Page 1

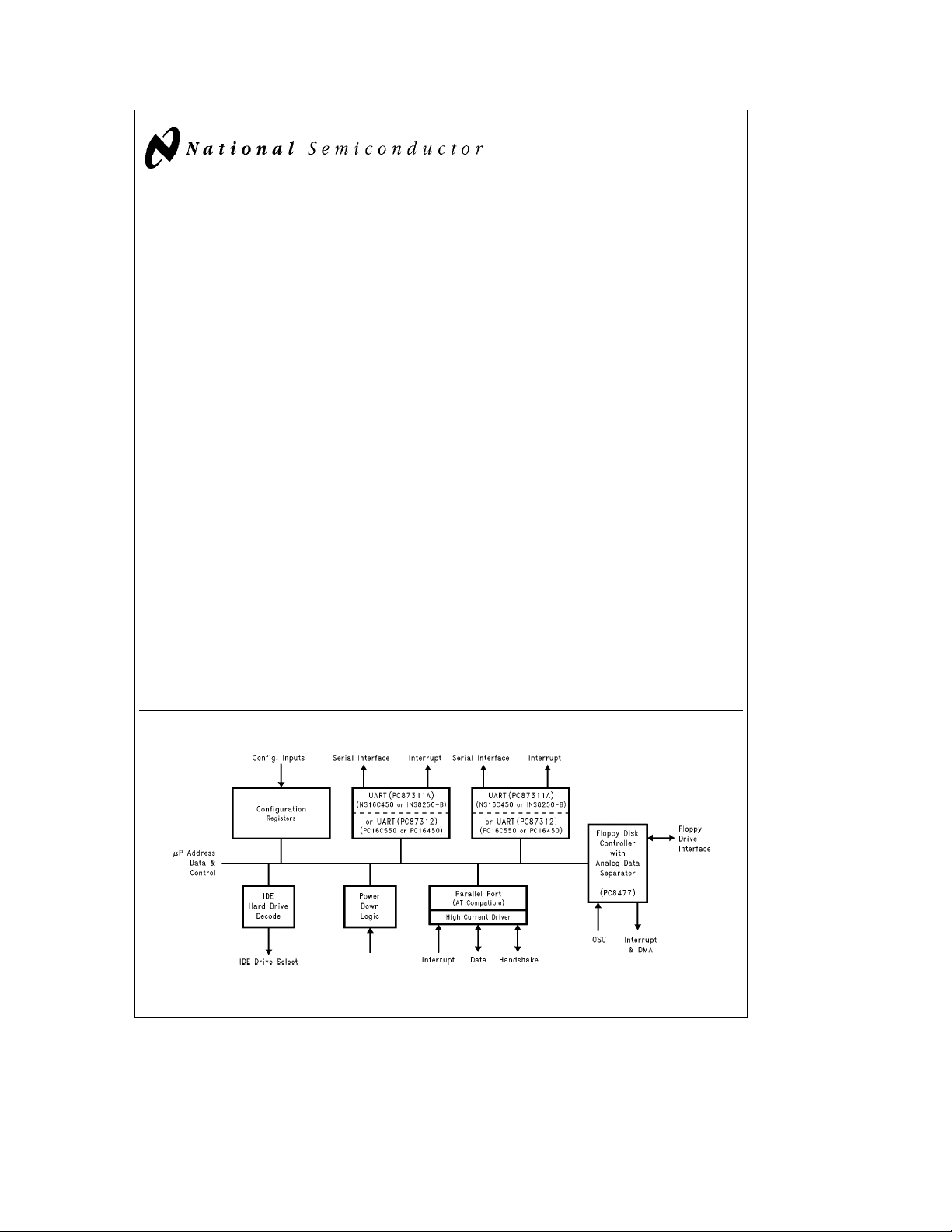

PC87311A/PC87312 (SuperI/OTMII/III)

Floppy Disk Controller with Dual UARTs,

Parallel Port, and IDE Interface

General Description

The PC87311A/12 incorporates a floppy disk controller

(FDC), two full function UARTs, a bidirectional parallel port,

and IDE interface control logic in one chip. The PC87311A

includes standard AT/XT address decoding for on-chip

functions and a Configuration Register, offering a single

chip solution to the most commonly used IBM

PC-XT

, and PC-ATÉperipherals. The PC87312 includes

É

standard AT address decoding for on-chip functions and a

Configuration Register set, offering a single chip solution to

the most commonly used ISA, EISA and Micro Channel peripherals.

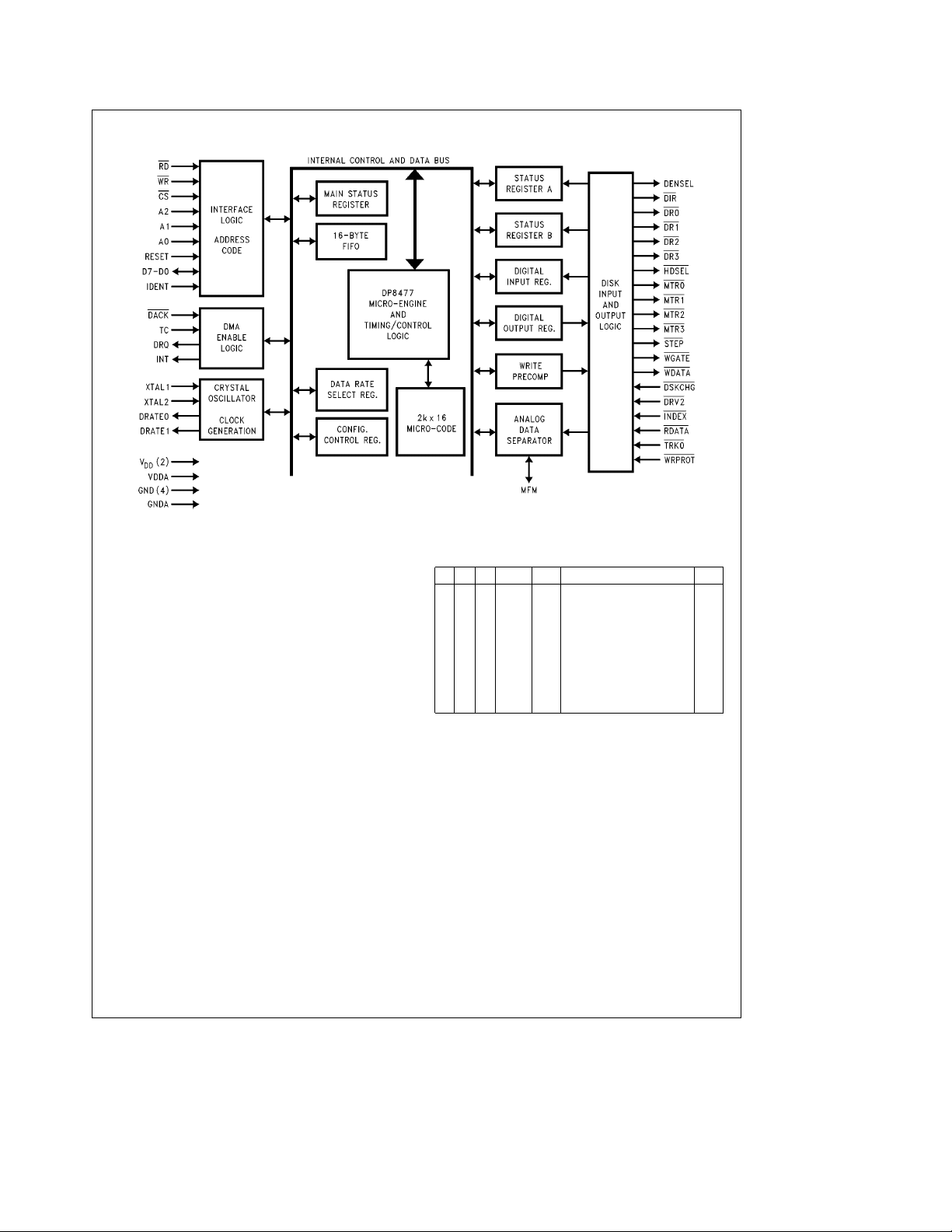

The on-chip FDC is software compatible to the PC8477,

which contains a superset of the DP8473 and NEC mPD765

and the N82077 floppy disk controller functions. The onchip analog data separator requires no external components and supports the 4 Mb drive format as well as the

other standard floppy drives used with 5.25

dia.

In the PC87311A, the UARTs are equivalent to two

INS8250N-Bs or NS16450s. The bidirectional parallel port

maintains complete compatibility with the IBM PC, XT and

AT. In the PC87312 the UARTs are equivalent to two

NS16450s or PC16550s. The bidirectional parallel port

maintains complete compatibility with the ISA, EISA and Micro Channel parallel ports.

The IDE control logic provides a complete IDE interface except for the signal buffers. The Configuration Registers consist of three byte-wide registers. An Index and a Data Register which can be relocated within the ISA I/O address space

access the Configuration Registers.

ÉPCÉ

and 3.5×me-

×

Features

Y

100% compatible with IBM PC, XT, and AT architectures (PC87311A), or ISA, EISA, and Micro Channel architectures (PC87312)

Y

FDC:

Ð Software compatible with the DP8473, the 765A and

,

the N82077

Ð 16-byte FIFO (default disabled)

Ð Burst and Non-Burst modes

Ð Perpendicular Recording drive support

Ð High performance internal analog data separator (no

external filter components required)

Ð Low power CMOS with power down mode

Y

UARTs:

Ð Software compatible with the INS8250N-B and the

NS16450 (PC87311A), or PC16550A and PC16450

(PC87312)

Y

Parallel Port:

Ð Bidirectional under either software or hardware

control

Ð Compatible with all IBM PC, XT and AT architectures

(PC87311A), or all ISA, EISA, and Micro Channel ar-

chitectures (PC87312)

Ð Back Voltage protection circuit against damage

caused when printer is powered up

Y

IDE Control Logic:

Ð Provides a complete IDE interface except for option-

al buffers

Y

Address Decoder:

Ð Provides selection of all primary and secondary ISA

addresses including COM 1 –4.

Y

100-pin PQFP package

Ð The PC87311A and PC87312 are pin compatible

October 1993

PC87311A/PC87312 (SuperI/O II/III) Floppy Disk Controller

with Dual UARTs, Parallel Port, and IDE Interface

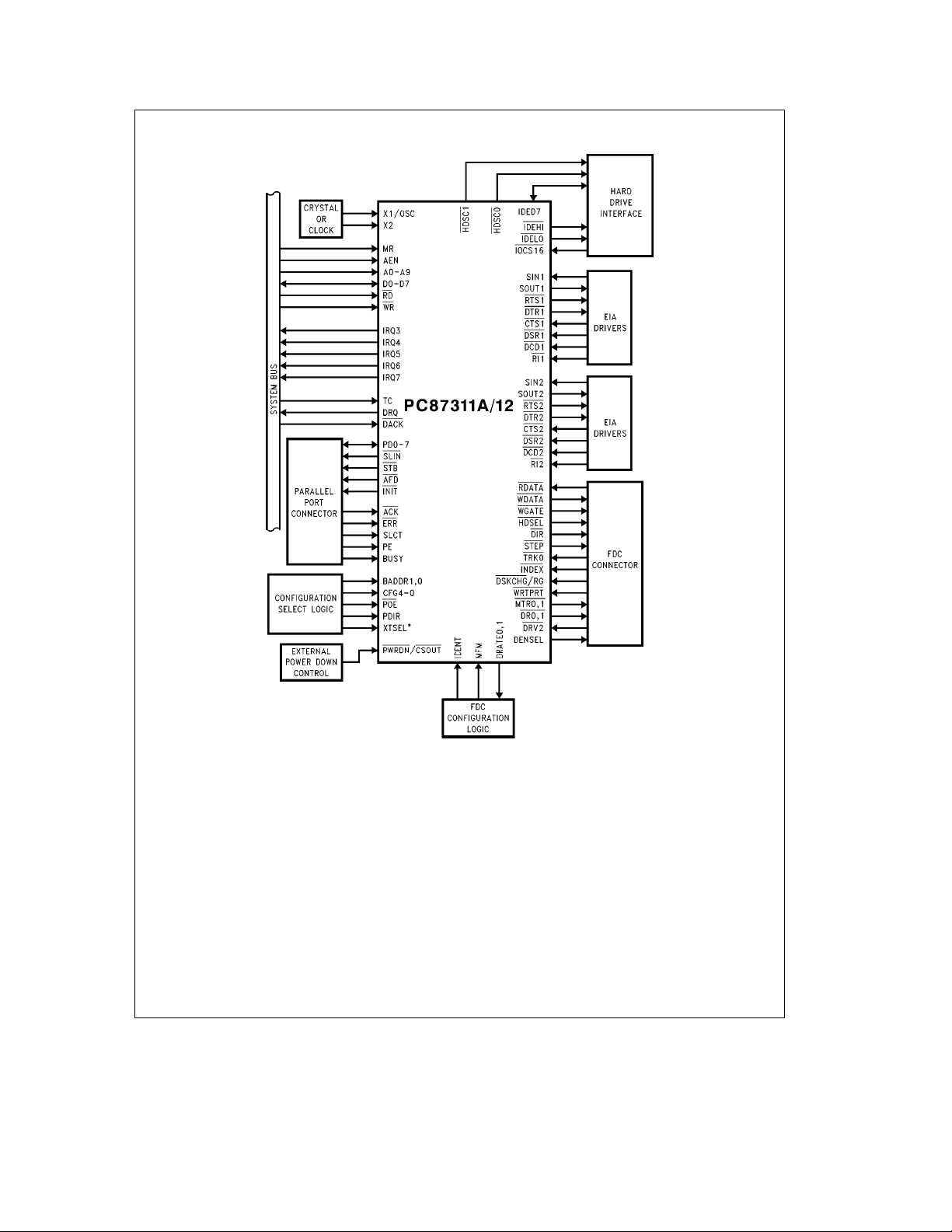

Block Diagram

TL/F/11362– 1

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

TM

SuperI/O

is a trademark of National Semiconductor Corporation.

IBM

,PCÉ, PC-ATÉ, PC-XTÉand PS/2Éare registered trademarks of International Business Machines Corporation.

