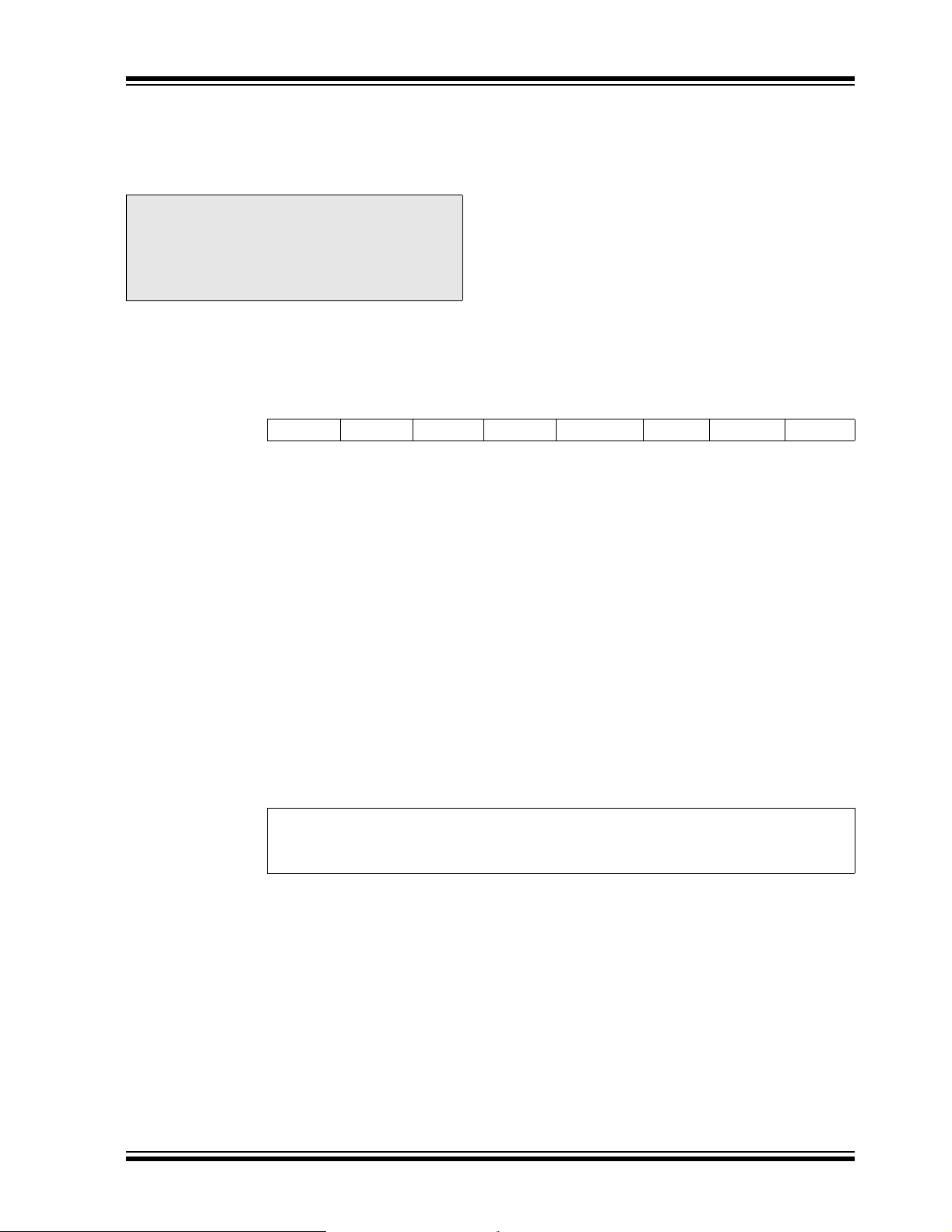

TABLE 4-1: SPECIAL FUNCTION REGISTER (SFR) SUMMARY (PIC10F200/202/204/206)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

00h INDF Uses Contents of FSR to Address Data Memory (not a physical register) xxxx xxxx 23

01h TMR0 8-bit Real-Time Clock/Counter xxxx xxxx 29, 33

(1)

02h

03h STATUS GPWUF CWUF

04h FSR Indirect Data Memory Address Pointer 111x xxxx 23

05h OSCCAL CAL6 CAL5 CAL4 CAL3 CAL2 CAL1 CAL0 FOSC4 1111 1110 21

06h GPIO

07h

N/A TRISGPIO

N/A OPTION GPWU

Legend: — = unimplemented, read as ‘0’, x = unknown, u = unchanged, q = value depends on condition.

Note 1: The upper byte of the Program Counter is not directly accessible. See S ection 4.7 “Program Counter” for an

PCL Low-order 8 bits of PC 1111 1111 22

(5)

—TOPD ZDCC00-1 1xxx

— — — — GP3 GP2 GP1 GP0 ---- xxxx 25

(4)

CMCON0 CMPOUT COUTEN POL CMPT0CS CMPON CNREF CPREF CWU 1111 1111 34

— — — — I/O Control Register ---- 1111 37

GPPU T0CS T0SE PSA PS2 PS1 PS0 1111 1111 20

explanation of how to access these bits.

2: Other (non Power-up) Resets include external Reset through MCLR

Reset.

3: See Table 9-1 for other Reset specific values.

4: PIC10F204/206 only.

5: PIC10F204/206 only. On all other devices, this bit is reserved and should not be used.

, Watchdog Timer and wake-up on pin change

Value on

Power-On

(2)

Reset

(3)

Page #

19

DS41239A-page 18 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

4.4 Status Register

This register contains the arithmetic status of the ALU,

the Reset status and the page preselect bit.

The Status register can be the destination for any

instruction, as with any other register. If the Status

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. These bit s are set or cleared ac cording to the

device logic. Furthermore, the TO

writable. Therefore, the result of an instruction with the

Status register as destination may be different than

intended.

and PD bits are not

For example, CLRF STATUS, will clear the upper three

bits and set the Z bit. Thi s leav es the Status register as

000u u1uu (where u = unchanged).

Therefore, it is recommended that only BCF, BSF and

MOVWF instructions be used to alter the Status register.

These instructions do no t affect the Z, DC or C bit s from

the Status register. For other instructions which do

affect Status bits, see Section 10.0 “Instruction Set

Summary”.

REGISTER 4-1: STATUS REGISTER (ADDRESS: 03h)

R/W-0 R/W-0 R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

GPWUF CWUF

bit 7 bit 0

bit 7 GPWUF: GPIO Reset bit

1 = Reset due to wake-up from Sleep on pin change

0 = After power-up or other Reset

bit 6 CWUF: Comparator Wake-up on Change Flag Bit

1 = Reset due to wake-up from Sleep on comparator change

0 = After power-up or other Reset conditions.

bit 5 Reserved: Do not use. Use of this bit may affect upward compatibility with future products.

bit 4 TO

bit 3 PD

bit 2 Z: Zero bit

bit 1 DC: Digit carry/borrow

bit 0 C: Carry/borrow bit (for ADDWF, SUBWF and RRF, RLF instructions)

: Time-out bit

1 = After power-up, CLRWDT instruction or SLEEP instruction

0 = A WDT time-out occurred

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

ADDWF

:

1 = A carry from the 4th low-order bit of the result occurred

0 = A carry from the 4th low-order bit of the result did not occur

:

SUBWF

1 = A borrow from the 4th low-order bit of the result did not occur

0 = A borrow from the 4th low-order bit of the result occurred

ADDWF

: SUBWF: RRF or RLF:

1 = A carry occurred 1 = A borrow did not occur Load bit with LSb or MSb, respectively

0 = A carry did not occur 0 = A borrow occurred

(1)

—TO PD ZDCC

bit (for ADDWF and SUBWF instructions)

(1)

Note 1: This bit is used on the PIC10F204/206. For code compatibili ty do not use this bit on

the PIC10F200/202.

