Page 1

1

®

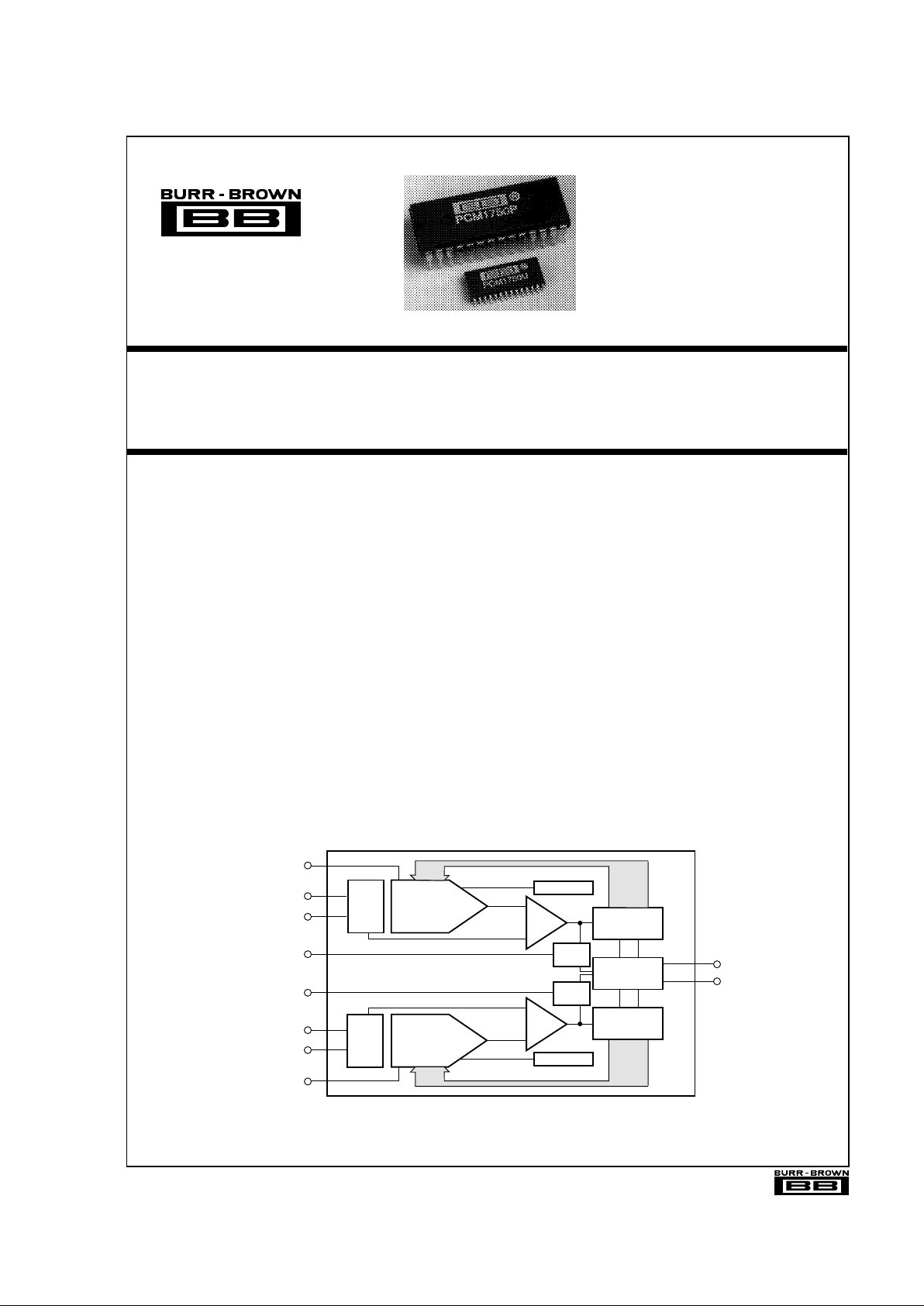

PCM1750

Dual CMOS 18-Bit Monolithic Audio

ANALOG-TO-DIGITAL CONVERTER

DESCRIPTION

The PCM1750 is a low cost, dual 18-bit CMOS

analog-to-digital converter optimized for dynamic signal applications. The PCM1750 features true co-phased

inputs with an internal sample/hold function for each

channel. The PCM1750 also comes complete with an

internal reference. Total power dissipation is less than

300mW max using ±5V voltage supplies. Low maximum Total Harmonic Distortion + Noise (–88dB max)

is 100% tested. The very fast PCM1750 is capable

of 4X x audio bandwidth oversampling rates on both

input channels simultaneously, providing greater freedom to designers in selecting input anti-aliasing filters.

PCM1750 outputs serial data in a format that is compatible with many digital filter chips and comes packaged in a space saving 28-pin plastic DIP or SOIC.

Offset Adj Right

18-Bit SAR

18-Bit SAR

CDAC

Right

S/H

CDAC

Left

S/H

Reference

V Left

S Left

S Right

Comp

Clock

Convert

Offset Adj Left

MSB Adj Right

MSB Adj Left

V Right

IN

IN

Shift Register

Control Logic

OUT

OUT

Comp

Reference

Latch

Latch

FEATURES

● DUAL 18-BIT LOW-POWER CMOS AUDIO

A/D CONVERTER

● FAST 4.5

µs MIN CONVERSION TIME

INCLUDING S/H

● VERY LOW MAX THD+N: –88dB Without

External Adjust

● COMPLETE WITH INTERNAL

REFERENCE AND DUAL S/H FUNCTION

● TWO CO-PHASE SAMPLED,

±2.75V

AUDIO INPUTS

● CAPABLE OF 4X PER CHANNEL

OVERSAMPLING RATE

● RUNS ON

±5V SUPPLIES AND

DISSIPATES 300mW MAX

● COMPACT 28-PIN PLASTIC DIP OR SOIC

International Airport Industrial Park • Mailing Address: PO Box 11400 • Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd. • Tucson, AZ 85706

Tel: (520) 746-1111 • Twx: 910-952-1111 • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

®

PCM1750P

PCM1750U

© 1990 Burr-Brown Corporation PDS-1084B Printed in U.S.A. October, 1993

Page 2

®

PCM1750 2

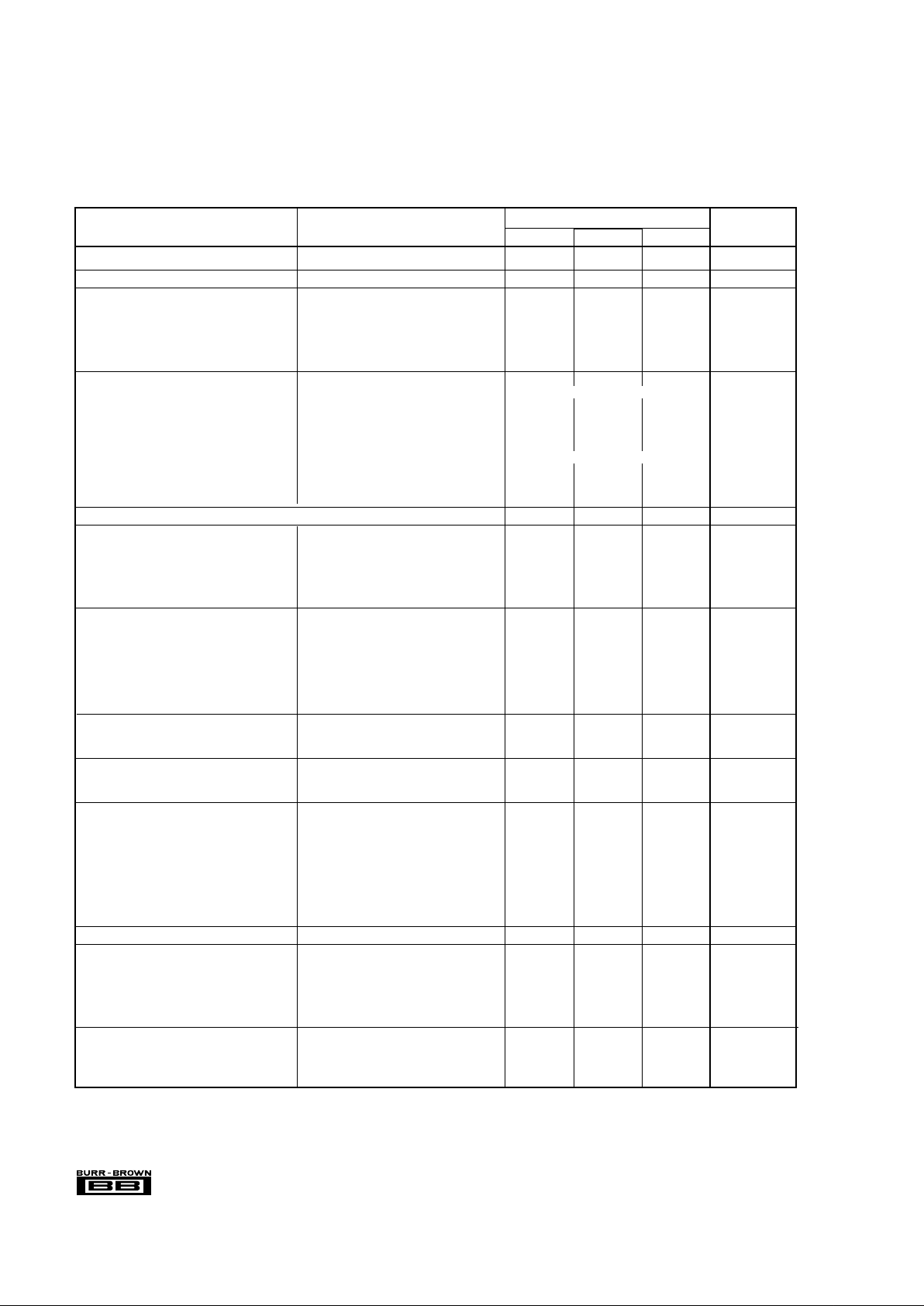

SPECIFICATIONS

ELECTRICAL

At 25°C, and ±VA = ±5.0V; +VD = +5.0V, unless otherwise noted. Where relevant, specifications apply to both left and right input/output channels.