É

C

1995 National Semiconductor Corporation RRD-B30M75/Printed in U. S. A.

TL/F/11362

Page 2

Table of Contents

1.0 PIN DESCRIPTION ААААААААААААААААААААААААААААААА6

2.0 CONFIGURATION REGISTERS АААААААААААААААААА12

2.1 Overview ААААААААААААААААААААААААААААААААААААА12

2.2 Software Configuration ААААААААААААААААААААААААА12

2.3 Hardware Configuration АААААААААААААААААААААААА12

2.4 Index and Data Registers ААААААААААААААААААААААА14

2.5 Base Configuration Registers ААААААААААААААААААА14

2.5.1 Function Enable Register (FER) АААААААААААА14

2.5.2 Function Address Register (FAR) ААААААААААА16

2.5.3 Power and Test Register (PTR)ААААААААААААА16

2.6 Power Down Options АААААААААААААААААААААААААА16

2.7 Power Up Procedure and Considerations ААААААААА17

2.7.1 Crystal Stabilization ААААААААААААААААААААААА17

2.7.2 UART Power-Up ААААААААААААААААААААААААА17

2.7.3 FDC Power-Up ААААААААААААААААААААААААААА17

3.0 FDC REGISTER DESCRIPTION АААААААААААААААААА17

3.1 Status Register A (SRA) АААААААААААААААААААААААА18

3.1.1 SRAРPS/2 Mode АААААААААААААААААААААААА19

3.1.2 SRAРModel 30 Mode АААААААААААААААААААА19

3.2 Status Register B (SRB) АААААААААААААААААААААААА19

3.2.1 SRBРPS/2 Mode АААААААААААААААААААААААА19

3.2.2 SRBРModel 30 Mode АААААААААААААААААААА19

3.3 Digital Output Register (DOR) ААААААААААААААААААА20

3.4 Tape Drive Register (TDR)АААААААААААААААААААААА20

3.5 Main Status Register (MSR) АААААААААААААААААААА20

3.6 Data Rate Select Register (DSR) АААААААААААААААА21

3.7 Data Register (FIFO)ААААААААААААААААААААААААААА22

3.8 Digital Input Register (DIR) ААААААААААААААААААААА22

3.8.1 DIRРPC-AT Mode ААААААААААААААААААААААА22

3.8.2 DIRРPS/2 Mode АААААААААААААААААААААААА22

3.8.3 DIRРModel 30 Mode ААААААААААААААААААААА22

3.9 Configuration Control Register (CCR) АААААААААААА23

3.9.1 CCRРPC-AT and PS/2 Modes АААААААААААА23

3.9.2 CCRРModel 30 Mode АААААААААААААААААААА23

3.10 Result Phase Status Registers ААААААААААААААААА23

3.10.1 Status Register 0 (ST0) ААААААААААААААААА23

3.10.2 Status Register 1 (ST1) ААААААААААААААААА23

3.10.3 Status Register 2 (ST2) ААААААААААААААААА24

3.10.4 Status Register 3 (ST3) ААААААААААААААААА24

4.0 FDC COMMAND SET DESCRIPTION ААААААААААААА24

4.1 Command Set Summary ААААААААААААААААААААААА24

4.2 Command Description ААААААААААААААААААААААААА28

4.2.1 Configure Command АААААААААААААААААААААА28

4.2.2 Dumpreg Command АААААААААААААААААААААА29

4.2.3 Format Track CommandААААААААААААААААААА29

4.2.4 Invalid CommandААААААААААААААААААААААААА32

4.2.5 Lock Command АААААААААААААААААААААААААА32

4.2.6 Mode Command ААААААААААААААААААААААААА32

4.2.7 NSC Command АААААААААААААААААААААААААА33

4.2.8 Perpendicular Mode CommandААААААААААААА33

4.2.9 Read Data Command ААААААААААААААААААААА34

4.2.10 Read Deleted Data Command АААААААААА36

4.2.11 Read ID Command АААААААААААААААААААА36

4.2.12 Read A Track Command ААААААААААААААА36

4.2.13 Recalibrate Command ААААААААААААААААА36

4.2.14 Relative Seek Command ААААААААААААААА36

4.2.15 Scan CommandsАААААААААААААААААААААА37

4.2.16 Seek CommandААААААААААААААААААААААА37

4.2.17 Sense Drive Status Command АААААААААА37

4.2.18 Sense Interrupt Command ААААААААААААА37

4.2.19 Set Track CommandААААААААААААААААААА38

4.2.20 Specify CommandААААААААААААААААААААА38

4.2.21 Verify Command АААААААААААААААААААААА39

4.2.22 Version Command АААААААААААААААААААА39

4.2.23 Write Data Command АААААААААААААААААА39

4.2.24 Write Deleted Data Command АААААААААА40

5.0 FDC FUNCTIONAL DESCRIPTION ААААААААААААААА40

5.1 Microprocessor InterfaceАААААААААААААААААААААА40

5.2 Modes of Operation АААААААААААААААААААААААААА41

5.3 Controller Phases АААААААААААААААААААААААААААА41

5.3.1 Command PhaseАААААААААААААААААААААААА41

5.3.2 Execution Phase АААААААААААААААААААААААА41

5.3.2.1 DMA ModeРFIFO Disabled ААААААА41

5.3.2.2 DMA ModeРFIFO Enabled АААААААА42

5.3.2.3 Interrupt ModeÐFIFO Disabled ÀÀÀÀ42

5.3.2.4 Interrupt ModeРFIFO Enabled ААААА43

5.3.2.5 Software Polling АААААААААААААААААА43

5.3.3 Result Phase ААААААААААААААААААААААААААА43

5.3.4 Idle PhaseАААААААААААААААААААААААААААААА43

5.3.5 Drive Polling Phase АААААААААААААААААААААА43

5.4 Data Separator АААААААААААААААААААААААААААААА43

5.5 Crystal Oscillator ААААААААААААААААААААААААААААА45

5.6 Perpendicular Recording Mode АААААААААААААААА46

5.7 Data Rate Selection АААААААААААААААААААААААААА47

5.8 Write Precompensation ААААААААААААААААААААААА47

5.9 FDC Low Power Mode LogicААААААААААААААААААА47

5.10 Reset Operation ААААААААААААААААААААААААААААА47

6.0 SERIAL PORTS АААААААААААААААААААААААААААААААА48

6.1 Introduction АААААААААААААААААААААААААААААААААА48

6.2 PC87311A Serial Ports ААААААААААААААААААААААААА48

6.2.1 Serial Port Registers АААААААААААААААААААААА48

6.2.2 Line Control Register (LCR)АААААААААААААААА48

6.2.3 Programmable Baud Rate GeneratorАААААААА51

6.2.4 Line Status Register (LSR)ААААААААААААААААА51

6.2.5 Interrupt Identification Register (IIR) АААААААА52

6.2.6 Interrupt Enable Register (IER) ААААААААААААА52

6.2.7 MODEM Control Register (MCR) ААААААААААА52

6.2.8 MODEM Status Register (MSR) АААААААААААА53

6.2.9 Scratchpad Register (SCR) АААААААААААААААА53

6.3 PC87312 Serial Ports АААААААААААААААААААААААААА53

6.3.1 Serial Port Registers АААААААААААААААААААААА53

6.3.2 Line Control Register (LCR)АААААААААААААААА53

6.3.3 Programmable Baud Rate GeneratorАААААААА56

2

Page 3

Table of Contents

6.3.4 Line Status Register (LSR) ААААААААААААААА56

6.3.5 FIFO Control Register (FCR)АААААААААААААА57

6.3.6 Interrupt Identification Register (IIR) ААААААА57

6.3.7 Interrupt Enable Register (IER) АААААААААААА57

6.3.8 MODEM Control Register (MCR) АААААААААА58

6.3.9 MODEM Status Register (MSR) ААААААААААА59

6.3.10 Scratchpad Register (SCR) ААААААААААААААА59

7.0 PARALLEL PORT АААААААААААААААААААААААААААААА59

7.1 Introduction АААААААААААААААААААААААААААААААААА59

7.2 Data Register (DTR) ААААААААААААААААААААААААААА60

7.3 Status Register (STR) АААААААААААААААААААААААААА60

7.4 Control Register (CTR) ААААААААААААААААААААААААА60

8.0 INTEGRATED DEVICE ELECTRONICS

INTERFACE (IDE) АААААААААААААААААААААААААААААА61

8.1 Introduction АААААААААААААААААААААААААААААААААА61

8.2 IDE Signals ААААААААААААААААААААААААААААААААААА61

9.0 DEVICE DESCRIPTION ААААААААААААААААААААААААА62

9.1 DC Electrical Characteristics АААААААААААААААААААА62

9.2 AC Electrical Characteristics АААААААААААААААААААА64

9.2.1 AC Test Conditions АААААААААААААААААААААА64

9.2.2 Clock Timing ААААААААААААААААААААААААААА64

9.2.3 Microprocessor Interface Timing АААААААААА65

9.2.4 Baudout Timing ААААААААААААААААААААААААА66

9.2.5 Transmitter Timing АААААААААААААААААААААА67

9.2.6 Receiver TimingААААААААААААААААААААААААА68

9.2.7 MODEM Control Timing АААААААААААААААААА69

9.2.8 DMA Timing АААААААААААААААААААААААААААА70

9.2.9 Reset Timing ААААААААААААААААААААААААААА71

9.2.10 Write Data Timing ААААААААААААААААААААААА71

9.2.11 Drive Control Timing ААААААААААААААААААААА72

9.2.12 Read Data Timing ААААААААААААААААААААААА72

9.2.13 IDE Timing ААААААААААААААААААААААААААААА72

9.2.14 Parallel Port Timing АААААААААААААААААААААА73

10.0 REFERENCE SECTION АААААААААААААААААААААААА74

10.1 Mnemonic Definitions for FDC Commands ААААААА74

10.2 Example Four Drive Circuit

Using the PC87311A/12 АААААААААААААААААААА75

List of Figures

FIGURE 2-1 PC87311A/87312 Configuration Registers АААААААААААААААААААААААААААААААААААААААААААААААААААААААААА12

FIGURE 3-1 FDC Functional Block DiagramААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА18

FIGURE 4-1 IBM, Perpendicular, and ISO Formats Supported by Format Command АААААААААААААААААААААААААААААААААА30

FIGURE 5-1 FDC Data Separator Block Diagram АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА44

FIGURE 5-2 PC87311A/87312 Dynamic Window Margin Performance ААААААААААААААААААААААААААААААААААААААААААААА45

FIGURE 5-3 Read Data AlgorithmРState DiagramААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА46

FIGURE 5-4 Perpendicular Recording Drive R/W Head and Pre-Erase Head АААААААААААААААААААААААААААААААААААААААА46

FIGURE 6-1 PC87311A Composite Serial Data АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА48

FIGURE 6-2 PC87312 Composite Serial Data ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА54

FIGURE 9-1 Clock Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА64

FIGURE 9-2 Microprocessor Read Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА65

FIGURE 9-3 Microprocessor Write Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА66

FIGURE 9-4 Baudout Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА66

FIGURE 9-5 Transmitter Timing ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА67

FIGURE 9-6a Receiver TimingАААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА68

FIGURE 9-6b PC87312 FIFO Mode Receiver Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА68

FIGURE 9-6c PC87312 Timeout Receiver Timing ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА69

FIGURE 9-7 MODEM Control Timing ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА69

FIGURE 9-8 DMA Timing ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА70

FIGURE 9-9 Reset Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА71

FIGURE 9-10 Write Data Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА71

FIGURE 9-11 Drive Control Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА72

FIGURE 9-12 Read Data Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА72

FIGURE 9-13 IDE Timing АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА72

FIGURE 9-14 Parallel Port Interrupt Timing (Compatible Mode) ААААААААААААААААААААААААААААААААААААААААААААААААААААА73

FIGURE 9-15 Parallel Port Interrupt Timing (Extended Mode) ААААААААААААААААААААААААААААААААААААААААААААААААААААААА73

FIGURE 9-16 Typical Parallel Port Data Exchange АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА73

FIGURE 10-1 PC87311A/87312 Four Floppy Drive Circuit ААААААААААААААААААААААААААААААААААААААААААААААААААААААААА75

FIGURE 10-2 IDE Interface Signal Equations ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА75

FIGURE 10-3 PC87311A/87312 Adapter Card Schematic ААААААААААААААААААААААААААААААААААААААААААААААААААААААААА76

3

Page 4

List of Tables

TABLE 2-1 Default Configurations Controlled by Hardware АААААААААААААААААААААААААААААААААААААААААААААААААААААААА13

TABLE 2-2 Index and Data Register Optional Locations ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА14

TABLE 2-3 Primary and Secondary Drive Address Selection ААААААААААААААААААААААААААААААААААААААААААААААААААААААА15

TABLE 2-4 Encoded Drive and Motor Pin Information ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА15

TABLE 2-5 Parallel Port AddressesААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА16

TABLE 2-6a COM Port Selection for UART1 АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА16

TABLE 2-6b COM Port Selection for UART2 АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА16

TABLE 2-7 Address Selection for COM3 and COM4 АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА16

TABLE 3-1 Register Description and AddressesАААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА18

TABLE 3-2 Drive Enable Values ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА20

TABLE 3-3 Tape Drive Assignment Values АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА20

TABLE 3-4 Write Precompensation Delays АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА21

TABLE 3-5 Default Precompensation Delays АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА21

TABLE 3-6 Data Rate Select Encoding ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА22

TABLE 4-1 Typical Format Gap Length ValuesААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА31

TABLE 4-2 DENSEL EncodingААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА33

TABLE 4-3 DENSEL Default EncodingАААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА33

TABLE 4-4 Effect of Drive Mode and Data Rate on Format and Write CommandsААААААААААААААААААААААААААААААААААААА34

TABLE 4-4a Effect of GAP and WG on Format and Write Commands АААААААААААААААААААААААААААААААААААААААААААААААА34

TABLE 4-5 Sector Size Selection АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА34

TABLE 4-6 SK Effect on Read Data CommandААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА35

TABLE 4-7 Result Phase Termination Values with No Error АААААААААААААААААААААААААААААААААААААААААААААААААААААААА35

TABLE 4-8 SK Effect on Read Deleted Data Command ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА36

TABLE 4-9 Maximum Recalibrate Step Pulses Based on R255 and ETRААААААААААААААААААААААААААААААААААААААААААААА36

TABLE 4-10 Scan Command Termination Values ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА37

TABLE 4-11 Status Register 0 Termination Codes ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА38

TABLE 4-12 Set Track Register Address ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА38

TABLE 4-13 Step Rate (SRT) Values АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА38

TABLE 4-14 Motor Off Time (MFT) ValuesАААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА39

TABLE 4-15 Motor On Time (MNT) Values ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА39

TABLE 4-16 Verify Command Result Phase Table ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА40

TABLE 6-1 PC87311A UART Register Addresses (AEN

TABLE 6-2 PC87311A Register Summary for an Individual UART ChannelААААААААААААААААААААААААААААААААААААААААААА49

TABLE 6-3 PC87311A UART Reset ConfigurationАААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА50

TABLE 6-4 PC87311A UART Divisors, Baud Rates, and Clock Frequencies ААААААААААААААААААААААААААААААААААААААААА51

TABLE 6-5 PC87311A Interrupt Control FunctionsАААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА52

TABLE 6-6 PC87312 UART Register Addresses (AEN

TABLE 6-7 PC87312 Register Summary for an Individual UART Channel АААААААААААААААААААААААААААААААААААААААААААА54

TABLE 6-8 PC87312 UART Reset Configuration ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА55

TABLE 6-9 PC87312 UART Divisors, Baud Rates, and Clock Frequencies ААААААААААААААААААААААААААААААААААААААААААА56

TABLE 6-10 PC87312 Interrupt Control Functions ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА58

TABLE 7-1 Parallel Interface Register Addresses АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА59

TABLE 7-2 Data Register Read and Write Modes АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА59

TABLE 7-3 Parallel Port Mode of Operation ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА59

TABLE 7-4 Parallel Port Reset StatesААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА60

TABLE 8-1 IDE Registers and Their ISA AddressesААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА61

TABLE 9-1 Nominal t

TABLE 9-2 Minimum t

TABLE 10-1 PC87311A/87312 Four Floppy Drive Encoding АААААААААААААААААААААААААААААААААААААААААААААААААААААААА75

