Datasheet PDSP16256A, PDSP16256AC, PDSP16256AC1R, PDSP16256B0, PDSP16256C0 Datasheet (MITEL)

...Page 1

PDSP16256/A

Programmable FIR Filter

DS3709 Issue 7.1 June 1999

Features

● Sixteen MACs in a Single Device

● Basic Mode is 16-Tap Filter at up to 25MHz

Sample Rates

● Programmable to give up to 128 Taps with

Sampling Rates Proportionally Reducing to

3·125MHz

● 16-bit Data and 32-bit Accumulators

● Can be configured as One Long Filter or Two

Half-Length Filters

● Decimate-by-two Option will Double the Filter

Length

● Coefficients supplied from Host System or local

EPROM

Applications

● High Performance Digital Filters

Description

The PDSP16256 contains sixteen multiplier accumulators, which can be multi cycled to provide

from 16 to 128 stages of digital filtering. Input data

and coefficients are both represented by 16-bit

two’s complement numbers with coefficients

converted internally to 12 bits and the results being

accumulated up to 32 bits.

In 16-tap mode the device samples data at the

system clock rate of up to 25MHz. If a lower sample

rate is acceptable then the number of stages can be

increased in powers of two up to a maximum of 128.

Each time the number of stages is doubled, the

sample clock rate must be halved with respect to the

system clock. With 128 stages the sample clock is

therefore one eighth of the system clock.

In all speed modes devices can be cascaded to

provide filters of any length, only limited by the

possibility of accumulator overflow. The 32-bit

results are passed between cascaded devices

without any intermediate scaling and subsequent

loss of precision.

Ordering Information

Commercial (0°C to 170°C)

PDSP16256A/C0/AC 25MHz, PGA package

Industrial (240°C to 185°C)

PDSP16256 B0/AC 20MHz, PGA package

PDSP16256 B0/GC 20MHz, QFP package

Military (255°C to 1125°C)

PDSP16256 MC/AC1R 20MHz, MIL-STD-883*

(latest revision), PGA package

PDSP16256 MC/GC1R 20MHz, MIL-STD-883*

(latest revision), QFP package

*See notes following Electrical Characteristics for further

information on MIL-STD-883 screening

Associated Products

PDSP16350 I/Q Splitter/NCO

PDSP16510A FFT Processor

The device can be configured as either one long

filter or two separate filters with half the number of

taps in each. Both networks can have independent

inputs and outputs.

Both single and cascaded devices can be operated

in decimate-by-two mode. The output rate is then

half the input rate, but twice the number of stages

are possible at a given sample rate. A single device

with a 20MHz clock would then, for example,

provide a 128-stage low pass filter, with a 5MHz

input rate and 2·5MHz output rate.

Coefficients are stored internally and can be down

loaded from a host system or an EPROM. The latter

requires no additional support, and is used in stand

alone applications. A full set of coefficients is then

automatically loaded at power on, or at the request

of the system. A single EPROM can be used to

provide coefficients for up to 16 devices.

Page 2

PDSP16256

CHANGE

COEFF

POWER-ON

RESET

RES

PDSP

16256

EPROM

GNDSCLK

OUTPUT

DATA

INPUT

DATA

EPROM

ADDR DATA

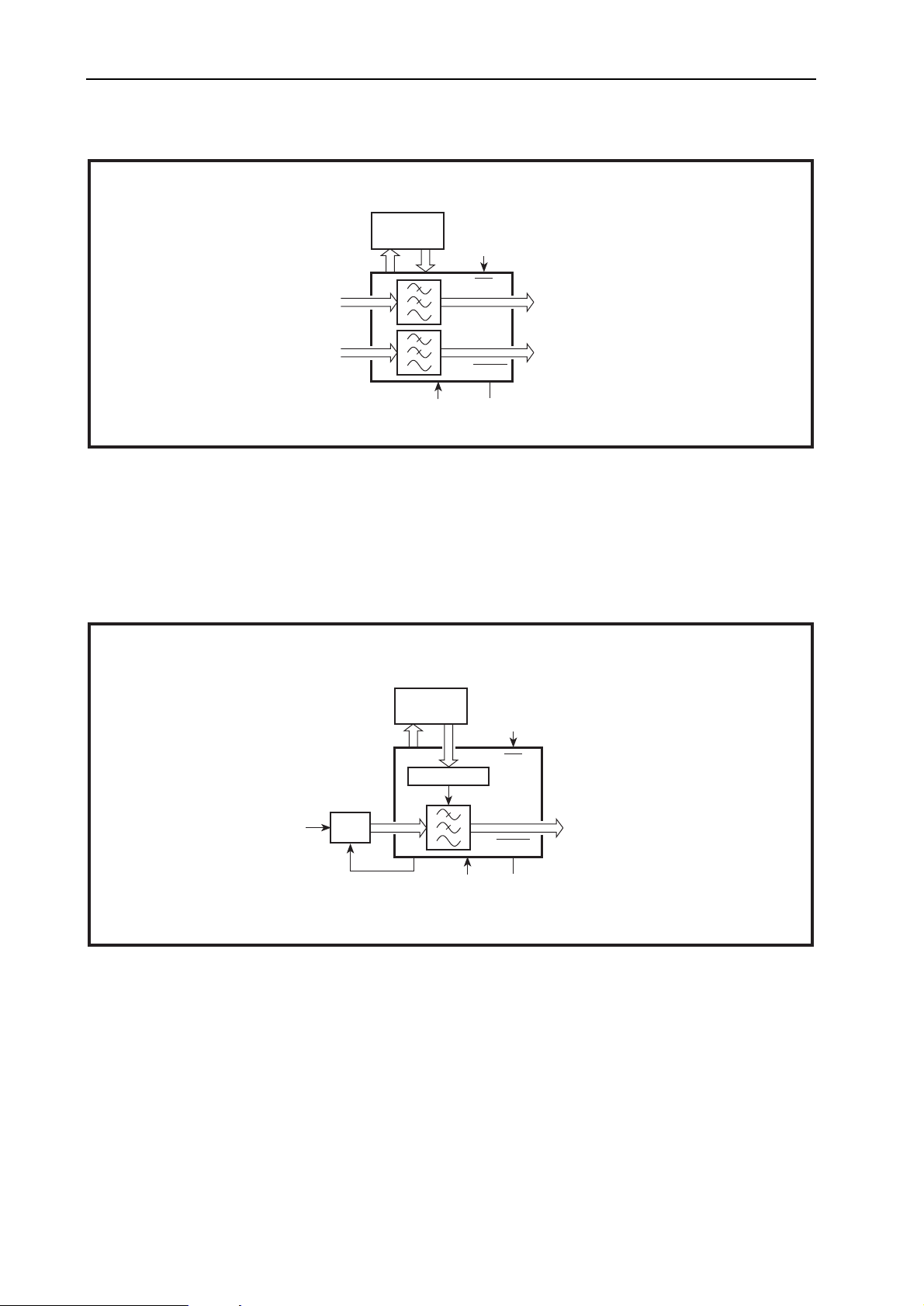

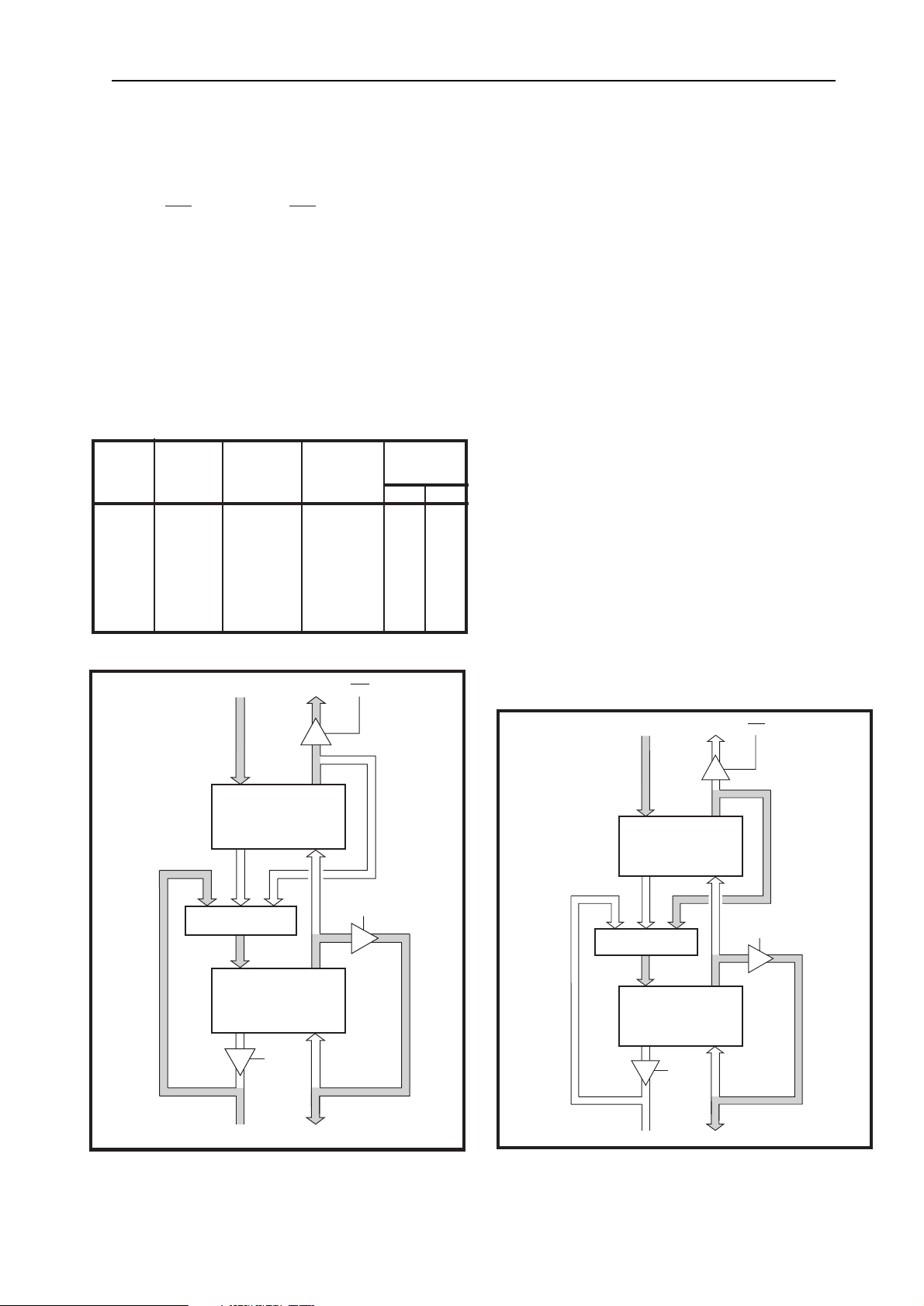

Figure. 1 A dual filter application

ANALOG

INPUT

EPROM

ADDR DATA

COEFFICIENTS

CHANGE

COEFF

POWER-ON

RESET

RES

PDSP

16256

ADC

CLKOP

EPROM

GNDSCLK

OUTPUT

Figure. 2 Typical system application

DATA

2

Page 3

PDSP16256

Signal

Description

DA15:0 16-bit data input bus to Network A.