NOTES: (1) Binary Two’s Complement coding. (2) The PCM1750 is tested and guaranteed at 5.2µs, however it will operate at 4.5µs. The dynamic performance is not

guaranteed or tested at this conversion rate. (3) Ratio of Signal

RMS

/ (Distortion

RMS

+ Noise

RMS

). (4) A/D converter sample frequency (4 x 48kHz; 4X oversampling per

channel). (5) A/D converter input frequency (signal level). (6) Referred to input signal level. (7) Ratio of (Distortion

RMS

+ Noise

RMS

) / Signal

RMS

. (8) Externally adjustable

to zero error. (9) Differential non-linearity error at bipolar major carry input code. Externally adjustable to zero error. (10) Full scale range (5.50V). (11) Refer to equivalent

circuit in Figure 1. (12) Worst case operating condition. Refer to typical performance curves.

PCM1750P, U

PARAMETER CONDITIONS MIN TYP MAX UNITS

RESOLUTION 18 Bits

DYNAMIC RANGE THD + N at –60dB Referred to Full Scale +88 +90 dB

ANALOG INPUT

Input Range ±2.75 V

Input Capacitance 20 pF

Aperture Delay 10 ns

Aperture Uncertainty (Jitter) 50 ps

rms

Full Power Input Bandwidth 500 kHz

DIGITAL INPUT/OUTPUT

Logic Family CMOS Compatible

Logic Level: V

IH

IIH = ±5µA +3.5 +VD + 0.3 V

V

IL

IIL = ±5µA –0.3 +1.5 V

V

OH

I

SOURCE

= 1.0mA +2.7 +4.7 V

V

OL

I

SINK

= 3.2mA +0.2 +0.4 V

Output Data Format Serial, MSB First, BTC

(1)

Convert Command Positive Edge

Convert Command Pulse Width 81 ns

Conversion Time Throughput Including Sample/Hold

(2)

4.5 5.2 20.8 µs

DYNAMIC CHARACTERISTICS (20Hz to 24kHz; 4X data decimated to 1X)

Signal-to-Noise Ratio

(3)

fs = 192kHz

(4)

; fIN = 1kHz (0dB)

(5)

+88 +90 dB

(6)

Total Harmonic Distortion + N

(7)

Without External Adjustments

f

IN

= 1kHz (0dB) fs = 192kHz –90 –88 dB

f

IN

= 1kHz (–20dB) fs = 192kHz –70 –68 dB

f

IN

= 1kHz (–60dB) fs = 192kHz –30 –28 dB

Channel Separation fs = 192kHz; f

IN

= 1kHz (0dB) and 0V +96 +108 dB

ACCURACY

Gain Error ±2 ±5%

Gain Mismatch Channel to Channel ±0.5 ±2.0 %

BPZ (Bipolar Zero) Error

(8)

±2mV

BPZ Error Mismatch Channel to Channel ±3mV

BPZ Differential Linearity Error

(9)

±0.002 % of FSR

(10)

Linearity Error ±0.003 % of FSR

Warm-up Time 1ms

DRIFT (With Internal Reference)

Gain 0°C to 70°C ±50 ppm/°C

Bipolar Zero 0°C to 70°C ±10 ppm of FSR/°C

DRIFT (Exclusive of Internal Reference)

Gain 0°C to 70°C ±10 ppm/°C

Bipolar Zero 0°C to 70°C ±3 ppm of FSR/°C

REFERENCE

V

REF

Output (Pins 19, 24):

Voltage +2.75 V

Current ±100 µA

Impedance 0.2 Ω

Accuracy ±25 mV

Drift 0°C to 70°C ±50 ppm/°C

V

REF

Input (Pins 18, P25):

Impedance

(11)

363 || 120 Ω || pF

POWER SUPPLY REJECTION % of V

IN

/ % of V

SUPPLY

(12)

0.03 % / %

POWER SUPPLY REQUIREMENTS

±V

A

Supply Voltage Range ±4.75 ±5.00 ±5.25 V

+V

D

Supply Voltage Range +4.75 +5.00 +5.25 V

+I

A

; +ID Combined Supply Current +VA; +VD = +5.0V +28 mA

–I

A

Supply Current –VA = –5.0V –13 mA

Power Dissipation ±V

A

= ±5.0V; +VD = +5.0V 210 300 mW

TEMPERATURE RANGE

Specification 0 +70 °C

Operating –40 +85 °C

Storage –60 +100 °C

Page 3

3

®

PCM1750

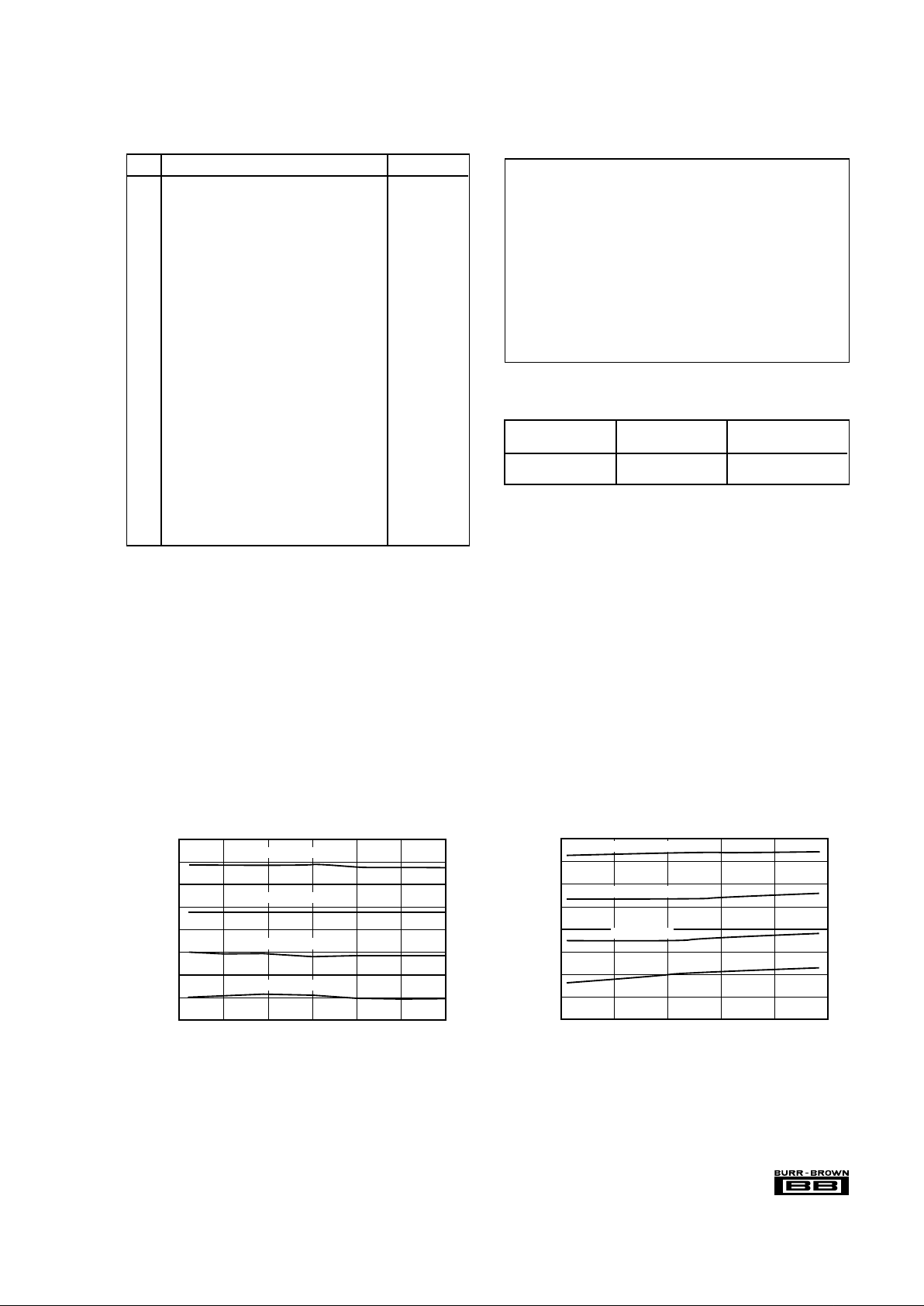

THD+N vs FREQUENCY

(Without 4X Digital Filter)

Frequency (kHz)

–20

–40

–60

–80

–100

0 20406080

100

V = –60dB

IN

V = –40dB

IN

IN

V = 0dB

IN

THD+N (dB)

V = –20dB

THD+N vs FREQUENCY

(With 4X Digital Filter)

–20

–40

–60

–80

–100

0 4 8 12 16 20 24

Frequency (kHz)

THD+N (dB)