Values АААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА64

ICP,tDRP

Values ААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААААА71

WDW

e

0) АААААААААААААААААААААААААААААААААААААААААААААААААААААА48

e

0) ААААААААААААААААААААААААААААААААААААААААААААААААААААААА53

4

Page 5

Basic Configuration

*Note: PC87311A only

TL/F/11362– 2

5

Page 6

1.0 Pin Description

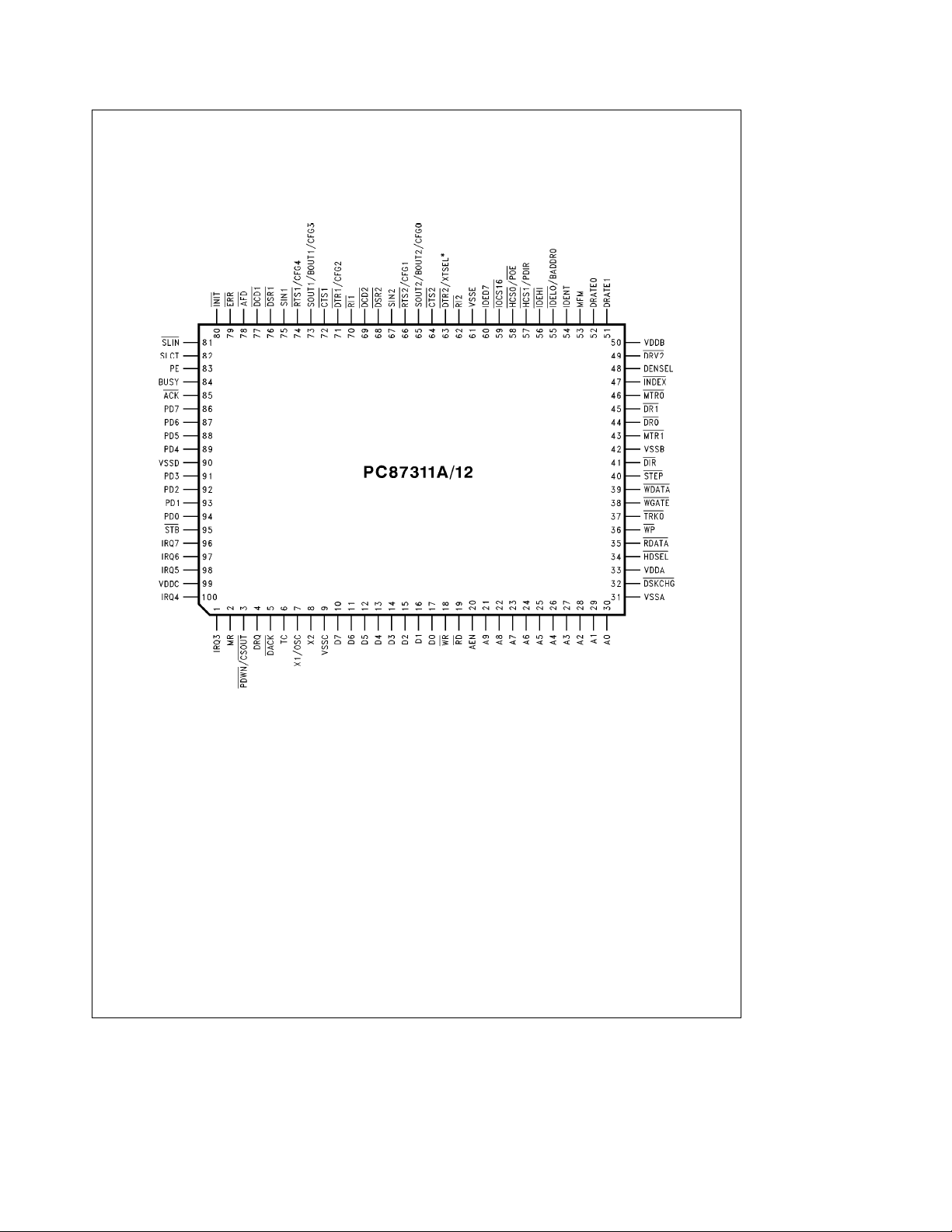

Connection Diagram

Plastic Quad Flatpak, EIAJ

*Note: XTSEL PC87311A only TL/F/11362– 3

Order Number PC87311AVF or PC87312VF

See NS Package Number VLJ100A

6

Page 7

1.0 Pin Description (Continued)

Symbol Pin I/O Function

A9–A0 21–30 I Address. These address lines from the microprocessor determine which internal register is accessed.

ACK 85 I Acknowledge. This input is pulsed low by the printer to indicate that it has received data from the

AFD 78 O Automatic Feed XT. When this signal is low the printer should automatically line feed after each line is

AEN 20 I Address Enable. This input disables function selection via A9 – A0 when it is high. Access to the FDC

BADDR0 55 I Base Address. This bit determines one of two base addresses from which the Index and Data

BOUT1,2 73, 65 O BAUD Output. This multi-function pin provides the associated serial channel Baud Rate generator

BUSY 84 I Busy. This pin is set high by the printer when it can’t accept another character. This pin has a nominal

CFG0–4 65, 66, I Default Configuration. These CMOS inputs select 1 of 32 default configurations in which the

71, 73,

74

CSOUT 3OChip Select Output. When the associated bit in the Power and Test Configuration Register is set, this

CTS1,2 72, 64 I Clear to Send. When low, this indicates that the MODEM or data set is ready to exchange data. The

D7–D0 10–17 I/O Data. Bi-directional data lines to the microprocessor. D0 is the LSB and D7 is the MSB. These signals

DACK 5IDMA Acknowledge. Active low input to acknowledge the FDC DMA request and enable the RD and

DCD1,2 77, 69 I Data Carrier Detect. When low, this indicates that the data carrier has been detected by the MODEM

DENSEL 48 O Density Select. Indicates when a high FDC density data rate (500 kb/s or 1 Mb/s) or a low density

DIR 41 O Direction. This output determines the direction of the floppy disk drive (FDD) head movement (active

A0–A9 are don’t cares during an FDC DMA transfer.

parallel port. This pin has a nominal 25 kX pull-up resistor attached.

printed. This pin will be in a TRI-STATEÉcondition 10 ns after a zero is loaded into the corresponding

Control Register bit. The system should pull this pin high using a 4.7 kX resistor.

Data Register during DMA transfer is NOT affected by this pin.

Registers will be offset (see Table 2-2). An internal pull-down resistor of 40 kX is on each pin. Use a

10 kX resistor to pull this pin to the required level during reset.

output signal, if test mode is selected in the Power and Test Configuration Register and the DLAB bit

(LCR7) is set. After Master Reset this pin provides the SOUT function. (See SOUT and CFG0–4 for

further information.)

25 kX pull-down resistor attached to it.

PC87311A/12 will power-up (see Table 2-1). An internal pull-down resistor of 40 kX is on each pin.

Usea10kXresistor to pull these pins to the required level during reset.

multi-function pin provides an active signal each time the internal address decoder decodes an

address enabled for the PC87311A/12. (See PWDN

CTS

signal is a MODEM status input whose condition the CPU can test by reading bit 4 (CTS) of the

MODEM Status Register (MSR) for the appropriate serial channel. Bit 4 is the complement of the CTS

signal. Bit 0 (DCTS) of the MSR indicates whether the CTS input has changed state since the previous

reading of the MSR. CTS

Note: Whenever the DCTS bit of the MSR is set an interrupt is generated if MODEM Status interrupts are enabled.

all have 24 mA (sink) buffered outputs.

WR

inputs during a DMA transfer. When in PC-AT or Model 30 mode, this signal is enabled by bit D3 of

the Digital Output Register (DOR). When in PS/2Émode, DACK is always enabled, and bit D3 of the

DOR is reserved. DACK

or data set. The DCD

7 (DCD) of the MODEM Status Register (MSR) for the appropriate serial channel. Bit 7 is the

complement of the DCD

changed state since the previous reading of the MSR.

Note: Whenever the DDCD bit of the MSR is set, an interrupt is generated if MODEM Status interrupts are enabled.

data rate (250 or 300 kb/s) has been selected. DENSEL is active high for high density (5.25

when IDENT is high, and active low for high density (3.5

programmable via the Mode command (see Section 4.2.6).

e

step in, inactiveestep out) during a seek operation. During read or writes, DIR will be inactive.

has no effect on the transmitter.

should be held high during PIO accesses.

signal is a MODEM status input whose condition the CPU can test by reading bit

signal. Bit 3 (DDCD) of the MSR indicates whether the DCD input has

for further information.)

drives) when IDENT is low. DENSEL is also

×

drives)

×

7

Page 8

1.0 Pin Description (Continued)

Symbol Pin I/O Function

DR0,1 44, 45 O Drive Select 0,1. These are the decoded drive select outputs that are controlled by Digital Output

DRATE0,1 52, 51 O Data Rate 0,1. These outputs reflect the currently selected FDC data rate, (bits 0 and 1 in the

DRQ 4 O DMA Request. Active high output to signal the DMA controller that a FDC data transfer is needed.

DRV2 49 I Drive2. This input indicates whether a second disk drive has been installed. The state of this pin is

DSKCHG 32 I Disk Change. The input indicates if the drive door has been opened. The state of this pin is available

DSR1,2 76, 68 I Data Set Ready. When low, this indicates that the data set or MODEM is ready to establish a

DTR1,2 71, 63 O Data Terminal Ready. When low, this output indicates to the MODEM or data set that the UART is

ERR 79 I Error. This input is set low by the printer when it has detected an error. This pin has nominal 25 kX

HCS0 58 O Hard Drive Chip Select 0. This output is active in the AT mode when the hard drive registers from

HCS1 57 O Hard Drive Chip Select 1. This output is active in the AT mode when the hard drive registers from

HDSEL 34 O Head Select. This output determines which side of the FDD is accessed. Active selects side 1,

IDED7 60 I/O IDE Bit 7. This pin provides the data bus bit 7 signal to the IDE hard drive during accesses in the

IDEHI 56 O IDE High Byte. This output enables the high byte data latch during a read or write to the hard drive if

IDELO 55 O IDE Low Byte. This output enables the low byte data latch during a read or write to the hard drive .

Register bits D0, D1. The Drive Select outputs are gated with DOR bits 4–7. These are active low

outputs. They are encoded with information to control four FDDs when bit 4 of the Function Enable

Register (FER) is set. (See MTR0,1

Configuration Control Register (CCR) or the Data Rate Select Register (DSR), whichever was written

to last). These pins are totem-pole buffered outputs (6 mA sink, 6 mA source).

When in PC-AT or Model 30 mode, this signal is enabled by bit D3 of the DOR. When in PS/2 mode,

DRQ is always enabled, and bit D3 of the DOR is reserved.

available from Status Register A in PS/2 mode.

from the Digital Input register. This pin can also be configured as the RGATE data separator

diagnostic input via the Mode command (see Section 4.2.6).

communications link. The DSR

reading bit 5 (DSR) of the MODEM Status Register (MSR) for the appropriate channel. Bit 5 is the

complement of the DSR

changed state since the previous reading of the MSR.

Note: Whenever the DDSR bit of the MSR is set, an interrupt is generated if MODEM Status interrupts are enabled.

ready to establish a communications link. The DTR

bit 0 (DTR) of the MODEM Control Register to a high level. A Master Reset operation sets this signal

to its inactive (high) state. In the PC87312, loop mode operation holds this signal to its inactive state.

(See CFG4–0 for further information.) In the PC87311A, loop mode operation holds this signal to its

inactive state if the XTSEL pin is high during reset. If the XTSEL pin is low during reset, the associated

pin state is controlled by the MCR0 bit during loop mode operation. (See XTSEL and CFG0–4 for

further information.)

pull-up resistor attached to it.

1F0–1F7h are selected if the primary address is used or when 170 – 177h are selected if the

secondary address is used. In the XT mode (PC87311A) this output is active if the addresses from

320–324h are selected. This output is inactive if the IDE interface is disabled via the Configuration

Register. (See POE for further information.)

3F6–7 are selected if the primary address is used or when 376 – 377 are selected if the secondary

address is used. In the XT mode (PC87311A) this output is inactive. This output is also inactive if the

IDE interface is disabled via the Configuration Register. (See PDIR for further information.)

inactive selects side 0.

address range 1F0–1F7h, 170 – 177h and 3F6h and 376h. This pin is TRI-STATE during read or write

accesses to 3F7h and 377h.

the hard drive returns IOCS16

Configuration Register.

This output is inactive if the IDE interface is disabled via the Configuration Register. (See BADDR0 for

further information.)

signal. Bit 1 (DDSR) of the MSR indicates whether the DSR input has

and Table 2-4 for more information.)

signal is a MODEM status input whose condition the CPU can test by

signal can be set to an active low by programming

. This output is inactive if the IDE interface is disabled via the

8

Page 9

1.0 Pin Description (Continued)

Symbol Pin I/O Function

IDENT 54 I Identity. During chip reset, the IDENT and MFM pins are sampled to determine the mode of operation

INDEX 47 I Index. This input signals the beginning of a FDD track.

INIT 80 O Initialize. When this signal is low it causes the printer to be initialized. This pin will be in a TRI-STATE

IOCS16 59 I I/O Chip Select 16-Bit. This input will be driven by the peripheral device when it can accommodate a

IRQ3,4 1, 100 O Interrupt 3 and 4. These are active high interrupts associated with the serial ports. IRQ3 presents the

IRQ5 98 O Interrupt 5. Active high output that indicates a parallel port interrupt. When enabled this bit follows the

IRQ6 97 O Interrupt 6. Active high output to signal the completion of the execution phase for certain FDC

IRQ7 96 O Interrupt 7. Active high output that indicates a parallel port interrupt. When enabled this bit follows the

MR 2 I Master Reset. Active high input that resets the controller to the idle state, and resets all disk interface

according to the following table:

IDENT MFM MODE

1 1 or NC PC-AT Mode

1 0 Illegal

0 1 or NC PS/2 Mode

0 0 Model 30 Mode

AT ModeÐThe DMA enable bit in the DOR is valid. TC is active high. Status Registers A and B are

disabled (TRI-STATE).

Model 30 ModeÐThe DMA enable bit in the DOR is valid. TC is active high. Status Registers A and B

are enabled.

PS/2 ModeÐThe DMA enable bit in the DOR is a don’t care, and the DRQ and IRQ6 signals will always

be enabled. TC is active low. Status Registers A and B are enabled.

After chip reset, the state of IDENT determines the polarity of the DENSEL output.

When IDENT is a logic ‘‘1’’, DENSEL is active high for the 500 kbs/1 Mbs data rates.

When IDENT is a logic ‘‘0’’, DENSEL is active low for the 500 kbs/1 Mbs data rates.

(See Mode command for further explanation of DENSEL.)

condition 10 ns after a zero is loaded into the corresponding Control Register bit. The system should pull

this pin high using a 4.7 kX resistor.

16-bit access.

signal if the serial channel has been designated as COM2 or COM4. IRQ4 presents the signal if the serial

port is designated as COM1 or COM3. The appropriate interrupt goes active whenever it is enabled via

IER, the associated Interrupt Enable bit (Modem Control Register bit 3, MCR3), and any of the following

conditions are active: Receiver Error, Receive Data available, Transmitter Holding Register Empty, or a

Modem Status Flag is set. The interrupt is reset low (inactive) after the appropriate interrupt service

routine is executed, after being disabled via the IER, or after a Master Reset. Either interrupt can be

disabled, putting them into TRI-STATE, by setting the MCR3 bit low.

ACK

signal input. When bit 4 in the parallel port Control Register is set and the parallel port address is

designated as shown in Table 2-5, this interrupt is enabled. When it is not enabled or when operating in

the XT mode this signal is TRI-STATE.

commands. Also used to signal when a data transfer is ready during a Non-DMA operation. When in

PC-AT or Model 30 mode, this signal is enabled by bit D3 of the DOR. When in PS/2 mode, IRQ6 is

always enabled, and bit D3 of the DOR is reserved.

ACK

signal input. When bit 4 in the parallel port Control Register is set and the parallel port address is

designated as shown in Table 2-5, this interrupt is enabled. When it is not enabled this signal is

TRI-STATE.

outputs to their inactive states. The DOR, DSR, CCR, Mode command, Configure command, and Lock

command parameters are cleared to their default values. The Specify command parameters are not

affected. The Configuration Registers are set to their selected default values.

9

Page 10

1.0 Pin Description (Continued)

Symbol Pin I/O Function

MFM 53 I/O MFM. During a chip reset when in PS/2 mode (IDENT low), this pin is sampled to select the PS/2 mode

MTR0,1 46, 43 O Motor Select 0,1. These are the motor enable lines for drives 0 and 1, and are controlled by bits

PD0–7 94– 91, I/O Parallel Port Data. These bidirectional pins transfer data to and from the peripheral data bus and the

89–86

PDIR 57 I Parallel Port Direction. During reset the state of this pin determines the direction of the parallel port

PDWN 3IPower Down. This multi-function pin will stop the clocks and/or the external crystal based on the

PE 83 I Paper End. This input is set high by the printer when it is out of paper. This pin has a nominal 25 kX

POE 58 I Parallel Port Output Enable. This pin is sensed during reset. If it is low, bit 7 of the Power and Test

RD 19 I Read. Active low input to signal a data read by the microprocessor.

