Page 1

查询PCF50603供应商

INTEGRATED CIRCUITS

DATA SH EET

PCF50603

Controller for power supply

and battery management

Preliminary specification 2003 Oct 31

Page 2

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

CONTENTS

1 FEATURES

1.1 System control

1.2 Supply voltage generation

1.3 Battery management

1.4 Subscriber identity module card interface

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 QUICK REFERENCE DATA

5 ORDERING INFORMATION

6 BLOCK DIAGRAM

7 PINNING

8 FUNCTIONAL DESCRIPTION

8.1 On/off control

8.1.1 Operating states

8.1.2 Reset generation

8.1.3 Watchdog timer

8.1.4 Automatic restart after battery removal

8.1.5 Debounce filters

8.2 Serial interface (I2C-bus)

8.3 Interrupt controller (INT)

8.4 Power supply modules

8.5 Main battery charger (MBC)

8.5.1 Supported charger plugs

8.5.2 External components

PCF50603

8.6 Backup battery charger (BBC)

8.7 SIM card interface (SIMI)

8.8 Battery voltage monitor (BVM)

8.9 Temperature high sensor (TS)

8.10 Real time clock (RTC)

8.11 Pulse-width modulator (PWM1 and PWM2)

8.12 LED modulator (LED1 and LED2)

8.13 General purpose outputs (GPO)

9 LIMITING VALUES

10 CHARACTERISTICS

11 APPLICATION INFORMATION

12 PACKAGE OUTLINE

13 SOLDERING

13.1 Introduction to soldering surface mount

packages

13.2 Reflow soldering

13.3 Wave soldering

13.4 Manual soldering

13.5 Suitability of surface mount IC packages for

wave and reflow soldering methods

14 DATA SHEET STATUS

15 DEFINITIONS

16 DISCLAIMERS

17 PURCHASE OF PHILIPS I2C COMPONENTS

2003 Oct 31 2

Page 3

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

1 FEATURES

1.1 System control

• Serial 400 kHz I2C-bus interface to transfer the control

data between the PCF50603 and the host controller

• On/Off Control (OOC) module to control the power

ramp-up and ramp-down sequences for the handset.

Furthermore it determines the supported system

operating states: NOPOWER, SAVE, STANDBY and

ACTIVE to realize minimum power consumption in all

states.

• Internal Current Controlled Oscillator (CCO) generates

the internal high clock frequency. The generated

frequency is typically 3.6 MHz.

• Anaccurate32.768 kHzoscillator.Thisoscillatorcanbe

used to supply the 32 kHz clock domains in the system,

to improve the accuracy of the internal clock and to

reduce the power consumption of the PCF50603.

• Interrupt controller (INT) that generates the interrupt

request for the host controller. All interrupt sources can

be masked.

• The Real Time Clock (RTC) module uses the 32 kHz

clock to provide time reference and alarm functions with

wake up control for the handset

• Oneaccessory recognition pin with debounce filters and

capability to start up the system (REC1_N)

• One accessory detection comparator input pin with

programmable threshold levels that issues an interrupt

when an accessory is connected (REC2_N)

• TwoPulse-WidthModulators(PWM1andPWM2)which

generate an output voltage with programmable duty

cycle and frequency

• Two LED modulators (LED1 and LED2) capable of

generating eight different blinking patterns with eight

different repetition periods

• Three General Purpose Outputs (GPO) programmable

via the serial interface. The GPOs are open-drain

NMOST outputs, capable of handling the full battery

voltage range and high sink currents. The GPOs can be

programmed to be continuously active LOW or 3-state,

in addition the GPO outputs can be controlled by the

LED or PWM modulators.

• Watchdog timer that can be activated by software.

PCF50603

1.2 Supply voltage generation

• The power supplies have three programmable activity

modes (OFF, ECO and ON). In the ACTIVE state, the

operation modes can be selected by the two external

pins PWREN1 and PWREN2.

• One Charge Pump (CP) with programmable output

voltage for the supply of white or blue LEDs

• Two 100 mA LDO voltage regulators (RF1REG and

RF2REG) with fixed output voltage (mask

programmable) for RF supplies. RF1REG and RF2REG

are optimized for low noise, high power supply rejection

and excellent load regulation.

• Two 150 mA LDO voltage regulators (D1REG and

D2REG) optimized for small external capacitors.

D1REG provides a programmable output voltage,

D2REG provides a fixed output voltage (mask

programmable).

• One 150 mA LDO voltage regulator (IOREG) dedicated

for the supply of the I/O pads. IOREG has a fixed output

voltage (mask programmable) and is optimized for a

small external capacitor.

• One 100 mA LDO voltage regulator (LPREG) with fixed

output voltage (mask programmable). In low power

operation (ECO) mode LPREG can be used to

permanently supply parts in the system in all activity

states.

• One 100 mA LDO voltage regulator (D3REG) with

programmableoutputvoltage.D3REGisoptimizedfora

small external capacitor.

• One 250 mA LDO voltage regulator (HCREG) with

programmableoutputvoltage. The high current HCREG

is optimized for applications like hands-free audio.

• D1REG, D2REG, D3REG, IOREG and LPREG support

ECO mode. In this mode the output current is limited to

1 mA and the internal power consumption is reduced

significantly.

• The Temperature high Sensor (TS) provides thermal

protection for the whole chip

• Enhanced ESD protection on all pins that connect to the

main battery pack

• Microphone bias voltage generator with low noise and

high power supply rejection (MBGEN).

2003 Oct 31 3

Page 4

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

1.3 Battery management

• Operates from a three cell NiCd/NiMH or a one cell

Li-ion battery pack

• Battery Voltage Monitor (BVM) to detect a too low main

battery voltage with programmable threshold levels.

A low battery condition is reported via the interrupt

mechanism.

• Charger control. There is an option between two

different charger control functions, depending on the

configuration:

– Configuration Constant Current Constant Voltage

(CCCV). Linear charger control supporting Li-ion as

well as NiCd/NiMH battery types for a wide range of

battery capacities.

– Configuration BATMAX comparator that compares

the battery voltage against a programmable

threshold voltage. This function can be activated by

software and is used to detect the end-of-charge.

• Supports the use of a backup battery that powers at

empty main battery situations. The backup battery is

used to supply the RTC, the internal state and the

LPVDDsupplyinit’sECOmode.Goldcaps,LiandLi-ion

cells are supported.

• Includes a Backup Battery Charger (BBC).

A rechargeable backup battery or backup capacitor can

be charged from the main battery. For charging, a

programmable constant voltage mode is supported.

PCF50603

1.4 Subscriber identity module card interface

• Two different modes that can be selected with the

Subscriber Identity Module card Interface (SIMI):

– Transparent interface including an arbiter and signal

level translators

– Subscriber Identity Module (SIM) card interface with

integrated sequencer, arbiter and signal level

translators. The sequencer supports and controls

card activation and de-activation, warm reset and

controlled clock stop for power-down modes.

• Dedicated SIM supply (SIMREG). Supports

3.0 V and 1.8 V cards, including a power saving ECO

mode for the power-down mode of the SIM card.

• Enhanced ESD protection on all pins that connect to the

SIM card contact pins.

2 APPLICATIONS

• Mobile phones.

3 GENERAL DESCRIPTION

The PCF50603 is a highly integrated solution for power

supply generation, battery management including

charging and a SIM card interface including supply

generation.Thedeviceiscontrolledbyahostcontrollervia

a 400 kHz I2C-bus serial interface.

