Page 1

PFCM Design Guide

PFCM Design Guide with Analog PFC IC

HP SPM & System Engineering Group

FAIRCHILD SEMICONDUCTOR

82-3, Dodang-Dong, Wonmi-ku, Puchon, Kyonggi-Do, KOREA

Tel) 82-32-680-1834, Fax) 82-32-680-1823

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

1

Page 2

PFCM Design Guide

Contents

1. System Configurations.......................................................................... 3

2. Protection Circuits................................................................................. 3

Over Current Protection (OCP).............................................................................................................. 3

Over Voltage Protection......................................................................................................................... 4

Under Voltage Protection....................................................................................................................... 4

3. Design Example (PFCM DEMO BOARD).............................................. 5

Operating conditions of PFCM demo board:........................................................................................... 5

Output capacitance and Inductance design............................................................................................ 5

Output Voltage Ripple & Output Capacitance. .....................................................................................5

Inductance & Input Current Ripple ........................................................... ......... ..... .... ..... ......... ............ 6

Open Loop Response................................................................................................................................ 6

Current Loop Amplifier................................................... ....................................................................... 7

Voltage Loop Amplifier .......................................................................................................................... 7

Control Loop Implementation................................................................................................................ 8

Current Loop................................................. ....................................................... ................................... 8

Voltage Loop........................................................................................................................................... 9

Other Parameters................................ ....................................................... .......................................... 10

Over Current Protection....................................................................................................................... 12

Over Voltage Protection....................................................................................................................... 13

DC-link Voltage Control........................................................................................................................... 14

4. Experimental Results........................................................................... 15

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

2

Page 3

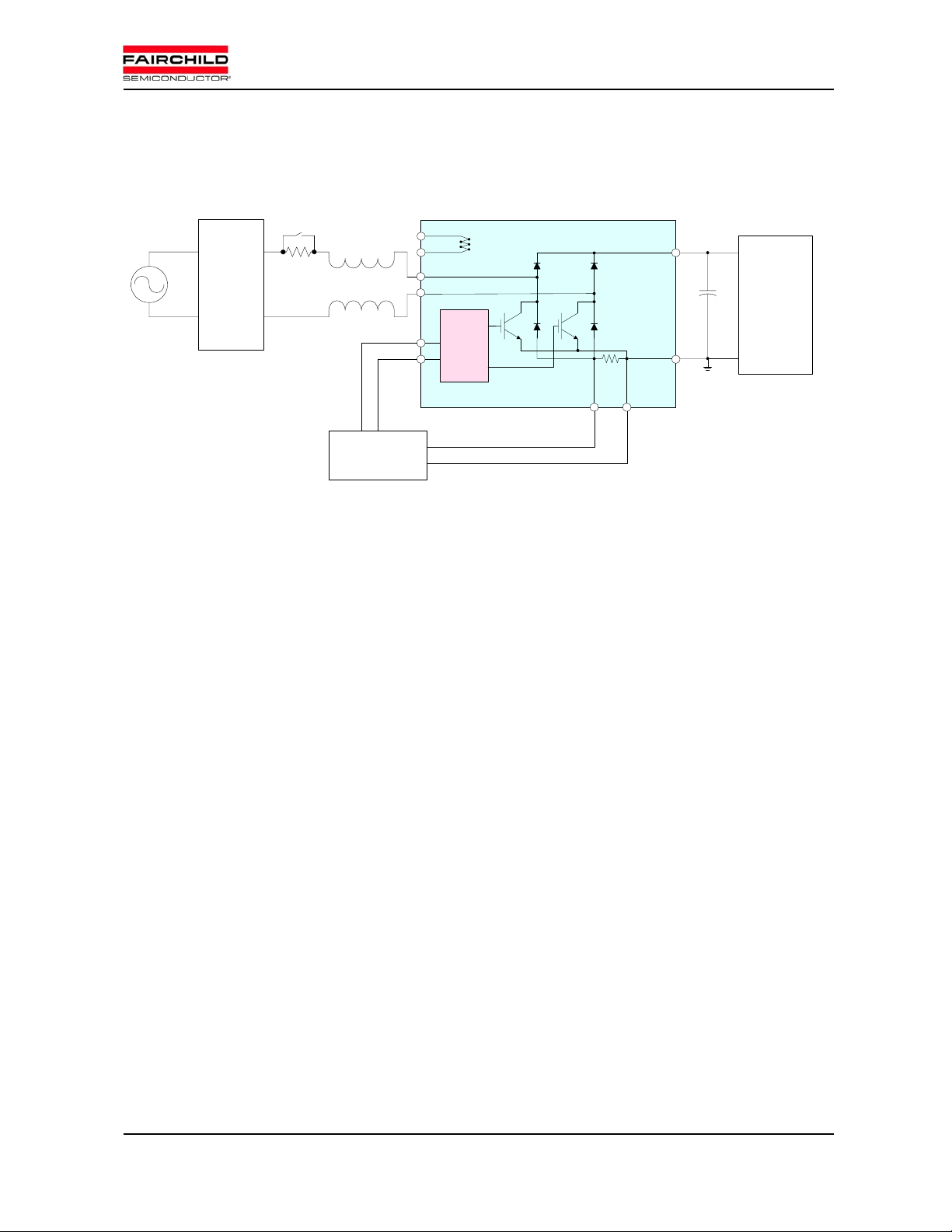

1. System Configurations

PFCM Design Guide

V

ac

Relay

N/ F

V

TH

R

TH

S

R

NTC

Thermistor

P

R

SPM

IN

(S)

LVIC

IN

(R)

Shunt

Resistor

V

AC-

N

N

SENSE

Control IC

Fig.1 Typical block diagram of PFCM system

An inrush-current prevention circuit is required due to the large DC link capacitance as shown in Fig. 1.

