Page 1

INTEGRATED CIRCUITS

DATA SH EET

PCF8549

65 × 102 pixels matrix LCD driver

Product specification

File under Integrated Circuits, IC12

1997 Nov 21

Page 2

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

FEATURES

• Single chip LCD controller/driver

• 65 row and 102 column outputs

• Display data RAM 65 × 102 bits

• On-chip:

– Generation of LCD supply voltage

– Generation of intermediate LCD bias voltages

– Oscillator requires no external components (external

clock also possible)

• 400 kHz Fast I2C Interface

• CMOS compatible inputs

• Mux rate: 65

• Logic supply voltage range V

• Voltage generator voltage range V

− VSS: 1.5 to 6 V

DD1

DD2/2_HV

− VSS:

2.4 to 5 V

• Display supply voltage range V

− VSS: 7.0 to 16 V

LCD

• Low power consumption, suitable for battery operated

systems

• Temperature compensation of V

LCD

• Interlacing for better display quality

• Slim chip layout, suited for chip-on-glass applications.

GENERAL DESCRIPTION

The PCF8549 is a low power CMOS LCD controller driver,

designed to drive a graphic display of 65 rows and

102 columns. All necessary functions for the display are

provided in a single chip, including on-chip generation of

LCD supply and bias voltages, resulting in a minimum of

external components and low power consumption. The

PCF8549 interfaces to most microcontrollers via an

I2C interface.

Packages

The PCF8549U/2 is available as bumped die. Sawn wafer

as chip sorted in chip tray. For further details see

Section “Bonding pads”.

Customized TCP upon request.

APPLICATIONS

• Telecom equipment

• Portable instruments

• Point of sale terminals.

ORDERING INFORMATION

TYPE NUMBER

NAME DESCRIPTION VERSION

PCF8549U/2/F1 TRAY chip with bumps in tray

PACKAGE

1997 Nov 21 2

Page 3

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

BLOCK DIAGRAM

VLCD2

VLCD1

Bias voltage generator

HVGEN

7 stages

C0 to C101

COLUMN DRIVERS

DATA LATCHES

Dual Ported RAM

65x102 Bit

R0 to R64

ROW DRIVERS

SHIFT REGISTER

OSCILLATOR

TIMING GENERATOR

OSC

IIC INTERFACE

SDA_out

SDA

SCL

1997 Nov 21 3

SA0

RES

Fig.1 Block diagram.

T1

DISPLAY CONTROL LOGIC

T3

T4

T2

T5T6T7

VDD1

VDD2

VDD2_HV

VSS1

VSS2

VSS2_HV

Page 4

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

PINNING

SYMBOL DESCRIPTION

R0 to R64 LCD row driver outputs

C0 to C101 LCD column driver outputs

V

SS1,2,2_HV

V

DD1,2,2_HV

V

LCD1,2

T1 test 1 input

T2 test 2 output

T3 test 3 I/O

T4 test 4 I/O

T5 test 5 input

T6 test 6 input

T7 test 7 input

SDA I

SCL I

SDA_OUT I

SA0 least significant bit of slave address

OSC oscillator

RES external reset input, low active

negative power supply

supply voltage

LCD supply voltage

2

C data input

2

C clock line

2

C output

Pin functions

R0 TO R64: ROW DRIVER OUTPUTS

These pads output the row signals.

TO C101: COLUMN DRIVER OUTPUTS

C0

These pads output the column signals.

V

SS1,2,2_HV

: NEGATIVE POWER SUPPLY RAILS

Negative power supplies.

V

DD1,2,2_HV

V

DD2

: POSITIVE POWER SUPPLY RAILS

and V

are the supply voltages for the internal voltage generator. Both have to be on the same voltage and

DD2_HV

may be connected together outside of the chip. If the internal voltage generator is not used, they should be both

connected to ground. V

V

DD2

V

LCD1,2

and V

: LCD POWER SUPPLY

DD2_HV

.

is used as power supply for the rest of the chip. This voltage can be a different voltage than

DD1

Positive power supply for the liquid crystal display. If the internal voltage generator is used, the two supply rails

V

LCD1

case, V

and V

LCD1

must be connected together. An external LCD supply voltage can be supplied using the V pad. In this

LCD2

has to be connected to ground, and the internal voltage generator has to be programmed to zero. If the

PCF8549 is in power-down mode, the external LCD supply voltage has to be switched off.

1997 Nov 21 4

Page 5

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

T1, T2, T3, T4, T5, T6 AND T7: TEST PADS

T1, T3, T4, T5, T6 and T7 must be connected to V

SS1

, T2

is to be left open. Not accessible to user.

2

SDA/SDA_OUT: I

CDATA LINES

Output and input are separated. If both pads are

connected together they behave like a standard I2C pad.

2

SCL: I

C CLOCK SIGNAL

Input for the I2C-bus clock signal.

LAVE ADDRESS

SA0: S

With the SA0 pin two different slave addresses can be

selected. That allows to connect two PCF8549 LCD

drivers to the same I2C-bus.

OSCILLATOR

OSC:

When the on-chip oscillator is used this input must be

connected to V

. An external clock signal, if used, is

DD1

connected to this input.

RES: RESET

FUNCTIONAL DESCRIPTION

Block diagram functions

O

SCILLATOR

The on-chip oscillator provides the clock signal for the

display system. No external components are required and

the OSC input must be connected to V

. An external

DD1

clock signal, if used, is connected to this input.

2

CINTERFACE

I

The I2C interface receives and executes the commands

sent via the I2C-bus. It also receives RAM-data and sends

them to the RAM. During read access the 8-bit parallel

data or the status register content is converted to a serial

data stream and output via the I2C-bus.

D

ISPLAY CONTROL LOGIC

The display control logic generates the control signals to

read out the RAM via the 101 bit parallel port. It also

generates the control signals for the row, and

column drivers.

ISPLAY DATA RAM (DDRAM)

D

This signal will reset the device. Signal is active low.

The PCF8549 contains a 65 × 102 bit static RAM which

stores the display data. The RAM is divided into 8 banks of

102 bytes and one bank of 102 bits

((8 × 8+1)×102 bits). During RAM access, data is

transferred to the RAM via the I2C interface. There is a

direct correspondence between X-address and column

output number.

IMING GENERATOR

T

The timing generator produces the various signals

required to drive the internal circuitry. Internal chip

operation is not disturbed by operations on the I2C-bus.

LCD

ROW AND COLUMN DRIVERS

The PCF8549 contains 65 row and 102 column drivers,

which connect the appropriate LCD bias voltages to the

display in accordance with the data to be displayed.