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

2004 Microchip Technology Inc. Preliminary DS41239A-page 19

PIC10F200/202/204/206

4.5 Option Register

The Option register is a 8-bit wide, write-only register,

which contains various control bits to configure the

Timer0/WDT prescaler and Timer0.

By executin g the OPTION instruction, the contents of

the W register will be transfe rred to the Option registe r.

A Reset sets the OPTION<7:0> bits.

REGISTER 4-2: OPTION REGISTER

W-1 W-1 W-1 W-1 W-1 W-1 W-1 W-1

GPWU

bit 7 bit 0

GPPU T0CS T0SE PSA PS2 PS1 PS0

Note: If TRIS bit is set to ‘0’, the wake-up on

change and pull-up functions are disabled

for that pin (i.e., note that TRIS overrides

Option control of GPPU

Note: If the T0CS bit is set to ‘1’, it will override

the TRIS function on the T0CKI pin.

and GPWU).

bit 7 GPWU

bit 6 GPPU

bit 5 T0CS: Timer0 Clock Source Select bit

bit 4 T0SE: Timer0 Source Edge Select bit

bit 3 PSA: Prescaler Assignment bit

bit 2-0 PS<2:0>: Prescaler Rate Select bits

: Enable Wake-up on Pin Change bit (GP0, GP1, GP3)

1 = Disabled

0 = Enabled

: Enable Weak Pull-ups bit (GP0, GP1, GP3)

1 = Disabled

0 = Enabled

1 = Transition on T0CKI pin (overrides TRIS on the T0CKI pin)

0 = Transition on internal instruction cycle clock, F

1 = Increment on high-to-low transition on the T0CKI pin

0 = Increment on low-to-high transition on the T0CKI pin

1 = Prescaler assigned to the WDT

0 = Prescaler assigned to Timer0

Bit Value Timer0 Rate WDT Rate

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

OSC/4

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS41239A-page 20 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

4.6 OSCCAL Register

The Oscillator Calibrati on (OSCCAL) register is used to

calibrate the internal precision 4 MHz oscillator. It

contains seven bit s for cal ibra tio n

Note: Erasing the device will also erase the pre-

programmed internal calibration value for

the internal oscillator. The calibration

value must be read prior to erasing the

part so it can be reprogrammed correctly

later.

After you move in the calibration constant, do not

change the value. See Section 9.2.2 “Internal 4 MHz

Oscillator”.

REGISTER 4-3: OSCCAL REGISTER (ADDRESS: 05h)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-0

bit 7 bit 0

bit 7-1 CAL<6:0>: Oscillator Calibration bits

0111111 = Maximum frequency

•

•

•

0000001

0000000 = Center frequency

1111111

•

•

•

1000000 = Minimum frequency

bit 0 FOSC4: INTOSC/4 Output Enable bit

1 = INTOSC/4 output onto GP2

0 = GP2/T0CKI/COUT applied to GP2

.

CAL6 CAL5 CAL4 CAL3 CAL2 CAL1 CAL0 FOSC4

(1)

Note 1: Overrides GP2/T0CKI/COUT control registers when enabled.

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

2004 Microchip Technology Inc. Preliminary DS41239A-page 21

PIC10F200/202/204/206

4.7 Program Counter

As a program instruction is executed, the Program

Counter (PC) will contain the address of the next

program instruction to be executed. The PC value is

increased by one every instruction cycle, unless an

instruction changes the PC.

For a GOTO instruction, bits 8:0 of the PC are provided

by the GOTO instruction word. The Program Counter

(PCL) is mapped to PC<7:0>.

For a CALL instruction, or any instruction where the

PCL is the destinatio n, bits 7:0 of the PC ag ain are pr ovided by the instruction word. However, PC<8> does

not come from the instruction word, but is always

cleared (Figure 4-5).

Instructions wh ere the PCL is th e destinatio n, or modif y

PCL instructions, include MOVWF PC, ADDWF PC and

BSF PC,5.

Note: Because PC<8> is cleared in the CALL

instruction or any modify PCL instruction,

all subroutine calls or computed jumps are

limited to the first 256 locations of any

program memory page (512 words long).

FIGURE 4-5: LOADING OF PC

BRANCH INSTRUCTIONS

GOTO Instruction

87 0

PC

PCL

Instruction Wor d

4.7.1 EFFECTS OF RESET

The PC is set upon a Reset, which means that the PC

addresses the last location in program memory (i.e.,

the oscillator calibration instruction). After executing

MOVLW XX, the PC will roll over to location 0000h and

begin executing user code.

4.8 Stack

The PIC10F200/204 devi ce s have a 2-deep, 8-b it wid e

hardware PUSH/POP stack.

The PIC10F202/206 devi ce s have a 2-deep, 9-b it wid e

hardware PUSH/POP stack.

A CALL instruction will PUSH the current value of Stack 1

into Stack 2 and then PUSH the current PC value,

incremented by o ne , i nt o Stack Level 1. If m ore th an t w o

sequential CALLs are executed, o nly the mo st recen t two

return addresse s a r e s tor ed .

A RETLW instruction will POP the contents of Stack

Level 1 into the PC and then copy Stack Level 2

contents into level 1. If more than two sequential

RETLWs are execute d, the stack will be fi lled with the

address previously stored in Stack Level 2. Note that

the W register will be loaded with the literal value

specified in the i nstruction. Th is is particu larly useful for

the implementation of data look-up tables within the

program memory.

Note 1: There are no Status bits to indicate stack

overflows or stack underflow conditions.

2: There are no instruction mnemonics

called PUSH or POP. These are actions

that occur from the e xecution of the CALL

and RETLW instructions.

CALL or Modify PCL Instruction

87 0

PC

Reset to ‘0’

DS41239A-page 22 Preliminary 2004 Microchip Technology Inc.

PCL

Instruction Word

PIC10F200/202/204/206

4.9 Indirect Data Addressing: INDF

and FSR Registers

The INDF register is not a physical register.

Addressing INDF actually addresses the register

whose address is contain ed in the FS R reg ist er (FSR

is a pointer). This is indirect addr es sing.

4.10 Indirect Addressing

• Register file 09 contains the value 10h

• Register file 0A contains the value 0Ah

• Load the value 09 into the FSR register

• A read of the INDF register will return the value

of 10h

• Increment the value of the FSR register by one

(FSR = 0A)

• A read of the INDR register now will return the

value of 0Ah.

Reading INDF itself indirectly (FSR = 0) will produce

00h. Writing to the INDF register indirectly results in a

no operation (although Status bits may be affected).

A simple program to clear RAM locations 10h-1Fh

using indirect addressing is shown in Example 4-1.

EXAMPLE 4-1: HOW TO CLEAR RAM

USING INDIRECT

ADDRESSING

MOVLW 0x10 ;initiali ze pointer

MOVWF FSR ;to RAM

NEXT CLRF INDF ;cle a r I N D F

;register

INCF FSR,F ;inc pointer

BTFSC FSR,4 ;all done?

GOTO NEXT ;NO, clear next

CONTINUE

: ;YES, continue

:

The FSR is a 5-bit wide register. It is used in conjunction with the INDF regis ter to indirectly a ddress the dat a

memory area.

The FSR<4:0> bits are used to select data memory

addresses 00h to 1Fh.

Note: PIC10F200/202/204/206 – Do not use

banking. FSR <7:5> are unimplemented

and read as ‘1’s.

