Page 1

INTEGRATED CIRCUITS

DATA SH EET

PCF8535

65 × 133 pixel matrix driver

Objective specification

File under Integrated Circuits, IC12

1999 Aug 24

Page 2

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 ORDERING INFORMATION

5 BLOCK DIAGRAM

5.1 Block diagram functions

5.1.1 Oscillator

5.1.2 Power-on reset

5.1.3 I2C-bus controller

5.1.4 Input filters

5.1.5 Display data RAM

5.1.6 Timing generator

5.1.7 Address counter

5.1.8 Display address counter

6 PINNING

6.1 Pin functions

6.1.1 R0 to R64

6.1.2 C0 to C132

6.1.3 V

6.1.4 V

6.1.5 V

6.1.6 V

6.1.7 V

and V

SS1

to V

DD1

LCDOUT

LCDIN

LCDSENSE

SS2

DD3

6.1.8 SDA

6.1.9 SDAOUT

6.1.10 SCL

6.1.11 SA0 and SA1

6.1.12 OSC

6.1.13 RES

6.1.14 T1, T2, T3, T4 and T5

7 FUNCTIONAL DESCRIPTION

7.1 Reset

7.2 Power-down

7.3 LCD voltage selector

7.4 Oscillator

7.5 Timing

7.6 Column driver outputs

7.7 Row driver outputs

7.8 Drive waveforms

7.9 Set multiplex rate

7.10 Bias system

7.10.1 Set bias system

7.11 Temperature measurement

7.11.1 Temperature read back

7.12 Temperature compensation

7.12.1 Temperature coefficients

7.13 V

OP

7.13.1 Set VOP value

7.14 Voltage multiplier control

7.14.1 S[1:0]

7.15 Addressing

7.15.1 Input addressing

7.15.2 Output addressing

7.16 Instruction set

7.16.1 RAM read/write command page

7.16.2 Function and RAM command page

7.16.3 Display setting command page

7.16.4 HV-gen command page

7.16.5 Special feature command page

7.16.6 Instruction set

7.17 I2C-bus interface

7.17.1 Characteristics of the I2C-bus

7.17.2 I2C-bus protocol

8 LIMITING VALUES (PROVISIONAL)

9 HANDLING

10 DC CHARACTERISTICS

11 AC CHARACTERISTICS

12 RESET TIMING

13 APPLICATION INFORMATION

14 BONDING PAD LOCATIONS

15 DEVICE PROTECTION DIAGRAM

16 TRAY INFORMATION

17 DEFINITIONS

18 LIFE SUPPORT APPLICATIONS

19 PURCHASE OF PHILIPS I2C COMPONENTS

20 BARE DIE DISCLAIMER

1999 Aug 24 2

Page 3

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

1 FEATURES

• Single-chip LCD controller/driver

• 65 row, 133 column outputs

• Display data RAM 65 × 133 bits

• 133 icons (last row is used for icons)

• Fast mode I2C-bus interface (400 kbits/s)

• Software selectable multiplex rates:

1:17,1:26,1:34,1:49and1:65

• On-chip:

– Generation of intermediate LCD bias voltages

– Oscillator requires no external components

(external clock also possible)

– Generation of V

LCD

.

• CMOS compatible inputs

• Software selectable bias configuration

• Logic supply voltage range V

• Supply voltage range for high voltage part V

V

DD3

to V

SS2

and V

4.5 to 5.5 V

SS3

• Display supply voltage range V

DD1

LCD

to V

to VSS:

4.5 to 5.5 V

SS1

DD2

and

– Mux rate 1 : 65: 8 to 16 V.

• Low power consumption, suitable for battery operated

systems

• Internal Power-on reset and/or external reset

• Temperature read back available

• Manufactured in N-well silicon gate CMOS process.

2 APPLICATIONS

• Automotive information systems

• Telecommunication systems

• Point-of-sale terminals

• Instrumentation.

3 GENERAL DESCRIPTION

The PCF8535 is a low power CMOS LCD row/column

driver, designed to drive dot matrix graphic displays at

multiplex rates of 1 : 17, 1 : 26, 1 : 34, 1 : 49 and 1 : 65.

Furthermore, it can drive up to 133 icons. All necessary

functions for the display are provided in a single chip,

including on-chip generation of LCD bias voltages,

resulting in a minimum of external components and low

power consumption. The PCF8535 is compatible with

most microcontrollers and communicates via an industry

standard two-line bidirectional I2C-bus serial interface.

All inputs are CMOS compatible.

4 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

PCF8535U − chip with bumps in tray −

1999 Aug 24 3

Page 4

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

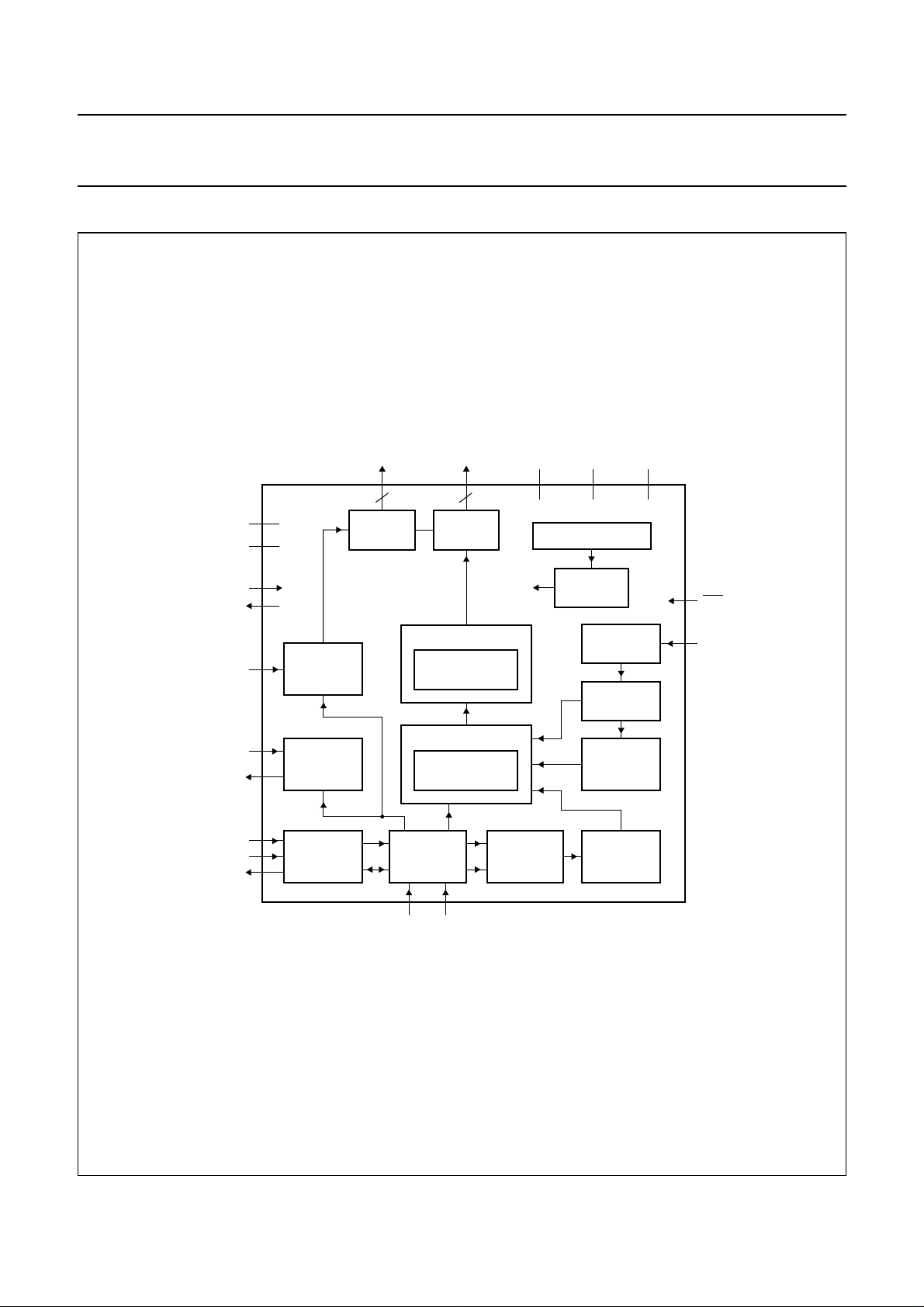

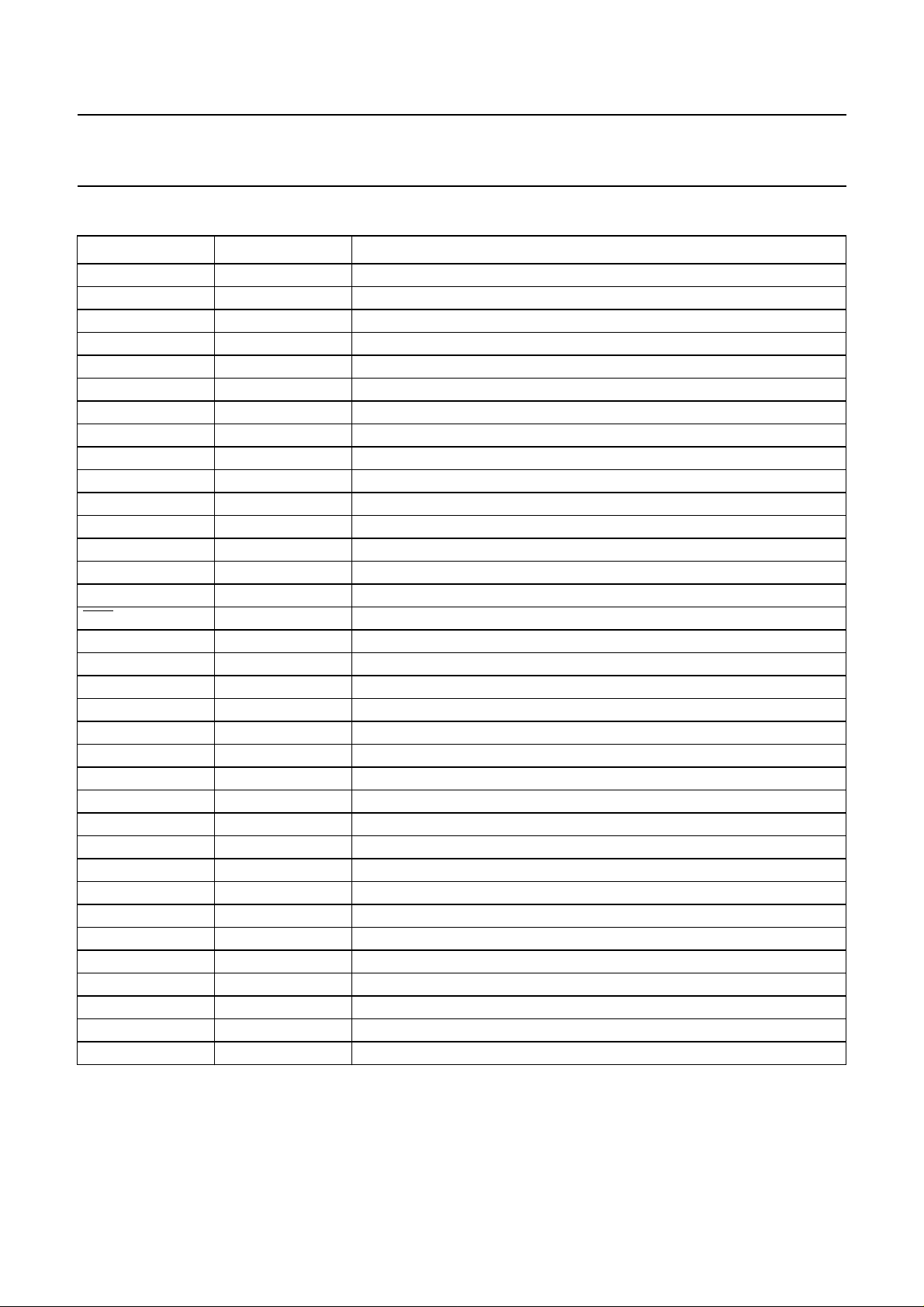

5 BLOCK DIAGRAM

handbook, full pagewidth

V

V

T4, T5

T1, T2, T3

V

LCDIN

V

LCDSENSE

V

LCDOUT

SDAOUT

SS1

SS2

SCL

SDA

BIAS

VOLTAGE

GENERATOR

V

LCD

GENERATOR

INPUT

FILTERS

R0 to R64

65

ROW

DRIVERS

PCF8535

C0 to C132

133

COLUMN

DRIVERS

DATA LATCHES

MATRIX

LATCHES

DISPLAY DATA RAM

MATRIX DATA

RAM

I2C-BUS

CONTROL

V

DD1

POWER-ON RESET

COMMAND

DECODER

V

DD2

INTERNAL

RESET

OSCILLATOR

TIMING

GENERATOR

DISPLAY

ADDRESS

COUNTER

ADDRESS

COUNTER

V

DD3

RES

OSC

SA0

SA1

Fig.1 Block diagram.

