Datasheet PEEL18CV8ZT-25, PEEL18CV8ZTI-25, PEEL18CV8ZJ-25, PEEL18CV8ZJI-25, PEEL18CV8ZP-25 Datasheet (ICT)

...Page 1

Commercial

PEEL™ 18CV8Z

CMOS Programmable Electrically Erasable Logic Device

Features

■

Ultra Low Power Operation

- Vcc = 5 Volts ±10%

- Icc = 10 µA (typical) at standby

- Icc = 2 mA (typical) at 1 MHz

■

CMOS Electrically Erasable T echnolog y

- Superior factory testing

-

Reprogrammable in plastic package

-

Reduces retrofit and development costs

■

Application Versatility

-

Replaces random logic

-

Super set of standard PLDs

-

Pin-to-pin compatible with 16V8

-

Ideal for use in power-sensitive systems

General Descri p ti on

The PEEL™18CV8Z is a Programmable Electrically Erasable

Logic (PEEL™) SPLD (Simple Programmable Logic Device)

that features ultra-low, automatic “zero” power-down operation.

The “zero power” (100 µA max. Icc) power-down mode makes

the PEEL™18CV8Z ideal for a broad range of battery-powered

portable equipment applications, from hand-held meters to PCMCIA modems. EE-reprogrammability provides both the convenience of fast reprogramming for product development and quick

product personalization in manufacturing, including Engineering

Change Orders.

