Page 1

INTEGRATED CIRCUITS

PDIUSBH11

Universal Serial Bus Hub

Product specification

Supersedes data of 1997 Apr 17

1997 Aug 01

Page 2

Philips Semiconductors Product specification

PDIUSBH1 1Universal Serial Bus Hub

FEA TURES

•Complies with the Universal Serial Bus specification Rev. 1.0

•Four downstream ports with per packet connectivity

•Embedded function with two endpoints (control and interrupt)

•Integrated FIFO memory for hub and embedded function

•Automatic protocol handling

•Versatile I

2

C interface

•Allows software control of monitor

•Compliant with USB Human Interface and Display Device Class

•Single 3.3V supply with 5V tolerant I/O

DESCRIPTION

The Philips Semiconductors PDIUSBH1 1 is a compound USB hub

IC (hub plus embedded function).

It is used in a microcontroller based system and communicates with

the system microcontroller over the I

approach to implementing a hub and embedded function allows the

designer to maintain the system microcontroller of choice and retain

existing architecture. This cuts down development time and offers

the most cost-effective solution.

Ideal applications for the IC include computer monitors and

keyboards.

The PDIUSBH11 conforms to the USB specification 1.0 and I

serial interface specification. It is also compliant with the USB

Human Input Device and Monitor Control Class specifications.

2

C serial bus. This modular

The embedded function of the PDIUSBH11 appears as PORT1 to

the host system and the four downstream ports are numbered 2

through 5.