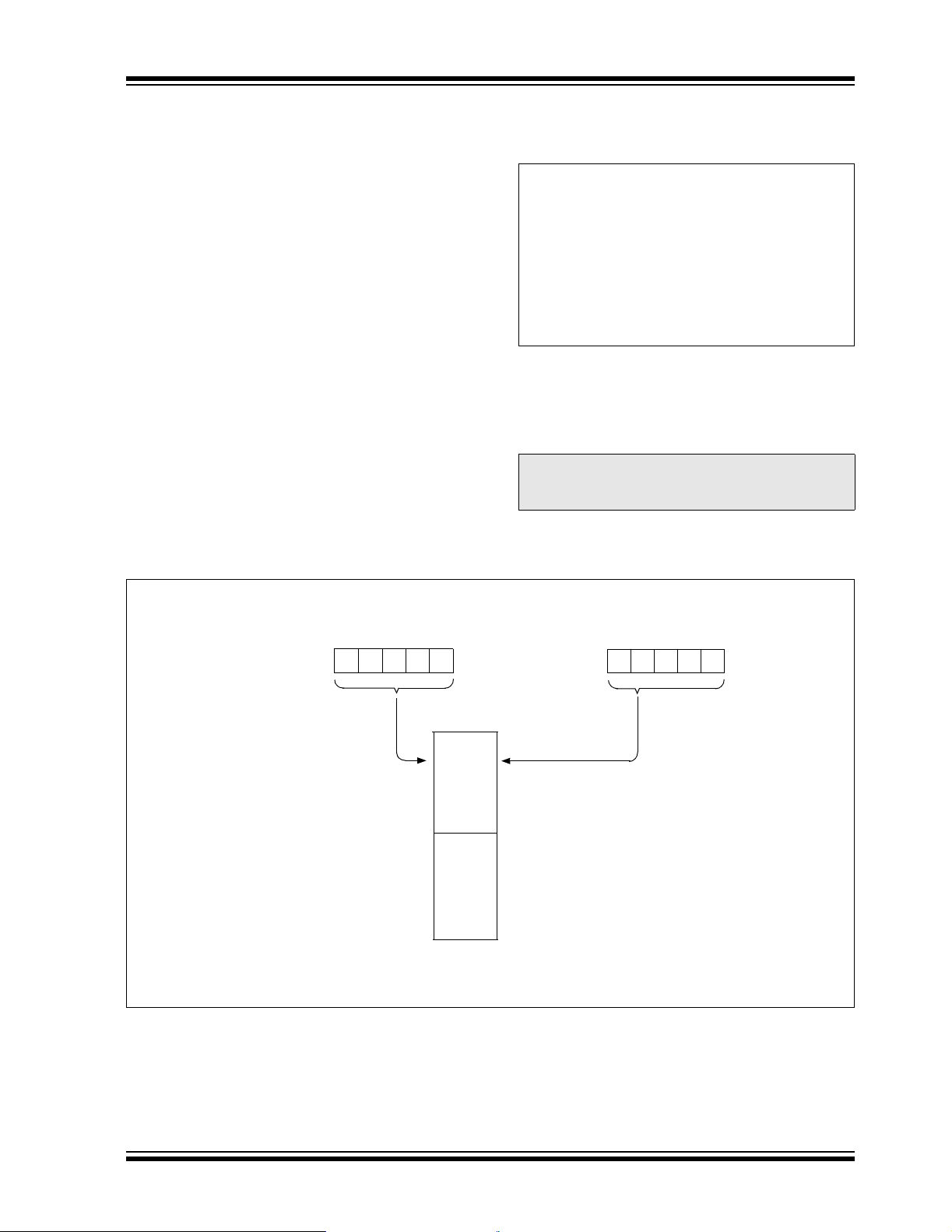

FIGURE 4-6: DIRECT/INDIRECT ADDRESSING (PIC10F200/202/204/206)

Direct Addressing

(opcode) 04

Location Select

00h

Data

Memory

Note 1: For register map detail, see Section 4.3 “D ata Memory Organization”.

0Fh

(1)

10h

1Fh

Bank 0

Indirect Addressing

(FSR)

4

Location Select

0

2004 Microchip Technology Inc. Preliminary DS41239A-page 23

PIC10F200/202/204/206

NOTES:

DS41239A-page 24 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

5.0 I/O PORT

As with any other register, the I/O register(s) can be

written and read under pro gram contro l. However, read

instructions (e.g., MOVF GPIO, W) always read the I/O

pins independent of the pin’s Input/Output modes. On

Reset, all I/O ports are defined as input (inputs are at

high-impedance) since the I/O control registers are all

set.

5.1 GPIO

GPIO is an 8-bit I/O register. Only the low-order 4 bits

are used (GP<3:0>). Bits 7 through 4 are unimplemented and read as ‘0’s. Please note that GP3 is an

input only pin. Pins GP0, GP1 and GP3 can be configured with weak pull-ups and also for wake-up on

change. The wake-up on change and weak pull-up

functions are not pin s electable. I f GP3/MCLR

ured as MCLR

, weak pull-up is always on and wake-up

on change for this pin is not enabled.

5.2 TRIS Registers

The Output Driver Control register is loaded with the

contents of the W register by executing the TRIS f

instruction. A ‘1’ from a TRIS register bi t puts the corresponding output driver in a High-impedance mode. A

‘0’ puts the contents of the output data latch on the

selected pins, enabling the output buffer. The exceptions are GP3, which is input only and the GP2/T0CKI/

COUT/FOSC4 pin, which may be contro lled by variou s

registers. See Table 5-1.

is config-

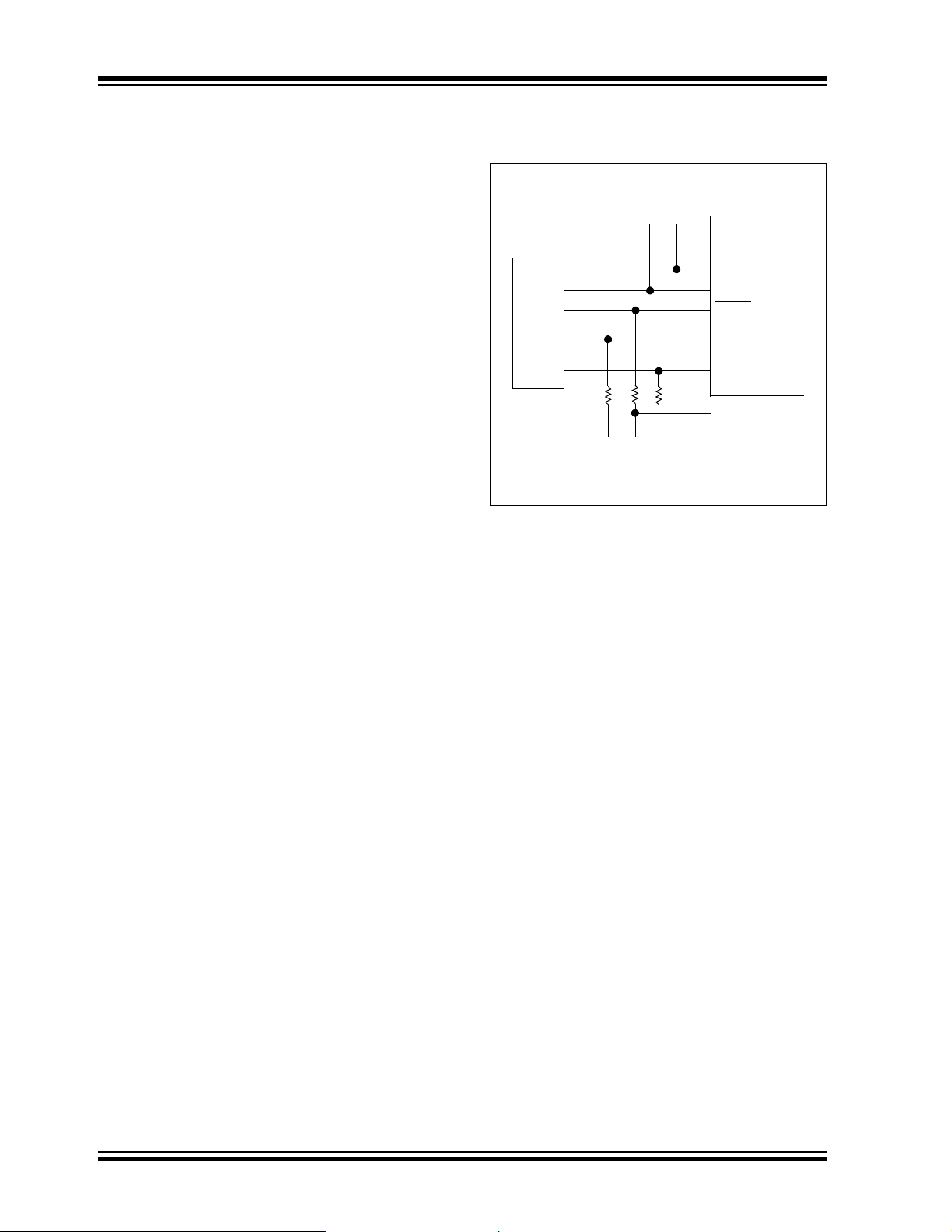

5.3 I/O Interfacing

The equivalent circuit for an I/O port pin is shown in

Figure 5-2. All port pins, except GP3 which is input

only , ma y be used for both in put and out put operati ons.