RDATA 35 I Read Data. This input is the raw serial data read from the floppy disk drive.

RI1,2 70, 62 I Ring Indicator. When low this indicates that a telephone ringing signal has been received by the

RTS1,2 74, 66 O Request to Send. When low, this output indicates to the MODEM or data set that the UART is ready to

SIN1,2 75, 67 I Serial Input. This input receives composite serial data from the communications link (peripheral device,

SLCT 82 I Select. This input is set high by the printer when it is selected. This pin has a nominal 25 kX pull-down

SLIN 81 O Select Input. When this signal is low it selects the printer. This pin will be in a TRI-STATE condition

(MFM high), or the Model 30 mode (MFM low). An internal pull-up or external pull-down 10 kX resistor

will select between the two PS/2 modes. When the PC-AT mode is desired, (IDENT high), MFM should

be left pulled high internally. MFM reflects the current data encoding format when RESET is inactive.

e

MFM

high, FMelow. Defaults to low after a chip reset. This signal can also be configured as the

PUMP data separator diagnostic output via the Mode command (see Section 4.2.6).

D7–D4 of the Digital Output register. They are active low outputs. They are encoded with information to

control four FDDs when bit 4 of the Function Enable Register (FER) is set. (See DR0,1

for more information.)

parallel port Data Register. These pins have high current drive capability. (See DC Electrical

Characteristics.)

data, if the PTR7

input (scanner) when PDIR

Usea10kXresistor to pull this pin to the required level during reset.

selections made in the Power and Test Register bits 1-2. (See CSOUT for additional information.)

pull-down resistor attached to it.

Register (PTR7) is set high and the parallel port will operate in the Extended Mode. In this mode

software determines the direction of parallel port data via the parallel port Control Register (CTR5). If

this pin is high (PTR7

by the state of PDIR pin at reset. An internal pull-down resistor of 40 kX is on this pin. Use a 10 kX

resistor to pull this pin to the required level during reset.

MODEM. The RI

of the MODEM Status Register (MSR) for the appropriate serial channel. Bit 6 is the complement of the

RI

signal. Bit 2 (TERI) of the MSR indicates whether the RI input has changed from low to high since the

previous reading of the MSR.

Note: Whenever the TERI bit of the MSR is set, an interrupt is generated if MODEM Status interrupts are enabled.

exchange data. The RTS

Control Register to a high level. A Master Reset operation sets this signal to its inactive (high) state. In

the PC87312, loop mode operation holds this signal to its inactive state. (See CFG0–4 for further

information.) In the PC87311A, loop mode operation holds this signal to its inactive state if the XTSEL

pin is high during reset. If the XTSEL pin is low during reset, the associated pin state is controlled by the

MCR1 bit during loop mode operation. (See CFG0–4 for further information.)

MODEM, or data set).

resistor attached to it.

10 ns after a zero is loaded into the corresponding Control Register bit. The system should pull this pin

high using a 4.7 kX resistor.

e

0. The direction will be output (printer) when PDIRe0 and PTR7e0 and it will be

e

1 and PTR7e0. An internal pull-down resistor or 40 kX is on this pin.

e

0) then the Compatible Mode is selected and the data direction is determined

signal is a MODEM status input whose condition the CPU can test by reading bit 6 (RI)

signal can be set to an active low by programming bit 1 (RTS) of the MODEM

and Table 2-4

10

Page 11

1.0 Pin Description (Continued)

Symbol Pin I/O Function

SOUT1,2 73, 65 O Serial Output. This output sends composite serial data to the communications link (peripheral device,

STB 95 O Data Strobe. This output indicates to the printer that valid data is available at the printer port. This pin

STEP 40 O Step. This output signal issues pulses to the disk drive at a software programmable rate to move the

TC 6 I Terminal Count. Control signal from the DMA controller to indicate the termination of a DMA transfer.

TRK0 37 I Track 0. This input indicates to the controller that the head of the selected floppy disk drive is at track

VDDA 33 Analog Supply. This pin is the 5V supply for the analog data separator.

VDDB,C 50, 99 Digital Supply. This is the 5V supply voltage for the digital circuitry.

VSSA 31 Analog Ground. This is the analog ground for the data separator.

VSSB-E 42, 9, Digital Ground. This is the ground for the digital circuitry.

90, 61

WR 18 I Write. Active low input to signal a write from the microprocessor to the controller.

WDATA 39 O Write Data. This output is the write precompensated serial data that is written to the selected floppy

WGATE 38 O Write Gate. This output signal enables the write circuitry of the selected disk drive. WGATE has been

WP 36 I Write Protect. This input indicates that the disk in the selected drive is write protected.

X1/OSC 7 I Crystal1/Clock. One side of an external 24 MHz crystal is attached here. If a crystal is not used, a TTL

X2 8 O Crystal2. One side of an external 24 MHz crystal is attached here. This pin is left unconnected if an

XTSEL* 63 I XT Select. When this pin is high during reset the chip will operate in the XT mode. When this pin is low

*Note: XTSEL is an option for the PC87311A only.

MODEM, or data set). The SOUT signal is set to a marking state (logic 1) after a Master Reset

operation. (See BOUT and CFG0–4 for further information on these pins.)

will be in a TRI-STATE condition 10 ns after a zero is loaded into the corresponding Control Register bit.

The system should pull this pin high using a 4.7 kX resistor.

head during a seek operation.

TC is accepted only when DACK

low in PS/2 mode.

zero.

disk drive. Precompensation is software selectable.

designed to prevent glitches during power up and power down. This prevents writing to the disk when

power is cycled.

or CMOS compatible clock is connected to this pin.

external clock is used.

during reset the chip will operate in the AT mode. An internal pull-down resistor of 40 kX is on this pin.

Usea10kXresistor to pull this pin to the required level during reset.

There are five differences between AT and XT mode. One concerns hard disk operation and the other

four concern UART operation. In AT mode the IDE hard drive chip selects (HCS0

for addresses 1F0–7H and 3F6, 7H; respectively. In XT mode the IDE chip select HCS0

addresses 320–3H and HCS1

bit (see Section 6.5 bit 6), the modem control outputs during loop back mode (see Section 6.8 bit 4), the

Scratch Pad Register (see Section 6.10), and the availability of edge (XT) or level (AT) sensitive UART

interrupts.

is active. TC is active high in PC-AT and Model 30 modes, and active

, HCS1) will be active

responds to

is inactive. The differences in UART operation are: the function of LSR

11

Page 12

2.0 Configuration Registers

2.1 OVERVIEW

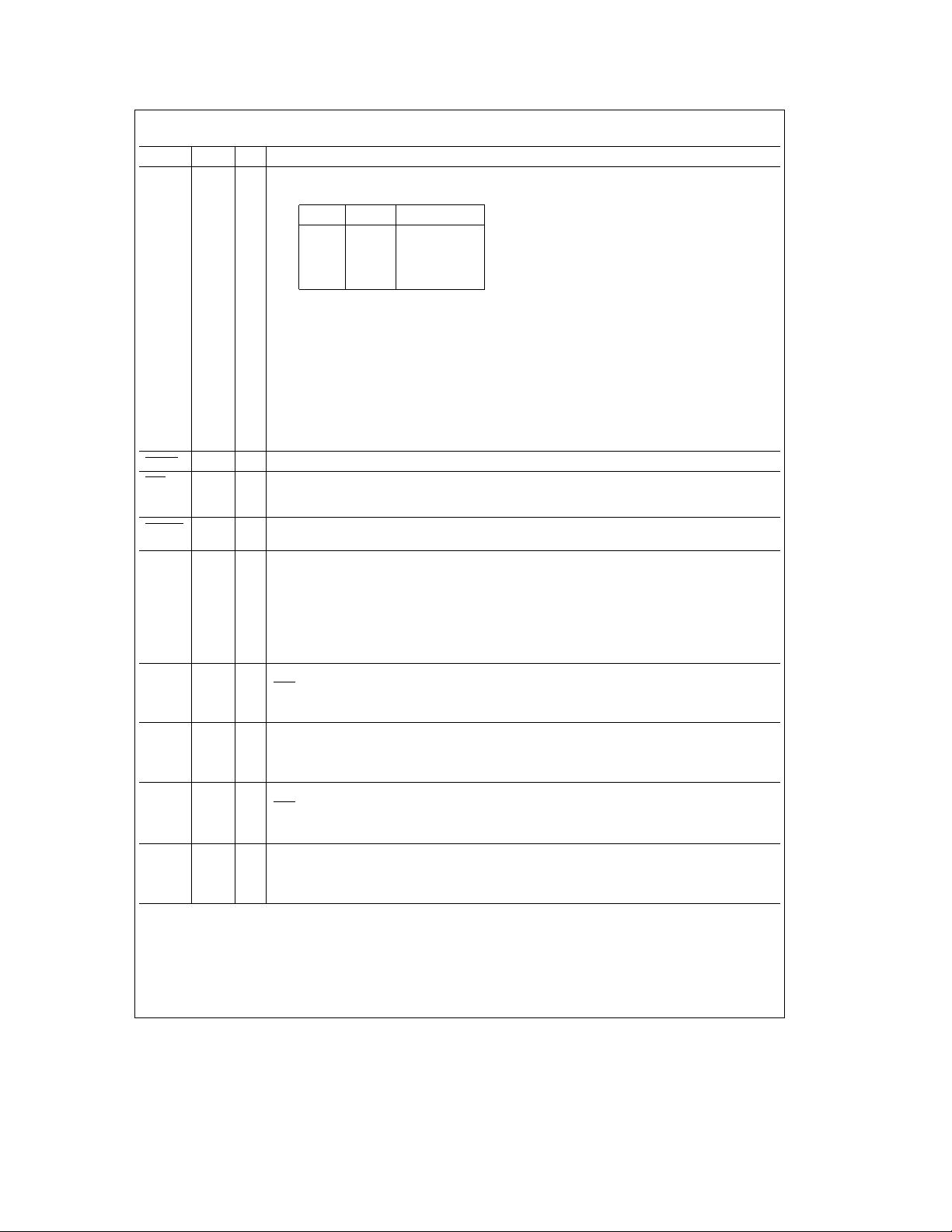

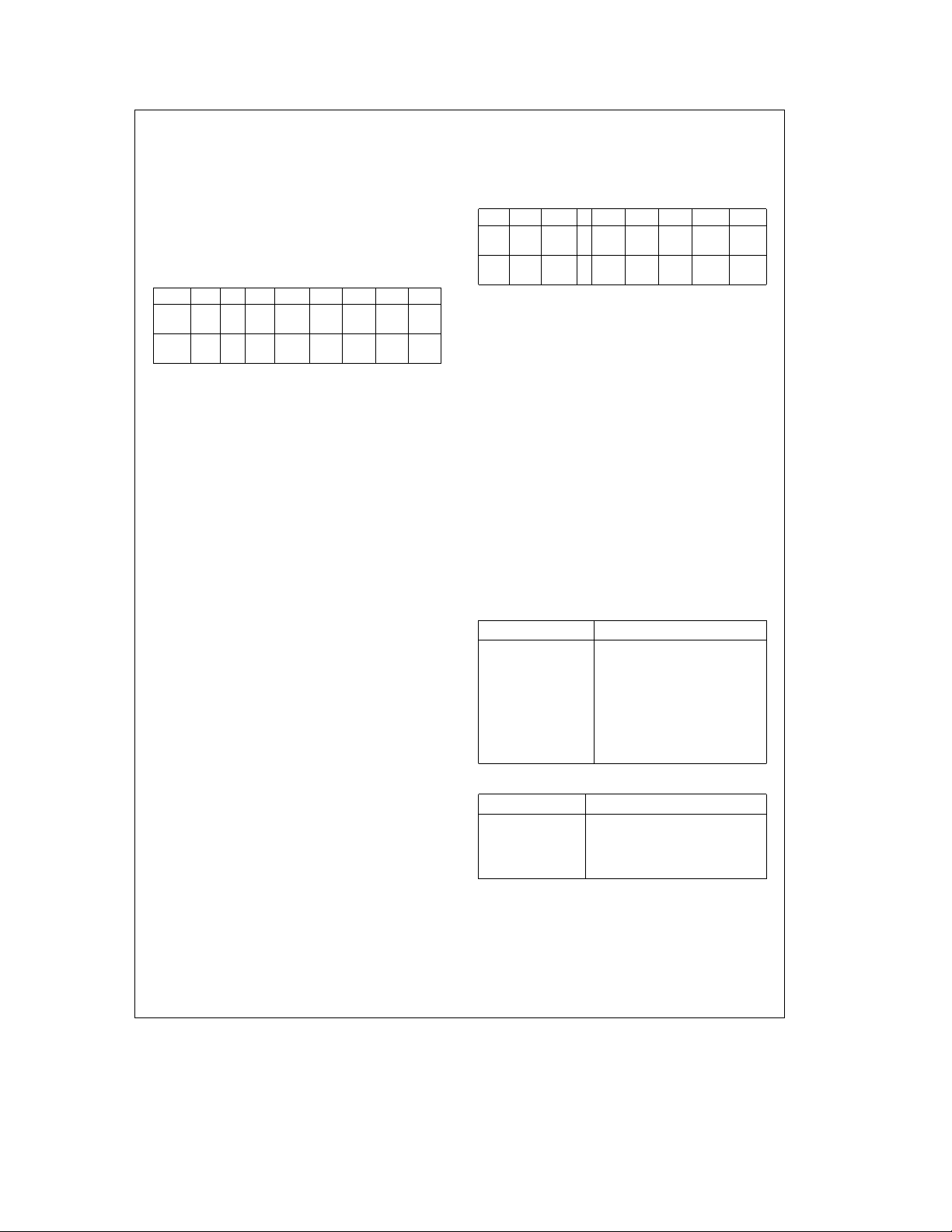

Three registers constitute the Base Configuration Register

set which controls the set-up of the PC87311A/12. In general, these registers control the enabling of each major

function (e.g., FDC, UARTs, parallel port, etc.), the I/O addresses of those functions, and whether those functions

power down via hardware control or not. These three configuration registers are called the Function Enable Register

(FER), the Function Address (FAR) Register and the Power

and Test Register (PTR).

These registers can be accessed via hardware or software.

During reset, the PC87311A/12 loads a set of default values selected by a hardware strapping option into the Configuration Registers. This defines the setting of all Configuration Registers via hardware.

An index and data register pair are used to read and write

these registers. Each Configuration Register is pointed to by

the value loaded into the Index Register. The data to be

written into the Configuration Register is transferred via the

Data register. Reading a Configuration Register is done in a

similar way (i.e., by pointing to it via the Index Register and

then reading its contents via the Data Register).

Accessing the Configuration Registers in this way requires

only two system I/O addresses. Since that I/O space is

shared by other devices the Index and Data Registers could

still be inadvertantly accessed, even though, there are only

two registers in this I/O address space. In order to reduce

the chances of an inadvertant access, a simple procedure

(Section 2.2) has been developed.

2.2 SOFTWARE CONFIGURATION

If the system requires access to the Configuration Registers

after reset, then the following procedure is used to change

data in the registers.

1. Determine the default location of the PC87311A/12 Index Register.

A. Check the two possible default locations (see Table

2-2) by reading them twice. The first byte is the ID byte

(88H). The second byte read is always 00H. Compare

the data read with the ID byte and then 00h. A match

will occur at the correct location. Note that the ID byte

is only issued from the Index Register during the first

read after a reset. Subsequent reads return the value

loaded into the Index Register. Bits 2 – 6 are reserved

and always read 0.

2. Load the Configuration Registers.

A. Disable CPU interrupts.

B. Write the index of the Configuration Register (00h –

02h) to the Index Register one time.

C. Write the correct data for the Configuration Register in

two consecutive write accesses to the Data Register.

D. Enable CPU interrupts.

3. Load the Configuration Registers (read-modify-write).

A. Disable CPU interrupts.

B. Write the index of the Configuration Register (00h –

02h) to the Index Register one time.

