Page 1

www.national.com

PC87307/PC97307 Plug and Play Compatible and PC97 Compliant SuperI/O

General Description

The PC87307/PC97307 (VUL) are functionally identical

parts that offer a single-chip solution to the most commonly

used ISA, EISA and MicroChannel

®

peripherals. This fully

Plug and Play (PnP) compatible chip incorporates a Floppy

Disk Controller (FDC), a Keyboard and mouse Controller

(KBC), a Real-Time Clock (RTC), two fast full function

UARTs, Infrared (IR) support, a full IEEE 1284 parallel port,

three general purpose chip select signals that can be programmed for game port control, and a separate configuration register set for each module. It also provides support for

power management (including a WATCHDOG timer) and

standard PC-AT address decoding for on-chip functions.

The Plug and Play (PnP) support in the device conforms to

the “

Plug and Play ISA Specification

” Version 1.0a, May 5,

1994.

The Infrared (IR) interface complies with the IrDA 1.0 SIR

and SHARP-IR standards, and supports all four basic protocols for Consumer-IR (TV-Remote) circuitry (RC-5, RC-5

extended, RECS80 and NEC).

Features

■ 100% compatible with Plug and Play requirements

specified in the “

Plug and Play ISA Specification

”, ISA,

EISA, and MicroChannel architectures

■ Meets PC97 requirements

PRELIMINARY

March 1998

PC87307/PC97307 Plug and Play Compatible and PC97

Compliant SuperI/O

Highlights

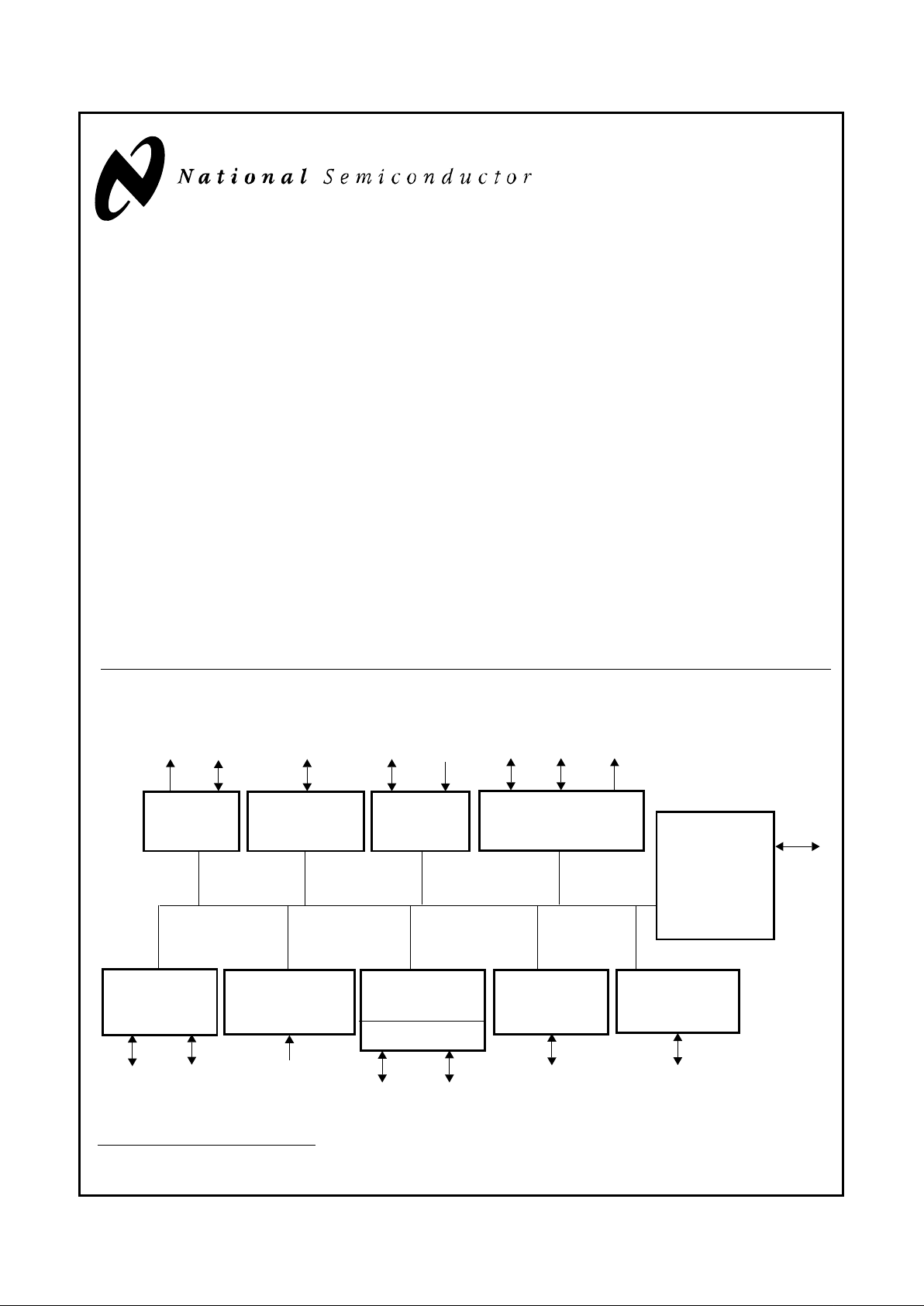

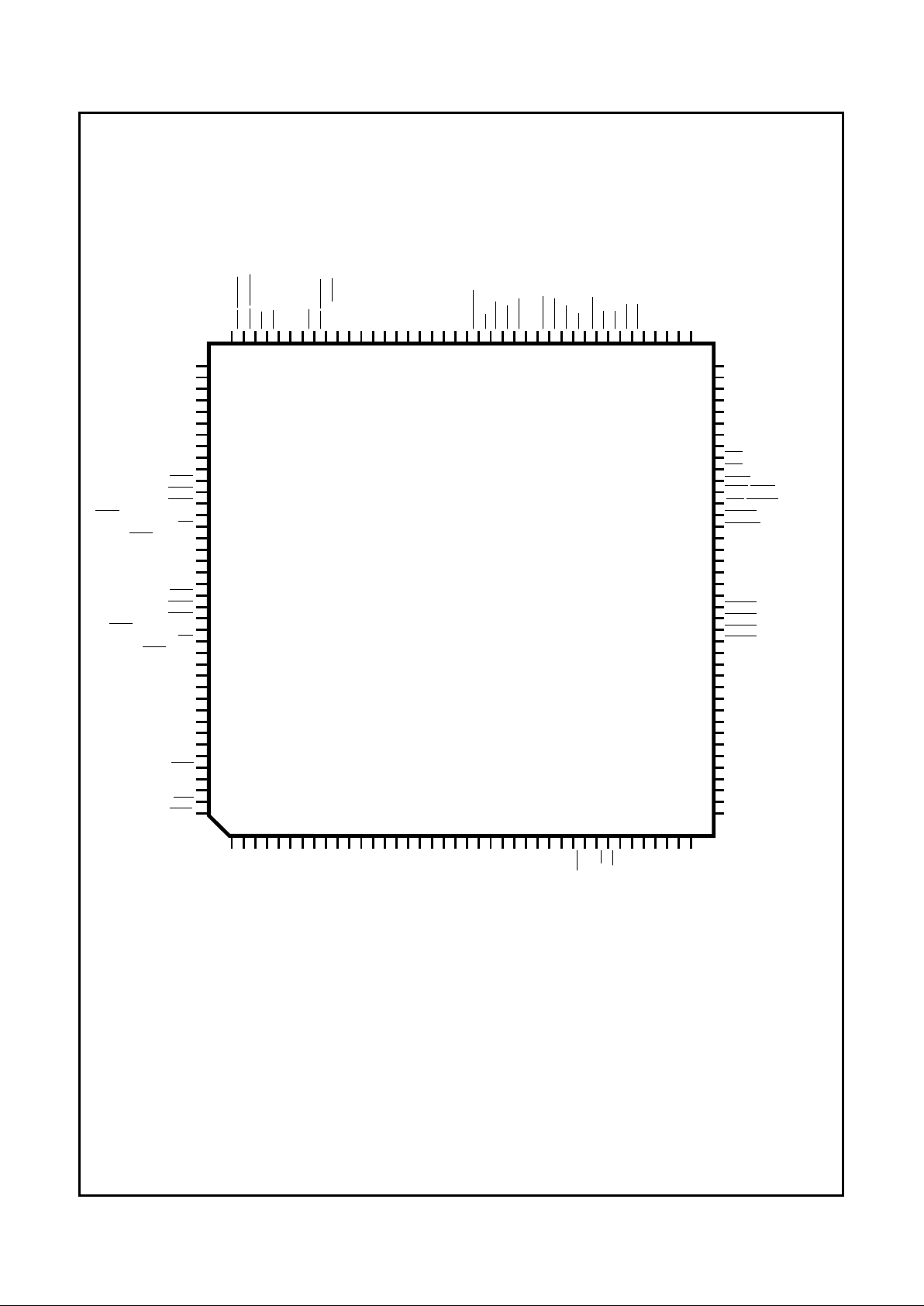

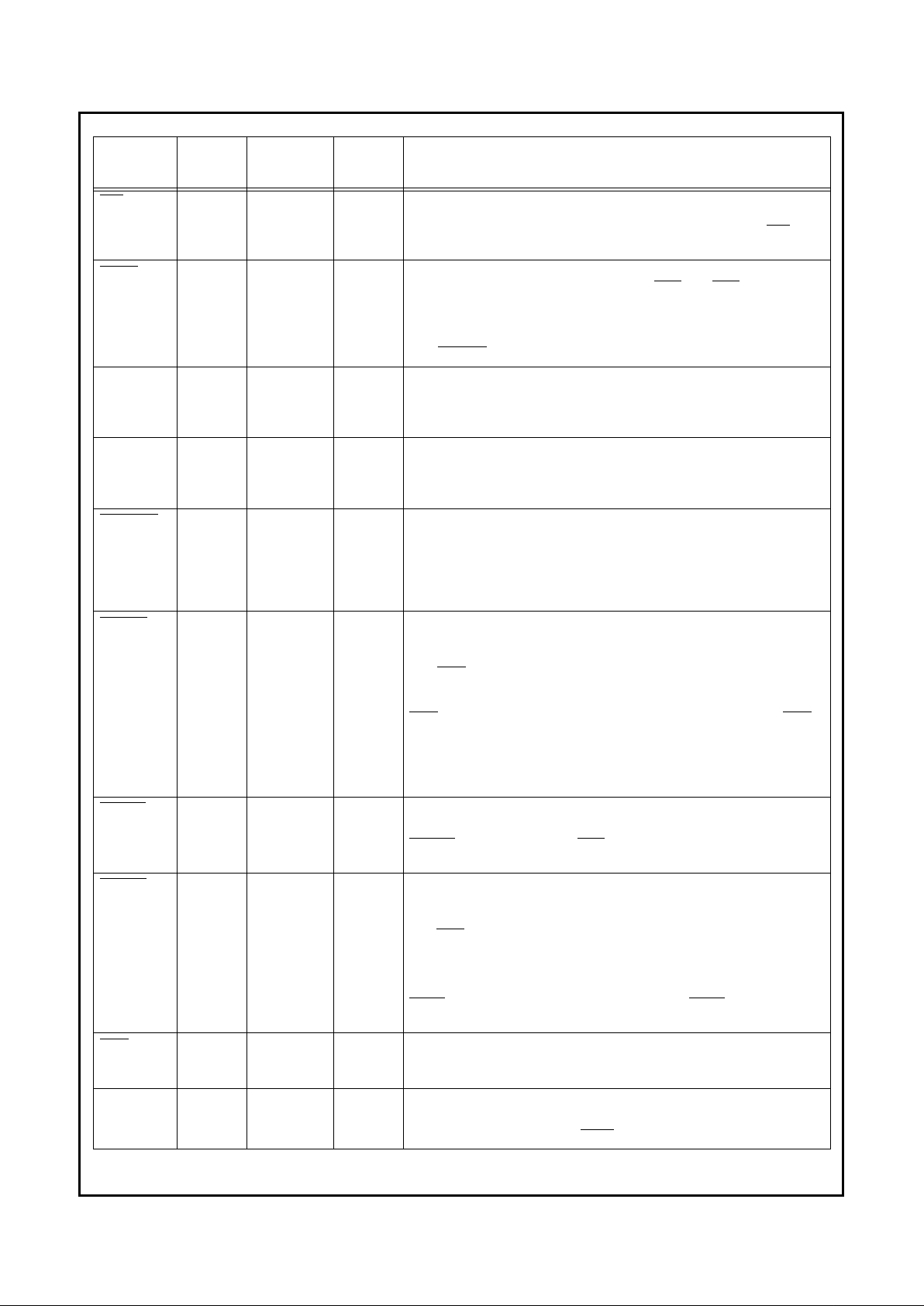

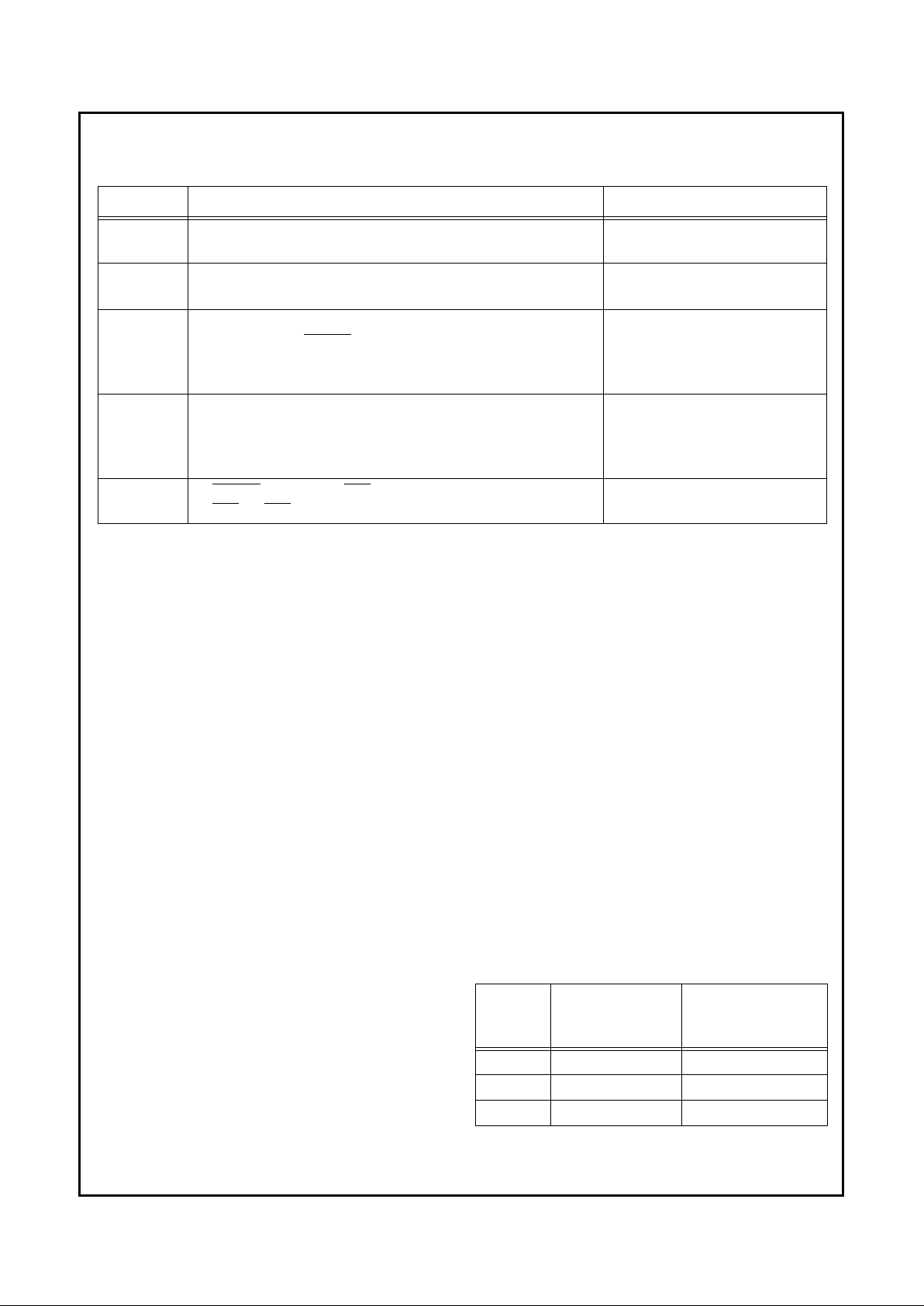

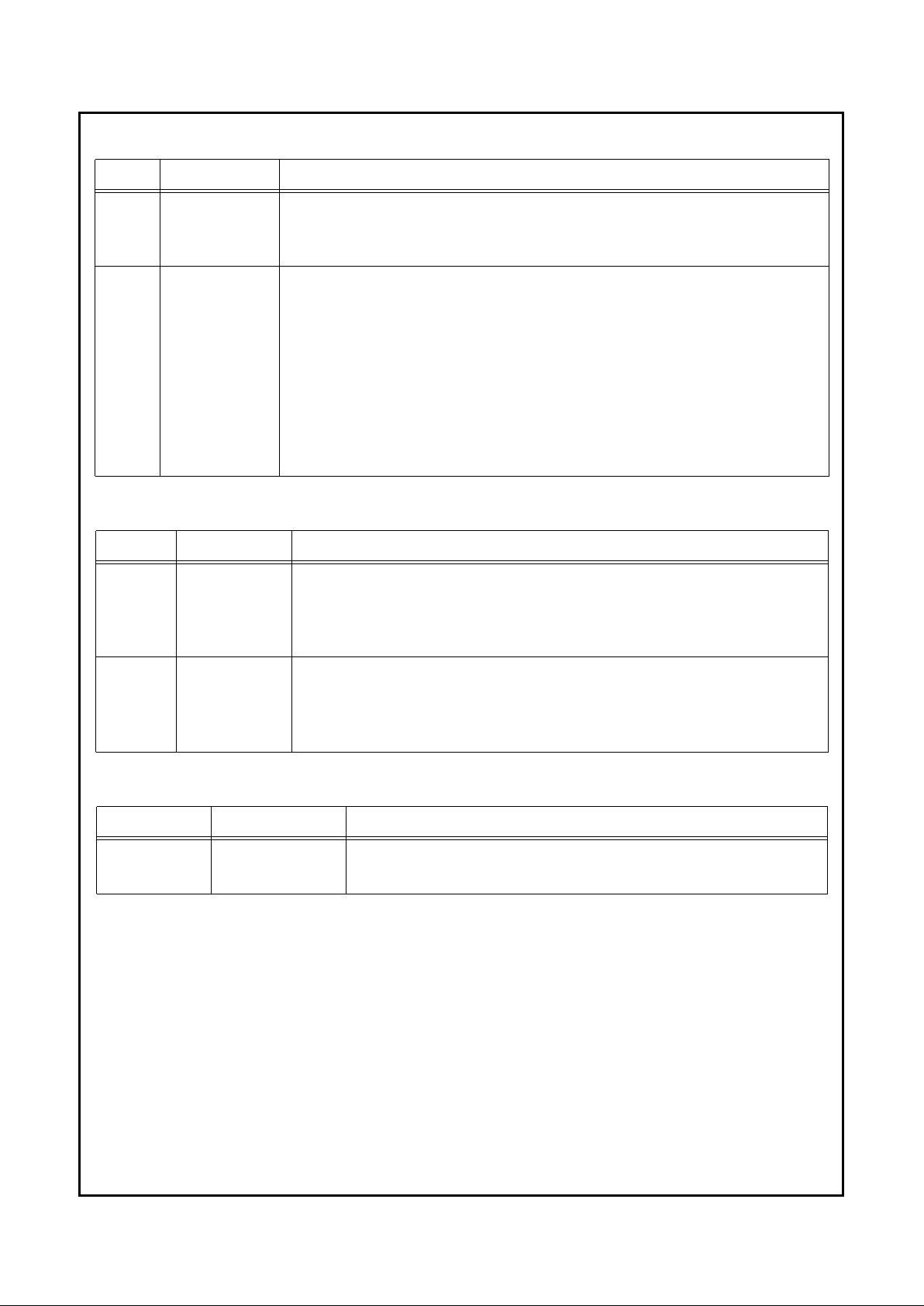

Block Diagram

Real-Time Clock

(Logical Device 2)

Floppy Disk

Controller (FDC)

with Digital Data

Separator (DDS)

(PC8477)

High Current Driver

Keyboard

Controller (KBC)

Power Management

Logic

µP Address

Floppy

Drive

Interface

Data Handshake

Data

Serial

Two UARTs + IR

(16550 or 16450)

X-Bus

IEEE1284

Control

Parallel Port

Interface

Infrared

Interface

Ports

(PnP)

IRQ

Control

DMA

Channels

(Logical Devices 5 & 6)

Interrupt

(RTC and APC)

Plug and Play

(Logical Device 8)

(Logical Device 0)

Data and

Control

(Logical Device 3)

Data and

Mouse

Controller

(Logical Device 1)

General Purpose

I/O Registers

(Logical Device 7)

I/O Ports

Data and

Control

(Logical Device 4)

Control

Control

© 1998 National Semiconductor Corporation

TRI-STATE® is a registered trademark of National Semiconductor Corporation.

IBM

®

, MicroChannel®, PC-AT® and PS/2® are registered trademarks of International Business Machines Corporation.

Microsoft

®

and Windows® are registered trademarks of Microsoft Corporation.

Page 2

2

Highlights

www.national.com

■ A special Plug and Play (PnP) module that includes:

— Flexible IRQs, DMAs and base addresses that meet

the Plug and Play requirements specified by Microsoft

®

in their 1995 hardware design guide for

Windows

®

and Plug and Play ISA Revision 1.0A

— Plug and Play ISA mode (with isolation mechanism

– Wait for Key state)

— Motherboard Plug and Play mode

■ A Floppy Disk Controller (FDC) that provides:

— A modifiable address that is referenced by a 16-bit

programmable register

— Software compatibility with the PC8477, which con-

tains a superset of the floppy disk controller functions in the µDP8473, the NEC µPD765A and the

N82077

— 13 IRQ channel options

— Four 8-bit DMA channel options

— 16-byte FIFO

— Burst and non-burst modes

— A high-performance, internal, digital data separator

that does not require any external filter components

— Support for standard 5.25" and 3.5" floppy disk

drives

— Automatic media sense support

— Perpendicular recording drive support

— Three-mode Floppy Disk Drive (FDD) support

— Full support for the IBM Tape Drive Register (TDR)

implementation of AT and PS/2 drive types

■ A Keyboard and mouse Controller (KBC) with:

— A modifiable address that is referenced by a 16-bit

programmable register, reported as a fixed address

in resource data

— 13 IRQ options for the keyboard controller

— 13 IRQ options for the mouse controller

— An 8-bit microcontroller

— Software compatibility with the 8042AH and

PC87911 microcontrollers

— 2 KB of custom-designed program ROM

— 256 bytes of RAM for data

— Five programmable dedicated open drain I/O lines

for keyboard controller applications

— Asynchronous access to two data registers and one

status register during normal operation

— Support for both interrupt and polling

— 93 instructions

— An 8-bit timer/counter

— Support for binary and BCD arithmetic

— Operation at 8 MHz,12 MHz or 16 MHz (programma-

ble option)

— Can be customized using the PC87323VUL, which

includes a RAM-based KBC, as a development platform for keyboard controller code