DB15:0 Delayed data output bus in the single filter mode. Connected to the data input bus of the next device in a

cascaded chain. Input to Network B in the dual filter modes.

X31:0 Expansion input bus in the single filter mode. Connected to the previous filter output in a cascaded chain.

The inputs are not used on a single device system or on the Termination device in a cascaded chain. The

X bus provides the output from Network B in both dual modes.

F31:0 In single filter mode this bus holds the main device output. In dual mode it holds the output from Network A.

FEN Filter enable. The first high present on an SCLK rising edge defines the first data sample. The control register

and coefficient memory must be configured befor FEN is enabled.The signal must stay active whilst valid

data is being received and must be low if FRUN is high.

DFEN Delayed filter enable. This output is connected to the Filter Enable input of the next device in a cascaded

chain when moving towards the termination device and with multiple stand-alone EPROM-loaded

configurations. It is used to coordinate the control logic within each device.

SWAP Selects either the upper or lower set of coefficients for Bank Swap. A low selects the lower bank, a high the

upper bank.

FRUN In EPROM load mode, when high this signal allows continuous filter operations to occur without the need for

the initial FEN edge. If the device is not a single, interface or master device then this pin must be tied low.

DCLR

A low on this signal on the SCLK rising edge will clear all the internal accumulators.

low for a single cycle, signal BUSY will indicate when the internal clearing is complete. After a clear the

need only remain

DCLR

device must be re-synchronised to the data stream using FEN. It is recommended that FEN is taken low

at the same time as clear. FEN may then be taken high to synchronise the data stream once BUSY has

returned low.

C15:0 16-bit coefficient input bus. In the Byte mode of operation, C15:8 have alternative uses as explained in the

text.

A7:0 Coefficient address bus. In the EPROM mode A7:0 are address outputs for an EPROM. In the remote host

mode they are inputs from the host. A7 is not used when coefficients are loaded as 16-bit words.

CCS This pin is similar in operation to A7:0 and provides a higher order address bit. When low the coefficients

WEN

CS

BYTE

EPROM

are loaded, when high the control register is loaded.

In the remote mode this pin is an input which when low enables the load operation. In the EPROM mode

it is an output which provides the write enable for other slave devices.

This pin is always an input and must also be low for the internal write operation to occur.

When this pin is tied low, coefficients are loaded as two 8-bit bytes. When the pin is high they are loaded

as 16-bit words. In the EPROM mode this pin is ignored.

When this pin is tied low coefficients are loaded as bytes from an external EPROM. The device outputs an

address on A7:0. When the pin is high coefficients must be loaded from a remote master. They can then

be transferred individually rather than as a complete set.

SCLK The main system clock; all operations are synchronous with this clock. The clock rate must be either 1, 2,

4, or 8 times the required data sampling rate. The factor used depends on the required filter length.

CLKOP This output, when used to enable SCLK, can provide a data sampling clock. It has the effect of dividing the

OEN

SCLK rate by 1, 2, 4 or 8 depending on the filter mode selected.

Tri-state enable for the F bus. When high the outputs will be high impedance.

device and does not therefore take effect until the first SCLK rising edge

OEN

is registered onto the

BUSY A high on this signal indicates that the device is completing internal operations and is not yet able to accept

RES

new data. The signal is used during automatic EPROM loading, reset and accumulator clearing.

When this pin is low the control logic and accumulators are reset. In the EPROM mode it will initiate a load

sequence when it goes high.

NOTES

1. Unused buses (e.g. X31:0 when the device is configured in single or termination mode) can be set to any value. They should however be

maintained at a valid logic level to avoid an increase in power consumption.

2. To ensure correct input voltage thresholds are maintained all the VDD and GND pins must be connected to adequate power and ground planes.