C. Read the configuration data in that register via the

Data Register.

D. Modify the configuration data.

E. Write the changed data for the Configuration Register

in two consecutive writes to the Data Register. The

register updates on the second consecutive write.

F. Enable CPU interrupts.

A single read access to the Index and Data Registers can

be done at any time without disabling CPU interrupts. When

the Index Register is read, the last value loaded into the

Index Register will be returned. When the Data Register is

read, the Configuration Register data pointed to by the Index Register will be returned.

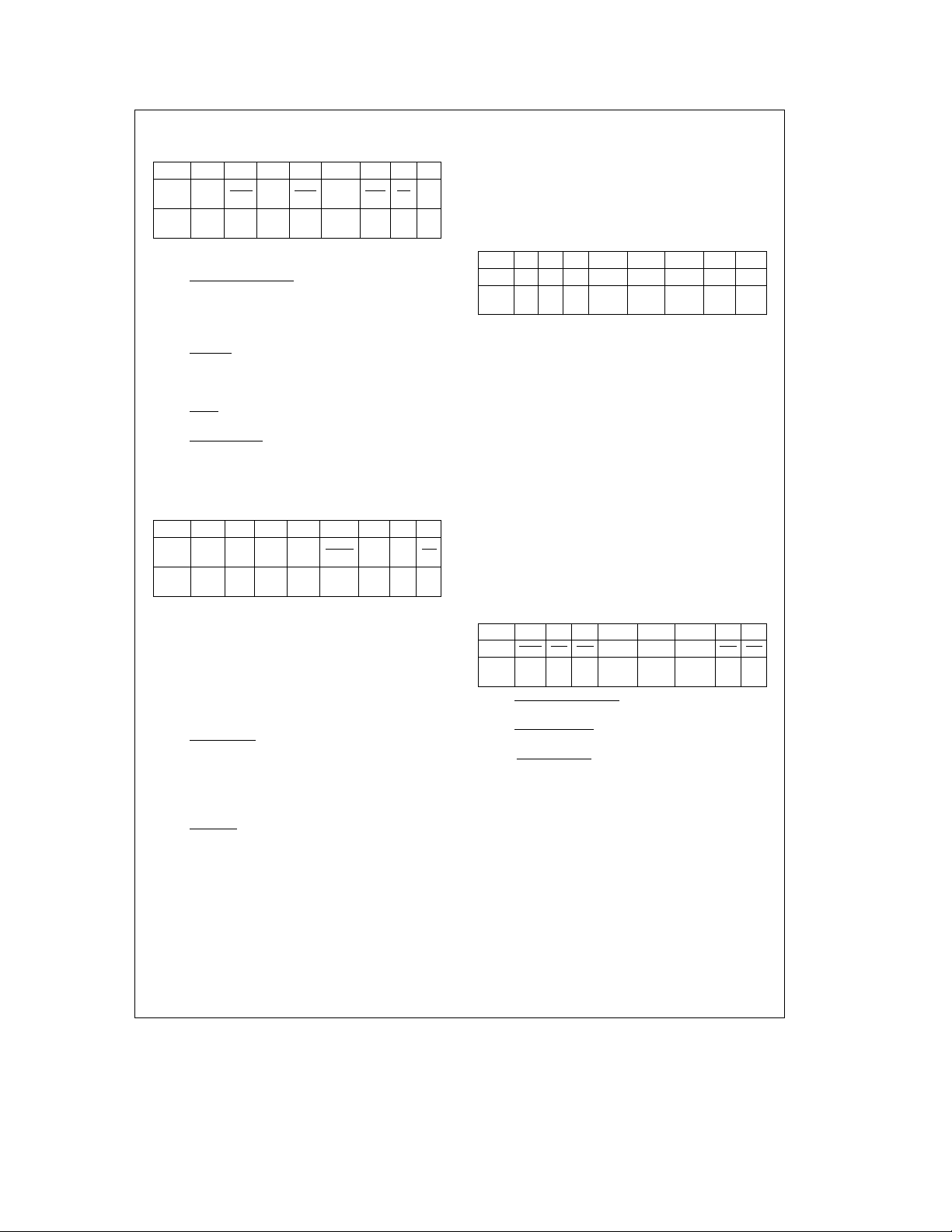

TL/F/11362– 38

TL/F/11362– 39

TL/F/11362– 40

FIGURE 2-1. PC87311A/12 Configuration Registers

2.3 HARDWARE CONFIGURATION

During reset, 1 of 32 possible sets of default values are

loaded into the Configuration Registers. A strapping option

on five pins (CFG0–4) selects the set of values that is loaded. This allows for automatic configuration without software

intervention. Table 2-1 shows the 32 possible default configurations. The default configuration can be modified by

software at any time after reset by using the access procedure described in the Software Configuration Section.

12

Page 13

2.0 Configuration Registers (Continued)

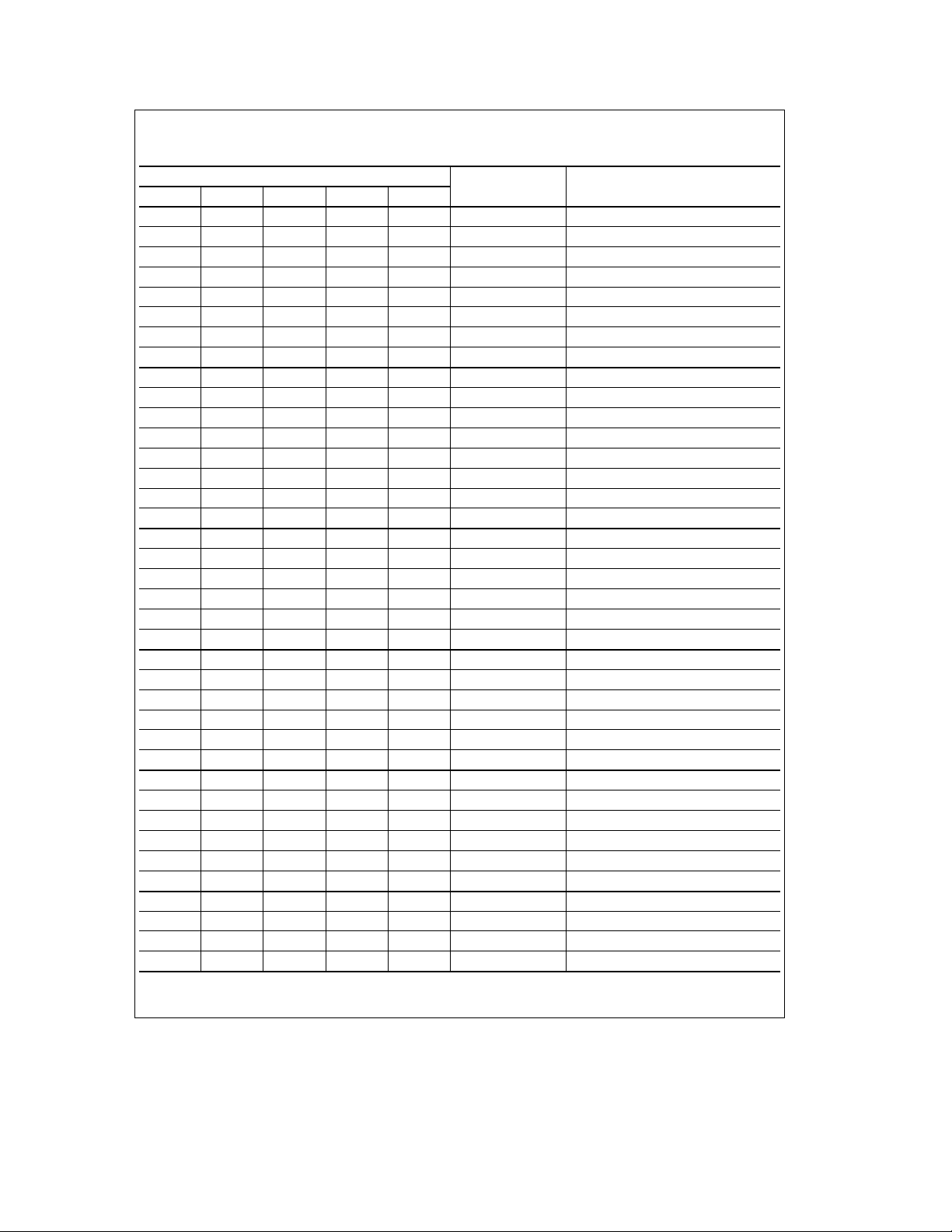

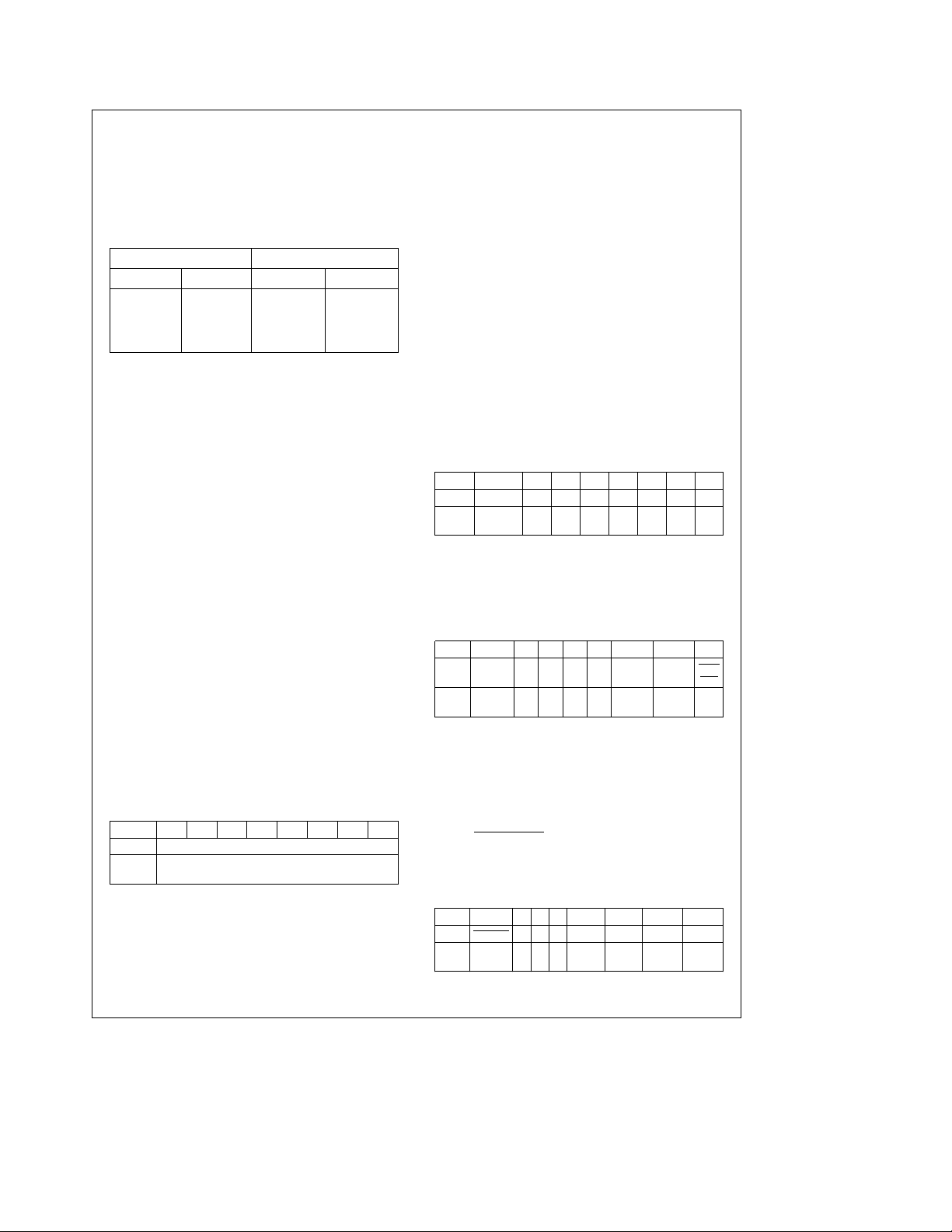

TABLE 2-1. Default Configurations Controlled by Hardware

Configuration Pins (CFGn)

43210

00000FAR

00001FAR

00010FAR

00011FAR

00100FAR

00101FAR

00110FAR

00111FAR

01000FAR

01001FAR

01010FAR

01011FAR

01100FAR

01101FAR

01110FAR

01111FAR

10000FAR

10001FAR

10010FAR

10011FAR

10100FAR

10101FAR

10110FAR

10111FAR

11000FAR

11001FAR

Data

(Hex)

FERe4F, CF FDC, IDE, UART1, UART2,llPORT

PTRe00 Power Down Clocks Option

e

10 PRI, PRI, COM1, COM2, LPT2

e

11 PRI, PRI, COM1, COM2, LPT1

e

11 PRI, SEC, COM1, COM2, LPT1

e

39 PRI, PRI, COM3, COM4, LPT1

e

24 PRI, PRI, COM2, COM3, LPT2

e

38 PRI, SEC, COM3, COM4, LPT2

FERe4B, CB FDC, IDE, UART1,llPORT

PTRe00 Power Down Clocks Option

e

00 PRI, PRI, COM1, LPT2

e

01 PRI, PRI, COM1, LPT1

e

01 PRI, SEC, COM1, LPT1

e

09 PRI, PRI, COM3, LPT1

e

08 PRI, PRI, COM3, LPT2

e

08 PRI, SEC, COM3, LPT2

FERe0F FDC, UART1, UART2,llPORT

PTRe00 Power Clocks Option

e

10 PRI, COM1, COM2, LPT2

e

11 PRI, COM1, COM2, LPT1

e

39 PRI, COM3, COM4, LPT1

e

24 PRI, COM2, COM3, LPT2

FERe49, C9 FDC, IDE,llPORT

PTRe00 Power Down Clocks Option

e

00 PRI, PRI, LPT2

e

01 PRI, PRI, LPT1

e

01 PRI, SEC, LPT1

e

00 PRI, SEC, LPT2

FERe07 UART1, UART2,llPORT

PTRe00 Power Down Clocks Option

e

10 COM1, COM2, LPT2

e

11 COM1, COM2, LPT1

e

39 COM3, COM4, LPT1

e

24 COM2, COM3, LPT2

FERe47, C7 IDE, UART1, UART2,llPORT

PTRe00 Power Down Clocks Option

e

10 PRI, COM1, COM2, LPT2

e

11 PRI, COM1, COM2, LPT1

Activated Functions

13

Page 14

2.0 Configuration Registers (Continued)

TABLE 2-1. Default Configurations Controlled by Hardware (Continued)

Configuration Pins (CFGn)

43210

11010FAR

11011FAR

11100FAR

11101FAR

11110FER

11111FER

Data

(Hex)

e

11 SEC, COM1, COM2, LPT1

e

39 PRI, COM3, COM4, LPT1

e

24 PRI, COM2, COM3, LPT2

e

38 SEC, COM3, COM4, LPT2

e

08 FDC

PTRe00 Power Down Clocks Option

FARe10, 80 PRI

e

00 None

PTRe02, 82 Power Down XTAL and Clocks

FARe10 NA

Activated Functions

Table 2-1 is organized in the following way. The logic values

of the 5 external Configuration Pins are associated with the

resulting Configuration Register Data and the activated

functions. The activated functions are grouped into 7 categories based on the data in the FER. In some cases the

data in the FER is given as one of two options. This is because the primary or secondary IDE address is chosen via

the FER.

The PTR has one value associated with the active functions

in the FER. This value allows the power down of all clocks

when the PWDN

functions are active after reset, activating the PWDN

also stop the crystal.

