Page 1

INTEGRATED CIRCUITS

DATA SH EET

PCF8801

LCD driver for 140 × 2 segments

Product specification

File under Integrated Circuits, IC12

2000 Feb 04

Page 2

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

FEATURES

• Single-chip LCD controller/driver

• Fixed backplane multiplexing at a rate of 1 : 2

• Internal LCD bias generation (0.5VDD)

• 140 segment outputs configured to drive seven

40-segment characters

• On-chip oscillator with one external resistor

• Wide power supply range (2.7 V up to 5.5 V)

• Low power consumption

• Compatible with most microprocessors/microcontrollers

• 1 MHz serial bus interface (280-bit shift register)

• Easily cascaded for large LCD applications (two

cascade directions possible)

• Compatible with chip-on-glass technology

• Manufactured by silicon gate CMOS process.

GENERAL DESCRIPTION

The PCF8801 is a peripheral device which interfaces a

multiplexed Liquid Crystal Display (LCD) having two

backplanes and up to 140 segments. It generates drive

signals at a multiplex rate of 1 : 2 allowing seven

40-segment (5 x 8) characters to be driven.

The chip can easily be cascaded for larger LCD

applications,andthedirectionoftheinformationflowinthe

cascadecanbeselected.ThePCF8801iscompatiblewith

most microprocessors/microcontrollers and

communicates via a serial bus interface comprising a

280-bit shift register.

Theoutputsaremultiplexedbyaclocksignalgeneratedby

the internal oscillator which needs only one external

resistor.Cascadeapplicationsonlyrequiretheclocksignal

to be generated by the first device with the internal

oscillators in the other devices disabled.

The PCF8801 is designed for chip-on-glass applications.

It has a narrow package with raised points (bumps) for

easy assembly on to LCD glass.