ORDERING INFORMATION

PACKAGES TEMPERATURE RANGE OUTSIDE NORTH AMERICA NORTH AMERICA PKG. DWG. #

32-pin plastic SO 0°C to +70°C PDIUSBH11 D PDIUSBH11 D SOT287-1

32-pin plastic SDIP 0°C to +70°C PDIUSBH11 NB PDIUSBH11 NB SOT232-1

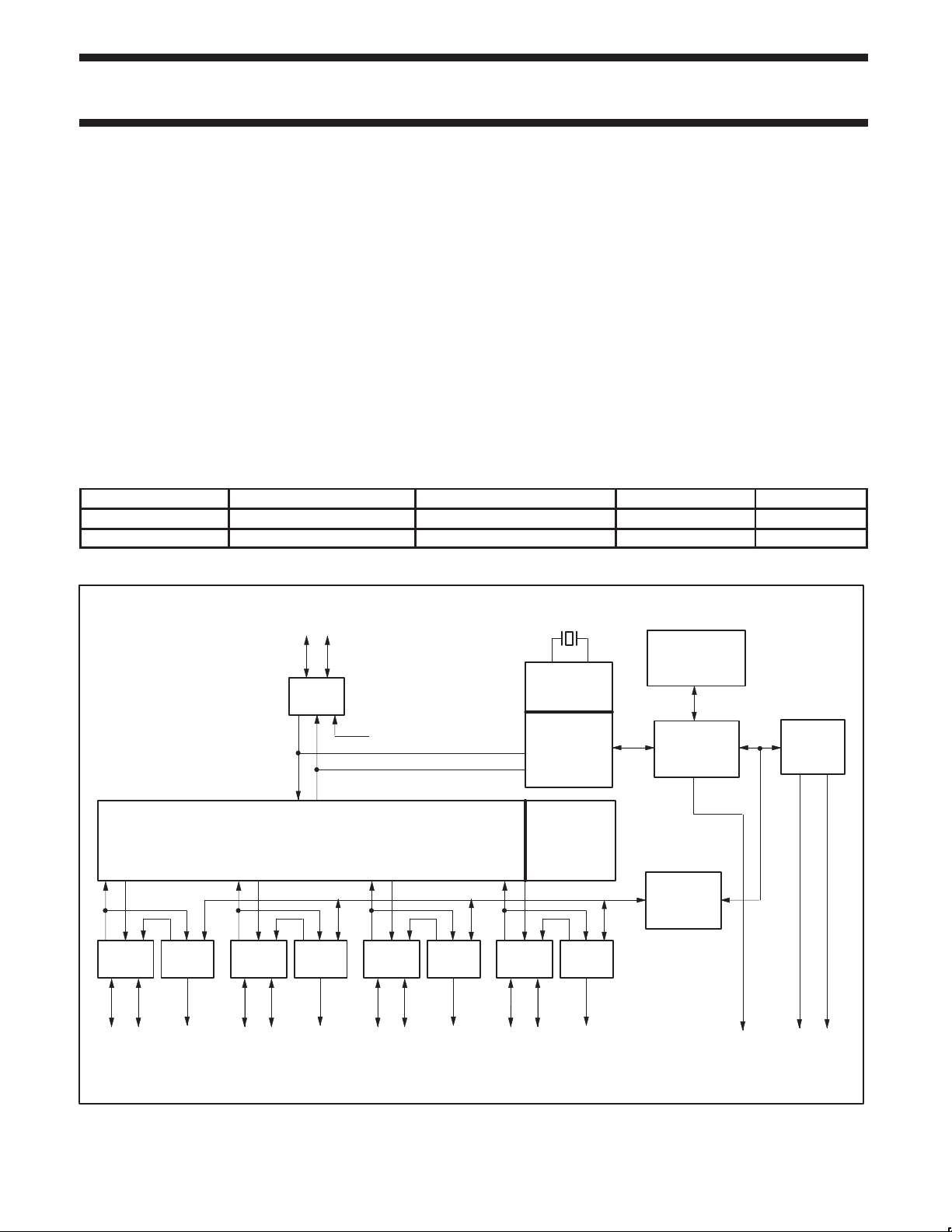

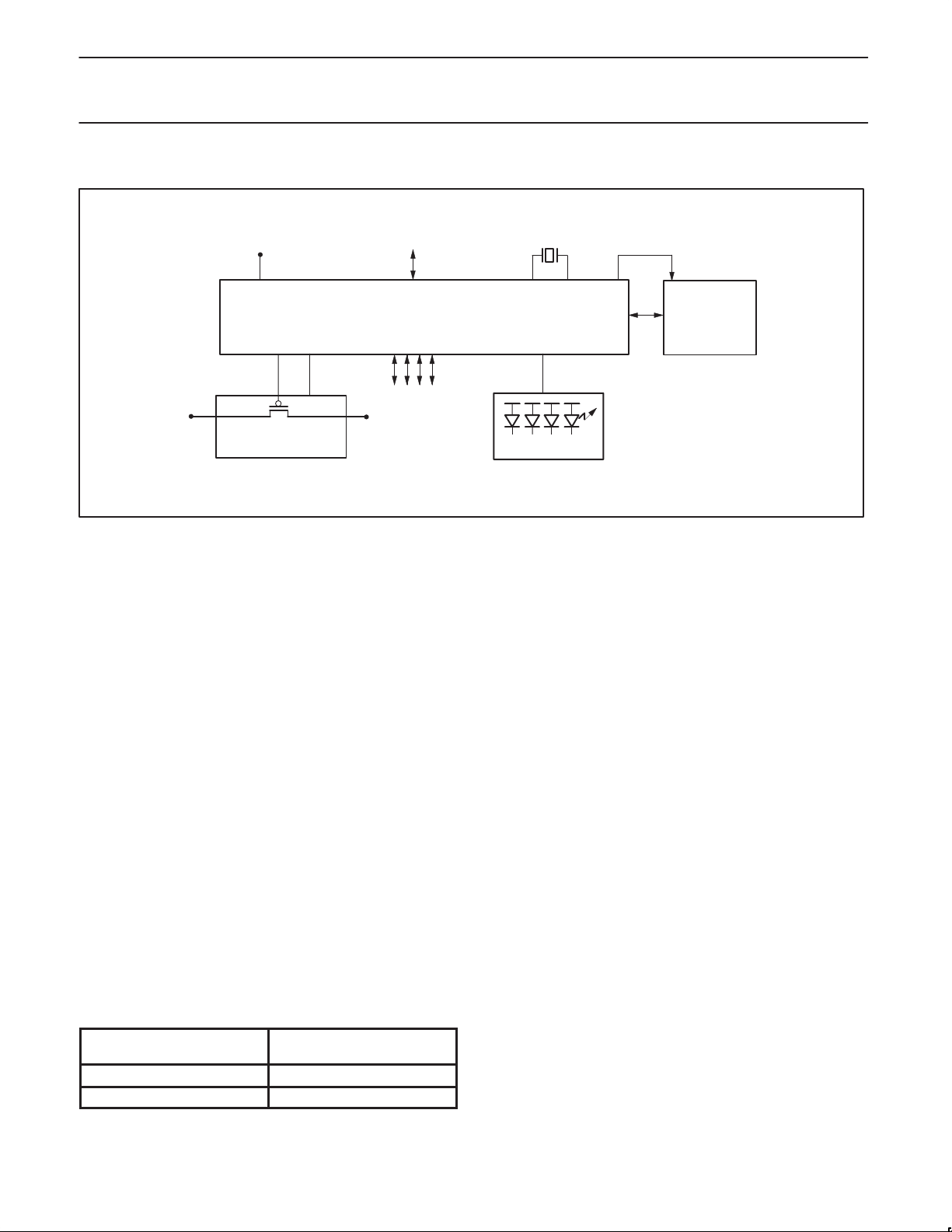

BLOCK DIAGRAM

UPSTREAM

PORT

D+

ANALOG

T

X/RX

D–

48 MHz

BIT CLOCK

RECOVERY

INTEGRATED

RAM

2

C

FULL SPEED

HUB

REPEATER

ANALOG

T

X/RX

D–D+

DOWNSTREAM

PORT 2

PORT

CONTROL

LED

ENABLE

ANALOG

T

X/RX

D–D+

DOWNSTREAM

PORT 3

PORT

CONTROL

LED

ENABLE

ANALOG

T

X/RX

D–D+

DOWNSTREAM

PORT 4

PORT

CONTROL

LED

ENABLE

ANALOG

T

X/RX

DOWNSTREAM

PORT 5

NOTE:

1. This is a conceptual block diagram and does not include each individual signal.

PHILIPS

SIE

END OF

FRAME

TIMERS

D–D+

PORT

CONTROL

LED

ENABLE

MEMORY

MANAGEMENT

UNIT

GENERAL

PORT

CONTROLLER

2

C

I

SLAVE

INTERFACE

INTERRUPT SDA SCL

SV00226

1997 Aug 01 853–1968 18238

2

Page 3

Philips Semiconductors Product specification

HUB

PDIUSBH11Universal Serial Bus Hub

Analog Transceivers

These transceivers interface directly to the USB cables through

some termination resistors. They are capable of transmitting and

receiving serial data at both “full speed” (12 Mbit/s) and “low speed”

(1.5 Mbit/s) data rates.

Hub Repeater

The hub repeater is responsible for managing connectivity on a per

packet basis. It implements packet signaling connectivity and

resume connectivity.

Low speed devices can be connected to downstream ports since the

repeater will not propagate upstream packets to downstream ports,

to which low speed devices are connected, unless they are

preceded by a PREAMBLE PID.

End of Frame Timers

This block contains the specified EOF1 and EOF2 timers which are

used to detect loss-of-activity and babble error conditions in the hub

repeater. The timers also maintain the low-speed keep-alive strobe

which is sent at the beginning of a frame.

General and Individual Port Controller

The general and individual port controllers together provide status

and control of individual downstream ports. Via the I

2

C-interface a

microcontroller can access the downstream ports and request or

change the status of each individual port.

Any change in the status or settings of the individual port will result

in an interrupt request. Via an interrupt register, the servicing

microcontroller can look up the downstream port which generated

ENDPOINT DESCRIPTIONS

The following table summarizes the endpoints supported by the PDIUSBH11.

FUNCTION

EMBEDDED

ENDPOINT

NUMBER

ENDPOINT TYPE TRANSFER TYPE DIRECTION

0 Default Control IN, OUT 8

1 Status change Interrupt IN 1

0 Default Control IN, OUT 8

1 Interrupt Interrupt IN 8

the interrupt and request its new status. Any port status change can

then be reported to the host via the hub status change (interrupt)

endpoint.

Bit Clock Recovery

The bit clock recovery circuit recovers the clock from the incoming

USB data stream using (4X) over-sampling principle. It is able to

track jitter and frequency drift specified by the USB spec.

Philips Serial Interface Engine (PSIE)

The Philips SIE implements the full USB protocol layer. It is

completely hardwired for speed and needs no firmware intervention.

The functions of this block include: synchronization pattern

recognition, parallel / serial conversion, bit stuffing / destuffing, CRC

checking / generation, PID verification / generation, address

recognition, handshake evaluation / generation.

Memory Management Unit (MMU) and Integrated RAM

The MMU and the integrated RAM is used to handle the large

difference in data-rate between USB, running in burst of 12 Mbit/s

and the I

This allows the microcontroller to read and write USB packets at its

own (low) speed through I

I

This block implements the necessary I

I

microcontroller whenever the PDIUSBH11 needs attention. As a

slave I

2

C interface to the microcontroller, running at 100 kbit/s.

2

C.

2

C Slave Interface

2

C allows for simple micro-coding. An interrupt is used to alert the

2

C device, the PDIUSBH11 I2C clock: SCL is an input and is

2

C interface protocol. A slave

controlled by the microcontroller.

MAXIMUM PACKET SIZE

(bytes)

PIN DESCRIPTION

The PDIUSBH11 has two modes of operation. The first mode

(Mode 0) enables the pins DNx_EN_N to power a LED indicating

the port is enabled. The second mode (Mode 1) utilizes the LED

enable pins as per port overcurrent condition pins.

1997 Aug 01

The voltage level at power up on the TEST1 and TEST2 pins

determine the PDIUSBH1 1 mode of operation. When both of the

pins are connected to Ground, Mode 0 is enabled. When pins

TEST1 and TEST2 are connected to Vcc, Mode 1 is enabled. Note

that in Mode 1 the pin DN2_EN_N remains an LED enable pin. Pin

TEST3 should always be connected to Ground at all times.

3

Page 4

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

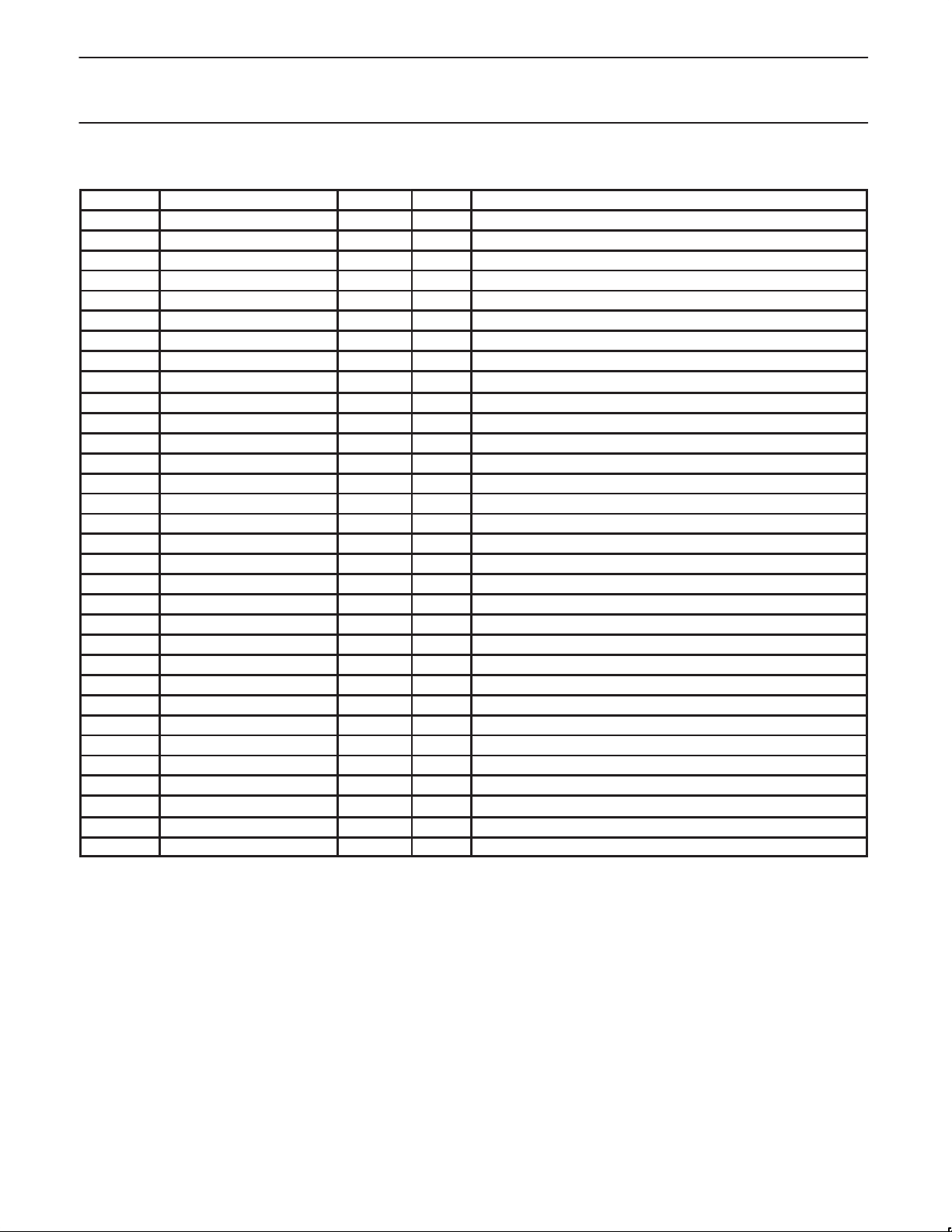

PIN DESCRIPTION (MODE 0)

