Page 1

1. Description

PDIUSBD12

USB interface device with parallel bus

Rev. 07 — 27 November 2001 Product data

The PDIUSBD12 is a cost and feature optimized USB device. It is normally used in

microcontroller based systems and communicates with the system microcontroller

over the high-speed general purpose parallel interface. It also supports local DMA

transfer.

This modular approach to implementing a USB interface allows the designer to

choose the optimum system microcontroller from the available wide variety. This

flexibility cuts down the development time, risks, and costs by allowing the use of the

existing architecture and minimize firmware investments. This results in the fastest

way to develop the most cost effective USB peripheral solution.

2. Features

The PDIUSBD12 fully conforms to the

to be compliant with most device class specifications: Imaging Class, Mass Storage

Devices, Communication Devices, Printing Devices, and Human Interface Devices.

As such, the PDIUSBD12 is ideally suited for many peripherals like Printer, Scanner,

External Mass Storage (Zip Drive), Digital Still Camera, etc. It offers an immediate

cost reduction for applications that currently use SCSI implementations.

The PDIUSBD12 low suspend power consumption along with the LazyClock output

allows for easy implementation of equipment that is compliant to the ACPI™,

OnNOW™, and USB power management requirements. The low operating power

allows the implementation of bus powered peripherals.

In addition, it also incorporates features like SoftConnect™, GoodLink™,

programmable clock output, low frequency crystal oscillator, and integration of

termination resistors. All of these features contribute to significant cost savings in the

system implementation and at the same time ease the implementation of advanced

USB functionality into the peripherals.

■ Complies with the

■ High performance USB interface device with integrated SIE, FIFO memory,

transceiver and voltage regulator

■ Compliant with most Device Class specifications

■ High-speed (2 Mbytes/s) parallel interface to any external microcontroller or

microprocessor

■ Fully autonomous DMA operation

■ Integrated 320 bytes of multi-configuration FIFO memory

■ Double buffering scheme for main endpoint increases throughput and eases

real-time data transfer

Universal Serial Bus specification Rev. 1.1

USB specification Rev. 1.1

. It is also designed

Page 2

Philips Semiconductors

■ Data transfer rates: 1 Mbytes/s achievable in Bulk mode, 1 Mbits/s achievable in

■ Bus-powered capability with very good EMI performance

■ Controllable LazyClock output during suspend

■ Software controllable connection to the USB bus (SoftConnect™)

■ Good USB connection indicator that blinks with traffic (GoodLink™)

■ Programmable clock frequency output

■ Complies with the ACPI, OnNOW and USB power management requirements

■ Internal Power-on reset and low-voltage reset circuit

■ Available in SO28 and TSSOP28 pin packages

■ Full industrial grade operation from −40 to +85 °C

■ Higher than 8 kV in-circuit ESD protection lowers cost of extra components

■ Full-scan design with high fault coverage (>99%) ensures high quality

■ Operation with dual voltages:

■ Multiple interrupt modes to facilitate both bulk and isochronous transfers.

PDIUSBD12

USB interface device with parallel bus

Isochronous mode

3.3 ±0.3 V or extended 5 V supply range of 4.0 to 5.5 V

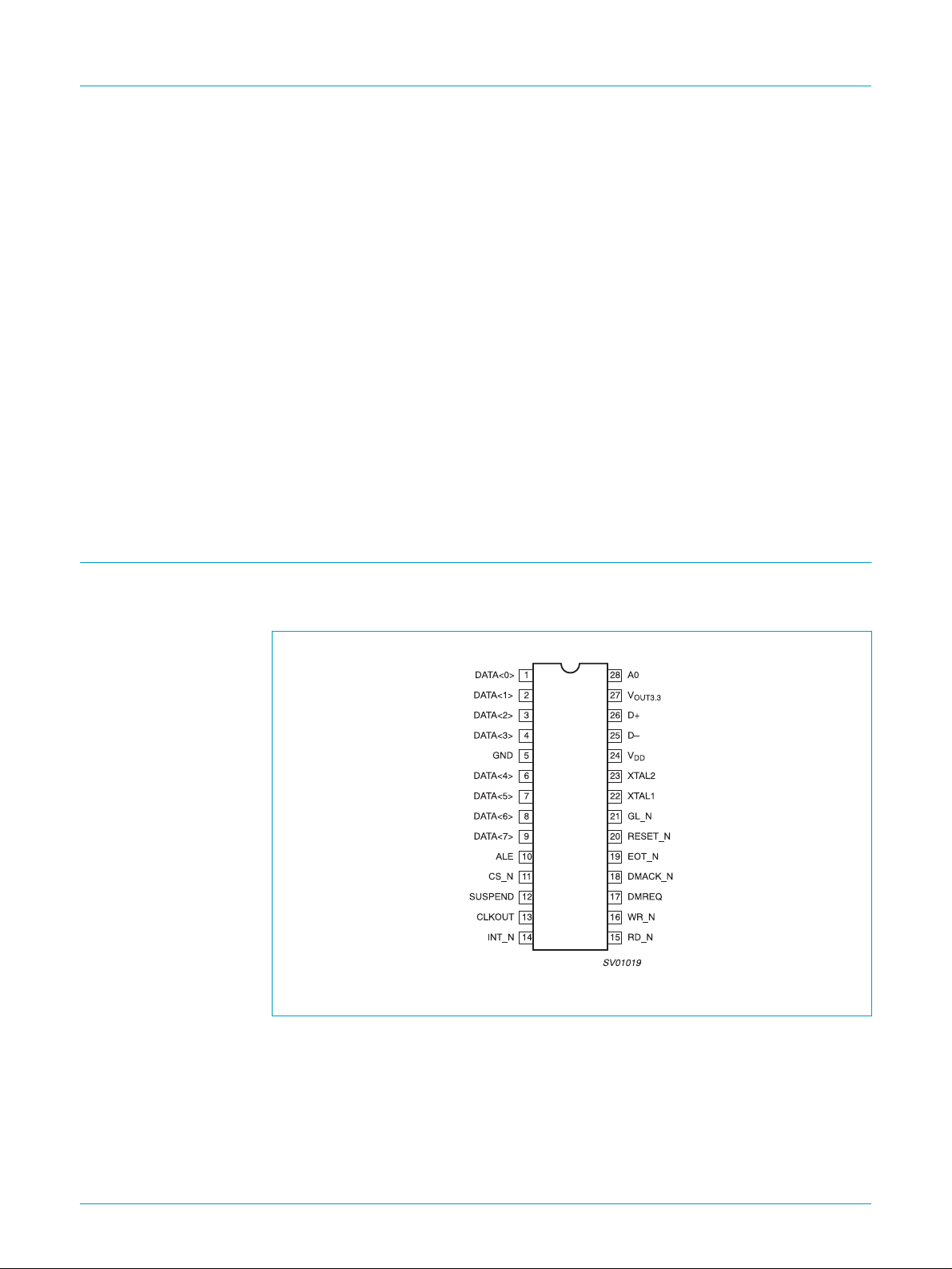

3. Pinning information

3.1 Pinning

Fig 1. Pin configuration.

9397 750 08969

Product data Rev. 07 — 27 November 2001 2 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 3

Philips Semiconductors

3.2 Pin description

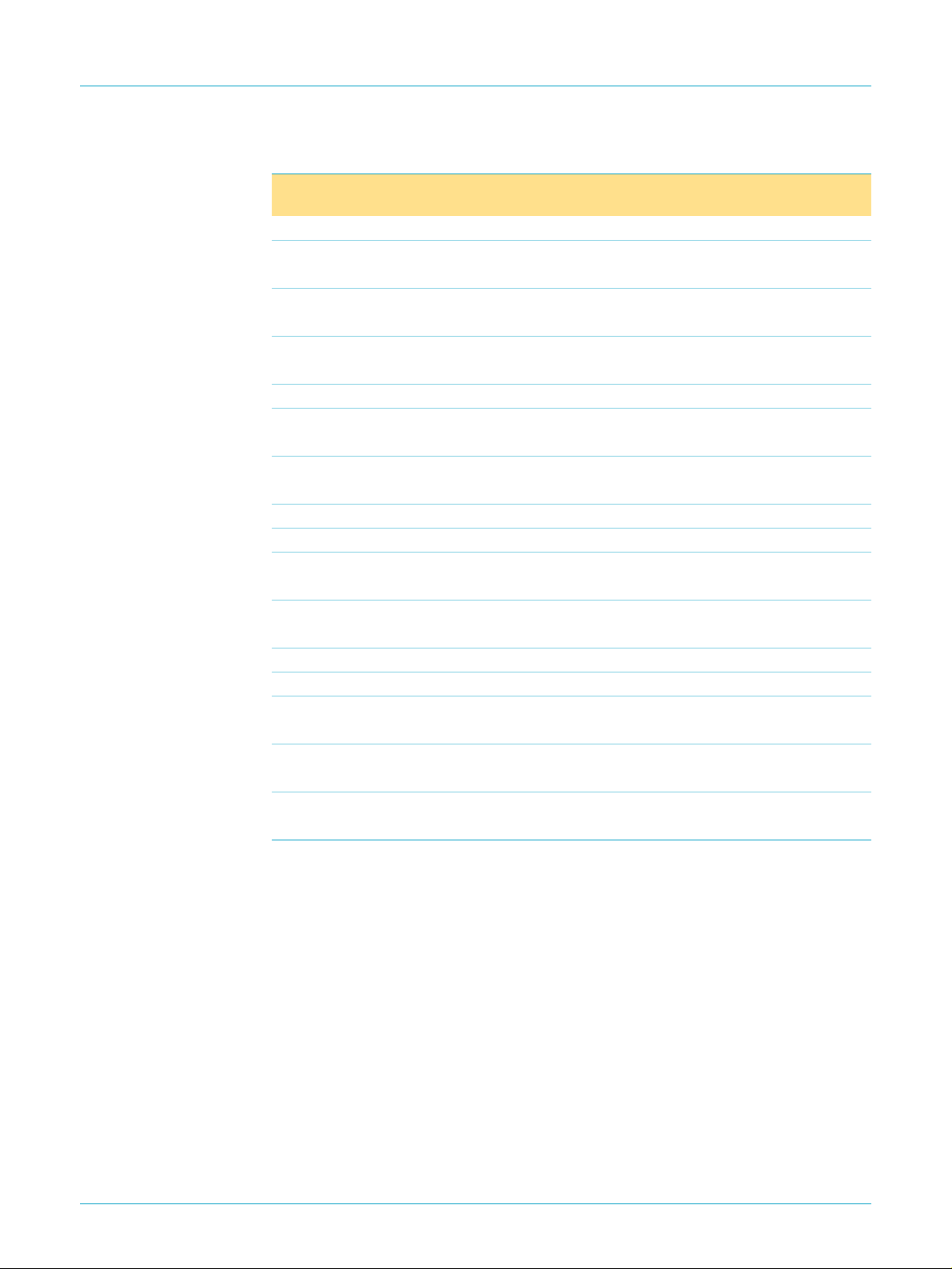

Table 1: Pin description

Symbol Pin Type

DATA <0> 1 IO2 Bit 0 of bidirectional data. Slew-rate controlled.