■ A Real-Time Clock (RTC) that has:

— A modifiable address that is referenced by a 16-bit

programmable register

— 13 IRQ options, with programmable polarity

— DS1287, MC146818 and PC87911 compatibility

— 242 bytes of battery backed up CMOS RAM in two

banks

— Selective lock mechanism for the RTC RAM

— Battery backed up century calendar in days, days of

the week, months and years, with automatic leapyear adjustment

— Battery backed-up time of day in seconds, minutes

and hours that allows a 12 or 24 hour format and adjustments for daylight savings time

— BCD or binary format for time keeping

— Three different maskable interrupt flags:

• Periodic interrupts - At intervals from 122 msec

to 500 msec

• Time-of-day alarm - At intervals from once per

second to once per day

• Updated Ended Interrupt - Once per second

upon completion of update

— Separate battery pin, 2.4 V operation that includes

an internal UL protection resistor

— 2 µA maximum power consumption during power

down

— Double-buffer time registers

■ An Advanced Power supply Control (APC) that controls

the main power supply to the system, using open-drain

output, as follows:

Power turned on when:

— The RTC reaches a pre-determined date and time.

— A high to low transition occurs on the

RI input signals

of the UARTs.

— A ring pulse or pulse train is detected on the

RING

input signal.

— A SWITCH input signal indicates a Switch On event

Powered turned off when:

— A SWITCH input signal indicates a Switch Off event

— A Fail-safe event occurs (power-save mode detect-

ed but the system is hung up).

— Software turns power off.

■ Two UARTs that provide:

— Software compatibility with the 16550A and the

16450

— A modifiable address that is referenced by a 16-bit

programmable register

— 13 IRQ channel options

— Shadow register support for write-only bits

— Four 8-bit DMA options for the UART with Infrared

support (UART2)

■ An enhanced UART and Infrared (IR) interface on the

UART2 that supports:

— UART data rates up to 1.5 Mbaud

— IrDA 1.0 SIR

— ASK-IR option of SHARP-IR

— DASK-IR option of SHARP-IR

— Consumer-IR (TV-Remote) circuitry

— A Plug and Play compatible external transceiver

■ A bidirectional parallel port that includes:

— A modifiable address that is referenced by a 16-bit

programmable register

Page 3

3

Highlights

www.national.com

— Software or hardware control

— 13 IRQ channel options

— Four 8-bit DMA channel options

— Demand mode DMA support

— An Enhanced Parallel Port (EPP) that is compatible

with the new version EPP 1.9, and is IEEE1284

compliant

— An Enhanced Parallel Port (EPP) that also supports

version EPP 1.7 of the Xircom specification.

— Support for an Enhanced Parallel Port (EPP) as

mode 4 of the Extended Capabilities Port (ECP)

— An Extended Capabilities Port (ECP) that is IEEE

1284 compliant, including level 2

— Selection of internal pull-up or pull-down resistor for

Paper End (PE) pin

— Reduction of PCI bus utilization by supporting a de-

mand DMA mode mechanism and a DMA fairness

mechanism

— A protection circuit that prevents damage to the par-

allel port when a printer connected to it powers up or

is operated at high voltages

— Output buffers that can sink and source14 mA

■ Three general purpose pins for three separate programmable chip select signals, as follows:

— Can be programmed for game port control

— The Chip Select 0 (

CS0) signal produces open drain

output and is powered by the V

CCH

— The Chip Select 1 (CS1) and 2 (CS2) signals have

push-pull buffers and are powered by the main V

DD

— Decoding of chip select signals depends on the ad-

dress and the Address Enable (AEN) signals, and

can be qualified using the Read (

RD) and Write

(

WR) signals.

■ 16 single-bit General Purpose I/O ports (GPIO):

— Modifiable addresses that are referenced by a 16-bit

programmable register

— Programmable direction for each signal (input or

output) with configuration lock

— Programmable drive type for each output pin (open-

drain or push-pull) with configuration lock

— Programmable option for internal pull-up resistor on

each input pin with configuration lock

— A back-drive protection circuit

■ An X-bus data buffer that connects the 8-bit X data bus

to the ISA data bus

■ Clock source options:

— Source is a 32.768 KHz crystal - an internal frequen-

cy multiplier generates all the required internal frequencies.

— Source may be either a 48 MHz or 24 MHz clock in-

put signal.

■ Enhanced Power Management (PM), including:

— Special configuration registers for power down

— WATCHDOG timer for power-saving strategies

— Reduced current leakage from pins

— Low-power CMOS technology

— Ability to shut off clocks to all modules

■ General features include:

— All accesses to the SuperI/O chip activate a Zero

Wait State (

ZWS) signal, except for accesses to the

Enhanced Parallel Port (EPP) and to configuration

registers

— Access to all configuration registers is through an In-

dex and a Data register, which can be relocated

within the ISA I/O address space

— 160-pin Plastic Quad Flatpack (PQFP) package

Page 4

4

Highlights

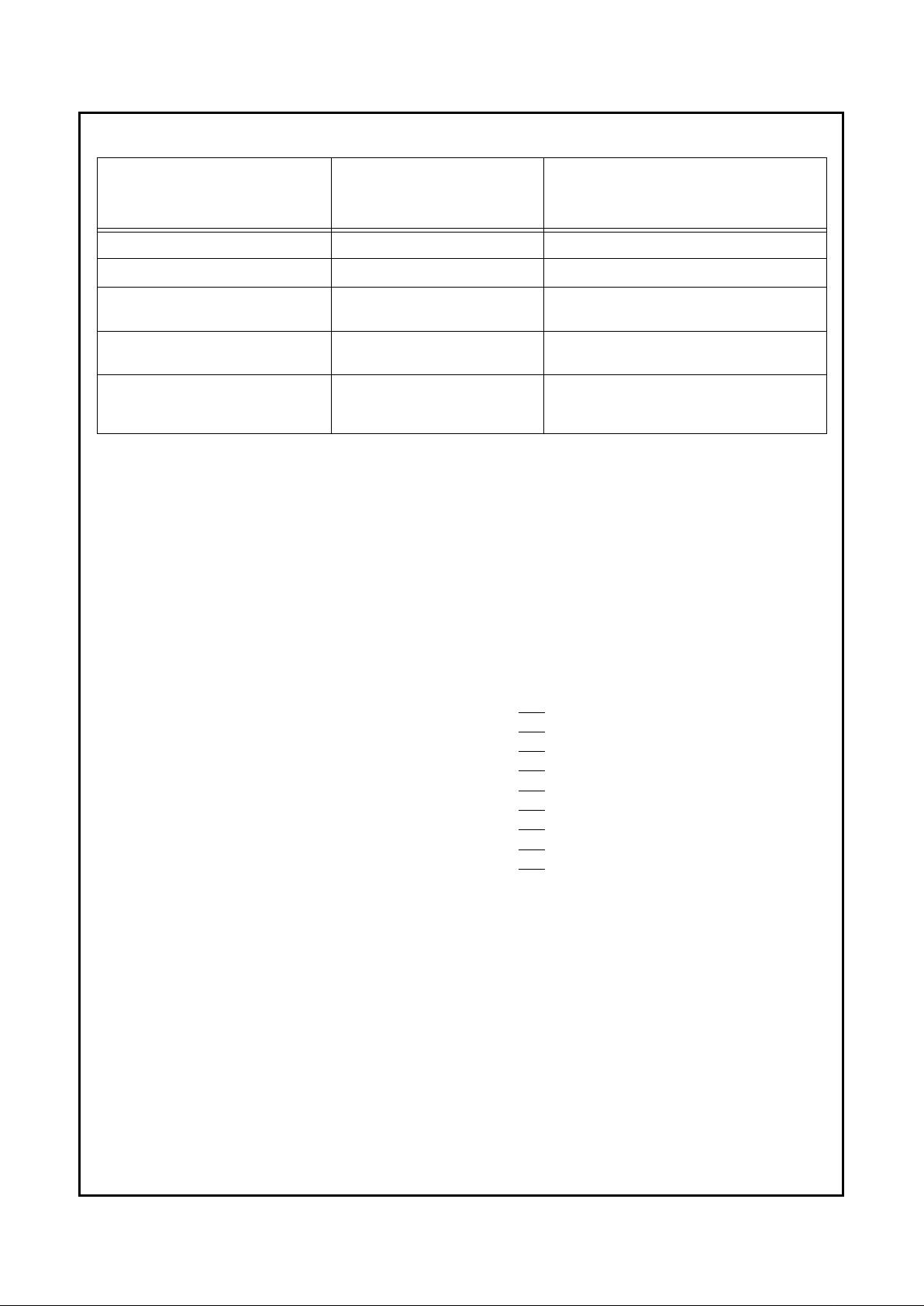

www.national.com

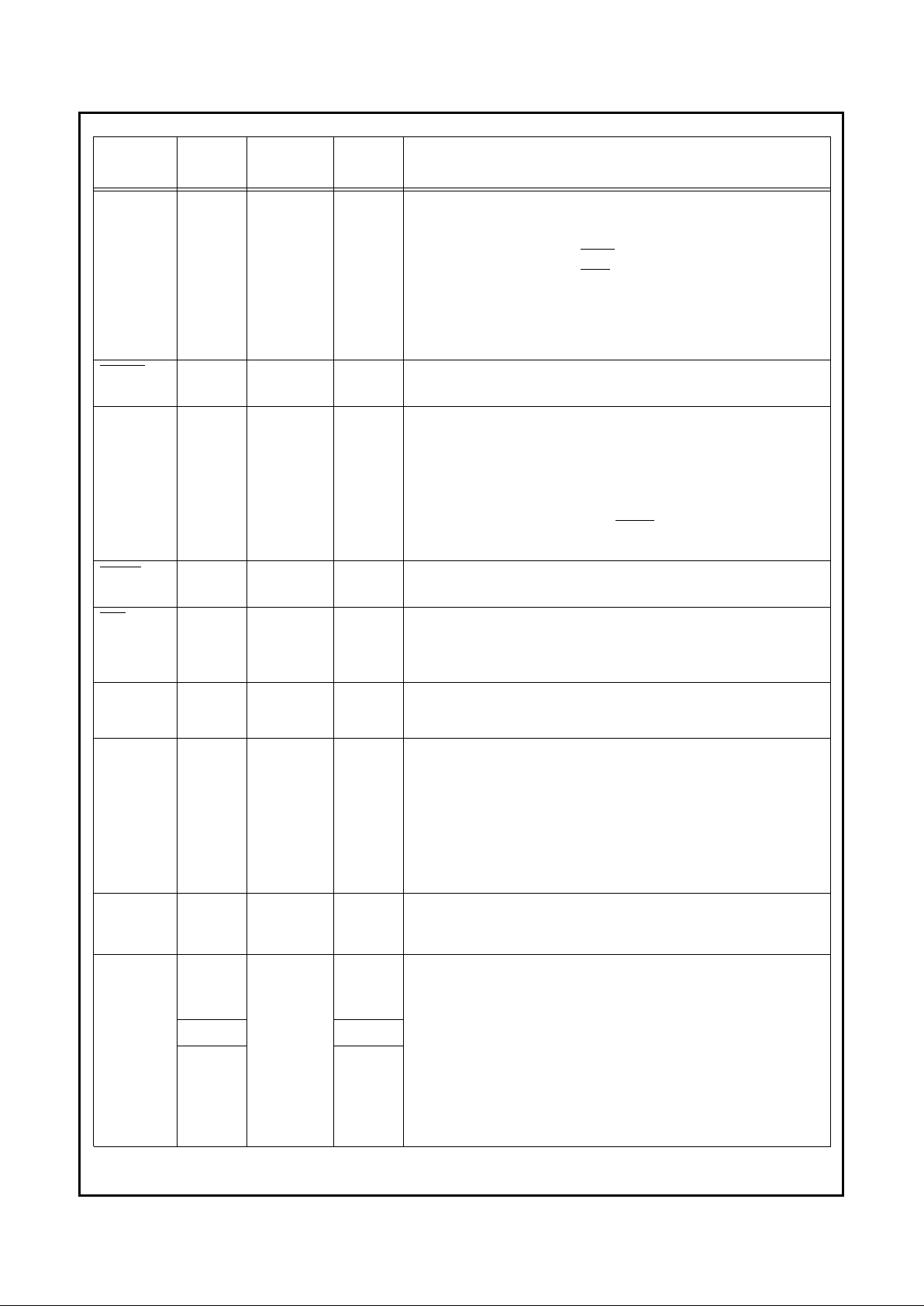

DRATE0

Parallel

Port

Connector

Configuration

Select Logic

Clock

Power

Management

EIA

Drivers

EIA

Drivers

FDC

Connector

ONCTL

ISA Bus

Basic Configuration

X1

MR

AEN

A15-0

D7-0

RD

WR

TC

PD7-0

SLIN/ASTRB

STB/WRITE

AFD/DSTRB

INIT

ACK

ERR

SLCT

PE

BUSY/WAIT

BADDR1,0

CFG3-0

V

CCH

SWITCH

RING

SIN1

SOUT1

RTS1

DTR1/BOUT1

CTS1

DSR1

DCD1

RI1

SIN2

SOUT2

RTS2

DTR2/BOUT2

CTS2

DSR2

DCD2

RI2

RDATA

WDATA

WGATE

HDSEL

DIR

STEP

TRK0

INDEX

DSKCHG

WP

MTR1,0

DR1,0

DENSEL

IOCHRDY

ZWS

RTC Crystal

and Power

V

BAT

X1C X2C

DRQ3-0

DACK3-0

P17,16,12

P21,20

KBCLK

KBDAT

MDAT

MCLK

CS2

Keyboard I/O

Interface

General

Purpose Registers

CS1,0

MSEN1,0

GPIO27-20

GPIO17-10

IRQ1

Infrared

Interface

IRRX2,1

IRTX

PC87307/PC97307

IRQ12-3

IRQ15-14

IRSL2-0

SELCS

X-Bus

XDCS

XD7-0

XDRD

WDO

POR

ID3-0

Page 5

5

Table of Contents

www.national.com

Table of Contents

Highlights.............................................................................................................................1

1.0

Signal/Pin Connection and Description

1.1 CONNECTION DIAGRAM .........................................................................................................14

1.2 SIGNAL/PIN DESCRIPTIONS ...................................................................................................15

2.0

Configuration

2.1 HARDWARE CONFIGURATION ...............................................................................................24

2.1.1 Wake Up Options ........................................................................................................24

2.1.2 The Index and Data Register Pair ...............................................................................24

2.1.3 The Strap Pins .............................................................................................................25

2.2 SOFTWARE CONFIGURATION ...............................................................................................25

2.2.1 Accessing the Configuration Registers ........................................................................25

2.2.2 Address Decoding .......................................................................................................25

2.3 THE CONFIGURATION REGISTERS .......................................................................................26

2.3.1 Standard Plug and Play (PnP) Register Definitions ....................................................27

2.3.2 Configuration Register Summary ................................................................................30

2.4 CARD CONTROL REGISTERS ................................................................................................34

2.4.1 SID Register (In PC87307) ..........................................................................................34

2.4.2 SID Register (In PC97307) ..........................................................................................34

2.4.3 SuperI/O Configuration 1 Register, Index 21h .............................................................34

2.4.4 SuperI/O Configuration 2 Register, Index 22h .............................................................35

2.4.5 Programmable Chip Select Configuration Index Register, Index 23h .........................35

2.4.6 Programmable Chip Select Configuration Data Register, Index 24h ..........................36

2.4.7 SRID Register (In PC97307 only) ................................................................................36

2.5 KBC CONFIGURATION REGISTER (LOGICAL DEVICE 0) ....................................................36

2.5.1 SuperI/O KBC Configuration Register, Index F0h .......................................................36

2.6 FDC CONFIGURATION REGISTERS (LOGICAL DEVICE 3) ..................................................36

2.6.1 SuperI/O FDC Configuration Register, Index F0h .......................................................36

2.6.2 Drive ID Register, Index F1h .......................................................................................37

2.7 PARALLEL PORT CONFIGURATION REGISTER (LOGICAL DEVICE 4) ...............................37

2.7.1 SuperI/O Parallel Port Configuration Register, Index F0h ...........................................37

2.8 UART2 AND INFRARED CONFIGURATION REGISTER (LOGICAL DEVICE 5) ....................38

2.8.1 SuperI/O UART2 Configuration Register, Index F0h ...................................................38

2.9 UART1 CONFIGURATION REGISTER (LOGICAL DEVICE 6) ................................................38

2.9.1 SuperI/O UART1 Configuration Register, Index F0h ...................................................38

2.10 PROGRAMMABLE CHIP SELECT CONFIGURATION REGISTERS ......................................39

2.10.1 CS0 Base Address MSB, Second Level Index 00h .....................................................39

2.10.2 CS0 Base Address LSB Register, Second Level Index 01h .......................................39

2.10.3 CS0 Configuration Register, Second Level Index 02h ................................................39

2.10.4 Reserved, Second Level Index 03h .............................................................................39

2.10.5 CS1 Base Address MSB Register, Second Level Index 04h ......................................40

2.10.6 CS1 Base Address LSB Register, Second Level Index 05h .......................................40

Page 6

6

Table of Contents

www.national.com

2.10.7 CS1 Configuration Register, Second Level Index 06h ................................................40

2.10.8 Reserved, Second Level Index 07h .............................................................................40

2.10.9 CS2 Base Address MSB Register, Second Level Index 08h ......................................40

2.10.10 CS2 Base Address LSB Register, Second Level Index 09h .......................................40

2.10.11 CS2 Configuration Register, Second Level Index 0Ah ................................................40

2.10.12 Reserved, Second Level Indexes 0Bh-0Fh .................................................................40

2.10.13 Not Accessible, Second Level Indexes 10h-FFh .........................................................40

2.11 CARD CONTROL REGISTER BITMAPS ..................................................................................41

3.0

Keyboard (and Mouse) Controller (KBC) (Logical Devices 0 and 1)

3.1 SYSTEM ARCHITECTURE .......................................................................................................43

3.2 FUNCTIONAL OVERVIEW .......................................................................................................44

3.3 DEVICE CONFIGURATION ......................................................................................................44

3.3.1 I/O Address Space ......................................................................................................44

3.3.2 Interrupt Request Signals ............................................................................................44

3.3.3 KBC Clock ...................................................................................................................45

3.3.4 Timer or Event Counter ...............................................................................................46

3.4 EXTERNAL I/O INTERFACES ..................................................................................................46

3.4.1 Keyboard and Mouse Interface ...................................................................................46

3.4.2 General Purpose I/O Signals .......................................................................................46

3.5 INTERNAL KBC - PC87307/PC97307 INTERFACE .................................................................47

3.5.1 The KBC DBBOUT Register, Offset 60h, Read Only ..................................................47

3.5.2 The KBC DBBIN Register, Offset 60h (F1 Clear) or 64h (F1 Set), Write Only ............47

3.5.3 The KBC STATUS Register, Offset 64h, Read Only ...................................................48

3.6 INSTRUCTION TIMING .............................................................................................................48

4.0

Real-Time Clock (RTC) and Advanced Power Control (APC) (Logical Device 2)

4.1 RTC OPERATION OVERVIEW .................................................................................................49

4.1.1 RTC Hardware and Functional Description .................................................................49

4.1.2 Timekeeping ................................................................................................................50

4.1.3 Power Supply ..............................................................................................................51

4.1.4 Interrupt Handling ........................................................................................................52

4.2 THE RTC REGISTERS .............................................................................................................52

4.2.1 RTC Control Register A (CRA), Index 0Ah ..................................................................52

4.2.2 RTC Control Register B (CRB), Index 0Bh .................................................................54

4.2.3 RTC Control Register C (CRC), Index 0Ch .................................................................54

4.2.4 RTC Control Register D (CRD), Index 0Dh .................................................................55

4.3 APC OVERVIEW .......................................................................................................................55

4.3.1 User Selectable Parameters ........................................................................................55

4.3.2 System Power States ..................................................................................................56

4.3.3 System Power Switching Logic ...................................................................................56

4.4 DETAILED FUNCTIONAL DESCRIPTION ................................................................................58

4.4.1 The ONCTL Signal ......................................................................................................58

4.4.2 Entering Power States .................................................................................................58

4.4.3 System Power-Up and Power-Off Activation Event Description ..................................59

Page 7

7

Table of Contents

www.national.com

4.5 APC REGISTERS ......................................................................................................................60

4.5.1 APC Control Register 1 (APCR1), Index 40h ..............................................................60

4.5.2 APC Control Register 2 (APCR2), Index 41h ..............................................................61

4.5.3 APC Status Register (APSR), Index 42h .....................................................................61

4.5.4 RAM Lock Register (RLR), Index 47h .........................................................................62

4.6 RTC AND APC REGISTER BITMAPS ......................................................................................62

4.6.1 RTC Register Bitmaps .................................................................................................62

4.6.2 APC Register Bitmaps .................................................................................................63

4.7 REGISTER BANK TABLES .......................................................................................................64

5.0

The Digital Floppy Disk Controller (FDC) (Logical Device 3)

5.1 FDC FUNCTIONS .....................................................................................................................66

5.1.1 Microprocessor Interface .............................................................................................66

5.1.2 System Operation Modes ............................................................................................66

5.2 DATA TRANSFER .....................................................................................................................67

5.2.1 Data Rates ...................................................................................................................67

5.2.2 The Data Separator .....................................................................................................67

5.2.3 Perpendicular Recording Mode Support .....................................................................68

5.2.4 Data Rate Selection .....................................................................................................68

5.2.5 Write Precompensation ...............................................................................................69

5.2.6 FDC Low-Power Mode Logic .......................................................................................69

5.2.7 Reset ...........................................................................................................................69

5.3 THE REGISTERS OF THE FDC ...............................................................................................70

5.3.1 Status Register A (SRA), Offset 00h ...........................................................................70

5.3.2 Status Register B (SRB), Offset 01h ...........................................................................71

5.3.3 Digital Output Register (DOR), Offset 02h ..................................................................71

5.3.4 Tape Drive Register (TDR), Offset 03h .......................................................................73

5.3.5 Main Status Register (MSR), Offset 04h, Read Operations ........................................74

5.3.6 Data Rate Select Register (DSR), Offset 04h, Write Operations ................................75

5.3.7 Data Register (FIFO), Offset 05h ................................................................................76

5.3.8 Digital Input Register (DIR), Offset 07h, Read Operations ..........................................77

5.3.9 Configuration Control Register (CCR), Offset 07h, Write Operations .........................78

5.4 THE PHASES OF FDC COMMANDS .......................................................................................78

5.4.1 Command Phase .........................................................................................................78

5.4.2 Execution Phase ..........................................................................................................78

5.4.3 Result Phase ...............................................................................................................80