Figure 2 shows typical waveforms. Unused outputs should

be left unconnected.

1997 Nov 21 5

Page 6

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

ROW 0

R0 (t)

ROW 2

R2 (t)

COL 0

C0 (t)

COL 1

C1 (t)

V

LCD

V

3

(t)

V

LCD

0 V

state1

V3 - V

V

V

LCD

V

3

- V

frame n+1frame n

V

LCD

V

2

V

3

V

4

V

5

V

SS

V

LCD

V

2

V

3

V

4

V

5

V

SS

V

LCD

V

2

V

3

V

4

V

5

V

SS

V

LCD

V

2

V

3

V

4

V

5

V

SS

2

2

V4 - V

0 V

V

5

V4 - V

- V

LCD

5

LCD

V

V

state1

state2

(t)

(t)

(t)

V

- V

LCD

2

0 V

state2

V3 - V

2

V

0 2 4 6 8 10 ...

0 2 4 6 8 10 ...

V

(t) = C1(t) - R0(t)

state1

V

(t) = C1(t) - R2(t)

state2

... 64

1 3 5 7 9 ...

... 63

Fig.2 Typical LCD driver waveforms.

1997 Nov 21 6

... 64

1 3 5 7 9 ...

... 63

V4 - V

0 V

V

5

V4 - V

- V

LCD

VSS=0V

5

LCD

Page 7

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

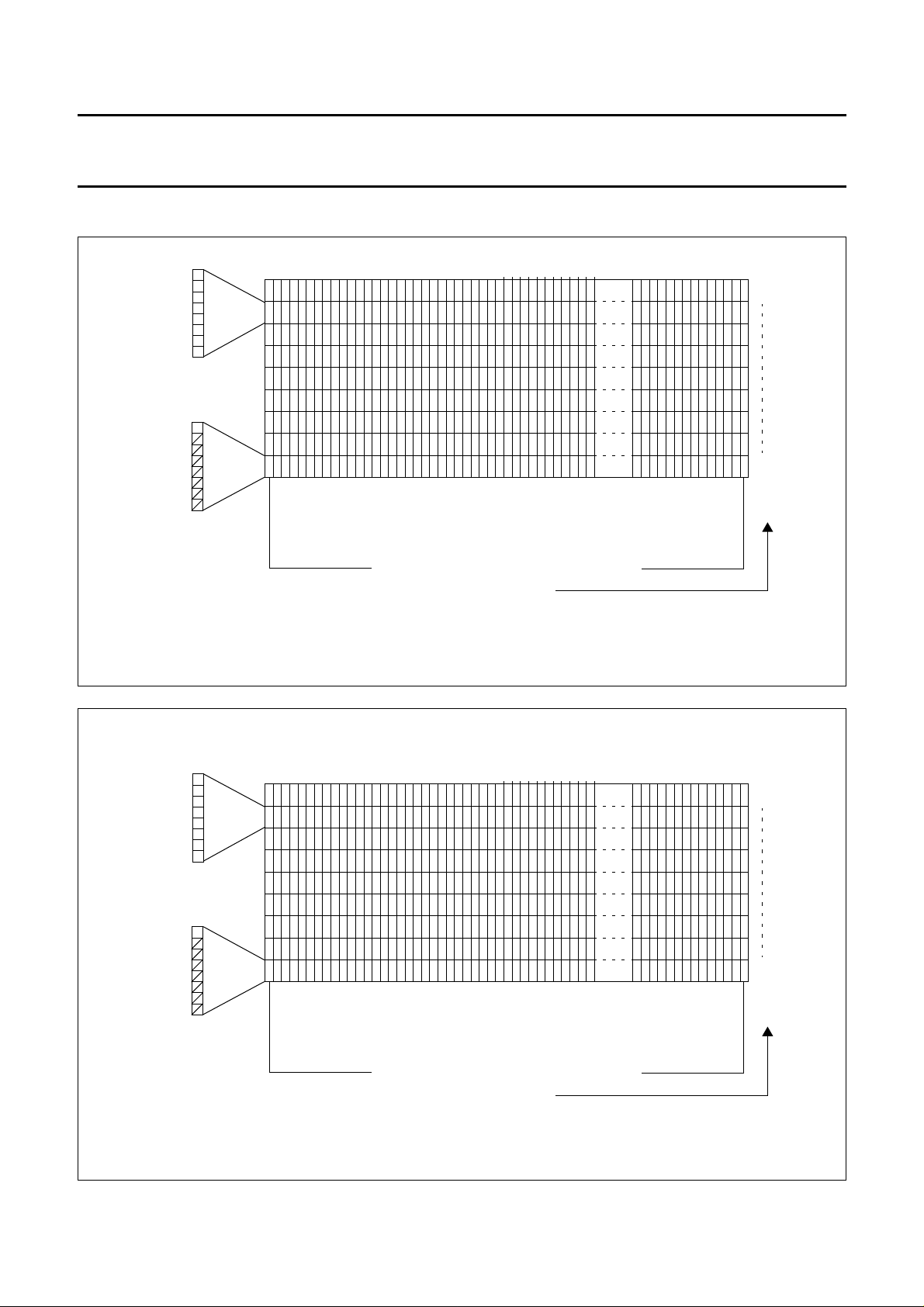

DDRAM

bank 0

bank 1

bank 2

bank 3

bank 7

bank 8

Fig.3 DDRAM to display mapping.

1997 Nov 21 7

Page 8

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

Addressing

The Display data RAM of the PCF8549 is accessed as

indicated in Figs 3, 4, 4, 6 and 7. The display RAM has a

matrix of 65 × 102 bits. The columns are addressed by the

address pointer. The address ranges are:

X 0 to 101 (1100101b) and Y 0 to 8 (1000b). Addresses

outside these ranges are not allowed. In vertical

addressing mode (V = 1) the Y address increments (see

Fig.7) after each byte. After the last Y address (Y = 8)

Y wraps around to 0 and X increments to address the next

column. In horizontal addressing mode (V = 0) the

X address increments (see Fig.6) after each byte. After the

last X address (X = 101) X wraps around to

0 and Y increments to address the next row. After the very

last address (X = 101 and Y = 8) the address pointers

wrap around to address (X = 0 and Y = 0).

The MX bit allows a horizontal mirroring: When MX = 1,

the X address space is mirrored: The addressX=0 is

then located at the right side (column 101) of the display

(see Fig.4). When MX = 0 the mirroring is disabled and the

address X = 0 is located at the left side (column 0) of the

display (see Fig.4).