The relay of the circuit should be closed after DC link capacitor is charged far enough. PFCM, mini-SPM and

control IC can share single GND stage. Usually, this GND and the N

terminal of PFCM should have the

SENSE

same potential. Large surge voltage is easily produced between P and N terminals by large current switching.

To reduce surge voltage it is important to shorten the DC link bus wiring between PFCM and DC link

capacitor. In addition, good high frequency characteristic capacitor, such as polypropylene film capacitor

should be mounted near to P and N terminals as a snubber.

2. Protection Circuits

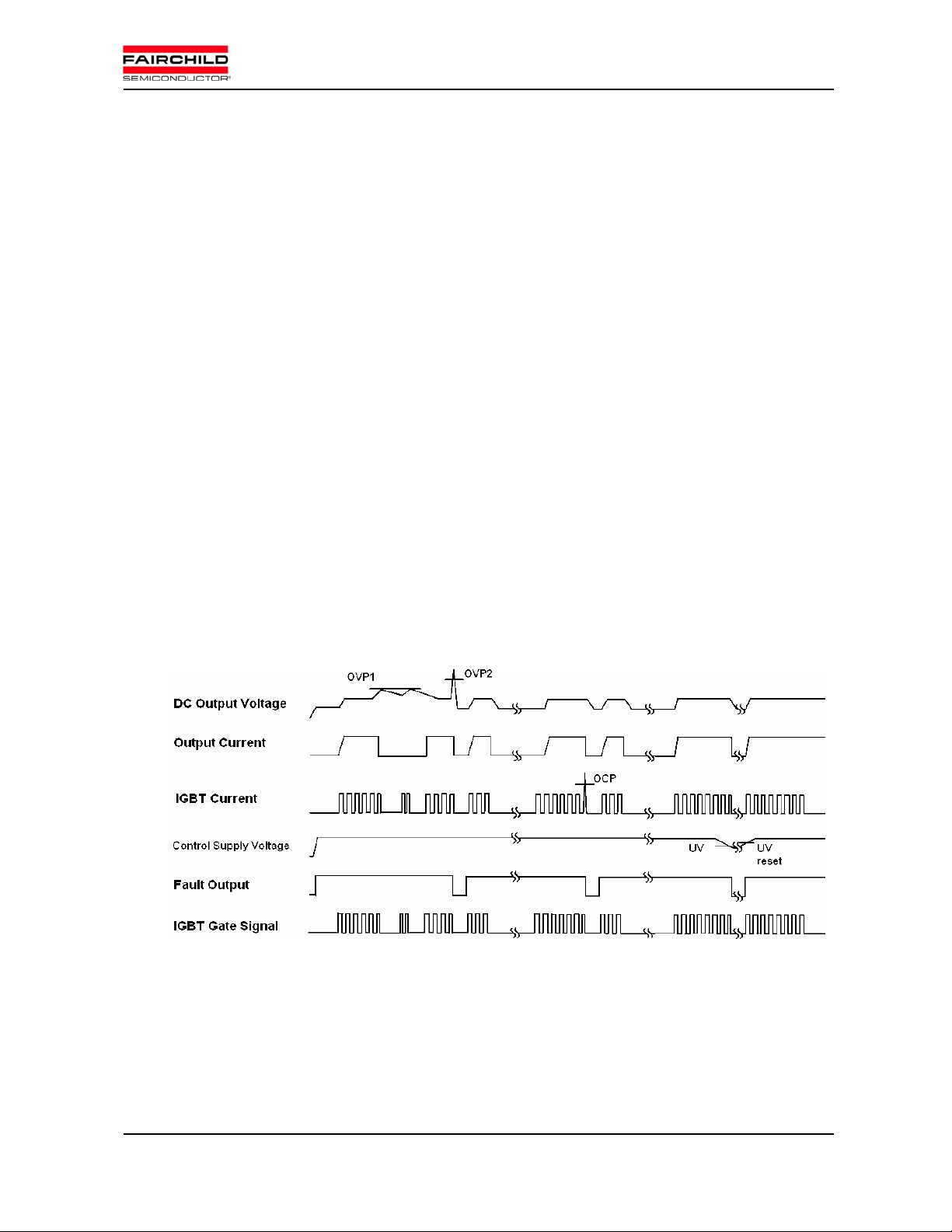

Following Fig. 2 shows the timing chart of protection function. There are two kind of protection level for

both OCP and OVP. Generally, PFC control ICs have its own OCP and OVP function. Also, user can make

the PFCM stop and output the FO signal under preset OC, OV condition using its Csc input.

Over Current Protection (OCP)

[OCP Level1 –P FCM ] PFCM can protect from over current situation. When OC(over current) situation

happens, the PFCM stops operating and generates fault out signal during fault-out duration time(set by C

And then after the duration, it works again according to the input command. Its total propagation delay time

may depend on outer op-amp speed. We recommend using a low cost slow op-amp solution with fast

protection. It is the OCP level2 protection described in next paragraph.