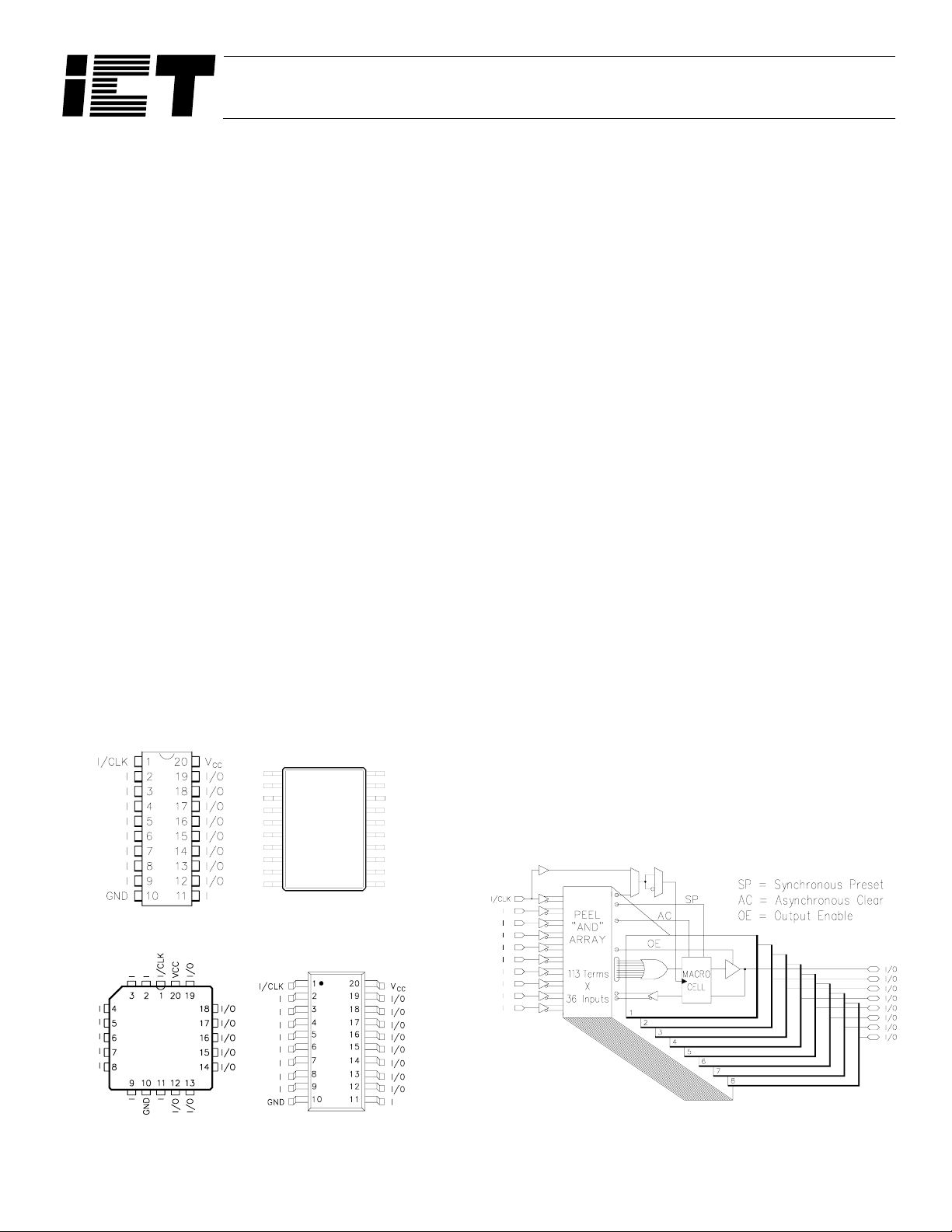

Figure 7 Pin Configuration

1

I/CLK

GND

2

I

3

I

4

I

5

I

6

I

7

I

8

I

9

I

10

VCC

20

I/O

19

I/O

18

I/O

17

I/O

16

I/O

15

I/O

14

I/O

13

I/O

12

I

11

-25

■

Architectural Flexibility

-

Enhanced architecture fits in more logic

-

113 product terms x 36 input AND array

-

10 inputs an d 8 I/O pins

-

12 possible macrocell configurations

-

Asynchronous clear, Synchronous preset

-

Independent output enables

-

Programmable clock; pin 1 or p-term

-

Programmable clock polarity

-

20 Pin DIP/SOIC/TSSOP and PL CC

The PEEL™18CV8Z is logically and functionally similar to

ICT’s 5 Volt PEEL™18CV8 and 3 Volt PEEL™18LV8Z. The

differences between the PEEL™18CV8Z and PEEL™18CV8

include the addition of programmable clock polarity, a product

term clock, and variable width product terms in the AND/OR

Logic Array.

Like the PEEL™18CV8, the PEEL™18CV8Z is logical superset

of the industry standard PAL16V8 SPLD. The PEEL™18CV8Z

provides additional architectural features that allow more logic to

be incorporated into the design. ICT’s JEDEC file translator

allows easy conversion of existing 20 pin PLD designs to the

PEEL™18CV8Z architecture without the need for redesign. The

PEEL™18CV8Z architecture allows it to replace over twenty

standard 20-pin DIP, SOIC, TSSOP and PLCC packages.

Figure 8 Block Diagram

CLK MUX (Optional)

DIP

PLCC

TSSOP

SOIC

™

1 of 10

Page 2

PEELTM 18CV8Z-25

I/CLK

(OPTIONAL)

ASYNCHRONOUS CLEAR

(TO ALL MACROCELLS)

MACRO

CELL

19

I/O

03478111215161920232427283132

112

0

1

2

9

35

1

10

11

18

17

I/O

I/O

MACRO

20

2

I

21

22

CELL

MACRO

CELL

33

3

I

34

35

16

MACRO

I/O

CELL

48

4

I

49

50

I/O

MACRO

15

CELL

65

5

I

66

67

I/O

MACRO

14

CELL

82

6

I

83

84

13

MACRO

I/O

CELL

97

7

I

98

99

12

MACRO

I/O

CELL

110

8

I

111

9

I

SYNCHRONOUS PRESET

(TO ALL MACROCELLS)