If the RM-bit (read-modify-write mode) is set, the address

is only incremented after a write, otherwise the address is

incremented after both read and write access to the

display data RAM.

1997 Nov 21 8

Page 9

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

DISPLAY DATA RAM STRUCTURE

MSB

0

LSB

MSB

8

LSB

MSB

LSB

MSB

LSB

0 X-address

Y-address

Fig.4 RAM format, addressing (MX = 0).

101

0

8

101

Fig.5 RAM format, addressing (MX = 1).

1997 Nov 21 9

X-address

Y-address

0

Page 10

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

012

102 103 104

204 205 206

306 307 308

408 409 410

510 511 512

612 613 614

714 715 716

816 817 818 917

0

101

0

Y-address

8

X-address

Fig.6 Sequence of writing data bytes into RAM with horizontal addressing (V = 0).

09

1 10

2

3

4

5

6

7

8 917

0

Fig.7 Sequence of writing data bytes into RAM with vertical addressing (V = 1).

1997 Nov 21 10

0

Y-address

8

101

Page 11

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

RAM access

If the D/C bit is 1 the RAM can be accessed in both read

and write access mode, depending on the R/W bit. The

data is written to the RAM during the acknowledge cycle.

Set Address

Set Read

Modify Write Mode

Read Data

Write Data

no

Finished?

period of the clock pulse as changes in the data line at this

time will be interpreted as a control signal.

TART AND STOP CONDITIONS (see Fig.10)

S

Both data and clock lines remain HIGH when the bus is not

busy. A HIGH-to-LOW transition of the data line, while the

clock is HIGH is defined as the START condition (S). A

LOW-to-HIGH transition of the data line while the clock is

HIGH is defined as the STOP condition (P).

YSTEM CONFIGURATION (see Fig.11)

S

• Transmitter: The device which sends the data to the bus

• Receiver: The device which receives the data from the

bus

• Master: The device which initiates a transfer, generates

clock signals and terminates a transfer

• Slave: The device addressed by a master

• Multi-Master: More than one master can attempt to

control the bus at the same time without corrupting the

message

• Arbitration: Procedure to ensure that, if more than one

master simultaneously tries to control the bus, only one

is allowed to do so and the message is not corrupted

• Synchronisation: Procedure to synchronize the clock

signals of two or more devices.

yes

END

Fig.8 Read modify write access.

2

C-BUS INTERFACE

I

2

Characteristics of the I

C-bus

The I2C-bus is for bi-directional, two-line communication

between different ICs or modules. The two lines are a

serial data line (SDA) and a serial clock line (SCL). Both

lines must be connected to a positive supply via a pull-up

resistor. Data transfer may be initiated only when the bus

is not busy.

IT TRANSFER (see Fig.9)

B

One data bit is transferred during each clock pulse. The

data on the SDA line must remain stable during the HIGH

CKNOWLEDGE (see Fig.12)

A

Each byte of eight bits is followed by an acknowledge bit.

The acknowledge bit is a HIGH signal put on the bus by

the transmitter during which time the master generates an

extra acknowledge related clock pulse. A slave receiver

which is addressed must generate an acknowledge after

the reception of each byte. Also a master receiver must

generate an acknowledge after the reception of each byte

that has been clocked out of the slave transmitter. The

device that acknowledges must pull-down the SDA line

during the acknowledge clock pulse, so that the SDA line

is stable LOW during the HIGH period of the acknowledge

related clock pulse (set-up and hold times must be taken

into consideration). A master receiver must signal an end

of data to the transmitter by not generating an

acknowledge on the last byte that has been clocked out of

the slave. In this event the transmitter must leave the data

line HIGH to enable the master to generate a stop

condition.

1997 Nov 21 11

Page 12

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

SDA

SCL

SDA

SCL

SDA

SCL

START condition

MASTER

TRANSMITTER/

RECEIVER

data line

stable;

data valid

change

of data

allowed

Fig.9 Bit transfer.

S

Fig.10 Definition of start and stop conditions.

SLAVE

RECEIVER

SLAVE

TRANSMITTER/

RECEIVER

TRANSMITTER

STOP condition

MASTER

P

MBC621

SDA

SCL

MBC622

MASTER

TRANSMITTER/

RECEIVER

MGA807

Fig.11 System configuration.

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

SCL FROM

MASTER

S

START

CONDITION

Fig.12 Acknowledgement on the I2C-bus.

1997 Nov 21 12

not acknowledge

acknowledge

MBC602

9821

clock pulse for

acknowledgement

Page 13

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

I2C-bus protocol

The PCF8549 supports both read and write access. The

R/W bit is part of the slave address.

Before any data is transmitted on the I2C-bus, the device

which should respond is addressed first. Two 7-bit slave

addresses (0111100 and 0111101) are reserved for the

PCF8549. The least significant bit of the slave address is

set by connecting the input SA0 to either logic 0 (V

1(V

DD1

).

SS1

) or

The I2C-bus protocol is illustrated in Fig.13.

The sequence is initiated with a START condition (S) from

the I2C-bus master which is followed by the slave address.

All slaves with the corresponding address acknowledge in

parallel, all the others will ignore the I2C-bus transfer. After

acknowledgement, one or more command words follow

which define the status of the addressed slaves. A

command word consists of a control byte, which defines

Co and D/C, plus a data byte (see Fig.13 and Table 1).

The last control byte is tagged with a cleared most

significant bit, the continuation bit Co. After a control byte

with a cleared Co-bit, only data bytes will follow. The state

of the D/

C-bit defines whether the data-byte is interpreted

as a command or as RAM-data.The control and data bytes

are also acknowledged by all addressed slaves on the bus.

After the last control byte, depending on the D/C bit

setting, either a series of display data bytes or command

data bytes may follow. If the D/C bit was set to ‘1’, these

display bytes are stored in the display RAM at the address

specified by the data pointer. The data pointer is

automatically updated and the data is directed to the

intended PCF8549 device. If the D/C bit of the last control

byte was set to ‘0’, these command bytes will be decoded

and the setting of the device will be changed according to

the received commands. The acknowledgement after

each byte is made only by the addressed slave. At the end

of the transmission the I2C-bus master issues a stop

condition (P).