4 QUICK REFERENCE DATA

VSS= REFGND = GND = 0 V; T

= −40 °C to +85 °C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

V

V

BAT

SAVE

CHG

main battery input voltage 0 − 5.7 V

backup battery input voltage 0 − 5.7 V

charger input voltage DC 0 − 15.0 V

rectified sine wave;

0 − 20.0 V

100 Hz to 120 Hz; note 1

V

CHGMIN

minimum charger voltage

− 2.7 − V

enabling MBC module

f

CLKCCO

high clock frequency 32 kHz clock available 3.42 3.6 3.78 MHz

Note

1. Not allowed in CCCV configuration.

2003 Oct 31 4

Page 5

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

5 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

PCF50603HN HVQFN48 plastic thermal enhanced very thin quad flat package; no leads;

48 terminals; body 6 × 6 × 0.85 mm

PCF50603

SOT778-1

2003 Oct 31 5

Page 6

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

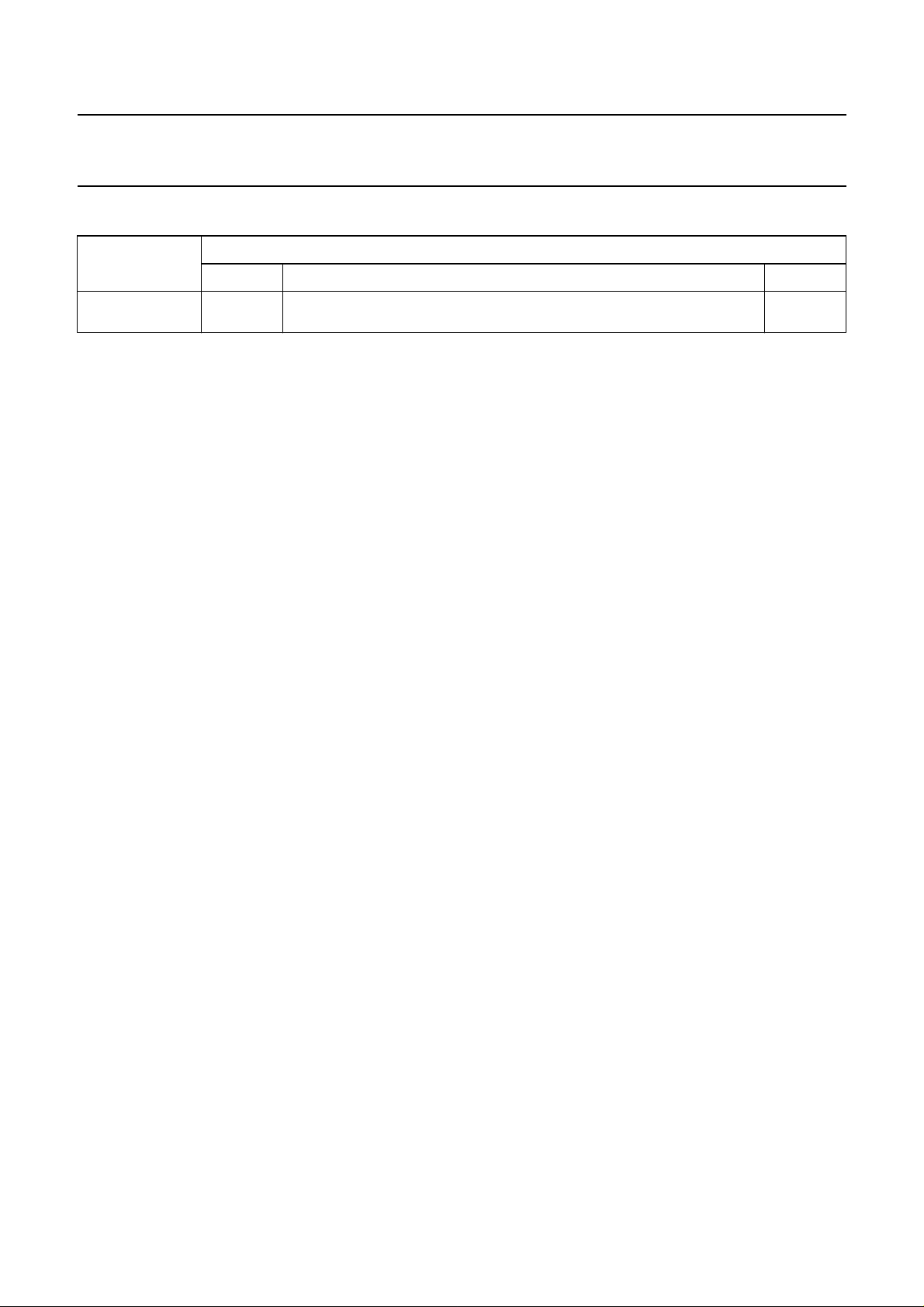

6 BLOCK DIAGRAM

OSCI

OSCO

25

26

UNIT

CLOCK

GENERATOR

BBC

IRQ_N

32kHz

OSCILLATOR

INT

CONTROLLER

CHGDRV

CHGCUR/

BATMAX

34

33

AND

BATMAX

COMPARATOR

MBC

31

BAT

V

BVM

SAVEVCHG

V

30

32

SUPPLY

MODULE

INTERNAL

VINT

29

CPVBAT

SCP

363738

CP

SCN

CPVDD

35

PCF50603

MDB679

HCREG

RF2REG

RF1REG

18 17

24

2320

22

19

RF1VDD RF2VDD HCVDDD3VDD

book, full pagewidth

27 11 4 6 5 101

ONKEY_N RSTHC_N CLK32K PWREN1 PWREN2 REC1_N

OOC

TS

PCF50603

system clocks

operation modes

temp_ok

ALARM

RTC AND

status data

control data

C-BUS

2

I

INTERFACE

3

2

reference voltage

bias currents

ON-CHIP

28

AUDIO

REFERENCE

DETECTION

12

13

PWM1 AND PWM2

GPO

48

47

46

internal supply

LED1 AND LED2

8

9

7

SIMI

434244

45

LPREG

D1REG

D2REG

IOREG

D3REG

SIMREG

41

LPD1VBAT LPVDD RF12VBAT HCVBAT

21

D1VDD

16

Fig.1 Block diagram.