Most of the variability available is through the FAR. Addresses controlled by the FAR are coded in the following

way:

PRI is the PRImary floppy or IDE address (i.e., 3F0 –7h

or 1F0 – 7, 3F6, 7h)

SEC is the SECondary IDE address (170 – 7, 376, 7h)

COM1 is the UART address at 3F8 – Fh

COM2 is the UART address at 2F8 – Fh

COM3 is the UART address at 3E8 – Fh

COM4 is the UART address at 2E8 – Fh

LPT1 is the parallel port (

LPT2 is the

The chosen addresses are given under active functions and

are in the same order as the active functions they are associated with. In other words, if the active functions are given

as FDC, IDE, UART1, UART2,

are given as PRI, PRI, COM1, COM2, LPT2; then the functions and the addresses are associated as follows: FDC

PRI, IDEePRI, UART1eCOM1, UART2eCOM2,

PORTeLPT2.

ll

2.4 INDEX AND DATA REGISTERS

One more general aspect of the Configuration Registers is

that the Index and the Data Register pair can be relocated

to any one of two locations. This is controlled through a

hardware strapping option on one pin (BADDR0) and it allows the registers to avoid conflicts with other adapters in

the I/O address space. Table 2-2 shows the address options.

pin goes active. In the last case where no

PORT ) address at 3BC – 3BEh

PORT address at 378 – 37Fh

ll

ll

PORT and the addresses

ll

pin will

TABLE 2-2. Index and Data

Register Optional Locations

BADDR0 Index Addr. Data Addr.

0 398h 399h

1 26Eh 26Fh

2.5 BASE CONFIGURATION REGISTERS

2.5.1 Function Enable Register (FER, Index 0)

This register enables and disables all major chip functions.

Disabled functions have their clocks automatically powered

down, but the data in their registers remains intact. It also

selects whether the FDC and the IDE controller will be located at their primary or secondary address.

Bit 0 When this bit is one the parallel port can be accessed

at the address specified in the FAR.

Bit 1 When this bit is one, UART1 can be accessed at the

address specified in the FAR. When this bit is zero,

access to UART1 is blocked and it will be in power

down mode. The UART1 registers retain all data in

power down mode. Caution: Any UART1 interrupt

that is enabled and active or becomes active after

UART1 is disabled will assert the associated IRQ pin

when UART1 is disabled. If disabling UART1 via software, clear the IRQ Enable bit (MCR3) to zero before

clearing FER 1. This is not an issue after reset because MCR3 will be zero until it is written.

Bit 2 When this bit is one, UART2 can be accessed at the

address specified in the FAR. When this bit is zero,

access to UART2 is blocked and it will be in power

e

14

down mode. The UART2 registers retain all data in

power down mode. Caution: Any UART2 interrupt

that is enabled and active or becomes active after

UART2 is disabled will assert the associated IRQ pin

when UART2 is disabled. If disabling UART2 via software, clear the IRQ Enable bit (MCR3) to zero before

clearing FER2. This is not an issue after reset because MCR3 will be zero until it is written.

Page 15

2.0 Configuration Registers (Continued)

Bit 3 When this bit is one, the FDC can be accessed at the

address specified in FER[5]. When this bit is zero access to the FDC is blocked and it will be in power

down mode. The FDC registers retain all data in power

down mode.

Bit 4 When this bit is zero the PC87311A/12 can control

two floppy disk drives directly without an external decoder. When this bit is one the two drive select signals

and two motor enable signals from the FDC are encoded so that four floppy disk drives can be controlled

(see Table 2-4). Controlling four FDDs requires an external decoder. The pin states shown in Table 2-4 are

a direct result of the bit patterns shown. All other bit

patterns produce pin states that should not be decoded to enable any drive or motor.

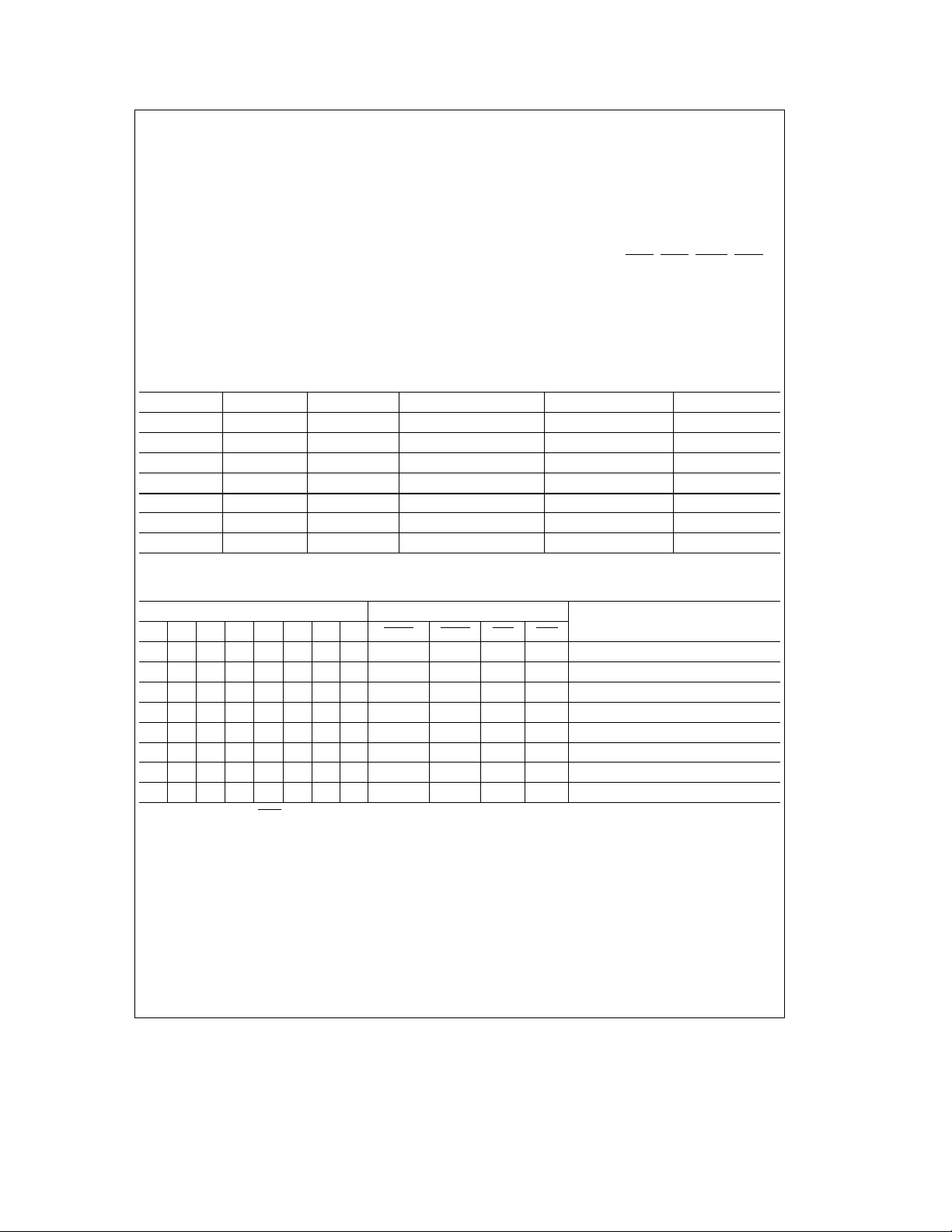

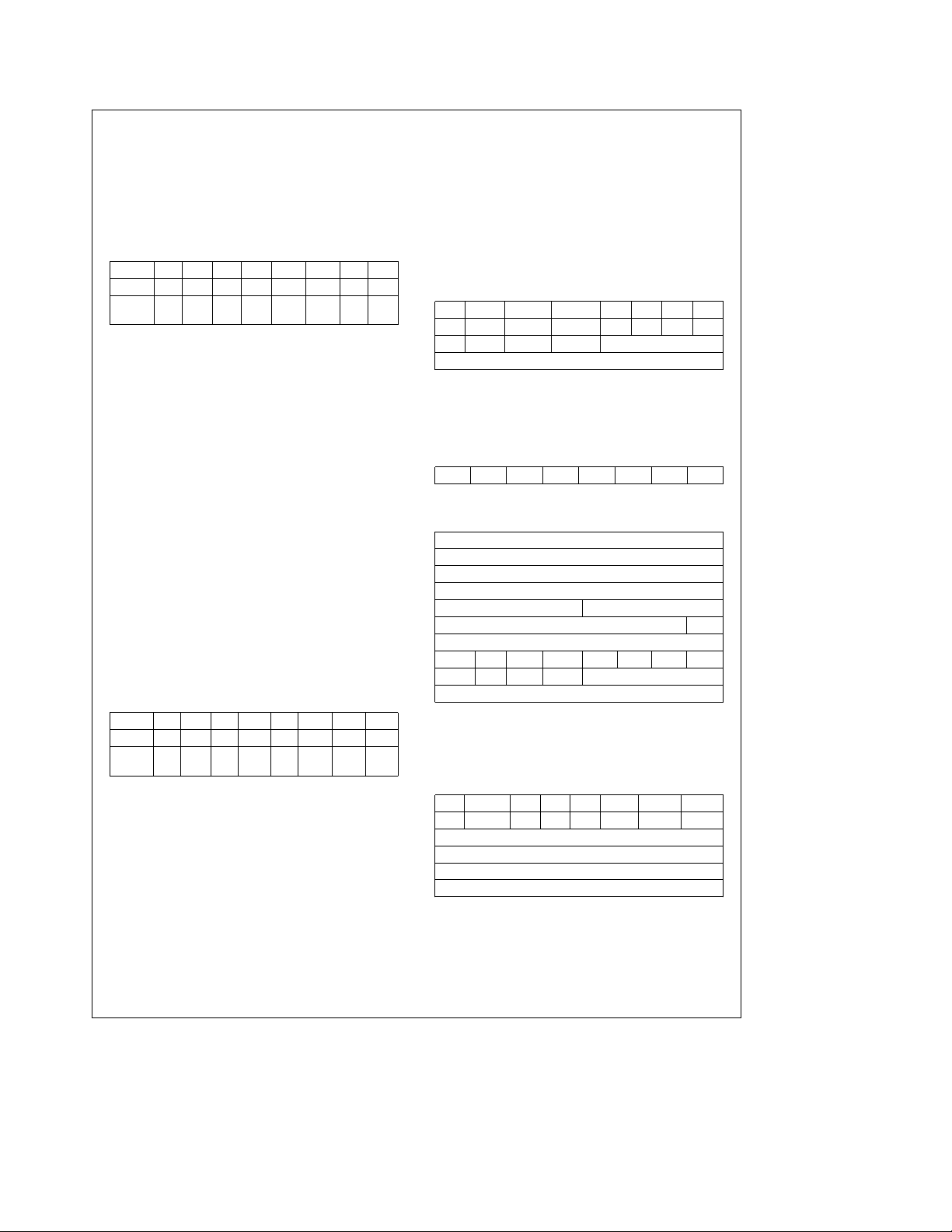

TABLE 2-3. Primary and Secondary Drive Address Selection

BIT 5 BIT 7 DRIVE AT AT XT (Note)

ÐÐ Ð Primary Secondary Ð

0 X FDC 3F0– 7h Ð Ð

1 X FDC Ð 370–7h Ð

X X FDC Ð Ð 3F0– 7h

X 0 IDE 1F0–7, 3F6, 3F7h Ð Ð

X 1 IDE Ð 170–7, 376-7h Ð

X X IDE Ð Ð 320– 3h

Note: PC87311A only

TABLE 2-4. Encoded Drive and Motor Pin Information (FER 4e1)

Digital Output Reg Drive Control Pins

7 6 5 4 3 2 1 0 MTR1 MTR0 DR1 DR0

XXX1X X 0 0 (Note 1) 0 0 0 Activate Drive 0 and Motor 0

XX1X X X 0 1 (Note 1) 0 0 1 Activate Drive 1 and Motor 1

X 1 X X X X 1 0 (Note 1) 0 1 0 Activate Drive 2 and Motor 2

1 X X X X X 1 1 (Note 1) 0 1 1 Activate Drive 3 and Motor 3

XXX0X X 0 0 (Note 1) 1 0 0 Activate Drive 0 and Deactivate Motor 0

XX0X X X 0 1 (Note 1) 1 0 1 Activate Drive 1 and Deactivate Motor 1

X 0 X X X X 1 0 (Note 1) 1 1 0 Activate Drive 2 and Deactivate Motor 2

0 X X X X X 1 1 (Note 1) 1 1 1 Activate Drive 3 and Deactivate Motor 3

Note 1: When FER4e1, MTR1 will present a pulse that is the inverted image of the IOW strobe. This inverted pulse will be active whenever an I/O write to

address 3F2h or 372h takes place. This pulse is delayed by 25 ns –80 ns after the leading edge of IOW and its leading edge can be used to clock data into an

external latch (e.g., 74LS175). Address 3F2h will be used if the FDC is located at the primary address (FER5

located at the secondary address (FER5

e

1). See the AC Electrical Characteristics (Section 9.2) for detailed timing.

Bit 5 This bit selects the primary or secondary FDC address

in the PC87312. In the PC87311A, this bit selects the

primary or secondary FDC address when in the AT

mode. In the XT mode it has no significance (see Table 2-3).

Bit 6 When this bit is a one the IDE drive interface can be

accessed at the address specified by FER bit 7. When

it is zero, access to the IDE interface is blocked, the

IDE control signals (i.e., HCS0

, HCS1, IDELO, IDEHI)

are held in the inactive state, and the IDED7 signal will

be in TRI-STATE.

Bit 7 This bit selects the primary or secondary IDE address

in the PC87312. In the PC87311A, this bit selects the

primary or secondary IDE address when in the AT

mode. In the XT mode it has no significance (see Table 2-3).

Decoded Functions

e

0) and address 372h will be used if the FDC is

15

Page 16

2.0 Configuration Registers (Continued)

e

2.5.2 Function Address Register (FAR, Index

This register selects the ISA I/O address range to which

each peripheral function will respond.

Bits 0,1 These bits select the parallel port address as

shown in Table 2-5:

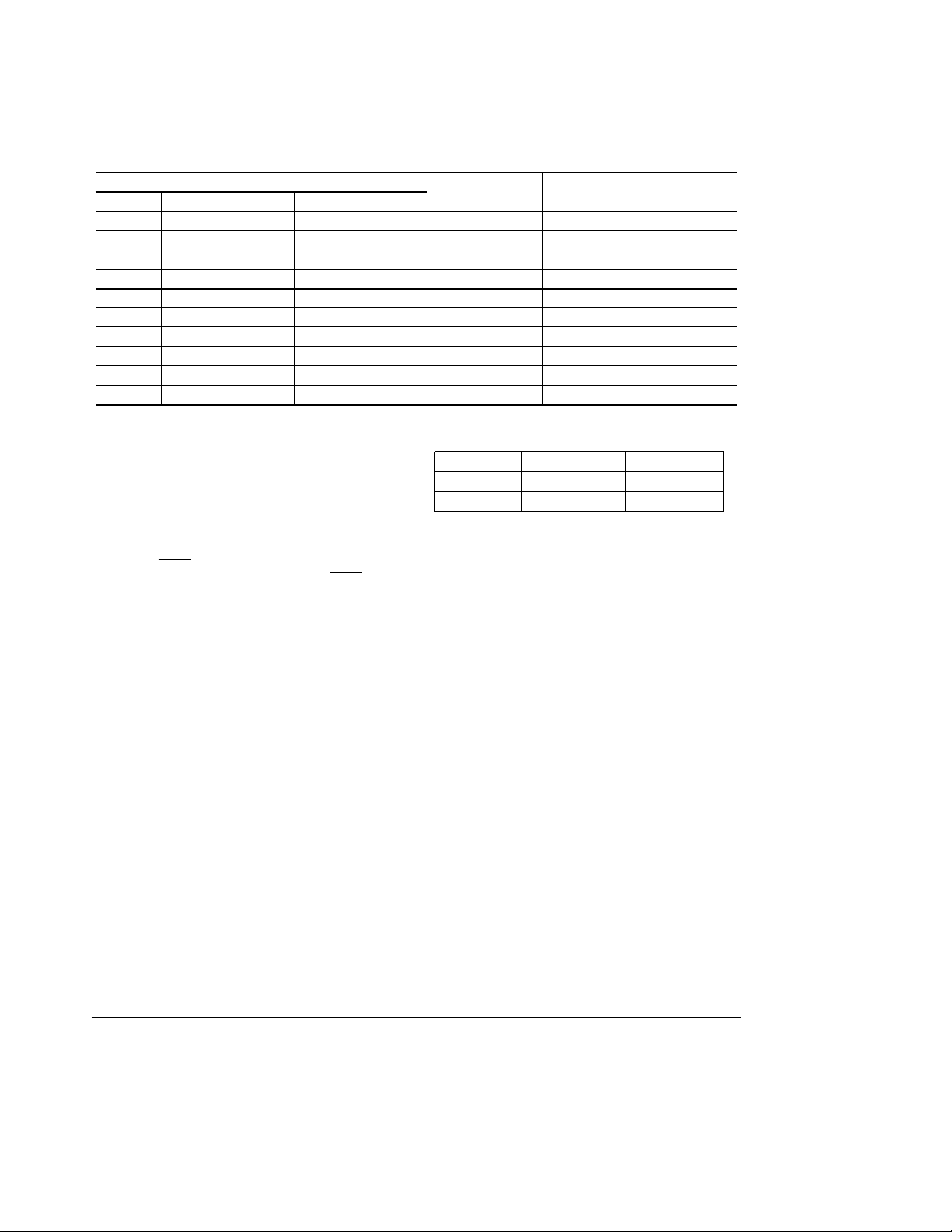

TABLE 2-5. Parallel Port Addresses

Bit1Bit

Parallel

0

Port

Address

InterruptATInterrupt

0 0 LPT2 (378– 37F) IRQ5 (Note) IRQ7

0 1 LPT1 (3BC– 3BE) IRQ7 IRQ7

1 0 LPT3 (278– 27F) IRQ5 IRQ7

1 1 Reserved TRI-STATE TRI-STATE

e

(CTR4

Note: The interrupt assigned to this address can be changed to IRQ7 by

setting Bit 3 of the power and test register.

