Page 1

Description

The PBL 386 61/2 Subscriber Line Interface Circuit (SLIC) is a 90 V bipolar integrated

circuit for use in Central Office, MUX and other telecommunications equipment. The

PBL 386 61/2 has been optimized for low total line interface cost and a high degree of

flexibility in different applications.

The PBL 386 61/2 emulates a transformer equivalent dc-feed, programmable

between 2x25 Ω and 2x900 Ω, with short loop current limiting adjustable to max

65 mA.

A second lower battery voltage may be connected to the device to reduce short

loop power dissipation. The SLIC automatically switches between the two battery

supply voltages without need for external components or external control.

The SLIC incorporates loop current and ring trip detection functions. The

PBL 386 61/2 is compatible with loop start signalling.

Two- to four-wire and four- to two-wire voice frequency (vf) signal conversion is

accomplished by the SLIC in conjunction with either a conventional CODEC/filter or

with a programmable CODEC/filter, e.g. SLAC, SiCoFi, Combo II. The programmable

line terminating impedance could be complex or real to fit every market.

Longitudinal line voltages are suppressed by a feedback loop in the SLIC and the

longitudinal balance specifications meet Bellcore TR909 requirements.

The PBL 386 61/2 package is 28-pin PLCC.

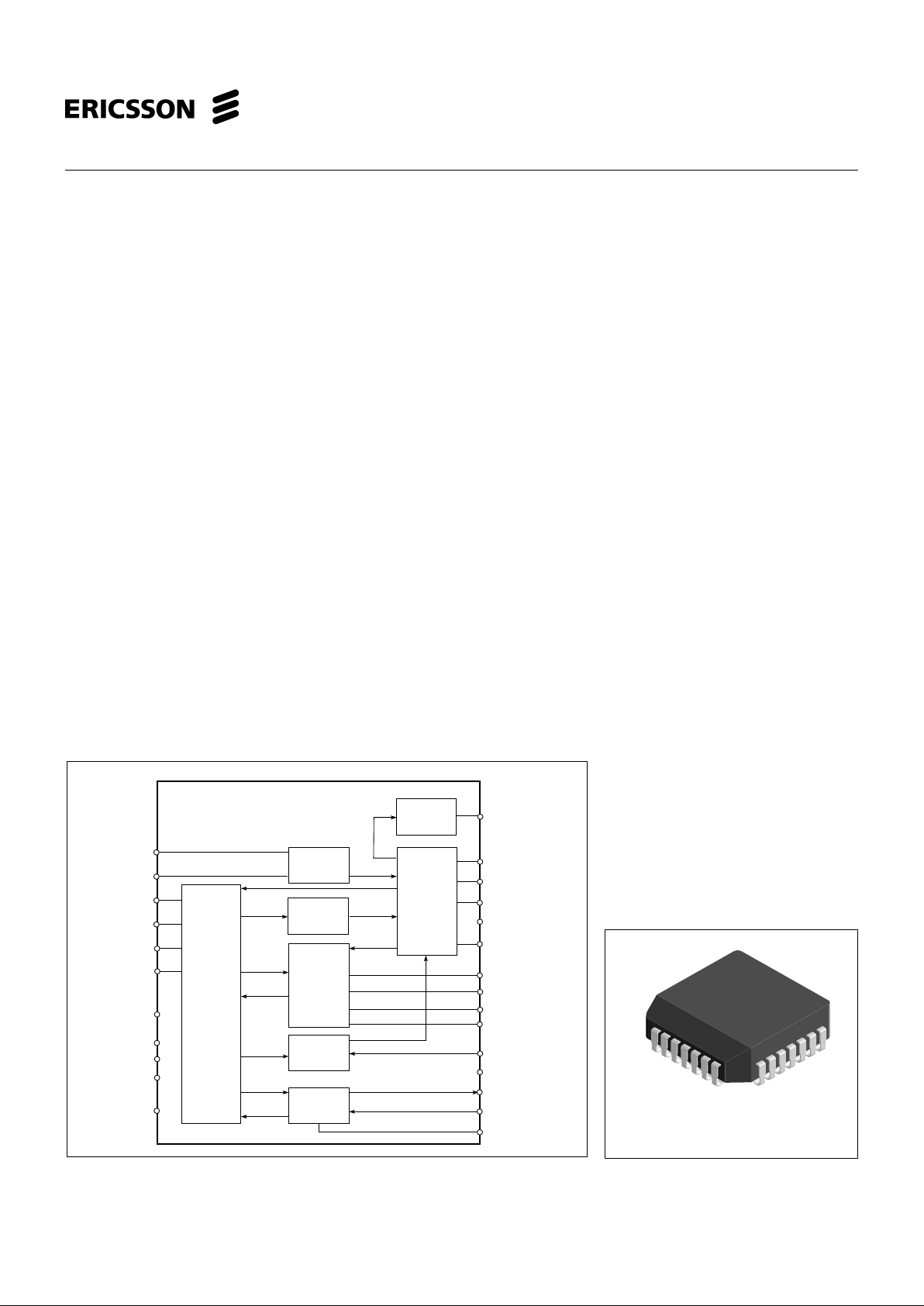

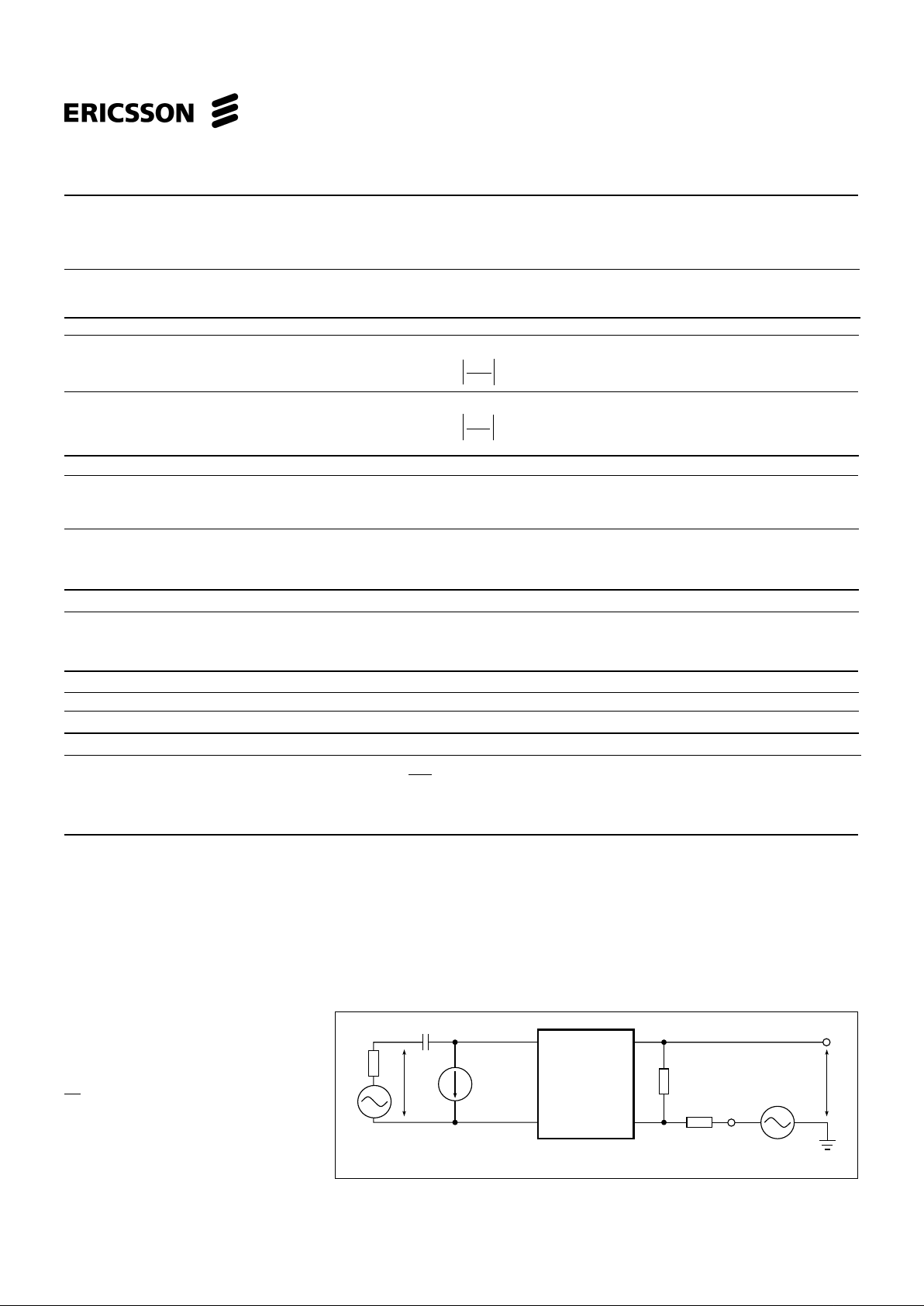

Figure 1. Block diagram.

February 2000

PBL 386 61/2

Subscriber Line

Interface Circuit

28-pin plastic PLCC

VF Signal

Transmission

Off-hook

Detector

Line Feed

Controller

and

Longitudinal

Signal

Suppression

Ring Trip

Two-wire

Interface

Input

Decoder and

Control

C1

C2

DET

REF

LP

VTX

RSN

DT

DR

TIPX

HP

RINGX

VCC

VEE

VBAT2

VBAT

AGND

C3

BGND

Comparator

Ground Key

Detector

Ring Relay

Driver

RRLY

PLD

PLC

PSGTS

AOV

VEE

PBL

386 61/2

Preliminary

Key Features

• Selectable overhead voltage principle

– All adaptive: The overhead voltage

follows 0.6 V

Peak

< signals < 6.2 V

Peak

.

– Semi adaptive: The overhead voltage

follows 3.1 V

Peak

< signals < 6.2 V

Peak

.

• Metering 2.2 V

rms

.

• High and low battery with automatic

switching

• Battery supply as low as -10 V

• Only +5 V in addition to GND

and battery (VEE optional)

• 39 mW on-hook power dissipation in

active state

• Long loop battery feed tracks V

Bat

for