1999 Aug 24 4

MGS669

Page 5

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

5.1 Block diagram functions

5.1.1 OSCILLATOR The on-chip oscillator provides the display clock for the

system; it requires no externalcomponents. Alternatively,

an external display clock may be provided via the OSC

input. The OSC input must be connected to V

DD1

or V

SS1

when not in use. During power-down additional current

saving can be made if the external clock is disabled.

5.1.2 POWER-ON RESET The on-chip Power-on reset initializes the chip after

power-on or power failure.

2

5.1.3 I

C-BUS CONTROLLER

The I2C-bus controller detects the I2C-bus protocol, slave

address, commands and display data bytes. It performs

the conversion of the data input (serial-to-parallel).

The PCF8535 acts as an I2C-bus slave and therefore

cannot initiate bus communication.

5.1.4 INPUT FILTERS Input filters are provided to enhance noise immunity in

electrically adverse environments; RC low-pass filters are

provided on the SDA, SCL and RES lines.

5.1.5 D

ISPLAY DATA RAM

The PCF8535 contains a 65 × 133 bit static RAM which

storesthe display data. The RAM is dividedinto9 banks of

133 bytes. The last bank is used for icon data and is only

one bit deep. During RAM access, data is transferred to

the RAM via the I2C-bus interface. There is a direct

correspondence between the X address and the column

output number.

5.1.6 TIMING GENERATOR The timing generator produces the various signals

required to drive the internal circuitry. Internal chip

operation is not disturbed by operations on the data bus.

5.1.7 ADDRESS COUNTER TheAddressCounter(AC)sendsaddressestotheDisplay

Data RAM (DDRAM) for writing.

5.1.8 DISPLAY ADDRESS COUNTER The display is generated by continuously shifting rows of

RAM data to the dot matrix LCD via the column outputs.

The display status (all dots on or off, normal or inverse

video) is set via the I2C-bus.

1999 Aug 24 5

Page 6

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

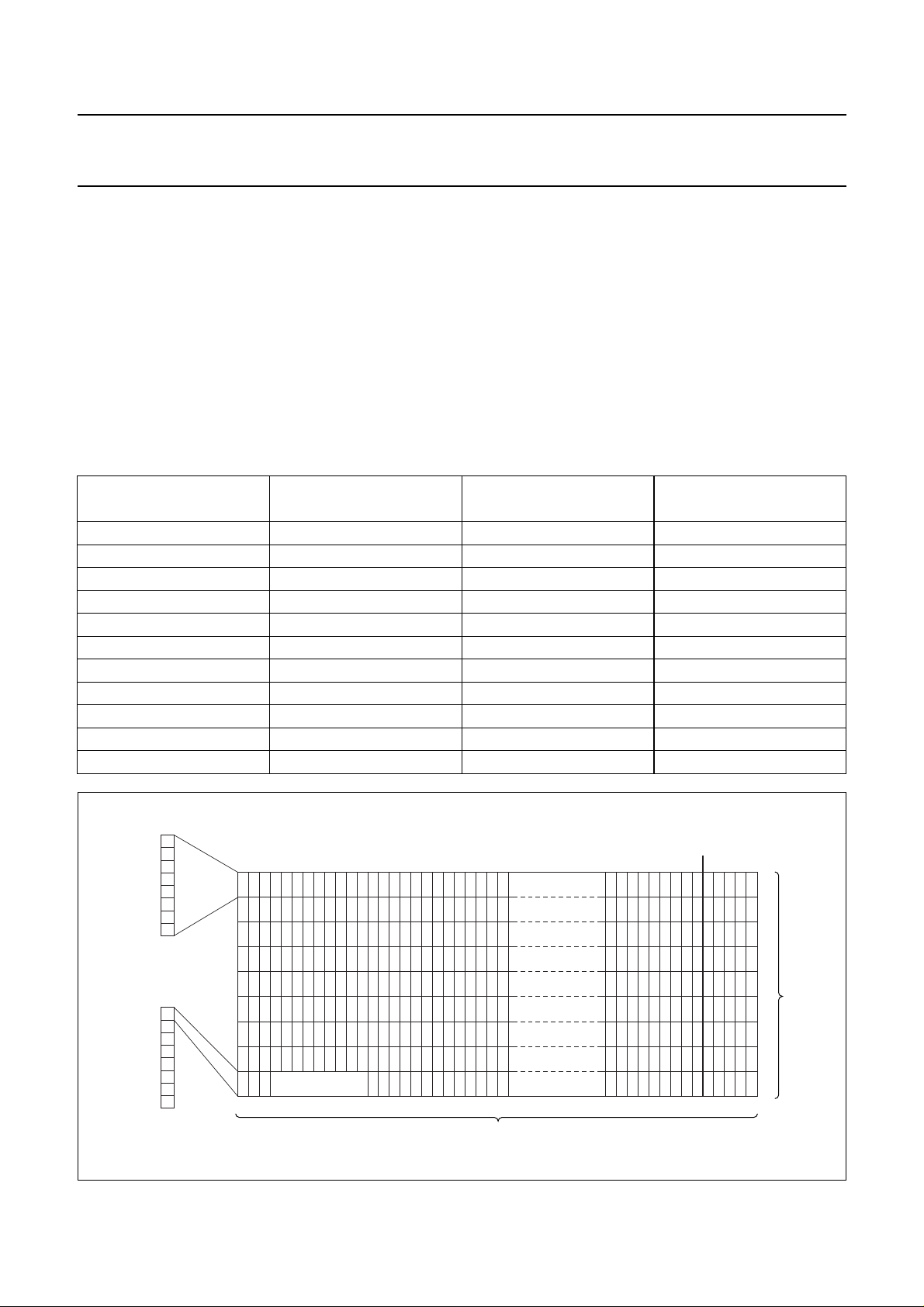

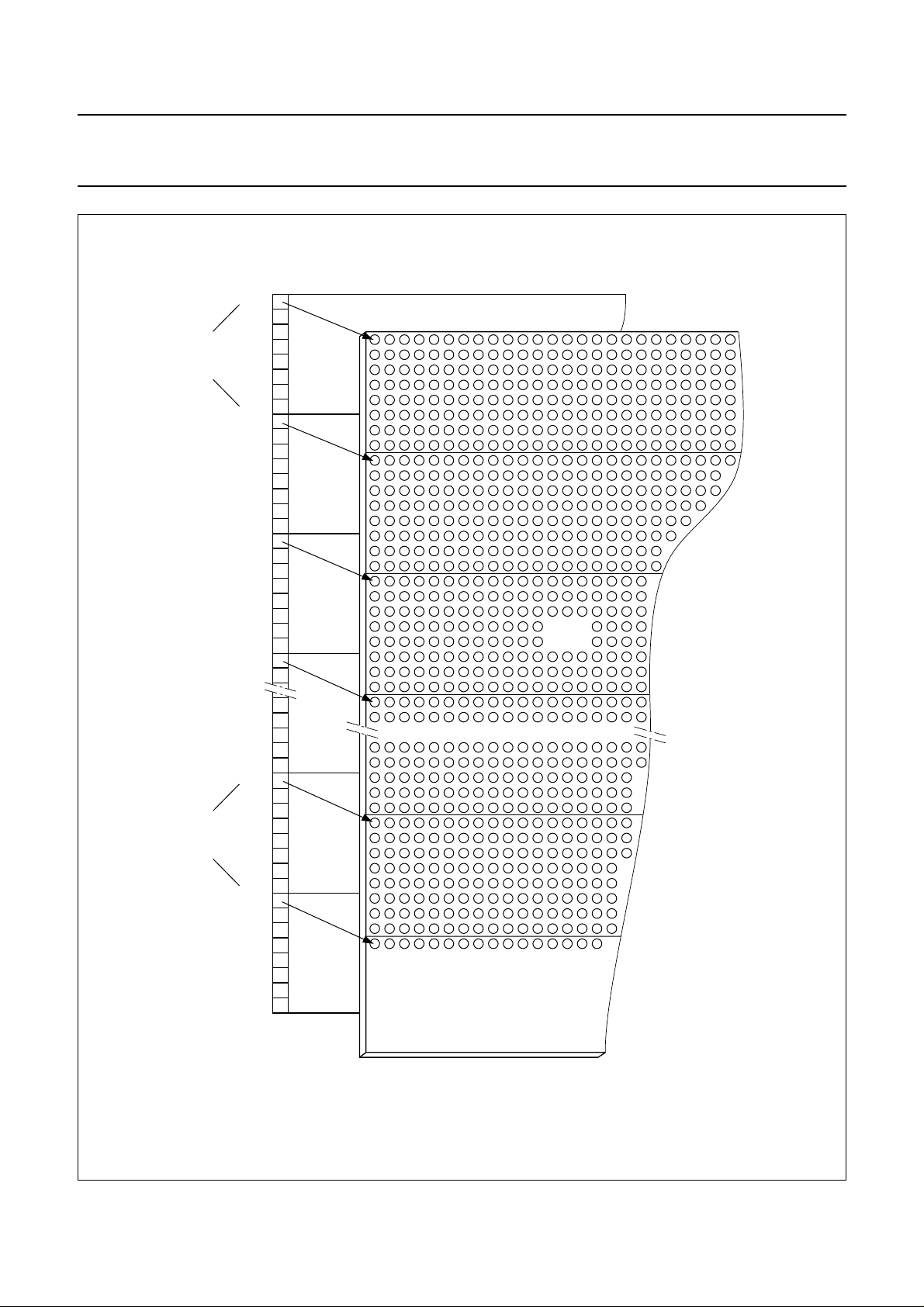

6 PINNING

SYMBOL PAD DESCRIPTION

1 dummy pad

2 bump/alignment mark 1

R0 to R15 3 to 18 LCD row driver outputs

C0 to C132 19 to 151 LCD column driver outputs

R47 to R33 152 to 166 LCD row driver outputs

167 bump/alignment mark 2

168 dummy pad

R48 to R64 169 to 185 LCD row driver outputs; R64 is icon row

186 bump/alignment mark 3

187 to 189 dummy pad

OSC 190 oscillator

V

LCDIN

V

LCDOUT

V

LCDSENSE

RES 207 external reset input (active LOW)

T3 208 test output 3

T2 209 test output 2

T1 210 test output 1

V

DD2

V

DD3

V

DD1

SDA 230 and 231 I2C-bus serial data inputs

SDAOUT 232 I2C-bus serial data output

SA1 233 I2C-bus slave address input

SA0 234 I2C-bus slave address input

V

SS2

V

SS1

T5 251 test input 5

T4 252 test input 4

SCL 254 and 255 I2C-bus serial clock inputs

R32 to R16 257 to 273 LCD row driver outputs

191 to 196 LCD supply voltage

197 to 203 voltage multiplier output

204 voltage multiplier regulation input (V

205 and 206 dummy pad

211 to 218 supply voltage 2

219 to 222 supply voltage 3

223 to 228 supply voltage 1

229 dummy pad

235 to 242 ground 2

243 to 250 ground 1

253 dummy pad

256 bump/alignment mark 4

LCD

)

6.1 Pin functions

6.1.1 R0 TO R64

These pads output the display row signals.

1999 Aug 24 6

Page 7

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

6.1.2 C0 TO C132

These pads output the display column signals.

6.1.3 V

V

and V

SS1

6.1.4 V

V

is the logic supply. V

DD1

multiplier. For split power suppliesV

AND V

SS1

SS2

DD1

SS2

must be connected together.

TO V

DD3

and V

DD2

are for the voltage

DD3

and V

DD2

DD3

must be

connectedtogether.If only one supply voltage is available,

all three supplies must be connected together.

6.1.5 V

If, in the application, an external V

LCDOUT

is used, V

LCD

LCDOUT

must be left open-circuit; otherwise (if the internal voltage

multiplier is enabled) the chip may be damaged. V

should not be driven when V

is below its minimum

DD1

LCDOUT

allowed value otherwise a low impedance path between

V

LCDOUT

6.1.6 V

This is the V

If the internal V

V

LCDIN

driven when V

otherwisea low impedance path between V

and V

LCDIN

will exist.

SS1

supply for when an external V

LCD

generator is used, then V

LCD

must be connected together. V

is below its minimum allowed value,

DD1

should not be

LCDIN

LCDIN

is used.