Bits 2–5 These bits determine which ISA I/O address range

is associated with each UART (see Tables 2-6a,

2-6b).

TABLE 2-6a. COM Port Selection for UART1

FAR UART1

Bit 3 Bit 2 COM

0 0 1 (3F8-F)

0 1 2 (2F8-F)

1 0 3 (Table 2 – 7)

1 1 4 (Table 2 – 7)

TABLE 2-6b. COM Port Selection for UART2

FAR UART2

Bit 5 Bit 4 COM

00 1

01 2

10 3

11 4

Note: COM3 and COM4 addresses are determined by Bits 6 and 7.

Bits 6,7 These bits select the addresses that will be used

for COM3 and COM4 (see Table 2-7).

TABLE 2-7. Address Selection for COM3 and COM4

Bit 7 Bit 6 COM3 IRQ4 COM4 IRQ3

0 0 3E8–Fh 2E8–Fh

0 1 338–Fh 238–Fh

1 0 2E8–Fh 2E0–7h

1 1 220–7h 228–Fh

2.5.3 Power and Test Register (PTR, Indexe2)

This register determines several power down features: the

power down method used when the power down pin

1)

XT

0) (CTR4e0)

Ý

Ý

(PWDN

) is asserted (crystal and clocks vs clocks only),

whether hardware power down is enabled, and provides a

bit for software power down of all enabled functions. It selects whether IRQ7 or IRQ5 is associated with LPT2. It puts

the enabled UARTs into their test mode. Independent of this

register the floppy disk controller can enter low power mode

via the Mode Command or the Data Rate Select Register.

Bit 0 Setting this bit causes all enabled functions to be

powered down. If the crystal power down option is

selected (see Bit 1) the crystal will also be powered

down. All register data is retained when the crystal or

clocks are stopped.

Bit 1 When the Power Down pin or Bit 0 is asserted this bit

determines whether the enabled functions will have

their internal clocks stopped (Bit 1

nal crystal (Bit 1

e

1) will be stopped. Stopping the

e

0) or the exter-

crystal is the lowest power consumption state of the

part. However, if the crystal is stopped, a finite

amount of time (E8 ms) will be required for crystal

stabilization once the Power Down pin (PWDN

)or

Bit 0 is deasserted. If all internal clocks are stopped,

but the crystal continues to oscillate, no stabilization

period is required after the Power Down pin or Bit 0 is

deasserted.

Bit 2 Setting this bit enables the chip select function of the

PWDN

/CSOUT pin. Resetting this bit enables the

power down function of this pin.

Bit 3 Setting this bit associates the parallel port with IRQ7

when the address for the parallel port is 378 – 37Fh

(LPT2). This bit is a ‘‘don’t care’’ when the parallel

port address is 3BC –3BEh (LPT1) or 278–27Fh

(LPT3).

Bit 4 Setting this bit puts UART1 into a test mode, which

causes its Baudout clock to be present on its SOUT1

pin if the Line Control Register bit 7 is set to 1.

Bit 5 Setting this bit puts UART2 into a test mode, which

causes its Baudout clock to be present on its SOUT2

pin if the Line Control Register bit 7 is set to 1.

Bit 6 Setting this bit to a one prevents all further write ac-

cesses to the Configuration Registers. Once this bit is

set by software it can only be cleared by a hardware

reset. After the initial hardware reset this bit is zero.

Bit 7 This bit determines the operating mode of the parallel

port. If PTR7 is low, then the parallel port is in Compatible Mode. If PTR7 is high, then the parallel port is

in Extended Mode. This bit will be the inverse of the

state of the POE

pin immediately after reset has oc-

curred. PTR7 can be programmed at any time.

2.6 POWER DOWN OPTIONS

There are various methods for entering the power down

mode. All methods result in one of three possible modes.

This section associates the methods of entering the power

down with the resulting mode.

Mode 1: The internal clock stops for a specific function (i.e.,

UART1 and/or UART2 and/or FDC).

This mode is entered by:

A. Clearing the FER bit for the specific function that will be

powered down. See Section 2.5.1 FER bits 1 – 3.

B. Also during reset by setting certain CFG0 – 4 pins. See

Table 2-1.

16

Page 17

2.0 Configuration Registers (Continued)

C. Or by executing the FDC Mode Command with the PTR

e

bit 1

0. (XTAL/CLK) See Section 4.2.6 LOW PWR.

D. Or by setting Data Rate Select Register bit 6 high in the

FDC with the PTR bit 1

Mode 2: The internal clocks are stopped for all enabled

functions.

Note: Clocks to disabled functions are always inactive.

This mode is entered by:

A. Clearing all FER bits for any enabled function. See Sec-

tion 2.5.1 (FER bits 1 –3).

B. Or by clearing PTR bits 1 (XTAL/CLK) and 2 (CSOUT/

PWDN select) and then asserting the PWDN

See Section 2.5.3 PTR bits 1,2 and Section 1.0 PWDN

pin.

C. Or by clearing PTR bit 1 and then setting PTR bit 0 (Pow-

er Down) high. See Section 2.5.3 (PTR bits 0 and 1).

Mode 3: The external crystal is stopped and internal clocks

are stopped for all enabled functions.

This mode is entered by:

A. Clearing all FER bits that enable the FDC, UART1, and

UART2 functions. See Section 2.5.1 (FER bits 1 – 3).

B. Setting PTR bit 1 (XTAL/CLK), clearing PTR bit 2

(CSOUT/PWDN select), and then asserting the PWDN

signal low. See Section 2.5.3 PTR bits 1,2 and Section

1.0 PWDN

C. Or by setting PTR bit 1 and then setting PTR bit 0 high.

See Section 2.5.3 PTR bits 0 and 1.

D. Or during reset by pulling CFG0 – 4 pins high.

E. Or by executing the FDC Mode Command with the PTR

bit 1

F. Or by setting Data Rate Select Register bit 6 high in the

FDC with the PTR bit 1

2.7 POWER-UP PROCEDURE AND CONSIDERATIONS

2.7.1 Crystal Stabilization

If the crystal is stopped by putting either the FDC or the

UARTs into low power mode, then a finite amount of time

(E8 ms) must be allowed for crystal stabilization during

subsequent power-up. The stabilization period can be

sensed by reading the Main Status Register in the FDC, if

the FDC is being powered up. (The Request for Master bit

will not be set forE8 ms.) If either one of the UARTs are

being powered up, but the FDC is not, then the software

must determine theE8 ms crystal stabilization period. Stabilization of the crystal can also be sensed by putting the

UART into local loopback mode and sending bytes until

they are received correctly.

2.7.2 UART Power-Up

The clock signal to the UARTs is controlled through the

Configuration Registers (FER, PTR). In order to restore the

clock signal to one or both UARTs the following conditions

must exist:

1. The appropriate enable bit (FER1,2) for the UART(s)

must be set

2. and the Power Down bit (PTR0) must not be set

pin.

e

1. See Section 4.2.6 LOW PWR.

e

0. See Section 3.6 bit 6.

e

1. See Section 3.6 bit 6.

signal low.

3. and if the PWDN pin option (PTR2) is used the CSOUT/

PDWN pin must be inactive.

If the crystal has been stopped follow the guidelines in Section 2.7.1 before sending data or signaling that the receiver

channel is ready.

2.7.3 FDC Power-Up

The clock signal to the FDC is controlled through the Configuration Registers, the FDC Mode Command and the Data

Rate Select Register. In order to restore the clock signal to

the FDC the following conditions must exist:

1. The appropriate enable bit (FER3) must be set

2. and the Power Down bit (PTR0) must not be set

3. and if the PWDN pin option (PTR2) is used the CSOUT/

PDWN pin must be inactive.

In addition to these conditions, one of the following must be

done to initiate the recovery from Power Down mode:

1. Read the Main Status Register until the ROM bit (MSR7)

is set

2. or write to the Data Rate Select Register and set the

Software Reset bit (DSR7)

3. or write to the Digital Output Register and set, and then

the clear Reset bit (DOR2)

4. or read the Data Register and the Main Status Register

until the ROM bit is set.

If the crystal has been stopped, read the RQM bit in the

Main Status Register until it is set. The RQM bit does not get

set until the crystal has stabilized.

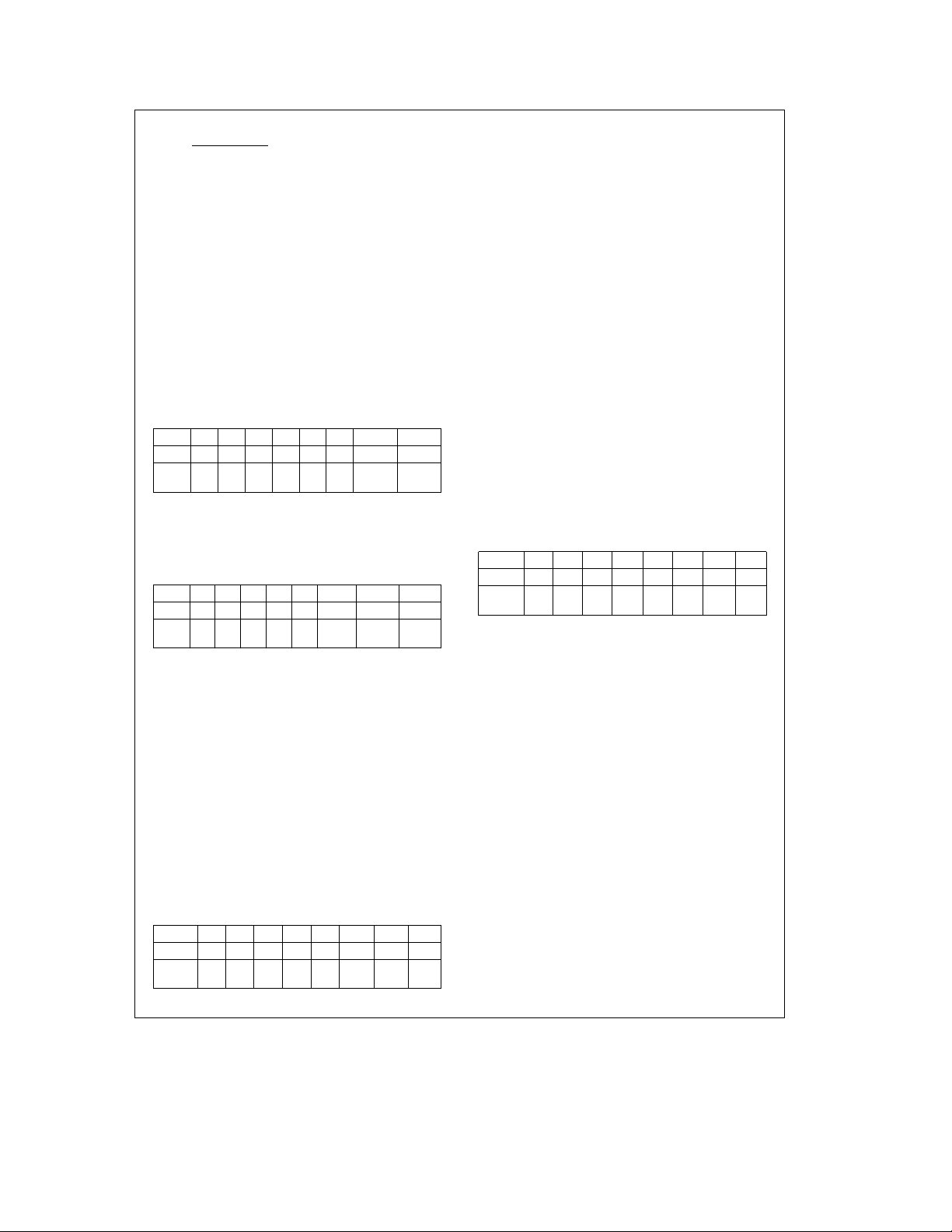

3.0 FDC Register Description

The floppy disk controller is suitable for all PC-AT, EISA,

PS/2, and general purpose applications. The operational

mode (PC-AT, PS/2, and Model 30) of the FDC is determined by hardware strapping of the IDENT and MFM pins.

DP8473 and N82077 software compatibility is provided. Key

features include the 16-byte FIFO, PS/2 diagnostic register

support, the perpendicular recording mode, CMOS disk interface, and a high performance analog data separator.

The FDC supports the standard PC data rates of 250 kb/s,

300 kb/s and 500 kb/s, and 1 Mb/s in MFM encoded data

mode, but is no longer guaranteed through functional testing to support the older FM encoded data mode. References to the older FM mode remain in this document to

clarify the true functional operation of the device.

The 1 Mb/s data rate is used by new high performance tape

and floppy drives emerging in the PC market today. The new

floppy drives utilize high density media which requires the

FDC supported perpendicular recording mode format. When

used with the 1 Mb/s data rate this new format allows the

use of 4 MB floppy drives which format ED media to 2.88

MB data capacity.

The high performance internal analog data separator needs

no external components. It improves on the window margin

performance standards of the DP8473, and is compatible

with the strict data separator requirements of floppy and

floppy-tape drives.