[OCP Level2 (SCP) –PFC control IC] By the peak current limit function of PFC control IC, the system

is protected from SC(Short Circuit) situation. The recommended current limit of OCP level 2 is higher than

FOD

).

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

3

Page 4

PFCM Design Guide

that of OCP level 1. It doesn’t generate the fault out signal but its response is very fast. It will protect the

system from short circuit situation during the propagation delay time of OCP level1.

Over Voltage Protection

OV (Over Voltage) protection can be also implemented by dual protection. The DC-link voltage

changes slowly because of its large capacitance. So OVP does not need fast response. Therefore it is

optional to activate the OVP of PFC controller.

[OVP Level 1 - PFC co ntroller] OVP level 1 suppresses voltage overshoot in transient situation. It

doesn’t generate fault out signal.

[OVP Level 2 – PFCM] The voltage level of OVP level 2 is higher than that of OVP level 1. When OV

situation happens, the PFCM stops operating and generates fault out signal during fault-out duration time(set

by C

Under Voltage Protection

). And then it works again.

FOD

IGBT gate will be interrupted when control voltage drops below UV trip level, and the protection will be realeased

automatically if the control voltage recovers to the UV reset level.

Fig.2 Timing chart of protection function

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

4

Page 5

PFCM Design Guide

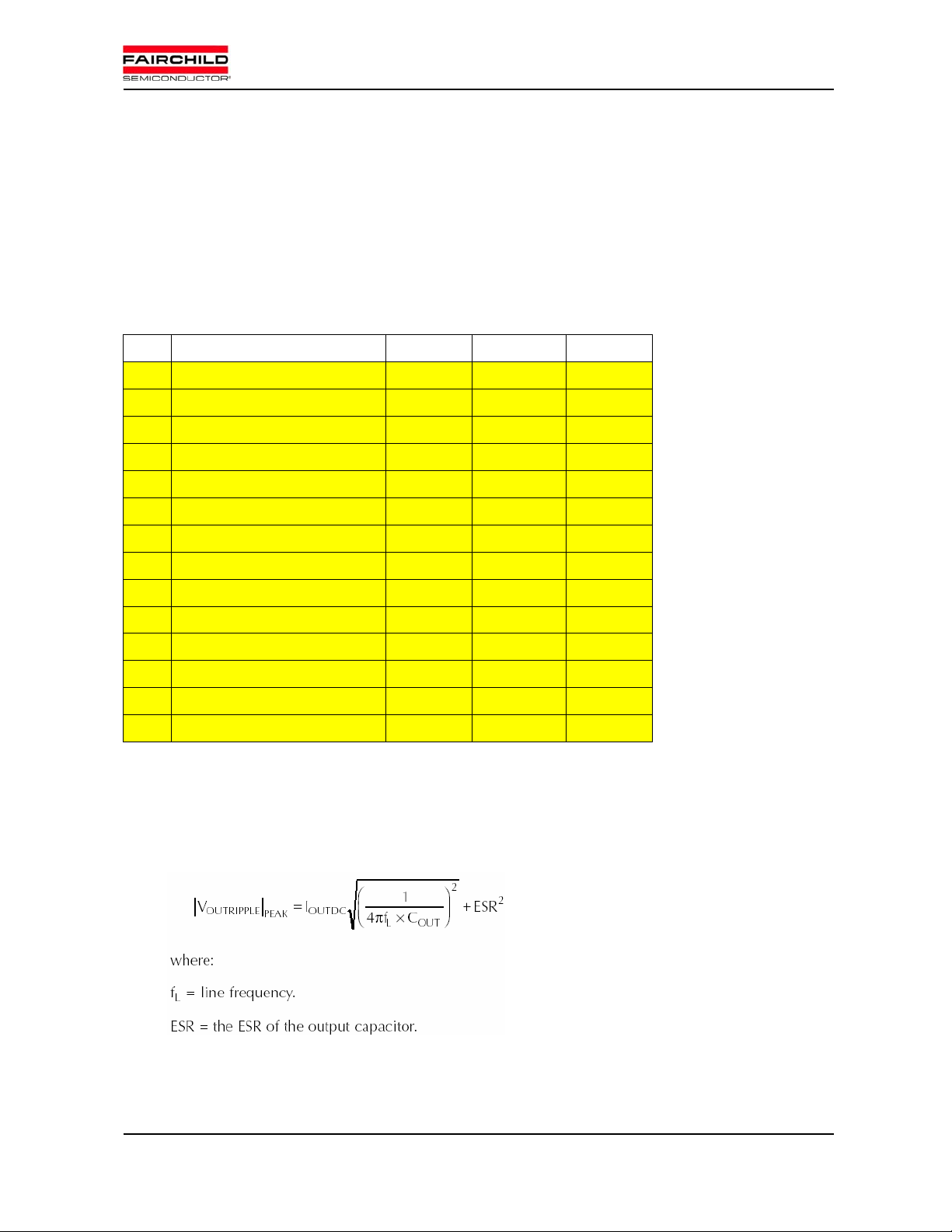

3. Design Exa mple (PFCM DEMO BOARD)

A general PFC example is implemented for 5[kW] air-conditioning applications whose input voltage is

187~276[V].