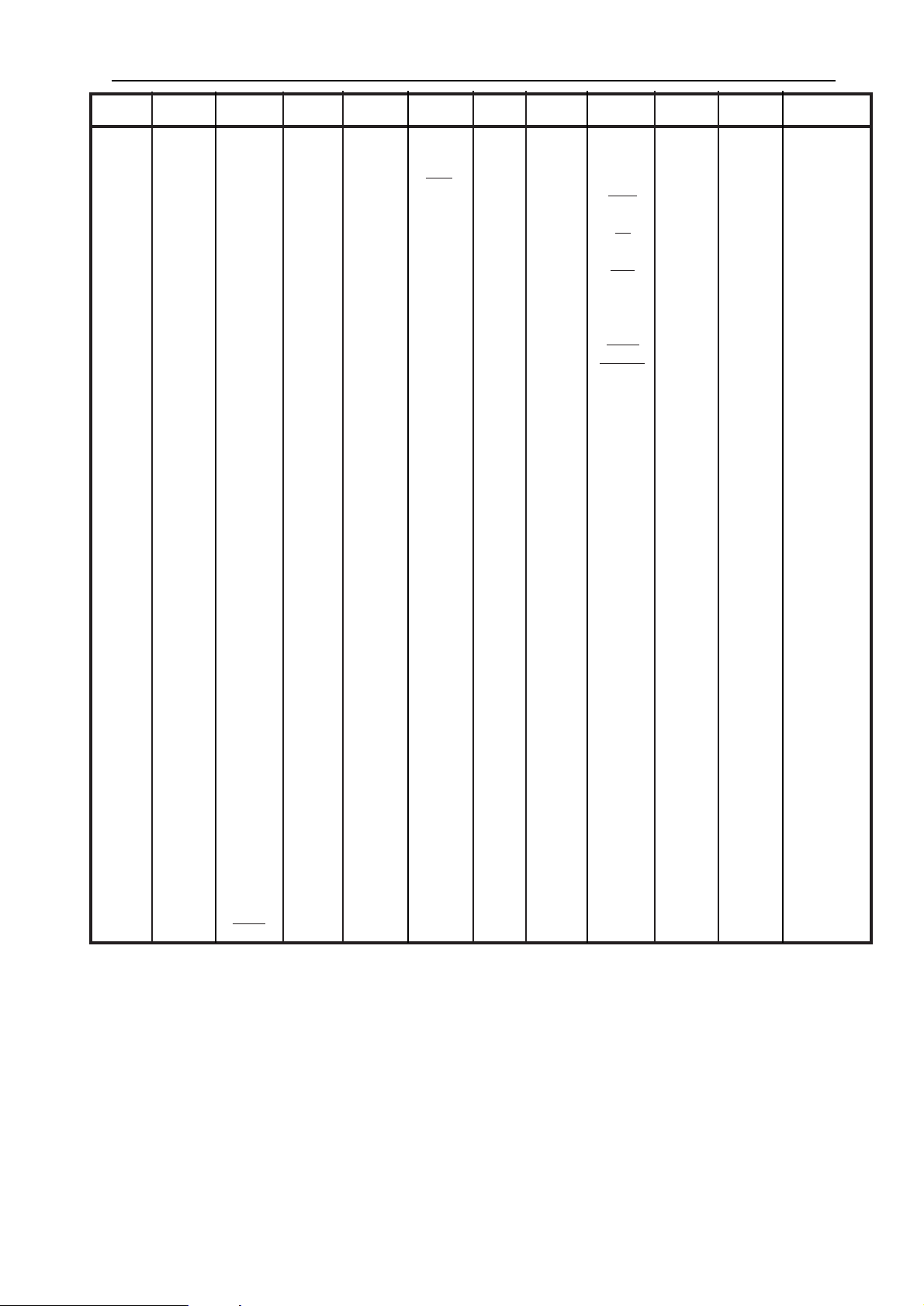

Table 1 Pin descriptions

3

Page 4

PDSP16256

EXTRA PIN D4,

CONNECTED TO D3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

AC144

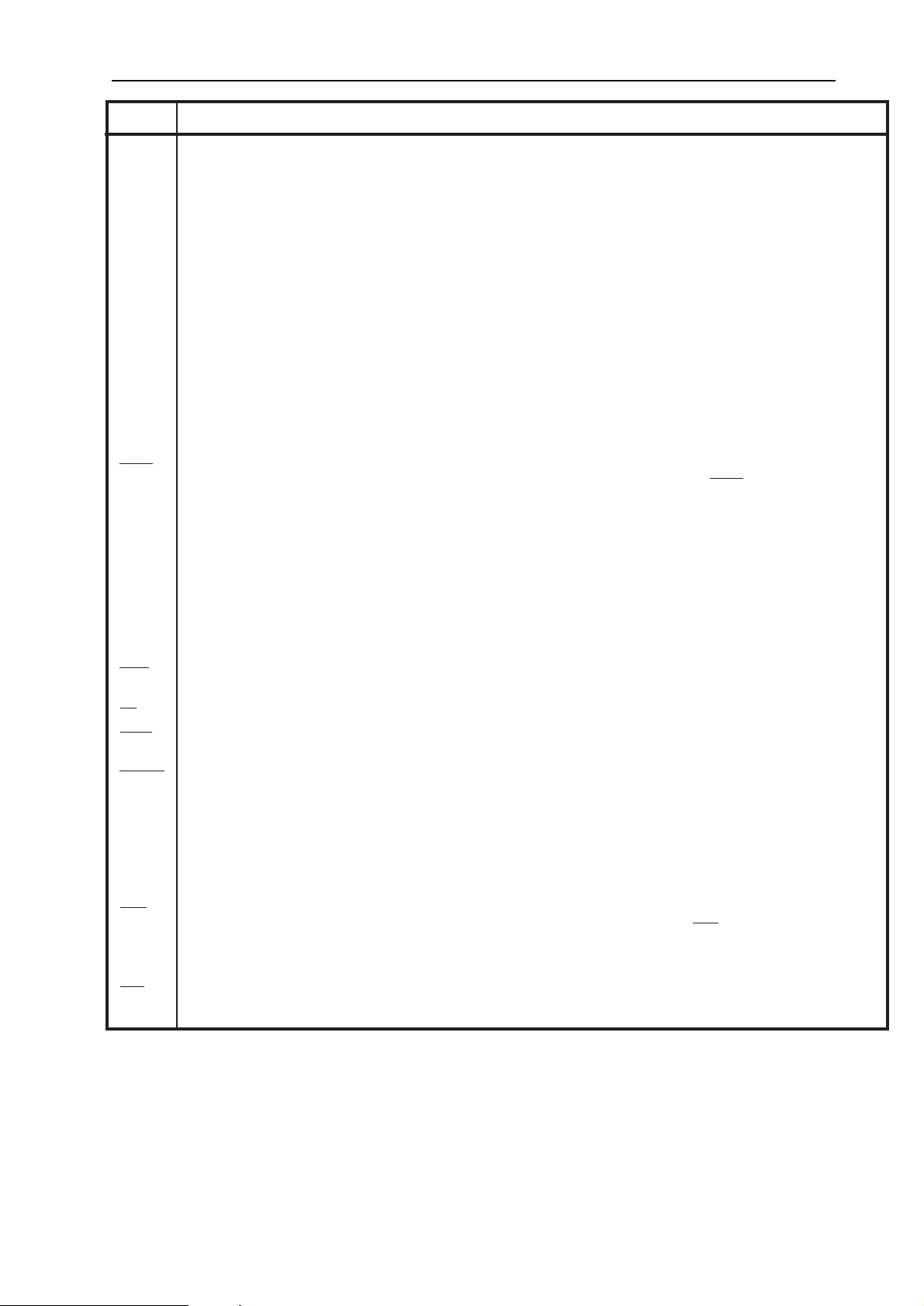

Fig. 3a Pin connections for 144 pin PGA package (bottom view)

PIN 1 INDEX

PIN 1

PIN 172

GC172

Fig. 3b Pin connections for 172 pin QFP (top view)

Figure. 3 Pin connection diagrams (not to scale). See T able 1 for signal descriptions and Table 2 for

pinouts.

4

Page 5

PDSP16256

GG

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

AC

A15

B15

D13

C14

G15

C15

D14

J15

E13

D15

E14

E15

F13

F14

F15

G14

G13

H14

H15

H13

J14

K15

-

J13

K14

L15

K13

L14

M15

L13

M14

N15

-

N14

M13

P15

P14

N13

R15

Signal

F0

F1

F2

F3

V

DD

F4

F5

GND

F6

F7

F8

F9

F10

F11

F12

GND

F13

F14

F15

V

DD

F16

F17

F18

F19

V

DD

F20

F21

GND

F22

F23

F24

F25

F26

F27

F28

GND

F29

F30

F31

V

DD

FEN

DFEN

DCLR

GG

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

AC

R14

N12

P13

R13

P12

N11

R12

P11

R11

R9

N10

P10

R10

P9

R7

N9

P8

R8

N8

P7

R6

-

N7

P6

R5

N6

P5

R4

-

N5

P4

R3

P3

N4

-

R2

P2

N3

-

-

R1

Signal

SWAP

GND

OEN

CLKOP

V

DD

DA0

DA1

DA2

DA3

DA4

DA5

GND

DA6

DA7

DA8

DA9

V

DD

DA10

DA11

DA12

DA13

DA14

DA15

GND

C0

C1

C2

C3

C4

C5

V

DD

C6

C7

C8

C9

C10

GND

C11

C12

C13

V

DD

GND

C14

GG

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

AC

P1

N2

N1

M2

L3

M1

M3

L2

L1

K3

K2

K1

J2

J3

G1

H2

H1

J1

H3

G2

F1

G3

F2

E1

F3

E2

D1

E3

D2

C1

C2

D3

B1

B2

C3

Signal

C15

-

-

GND

GND

WEN

CCS

CS

-

V

DD

RES

SLCK

GND

-

V

DD

BYTE

EPROM

A0

A1

A2

A3

A4

V

DD

A5

A6

GND

A7

DB0

DB1

DB2

-

GND

DB3

DB4

DB5

DB6

DB7

-

V

DD

DB8

DB9

DB10

DB11

DB12

DB13

DB14

-

GND

DB15

-

V

DD

GG

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

AC

A1

A2

C4

B3

A3

B4

C5

A4

B5

A5

A7

C6

B6

A6

B7

C7

B8

A9

A8

C8

B9

A10

C9

B10

A11

C10

-

B11

A12

C11

-

B12

A13

B13

C12

A14

-

B14

-

C13

Signal

GND

BUSY

X0

V

DD

X1

X2

X3

X4

X5

X6

GND

X7

X8

V

DD

X9

X10

X11

X12

X13

X14

GND

X15

X16

X17

X18

X19

X20

X21

X22

GND

X23

X24

X25

V

DD

X26

X27

X28

X29

X30

GND

X31

V

DD

FRUN

NOTE. All GND and VDD pins must be used

T able 2 Pin connections for AC144 and GC172 packages

5

Page 6

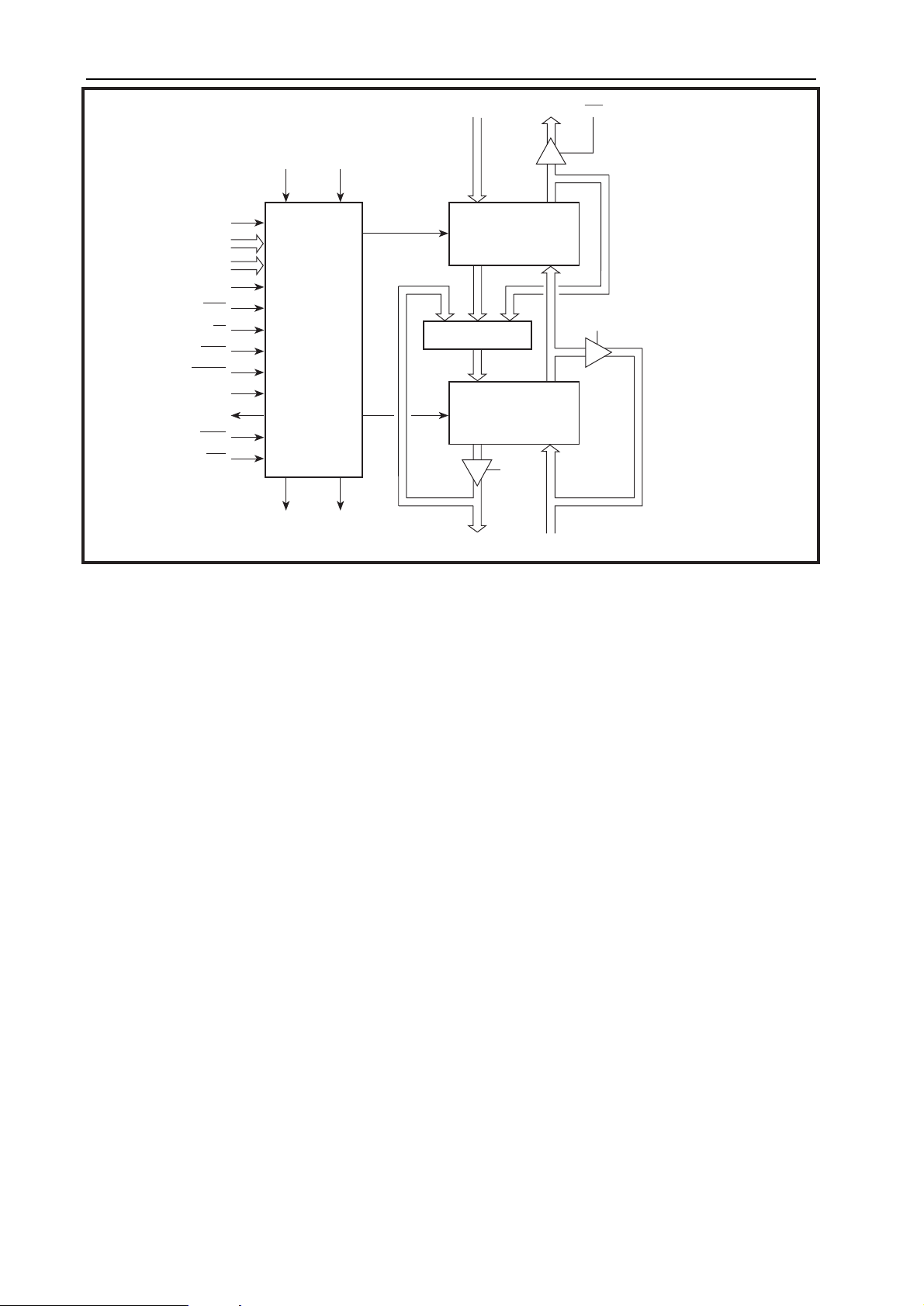

PDSP16256

DA15:0 F31:0 OEN

SCLK FRUN

SWAP

A7:0

C15:0

CCS

WEN

CS

BYTE

EPROM

FEN

DFEN

DCLR

RES

COEFFICIENT

STORAGE

AND

CONTROL

CLKOP BUSY

Figure. 4 Block Diagram

Operational Overview

The PDSP16256 is an application specific FIR filter for

use in high performance digital signal processing

systems. Sampling rates can be up to 25MHz. The

device provides the filter function without any software

development, and the options are simply selected by

loading a control register. The device can be user

configured as either a single filter, or as two separate

filters. The latter can provide two independent filters for

the in-phase and quadrature channels after IQ splitting,

or can provide two filters in cascade for greater stop

band rejection.

The device operates from a system clock, with rates up

to 25MHz. This clock must be 1, 2, 4, or 8 times the

required sampling frequency, with the higher

multiplication rates producing longer filter networks at

the expense of lower sampling rates. Devices can be

connected in cascade to produce longer filter lengths.

This can be accomplished without the need for any

additional external data delays, and all the single device

options remain available.

Continuous inputs are accepted, and continuous results

produced after the internal pipeline delay. Connection

can be made directly to an A-D converter. The filter

operation can be synchronised to a Filter Enable signal

(FEN) whose positive going edge marks the first data

sample. The internal multiplier accumulator array can be

cleared with a dedicated input. This is necessary if

erroneous results obtained during the normal data ‘flush

6

NETWORK

A

DUAL

MUX

NETWORK

B

SINGLE

MODE

DB15:0 X31:0

MODE

through’ are not permissible in the system.

Coefficients can be loaded from a host system using a

conventional peripheral interface and separate data

bus. Alternatively, they can be loaded as a complete set

from a byte wide EPROM. The device produces

addresses for the EPROM and a BUSY output indicates

that the transfer is occurring. Up to sixteen devices can

have their coefficients supplied from a single EPROM.

These devices need not necessarily be part of the same

filter network.