DATA <1> 2 IO2 Bit 1 of bidirectional data. Slew-rate controlled.

DATA <2> 3 IO2 Bit 2 of bidirectional data. Slew-rate controlled.

DATA <3> 4 IO2 Bit 3 of bidirectional data. Slew-rate controlled.

GND 5 P Ground.

DATA <4> 6 IO2 Bit 4 of bidirectional data. Slew-rate controlled.

DATA <5> 7 IO2 Bit 5 of bidirectional data. Slew-rate controlled.

DATA <6> 8 IO2 Bit 6 of bidirectional data. Slew-rate controlled.

DATA <7> 9 IO2 Bit 7 of bidirectional data. Slew-rate controlled.

ALE 10 I Address Latch Enable. The falling edge is used to close the

CS_N 11 I Chip Select (Active LOW).

SUSPEND 12 I,OD4 Device is in Suspend state.

CLKOUT 13 O2 Programmable Output Clock (slew-rate controlled).

INT_N 14 OD4 Interrupt (Active LOW).

RD_N 15 I Read Strobe (Active LOW).

WR_N 16 I Write Strobe (Active LOW).

DMREQ 17 O4 DMA Request.

DMACK_N 18 I DMA Acknowledge (Active LOW).

EOT_N 19 I End ofDMA Transfer(Active LOW). Double up as V

RESET_N 20 I Reset (Active LOW and asynchronous). Built-in Power-onreset

GL_N 21 OD8 GoodLink LED indicator (Active LOW)

XTAL1 22 I Crystal Connection 1 (6 MHz).

XTAL2 23 O Crystal Connection 2 (6 MHz). If external clock signal, instead

V

CC

D− 25 A USB D− data line.

D+ 26 A USB D+ data line.

USB interface device with parallel bus

[1]

Description

latch of the address information in a multiplexed address/ data

bus. Permanently tied LOW for separate address/ data bus

configuration.

EOT_N is only valid when asserted together with DMACK_N

and either RD_N or WR_N.

circuit present on chip, so pin can be tied HIGH to V

of crystal, is connected to XTAL1, then XTAL2 should be

floated.

24 P Voltage supply (4.0 − 5.5 V).

To operate the IC at 3.3 V, supply 3.3 V to both V

pins.

PDIUSBD12

sensing.

BUS

.

CC

and V

CC

OUT3.3

9397 750 08969

Product data Rev. 07 — 27 November 2001 3 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 4

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 1: Pin description

Symbol Pin Type

V

OUT3.3

A0 28 I Address bit. A0 = 1 selects command instruction; A0 = 0 selects

[1] O2 : Output with 2 mA drive

OD4: Output Open Drain with 4 mA drive

OD8: Output Open Drain with 8 mA drive

IO2: Input and Output with 2 mA drive

O4: Output with 4 mA drive.

27 P 3.3 V regulated output. To operate the IC at 3.3 V, supply a

…continued

[1]

Description

3.3 V to both V

the data phase. This bit is a don’t care in a multiplexedaddress

and data bus configuration and should be tied HIGH.

CC

and V

OUT3.3

pins.