V = –60dB

IN

V = –40dB

IN

V = –20dB

IN

V = 0dB

IN

PIN ASSIGNMENTS

PIN DESCRIPTION MNEMONIC

1 –5V Analog Supply Voltage –V

A

2 +5V Analog Supply Voltage +V

A

3 Serial Output (Left Channel) SOUTL

4 External Clock Input CLK

5 +5V Analog Supply Voltage +V

A

6 +5V Digital Voltage Supply +V

D

7 +5V Digital Voltage Supply +V

D

8 Digital Common Connection DCOM

9 Analog Common Connection ACOM

10 Digital Common Connection DCOM

11 Convert Command Input CONVERT

12 Serial Output (Right Channel) SOUTR

13 +5V Analog Supply Voltage +V

A

14 –5V Analog Supply Voltage –V

A

15 Offset Adjust (Right Channel) OFF

ADJR

16 MSB Adjust (Right Channel) MSB

ADJR

17 Analog Voltage Input (Right Channel; ±2.75V) V

INR

18 Reference Voltage Input (Right Channel) VREF

INR

19 Reference Voltage Output (Right Channel) VREF

OUTR

20 Analog Common Connection ACOM

21 Reference Voltage Decouple VREF

CAP

22 Reference Common Connection RCOM

23 Analog Common Connection ACOM

24 Reference Voltage Output (Left Channel) VREF

OUTL

25 Reference Voltage Input (Left Channel) VREF

INL

26 Analog Voltage Input (Left Channel; ±2.75V) V

INL

27 MSB Adjust (Left Channel) MSB

ADJL

28 Offset Adjust (Left Channel) OFF

ADJL

Analog Input Voltage (VIN) .................................. –VA –0.3V to +VA + 0.3V

+V

A

; +VD to ACOM/DCOM............................................................0 to +7V

–V

A

to ACOM/DCOM .................................................................... 0 to –7V

–V

A

to +VA; +VD.........................................................................0 to +14V

ACOM to DCOM .................................................................................. ±1V

Digital Inputs (pins 4, 11) to DCOM ........................... –0.3V to +V

D

+ 0.3V

Power Dissipation .......................................................................... 400mW

Lead Temperature, (soldering 10s)................................................ +300°C

Max Junction Temperature .............................................................. 165°C

Thermal Resistance,

θ

JA

: Plastic DIP............................................ 80°C/W

Thermal Resistance,

θ

JA

: Plastic SOIC .......................................100°C/W

NOTE: Stresses above those listed under Absolute Maximum Ratings may

cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability.

ABSOLUTE MAXIMUM RATINGS

TYPICAL PERFORMANCE CURVES

At 25°C, and ±VA = ±5.0V; +VD = +5V, unless otherwise noted. Where relevant, specifications apply to both left and right input output channels.

PACKAGE INFORMATION

PACKAGE DRAWING

MODEL PACKAGE NUMBER

(1)

PCM1750P 28-Pin Plastic DIP 215

PCM1750U 28-Pin Plastic SOIC 217

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix D of Burr-Brown IC Data Book.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

Page 4

®

PCM1750 4

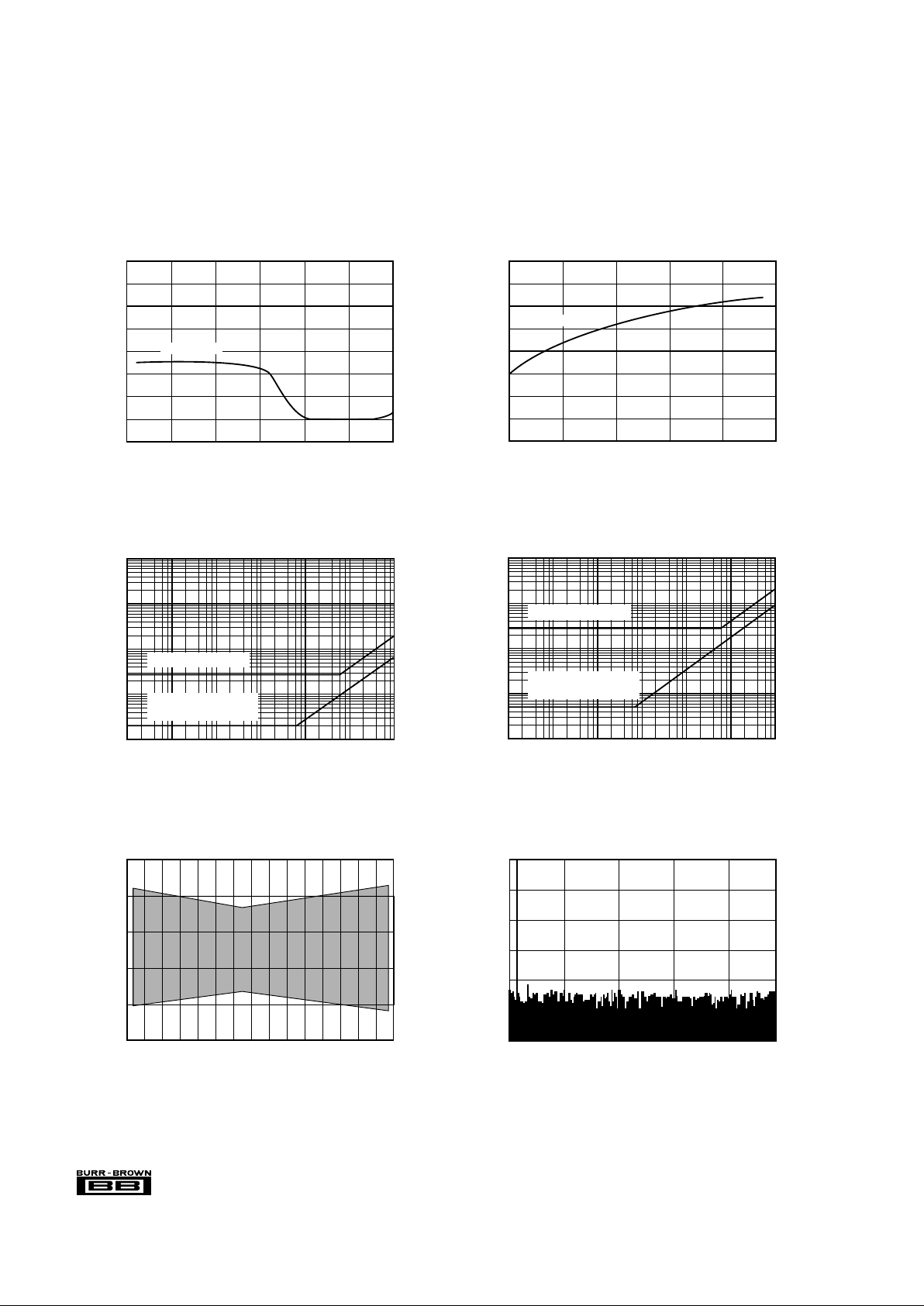

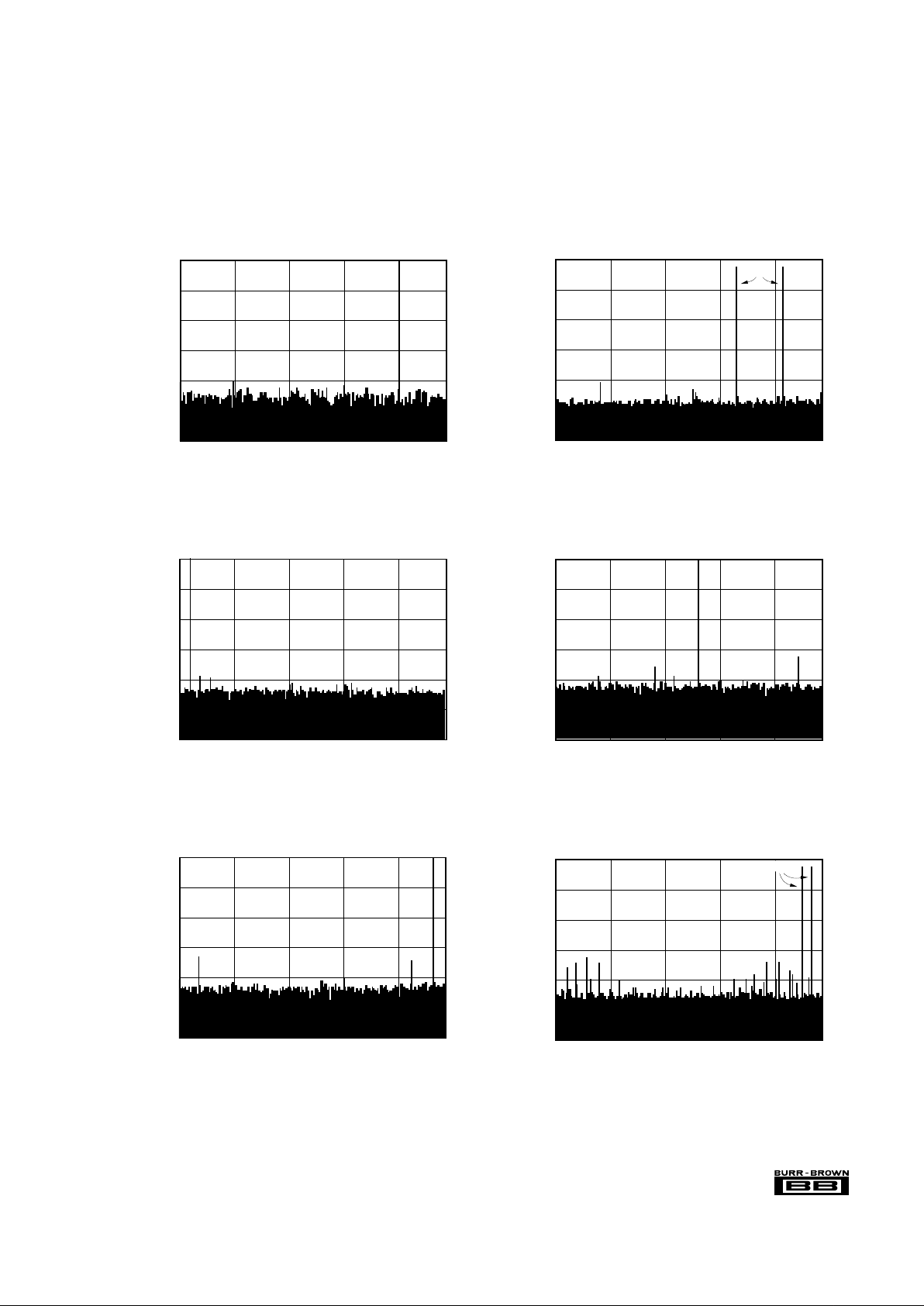

FFT 850Hz (24kHz BW; 2048 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

510152024

TYPICAL PERFORMANCE CURVES (CONT)

At 25°C, and ±VA = ±5.0V; +VD = +5.0V, unless otherwise noted. Where relevant, specifications apply to both left and right input-output channels.