If the R/W bit is set to one in the slave-address, the chip

will output data immediately after the slave-address

according to the D/C bit, which was sent during the last

write access. If no acknowledge is generated by the

master after a byte, the driver stops transferring data to the

master.

acknowledgement

from PCF8549

S

111 001

S AA A

slave address

111 001

S AA A A

slave address

111 001

1110

PCF8549

slave address

0

0

acknowledgement

S

0

S

R

A

W

0

DC1

Co

from Master

1

acknowledgement

from PCF8549

control byte

2n > 0 bytes

acknowledgement

from Master

data byte data byte

data byte

data byte

acknowledgement

from PCF8549

A

Co

acknowledgement

from Master

Fig.13 I2C-bus protocol.

DC0

acknowledgement

control byte

1 byte

from PCF8549

data byte

n > 0 bytes

MSB................. LSB

acknowledgement

from Master

C

DC00 0 000 A

O

Control Byte

data byte

acknowledgement

from PCF8549

PA

A

PA A

1997 Nov 21 13

Page 14

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

INSTRUCTIONS

The instruction format is divided into two modes: If D/C is set low, the status byte can be read or commands can be sent

to the chip, depending on the R/W signal. If D/C is set high, the DDRAM will be accessed. Every instruction can be sent

in any order to the PCF8549.

Table 1 Instruction set

INSTRUCTION D/

CR/W

DESCRIPTION

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

H=0or1

COMMAND BYTE

NOP 0 0 0 0 0 0 0 0 0 0 no operation

Function Set 0 0 0 0 1 MX MY PD V H power down control; entry mode;

Extended Instruction Set control (H)

Read Status Byte 0 1

Write Data 1 0

Read Data 1 1

X X D E MX MY X reads status byte

PD

D

D

D

D

D

D

D

D

D

6

5

4

3

2

7

D

D

D

D

6

5

7

4

D

3

1

D

2

1

writes data to RAM

0

D

reads data from RAM

0

H=0

Set Read Modify

Write

Reserved 0 0 0 0 0 0 0 1 X X do not use

Display Control 0 0 0 0 0 0 1 D 0 E sets display configuration

Reserved 0 0 0 0 0 1 X X X X do not use

Set Y address of

RAM

Set X address of

RAM.

0 0 0 0 0 0 0 0 1 RM sets the read-modify-write mode

Y

Y

Y

000100Y

X

001X

6

5

X

4

3

X

3

2

X

2

1

X

1

sets Y-address of RAM: 0 ≤ Y ≤ 8

0

X

sets X-address of RAM: 0 ≤ X ≤ 101

0

H=1

Reserved 0 0 0 0 0 0 0 0 0 1 do not use

Reserved 0 0 0 0 0 0 0 0 1 X do not use

Temperature Control 0 0 0 0 0 0 0 1 TC

Reserved 0 0 0 0 0 0 1 X X X do not use

Bias System 0 0 0 0 0 1 0 BS

2

Reserved 0 0 0 1 X X X X X X do not use (reserved for test...)

Set V

OP

001V

OP6VOP5VOP4VOP3VOP2VOP1VOP0

TC0set temperature coefficient (TCx)

1

BS1BS0Set Bias System(BSx)

write VOP to register

1997 Nov 21 14

Page 15

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

Table 2 Explanations for symbols in Table 1

BIT 0 1 RESET STATE

PD chip is active chip is in power down mode 1

V horizontal addressing vertical addressing 0

H use basic instruction set use extended instruction set 0

MX normal X-addressing X-address is mirrored 0

MY display is not vertically mirrored display is vertically mirrored 0

RM read-modify-write mode is disabled read-modify-write mode is enabled 0

D and E 00 display blank D = 0

10 normal mode

01 all display segments on

11 inverse video mode

TC[1 : 0] 00 V

01 V

10 V

11 V

temperature coefficient 0 TC[1 : 0] = 00

LCD

temperature coefficient 1

LCD

temperature coefficient 2

LCD

temperature coefficient 3

LCD

BS[2 : 0] bias system BS[2 : 0] = 000

E=0

External reset (RES)

After power-on a reset pulse has to be applied immediately to the chip, as it is in an undefined state. A reset of the chip

can be achieved with the external reset pin. After the reset the LCD driver is set to the following status:

• Power down mode (PD = 1)

• All LCD-outputs at VSS (display off)

• Read-modify-write mode is disabled (RM = 0)

• Horizontal addressing (V = 0)

• Normal instruction set (H = 0)

• Normal display (MX = MY = 0)

• Display blank (E = D = 0)

• Address counter X[6 : 0] = 0 and Y[3 : 0] = 0

• Temperature coefficient (TC[1 : 0] = 0)

• Bias system (BS[2 : 0] = 0)

• Read-modify-write mode disabled (RM = 0)

• V

is equal to 0, the HV generator is switched off (VOP[6:0]=0)

LCD

• After power-on, RAM data are undefined; The reset signal does not change the content of the RAM.

Set read-modify-write

When RM = 0, the read-modify-write mode is disabled. The X/Y-address counter is incremented after every read or write

access to the display data RAM.

When RM = 1, the read-modify-write mode is enabled. In this mode the X/Y-address is incremented only after a write

access to the display data RAM. The X/Y-address will not be incremented after a read access to the RAM.

1997 Nov 21 15

Page 16

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

Function Set

PD (

POWER DOWN)

• All LCD outputs at VSS (display off)

• Bias generator and V

generator off

LCD

• Oscillator off (external clock possible)

• V

can be disconnected

LCD

• Parallel bus, command, etc. function

• RAM contents not cleared; RAM data can be written.

V

When V = 0, the horizontal addressing is selected. The

data is written into the RAM as shown in Fig.6. When

V = 1, the vertical addressing is selected. The data is

written into the RAM as shown in Fig.7.

H

When H = 0 the commands ‘display control’, ‘set

Y address’ and ‘set X address’ can be performed, when

H = 1 the other commands can be executed. The

commands ‘write data’ and ‘function set’ can be executed

in both cases.

MX

When MX = 0, the display is written from left to right (X = 0

is on the left side, X = 100 is on the right side of the

display). When MX = 1 the display is written from right to

left (X = 0 is on the right side, X = 100 is on the left side of

the display).

MY

When MY = 1, the display is mirrored vertically.

Display Control

AND E

D

The bits D and E select the display mode (see Table 2).

Set Y address of RAM

Y[3 : 0] defines the Y address vector address of the RAM.

Table 3 X-/Y-Address range

YYYY

3 210

CONTENT ALLOWED X-RANGE

0000 bank 0 (display RAM) 0 to 101

0001 bank 1 (display RAM) 0 to 101

0010 bank 2 (display RAM) 0 to 101

0011 bank 3 (display RAM) 0 to 101

0100 bank 4 (display RAM) 0 to 101

0101 bank 5 (display RAM) 0 to 101

0110 bank 6 (display RAM) 0 to 101

0111 bank 7 (display RAM) 0 to 101

1000 bank 8 (display RAM) 0 to 101

In bank 8 only the MSB is accessed.