4. Ordering information

Table 2: Ordering information

Packages Temperature range Outside North America North America Pkg. Dwg. #

28-pin plastic SO −40 °C to +85 °C PDIUSBD12 D PDIUSBD12 D SOT136-1

28-pin plastic TSSOP −40 °C to +85 °C PDIUSBD12 PW PDIUSBD12PW DH SOT361-1

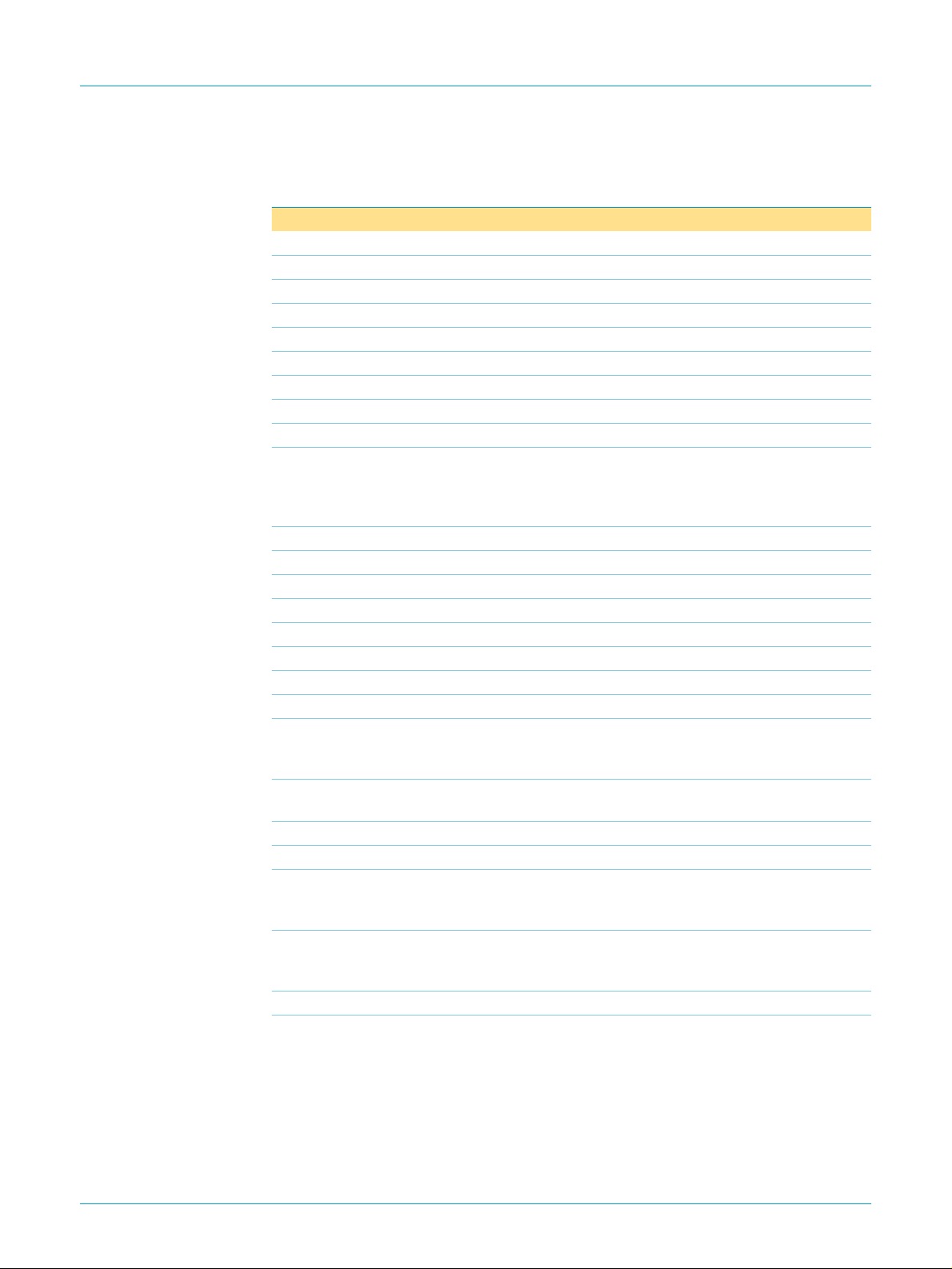

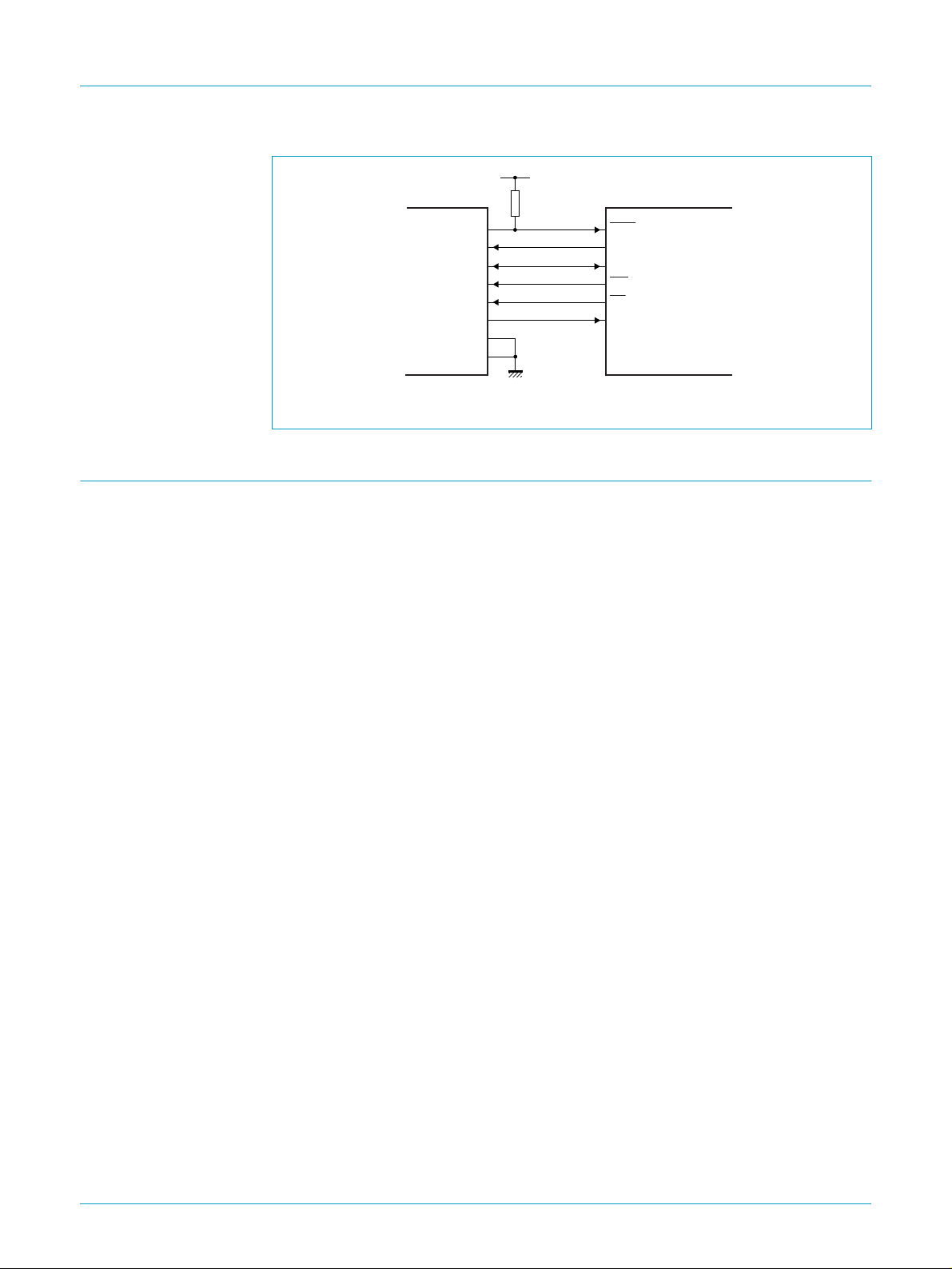

5. Block diagram

This is a conceptual block diagram and does not include each individual signal.

Fig 2. Block diagram.

9397 750 08969

Product data Rev. 07 — 27 November 2001 4 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 5

Philips Semiconductors

6. Functional description

6.1 Analog transceiver

The integrated transceiver interfaces directly to the USB cables through termination

resistors.

6.2 Voltage regulator

A 3.3 V regulator is integrated on-chip to supply the analog transceiver. This voltage

is also provided as an output to connect to the external 1.5 kΩ pull-up resistor.

Alternatively, the PDIUSBD12 provides SoftConnect technology with an integrated

1.5 kΩ pull-up resistor.

6.3 PLL

A 6 MHz to 48 MHz clock multiplier PLL (Phase-Locked Loop) is integrated on-chip.

This allows for the use of a low-cost 6 MHz crystal. EMI is also minimized due to the

lower frequency crystal. No external components are needed for the operation of the

PLL.

PDIUSBD12

USB interface device with parallel bus

6.4 Bit clock recovery

The bit clock recovery circuit recovers the clock from the incoming USB data stream

using 4× oversampling principle. It is able to track jitter and frequency drift specified

by the USB specification.

6.5 Philips Serial Interface Engine (PSIE)

The Philips SIE implements the full USB protocol layer. It is completely hardwired for

speed and needs no firmware intervention. The functions of this block include:

synchronization pattern recognition, parallel/serial conversion, bit stuffing/de-stuffing,

CRC checking/generation, PID verification/generation, address recognition, and

handshake evaluation/generation.

6.6 SoftConnect

The connection to the USB is accomplished by bringing D+ (for high-speed USB

device)HIGH through a 1.5 kΩ pull-up resistor. In the PDIUSBD12, the 1.5 kΩ pull-up

resistor is integrated on-chip and is not connected to VCC by default. The connection

is established through a command sent by the external/system microcontroller. This

allows the system microcontroller to complete its initialization sequence before

deciding to establish connection to the USB. Re-initialization of the USB bus

connection can also be performed without requiring to pull out the cable.

The PDIUSBD12 will check for USB V

established. V

description” for details. Sharing of V

accomplished by using V

open-drain output of the DMA controller pin.

sensing is provided through pin EOT_N. See Section 3.2 “Pin

BUS

voltage as the pull-up voltage for the normally

BUS

availability before the connection can be

BUS

sensing and EOT_N can be easily

BUS

9397 750 08969

Product data Rev. 07 — 27 November 2001 5 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 6

Philips Semiconductors

It should be noted that the tolerance of the internal resistors is higher (25%) than that

specified by the USB specification (5%). However, the overall VSE voltage

specification for the connection can still be met with good margin. The decision to

make sure of this feature lies with the users.

6.7 GoodLink

Good USB connection indication is provided through GoodLink technology. During

enumeration, the LED indicator will blink ON momentarily corresponding to the

enumeration traffic. When the PDIUSBD12 is successfully enumerated and

configured, the LED indicator will be permanently ON. Subsequent successful (with

acknowledgement) transfer to and from the PDIUSBD12 will blink OFF the LED.

During suspend, the LED will be OFF.

This feature provides a user-friendly indicator on the status of the USB device, the

connected hub and the USB traffic. It is a useful field diagnostics tool to isolate faulty

equipment. This feature helps lower field support and hotline costs.

6.8 Memory Management Unit (MMU) and Integrated RAM

PDIUSBD12

USB interface device with parallel bus

The MMU and the integrated RAM buffer the difference in speed between USB,

running in bursts of 12 Mbits/s and the parallel interface to the microcontroller. This

allows the microcontroller to read and write USB packets at its own speed.

6.9 Parallel and DMA Interface

A generic parallel interface is defined for ease-of-use, speed, and allows direct

interfacing to major microcontrollers. To a microcontroller, the PDIUSBD12 appears

as a memory device with 8-bit data bus and 1 address bit (occupying 2 locations).

The PDIUSBD12 supports both multiplexed and non-multiplexed address and data

bus. The PDIUSBD12 also supports DMA (Direct Memory Access) transfer which

allows the main endpoint (endpoint 2) to directly transfer to and from the local shared

memory. Both single-cycle and burst mode DMA transfers are supported.

6.10 Example of parallel interface to an 80C51 microcontroller

In the example shown in Figure 3, the ALE pin is permanently tied LOW to signify a

separate address and data bus configuration. The A0 pin of the PDIUSBD12

connects to any of the 80C51 I/O ports. This port controls the command or data

phase to the PDIUSBD12. The multiplexed address and data bus of the 80C51 can

now be connected directly to the data bus of the PDIUSBD12. The address phase will

be ignored by the PDIUSBD12. The clock input signal of the 80C51 (pin XTAL1) can

be provided by output CLKOUT of the PDIUSBD12.

9397 750 08969

Product data Rev. 07 — 27 November 2001 6 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 7

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

7. DMA transfer

PDIUSBD12

INT_N

A0

DATA [7:0

Fig 3. Example of a parallel interface to an 80C51 microcontroller.

]

WR_N

RD_N

CLKOUT

CS_N

ALE

INTO/P3.2

ANY I/O PORT (e.g. P3.3)

P [0.7:0.0]/AD [7:0

WR/P3.6

RD/P3.7

XTAL1

80C51

]

SV00870

Direct Memory Address (DMA) allows an efficient transfer of a block of data between

the host and local shared memory.Using a DMA controller, data transfer between the

PDIUSBD12’s main endpoint (endpoint 2) and local shared memory can happen

autonomously without local CPU intervention.

Preceding any DMA transfer, the local CPU receives from the host the necessary

setup information and programs the DMA controller accordingly. Typically, the DMA

controller is set up for demand transfer mode and the byte count register and the

address counter are programmed with the right values. In this mode, transfers occur

only when the PDIUSBD12 requests them and are terminated when the byte count

register reaches zero. After the DMA controller has been programmed, the DMA

enable bit of the PDIUSBD12 is set by the local CPU to initiate the transfer.

The PDIUSBD12 can be programmed for single-cycle DMA or burst mode DMA. In

single-cycle DMA, the DMREQ pin is deactivated for every single acknowledgement

by the DMACK_N before being re-asserted. In burst mode DMA, the DMREQ pin is

kept active for the number of bursts programmed in the device before going inactive.

This process continues until the PDIUSBD12 receives a DMA termination notice

through pin EOT_N. This will generate an interrupt to notify the local CPU that DMA

operation is completed.

For DMA read operation, the DMREQ pin will only be activated whenever the buffer is

full, signalling that the host has successfully transferred a packet to the PDIUSBD12.

With the double buffering scheme, the host can start filling up the second buffer while

the first buffer is being read out. This parallel processing increases the effective

throughput. When the host does not fill up the buffer completely (less than 64 bytes or

128 bytes for single direction ISO configuration), the DMREQ pin will be deactivated

at the last byte of the buffer regardless of the current DMA burst count. It will be

re-asserted on the next packet with a refreshed DMA burst count.

Similarly, for DMA write operations, the DMREQ pin remains active whenever the

buffer is not full. When the buffer is filled up, the packet is sent over to the host on the

next IN token and DMREQ will be reactivated if the transfer was successful. Also, the

double buffering scheme here will improve throughput. For non-isochronous transfer

(bulk and interrupt), the buffer needs to be completely filled up by the DMA write

9397 750 08969

Product data Rev. 07 — 27 November 2001 7 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 8

Philips Semiconductors

operation before the data is sent to the host. The only exception is at the end of DMA

transfer, when the reception of pin EOT_N will stop DMA write operation and the

buffer content will be sent to the host on the next IN token.

For isochronous transfers, the local CPU and DMA controller have to guarantee that

they are able to sink or source the maximum packet size in one USB frame (1 ms).

The assertion of pin DMACK_N automatically selects the main endpoint (endpoint 2),

regardless of the current selected endpoint. The DMA operation of the PDIUSBD12

can be interleaved with normal I/O access to other endpoints.

DMA operation can be terminated by resetting the DMA enable register bit or the

assertion of EOT_N together with DMACK_N and either RD_N or WR_N.

The PDIUSBD12 supports DMA transfer in single address mode and it can also work

in dual address mode of the DMA controller. In the single address mode, DMA

transfer is done via the DREQ, DMACK_N, EOT_N, WR_N and RD_N control lines.

In the dual address mode, pins DMREQ, DMACK_N and EOT_N are not used;

instead CS_N, WR_N and RD_N control signals are used. The I/O mode Transfer

Protocol of PDIUSBD12 needs to be followed. The source of the DMAC is accessed

during the read cycle and the destination during the write cycle. Transfer needs to be

done in two separate bus cycles, storing the data temporarily in the DMAC.