14 15

40 39

SIMD3VBAT IOVDD IOD2VBAT D2VDD

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2003 Oct 31 6

SCL

SDA

REFC

REC2_N

MICBIAS

GPO1

GPO2

GPO3

SIMIOHC

SIMCKHC

SIMIOCD

SIMCKCD

SIMRSHC_N

SIMEN

SIMVCC

SIMRSCD_N

Page 7

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

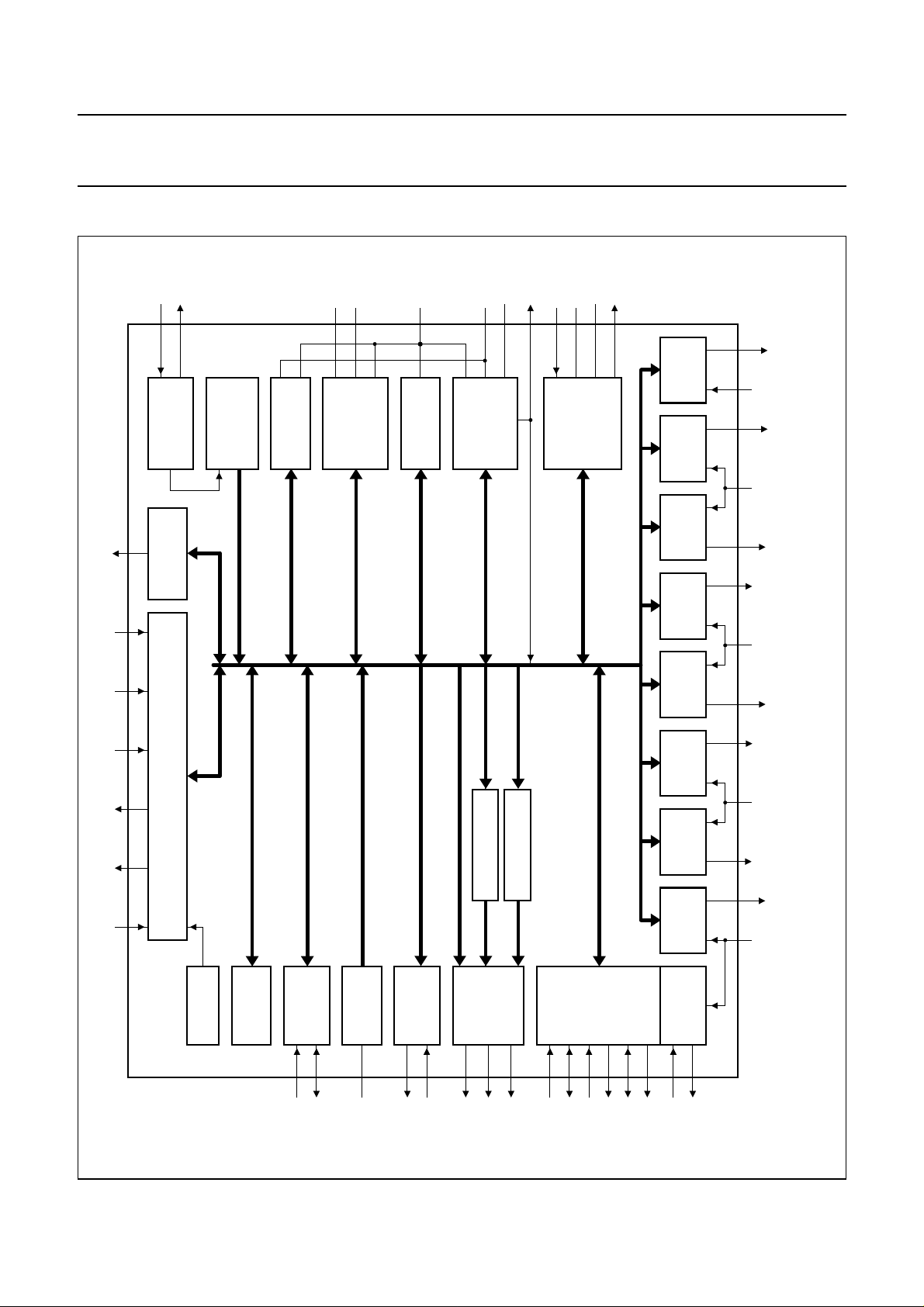

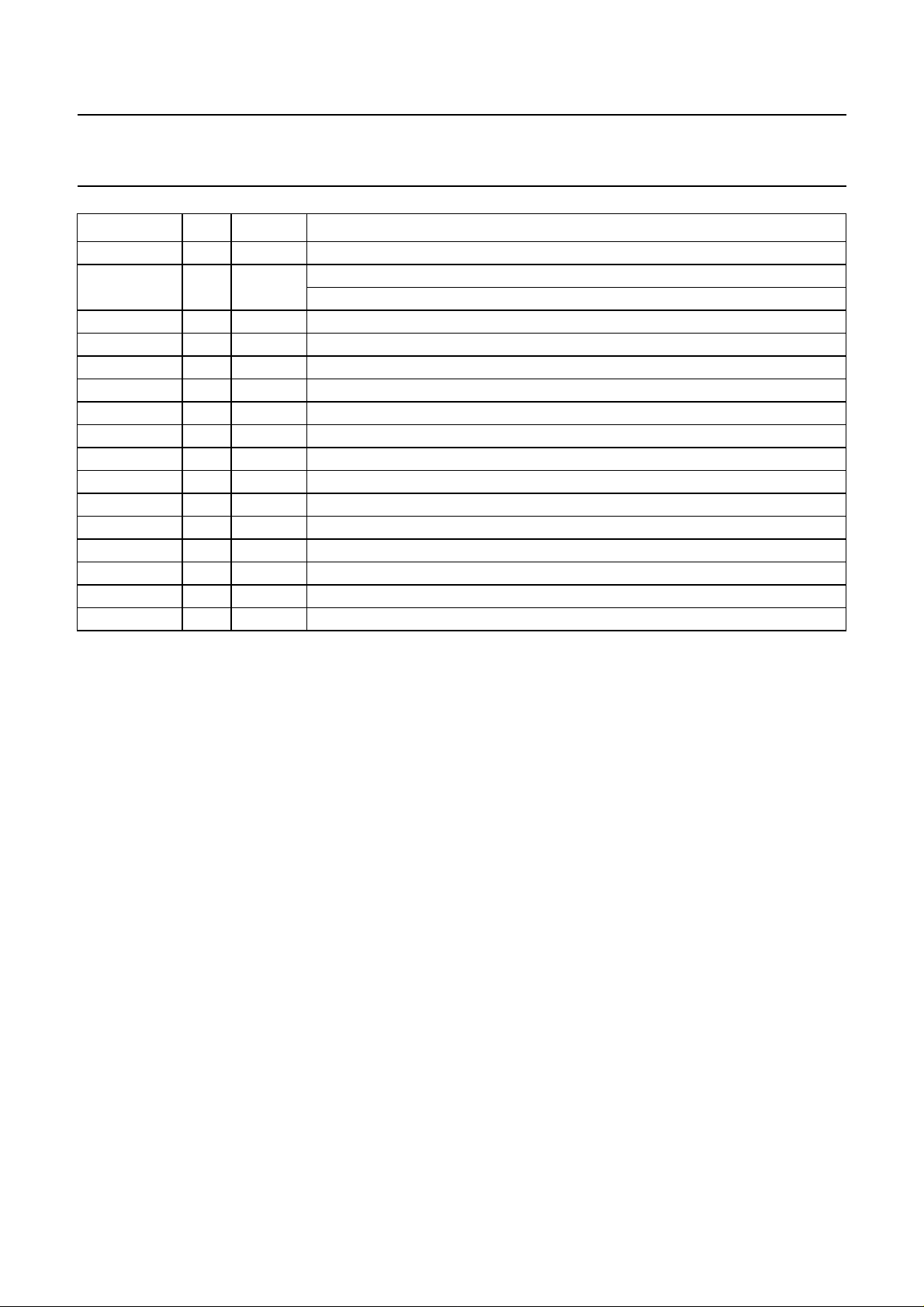

7 PINNING

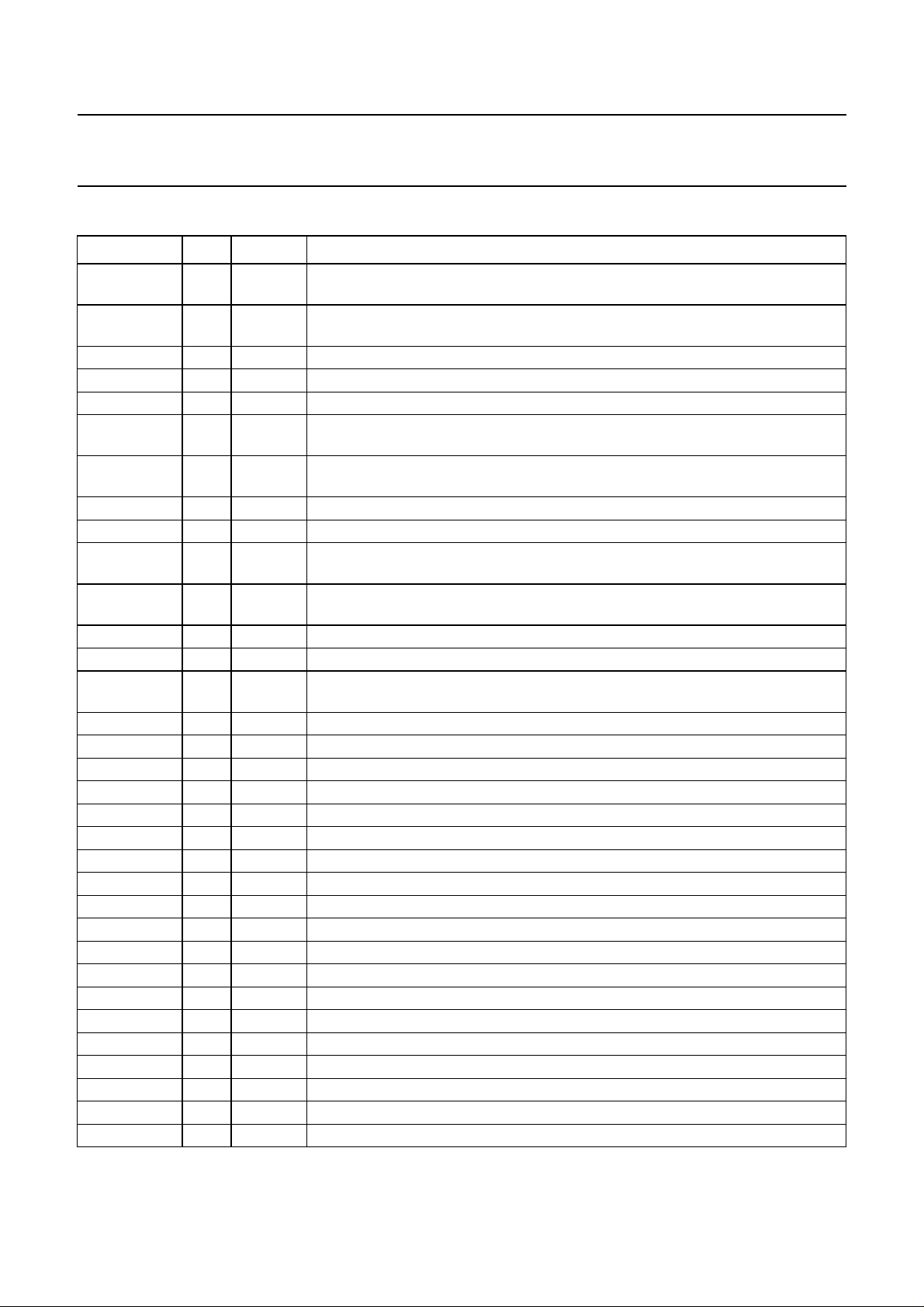

SYMBOL PIN SUPPLY DESCRIPTION

VSS and

REFGND

− n.a. ground and VSS pads of all modules are connected to the ground plane of the

package

REC1_N 1 VINT accessory recognition input with debounce filter (active LOW); input with internal

pull-up resistor to VINT

2

SCL 2 IOVDD I

SDA 3 IOVDD I

C-bus clock input

2

C-bus data input and output

CLK32K 4 IOVDD 32.768 kHz digital clock output; in ACTIVE state and IOVDD is on

PWREN2 5 IOVDD control signal input; selects in combination with PWREN1 the ON, OFF or ECO

mode of the linear regulators

PWREN1 6 IOVDD control signal input; selects in combination with PWREN2 the ON, OFF or ECO

mode of the linear regulators

SIMRSHC_N 7 IOVDD SIM reset input from host controller (active LOW)

SIMCKHC 8 IOVDD SIM clock input from host controller

SIMIOHC 9 IOVDD SIM I/O data to or from the host controller with an internal pull-up resistor to

IOVDD

IRQ_N 10 IOVDD interrupt request output to host controller (active LOW); open-drain output with an

internal pull-up resistor to IOVDD

RSTHC_N 11 IOVDD reset output to host controller (active LOW)

MICBIAS 12 n.a. microphone bias output voltage

REC2_N 13 MICBIAS accessory recognition input with debounce filter and programmable threshold

(active LOW)

IOVDD 14 n.a. IOREG output voltage

IOD2VBAT 15 n.a. IOREG and D2REG input voltage

D2VDD 16 n.a. D2REG output voltage

HCVDD 17 n.a. HCREG output voltage

HCVBAT 18 n.a. HCREG input voltage

LPVDD 19 n.a. LPREG output voltage

LPD1VBAT 20 n.a. LPREG and D1REG input voltage

D1VDD 21 n.a. D1REG output voltage

RF1VDD 22 n.a. RF1REG output voltage

RF12VBAT 23 n.a. RF1REG and RF2REG input voltage

RF2VDD 24 n.a. RF2REG output voltage

OSCO 25 VINT 32.768 kHz oscillator output

OSCI 26 VINT 32.768 kHz oscillator input

ONKEY_N 27 VINT On-key (active LOW); input with internal pull-up resistor to VINT

REFC 28 n.a. reference voltage bypass capacitor connection

VINT 29 n.a. internal supply voltage output

V

V

V

SAVE

BAT

CHG

30 n.a. backup battery supply voltage

31 n.a. main battery supply voltage

32 n.a. charger voltage

(1)

2003 Oct 31 7

Page 8

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

SYMBOL PIN SUPPLY DESCRIPTION

CHGDRV 33 n.a. drive of external charger circuitry (configuration CCCV)

CHGCUR/

BATMAX

CPVDD 35 n.a. charge pump output voltage

CPVBAT 36 n.a. charge pump input voltage

SCP 37 n.a. switching capacitor positive side

SCN 38 n.a. switching capacitor negative side

D3VDD 39 n.a. D3REG output voltage