For input operations , the se ports are non-latching. Any

input must be present until read by an input instruction

(e.g., MOVF GPIO, W). The outputs are latched and

remain unchanged unt il t he outp ut latc h is rewri tten. To

use a port pin as output, the corresponding direction

control bit in TRIS must be cleared (= 0). For use as an

input, the corresponding TRIS bit must be set. Any I/O

pin (except GP3) can be programmed individually as

input or output.

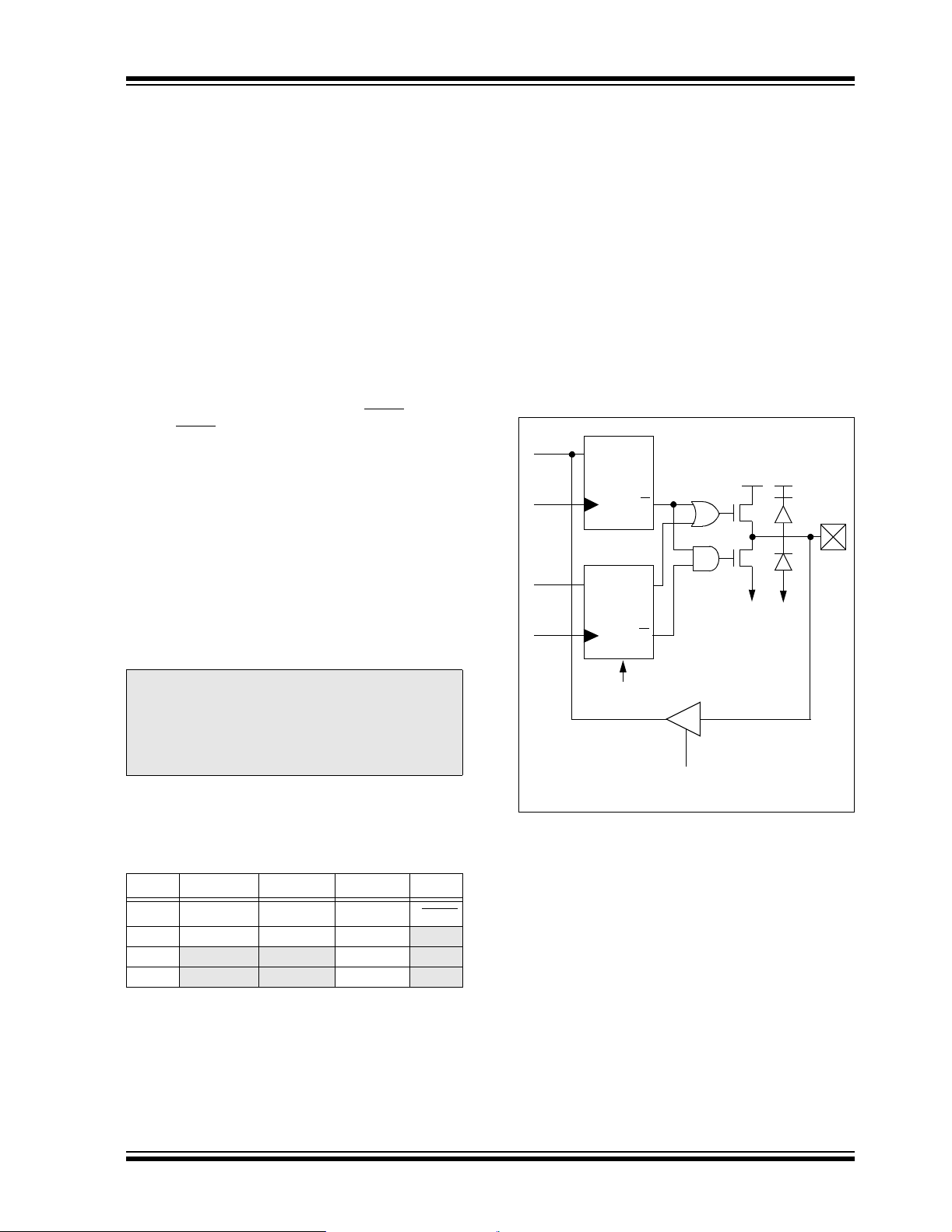

FIGURE 5-1: PIC10F200/202/204/206

EQUIVALENT CIRCUIT

FOR A SINGLE I/O PIN

Data

Bus

WR

Port

W

Reg

TRIS ‘f’

D

D

Data

Latch

CK

TRIS

Latch

CK

Q

VDD

VDD

Q

Q

Q

P

N

SS

VSS

V

I/O

pin

Note: A read of the ports reads the pins, not the

output data latches. That is , if an output

driver on a pin is enab led and driv en high,

but the external system is holding it low, a

read of the port will indicate that the pin is

low.

The TRIS registers are “write-only” and are set (output

drivers disabled) upon Reset.

TABLE 5-1: ORDER OF PRECEDENCE

FOR PIN FUNCTIONS

Priority GP0 GP1 GP2 GP3

1 CIN+ CIN- FOSC4 I/M

2 TRIS GPIO TRIS GPIO COUT —

3

4

— —T0CKI—

— —TRIS GPIO—

CLR

Reset

Note 1: See Table 3-2 for buffer type.

(1)

RD Port

2004 Microchip Technology Inc. Preliminary DS41239A-page 25

PIC10F200/202/204/206

TABLE 5-2: SUMMARY OF PORT REGISTERS

Address Nam e Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

N/A TRISGPIO

N/A OPTION

03h STATUS GPWUF CWUF

06h GPIO — — — — GP3 GP2 GP1 GP0 ---- xxxx ---- uuuu

Legend: Shaded cells are not used by Port registers, read as ‘0’, — = unimplemented, read as ‘0’, x = unknown, u = unchanged,

q = depends on condition.

Note 1: If Reset was due to wake-up on pin change, then bit 7 = 1. All other Resets will cause bit 7 = 0.

2: If Reset was due to wake-up on comparator change, then bit 6 = 1. All other Resets will cause bit 6 = 0.

— —

GPWU

GPPU T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

— —

— TO PD Z DC C 00-1 1xxx qq-q quuu

I/O Control Register

Value on

Power-On

Reset

---- 1111 ---- 1111

Value on

All Other Resets

(1, 2)

5.4 I/O Programming Considerations

5.4.1 BIDIREC TION AL I/O PORTS

Some instructions operate internally as read followed

by write operations. The BCF and BSF instructions, for

example, read the entire po rt into the CPU, execute the

bit operation and rewrite the result. Caution must be

used when these instructions are applied to a port

where one or more pins are used as input/ outp uts. For

example, a BSF operation on bit 2 of GPIO will cause

all eight bits of GPIO to be read into the CPU, bit 2 to

be set and the GPIO value to be written to the output

latches. If another bit of GPIO is us ed as a bidire ctional

I/O pin (say bit 0) and it is defined as an input at this

time, the input signal present on the pin itself would be

read into the CPU a nd rewr itten to the d ata latch of thi s

particular pin, overwr iting the previous cont ent. As long

as the pin stays in the Input mode, no problem occurs.