17

Page 18

3.0 FDC Register Description (Continued)

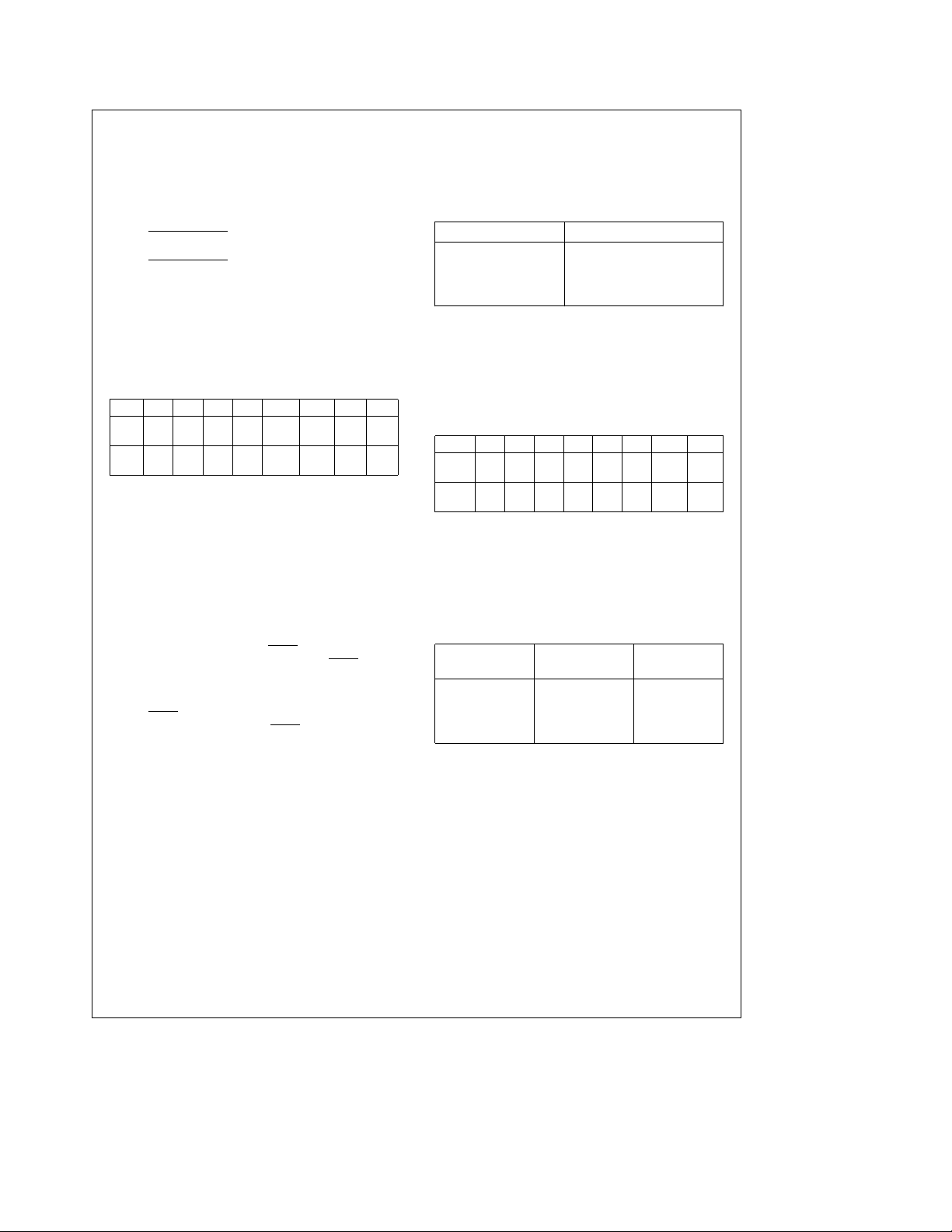

FIGURE 3-1. FDC Functional Block Diagram

The FDC contains write precompensation circuitry that will

default to 125 ns for 250, 300, and 500 kb/s (41.67 ns at

1 Mb/s). These values can be overridden in software to

disable write precompensation or to provide levels of precompensation up to 250 ns. The FDC has internal 24 mA

data bus buffers which allow direct connection to the system bus. The internal 40 mA totem-pole disk interface buffers are compatible with both CMOS drive inputs and 150X

resistor terminated disk drive inputs.

The following FDC registers are mapped into the addresses

shown below, with the base address range being provided

by the on-chip address decoder pin. For PC-AT or PS/2

applications, the diskette controller primary address range is

3F0 to 3F7 (hex), and the secondary address range is 370

to 377 (hex). The FDC supports three different register

modes: the PC-AT mode, PS/2 mode (Micro Channel systems), and the Model 30 mode (Model 30). See Section 5.1

for more details on how each register mode is enabled.

When applicable, the register definition for each mode of

operation will be given. If no special notes are made, then

the register is valid for all three register modes.

TL/F/11362– 4

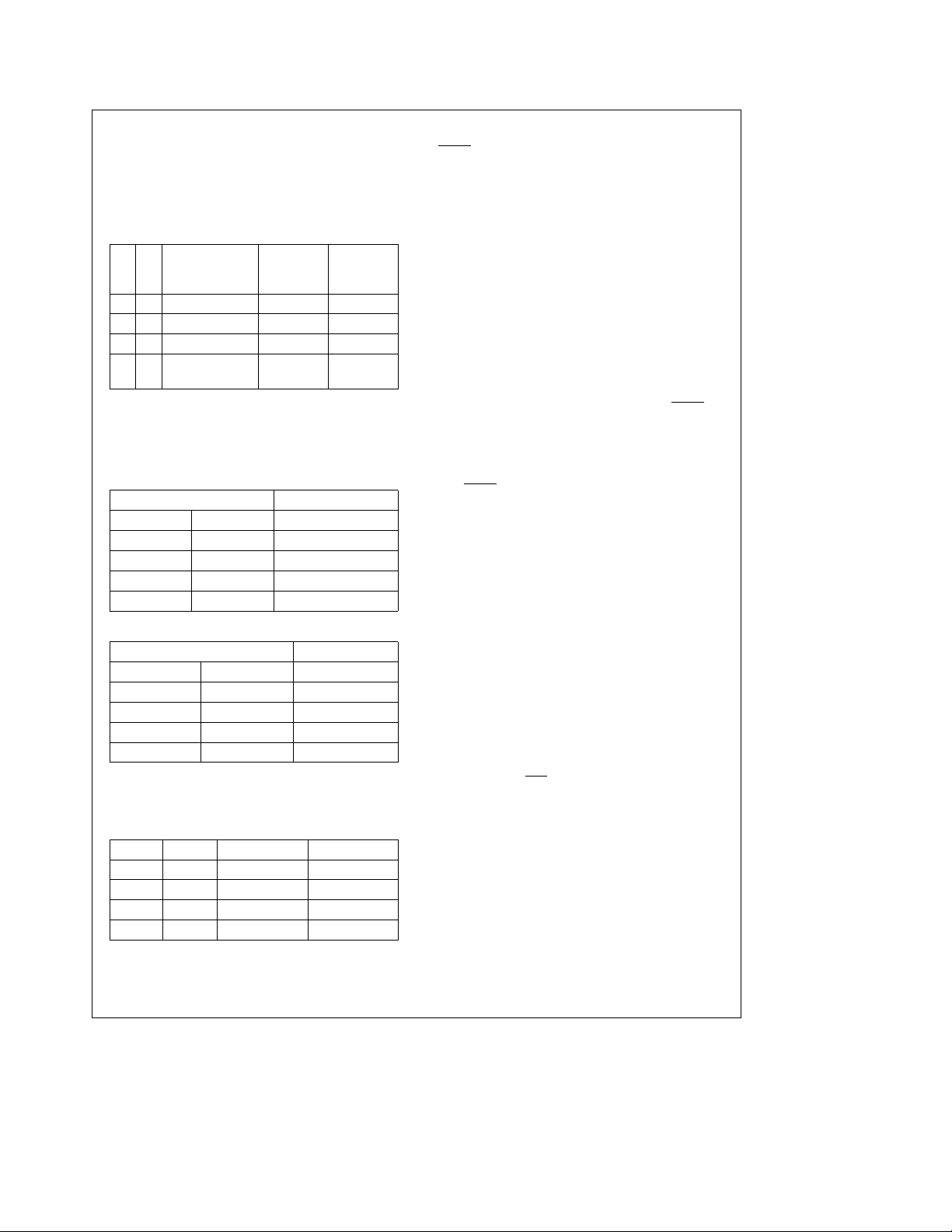

TABLE 3-1. Register Description and Addresses

A2 A1 A0 IDENT R/W Register

0 0 0 0 R Status Register A SRA

0 0 1 0 R Status Register B SRB

0 1 0 X R/W Digital Output Register DOR

0 1 1 X R/W Tape Drive Register TDR

1 0 0 X R Main Status Register MSR

1 0 0 X W Data Rate Select Register DSR

1 0 1 X R/W Data Register (FIFO) FIFO

1 1 0 X X None (Bus TRI-STATE)

1 1 1 X R Digital Input Register DIR

1 1 1 X W Configuration Control Register CCR

Note: SRA and SRB are enabled by IDENTe0 during a chip reset only.

3.1 STATUS REGISTER A (SRA) Read Only

This is a read-only diagnostic register that is part of the

PS/2 floppy controller register set, and is enabled when in

the PS/2 or Model 30 mode. This register monitors the state

of the IRQ6 pin and some of the disk interface signals. The

SRA can be read at any time when in PS/2 mode. In the

PC-AT mode, D7 – D0 are TRI-STATE during a mP read.

18

Page 19

3.0 FDC Register Description (Continued)

3.1.1 SRAÐPS/2 Mode

D7 D6 D5 D4 D3 D2 D1 D0

DESC IRQ6

RESET

COND

D7 Interrupt Pending: This active high bit reflects the

D6 2nd Drive Installed

D5 Step: Active high status of the STEP disk interface

D4 Track 0

D3 Head Select: Active high status of the HDSEL disk

D2 Index

D1 Write Protect

D0 Direction: Active high status of the DIR disk inter-

3.1.2 SRAÐ Model 30 Mode

DESC IRQ6

RESET

COND

D7 Interrupt Pending: This active high bit reflects that

D6 DMA Request: Active high status of the DRQ signal.

D5 Step: Active high status of the latched STEP disk

D4 Track 0: Active high status of TRK0 disk interface

D3 Head Select

D2 Index: Active high status of the INDEX disk inter-

D1 Write Protect: Active high status of the WP disk

D0 Direction

DRV2

PEND

0 N/A 0 N/A 0 N/A N/A 0

STEP TRK0 HDSEL INDX WP DIR

state of the IRQ6 pin.

: Active low status of the

DRV2 disk interface input, indicating if a second

drive has been installed.

output.

: Active low status of the TRK0 disk inter-

face input.

interface output.

: Active low status of the INDEX disk interface

input.

: Active low status of the WP disk in-

terface input.

face output.

D7 D6 D5 D4 D3 D2 D1 D0

DRQ STEP TRK0 HDSEL

PEND

0 0 0 N/A 1 N/A N/A 1

INDX WP DIR

state of the IRQ6 pin.

interface output. This bit is latched with the STEP

output going active, and is cleared with a read from

the DIR, or with a hardware or software reset.

input.

: Active low status of the HDSEL disk

interface output.

face input.

interface input.

: Active low status of the DIR disk inter-

face output.

3.2 STATUS REGISTER B (SRB) Read Only

This is a read-only diagnostic register that is part of the

PS/2 floppy controller register set, and is enabled when in

the PS/2 or Model 30 mode. The SRB can be read at any

time when in PS/2 mode. In the PC-AT mode, D7–D0 are

TRI-STATE during a mP read.

3.2.1 SRBÐPS/2 Mode

D7 D6 D5 D4 D3 D2 D1 D0

DESC 1 1 DR0 WDATA RDATA WGATE MTR1 MTR0

RESET

N/A N/A 0 0 0 0 0 0

COND

D7 Reserved: Always 1.

D6 Reserved: Always 1.

D5 Drive Select 0: Reflects the status of the Drive Se-

lect 0 bit in the DOR (address 2, bit 0). This bit is

cleared after a hardware reset, not a software reset.

D4 Write Data: Every inactive edge transition of the

WDATA disk interface output causes this bit to

change states.

D3 Read Data: Every inactive edge transition of the

RDATA disk interface output causes this bit to

change states.

D2 Write Gate: Active high status of the WGATE disk

interface output.

D1 Motor Enable 1: Active high status of the MTR1

disk interface output. Low after a hardware reset,

unaffected by a software reset.

D0 Motor Enable 0: Active high status of the MTR0

disk interface output. Low after a hardware reset,

unaffected by a software reset.

3.2.2 SRBÐModel 30 Mode

D7 D6 D5 D4 D3 D2 D1 D0

DESC DRV2 DR1 DR0 WDATA RDATA WGATE DR3 DR2

RESET

N/A 1 1 0 0 0 1 1

COND

D7 2nd Drive Installed: Active low status of the

DRV2 disk interface input.

D6 Drive Select 1

: Active low status of the DR1 disk

interface output.

D5 Drive Select 0

: Active low status of the DR0 disk

interface output.

D4 Write Data: Active high status of latched WDATA

signal. This bit is latched by the inactive going edge

of WDATA and is cleared by a read from the DIR.

This bit is not gated by WGATE.

19

Page 20

3.0 FDC Register Description (Continued)

D3 Read Data: Active high status of latched RDATA

signal. This bit is latched by the inactive going edge

of RDATA and is cleared by a read from the DIR.

D2 Write Gate: Active high status of latched WGATE

signal. This bit is latched by the active going edge of

WGATE and is cleared by a read from the DIR.

D1 Drive Select 3

interface output. (Note 1)

D0 Drive Select 2

interface output. (Note 1)

3.3 DIGITAL OUTPUT REGISTER (DOR) Read/Write

The DOR controls the drive select and motor enable disk

interface outputs, enables the DMA logic, and contains a

software reset bit. The content of the DOR is set to 00 (hex)

after a hardware reset, and is unaffected by a software reset. (Note 2)

DOR

D7 D6 D5 D4 D3 D2 D1 D0

DESC MTR3 MTR2 MTR1 MTR0 DMAEN RESET

RESET

0000 0 0 0 0

COND

D7 Motor Enable 3: This bit controls the MTR3 disk

interface output.A1inthis bit causes the MTR3 pin

to go active. (Note 1)

D6 Motor Enable 2: Same function as D7 except for

MTR2. (Note 1)

D5 Motor Enable 1: Same function as D7 except for

MTR1.

D4 Motor Enable 0: Same function as D7 except for

MTR0.

D3 DMA Enable: This bit has two modes of operation.

PC-AT mode or Model 30 mode: Writinga1tothis

bit will enable the DRQ, DACK

Writinga0tothis bit will disable the DACK

pins and TRI-STATE the DRQ and the IRQ6 pins.

This bit is a 0 after a reset when in these modes.

PS/2 mode: This bit is reserved, and the DRQ,

DACK

, TC, and IRQ6 pins will always be enabled.

During a reset, the DRQ, DACK

will remain enabled, and D3 will be a 0.

D2 Reset Controller: Writinga0tothis bit resets the

controller. It will remain in the reset condition until a

1 is written to this bit. A software reset does not

affect the DSR, CCR, and other bits of the DOR. A

software reset will affect the Configure and Mode

command bits (see Section 4.0 Command Set Description). The minimum time that this bit must be

low is 100 ns. Thus, toggling the Reset Controller bit

during consecutive writes to the DOR is an acceptable method of issuing a software reset.

D1,D0 Drive Select: These two bits are binary encoded for

the four drive selects DR0–DR3, so that only one

drive select output is active at a time. (Note 1)

: Active low status of the DR3 disk

: Active low status of the DR2 disk

DRIVE DRIVE

SEL 1 SEL 0

, TC, and IRQ6 pins.

and TC

, TC, and IRQ6 lines

It is common programming practice to enable both the motor enable and drive select outputs for a particular drive.

Table 3-2 below shows the DOR values to enable each of

the four drives.

TABLE 3-2. Drive Enable Values

Drive DOR Value

0 1C (hex)

12D

24E

38F

3.4 TAPE DRIVE REGISTER (TDR) Read/Write

This register is used to assign a particular drive number with

the tape drive support mode of the data separator. All other

logical drives are assigned floppy drive support with the

data separator. Any future reference to the assigned tape

drive will invoke tape drive support. The TDR is unaffected

by a software reset.

TDR

D7 D6 D5 D4 D3 D2 D1 D0

DESC

RESET

COND

XXXXXX

N/A N/A N/A N/A N/A N/A 0 0

TAPE TAPE

SEL 1 SEL 0

D7–D2 Reserved: These bits are ignored when written to

and are TRI-STATE when read.

D1,D0 Tape Select 1,0: These two bits assign a logical