THD vs FREQUENCY

(Without 4X Digital Filter)

Frequency (kHz)

THD (dB)

–70

–80

–90

–100

–110

0 20406080100

V = 0dB

IN

THD vs FREQUENCY

(With 4X Digital Filter)

Frequency (kHz)

–70

–80

–90

–100

–110

THD (dB)

V = 0dB

IN

0 4 8 12 16 20 24

PSR vs FREQUENCY

(–5V SUPPLY)

1

0.1

0.01

0.001

0.0001

% / %

1 10 100 1k 10k 100k 1M

Frequency (Hz)

% of V /% of V

IN SUPPLY

At BPZ:

% of FSR / % of V

SUPPLY

PSR vs FREQUENCY

(+5V SUPPLIES)

1

0.1

0.01

0.001

0.0001

% / %

1 10 100 1k 10k 100k 1M

Frequency (Hz)

% of V /% of V

IN SUPPLY

At BPZ:

% of FSR / % of V

SUPPLY

V vs TEMPERATURE

(V Outputs)

Temperature in °C

2.80

2.78

2.76

2.74

2.72

2.70

–40 –20 0 20 40 60 80 100

V

REF

(V)

REF

REF

Page 5

5

®

PCM1750

FFT 88kHz and 92kHz (96kHz BW; 16384 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

20 40 60 80 96

–6dB

FFT 92kHz (96kHz BW; 2048 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

20 40 60 80 96

FFT 20kHz (24kHz BW; 2048 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

510152024

TYPICAL PERFORMANCE CURVES (CONT)

At 25°C, and ±VA; +VD = ±5V, unless otherwise noted. Where relevant, specifications apply to both left and right input-output channels.

FFT 17kHz and 21kHz (24kHz BW; 16384 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

510152024

–6dB

FFT 3.7kHz (96kHz BW; 2048 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

20 40 60 80 96

FFT 52kHz (96kHz BW; 2048 POINTS)

0

–25

–50

–75

–100

–125

–150

Amplitude (dB)

0

Frequency (kHz)

20 40 60 80 96

Page 6

®

PCM1750 6

25k

25k

150k

5k

5k

12a

3b

3a

2b

1b

1a

2T

1T

3T

12T

off

S

C

V

REF

P16, P27

+V (+5V)

P15, P28

.01µF

P19, P24

500

13.25k

A1

A2

Latch

Comparator

Data Out

AZ

CAZ

(MSB)

S

V

C

10PF

1

2

3

IN

REF

5PF

20PF

1

L

V

S

S

3

C

2

C

1

1

CAZ

2

AZ

2

AZ

CAZ

3

3

CAZ

4

AZ

4

47k

A

.01µF

+V (+5V)

A

off

C

R

offb

500

R

12b

R

S

12T

R

R

R

S

3T

C

S

2T

C

S

1T

C

R

R

a

b

R

R

Ω

Ω

Ω

Ω

Ω

Ω

Ω

2a

R

Ω

Ω

100mV

H1 H2

P18, P25

V

Simplified

V Circuit

REFIN

REFIN

+V (+5V)

A

917

Ω

P18, P25

V

REFIN

R

offa

47k

Ω

V

REFOUT

Optional External

Adjustment Circuitry

TDAC

Auto-Zeroed Comparator

CDAC

0 to 120pF

(Code

dependent)

MSB Adj

Off Adj

= 2.75V

600

Ω

13.25k

Ω

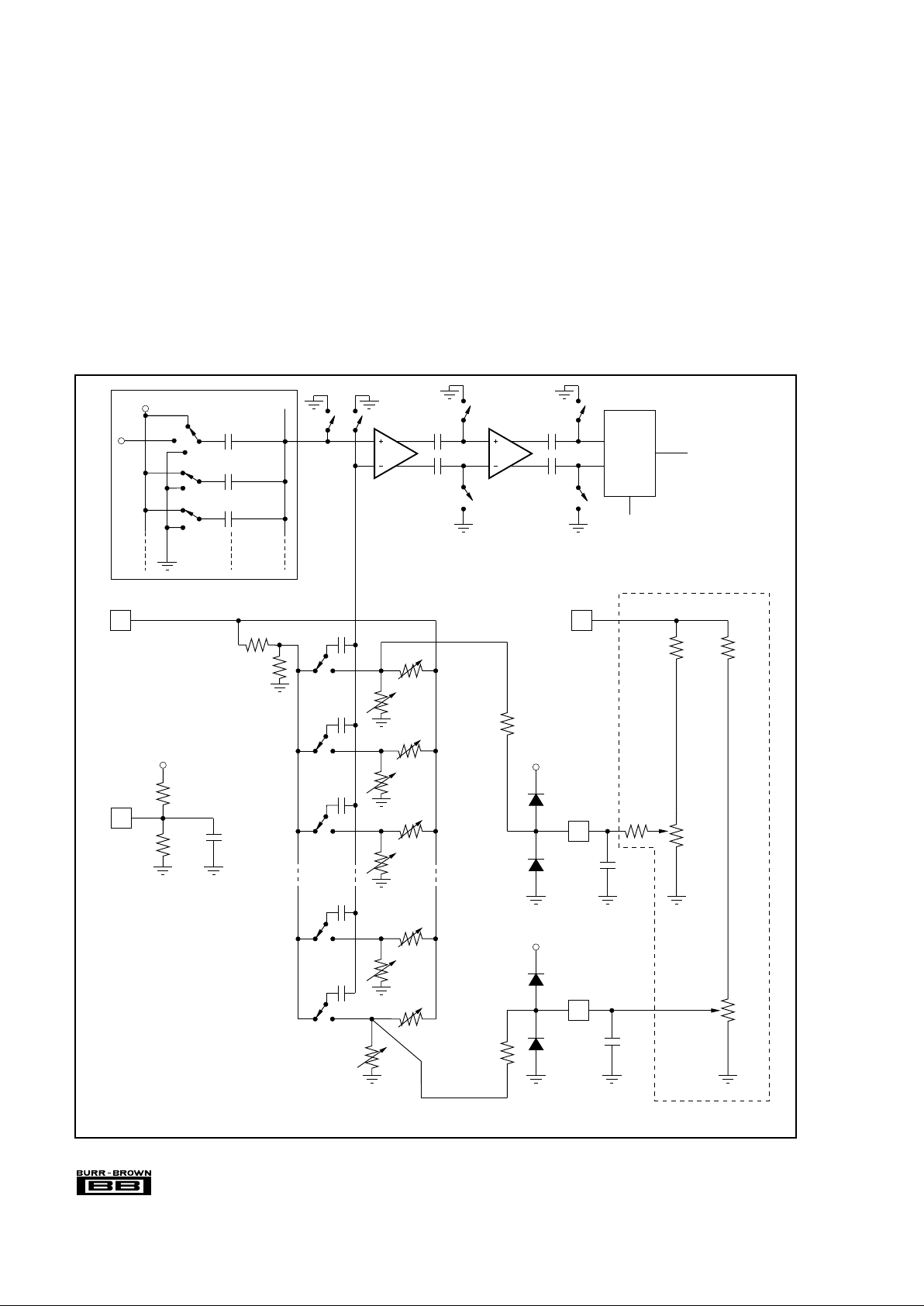

THEORY OF OPERATION

OVERVIEW

The PCM1750 is a dual 18-bit successive approximation

CMOS analog-to-digital converter with serial data outputs

designed especially for digital audio and similar applications. The single-chip converter is fabricated on a 3µ P-well

CMOS process which includes poly-poly capacitors, lasertrimmable nichrome resistors, and two layers of interconnect

metal. The dual converter employs a switched capacitor

architecture which provides separate, simultaneous S/H

(sample/hold) functions for each input channel. The separate

S/H for each channel results in a desired feature called

co-phase sampling which means that both S/H circuits are

switched at the same time into the HOLD mode to capture

their respective input signals simultaneously. This eliminates phasing errors produced by alternative architecture

ADCs which do not sample the two input channels at the

same time.

Switched binary-weighted poly-poly capacitors are used in

CDAC (capacitive digital-to-analog converter) configurations to form the successive approximation converter sec-

FIGURE 1. PCM1750 Simplified Circuit Diagram.

Page 7

7

®

PCM1750

tions of the PCM1750. Two other switched-capacitor TDACs

(trim-DACs, which employ laser-trimmed nichrome resistors) are also used to provide small correction voltages to the

latching comparators. These small correction voltages compensate for ratio matching errors of the binary-weighted

capacitors in the CDAC. The comparators contain autozeroed

preamplifier stages ahead of the latching amplifier stage to

produce a one bit, serial data stream that controls the

successive approximation algorithm for each channel of the

PCM1750.

To simplify user application, the PCM1750 includes an

internal band-gap reference with fast settling buffer amplifiers to drive the CDACs. The dual converters operate synchronously (to minimize digital noise conversion errors)

using an external system clock (normally at 1X, 2X or 4X

the standard 48kHz audio sampling rate). By operating at a

2X or 4X oversampling rate the roll-off requirement for the

input anti-aliasing filters is relaxed. For example, 1X systems typically use a 9 to 11 pole LPF (low pass filter)

whereas a 4X system can use a 6th (or smaller) order filter

when an appropriate digital filter such as the DF1750 is used

in conjunction with the sampling system. Oversampling also

has the added benefit of improved signal to noise ratio and

total harmonic distortion. Two serial outputs, one for each

input channel, provide binary-two’s-complement coded output to an optional external digital decimation filter when

over sampling operation is desired. The use of the optional

companion digital filter, the DF1750, is described later in

the installation and application sections of this product data

sheet. A separate product data sheet is also available for the

Burr-Brown DF1750 giving all the specifications and performance diagrams associated with this digital filter.