PDIUSBD12

USB interface device with parallel bus

8. Endpoint description

The PDIUSBD12 endpoints are sufficiently generic to be used by various device

classes ranging from Imaging, Printer, Mass Storage and Communication device

classes. The PDIUSBD12 endpoints can be configured for 4 operating modes

depending on the Set mode command. The 4 modes are:

Mode 0 Non-isochronous transfer (Non-ISO mode)

Mode 1 Isochronous output only transfer (ISO-OUT mode)

Mode 2 Isochronous input only transfer (ISO-IN mode)

Mode 3 Isochronous input and output transfer (ISO-I/O mode).

9397 750 08969

Product data Rev. 07 — 27 November 2001 8 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 9

Philips Semiconductors

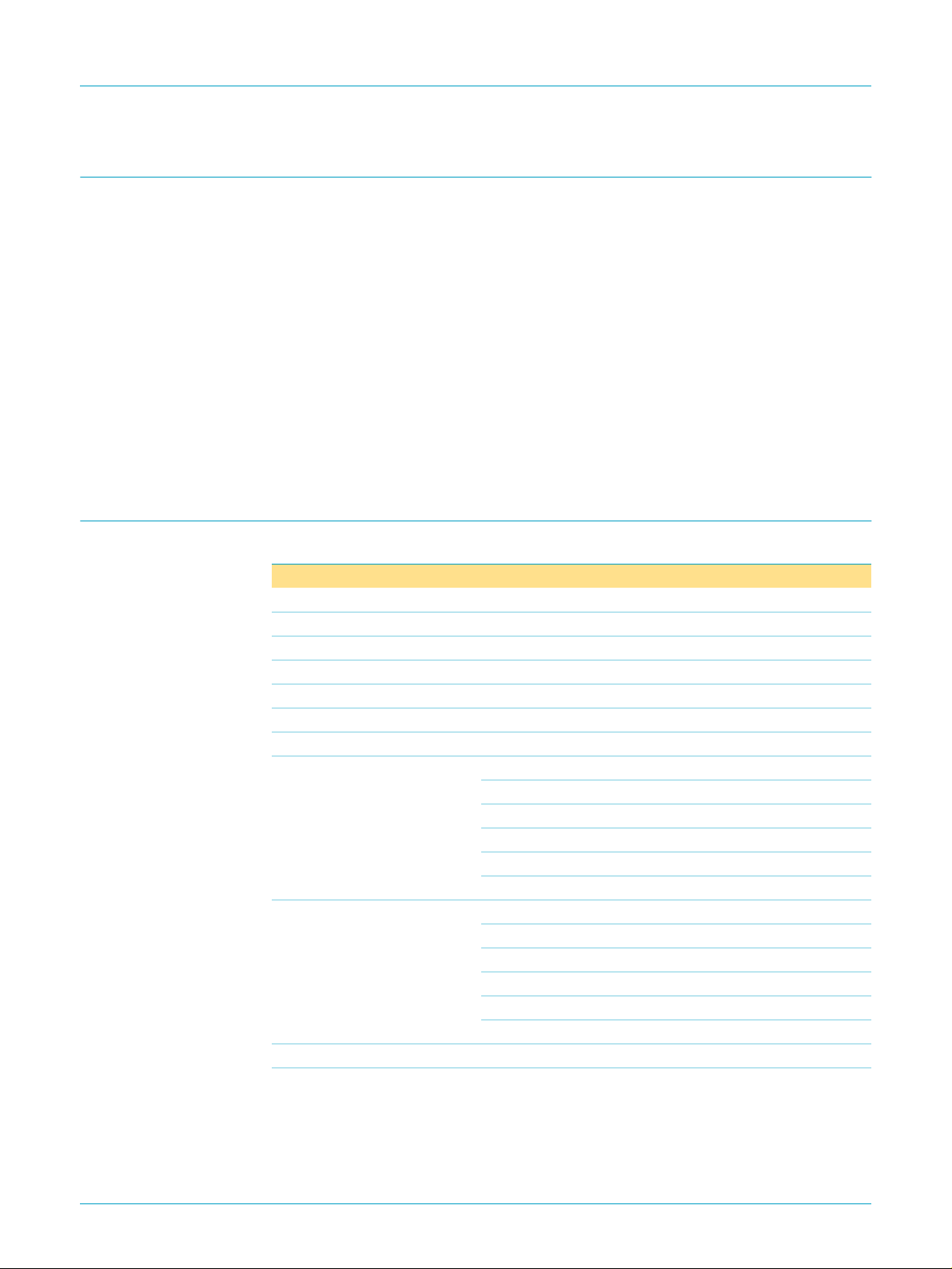

Table 3: Endpoint Configuration

Endpoint

number

Mode 0 (Non-ISO mode)

0 0 Control OUT 16

1 2 Generic

2 4 Generic

Mode 1 (ISO-OUT mode)

0 0 Control OUT 16

1 2 Generic

2 4 Isochronous

Mode 2 (ISO-IN mode)

0 0 Control OUT 16

1 2 Generic

2 5 Isochronous

Mode 3 (ISO-I/O mode)

0 0 Control OUT 16

1 2 Generic

2 4 Isochronous

PDIUSBD12

USB interface device with parallel bus

Endpoint

Transfer type Direction

index

1IN16

[2]

OUT 16

3IN16

[2][3]

OUT 64

5IN64

1IN16

[2]

OUT 16

3IN16

[3]

OUT 128

1IN16

[2]

OUT 16

3IN16

[3]

IN 128

1IN16

[2]

OUT 16

3IN16

[3]

OUT 64

5IN64

[1]

Max. Packet

size (bytes)

[4]

[4]

[4]

[4]

[4]

[4]

[1] IN: input for the USB host; OUT: output from the USB host.

[2] Generic endpoints can be used either as Bulk or Interrupt endpoint.

[3] The main endpoint (endpoint number 2) is double-bufferedto ease synchronization with the real-time

applications and to increase throughput. This endpoint supports DMA access.

[4] Denotes double buffering. The size shown is for a single buffer.

9397 750 08969

Product data Rev. 07 — 27 November 2001 9 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 10

Philips Semiconductors

9. Main endpoint

The main endpoint (endpoint number 2) is the primary endpoint for sinking or

sourcing relatively large amounts of data. It implements the following features to ease

this task:

• Double buffering. This allows parallel operation between USB access and local

CPU access thus increasing throughput. Buffer switching is handled automatically.

This results in transparent buffer operation.

• DMA (Direct Memory Access) operation. This can be interleaved with normal I/O

operation to other endpoints.

• Automatic pointer handling during DMA operation. No local CPU intervention is

necessary when ‘crossing’ the buffer boundary.

• Configurableendpoint for either isochronous transfer or non-isochronous (bulk and

interrupt) transfer.

10. Command summary

PDIUSBD12

USB interface device with parallel bus

Table 4: Command summary

Name Destination Code (Hex) Transaction

Initialization commands

Set Address/Enable Device D0 Write 1 byte

Set Endpoint Enable Device D8 Write 1 byte

Set mode Device F3 Write 2 bytes

Set DMA Device FB Write/Read 1 byte

Data flow commands

Read Interrupt Register Device F4 Read 2bytes

Select Endpoint Control OUT 00 Read 1 byte (optional)

Control IN 01 Read 1 byte (optional)

Endpoint 1 OUT 02 Read 1 byte (optional)

Endpoint 1 IN 03 Read 1 byte (optional)

Endpoint 2 OUT 04 Read 1 byte (optional)

Endpoint 2 IN 05 Read 1 byte (optional)

Read Last Transaction Status Control OUT 40 Read 1 byte

Control IN 41 Read 1 byte

Endpoint 1 OUT 42 Read 1 byte

Endpoint 1 IN 43 Read 1 byte

Endpoint 2 OUT 44 Read 1 byte

Endpoint 2 IN 45 Read 1 byte

Read Buffer Selected Endpoint F0 Read nbytes

Write Buffer Selected Endpoint F0 Write n bytes

9397 750 08969

Product data Rev. 07 — 27 November 2001 10 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 11

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 4: Command summary

Name Destination Code (Hex) Transaction

Set Endpoint Status Control OUT 40 Write 1 byte

Acknowledge Setup Selected Endpoint F1 None

Clear Buffer Selected Endpoint F2 None

Validate Buffer Selected Endpoint FA None

General commands

Send Resume F6 None

Read Current Frame Number F5 Read 1 or 2 bytes

11. Command description

11.1 Command procedure

There are three basic types of commands: Initialization, Data Flow and General

commands. Respectively, these are used to initialize the function; for data flow

between the function and the host; and some general commands.

…continued

Control IN 41 Write 1 byte

Endpoint 1 OUT 42 Write 1 byte

Endpoint 1 IN 43 Write 1 byte

Endpoint 2 OUT 44 Write 1 byte

Endpoint 2 IN 45 Write 1 byte

11.2 Initialization commands

Initialization commands are used during the enumeration process of the USB

network. These commands are used to enable the function endpoints. They are also

used to set the USB assigned address.

11.2.1 Set Address/Enable

Code (Hex) — D0

Transaction — write 1 byte

This command is used to set the USB assigned address and enable the function.

7654320100

ADDRESS: The value written becomes the address.

ENABLE: A ‘1’ enables this function.

Fig 4. Set Address/Enable command: bit allocation.

000000

POWER ON VALUE

ADDRESS

ENABLE

SV00825

9397 750 08969

Product data Rev. 07 — 27 November 2001 11 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 12

Philips Semiconductors

11.2.2 Set endpoint enable

Code (Hex) — D8

Transaction — write 1 byte

The generic/Isochronous endpoints can only be enabled when the function is enabled

via the Set Address/Enable command.

Fig 5. Set endpoint enable command: bit allocation.

PDIUSBD12

USB interface device with parallel bus

GENERIC/ISOCHRONOUS ENDPOINT: A value of ‘1’ indicates the generic/isochronous

endpoints are enabled.

11.2.3 Set mode

Code (Hex) — F3

Transaction — write 2 bytes

The Set mode command is followed by two data writes. The first byte contains the

configuration bits. The second byte is the clock division factor byte.

See Table 5 for bit allocation.

Fig 6. Set mode command, Configuration byte.