Operating conditions of PFCM demo board:

Table 1. The operating conditions.

Item Symbol Value Unit

1 Switching Frequency Fsw 40 KHz

2 Minimum Input Voltage Vimin 176 Vac

3 Nominal Input Voltage Vinom 220 Vac

4 Maximum Input Voltage Vimax 264 Vac

5 Output Max. Power Po 5000 W

6 Minimum Output Voltage Vom in 350 Vdc

7 Nominal Output Voltage Vonom 380 Vdc

8 OVP level 1 V

9 OVP level 2 V

420 V

OV1

440 V

OV2

10 Peak Ripple Current Iripple 5 A

11 OCP Level1 Iocp1 40 A

12 OCP Level2 (SCP) Iocp2 50 A

13 Shunt Resistor Rsh 2 MOhm

14 DC Capacitor Cout 940 uF

Output capacitance and Inductance design

Output Voltage Ripple & Output Capacitance

Voltage ripple of V

(470[uF] x 2)

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

can be reduced by employing large C

DC

5

. In demo board, C

OUT

is set to 940[uF]

OUT

Page 6

Inductance & Input Current Ripple

∴

where: ΔI

V

V

: Peak to peak current of PFC inductor

Lp-p

: Input AC voltage

IN

: DC link Voltage

OUTDC

f : Switching frequency

L : Inductance of PFC inductor

VVV

OUTDC

fL

4

INOUTDCIN

(

=Δ

I

L

PP

−

I

fLV

OUTDC

)( =Δ

PP

−

V

MAXL

PFCM Design Guide

)( −

1

VV

=∵

2

)

OUTDCIN

V

OUTDC

L

Î

AI

5)( =Δ

MAXL

PP

−

20Hf

380

==

4000020

⋅

=

][475

μ

(fs=40kHz)

Current ripple is decided by switching frequency and inductance. To reduce current ripple, high

switching frequency and large inductance value is required. It means that employing higher switching

frequency can reduce inductor size. But the power losses will increase and it requires more efficient heat

sink structure.