LCD

LCDOUT

andV

and

SS1

will exist.

and the Indium Tin Oxide (ITO) track resistance. It is

possible that during the acknowledge cycle the PCF8535

will not be able to create a valid logic 0 level. By splitting

the SDA input from the SDAOUT output the device could

be used in a mode that ignores the acknowledge bit.

In COG applications where the acknowledge cycle is

required or where read back is required, it is necessary to

minimizethetrackresistancefromtheSDAOUT pad to the

system SDA line to guarantee a valid LOW level.

6.1.10 SCL

2

C-bus serial clock input.

I

6.1.11 SA0 AND SA1

Least significant bits of the I2C-bus slave address.

Table 1 Slave address; see note 1

SA1 AND SA0 MODE SLAVE ADDRESS

0 and 0 write 78H

read 79H

0 and 1 write 7AH

read 7BH

1 and 0 write 7CH

read 7DH

1 and 1 write 7EH

read 7FH

6.1.7 V

LCDSENSE

This is the input to the internal voltage multiplier regulator.

It must be connected to V

LCDOUT

when the internal voltage

generator is used otherwise it may be left open-circuit.

V

LCDSENCE

should not be driven when V

is below its

DD1

minimum allowed value, otherwise a low impedance path

between V

LCDSENCE

and V

will exist.

SS1

6.1.8 SDA I2C-bus serial data input.

6.1.9 SDAOUT SDAOUT is the serial data acknowledge for the I2C-bus.

By connecting SDAOUT to SDA externally, the SDA line

becomes fully I2C-bus compatible. Having the

acknowledge output separated from the serial data line is

advantageous in Chip-On-Glass (COG) applications.

In COG applications where the track resistance from the

SDAOUT pad to the system SDA line can be significant, a

potential divider is generated by the bus pull-up resistor

1999 Aug 24 7

Note

1. The slave address is a concatination of the following

bits {01111, SA1, SA0 and R/W}.

6.1.12 OSC

If the on-chip oscillator is used this input must be

connected to V

DD1

or V

SS1

.

6.1.13 RES

External reset pad: when this pad is LOW the chip will be

reset; see Section 7.1. If an external reset is not required,

this pad must be tied to V

. Timing for the RES pad is

DD1

given in Chapter 12.

6.1.14 T1, T2, T3, T4 AND T5

In applications T4 and T5 must be connected to VSS.

T1, T2 and T3 are to be left open-circuit.

Page 8

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

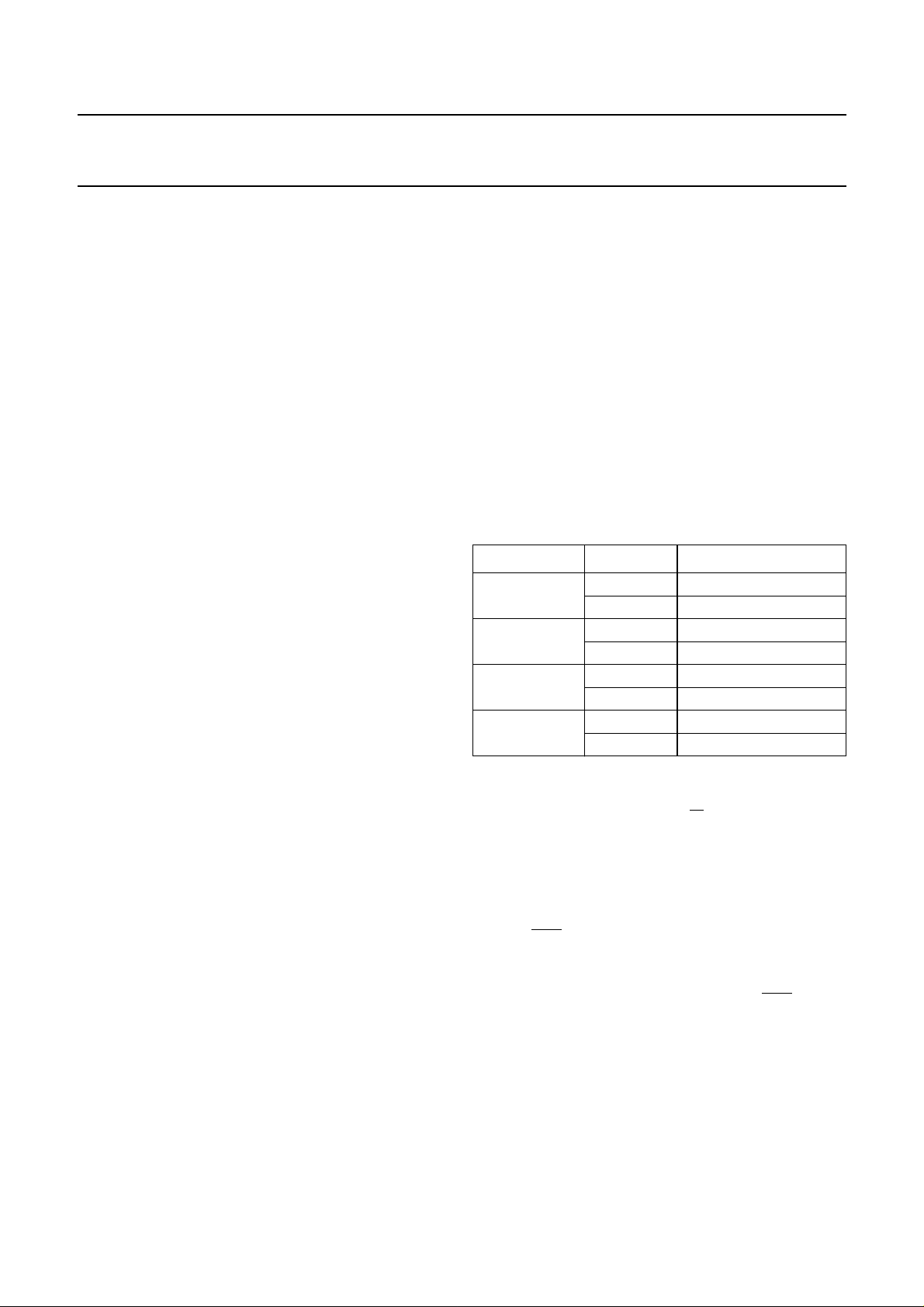

7 FUNCTIONAL DESCRIPTION

The PCF8535 is a low power LCD driver designed to interface with microprocessors/microcontrollers and a wide variety

of LCDs.

The host microprocessor/microcontroller and the PCF8535 are both connected to the I2C-bus. The SDA and SCL lines

must be connected to the positive power supply via pull-up resistors. The internal oscillator requires no external

components. The appropriate intermediate biasing voltage for the multiplexed LCD waveforms are generated on-chip.

The only other connections required to complete the system are to the power supplies (VDD,VSSand V

capacitors for decoupling V

LCD

and VDD.

) and suitable

LCD

handbook, full pagewidth

V

to V

DD1

V

DD(I2C)

V

SS1, VSS2

DD3

RES

SA0

SA1

SCL

SDA

V

LCD

DD2

DD1,VDD3

V

V

HOST

MICROPROCESSOR/

R

R

pu

pu

MICROCONTROLLER

V

SS

SS1VSS2

V

PCF8535

133 column drivers

65 row drivers

LCD PANEL

MGS670

Fig.2 Typical system configuration.

1999 Aug 24 8

Page 9

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.1 Reset

The PCF8535 has two reset modes; internal Power-on

reset or external reset. Reset initiated from either the RES

pad or the internal Power-on reset block will initialize the

chip to the following starting condition:

• Power-down mode (PD = 1)

• Horizontal addressing (V = 0); no mirror X or Y

(MX = 0 and MY = 0)

• Display blank (D = 0 andE=0)

• Address counter X[6:0] = 0, Y[2:0] = 0 and XM0=0

• Bias system BS[2:0] = 0

• Multiplex rate M[2:0] = 0 (Mux rate1:17)

• Temperature control mode TC[2:0] = 0

• HV-gen control, HVE = 0 the HV generator is switched

off, PRS = 0 and S[1:0] = 00

• V

LCDOUT

is equal to 0 V

• RAM data is unchanged (Note: RAM data is undefined

after power-up)

• All row and column outputs are set to VSS (display off)

• TRS and BRS are set to zero

• Direct mode is disabled (DM = 0)

• Internal oscillator is selected, but not running (EC = 0)

• Bias current set to low current mode (IB = 0).

7.3 LCD voltage selector

The practical value for VOP is determined by equating

V

with defined LCD threshold voltage (Vth), typically

off(rms)

when the LCD exhibits approximately 10% contrast.

7.4 Oscillator

The internal logic operation and the multi-level drive

signals of the PCF8535 are clocked by the built-in RC

oscillator. No external components are required.

7.5 Timing

ThetimingofthePCF8535organizestheinternaldataflow

of the device. The timing also generates the LCD frame

frequency which is derived from the clock frequency

generated in the internal clock generator.

7.6 Column driver outputs

The LCD drive section includes 133 column outputs

(C0 to C132) which should be connected directly to the

LCD. The column output signals are generated in

accordance with the multiplexed row signals and with the

data in the display latch. When less than 133 columns are

required the unused column outputs should be left

open-circuit.

7.7 Row driver outputs

7.2 Power-down

During power-down all static currents are switched off (no

internal oscillator, no timing and no LCD segment drive

system) and all LCD outputs are internally connected to

VSS. The serial bus function remains active.

The LCD drive section includes 65 row outputs

(R0 to R64) which should be connected directly to the

LCD. The row output signals are generated in accordance

with the selected LCD drive mode. If lower Mux rates or

less than 65 rows are required, the unused outputs should

be left open-circuit.

1999 Aug 24 9

Page 10

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

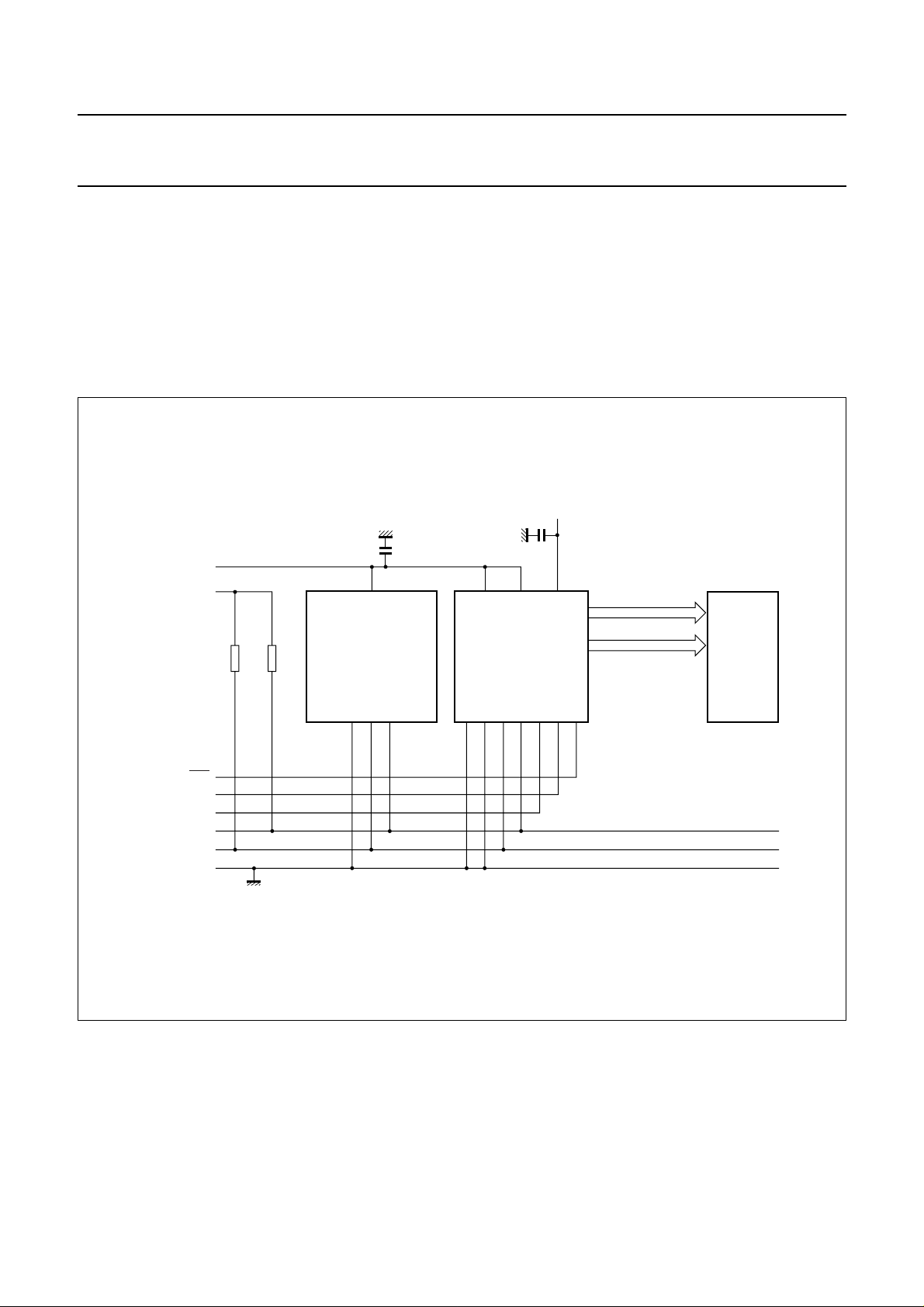

7.8 Drive waveforms

ROW 0

R0 (t)

ROW 1

R1 (t)

COL 0

C0 (t)

COL 1

C1 (t)

V

LCD

V3 − V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

− V

SS

SS

frame n frame n + 1

V

state1

V

state2

(t)

(t)

V

− V

LCD

V

V

V

(t) = C1(t) − R0(t).

state1

V

(t) = C1(t) − R1(t).

state2

state1

state2

(t)

(t)

0 V

V3 − V

V

LCD

V3 − V

V

LCD

0 V

V3 − V

2

SS

− V

SS

SS

− V

2

SS

012345678... ... 64 01234567 8... ... 64

Fig.3 Typical LCD driver waveforms.