However, if bit 0 is switched into Output mode later on,

the content of the data latch may now be unknown.

Example 5-1 shows the effect of two sequential

Read-Modify-Write instructions (e.g., BCF, BSF, etc.)

on an I/O port.

A pin actively outputting a high or a low should not be

driven from external devices at the same time in order

to change the level on this pin (“wired OR”, “wired

AND”). The resulting high out put current s may damag e

the chip.

EXAMPLE 5-1: READ-MODIFY -WRITE

INSTRUCTIONS ON AN

I/O PORT

;Initial GPIO Settings

;GPIO<3:2> Inputs

;GPIO<1:0> Outputs

;

; GPIO latch GPIO pins

; ---------- ----------

BCF GPIO, 1 ;---- pp01 ---- pp11

BCF GPIO, 0 ;---- pp10 ---- pp11

MOVLW 007h;

TRIS GPIO ;---- pp10 ---- pp11

;

Note 1: The user may have expected the pin values

to be ---- pp00. The 2nd BCF caused GP1

to be latched as the pin value (High).

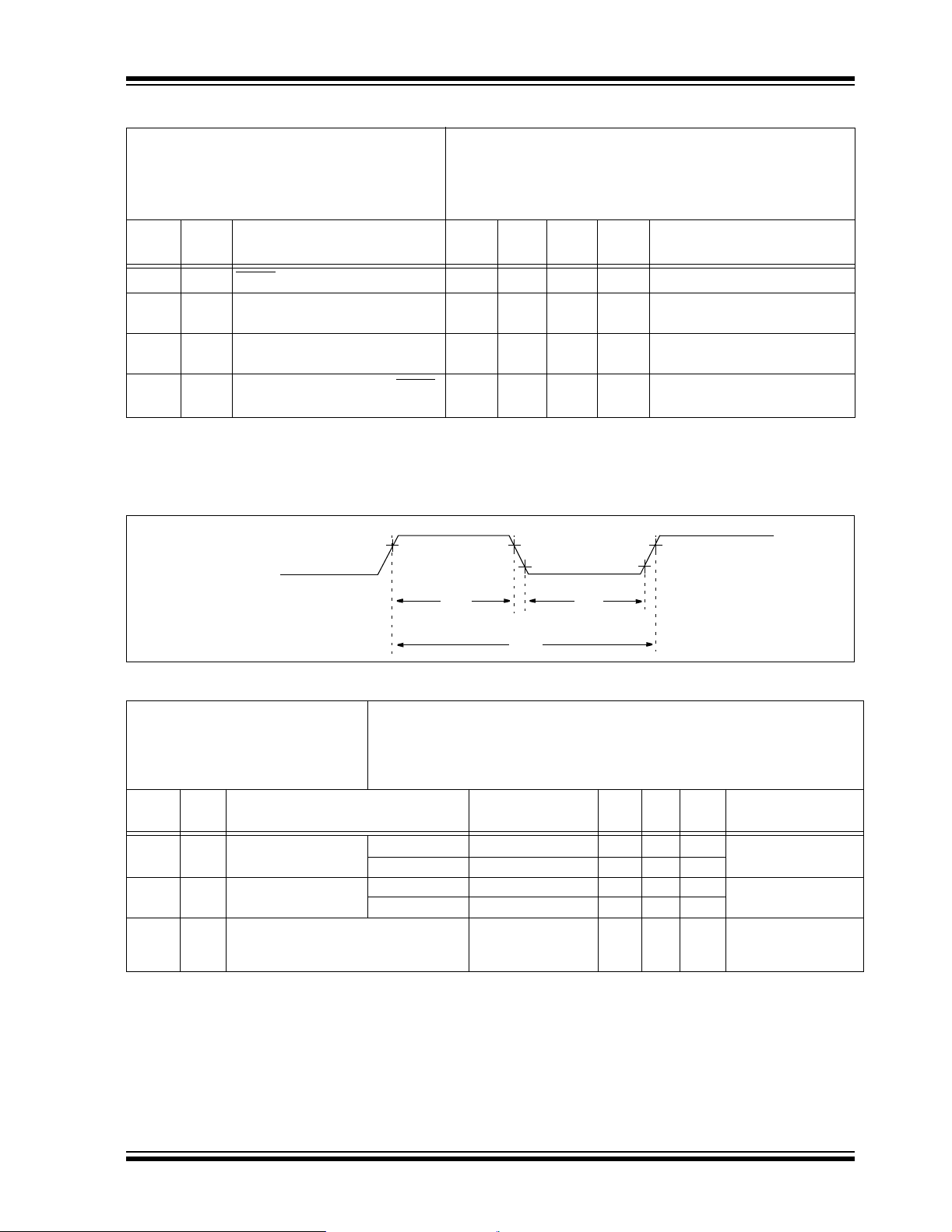

5.4.2 SUCCESSIVE OPERATIONS ON

I/O PORTS

The actual write to an I/O port happens at the end of an

instruction cy cle, whe rea s for readin g, th e data must be

valid at the beginning of the instruction cycle (Figure 5-2).

Therefore, care must be exercised if a write followed by

a read operation is carried out on the same I/O port. The

sequence of instructions should allow the pin voltage to

stabilize (load dependent) before the next instruction

causes that f ile to b e read int o th e CPU . Oth erwis e, t he

previous stat e of that pin may be re ad into the CPU rathe r

than the new state. When in doubt, it is better to separate

these instru ctions with a NOP or another instruction not

accessing this I/O port.

DS41239A-page 26 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

FIGURE 5-2: SUCCESSIVE I/O OPERATION (PIC10F200/202/204/206)

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

Instruction

Fetched

GP<2:0>

Instruction

Executed

PC PC + 1 PC + 2

MOVWF GPIO NOP

Port pin

written here

MOVWF GPIO

(Write to GPIO)

Port pin

sampled here

(Read GPIO)

PC + 3

NOPMOVF GPIO, W

NOPMOVF GPIO,W

This example shows a write to GPIO followed

by a read from GPIO.

Data setup time = (0.25 T

where: T

CY = instruction cycle.

PD = propagation delay

T

Therefore, at higher clock frequencies, a

write followed by a read may be problematic.

CY – TPD)

2004 Microchip Technology Inc. Preliminary DS41239A-page 27

PIC10F200/202/204/206

NOTES:

DS41239A-page 28 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

6.0 TIMER0 MODULE AND TMR0 REGISTER (PIC10F200/202)

The Timer0 module has the following features:

• 8-bit timer/counter register, TMR0

• Readable and writable

• 8-bit software programmable prescaler

• Internal or external clock select:

- Edge select for external clock

Figure 6-1 is a simplified block diagram of the Timer0

module.

Timer mode is selected by clearing the T0CS bit

(Option<5>). In Timer mode, the Timer0 module will

increment every ins tru cti on cy cl e (w i tho ut p r es ca ler). If

TMR0 register is written, the increment is inhibited for

the following two cycles (Figure 6-2 and Figure 6-3).

The user can work around this by writing an adjusted

value to the TMR0 register.