SAMPLE (TRACKING) MODE

After each conversion, the dual ADC returns to the SAMPLE

mode in order to track the input signals. The switches shown

in the simplified circuit diagram of Figure 1 will then be in

the following states: S1 connects V

IN

to C1 ; S2 to S18

connect C2 to C18 to V

REF

; H1 and H2 connect the top

plates of the capacitor arrays to analog common; and the

latching comparator is switched into its auto-zero mode by

closing AZ1 to AZ4. Notice that C1 serves two purposes: it

samples and stores the input signal V

IN

and it is the MSB of

the CDAC. Storing V

REF

on C2 to C18 creates a bipolar

offset, enabling V

IN

to cover a span from –V

REF

to +V

REF

.

The 1/f noise as well as the DC input offset voltage of the

comparator are removed by an autozeroing cycle which

* Clock from optional digital filter chip (DF1750 4x decimation filter).

P11 (CONVERT)

P4 (EXT CLK IN)

3

4

1

2

18 1916 17

*Master

System

Clock

64 1 2 3 4 5 6 7 8 9 10111213141516 50 515253 54 55 56 57 58 59 60 61 62 63 64 1 2

Bit 1

MSB

Bit 2

Bit 3

Bit 16 Bit 17

Bit 1

MSB

Bit 2

Bit 3 Bit 16 Bit 17

Bit 4

Bit 4

Bit 18

LSB

Bit 18

LSB

INTERNAL

S/H

CONTROL

SR1

SR2

SR3

P3 (SOUT L)

P12 (SOUT R)

Bit 3 test time

Bit 2 test time

Bit 1 test time

HOLD SAMPLE

FIGURE 2. PCM1750 Input/Output Timing Diagram.

Page 8

®

PCM1750 8

occurs during the SAMPLE period (see the timing diagram

shown in Figure 2). These errors are stored on the AC

coupling capacitors (CAZ1 to CAZ4, shown in Figure 1)

between the gain stages. During the SAMPLE period the

inputs to gain stages A1 and A2 and the latch are grounded

by switches H1, H2, and AZ1 to AZ4. Capacitors CAZ1 and

CAZ2 track the amplified offset voltage of gain stage A1

and capacitors CAZ3 and CAZ4 do the same for A2. At the

beginning of a conversion cycle, the autozeroing switches

open and the instantaneous amplified value of both the DC

offset voltage and the low-frequency flicker noise is stored

on the coupling capacitors to produce zero comparator offset

during a conversion cycle.

SUCCESSIVE APPROXIMATION

CONVERSION PROCESS

The timing diagram in Figure 2 illustrates the successive

approximation routine of the PCM1750. Control signals

CONVERT and CLK are derived from a master system

clock which comes from a 256f

S

(256 X the base sampling

frequency of 48kHz) clock used by the optional digital filter.

There are 64 clocks shown in the timing diagram because the

PCM1750 is shown operating at 4 times the standard 48kHz

sample rate (192kHz).

Several events occur on the rising edge of the CONVERT

command. Switches AZ1 to AZ4, H1 and H2 open and

switch S1 reconnects the MSB capacitor, C1, from V

IN

to

analog common (see Figure 1). This terminates the comparator auto-zero cycle and simultaneously switches (cophase sampling) both converters from tracking their respective input signals into the HOLD mode, thus capturing the

instantaneous value of V

IN

(with a small delay specified as

the aperture time).

At the start of a conversion cycle when S1 is switched to

analog common, the sampled input signal V

IN

will appear at

the comparator input as –V

IN

/2 due to the 2-to-1 capacitive

divider action of Cl = C2 + C3 + ... C18. In a somewhat

similar manner, V

REF

is transferred to the comparator input

as –V

REF

/2 to create a bipolar offset.

The 19-bit shift register, shown in Figure 4, controls testing

of the bits of the dual ADCs beginning with bit-1 (MSB) and

proceeding one bit at a time to bit-18 (LSB), leaving ON

those bits that don’t cause the cumulative value of the

CDAC to exceed the original input value and leaving OFF

those bits that do. Since the bits of both channels are tested

together, only one shift register is required to control both

ranks of 18 data latches.

For example, the testing of bit-2 proceeds in the following

manner. The positive pulse from the second shift register

element SR2, (see Figure 2 and 4) is applied to the bit-2 data

latch and NOR gate. The NOR gate in turn drives S2 and

switches bit-2 at the beginning of the bit-2 test interval. Note

that the bit interval must be long enough to allow both the

comparator input to settle and the comparator to respond. On

1

2

18 19 3

*Optional

Digital Filter

54

555657 58 59 606162 63 64123456

78910 11 12

T1

T4

T6

T3

T5

T7

T9

REF

T

Convert

Ext Clk In

SOUT

Bit 18

LSB

Bit 1

MSB

Bit 2

Bit 17

T8

T2

PARAMETER DESCRIPTION MIN NOMINAL MAX UNITS

T1 (1 x TREF) Convert Command High 24 33 55 % of T4

T2 (6 x TREF) S/H Acquisition Time 420 486 ns

T3 (4 x TREF) Convert to Clock time 281 326 1302 ns

T4 (3 x TREF) Master Clock Input 211 244 977 ns

T5 (1 x TREF) Clock High 24 33 55 % of T4

T6 (2 x TREF) Clock Low 45 67 76 % of T4

T7 Data Hold Time 10 ns

T8 Data Setup Time 100 ns

T9 Data Valid Time 120 154 1212 ns

TCONV (64 x TREF) Conversion Throughput Time 4.5 5.2 20.8 µs

TREF (Sample Rate /64) Ext Digital Filter Clock 70 81 326 ns

Note: The nominal timing shown in this diagram is all done automatically by the DF1750 digital filter. Only the

optional digital filter clock is required when the DF1750 is used.

FIGURE 3. PCM1750 Setup and Hold Timing Diagram.

Page 9

9

®

PCM1750

the next rising edge of CLKIN, at the end of the test interval,

the comparator latch is strobed, providing a feedback logic

level which tells the second data latch if bit-2 should be kept

or rejected. This logic level is stored in the data latch and is

passed on to switch S2 via the NOR gate on the falling edge

of the pulse from SR2. This decision to keep or reject bit-2

moves the comparator input closer to a null condition,

namely, zero potential. This sequential process continues for

bit-3 through bit-18 and nulls the comparator inputs to

within a value limited by the total system noise and the

resolution/speed of the comparator.

Notice from the timing diagram in Figure 2 that the successive approximation algorithm operates synchronously with

an external clock to minimize digitally-coupled switching

noise from corrupting either the sample-to-hold operation or

the critical comparator bit decisions. The two serial output

data streams are derived synchronously from the respective

latched comparator outputs and are available after a delay of

one CLKIN cycle as illustrated in Figure 2. The serial output

driver cells are TTL and CMOS compatible.

DIFFERENTIAL LINEARITY CALIBRATION

To understand the calibration of the PCM1750 it is necessary to discuss some of the characteristics of poly-poly

capacitors. Poly capacitors are known to have equal or better

stability and matching properties when compared to other

precision components such as thin film resistors. On a well

controlled process, ratio matching is typically 0.1%— a

very respectable number for an untrimmed component. Even

more impressive is their ratio tracking versus temperature of

approximately 0.1ppm/°C.

Achieving DLE (differential linearity error) of less than 1/2

LSB at the 16-bit level requires ratio matching of the more

significant bits to about 0.001%. Since the untrimmed ratio

matching of poly capacitors is about two orders of magnitude larger than this requirement, a one-time factory calibration of the upper bits is required as described in the next

section. Next, consider the effect of temperature due to the

ratio tracking of 0.lppm/°C. Over a 50°C span, DLE will

change less than 1LSB at 18-bits; therefore, recalibration at

temperature extremes is not necessary. Because of this

excellent stability versus temperature (and versus time, also),

the one-time factory calibration to correct initial DLE is

more than satisfactory in meeting the accuracy requirements

of the PCM1750.

TDAC OPERATION

Operation of the TDAC (trim DAC), which is laser trimmed

at the wafer level, is described using bit-1 as an example.

Switch S1T (see Figure 1) operates between two voltage

levels—a reference level set by voltage divider Ra, Rb and

a laser trimmable level set by R1a, R1b. The differences of

these two levels is coupled by capacitor C1T to the minus

input of the comparator to generate a correction voltage for

DQ

LR

DQ

R

SR

2

DQ

L

R

DQ

L

R

DQ

R

SR

18

DQ

L

R

DQ

L

R

DQ

S

SR

1

DQ

L

R

DQ

R

SR

19

Control

Logic

To MSB

Switches Left

To Bit 2

Switches Left

To Bit 18

Switches Left

To MSB

Switches Right

To Bit 2

Switches Right

To Bit 18

Switches Right

Serial Data

From Latching

Comparator

Serial Data

From Latching

Comparator

Data

Latches

Left Channel

19-Bit

Shift

Register

Data

Latches

Right Channel

FIGURE 4. PCM1750 Successive Approximation Logic Diagram.

Page 10

®

PCM1750 10

A Gain Change

Rotates

Transfer

Function

Offset Change

Shifts

Transfer

Function

1FFFF

H

1FFFE

H

00001

00000

H

3FFFF

H

20001

H

20000

H

Digital Output

* Gain drift (mostly due to reference drift) rotates the transfer function

around the bipolar zero code (00000 ).

NOTE: As the power supply voltages change (mostly due to the +V

supply), the transfer function rotates around BPZ. See the power

supply rejection specification in the spec table.