1999 Aug 24 10

V4 − V

0 V

VSS − V

V4 − V

V

− V

SS

V4 − V

0 V

VSS − V

V4 − V

V

− V

SS

MGS671

5

5

LCD

LCD

5

5

LCD

LCD

Page 11

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.9 Set multiplex rate

The PCF8535 can be used to drive displays of varying sizes. The multiplex mode selected controls which rows are used.

In all cases, the last row is always driven and is intended for icons. If Top Row Swap (TRS) is at logic 1 then the icon row

will be output on pad R48. M[2:0] selects the multiplex rate (see Table 2).

Table 2 Multiplex rates

M[2] M[1] M[0] MULTIPLEX RATE ACTIVE ROWS

0 0 0 1 : 17 R0 to R15 and R64

0 0 1 1 : 26 R0 to R24 and R64

0 1 0 1 : 34 R0 to R32 and R64

0 1 1 1 : 49 R0 to R47 and R64

1 0 0 1:65 R0toR64

101 − 111 do not use −

7.10 Bias system

7.10.1 SET BIAS SYSTEM

The bias voltage levels are set in the ratio of R − R − nR − R − R. Differentmultiplex rates require differentfactors n. This

is programmed by BS[2:0]. For optimum bias values, n can be calculated from:

n Mux rate 3–=

Changing the bias system from the optimum will have a consequence on the contrast and viewing angle. One reason to

come away from the optimum would be to reduce the required V

. A compromise between contrast and VOP must be

OP

found for any particular application.

Table 3 Programming the required bias system

BS[2] BS[1] BS[0] n BIAS MODE TYPICAL MUX RATES

00071/

00161/

01051/

01141/

10031/

10121/

11011/

1110

11

10

9

8

7

6

5

1

/

4

1 : 100

1:80

1:65

1:49

1:33

1:26

1:17

1:9

1999 Aug 24 11

Page 12

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

Table 4 Example of LCD bias voltage for1/7bias, n = 3

1

SYMBOL BIAS VOLTAGE FOR

V1 V

V2

V3

V4

V5

V6 V

6

/7× V

5

/7× V

2

/7× V

1

/7× V

LCD

SS

/7BIAS

LCD

LCD

LCD

LCD

7.11 Temperature measurement

7.11.1 T

EMPERATURE READ BACK

The PCF8535 has an in-built temperature sensor.

For power saving, the sensor should only be enabled

when a measurement is required. It will not operate in

power-down mode. The temperature read back requires a

clock to operate. Normally the internal clock is used but, if

the device is operating from an external clock, then this

must be present for the measurement to work. V

V

mustalso be applied. A measurement is initialized by

DD3

DD2

and

setting the SM bit. Once started the SM bit will be

automatically cleared. An internal oscillator will be

initialized and allowed to warm-up for approximately

2 frame periods. After this the measurement starts and

lasts for a maximum of 2 frame periods.

Temperature data is returned via a status register. During

the measurement the register will contain zero. Once the

measurement is completed the register will be updated

with the current temperature (non zero value). Because

the I2C-bus interface is asynchronous to the temperature

measurement, read back prior to the end of the

measurement is not guaranteed. If this mode is required

the register should be read twice to validate the data.

For calibrating the temperature read-out a measurement

must be taken at a defined temperature. The offset

between the ideal read-out and the actual result has to be

stored into a non-volatile register (e.g. EEPROM);

Offset TR

where TR

meas

TR

–=

ideal

meas

is the actual temperature read-out of the

(2)

PCF8535.

The calibrated temperature read-out can be calculated for

each measurement as follows:

TR

cal

TR

meas

Offset+=

(3)

The accuracy after the calibration is ±6.7% (plus ±1 lsb) of

the difference between the current temperature and the

calibration temperature. For this reason a calibration at or

near the most sensitive temperature for the display is

recommended.

E.g. for a calibration at 25 °C with the current temperature

at −20 °C, the absolute error may be calculated as:

Absolute error = 0.067 × (25 °C −−20 °C)

= ±3 °C+±1 lsb = ±4.17 °C.

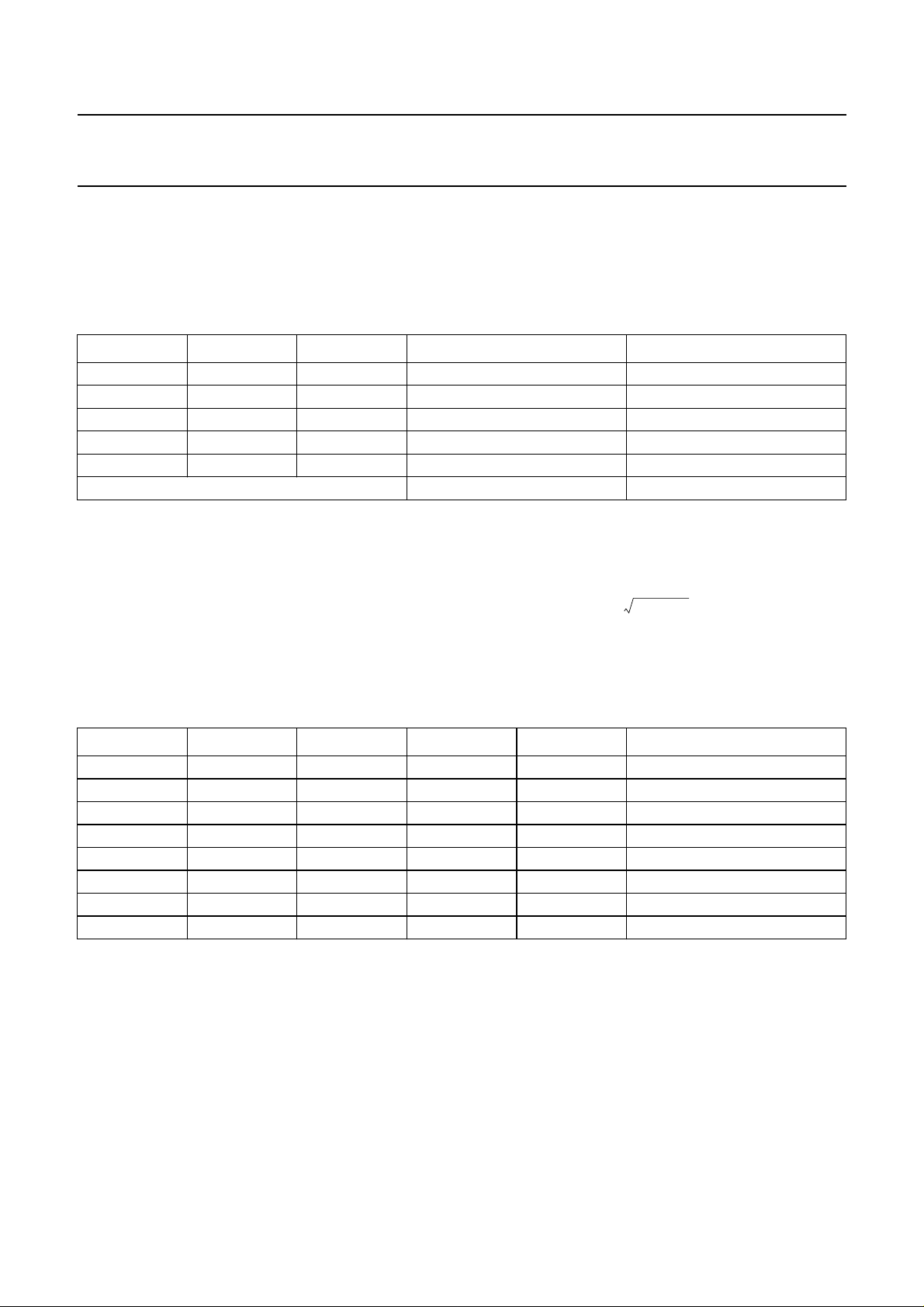

7.12 Temperature compensation

7.12.1 TEMPERATURE COEFFICIENTS Due to the temperature dependency of the liquid crystals

viscosity the LCD controlling voltage,V must be increased

at lower temperatures to maintain optimum contrast.

Figure 4 shows V

as a function of temperature for a

LCD

typical high multiplex rate liquid.

Inthe PCF8535 the temperature coefficient of V

LCD

canbe

selected from 8 values by setting bits TC[2:0],

see Table 5.

The ideal temperature read-out can be calculated as

follows;

TR

128 T 27 °C–()

ideal

×+=

-- c

(1)

1

where T is the on-chip temperature in °C and c is the

conversion constant; c = 1.17 °C/lsb.

Toimprove the accuracy of the temperature measurement

a calibration is recommended during the assembly of the

final product.

1999 Aug 24 12

Page 13

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, halfpage

V

LCD

Fig.4 V

as function of liquid crystal temperature (typical values).

LCD

Table 5 Selectable temperature coefficients

TC[2] TC[1] TC[0] TC VALUE UNIT

000 0 1/°C

001−0.44 × 10

010−1.10 × 10

011−1.45 × 10

100−1.91 × 10

101−2.15 × 10

110−2.32 × 10

111−2.74 × 10

7.13 V

7.13.1 SET V

OP

OP

VALUE

−3

−3

−3

−3

−3

−3

−3

1/°C

1/°C

1/°C

1/°C

1/°C

1/°C

1/°C

The voltage at the reference temperature can be

calculated as: [V

V

LCD

Tcut()

The operating voltage, V

(T=T

LCD

aVOPb×+()=

)]

cut

, can be set by software.

OP

(4)

The generated voltage is dependent on the temperature,

programmed Temperature Coefficient (TC) and the

programmed voltage at the reference temperature (T

V

LCD

aVOPb×+()1TT

The values for T

, a and b are given in Table 6.

cut

–()TC×()+()×=

cut

cut

):

(5)

The maximumvoltagethatcan be generated is dependent

on the voltage V

and the display load current.