11

I

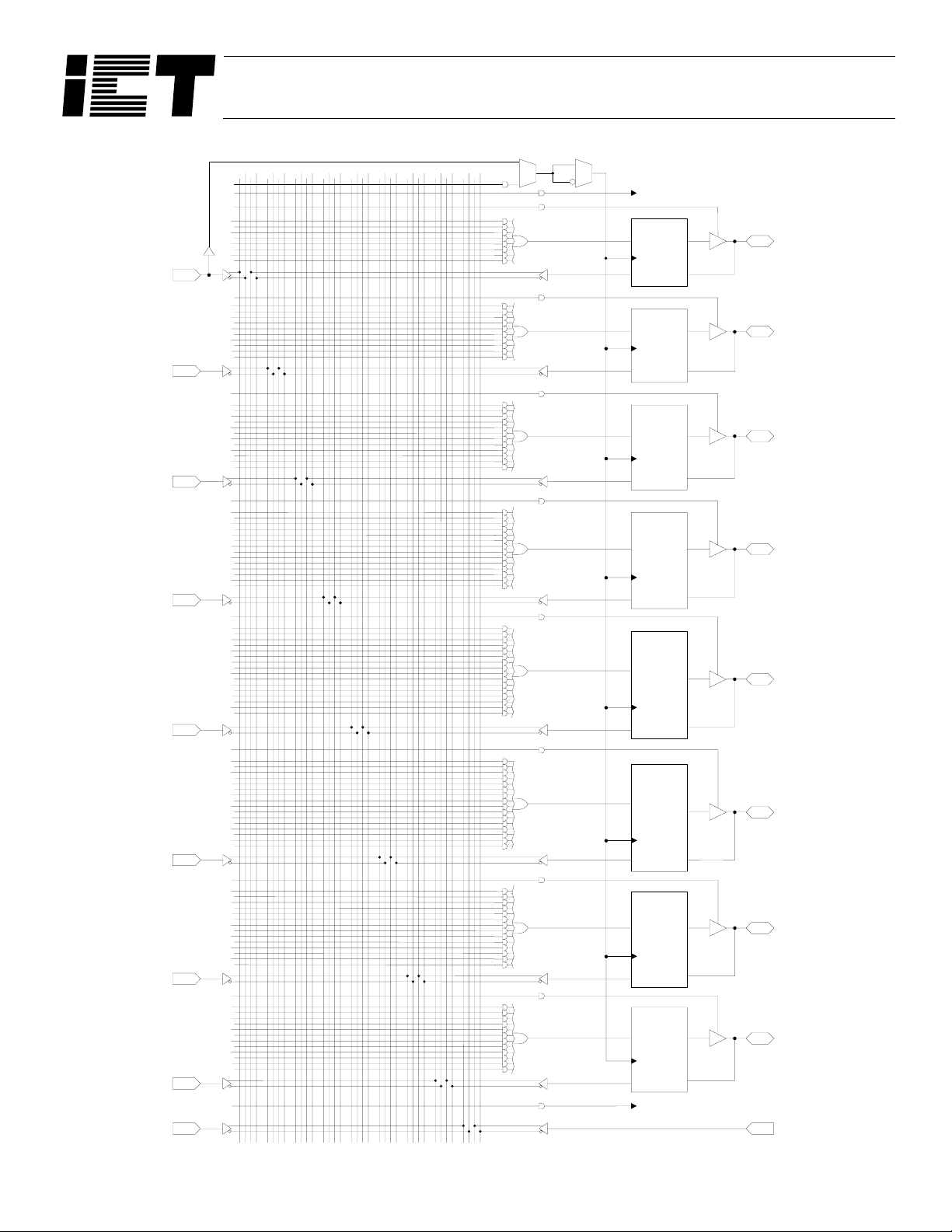

Figure 9 PEEL™18CV8Z Logic Array Diagram

2 of 10

Page 3

PEELTM 18CV8Z-25

Function Description

The PEEL™18CV8Z implements logic functions as sum-ofproducts expressions in a programmable-AND/fixed-OR logic

array. User-defined functions are created by programming the

connections of input signals into the array. User-configurable

output structures in the form of I/O macrocells further increase

logic flexibility.