maximum line voltage

• 44 V open loop voltage @ -48 V battery

feed

• Constant loop voltage for line

leakage <5 mA

• On-hook transmission

• Full longitudinal current capability

during on-hook

• Programmable loop & ring-trip detector

threshold

• Analog temperature guard

1

Page 2

PBL 386 61/2

2

Preliminary

Maximum Ratings

Parameter Symbol Min Max Unit

Temperature, Humidity

Storage temperature range T

Stg

-55 +150 °C

Operating temperature range T

Amb

-40 +110 °C

Operating junction temperature range, Note 1 T

J

-40 +140 °C

Power supply, 0°C ≤ T

Amb

≤ +70°C

V

CC

with respect to AGND V

CC

-0.4 6.5 V

V

EE

with respect to AGND V

EE

V

Bat

0.4 V

V

Bat

with respect to BGND, continuous V

Bat

-75 0.4 V

V

Bat

with respect to BGND, 10 ms V

Bat

-80 0.4 V

V

Bat2

with respect to A/BGND V

Bat2

V

Bat2

0.4 V

Power dissipation

Continuous power dissipation at T

Amb

≤ +70 °CP

D

1.5 W

Ground

Voltage between AGND and BGND V

G

-5 VCC V

Relay Driver

Ring relay supply voltage BGND +13 V

Ring relay current 75 mA

Ring trip comparator

Input voltage V

DT

, V

DR

V

Bat

V

CC

V

Input current I

DT

, I

DR

-5 5 mA

Digital inputs, outputs (C1, C2, DET)