0.00V

+2.749979–20.98µV–2.75

HEX

H

bit-1. The switches of the CDAC and the switches of the

TDAC operate concurrently with each other, that is, when a

decision is made to keep or reject bit-1, the same decision is

made for the correction voltage for bit-1. Even though the

ratio stability of the nichrome resistors used in the TDAC

may not be as good as the poly capacitors, it is inconsequential because the correction voltage of each bit has a limited

range of adjustment.

The DLE at the major carry (a code change from 111...111

to 000...000; in binary two’s complement coding) is typically ±1/2 LSB at the 16-bit level, which is sufficient to

provide 90dB SNR and –30dB low level distortion (–60dB

input). For applications requiring less DLE at the major

carry, a pin is provided for each channel to make an external

MSB adjustment.

DISCUSSION

OF SPECIFICATIONS

RESOLUTION AND DYNAMIC RANGE

The theoretical resolution of the PCM1750 is 18-bits. The

maximum possible number of output codes or counts at 18bits is 262,144 or 108dB (calculated by raising 2 to the 18th

power). The relative accuracy of any A/D converter, however, is more a function of it’s absolute linearity and signalto-noise ratio than how many bits of resolution it has. These

more pertinent specifications are described later in this

section.

Dynamic range, as it is usually defined for digital audio

converters, is the measure of THD+N at an effective input

signal level of –60dB referred to 0dB. For the PCM1750 this

value is typically 90dB and a minimum of 88dB (for audio

bandwidth = 20Hz to 24kHz, THD+N at –60db = –30 db typ,

–28dB max; f

IN

= 1kHz and fS = 192kHz). Resolution is also

commonly used as a theoretical measure of dynamic range,

but it does not take into account the effects of distortion and

noise at low signal levels.

ANALOG INPUT RANGE

The analog input range for the PCM1750 is a bipolar ±2.75V

(nominal). Table I gives the precise input/output and voltage/code relationships for the PCM1750. Figure 5 shows

these same relationships in a graphical format. It should be

noted that the computed voltage input levels represent center

values (the midpoint between code transitions). Output coding is in binary two’s complement.

DIGITAL OUTPUT ANALOG INPUT VOLTAGE INPUT

262144 LSBs Full Scale Range 5.50000000V

1 LSB Minimum Step Size 20.98083496µV

1FFFF

HEX

+Full Scale +2.74997902V

00000

HEX

Bipolar Zero 0.00000000V

3FFFF

HEX

Bipolar Zero –1LSB –0.00002098V

20000

HEX

–Full Scale –2.75000000V

TABLE I. Analog Input to Digital Output Relationships.

From Figure 5, the effects of offset and gain errors can be

visualized. These errors can change value in response to

changes in temperature and/or supply voltage. In addition,

gain error (or the full scale range, FSR) changes in direct

proportion to the VREF

IN

voltage value.

SAMPLE AND HOLD PARAMETERS

Aperture Delay and Uncertainty

Aperture delay is the time required to switch from the

SAMPLE to HOLD mode. This time is typically 10ns for the

PCM1750 and it is constant. Aperture uncertainty (jitter) is

the amount of uncertainty associated with the aperture delay.

Aperture uncertainty affects the overall accuracy of the

converter and is greatest at the maximum input frequency of

the converter. The formula for determining the maximum

input frequency (f

MAX

) for a given error contribution due to

aperture uncertainty is: f

MAX

=(2XπXt

jitter

X 2N)–1 where

t

jitter

is the RMS aperture uncertainty and 2N is the desired

SNR (signal-to-noise ratio) expressed in total number of

quantization levels. A 15-bit SNR, therefore, would be

expressed as 2

15

or 32768. Using the typical PCM1750

aperture jitter of 50ps

rms

and an SNR at the 15-bit level, f

MAX

= (2 X π X 50ps X 32768)–1 or 97.1kHz. This matches very

closely with the rated dynamic accuracy of the PCM1750

where THD+N = –88dB max. This means the typical aperture jitter of PCM1750 only becomes a factor when input

signals to it exceed 97kHz and/or an SNR greater than 15

bits is desired.

Input Bandwidth

The full power bandwidth of the PCM1750 is that input

frequency above which significant distortion is observed

(THD+N > 10-bits or –60dB for a full scale input signal). In

the data sheet, this number is specified as typically being

500kHz. In wideband operation (when no digital filter is

used) the additional full power bandwidth of the PCM1750

FIGURE 5. Analog Input to Digital Output Diagram.

Page 11

11

®

PCM1750

can be used to purposely alias a band-limited signal down

into the baseband of the converter. This technique is called

undersampling and can be used to directly down-convert an

intermediate frequency riding on a much higher carrier

frequency.

DIGITAL I/O AND TIMING

Input/Output Logic Compatibility

Digital logic on the PCM1750 is CMOS compatible. Digital

outputs on the PCM1750 are capable of driving a minimum

of two standard TTL input loads.

Digital output coding is in binary two’s complement. Table I

gives the precise input/output voltage/code relationships for

the PCM1750. Figure 5 shows these same relationships in a

graphical format.

Convert Command and External Clock Input

A conversion is initiated on its positive going edge of the

convert command. Although the convert command can return low at any time (prior to 50ns before the rising edge of

the 19th clock), a typical convert command pulse width of

81ns (as called out in Figure 3) is specified for a 192kHz

sample rate (f

S

). The reason for a pulse width spec is to

reduce problems associated with digital logic feedthrough

noise. The return of convert command to a logic low level in

the specified time interferes least with the successive approximation process. Also, it should be noted that putting

fast logic edges (<5ns) on convert command (P11) and the

external clock input (P4) may cause logic feedthrough to the

analog stages in the converter and will result in added

distortion during the sampling and conversion process.

Using the optional DF1750 digital filter provides adequately

slow transitions to maintain full specification performance.

If necessary, an external RC, on the convert command line

may be used to slow fast logic edges.

As with the convert command, the external clock input is

positive edge triggered and is not duty-cycle dependent

other than to improve digital feedthrough noise immunity. A

50% duty cycle clock can be used instead of 33% if desired.

Refer to Figure 3 for recommended timing relationships.

Regardless of what clock duty cycle is used, all operations

relating to valid data clocking should be synchronized to the

rising edge of the clock input.

Although there is a maximum conversion time called out in

the specification table, the PCM1750 can have a considerably longer conversion cycle. Droop of the internal capacitors will ultimately determine what the true maximum

conversion time can be. The min/typ/max times shown in

Figure 3 are based on minimum sample rate of 48kHz, a

typical of 192kHz, and a maximum of 222kHz. All specifications are tested at 192kHz. The minimum sample rate

assumption is based on clock periods that increase as time

between convert commands increases. Any sample rate

down to near DC can be utilized by observing maximum

clock cycle requirements and spacing convert commands to

achieve lower sample rates. This means that the time interval

T2 shown in Figure 3 does not have a maximum value.

Clock Lockout

Any number of clocks can be given to the PCM1750 beyond

the 19 required for normal operation. If a continuous clock

is used, all clocks beyond the 19th are gated off by the

PCM1750’s internal logic until the next positive going edge

of the convert command. The converter also goes into the

sample (track) mode starting on the positive edge of the 19th

clock until the next positive edge of the convert command,

regardless of how many additional clocks are offered. The

ideal operation of the converter stops the clock input after

the 19th during this critical signal acquisition time. This is

the timing shown in Figure 3 . The critical timing aspect that

must be observed if a clock input other than the recommended is used, is that ample time following the positive

edge of convert command proceed the next rising clock

edge. If this time is shortened, the most important bit-1

(MSB) decision, which is finalized on the first clock edge

after convert command, will be adversely affected. In other

words, the clock input cannot have a rising edge during the

time interval T3 shown in Figure 3.

SIGNAL-TO-NOISE RATIO

Another specification for A/D converters is signal-to-noise

ratio (SNR). For this measurement, a full-scale 1kHz signal

is applied and the sampling rate of the PCM1750 is set at

192kHz. An FFT is performed on the digital output and the

noise power in the non-harmonic audio-bandwidth frequency

bins (20Hz to 24kHz) is summed and expressed in relation

to the full-scale input signal.

One advantage of using the PCM1750 in this oversampled

mode with the optional DF1750 digital decimation filter is

that the converter noise is spread over the full 0Hz to 96kHz

passband and then suppressed by the digital filter stopband

attenuation (from 24kHz to 96kHz). This effectively increases the SNR of the PCM1750 by 6dB when it is used as

an audio bandwidth converter. The other advantage is that

the need for a higher-order anti-aliasing input filtering is

greatly reduced.

THD + N

The key specification for the PCM1750 is total harmonic

distortion plus noise (THD+N). In terms of signal measurement, THD+N is the ratio of Distortion

RMS

+ Noise

RMS

/

Signal

RMS

expressed in dB. For the PCM1750, THD+N is

100% tested at all three specified input levels using the

production test setup shown in Figure 6. For this measurement, as with the SNR test, a full-scale 1kHz signal is

applied and the sampling rate of the PCM1750 is set at

192kHz (which is 4X the standard digital audio sample rate

of 48kHz). An FFT is performed on the digital output and

the total power in all audio-bandwidth frequency bins (20Hz

to 24kHz) is summed and expressed in relation to the fullscale input signal.

For the audio band, the THD+N of the PCM1750 is essentially flat for all frequencies and input signal levels. In the

Typical Performance Curves THD+N versus Frequency

Page 12

®

PCM1750 12

plots are shown at four different input signal levels (with and

without a 4X decimation filter): 0dB, –20dB, –40dB, and –

60dB.

CHANNEL SEPARATION

To test channel separation a 1kHz signal sampled at 192kHz

is placed on one input of the PCM1750 while the other input

is held at 0V. An FFT is performed on the idle (0V) channel

and the result checked to insure that the 1kHz tone is

suppressed by a minimum of 96dB.