SIMD3VBAT 40 n.a. SIMREG and D3REG input voltage

SIMVCC 41 n.a. SIMREG output voltage

SIMIOCD 42 SIMVCC SIM I/O data to/from the SIM card; internal pull-up resistor to SIMVCC

SIMCKCD 43 SIMVCC SIM clock output to the SIM card

SIMRSCD_N 44 SIMVCC SIM reset output to the SIM card (active LOW)

SIMEN 45 IOVDD enable SIMI and SIMREG

GPO3 46 n.a. general purpose open-drain output 3

GPO2 47 n.a. general purpose open-drain output 2

GPO1 48 n.a. general purpose open-drain output 1

34 n.a. configuration CCCV: charger current feedback

configuration BATMAX: open-drain output of BATMAX comparator

(1)

Note

1. One ESD diode reverse biased to VSSexcept pin V

between pad and VSS.

who has one clamp in series with a 500 Ω resistor connected

CHG

2003 Oct 31 8

Page 9

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

handbook, full pagewidth

MICBIAS

RSTHC_N

IRQ_N

SIMIOHC

SIMCKHC

SIMRSHC_N

PWREN1

PWREN2

CLK32K

SDA

SCL

REC1_N

LPVDD

HCVDD

REC2_N

IOVDD

IOD2VBAT

1314151617181920212223

12 25

11 26

10 27

9 28

8 29

7 30

6 31

5 32

4 33

3 34

2 35

1 36

4847464544434241403938

GPO3

GPO1

GPO2

HCVBAT

D2VDD

PCF50603HN

SIMEN

SIMCKCD

SIMRSCD_N

LPD1VBAT

SIMVCC

SIMIOCD

D1VDD

RF12VBAT

RF1VDD

SCN

D3VDD

SIMD3VBAT

RF2VDD

24

37

SCP

OSCO

OSCI

ONKEY_N

REFC

VINT

V

SAVE

V

BAT

V

CHG

CHGDRV

CHGCUR/BATMAX

CPVDD

CPVBAT

MDB680

PCF50603

Bottom view.

All GND and VSS pads are connected to the ground plane.

Fig.2 Pin configuration.

2003 Oct 31 9

Page 10

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

8 FUNCTIONAL DESCRIPTION

8.1 On/off control

8.1.1 OPERATING STATES

The PCF50603 has four operating states (see Fig.3):

• NOPOWER

• SAVE

• STANDBY

• ACTIVE.

handbook, full pagewidth

SAVE

V

< V

BAT

VERY_LOW_BAT

V

SAVE

V

CHG

AND

> V

VERY_LOW_BACK

OR

> V

VERY_LOW_BAT

V

V

SAVE

V

BAT

CHG

NOPOWER

< V

< V

< V

PCF50603

VERY_LOW_BAT

AND

VERY_LOW_BACK

AND

VERY_LOW_BAT

Fig.3 State diagram.

8.1.2 RESET GENERATION

TheOOC generates an internal and an external reseteach

time the system goes from STANDBY to ACTIVE state. All

registersfor the regulators and convertersarereset to their

default values.

STANDBY

V

> V

BAT

VERY_LOW_BAT

ACTIVE

V

> V

BAT

LOW_BAT

MDB681

The RSTHC_N is kept LOW for minimum 10 ms after

entering the ACTIVE state. If the IOREG supply is

switched off, RSTHC_N becomes LOW again (see Fig.4).

A special condition occurs when the main battery voltage

drops below the V

VERY_LOW_BAT

limit of typically 2.7 V; the

RSTHC_N is asserted in order to shut down the host

controller immediately (see Fig.5).

2003 Oct 31 10

Page 11

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

handbook, full pagewidth

system

state

RSTHC_N

xxVDD

32 kHz

oscillator

CLK32K

Before the supplies are turned on, the internal 32 kHz clock is already stable. After

power up of the IOVDD supply the external clock on pin CLK32K becomes available.