Architecture Overview

The PEEL™18CV8Z architecture is illustrated in the block diagram of Figure 8. Ten dedicated inputs and 8 I/Os provide up to

18 inputs and 8 outputs for creation of logic functions. At the

core of the device is a programmable electrically-erasable AND

array that drives a fixed OR array. With this structure, the

PEEL™18CV8Z can implement up to eight sum-of-products

logic expressions.

Associated with each of the eight OR functions is an I/O macrocell that can be independently programmed to one of 12 different

configurations. The programmable macrocells allow each I/O to

be used to create sequential or combinatorial logic functions of

active-high or active-low polarity, while providing three different

feedback paths into the AND array.

AND/OR Logic Array

The programmable AND array of the PEEL™1 8CV8Z (sh own in

Figure 9) is formed by input lines intersecting product terms. The

input lines and product terms are used as follows:

■

36 Input Lines:

– 20 input lines carry the true and complement of the signals

applied to the 10 input pins

– 16 additional lines carry the true and complement values of

feedback or input signals from the 8 I/Os

effect on the output function).

Variable Product Term Distribution

The PEEL™18CV8Z provides 113 product terms to drive the

eight OR functions. These product terms are distributed among

the outputs in groups of 8, 10, 12, 14, and 16 to form l ogical s ums

(see Figure 9). This distribution allows optimum use of the

device resources.

Programmable I/O Macrocell

The unique twelve-configuration output macrocell prov ides complete control over the architecture of each output. The ability to

configure each output independently lets you to tailor the configuration of the PEEL™18CV8Z to the precise requirements of

your design.

Macrocell Architecture

Each I/O macrocell, as shown in Figure 9, consists of a D-type

flip-flop and two signal-select multiplexers. The co nfiguration of

each macrocell is determined by the four EEPROM bits controlling these multiplexers. These bits determine output polarity, output type (registered or non-registered) and input-feedback path

(bidirectional I/O, combinatorial feedback). Refer to Table 1 for

details.

Equivalent circuits for the twelve macrocell configurations are

illustrated in Figure 11. In addition to emulating the four PALtype output structures (configurations 3, 4, 9, and 10), the macrocell provides eight additional configurations. When creating a

PEEL™ device design, the desired macrocell configuration is

generally specified explicitly in the design file. When the desi gn

is assembled or compiled, the macrocell configuration bits are

defined in the last lines of the JEDEC programming file.

■

113 product terms:

102 product terms are used to form sum of product functions

–

– 8 output enable terms (one for each I/O)

– 1 global synchronous pr eset term

– 1 global asynchronous clear term

– 1 programmable clock term

At each input-line/product-term intersection, there is an

EEPROM memory cell that determines whether or not there is a

logical connection at that intersection. Each product term is

essentially a 36-input AND gate. A product term that is connected to both the true and complement of an input signal will

always be FALSE and thus will not affect the OR function that it

drives. When all the connections on a product term are opened, a

“don’t care” state exists and that term will always be TRUE.

When programming the PEEL™18CV8Z, the device programmer first performs a bulk erase to remove the previous pattern.

The erase cycle opens every logical connection in the array. The

device is configured to perform the user-defined function by programming selected connections in the AND array. (Note that

PEEL™ device programmers automatically program all of the

connections on unused product terms so that they will have no

Output Type

The signal from the OR array can b e fed directly to th e ou tput pin

(combinatorial function) or latched in the D-type flip-flop (registered function). The D-type flip-flop latches data on the rising

edge of the clock and is controlled by the global preset and clear

terms. When the synchronous preset term is satisfied, the Q output of the register is set HIGH at the next rising edge of the clock

input. Satisfying the asynchronous clear sets Q LOW, regardless

of the clock state. If both terms are satisfied simultaneously, the

clear will override the preset.