DD2

Two overlapping VOP ranges are selectable via the

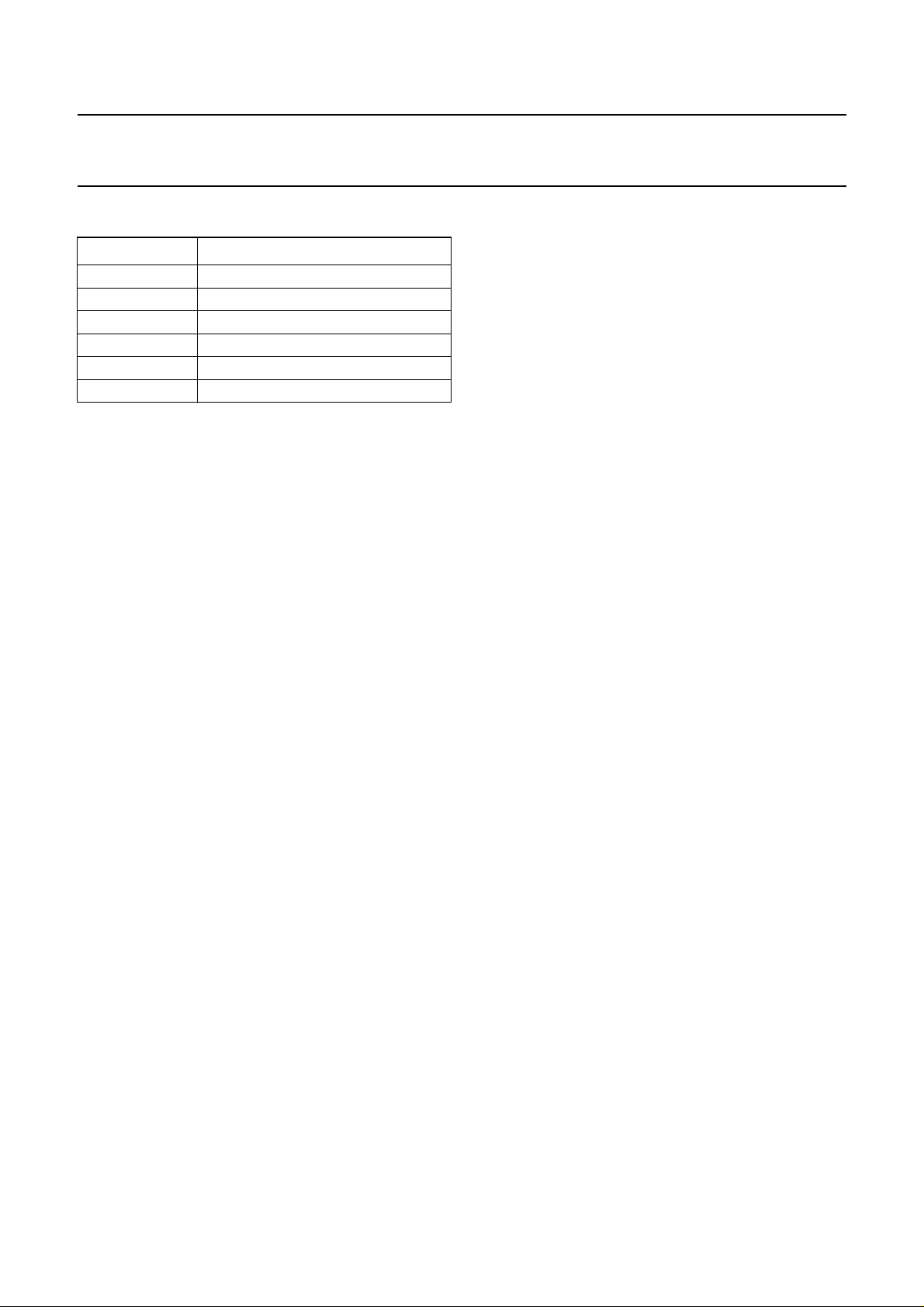

command page “Hv-gen control”, see Fig.5.

MGS473

0 °C

T

The low range offers programming from 4.5 to 10.215 V,

with the high range from 10.215 to 15.93 V at the cut point

temperature, T

. Care must be taken, when using

cut

temperature coefficients, that the programmed voltage

does not exceed the maximum allowed V

LCD

voltage,

see Chapter 10.

Fora particular liquid, the optimumV

canbe calculated

LCD

for a given multiplex rate. For a Mux rate of 1 : 65, the

optimum operating voltage of the liquid can be calculated

as:

V

LCD

where V

165+

---------------------------------------

×

–

21

is the threshold voltage of the liquid crystal

th

----------

1

65

V

× 6.85 Vth×==

th

material used.

Table 6 Values for parameters of the HV generator

programming

SYMBOL BITS VALUE UNIT

a PRS = 0 4.5 V

PRS = 1 10.215 V b 0.045 V T

cut

27 °C

(6)

1999 Aug 24 13

Page 14

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, full pagewidth

V

LCD

b

a

00 01 02

VOP[6:0] programming (00H to 7FH, programming range LOWand HIGH).

03 04 05 06 . . . 5F 6F 7F 00 01 02 03 04 05 06 . . . 5F 6F 7F

LOW HIGH

Fig.5 VOP programming of PCF8535.

7.14 Voltage multiplier control

7.14.1 S[1:0] The PCF8535 incorporates a software configurable

voltage multiplier. After reset (RES) the voltage multiplier

is set to 2 × V

. Other voltage multiplier factors are set

DD2

via the HV-gen command page. Before switching on the

charge pump, the charge pump has to be pre-charged

using the following sequence.

A starting state of HVE = 0, DOF = 0, PD = 1 and DM = 0

is assumed. A small delay between steps is indicated.

The recommended wait period is 20 µs per 100 nF of

capacitance on V

LCD1

.

1. Set DM = 1 and PD = 0

2. Delay

3. Set the multiplication factor to 2 by setting S[1:0] = 00

4. Set the required VOP and PRS.

5. Set HVE = 1 to switch-on the charge pump with a

multiplication factor of 2

6. Delay

7. Increase the number of stages, one at a time, with a

delay between each until the required level is

achieved.

MGS472

Table 7 HV generator multiplication factor

S[1] S[0] MULTIPLICATION FACTOR

00 2× V

01 3× V

10 4× V

11 5× V

DD2

DD2

DD2

DD2

1999 Aug 24 14

Page 15

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15 Addressing

Addressing of the RAM can be split into two parts; input

addressing and output addressing. Input addressing is

concerned with writing data into the RAM. Output

addressing is almost entirely automatic and taken care of

by the device, however, it is possible to affect the output

mode.

7.15.1 INPUT ADDRESSING

Data is down loaded byte wise into the RAM matrix of the

PCF8535 as indicated in Figs 6 to 10.

Table 8 Effect of X-RAM page pointer

X ADDRESS POINTER

X-RAM PAGE POINTER

XM

0

0 0 C0 C132 1 0 C1 C131 2 0 C2 C130

:::: 125 0 C125 C7 126 0 C126 C6 127 0 C127 C5

0 1 C128 C4 1 1 C129 C3

::::

4 1 C132 C0

The display RAM has a matrix of 65 × 133 bits.

The columns are addressed by a combination of the

X address pointer and the X-RAM page pointer, whilst the

rows addressed in groups of 8 by the Y address pointer.

The X address pointer has a range of 0 to 127 (7FH).

Its range can be extended by the X-RAM page pointer,

XM0. The Y address pointer has a range of 0 to 8 (08H).

The PCF8535 is limited to 133 columns by 65 rows,

addressing the RAM outside of this area is not allowed.

ADDRESSED COLUMN

MX = 0

ADDRESSED COLUMN

MX = 1

Banks 1 to 7 use

the entire byte

handbook, full pagewidth

MSB

LSB

Bank 8 is only

1 bit deep and

uses the MSB

MSB

LSB

01234

icon data

56789

101112131415161718192021222324

Fig.6 RAM format, input addressing.

1999 Aug 24 15

.. .. .. ..

X address

XM0 = 1XM0 = 0

0

1

2

3

4

5

Y address

6

7

8

119

123

120

121

122

124

125

126

127

01234

MGS673

Page 16

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

Data byte in location

X = 0, Y = 0, MX0 = 0

(MX = 0, MY = 0)

MSB

LSB

bank 0

top of LCD

R0

bank 1

R8

bank 2

R16

LCD

bank 3

R24

MSB

Data byte in location

Y = 7, X = 0, MX0 = 0

(MX = 0, MY = 0)

LSB

bank 7

bank 8

Fig.7 DDRAM to display mapping.

1999 Aug 24 16

R56

R64

MGS674

Page 17

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

Two automated addressing modes are available; vertical

addressing (V = 1) and horizontal addressing (V = 0).

These modes change the way in which the

auto-incrementing of the address pointers is handled and

are independent of multiplex rate. The auto-incrementing

works in a way so as to aid filling of the entire RAM. It is

not a prerequisite of operation that the entire RAM is filled;

inlowermultiplex modes not all of the RAM will beneeded.

For these multiplex rates, use of horizontal addressing

mode (V = 0) is recommended.

Addressing the icon row is a special case as these RAM

locations are not automatically accessed. These locations

must be explicitly addressed by setting the Y address

pointer to 8.

The Y address pointer does not auto-increment when the

X address over or underflows, it stays set to 8. Writing

icon data is independent of the vertical and horizontal

addressing mode, but is effected by the mirror X bit as

described in Sections 7.15.1.2 and 7.15.1.3.

The addressing modes may be further modified by the

mirror X bit MX. This bit causes the data to be written into

the RAM from right to left insteadof the normal left to right.

This effectively flips the display about the Y axis. The MX

bit affects the mode of writing into the RAM, changing the

MX bit after RAM data is written will not flip the display.

7.15.1.1 Vertical addressing: non-mirrored;

V = 1 and MX = 0

In the vertical addressing mode data is written top to

bottom and left to right. Here, the Y counter will

auto-incrementfrom0 to 7 and then wrap around to 0 (see

Fig.8). On each wrap over, the X counter will increment to

address the next column. When the X counter wraps over

from 127 to 0, the XM0 bit will be set. The last address

accessible is Y = 7, X = 4 and XM0= 1; after this access

the counter will wrap around to Y = 0, X = 0 and XM0=0.

handbook, full pagewidth

byte number

byte order for

icon data

Fig.8 Sequence of writing data bytes into the RAM with normal vertical addressing (V = 1 and MX = 0).

26 25 24

....

15 14 13 12 11 10 9 8

23 22 21 20 19 18 17 16

076543210

1

2

01234

icon data

56789

12131415161718192021222324

101112131415161718192021222324

.... ....

X address

XM0 = 1XM0 = 0

1035 1034 1033 1032

....

....

1060

1061

1062

0

1

2

3

4

5

Y address

6

....

1012

1013

1014

1016

1017

1018

1019

1020

1021

1022

1024

1025

1026

1027

1028

1029

1030

7

1031

128

129

130

131

01234

1063

132

8

MGS675

1015

1023

119

123

124

125

122

122

123

124

125

126

126

127

127

120

121

119

120

121

1999 Aug 24 17

Page 18

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15.1.2 Vertical addressing: mirrored; V = 1 and MX = 1

It is also possible to write data from right to left, instead of from the normal left to right, still going top to bottom. In the

mirrored vertical addressing mode the Y counter will auto-increment from 0 to 7 and then wrap around to 0 (see Fig.9).

On each wrap-over, the X counter will decrement to address the preceding column. The XM0 bit will be automatically

toggled each time the X address counter wraps over from 0. The last address accessible is Y = 7, X = 0 and XM0=0;

after this access the counter will wrap around to Y = 0, X = 4 and XM0=1.

handbook, full pagewidth

byte number

byte order for

icon data

....

1053 1052

1054

1055

132 1063 1062 1061 1060 1059 1058 1057 1056

131

130

01234

icon data

56789

119

118

117

116

120

101112131415161718192021222324

111

115

114

113

112

110

109

108

.... ....

13

119

121110

120

121

122

987

123

124

125

48

50 49

....

6

126

XM0 = 1XM0 = 0

32

40

33

41

34

42

35

43

36

44

37

45

....

38

30

46

39

31747

43210

5

01234

127

X address

Fig.9 Sequence of writing data bytes into the RAM with mirrored vertical addressing (V = 1 and MX = 1).

....

8

9

10

0

0

1

1

2

3

432

4

5

5

6

6

7

8

Y address

MGS676

1999 Aug 24 18

Page 19

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15.1.3 Horizontal addressing: non-mirrored; V = 0 and MX = 0

In horizontal addressing mode data is written from left to right and top to bottom. Here, the X counter will auto-increment

from 0 to 127, set the XM0, then count 0 to 4 before wrapping around to 0 and clearing the XM0bit (see Fig.10). On each

wrap-over, the Y counter will increment. The last address accessible is Y = 7, X = 4 and XM0= 1; after this access the

counter will wrap around to Y = 0, X = 0 and XM0=0.

handbook, full pagewidth

124

1055

124

124

125

....

1056

125

125

126

924

1057

126

126

127

925

1058

127

127

XM0 = 1XM0 = 0

128

129

130

131

927

928

929

926

1059

1060

1061

1062

128

129

130

131

01234

132

930

1063

132

byte number

byte order for

icon data

2

3456789

136

934

932 1341933 135

0 931 133 0

1

2

01234

....

935

936

icon data

56789

101112131415161718192021222324

937

938

939

940

941

942

943

944

945

946

12131415161718192021222324

11

10

12131415161718192021222324

947

948

949

950

951

952

953

954

955

.... ....

119

1050

119

119

120

1051

120

120

121

1052

121

121

122

1053

122

122

123

1054

123

123

X address

Fig.10 Sequence of writing data bytes into the RAM with normal horizontal addressing (V = 0 and MX = 0).

