Page 1

PC356NT/PC358

PC356NT/PC358

Mini-Flat Package,

High Collector-emitter Voltage

Type Photocoupler

■ Features

1. High collector-emitter voltage

(PC358 •••V

: 120V, PC356NT•••V

CEO

2. Opaque type, mini-flat package

PC356NT/

3. Subminiature type

(The volume is smaller than that of our

PC358 (1-channel

conventional DIP type by as far as 30%.

)

)

4. Isolation voltage between input and output

PC356NT/ •••V

5. Recognized by UL (No. E64380

■ Applications

PC358

: 3 750V

iso

rms

)

1. Hybrid substrates that require high density

mounting

2. Programmable controllers

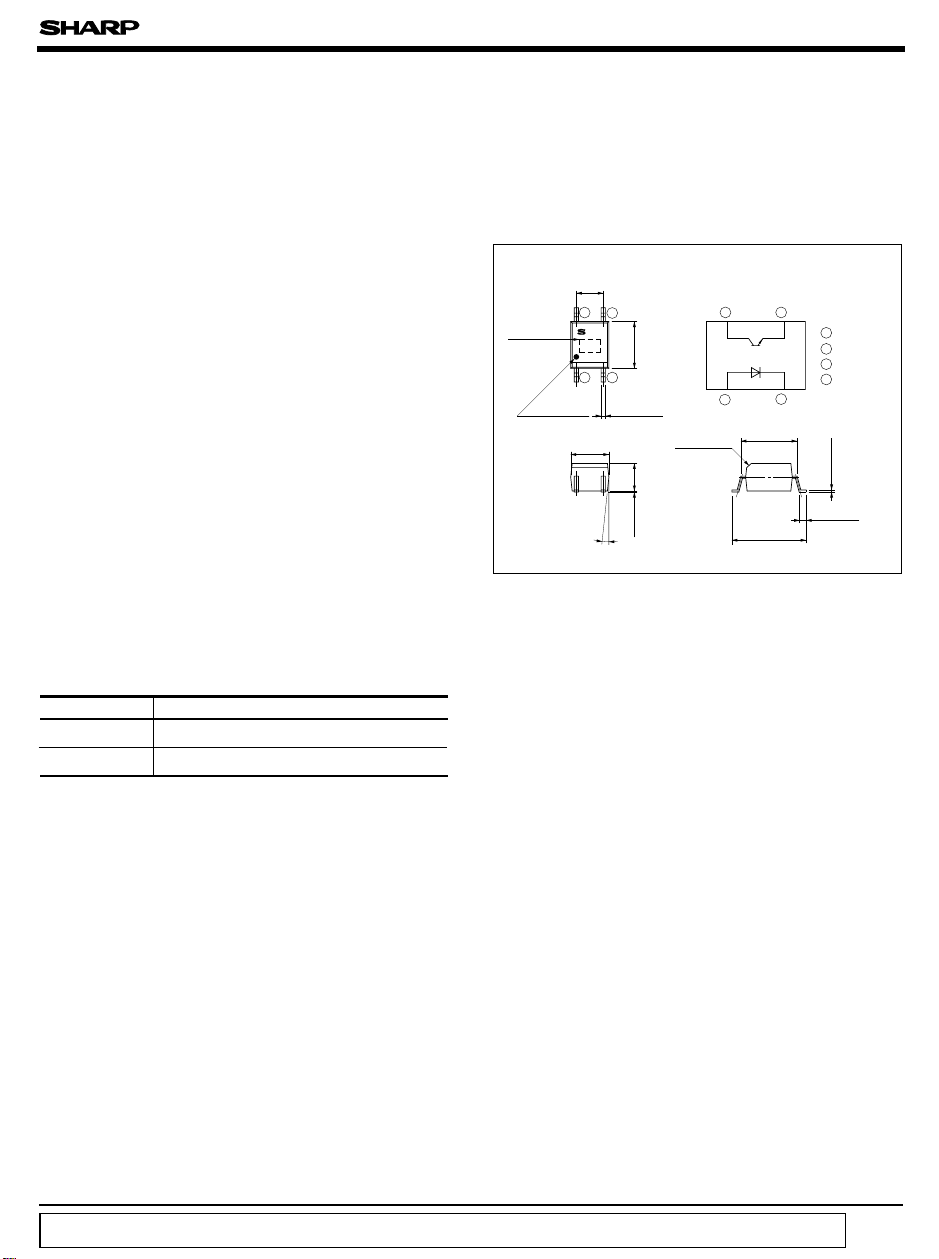

■ Package Specifications

Model No. Package specifications

PC356NT

PC358

Taping reel diameter 178mm (750pcs.

Taping reel diameter 370mm (3000pcs.