ORDERING INFORMATION

TYPE

NUMBER

PCF8801U − chip with bumps in tray −

NAME DESCRIPTION VERSION

PACKAGE

2000 Feb 04 2

Page 3

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

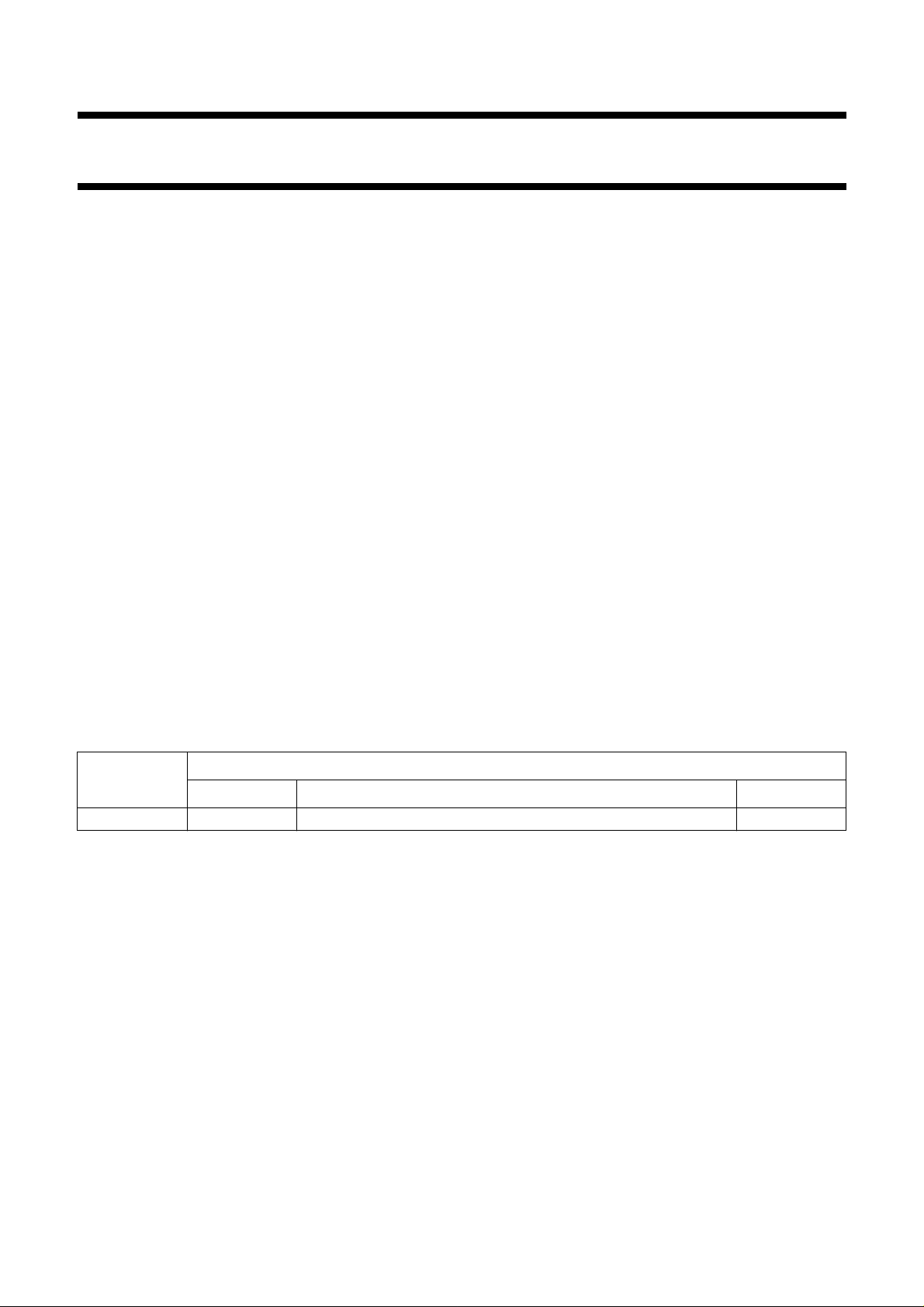

BLOCK DIAGRAM

handbook, full pagewidth

LDPI

LDNI

DI1

DO1

DIR

CLKI

CLKO

DO2

280-BIT

BI-

DIRECTIONAL

SHIFT

REGISTER

SH1_1

SH140_2

280-BIT

OUTPUT

REGISTER

IO1_1

IO140_2

OUTPUT

MULTIPLEXER

OM1

OM140

ROUTING

BLOCK

OUTPUT

DRIVERS

LDPO

LDNO

S1

S140

DI2

OSCI

OSCO

INT_OSCO

REXT

LCD BIAS GENERATOR

V

÷2

÷4

INTERNAL OSCILLATOR POWER-ON-RESET

T2 T3

T1

PCF8801

V

V

SS1

SS3VSS5VDD1

V

SS2VSS4

COMMON

M

V

V

DD2VDD4

BACKPLANE DRIVERSFRAME GENERATOR

DD3VDD5

MID

Fig.1 Block diagram.

COM1

COM2

RESET

MGL915

2000 Feb 04 3

Page 4

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

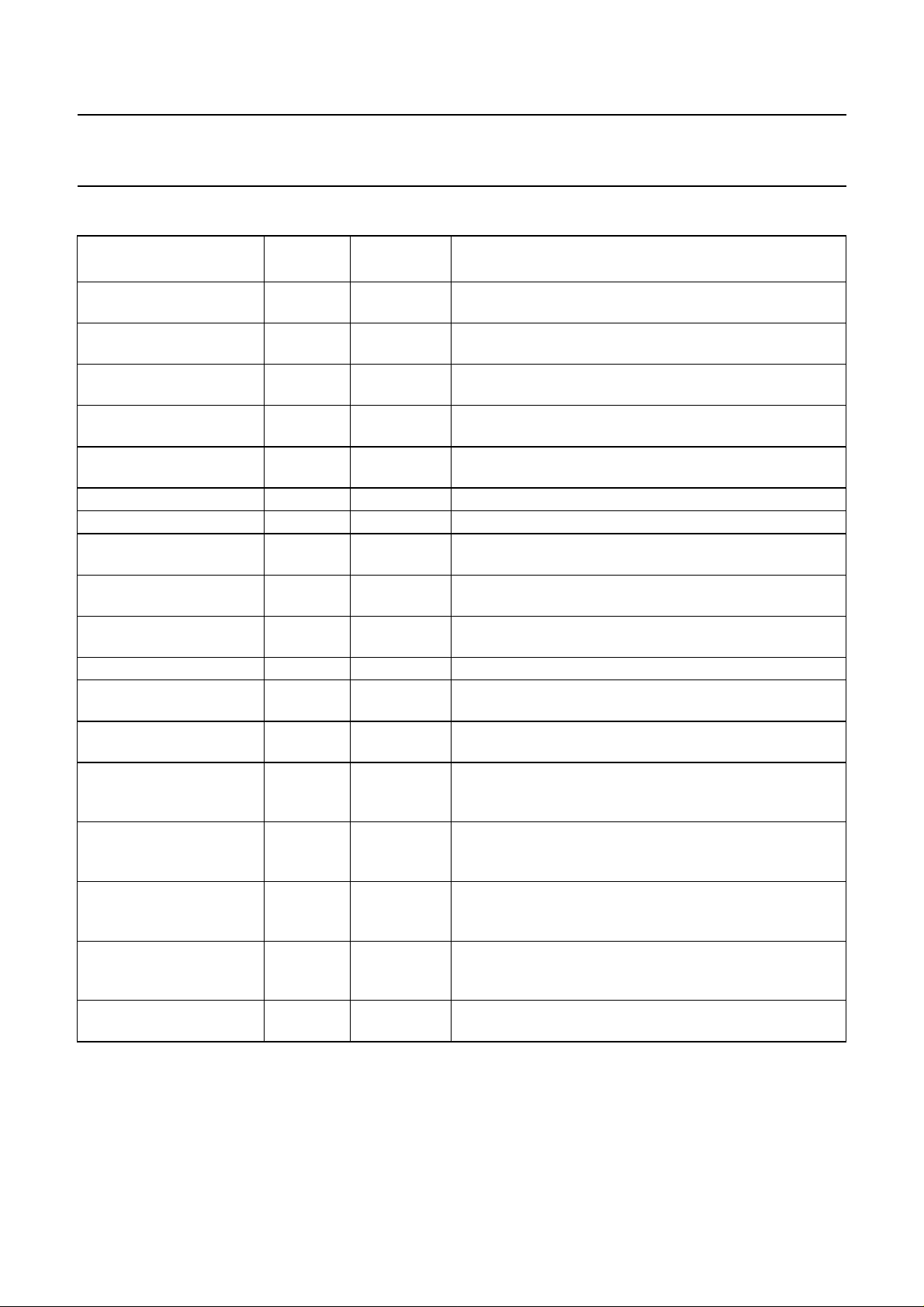

PINNING

SIMPLIFIED

SYMBOL

DD

(1)