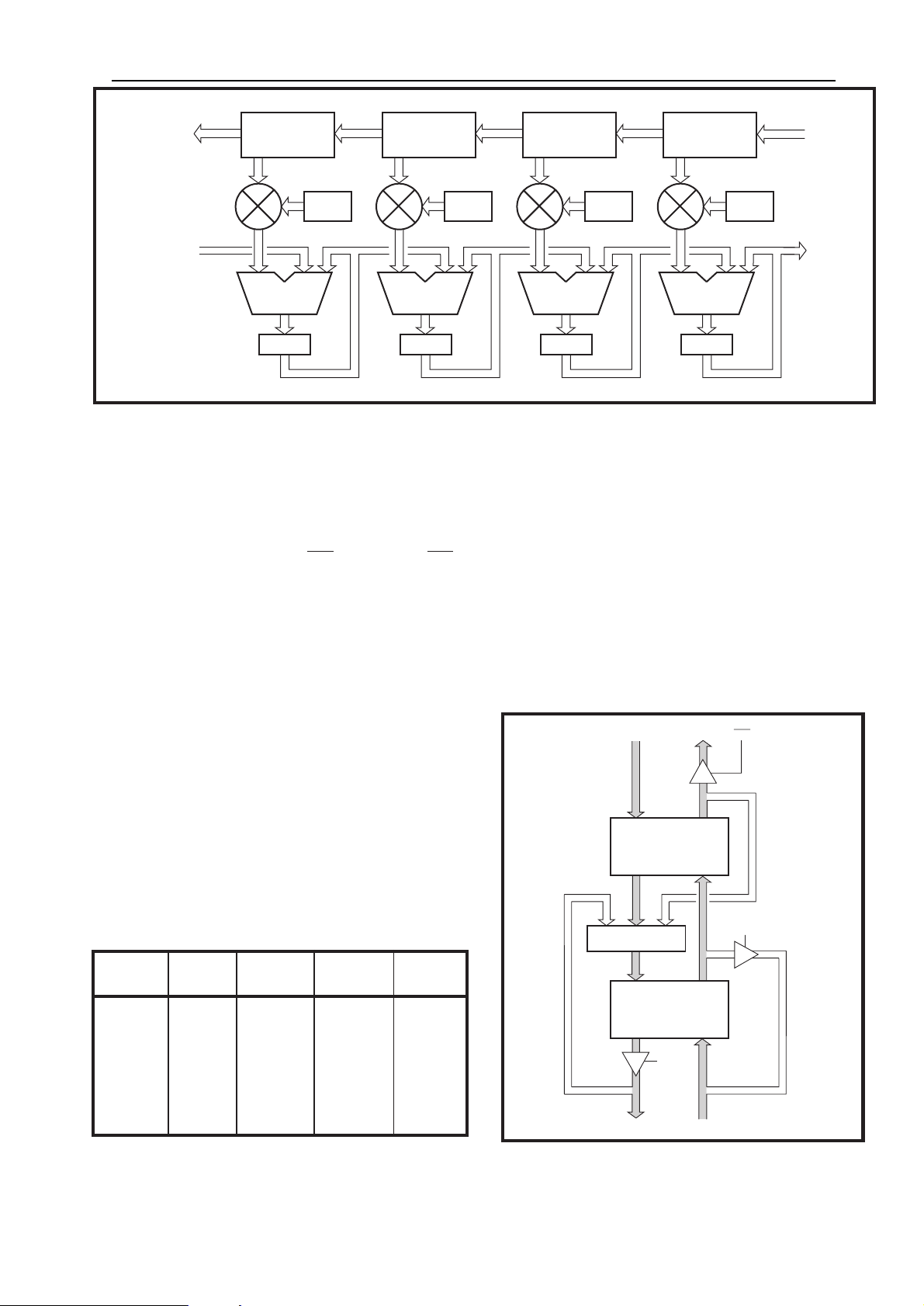

Each of the filter networks shown in Fig. 4 contains eight

systolic multiplier accumulator stages; an example with

four stages is shown in Fig. 5. Input data flows through

the delay lines and is presented for multiplication with the

required coefficient. This is added to either the last result

from this accumulator or the result from the previous

accumulator. The filter results progress along the adders

at the data sample rate. If the sample rate equals SCLK

divided by four, for example, then the accumulated result

is passed onto the next stage every fourth cycle. The

structure described is highly efficient when used to

calculate filtered results from continuous input data.

A comprehensive digital filter design program is

available for PC compatible machines. This will optimise

the filter coefficients for the filter type required and

number of taps available at the selected sample rate

within the PDSP16256 device. An EPROM file can be

automatically generated in Motorola S-record format.

Page 7

PDSP16256

DATA

OUT

ACCUMULATE

EXPANSION

IN

DATA

DELAY LINE

COEFF

ADDER

2

1

Z

RAM

DATA

DELAY LINE

COEFF

ADDER

2

1

Z

RAM

Figure. 5 Filter network diagram

Single Filter Options

When operating as a single filter the device accepts data

on the 16-bit DA bus at the selected sample rate, see

Figs. 5 and 6. Results are presented on the 32-bit F bus,

which may be tristated using the

registered onto the device and does not therefore take

effect until the first SCLK rising edge. Devices may be

cascaded this allows filters with more taps than available

from a single device. To accomplish this two further

buses are utilised. The DB bus presents the input data to

the next device in cascade after the appropriate delay,

while, partial results are accepted on the X bus.

input. Signal

OEN

OEN

DATA

DELAY LINE

COEFF

ADDER

2

1

Z

RAM

DATA

DELAY LINE

COEFF

ADDER

2

1

Z

RAM

the higher frequency components present in the input.

The Nyquist criterion, specifying that the sampling rate

must be at least double the highest frequency component, can still then be satisfied even though the sampling

rate has been halved.

is

The system clock latency for a single device is shown in

Table 3. This is defined as the delay from a particular data

sample being available on the input pins to the first result

including that input appearing on the output pins. It does

not include the delay needed to gather N samples, for an

N tap filter, before a mathematically correct result is

obtained.

DATA

IN

RESULT

OUT

Single filter mode is selected by setting control register bit

15 to a one. The required filter length is then selected

using control register bits 14 and 13 as summarised in

Table 3. The options define the number of times each

multiplier accumulator is used per sample clock period.

This can be once, twice, four times, or eight times.

In addition a normal/decimate bit (CR12) allows the filter

length to be doubled at any sample rate. This is possible

when the filter coefficients are selected to produce a low

pass filter, since the filtered output would then not contain

CR Input Output Filter Setup

14 13 12 Rate Rate Length Latency

0 0 0 SCLK SCLK 16 Taps 16

0 0 1 SCLK SCLK/2 32 Taps 17

0 1 0 SCLK/2 SCLK/2 32 Taps 16

0 1 1 SCLK/2 SCLK/4 64 Taps 18

1 0 0 SCLK/4 SCLK/4 64 Taps 20

1 0 1 SCLK/4 SCLK/8 128 Taps 24

1 1 0 SCLK/8 SCLK/8 128 Taps 24

Table 3 Single Filter options Figure. 6 Single Filter bus utilisation

DA15:0 F31:0 OEN

NETWORK

A

DUAL

MUX

NETWORK

B

SINGLE

MODE

DB15:0 X31:0

MODE

7

Page 8

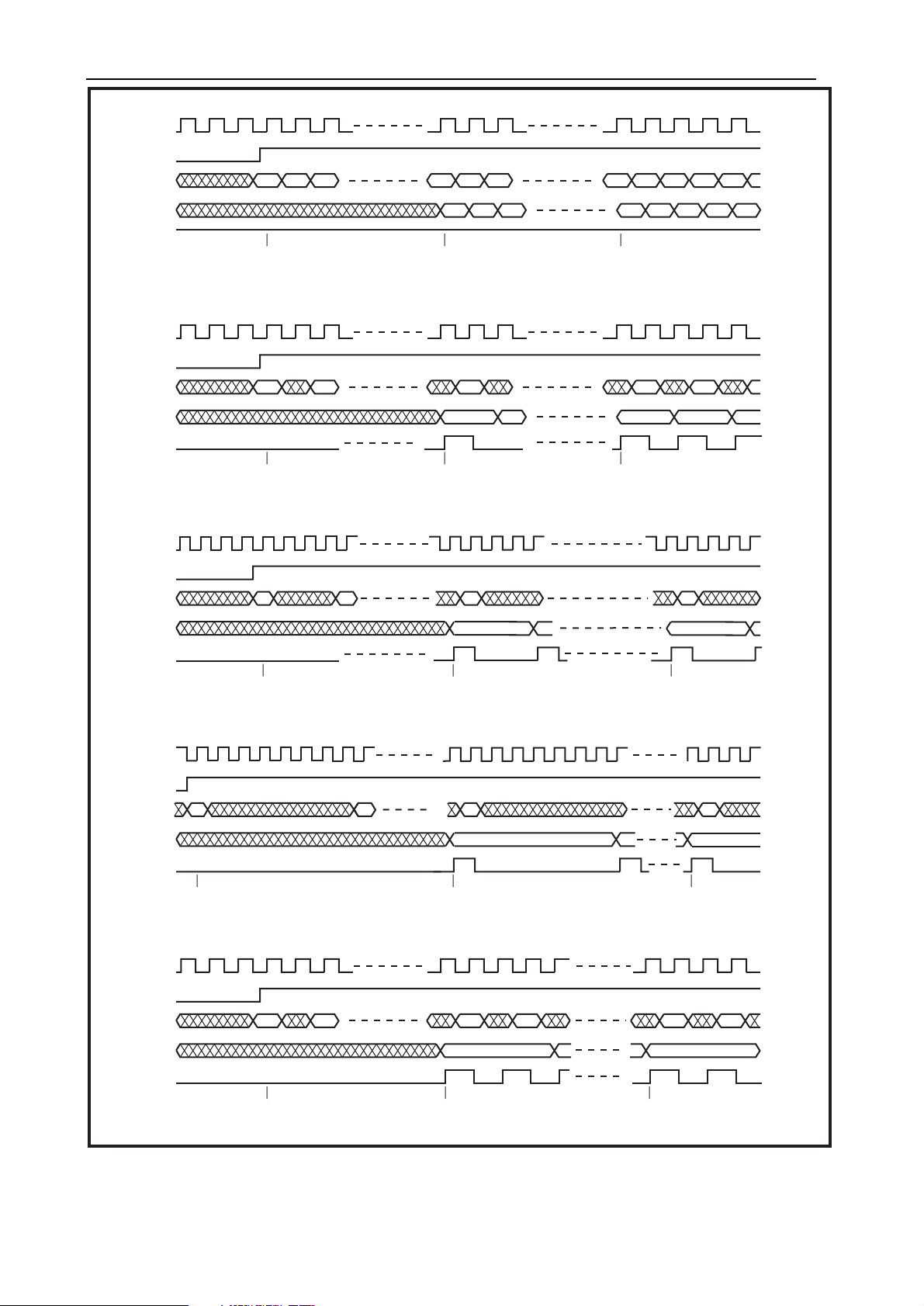

PDSP16256

SPEED MODE 0 (Data input and output at f

SCLK

FEN

DA15:0

F31:0

CLKOP

123

ABC

) CR14:13 = 00, CR12 = 0. CLKOP held high.