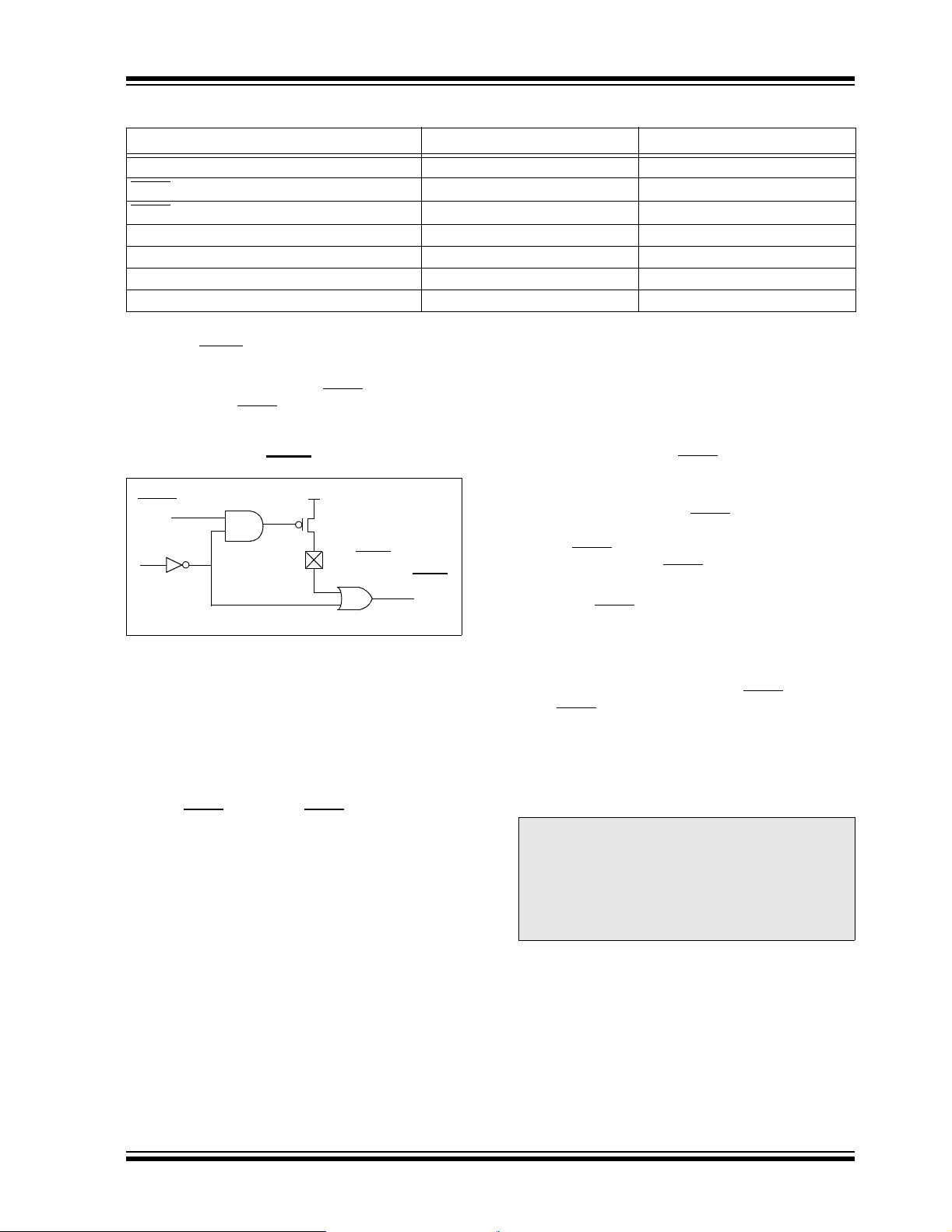

FIGURE 6-1: TIMER0 BLOCK DIAGRAM

GP2/T0CKI

Pin

T0SE

FOSC/4

0

1

T0CS

Programmable

PS2, PS1, PS0

(1)

Prescaler

Counter mode is selected by setting the T0CS bit

(Option<5>). In this mode, Timer0 will increment either

on every rising or falling edge of pin T0CKI. The T0SE

bit (Option<4>) determines the source edge. Clearing

the T0SE bit selects the ris ing edge. Restrictio ns on the

external clock input are discussed in detail in

Section 6 .1 “Using Timer0 wit h an External Clock

(PIC10F200/202)”.

The prescaler may be used by either the Timer0

module or the Watchdog Timer, but not both. The

prescaler assignment is controlled in software by the

control bit, PSA (Option<3>). Clearing the PSA bit will

assign the prescaler to Timer0. The prescaler is not

readable or writabl e. When the prescaler is assi gned to

the Timer0 module, prescale values of 1:2, 1:4, 1:256

are selectable. Section 6.2 “Prescaler” details the

operation of the prescaler.

A summary of registers associated with the Timer0

module is found in Table6-1.

Data Bus

PS

OUT

1

(2)

3

0

PSA

(1)

(1)

Sync with

Internal

Clocks

(2 TCY delay)

TMR0 reg

PSOUT

Sync

8

Note 1: Bits T0CS, T0SE, PSA, PS2, PS1 and PS0 are located in the Option register.

2: The prescaler is shared with the Watchdog Ti m er (Figure 6-5).

FIGURE 6-2: TIMER0 TIMING: INTERNAL CLOCK/NO PRESCALE

PC

(Program

Counter)

Instruction

Fetch

Timer0

Instruction

Executed

Q1 Q2 Q3 Q4

PC – 1

T0

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC PC + 1 PC + 2 PC + 3 PC + 4 PC + 6

MOVWF TMR0 MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W

T0 + 1 T0 + 2 NT0

Write TMR0

executed

Read TMR0

reads NT0

Read TMR0

reads NT0

Read TMR0

reads NT0

PC + 5

NT0 + 1

Read TMR0

reads NT0 + 1

NT0 + 2

Read TMR0

reads NT0 + 2

2004 Microchip Technology Inc. Preliminary DS41239A-page 29

PIC10F200/202/204/206

FIGURE 6-3: TIMER0 TIMING: INTERNAL CLOCK/PRESCALE 1:2

PC

(Program

Counter)

Instruction

Fetch

Timer0

Instruction

Executed

Q1 Q2 Q3 Q4

PC – 1

T0

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC PC + 1 PC + 2 PC + 3 PC + 4 PC + 6

MOVWF TMR0 MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W

T0 + 1 NT0

Write TMR0

executed

Read TMR0

reads NT0

Read TMR0

reads NT0

Read TMR0

reads NT0

PC + 5

Read TMR0

reads NT0 + 1

TABLE 6-1: REGISTERS ASSOCIATED WITH TIMER0

Address Na m e Bit 7 B it 6 Bit 5 Bit 4 B it 3 Bit 2 Bit 1 Bit 0

01h TMR0 Timer0 – 8-bit Real-Time Clock/Counter xxxx xxxx

N/A OPTION GPWU GPPU T0CS T0SE PSA PS2 PS1 PS0 1111 1111

N/A TRISGPIO

(1)

— —

— —

I/O Control Register ---- 1111

Legend: Shaded cells not used by Timer0. — = unimplemented, x = unknown, u = unchanged.

Note 1: The TRIS of the T0CKI pin is overridden when T0CS = 1.

6.1 Using Timer0 with an External

Clock (PIC10F200/202)

When an external clock input i s used for T i mer0, it must

meet certain requ ir e me nts. The ex t er na l cl oc k req u ir ement is due to internal phas e clock (TOSC) synchroniza-

tion. Also, there is a dela y in the ac tual inc remen ting of

Timer0 after synchronization.

6.1.1 EXTERNAL CLOCK

SYNCHRONIZATION

When no prescaler is used, the external clock input is

the same as the prescaler outp ut. The synch ronization

of T0CKI with the internal phase clocks is accomplished by sampli ng the presc aler output on the Q2 and

Q4 cycles of the internal phase clocks (Figure 6-4).

Therefore, it is necessary for T0CKI to be high for at

least 2 T

for at least 2 T

OSC (and a small RC delay of 2 Tt0H) and low

OSC (and a small RC delay of 2 Tt0H).

Refer to the electrical specification of the desired

device.

When a prescaler is used, the external clock input is

divided by the asynchronous ripple counter-type

prescaler, so that t he presc aler out put is symmetric al.

For the external clock to meet the sampling requirement, the ripple counter must be taken into account.