5.4.4 Idle Phase ....................................................................................................................80

5.4.5 Drive Polling Phase .....................................................................................................80

5.5 THE RESULT PHASE STATUS REGISTERS ..........................................................................81

5.5.1 Result Phase Status Register 0 (ST0) .........................................................................81

5.5.2 Result Phase Status Register 1 (ST1) .........................................................................81

5.5.3 Result Phase Status Register 2 (ST2) .........................................................................82

5.5.4 Result Phase Status Register 3 (ST3) .........................................................................83

5.6 FDC REGISTER BITMAPS .......................................................................................................84

5.6.1 FDC Standard Register Bitmaps .................................................................................84

Page 8

8

Table of Contents

www.national.com

5.6.2 FDC Result Phase Status Register Bitmaps ...............................................................85

5.7 THE FDC COMMAND SET .......................................................................................................86

5.7.1 Abbreviations Used in FDC Commands ......................................................................87

5.7.2 The CONFIGURE Command ......................................................................................88

5.7.3 The DUMPREG Command .........................................................................................88

5.7.4 The FORMAT TRACK Command ...............................................................................89

5.7.5 The INVALID Command ..............................................................................................92

5.7.6 The LOCK Command ..................................................................................................92

5.7.7 The MODE Command .................................................................................................92

5.7.8 The NSC Command ....................................................................................................94

5.7.9 The PERPENDICULAR MODE Command .................................................................94

5.7.10 The READ DATA Command .......................................................................................96

5.7.11 The READ DELETED DATA Command ......................................................................98

5.7.12 The READ ID Command .............................................................................................99

5.7.13 The READ A TRACK Command ...............................................................................100

5.7.14 The RECALIBRATE Command .................................................................................100

5.7.15 The RELATIVE SEEK Command ..............................................................................101

5.7.16 The SCAN EQUAL, the SCAN LOW OR EQUAL and the SCAN HIGH OR EQUAL

Commands ..........................................................................................................101

5.7.17 The SEEK Command ................................................................................................102

5.7.18 The SENSE DRIVE STATUS Command ..................................................................103

5.7.19 The SENSE INTERRUPT Command ........................................................................103

5.7.20 The SET TRACK Command ......................................................................................104

5.7.21 The SPECIFY Command ..........................................................................................105

5.7.22 The VERIFY Command .............................................................................................106

5.7.23 The VERSION Command ..........................................................................................108

5.7.24 The WRITE DATA Command ....................................................................................108

5.7.25 The WRITE DELETED DATA Command ..................................................................109

5.8 EXAMPLE OF A FOUR-DRIVE CIRCUIT USING THE PC87307/PC97307 ...........................110

6.0

Parallel Port (Logical Device 4)

6.1 PARALLEL PORT CONFIGURATION ....................................................................................111

6.1.1 Parallel Port Operation Modes ..................................................................................111

6.1.2 Configuring Operation Modes ....................................................................................111

6.1.3 Output Pin Protection ................................................................................................111

6.2 STANDARD PARALLEL PORT (SPP) MODES ......................................................................111

6.2.1 Standard Parallel Port (SPP) Modes Register Set ....................................................112

6.2.2 SPP Data Register (DTR), Offset 00h .......................................................................112

6.2.3 Status Register (STR), Offset 01h .............................................................................113

6.2.4 SPP Control Register (CTR), Offset 02h ...................................................................114

6.3 ENHANCED PARALLEL PORT (EPP) MODES ......................................................................115

6.3.1 Enhanced Parallel Port (EPP) Register Set ..............................................................115

6.3.2 SPP or EPP Data Register (DTR), Offset 00h ...........................................................115

6.3.3 SPP or EPP Status Register (STR), Offset 01h ........................................................115

6.3.4 SPP or EPP Control Register (CTR), Offset 02h .......................................................116

6.3.5 EPP Address Register (ADDR), Offset 03h ...............................................................116

6.3.6 EPP Data Register 0 (DATA0), Offset 04h ................................................................116

Page 9

9

Table of Contents

www.national.com

6.3.7 EPP Data Register 1 (DATA1), Offset 05h ................................................................116

6.3.8 EPP Data Register 2 (DATA2), Offset 06h ................................................................116

6.3.9 EPP Data Register 3 (DATA3), Offset 07h ................................................................117

6.3.10 EPP Mode Transfer Operations ................................................................................117

6.3.11 EPP 1.7 and 1.9 Zero Wait State Data Write and Read Operations .........................118

6.4 EXTENDED CAPABILITIES PARALLEL PORT (ECP) ...........................................................119

6.4.1 ECP Modes ...............................................................................................................119

6.4.2 Software Operation ....................................................................................................119

6.4.3 Hardware Operation ..................................................................................................119

6.5 ECP MODE REGISTERS ........................................................................................................120

6.5.1 Accessing the ECP Registers ....................................................................................120

6.5.2 Second Level Offsets ................................................................................................120

6.5.3 ECP Data Register (DATAR), Bits 7-5 of ECR = 000 or 001, Offset 000h ................121

6.5.4 ECP Address FIFO (AFIFO) Register, Bits 7-5 of ECR = 011, Offset 000h ..............121

6.5.5 ECP Status Register (DSR), Offset 001h ..................................................................121

6.5.6 ECP Control Register (DCR), Offset 002h ................................................................122

6.5.7 Parallel Port Data FIFO (CFIFO) Register, Bits 7-5 of ECR = 010, Offset 400h .......122

6.5.8 ECP Data FIFO (DFIFO) Register, Bits 7-5 of ECR = 011, Offset 400h ...................122

6.5.9 Test FIFO (TFIFO) Register, Bits 7-5 of ECR = 110, Offset 400h .............................123

6.5.10 Configuration Register A (CNFGA), Bits 7-5 of ECR = 111, Offset 400h ..................123

6.5.11 Configuration Register B (CNFGB), Bits 7-5 of ECR = 111, Offset 401h ..................123

6.5.12 Extended Control Register (ECR), Offset 402h .........................................................124

6.5.13 ECP Extended Index Register (EIR), Offset 403h .....................................................125

6.5.14 ECP Extended Data Register (EDR), Offset 404h ....................................................126

6.5.15 ECP Extended Auxiliary Status Register (EAR), Offset 405h ...................................126

6.5.16 Control0, Second Level Offset 00h ............................................................................126

6.5.17 Control2, Second Level Offset 02h ............................................................................126

6.5.18 Control4, Second Level Offset 04h ............................................................................127

6.5.19 PP Confg0, Second Level Offset 05h ........................................................................127

6.6 DETAILED ECP MODE DESCRIPTIONS ...............................................................................128

6.6.1 Software Controlled Data Transfer (Modes 000 and 001) .........................................128

6.6.2 Automatic Data Transfer (Modes 010 and 011) ........................................................128

6.6.3 Automatic Address and Data Transfers (Mode 100) .................................................130

6.6.4 FIFO Test Access (Mode 110) ..................................................................................130

6.6.5 Configuration Registers Access (Mode 111) .............................................................130

6.6.6 Interrupt Generation ..................................................................................................130

6.7 PARALLEL PORT REGISTER BITMAPS ...............................................................................131

6.7.1 EPP Modes Parallel Port Register Bitmaps ...............................................................131

6.7.2 ECP Modes Parallel Port Register Bitmaps ..............................................................132

6.8 PARALLEL PORT PIN/SIGNAL LIST ......................................................................................134

7.0

UART1 and UART2 (with IR) (Logical Devices 5 and 6)

7.1 FEATURES ..............................................................................................................................135

7.2 FUNCTIONAL MODES OVERVIEW .......................................................................................135

7.2.1 UART Modes: 16450 or 16550, and Extended ..........................................................135

7.2.2 Sharp-IR, IrDA SIR Infrared Modes ...........................................................................135

Page 10

10

Table of Contents

www.national.com

7.2.3 Consumer IR Mode ...................................................................................................135

7.3 REGISTER BANK OVERVIEW ...............................................................................................136

7.4 UART MODES – DETAILED DESCRIPTION ..........................................................................136

7.4.1 16450 or 16550 UART Mode .....................................................................................137

7.4.2 Extended UART Mode ...............................................................................................137

7.5 SHARP-IR MODE – DETAILED DESCRIPTION .....................................................................138

7.6 SIR MODE – DETAILED DESCRIPTION ................................................................................138

7.7 CONSUMER-IR MODE – DETAILED DESCRIPTION ............................................................138

7.7.1 Consumer-IR Transmission .......................................................................................138

7.7.2 Consumer-IR Reception ............................................................................................138

7.8 FIFO TIME-OUTS ....................................................................................................................139

7.8.1 UART, SIR or Sharp-IR Mode Time-Out Conditions .................................................139

7.8.2 Consumer-IR Mode Time-Out Conditions .................................................................139

7.8.3 Transmission Deferral ...............................................................................................139

7.9 AUTOMATIC FALLBACK TO A NON-EXTENDED UART MODE ..........................................140

7.10 OPTICAL TRANSCEIVER INTERFACE .................................................................................140

7.11 BANK 0 – GLOBAL CONTROL AND STATUS REGISTERS .................................................140

7.11.1 Receiver Data Port (RXD) or the Transmitter Data Port (TXD), Bank 0, Offset 00h .141

7.11.2 Interrupt Enable Register (IER), Bank 0, Offset 01h .................................................141

7.11.3 Event Identification Register (EIR), Bank 0, Offset 02h .............................................143

7.11.4 FIFO Control Register (FCR), Bank 0, Offset 02h .....................................................145

7.11.5 Link Control Register (LCR), Bank 0, Offset 03h, and Bank Selection Register (BSR),

All Banks, Offset 03h ...........................................................................................145

7.11.6 Bank Selection Register (BSR), All Banks, Offset 03h ..............................................147

7.11.7 Modem/Mode Control Register (MCR), Bank 0, Offset 04h ......................................147

7.11.8 Link Status Register (LSR), Bank 0, Offset 05h ........................................................148

7.11.9 Modem Status Register (MSR), Bank 0, Offset 06h ..................................................149

7.11.10 Scratchpad Register (SPR), Bank 0, Offset 07h .......................................................150

7.11.11 Auxiliary Status and Control Register (ASCR), Bank 0, Offset 07h ...........................150

7.11.12 Legacy Baud Generator Divisor Ports (LBGD(L) and LBGD(H)),

Bank 1, Offsets 00h and 01h ...............................................................................151

7.11.13 Link Control Register (LCR) and Bank Select Register (BSR), Bank 1, Offset 03h ..152

7.12 BANK 2 – EXTENDED CONTROL AND STATUS REGISTERS ............................................152

7.12.1 Baud Generator Divisor Ports, LSB (BGD(L)) and

MSB (BGD(H)),Bank 2, Offsets 00h and 01h ......................................................152

7.12.2 Extended Control Register 1 (EXCR1), Bank 2, Offset 02h ......................................154

7.12.3 Link Control Register (LCR) and Bank Select Register (BSR), Bank 2, Offset 03h ..155

7.12.4 Extended Control and Status Register 2 (EXCR2), Bank 2, Offset 04h ....................155

7.12.5 Reserved Register, Bank 2, Offset 05h .....................................................................155

7.12.6 TX_FIFO Current Level Register (TXFLV), Bank 2, Offset 06h ................................155

7.12.7 RX_FIFO Current Level Register (RXFLV), IrDA or Consumer-IR Modes,

Bank 2, Offset 07h ..............................................................................................156

7.13 BANK 3 – MODULE REVISION ID AND SHADOW REGISTERS ..........................................156

7.13.1 Module Revision ID Register (MRID), Bank 3, Offset 00h .........................................156

7.13.2 Shadow of Link Control Register (SH_LCR), Bank 3, Offset 01h ..............................157

Page 11

11

Table of Contents

www.national.com

7.13.3 Shadow of FIFO Control Register (SH_FCR), Bank 3, Offset 02h ............................157

7.13.4 Link Control Register (LCR) and Bank Select Register (BSR), Bank 3, Offset 03h ..157

7.14 BANK 4 – IR MODE SETUP REGISTER ................................................................................157

7.14.1 Reserved Registers, Bank 4, Offsets 00h and 01h ...................................................157

7.14.2 Infrared Control Register 1 (IRCR1), Bank 4, Offset 02h ..........................................157

7.14.3 Link Control Register (LCR) and Bank Select Register (BSR), Bank 4, Offset 03h ..158

7.14.4 Reserved Registers, Bank 4, Offsets 04h -07h .........................................................158

7.15 BANK 5 – INFRARED CONTROL REGISTERS .....................................................................158

7.15.1 Reserved Registers, Bank 5, Offsets 00h -02h .........................................................158

7.15.2 (LCR/BSR) Register, Bank 5, Offset 03h ..................................................................158

7.15.3 Infrared Control Register 2 (IRCR2), Bank 5, Offset 04h ..........................................158

7.15.4 Reserved Registers, Bank 5, Offsets 05h -07h .........................................................158

7.16 BANK 6 – INFRARED PHYSICAL LAYER CONFIGURATION REGISTERS .........................159

7.16.1 Infrared Control Register 3 (IRCR3), Bank 6, Offset 00h ..........................................159

7.16.2 Reserved Register, Bank 6, Offset 01h .....................................................................159

7.16.3 SIR Pulse Width Register (SIR_PW), Bank 6, Offset 02h .........................................159

7.16.4 Link Control Register (LCR) and Bank Select Register (BSR), Bank 6, Offset 03h ..159

7.16.5 Reserved Registers, Bank 6, Offsets 04h-07h ..........................................................159

7.17 BANK 7 – CONSUMER-IR AND OPTICAL TRANSCEIVER CONFIGURATION REGISTERS 159

7.17.1 Infrared Receiver Demodulator Control Register (IRRXDC), Bank 7, Offset 0 .........160

7.17.2 Infrared Transmitter Modulator Control Register (IRTXMC), Bank 7, Offset 01h ......160

7.17.3 Consumer-IR Configuration Register (RCCFG), Bank 7, Offset 02h ........................163

7.17.4 Link Control/Bank Select Registers (LCR/BSR), Bank 7, Offset 03h ........................163

7.17.5 Infrared Interface Configuration Register 1 (IRCFG1), Bank 7, Offset 04h ...............163

7.17.6 Reserved Register, Bank 7, Offset 05h .....................................................................164

7.17.7 Infrared Interface Configuration 3 Register (IRCFG3), Bank 7, Offset 06h ...............164

7.17.8 Infrared Interface Configuration Register 4 (IRCFG4), Bank 7, Offset 07h ...............164

7.18 UART2 REGISTER WITH FAST IR REGISTER BITMAPS ....................................................165

8.0

General Purpose Input and Output (GPIO) Ports (Logical Device 7) and Chip

Select Output Signals

8.1 GENERAL PURPOSE INPUT AND OUTPUT (GPIO) PORTS ...............................................170

8.2 PROGRAMMABLE CHIP SELECT OUTPUT SIGNALS .........................................................171

9.0

Power Management (Logical Device 8)

9.1 POWER MANAGEMENT OPTIONS .......................................................................................172

9.1.1 Configuration Options ................................................................................................172