PIN NO PIN SYMBOL I/O DRIVE NAME AND FUNCTION

1 TEST1 I Connect to Ground

2 TEST2 I Connect to Ground

3 TEST3 I Connect to Ground

4 RESET_N I ST Power-on reset

5 GND POWER Ground reference

6 XTAL1 I/O Crystal connection 1 (48MHz)

7 XTAL2 I/O Crystal connection 2 (48MHz)

8 CLK12MHZ O 2mA 12MHz output clock for external devices

9 V

10 OCURRENT_N I ST Over-current notice to the device

11 SWITCH_N O OD8 Enables power to downstream ports

12 SUSPEND O 4mA Device is in suspended state

13 DN2_EN_N O OD8 Downstream port 2 LED enable indicator

14 DN3_EN_N O OD8 Downstream port 3 LED enable indicator

15 DN4_EN_N O OD8 Downstream port 4 LED enable indicator

16 DN5_EN_N O OD8 Downstream port 5 LED enable indicator

17 INT_N O OD4 Connect to microcontroller interrupt

18 SDA I/O OD4 I2C bi-directional data

19 SCL I/O OD4 I2C bit-clock

20 GND POWER Ground reference

21 DN5_DP AI/O Downstream port 5 D+ connection

22 DN5_DM AI/O Downstream port 5 D– connection

23 DN4_DP AI/O Downstream port 4 D+ connection

24 DN4_DM AI/O Downstream port 4 D– connection

25 DN3_DP AI/O Downstream port 3 D+ connection

26 DN3_DM AI/O Downstream port 3 D– connection

27 DN2_DP AI/O Downstream port 2 D+ connection

28 DN2_DM AI/O Downstream port 2 D- connection

29 AGND POWER Analog Ground reference

30 AV

31 UP_DP AI/O Upstream D+ connection

32 UP_DM AI/O Upstream D- connection

CC

CC

POWER

POWER

Voltage supply 3.3V 0.3V

Analog voltage supply 3.3V 0.3V

1997 Aug 01

4

Page 5

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

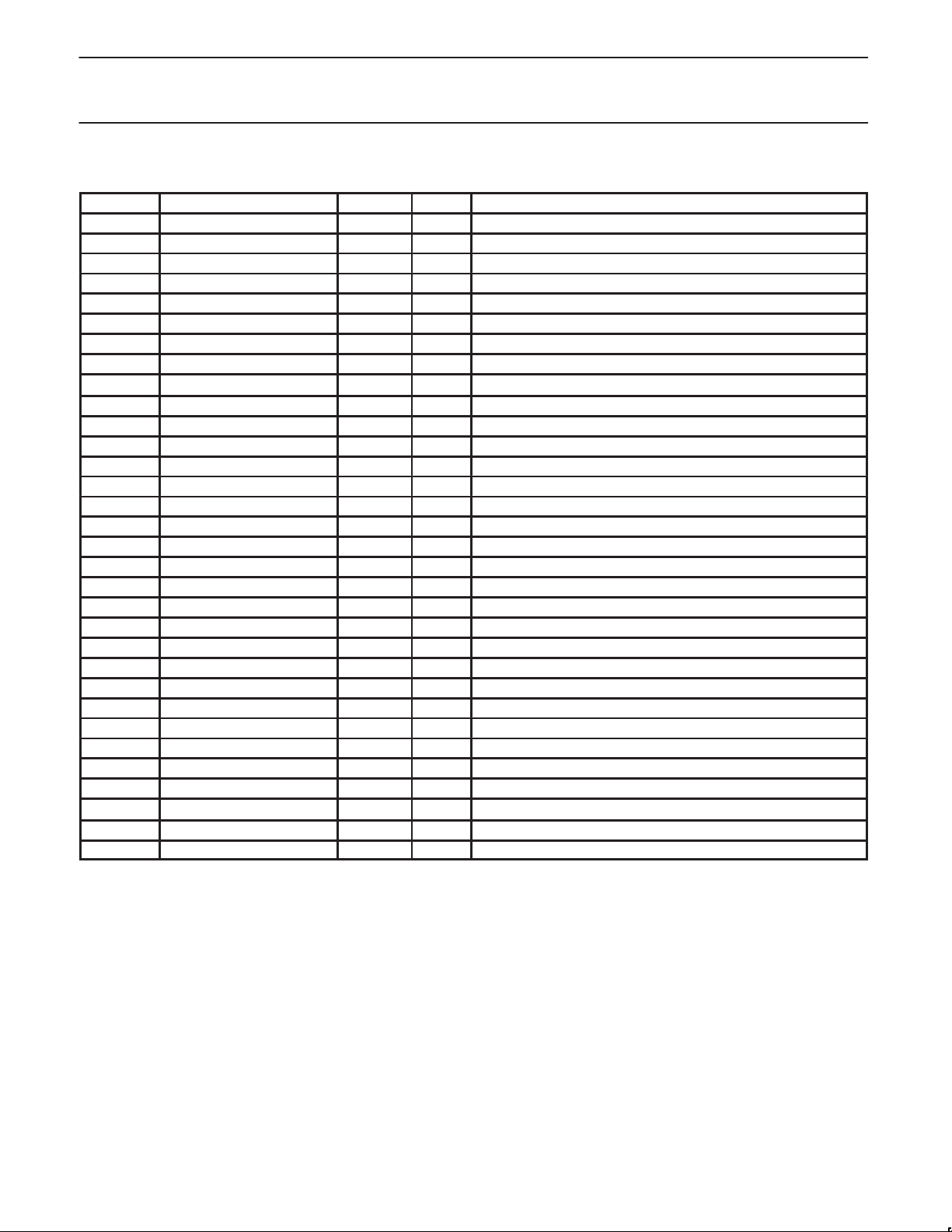

PIN DESCRIPTION (MODE 1)

PIN NO PIN SYMBOL I/O DRIVE NAME AND FUNCTION

1 TEST1 I Connect to V

2 TEST2 I Connect to V

3 TEST3 I Connect to Ground

4 RESET_N I ST Power-on reset

5 GND POWER Ground reference

6 XTAL1 I/O Crystal connection 1 (48MHz)

7 XTAL2 I/O Crystal connection 2 (48MHz)

8 CLK12MHZ O 2mA 12MHz output clock for external devices

9 V

10 OCURRENT2_N I ST Downstream port 2 over-current notice

11 SWITCH_N O OD8 Enables power to downstream ports

12 SUSPEND O 4mA Device is in suspended state

13 DN2_EN_N O OD8 Downstream port 2 LED enable indicator

14 OCURRENT3_N I ST Downstream port 3 over-current notice

15 OCURRENT4_N I ST Downstream port 4 over-current notice

16 OCURRENT5_N I ST Downstream port 5 over-current notice

17 INT_N O OD4 Connect to microcontroller interrupt

18 SDA I/O OD4 I2C bi-directional data

19 SCL I/O OD4 I2C bit-clock

20 GND POWER Ground reference

21 DN5_DP AI/O Downstream port 5 D+ connection

22 DN5_DM AI/O Downstream port 5 D– connection

23 DN4_DP AI/O Downstream port 4 D+ connection

24 DN4_DM AI/O Downstream port 4 D- connection

25 DN3_DP AI/O Downstream port 3 D+ connection

26 DN3_DM AI/O Downstream port 3 D- connection

27 DN2_DP AI/O Downstream port 2 D+ connection

28 DN2_DM AI/O Downstream port 2 D- connection

29 AGND POWER Analog Ground reference

30 AV

31 UP_DP AI/O Upstream D+ connection

32 UP_DM AI/O Upstream D- connection

NOTES:

1. Signals ending in _N indicate active low signals.

ST: Schmitt Trigger

OD4, OD8: Open Drain with 4 or 8 mA drive

AI/O: Analog I/O

CC

CC

POWER

POWER

Voltage supply 3.3V 0.3V

Analog voltage supply 3.3V 0.3V

CC

CC

1997 Aug 01

5

Page 6

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

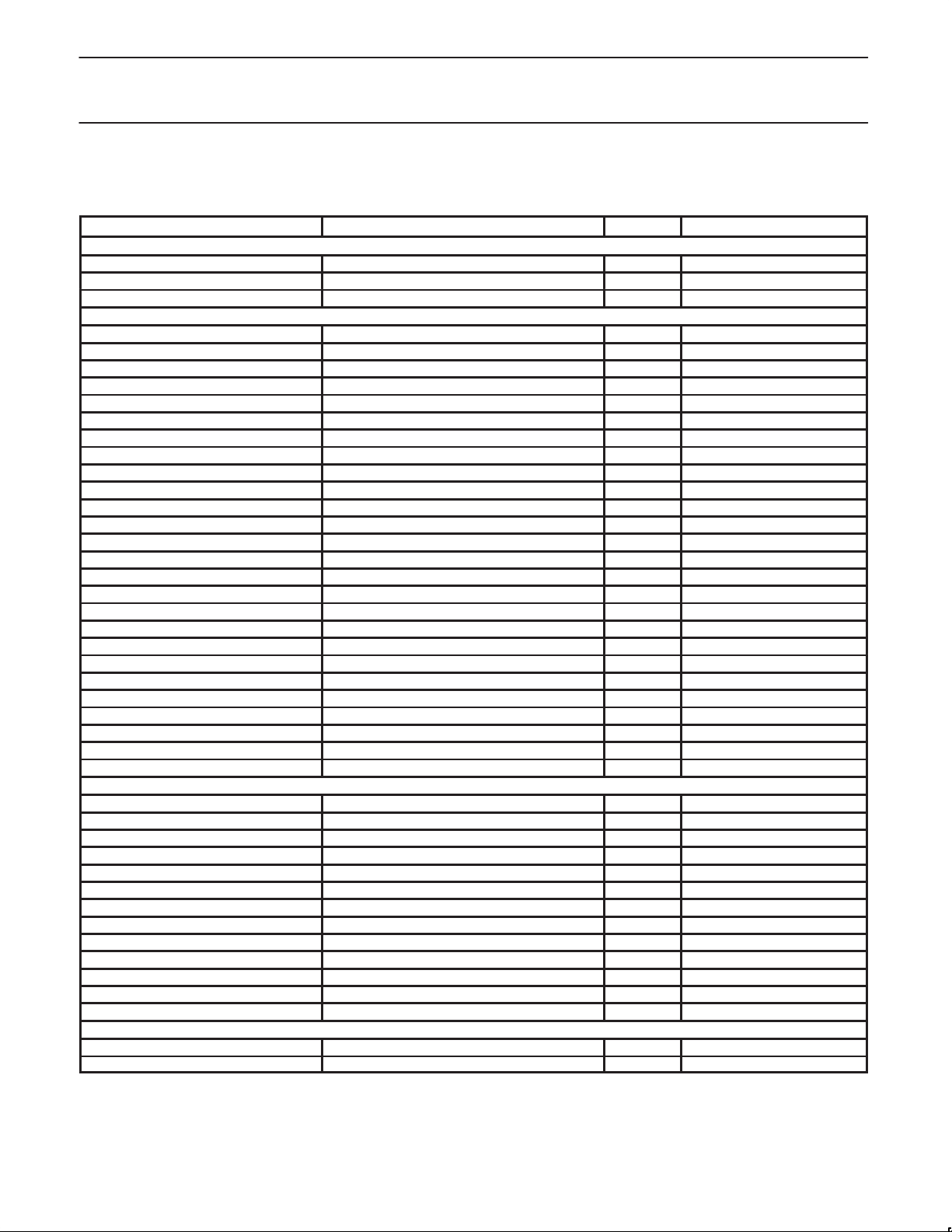

APPLICATION DIAGRAM

USB

3.3V

UPSTREAM

48MHz

12MHz

H11

USB

5V

POWER SWITCH

AND

OVERCURRENT CIRCUIT

I2C Interface.

2

The I

C bus is used to interface to an external microcontroller

DOWNSTREAM

SWITCHED

5V

needed to control the operation of the hub. For cost consideration,

the target system microcontroller can be shared and utilized for this

purpose. The PDIUSBH11 implements a slave I

2

C interface. When

the PDIUSBH11 needs to communicate with the microcontroller it

asserts an interrupt signal. The microcontroller services this

interrupt by reading the appropriate status register on the

PDIUSBH11 through the I

2

I

C serial bus, refer to the I2C handbook, Philips order number 9397

2

C bus. (For more information about the

750 00013).

2

The I

C interface on the PDIUSBH11 defines two types of

transactions :

1. command transaction

A command transaction is used to define which data (e.g., status

byte, buffer data, ...) will be read from / written to the USB

interface in the next data transaction. A data transaction usually

follows a command transaction.

2. data transaction

A data transaction reads data from / writes data to the USB

interface. The meaning of the data is dependent on the

command transaction which was sent before the data

transaction.

I2C

ENABLE LED

Protocol

2

An I

C transaction starts with a ‘Start Condition’, followed by an

µC

SV00227

address. When the address matches either the command or data

address the transaction starts and runs until a ‘Stop Condition’ or

another ‘Start Condition’ (repeated start) occurs.

The command address is write-only and is unable to do a read. The

next bytes in the message are interpreted as commands. Several

command bytes can be sent after one command address. Each of

the command bytes is acknowledged and passed on to the Memory

Management Unit inside the PDIUSBH11.

When the start condition address matches the data address, the

next bytes are interpreted as data. When the RW bit in the address

indicates a ‘master writes data to slave’ (=‘0’) the bytes are received,

acknowledged and passed on to the Memory Management Unit. If

the RW bit in the address indicates a ‘master reads data from slave’

(=‘1’) the PDIUSBH11 will send data to the master. The I

must acknowledge all data bytes except the last one. In this way the

2

I

C interface knows when the last byte has been transmitted and it

2

C-master

then releases the SDA line so that the master controller can

generate the STOP condition.

Repeated start support allows another packet to be sent without

generating a Stop Condition.

Two addresses are used to differentiate between command and

data transactions. Writing to the command address is interpreted as

a command, while reading from / writing to the data address is used

to transfer data between the PDIUSBH11 and the controller.

ADDRESS TABLE

TYPE OF ADDRESS

Command 0011 011 (binary)

Data 0011 010 (binary)

1997 Aug 01

PHYSICAL ADDRESS

(MSB to LSB)

Timing

When the master writes data to the PDIUSBH11, the data is

sampled 1 micro-second after the rising edge of SCL. When the

PDIUSBH11 writes data to the master, the data is driven 1

micro-second after the falling edge of SCL.

6

Page 7

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

COMMAND SUMMARY

Some commands have the same command code (e.g., Read Buffer and Write Buffer). In these cases, the direction of the Data Phase (read or

write) indicates which command is executed.