DESCRIPTION

Power supply for output drivers, backplane drivers and LCD

V

DD1

SYMBOL PAD

to V

DD4

28, 27, 3, 4 V

bias generator; 4 pads connected internally

V

SS1

to V

SS4

30, 29, 1, 2 V

SS

Ground for output drivers, backplane drivers and LCD bias

generator; 4 pads connected internally

V

V

DD5

SS5

16 V

15 V

DD

SS

Power supply for remaining circuitry; connect externally to

V

to V

DD1

DD4

Ground for remaining circuitry; connect externally to

V

to V

SS1

SS4

REXT 10 Enable internal oscillator input; connected via an external

resistor

RESET 14 Reset input; active HIGH

T1 to T3 13, 17, 18 Test pads; must remain unconnected

COM1_1, COM1_2 31, 173 COM1 First pair of identical 3-level LCD backplane outputs; each

pad is located on opposite sides of the die

COM2_1, COM2_2 32, 174 COM2 Second pair of identical 3-level LCD backplane outputs;

each pad is located on opposite sides of the die

DIR 19 Data direction control input; its voltage level determines the

direction in which data is shifted

S1 to S140 33 to 172 LCD driver outputs

DI1, DI2 24, 7 DI Data input; the status of DIR determineswhich pad is valid;

each pad is located on opposite sides of the die

DO1, DO2 23, 8 DO Data outputs; both identical; both always valid; for cascade

use; each pad is located on opposite sides of the die

LDP1, LDP2 26, 5 LDPI, LDPO Data load control input (LDPI) and output (LDPO) on rising

edge; the status of DIR determines which pad is valid; each

pad is located on opposite sides of the die

LDN1, LDN2 25, 6 LDNI, LDNO Data load control input (LDNI) and output (LDNO) on falling

edge; the status of DIR determines which pad is valid; each

pad is located on opposite sides of the die

CLK1, CLK2 22, 9 CLKI, CLKO Data shift clock input (CLKI) and output (CLKO); the status

of DIR determineswhich pad is valid; for cascade use; each

pad is located on opposite sides of the die

OSC1, OSC2 21, 11 OSCI, OSCO LCD multiplexing clock input (OSCI) and output (OSCO);

the status of DIR determines which pad is valid; each pad is

located on opposite sides of the die

INT_OSCO1, INT_OSCO2 20, 12 INT_OSCO Internal oscillator outputs; both identical; each pad is

located on opposite sides of the die

Note

1. These symbols simplify descriptions in this data sheet where several pads have the same function and also indicate

the direction of data on pads which can be selected to be either an input or an output.

2000 Feb 04 4

Page 5

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

FUNCTIONAL DESCRIPTION

Refer to block diagram Fig.1. The PCF8801 comprises a

bi-directional 280-bit input shift register, 280-bit output

register,output multiplexer providing140-segmentoutputs

via a routing block and output drivers, two 3-level

backplane outputs, internal oscillator and internal

power-on reset circuit. To reduce the length of routing

requiredbetween cascaded chipsinmultiple chip-on-glass

applications, all inputs/outputs for control lines, clock

signals and data are provided at both sides of the narrow

package.

Shift register

The 280-bit bi-directional shift register shifts data on the

rising edge of clock signal CLKI. The shift register output

bits are called SH1_1, SH1_2 to SH140_1, SH140_2.

The direction in which data is shifted and the pads that are

valid for inputs DI, CLKI and output CLKO, is determined

by the voltage level on pad DIR. The voltage on pad DIR

mustbe tied to either VDDorVSSandmust not be switched

when the PCF8801 is operating. Therelationship between

the status of pad DIR and the other pads connected to the

shift register is shown in Table 1.

Table 1 280-bit bi-directional shift register pads

VALID PAD

SHIFT DIRECTION

DIR = 1 DIR = 0

Data input DI

(1)

Data output DO

(2)

DI1 DI2

DO1 and DO2 DO1 and DO2

Clock input CLKI CLK1 CLK2

Clock output CLKO

(2)

CLK2 CLK1

First bit shifted SH140_2 SH1_1

Last bit shifted

(3)

SH1_1 SH140_2

Notes

1. The invalid DI pad must be connected to either VDDor

VSS.

2. Pads DOand CLKO are used when PCF8801devices

are connected in cascade.

3. The last bit is loaded into a flip-flop whose output is

connectedtopad DO.Thevalue of the last bit appears

at pad DO delayed by a1⁄2CLKI period.

Output register

The280-databits(SH1_1,SH1_2 to SH140_1, SH140_2)

from the output of the shift register are transferred to the

input of the 280 bit output register. Data is transferred

when either pad LDPI goes HIGH or when pad LDNI goes

LOW. The output register bits are called IO1_1, IO1_2

to IO140_1, IO140_2. The pads that are valid for

inputs LDPI, LDNI, OSCI, and outputs LDPO, LDNO,

OSCO are determined by the voltage level on pad DIR.

During a positive pulse on pad LDPI, pad LDNI must stay

HIGH, or during a negative pulse on pad LDNI, pad LDPI

must stay LOW. The voltage on pad DIR must be tied to

either VDD or VSS and must not be switched when the

PCF8801 is operating. The relationship between the

status of pad DIR and the other pads connected to the

output register is shown in Table 2.

Table 2 280-bit output register pads

VALID PAD

SHIFT DIRECTION

DIR = 1 DIR = 0

Data load input LDPI LDP1 LDP2

Data load output LDPO LDP2 LDP1

Data load input LDNI LDN1 LDN2

Data load output LDNO LDN2 LDN1

Multiplexing clock input OSCI OSC1 OSC2

Multiplexing clock output OSCO OSC2 OSC1

Output multiplexer, frame generator and backplane

drivers

The 280 data bits (IO1_1, IO1_2 to IO140_1, IO140_2)

from the output register are transferred to the input of the

output multiplexer which multiplexes the data at the rate of

1 : 2. The 140 output bits from the output multiplexer are

called OM1 to OM140. The frame generator outputs two

control signals derived from the LCD multiplex clock

(OSCI) called COMMON (1⁄2f

) and M (1⁄4f

OSC

OSC

) which

control the output multiplexer and the backplane drivers.