GAIN AND OFFSET ERRORS

Initial gain and bipolar offset errors are laser trimmed at the

wafer level and 100% final tested to insure compliance with

the electrical specifications. Bipolar offset errors can be

further reduced to zero by using the optional offset adjustment circuitry shown in the connection diagram (Figure 7).

Gain errors can be adjusted by varying V

REF

to either

channel of the converter. This is accomplished by either

using an adjustable external reference or by placing buffer

amplifiers with adjustable gain between VREF

OUT

and

VREF

IN

as shown in Figure 8a.

INTEGRAL AND DIFFERENTIAL LINEARITY

DC Linearity Testing

The absolute linearity of the PCM1750 is on the order of 15

bits or more as can be seen from the THD versus Frequency

plots in the Typical Performance Curves. Not every code in

the converter must be 15-bit linear to achieve the specified

THD+N performance, but a very high percentage will be

that linear. The same observation also applies to differential

linearity errors in the PCM1750. Because the PCM1750 is

not 100% tested for DC linearity specifications, no minimum or maximum specifications are given for integral or

differential linearity errors.

No Missing Codes Operation

A no missing codes specification is not given for the

PCM1750 for the same reasons as given above. The

PCM1750, however, typically has fewer than 16 codes (less

than 0.01%) missing at a 14-bit resolution level. A 100% no

missing codes specification cannot be maintained above the

12-bit level, although this has very little impact on overall

dynamic performance (THD+N). The few missing codes

that do occur at higher resolution levels are at the bit-2 and

lower major carry transitions of the converter. There are

typically no missing codes (at 14 bits) around the critical

bipolar zero operation zone (±1/8 of full scale range around

bipolar zero or 0V). The critical bipolar differential linearity

error can be reduced from its initial value to zero using the

optional MSB adjustment circuitry shown in the connection

diagram (Figure 7).

REFERENCE

The gain drift of the PCM1750 is primarily due to the drift

associated with the reference. Better drift performance can

be achieved using an external reference like the ones explained in the applications section (Figures 8b, 8c). The

Typical Performance Curves plot of V

REF

Output versus

Temperature shows the full range of operation including

initial error and typical gain drift. Pertinent performance

data are found in the electrical specification table.

Reference Bypass

Both P18 and P25 (VREF

IN

) should be bypassed with a

10µF to 47µF tantalum capacitor. If there are important

system reasons for using the PCM1750 reference externally,

the outputs of P19 and P24 must be appropriately buffered,

and bypassed (see Figure 8).

FIGURE 6. PCM1750 Production Test Setup.

PCM1750

Low Pass

Filter

FTT

Analyzer

High

Accuracy

Sine Wave

Generator

Timing

Control

f = 192kHz

f = 1kHz

Serial Data Left

Serial Data Right

IN

V

INL

INR

V

s

Parametric

Tester

Page 13

13

®

PCM1750

POWER SUPPLY REJECTION

Because of the architecture of the PCM1750, power supply

rejection varies with input signal size. The spec table value

is expressed in the relative terms of percent of V

IN

per

percent change of the supply voltage. The PSR versus

Frequency plot in the Typical Performance Curves show

PSR expressed versus an increase in power supply ripple

frequency.

PERFORMANCE OVER TEMPERATURE

Specification Temperatures

All critical specifications are tested at 25°C. The drift

specification temperature range is from 0°C to +70°C. The

PCM1750 will operate over the wider temperature range of

–40°C to +85°C.

Gain and Offset Drift

Although the PCM1750 is primarily meant for use in dynamic applications, specifications are also given for more

traditional DC drift parameters such as temperature gain and

offset drift. The primary cause of drift in the PCM1750 is the

bandgap reference. Much lower gain drift can be realized if

necessary by using any circuit similar to the external reference circuits shown in Figure 8. Also, refer to the Typical

Performance Curves of V

REF

Output versus Temperature.

Dynamic Performance

Dynamic performance is predominated by the absolute linearity of the PCM1750. Because of the excellent ratio

tracking versus temperature of poly-poly capacitors, there is

virtually no change in dynamic performance of the converter

over temperature (primarily THD+N). The dynamic specifications over temperature cannot be guaranteed, however, as

they are not 100% tested.

INST ALLATION

ANTI-ALIASING FILTER

To prevent unwanted input signals from being aliased into

the passband of the converter, it is necessary to suppress all

out of band signals above 1/2 the sampling frequency of the

ADC by using a low-pass filter. The requirement for an antialiasing filter, however, can be reduced by using oversampling

techniques. By raising the sample rate of the converter by a

factor of 2 or even 4, the roll off of the anti-aliasing filter can

be reduced. In Figure 9, a 6th order, linear-phase, antialiasing filter is implemented using low-cost dual audio op

amps. This filter will suppress frequencies above 96kHz by

80dB. For many applications a 4th or 2nd order anti-aliasing

filter will be adequate when using the PCM1750 in the 4x

oversampling mode.

FIGURE 7. PCM1750 Connection Diagram.

+

10µF*

or

47µF

0.1µF

150kΩ

25kΩ

47kΩ

25kΩ

+

10µF*

or

47µF

10µF*

+

+5V

–5V

= Connect directly to ground plane

Optional External Adjust

–V

+V

SOUT Left

Ext Clk In

+V

+V

+V

DCOM

ACOM

DCOM

Convert

SOUT Right

+V

–V

Offset Adj Left

MSB Adj Left

V Left

Ref In Left

Ref Out Left

ACOM

Ref Com

Ref Bypass

ACOM

Ref Out Right

Ref In Right

V Right

MSB Adj Right

Offset Adj Right

IN

IN

A

A

D

D

D

A

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

150kΩ

25kΩ

47kΩ

25kΩ

Optional External Adjust

10Ω

10Ω

10µF*

+

220pF

150Ω

220pF

47kΩ

0.01µF

0.01µF

0.01µF

0.01µF

47kΩ

(low

leakage,

ceramic)

* High quality tantalum.

28

27

26

25

24

23

22

21

20

19

18

17

16

15

150Ω

Page 14

®

PCM1750 14

INPUT SIGNAL CONDITIONING

RC Input Circuit

Note the 150Ω resistors and 220pF capacitors on each

analog input as shown in the connection diagram (Figure 7).

This input circuit configuration is required to achieve optimum SNR performance of the PCM1750. Various other

component values will yield satisfactory results, but the

resistor should never exceed 200Ω.

Buffer Amplifier

To avoid introducing distortion, the PCM1750 input must be

driven by a low active impedance source (op amps such as

the NE5532, Burr-Brown OPA2604, or equivalent are ideal).

EXTERNAL ADJUSTMENTS

The simplified circuit diagram (see Figure 1) shows one of

two complete channels on the PCM1750. The input switched

capacitors, trim DAC and comparator are detailed. The trim

DAC switches are activated whenever the corresponding bit

is chosen during the successive approximation routine. The

first 12 bits of the ADC have corresponding trim DAC

circuits. The R1a to R12a and R1b to R12b resistors can be

laser trimmed at the wafer level if necessary to correct for

any nonlinearities. The nominal voltage for the internally

generated V

REF

is 2.75V and it is a relatively low impedance, buffered voltage output. It should be noted that just

the act of connecting the optional adjustment circuits will

affect the MSB DLEs and bipolar offsets since it is unlikely

that the initial potentiometer settings (even if centered)

would match the factory trimmed null potentials. If connected, the potentiometers must be properly adjusted.

MSB Adjust

The MSB adjust pin connects to the center of the R1a/R1b

resistive divider for bit-1. After laser trimming this point is

nominally 100mV. All the MSB and offset adjust pins

should be connected to ground using a 0.01µF capacitor,

especially if traces to the potentiometers are long. If the

adjust pins are not used, they should still be bypassed to

ground.

Since there are internal 5kΩ resistors and clamp diodes to

both ground and +5V on the MSB and offset adjust pins,

there are obvious limits to their range of adjustment. With a

nominal internal voltage on these points of +100mV, there

will be a greater limitation in making negative adjustments

than positive. A negative voltage at either adjustment pin,

however, is acceptable up to one diode drop (–0.6V) below

ground.

The preferred method of MSB DLE adjustment is to input a

small level signal and adjust for minimum THD+N.

Offset Adjust

The offset adjust switch (S

OFF

) position is controlled by

whether the ADC is in the sample or hold mode. Switching

from sample to hold effectively allows any charge offsets

associated with the sampling process to be eliminated.

Grounding the input to the converter as far ahead of the A/D

as possible (in front of the anti-aliasing filter for example)

and then adjusting the bipolar zero error will remove the

offsets associated with the entire sampling system.

LAYOUT CONSIDERATIONS

Power Requirements

Noise on the power supply lines can degrade converter

performance, especially noise and spikes from a switching

power supply. Appropriate supplies or filters must be used.

Although the PCM1750 positive supplies have separate

digital and analog +5V, for most applications the +5V

digital supply pins should be connected to the +5V analog

supply. If they aren’t connected together, a potential latchup

condition can occur when the power supplies are not turned

on at the same time. If one supply pin is powered and the

other is not, the PCM1750 may latch up and draw excessive

current. In normal operation, this is not a problem because

both +V

A

and +VD should be connected together. However,

during evaluation, incoming inspection, repair, etc., where

the potential of a “hot” socket exists, care should be taken to

power the PCM1750 only after it has been socketed.

All supplies should be bypassed as shown in Figure 7. The

bypass capacitors should placed as close to their respective

supply pins as possible. Additional .01µF capacitors may be

placed in parallel with the larger value capacitors to increase

high-frequency rejection, but generally they are not required

when high quality tantalums are used. The 0.1µF capacitor

between P21 and P22 should be a low leakage type (such as

ceramic) and must be put as close to these pins as possible

to reduce noise pickup.

FIGURE 8a. Circuit for External Gain Adjustment Using the

Internal Reference.