Open Loop Response

Fig.3 Block diagram of PFC control IC

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

6

Page 7

PFCM Design Guide

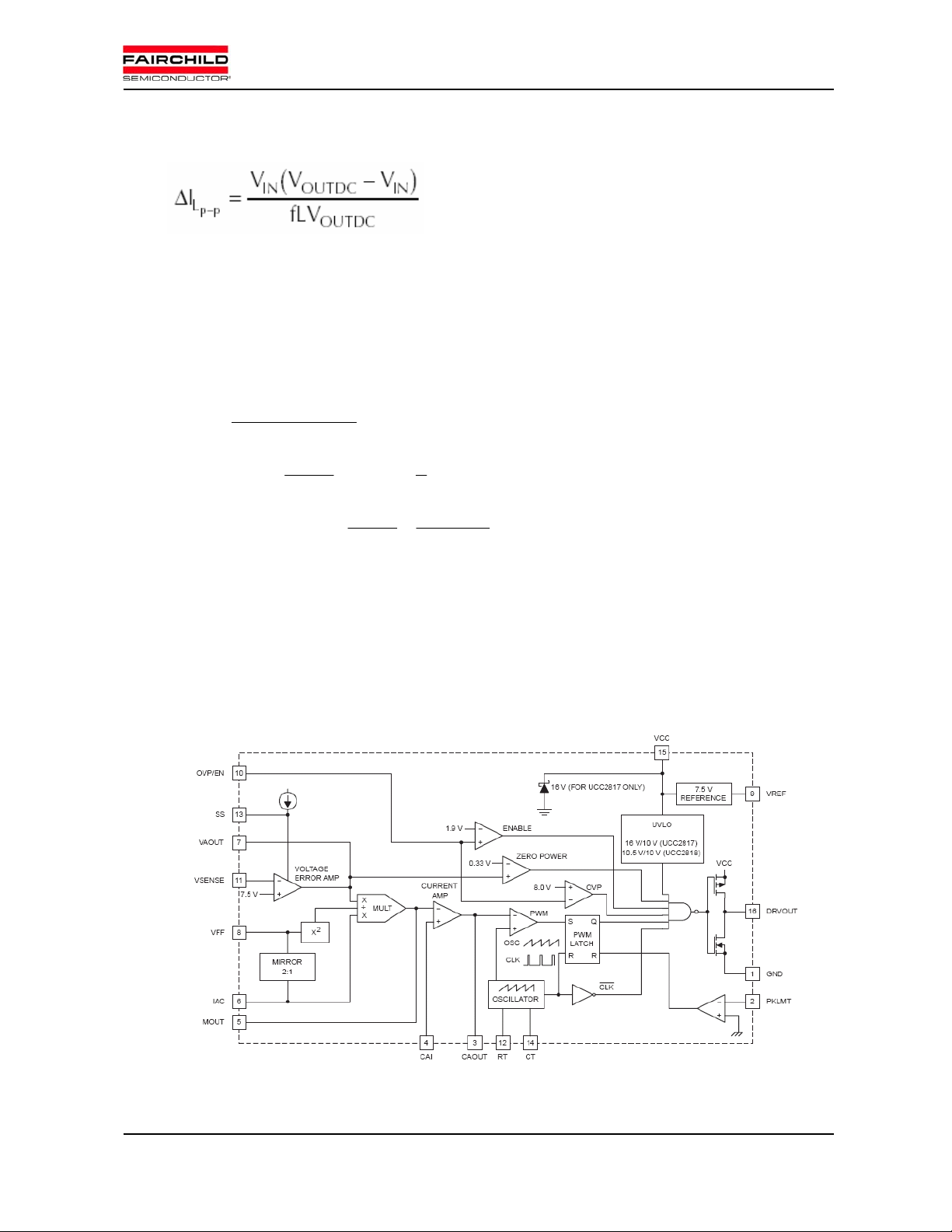

The following is the block diagram of PFC controller ucc3818. The average current mode control is

composed of two types of loops- voltage loop and current loop. The voltage loop controls the output DC-Link

voltage. It regulates the output voltage. There is a 120[Hz] ripple voltage in the output DC-Link, which is

caused by the 60[Hz] ac input current. Hence, the voltage loop must be designed to be slow enough to reject

the 120[Hz] ripple voltage.

In general CCM (Continuous Current Mode) PFC IC, there is a multiplier. It multiplies V

voltage loop) by I

voltage). The output(

The difference between the voltage of I

sensing resister is amplified by the current loop. The V

(reference of input ac current shape) and then divides it by V

AC

IVKI⋅

ACEA

MO

⋅=

V

) of a multiplier is the reference of the PFC’s input current(IAC).

2

RMS

pin(output of the multiplier) and the voltage of the current

MO

(output of the current loop) is the reference voltage

EA

(reference of rms input

RMS

to the comparameter that generates the gating signal. Current loop should be fast enough to catch up with

the 120[Hz] input ac current. But too fast speed can distort the current shape due to the switching noise.

Therefore, the current loop must be designed to be fast enough to catch up with the 120[Hz] rectified input

current, but not too fast for switching noise immunity.

(the output of

EA

Current Loop Amplifier

Eq. 1 shows the open loop response of power stage. (Refer to UCC3818 datasheet)

G

PST

S

IAOUT

where: V

V

V

R

sV

)(

sV

: Voltage of shunt resistor

S

: Voltage of RMO

IAOUT

: DC link Voltage

DC

: Shunt resistance for current sensing (2mohm)

SH

RV

== (UCC3818) (Eq.1)

SHDC

sL

4)(

L : PFC inductance

s : jω(= j⋅2πf)

Voltage Loop Amplifier

Eq. 2 shows the open loop response of power stage. (Refer to UCC3818 datasheet)

P

G

=

LOV

...

where: P

C

V

ΔV

IN

OUT

OUTDC

IN

Δ

VVsC

(UCC3818) (Eq.2)

EAOUTOUTDCOUT

: Input power

: DC link capacitance

: DC link voltage

: Error amplifier output difference (≈5V)

EAOUT

s : jω(= j⋅2πf)

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

7

Page 8

PFCM Design Guide

Control Loop Implementation

Current Loop

[Step 1] Crossover frequency

Theoretical crossover frequency is given by following equation.

f

S

f

C

[Step 2] Fz and Fp decision

f

C

f

Z

[Step 3] Rz, Cp, Cz decision

is same to RMO. (Refer to “other parameters” in page 10)

R

i

R

= 470[Ω],

i

In Eq.1,

G

Therefore it requires 40dB boosting at fc(=6.6kHz).

kHz

7.66⇒= (Eq.3)

3.32==

kHz

=

C

6.6

, kHzff

kHzfPST

RV

sL

ZP

206==

π

RV

SHDCSHDC

Lf

)2(44

C

dB

8.390103.0

−====

R

is given by Eq.7.

z

R

z

G

dB

R

40log20 == Æ R

i

dB

= 47[kΩ],

z

From Eq.4 ,Eq.5, Cp and Cz is given.

= 180[pF], Cz = 1[nF]

C

p

1

f

=

z

π

2

f

=

p

π

2

(Eq.4)

CR

zz

CC

+

pz

(Eq.5)

CCR

pzz

R

i

R

IA

IA

MO

R

z

C

CA

z

OUT

C

p

-

+

Fig.4 Current loop circuit

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

8

Page 9

(

=

FZ=3.3kHz

PFCM Design Guide

FC=6.7kHz

FP=20kHz

Voltage Loop

G

A resistor(R

replaced by small SMD type capacitor.

Æ

Fig.5 Desired current error amplifier response

[1]

[2]

[3]

=

LOV

...