The operation of the output multiplexer is defined in

Table 3.

2000 Feb 04 5

Page 6

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

Table 3 Output multiplexer truth table

n = 1 to 140; X = don’t care.

CONTROL INPUT DATA INPUT

DAT A

OUTPUT

COMMON M IOn_1 IOn_2 OMn

000X0

001X1

10X00

10X11

010X1

011X0

11X01

11X10

The backplane drivers generate two output signals called

COM1 and COM2 which connect directly to LCD

backplane 1 and to backplane 2 respectively.

These signals have 3 voltage levels called V

VSS, where VSS= 0 V and V

=1⁄2VDD.V

MID

DD,VMID

MID

and

is the LCD

bias voltage generated by the LCD bias generator.

Figure 2 is a timing diagram for the output multiplexer,

frame generator and backplane drivers.

Routing block and output drivers

Thelayout of the LCD interconnection requires eachof the

140 outputs (OM1 to OM140) from the output multiplexer

to be mapped to the corresponding pixel in each LCD

character by the routing block. The outputs of the routing

block are fed to output drivers whose outputs are

pads S1 to S140. Table 4 shows which pixel is driven by

which data bit output by the shift register for the first LCD

character. There are 7 characters in total, each character

has 40 data points, so routing is performed on a

point-by-point basis.

A pixel has 2 segments which are activated by backplane

drive signals COM1 and COM2 respectively. If DIR = 0,

the first data bit of the data stream to be loaded into the

shift register is routed to the first pixel. Data bit SH1_1 is

routed to pixel 1, activated by COM1, and data bit SH1_2

is routed to pixel 1, activated by COM2.

handbook, full pagewidth

RESET

OSC

COMMON

COM1

COM2

OMn

(n = 1 to 140)

M

IOn_1

IOn_2 IOn_1 IOn_2 IOn_1 IOn_2 IOn_1 IOn_2 IOn_1

Fig.2 Timing diagram for output multiplexer, frame generator and backplane drivers.

2000 Feb 04 6

t

MGL916

Page 7

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

Table 4 Routing of data to LCD pixels

(First 20 bits, DIR = 0).

SHIFT REGISTER DATA OUTPUT LCD PIXEL

SH1_1 7

SH1_2

SH2_1 5

SH2_2

SH3_1 3

SH3_2

SH4_1 1

SH4_2

SH5_1 9

SH5_2

SH6_1 6

SH6_2

SH7_1 4

SH7_2

SH8_1 2

SH8_2

SH9_1 11

SH9_2

SH10_1 10

SH10_2

SH11_1 8

SH11_2

SHIFT REGISTER DATA OUTPUT LCD PIXEL

SH12_1 12

SH12_2

SH13_1 13

SH13_2

SH14_1 14

SH14_2

SH15_1 17

SH15_2

SH16_1 19

SH16_2

SH17_1 15

SH17_2

SH18_1 16

SH18_2

SH19_1 18

SH19_2

SH20_1 20

SH20_2

ThePCF8801supports a 5 × 8 LCD character structure as

shown in Fig.3. Because the bottom line of pixels are not

often used in most applications, their data could be used

instead to control LCD icons.

handbook, full pagewidth

top of LCD

1 2 12 19 20

1 2 12 19 20

3481718

3481718

5 6 10 14 16

5 6 10 14 16

7 9 11 13 15

7 9 11 13 15

pixel locations

Fig.3 LCD character pixel locations (looking from front).

2000 Feb 04 7

top of LCD

1 2 12 19

34817

6101416

6101416

7 9 11 13 15

pixels used to display digit 2

MGL917

Page 8

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

Internal oscillator

The internal oscillator generates two identical LCD

multiplexing clock signals (INT_OSCO) having aminimum

frequency of 240 Hz at pads INT_OSCO1 and

INT_OSCO2. The internal oscillator is enabled by

connecting an external resistor between pad REXT

and VDD, and disabled (INT_OSCO = 0) by connecting

pad REXTto VSS.An external resistor value of 330 kΩ will

typically generate a frequency of 500 Hz.

For cascade applications, the first chip in the cascade

should have pad INT_OSCO connected to pad OSCI.

Each OSCI pad of all subsequent chips should be

connected to the OSCO pad of the previous chip (see

Fig.4). The signal applied to the OSCI pad must always be

a clock signal; applying a DC signal could damage the

LCD.

Power-on reset and external reset

At power-on, the PCF8801 resets to the following

conditions:

• The shift register and the output register sets all bits to 0

• The frame generator outputs (COMMON and M) are 0

• The multiplexed outputs (S1 to S140) to the LCD pixels

are 0

• The backplane driver outputs (COM1 and COM2) are 0

until the first falling edge of OSCI (see Fig.2).

A positive pulse on pad RESET (active HIGH) has the

same effect as the power-on reset. A HIGH-level on

pad RESET disables all clock inputs, the bias generator,

and the internal oscillator (INT_OSCO = 0). If the RESET

input is not used, it is advisable to connect its pad directly

to the adjacent pad V

. However, if the RESET input is

SS5

to be used in a chip-on-glass application, it is strongly

advised that the RESET input is connected in series with

an on-glass resistance to reduce its sensitivity to

ESD/EMCdisturbances. The minimum value of resistance

recommended by the ITO is 8 kΩ.