Set X address of RAM

The X address points to the columns. The range of X is 0 to 101(65 hex).

Temperature Control

Due to the temperature dependency of the liquid crystals viscosity the LCD controlling voltage V

must be increased

LCD

with lower temperature to maintain optimal contrast. There are 4 different temperature coefficients available in the

1997 Nov 21 16

Page 17

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

PCF8549 (see Fig.14). The coefficients are selected by the two bits TC[1 : 0]. Table 6 shows the typical values of the

different temperature coefficients. The coefficients are proportional to the programmed V

V

LCD

LCD

.

16oC(typ)

temperature

Fig.14 Temperature coefficients.

Bias value:

The bias voltage levels are set in the ratio of R − R − nR − R − R giving a bias system. The resulting bias levels

1

------------ n4+

are shown in table 5.

Different multiplex rates require different factors n (see Table 4). This is programmed by BS[2 : 0]. For MUX 1 : 65 the

optimum bias value n is given by:

resulting in

1

⁄9bias.

nm3– 65 3– 5.06 5== ==

Table 4 Programming the required Bias system

BS[2] BS[1] BS[0] n b (RES. COUNT) MUX RATE

0007 11 1:100

0016 10 1:81

0105 9 1:64

0114 8 1:49

1003 7 1:36

1997 Nov 21 17

Page 18

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

BS[2] BS[1] BS[0] n b (RES. COUNT) MUX RATE

1012 6 1:24

1101 5 1:16

1110 4 1:9

Table 5 LCD bias voltage

SYMBOL BIAS VOLTAGES⁄

V1 V

V2 (b-1)/b × V

V3 (b-2)/b × V

V4 2/b × V

V5 1/b × V

V6 V

LCD

LCD

LCD

LCD

LCD

SS

Set V

The operation voltage V

value:

OP

can be set by software. The generated voltage is dependent of the temperature, the

LCD

programmed temperature coefficient (TC), and the programmed voltage at reference temperature (T

V

The voltage at reference temperature (V

LCD

LCD

a VOP+ b⋅()TT

(T=T

)) can be calculated as:

CUT

V

LCD

aVOP+ b⋅()=

–()TC⋅+=

CUT

The parameters are explained in table 6.

The maximum voltage that can be generated is depending on the V

DD2/2_HV

Voltage and the display load current. The

relation ship is shown in Fig.16.

The charge pump is turned off if Vop[6 : 0] is set to zero.

For Mux 1 : 65 the optimum operation voltage of the liquid can be calculated as:

V

LCD

where V

165+

--------------------------------------21

⋅

is the threshold voltage of the liquid crystal material used.

th

1

–

----------

65

6.85 Vth⋅=⋅=

V

th

CUT

).

(1)

(2)

1997 Nov 21 18

Page 19

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

V

LCD

b

a

00 01 02 03 04 05 06 07 08 09 0A ...

VOP[6:0] (programmed) [00 hex ... 7F hex]

Fig.15 VOP programming of PCF8549.

Table 6 Typical values for parameters for the HV-Generator programming

SYMBOL VALUE UNIT

a 7.06 V

b 0.06 V

T

CUT

16

TC 00 V/

0.142 103–V

LCD

TT

=()⋅⋅–

CUT

01 V/

3–

V

TT

1.3 10

LCD

=()⋅⋅–

CUT

10 V/

2.467 10

3–

V

TT

LCD

=()⋅⋅–

CUT

11 V/

3–

V

TT

3.483 10

LCD

=()⋅⋅–

CUT

0

C

o

C

o

C

o

C

o

C

1997 Nov 21 19

Page 20

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC 134); all voltages referred to VSS = 0V unless otherwise

specified.

SYMBOL PARAMETER MIN MAX UNIT

V

DD

V

LCD

I

SS

V

i/VO

V

OLCD

I

i

I

o

P

TOT

P

O

T

AMB

T

STG

supply voltage range -0.5 +7 V

supply voltage range LCD -0.5 +17 V

supply current -50 50 mA

input/output voltage range -0.5 VDD+0.5 V

LCD output voltage range -0.5 V

+0.5 V

LCD

DC input current -10 10 mA

DC output current -10 10 mA

power dissipation per package - 300 mW

power dissipation per output - 50 mW

operating ambient temperature.

-40 +85 °C

range

storage temperature range -65 +150 °C

Notes

1. Stresses above those listed under Limiting Values may cause permanent damage to the device.

2. Parameters are valid over operating temperature range unless otherwise specified. All voltages are with respect to

VSS unless otherwise noted.

3. with external LCD supply voltage external supplied (voltage generator disabled). V

DDmax

(V

DD2,VDD2_HV

) is 5V if

LCD supply voltage is internally generated (voltage generator enabled).

HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However, to be totally safe, it is

desirable to take normal precautions appropriate to handling MOS devices (see “Handling MOS Devices”). The PCF8549

withstands the following stress:

• approximately 1.0kV Human Body Model

• approximately 150V Machine Model

1997 Nov 21 20

Page 21

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

DC CHARACTERISTICS

Table 7 V

= 1.5 to 6 V; V

DD1

= −40 to +85 °C; unless otherwise specified.

T

amb

DD2/2_HV

= 2.4 to 5.0 V; V

DD2

= V

DD2_HV

; V

SS1

= V

SS2

= V

SS2_HV

= 0 V; V

LCD

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNIT

V

DD1

Logic supply

1.5 3 6 V

voltage range

V

DD2,

V

DD2_HV

I

VDD1

I

VDD2/2_HV

I

VDD1

I

VDD2/2_HV

I

VDD1

I

LCD

V

LCD(tol)

V

IL

HV Generator

supply range

supply current

internal V

LCD

supply current

internal V

LCD

supply current

external V

LCD

supply current

external V

LCD

V

= 10.0V; f

LCD

display load = 0;

V

= 10.0V; f

LCD

display load = 0;

V

= 10.0V; f

LCD

display load = 0;

V

= 10.0V; f

LCD

display load = 0;

scl

scl

scl

scl

= 0;

= 0;

(1)(5)

= 0;

= 0;

(2)(5)

supply current power-down mode; V

f

= 0; display load = 0

scl

supply current

external V

V

LCD

LCD

tolerance

internal generated

V

= 10 V; f

LCD

SCL

= 0,

display load = 0; (2)

VDD = 2.7V; V

display load = 0;

LCD

(3)(4)(6)

= 10V; f

LOW level input volt-

LCD

= 0V;

SCL

= 0;

2.4 5 V

30 80 µA

600 1200 µA

30 80 µA

010µA

0.5 10 µA

50 130 µA

+/- 500 mV

V

SS

0.3VDDV

age

=7to16V;

V

IH

HIGH level input

0.7 V

DD

voltage

I

I

R

OL

L

ROW

LOW level output

current (SDA)

leakage current VI= V

Row output resis-

VOL = 0.4V;

V

=5V

DD1

or V

DD1

SS1

3.0 mA

-1 +1 µA

12 20 kOhm

tance R0 to R64

R

COL

Column output resis-

12 20 kOhm

tance C0 to C101

Note

1. When a display is connected the I

2. With external V

, the display load current does not translate into increased I

LCD

VDD2_HV

increases with 7 x display load current due to 7 stage charge pump.