9397 750 08969

Product data Rev. 07 — 27 November 2001 12 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 13

Philips Semiconductors

Table 5: Set mode command, Configuration byte: bit allocation

Bit Symbol Description

7 to 6 ENDPOINT

4 SoftConnect A ‘1’ indicates that the upstream pull-up resistor will be connected

3 INTERRUPT

2 CLOCK

1NO

CONFIGURAT

ION

MODE

RUNNING

LAZYCLOCK

PDIUSBD12

USB interface device with parallel bus

These two bits set the endpoint configurations as follows:

mode 0 (Non-ISO mode)

mode 1 (ISO-OUT mode)

mode 2 (ISO-IN mode)

mode 3 (ISO-I/O mode)

See Section 8 “Endpoint description” for more details.

is available. A ‘0’ means that the upstream resistor will not

if V

BUS

be connected. The programmed value will not be changed by a

bus reset.

A ‘1’ indicates that all errors and “NAKing” are reported and will

generate an interrupt. A ‘0’ indicates that only OK is reported. The

programmed value will not be changed by a bus reset.

A ‘1’ indicates that the internal clocks and PLL are always running

even during Suspend state. A ‘0’ indicates that the internal clock,

crystal oscillator and PLL are stopped whenever not needed. To

meet the strict Suspend current requirement, this bit needs to be

set to ‘0’. The programmed value will not be changed by a bus

reset.

A ‘1’ indicates that CLKOUT will not switch to LazyClock. A ‘0’

indicates that the CLKOUT switches to LazyClock 1ms after the

Suspend pin goes HIGH. LazyClock frequency is 30 kHz ± 40%.

The programmed value will not be changed by a bus reset.

76 54 3 21110

See Table 6 for bit allocation.

10XX00

POWER ON VALUE

CLOCK DIVISION FACTOR

RESERVED

SET_TO_ONE

SOF-ONLY INTERRUPT MODE

SV00862

Fig 7. Set mode command, Clock division factor byte.

9397 750 08969

Product data Rev. 07 — 27 November 2001 13 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 14

Philips Semiconductors

Table 6: Clock division factor byte: bit allocation

Bit Symbol Description

7 SOF-ONLY

6 SET_TO_ONE This bit needs to be set to 1 prior to any DMA read or DMA write

3 to 0 CLOCK DIVISION

11.2.4 Set DMA

INTERRUPT MODE

FACTOR

PDIUSBD12

USB interface device with parallel bus

Setting this bit to 1 will cause the interrupt line to be activated

due to the Start Of Frame clock (SOF) only, regardless of the

setting of Pin-Interrupt mode, bit 5 of set DMA.

operation. This bit should always be set to 1 after power. It is

zero after Power-on reset.

The value indicates the clock division factor for CLKOUT. The

output frequency is 48 MHz/(N+1) where N is the Clock Division

Factor. The reset value is 11. This will produce the output

frequency of 4 MHz which can then be programmed up or down

by the user. The minimum value is 1 giving the range of

frequency from 4 to 24 MHz. The minimum value of N is 0,

giving a maximum frequency of 48 MHz. The maximum value of

N is 11 giving a minimum frequency of 4 MHz. The PDIUSBD12

design ensures no glitching during frequency change. The

programmed value will not be changed by a bus reset.

Code (Hex) — FB

Transaction — read/write 1 byte

The set DMA command is followed by one data write/read to/from the DMA

configuration register.

DMA Configuration register: During DMA operation, the two-byte buffer header

(status and byte length information) is not transferred to/from the local CPU. This

allows DMA data to be continuous and not interleaved by chunks of these headers.

For DMA read operations, the header will be skipped by the PDIUSBD12. See

Section 11.3.5 “Read buffer” command. For DMA write operations, the header will be

automatically added by the PDIUSBD12. This provides for a clean and simple DMA

data transfer.

See Table 7 for bit allocation.

Fig 8. Set DMA command.

9397 750 08969

Product data Rev. 07 — 27 November 2001 14 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 15

Philips Semiconductors

Table 7: Set DMA command: bit allocation

Bit Symbol Description

7 ENDPOINT INDEX 5

6 ENDPOINT INDEX 4

5 INTERRUPT PIN

4 AUTO RELOAD When this bit is set to ‘1’, the DMA operation will

3 DMA DIRECTION This bit determines the direction of data flow during a

2 DMA ENABLE Writing a ‘1’ to this bit will start DMA operation through

1 to 0 DMA BURST Selects the burst length for DMA operation:

INTERRUPT ENABLE

INTERRUPT ENABLE

MODE

PDIUSBD12

USB interface device with parallel bus

A ‘1’ allows for an interrupt to be generated whenever

the endpoint buffer is validated (see Section 11.3.8

“Validate buffer” command). Normally turned off for

DMA operation to reduce unnecessary CPU servicing.

A ‘1’ allows for an interrupt to be generated whenever

the endpoint buffer contains a valid packet. Normally

turned off for DMA operation to reduce unnecessary

CPU servicing.

A ‘0’ signifies a normal interrupt pin mode where an

interrupt is generated as a logical OR of all the bits in

the interrupt registers. A ‘1’ signifies that the interrupt

will occur when Start of Frame clock (SOF) is seen on

the upstream USB bus. The other normal interrupts are

still active.

automatically restart.

DMA transfer. A ‘1’ means external shared memory to

PDIUSBD12 (DMA Write); a ‘0’ means PDIUSBD12 to

the external shared memory (DMA Read).

the assertion of pin DMREQ. The main endpoint buffer

needs to be full (for DMA Read) or empty (for DMA

Write) before DMREQ will be asserted. In a single

cycle DMA mode, the DMREQ is deactivated upon

receiving DMACK_N. In burst mode DMA, the DMREQ

is deactivated after the number of burst is exhausted.

It is then asserted again forthe next burst. This process

continues until EOT_N is asserted together with

DMACK_N and either RD_N or WR_N, which will reset

this bit to ‘0’ and terminate the DMA operation. The

DMA operation can also be terminated by writing a

‘0’ to this bit.

00 Single-cycle DMA

01 Burst (4-cycle) DMA

10 Burst (8-cycle) DMA

11 Burst (16-cycle) DMA

11.3 Data flow commands

Data flow commands are used to manage the data transmission between the USB

endpoints and the external microcontroller. Much of the data flow is initiated via an

interrupt to the microcontroller. The microcontroller utilizes these commands to

access and determine whether the endpoint FIFOs have valid data.

11.3.1 Read interrupt register

Code (Hex) — F4

Transaction — read 2 bytes

9397 750 08969

Product data Rev. 07 — 27 November 2001 15 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 16

Philips Semiconductors

This command indicates the origin of an interrupt. The endpoint interrupt bits

(bits 0 to 5) are cleared by reading the endpoint last transaction status register

through Read Last Transaction Status command. The other bits are cleared after

reading the interrupt registers.

Fig 9. Interrupt Register, byte 1.

PDIUSBD12

USB interface device with parallel bus

See Table 8 for bit allocation.

DMA EOT: This bit signifies that DMA operation is completed.

Fig 10. Interrupt Register, byte 2: bit allocation.

Table 8: Read interrupt register, byte 1: bit allocation

Bit Symbol Description

7 SUSPEND CHANGE When the PDIUSBD12 did not receive 3 SOFs, it will go into

suspend state and the Suspend Change bit will be HIGH. Any

change to the suspend or awake state will set this bit HIGH and

generate an interrupt.

6 BUS RESET After a bus reset an interrupt will be generated this bit will be ‘1’.

A bus reset is identical to a hardware reset through the RESET_N

pin with the exception that a bus reset generates an interrupt

notification and the device is enabled at default address 0.

9397 750 08969

Product data Rev. 07 — 27 November 2001 16 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 17

Philips Semiconductors

11.3.2 Select Endpoint

Code (Hex) — 00 to 05

Transaction — read 1 byte (optional)

The Select Endpoint command initializes an internal pointer to the start of the

selected buffer. Optionally, this command can be followed by a data read, which

returns this byte.

Fig 11. Select Endpoint command: bit allocation.

PDIUSBD12

USB interface device with parallel bus

FULL/EMPTY: A ‘1’ indicates the buffer is full, ‘0’ indicates an empty buffer.

STALL: A ‘1’ indicates the selected endpoint is in the stall state.

11.3.3 Read Endpoint status

Code (Hex) — 80 to 85

Transaction — read 1 byte

765432x1x0

Fig 12. Read Endpoint status: bit allocation.

x00x00

11.3.4 Read last transaction status register

Code (Hex) — 40 to 45

Transaction — read 1 byte

RESERVED

SETUP PACKET

RESERVED

BUFFER 0 FULL

BUFFER 1 FULL

ENDPOINT STALLED

004aaa056

The Read Last Transaction Status command is followed by one data read that returns

the status of the last transaction of the endpoint. This command also resets the

corresponding interrupt flag in the interrupt register, and clears the status, indicating

that it was read.

9397 750 08969

Product data Rev. 07 — 27 November 2001 17 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 18

Philips Semiconductors

This command is useful for debugging purposes. Since it keeps track of every

transaction, the status information is overwritten for each new transaction.

Fig 13. Read last transaction status register.

Table 9: Read last transaction status register: bit allocation

Bit Symbol Description

7 PREVIOUS STATUS

6 DATA 0/1 PACKET A ‘1’ indicates the last successful received or sent packet

5 SETUP PACKET A ‘1’ indicates the last successful received packet had a

4 to 1 ERROR CODE See Table 10 “Error codes”.

0 DATA

See Table 9 for bit allocation.

NOT READ

RECEIVE/TRANSMIT

SUCCESS

PDIUSBD12

USB interface device with parallel bus

A ‘1’ indicates a second event occurred before the

previous status was read.

had a DATA1 PID.

SETUP token (this will always read ‘0’ for IN buffers).

A ‘1’ indicates data has been received or transmitted

successfully.

Table 10: Error codes

Error

code (Binary)

0000 No Error

0001 PID encoding Error; bits 7 to 4 are not the inversion of bits 3 to 0

0010 PID unknown; encoding is valid, but PID does not exist

0011 Unexpected packet; packet is not of the type expected (= token, data or

0100 Token CRC Error

0101 Data CRC Error

0110 Time Out Error

0111 Never happens

1000 Unexpected End-Of-Packet

1001 Sent or received NAK

1010 Sent Stall, a token was received, but the endpoint was stalled

9397 750 08969

Product data Rev. 07 — 27 November 2001 18 of 36

Description

acknowledge), or SETUP token to a non-control endpoint

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 19

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 10: Error codes

Error

code (Binary)

1011 Overflow Error, the received packet was longer than the available buffer

1101 Bitstuff Error

1111 Wrong DATA PID; the received DATA PID was not the expected one

11.3.5 Read buffer

Code (Hex) — F0

Transaction — read multiple bytes (max. 130)

The Read Buffer command is followed by a number of data reads, which returns the

contents of the selected endpoint data buffer. After each read, the internal buffer

pointer is incremented by 1.