VD

f

CV

G

dB

G

dB

G

dB

P

IN

) is added between E/A input and sensing resistor. By virtue of large RVD, CVF can be

VD

Ω= kR

120 (>R

VDVF

1

π

2

log20=

log20= (Eq.7)

log20=

Δ

EAOUTOUTDCOUT

VS

Ω≈⋅= MRR

18

<<=

CR

VFVD

π

2

R

z

R

i

π

2

=

)

(>RVD)

120

Æ CVF=1uF

1

(Eq.6)

CfR

zi

1

(Eq.8)

CfR

pi

5000

π

CV

=

5380001.02

⋅⋅⋅

419

ffVVsC

3.1

)

Hzf

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

9

Page 10

Other Parameters

RT, CT: Switching frequency decision

f

=

R

= 15[kΩ]

T

C

= 1[nF]

T

Î F

R

: (Refer to fig.4)

MO

6.0

CR

TT

= 40[kHz]

s

Vdc

R

VL

R

VD

R

VS

Fig.6 Voltage loop circuit

PFCM Design Guide

R

VF

C

VF

EA

-

V

ref

EA

OUT

⋅

RI

MO

I

_

=

R

GMMAX

sensepeakAC

=

(Assuming the input current is 50A

= 470[Ω]

Î R

MO

= 0.002[Ω]( small resistance can cause distortions at low level current)

R

sense

R

& Optocoupler circuit:

AC

002.0250

⋅

6

−

10300

×

@ VAC = 100V

RMS

RMS

][470471

Ω≈=

)

Optocuopler: TLP180

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

10

Page 11

PFCM Design Guide

=×Ω

RAX

VCC

1

4

Optocoupler

2

3

RL

CL

RAC

Rc1

Rc2

-

+

Fig.7 Input AC voltage sensing circuit

RFF

ISIN

E

VFF

UCC3818

CFF

R

and RL depend on optocoupler :

AX

⋅

V

RMS

=

R

AX

I

LINEAR

Æ

2

max_

=

max_

2270

⋅

3

−

106

×

+++

][64

Ω=

k

)245.0]([18181818 Wk

V

PEAKRL

V

FF

R

AC

R

L

, RC2 , CL, and an op-ampÆ I

R

C1

= 1[uF], RC1 = 0[Ω], RC2 = 150[Ω],

C

L

:

R

= 33[kΩ], CFF = 100[uF]

FF

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

_

I

AC

max_

][390 Ω=

][4.1 VVFF= (when, input voltage V

9

==

3

−

105.0

×

SINE

AC

][18

Ω=

k

off-set compensation

= 90[VAC])

11

Page 12

Over Current Protection

∴

∴

PFCM Design Guide

OCP

+

OUT

PFCM

R

19

R

40

R

VAC-

18

Fig.8 Over current protection circuit

R

37

R

38

VREF(7.5V)

PKLIMIT

UCC3818

The actual protection level can be slightly different from the calculated value. It depends on PCB

layout pattern. About demo board, the designed values are:

R

= R40 = 1.2[kΩ], R19 = R37 = 82[kΩ], R38 = 1.5[kΩ]

18

And the expected OC levels are:

1) OCP level 1

)(

R

38

R

37

=

V

REF

][40 AIPK≈

−+

++

RRR

RIRVRR

194018

PKSHREF

I

PK

⎛

V

REF

⎜

⎜

RR

19401918

SH

⎝

R

38

RR

4018

()

R

37

⎞

⎟

++−+=⇒

RRR

401918

⎟

⎠

2) OCP level 2

RR

+

R

18

V

4019

REF

IR

][50 AIPK≈

I

=⇒=

PKSH

PK

VR

18

REF

()

SH

+

RRR

4019

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

12

Page 13

Over Voltage Protection

About demo board, the designed values are:

PFCM Design Guide

Vdc

R

Z

OVP1

R

Y

OVP2

R

X

Fig.9 Over voltage protection circuit

= 15 [kΩ], RY = 1.8 [kΩ], RZ = 870 (270+270+330) [kΩ]

R

X

And the expected OC levels are:

1) OVP level 1

RR

+

YX

++

2) OVP level 2

R

X

++

V

_

OVREF

RRR

ZYX

RRR

ZYX

_

PKDC

V

REF

V

_

V

PKDC

V

V

=⇒=

PKDC

=⇒=

PKDC

_

++

RR

+

++

R

X

RRR

ZYX

__

REF

OVREF

15

YX

RRR

ZYX

8.886

=⋅=

][4228

VV

8.16

8.886

=⋅=

][4435.7

VV

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

13

Page 14

DC-link Voltage Control

Vdc

R

VL

PFCM Design Guide

R

VF

C

VF

R

VD

EA

-

V

R

VS1

R

VS2

OP-AMP

Fig.10 DC link voltage control circuit

ref

Outer

EA

OUT

R

D1

D2

R

The relation between V

⎛

⎛

⎜

5.7

⎜

⎝

R

⎜

RV

VLDC

⎜

⎝

and parameters is:

DC

VD

⎞

11

⎟

++=

⎟

RRRR

VSVFVSVF

⎠

⎞

R

VD

⎟

1

++

⎟

⎠

⎛

1

⎜

⎜

RR

VFVF

⎝

RR

++−

VLVD

The variable V

voltage is available by just changing V

DC

voltage. VEA, the output of voltage error

SIG

amplifier changes from 0 to 5.5V as its load current. In no load condition, V

voltage of V

will be the highest value. The next graph shows V

DC

and VDC voltage. The voltage of VDC in

SIG

low load condition is higher than that of max. load condition.

V

SIG

⎞

RR

VDVL

⎟

V

EA

⎟

R

VS

⎠

value is almost zero. And the

EA

⎛

R

VL

−

R

VS

R

D

⎜

⎜

1111

⎝

1

RR

+

DD

21

⎞

⎟

V

SIG

⎟

⎠

[V]

V

DC

Min. load

Max. load

V

[V]

SIG

Fig.11. DC link voltage vs. control voltage

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

14

Page 15

PFCM Design Guide

4. Experimental Results

Fig. 12 shows the overall schematics of implemented PFC converter. Table 2 shows the components

that are used for the implemented hardware. Fig. 13 shows the input ac current and DC-link voltage

waveforms. These figures’ details are shown in table 3.