SCLK

16 17 18

First data point (A)

is read on edge 1

SPEED MODE 1 (Data input and output at half f

SCLK

FEN

DA15:0

F31:0

CLKOP

123

AB

SCLK

16 17 18

First data point (A)

is read on edge 1

SPEED MODE 2 (Data input and output at a quarter f

SCLK

FEN

DA15:0

123

AB

45 23 24

A′ B′ C′

First valid result

including data point (A)

available after edge 16

) CR14:13 = 01, CR12 = 0

A′ B′

First valid result

including data point (A)

available after edge 16

) CR14:13 = 10, CR12 = 0

SCLK

20 21 22

31 32 33

A′′ B′′ C′′

34 35

D′′ E′′

Valid result contains

the first 16 data points

available after edge 31

78 79 80

A′′ B′′ C′′

81 82

Valid result contains

the first 32 data points

available after edge 78

272 273

274 275 276

F31:0

CLKOP

First data point (A)

is read on edge 1

SPEED MODE 3 (Data input and output at an eighth f

SCLK

FEN

DA15:0

F31:0

CLKOP

SPEED MODE 1 Decimating (Data input at half f

SCLK

FEN

DA15:0

F31:0

123

A

45

First data point (A)

is read on edge 1

123

AB

6789

B

SCLK

18 19 20

A′ B′

First valid result

including data point (A)

available after edge 20

) CR14:13 = 11, CR12 = 0

SCLK

24 25 26

A′ B′

27 28

29 30 31 32

First valid result

including data point (A)

available after edge 24

and output at a quarter f

21 22

B′

SCLK

A′′ B′′

Valid result contains

the first 64 data points

available after edge 272

1040

1041 1042 1043

A′′

Valid result contains

the first 128 data points

available after edge 1040

) CR14:13 = 01, CR12 = 1.

142 143 144

B′′

145

CLKOP

First data point (A)

is read on edge 1

First valid result

including data point (A)

available after edge 18

Valid result contains

the first 64 data points

available after edge 142

Figure. 7 Single Filter timing diagrams

8

Page 9

PDSP16256

Dual Indipendant Filter Options

When operating as two independent filters the device

accepts 16 bit data on both the DA and DB buses at the

selected sample rate, see Fig. 8. Results are available

from both the F and X buses. The F bus may be tristated

using the

OEN

input. Signal

device and does not therefore take effect until the first

SCLK rising edge

Each filter must be configured in the same manner, and

multiple device expansion is not possible due to the pin

re-organization. The latter requirement can, of course,

still be satisfied by several devices configured as single

filters.

Dual independent filter mode is selected by setting

control register bits 15 and 4 to a zero. The required filter

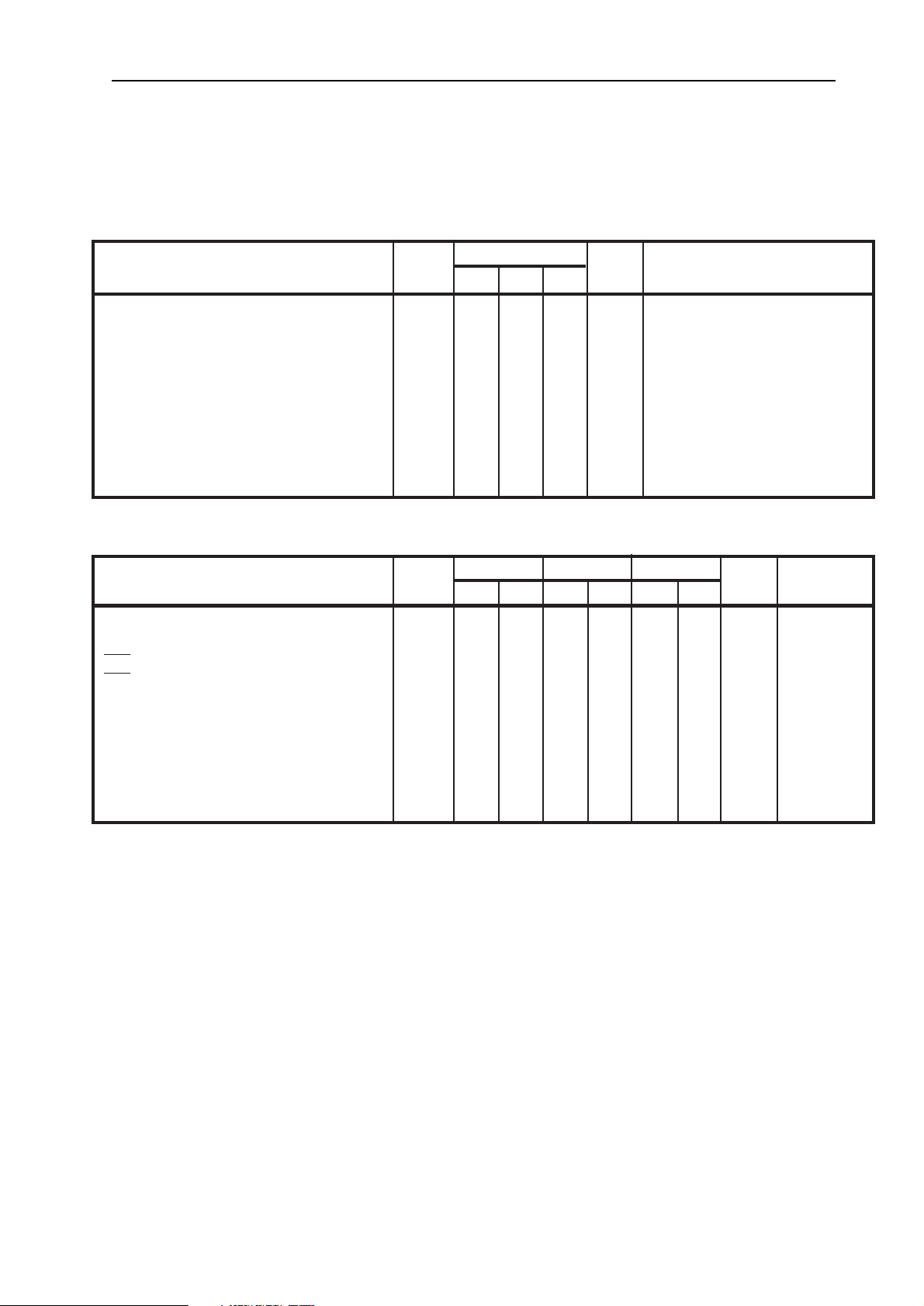

CR Input Output Filter Setup

141312 Rate Rate Length Latency

0 0 0 SCLK SCLK 8 Taps 16 27

0 0 1 SCLK SCLK/2 16 Taps 17 0 1 0 SCLK/2 SCLK/2 16 Taps 16 28

0 1 1 SCLK/2 SCLK/4 32 Taps 18 1 0 0 SCLK/4 SCLK/4 32 Taps 20 36

1 0 1 SCLK/4 SCLK/8 64 Taps 24 1 1 0 SCLK/8 SCLK/8 64 Taps 24 40

Table 4. Dual Filter options

DA15:0 F31:0 OEN

OEN

is registered onto the

Ind Cas

length is selected using control register bits 14 and 13 as

summarised in Table 4, which also shows the resulting

latency. As in single filter mode normal or decimate-bytwo operation can be selected using control register bit

12.

Dual Cascaded Filter Options

When operating as two cascaded filters the device accepts 16 bit data on the DA bus at the selected sample

rate. Results are presented on the 32-bit X bus, see Fig.

9. Each filter must be configured in the same manner.

Multiple device expansion is not possible in this mode.

Dual cascaded filter mode is selected by setting control

register bit 15 to a zero and bit 4 to a one. The required

filter length is selected using control register bits 14 and

13 as summarised in Table 4, which also shows the

resulting latency. The decimate-by-two option is not

available in this mode.

The data for the second filter network is extracted as the

middle 16 bits from the first networks accumulated result.

For successful operation the first filter network must have

unity gain. See the section on filter accuracy for more

details.

The cascade option is used to increase the stop band

rejection in a practical filter application. Theoretically,

increasing the number of taps in an FIR filter will increase

the stop band rejection, but this assumes floating point

calculations with no accuracy limitations. In practice, with

fixed point arithmetic, better performance is achieved

with two smaller filters in series.

NETWORK

A

MUX

NETWORK

B

SINGLE

MODE

DB15:0 X31:0

DUAL

MODE

DA15:0 F31:0 OEN

NETWORK

A

DUAL

MUX

NETWORK

B

SINGLE

MODE

DB15:0 X31:0

MODE

Figure. 9 Dual cascaded filter bus utilisationFigure. 8 Dual independent filter bus utilisation

9

Page 10

PDSP16256

Filter Accuary

Input data and coefficients are both represented by 16bit two’s complement numbers. The coefficients are

converted to twelve bits by rounding towards zero. This

is achieved as follows. If the coefficient is positive then

the least significant 4 bits are discarded. If the coefficient

is negative then the logical ‘OR’ of the least significant 4

bits are added to the remainder of the word. Twelve bit

coefficients can be used directly provided the least

significant four bits are set to zero.

INPUT DATA

COEFFICIENT

The FIR filter results are calculated using a multiplier

accumulator structure as shown in Fig. 10. The truncation and word growth allowed for in the data path are

explained in Fig. 10. The 16-bit data and 12-bit coefficient inputs (each with one sign bit before the binary

point), are presented to the multiplier. This produces a

28-bit result with two bits before the binary point. Producing the full 28-bit result ensures that if both the data and

coefficients are set to logic 1 a valid result is generated.

Prior to entering the accumulator the least significant 4

bits of the multiplier result are truncated and the resulting

24 bits sign extended to 32 bits. The final accumulator

result is 32 bits with 10 bits before the binary point. Thus

9 bits of word growth are allowed within the accumulator.

All accumulator bits are made available on the output

pins.