The buffer pointer is not reset to the top of the buffer by the Read Buffer command.

This means that reading or writing a buffer can be interrupted by any other command

(except for Select Endpoint).

The data in the buffer are organized as follows:

• byte 0: reserved; can have any value

• byte 1: number/length of data bytes

• byte 2: data byte 1

• byte 3: data byte 2

• etc.

…continued

Description

space

The first two bytes will be skipped in the DMA read operation. Thus, the first read will

get Data byte 1, the second read will get Data byte 2, etc. The PDIUSBD12 can

determine the last byte of this packetthrough the EOP termination of the USB packet.

11.3.6 Write buffer

Code (Hex) — F0

Transaction — write multiple bytes (max. 130)

The Write Buffer command is followed by a number of data writes, which load the

endpoints buffer. The data must be organized in the same way as described in the

Read Buffer command. The first byte (reserved) should always be ‘0’.

During DMA write operation, the first two bytes will be bypassed. Thus, the first write

will write into Data byte 1, the second write will write into Data byte 2, etc. For

non-isochronous transfer (bulk or interrupt), the buffer should be completely filled

before the data is sent to the host and a switch to the next buffer occurs. The

exception is at the end of DMA transfer indicated by activation of EOT_N, when the

current buffer content (completely full or not) will be sent to the host.

Remark: There is no protection against writing or reading over a buffer’s boundary or

against writing into an OUT buffer or reading from an IN buffer. Any of these actions

could cause an incorrect operation. Data in an OUT bufferare only meaningful after a

9397 750 08969

Product data Rev. 07 — 27 November 2001 19 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 20

Philips Semiconductors

successful transaction. The exception is during DMA operation on the main endpoint

(endpoint 2), in which case the pointer is automatically pointed to the second buffer

after reaching the boundary (double buffering scheme).

11.3.7 Clear buffer

Code (Hex) — F2

Transaction — none

When a packet is received completely, an internal endpoint buffer full flag is set. All

subsequent packets will be refused by returning a NAK. When the microcontroller has

read the data, it should free the buffer by the Clear Buffer command. When the buffer

is cleared, new packets will be accepted.

11.3.8 Validate buffer

Code (Hex) — FA

Transaction — none

When the microprocessor has written data into an IN buffer, it should set the buffer

full flag by the Validate Buffer command. This indicates that the data in the buffer are

valid and can be sent to the host when the next IN token is received.

PDIUSBD12

USB interface device with parallel bus

11.3.9 Set endpoint status

Code (Hex) — 40 to 45

Transaction — write 1 byte

A stalled control endpoint is automatically unstalled when it receives a SETUP token,

regardless of the content of the packet. If the endpoint should stay in its stalled state,

the microcontroller can re-stall it.

When a stalled endpoint is unstalled (either by the Set Endpoint Status command or

by receiving a SETUP token), it is also re-initialized. This flushes the buffer and if it is

an OUT buffer it waits for a DATA 0 PID, if it is an IN buffer it writes a DATA 0 PID.

Even when unstalled, writing Set Endpoint Status to ‘0’ initializes the endpoint.

STALLED: A ‘1’ indicates the endpoint is stalled.

Fig 14. Set endpoint status: bit allocation.

11.3.10 Acknowledge setup

Code (Hex) — F1

Transaction — none

9397 750 08969

Product data Rev. 07 — 27 November 2001 20 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 21

Philips Semiconductors

The arrival of a SETUP packet flushes the IN buffer and disables the Validate Buffer

and Clear Buffer commands for both IN and OUT endpoints.

The microcontroller needs to re-enable these commands by the Acknowledge Setup

command. This ensures that the last SETUP packet stays in the buffer and no packet

can be sent back to the host until the microcontroller has acknowledged explicitly that

it has seen the SETUP packet.

The microcontroller must send the Acknowledge Setup command to both the IN and

OUT endpoints.

11.4 General commands

11.4.1 Send resume

Code (Hex) — F6

Transaction — none

Sends an upstream resume signal for 10 ms. This command is normally issued when

the device is in suspend. The RESUME command is not followed by a data read or

write.

PDIUSBD12

USB interface device with parallel bus

11.4.2 Read current frame number

Code (Hex) — F5

Transaction — read 1 or 2 bytes

This command is followed by one or two data reads and returns the frame number of

the last successfully received SOF. The frame number is returned Least Significant

byte first.

Fig 15. Read current frame number.

9397 750 08969

Product data Rev. 07 — 27 November 2001 21 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 22

Philips Semiconductors

12. Interrupt modes

Table 11: Interrupt modes

SOF-ONLY INTERRUPT MODE

0 0 Normal

0 1 Normal + SOF

1 X SOF only

[1] Bit 7 of Clock division factor byte of Set mode command (see Table 6).

[2] Bit 5 of Set DMA command (see Table 7).

[3] Normal interrupts from Interrupt Register.

13. Limiting values

Table 12: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CC

V

I

I

latchup

V

esd

T

stg

P

tot

[1] Equivalent to discharging a 100 pF capacitor via a 1.5 kΩ resistor.

[2] Values are given for device only; in-circuit V

PDIUSBD12

USB interface device with parallel bus

[1]

INTERRUPT PIN MODE

supply voltage −0.5 +6.0 V

input voltage −0.5 VCC + 0.5 V

latchup current VI< 0 or VI>V

electrostatic discharge

ILI<1µA

CC

voltage

storage temperature −60 +150 °C

total power dissipation VCC= 5.5 V − 95 mW

= ±8000 V.

esd(max)

[2]

Interrupt types

− 100 mA

[1][2]

−±2000 V

[3]

[3]

Table 13: Recommended operating conditions

Symbol Parameter Conditions Min Max Unit

V

CC1

DC supply voltage

(Main mode)

V

CC2

DC supply voltage

(Alternate mode)

apply V

pin only

apply V

and V

V

CC

CC1

CC2

to V

to both

out3.3

CC

4.0 5.5 V

3.0 3.6 V

pins

V

I

V

I/O

V

AI/O

DC input voltage 0 5.5 V

DC input voltage for I/O 0 5.5 V

DC input voltage for

0 3.6 V

analog I/O

V

O

T

amb

DC output voltage 0 V

operating ambient

temperature in free air

See Section 14

and Section 15

−40 +85 °C

CC

V

per device.

9397 750 08969

Product data Rev. 07 — 27 November 2001 22 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 23

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

14. Static characteristics

Table 14: DC characteristics (digital pins)

Symbol Parameter Conditions Min Typ Max Unit

Input levels

V

IL

V

IH

V

HYS

Output levels

V

OL

V

OH

Leakage current

I

OZ

I

L

I

S

I

O

LOW level input voltage −−0.8 V

HIGH level input voltage 2.0 −− V

hysteresis voltage ST (Schmitt Trigger) pins 0.4 − 0.7 V

LOW level output voltage IOL= rated drive

I

=20µA

OL

HIGH level output voltage IOH= rated drive

I

=20µA

OH

−−0.4

0.1

2.4

−− V

VCC− 0.1

V

V

V

OFF-state current OD (Open Drain) pins −−±5 µA

input leakage current −−±5 µA

suspend current oscillatorstopped and inputs

to GND/V

CC

--15µA

operating current - 15 mA

Table 15: DC characteristics (AI/O pins)

Symbol Parameter Conditions Min Max Unit

Leakage current

I

LO

Hi-Z state data line leakage 0 V < VIN < 3.3 V −±10 µA

Input levels

V

DI

V

CM

V

SE

differential input sensitivity |(D+) − (D−)| 0.2 − V

differential common mode range includes VDI range 0.8 2.5 V

single-ended receiver threshold 0.8 2.0 V

Output levels

V

OL

V

OH

static output LOW RL of 1.5 kΩ to 3.6 V − 0.3 V

static output HIGH RL of 15 kΩ to GND 2.8 3.6 V

Capacitance

C

IN

transceiver capacitance pin to GND − 20 pF

Output resistance

[1]

Z

DRV

driver output resistance steady state drive 29 44 Ω

Pull-up resistance

Z

PU

[1] Includes external resistors of 18 Ω±1% on D+ and D−.

pull-up resistance SoftConnect = ON 1.1 1.9 kΩ

9397 750 08969

Product data Rev. 07 — 27 November 2001 23 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 24

Philips Semiconductors

15. Dynamic characteristics

PDIUSBD12

USB interface device with parallel bus

Table 16: AC characteristics (AI/O pins; FULL speed)

[1]

CL= 50 pF; RPU= 1.5 kΩ on D+ to VCC; unless otherwise specified.

Symbol Parameter Conditions Min Max Unit

Driver characteristics

t

R

t

F

t

RFM

V

CRS

rise time 10% to 90% 4 20 ns

fall time 10% to 90% 4 20 ns

rise/fall time matching (tR/tF) 90 110 %

output signal crossover voltage 1.3 2.0 V

Driver timings

t

EOPT

t

DEOP

source EOP width see Figure 16 160 175 ns

differential data to EOP transition skew see Figure 16 −2+5ns

Receiver timings:

t

JR1

t

JR2

t

EOPR1

receiver data jitter tolerance to next transition −18.5 +18.5 ns

receiver data jitter tolerance for paired transitions −9+9ns

EOP width at receiver must reject as EOP;

[2]

40 -ns

see Figure 16

t

EOPR2

EOP width at receiver must accept as EOP;

[2]

82 − ns

see Figure 16

[1] Test circuit, see Figure 22.

[2] Characterized but not implemented as production test. Guaranteed by design.

t

PERIOD

DIFFERENTIAL

DATA LINES

CROSSOVER POINT

DIFFERENTIAL DATA TO

SEO/EOP SKEW

N * t

PERIOD

+ t

DEOP

CROSSOVER POINT

EXTENDED

SOURCE EOP WIDTH: t

RECEIVER EOP WIDTH: t

EOPT

EOPR1

, t

EOPR2

SV00837

Fig 16. Differential data-to-EOP transition skew and EOP width.