VDD2_HV

3. For TC1, TC2 and TC3

4. The maximum possible VLCD voltage that may be generated is dependent on voltage (V

(display) load.

5. V

DD2 VDD2_HV

connected together

6. Difference to the theoretical value given by equation 1

V

DD

.

DD2/2_HV

V

), temperature and

1997 Nov 21 21

Page 22

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

AC CHARACTERISTICS

Table 8 V

= 1.5 to 6 V; V

DD1

= −40 to +85 °C; unless otherwise specified.

T

amb

DD2/2_HV

= 2.4 to 5.0 V; V

DD2

= V

DD2_HV

; V

SS1

= V

SS2

= V

SS2_HV

= 0 V; V

=7to16V;

LCD

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

f

OSC

f

EXT

t

start

f

FRAME

t

VHRL

t

PWRES

2

C timing characteristics

I

f

SCLK

t

LOW

t

HIGH

t

SU;Data

t

HD;Data

t

R

t

F

c

b

oscillator frequency 19 32 64 kHz

external clock frequency

oscillator start up time

frame frequency f

VDD to RES Low

(2)

(5)

EXT

(5)

= 32 kHz;

(1)

10 32 64 kHz

− 450 1600 us

− 62 − Hz

1ms

reset low pulse width 400 −−ns

SCL clock frequency

(6)

DC − 400 kHz

SCL clock low period 1.3 −−us

SCL clock high period 0.6 −−us

Data set-up time 100 −−ns

Data hold time 0 − 0.9 us

SCL and SDA rise time

SCL and SDA fall time

Capacitive load represented by each

(3)

(3)

20 + 0.1 Cb − 300 ns

20 + 0.1 Cb − 300 ns

−−400 pF

bus line

t

SU;STA

setup time for a repeated START con-

0.6 −−us

dition

t

HD;STA

t

SU;DAT

t

HD;DAT

t

SU;STO

t

SW

t

BUF

start condition hold time 0.6 −−us

data set-up time 100 −−ns

data hold-time 0 −−ns

setup time for STOP condition 0.6 −−us

tolerable spike width on bus

BUS free time between a STOP and

(4)

−−50 ns

1.3 −−us

START condition

Note

f

EXT

f

1.

FRAME

=

---------- 520

2. Duty cycle of 50 +/-5%.

3. The rise and fall times specified here refer to the driver device (i.e. not PCF8549) and are part of the general fast

2

I

C-bus specification. When PCF8549 asserts an acknowledge on SDA, the minimum fall time is 10ns. Cb=

capacitive load per bus line.

4. The device inputs SDA and SCL are filtered and will reject spikes on the bus lines of width < t

SW(max)

.

5. Not tested in production

6. Only for VDD1= 2V to 6V

1997 Nov 21 22

Page 23

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

TYPICAL CHARACTERISTICS

16V

15V

I=0uA

14V

I=10uA

VLCD

I=20uA

13V

I=40uA

12V

1V

0V

Fig.16 VLCD dependency of VDD2,

VDD2_HV and load current. Programmed

VLCD=15.8V (@ Room Temperature in

2V 3V 4V 5V

VDD2, VDD2_HV

special Test mode)

RESET

VDD

RES

t

VHRL

Fig.17 Reset timing.

t

PWRES

1997 Nov 21 23

Page 24

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

APPLICATION INFORMATION

Table 9 programming example for PCF8549

STEP DISPLAY OPERATION

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

1I2C start

2 0 1 1 1 1 0 0 0 Slave address for write

3 0 0 0 0 0 0 0 0 Control byte with cleared C

and D/C set to 0.

4 0 0 1 0 0 0 0 1 Function Set

PD = 0; V = 0; select extended

instruction set (H = 1 mode)

5 0 0 0 1 0 0 1 0 Set Bias System 2. This is the

recommended Bias System for a

multiplex rate 1:65

6 1 1 1 0 1 0 1 0 set V

OP

VOP is set to a +16 × b [V].

Please note: The required

voltage is depending on the

liquid.

7 0 0 1 0 0 0 0 0 Function Set

PD = 0; V = 0; select normal

instruction set (H = 0 mode)

8 0 0 0 0 1 1 0 0 Display Control

set normal mode

(D = 1 and E = 0)

2

9I

C start Restart: To write into the Display

RAM the D/C must be set to 1;

therefore a control byte is

needed.

10 0 1 1 1 1 0 0 0 Slave address for write

11 0 1 0 0 0 0 0 0 Control byte with cleared C

and D/C set to 1.

12 1 1 1 1 1 0 0 0 Data Write

Y and X are initialized to 0 by

default, so they aren’t set here

bit

O

bit

O

13 1 0 1 0 0 0 0 0 Data Write

14 1 1 1 0 0 0 0 0 Data Write

1997 Nov 21 24

Page 25

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

STEP DISPLAY OPERATION

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

15 0 0 0 0 0 0 0 0 Data Write

16 1 1 1 1 1 0 0 0 Data Write

17 0 0 1 0 0 0 0 0 Data Write

18 1 1 1 1 1 0 0 0 Data Write

2

19 I

C start Restart

20 0 1 1 1 1 0 0 0 Slave address for write

21 1 0 0 0 0 0 0 0 Control byte with set C

D/C set to 0.

22 0 0 0 0 1 1 0 1 Display Control

Set inverse video mode

(D = 1 and E = 1)

bit and

O

23 1 0 0 0 0 0 0 0 Control byte with set CO bit and

D/C set to 0.

24 1 0 0 0 0 0 0 0 Set X address of RAM

set address to ‘0000000’

25 1 1 0 0 0 0 0 0 Control byte with set CO bit and

D/C set to 1.