STANDBY STANDBYACTIVE

t

= 10 ms

reset

PCF50603

MDB682

handbook, full pagewidth

system

state

RSTHC_N

SIM activation

xxVDD

32 kHz

oscillator

CLK32K

Fig.4 Reset generation timing diagram (STANDBY - ACTIVE - STANDBY transition).

STANDBY STANDBYACTIVE

t

= 10 ms

reset

SIM emergency deactivation

MDB683

Before the supplies are turned on, the internal 32 kHz clock is already stable. After

power up of the IOVDD supply the external clock on pin CLK32K becomes available.

Fig.5 Reset generation timing diagram (STANDBY - ACTIVE - STANDBY transition).

2003 Oct 31 11

Page 12

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

8.1.3 WATCHDOG TIMER

The OOC contains a WatchDog Timer (WDT). By default

it is not activated. It can be activated by setting

bit WDT_RST in the OOCC register to logic 1. Once this

bithasbeenset,the watchdog is enabled, and needs to be

cleared once every eight seconds. If the watchdog is not

reset in time, the PCF50603 automatically goes to the

STANDBY state when the watchdog timer expires. Status

bit WDTEXP is set when the watchdog timer expires. After

each ACTIVE to STANDBY transition the WDT is disabled

and needs to be activated again by software when

entering the ACTIVE state.

8.1.4 AUTOMATIC RESTART AFTER BATTERY REMOVAL

The PMU allows for an automatic restart from SAVE to

ACTIVE state when the main battery is removed for a

period less than two seconds (t

BATRMLIM

especially convenient to avoid accidental switch-off of the

). This feature is

PCF50603

phone due to mechanical bounce on the battery. The

automatic restart is enabled or disabled by control

bit BATRM_EN in the OOCC register. By default this

automatic restart feature is disabled.

Status bit BATRMSTAT in the OOCS2 register indicates

whetherthe PMU returned to ACTIVE stateduetoa restart

after battery removal. The status bit remains active until

the PMU returns to STANDBY or SAVE state.

Figure 6 shows the timing for an automatic restart due to

battery removal.

This feature is only triggered by battery removal

(V

< 2.7 V). All other shut-down conditions like, low

BAT

battery, high temperature, programming GO_STDBY do

not trigger this function.

This feature is only applicable upon the condition that a

BBC (V

SAVE>VVERY_LOW_BACK

) is available in the system.

handbook, full pagewidth

(internal status bit)

system

state

V

BAT

V

SAVE

CLK32K

RSTHC_N

xxVDD

BATRMSTAT

ACTIVE

V

LOW_BAT

V

VERY_LOW_BAT

V

LOW_BACK

SAVE

<t

BATRMLIM

t

reset

ACTIVE

MCE539

Fig.6 Automatic restart after battery removal.

2003 Oct 31 12

Page 13

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

8.1.5 DEBOUNCE FILTERS

Fig.7 is applicable for all debounce filters in the PCF50603.

handbook, full pagewidth

The debounced signal keeps the old value until the new value has been stable for at least the applicable debounce time. Any spike (>30 ms) in the

original signal will reset the debounce timer again. This filter suppresses all signal changes that are shorter than the debounce time.

un-debounced

debounced

interrupts

t

debounce

falling edge

Fig.7 Definition of debounce filter.

t

debounce

rising edge

MDB684

8.2 Serial interface (I2C-bus)

The I2C-bus is the serial interface of the PCF50603.

A detailed description of the I2C-bus specification,

including applications, is given in the brochure: The

I2C-bus and how to use it, order no. 9398 393 40011 or

I2C-bus Peripherals Data Handbook IC12.

8.3 Interrupt controller (INT)

The PCF50603 uses the interrupt controller to indicate to

thesystemcontroller if the status of the PCF50603 change

and that an action of the system controller is required.

Interrupts can be generated by several modules of the

PCF50603. The interrupt generator handles all interrupts

with the same priority. Priority setting shall be done by the

system controller software.

There are no timing requirements for interrupt service

response times. All events that require immediate actions

are performed by the PCF50603 without any action by the

system controller.

The function of the interrupt module is to capture, mask

and combine the interrupt signals from the modules that

can generate an interrupt. All interrupts are combined in

the interrupt signal IRQ_N. The IRQ_N signal is

implemented as an open-drain output with an internal

pull-up resistor.

The interrupt module is powered in all states (except

NOPOWER) and retains the register values. Events that

occur in the STANDBY state, are captured and can be

read out by the system controller once the system is in the

ACTIVE state.

The IRQ_N signal is asserted in the ACTIVE state

whenever one or more PCF50603 interrupts are active.

Each interrupt register (8-bits) is cleared when it is read

(R&C) through the I

2

C-bus interface. New interrupts that

occur during a R&C action are captured in an intermediate

register (see Figs.8 and 9).

All interrupts related to shut-down conditions (LOWBAT,

ONKEY1S and HIGHTMP) are automatically cleared on a

transition from ACTIVE to STANDBY state.

All interrupts can be masked: this effectively prevents that

IRQ_N is asserted for masked interrupts. Masking is

implementedwith a mask bit in the mask registers for each

interrupt source. Nevertheless, the interrupt status

registers still provide the actual interrupt status of the

masked interrupts, which allows polling of the interrupt

status registers. Note that if the mask bit is cleared for an

active interrupt, the IRQ_N line goes LOW at the next

falling edge of the output pin CLK32K.

2003 Oct 31 13

Page 14

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

handbook, full pagewidth

IRQ_N

2

I

C-bus

read request &

address

read

INT1

PCF50603

(1)

read

INT2

read

INT3

MDB685

Read access can be done with or without incremental addressing.

(1) IRQ_N becomes inactive high as soon as the read sequence of the last INTx register containing an active interrupt starts.

Fig.8 Interrupt timing; no interrupt captured during read sequence.

handbook, full pagewidth

IRQ_N

I

2

C-bus

read request &

address

read

INT1

(1)

read

INT2

minimal 1 CLK32

read

INT3

MDB686

Read access can be done with or without incremental addressing.

(1) IRQ_N becomes inactive high as soon as the read sequence of the last INTx register containing an active interrupt starts.

Fig.9 Interrupt timing; interrupt captured during read sequence.

2003 Oct 31 14

Page 15

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

8.4 Power supply modules

In total 11 power supply modules are available in the PCF50603; see Table 1:

• Threeregulators for supplying the digital and analog circuitry (D1REG, D2REG and D3REG). These regulators support

the ECO mode

• One regulator for high current supply (HCREG)

• One regulator for the SIMI supply (SIMREG)

• One charge pump (CP)

• One regulator for supplying the I/O pads (IOREG). This regulator supports the ECO mode

• One regulator for low power supply (LPREG). This regulator supports the ECO mode, the LPREG is the only regulator

that can be enabled in SAVE and STANDBY state (ECO mode only)

• Two low-noise regulators for RF supply (RF1REG and RF2REG)

• One ultra low-noise regulator for supplying a microphone (MBGEN).

Table 1 Power supply modules; VSS= REFGND = GND = 0 V; T

SUPPLY

NAME

NOMINAL

CURRENT

(mA)

MINIMUM

VOLTAGE

(V)

MAXIMUM

VOLTAGE

(V)

VOLTAGE

STEPS

(mV)

= −40 °C to +85 °C; unless otherwise specified.

amb

RESET

VOLTAGE

(V)

ECO

MODE

PSRR

(dB)

SIZEEXTERNAL

(1)

CAPACITOR

(nF)

(2)

Programmable power supplies

D1REG 150 1.20 3.20 100 note 3 yes 60 470

D3REG 100 1.20 3.20 100 note 3 yes 60 470

(6)

(4)

2.60 3.20 200 note 3 no 60 4700

(5)

60 1000

3.50 5.00 500 note 3 no − 220/4700

(7)

HCREG 250

SIMREG 20 1.80 3.00 − 1.8 yes

CP 75

Fixed power supplies, mask programmable

D2REG 150 1.20 3.20 100 note 3 yes 60 470

IOREG 150 1.20 3.20 100 note 3 yes 60 470

LPREG 100 1.20 3.20 100 note 3 yes 60 470

RF1REG

RF2REG

(8)

(8)

100 2.60 3.00 100 note 3 no 70 4700

100 2.60 3.00 100 note 3 no 70 4700

Fixed power supply

MBGEN 1.5 2.15 2.15 − 2.15 yes 110 4700

Notes

1. Typical value, 100 Hz < f < 1000 Hz.

2. Typical values assume X5R or X7R type of capacitor.

3. Mask programmable for reset settings of different types.

4. Under specific conditions a nominal current of 300 mA can be delivered.

5. When SIMI is in Power-down mode.

6. Maximum current depends on the selected output voltage. At 3.50 V, 4.00 V and 4.50 V the maximum output current

is 75 mA. At 5.00 V output voltage the maximum output current is 50 mA.