0

1

2

3

4

5

6

7

8

Y address

MGS677

1999 Aug 24 19

Page 20

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15.1.4 Horizontal addressing: mirrored; V = 0 and MX = 1

It is also possible to write data from right to left, instead of from the normal left to right, still going top to bottom. In the

mirrored horizontal addressing mode the X counter will auto-decrement from 4 to 0, clear the XM0, then count 127 to 0

before wrapping around to 4 and setting the XM0 bit (see Fig.10). On each wrap-over, the Y counter will increment.

The last address accessible is Y = 7, X = 0 and XM0= 0; after this access the counter will wrap around to Y = 0, X = 4

and XM0=1.

handbook, full pagewidth

939

124

938

125

937

6

126

56789

936

5

127

XM0 = 1XM0 = 0

4

321

....

136

135

935

934

933

43210

01234

134

932

0

133

931

byte number

byte order for

icon data

130

129

131

929

928

927

1060

1062

1061

132 1063 930 132

131

130

01234

128

127

126

926

925

924

1059

1058

1057

icon data

56789

119

118

117

116

125

124

123

122

121

120

115

....

1056

1055

1054

1053

1052

1051

1050

1049

1048

1047

1046

119

118

117

116

120

101112131415161718192021222324

115

114

1045

114

113

1044

113

112

1043

112

111

110

109

108

1042

1041

1040

1039

111

110

109

108

.... ....

13

944

13

119

11

12

942

943

121110

120

121

10

941

122

940

987

123

X address

Fig.11 Sequence of writing data bytes into the RAM with mirrored horizontal addressing (V = 0 and MX = 1).

0

1

2

3

4

5

6

7

8

MGS678

Y address

1999 Aug 24 20

Page 21

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15.2 OUTPUT ADDRESSING The output addressing of the RAM is done automatically in accordance with the currently selected multiplex rate.

Normally the user would not need to make any alterations to the addressing. There are, however, circumstances

pertainingtovarious connectivity of the device on a glassthatwouldbenefit from some in-built functionality. Three modes

exist that enable the user to modify the output addressing, namely:

1. MY, mirror the Y axis. This mode effectively flips the display about the X axis, resulting in an upside down display.

Theeffect is observable immediately the bit ismodified. This is useful if thedeviceis to be mounted above thedisplay

area instead of below.

2. Bottom Row Swap (BRS). This mode swaps the order of the rows on the bottom

aide routing to the display when it is not possible to pass tracks under the device; a typical example would be in tape

carrier package. This mode is often used in conjunction with TRS.

3. Top Row Swap (TRS). As with BRS, but swaps the order of rows on the top

7.15.2.1 Mirror Y, MY

As described above, the Y axis is mirrored in the X axis.

(1)

edge of the chip. This is useful to

(1)

edge of the chip.

handbook, full pagewidth

MY = 0

Mirror

MY = 1

Y axis

Y axis

C0C1C2C3C4C5C6C7C8C9C10

R0

R1

R2

R3

R4

R5

R6

R7

R8

....

R64

R55

R56

R57

R58

R59

R60

R61

R62

R63

R64

... icons ...

... icons ...

C11

C12

C13

C14

C15

C16

C17

C18

C19

C20

C21

C22

C23

C24

C25

C26

MGS679

C27

..

C28

Fig.12 Mirror Y behaviour (Mux rate 1 : 65).

(1) The top edge is defined as the edge containing the user interface connections. The bottom edge is the opposing edge.

1999 Aug 24 21

Page 22

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15.2.2 Bottom Row Swap

Here the order of the row pads is modified. Each block of rows is swapped about its local Y axis.

handbook, full pagewidth

R16 R32 R64 R48

INTERFACE

COLUMNS

R15 R0

R33 R47

Fig.13 Bottom row swap.

7.15.2.3 Top Row Swap

Here the order of the row pads is modified. Each block of rows is swapped about its local Y axis.

MGS680

handbook, full pagewidth

R32 R16 R48 R64

INTERFACE

COLUMNS

R0 R15

Fig.14 Top row swap.

1999 Aug 24 22

R47 R33

MGS681

Page 23

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.15.2.4 Output row order

The order in which the rows are activated is a function of bits MY, TRS, BRS and the selected multiplex mode.

Tables 9 to 12 give the order in which the rows are activated. In all cases, the RAM is accessed in a linear fashion,

starting at zero with a jump to the last row for the icon data.

Table 9 Row order for BRS = 0 and TRS = 0

MULTIPLEX MODE MY = 0 MY = 1

1 : 17 R0 to R15 and R64 R15 to R0 and R64

1 : 26 R0 to R24 and R64 R24 to R0 and R64

1 : 33 R0 to R31 and R64 R31 to R0 and R64

1 : 49 R0 to R47 and R64 R47 to R0 and R64

1 : 65 R0 to R64 R63 to R0 and R64

Table 10 Row order for BRS = 1 and TRS = 0

MULTIPLEX MODE MY = 0 MY = 1

1 : 17 R15 to R0 and R64 R0 to R15 and R64

1 : 26 R15 to R0, R16 to R24 and R64 R24 to R16, R0 to R15 and R64

1 : 33 R15 to R0, R16 to R31 and R64 R31 to R16, R0 to R15 and R64

1 : 49 R15 to R0, R16 to R32, R47 to R33

and R64

1 : 65 R15 to R0, R16 to R32, R47 to R33

and R48 to R64

R33 to R47, R32 to R16, R0 to R15

and R64

R63 to R48, R33 to R47, R32 to R16,

R0 to R15 and R64

Table 11 Row order for BRS = 0 and TRS = 1

MULTIPLEX MODE MY = 0 MY = 1

1 : 17 R0 to R15 and R48 R15 to R0 and R48

1 : 26 R0 to R15, R32 to R24 and R48 R24 to R32, R15 to R0 and R48

1 : 33 R0 to R15, R32 to R17 and R48 R17 to R32, R15 to R0 and R48

1 : 49 R0 to R15, R32 to R16, R33 to R47

and R48

1 : 65 R0 to R15, R32 to R16, R33 to R47

and R64 to R48

Table 12 Row order for BRS = 1 and TRS = 1

MULTIPLEX MODE MY = 0 MY = 1

1 : 17 R15 to R0 and R48 R0 to R15 and R48

1 : 26 R15 to R0, R32 to R24 and R48 R0 to R15, R32 to R24 and R48

1 : 33 R15 to R0, R32 to R17 and R48 R0 to R15, R17 to R32 and R48

1 : 49 R15 to R0, R32 to R16, R47 to R33

and R48

1 : 65 R15 to R0, R32 to R16, R47 to R33

and R64 to R48

R47 to R33, R16 to R32, R15 to R0

and R48

R49 to R64, R47 to R33, R16 to R32,

R15 to R0 and R48

R0 to R15, R16 to R32, R33 to R47

and R48

R0 to R15, R16 to R32, R33 to R47,

R47 to R64 and R48

1999 Aug 24 23

Page 24

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.16 Instruction set

Data accesses to the PCF8535 can be broken down into

two areas, those that define the operating mode of the

device and those that fill the display RAM; the distinction

being the D/C bit. When the D/C bit is at logic 0, the chip

will respond to instructions as defined in Table 16. When

the D/C bit is at logic 1, the chip will store data into the

RAM. Data may be written to the chip that is independent

to the presence of the display clock.

There are 4 instruction types. Those which:

1. Define PCF8535 functions such as display configuration, etc.

2. Set internal RAM addresses

3. Perform data transfer with internal RAM

4. Others.

In normal use, category 3 instructions are the most

frequently used. To lessen the MPU program load,

automatic incrementing by one of the internal RAM

address pointers after each data write is implemented.

The instruction set is broken down into several pages,

each command page being individually addressed via the

H[2:0] bits.

7.16.1 RAM READ/WRITE COMMAND PAGE

This page is special in that it is accessible independently

of the H bits. This page is mainly used as a stepping stone

to other pages. Sending the ‘Default H[2:0]’ command will

cause an immediate step to the ‘Function and RAM

command page’ which will allow the H[2:0] bits to be set.

7.16.2 FUNCTION AND RAM COMMAND PAGE

7.16.2.1 Command page

Setting H[2:0] will move the user immediately to the

required command page. Pages not listed should not be

accessed as the behaviour is not defined.

• Oscillator off

• V

• I2C-bus interface accesses are possible

• RAM contents are not cleared; RAM data can be written

• Register settings remain unchanged.

V

When V = 0, horizontal addressing is selected. When

V = 1, vertical addressing is selected. The behaviour is

described in Section 7.15.

may be disconnected

LCDIN

7.16.2.3 RAM page

The XM0bit extends the RAM into a second page. The bit

may be considered to be the Most Significant Bit (MSB) of

an 8-bit X address. The behaviour is described in

Section 7.15.

7.16.2.4 Set Yaddress

The Y address is used as a pointer to the RAM for RAM

writing. The range is 0 to 8. Each bank corresponds to a

set of 8 rows, the only exception being bank 8, which

contains the icon data and is only 1-bit deep;see Table 13.

Table 13 Yaddress pointer

Y[3] Y[2] Y[1] Y[0] BANK ROWS

0000bank 0 R0 to R7

0001bank 1 R8 to R15

0010bank 2 R16 to R23

0011bank 3 R24 to R31

0100bank 4 R32 to R39

0101bank 5 R40 to R47

0110bank 6 R48 to R55

0111bank 7 R56 to R63

1000bank 8

(icons)

R64

7.16.2.2 Function set

PD

When PD = 1, the LCD driver is in power-down mode:

• All LCD outputs at V

1999 Aug 24 24

SS

Page 25

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.16.2.5 Set X address

The X address is used as a pointer to the RAM for RAM

writing. The range of X is 0 to 127 (7FH) and may be

extended by the XM0bit. The combined value of XM0and

X address directly corresponds to the display column

number when MX = 0 and corresponds to the inverse

display column number when MX = 1; see Table 14.

Table 14 X address pointer

XM

, X[6:0]

0

0 C0 C132 1 C1 C131 2 C2 C130 3 C3 C129

:: : 129 C129 C3 130 C130 C2 131 C131 C1 132 C132 C0

7.16.3 DISPLAY SETTING COMMAND PAGE

ADDRESSED

COLUMN, MX = 0

ADDRESSED

COLUMN, MX = 1

7.16.3.1 Display control

7.16.3.3 Bias system

BS[2:0] sets the bias system; see Section 7.10.

7.16.3.4 Display size

Physically large displays require stronger drivers. Bit IB

enables the user to select a stronger driving mode and

should be used if suitable display quality can not be

achieved with the default setting.

7.16.3.5 Multiplex rate

M[2:0] sets the multiplex rate; see Section 7.9.

7.16.4 HV-GEN COMMAND PAGE

7.16.4.1 HV-gen control

PRS

Programmable charge pump range select. This bit defines

whether the programmed voltage for VOP is in the low or

the high range. The behaviour of this bit is further

described in Section 7.13.

HVE

High voltage generator enable. When set to logic 0, the

charge pump is disabled. When set to logic 1, the charge

pump is enabled.

The D and E bits set the display mode as given in

Table 15.

Table 15 Display control

D E MODE

0 0 display blank 1 0 normal mode 0 1 all display segments on 1 1 inverse video

7.16.3.2 External display control

Mirror X and mirror Y have the effect of flipping the display

left to right or top to bottom respectively. MX works by

changing the order data that is written into the RAM.

As such, the effects of toggling MX will only be seen after

data is written into the RAM. MY works by reversing the

order that column data is accessed relative to the row

outputs. The effect of toggling MY will be seen

immediately. The behaviour of both of these bits is further

described in Section 7.15.

7.16.4.2 HV-gen stages

S[1:0] set the multiplication factor of the charge pump

ranging from times 2 to times 5. The behaviour of these

bits is further described in Section 7.14.

7.16.4.3 Temperature coefficients

TC[2:0] set the required temperature coefficient.

The behaviour of these bits is further described in

Section 7.12.

7.16.4.4 Temperature measurement control

The SM bit is used to initiate a temperature measurement.

The SM bit is automatically cleared at the end of the

measurement. The behaviour of this bit is further

described in Section 7.11.

7.16.4.5 V

VOP[6:0] sets the required operating voltage for the

display.

LCD

control

1999 Aug 24 25

Page 26

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.16.5 SPECIAL FEATURE COMMAND PAGE

7.16.5.1 State control

DM

Direct mode allows V

V

. This may be useful in systems where VDD is to be

DD2

used for V

LCD

.

to be sourced directly from

LCDOUT

DOF

Displayoffwillturnoffall internal analog circuitry that is not

required for temperature measurement.

As a consequence the display will be turned off. This

mode is only required if temperature measurements are

required whilst in power-down mode.

7.16.5.2 Oscillator setting

The internal oscillator may be disabled and the source

clock for the display derived from the OSC pad. It is

important to remember that LCDs are damaged by DC

voltages and that the clock, whether derived internally or

externally, should never be disabled whilst the display is

active. The internal oscillator is switched off during

power-down mode.