26 0 0 0 0 0 0 0 0 Data Write

27 0 0 0 0 0 0 0 0 Control byte with cleared C

bit

O

and D/C set to 0.

28 1 0 0 0 0 0 0 0 Set X address of RAM

Set address to ‘0000000’

29 0 0 0 0 0 0 0 1 Set Read Modify Write Mode

1997 Nov 21 25

Page 26

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

STEP DISPLAY OPERATION

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

2

30 I

C start Restart

31 0 1 1 1 1 0 0 0 Slave address for write

32 1 1 0 0 0 0 0 0 Control byte with set C

D/C set to 1.

2

33 I

C start Restart

34 0 1 1 1 1 0 0 1 Slave address for read

35 1 0 0 0 0 0 0 0 Read Data From

Address ‘0000000’

36 1 0 0 0 0 0 0 0 Read Data From

Address ‘0000000’ again.

Master does not send an

acknowledge to stop the read

access.

2

37 I

C start Restart

38 0 1 1 1 1 0 0 0 Slave address for write

39 1 1 0 0 0 0 0 0 Control byte with set C

D/C set to 1.

40 1 1 1 1 1 0 0 0 Write Data

bit and

O

bit and

O

41 1 0 0 0 0 0 0 0 Control byte with set CO bit and

D/C set to 0.

2

42 I

C start Restart

43 0 1 1 1 1 0 0 1 Slave address for read

44 1 0 0 0 0 0 0 0 Read Status Byte

APPLICATION INFORMATION

1997 Nov 21 26

Page 27

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

VDD1

SCL

PCF8549

SDA

SDA_OUT

SCL

VDD1

Microcontroller

SDA

Fig.18 Application diagram: Connecting the I2C Interface

1997 Nov 21 27

Page 28

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

DISPLAY 102x65

33

VDD1 VSS– 1.5V≥

VDD2 VSS– 2.4V≥

VDD2HV VDD2=

C1 100nF≥

C

2 100nF≥

3 1uF≥

C

4 100nF≥

C

PCF8549

13

C2

C1

C4

LCD

V

VDD1

I/O

C3

VSS

VDD2

VDD2_HV

Fig.19 Application diagram: Connecting the power supplies

32102

The pinning of the PCF8549 is optimized for single plane wiring e.g. for chip-on-glass display modules.

Display size: 65 × 102 pixels.

CHIP INFORMATION

The PCF8549 is manufactured in n-well CMOS technology.

The substrate is on V

1997 Nov 21 28

potential.

SS

Page 29

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

BONDING PADS

VALUE UNIT

Pad pitch min. 100 µm

Pad size, alumin. 80 × 100 µm

Passivation. 48 × 78 µm

Bumps 60 (±6) × 90 (±6) × 17.5 (±5) µm

Wafer thickness 380 (±25) µm

1997 Nov 21 29

Page 30

Philips Semiconductors Product specification

111

1

65 × 102 pixels matrix LCD driver PCF8549

Dummy

R31

R1

OSC

VDD1

VDD2

VDD2_HV

RES

SDA_OUT

SDA

SCL

T2

SA0

T7

T6

T5

T4

T3

T1

VSS1

VSS2_HV

Recognition

Pattern

Pad 1

DUMMY

R63

R33

C0

16.39mm

VSS2

VLCD_1

VLCD2

R0

R30

Dummy

PC8549

2.74mm

Fig.20 Pads.

1997 Nov 21 30

Recognition

pattern

C101

R32

R34

R64

DUMMY

Page 31

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

Table 10 Bonding pad locations (dimensions in um).