7. The CP module requires both a switching capacitor as well as an output capacitor.

8. Optimized for low noise (30 µV RMS value, 400 Hz < f < 80 kHz).

2003 Oct 31 15

Page 16

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

8.5 Main battery charger (MBC)

The main battery charger (MBC) module provides a

completeconstant-current/constant-voltage linear charger

controller for lithium-ion (Li-ion) batteries (in CCCV

configuration) or a programmable battery threshold level

detector for end-of-charge indication (configuration

BATMAX). Nickel-cadmium (NiCd) and Nickel metal

hydride (NiMH) batteries can also be charged with

constant current.

Only an external power PNP transistor is required to

control the charge current. The CC and CCCV control

circuitry is fully integrated in the PCF50603 charging

module.

In CCCV configuration the charging process for

Li-ion/Li-pol batteries is performed under control of the

host controller. The communication between the

PCF50603 charger module and the host controller is

interrupt based, which simplifies the control of the

PCF50603.

PCF50603

The fast charge current is determined by the value of the

external sense resistor. The charge current in the pre and

trickle charge phase is programmable as a ratio of the fast

charge current.

In BATMAX configuration an end-of-charge indication is

available on the BATMAX pin.

8.5.1 SUPPORTED CHARGER PLUGS

The PCF50603 charger circuitry supports the following

type of charger plugs (see Fig.10):

• Regulated charger plugs with output voltage at least

0.5 V above the battery voltage with a maximum of 10 V

and with current limitation up to 3C of the used battery

(CCCV and BATMAX configuration)

• Non regulated charger plugs with peak output voltages

up to 20 V with a duration of less than 14 ms and with

current limitation up to 3C of the used battery (BATMAX

configuration only).

handbook, full pagewidth

10 V

2.7 V

V

CHG

Regulated charger plug. Non regulated charger plug.

I

CHG

15 V

10 V

2.7 V

V

CHG

< 14 ms

Fig.10 Characteristics of the supported charger plugs.

< 14 ms

t

MDB687

2003 Oct 31 16

Page 17

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

8.5.2 EXTERNAL COMPONENTS

A small discrete circuit must be used to control the charge current (see Fig.11).

handbook, halfpage

(1) The charge switch requires a current gain in the range of 50 to 400 for stable loop operation.

Fig.11 Charge current external circuitry.

V

CHG

CHGDRV

CHGCUR

V

BAT

0.15 Ω

BC869

R

sense

(1)

MDB688

PCF50603

8.6 Backup battery charger (BBC)

The BBC is implemented as a voltage limited current

source with a selectable output resistor. It offers the

following features:

• Selectableoutput resistor to reduce the current at higher

voltages

• Four programmable charge currents

• Two programmable maximum limiting voltages

• The BBC can be enabled in the ACTIVE state; in all

other states the BBC is disabled.

8.7 SIM card interface (SIMI)

The SIMI provides the facilities to communicate with SIM.

It offers the following features:

• Support for transparent mode. The host controller

controls the communication with the SIM card, including

the activation and deactivation sequences.

• Support for sequencer mode. The internal sequencer of

the PCF50603 performs the activation and deactivation

sequences.

• Includes a dedicated linear regulator for the SIM card

supply(SIMREG) supporting both 1.8 V and 3.0 V cards

• Provides level-shifters for the SIM interfacing signals.

The level-shifters translate the host controller signal

levels (IOVDD) to SIM card signal levels (SIMVCC) and

vice versa.

• In transparent mode the SIMEN input allows the host

controller to have direct control over the SIM card

supply. In sequencer mode the SIMEN input indicates

the presence of a SIM card.

• Enhanced ESD protection on all SIM contact pins

• The SIMI and SIMREG can be enabled in the ACTIVE

state. In all other states the SIMI and SIMREG are

disabled.

8.8 Battery voltage monitor (BVM)

The BVM monitors the main battery voltage. It offers the

following features:

• Programmable low battery threshold (V

LOW_BAT

)

• Hysteresis and selectable debounce filter built in to

prevent fast cycling

• The BVM is enabled in all activity states.

The BVM observes permanently the main battery voltage

and generates a LOWBAT interrupt if the battery voltage

drops below the programmed threshold voltage V

LOW_BAT

(see Fig.12). When a LOWBAT interrupt is generated in

ACTIVE state, the host controller should initiate a

transition to STANDBY state. In case the host controller

does not initiate a transition to the STANDBY state within

eight seconds after the interrupt occurred, the OOC forces

the PCF50603 to the STANDBY state in order to prevent a

too deep discharge of the battery.

2003 Oct 31 17

Page 18

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

handbook, full pagewidth

V

LOW_BAT

8.9 Temperature high sensor (TS)

The TS monitors the junction temperature of the

PCF50603. It offers the following features:

• Fixed temperature threshold

• Hysteresis and debounce filter built in to prevent fast

cycling

• The TS is enabled in ACTIVE state, in all other states

the TS is disabled.

The behaviour of the TS is shown in Figure 13.

V

BAT

LOWBAT

interrupt

V

Fig.12 BVM and LOWBAT behaviour.

PCF50603

V

hys

t

debounce

t

MDB689

A HIGHTMP interrupt is generated when the temperature

threshold is passed for more than 62 ms (debouncing

time). When a HIGHTMP interrupt is generated the host

controller should initiate a transition to STANDBY state.

In case the host controller does not initiate a transition to

the STANDBY state within 1 second after the interrupt

occurred,theOOCforcesthe PCF50603 to the STANDBY

state in order to prevent damage to the circuit.

The hysteresis and debounce time have been built in to

prevent fast cycling of the HIGHTMP signal.

The TS can not be disabled via the I2C-bus.

handbook, full pagewidth

150 °C

130

HIGHTMP

interrupt

°C

T

j

t

debounce

Fig.13 TS behaviour.

2003 Oct 31 18

T

hys

t

debounce

t

MDB690

Page 19

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

8.10 Real time clock (RTC)

The RTC module provides the time information to the

handset based on a 1 Hz clock frequency. Basically it is a

32-bit counter counting elapsed seconds.

• The RTC module contains one alarm function that

generates an interrupt if the actual RTC time equals the

content of the alarm register. The alarm registers are

preset to all 1 s which effectively disables the alarm;

effectively no alarm interrupt will be generated as long

as the RTC counter does not overflow. It is

recommended to mask the ALARM interrupt before a

new value is written to the alarm registers, in order to

preventinterrupts during the write actions (a new setting

may require up to 4 register writes).

• The RTC module is able to generate an interrupt each

second (SECOND interrupt) as well as each minute

(MINUTE interrupt). When the RTC starts up the first

time (after transition from NOPOWER state) the minute

interruptis aligned with each 60 seconds crossing. If the

synchronization with the 60 second crossing is required

after reprogramming the RTC time registers it is up to

the software to program the RTC time registers with a

modulo 60 value.

PCF50603

8.12 LED modulator (LED1 and LED2)

The PCF50603 contains two LED modulators (LED1 and

LED2), which can be selected as input for any of the GPO

outputs. The LED modulator of the PCF50603 is used for

the control of the indicator LEDs. They offer the following

features:

• The LED driver can select eight different repetition

periods

• Capable of generating eight different blinking patterns.

The selected pattern is generated once per repetition

period

• The LED can be used as a status indicator during the

ACTIVE state or when a charger is connected.

8.13 General purpose outputs (GPO)

The PCF50603 contains three high current (100 mA)

open-drain GPOs. They offer the following features:

• Each GPO can be configured as a constant LOW level,

a high impedance, a LED modulator output, a PWM

output or as the complementary PWM output PWM

• The GPOs can sink 100 mA from any supply or battery

voltage.