9.1.2 The WATCHDOG Feature .........................................................................................172

9.2 THE POWER MANAGEMENT REGISTERS ..........................................................................172

9.2.1 Power Management Index Register, Base Address + 00h ........................................172

9.2.2 Power Management Data Register, Base Address + 01h .........................................173

9.2.3 Function Enable Register 1 (FER1), Index 00h .........................................................173

9.2.4 Function Enable Register 2 (FER2), Index 01h .........................................................173

9.2.5 Power Management Control 1 Register (PMC1), Index 02h .....................................174

9.2.6 Power Management Control 2 Register (PMC2), Index 03h .....................................174

Page 12

12

Table of Contents

www.national.com

9.2.7 Power Management Control 3 Register (PMC3), Index 04h .....................................175

9.2.8 Watchdog Time-Out (WDTO) Register, Index 05h ....................................................175

9.2.9 WATCHDOG Configuration Register (WDCF), Index 06h ........................................175

9.2.10 WATCHDOG Status Register (WDST), Index 07h ....................................................176

9.3 POWER MANAGEMENT REGISTER BITMAPS ....................................................................177

10.0

X-Bus Data Buffer

10.1 FUNCTIONAL OVERVIEW .....................................................................................................179

10.2 MAPPING ................................................................................................................................179

11.0

The Internal Clock

11.1 THE CLOCK SOURCE ............................................................................................................180

11.2 THE INTERNAL ON-CHIP CLOCK MULTIPLIER ...................................................................180

11.3 SPECIFICATIONS ...................................................................................................................180

12.0

Interrupt and DMA Mapping

12.1 IRQ MAPPING .........................................................................................................................181

12.2 DMA MAPPING .......................................................................................................................181

13.0

Device Description

13.1 GENERAL DC ELECTRICAL CHARACTERISTICS ...............................................................182

13.1.1 Recommended Operating Conditions .......................................................................182

13.1.2 Absolute Maximum Ratings .......................................................................................182

13.1.3 Capacitance ...............................................................................................................182

13.1.4 Power Consumption Under Recommended Operating Conditions ...........................183

13.2 DC CHARACTERISTICS OF PINS, BY GROUP ....................................................................183

13.2.1 Group 1 ......................................................................................................................183

13.2.2 Group 2 ......................................................................................................................184

13.2.3 Group 3 ......................................................................................................................184

13.2.4 Group 4 ......................................................................................................................184

13.2.5 Group 5 ......................................................................................................................185

13.2.6 Group 6 ......................................................................................................................185

13.2.7 Group 7 ......................................................................................................................185

13.2.8 Group 8 ......................................................................................................................186

13.2.9 Group 9 ......................................................................................................................186

13.2.10 Group 10 ....................................................................................................................187

13.2.11 Group 11 ....................................................................................................................187

13.2.12 Group 12 ....................................................................................................................188

13.2.13 Group 13 ....................................................................................................................188

13.2.14 Group 14 ....................................................................................................................189

13.2.15 Group 15 ....................................................................................................................189

13.2.16 Group 16 ....................................................................................................................189

13.2.17 Group 17 ....................................................................................................................190

13.2.18 Group 18 ....................................................................................................................190

13.2.19 Group 19 ....................................................................................................................190

Page 13

13

Table of Contents

www.national.com

13.2.20 Group 20 ....................................................................................................................190

13.2.21 Group 21 ....................................................................................................................190

13.2.22 Group 22 ....................................................................................................................191

13.2.23 Group 23 ....................................................................................................................191

13.3 AC ELECTRICAL CHARACTERISTICS ..................................................................................191

13.3.1 AC Test Conditions TA = 0 °C to 70 °C, VDD = 5.0 V ±10% ......................................191

13.3.2 Clock Timing ..............................................................................................................192

13.3.3 Microprocessor Interface Timing ...............................................................................193

13.3.4 Baud Output Timing ...................................................................................................195

13.3.5 Transmitter Timing .....................................................................................................196

13.3.6 Receiver Timing .........................................................................................................197

13.3.7 UART, Sharp-IR and Consumer-IR Timing ...............................................................199

13.3.8 SIR Timing .................................................................................................................200

13.3.9 IRSLn Write Timing ...................................................................................................200

13.3.10 Modem Control Timing ..............................................................................................201

13.3.11 DMA Timing ...............................................................................................................202

13.3.12 Reset Timing .............................................................................................................204

13.3.13 Write Data Timing ......................................................................................................204

13.3.14 Drive Control Timing ..................................................................................................205

13.3.15 Read Data Timing ......................................................................................................205

13.3.16 Parallel Port Timing ...................................................................................................206

13.3.17 Enhanced Parallel Port 1.7 Timing ............................................................................207

13.3.18 Enhanced Parallel Port 1.9 Timing ............................................................................208

13.3.19 Extended Capabilities Port (ECP) Timing ..................................................................209

13.3.20 GPIO Write Timing ....................................................................................................210

13.3.21 RTC Timing ...............................................................................................................210

13.3.22 APC Timing ...............................................................................................................211

13.3.23 Chip Select Timing ....................................................................................................212