Pad Pad name X Y

1 T2 7359.5 2462

2 SA0 6958 2462

3 T7 6679 2462

4 T6 6400 2462

5 T5 6121 2462

6 T4 5841.5 2462

7 T3 5431.5 2462

8 T1 5022 2462

9 VSS1 4724 2458

10 VSS1 4624 2458

11 VSS2_HV 4359 2458

12 VSS2_HV 4259 2458

13 VSS2_HV 4159 2458

14 VSS2 3458.5 2458

15 VLCD1 2580 2462

16 VLCD2 2294 2462

17 ROW<0> 1870 2437

18 ROW<2> 1770 2437

19 ROW<4> 1670 2437

20 ROW<6> 1570 2437

21 ROW<8> 1470 2437

22 ROW<10> 1370 2437

23 ROW<12> 1270 2437

24 ROW<14> 1170 2437

25 ROW<16> 1070 2437

26 ROW<18> 970 2437

27 ROW<20> 870 2437

28 ROW<22> 770 2437

29 ROW<24> 670 2437

30 ROW<26> 570 2437

31 ROW<28> 470 2437

32 ROW<30> 370 2437

33 Dummy 4 270 2437

34 Dummy 5 170 2437

35 Dummy 6 70 2437

36 Dummy 3 70 84

37 Dummy 2 170 84

38 Dummy 1 270 84

39 ROW<64> 370 84

40 ROW<62> 470 84

Pad Pad name X Y

41 ROW<60> 570 84

42 ROW<58> 670 84

43 ROW<56> 770 84

44 ROW<54> 870 84

45 ROW<52> 970 84

46 ROW<50> 1070 84

47 ROW<48> 1170 84

48 ROW<46> 1270 84

49 ROW<44> 1370 84

50 ROW<42> 1470 84

51 ROW<40> 1570 84

52 ROW<38> 1670 84

53 ROW<36> 1770 84

54 ROW<34> 1870 84

55 ROW<32> 2137 84

56 COL<101> 2812 84

57 COL<100> 2914 84

58 COL<99> 3014 84

59 COL<98> 3114 84

60 COL<97> 3214 84

61 COL<96> 3314 84

62 COL<95> 3560 84

63 COL<94> 3660 84

64 COL<93> 3760 84

65 COL<92> 3860 84

66 COL<91> 3960 84

67 COL<90> 4060 84

68 COL<89> 4160 84

69 COL<88> 4260 84

70 COL<87> 4360 84

71 COL<86> 4460 84

72 COL<85> 4560 84

73 COL<84> 4660 84

74 COL<83> 4760 84

75 COL<82> 4860 84

76 COL<81> 4960 84

77 COL<80> 5060 84

78 COL<79> 5306 84

79 COL<78> 5406 84

80 COL<77> 5506 84

1997 Nov 21 31

Page 32

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

Pad Pad name X Y

81 COL<76> 5606 84

82 COL<75> 5706 84

83 COL<74> 5806 84

84 COL<73> 5906 84

85 COL<72> 6006 84

86 COL<71> 6106 84

87 COL<70> 6206 84

88 COL<69> 6306 84

89 COL<68> 6406 84

90 COL<67> 6506 84

91 COL<66> 6606 84

92 COL<65> 6706 84

93 COL<64> 6806 84

94 COL<63> 7052 84

95 COL<62> 7152 84

96 COL<61> 7252 84

97 COL<60> 7352 84

98 COL<59> 7452 84

99 COL<58> 7552 84

100 COL<57> 7652 84

101 COL<56> 7752 84

102 COL<55> 7852 84

103 COL<54> 7952 84

104 COL<53> 8052 84

105 COL<52> 8152 84

106 COL<51> 8252 84

107 COL<50> 8352 84

108 COL<49> 8452 84

109 COL<48> 8552 84

110 COL<47> 8798 84

111 COL<46> 8898 84

112 COL<45> 8998 84

113 COL<44> 9098 84

114 COL<43> 9198 84

115 COL<42> 9298 84

116 COL<41> 9398 84

117 COL<40> 9498 84

118 COL<39> 9598 84

119 COL<38> 9698 84

120 COL<37> 9798 84

Pad Pad name X Y

121 COL<36> 9898 84

122 COL<35> 9998 84

123 COL<34> 10098 84

124 COL<33> 10198 84

125 COL<32> 10298 84

126 COL<31> 10544 84

127 COL<30> 10644 84

128 COL<29> 10744 84

129 COL<28> 10844 84

130 COL<27> 10944 84

131 COL<26> 11044 84

132 COL<25> 11144 84

133 COL<24> 11244 84

134 COL<23> 11344 84

135 COL<22> 11444 84

136 COL<21> 11544 84

137 COL<20> 11644 84

138 COL<19> 11744 84

139 COL<18> 11844 84

140 COL<17> 11944 84

141 COL<16> 12044 84

142 COL<15> 12290 84

143 COL<14> 12390 84

144 COL<13> 12490 84

145 COL<12> 12590 84

146 COL<11> 12690 84

147 COL<10> 12790 84

148 COL<9> 12890 84

149 COL<8> 12990 84

150 COL<7> 13090 84

151 COL<6> 13190 84

152 COL<5> 13290 84

153 COL<4> 13390 84

154 COL<3> 13490 84

155 COL<2> 13590 84

156 COL<1> 13690 84

157 COL<0> 13790 84

158 ROW<33> 14204 84

159 ROW<35> 14304 84

160 ROW<37> 14404 84

1997 Nov 21 32

Page 33

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

Pad Pad name X Y

161 ROW<39> 14504 84

162 ROW<41> 14604 84

163 ROW<43> 14704 84

164 ROW<45> 14804 84

165 ROW<47> 14904 84

166 ROW<49> 15004 84

167 ROW<51> 15104 84

168 ROW<53> 15204 84

169 ROW<55> 15304 84

170 ROW<57> 15404 84

171 ROW<59> 15504 84

172 ROW<61> 15604 84

173 ROW<63> 15704 84

174 Dummy 7 15804 84

175 Dummy 8 15904 84

176 Dummy 9 16004 84

177 Dummy 12 15961 2437

178 Dummy 11 15861 2437

179 Dummy 10 15761 2437

180 ROW<31> 15661 2437

181 ROW<29> 15561 2437

182 ROW<27> 15461 2437

183 ROW<25> 15361 2437

184 ROW<23> 15261 2437

185 ROW<21> 15161 2437

186 ROW<19> 15061 2437

187 ROW<17> 14961 2437

188 ROW<15> 14861 2437

189 ROW<13> 14761 2437

190 ROW<11> 14661 2437

191 ROW<9> 14561 2437

192 ROW<7> 14461 2437

193 ROW<5> 14361 2437

194 ROW<3> 14261 2437

195 ROW<1> 14161 2437

196 OSC 13738 2462

197 VDD1 13147 2461

198 VDD1 13047 2461

199 VDD1 12947 2461

200 VDD2 12145 2461

Pad Pad name X Y

201 VDD2_HV_IN11145 2461

202 VDD2_HV_IN11045 2461

203 VDD2_HV_IN10945 2461

204 RES_B_IN 10627 2462

205 SDA_OUT 10333.552462

206 SDA_IN 9412.4 2462

207 SDA_IN 9212.4 2462

208 SCL_IN 8256.8 2462

209 SCL_IN 8056.8 2462

Recpat C1 16275 2437

Recpat C2 2301 80

Recpat F 304 1824

1997 Nov 21 33

Page 34

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

2

PURCHASE OF PHILIPS I

C COMPONENTS

Purchase of Philips I

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

2

C components conveys a license under the Philips’ I2C patent to use the

1997 Nov 21 34

Page 35

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver PCF8549

NOTES

1997 Nov 21 35

Page 36

Philips Semiconductors – a worldwide company

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +61 2 9805 4455, Fax. +61 2 9805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213, Tel. +43 160 1010,

Fax. +43 160 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 200 733, Fax. +375 172 200 773

Belgium: see The Netherlands

Brazil: seeSouth America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15thfloor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 689 211, Fax. +359 2 689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard 80, PB 1919, DK-2300 COPENHAGEN S,

Tel. +45 32 88 2636, Fax. +45 31 57 0044

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615800, Fax. +358 9 61580920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 40 99 6161, Fax. +33 1 40 99 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 23 53 60, Fax. +49 40 23 536 300

Greece: No. 15, 25th March Street, GR 17778 TAVROS/ATHENS,

Tel. +30 1 4894 339/239, Fax. +30 1 4814 240

Hungary: seeAustria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IV Novembre 3,

20124 MILANO, Tel. +39 2 6752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku, TOKYO 108,

Tel. +81 3 3740 5130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska 10, PL 04-123 WARSZAWA,

Tel. +48 22 612 2831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 1231,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 7430 Johannesburg 2000,

Tel. +27 11 470 5911, Fax. +27 11 470 5494

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 3 301 6312, Fax. +34 3 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 632 2000, Fax. +46 8 632 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2686, Fax. +41 1 481 7730

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2865, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640 GÜLTEPE/ISTANBUL,

Tel. +90 212 279 2770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 181 730 5000, Fax. +44 181 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 625 344, Fax.+381 11 635 777

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p,

P.O. Box 218, 5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. 1997 SCA56

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Internet: http://www.semiconductors.philips.com

Printed in The Netherlands 417067/1200/01/pp36 Date of release: 1997Nov 21 Document order number: 9397 750 03044

Loading...

Loading...