In cascade mode the middle 16 bits from the network A

accumulator are fed round to the network B data inputs,

see Fig. 11.

INPUT DATA

S

ADDER

ACCUMULATOR

RESULT

Figure. 10 Multiplier Accumulator

-14-13-12-11-10-9-8-7-6-5-4-3-2-1 -15

10

COEFFICIENT

MULTIPLIER RESULT

ACCUMULATOR RESULT

S S S S S S S S S 0

ACCUMULATOR RESULT

S 8 7 6 5 4 3 2 1 0

S

S 0 -26

-11-10-9-8-7-6-5-4-3-2-1

Multiplication producing a 28-bit result

Sign extended to 32 bits, least significant 4 bits truncated

These bits are passed to filter network B during cascade mode

Figure. 11 Filter accuracy

-25-24-23-22-14-13-12-11-10-9-8-7-6-5-4-3-2-1

-22-14-13-12-11-10-9-8-7-6-5-4-3-2-1

-22-14-13-12-11-10-9-8-7-6-5-4-3-2-1

Page 11

Cascading Devices

PDSP16256

When the filter requirements are beyond the capabilities

of a single device, it is possible to connect several

devices in cascade increasing the number of taps available at the required sample rate. Within each device all

filter length, decimate, and bank swap options are still

possible, but each device in the chain must be similarly

programmed and configured as a single filter.

The number of devices which can be cascaded is only

limited by the possibility of overflow in the 32-bit intermediate accumulations. If more than sixteen devices are

cascaded in auto EPROM load mode, then an additional

EPROM will be needed.

In modes where the data sample rate does not equal the

clock rate. Then the cascade arrangement shown in Fig.

12 is used. Delayed data is passed from device to device

in one direction, while intermediate results flow in the

opposite direction. The interface device both accepts the

input data and produces the final result. It is not necessary for each device to know its exact position in the

chain, but the device which receives the input data and

produces the final result must be identified, as must the

device which terminates the chain. The former is known

as the Interface device and the latter as the Termination

device, all others are Intermediate devices. Control

Register bits CR11:10 are used to define these positions

as shown in Table 6.

The control logic in each of the devices must be synchronised with respect to the Interface device. This is achieved

by connecting the Delayed Filter Enable output (DFEN)

to the Filter Enable input (FEN) of the next device in the

chain. The Interface device, itself, needs a FEN signal

produced by the system, unless in EPROM mode, where

FRUN may be pulled high. Even when the latter is true,

the FEN connection must be made between the remaining devices in the chain. By effectively extending the

filter length, the cascade latency is therefore the same

as for the single device in the same mode. Once the

pipeline is initially flushed the latency is as given in

Table 3.

When devices are cascaded such that the data sample

rate equals the clock rate, (Control register bits 14:13 =

00), then a different cascade configuration must be

used. This is shown in Fig. 13. The number of devices

that can be cascaded is, again, only limited by the 32-bit

accumulators.

In this mode the delayed data is passed from device to

device in the same direction as the intermediate results.

The device which accepts the input data is now at the

opposite end of the chain to the device which produces

the final result. The control logic in each of the devices

must be synchronised this is achieved by connecting all

the device FEN inputs to the global FEN. The cascade

latency for the complete filter is built up from the 12

delays from the termination device, 8 delays from the

interface device and additional intermediate devices

each adding 4 delays.

Avalable Options

RESULTS

DATA IN FEN

DA15:0

INTERFACE

DEVICE

DB15:0

DA15:0

INTERMEDIATE

DB15:0

DA15:0

TERMINATION

DEVICE

DB15:0

OUT

FEN F31:0

DFEN X31:0

FEN F31:0

DEVICE

DFEN X31:0

FEN F31:0

DFEN X31:0

Figure. 12 Three-device cascaded system

No more than 128 coefficients can be stored internally.

This limits the filter length / decimate / bank swap options

to those which do not require more than that number of

coefficients. Thus when a filter with 128 taps is to be

implemented in a single device, it is not possible to

decimate or bank swap. When a filter with 64 taps is

implemented, decimate or bank swap are possible, but

not both. With all other filter lengths, all decimate and

bank swap configurations are possible.

11

Page 12

PDSP16256

FENRESULTS

FEN F31:0

DB15:0

INTERFACE

DEVICE

DFEN X31:0

DA15:0

FEN F31:0

DB15:0

INTERMEDIATE

DEVICE

DFEN X31:0

DA15:0

FEN F31:0

DB15:0

TERMINATION

DEVICE

DFEN X31:0

DA15:0

DATA IN

OUT

Figure. 13 Full speed cascaded system

12

127

127

0

64

63

0

128 TAP

NO SWAP

POSSIBLE

64 TAP

FILTER B

NO SWAP

POSSIBLE

FILTER A

NO SWAP

POSSIBLE

127

127

64

63

96

95

64

63

32

31

0

0

127

UPPER

BANK

64

63

NOT USED

UPPER

BANK

LOWER

BANK

32

31

LOWER

BANK

0

(a) Single Filters

127

B UPPER

BANK

NOT USED

A UPPER

BANK

64

63

B UPPER

B LOWER

BANK

A LOWER

BANK

48

47

A UPPER

32

31

B LOWER

16

15

A LOWER

0

(b) Dual Filters

Figure. 14 Coefficient memory map

127

32

31

16

15

127

32

31

0

0

16 TAP32 TAP64 TAP

NOT USED

UPPER

BANK

LOWER

BANK

8 TAP16 TAP32 TAP

NOT USED

B UPPER

A UPPER

B LOWER

A LOWER

Page 13

PDSP16256

Filter Control

Two control modes are available selected by input

signal FRUN. In EPROM load mode, when FRUN is

tied high the device will commence operation once the

coefficients have been loaded. The CLKOP signal

indicates when new input data is required and that new

results are available, see Fig. 7. In both EPROM and

remote master load modes, when FRUN is tied low

filter operation will not commence until a high has been

detected on signal FEN. This mode allows synchronisation to an existing data stream. FEN should be taken

high when the first valid data sample is available so

that both are read into the device on the next SCLK

rising edge. Proper device operation requires FEN to

be low during control register and coefficient loading

both in EPROM mode and Remote Master mode. After

loading coefficients, filter operation is determined by

FRUN and FEN as described above.

During device reset

mum of 16 SCLK cycles. After a reset the control

register returns to its default state of 8C80

places the device into the following mode :

●

Single filter

●

Sample rate equal to the clock rate

●

Non-decimating

●

A single device (Not in a cascade chain)

●

Bank swap selected by bit in the control register

Coeficient Bank Swap

A Bank Swap feature is provided which allows all

coefficients to be simultaneously replaced with a different set. A bit in the Control Register (CR7) allows

the swap to be controlled by either input signal SWAP

or Control Register bit (CR6). The latter is useful if the

device is controlled by a microprocessor, when driving

a separate pin would entail additional address decoding logic and an external latch.

If SWAP or bit CR6 is low, the coefficients used will be

those loaded into the lower banks illustrated in Fig. 14.

When the SWAP or CR6 is high, the upper banks are

used.

The actual swap will occur when the next sampling

clock active going transition occurs. This can be up to

seven system clocks later than the swap transition,

and is filter length dependent. The first valid filtered

output will then occur after the pipeline latencies given

in Tables 3 and 4.

must be held low for a mini-

RES

HEX

. This

Loading Coefficients

When the device is to operate in a stand alone

application then the coefficients can be down loaded

as a complete set from a previously programmed

EPROM. Alternatively if the system contains a microprocessor they can be individually transferred from a

remote master under software control. In any mode

the system clock must be present and stable during

the transfer, and the addressing scheme is such that

the least significant address specifies the coefficient

applied to the first multiplier seen by incoming data.

The addresses used during the load operation are

those illustrated in Fig. 15. The Control Register is

loaded when CCS is high. In byte mode address A0 is

used to select the portion of control register loaded,

otherwise the address bits are redundant. When an

EPROM is used to provide coefficients, this redundancy causes the number of locations needed for any

device to be double that for the coefficients alone.

Auto EPROM LOAD

When

EPROM

the role of a master device in the system and controls

the loading of coefficients from an external EPROM,

see Fig.15. A load sequence commences when

the

RES

coefficient has been loaded. BUSY goes high to

indicate that a load sequence is occurring and the

filter output is invalid. The device will not commence

a filter operation until the FEN edge is received after

BUSY has gone low. This requirement can be avoided

if FRUN is tied high.

The address bus pins become outputs on the Master

device, and produce a new address every four system

clock periods. This four clock interval, minus output

delays and the data set up time, defines the available

EPROM access time.

The coefficients are always loaded as bytes. The

state ofb the

nored. This arrangement also allows the eight most

significant coefficient bus pins (C15:8) to be used for

other purposes as described later. Since the 16-bit

coefficients are loaded in two bytes the A0 pin specifies the required byte. The maximum number of

stored coefficients is 128, eight address outputs are

therefore provided for the EPROM. These eight outputs from the Master must also drive the address

inputs on the slave devices.

is tied low, the PDSP16256 assumes

input goes high, and will continue until every

pin on the master device is ig-

BYTE

13

Page 14

PDSP16256

SCLK

A7:0

CCS

RES

BUSY

SCLK

A7:0

CCS

C15:12

00 01

LOAD MASTER CONTROL

REGISTER

00 01

LOAD FIRST COEFFICIENT

VALID ADDR VALID ADDR

LOAD LAST COEFFICIENT

00

Fig. 15a EPROM load sequence

FE FF 00 01 00 01 FE FF 00 01 00 01

0000 0001 0001 0010

LOAD LAST

MASTER

COEFFICIENT

LOAD SLAVE 1

CONTROL

REGISTER

LOAD SLAVE 1

COEFFICIENTS

LOAD LAST

SLAVE 1

COEFFICIENT

LOAD SLAVE 2

CONTROL

REGISTER

LOAD SLAVE 2

COEFFICIENTS

Fig. 15b EPROM load sequence for a cascaded system

Figure. 15 EPROM load sequence timing diagrams

EPROM

ADDRESS

LSB

MSB

DATA

A7:0

CCS

C15:12

C7:0

A7:0

CCS

C15:12

C7:0

A7:0

CCS

C15:12

C7:0

PDSP16256

MASTER

PDSP16256

SLAVE 1

PDSP16256

SLAVE 2

C11:8

CS

EPROM

BYTE

WEN

C11:8

CS

EPROM

BYTE

WEN

C11:8

CS

EPROM

BYTE

WEN

(2 SLAVES)

0010

GND

GND

GND

0001

GND

V

DD

GND

0010

GND

V

DD

GND

14

Figure. 16 Three device auto EPROM load

Page 15

PDSP16256

When the filter length is less than the maximum, the

PDSP16256 will only transfer the correct number of

coefficients, and one or more significant address bits

will remain low. Sufficient coefficients are always loaded

to allow for a possible Bank Swap to occur, and the

EPROM allocation must allow for this even if the

feature is not to be used. Table 5 shows the number of

coefficients loaded for each of the modes.