Page 14

14

Signal/Pin Connection and Description

www.national.com

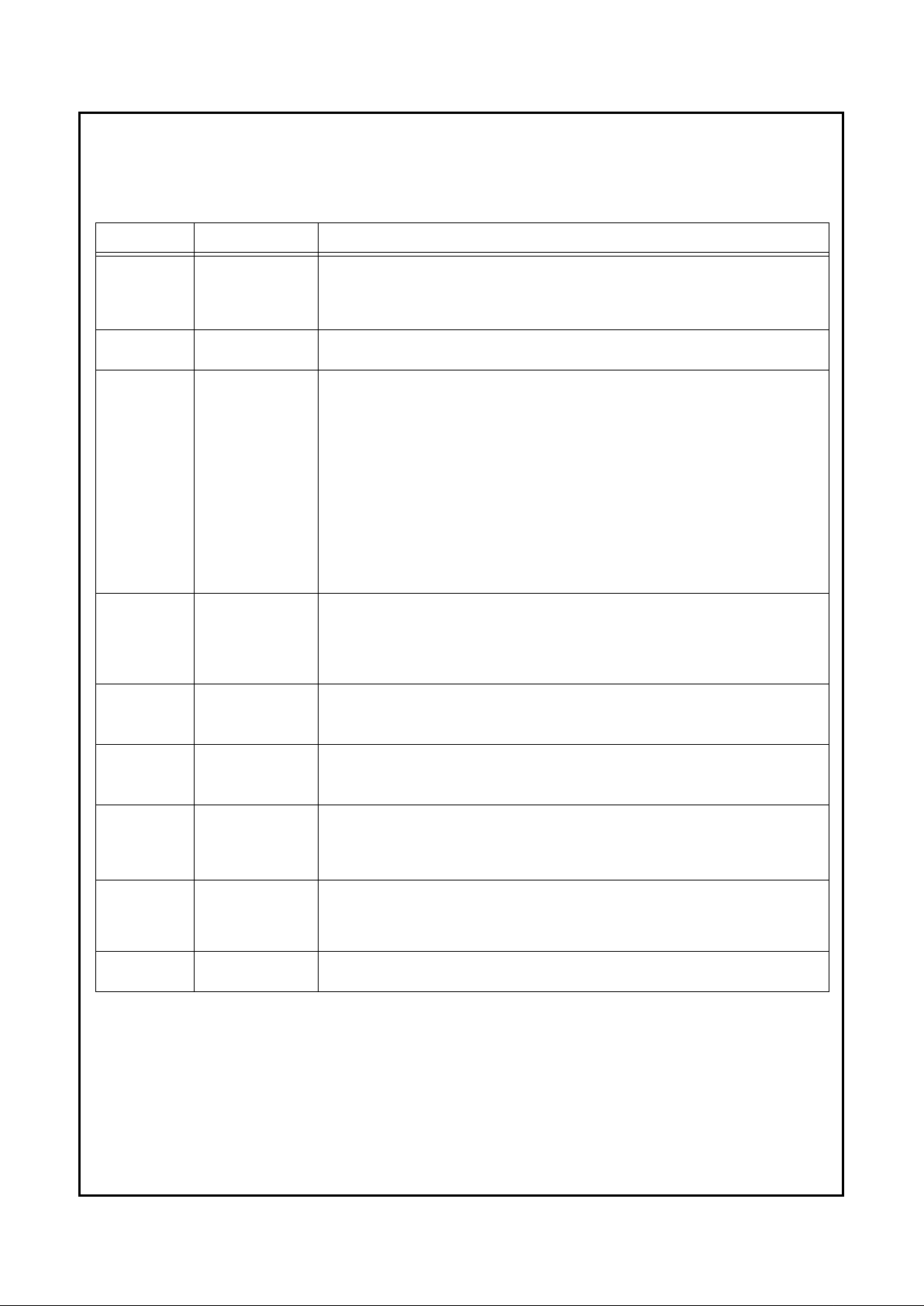

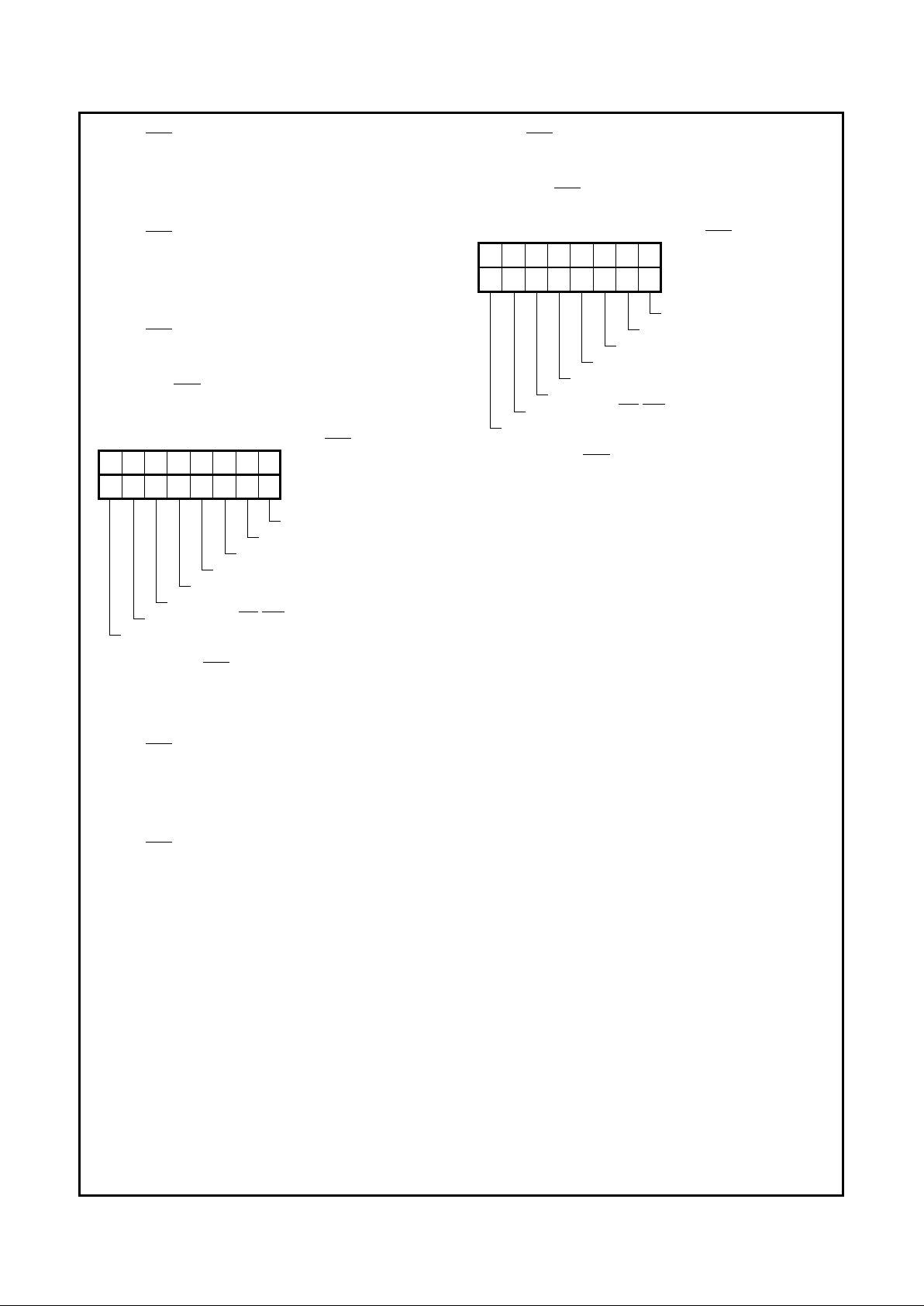

1.0 Signal/Pin Connection and Description

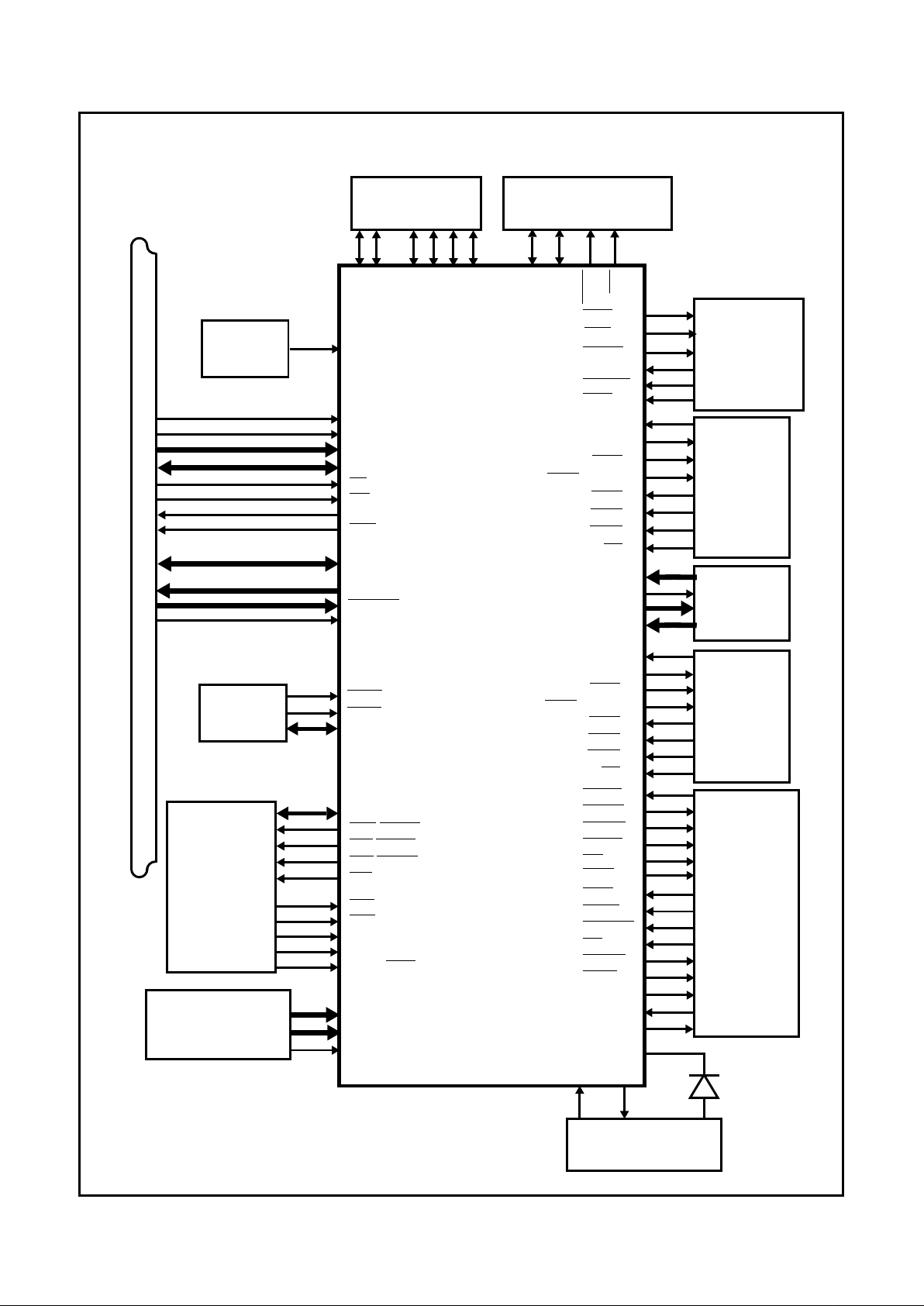

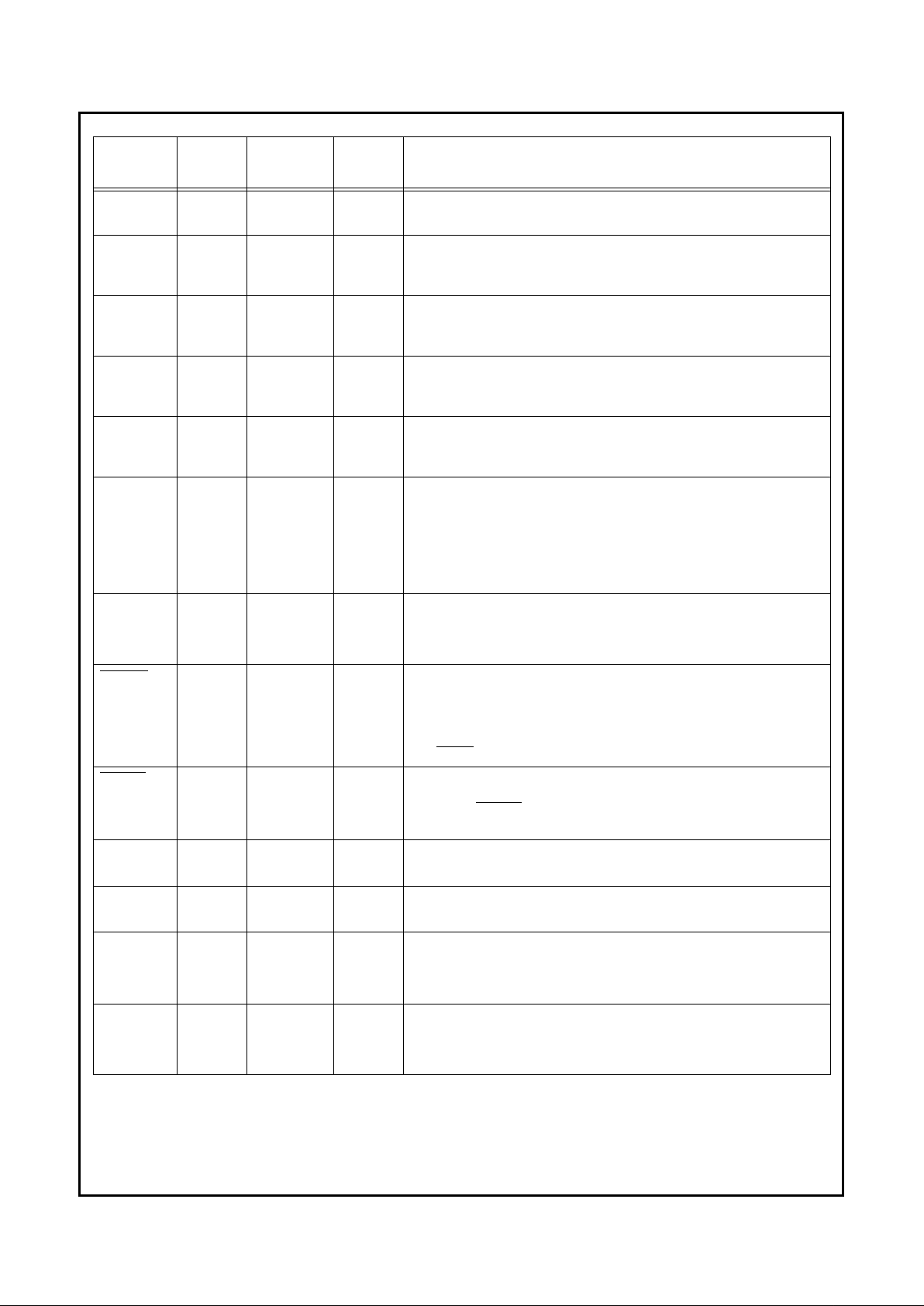

1.1 CONNECTION DIAGRAM

80

75

70

65

60

55

50

1 5 10 15 20 25 30

859095100

4035

PC87307/PC97307

105110115120

45

41

81

121

125

130

135

140

145

150

155

160

A1

A2

V

SS

V

DD

A3A4A5A6A7A8A9

A10

A11

A12

A13

IOCHRDY

RD

ZWS

WGATE

TRK0WPRDATA

HDSEL

A0

MTR1

DSKCHG

DIR

STEP

WDATA

MSEN1

DENSEL

INDEX

MTR0

DR1

DR0

XDRD/ID3

MSEN0

V

DD

P21

P20

P17

P16

P12

GPIO10

GPIO11

GPIO12

GPIO13

CS2/XD1

STB/WRITE

V

SS

V

DD

SLIN/ASTRB

SLCTPEBUSY/

WAIT

ACK

V

DD

INIT

D7

CS1/XD0

X1

V

SS

D0D1D2D3D4D5D6

MR

X2C

V

CCH

A15

A14

V

BAT

X1C

VSSVDDKBCLK

KBDAT

MDAT

MCLK

IRQ15

IRQ14

IRQ12

IRQ11

DACK3

DRATE0

DTR1/BADDR0/BOUT1

RI1

DCD1

DSR1

SIN1

RTS1/BADDR1

SOUT1/CFG0

CTS1

IRQ10

AEN

WR

TC

IRQ9

IRQ8

IRQ7

IRQ6

IRQ1

IRQ3

IRQ4

IRQ5

GPIO14

GPIO15

GPIO16

GPIO17/WDO

GPIO20/IRSL1/ID1

GPIO21/IRSL2/IRSL0/ID2

GPIO22/POR

V

SS

V

DD

DRQ1

DRQ0

DACK2

DACK1

DACK0

DRQ2

DRQ3

ERR

V

SS

V

SS

V

SS

DTR2/CFG1/BOUT2

RI2

DCD2

DSR2

SIN2

RTS2/CFG2

SOUT2/CFG3

CTS2

AFD/DSTRB

PD0

PD1

PD2

PD3

PD4

PD5

PD6

PD7

V

SS

IRTX

IRRX1

IRRX2/IRSL0/ID0

IRSL1/XD7/ID1

IRSL2/XD6/SELCS/GPIO21

GPIO27/XD5

GPIO26/XD4

GPIO25/XD3

GPIO24/XD2

CS0/CSOUT-NSC-Test

ONCTL

SWITCH

RING/XDCS

GPIO23/

RING

Order Number PC87307VUL/PC97307VUL

See NS Package Number VUL160A

PlasticQuad Flatpack (PQFP), EIAJ

Page 15

15

Signal/Pin Connection and Description

www.national.com

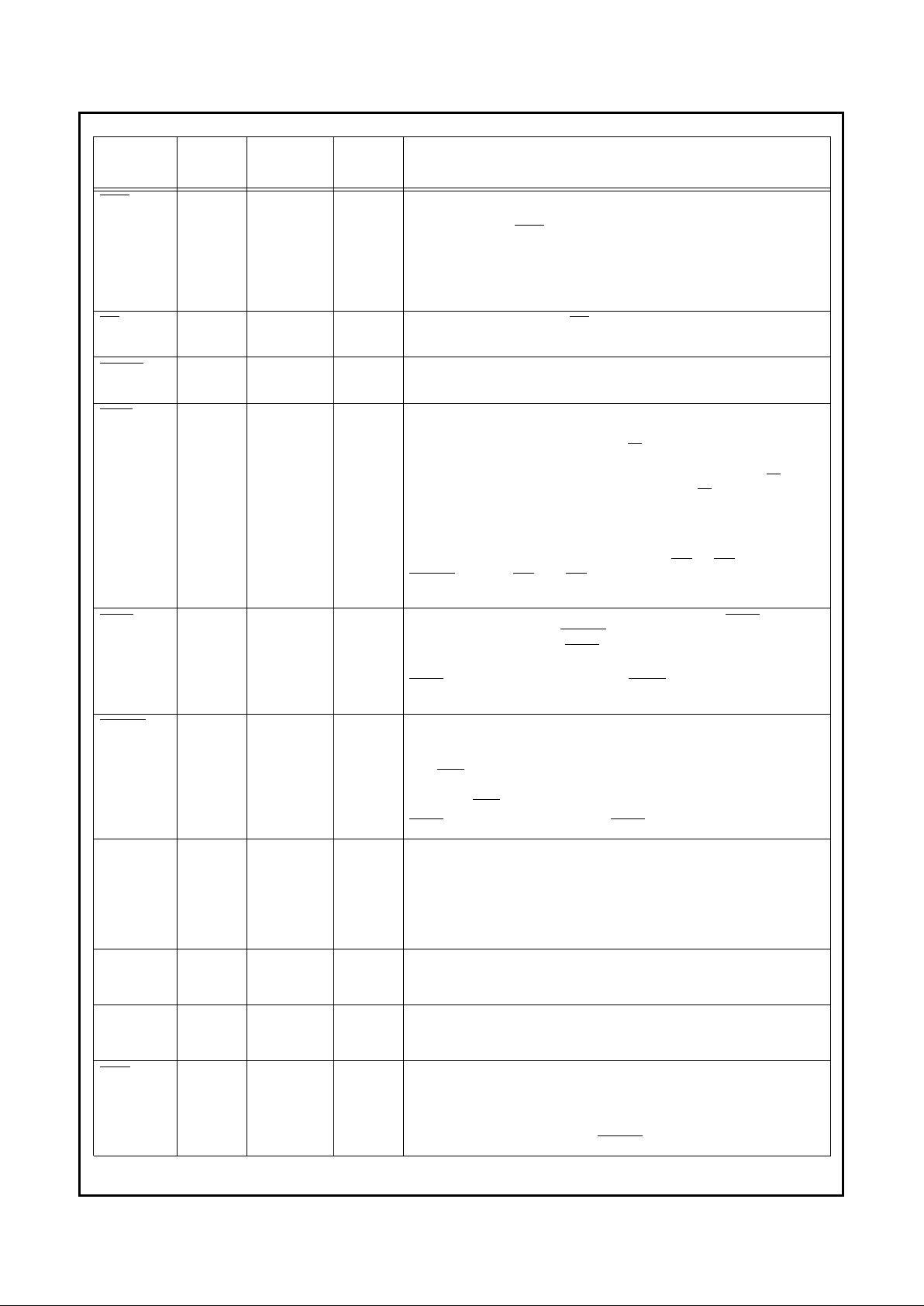

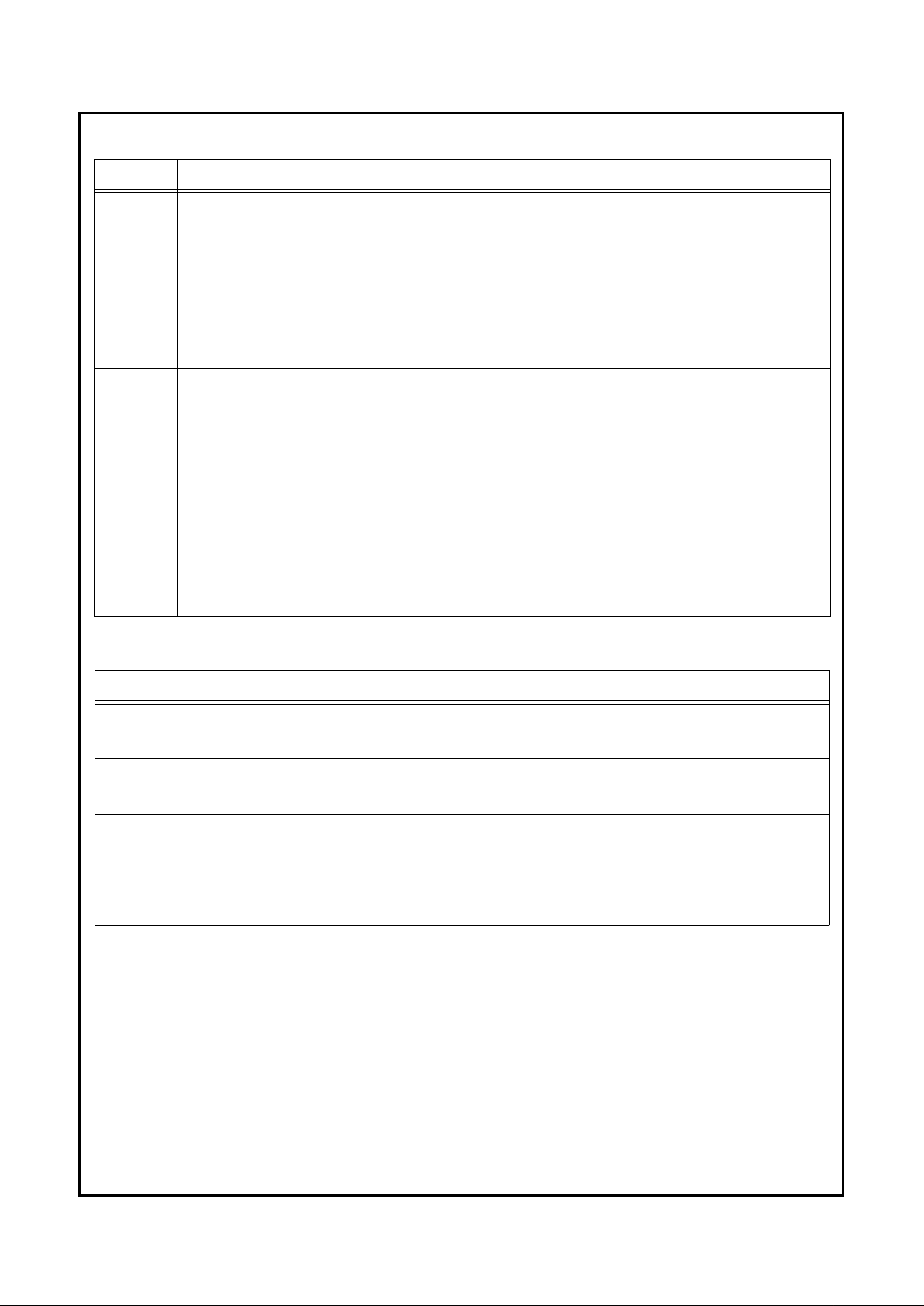

1.2 SIGNAL/PIN DESCRIPTIONS

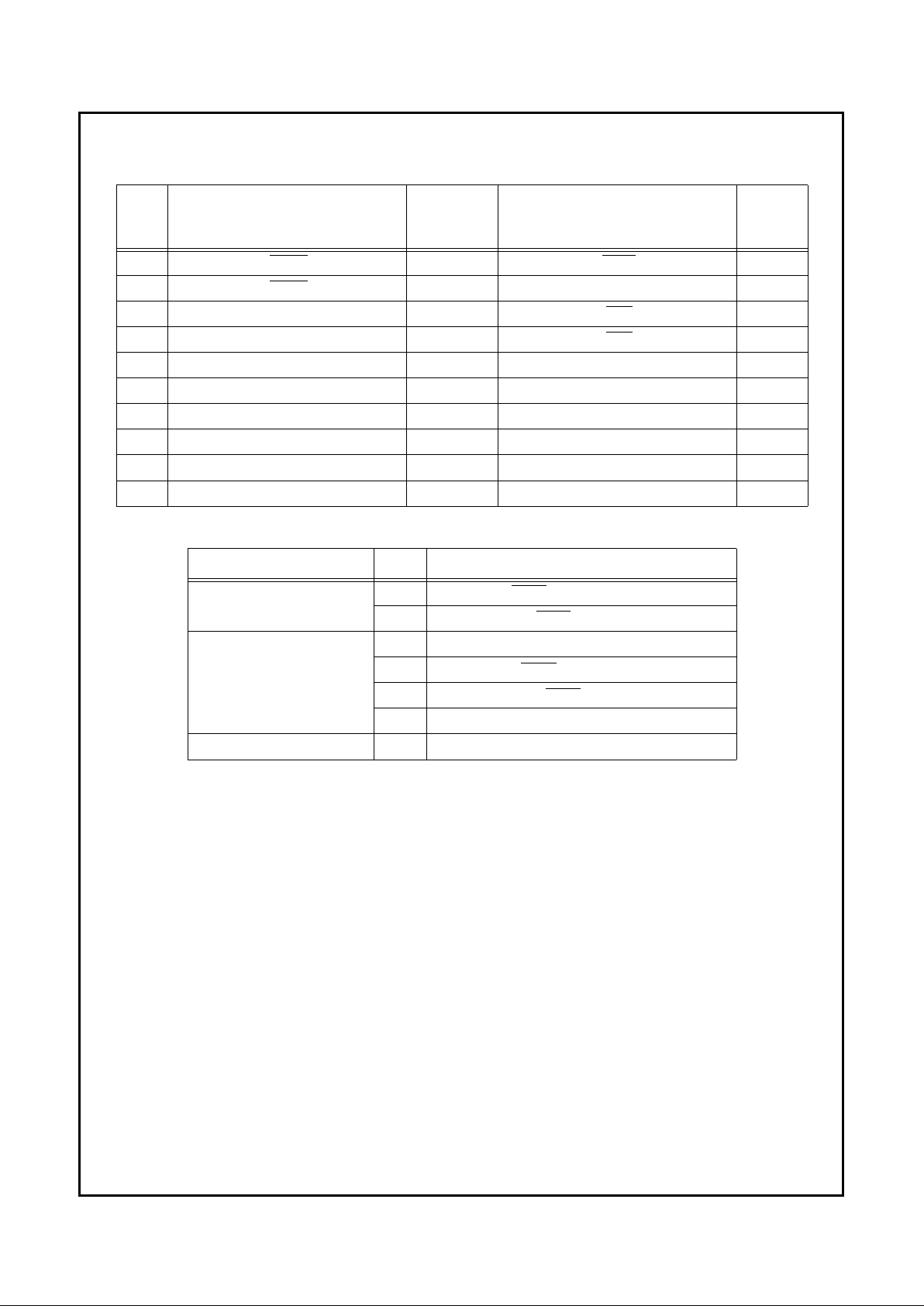

Table 1-1 lists the signals of the part in alphabetical order and shows the pin(s) associated with each. Table 1-2 on page 23

lists the X-Bus Data Buffer (XDB) signals that are multiplexed and Table 1-3 on page 23 lists the pins that have strap functions during reset.

The Module column indicates the functional module that is associated with these pins. In this column, the System label indicates internal functions that are common to more than one module.

The I/O and Group # column describes whether the pin is an input, output, or bidirectional pin (marked as Input, Output or

I/O, respectively). This column also specifies the DC characteristics group to which this pin belongs. See Section 13.2 on

page 183 for details.

Refer to the glossary for an explanation of abbreviations and terms used in this table, and throughout this document. Use

the Table of Contents to find more information about each register.