When using an external clock and disabling it during

power-down mode will further reduce the standby current.

If it is not possible to disable it externally then it is worth

notingthatbyselectingtheinternalclock,which is disabled

during power-down mode, the same effect may be

achieved.

7.16.5.3 COG/TCP

The chip may be mounted on either a glass, foil or tape

carrier package. For these applications, different

organizations of the row pads are required to negate the

necessity of routing under the device. The TRS and BRS

allowfor this swapping. The behaviour of bothofthese bits

is further described in Section 7.15.

7.16.6 INSTRUCTION SET

Table 16 Instruction set

INSTRUCTION D/CR/W

(1)

I2C-BUS COMMAND BYTE

I2C-BUS COMMANDS

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

H[2:0] = XXX; RAM read/write command page

Write data 1 0 D

Read status 0 1 D

D

D

D

D

D

D

D

7

6

5

4

3

2

1

D

D

D

D

D

7

6

5

4

3

D

2

1

writes data to display RAM

0

D

returns result of

0

temperature measurement

NOP 00 00000000no operation

Default H[2:0] 0 0 0 0 000001jump to H[2:0] = 111

H[2:0] = 111; function and RAM command page

Command page 0 0 0 0 001H2H

H

1

select command page

0

Function set 0 0 0 0 010PDV0power-down control, data

entry mode

RAM page 0 0 0 0 100XM00 0 set RAM page for X address

Set Yaddress of

RAM

Set X address of

RAM

00 0100Y3Y

00 1X6X

X

5

X

4

3

Y

Y

2

1

sets Yaddress of RAM

0

0 ≤ Y ≤ 8

X

X

X

2

1

sets X address of RAM

0

0 ≤ X ≤ 127

1999 Aug 24 26

Page 27

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

INSTRUCTION D/CR/W

(1)

I2C-BUS COMMAND BYTE

I2C-BUS COMMANDS

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

H[2:0] = 110; display setting command page

Display control 0 0 0 0 0001DEsets display mode

External display

00 00001MXMY0mirror X, mirror Y

control

Bias system 0 0 0 0 010BS2BS1BS0set bias system

Display size 0 0 0 0 100IB00set current for bias system

Multiplex rate 0 0 1 0 000M2M1M

set multiplex rate

0

H[2:0] = 101; HV-gen command page

HV-gen control 0 0 0 0 0001PRSHVEV

range, enable/disable

LCD

HV-gen

HV-gen stages 0 0 0 0 0010S1S

# of HV-gen voltage

0

multiplication

Temperature

00 00010TC2TC1TC0set temperature coefficient

coefficients

Temperature

measurement

00 0010000SMstart temperature

measurement

control

V

control 0 0 1 V

LCD

OP6VOP5VOP4VOP3VOP2VOP1VOP0

set V

0 ≤ V

LCD

LCD

register

≤ 127

H[2:0] = 011; special feature command page

State control 0 0 0 0 0001DOFDMdisplay off, direct mode

Oscillator setting 0 0 0 0 0010EC0enable/disable the internal

oscillator

COG/TCP 0 0 0 1 0 TRS BRS 0 0 0 top row swap, bottom row

swap

Note

1. R/W is set in the slave address.

1999 Aug 24 27

Page 28

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

Table 17 Description of the symbols used in Table 16

BIT 0 1

PD chip is active chip is in power-down mode

V horizontal addressing vertical addressing

HVE voltage multiplier disabled voltage multiplier enabled

PRS V

SM no measurement start measurement

MX no X mirror mirror X

MY no Y mirror mirror Y

TRS top row swap inactive top row swap active

BRS bottom row swap inactive bottom row swap active

EC internal oscillator enabled; OSC pad ignored internal oscillator disabled; OSC pad enabled for

(1)

DM

(1)

DOF

IB low current mode for smaller displays high current mode for larger displays

programming range LOW V

LCD

programming range HIGH

LCD

input

direct mode disabled direct mode enabled

display off mode disabled display off mode enabled

Note

1. Conditional on other bits.

Table 18 Priority behaviour of bits PD, DOF, HVE and DM; note 1

PD DOF HVE DM MODE

1 X X X chip is in power-down mode as defined under PD

0 1 X X all analog blocks except those required for temperature measurement are off

0 0 1 X chip is active and using the internal V

0001chip is active and using VDD as V

LCD

0000chip is active and using an external V

generator

LCD

generator attached to V

LCD

LCDIN

Note

1. X = don’t care state.

1999 Aug 24 28

Page 29

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.17 I2C-bus interface

7.17.1 C

HARACTERISTICS OF THE I

2

C-BUS

The I2C-bus is for bidirectional, two-line communication

between different ICs or modules. The two lines are a

serial data line (SDA) and a serial clock line (SCL). Both

lines must be connected to a positive supply via a pull-up

resistor. Data transfer may be initiated only when the bus

is not busy.

7.17.1.1 Bit transfer

One data bit is transferred during each clock pulse.

The data on the SDA line must remain stable during the

HIGH period of the clock pulse as changes in the data line

at this time will be interpreted as a control signal.

Bit transfer is illustrated in Fig.15.

7.17.1.2 START and STOP conditions

Bothdataand clock lines remain HIGH when the bus is not

busy. A HIGH-to-LOW transition of the data line, while the

clock is HIGH is defined as the START condition (S).

A LOW-to-HIGH transition of the data line while the clock

is HIGH is defined as the STOP condition (P). The START

and STOP conditions are illustrated in Fig.16.

7.17.1.3 System configuration

The system configuration is illustrated in Fig.17.

• Transmitter: the device which sends the data to the bus

• Receiver: the device which receives the data from the

bus

• Master: the device which initiates a transfer, generates

clock signals and terminates a transfer

• Slave: the device addressed by a master

• Multi-master: more than one master can attempt to

control the bus at the same time without corrupting the

message

• Arbitration: procedure to ensure that, if more than one

master simultaneously tries to control the bus, only one

is allowed to do so and the message is not corrupted

• Synchronization: procedure to synchronize the clock

signals of two or more devices.

7.17.1.4 Acknowledge

Each byte of 8 bits is followed by an acknowledge bit.

The acknowledge bit is a HIGH signal put on the bus by

the transmitter during which time the master generates an

extra acknowledge related clock pulse. A slave receiver

which is addressed must generate an acknowledge after

the reception of each byte. Also a master receiver must

generate an acknowledge after the reception of each byte

that has been clocked out of the slave transmitter.

The device that acknowledges must pull-down the SDA

line during the acknowledge clock pulse, so that the SDA

line is stable LOW during the HIGH period of the

acknowledge related clock pulse (set-up and hold times

must be taken into consideration). A master receiver must

signal an end of data to the transmitter by not generating

anacknowledge on the last bytethat has been clocked out

of the slave. In this event the transmitter must leave the

data line HIGH to enable the master to generate a STOP

condition. Acknowledgement on the I2C-bus is illustrated

in Fig.18.

handbook, full pagewidth

SDA

SCL

data line

stable;

data valid

Fig.15 Bit transfer.

1999 Aug 24 29

change

of data

allowed

MBC621

Page 30

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, full pagewidth

SDA

SDA

SDA

SCL

SCL

START condition

MASTER

TRANSMITTER/

RECEIVER

S

STOP condition

Fig.16 Definition of START and STOP conditions.

SLAVE

RECEIVER

SLAVE

TRANSMITTER/

RECEIVER

MASTER

TRANSMITTER

Fig.17 System configuration.

P

SCL

MBC622

MASTER

TRANSMITTER/

RECEIVER

MGA807

handbook, full pagewidth

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

SCL FROM

MASTER

S

START

condition

Fig.18 Acknowledgement on the I2C-bus.

1999 Aug 24 30

not acknowledge

acknowledge

acknowledgement

9821

clock pulse for

MBC602

Page 31

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

7.17.2 I2C-BUS PROTOCOL The PCF8535 is a slave receiver/transmitter. If data is to

be read from the device the SDAOUT pad must be

connected, otherwise SDAOUT is unused.

Before any data is transmitted on the I2C-bus, the device

which should respond is addressed. Four slave

addresses,0111100,0111101,0111110and 0111111 are

reserved for the PCF8535. The Least Significant Bits

(LSBs) of the slave address is set by connecting

SA1 and SA0 to either logic 0 (VSS) or logic 1 (VDD).

A sequence is initiated with a START condition (S) from

the I2C-bus master which is followed by the slave address.

All slaves with the corresponding address acknowledge in

parallel, all the others will ignore the I2C-bus transfer.

After the acknowledgement cycle of a write, a control byte

follows which defines the destination for the forthcoming

data byte and the mode for subsequent bytes. For a read,

thePCF8535willimmediatelystarttooutputtherequested

data until a NOT acknowledge is transmitted by the

master. The sequence should be terminated by a STOP in

the event that no further access is required for the time

being, or by a RE-START, should further access be

required.

For ease of operation a continuation bit, Co, has been

included. This bit allows the user to set-up the chip

configurationandtransmitRAMdatainoneaccess.Adata

selection bit, D/

C, defines the destination for data. These

bits are contained in the control byte. DB5 to DB0 should

be set to logic 0. These bits are reserved for future

expansion.

Table 19 Co and D/C definitions

BIT 0/1 R/W ACTION

Co 0 n.a. last control byte to be sent: only a stream of data bytes are allowed to follow; this stream may

only be terminated by a STOP or RE-START condition

1 another control byte will follow the data byte unless a STOP or RE-START condition is received

D/C 0 0 data byte will be decoded and used to set up the device

1 data byte will return the contents of the currently selected status register

1 0 data byte will be stored in the display RAM

1 no provision for RAM read back is provided

An example of a write access is given in Fig.19. Here, multiple instruction data is sent, followed by multiple display bytes.

An example of a read access is given in Fig.20.

handbook, full pagewidth

S01111

acknowledgement

from PCF8535

S

S

A

1

A

0

1

0A

D/C D/C

CoR/W

acknowledgement

from PCF8535

control byte

A data byte data byte

2n ≥ 0 bytes

acknowledgement

from PCF8535

A

0A AP

Co

acknowledgement

from PCF8535

control byte

1 byteslave address

acknowledgement

from PCF8535

n ≥ 0 bytes

MSB . . . . . . . . . . . LSB

MGS682

data pointer

update

Fig.19 Master transmits to slave receiver; write mode.

1999 Aug 24 31

Page 32

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, full pagewidth

S01111

slave address

acknowledgement

from PCF8535

S

S

A

A

1

0

R/W

1A

temp. read out value

NOT acknowledgement

from master

AP

STOP condition

MGS683

Fig.20 Master reads a slaves’ status register.

8 LIMITING VALUES (PROVISIONAL)

In accordance with the Absolute Maximum Rating System (IEC 134); notes 1, 2 and 3.

SYMBOL PARAMETER MIN. MAX. UNIT

V

DD

I

DD

V

LCD

I

LCD

I

SS

VI/V

I

I

I

O

P

tot

O

supply voltage −0.5 +7.0 V

supply current −50 +50 mA

LCD supply voltage −0.5 +17.0 V

LCD supply current −50 +50 mA

negative supply current −50 +50 mA

input/output voltage (any input/output) −0.5 VDD+ 0.5 V

DC input current −10 +10 mA

DC output current −10 +10 mA

total power dissipation per package − 300 mW

P/out power dissipation per output − 30 mW

T

T

T

amb

stg

j(max)

ambient temperature −40 +85 °C

storage temperature −65 +150 °C

maximum junction temperature − 150 °C

Notes

1. Stresses above these values listed may cause permanent damage to the device.

2. Parameters are valid over the operating temperature range unless otherwise specified. All voltages are referenced

to VSS unless otherwise specified.

3. VSS=0V.

9 HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However, to be totally safe, it is

recommended to take normal precautions appropriate to handling MOS devices (see

“Handling MOS Devices”

).