CEO

: 80V

■ Outline Dimensions

PC356NT/PC358

)

)

)

Model No.

356/358

Anode

mark

2.54

3.6

(

Unit : mm

± 0.2

4.4

± 0.1

± 0.2

2.6

± 0.1

0.1

Internal connection

diagram

12

5.3

C0.4

Input side

7.0

± 0.3

+ 0.2

- 0.7

34

± 0.25

4

3

21

0.4

± 0.3

6˚

1 Anode

2 Cathode

3 Emitter

4 Collector

± 0.05

0.2

+ 0.4

0.5

- 0.2

)

“ In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in equipment using any of SHARP's devices, shown in catalogs,

data books, etc. Contact SHARP in order to obtain the latest version of the device specification sheets before using any SHARP's device. ”

Page 2

PC356NT/PC358

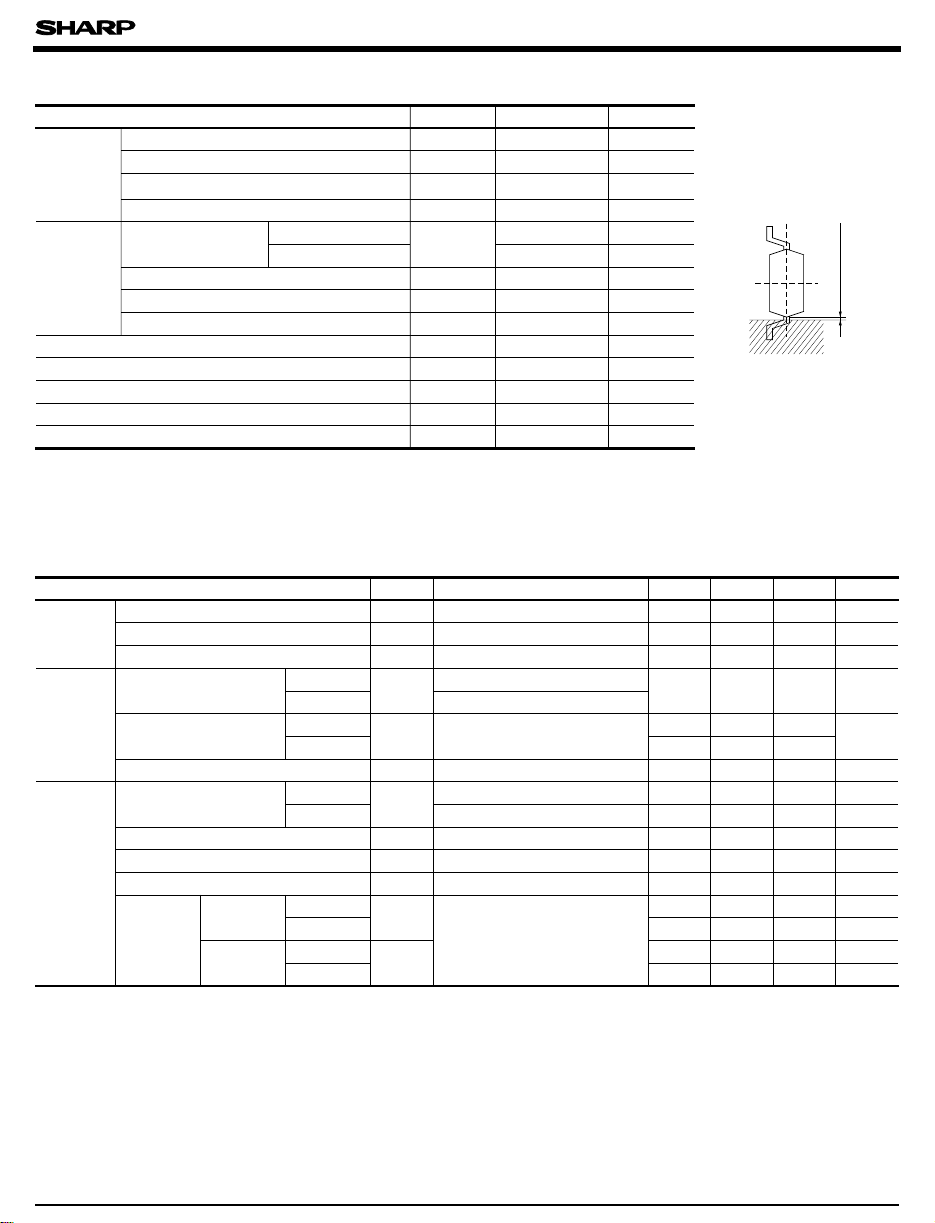

■ Absolute Maximum Ratings

Parameter

Forward current

*1

Input

Peak forward current

Reverse voltage

Power dissipation

PC356NT

PC358

Output

Collector-emitter

voltage

Emitter-collector voltage

Collector current

Collector power dissipation

Total power dissipation

*2

Isolation voltage

Operating temperature

Storage temperature

*3

Soldering temperature

*1 Pulse width<=100µs, Duty ratio : 0.001

*2 40 to 60%RH, AC for 1 minute

*3 For 10 senconds

■ Electro-optical Characteristics

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Forward voltage V

Input

Output

Transfercharacteristics

Reverse current

Terminal capacitance

Collector dark current

Collector-emitter

breakdown voltage

PC356NT

PC358

PC356NT

PC358

Emitter-collector breakdown voltage

Current transfer ratio

PC356NT

PC358

Collector-emitter saturation voltage

Isolation resistance R

Floating capacitance C

PC356NT

PC358

PC356NT

PC358

Response

time

Rise time

Fall time

Symbol Rating Unit

50 mA

1A

6V

70 mW

80 V

6V

50 mA

150 mW

170 mW

3 750

- 30 to + 100

- 40 to + 125

260 ˚C

=0= 20V, I

=0

=5V

CE

=5V

CE

BV

BV

V

I

F

I

FM

V

R

P

V

CEO

V

ECO

I

C

P

C

P

tot

V

iso

T

opr

T

stg

T

sol

= 20mA - 1.2 1.4 V

FIF

VR=4V -

I

R

V= 0, f= 1kHz

C

t

V

I

CEO

CTR

CE(sat

CE F

V

= 40V, I

CE F

= 0.1mA, IF=0

CEOIC

I=10µA, I = 0 6 - - V

EF