Output Polarity

Each macrocell can be configured to implement active-high or

active-low logic. Programmable polarity eliminates the need for

external inverters.

Output Enable

The output of each I/O macrocell can be enabled or disabled

under the control of its associated programmable output enable

product term. When the logical conditions programmed on the

output enable term are satisfied, the output signal is pro pagated to

3 of 10

Page 4

PEELTM 18CV8Z-25

the I/O pin. Otherwise, the output buffer is switched into the

high-impedance state.

Under the control of the output enable term, the I/O pin can function as a dedicated input, a dedicated output, or a bi-directional I/

O. Opening every connection on the output enable te rm will permanently enable the output buff er and yield a dedicated output.

Conversely, if every connection is intact, the enable term will

always be logically false and the I/O will function as a dedicated

input.

Input/Feedback Select

The PEEL™18CV8Z macrocell also provides control over the

feedback path. The input/feedback signal associated with each I/

O macrocell can be obtained from three different locations; from

the I/O input pin, from the Q

output of the flip-flop (registered

feedback), or directly from the OR gate (combinatorial feedback).

Bi-directional I/O

The input/feedback signal is taken from the I/O pin when using

the pin as a dedicated input or as a bi-directional I/O. (Note that it

is possible to create a registered output function with a bi-directional I/O, refer to Figure 9).

Combinatorial Feedback

The signal-select multiplexer gives the macrocell the ability to

feedback the output of the OR gate, bypassing the output buffer,

regardless of whether the output function is registered or combinatorial. This feature allows the creation of asynchronous latches,

even when the output must be disabled. (Refer to configurations

5, 6, 7, and 8 in Figure 11.)

tion, registered feedback allows for the internal latching of states

without giving up the use of the external output.

Programmable Clock Options

A unique feature of the PEEL™18CV8Z is a programmable

clock multiplexer that allows the user to select true or co mplement forms of either input pin or product-term clock sources.

Zero Power Feature

The CMOS PEEL™18CV8Z features “Zero-Power” standby

operation for ultra-low power consumption. With the “ZeroPower” feature, transition- detect ion ci rcu itr y mon i tors the input s ,

I/Os (including CLK) and feedbacks. If these signals do not

change for a period of time greater than approximately two t

PD

’s,

the outputs are latched in their current state and the device automatically powers down. When the next signal transition is

detected, the device will “wake up” for active operation until the

signals stop switching long enough to trigger the next powerdown. (Note that the tPD is approximately 5 ns. slower on the

first transition from sleep mode.)

As a result of the “Zero-Power” feature, significant power savings can be realized for combinatorial or sequential operations

when the inputs or clock change at a modest rate. See Figure 5.

Figure 10 Typical ICC vs. Input Clock Frequency

for the 18CV8Z

100

10

Figure 9 Block Diagram of the PEEL™18CV8Z

I/O Macrocell

Registered Feedback

Feedback also can be taken from the register, regardless of

whether the output function is programmed to be combinatorial

or registered. When implementing a combinatorial output func-

1

ICC in mA.

0.1

0.01

0.001

0.001

0.01 0.1 1 10

Frequency in MHz

4 of 10

Page 5

PEELTM 18CV8Z-25

Configuration

Input/Feedback Select Output Select

# A B C D

10010

21010 Active High

30100

41100 Active High

50011

61011 Active High

70111

81111 Active High

90000

10 1000 Active High

11 0110

12 1110 Active High

Bi-directional I/O

Combinatorial Feedback

Register Feedback

Register

Combinatorial

Register

Combinatorial

Register

Combinatorial

Active Low

Active Low

Active Low

Active Low

Active Low

Active Low

5 of 10

Page 6

PEELTM 18CV8Z-25

Design Security

The PEEL™18CV8Z provides a special EEPROM security bit

that prevents unauthorized reading or copying of designs programmed into the device. The security bit is set by the PLD programmer, either at the conclusion of the programming cycle or as

a separate step, after the device has been programmed. Once the

security bit is set it is impossible to verify (read) or program the

PEEL™ until the entire device has first been erased with the

bulk-erase function.