Cascading

To reduce the length of routing required between

cascaded chips on-glass, all inputs/outputs for control

lines, clock signals and data are provided at both sides of

the narrow package. An example of cascading is shown in

Fig.4.

handbook, full pagewidth

DATA IN

CLOCK

V

DD

LOAD

330 kΩ

V

DD

R

ext

V

SS

DIR

DI DO

CLKI CLKO

LDPI

LDNI

OSCI

INT_OSCO

REXT

LDPO

LDNO

OSCO

PCF8801 PCF8801

RESET

V

SS

chip 1 chip 2

Fig.4 Example of cascading.

2000 Feb 04 8

V

SS

DIR

DI DO

CLKI CLKO

LDPI

V

V

DD

SS

LDNI

OSCI

INT_OSCO

REXT

RESET

V

SS

LDPO

LDNO

OSCO

MGL918

Page 9

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134); stresses greater than the values shown may

cause permanent damage to the device; parameters are valid over the ambient temperature range; all voltages are with

respect to VSS.

SYMBOL PARAMETER MIN. MAX. UNIT

V

DD

V

I

V

O

I

I

I

O

I

DD

I

SS

P

tot

P/out power dissipation per output − 10 mW

T

amb

T

stg

supply voltage −0.5 +6.5 V

input voltage VSS− 0.5 VDD+ 0.5 V

output voltage VSS− 0.5 VDD+ 0.5 V

DC input current −10 +10 mA

DC output current −10 +10 mA

VDD current −50 +50 mA

VSS current −50 +50 mA

total power dissipation − 500 mW

ambient temperature −40 +85 °C

storage temperature −65 +150 °C

HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However it is good practice to take

normal precautions appropriate to handling MOS devices (see

“Handling MOS devices”

).

DC CHARACTERISTICS

VDD= 2.7 to 5.5 V; VSS=0V; T

= −40 to +85 °C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

I

q

I

DD3

DD

supply voltage 2.7 3 or 5 5.5 V

quiescent supply current RESET = 1; note 1 − 2.5 10 µA

normal mode supply

current

CLKI = 0;

OSCI = INT_OSCO;

− 32 100 µA

note 1

Logic

V

IL

V

IH

I

OL

I

OH

I

LI

V

POR

C

i

C

o

LOW-level input voltage note 2 V

HIGH-level input voltage 0.7V

SS

DD

LOW-level output current VOL= 0.4 V; VDD=5V 1 3 − mA

HIGH-leveloutput current VOH= 4.6 V; VDD=5V −−3−1mA

input leakage current VI=VDD or V

Power-on reset voltage VDD<V

POR

SS

−10 +1µA

0.8 1.2 1.6 V

input capacitance −−15 pF

output capacitance −−15 pF

0.33V

0.37V

DD

DD

0.2V

V

DD

DD

V

V

2000 Feb 04 9

Page 10

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Outputs to LCD

V

COM(tol)

output voltage tolerance

on pad COM1 and

pad COM2

R

o(COM)

output resistance on

VDD= 5 V; note 3 − 530kΩ

pad COM1 and

pad COM2

R

o(S)

output resistance on

pads S0 to S140

Notes

1. Outputs to LCD are unloaded (open-circuit); inputs are at VSSor VDD; R

2. All Schmitt trigger inputs.

3. Measured one at a time; load current 30 µA.

−135 −10 to +10 +135 mV

− 730kΩ

= 330 kΩ.

ext

AC CHARACTERISTICS

VDD= 2.7 to 5.5 V; VSS=0V;T

within V

DD

and T

range, and are referenced to VILand VIH with an input voltage swing of VSSto VDD. The serial

amb

= −40 to +85 °C; unless otherwise specified; all timing parameter values are valid

amb

interface timing parameters are defined in Fig.5.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

R

f

ext

osc

external resistor 264 330 396 kΩ

oscillator frequency at

note 1 240 500 1000 Hz

pad INT_OSCO and

pad OSCI

t

H(OSC)

t

L(OSC)

f

clk(CLK)

HIGH time on pad OSCI 400 −−ns

LOW time on pad OSCI 400 −−ns

datashiftclockfrequency

−−1000 kHz

on pad CLKI

t

H(CLK)(LD)

HIGHtimeonpads CLKI,

400 −−ns

LDPI and LDNI

t

L(CLK)(LD)

LOW time on pads CLKI,

400 −−ns

LDPI and LDNI

t

su(DI-CLK)

t

h(D)

set-up time DI to CLKI 50 −−ns

data input hold time DI stable after CLKI

500 −−ns

rise

t

sep

separation time between

800 −−ns

active edges of CLKI,

LDPI and LDNI

Note

1. Frequency accuracy is valid within V

DD

amb

and R

. Typical output duty cycle is 50 : 50.

ext

, T

2000 Feb 04 10

Page 11

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

t

t

sep

su(DI-CLK)

f

clk(CLK)

t

h(D)

t

L(CLK)(LD)

1

t

sep

t

sep

MGL919

handbook, full pagewidth

DI

CLK

LDN

LDP

t

sep

t

H(CLK)(LD)

Fig.5 Serial interface timing.

2000 Feb 04 11

Page 12

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

BONDING PAD INFORMATION

The PCF8801 is manufactured using n-well CMOS

technology.

Table 5 Bonding pad locations

All x/y coordinates represent the position of the centre of

each pad (in µm) with respect to the centre (x/y = 0) of the

chip (see Fig.6).