ECO

= 1mA, V 100

I

F

I

= 5mA, V

F

)

IF= 20mA, IC= 1mA - 0.2 V

DC500V, 40 to 60%RH

ISO

V= 0, f= 1MHz - 0.6 1.0 pF

f

t

r

VCE= 2V, IC= 2mA

= 100Ω

R

L

t

f

(

Ta= 25˚C

V120

V

˚C

˚C

)

Soldering area

0.2mm or more

rms

(

Ta= 25˚C

-

10

-

30

250

-7

-- A

80

1x10

--

--120

- 400 %

50 600

-%

-

10

5x10

11

10

- Ω

-6-µs

-18µs

4

-8-µs

-18µs

3

)

µA

pF

V

Page 3

PC356NT/PC358

Fig. 1 Forward Current vs.

Ambient Temperature

70

60

)

50

mA

(

F

40

30

20

Forward current I

10

0

0 25 50 75 100 125

-30

Ambient temperature Ta (˚C

)

Fig. 3 Collector Power Dissipation vs.

Ambient Temperature

200

)

mW

150

(

C

100

50

Collector power dissipation P

0

0 25 50 75 100 125

-30

Ambient temperature T

a

(˚C

)

Fig. 5 Peak Forward Current vs. Duty Ratio

Fig. 2 Diode Power Dissipation vs.

Ambient Temperature

100

)

mW

(

80

70

60

40

Diode power dissipation P

20

0

-30

0 50 55 100

)

Ambient temperature T

a

(˚C

Fig. 4 Total Power Dissipation vs.

Ambient Temperature

300

)

250

mW

(

200

tot

170

150

100

50

Total power dissipation P

0

-30

05025 100

Ambient temperature Ta (˚C

)

Fig. 6 Forward Current vs. Forward Voltage

10000

5000

)

2000

mA

(

1000

FM

500

200

100

50

Peak forward current I

20

10

5

-3

5252525

-2

10

Duty ratio

Pulse width <=100µs

T

= 25˚C

a

10

500

200

)

100

mA

(

50

F

20

10

5

Forward current I

1

-1

110

020.5 1.0 1.5 2.0 2.5 3.0 3.5

= 75˚C

T

a

50˚C

Forward voltage VF (V

25˚C

0˚C

- 25˚C

)

Page 4

PC356NT/PC358

Fig. 7-a Current Transfer Ratio vs.

Forward Current

500

)

400

%

(

300

200

Current transfer ratio CTR

100

0

0.1

1 10 100 100101

Forward current I

(

PC356NT

VCE=5V

T

= 25˚C

a

(mA

F

)

)

Fig. 8-a Collector Current vs.

Collector-emitter Voltage

50

40

)

mA

(

C

Collector current I

= 30mA

F

I

30

20

10

0

0

Collector-emitter voltage V

20mA

10mA

5mA

1mA

P

= 150mW

C

(

PC356NT

= 25˚C

T

a

)

(V

CE

)

108642

Fig. 9-a Relative Current Transfer Ratio vs.