If several devices are cascaded, only one device

assumes the role of the Master by having its

grounded. It produces a

signal for the other de-

WEN

EPROM

pin

vices, plus four higher order address outputs on C15:12,

see Fig. 16. The extra address bits on C15:12 define

separate areas of EPROM, containing coefficients for

up to fifteen additional devices. The least significant

block of memory must always be allocated to the

Master device. The additional devices need not in

practice be all part of the same cascaded chain, but

can consist of several independent filters. They must,

however, all havetheir

pins tied low. FRUN can

BYTE

still be used to start these independent filters after all

the devices have been loaded. In this case, however,

each slave FEN pin should be driven by DFEN from the

master device.

When one EPROM is supplying information for several

devices, some means of selectively enabling each

additional device must be provided. This is achieved

by using the C11:8 pins on the slave devices as binary

coded inputs to define one to fifteen extra devices.

These coded inputs always correspond to the block

address used for the segment of EPROM allocated to

that device. Code ‘all zeros’ must not be used since the

Master device has implied use of the bottom segment.

This is necessary since the C11:8 pins are alternatively used on the Master device to define the number

of devices supported by the EPROM.

In addition to providing the most significant addresses

to the EPROM, the C15:12 address outputs from the

master device must also drive the C15:12 inputs on the

slave devices. These C15:12 inputs are internally

compared to the C11:8 inputs to decide if that device

is currently to be loaded. This approach avoids the

need for external decoders and makes theCSinput

redundant. This input, however, must be tied low on

every device in an EPROM supported system.

The Control Coefficient pin (CCS) is used to define

when the control register is to be loaded. It becomes an

output on the Master device which provides an EPROM

address bit next in significance above A7:0, and also

drives the CCS inputs on the slave devices. This output

is high for the first two EPROM transfers in order to

access the control information, and then remains low

whilst the coefficients are loaded. This control information is thus not stored adjacent to the coefficients within

the EPROM, and in fact the EPROM must provide

twice the storage necessary to contain the coefficients

alone. All but two of the bytes in the additional half are

redundant. See Fig.17 for the EPROM memory map.

DEVICE 2

DEVICE 1

COEFFICIENTS

PER DEVICE

32 64 128

511

255

194

193

192

191

386

385

384

383

128

127

256

255

66

65

64

63

130

129

128

127

0

Control Number of

Register Coefficients

Loaded

1023

NOT USED

770

769

CONTROL REG

768

767

FILTER

COEFFICIENTS

512

511

NOT USED

258

257

CONTROL REG

256

255

FILTER

COEFFICIENTS

0

0

NOTE:

The EPROM memory map assumes that, for the 32 and 64

coefficient per device options, the unused address pins are

unconnected. If all address pins are connected as shown in

Fig. 16 then the 128 coefficients per device memory map

column should be used. Only those coefficients required will be

read, hence the upper portions of the coefficient address space

will be ignored.

14 13 12

000 32

001 64

010 64

011 128

100 128

101 128

110 128

1 1 1 Invalid Mode

Table 5. Number of coefficients loaded

Figure. 17 EPROM Memory Map

15

Page 16

PDSP16256

Using a Remote Master

When a remote master is used to load

coefficients,

EPROM

must be tied high and a

conventional peripheral interface is then provided. It

is not possible, however, to read coefficients already

stored. The master supplies an address and data

bus, and writes to the PDSP16256 occur under the

control of synchronousCSand

inputs. The

WEN

Coefficient Control Register pin (CCS) must be driven

by a master address line higher in significance than

A7:0. Both the

andCSsignals must be low for

WEN

the load operation to occur. When loading the control

register theCSsignal must be held low for a further 2

cycles, see Fig. 20. Since the internal write operation

is actually performed with the system clock, it is

necessary for the clock to be present during the

transfer.

The

input defines whether coefficients are

BYTE

loaded as a single 16 bit word or two 8-bit bytes. The

latter saves on connections to the remote master.

Address bits A7:0 are used in byte mode. 16-bit word

mode uses bits A6:0, A7 being redundant. When

writing in byte mode the least significant byte (A0 = 0)

must be written first followed by the most significant

byte (A0 = 1).

In byte mode the internal comparison between C15:12

and C11:8 is made, regardless of the state of

EPROM

For this reason pins C15:8 should all be tied low when

a remote master is used with byte transfers. This

ensures that the internal comparison gives equality

and allows the load operation to occur.

The address and coefficient buses plus

the

andCSsignals must all meet the specified

WEN

set up and hold times with respect to the system

clock, see Fig 20 and Switching Characteristics.

This synchronous interface is optimum for the

majority of high end applications, when individual

coefficients must be updated at sample clock rates.

However, if the coefficients are to be loaded under

software control from a general purpose

microprocessor, the processor’s

WRITE STROBE

probably be asynchronous with the SCLK clock

used by the PDSP16256. In this case external

synchronising logic is needed, as shown in Fig.18.

Fig. 19 shows the recommended loading sequence

and filter operation initiation. The simplest technique

is to reset the device prior to loading a set of

coefficients. Coefficients may be loaded once BUSY

returns low or 22 cycles after

is taken high.

RES

When loading a device from a remote master the

control register must be loaded first followed by the

filter coefficients. Fig. 19 shows the required loading

sequence, two examples are given one for byte

mode the other for word mode. A gap of at least one

cycle must be left after loading the control register

.

before loading the first coefficient.

Filter operations are started by presenting the first

data word at the same time as raising signal FEN;

FRUN should always be low.

will

16

Page 17

SCLK

PDSP16256

PROCESSOR WRITE STROBE

SCLK

PROCESSOR WRITE STROBE

REGISTERED STROBE

PDSP16256 WEN

ADDRESS/DATA

A7:0/C15:0

ADDRESS

DATA

REGISTERED INTO

SYNCHRONISATION

REGISTER

DQ

COEFFICIENT

LOAD

STATE MACHINE

WEN

PDSP

16256

HOLD

CIRCUIT

STROBE

ADDRESS AND DATA VALID

A7:0 AND C15:0 HELD AFTER FALLING EDGE OF WRITE STROBE

STROBE

REGISTERED

INTO STATE

MACHINE

A7:0

C15:0

COEFFICIENT

INPUT CLOCKED

TO PDSP16256 ON

THIS EDGE

Figure. 18 Remote Master synchronisation

17

Page 18

PDSP16256

DEVICE RESET

1234567 1617 373839

SCLK

RES

BUSY

RES must be held low

for 16 cycles

BYTE WIDE COEFFICIENT LOAD

1234567

SCLK

CCS

A7:0

C15:0

CS

WEN

Control register loaded

with CCS high

00 01 00 01 02 03 3E 3F

00 AC 10 00 20 00 00 02

Blank cycles Coefficients loaded into the required address location.

BUSY goes active Coefficient loading may start

once BUSY has returned low

8 67 68 69 70 71

CS

This example uses byte wide loading (

BYTE

held low).

must be maintained

for two cycles

WORD WIDE COEFFICIENT LOAD

1234567

SCLK

CCS

A7:0

C15:0

CS

WEN

Control register loaded

00 01 02 03 1E 1F

AC00 0020 0030 0040 0050 001F 0200

00

0010

Blank cycles Coefficients loaded into the required address location.

with CCS high

START OF FILTER OPERATION

1234567

SCLK

FEN

DA15:0

F31:0

0010

0000

0020 0030 0040 0050 00A0

8 34 35 36 37 38

04

This example uses word wide loading (

8 916171819

BYTE

held high).

0090

0001

0001 0004 00040000 0000 0000 0000 0000 0000 0000 0000 0000

18

CLKOP

The first data sample

is read as FEN goes high

The first result available. CLKOP

indicates the first active result cycle

Figure. 19 Device startup timing diagrams

Page 19

Control Register

PDSP16256

The internal operation of the PDSP16256 is

controlled by the status of a 16-bit control register. In

the dual filter modes both networks are controlled by

the same register. The significance of the various

bits are shown in Table 6. Tables 7 and 8 define the

control register bit interdependence for the filter and

bank swapping modes.

Bits Decode Function

15 0 Dual filter mode

15 1 Single filter mode

14:13 00 Sample rate is the system clock

14:13 01 Sample rate is half the system clock

14:13 10 Sample rate is quarter the system

clock

14:13 11 Sample rate is eighth the system clock

12 0 Output rate equals the input rate

12 1 Decimate-by-two

11:10 00 Intermediate device

11:10 01 Interface device

11:10 10 Termination device

11:10 11 Single device

9:8 00 These bits MUST be at logical zero

7 0 Bank swap is controlled by input pin

7 1 Bank swap is controlled by Bit 6

6 0 Lower bank if bit 7 is set

6 1 Upper bank if bit 7 is set

5 This bit must be at logical zero

4 0 Two independent filters

4 1 Two filters in cascade

3:0 These bits MUST be at logical zero

The control register is double buffered. This allows

the writing of a new control word without affecting the

current operation of the device. To activate the new

control register after it has been written to the device

the bank swap signal must be toggled. After a reset

the active control register is loaded directly and bank

swap need not be used.