COORDINATES

SYMBOL PAD

xy

V

SS3

V

SS4

V

DD3

V

DD4

1 −5644.4 382.4

2 −5644.4 307.4

3 −5644.4 232.4

4 −5644.4 157.4

LDP2 5 −5644.4 82.4

LDN2 6 −5644.4 −15.0

DI2 7 −5644.4 −115.0

DO2 8 −5644.4 −215.0

CLK2 9 −5644.4 −315.0

REXT 10 −5238.3 −439.4

OSC2 11 −5138.3 −439.4

INT_OSCO2 12 −5038.3 −439.4

T1 13 −4913.3 −439.4

RESET 14 −134.6 −439.4

V

V

SS5

DD5

15 −47.1 −439.4

16 53.4 −439.4

T2 17 4791.2 −439.4

T3 18 4916.2 −439.4

DIR 19 5041.2 −439.4

INT_OSCO1 20 5141.2 −439.4

OSC1 21 5241.2 −439.4

CLK1 22 5644.4 −314.9

DO1 23 5644.4 −214.9

DI1 24 5644.4 −114.9

LDN1 25 5644.4 −14.9

LDP1 26 5644.4 83.4

V

V

V

V

DD2

DD1

SS2

SS1

27 5644.4 158.4

28 5644.4 233.4

29 5644.4 308.4

30 5644.4 383.4

COM1_1 31 5401.7 440.0

COM2_1 32 5326.7 440.0

SYMBOL PAD

COORDINATES

xy

S1 33 5251.7 440.0

S2 34 5176.7 440.0

S3 35 5101.7 440.0

S4 36 5026.7 440.0

S5 37 4951.7 440.0

S6 38 4876.7 440.0

S7 39 4801.7 440.0

S8 40 4726.7 440.0

S9 41 4651.7 440.0

S10 42 4576.7 440.0

S11 43 4501.7 440.0

S12 44 4426.7 440.0

S13 45 4351.7 440.0

S14 46 4276.7 440.0

S15 47 4201.7 440.0

S16 48 4126.7 440.0

S17 49 4051.7 440.0

S18 50 3976.7 440.0

S19 51 3901.7 440.0

S20 52 3826.7 440.0

S21 53 3751.7 440.0

S22 54 3676.7 440.0

S23 55 3601.7 440.0

S24 56 3526.7 440.0

S25 57 3451.7 440.0

S26 58 3376.7 440.0

S27 59 3301.7 440.0

S28 60 3226.7 440.0

S29 61 3151.7 440.0

S30 62 3076.7 440.0

S31 63 3001.7 440.0

S32 64 2926.7 440.0

S33 65 2851.7 440.0

S34 66 2776.7 440.0

S35 67 2701.7 440.0

S36 68 2626.7 440.0

S37 69 2551.7 440.0

S38 70 2476.7 440.0

S39 71 2401.7 440.0

2000 Feb 04 12

Page 13

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

SYMBOL PAD

COORDINATES

xy

S40 72 2326.7 440.0

S41 73 2251.7 440.0

S42 74 2176.7 440.0

S43 75 2101.7 440.0

S44 76 2026.7 440.0

S45 77 1951.7 440.0

S46 78 1876.7 440.0

S47 79 1801.7 440.0

S48 80 1726.7 440.0

S49 81 1651.7 440.0

S50 82 1576.7 440.0

S51 83 1501.7 440.0

S52 84 1426.7 440.0

S53 85 1351.7 440.0

S54 86 1276.7 440.0

S55 87 1201.7 440.0

S56 88 1126.7 440.0

S57 89 1051.7 440.0

S58 90 976.7 440.0

S59 91 901.7 440.0

S60 92 826.7 440.0

S61 93 751.7 440.0

S62 94 676.7 440.0

S63 95 601.7 440.0

S64 96 526.7 440.0

S65 97 451.7 440.0

S66 98 376.7 440.0

S67 99 301.7 440.0

S68 100 226.7 440.0

S69 101 151.7 440.0

S70 102 76.7 440.0

S71 103 −73.3 440.0

S72 104 −148.3 440.0

S73 105 −223.3 440.0

S74 106 −298.3 440.0

S75 107 −373.3 440.0

S76 108 −448.3 440.0

S77 109 −523.3 440.0

S78 110 −598.3 440.0

SYMBOL PAD

COORDINATES

xy

S79 111 −673.3 440.0

S80 112 −748.3 440.0

S81 113 −823.3 440.0

S82 114 −898.3 440.0

S83 115 −973.3 440.0

S84 116 −1048.3 440.0

S85 117 −1123.3 440.0

S86 118 −1198.3 440.0

S87 119 −1273.3 440.0

S88 120 −1348.3 440.0

S89 121 −1423.3 440.0

S90 122 −1498.3 440.0

S91 123 −1573.3 440.0

S92 124 −1648.3 440.0

S93 125 −1723.3 440.0

S94 126 −1798.3 440.0

S95 127 −1873.3 440.0

S96 128 −1948.3 440.0

S97 129 −2023.3 440.0

S98 130 −2098.3 440.0

S99 131 −2173.3 440.0

S100 132 −2248.3 440.0

S101 133 −2323.3 440.0

S102 134 −2398.3 440.0

S103 135 −2473.3 440.0

S104 136 −2548.3 440.0

S105 137 −2623.3 440.0

S106 138 −2698.3 440.0

S107 139 −2773.3 440.0

S108 140 −2848.3 440.0

S109 141 −2923.3 440.0

S110 142 −2998.3 440.0

S111 143 −3073.3 440.0

S112 144 −3148.3 440.0

S113 145 −3223.3 440.0

S114 146 −3298.3 440.0

S115 147 −3373.3 440.0

S116 148 −3448.3 440.0

S117 149 −3523.3 440.0

2000 Feb 04 13