Signature Word

The signature word feature allows a 64-bit code to be programmed into the PEEL™18CV8Z if the software option is used.

The code can be read back even after the security bit has been set.

The signature word can be used to identify the pattern programmed into the device or to record the design revision, etc.

Programming Support

ICT’s JEDEC file translator allows easy conversion of existing

20 pin PLD designs to the PEEL™18CV8Z, without the need for

redesign. ICT supports a broad range of popular third party

design entry systems, including Data I/O Synario and Abel, Logical Devices CUPL and others. ICT also offers (for free) its proprietary PLACE software, an easy-to-use entry level PC-based

software development system.

Programming support includes all the popular third party programmers; Data I/O, Logical Devices, and numerous others. ICT

also provides a low cost development programmer system, the

PDS-3.

6 of 10

Page 7

PEELTM 18CV8Z-25

This device has been designed and tested for the specified operating ranges. Proper operation outside of these levels is not guaranteed. Exposure to absolute maximum ratings may cause

Absolute Maximum Ratings

Symbol Parameter Conditions Rating Unit

CC

V

I

, V

V

O

I

ST

T

LT

T

Supply Voltage Relative to Grou nd -0.5 to + 7.0 V

O

Voltage A ppl ied to Any Pin

Output Current Per Pin (IOL, IOH)±25mA

Storage Temperature -65 to +150 °C

Lead Temperature Soldering 10 Seconds +300 °C

2

Relative to Ground

Operating Range

Symbol Parameter Conditions Min Max Unit

permanent damage.

1

-0.5 to VCC + 0.6 V

Vcc Supply Voltage

T

T

A

R

T

F

T

RVCC

Ambient Temperature

Clock Rise Time See Note 3. 20 ns

Clock Fall Time See Note 3. 20 ns

V

Rise Time

CC

Commercial 4.75 5.25 V

Industrial 4.5 5.5 V

Commercial 0 +70 °C

Industrial -40 +85 °C

See Note 3. 250 ms

D.C. Electrical Characteristics Over the operating range (Unless otherwise specified)

Symbol Parameter Conditions Min Max Unit

OH

V

V

C

V

V

V

V

I

CCS

I

CC

I

C

OUT

OHC

OL

OLC

IH

IL

IL

I

SC

IN

9

10

7

Output HIGH Voltage - TTL VCC = Min, IOH = -4.0 mA 2.4 V

Output HIGH Voltage - CMOS VCC = Min, IOH = -10.0 µA VCC - 0.3 V

Output LOW Voltage - TTL VCC = Min, IOL = 16.0 mA 0.5 V

Output LOW Voltage - CMOS VCC = Min, IOL = 10.0 µA 0.15 V

Input HIGH Voltage 2.0 VCC + 0.3 V

Input LOW Voltage -0.3 0.8 V

Input and I/O Leakage Curre nt VCC = Max, GND ≤ VIN ≤ VCC, I/O = High Z ±10 µA

Output Short Circuit Current VCC = Max, VO = 0.5V, TA = 25°C -30 -135 mA

VCC Current, Standby

VCC Current, f=1MHz

Input Capacitance

7

Output Capacitance 12 pF

VIN = 0V or V

VIN = 0V or V

TA = 25 ° C , VC C = Ma x @ f = 1 MHz

CC

, All Outputs disabled

CC

, All Outputs disabled

4

4

10 (typ) 100 µA

2 (typ) 5 mA

6pF

7 of 10

Page 8

A.C. Electrical Characteristics

Over the operating range

8

PEELTM 18CV8Z-25

Symbol Parameter

PD

t

t

t

CO1

t

CO2

t

t

t

t

CL

t

t

MAX1

f

MAX2

f

MAX3

f

AW

t

t

t

RESET

t

OE

OD

CF

SC

HC

, t

CP

AP

AR

CH

Input5 to non-registered output

Input5 to output enable

Input5 to output disable

Clock to Output 15 ns

Clock to comb. output delay via internal registered feedback 35 ns

Clock to Feedback 9 ns

Input5 or feedback setup to cloc k

Input5 hold after clock

Clock low time, cloc k hi gh ti m e

Min clock per i od Ext (tSC + t

Internal fe edback (1/tSC+tCF)