8.11 Pulse-width modulator (PWM1 and PWM2)

The two PWMs (PWM1 and PWM2) offer the following

features:

• Programmable frequency and duty cycle

• Any of the GPOs can be connected to either the PWMs

or the inverse of the PWMs

• The PWMs can be independently enabled in ACTIVE

state. In all other states the PWMs are disabled.

2003 Oct 31 19

Page 20

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

9 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

V

V

V

I

I

I

O

P

T

T

V

BAT

SAVE

CHG

I

tot

amb

stg

esd

main battery voltage −0.5 +6.5 V

backup battery input voltage −0.5 +6.5 V

charger input voltage −0.5 +20 V

input voltage on any pin with

−0.5 +6.5 V

respect to REFGND

input current at any input −10 +10 mA

output current at any output −10 +10 mA

total power dissipation − 2000 mW

operating ambient

−40 +85 °C

temperature

storage temperature −55 +150 °C

electrostatic discharge

voltage

HBM; note 1

pins SIMEN, IOD2VBAT, SIMD3VBAT,

−±6000 V

SIMRSCD_N, SIMCKCD, SIMIOCD,

V

, V

BAT

, CPVBAT, LPD1VBAT,

SAVE

REC1_N, SIMVCC, RF12VBAT,

HCVBAT, REC2_N

pin V

CHG

−±4000 V

other pins −±2000 V

MM; note 2 −±200 V

Notes

1. Human Body Model: equivalent to discharging a 100 pF capacitor via a 1.5 kΩ resistor.

2. Machine Model: equivalent to discharging a 200 pF capacitor via a 0 Ω resistor.

10 CHARACTERISTICS

V

= REFGND = GND = 0 V; T

SS

= −40 °C to +85 °C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

V

V

BAT

SAVE

CHG

main battery input voltage 0 − 5.7 V

backup battery input voltage 0 − 5.7 V

charger input voltage DC 0 − 15.0 V

rectified sine wave;

0 − 20.0 V

100 Hz to 120 Hz; note 1

V

CHGMIN

minimum charger voltage

− 2.7 − V

enabling MBC module

f

CLKCCO

high clock frequency 32 kHz clock available 3.42 3.6 3.78 MHz

D1 regulator

V

O

I

O

output voltage 1.20 − 3.20 V

output current −−150 mA

2003 Oct 31 20

Page 21

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

D3 regulator

V

O

I

O

HC regulator

V

O

I

O

SIM regulator

V

O

I

O

CP regulator

V

O

I

O

D2 regulator

V

O

I

O

IO regulator

V

O

I

O

LP regulator

V

O

I

O

RF1 regulator

V

O

I

O

RF2 regulator

V

O

I

O

MBGEN regulator

V

O

I

O

Notes

1. Under specific conditions a nominal current of 300 mA can be delivered.

2. Maximum current depends on the selected output voltage. At 3.50 V, 4.00 V and 4.50 V the maximum output current

is 75 mA. At 5.00 V output voltage the maximum output current is 50 mA.

output voltage 1.20 − 3.20 V

output current −−100 mA

output voltage 2.60 − 3.20 V

output current note 1 −−250 mA

output voltage 1.80 − 3.00 V

output current −−20 mA

output voltage 3.50 − 5.00 V

output current note 2 −−75 mA

output voltage 1.20 − 3.20 V

output current −−150 mA

output voltage 1.20 − 3.20 V

output current −−150 mA

output voltage 1.20 − 3.20 V

output current −−100 mA

output voltage 2.60 − 3.00 V

output current −−100 mA

output voltage 2.60 − 3.00 V

output current −−100 mA

output voltage 2.15 − 2.15 V

output current −−1.5 mA

2003 Oct 31 21

Page 22

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

11 APPLICATION INFORMATION

handbook, full pagewidth

MAIN

BATTERY

2.2 µF

V

CHG

RF1VDD

RF2VDD

SCP

SCN

CPVDD

GPO3

GPO2

GPO1

OSCI

OSCO

SIMEN

SIMVCC

V

BAT

31

34

33

32

27

22

24

37

38

35

46

47

48

26

25

45

44

42

43

41

BATTERY

CHARGER

CONSTANT

CURRENT

RF

UNIT

back light

back light

32.768 kHz

IOVDD

card present

SIM

CARD

READER

+

−

EL lamp

2.2 µF

or

DC

10 MΩ

DC

R

SENSE

(3)

on key

4700 nF

4700 nF

220 nF

4700 nF

10 pF

10 pF

10 kΩ

SIMRSCD_N

1000 nF

CHGCUR

CHGDRV

ONKEY_N

SIMIOCD

SIMCKCD

RF12VBAT

23

LPD1VBAT

20

IOD2VBAT

15

PCF50603

REFGND/V

SIMD3VBAT

40

SS

CPVBAT

36

HCVBAT

18

30

29

28

12

17

19

13

1

21

14

16

39

6

5

11

10

4

3

2

9

8

7

V

SAVE

VINT

REFC

MICBIAS

HCVDD

LPVDD

REC2_N

REC1_N

D1VDD

IOVDD

D2VDD

D3VDD

PWREN1

PWREN2

RSTHC_N

IRQ_N

CLK32K

SDA

SCL

SIMIOHC

SIMCKHC

SIMRSHC_N

battery

backup

470 nF

100 nF

4700

nF

(1)

4700

nF

(2)

470

nF

headset

from bottom

connector

470 nF

470 nF

470 nF

470 nF

1 kΩ 1 kΩ

revmod

PCF50603

RAM 1.8 V

FLASH 1.8 V

AUXADCx

MICP

MICN

VDDA

VDDD

PCF5213

VDDE3

VDDA

VDDC

VDDE1

VDDE2

LOWVOLT_N

ONKEY

AUXON_N

GPON0

RFSIGx

RSTON

SIMERRN

CLK32I

SDA

SCL

SIMIO

SIMCLK

GPOx

MDB691

(1) HCVDD is reserved for hands free audio supply.

(2) LPVDD not used in the system.

(3) Connect V

to ground if charger is used in BATMAX configuration.

CHG

Fig.14 Application diagram.