9397 750 08969

Product data Rev. 07 — 27 November 2001 24 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 25

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 17: AC characteristics (parallel interface)

Symbol Parameter Conditions Min Max Unit

ALE timings

t

LH

t

AVLL

t

LLAX

Write timings

t

CLWL

t

WHCH

t

AVWL

t

WHAX

t

WL

t

WDSU

t

WDH

t

WC

t

(WC - WD)

Read timings

t

CLRL

t

RHCH

t

AVRL

t

RL

t

RLDD

t

RHDZ

t

RC

t

(WC - RD)

ALE HIGH pulse width 20 − ns

address valid to ALE LOW time 10 − ns

ALE LOW to Address transition time − 10 ns

CS_N (DMACK_N) LOW to WR_N LOW time 0

[1]

− ns

WR_N HIGH to CS_N (DMACK_N) HIGH time 5 − ns

A0 Valid to WR_N LOW time 0

[1]

130

− ns

[2]

-ns

WR_N HIGH to A0 transition time 5 − ns

WR_N LOW pulse width 20 − ns

write data setup time 30 − ns

write data hold time 10 − ns

write cycle time 500

[3]

− ns

write command to write data 600 - ns

CS_N (DMACK_N) LOW to RD_N LOW time 0

[1]

130

− ns

[2]

-ns

RD_N HIGH to CS_N (DMACK_N) HIGH time 5 − ns

A0 Valid to RD_N LOW time 0

[1]

− ns

RD_N LOW pulse width 20 − ns

RD_N LOW to Data Driven time − 20 ns

RD_N HIGH to Data Hi-Z time − 20 ns

read cycle time 500

[3]

− ns

write command to read data 600 - ns

[1] Can be negative.

[2] For DMA access only on the module 64th byte and the second last (EOT-1)byte.

[3] The tWC and tRC timings are valid for back-to-back data access only.

Fig 17. ALE timing.

9397 750 08969

Product data Rev. 07 — 27 November 2001 25 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 26

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

t

CLRL

t

CS_N

DMACK_N

A0

WR_N

DATA[7:0]

RD_N

DATA[7:0] VALID DATA

CLWL

t

AVRL

t

AVWL

COMMAND = 1, DATA = 0

t

WL

t

WDSU

VALID DATA

t

RL

t

RLDD

t

RHCH

t

WHCH

t

WHAX

t

WDH

t

RHDZ

t

(WC - WD)

t

(WC - RD)

t

RHNDV

t

WC

t

RC

VALID DATA

t

RLDD

004aaa058

Fig 18. Parallel interface timing (I/O and DMA).

Table 18: AC characteristics (DMA)

Symbol Parameter Conditions Min Max Unit

Single-cycle DMA timings

t

AHRH

t

SHAH

t

RHSH

t

EL

DMACK_N HIGH to DMREQ HIGH time − 330 ns

RD_N/WR_N HIGH to DMACK_N HIGH time 130 − ns

DMREQ HIGH to RD_N/WR HIGH time 120 − ns

EOT_N LOW pulse width simultaneous DMACK_N,

10 - ns

RD_N/WR_N and EOT_N

LOW time

Burst DMA timings

t

SLRL

t

RHNDV

RD_N/WR_N LOW to DMREQ LOW time - 40 ns

RD_N (only) HIGH to next data valid − 420 ns

EOT timings

t

ELRL

EOT_N LOW to DMREQ LOW time − 40 ns

9397 750 08969

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Product data Rev. 07 — 27 November 2001 26 of 36

Page 27

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

DMREQ

DMACK_N

RD_N/WR_N

EOT_N

t

RHSH

t

EL

(1)

t

AHRH

t

EOT_N is considered valid when DMACK_N, RD_N/WR_N and EOT_N are all LOW.

Fig 19. Single-cycle DMA timing.

t

RHSH

DMREQ

SHAH

t

SLRL

SV00874

DMACK_N

RD_N/WR_N

Fig 20. Burst DMA timing.

t

SHAH

SV00875

Fig 21. DMA terminated by EOT.

9397 750 08969

Product data Rev. 07 — 27 November 2001 27 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 28

Philips Semiconductors

16. Test information

The dynamic characteristics of the analog I/O ports (D+ and D−) as listed in Table 16,

were determined using the circuit shown in Figure 22.

Fig 22. Load for D+/D−.

D. U. T.

1.5kΩ IS INTERNAL

22Ω

PDIUSBD12

USB interface device with parallel bus

TEST POINT

C

= 50pF

15kΩ

L

SV00849

9397 750 08969

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Product data Rev. 07 — 27 November 2001 28 of 36

Page 29

Philips Semiconductors

17. Package outline

PDIUSBD12

USB interface device with parallel bus

SO28: plastic small outline package; 28 leads; body width 7.5 mm

D

c

y

Z

28

pin 1 index

1

e

15

14

w M

b

p

SOT136-1

E

H

E

Q

A

2

A

1

L

p

L

detail X

(A )

A

X

v M

A

A

3

θ

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT136-1

A

A1A2A3b

max.

0.30

2.65

0.10

0.012

0.10

0.004

p

2.45

2.25

0.096

0.089

IEC JEDEC EIAJ

075E06 MS-013

0.25

0.01

0.49

0.36

0.019

0.014

0.32

0.23

0.013

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

(1)E(1) (1)

cD

18.1

17.7

0.71

0.69

REFERENCES

eHELLpQ

7.6

7.4

0.30

0.29

1.27

0.050

10.65

10.00

0.419

0.394

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

0.25

0.25 0.1

0.01

0.01

EUROPEAN

PROJECTION

ywv θ

Z

0.9

0.4

0.035

0.004

0.016

ISSUE DATE

97-05-22

99-12-27

o

8

o

0

Fig 23. SO28 package outline.

9397 750 08969

Product data Rev. 07 — 27 November 2001 29 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 30

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

TSSOP28: plastic thin shrink small outline package; 28 leads; body width 4.4 mm

D

c

y

Z

28

pin 1 index

15

A

2

A

1

114

w M

b

e

p

E

H

E

detail X

SOT361-1

A

X

v M

A

Q

(A )

3

A

θ

L

p

L

0 2.5 5 mm

scale

DIMENSIONS (mm are the original dimensions)

UNIT A1A2A3b

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic interlead protrusions of 0.25 mm maximum per side are not included.

A

max.

0.15

mm

1.10

OUTLINE

VERSION

SOT361-1 MO-153

0.05

0.95

0.25

0.80

IEC JEDEC EIAJ

p

0.30

0.19

(1)E(2) (1)

cD

0.2

9.8

0.1

9.6

REFERENCES

eHELLpQZywv θ

4.5

4.3

0.65

6.6

6.2

0.75

0.50

0.4

0.3

EUROPEAN

PROJECTION

o

0.8

0.13 0.10.21.0

ISSUE DATE

95-02-04

99-12-27

0.5

8

o

0

Fig 24. TSSOP28 package outline.

9397 750 08969

Product data Rev. 07 — 27 November 2001 30 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 31

Philips Semiconductors

18. Soldering

18.1 Introduction to soldering surface mount packages

This text gives a very brief insight to a complex technology. A more in-depth account

of soldering ICs can be found in our

Packages

There is no soldering method that is ideal for all surface mount IC packages. Wave

soldering can still be used for certain surface mount ICs, but it is not suitable for fine

pitch SMDs. In these situations reflow soldering is recommended.

18.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and

binding agent) to be applied to the printed-circuit board by screen printing, stencilling

or pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example, convection or convection/infrared

heating in a conveyor type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending on heating method.

PDIUSBD12

USB interface device with parallel bus

Data Handbook IC26; Integrated Circuit

(document order number 9398 652 90011).

Typical reflow peak temperatures range from 215 to 250 °C. The top-surface

temperature of the packages should preferable be kept below 220 °C for thick/large

packages, and below 235 °C small/thin packages.

18.3 Wave soldering

Conventional single wave soldering is not recommended for surface mount devices

(SMDs) or printed-circuit boards with a high component density, as solder bridging

and non-wetting can present major problems.

To overcome these problems the double-wave soldering method was specifically

developed.

If wave soldering is used the following conditions must be observed for optimal

results:

• Use a double-wave soldering method comprising a turbulent wave with high

upward pressure followed by a smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint longitudinal axis is preferred to be

parallel to the transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis must be parallel to the

transport direction of the printed-circuit board.

The footprint must incorporate solder thieves at the downstream end.

• For packages with leads on four sides, the footprint must be placed at a 45° angle

to the transport direction of the printed-circuit board. The footprint must

incorporate solder thieves downstream and at the side corners.

9397 750 08969

Product data Rev. 07 — 27 November 2001 31 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 32

Philips Semiconductors

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time is 4 seconds at 250 °C. A mildly-activated flux will eliminate the

need for removal of corrosive residues in most applications.

18.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low

voltage (24 V or less) soldering iron applied to the flat part of the lead. Contact time

must be limited to 10 seconds at up to 300 °C.

When using a dedicated tool, all other leads can be soldered in one operation within

2 to 5 seconds between 270 and 320 °C.

18.5 Package related soldering information

Table 19: Suitability of surface mount IC packages for wave and reflow soldering

Package Soldering method

BGA, HBGA, LFBGA, SQFP, TFBGA not suitable suitable

HBCC, HLQFP, HSQFP, HSOP, HTQFP,

HTSSOP, HVQFN, SMS

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

PDIUSBD12

USB interface device with parallel bus

methods

Wave Reflow

not suitable

[3]

, SO, SOJ suitable suitable

[2]

[3][4]

[5]

suitable

suitable

suitable

[1]

[1] All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the

maximum temperature (with respect to time) and body size of the package, there is a risk that internal

or external package cracks may occur due to vaporization of the moisture in them (the so called

popcorn effect). For details, refer to the Drypack information in the

Circuit Packages; Section: Packing Methods

[2] These packages are not suitable for wave soldering. On versions with the heatsink on the bottom

side, the solder cannot penetrate between the printed-circuit board and the heatsink. On versions with

the heatsink on the top side, the solder might be deposited on the heatsink surface.

[3] If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

[4] Wave soldering is only suitable for LQFP, QFP and TQFP packages with a pitch (e) equal to or larger

than 0.8 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

[5] Wave soldering is only suitable forSSOP and TSSOP packages with a pitch (e) equal to or larger than

0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

9397 750 08969

Product data Rev. 07 — 27 November 2001 32 of 36

.