HEADER 7

OVP1

VCC

12

Vin

TP

1

R13

10

1 2

PWIN

CNT2

1

2

3

4

5

6

7

R46

0

1 2

VREF

Vfo

TP

VCC

1

ENA

-FAULT

VSIG

VCC

U8A

411

OVP

R32

1

TP

20K

3

+

1 2

1

2

-

KA224

C30

C31

101

AC1

VTR-250

AC2

VTR-250

104

1

2

1

2

143

D5

DF08S

VREF

C34

104

12

RV1

SVC471D

R4

1 2

18K 3216

-+

R49

2

1 2

18K 3216

1 2

1 2

+

C8

33uF/35V

C10

101

C11

PCFN-112

PCFN-112

R34

20K

1 2

C35

101

K1

K2

333

C13

101

VCC

C27

104

U8B

411

5

+

7

6

-

KA224

3

3

J1

VTR-250

t

2

J5

VTR-250

VCC

12

54

ISO1

TLP181

12

R5

390

R48

C15

150

105

C14

104

R37

82K

PKLIMIT

R38

1.5K

2

1

4

2

1

4

RT1

NTC

1 2

F1

220V/30A

112

R51

1 2

18K 3216

R50

1 2

18K 3216

TP2

1

TP

Fig.12. Schematic diagram of the implemented PFC converter.

NOTE:

1. C8 and C9 should be close as possible!

U4

C9

104

1

Vcc

2

COM(L)

3

NC

4

IN(R)

5

IN(S)

6

VFO

7

CFOD

8

CSC

9

NC

10

Csc

NC

TP

11

1

NC

12

NC

13

NC

14

NC

R31

15

20K

NC

16

NC

1 2

17

NC

18

NC

19

RTH

20

VTH

SPM27-GA

1 Ipk

TP

U7

7812

12V

3

C44

105

D1

US1J

RY

1

R23 10K

TP

123Q1

BSS133

R24

10K

J6

VTR-250

1

2

1

2

R53

1 2

C2

224/275V

470K 5025

R3

1 2

470K 5025

1

2

1

2

J2

VTR-250

Vac

1

TP

Offset

1

TP

14

NR/VAC-

IN1COM2OUT

NSENSE

P

VTR-250

1

27

PR

26

S

25

R

24

N

23

NC

22

21

VCC

R52

1 2

470K 3216

12

R1

470K 3216

R2

C1

47K

105

U8D

KA224

-

13

+

12

4 11

VCC

DCP

C12

224/630V

DCN

N

VTR-250

1

2

1 2

1 2

R20

470

1 2

CAO

TP

1

2

R55

270K 3216 F

1 2

VAO

1

TP

12

R9

15K 2012 F

R29

1 2

U5

UC3818

GND

DRVOUT

PKLMT

CAOUT

CAI

MOUT

IAC

VAOUT

VFF8VREF

1

VREF

JP1

FAN

1

2

3

12

R6

270K 3216 F

R44

270K 3216 F

1 2

JP2

8

C38

JUMPER

104

16

PWIN

15

VCC

14

13

12

11

10

9

R25

15K

1 2

C26

101

C19

105

Title

<Title>

Size Document Number Rev

<Doc> <RevCode>

C

Date: Sheet

3.9K 2012 F

VSENSE

OVP/EN

Vref

TP

1 2

VCC

CT

SS

RT

U8C

KA224

-

9

+

10

R28 1M

4 11

1 2

VSIG

C29

R30

VCC

104

1M

1 2

C17

102

VCC

C24

105

C21

104

VCC

10K

R41

123Q2

1 2

D12

Zener 5.6V

R8

4.7k

ENA

C37

104

1

PFC SW

SW SPDT - 1

2

3

GND

Vcc

1

1

TP

TP

VCC

of

11Thursday, September 08, 2005

KRC102

D8

VCC

LED

12

R7

270K 3216 F

C5

470uF/450V

R47

56

C40

183

C25

105

330K 3216 F

12

R45

270K 3216 F

R54

OVP1

1 2

1

TP

OVP1

12

R10

1.8k 2012 F

OVP2

1

TP

OVP2

12

R43

15K 2012 F

VREF

R19

82K

1 2

PKLIMIT

R40

1.2K

1 2

1

2

3

4

5

6

7

12

+

R26

C23

33K

33uF/25V

1 2

1

Vff

TP

12

12

+

C4

+

470uF/450V

TP5

1

TP

R21

470

C39

821

1 2

R18

1.2K

C36

152

R17

C16

47K

181

1 2

C18

102

Iac

TP

1

R22 18K

1 2

R42

R27

120K

1M

1 2

1 2

FAN SUPLY

12V

R11 0

12V

12V

1

TP

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

15

Page 16

PFCM Design Guide

Table 2. BOM of PFCM demo board.