Ambient Temperature

150

)

%

(

100

(

PC356NT

IF= 1mA

V

=5V

CE

)

Fig. 7-b Current Transfer Ratio vs.

Forward Current

200

180

)

160

%

(

140

120

100

80

60

Current transfer ratio CTR

40

20

0

0.1

Forward current IF (mA

V

CE

T

a

)

(

PC358

=5V

= 25˚C

)

50

Fig. 8-b Collector Current vs.

Collector-emitter Voltage

30

24

)

mA

(

C

18

12

Collector current I

6

0

= 30mA

I

F

20mA

10mA

1.8 3.6 5.4 7.2 9.0

0

Collector-emitter voltage V

(

PC358

Pc=150mW

5mA

)

(V

CE

)

Fig. 9-b Relative Current Transfer Ratio vs.

Ambient Temperature

150

)

%

(

(

PC358

I

= 5mA

F

V

=5V

CE

)

50

Relative current transfer ratio

0

-30

Ambient temperature T

100

Relative current transfer ratio

40

)

(˚C

a

100200

80

60

50

-30

Ambient temperature T

806040200

100

)

(˚C

a

Page 5

PC356NT/PC358

Fig.10-a Collector-emitter Saturation Voltage

vs. Ambient Temperature

0.16

0.14

0.12

0.10

0.08

)

V

0.06

(

)

sat

(

0.04

CE

Collector-emitter saturation voltage

V

0.02

0

-30

020406080

Ambient temperature T

(

PC356NT

IF= 20mA

I

= 1mA

C

)

(˚C

a

)

100

Fig.11-a Collector Dark Current vs.

Ambient Temperature

-5

10

5

-6

)

10

A

(

5

CEO

-7

10

5

-8

10

5

-9

10

5

Collector dark current I

-10

10

5

-11

10

-30

020406080

Ambient temperature Ta (˚C

(

PC356NT

= 20V

V

CE

)

)(

100

Fig.10-b Collector-emitter Saturation Voltage

vs. Ambient Temperature

0.16

0.14

0.12

0.10

0.08

)

V

(

)

0.06

sat

(

CE

0.04

Collector-emitter saturation voltage

V

0.02

0

-30

020406080

Ambient temperature Ta (˚C

(

PC358

IF= 20mA

I

= 1mA

C

)

)

100

Fig.11-b Collector Dark Current vs.

Ambient Temperature

-5

10

5

-6

)

10

A

(

5

CEO

-7

10

5

-8

10

5

-9

10

5

Collector dark current I

-10

10

5

-11

10

020406080

-30

Ambient temperature Ta (˚C

V

PC358

= 40V

CE

)

)

100

Fig.12-a Response Time vs. Load Resistance Fig.12-b Response Time vs. Load Resistance

500

V

CE

I

C

200

T

a

100

)

50

µs

(

20

10

5

Response time

2

1

0.5

0.2

0.1

0.01

(

PC356NT

=2V

= 2mA

= 25˚C

t

f

t

r

t

d

t

s

Load resistance R Load resistance R

(kΩ

L

)(

V

=2V

CE

I

= 2mA

C

T

= 25˚C

a

)

100

µ s

(

PC358

t

r

t

f

)

10

t

Response time

1

1010.1

0.1

0.01

0.1 1 10

)

d

t

s

100

)

(kΩ

L

Page 6

Input

Test Circuit for Response Time

V

CC

Output

Input

Output

t

d

R

R

D

L

PC356NT/PC358

10%

90%

t

s

t

t

r

f

Fig.13-a Collector-emitter Saturation

Voltage vs. Forward Current

4.8

I

C

3.6

2.4

)

V

(

)

1.2

sat

(

CE

Collector-emitter saturation voltage

V

0

0

Forward current I

= 0.5mA

1mA

3mA

5mA

7mA

(

PC356NT

(mA

F

)

Ta= 25˚C

1512963

)

■ Temperature Profile of Soldering Reflow

30 seconds

230˚C

200˚C

180˚C

1 minute

25˚C

2 minutes 1.5 minutes 1 minute

Fig.13-b Collector-emitter Saturation

Voltage vs. Forward Current

4.8

3.6

2.4

)

V

(

)

sat

(

1.2

CE

V

Collector-emitter saturation voltage

0

(1)

One time soldering reflow is recommended

I

= 0.5mA

C

1.0mA

3.0mA

5.0mA

7.0mA

Forward current IF (mA

(

PC358

= 25˚C

T

a

)

within the condition of temperature and

time profile shown below.

(2)

When using another soldering method such

as infrared ray lamp, the temperature may

rise partially in the mold of the device.

Keep the temperature on the package of

the device within the condition of above (1).

Please refer to the chapter

●

“ Precautions for Use ” .

)

1512963

Loading...

Loading...