COMMAND NAME

Initialization Commands

Set Address / Enable Hub D0h Write 1 byte

Set Endpoint Enable Hub + Embedded Function D8h Write 1 byte

Data Flow Commands

Read Interrupt Register F4h Read 1 byte

Select Endpoint Hub Control OUT 00h Read 1 byte (optional)

Embedded Function Control OUT 02h Read 1 byte (optional)

Embedded Function Control IN 03h Read 1 byte (optional)

Embedded Function Interrupt 04h Read 1 byte (optional)

Read Last Transaction Status Hub Control OUT 40h Read 1 byte

Embedded Function Control OUT 42h Read 1 byte

Embedded Function Control IN 43h Read 1 byte

Embedded Function Interrupt 44h Read 1 byte

Read Endpoint Status Hub Control OUT 80h Read 1 byte

Embedded Function Control OUT 82h Read 1 byte

Embedded Function Control IN 83h Read 1 byte

Embedded Function Interrupt 84h Read 1 byte

Read Buffer Selected Endpoint F0h Read n bytes

Write Buffer Selected Endpoint F0h Write n bytes

Set Endpoint Status Hub Control OUT 40h Write 1 byte

Embedded Function Control OUT 42h Write 1 byte

Embedded Function Control IN 43h Write 1 byte

Embedded Function Interrupt 44h Write 1 byte

Acknowledge Setup Selected Endpoint F1h None

Clear Buffer Selected Endpoint F2h None

Validate Buf fer Selected Endpoint FAh None

Hub Commands

Clear Port Feature Port 2 E0h Write 1 byte

Set Port Feature Port 2 E8h Write 1 byte

Get Port Status Port 2 E0h Read 1 or 2 bytes

Set Status Change Bits F7h Write 1 byte

General Commands

Send Resume F6h None

Read Current Frame Number F5h Read 1 or 2 bytes

RECIPIENT CODING DATA PHASE

Embedded Function D1h Write 1 byte

Hub Control IN 01h Read 1 byte (optional)

Hub Control IN 41h Read 1 byte

Hub Control IN 81h Read 1 byte

Hub Control IN 41h Write 1 byte

Port 3 E1h Write 1 byte

Port 4 E2h Write 1 byte

Port 5 E3h Write 1 byte

Port 3 E9h Write 1 byte

Port 4 EAh Write 1 byte

Port 5 EBh Write 1 byte

Port 3 E1h Read 1 or 2 bytes

Port 4 E2h Read 1 or 2 bytes

Port 5 E3h Read 1 or 2 bytes

1997 Aug 01

7

Page 8

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

COMMAND DESCRIPTIONS

Command Procedure

There are four basic types of commands: Initialization, Data, Hub Specific and General commands. Respectively, these are used t o initialize the

hub and embedded function; for data flow between the hub, embedded function and the host; some hub specific commands for controlling

individual downstream ports; and some general commands.

Initialization Commands

Initialization commands are used during the enumeration process of the USB network. These commands are used to enable the hub and

embedded function endpoints. They are also used to set the USB assigned address.

Set Address / Enable

Command : D0h (Hub), D1h (Embedded Function)

Data : Write 1 byte

This command is used to set the USB assigned address and enable the hub or embedded function respectively. The hub always powers up

disabled and should be enabled after a bus RESET.

706050403020100

0

ADDRESS THE VALUE WRITTEN BECOMES THE ADDRESS

ENABLE A ‘1’ ENABLES THIS FUNCTION

POWER ON VALUE

ADDRESS

ENABLE

SV00385

Set Endpoint Enable

Command : D8h

Data : Write 1 byte

Interrupt endpoints can only be enabled when the hub/function is enabled via the Set Address/Enable command.

7X6X5X4X3X20100

X

POWER ON VALUE

HUB’S INTERRUPT ENDPOINT

FUNCTION’S INTERRUPT ENDPOINT

RESERVED

1997 Aug 01

HUB’S INTERRUPT ENDPOINT A VALUE OF ‘1’ INDICATES THE HUB’S INTERRUPT ENDPOINT IS ENABLED.

FUNCTION’S INTERRUPT ENDPOINT A VALUE OF ‘1’ INDICATES THE EMBEDDED FUNCTION’S INTERRUPT ENDPOINT IS ENABLED.

SV00387

8

Page 9

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Data Flow Commands

Data flow commands are used to manage the data transmission between the USB endpoints and the monitor. Much of the data flow is initiated

via an interrupt to the microcontroller. The microcontroller utilizes these commands to access and determine whether the endpoint FIFOs have

valid data.

Read Interrupt Register

Command : F4h

Data : Read 1 byte

This command indicates the origin of an interrupt. A “1” indicates an interrupt occurred at this endpoint. The bits are cleared by reading the

endpoint status register through Read Endpoint Status command.

After a bus reset an interrupt will be generated, however all bits in the interrupt register will be 0. The interrupt is internally cleared by reading

the interrupt register. A bus reset is completely identical to the hardware reset through the RESET_N pin with the sole difference of interrupt

notification.

The hub interrupt endpoint is handled internally by the PDIUSBH11 hardware without the need of microcontroller intervention.

7X6X50403020100

X

POWER ON VALUE

HUB CONTROL OUT ENDPOINT

HUB CONTROL IN ENDPOINT

FUNCTION CONTROL OUT ENDPOINT

FUNCTION CONTROL IN ENDPOINT

FUNCTION INTERRUPT ENDPOINT

RESERVED

SV00505

Select Endpoint

Command : 00–04h

Data : Optional Read 1 byte

The Select Endpoint command initializes an internal pointer to the start of the Selected buffer. Optionally, this command can be followed by a

data read, which returns 0 if the buffer is empty and 1 if the buffer is full.

7X6X5X4X3X2X100

X

POWER ON VALUE

FULL / EMPTY

1997 Aug 01

RESERVED

FULL / EMPTY A ‘1’ INDICATES THE BUFFER IS FULL, ‘0’ INDICATES AN EMPTY BUFFER

SV00506

9

Page 10

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Read Last Transaction Status

Command : 40–44h

Data : Read 1 byte

The

Read Last Transaction Status

command also resets the corresponding interrupt flag in the interrupt register, and clears the status, indicating that it was read.

This command is useful for debugging purposes. Since it keeps track of every transaction, the status information is overwritten for each new

transaction.

706050403020100

0

command is followed by one data read that returns the status of the last transaction of the endpoint. This

POWER ON VALUE

DATA RECEIVE / TRANSMIT SUCCESS

ERROR CODE (SEE TABLE 1)

SETUP PACKET

DATA 0/1 PACKET

PREVIOUS STATUS NOT READ

DATA RECEIVE / TRANSMIT SUCCESS A ‘1’ INDICATES DATA HAS BEEN RECEIVED OR TRANSMITTED SUCCESSFULLY

ERROR CODE SEE TABLE 1

SETUP PACKET A ‘1’ INDICATES THE LAST RECEIVED PACKET HAD A SETUP TOKEN (THIS ALWAYS READ ‘0’ FOR IN BUFFERS.

DATA 0/1 PACKET A ‘1’ INDICATES THAT THE LAST RECEIVED OR SENT PACKET HAD A DATA1 PID

PREVIOUS STATUS NOT READ A ‘1’ INDICATES A SECOND EVENT OCCURRED BEFORE THE PREVIOUS STATUS WAS READ.

Table 1.

ERROR CODE RESULT

0000 No Error

0001 PID Encoding Error, Bits 7–4 are not the inversion of bits 3–0

0010 PID Unknown, encoding is valid, but PID does not exist

0011 Unexpected Packet, Packet is not of the type expected (= token, data or acknowledge), or SETUP token to a

0100 Token CRC Error

0101 Data CRC Error

0110 Time Out Error

0111 Babble Error

1000 Unexpected End of Packet

1001 Sent or Received NAK

1010 Sent Stall, a token was received, but the endpoint was stalled

1011 Overflow Error, the received packet was longer than the available buffer space

1101 Bitstuff Error

1111 Wrong DATA PID, the received DATA PID was not the expected one

SV00507

non-control endpoint

1997 Aug 01

10

Page 11

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Read Endpoint Status

Command : 80–84h

Data : Read 1 byte

0

070605040302010

POWER ON VALUE

RESERVED

SETUP PACKET

STALL

DATA 0/1 PACKET

BUFFER FULL

RESERVED

SETUP PACKET A ‘1’ INDICATES THE LAST RECEIVED PACKET WAS A SETUP TOKEN

STALL A ‘1’ INDICATES THE ENDPOINT IS STALLED

DATA 0/1 PACKET A ‘1’ INDICATES THAT THE LAST RECEIVED OR SENT PACKET HAD A DATA1 PID

BUFFER FULL A ‘1’ INDICATES THAT THE BUFFER IS FULL

SV00508

Read Buffer

Command : F0h

Data : Read multiple bytes (max 10)

The Read Buffer command is followed by a number of data reads, which return the contents of the selected endpoint data buffer. After each

read, the internal buffer pointer is incremented by 1.

The buffer pointer is not reset to the buffer start by the Read Buffer command. This means that reading or writing a buf fer can be interrupted by

any other command (except for Select Endpoint), or can be done by more than one I2C transaction (read the first 2 bytes to get the number of

data bytes, then read the rest in other transactions).

The data in the buffer are organized as follows:

•byte 0: reserved: can have any value

•byte 1: Number / length of data bytes

•byte 2: Data byte 1

•byte 3: Data byte 2

Write Buffer

Command : F0h

Data : Write multiple bytes (max 10)

The Write Buffer command is followed by a number of data writes, which load the endpoints buffer. The data must be organized in the same

way as described in the Read Buffer command. The first byte (reserved) should always be 0. As in the Read Buffer command, the data can be

split up into different I2C data transactions.