Item Part Reference Quantity

1 C-Ceramic : 101 2012 C10,C13,C26,C30,C35 5

2 C-Ceramic : 102 2012 C17,C18 2

3 C-Ceramic : 104 2012 SC2,SC4,C9,C14,C21,C27,C29,C31,C34,C37,C38 11

4 C-Ceramic : 105 2012 C1,C15,C19,C24,C25,C44,SC6 7

5 C-Ceramic : 152 2012 C36 1

6 C-Ceramic : 183 2012 C40 1

7 C-Ceramic : 221 2012 C16 1

8 C-Ceramic : 333 2012 C11,SC7 2

9 C-Ceramic : 821 2012 C39 1

10 C-Elec : 220uF 35V SC5 1

11 C-ELEC : 33uF 35V C8,C23 2

12 C-ELEC : 470uF 450V C4,C5 2

13 C-Elec : 47uF 35V SC3 1

14 C-FILM : 105 630V C12 1

15 C-FILM : 220nF AC275V C2 1

16 Connector : 7-pin, 2.54mm pitch CNT2 1

17 DIODE : US1J D1,SD2,SD3,SD4 4

18 FAN connector : 3-pin, 2.54mm pitch JP1 1

19 FPS : KA5M02659RN U10 1

20 Fuse : 220V/20A F1 1

21 JUMPER : 2-pin, 2.54mm pitch JP2 1

22 LED D8 1

23 Main Relay : PCFN-112 K1,K2 2

24 Mosfet : BSS138 Q1 1

25 NTC : 6D-22 RT1 1

26 Op-Amp : KA224 U8 1

27 Opto-coupler : TLP180 ISO1 1

28 Opto-coupler : TLP181 ISO2 1

29 PFC IC : UC3818 U5 1

30 PFCM : FPDB30PH60 U4 1

31 R-Chip : 0ohm, 1/8W, J, 2012 R11,R46 2

32 R-Chip : 1.2Kohm, 1/8W, J, 2012 R40,R18 2

33 R-Chip : 1.5Kohm, 1/8W, J, 2012 R38 1

34 R-Chip : 1.8kohm, 1/8W, F, 2012 SR6,R10 2

35 R-Chip : 1.8kohm, 1/8W, J, 2012 SR2 1

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

16

Page 17

PFCM Design Guide

36 R-Chip : 100kohm, 1/2W, J, 5025 SR7,SR8 2

37 R-Chip : 10Kohm, 1/8W, J, 2012 SR4,R23,R24,R41 4

38 R-Chip : 10ohm, 1/8W, J, 2012 R13 1

39 R-Chip : 10ohm, 1/8W, J, 2012 SR1 1

40 R-Chip : 120Kohm, 1/8W, J, 2012 R42 1

41 R-Chip : 150ohm, 1/8W, J, 2012 R48 1

42 R-Chip : 15Kohm, 1/8W, J, 2012 R9,R25,R43 3

43 R-Chip : 18Kohm, 1/4W, J, 3216 R4,R49,R50,R51 4

44 R-Chip : 18Kohm, 1/8W, J, 2012 R22 1

45 R-Chip : 1Mohm, 1/8W, J, 2012 R27,R28,R30 3

46 R-Chip : 20Kohm, 1/8W, J, 2012 R31,R32,R34 3

47 R-Chip : 270Kohm, 1/4W, F, 3216 R6,R7,R44,R45,R55 5

48 R-Chip : 3.3kohm, 1/8W, J, 2012 SR3 1

49 R-Chip : 3.9Kohm, 1/8W, J, 2012 R29 1

50 R-Chip : 33Kohm, 1/8W, J, 2012 R26 1

51 R-Chip : 330Kohm, 1/4W, F, 3216 R54 1

52 R-Chip : 390ohm, 1/8W, J, 2012 R5 1

53 R-Chip : 4.7Kohm, 1/8W, J, 2012 R8 1

54 R-Chip : 470Kohm, 1/4W, F, 3216 R1,R3,R52,R53 4

55 R-Chip : 470ohm, 1/8W, J, 2012 R20,R21 2

56 R-Chip : 47Kohm, 1/8W, J, 2012 R2,R17 2

57 R-Chip : 56ohm, 1/8W, J, 2012 R47 1

58 R-Chip : 82Kohm, 1/8W, J, 2012 R19,R37 2

59 R-Chip : 9kohm, 1/8W, F, 2012 SR5 1

60 Regulator : KA78M12 U7 1

61 Switch : SW SPDT - 1 PFC SW 1

62 Terminal : VTR-250 J1,J2,J5,J6,AC1,AC2,P,N 8

63 TR : KRC102 Q2 1

64 Transformer : EI-1916 T1 1

65 TVS : SMBJ170 SD1 1

66 Varistor : SVC471D RV1 1

67 Voltage detector : KA431A SD5 1

68 Zener Diode : 1N4734A, 5.6V D12 1

69 Bridge Diode : DF08S D5 1

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

17

Page 18

PFCM Design Guide

(50V/div)

V

DC

(10A/div)

I

IN

Fig. 13. Full load test results (I

= 15A

IN

RMS

)

Table 3. Power factor and input power measurement.

V

Fig.13

* VAC and IAC are RMS values

[V] IAC [A]

AC

220 15

Power [kW]

3.3

Power Factor [%]

99

Feb. 2006 FAIRCHILD SEMICONDUCTOR – System Engineering Group

18

Loading...

Loading...