Data Handbook IC26; Integrated

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 33

Philips Semiconductors

USB interface device with parallel bus

19. Revision history

Table 20: Revision history

Rev Date CPCN Description

07 20011127 Product specification (7379 750 08969). Modifications:

• Changed in Section 2 “Features” second to last item: 3.6 into 4.0 V.

• In Section 7 “DMA transfer” 5th paragraph changed ‘activation’ to ‘reception’.

• In Section 11.3.5 “Read buffer” the first paragraph is added.

• In Section 13 “Limiting values” Table 12 “Limiting values” the last note is removed.

• In Section 14 “Static characteristics” Table 14 “DC characteristics (supply pins)” has been

removed; the applicable Parameters have been moved to the next Table and their Symbols

have been changed.

• In Section 14 “Static characteristics” Table 15 “DC characteristics (AI/O pins)” first item both

Symbol and Parameter are changed.

• In Section 15 “Dynamic characteristics” made the following changes to Table 16 “Thermal

characteristics”

– Third item both Symbol and Parameter are changed

– Second to last item Max value moved to Min column.

• In Section 15 “Dynamic characteristics” Table 17 “AC characteristics (parallel interface)” at

two locations a value of ‘130’ has been added in Min column.

• Added Section 11.3.3 “Read Endpoint status”.

• Made the following changes in Table 17 “AC characteristics (parallel interface)”

– Added t

– Added t

– Added the last two table notes.

(WC - WD)

(WC - RD)

• In Figure 18 “Parallel interface timing (I/O and DMA).”, added t

• In Table 12 “Limiting values” on page 22, changed I

• In Section 6.6 “SoftConnect” added the sentence “The decision to make sure of this feature

lies with the users." as the last sentence.

• In Table 5 “Set mode command, Configuration byte: bit allocation”, changed the bit from “7”

to “7 to 6” in the first row.

• In Table 6 “Clock division factor byte: bit allocation”, added the sentence “The minimum

value is 1 giving the range of frequency from 4 to 24 MHz” to the description of bit 3.

• Changed flow in the Section 11.3.1 “Read interrupt register”. Moved Figure 10 “Interrupt

Register, byte 2: bit allocation.”before Table 8 “Read interrupt register, byte 1: bit allocation”.

• In the Table 12 “Limiting values”:

– changed value in the Max field of I

– changed value in the Max field of V

– added V

CC

• In the Table 13 “Recommended operating conditions”, added 4.0 in the Min field of V

• In the Table16 “AC characteristics (AI/O pins; FULL speed)

condition column of the first two symbols.

to the Write Timings section.

to the Read Timings section.

from 200 t0 100

latchup

from 4000 to 2000

esd

= 5.5 V in the Conditions field of P

tot

LI

.

PDIUSBD12

(WC - WD),t(WC - RD)

<1µA.

[1]

”, removed |VOH-VOL| from the

and t

RHNDV

CC1

.

.

9397 750 08969

Product data Rev. 07 — 27 November 2001 33 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 34

Philips Semiconductors

PDIUSBD12

USB interface device with parallel bus

Table 20: Revision history

Rev Date CPCN Description

07 20011127 Modifications (continued):

…continued

• Made the following changes in Table 18 “AC characteristics (DMA)”:

– Parameter ‘DMACK_N HIGH to DMREQ HIGH time’ changed the Max value from 550 to

330.

– Removed the timings tWA and t

– Added the timing t

– Changed the Min value of t

– Removed the timing t

– Section ‘Burst DMA timings’ changed Parameters and their values.

– Added the timing t

06 20010423 Product specification; version 6. Supersedes PDUIUSBD12_5 of 19990108

(9397 750 04979).

Data sheet modifications:

RHSH

WSH

RHNDV

row.

SHAH

row.

row.

.

ALRL

from 10 to 130.

• Converted to DBII template.

• Section 12 "Interrupt modes" added.

• Section 16 "Test information" created.

9397 750 08969

Product data Rev. 07 — 27 November 2001 34 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 35

Philips Semiconductors

20. Data sheet status

PDIUSBD12

USB interface device with parallel bus

Data sheet status

Objective data Development This data sheet contains data from the objectivespecification for product development.Philips Semiconductors

Preliminary data Qualification This data sheet contains data from the preliminary specification. Supplementary data will be published at a

Product data Production This data sheet contains data from the product specification. Philips Semiconductors reserves the right to

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at

URL http://www.semiconductors.philips.com.

[1]

Product status

21. Definitions

Short-form specification — The data in a short-form specification is

extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with

the Absolute Maximum Rating System (IEC 60134). Stress above one or

more of the limiting values may cause permanent damage to the device.

These are stress ratings only and operation of the device at these or at any

other conditions above those given in the Characteristics sections of the

specification is not implied. Exposure to limiting values for extended periods

may affect device reliability.

Application information — Applications that are described herein for any

of these products are for illustrative purposes only. Philips Semiconductors

make no representation or warranty that such applications will be suitable for

the specified use without further testing or modification.

22. Disclaimers

Life support — These products are not designed for use in life support

appliances, devices, or systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips Semiconductors

[2]

Definition

reserves the right to change the specification in any manner without notice.

later date. Philips Semiconductors reserves the right to change the specification without notice, in order to

improve the design and supply the best possible product.

make changes at any time in order to improve the design, manufacturing and supply. Changes will be

communicated according to the Customer Product/Process Change Notification (CPCN) procedure

SNW-SQ-650A.

customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to

make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve

design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no

licence or title under any patent, copyright, or mask work right to these

products, andmakes no representations or warrantiesthat these products are

free from patent, copyright,or mask work right infringement, unless otherwise

specified.

23. Trademarks

ACPI — is an open industry specification for PC power management,

co-developed by Intel Corp., Microsoft Corp. and Toshiba

GoodLink — is a trademark of Koninklijke Philips Electronics N.V.

OnNow — is a trademark of Microsoft Corp.

SoftConnect — is a trademark of Koninklijke Philips Electronics N.V.

Contact information

For additional information, please visit http://www.semiconductors.philips.com.

For sales office addresses, send e-mail to: sales.addresses@www.semiconductors.philips.com. Fax: +31 40 27 24825

9397 750 08969

Product data Rev. 07 — 27 November 2001 35 of 36

© Koninklijke Philips Electronics N.V. 2001. All rights reserved.

Page 36

Philips Semiconductors

Contents

PDIUSBD12

USB interface device with parallel bus

1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Pinning information. . . . . . . . . . . . . . . . . . . . . . 2

3.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 Ordering information. . . . . . . . . . . . . . . . . . . . . 4

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6 Functional description . . . . . . . . . . . . . . . . . . . 5

6.1 Analog transceiver . . . . . . . . . . . . . . . . . . . . . . 5

6.2 Voltage regulator. . . . . . . . . . . . . . . . . . . . . . . . 5

6.3 PLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.4 Bit clock recovery . . . . . . . . . . . . . . . . . . . . . . . 5

6.5 Philips Serial Interface Engine (PSIE) . . . . . . . 5

6.6 SoftConnect . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.7 GoodLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.8 Memory Management Unit (MMU)

and Integrated RAM. . . . . . . . . . . . . . . . . . . . . 6

6.9 Parallel and DMA Interface. . . . . . . . . . . . . . . . 6

6.10 Example of parallel interface to an

80C51 microcontroller . . . . . . . . . . . . . . . . . . . 6

7 DMA transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8 Endpoint description. . . . . . . . . . . . . . . . . . . . . 8

9 Main endpoint. . . . . . . . . . . . . . . . . . . . . . . . . . 10

10 Command summary . . . . . . . . . . . . . . . . . . . . 10

11 Command description. . . . . . . . . . . . . . . . . . . 11

11.1 Command procedure . . . . . . . . . . . . . . . . . . . 11

11.2 Initialization commands . . . . . . . . . . . . . . . . . 11

11.2.1 Set Address/Enable . . . . . . . . . . . . . . . . . . . . 11

11.2.2 Set endpoint enable . . . . . . . . . . . . . . . . . . . . 12

11.2.3 Set mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11.2.4 Set DMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11.3 Data flow commands . . . . . . . . . . . . . . . . . . . 15

11.3.1 Read interrupt register . . . . . . . . . . . . . . . . . . 15

11.3.2 Select Endpoint. . . . . . . . . . . . . . . . . . . . . . . . 17

11.3.3 Read Endpoint status . . . . . . . . . . . . . . . . . . . 17

11.3.4 Read last transaction status register . . . . . . . 17

11.3.5 Read buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11.3.6 Write buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11.3.7 Clear buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.3.8 Validate buffer. . . . . . . . . . . . . . . . . . . . . . . . . 20

11.3.9 Set endpoint status. . . . . . . . . . . . . . . . . . . . . 20

11.3.10 Acknowledge setup. . . . . . . . . . . . . . . . . . . . . 20

11.4 General commands . . . . . . . . . . . . . . . . . . . . 21

11.4.1 Send resume . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.4.2 Read current frame number . . . . . . . . . . . . . . 21

12 Interrupt modes . . . . . . . . . . . . . . . . . . . . . . . . 22

13 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 22

14 Static characteristics. . . . . . . . . . . . . . . . . . . . 23

15 Dynamic characteristics . . . . . . . . . . . . . . . . . 24

16 Test information. . . . . . . . . . . . . . . . . . . . . . . . 28

17 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 29

18 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

18.1 Introduction to soldering surface mount

packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

18.2 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 31

18.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 31

18.4 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 32

18.5 Package related soldering information. . . . . . 32

19 Revision history . . . . . . . . . . . . . . . . . . . . . . . 33

20 Data sheet status. . . . . . . . . . . . . . . . . . . . . . . 35

21 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

22 Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

23 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

© Koninklijke Philips Electronics N.V. 2001.

Printed in The Netherlands

All rights are reserved. Reproduction in whole or in part is prohibited without the prior

written consent of the copyright owner.

The information presented in this document does not form part of any quotation or

contract, is believed to be accurate and reliable and may be changed without notice. No

liability will be accepted by the publisher for any consequence of its use. Publication

thereof does not convey nor imply any license under patent- or other industrial or

intellectual property rights.

Date of release: 27 November 2001 Document order number: 9397 750 08969

Loading...

Loading...