WARNING

There is no protection against writing or reading over a buffer’s boundary or against writing into an OUT buffer or reading from an IN buffer. Any

of these actions could cause an incorrect operation. Data in an OUT buffer are only meaningful after a successful transaction.

1997 Aug 01

11

Page 12

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Clear Buffer

Command : F2h

Data : None

When a packet is received completely, an internal endpoint buffer full flag is set. All subsequent packets will be refused by returning a NACK.

When the microcontroller has read the data, it should free the buffer by the Clear Buffer command. When the buffer is cleared new packets will

be accepted.

V alidate Buffer

Command : FAh

Data : None

When the microprocessor has written data into an IN buffer, it should set the buffer full flag by the Validate Buffer command. This indicates that

the data in the buffer are valid and can be sent to the host when the next IN token is received.

Set Endpoint Status

Command : 40–44h

Data : Write 1 byte

A stalled control endpoint is automatically unstalled when it receives a SETUP token, regardless of the content of the packet. If the endpoint

should stay in its stalled state, the microcontroller can re–stall it.

When a stalled endpoint is unstalled (either by the Set Endpoint Status command or by receiving a SETUP token), it is also re–initialized. This

flushes the buffer and if it is an OUT buffer it waits for a DATA 0 PID, if it is an IN buffer it writes a DATA 0 PID.

Even when unstalled, writing Set Endpoint Status to ‘0’ initializes the endpoint.

X7X6X5X4X3X2X100POWER ON VALUE

STALLED

RESERVED

STALLED A ‘1’ INDICATES THE ENDPOINT IS STALLED

SV00509

Acknowledge Setup

Command : F1h

Data : None

The arrival of a SETUP packet flushes the IN buffer and disables the Validate Buffer

endpoints.

The microcontroller needs to re–enable these commands by the

in the buffer and no packet can be sent back to the host until the microcontroller has acknowledged explicitly that it has seen the SETUP packet.

The microcontroller must send the Acknowledge Setup

Acknowledge Setup command. This ensures that the last SETUP packet stays

command to both the IN and OUT endpoints.

and Clear Buffer commands for both IN and OUT

1997 Aug 01

12

Page 13

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Hub Commands

Hub commands are used to report connectivity and power status between the hub and the host. These commands allow the host to enable

each port individually and get any change of status such as new connectivity information.

Clear/Set Port Feature

Command : E0–E3h (Clear) and E8h–EBh (Set)

Data : Write 1 byte

When the controller receives a

•The request applies to port 1, the embedded port. In this case the request should be handled internally by the controller.

•If the request applies to ports 2 through 5, the controller should translate the request into a Set Feature or Clear Feature command towards

the PDIUSBH11.

When the PDIUSBH11 is configured in mode 0, there is only one power switch output and one overcurrent input. This means that th e

F_PORT_POWER and C_PORT_OVERCURRENT features are not port specific. For these features, any of the Set / Clear Feature commands

can be used. The specific port assignment is ignored.

When the PDIUSBH11 is configured in mode 1, there is still only one power switch output but there are four individual overcurrent input pins

corresponding to each port. This means that the F_PORT_POWER feature is port specific and the C_PORT_OVERCURRENT feature is not

port specific.

Setting the F_PORT_POWER feature turns the power on when it is off and turns the overcurrent detection on only when the power is already

on. This allows to have a short period of overcurrent condition at the moment that power is switched on. For this reason, the F_PORT_POWER

feature needs to be set twice. Clearing this feature turns both the power and the overcurrent detection off.

The data written in the data phase is the feature code described in Table 2.

Set Feature or a Clear Feature request, there are two possibilities:

Table 2.

FEATURE FEATURE CODE SET CLEAR

F_PORT_ENABLE 0 Enables a port Disables a port

F_PORT_SUSPEND 1 Suspends a port Resumes a port

FC_PORT_RESET 2 Resets a port Clears a port Reset Change bit

F_PORT_POWER 3 Powers all ports Unpowers all ports

C_PORT_CONNECTION 4 – Clears a port Connection Change bit

C_PORT_ENABLE 5 – Clears a port Enable Change bit

C_PORT_SUSPEND 6 – Clears a port Suspend Change bit

C_PORT_OVERCURRENT 7 – Clears a port (Mode 1) or hub (Mode 0) Overcurrent Change bit

1997 Aug 01

13

Page 14

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Get Port Status

Command : E0h–E3h

Data : Read 1 or 2 bytes

The Get Port Status Command can be followed by one or two data reads. The first byte returned contains the port status. The second byte

returned is the port status change byte.

PORT STATUS BYTE

706050403020100

X

POWER ON VALUE

CONNECT

ENABLED

SUSPEND

OVER-CURRENT

RESET

POWER

LOW SPEED

RESERVED

CONNECT A ‘1’ INDICATES THAT A DEVICE IS CONNECTED ON THIS PORT OF THE HUB

ENABLED A ‘1’ INDICATES THAT THIS PORT IS ENABLED

SUSPEND A ‘1’ INDICATES THAT THIS PORT IS SUSPENDED

OVERCURRENT A ‘1’ INDICATES THAT OVERCURRENT CONDITION EXISTS ON THIS PORT.

RESET A ‘1’ INDICATES THAT BUS RESET ON THIS PORT IS IN PROGRESS.

POWER A ‘1’ INDICATES THAT POWER IS SUPPLIED TO DOWNSTREAM PORTS.

LOW SPEED A ‘1’ INDICATES THAT LOW SPEED DEVICE IS CONNECTED TO THIS PORT.

IN MODE 0 OF OPERATION, THIS BIT IS THE SAME FOR ALL PORTS.

IN MODE 1, INDIVIDUAL PORT OVERCURRENT INDICATION IS POSSIBLE.

WHEN RESET IS COMPLETED (NORMAL DURATION OF 10MS), THIS BIT INDICATES A ‘0’.

SINCE THE PDIUSBH11 SUPPORTS GANG MODE POWER SWITCHING,

THIS BIT IS THE SAME FOR ALL PORTS.

THIS BIT IS ONLY VALID WHEN CONNECT BIT IS A ‘1’.

SV00503

Port Status Change Byte

The description for the Port Status Change Byte is similar to the Port Status Byte except that the value of the bits are ‘1’ only when a change

has occurred.

0

X7X6X5040302010

POWER ON VALUE

CONNECT

ENABLED

SUSPEND

OVERCURRENT

RESET

1997 Aug 01

RESERVED

SV00510

14

Page 15

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

Set Status Change Bits

Command : F7h

Data : Write 1 byte

For assembling the hub’s status change register, the device needs some additional information from the controller, i.e. the Local Power Status

Change bit and the embedded function Status Change bit.

These are provided by the Set Status Change Bits command. This command is always followed by one data write which contains the Local

Power Status Change bit at the LSB and the embedded function Status Change bit at position 1. All other bits should be 0.

0

X7X6X5X4X3X2010

POWER ON VALUE

LOCAL POWER

EMBEDDED FUNCTION

RESERVED

SV00511

GENERAL COMMANDS

Send Resume

Command : F6h

Data : None

Sends an upstream resume signal for 10 ms. This command is normally issued when the device is in suspend. The RESUME command is not

followed by a data read or write.

The PDIUSBH11 automatically sends a RESUME command when an event occurs downstream.

Read Current Frame Number

Command : F5h

Data : Read 1 or 2 bytes

This command is followed by one or two data reads and returns the frame number of the last successfully received SOF. The frame number is

returned Least Significant Byte first.

7X6X5X4X3X2X1X0

X

7X6X5X4X3X2X1X0

X

LEAST SIGNIFICANT BYTE

MOST SIGNIFICANT BYTE

SV00512

EMBEDDED FUNCTION

The USB host sees no difference between the embedded function and a function connected to one of the downstream ports. Some of the port

commands sent by the host must be handled appropriately by the embedded function to appear as any other downstream port.

The micro controller maintains a series of status and status change bits for the embedded function as described in the Get Port Status

command section. From these bits, the Status Change bit for the embedded function is derived (i.e. the port specific Status Change bits). This

Status Change bit is then provided to the PDIUSBH11 by the Set Status Change Bits command.