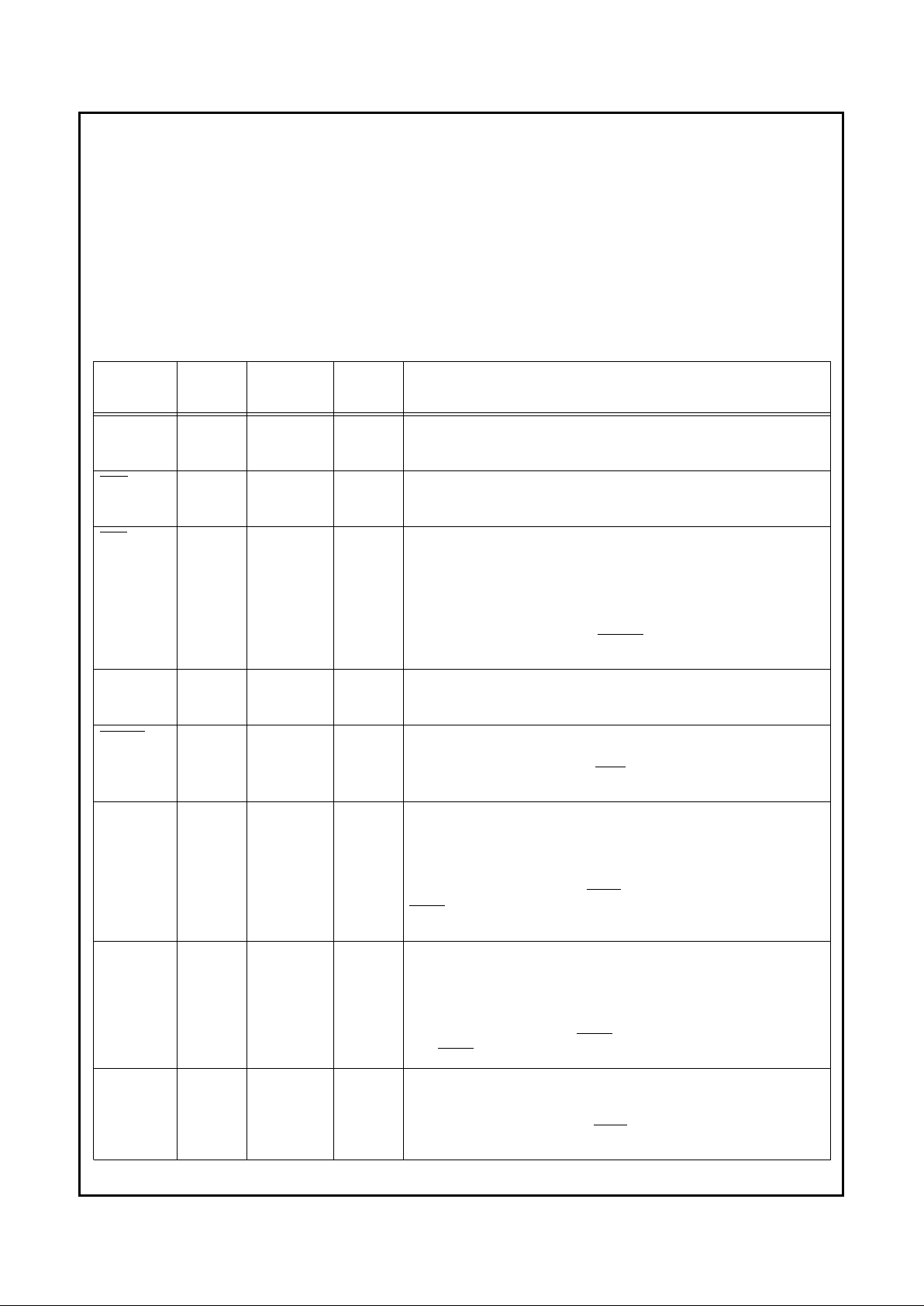

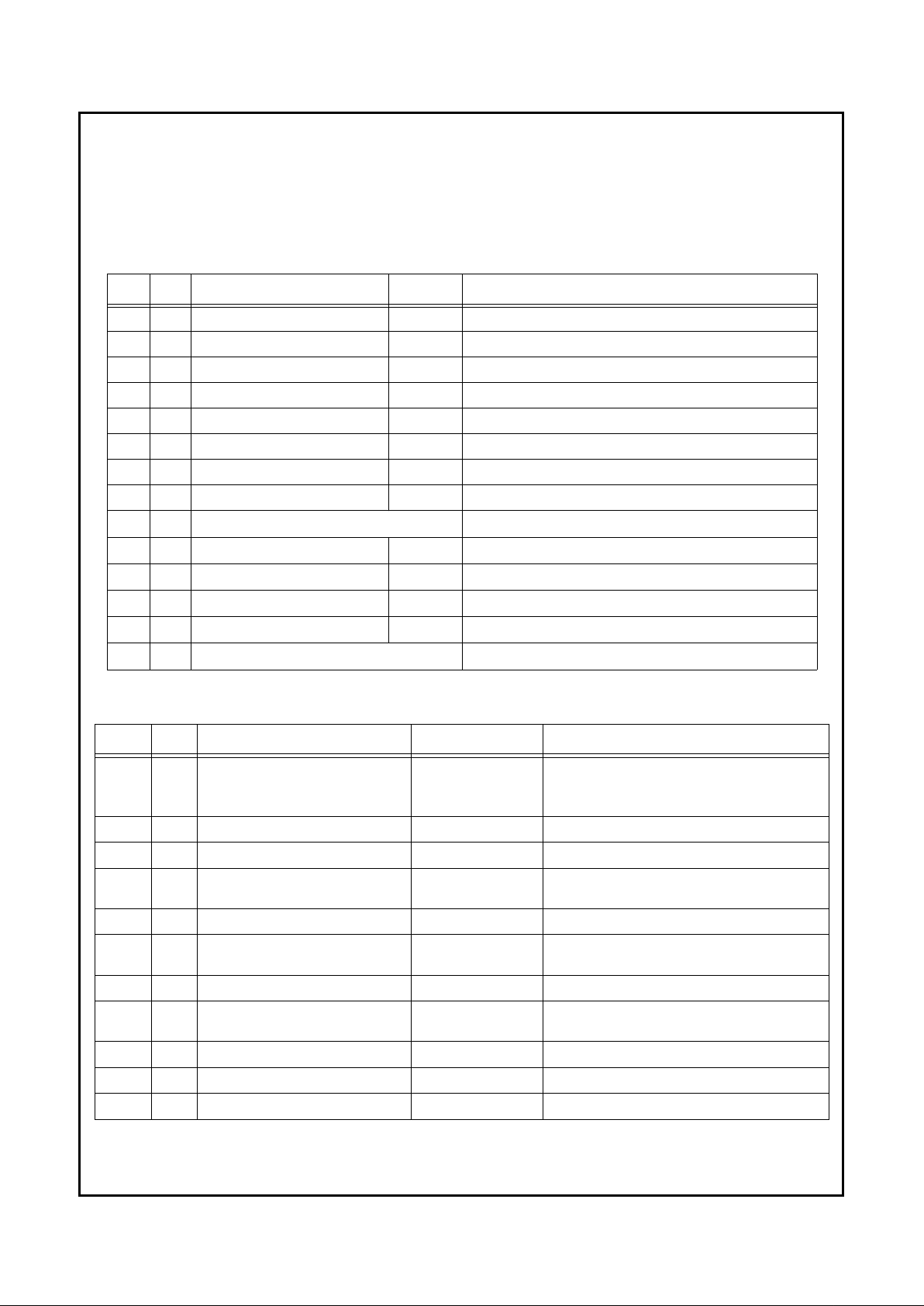

TABLE 1-1. Signal/Pin Description Table

Signal/Pin

Name

Pin

Number

Module

I/O and

Group #

Function

A15-0 29-26,

23-12

ISA-Bus Input

Group 1

ISA-Bus Address – A15-0 are used for address decoding on any

access except DMA accesses, on the condition that the AEN signal

is low. See Address Decoding in Section 2.2.2 on page 25.

ACK 113 Parallel Port Input

Group 3

Acknowledge – This input signal is pulsed low by the printer to

indicate that it has received data from the parallel port. It is pulled up

by an internal nominal 25 KΩ pull-up resistor.

AFD 119 Parallel Port I/O

Group 13

Automatic Feed – When this signal is low the printer should

automatically feed a line after printing each line. This pin is in TRISTATE after a 0 is loaded into the corresponding control register bit.

An external 4.7 KΩ pull-up resistor should be attached to this pin.

For Input mode see bit 5 in “Control0, Second Level Offset 00h” on

page 126.

This signal is multiplexed with DSTRB. See Table 6-12 on page 134

for more information.

AEN 30 ISA-Bus Input

Group 1

DMA Address Enable – This input signal disables function selection

via A15-0 when it is high. Access during DMA transfer is not affected

by this signal.

ASTRB 118 Parallel Port Output

Group 1

Address Strobe (EPP) – This signal is used in EPP mode as an

address strobe. It is active low.

This signal is multiplexed with

SLIN. See Table 6-12 on page 134 for

more information.

BADDR1,0 136, 134 Configuration Input

Group 5

Base Address Strap Pins 0 and 1 – These pins determine the base

addresses of the Index and Data registers, the value of the Plug and

Play ISA Serial Identifier and the configuration state immediately after

reset. These pins are pulled down by internal 30 KΩ resistors.

External 10 KΩ pull-up resistors to V

DD

should be employed.

BADDR1 is multiplexed with

RTS1. BADDR0 is multiplexed with

DTR1 and BOUT1. See Table 2-2 on page 25 and Section 2.1 on

page 24.

BOUT2,1 144, 134 UART1,

UART2

Output

Group 17

Baud Output – This multi-function pin provides the associated serial

channel Baud Rate generator output signal if test mode is selected,

i.e., bit 7 of the EXCR1 register is set. (See Section “Bit 7 - Baud

Generator Test (BTEST)” on page 155.)

After Master Reset this pin provides the SOUT function.

BOUT2 is multiplexed with

DTR2 and CFG1. BOUT1 is multiplexed

with

DTR1 and BADDR0.

BUSY 111 Parallel Port Input

Group 2

Busy – This pin is set high by the printer when it cannot accept

another character. It is internally connected to a nominal 25 KΩ pulldown resistor.

This signal is multiplexed with

WAIT. See Table 6-12 on page 134 for

more information.