Page 14

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

SYMBOL PAD

COORDINATES

xy

S118 150 −3598.3 440.0

S119 151 −3673.3 440.0

S120 152 −3748.3 440.0

S121 153 −3823.3 440.0

S122 154 −3898.3 440.0

S123 155 −3973.3 440.0

S124 156 −4048.3 440.0

S125 157 −4123.3 440.0

S126 158 −4198.3 440.0

S127 159 −4273.3 440.0

S128 160 −4348.3 440.0

S129 161 −4423.3 440.0

S130 162 −4498.3 440.0

S131 163 −4573.3 440.0

S132 164 −4648.3 440.0

S133 165 −4723.3 440.0

S134 166 −4798.3 440.0

S135 167 −4873.3 440.0

S136 168 −4948.3 440.0

S137 169 −5023.3 440.0

S138 170 −5098.3 440.0

S139 171 −5173.3 440.0

S140 172 −5248.3 440.0

COM1_2 173 −5323.3 440.0

COM2_2 174 −5398.3 440.0

Alignment marks

TARGET1 −−5645.0 −440.0

TARGET2 − 5645.0 −440.0

Dummy pads

Dummy1 −−5644.4 458.4

Dummy2 − 5644.4 458.4

Dummy3 −−4102.7 −439.4

Dummy4 −−4027.7 −439.4

Dummy5 −−3952.7 −439.4

Dummy6 −−3877.7 −439.4

Dummy7 −−3802.7 −439.4

Dummy8 −−3727.7 −439.4

Dummy9 −−3652.7 −439.4

Dummy10 −−3577.7 −439.4

SYMBOL PAD

COORDINATES

xy

Dummy11 −−3502.7 −439.4

Dummy12 −−3427.7 −439.4

Dummy13 −−3352.7 −439.4

Dummy14 −−3277.7 −439.4

Dummy15 −−3202.7 −439.4

Dummy16 −−3127.7 −439.4

Dummy17 −−3052.7 −439.4

Dummy18 −−2977.7 −439.4

Dummy19 −−2902.7 −439.4

Dummy20 −−2827.7 −439.4

Dummy21 −−2752.7 −439.4

Dummy22 −−2677.7 −439.4

Dummy23 −−2602.7 −439.4

Dummy24 −−2527.7 −439.4

Dummy25 −−2452.7 −439.4

Dummy26 −−2377.7 −439.4

Dummy27 −−2302.7 −439.4

Dummy28 −−2227.7 −439.4

Dummy29 −−2152.7 −439.4

Dummy30 −−2077.7 −439.4

Dummy31 −−2002.7 −439.4

Dummy32 −−1927.7 −439.4

Dummy33 −−1852.7 −439.4

Dummy34 −−1777.7 −439.4

Dummy35 −−1702.7 −439.4

Dummy36 −−1627.7 −439.4

Dummy37 −−1552.7 −439.4

Dummy38 −−327.4 −439.4

Dummy39 − 140.9 −439.4

Dummy40 − 215.9 −439.4

Dummy41 − 290.9 −439.4

Dummy42 − 1231.0 −439.4

Dummy43 − 1306.0 −439.4

Dummy44 − 1381.0 −439.4

Dummy45 − 1456.0 −439.4

Dummy46 − 1531.0 −439.4

Dummy47 − 1606.0 −439.4

Dummy48 − 1681.0 −439.4

Dummy49 − 1756.0 −439.4

2000 Feb 04 14

Page 15

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

SYMBOL PAD

COORDINATES

xy

Dummy50 − 1831.0 −439.4

Dummy51 − 1906.0 −439.4

Dummy52 − 1981.0 −439.4

Dummy53 − 2056.0 −439.4

Dummy54 − 2131.0 −439.4

Dummy55 − 2206.0 −439.4

Dummy56 − 2281.0 −439.4

Dummy57 − 2356.0 −439.4

Dummy58 − 2431.0 −439.4

Dummy59 − 2506.0 −439.4

Dummy60 − 2581.0 −439.4

Dummy61 − 2656.0 −439.4

Dummy62 − 2731.0 −439.4

Dummy63 − 2806.0 −439.4

Dummy64 − 2881.0 −439.4

Dummy65 − 2956.0 −439.4

Dummy66 − 3031.0 −439.4

Dummy67 − 3106.0 −439.4

Dummy68 − 3181.0 −439.4

Dummy69 − 3256.0 −439.4

Dummy70 − 3331.0 −439.4

Dummy71 − 3406.0 −439.4

SYMBOL PAD

COORDINATES

xy

Dummy72 − 3481.0 −439.4

Dummy73 − 3556.0 −439.4

Dummy74 − 3631.0 −439.4

Dummy75 − 3706.0 −439.4

Dummy76 − 3781.0 −439.4

Dummy77 − 3856.0 −439.4

Dummy78 − 3931.0 −439.4

Dummy79 − 4006.0 −439.4

Dummy80 − 4081.0 −439.4

Dummy81 − 4156.0 −439.4

Dummy82 − 4231.0 −439.4

Dummy83 − 4306.0 −439.4

Dummy84 − 4381.0 −439.4

Dummy85 − 4456.0 −439.4

Dummy86 − 4531.0 −439.4

Dummy87 − 4606.0 −439.4

Dummy88 − 4681.0 −439.4

Chip corners (unsawn wafer)

BOTLEFT −−5780.0 −600.0

TOPRIGHT − 5780.0 600.0

2000 Feb 04 15

Page 16

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2000 Feb 04 16

handbook, full pagewidth

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

≈1.2

mm

V

SS3

V

SS4

V

DD3

V

DD4

LDP2

LDN2

DI2

DO2

CLK2

BOTLEFT

y

COM2_2

TARGET2

x

COM1_2

S140

. . .