Therefore, it is necessa ry for T0CKI to h ave a perio d of

at least 4 T

OSC (and a small RC delay of 4 Tt0H) div ided

by the prescaler value. The on ly requirem ent on T0CKI

high and low time is that they do not violate the

minimum pulse width requirement of Tt0H. Refer to

parameters 40 , 41 a nd 42 in the electrical specification

of the desired device.

Value on

Power-On

Reset

NT0 + 1

Read TMR0

reads NT0 + 2

Val ue on

All Other

Resets

uuuu uuuu

1111 1111

---- 1111

DS41239A-page 30 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

6.1.2 TIMER0 INCREMENT DELAY

Since the prescaler output is synchronized with the

internal clocks, there is a small delay from the time the

external clock edge occurs to the time the Timer0

module is actually incremented. Figure 6-4 shows the

delay from the external clock edge to the timer

incrementing.

FIGURE 6-4: TIMER0 TIMING WITH EXTERNAL CLOCK

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

External Clock Input or

Prescaler Output

External Clock/Prescaler

Output After Sampling

Increment Timer0 (Q4)

(2)

(1)

(3)

Small pulse

misses sampling

Timer0

Note 1: Delay from clock input change to Timer0 increment is 3 T

in measuring the interval between two edges on Timer0 input = ±4 T

2: External clock if no prescaler selected; prescaler output otherwise.

3: The arrows indicate the points in time where sampling occurs.

6.2 Prescaler

An 8-bit counter is available as a prescaler for the

Timer0 module or as a postscaler for the Watchdog

Timer (WDT), respectively (see Section 9.6 “Watch-

dog Timer (WDT)”). For simplicity, this counter is

being referred to as “prescaler” throughout this data

sheet.

Note: The prescaler may be used by either the

Timer0 module or the WDT, but not both.

Thus, a prescaler assignment for the

Timer0 module means that there is no

prescaler for the WDT and vice versa.

The PSA and PS<2:0> bits (Option<3:0>) determine

prescaler assignment and prescale ratio.

When assigned to the Timer0 module, all instructions

writing to the TMR0 register (e.g., CLRF 1, MOVWF 1,

BSF 1,x, etc.) will clear the prescaler . When assi gned

to WDT, a CLRWDT instruction will clear the prescaler

along with the WDT. The prescaler is neither readable

nor writable. On a Reset, the prescal er conta ins all ‘0’s.

T0 T0 + 1 T0 + 2

OSC to 7 T OSC (Duration of Q = TOSC). Therefore, the error

OSC max.

6.2.1 SWITCHING PRESCALER

ASSIGNMENT

The prescaler assignment is fully under software

control (i.e., it can be changed “on-the-fly” during program execution). To avoid an unintended device Re set,

the following instruction sequence (Example 6-1) must

be executed when changing the prescaler assignment

from Timer0 to the WDT.

EXAMPLE 6-1: CHANGIN G PRESCALER

(TIMER0 → WDT)

CLRWDT ;Clear WDT

CLRF TMR0 ;Clear TMR0 & Prescaler

MOVLW ‘00xx1111’b ;These 3 lines (5, 6, 7)

OPTION ;are required only if

;desired

CLRWDT ;PS<2:0> are 000 or 001

MOVLW ‘00xx1xxx’b ;Set Postscaler to

OPTION ;desired WDT rate

2004 Microchip Technology Inc. Preliminary DS41239A-page 31

PIC10F200/202/204/206

To change the prescaler from the WDT to the Timer0

EXAMPLE 6-2: CHANGIN G PRESCALER

module, use the seque nce show n in Example6-2. This

sequence must b e used even if the WDT is dis abled . A

CLRWDT instruction should be executed before

switching the prescaler.

CLRWDT ;Clear WDT and

MOVLW ‘xxxx0xxx’ ;Select TMR0, new

OPTION

FIGURE 6-5: BLOCK DIAGRAM OF THE TIMER0/WDT PRESCALER

TCY (= FOSC/4)

PSA

0

M

U

X

1

(1)

T0CS

M

U

X

(1)

8-bit Prescaler

8-to-1MUX

1

M

U

X

0

(1)

PSA

8

PS<2:0>

GP2/T0CKI

Pin

Watchdog

Timer

(2)

T0SE

(1)

0

1

(WDT→TIMER0)

;prescaler

;prescale value and

;clock source

Data Bus

Sync

2

Cycles

(1)

TMR0 reg

8

WDT Enable bit

Note 1: T0CS, T0SE, PSA, PS<2:0> are bits in the Option register.

2: T0CKI is shared with pin GP2 on the PIC10F200/202/204/206.

0

MUX

WDT

Time-Out

1

(1)

PSA

DS41239A-page 32 Preliminary 2004 Microchip Technology Inc.

PIC10F200/202/204/206

7.0 TIMER0 MODULE AND TMR0 REGISTER (PIC10F204/206)

The Timer0 module has the following features:

• 8-bit timer/counter register, TMR0

• Readable and writable

• 8-bit software programmable prescaler

• Internal or external clock select:

- Edge select for external clock

- External clock from either the T0CKI pin or

from the output of the comparator

Figure 7-1 is a simplified block diagram of the Timer0

module.

Timer mode is selected by clearing the T0CS bit

(Option<5>). In Timer mode, the Timer0 module will

increment every ins tru cti on cy cl e (w i tho ut p r es ca ler). If

TMR0 register is written, the increment is inhibited for

the following two cycles (Figure 7-2 and Figure 7-3).

The user can work around this by writing an adjusted

value to the TMR0 register.

There are two types of Counter mo de. The first Counter

mode uses the T0CKI pin to increment Timer0. It is

selected by setting the T0CS bit (Option<5>), setting

the CMPT0CS

COUTEN

increment either on every rising or falling edge of pin

T0CKI. The T0SE bit (Option<4>) determines the

source edge. Clearing the T0SE bit selects the rising

edge. Restrictions on the external clock input are

discussed in detail in Section 7.1 “Using Timer0 with

an External Clock (PIC10F204 /206)”.

bit (CMCON0<4>) and setting the

bit (CMCON0<6>). In this mode, Timer0 will

The second Counter mo de use s the out put of the comparator to increment Timer0. It can be entered in two

different ways. The first way is selected by setting the

T0CS bit (Option<5>) and clearing the CMPT0CS

(CMCON<4>); (COUTEN

([CMCON<6>]) does not

bit

affect this mode of operation. This enables an internal

connection between the comparator and the Timer0.

The second way is selected by setting the T0CS bit

(Option<5>), setting the CMPT0CS

and clearing the COUTEN

bit (CMCON0<4>)

bit (CMCON0<6>). This

allows the output of t he compa rator onto the T0 CKI pin,

while keeping the T0CKI input active. Therefore, any

comparator change on the COUT pin is fed back into

the T0CKI input. The T0SE bit (Op tion<4> ) determi nes

the source edge. Clearing the T0SE bit selects the

rising edge. Restrictions on the external clock input as

discussed in Section 7.1 “Using Timer0 with an

External Clock (PIC10F204/206)”

The prescaler may be used by either the Timer0

module or the Watchdog Timer, but not both. The

prescaler assignment is controlled in software by the

control bit, PSA (Option<3>). Clearing the PSA bit will

assign the prescaler to Timer0. The prescaler is not

readable or writabl e. When the prescaler is assi gned to

the Timer0 module, prescale values of 1:2, 1:4,...,

1:256 are selectable. Section 7.2 “Prescaler” details

the operation of the prescaler.

A summary of registers associated with the Timer0

module is found in Table7-1.

FIGURE 7-1: TIMER0 BLOCK DIAGRAM (PIC10F204/206)

T0CKI

Pin

FOSC/4

Internal

Comparator

Output

Note 1: Bits T0CS, T0SE, PSA, PS2, PS1 and PS0 are located in the Option register.

2: The prescaler is shared with the Watchdog Timer (Figure 7-5).