External Feedback (1/tCP)

No Feedback (1/tCL+tCH)

Asynchronous Reset Pulse Width 25 ns

Input5 to Asynchronous Reset

Asynchronous Reset recov er y time 25 ns

Power-on reset time for registers in clear state

6

6

8

CO1

)30ns

11

11

11

-25 / I-25

Units

Min Max

25 ns

25 ns

25 ns

15 ns

0ns

13 ns

41.6 MHz

33.3 MHz

38.4 MHz

25 ns

12

5µs

Switching Waveforms

Registered Feedback,

Synchronous Preset

Notes:

1. Minimum DC input is -0.5V, however, inputs may undershoot to -2.0V for periods less than 20 ns.

I

2. V

and VO are not specified for program/verify operation.

3. Test Points for Clock and V

levels.

4. I/O pins are 0V and V

5. “Input” refers to an inpu t pi n signal.

OE

6. t

is measured from input transition to V

OD

is measured from input tra nsition to VOH-0.1V or VOL+0.1V; V

T

7. Capacitances are tested on a sample basis.

Inputs, I/O,

Clock

Asynchronous

Reset

Registered

Outputs

Combinatorial

Outputs

CC

in tR and tF are referenced at the 10 % and 90%

CC

.

REF

±0.1V,

REF=VL.

8. Test conditions assume: signal transition times of 3ns or less from the 10% and

90% points, timing reference levels of 1.5V (Unless otherwise spec ifi e d).

9. Test one output at a time for a duration of less than 1 second.

CC

for a typical a p plication: This paramete r is tested with the d evice pro-

10. I

grammed as an 8-bi t Co unter.

11. Parameters are not 100% tested. Specifications are based on initial characterization and a re te ste d a fter an y de sig n pr oce s s modi fi ca tion th at mi gh t affect operational frequency.

12. All input at GND.

8 of 10

Page 9

PEEL™ Device and Array Test Loads

5.0 VStandard

Load

Thevenin

Equivalent

PEELTM 18CV8Z-25

L

V

Output

L

C

R2

Output

Technology R1 R2 R

CMOS 480kΩ 480kΩ 228kΩ 2.375V 33 pF

TTL 235Ω 159Ω 95Ω 2.02V 33 pF

R1

L

R

CL

L

V

L

Ordering Information

Part Number Speed Temperature Package

PEEL18CV8ZP-25 25ns Commercial 20-pin Plastic DIP

PEEL18CV8ZJ-25 25ns Commercial 20-pin PLCC

PEEL18CV8ZS-25 25ns Commercial 20-pin SOIC

PEEL18CV8ZT-25 25ns Commercial 20-pin TSSOP

PEEL18CV8ZPI-25 25ns Industrial 20-pin Plastic DIP

PEEL18CV8ZJI-25 25ns Industrial 20-pin PLCC

PEEL18CV8ZSI-25 25ns Industrial 20-pin SOIC

PEEL18CV8ZTI-25 25ns Industrial 20-pin TSSOP

C

L

Part Number

PEEL™18CV8Z

Package

P = 20-pin Plastic 300mil DIP

J = 20-pin Plastic (J) Leaded Chip Carrier (PLCC)

S = 20-pin SOIC 300 mil Gullwing

T = 20-pin TSSOP 170 mil

Device

Suffix

PI-25

Speed

–25 = 25ns tpd

Temperature Grade

(Blank) = Commercial 0 to 70° C

I = Industrial –40 to +85° C

9 of 10

Page 10

Loading...

Loading...