Control

Register

Bits

15 4

0 0 Two independent filters

0 1 Two filters in cascade

1 X Single Filter

Function

Table 7 Control register filter mode bits

Control

Register

Bits

765

0 X 0 Control by input pin

1 0 0 Lower bank selected

1 1 0 Upper bank selected

X X 1 Swap on every sample clock

Function

Table 8 Control register bank swap bits

Table 6 Control register bit allocation

19

Page 20

PDSP16256

SCLK

CCS

CS

WEN

C15:0

A7:0

t

VALID ADDRESS

HS

VALID DATA

t

HH

(a) Coefficient Write

Figure. 20 Remote Master setup and hold timings

SCLK

A7:0

C15:12

CCS

C7:0

SCLK

t

CL

CCS

CS

WEN

C15:0

A7:0

t

VALID ADDRESS

t

HS

VALID DATA

HH

(b) Control Register Write

∼

CLK 1 CLK 2 CLK 9

t

CD

VALID ADDRESS

VALID ADDRESS

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

∼

tHSt

∼

∼

∼

∼

t

HH

CD

t

CH

t

HH

SCLK

OEN

F31:0

OUTPUT PINS

INPUT PINS

Figure. 21 EPROM load timings

t

CZF

t

HIGH Z

CL

t

t

OS

t

CD

VALID DATA

VALID DATA VALID DATAVALID DATA

OH

Figure. 22 Operating timings

t

CH

t

CVF

VALID DATA

tHSt

HH

20

Page 21

PDSP16256

Electrical Characteristics

The Electrical Characteristics are guaranteed over the following range of operating conditions, unless

otherwise stated:

Commercial: T

IndustriaL: T

Military: T

AMB =

= 0°C to+70°C, VDD = +5V±5%, GND = 0V

AMB

= -40°C to +85°C, VDD = +5V±10%, GND = 0V

AMB

-55°C to +125°C, VDD = +5V±10%, GND = 0V

Static Characteristics

Characteristic Symbol

Output high voltage

Output low voltage

Input high voltage (CMOS)

Input low voltage (CMOS)

Input high voltage (TTL)

Input low voltage (TTL)

Input leakage current

Input capacitance

Output leakage current

Output short circuit current

V

OH

V

OL

V

IH

V

IL

V

IH

V

IL

I

IN

C

IN

I

OZ

I

OS

Switching Characteristics (see Figs. 20, 21 and 22)

Characteristic

Input signal setup to clock rising edge

Input signal hold after clock rising edge

set up to clock rising edge

OEN

hold after clock rising edge

OEN

Clock rising edge to output signal valid

Clock frequency

Clock high time

Clock low time

Clock to data valid F bus from high impedance

Clock to data high impedance F bus

V

current

DD

NOTE 1. VDD = 15·5V, outputs unloaded, clock frequency = Max.

Symbol

t

HS

t

HH

t

OS

t

OH

t

CD

f

SCLK

t

CH

t

CL

t

CVF

t

CZF

I

DD

Value

Min. Typ. Max.

2·4

-

0·4

3·5

-

1·0

2·0

-

210

0·8

110

10

250

10

Commercial

Max.

Min.

8

4

20

4

5

18

11

-

-

-

-

-

-

26

25

-

30

30

400

150

300

Industrial

Min. Max.

20

20

12

Units

-

-

-

V

IOH = 4mA

V

I

V

SCLK input only

V

SCLK input only

V

All other inputs

V

All other inputs

µA

GND < V

= 4mA

OH

Conditions

< V

IN

DD

pF

µA

GND < V

mA

VDD = 15·5V

Military

Min.

8

-

8

4

-

4

-

20

4

-

4

5

28

-

20

-

30

-

30

5

-

-

20

-

12

-

-

380

Max.

-

-

-

28

20

-

30

30

380

OUT

< V

MHz

mA

DD

ns

ns

ns

ns

ns

ns

ns

ns

ns

ConditionsUnits

30pF

See Fig. 23

See Fig. 23

See Note 1

21

Page 22

PDSP16256

Test Waveform measurement level

Delay from

output high

to output

high impedance

Delay from

output low

to output

high impedance

Delay from

output high

impedance to

output low

1·5V

V

H

V

L

0·5V

0·5V

0·5V

1·5V

I

OL

DUT

30pF

Delay from

output high

impedance to

output high

V

is the voltage reached when the output is driven high

H

VL is the voltage reached when the output is driven low

1·5V

0·5V

Figure. 23 Three state delay measurement

Absolute Maximum Ratings (Note 1)

Supply voltage, V

Input voltage, V

Output voltage, V

Clamp diode current per pin, I

Static discharge voltage (HBM)

Storage temperature, T

Maximum junction temperature, T

DD

IN

OUT

S

(see note 2)

K

JMAX

Commercial grade

Industrial grade

Military grade

Package power dissipation

Thermal resistance, Junction-to-Case, θ

NOTES

1. Exceeding these ratings may cause permanent

damage. Functional operation under these conditions

is not implied.

2. Maximum dissipation should not be exceeded for

more than 1 second, only one output to be tested at

any one time.

3. Exposure to absolute maximum ratings for extended

periods may affect device reliablity.

4. Current is defined as negative into the device.

5. The θ

data assumes that heat is extracted from the

JC

top of the package.

6. Maximum junction temperature, T

with power applied.

20·5V to 17·0V

20·5V to VDD 10·5V

20·5V to V

10·5V

DD

18mA

500V

265°C to1150°C

1100°C

1110°C

1150°C

3000mW

JC

, is specified

JMAX

5°C/W

I

OH

Three state delay measurement load

PDSP16256 MC AC1R and PDSP16256 MC GC1R

(MIL-STD-883 PARTS)

Polyimide is used as an inter-layer dielectric as

glassification. Polymeric material meeting the

requirements of MIL-STD-883 test method 5011 is used

for die attach.

Life tesst/burn-in connections are given in Tables 9 and

10 on the following pages.

Change Notification

The change notification requirements of MIL-PRF-38535

will be implemented on MIL-STD-883 grade devices.

Known customers will be notified of any changes since

the last buy when ordering further parts if significant

changes have been made.

Rev.

DateAMAR 1993BSEPT 1995CJAN 1998DAUG 1998

22

Page 23

PDSP16256

Pin

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

C1

C2

C3

C4

C5

C6

C7

Voltage

N/C

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

15·0V

0V/180k

0V

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

N/C

N/C

N/C

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

N/C

N/C

N/C

N/C

0V/180k

0V/180k

0V/180k

0V/180k

Pin

C8

C9

C10

C11

C12

C13

C14

C15

D1

D2

D3

D4

D13

D14

D15

E1

E2

E3

E13

E14

E15

F1

F2

F3

F13

F14

F15

G1

G2

G3

G13

G14

G15

H1

H2

H3

H13

Voltage

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

0V

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

15·0V

N/C

N/C

N/C

N/C

15·0V

15·0V/180k

15·0V/180k

15·0V/180k

N/C

Pin

H14

H15

J1

J2

J3

J13

J14

J15

K1

K2

K3

K13

K14

K15

L1

L2

L3

L13

L14

L15

M1

M2

M3

M13

M14

M15

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

N11

Voltage

N/C

N/C

0V

0V/180k

0V/180k

N/C

N/C

0V

0V/180k

0V/180k

0V/180k

N/C

N/C

N/C

15·0V

15·0V

RESET

N/C

N/C

N/C

CLOCK

15·0V

0V

N/C

N/C

N/C

0V

15·0V

15·0V/180k

15·0V

15·0V

0V

0V

15·0V

15·0V

0V

0V

Pin

N12

N13

N14

N15

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

Voltage

15·0V

N/C

N/C

N/C

15·0V/180k

15·0V/180k

15·0V

15·0V

0V

0V

15·0V

15·0V

15·0V

0V

0V

0V

N/C

0V

N/C

0V/180k

15·0V

15·0V

0V

0V

15·0V

15·0V

15·0V

0V

15·0V

0V

0V

0V

15·0V

N/C

Table 9 Life test/burn-in connections for PDSP16256 MC AC1R (PGA). NOTE: PDA is 5% and based on

groups 1 and 7

23

Page 24

PDSP16256

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Voltage

N/C

N/C

N/C

N/C

15·0V

N/C

N/C

0V

N/C

N/C

N/C

N/C

N/C

N/C

N/C

0V

N/C

N/C

N/C

15·0V

N/C

N/C

N/C

N/C

15·0V

N/C

N/C

0V

N/C

N/C

N/C

N/C

N/C

N/C

N/C

0V

N/C

N/C

N/C

15·0V

0V

N/C

N/C

Pin

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

Voltage

15·0V

0V

15·0V

N/C

15·0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

15·0V

15·0V

15·0V

15·0V

15·0V

15·0V

15·0V

15·0V

15·0V

0V

0V

0V

0V

0V

0V

0V

15·0V

15·0V

15·0V

15·0V

15·0V

15·0V

0V

15·0V

15·0V/180k

15·0V/180k

15·0V

0V

0V/180k

Pin

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

Voltage

15·0V/180k

0V

0V

15·0V

0V

15·0V

15·0V

RESET

CLOCK

0V

15·0V

15·0V

15·0V

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

15·0V

15·0V/180k

15·0V/180k

0V

15·0V/180k

N/C

N/C

N/C

0V

N/C

N/C

N/C

N/C

N/C

15·0V

N/C

N/C

N/C

N/C

N/C

N/C

N/C

0V

N/C

15·0V

Pin

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

Voltage

0V

N/C

0V/180k

15·0V

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

0V

0V/180k

0V/180k

15·0V

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

0V/180k

0V

0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

0V

15·0V/180k

15·0V/180k

15·0V/180k

15·0V

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

15·0V/180k

0V

15·0V/180k

15·0V

0V

Table 10 Life test/burn-in connections for PDSP16256 MC GC1R (QFP). NOTE: PDA is 5% and based on

groups 1 and 7

24

Page 25

Page 26

Page 27

Page 28

http://www.mitelsemi.com

World Headquarters - Canada

Tel: +1 (613) 592 2122

Fax: +1 (613) 592 6909

North America Asia/Pacific Europe, Middle East,

Tel: +1 (770) 486 0194 Tel: +65 333 6193 and Africa (EMEA)

Fax: +1 (770) 631 8213 Fax: +65 333 6192 Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

Information relating to products and services furnished herein by Mitel Corporation or its subsidiaries (collectively “Mitel”) is believed to be reliable. However, Mitel assumes no

liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any such information, product or service or for any infringement of

patents or other intellectual property rights owned by third parties which may result from such application or use. Neither the supply of such information or purchase of product or

service conveys any license, either express or implied, under patents or other intellectual property rights owned by Mitel or licensed from third parties by Mitel, whatsoever.

Purchasers of products are also hereby notified that the use of product in certain ways or in combination with Mitel, or non-Mitel furnished goods or services may infringe patents or

other intellectual property rights owned by Mitel.

This publication is issued to provide information only and (unless agreed by Mitel in writing) may not be used, applied or reproduced for any purpose nor form part of any order or

contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information appearing in this

publication are subject to change by Mitel without notice. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or

service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of use will be satisfactory in a specific

piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such information and to ensure that any publication or

data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or parameters. These products are not suitable for use in

any medical products whose failure to perform may result in significant injury or death to the user. All products and materials are sold and services provided subject to Mitel’s

conditions of sale which are available on request.

M Mitel (design) and ST-BUS are registered trademarks of MITEL Corporation

Mitel Semiconductor is an ISO 9001 Registered Company

Copyright 1999 MITEL Corporation

All Rights Reserved

Printed in CANADA

TECHNICAL DOCUMENTATION - NOT FOR RESALE

Loading...

Loading...