1997 Aug 01

15

Page 16

Philips Semiconductors Product specification

SYMBOL

PARAMETER

CONDITIONS

UNIT

MIN.MAX

PDIUSBH11Universal Serial Bus Hub

Host Requests

SetFeature PORT_RESET

Reinitialize the embedded function and set the Reset Change bit to indicate that the reset has completed. Reset the Enable Status bit, enable

the embedded function and set its address to 0 by the Set embedded function Address / Enable command. Disable the embedded function

interrupt endpoint by the Set Endpoint Enable command.

SetFeature PORT_ENABLE

Enable the function by the Set embedded function Address / Enable command. Set the Enable Status bit.

SetFeature PORT_SUSPEND

Disable the function by the Set embedded function Address / Enable command. Reset the Enable Status bit and set the Suspend Status bit.

ClearFeature PORT_ENABLE

Disable the function by the Set embedded function Address / Enable command. Reset the Enable Status bit.

ClearFeature PORT_SUSPEND

Enable the function by the Set embedded function Address / Enable command. Set the Enable Status bit, reset the Suspend Status bit; set the

Resume Status Change bit to indicate that the resume has completed.

ClearFeature any Change Indicator

Clear the corresponding status change bit.

Babbling Condition

When the embedded function causes a babbling condition, the function is automatically disabled by the PDIUSBH11. As soon as the micro

controller detects the babbling error , it must set the Enable Status Change bit and reset the Enable Status bit.

Remote WakeUp

There are three scenarios a remote wakeup can occur. The following describes the course of actions for each of the cases:

1. The device is not suspended and the embedded port is suspended

– Enable back the function by setting the enable bit in the Set Address/Enable register and update the following status bits in the

micro–controller program: reset the Suspend Status bit, set the Enable Status bit and set the Suspend Status Change bit.

2. The device is suspended and the embedded port is suspended.

– Send an upstream Resume using the Send Resume command, enable back the function by setting the enable bit in the Set

Address/Enable register and update the following status bits in the micro–controller program: reset the Suspend Status bit, set the Enable

Status bit and set the Suspend Status Change bit.

3. The device is suspended and the embedded port is enabled

– Send an upstream resume using the Send Resume command

RECOMMENDED OPERATING CONDITIONS

LIMITS

.

V

T

V

V

CC

V

I/O

AI/O

V

amb

DC supply voltage 3.0 3.6 V

DC Input voltage range 0 5.5 V

I

DC input range for I/O 0 5.5 V

DC input range for analog I/O 0 V

DC output voltage range 0 V

O

Operating ambient temperature range in

free air

See DC and AC characteristics

per device

0 +70 °C

CC

CC

V

V

1997 Aug 01

16

Page 17

Philips Semiconductors Product specification

SYMBOL

PARAMETER

CONDITIONS

UNIT

PDIUSBH11Universal Serial Bus Hub

ABSOLUTE MAXIMUM RATINGS

1

In accordance with the Absolute Maximum Rating System (IEC 134) Voltages are referenced to GND (ground = 0V)

LIMITS

MIN MAX

I

GND

V

I

V

I

V

I

I

T

P

DC supply voltage –0.5 +4.6 V

CC

DC input diode current VI < 0 – -50 mA

IK

V

DC input voltage Note 2 –0.5 +5.5 V

I

DC input voltage range for I/O’s –0.5 V

I/O

DC output diode current VO > VCC or VO < 0 –

OK

DC output voltage Note 2 –0.5 VCC +0.5 V

O

DC output source or sink current for digital

O

pins

DC output source or sink current for D+/D–

O

pins

, I

DC VCC or GND current –

CC

Storage temperature range –60 +150 °C

stg

Power dissipation per package mW

tot

VO = 0 to V

VO = 0 to V

CC

CC

–

–

CC

100

+0.5 V

50

15

50

mA

mA

mA

mA

NOTES:

1. Stresses beyond those listed may cause permanent damage to the device. These are stress ratings only and functional operation of the

device at these or any other conditions beyond those indicated under “recommended operating conditions” is not implied. Exposure to

absolute-maximum-rated conditions for extended periods may affect device reliability .

2. The input and output voltage ratings may be exceeded if the input and output clamp current ratings are observed.

1997 Aug 01

17

Page 18

Philips Semiconductors Product specification

PARAMETER

VOLLOW level out ut

V

VOHHIGH level out ut

V

PARAMETER

PDIUSBH11Universal Serial Bus Hub

DC CHARACTERISTICS (DIGIT AL PINS)

LIMITS

MIN TYP MAX

Input Levels:

V

V

VTLH LOW to HIGH threshold voltage ST (Schmitt Trigger) pins 80 %V

VTHL HIGH to LOW threshold voltage ST (Schmitt Trigger) pins 20 %V

VHYS Hysteresis voltage ST (Schmitt Trigger) pins 1.1 V

Output Levels:

Leakage Current:

I

OZ

I

LOW level input voltage 0.9 V

IL

HIGH level input voltage 2.5 V

IH

I

= rated drive 0.4

p

p

OL

IOL = 20µA 0.1

I

= rated drive VCC –0.4

OH

IOH = 20µA VCC –0.1

OFF-state current OD (Open Drain) pins

Input leakage current

I

5

1

CC

CC

µA

µA

DC CHARACTERISTICS (AI/O PINS)

LIMITS

MIN MAX

Leakage Current:

I

LO

Input Levels:

VDI Differential input sensitivity |(D+) – (D–)|

VCM Differential common mode range Includes VDI range 0.8 2.5 V

VSE Single ended receiver threshold 0.8 2.0 V

Output Levels:

V

OL

V

OH

Capacitance:

C

IN

Output Resistance:

ZDRV

NOTES:

1. D+ is the generic symbol for the USB positive data pins: UP_DP, DN2_DP, DN3_DP, DN4_DP, DN5_DP. D– is the generic symbol for the

USB negative data pins: UP_DM, DN2_DM, DN3_DM, DN4_DM, DN5_DM.

2. Includes external resistors of 24 1% each on D+ and D–.

Hi–Z state data line leakage 0V < VIN < 3.3V

1

Static output LOW

Static output HIGH

Transceiver capacitance

2

Driver output resistance Steady state drive 28 43

RL of 1.5K to 3.6V

RL of 15K to GND

Pin to GND 20 pF

0.2 V

2.8 3.6 V

10

0.3 V

µA

1997 Aug 01

18

Page 19

Philips Semiconductors Product specification

SYMBOL

PARAMETER

TEST CONDITIONS

UNIT

PDIUSBH11Universal Serial Bus Hub

LOAD FOR D+/D–

V

TEST POINT

CC

D. U. T .

CL = 50pF, FULL SPEED

= 50 pF, LOW SPEED (MIN TIMING)

C

L

= 350pF, LOW SPEED (MAX TIMING)

C

L

* 1.5K OHM ON D– (LOW SPEED) OR D+ (FULL SPEED) ONLY

24 OHM

15K OHM

AC CHARACTERISTICS (AI/O PINS. FULL SPEED)

Driver Characteristics:

Transition time:

T

V

T

R

T

RFM

CRS

Rise time

Fall tIme

F

Rise/Fall tIme matching (TR/TF) 90 110 %

Output signal crossover voltage 1.3 2.0 V

Driver Timings:

T

T

EOPT

DEOP

Source EOP width Figure 1 160 175 ns

Differential data to EOP transition skew Figure 1 –2 5 ns

Receiver Timings:

Receiver data jitter tolerance

T

JR1

T

JR2

To next transition

For paired transitions

EOP width at receiver

T

EOPR1

T

EOPR2

Must reject as EOP

Must accept

Hub Timings:

T

HDD

T

SOP

T

EOPDR

T

HESK

Hub differential data delay Figure 2 40 ns

Data bit width distortion after SOP Figure 2 –5 3 ns

Hub EOP delay relative to T

Hub EOP output width skew Figure 3 –15 +15 ns

HDD

CL = 50pF;

= 1.5KΩ on D+ to V

R

pu

Between 10% and 90%

Characterized and not Tested.

Guaranteed by Design.