1999 Aug 24 32

Page 33

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

10 DC CHARACTERISTICS

VDD= 4.5 to 5.5 V; VSS=0V; V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

V

LCDIN

I

LCDIN

V

LCDOUT

V

DD1

V

DD2

V

DD3

I

DD

LCD supply voltage Mux mode 1 : 65 8.0 − 16.0 V

LCD supply current normal mode; notes 1 and 2 − 40 90 µA

generated supply voltage LCD voltage generator

,

supply voltage 4.5 − 5.5 V

,

supply current power-down mode;

Logic

V

IL

V

IH

I

OL

I

L

LOW-level input voltage V

HIGH-level input voltage 0.7VDD− V

LOW-level output current (SDA) VOL= 0.4 V; VDD= 5 V 3.0 −−mA

leakage current VI=VDDor V

Column and row outputs

R

o(col)

R

o(row)

V

bias(col)

V

bias(row)

column output resistance C0 to C132 V

row output resistance R0 to R33 V

bias tolerance C0 to C132 −100 0 +100 mV

bias tolerance R0 to R64 −100 0 +100 mV

Temperature coefficient

t

cut

cut point temperature T

= 4.5 to 16.0 V; T

LCD

= −40 to +85 °C; unless otherwise specified.

amb

Mux mode 1 : 49 8.0 − 16.0 V

Mux mode 1 : 34 −−16.0 V

Mux mode 1 : 26 −−16.0 V

Mux mode 1 : 17 −−16.0 V

normal mode; notes 1 and 4 − 18 40 µA

−−16.0 V

enabled

− 210µA

notes 1, 3 and 5

display off mode;

−−−µA

notes 1 and 5

normal mode; notes 1 and 6 − 160 350 µA

normal mode; notes 1 and 2 − 40 90 µA

SS

SS

= 12 V; note 7 −−10 kΩ

LCD

= 12 V; note 7 −−3.0 kΩ

LCD

= −20 to +70 °C − 27 −°C

amb

−1 − +1 µA

− 0.3VDDV

DD

V

Notes

1. LCD outputs are open-circuit, inputs at V

2. Conditions are: V

DD1

to V

= 5.0 V, V

DD3

or VSS, bus inactive, f

DD

= 12.0 V and external V

LCD

= typical internal oscillator frequency.

OSC

.

LCD

3. Power-down mode. During power-down all static currents are switched off.

4. Conditions are: V

5. Internal V

generation or external V

LCD

6. Conditions are: V

7. I

=10µA. Outputs tested one at a time.

LCD

DD1

DD1

to V

to V

= 5.0 V, V

DD3

= 5.0 V, V

DD3

LCD=VDD2

.

LCD

= 12.0 V and voltage multiplier = 3VDD.

LCD

and external V

LCD

.

1999 Aug 24 33

Page 34

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

11 AC CHARACTERISTICS

VDD= 4.5 to 5.5 V; VSS=0V; V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

f

fr(LCD)

f

clk(ext)

t

W(RESL)

t

W(RESH)

t

SU;RESL

t

R(op)

LCD frame frequency (internal clock) 48 80 165 Hz

external clock frequency see Table 20 120 − 410 kHz

reset LOW pulse width 1 −−µs

reset HIGH pulse width 5 −−µs

reset LOW pulse set-up time after power-on notes 1 and 2 −−30 µs

end of reset pulse to interface being operational −−3 µs

Serial-bus interface; note 3

f

SCL

t

LOW

t

HIGH

t

SU;DAT

t

HD;DAT

t

r

t

f

C

b

t

SU;STA

t

HD;STA

t

SU;STO

t

SP

t

BUF

SCL clock frequency 0 − 400 kHz

SCL clock LOW period 1.3 −−µs

SCL clock HIGH period 0.6 −−µs

data set-up time 100 −−ns

data hold time 0 − 0.9 µs

SCL, SDA rise time note 4 20 + 0.1Cb− 300 ns

SCL, SDA fall time note 4 20 + 0.1Cb− 300 ns

capacitive load represented by each bus line −−400 pF

set-up time for a repeated START condition 0.6 −−µs

START condition hold time 0.6 −−µs

set-up time for STOP condition 0.6 −−µs

tolerable spike width on bus −−50 ns

bus free time between a STOPand START

condition

= 4.5 to 16.0 V; T

LCD

= −40 to +85 °C; unless otherwise specified.

amb

1.3 −−µs

Notes

DD1

to V

1. V

2. Decoupling capacitor V

reduces t

=5V.

DD3

SU;RESL

and VSS= 100 nF (higher capacitor size increases t

LCD

SU;RESL

and higher V

DD1

to V

DD3

).

3. All timing values are valid within the operating supply voltage and ambient temperature range and are referenced to

VILand VIH with an input voltage swing of VSSto VDD.

4. Cb= total capacitance of one bus line in pF.

1999 Aug 24 34

Page 35

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

handbook, full pagewidth

SDA

t

BUF

SCL

SDA

MGA728

Table 20 External clock frequency

MUX MODE DIVISION RATIO

1 : 65 3168 253 kHz

1 : 48 3136 251 kHz

1 : 33 2720 218 kHz

1 : 26 2592 207 kHz

1 : 17 2592 207 kHz

t

LOW

t

HD;STA

t

r

t

SU;STA

t

Fig.21 I2C-bus timing diagram.

EXTERNAL CLOCK FREQUENCY FOR AN 80 Hz FRAME

FREQUENCY (DIVISION RATIO × 80 Hz)

HD;DAT

t

HIGH

t

f

t

SU;DAT

t

SU;STO

1999 Aug 24 35

Page 36

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

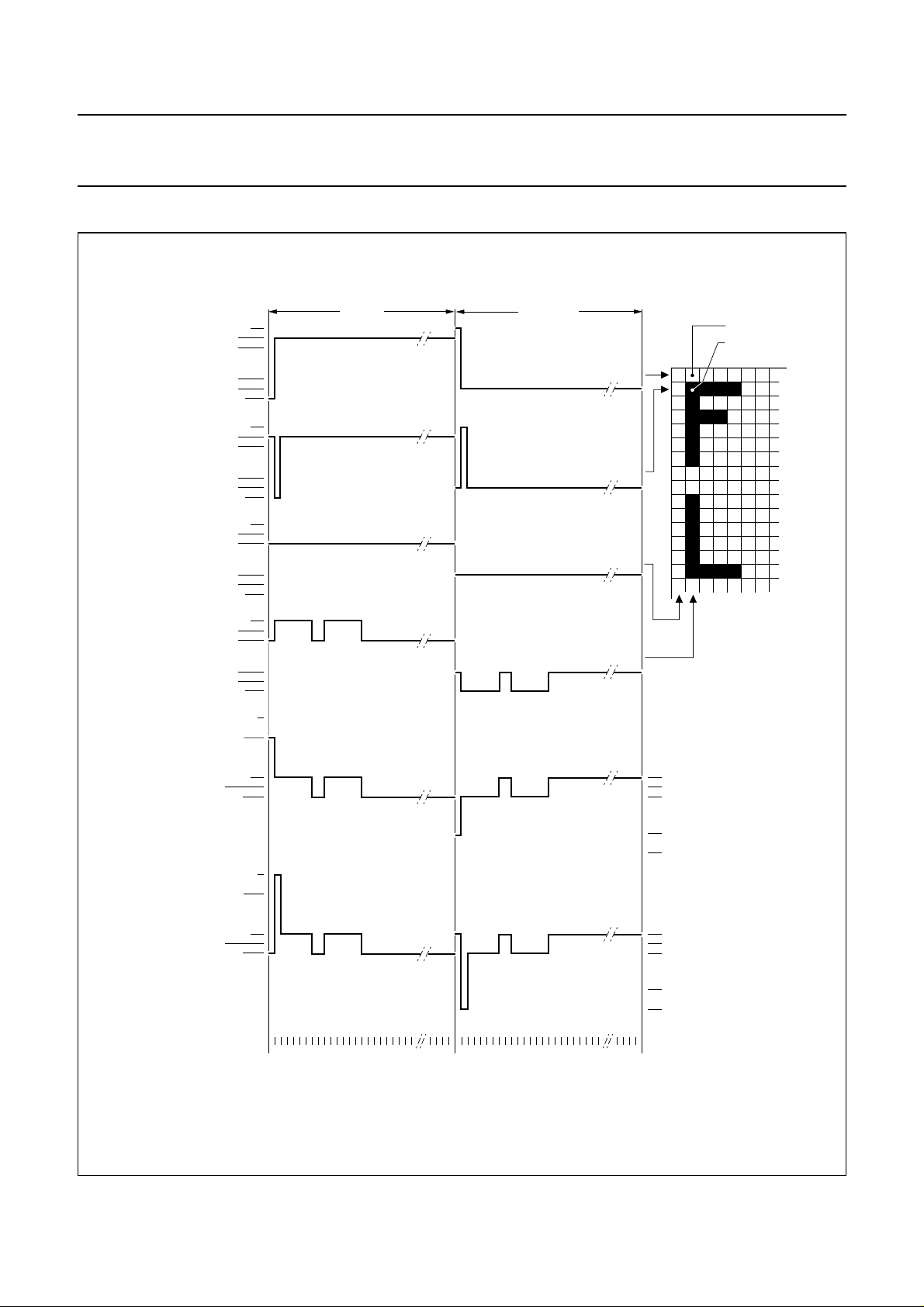

12 RESET TIMING

handbook, full pagewidth

V

RES

V

RES

RES

SDA,

SCL

DD

DD

t

W(RESL)

t

SU;RESL

t

W(RESL)

t

W(RESH)

t

R(op)

t

W(RESH)

t

W(RESL)

t

W(RESL)

MGS684

Fig.22 Reset timing.

1999 Aug 24 36

Page 37

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

13 APPLICATION INFORMATION Table 21 Programming example for PCF8535

STEP SERIAL BUS BYTE DISPLAY

1 START condition BLANK start

2 DB70DB61DB51DB41DB31DB2

SA1

DB1

DB00BLANK slave address, R/W=0

SA0

3 DB70DB60DB50DB40DB30DB20DB10DB00BLANK control byte, Co = 0, D/C=0

4 DB70DB60DB50DB40DB30DB20DB10DB01BLANK H[2:0] independent command;

5 DB70DB60DB50DB41DB30DB20DB10DB00BLANK function and RAM command page;

6 DB70DB60DB50DB40DB31DB21DB11DB00BLANK function and RAM command page;

7 DB70DB60DB50DB41DB30DB20DB11DB00BLANK display setting command page; set

8 DB70DB60DB50DB40DB30DB21DB11DB00BLANK display setting command page; set

9 DB71DB60DB50DB40DB30DB21DB10DB00BLANK select Mux rate 1 : 65

(1)

OPERATION

select function and RAM command

page H[1:0] = 111

PD = 0, V = 0

select display setting command

page H[1:0] = 110

bias system to1/9BS[2:0] = 010

normal mode (D = 1, E = 0)

10 DB70DB60DB50DB40DB30DB20DB10DB01BLANK H[2:0] independent command;

select function and RAM command

page H[1:0] = 111

11 DB70DB60DB50DB40DB31DB21DB10DB01BLANK function and RAM command page;

select Hv-gen command page

H[1:0] = 101

12 DB70DB60DB50DB40DB31DB20DB10DB01BLANK Hv-gen command page; select

voltage multiplication factor 3

S[1:0] = 01

13 DB70DB60DB50DB41DB30DB20DB11DB00BLANK Hv-gen command page; select

temperature coefficient 2

TC[2:0] = 010

14 DB71DB60DB51DB40DB31DB20DB10DB00BLANK Hv-gen command page; set

V

= 12.02 V;

LCD

VOP[6:0] = 0101000

15 DB70DB60DB50DB40DB30DB21DB11DB01BLANK Hv-gen command page; select high

V

programming range

LCD

(PRS = 1), voltage multiplier on

(HVE = 1)

16 START condition BLANK repeat start

17 DB70DB61DB51DB41DB31DB2

SA1

DB1

DB00BLANK slave address, R/W=0

SA0

18 DB70DB61DB50DB40DB30DB20DB10DB00BLANK control byte, Co = 0, D/C=1

1999 Aug 24 37

Page 38

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

STEP SERIAL BUS BYTE DISPLAY

19 DB70DB60DB50DB41DB31DB21DB11DB0

1

20 DB70DB60DB50DB40DB30DB21DB10DB0

1

21 DB70DB60DB50DB40DB30DB21DB11DB0

1

22 DB70DB60DB50DB40DB30DB20DB10DB0

0

(1)

MGS405

MGS406

MGS407

MGS408

OPERATION

data write; Y, X are initialized to

logic 0 by default, so they are not

set here

data write

data write

data write

23 DB70DB60DB50DB41DB31DB21DB11DB0

data write

1

MGS409

24 DB70DB60DB50DB40DB30DB21DB10DB0

data write

0

MGS410

25 DB70DB60DB50DB41DB31DB21DB11DB0

1

data write, last data, stop

transmission

MGS411

26 START condition repeat start

27 DB70DB61DB51DB41DB31DB2

SA1

DB1

SA0

DB0

0

slave address, R/W=0

MGS411

1999 Aug 24 38

Page 39

Philips Semiconductors Objective specification

65 × 133 pixel matrix driver PCF8535

STEP SERIAL BUS BYTE DISPLAY

28 DB71DB60DB50DB40DB30DB20DB10DB0