2003 Oct 31 22

Page 23

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

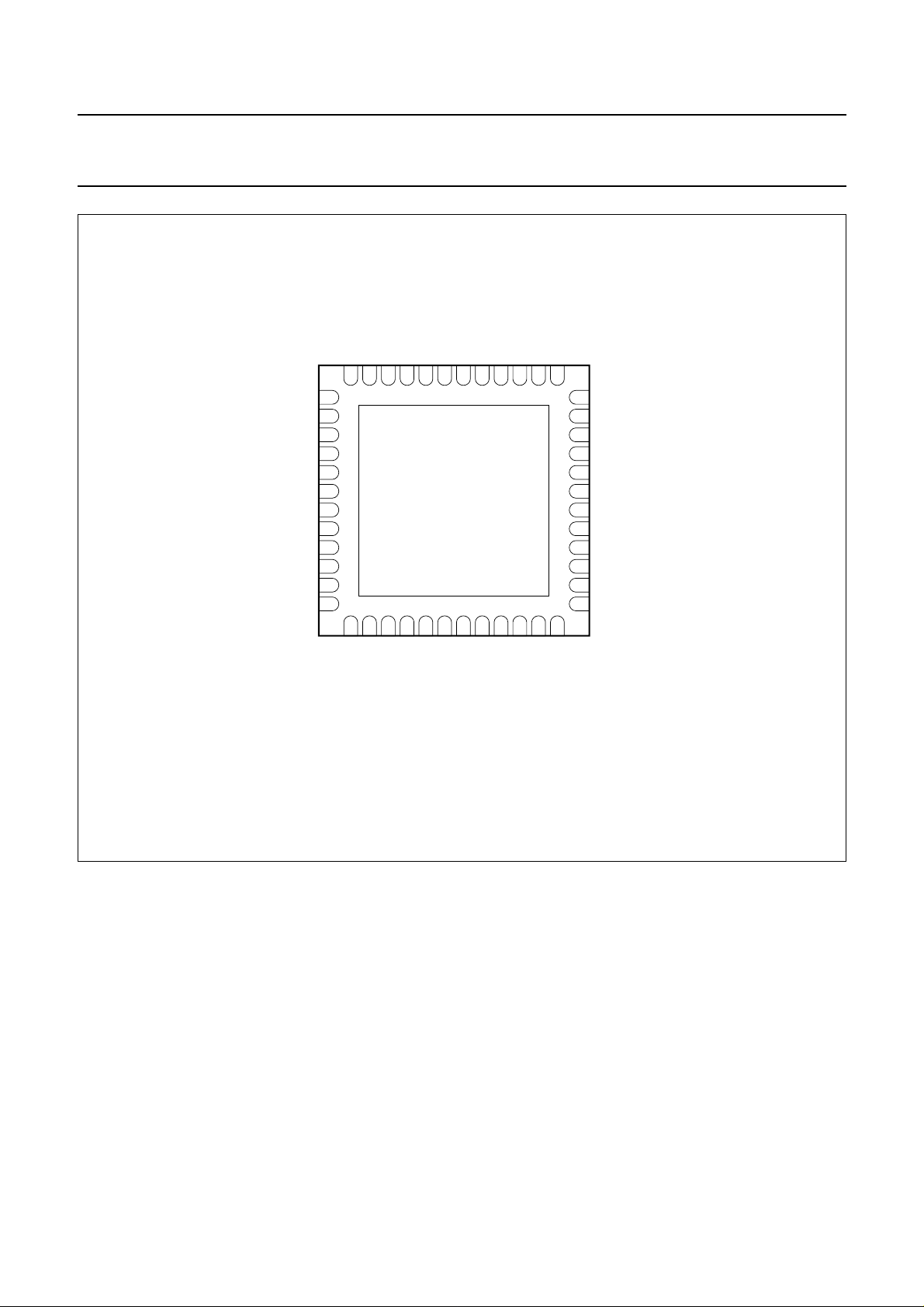

12 PACKAGE OUTLINE

HVQFN48: plastic thermal enhanced very thin quad flat package; no leads;

48 terminals; body 6 x 6 x 0.85 mm

A

D

terminal 1

index area

B

E

A

PCF50603

SOT778-1

A

1

detail X

c

e

1

D

4.25

3.95

1/2 e

b

25

1/2 e

36

E

4.25

3.95

37

scale

h

e

1

4.4

0.41

D

h

0 2.5 5 mm

(1)

E

h

6.1

5.9

REFERENCES

e

13 24

L

12

E

h

1

terminal 1

index area

DIMENSIONS (mm are the original dimensions)

Note

1. Plastic or metal protrusions of 0.075 mm maximum per side are not included.

(1)

A

UNIT

mm

OUTLINE

VERSION

SOT778-1 - - -- - - - - -

max.

A

0.05

0.00

1

48

bc

0.25

0.15

(1)

D

6.1

0.2

5.9

IEC JEDEC JEITA

e

v

w

e

4.4

C

y

w

C

1

ye

0.05 0.1

EUROPEAN

PROJECTION

y

1

M

ACCB

M

e

2

L

2

0.5

0.1v0.05

0.3

y

X

ISSUE DATE

02-07-05

2003 Oct 31 23

Page 24

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

13 SOLDERING

13.1 Introduction to soldering surface mount

packages

Thistext gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering can still be used for

certainsurface mount ICs, but it is not suitable forfinepitch

SMDs. In these situations reflow soldering is

recommended.

13.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

totheprinted-circuitboardby screen printing, stencilling or

pressure-syringe dispensing before package placement.

Driven by legislation and environmental forces the

worldwide use of lead-free solder pastes is increasing.

Several methods exist for reflowing; for example,

convection or convection/infrared heating in a conveyor

type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending

on heating method.

Typical reflow peak temperatures range from

215 to 270 °C depending on solder paste material. The

top-surface temperature of the packages should

preferably be kept:

• below 220 °C (SnPb process) or below 245 °C (Pb-free

process)

– for all BGA and SSOP-T packages

– for packages with a thickness ≥ 2.5 mm

– for packages with a thickness < 2.5 mm and a

volume ≥ 350 mm3 so called thick/large packages.

• below 235 °C (SnPb process) or below 260 °C (Pb-free

process) for packages with a thickness < 2.5 mm and a

volume < 350 mm3 so called small/thin packages.

Moisture sensitivity precautions, as indicated on packing,

must be respected at all times.

13.3 Wave soldering

Conventional single wave soldering is not recommended

forsurface mount devices (SMDs) or printed-circuit boards

PCF50603

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackages with leads on four sides, the footprint must

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time of the leads in the wave ranges from

3 to 4 seconds at 250 °C or 265 °C, depending on solder

material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

13.4 Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

2003 Oct 31 24

Page 25

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

13.5 Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

BGA, LBGA, LFBGA, SQFP, SSOP-T

DHVQFN, HBCC, HBGA, HLQFP, HSQFP, HSOP, HTQFP,

(1)

(3)

, TFBGA, VFBGA not suitable suitable

not suitable

HTSSOP, HVQFN, HVSON, SMS

(5)

PLCC

, SO, SOJ suitable suitable

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO, VSSOP not recommended

(8)

PMFP

not suitable not suitable

Notes

1. FormoredetailedinformationontheBGApackagesrefer to the

“(LF)BGAApplicationNote

from your Philips Semiconductors sales office.

2. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

3. These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no account

be processed through more than one soldering cycle or subjected to infrared reflow soldering with peak temperature

exceeding 217 °C ± 10 °C measured in the atmosphere of the reflow oven. The package body peak temperature

must be kept as low as possible.

4. These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the solder

cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink on the top side,

the solder might be deposited on the heatsink surface.

5. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

6. Wave soldering is suitable for LQFP, TQFP and QFP packages with a pitch (e) larger than 0.8 mm; it is definitely not

suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

7. Wave soldering is suitable for SSOP, TSSOP, VSO and VSSOP packages with a pitch (e) equal to or larger than

0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

8. Hot bar or manual soldering is suitable for PMFP packages.

SOLDERING METHOD

WAVE REFLOW

(4)

(5)(6)

(7)

suitable

suitable

suitable

”(AN01026);orderacopy

(2)

.

2003 Oct 31 25

Page 26

Philips Semiconductors Preliminary specification

Controller for power supply

PCF50603

and battery management

14 DATA SHEET STATUS

LEVEL

I Objective data Development This data sheet contains data from the objective specification for product

II Preliminary data Qualification This data sheet contains data from the preliminary specification.

III Product data Production This data sheet contains data from the product specification. Philips

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

3. For data sheets describing multiple type numbers, the highest-level product status determines the data sheet status.

DATA SHEET

STATUS

(1)

PRODUCT

STATUS

(2)(3)

DEFINITION

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Relevant changes will

be communicated via a Customer Product/Process Change Notification

(CPCN).

15 DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

atthese or at any other conditions above those given in the

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentation or warranty that such applicationswillbe

suitable for the specified use without further testing or

modification.

16 DISCLAIMERS

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips

Semiconductorscustomers using or selling theseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes in the products including circuits, standard cells, and/or software described or contained herein in order to improve design

and/or performance. When the product is in full production

(status ‘Production’), relevant changes will be

communicated via a Customer Product/Process Change

Notification (CPCN). Philips Semiconductors assumes no

responsibility or liability for the use of any of these

products, conveys no licence or title under any patent,

copyright, or mask work right to these products, and

makes no representations or warranties that these

products are free from patent, copyright, or mask work

right infringement, unless otherwise specified.

2003 Oct 31 26

Page 27

Philips Semiconductors Preliminary specification

Controller for power supply

and battery management

17 PURCHASE OF PHILIPS I2C COMPONENTS

Purchase of Philips I

components in the I2C system provided the system conforms to the I2C specification defined by

Philips. This specification can be ordered using the code 9398 393 40011.

2

C components conveys a license under the Philips’ I2C patent to use the

PCF50603

2003 Oct 31 27

Page 28

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2003

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands R54/01/pp28 Date of release: 2003 Oct 31 Document order number: 9397 750 11771

SCA75

Page 29

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...