3: Bit CMPT0CS

1

0

CMPT0CS

(1)

T0SE

(3)

is located in the CMCON0 register, CMCON0<4>.

0

T0CS

1

(1)

Programmable

Prescaler

3

PS2, PS1, PS0

PS

1

(2)

0

PSA

(1)

(1)

OUT

(2 TCY delay)

Sync with

Internal

Clocks

Data Bus

8

TMR0 reg

PSOUT

Sync

2004 Microchip Technology Inc. Preliminary DS41239A-page 33

PIC10F200/202/204/206

FIGURE 7-2: TIMER0 TIMING: INTERNAL CLOCK/NO PRESCALE

PC

(Program

Counter)

Instruction

Fetch

Timer0

Instruction

Executed

Q1 Q2 Q3 Q4

PC – 1

T0

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC PC + 1 PC + 2 PC + 3 PC + 4 PC + 6

MOVWF TMR0 MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W

T0 + 1 T0 + 2 NT0

Write TMR0

executed

Read TMR0

reads NT0

Read TMR0

reads NT0

Read TMR0

reads NT0

PC+5

NT0 + 1

Read TMR0

reads NT0 + 1

NT0 + 2

Read TMR0

reads NT0 + 2

FIGURE 7-3: TIMER0 TIMING: INTERNAL CLOCK/PRESCALE 1:2

PC

(Program

Counter)

Instruction

Fetch

Timer0

Instruction

Executed

Q1 Q2 Q3 Q4

PC – 1

T0

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC PC + 1 PC + 2 PC + 3 PC + 4 PC + 6

MOVWF TMR0 MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W

T0 + 1 NT0

Write TMR0

executed

Read TMR0

reads NT0

Read TMR0

reads NT0

Read TMR0

reads NT0

PC + 5

Read TMR0

reads NT0 + 1

NT0 + 1

Read TMR0

reads NT0 + 2

TABLE 7-1: REGISTERS ASSOCIATED WITH TIMER0

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

01h TMR0 Timer0 – 8-bit Real-Time Clock/Counter xxxx xxxx uuuu uuuu

07h CMCON0

N/A OPTION

N/A TRISGPIO

CMPOUT COUTEN

GPWU GPPU T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

(1)

— — — — I/O Control Register ---- 1111 ---- 1111

POL CMPT0CS CMPON CNREF CPREF CWU 1111 1111 uuuu uuuu

Value on

Power-On

Reset

Legend: Shaded cells not used by Timer0. — = unimplemented, x = unknown, u = unchanged.

Note 1: The TRIS of the T0CKI pin is overridden when T0CS = 1.

Value on

All Other

Resets

7.1 Using Timer0 with an External

Clock (PIC10F204/206)

When an external clock input i s used for T i mer0, it must

meet certain requ ir e me nts. The ex t er na l cl oc k req u ir ement is due to internal phas e clock (TOSC) synchroniza-

tion. Also, there is a dela y in the ac tual inc remen ting of

Timer0 after synchronization.

7.1.1 EXTERN AL CLOCK

SYNCHRONIZATION

When no pr escal er is us ed, t he ex ternal clock inpu t is

the same as the prescaler outp ut. Th e synchronization

of an external clock with the internal phase clocks is

accomplished by sampling the prescaler output on the

Q2 and Q4 cycles of the internal phase clocks

small RC delay of 2 Tt0H) and low for at least 2 T

(and a small RC delay of 2 Tt 0H). Refer to the electri cal

specification of the desired device.

When a prescaler is used, the external clock input is

divided by the asynchronous ripple counter type

prescaler, so that t he presc aler out put is symmetric al.

For the external clock to meet the sampling requirement, the ripple counter must be taken into account.

Therefore, it is necessary for T0CKI or the comparator

output to ha ve a p er i od of at le a st 4 T

OSC (and a small

RC delay of 4 Tt0H) divided by the pre scaler value. The

only requirement on T0CKI or the comparator output

high and low time is that they do not violate the

minimum pulse width requirement of Tt0H. Refer to

parameters 40 , 41 a nd 42 in the electrical specification

of the desired device.

OSC

(Figure 7-4). Therefore, it is neces sary for T0CKI or the

comparator out put to b e h igh for a t l eas t 2 T

DS41239A-page 34 Preliminary 2004 Microchip Technology Inc.

OSC (and a

PIC10F200/202/204/206

7.1.2 TIMER0 INCREMENT DELAY

Since the prescaler output is synchronized with the

internal clocks, there is a small delay from the time the

external clock edge occurs to the time the Timer0

module is actually incremented. Figure 7-4 shows the

delay from the external clock edge to the timer

incrementing.

FIGURE 7-4: TIMER0 TIMING WITH EXTERNAL CLOCK

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

External Clock Input or

Prescaler Output

External Clock/Prescaler

Output After Sampling

Increment Timer0 (Q4)

(2)

(1)

(3)

Small pulse

misses sampling

Timer0

Note 1: Delay from clock input change to Timer0 increment is 3 T

in measuring the interval between two edges on Timer0 input = ±4 T

2: External clock if no prescaler selected; prescaler output otherwise.

3: The arrows indicate the points in time where sampling occurs.

7.2 Prescaler

An 8-bit counter is available as a prescaler for the

Timer0 module or as a postscaler for the Watchdog

Timer (WDT), respectively (see Figure 9-6). For

simplicity, this counter is being referred to as

“prescaler” throughout this data sheet.

Note: The prescaler may be used by either the

Timer0 module or the WDT, but not both.

Thus, a prescaler assignment for the

Timer0 module means that there is no

prescaler for the WDT and vice versa.

The PSA and PS<2:0> bits (Option<3:0>) determine

prescaler assignment and prescale ratio.

When assigned to the Timer0 module, all instructions

writing to the TMR0 register (e.g., CLRF 1, MOVWF 1,

BSF 1,x, etc.) will clear the prescaler . When assi gned

to WDT, a CLRWDT instruction will clear the prescaler

along with the WDT. The prescaler is neither readable

nor writable. On a Reset, the prescal er conta ins all ‘0’s.

T0 T0 + 1 T0 + 2

OSC to 7 T OSC (Duration of Q = TOSC). Therefore, the error

OSC max.

7.2.1 SWITCHING PRESCALER

ASSIGNMENT

The prescaler assignment is fully under software

control (i.e., it can be changed “on-the-fly” during program execution). To avoid an unintended device Re set,

the following instruction sequence (Example 7-1) must

be executed when changing the prescaler assignment

from Timer0 to the WDT.

EXAMPLE 7-1: CHANGIN G PRESCALER

(TIMER0 → WDT)

CLRWDT ;Clear WDT

CLRF TMR0 ;Clear TMR0 & Prescaler

MOVLW ‘00xx1111’b ;These 3 lines (5, 6, 7)

OPTION ;are required only if

;desired

CLRWDT ;PS<2:0> are 000 or 001

MOVLW ‘00xx1xxx’b ;Set Postscaler to

OPTION ;desired WDT rate

2004 Microchip Technology Inc. Preliminary DS41239A-page 35

PIC10F200/202/204/206

To change the prescaler from the WDT to the Timer0

EXAMPLE 7-2: CHANGIN G PRESCALER

module, use the se quenc e sho wn i n Exampl e 7.2. This

sequence must b e used even if the WDT is dis abled . A

CLRWDT instruction should be executed before

switching the prescaler.

CLRWDT ;Clear WDT and

MOVLW ‘xxxx0xxx’ ;Select TMR0, new

OPTION

FIGURE 7-5: BLOCK DIAGRAM OF THE TIMER0/WDT PRESCALER

Pin

(2)

TCY (= FOSC/4)

1

0

CMPT0CS

Watchdog

Timer

T0SE

(3)

0

M

U

X

1

(1)

0

M

U

X

1

(1)

PSA

T0CS

(1)

8-bit Prescaler

8-to-1MUX

1

M

U

X

0

(1)

PSA

8