10µF

+

18

1kΩ

19

1/2 5532

VREF

VREF

INR

OUTR

10µF

+

25

1kΩ

24

1/2 5532

VREF

VREF

INL

OUTL

39kΩ

+5V

–5V

+5V

–5V

50kΩ 50kΩ

1µF

+

1µF

+

39kΩ

Page 15

15

®

PCM1750

The PCM1750 is sensitive to supply voltages outside the

absolute maximum ratings shown in the specification tables.

Do not exceed –8V on the negative supplies at any time or

irreversible damage may occur. Note the 10Ω resistors in

series with each –5V supply line (shown in Figure–7) to help

protect the part from severe damage if the supplies are overranged momentarily.

Grounding Requirements

Because of the high resolution and linearity of the PCM1750,

system design problems such as ground path resistance and

contact resistance become very important.

The ACOM and DCOM pins are separated internally on the

PCM1750. To eliminate unwanted ground loops, all commons (both analog and digital) should be connected to the

same low-impedance ground plane. This should be an analog ground plane separate from other high-frequency digital

ground planes on the same board. If the analog and digital

commons of the PCM1750 are connected to different ground

planes, care should be taken to keep them within 0.6V of

each other to insure proper operation of the converter.

A ground plane is usually the best solution for preserving

dynamic performance and reducing noise coupling into

sensitive converter circuits. Where any compromises must

be made, the common return of the analog input signals

should be referenced to the ACOM pins. This will prevent

voltage drops in the power supply returns from appearing in

series with the input signal.

Coupling between analog input and digital lines should be

minimized by careful layout. For instance, if the lines must

cross, they should do so at right angles. Parallel analog and

digital lines should be separated from each other by a pattern

connected to common.

If external MSB and offset adjust potentiometers are used,

the potentiometers and related resistors should be located as

close to the PCM1750 as possible.

Minimizing “Glitches”

Coupling of external transients into an analog-to-digital

converter can cause errors which are difficult to debug. Care

should be taken to avoid glitches during critical times in the

sampling and conversion process. Since the PCM1750 has

an internal sample/hold function, the signal that switches it

into the HOLD state (CONVERT going HIGH) is critical, as

it would be on any sample/hold amplifier. The CONVERT

rising edge should have minimal ringing, especially during

the 20ns after it rises.

APPLICATIONS

USING A DIGITAL FILTER

A 4x decimation filter is available for the PCM1750 called

the DF1750. It is available in a 28-pin DIP or a 40-pin SOIC

package. The use of this filter greatly eases the implementation of the PCM1750 in audio band applications.

10µF

+

18

1/2 5532

10µF

+

25

1/2 5532

VREF

INL

VREF

INR

MC1403

+5V

2.5V

+

24

VREF

OUTL

+

19

VREF

OUTR

1µF

1µF

2.75V

2.75V

+

1µF

+

1µF

909Ω

909Ω

1kΩ

1kΩ

10kΩ

10kΩ

3

1

2

0.1µF

26.36kΩ

1/2 5532

1/2 5532

10kΩ

REF102

+15

10µF

+

18

10µF

+

25

VREF

INL

VREF

INR

+

24

VREF

OUTL

+

19

VREF

OUTR

1µF

1µF

2.75V

2.75V

6

8

10V

4

2

+

1µF

FIGURE 8b. External Reference Circuit Using Standard

2.5V Reference.

FIGURE 8c. Low Noise, Low Drift External Reference

Circuit.

Page 16

®

PCM1750 16

FIGURE 9. Complete Sampling A/D Circuit with Anti-aliasing and Digital Filter, (44.1kHz output data rate).

150

47k

47k

47k

150k

150k

25k

25k

25k

Ω

Ω

Ω

ΩΩΩ

Ω

Ω

Ω

1.00MΩ

10

10

Ω

Ω

10

µ

F

+

+

+

+

+5V

+5V

+5V

–5V

10pF

16.9344 MHz

10

10

0.01

0.01

0.1

µ

µ

µ

µ

µ

F

F

F

F

F

220pF

220pF

–VA

+VA

SOUTL

CLK

+VD

+VD

+VD

DCOM

ACOM

DCOM

CONVERT

SOUTR

+VA

–VAOFF ADJ

MSB ADJ

VINR

VREF IN

VREF OUT

ACOM

REF CAP

REF COM

ACOM

VREF OUT

VREF IN

VINL

MSB ADJ

OFF ADJ

CKO

SCSL1

SCSL2

TEST

2DS

IMOD

VSS2

DINRCCBBC

IBCK

IBO

DINL

VDD2 OW20

FSEN

LRCK

LRPOL

OBPOL

WDCK

VSS1

BCK

DOUT

MUTE

XTI

XTO

CKEN

VDD1

Interleaved

Digital Output

PCM1750P

DF1750P

(28-PIN DIP PKG)

AGND DGND

25kΩ

47kΩ

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

15

16

17

18

19

20

21

22

23

24

25

26

27

28

10pF

10

µ

F

3.92k 1.33k

3.92k

7.32k

7.32k

7.32k

7.32k

A2*

A1*

1000pF

1000pF

1000pF

A1*

A3*

3.48k

1000pF

A2*

1000pF

1000pF

1.33k

A5*

A5*

A6*

A4*

A4*

3.92k

3.48k

1000pF

7.32k

7.32k

1000pF

1000pF

1000pF

7.32k

7.32k

1.33k

3.92k

1.33k

1000pF

3.48k

3.48k

A6*

A3*

ΩΩ

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Right Channel

Analog Input

Left Channel

Analog Input

3

2

1

7

6

5

7

6

5

7

6

5

3

2

1

7

6

5

7

6

5

3

2

1

3

2

1

3

2

1

3

2

1

7

6

5

Ω

150Ω

0.01µF

0.01µF

1000pF

*A1 - A6 = 1/2 Burr-Brown OPA2604 with ±15V supplies (or NE5532 equivalent with ±5V supplies).

Page 17

17

®

PCM1750

USING AN EXTERNAL REFERENCE

Normally VREF

OUT

is connected directly to VREFIN. The

typical value for V

REF

versus Temperature is shown in the

Typical Performance Curves. If better drift or power supply

rejection performance is desired, one of the external reference circuits shown in Figures 8b and 8c can be used. Note

that the decoupling capacitors are still connected to VREF

IN

.

External gain adjustment is now possible by using the

variable output options available on some precision voltage

references or by varying the gain on external buffer amplifiers. The range of acceptable external references is from

+2.0V to +V

A

– 2.0V, with 2.5V types being the most

commonly available. Full scale input voltage range will be

±VREF

IN

(a +2.5V VREFIN results in a ±2.5V input range).

If an external reference is used, P19 and P24 must be

bypassed with at least 1µF capacitors.

SAMPLING A/D SYSTEM

Figure 9 is a partial schematic of the demonstration fixture

for the PCM1750 (orderable by model number DEM1133).

It shows the implementation of (1) a 6th order, linear-phase,

anti-aliasing filter (22kHz low-pass); (2) the PCM1750P

A/D converter; and (3) a 4x digital decimation filter called

the DF1750P. Not shown on this schematic, but included on

the demo fixture, are latched parallel data outputs with

strobe and a serial digital interface format (SPDIF) data

transmitter. Also included on the DEM1133 are user breadboard areas for application specific circuit implementation.

CONNECTION TO DSP WITH DIGITAL FILTER

The PCM1750 and DF1750 combination can be connected to

the serial ports of most popular DSP processor ICs (such as

those made by AT&T, Motorola, TI, and AD) by adding a

small amount of external glue logic. Figures 10 and 11 show

the timing diagram and schematic for this interface.

To use this interface, the DSP processor IC must be configured

for 32-bit word inputs. The glue logic generates a flag bit, as

the first bit of the 32-bit word, that signifies either left or right

channel data. The flag bit will be low for left channel data and

high for right channel data.

The DF1750 can be configured for either 16- or 20-bit data,

although only 16-bit data is shown in Figure 10. After the data

is transferred into the DSP processor IC, it must be shifted

toward the LSB by one bit in order to compensate for a clock

delay in the glue logic.

FIGURE 10. PCM1750/DF1750 To DSP IC Timing Diagram.

LRCK

(LRPOL = H)

WDCK

Frame Syn L

Flag Enable

Bit Clock

Data to DSP

DATA DATA

Channel Flag (Right Channel)

Page 18

®

PCM1750 18

FIGURE 11. PCM1750/DF1750 to DSP IC Schematic.

98U3

74HC74

+5V

+5V

D

Q

PR

CQ

13

10

D

Q

CL

CQ

1

4

5

6

U3

74HC74

+5V

+5V

98U2

74HC74

+5V

D

Q

CL

CQ

13

10

D

Q

CL

CQ

1

4

5

6

U2

74HC74

+5V

2

3

12

11

2

3

12

11

PR

PR

PR

U4

74HC08

U4

74HC08

U5

74HC32

6

3

3

1

2

4

5

1

2

Data In

Frame

Sync

Bit

Clock

WDCK

OBPOL

+5V

DOUT

BCK

LRCK

LRPOL

U1

74HC04

2

1

TMS32020/C20/C25

DSP56001

ADSP-2102/2105

DF1750

98U3

74HC74

+5V

+5V

D

Q

PR

CQ

13

10

D

Q

CL

CQ

1

4

5

6

U3

74HC74

+5V

+5V

98U2

74HC74

+5V

D

Q

CL

CQ

13

10

D

Q

CL

CQ

1

4

5

6

U2

74HC74

+5V

2

3

12

11

2

3

12

11

PR

PR

PR

U4

74HC08

U4

74HC08

U5

74HC32

6

3

3

1

2

4

5

1

2

Data In

ILD

ICK

WDCK

OBPOL

+5V

DOUT

BCK

LRCK

LRPOL

U1

74HC04

2

1

DSP16/DSP32C

DF1750

CL

CL

Loading...

Loading...