REXT

OSC2

(1)

0.88 mm

T1

INT_OSCO2

pitch

. . .

S71

y

0

0

SS5

V

RESET

≈11.56 mm

V

S70

DD5

. . .

. . .

PCF8801

T3

T2

DIR

INT_OSCO1

MGL921

S1

COM2_1

COM1_1

x

OSC1

TARGET2

TOPRIGHT

V

SS1

V

SS2

V

DD1

V

DD2

LDP1

LDN1

DI1

DO1

CLK1

(1)

(1) Pattern recognition mark is metal circle of diameter 100 µm.

Fig.6 Bonding pad locations.

Page 17

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

handbook, full pagewidth

V

V

DDn

SSn

(1)

V

DD1

V

DD5

V

DD5

V

SS5

(3)

SUBSTRATE

(2)

V

SS1

V

SS5

V

DD1

V

SS5

V

DD5

V

SS1

(3)

note 4 note 5

V

SS1

V

DD5

V

SS5

note 6

V

MGL922

SS5

(1) Pads V

(2) Pads V

(3) V

(4) Pads COM1, COM2, S1 to S140.

(5) Pads CLKI, OSCI, LDPI, LDNI, INT_OSCO, CLKO, OSCO, LDPO, LDNO, DO, T2.

(6) Pads REXT, DIR, RESET, DI, T1, T3.

SS1

DD1

SS1

and V

to V

; internally linked by metal connections.

DD4

to V

; internally linked by metal connections.

SS4

are internally linked by the substrate resistance.

SS5

Fig.7 Device protection diagram.

2000 Feb 04 17

Page 18

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

TRAY INFORMATION

handbook, full pagewidth

x

y

F

For the dimensions of x, y and A to F, see Table 7.

A

E

C

D

B

MGL928

handbook, halfpage

PCF8801

MGL929

The orientation of the IC in a pocket is indicated by the

position of the IC type name on the die surface with respect to

the chamfer on the upper left corner of the tray. Refer to Fig.6

for the orientation and position of the type name on the die

surface.

Fig.9 Tray alignment.

Fig.8 Tray details.

Table 6 Bonding pad dimensions

Pad pitch min. 75 µm

Pad size, aluminium 62 × 100 µm

Bump dimensions 50 × 90 × 17.5 (±5) µm

Wafer thickness approx. 380 µm

Table 7 Tray dimensions

DIM. DESCRIPTION VALUE

A pocket pitch, in thex direction 13.97 mm

B pocket pitch, in the y direction 3.20 mm

C pocket width, in the x direction 11.66 mm

D pocket width, in the y direction 1.30 mm

E tray width, in thex direction 50.80 mm

F tray width, in the y direction 50.80 mm

x no. pockets in the x direction 3

y no. pockets in the y direction 14

2000 Feb 04 18

Page 19

Philips Semiconductors Product specification

LCD driver for 140 × 2 segments PCF8801

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

2000 Feb 04 19

Page 20

Philips Semiconductors – a w orldwide compan y

Argentina: see South America

Australia: 3 Figtree Drive, HOMEBUSH, NSW 2140,

Tel. +61 2 9704 8141, Fax. +61 2 9704 8139

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101 1248, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 20 0733, Fax. +375 172 20 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 68 9211, Fax. +359 2 68 9102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Sydhavnsgade 23, 1780 COPENHAGEN V,

Tel. +45 33 29 3333, Fax. +45 33 29 3905

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615 800, Fax. +358 9 6158 0920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 2353 60, Fax. +49 40 2353 6300

Hungary: see Austria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: PT Philips Development Corporation, Semiconductors Division,

Gedung Philips, Jl. Buncit Raya Kav.99-100, JAKARTA 12510,

Tel. +62 21 794 0040 ext. 2501, Fax. +62 21 794 0080

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Via Casati, 23 - 20052 MONZA (MI),

Tel. +39 039 203 6838, Fax +39 039 203 6800

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku,

TOKYO 108-8507, Tel. +81 3 3740 5130, Fax. +81 3 3740 5057

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381, Fax +9-5 800 943 0087

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Pakistan: see Singapore

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Al.Jerozolimskie 195 B, 02-222 WARSAW,

Tel. +48 22 5710 000, Fax. +48 22 5710 001

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 319762,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 58088 Newville 2114,

Tel. +27 11 471 5401, Fax. +27 11 471 5398

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 93 301 6312, Fax. +34 93 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 5985 2000, Fax. +46 8 5985 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2741 Fax. +41 1 488 3263

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2886, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Yukari Dudullu, Org. San. Blg., 2.Cad. Nr. 28 81260 Umraniye,

ISTANBUL, Tel. +90 216 522 1500, Fax. +90 216 522 1813

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 208 730 5000, Fax. +44 208 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 3341 299, Fax.+381 11 3342 553

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. SCA

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

2000

Internet: http://www.semiconductors.philips.com

69

Printed in The Netherlands 465006/01/pp20 Date of release: 2000 Feb 04 Document order number: 9397 750 06536

Loading...

Loading...