Figure 1

CL = 50pF;

= 1.5KΩ on D+ to V

R

pu

Figure 3 0 15 ns

S1

C

L

1.5K OHM*

TEST

D–/LS

D+/LS

D–/FS

D+/FS

S1

CLOSE

OPEN

OPEN

CLOSE

SV00237

LIMITS

MIN MAX

CC

4

4

–18.5

–9

40

20

20

18.5

9

ns

ns

ns

82

CC

1997 Aug 01

19

Page 20

Philips Semiconductors Product specification

SYMBOL

PARAMETER

TEST CONDITIONS

UNIT

PDIUSBH11Universal Serial Bus Hub

AC CHARACTERISTICS (AI/O PINS. LOW SPEED)

LIMITS

MIN MAX

Driver Characteristics:

CL = 50pF and 350pF;

= 1.5KΩ on D– to V

R

pu

CC

Transition time:

V

T

LR

T

LF

LCRS

Rise time

Fall tIme

Output signal crossover voltage 1.3 2.0 V

Driver Timings:

T

LEOPT

T

LDEOP

Source EOP width Figure 1 1.25 1.50 ns

Differential data to EOP transition skew Figure 1 –40 100 ns

Receiver Timings:

EOP width at receiver

T

LEOPR1

T

LEOPR2

Must reject as EOP

Must accept

Hub Timings:

T

LHDD

T

LSOP

T

LEOPDR

T

LHESK

Hub differential data delay Figure 2 300 ns

Data bit width distortion after SOP Figure 2 –65 45 ns

Hub EOP delay relative to T

Hub EOP output width skew Figure 3 –300 +300 ns

HDD

Between 10% and 90%

= 50pF

C

L

= 350pF

C

L

= 50pF

C

L

= 350pF

C

L

Figure 1

75

75

330

300

300

ns

ns

675

CL = 50pF and 350pF;

= 1.5KΩ on D– to V

R

pu

CC

Figure 3 0 200 ns

DIFFERENTIAL

DATA LINES

T

PERIOD

CROSSOVER

CROSSOVER

POINT

DIFFERENTIAL DATA TO

SEO/EOP SKEW

N* T

PERIOD

+ T

DEOP

POINT EXTENDED

SOURCE EOP WIDTH: T

RECEIVER EOP WIDTH: T

Figure 1. Differential Data to EOP Transition Skew and EOP Width

EOPT

EOPR1

, T

EOPR2

SV00513

1997 Aug 01

20

Page 21

Philips Semiconductors Product specification

PDIUSBH11Universal Serial Bus Hub

V

DD

UPSTREAMDIFFERENTIAL

DATA

V

SS

DOWNSTREAMDIFFERENTIAL

DATA

V

SS

A. DOWNSTREAM HUB DELAY B. UPSTREAM HUB DELAY

SOP DISTORTION

= T

T

SOP

HDD

LOW SPEED TIMINGS ARE DETERMINED IN THE SAME WAY FOR:

T

AND T

LHDD

(SOP) – T

LSOP

CROSSOVER

POINT

Hub Delay

Downstream

T

(NEXT J)

HDD

HDD

CROSSOVER

POINT

DOWNSTREAM

DIFFERENTIAL

DATA

UPSTREAM

DIFFERENTIAL

DATA

Figure 2. Hub Differential Data Delay and SOP Distortion

CROSSOVER

POINT

Hub Delay

Upstream

T

HDD

CROSSOVER

POINT

SV00514

V

DD

UPSTREAMDIFFERENTIAL

DATA

V

SS

DOWNSTREAMDIFFERENTIAL

DATA

V

SS

DOWNSTREAM

PORT

UPSTREAM

END OF CABLE

T

EOP–

T

EOP–

T

EOP+

CROSSOVER

POINT

EXTENDED

CROSSOVER

POINT

EXTENDED

A. DOWNSTREAM EOP DELAY B. UPSTREAM EOP DELAY

EOP DELAY

= T

T

EOPD

EOP–

EOP DELAY RELATIVE TO T

= T

= T

, T

EOPD

EOP+

LEOPDR

– T

– T

, AND T

T

EOPDR

EOP SKEW

T

HESK

LOW SPEED TIMINGS ARE DETERMINED IN THE SAME WAY FOR:

T

LEOPD

HDD

EOP–

HDD

LHESK

Figure 3. Hub EOP Delay and EOP Skew

T

EOP+

CROSSOVER

POINT

EXTENDED

CROSSOVER

POINT

EXTENDED

SV00515

1997 Aug 01

21

Page 22

Philips Semiconductors Product specification

SYMBOL

PARAMETER

UNIT

PDIUSBH11Universal Serial Bus Hub

AC CHARACTERISTICS (I2C)

All timing values are valid within the operating supply voltage and ambient temperature range and reference to VIL and VIH with an input voltage

swing of V

I2C-bus timing (see Figure ; Note )

1. A detailed description of the I2C-bus specification, with applications, is given in brochure ‘‘

may be ordered using the code 9398 393 40011.

f

SCL

t

SP

t

BUF

t

SU;STA

t

HD;STA

t

LOW

t

HIGH

t

r

t

f

t

SU;DAT

t

HD;DAT

t

VD;DAT

t

SU;STO

and VDD.

SS

LIMITS

MIN TYP MAX

SCL clock frequency – – 100 kHZ

Tolerable spike width on bus – – 100 ns

Bus free time 4.7 – – µs

Start condition set-up time 4.7 – – µs

Start condition hold time 4.0 – – µs

SCL LOW time 4.7 – – µs

SCL HIGH time 4.0 – – µs

SCL and SDA rise times – – 1.0 µs

SCL and SDA fall times – – 0.3 µs

Data set-up time 250 – – ns

Data hold time 0 – – ns

SCL LOW to data out valid – – 3.4 µs

Stop condition set-up time 4.0 – – µs

The I2C-bus and how to use it

”. This brochure

PROTOCOL

SCL

SDA

START

CONDITION

(S)

t

SU;STA

t

BUF

t

HD;STA

t

LOW

BIT 7

MSB

(A7)

t

HIGH

t

r

t

f

t

SU;DAT

BIT 6

(A6)

1/f

SCL

t

HD;DAT

BIT 0

LSB

(R/W)

ACKNOWLEDGE

(A)

t

VD:DAT

Figure 4. I2C-bus timing diagram; rise and fall times refer to VIL and V

IH

STOP

CONDITION

(P)

t

SU;STO

SV00756

1997 Aug 01

22

Page 23

Philips Semiconductors Product specification

PDIUSBH1 1Universal Serial Bus Hub

SO32: plastic small outline package; 32 leads; body width 7.5mm SOT287-1

1997 Aug 01

23

Page 24

Philips Semiconductors Product specification

PDIUSBH1 1Universal Serial Bus Hub

SDIP32: plastic shrink dual in-line package; 32 leads (400 mil) SOT232-1

1997 Aug 01

24

Page 25

Philips Semiconductors Product specification

PDIUSBH1 1Universal Serial Bus Hub

NOTES

1997 Aug 01

25

Page 26

Philips Semiconductors Product specification

PDIUSBH1 1Universal serial bus hub

DEFINITIONS

Data Sheet Identification Product Status Definition

Objective Specification

Preliminary Specification

Product Specification

Formative or in Design

Preproduction Product

Full Production

Philips Semiconductors and Philips Electronics North America Corporation reserve the right to make changes, without notice, in the products,

including circuits, standard cells, and/or software, described or contained herein in order to improve design and/or performance. Philips

Semiconductors assumes no responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright,

or mask work right to these products, and makes no representations or warranties that these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified. Applications that are described herein for any of these products are for illustrative purposes

only. Philips Semiconductors makes no representation or warranty that such applications will be suitable for the specified use without further testing

or modification.

LIFE SUPPORT APPLICA TIONS

Philips Semiconductors and Philips Electronics North America Corporation Products are not designed for use in life support appliances, devices,

or systems where malfunction of a Philips Semiconductors and Philips Electronics North America Corporation Product can reasonably be expected

to result in a personal injury. Philips Semiconductors and Philips Electronics North America Corporation customers using or selling Philips

Semiconductors and Philips Electronics North America Corporation Products for use in such applications do so at their own risk and agree to fully

indemnify Philips Semiconductors and Philips Electronics North America Corporation for any damages resulting from such improper use or sale.

Philips Semiconductors

811 East Arques Avenue

P.O. Box 3409

Sunnyvale, California 94088–3409

Telephone 800-234-7381

This data sheet contains the design target or goal specifications for product development. Specifications

may change in any manner without notice.

This data sheet contains preliminary data, and supplementary data will be published at a later date. Philips

Semiconductors reserves the right to make changes at any time without notice in order to improve design

and supply the best possible product.

This data sheet contains Final Specifications. Philips Semiconductors reserves the right to make changes

at any time without notice, in order to improve design and supply the best possible product.

Copyright Philips Electronics North America Corporation 1997

All rights reserved. Printed in U.S.A.

1997 Apr 17

26

Loading...

Loading...