Page 16

16

Signal/Pin Connection and Description

www.national.com

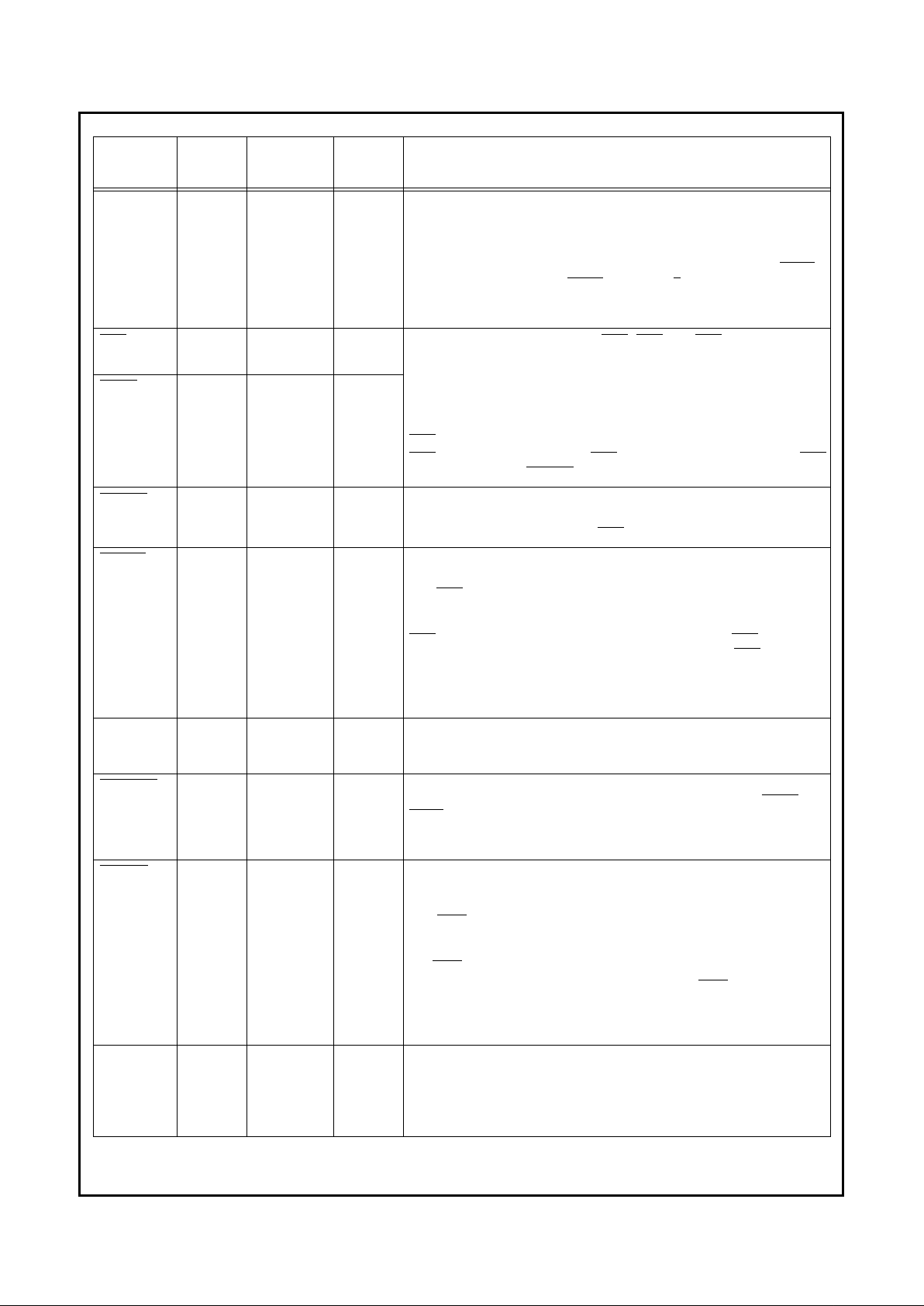

CFG3-0 148, 146,

144, 138

Configuration Input

Group 5

Configuration Strap Pins 3-0 – These pins determine the default

configuration upon power up. These pins are pulled down by internal

30 KΩ resistors. External 10 KΩ pull-up resistors to V

DD

should be

employed.

CFG3 is multiplexed with SOUT2. CFG2 is multiplexed with

RTS2.

CFG1 is multiplexed with

DTR2 and BOUT2. CFG0 is multiplexed

with SOUT1. See Table 2-2 on page 25 and Section 2.1 on page 24

for more information.

CS0 68 General

Purpose

Output

Group 21

Programmable Chip Select – CS0, CS1 and CS2 are

programmable chip select and/or latch enable and/or output enable

signals that have many uses, for example, as game ports or for I/O

port expansion.

The decoded address and the assertion conditions are configured via

the chip configuration registers. See Section 2.3 on page 26.

CS0 is an open-drain pin that is in TRI-STATE unless VDD is applied.

CS2 is multiplexed with XD1, CS1 is multiplexed with XD0, and CS0

is multiplexed with

CSOUT-NSC-Test.

CS2,1 72, 71 General

Purpose

I/O

Group 9

CSOUTNSC-Test

68 NSC use Output

Group 21

Chip Select Read Output, NSC-Test – National Semiconductor test

output. This is an open-drain output signal.

This signal is multiplexed with

CS0.

CTS2,1 141, 131 UART1,

UART2

Input

Group 1

UART1 and UART2 Clear to Send – When low, these signals indicate

that the modem or other data transfer device is ready to exchange data.

The

CTS signal is a modem status input signal whose condition the

CPU can test by reading bit 4 (CTS) of the Modem Status Register

(MSR) for the appropriate serial channel. Bit 4 is the complement of the

CTS signal. Bit 0 (DCTS) of MSR indicates whether the CTS input signal

has changed state since the previous reading of MSR.

CTS has no

effect on the transmitter.

Whenever the DCTS bit of the MSR is set, an interrupt is generated

if modem status interrupts are enabled.

D7-0 10-3 ISA-Bus I/O

Group 8

ISA-Bus Data – Bidirectional data lines to the microprocessor. D0 is

the LSB and D7 is the MSB. These signals have 24 mA (sink)

buffered outputs.

DACK3-0 59-56 ISA-Bus Input

Group 1

DMA Acknowledge 0,1,2 and 3 – These active low input signals

acknowledge a request for DMA services and enable the

IOWR and

IORD input signals during a DMA transfer. These DMA signals can

be mapped to the following logical devices: FDC, UART1, UART2 or

parallel port.

DCD2,1 142, 132 UART1,

UART2

Input

Group 1

UART1 and UART2 Data Carrier Detected – When low, this signal

indicates that the modem or other data transfer device has detected

the data carrier.

The

DCD signal is a modem status input signal whose condition the

CPU can test by reading bit 7 (DCD) of the Modem Status Register

(MSR) for the appropriate serial channel. Bit 7 is the complement of

the

DCD signal.

Bit 3 (DDCD) of the MSR indicates whether the

DCD input signal has

changed state since the previous reading of MSR. Whenever the

DDCD bit of the MSR is set, an interrupt is generated if modem

status interrupts are enabled.

DENSEL 94 FDC Output

Group 16

Density Select (FDC) – Indicates that a high FDC density data rate

(500 Kbps or 1 Mbps) or a low density data rate (250 or 300 Kbps)

is selected.

DENSELs polarity is controlled by bit 5 of the SuperI/O FDC

Configuration register as described in Section 2.6.1 on page 36.

Signal/Pin

Name

Pin

Number

Module

I/O and

Group #

Function

Page 17

17

Signal/Pin Connection and Description

www.national.com

DIR 90 FDC Output

Group 16

Direction (FDC) – This output signal determines the direction of the

Floppy Disk Drive (FDD) head movement (active = step in, inactive =

step out) during a seek operation. During reads or writes,

DIR is

inactive.

DR1,0 88, 87 FDC Output

Group 16

Drive Select 0 and 1 (FDC) – These active low output signals are

the decoded drive select output signals.

DR0 and DR1 are controlled

by Digital Output Register (DOR) bits 0 and 1. They are encoded with

information to control four FDDs when bit 7 of the SuperI/O FDC

Configuration register is 1, as described in Section 2.6.1 on page 36.

See

MTR0,1 for more information.

DRATE0 84 FDC Output

Group 20

Data Rate 0 (FDC) – This output signal reflects the value of bit 0 of

the Configuration Control Register (CCR) or the Data Rate Select

Register (DSR), whichever was written to last. Output from the pin is

totem-pole buffered (6 mA sink, 6 mA source).

DRQ3-0 55-52 ISA-Bus Output

Group 18

DMA Request 0, 1, 2 and 3 – These active high output signals

inform the DMA controller that a data transfer is needed. These DMA

signals can be mapped to the following logical devices: Floppy Disk

Controller (FDC), UART1, UART2 or parallel port.

DSKCHG 99 FDC Input

Group 1

Disk Change (FDC) – This input signal indicates whether or not the

drive door has been opened. The state of this pin is available from

the Digital Input Register (DIR). This pin can also be configured as

the RGATE data separator diagnostic input signal via the MODE

command. See the MODE command in Section 5.7.7 starting on

page 92.

DSR2,1 143, 133 UART1,

UART2

Input

Group 1

Data Set Ready – When low, this signal indicates that the data

transfer device, e.g., modem, is ready to establish a communications

link.

The

DSR signal is a modem status input signal whose condition the

CPU can test by reading bit 5 (DSR) of the Modem Status Register

(MSR) for the appropriate channel. Bit 5 is the complement of the

DSR signal. Bit 1 (DDSR) of the MSR indicates whether the DSR

input signal has changed state since the previous reading of the

MSR.

Whenever the DDSR bit of the MSR is set, an interrupt is generated

if modem status interrupts are enabled.

DSTRB 119 Parallel Port Output

Group 23

Data Strobe (EPP) – This signal is used in EPP mode as a data

strobe. It is active low.

DSTRB is multiplexed with AFD. See Table 6-12 on page 134 for

more information.

DTR2,1 144, 134 UART1,

UART2

Output

Group 17

Data Terminal Ready – When low, this output signal indicates to the

modem or other data transfer device that the UART1 or UART2 is

ready to establish a communications link.

The

DTR signal can be set active low by programming bit 0 (DTR) of

the Modem Control Register (MCR) to high (1).

A Master Reset (MR) deactivates this signal high, and loopback

operation holds this signal inactive.

DTR2 is multiplexed with CFG1 and BOUT2. DTR1 is multiplexed

with BADDR0 and BOUT1.

ERR 116 Parallel Port Input

Group 3

Error – This input signal is set active low by the printer when it has

detected an error. This pin is internally connected to a nominal 25 KΩ

pull-up resistor.

GPIO17-10 156-149 General

Purpose

I/O

Group 10

General Purpose I/O Signals 17-10 – General purpose I/O signals

of I/O Port 1.

GPIO17 is multiplexed with

WDO.

Signal/Pin

Name

Pin

Number

Module

I/O and

Group #

Function

Page 18

18

Signal/Pin Connection and Description

www.national.com

GPIO20

GPIO21

GPIO22

GPIO23

GPIO27-24

157

77, 158

159

160

76-73

General

Purpose

I/O

Group 10

General Purpose I/O Signals 27-20 – General purpose I/O port 2

signals.

GPIO27-24 are multiplexed with XD5-2, respectively.

GPIO23 is multiplexed with

RING.

GPIO22 is multiplexed with

POR.

GPIO21 is multiplexed on pin 158 with IRSL2, IRSL0 and on pin 77

with IRSL2, SELCS and XD6. See “SuperI/O Configuration 2

Register, Index 22h” on page 35.

GPIO20 is multiplexed with IRSL1.

HDSEL 92 FDC Output

Group 16

Head Select – This output signal determines which side of the FDD

is accessed. Active low selects side 1, inactive selects side 0.

ID0

ID1

ID2

ID3

79

78 or 157

158

70

UART2 Input

Group 1

Identification – These ID signals identify the infrared transceiver for

Plug and Play support. These pins are read after reset.

ID0 is multiplexed on pin 79 with IRRX2 and IRSL0.

ID1 is multiplexed on pin 78 with IRSL1 and XD7, or on pin 157 with

GPIO20 and IRSL1.

ID2 is multiplexed on pin 158 with GPIO21, IRSL2 and IRSL0.

ID3 is multiplexed on pin 70 with

XDRD.

See Table 1-2 on page 23 for more information.

INDEX 97 FDC Input

Group 1

Index – This input signal indicates the beginning of an FDD track.

INIT 117 Parallel Port I/O

Group 13

Initialize – When this signal is active low, it causes the printer to be

initialized. This signal is in TRI-STATE after a 1 is loaded into the

corresponding control register bit.

An external 4.7 KΩ pull-up resistor should be employed.

IOCHRDY 32 ISA-Bus Output

Group 22

I/O Channel Ready – This is the I/O channel ready open drain

output signal. When IOCHRDY is driven low, the EPP extends the

host cycle.

IRQ1

IRQ5-3

IRQ12-6

IRQ15,14

36

39-37

47-41

49,48

ISA-Bus I/O

Group 15

Interrupt Requests 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 14 and 15 – IRQ

polarity and push-pull or open-drain output selection is software

configurable by the logical device mapped to the IRQ line.

Keyboard Controller (KBC) or Mouse interrupts can be configured by

the Interrupt Request Type Select 0 register (index 71h) as either

edge or level.

The parallel port interrupt is either edge or level, according to the

operation mode (default edge, configured by the SuperI/O Parallel

Port Configuration register at index F0h).

IRRX2,1 79, 80 UART2

(SIR)

Input

Group 1

Infrared Reception 1 and 2 – Infrared serial input data.

IRRX2 is multiplexed with IRSL0 and ID0. See Table 1-2 on page 23

for more information.

IRSL0

IRSL1

IRSL2

79 or 158

78 or 157

77 or 158

UART2

(SIR)

Output

Infrared Control Signals 0, 1 and 2 – These signals control the

Infrared analog front end. The pins on which these signals are driven

is determined by the SuperI/O Configuration 2 register (index 22h).

See Section 2.4.4 on page 35. IRSL0 or ID0/IRRX2 on pin 79 is

determined by UART2 bit 5 of the IRCFG4 register (See page 165).

IRSL0 is multiplexed on pin 79 with IRRX2 and ID0, or on pin 158

with GPIO21, IRSL2 and ID2.

IRSL1 is multiplexed on pin 78 with XD7 and ID1, or on pin 157 with

GPIO20 and ID1.

IRSL2 is multiplexed on pin 77 with XD6, SELCS and GPIO21, or on

pin 158 with GPIO21, IRSL0 and ID2.

79, 78, 77

Group 17

158, 157

Group 10

Signal/Pin

Name

Pin

Number

Module

I/O and

Group #

Function

Page 19

19

Signal/Pin Connection and Description

www.national.com

IRTX 81 UART2

(SIR)

Output

Group 19

Infrared Transmit – Infrared serial output data.

KBCLK 102 KBC I/O

Group 11

Keyboard Clock – This I/O pin transfers the keyboard clock between

the SuperI/O chip and the external keyboard using the PS/2 protocol.

This pin is connected internally to the internal TO signal of the KBC.

KBDAT 103 KBC I/O

Group 11

Keyboard Data – This I/O pin transfers the keyboard data between

the SuperI/O chip and the external keyboard using the PS/2 protocol.

This pin is connected internally to KBC’s P10.

MCLK 104 KBC I/O

Group 11

Mouse Clock – This I/O pin transfers the mouse clock between the

SuperI/O chip and the external keyboard using the PS/2 protocol.

This pin is connected internally to KBC’s T1.

MDAT 105 KBC I/O

Group 11

Mouse Data – This I/O pin transfers the mouse data between the

SuperI/O chip and the external keyboard using the PS/2 protocol.

This pin is connected internally to KBC’s P11.

MR 51 ISA-Bus Input

Group 1

Master Reset – An active high MR input signal resets the controller

to the idle state, and resets all disk interface output signals to their

inactive states. MR also clears the DOR, DSR and CCR registers,

and resets the MODE command, CONFIGURE command, and LOCK

command parameters to their default values. MR does not affect the

SPECIFY command parameters. MR sets the configuration registers

to their selected default values.

MSEN1,0 83, 82 FDC Input

Group 4

Media Sense – These input pins are used for media sensing when

bit 6 of the SuperI/O FDC Configuration register (at index F0h) is 1.

See Section 2.6.1 on page 36. Each pin has a 40 KΩ internal pull-up

resistor.

MTR1,0 86, 85 FDC Output

Group 16

Motor Select 1,0 – These motor enable lines for drives 0 and 1 are

controlled by bits D7-4 of the Digital Output Register (DOR). They are

output signals that are active when they are low. They are encoded with