Input voltage V

ID

-0.4 V

CC

V

Output voltage (DET not active) V

OD

-0.4 V

CC

V

Output current (DET) I

OD

30 mA

TIPX and RINGX terminals, 0°C < T

Amb

< +70°C, V

Bat

= -50 V

TIPX or RINGX current I

TIPX

, I

RINGX

-110 +110 mA

TIPX or RINGX voltage, continuous (referenced to AGND), Note 2 V

TA

, V

RA

V

Bat

2V

TIPX or RINGX, pulse < 10 ms, t

Rep

> 10 s, Note 2 VTA, V

RA

V

Bat

- 20 5 V

TIPX or RINGX, pulse < 1 µs, t

Rep

> 10 s, Note 2 VTA, V

RA

V

Bat

- 40 10 V

TIP or RING, pulse < 250 ns, t

Rep

> 10 s, Note 3 VTA, V

RA

V

Bat

- 70 15 V

Recommended Operating Condition

Parameter Symbol Min Max Unit

Ambient temperature T

Amb

0 +70 °C

Maximum supplied V

CC

with respect to AGND V

CC

4.75 5.25 V

V

EE

with respect to AGND V

EE

V

Bat

-4.75 V

V

Bat

with respect to BGND V

Bat

-58 -10 V

V

Bat2

with respect to BGND V

Bat2

V

Bat

-10 V

Notes

1. The circuit includes thermal protection. Operation above max. junction temperature may degrade device reliability.

2. A diode in series with the VBat input increases the permitted continuous voltage and pulse < 10 ms to -85 V. A pulse

≤1µs is increased to the greater of |-70V| and |VBat -40V|.

3. R

F1

and RF2 ≥20 Ω are also required. Pulse is supplied to TIP and RING outside RF1 and RF2.

Page 3

PBL 386 61/2

3

Preliminary

Electrical Characteristics

0 °C ≤ T

Amb

≤ +70 °C, VCC = +5V ±5 %, VEE = -5V ± 5%, V

Bat

= -58V to -40V, RLC=18.7kΩ, IL = 27 mA, ZL = 600 Ω, RF1, RF2 = 0 Ω,

R

Ref

= 15kΩ, CHP = 68nF, CLP=0.33 µF, RT = 120 kΩ, RSG = 24 kΩ, RRX = 120 kΩ, AOV and V

Bat2

pin not connected, unless

otherwise specified. Current definition: current is positive if flowing into a pin.

Ref

Parameter fig Conditions Min Typ Max Unit

Two-wire port

Overload level, V

TRO ,ILDC

> 10 mA 2 Active state

1% THD, Note 1 3.1 V

Peak

On-Hook, I

LDC

≤ 5 mA 1.4 V

Peak

Input impedance, Z

TR

Note 2 ZT/200

Longitudinal impedance, Z

LoT

, Z

LoR

0 < f < 100 Hz 20 35 Ω/wire

Longitudinal current limit, I

LoT

, I

LoR

active state 28 mA

rms

/wire

Longitudinal to metallic balance, B

LM

IEEE standard 455-1985, ZTRX = 736 Ω, active state

0.2 kHz < f < 1.0 kHz 55 dB

1.0 kHz < f < 3.4 kHz 55 dB

Longitudinal to metallic balance, B

LME

3 active state

E

Lo

B

LME

= 20 • Log 0.2 kHz ≤ f ≤ 1.0 kHz 55 dB

V

TR

1.0 kHz < f < 3.4 kHz 55 dB

Longitudinal to four-wire balance, B

LFE

3 active state

E

Lo

B

LFE

= 20 • Log 0.2 kHz ≤ f ≤ 1.0 kHz 61 dB

V

TX

1.0 kHz < f < 3.4 kHz 61 dB

Metallic to longitudinal balance, B

MLE

4 active state

VTR

0.2 kHz < f < 3.4kHz 40 dB

B

MLE

= 20 • Log

V

Lo

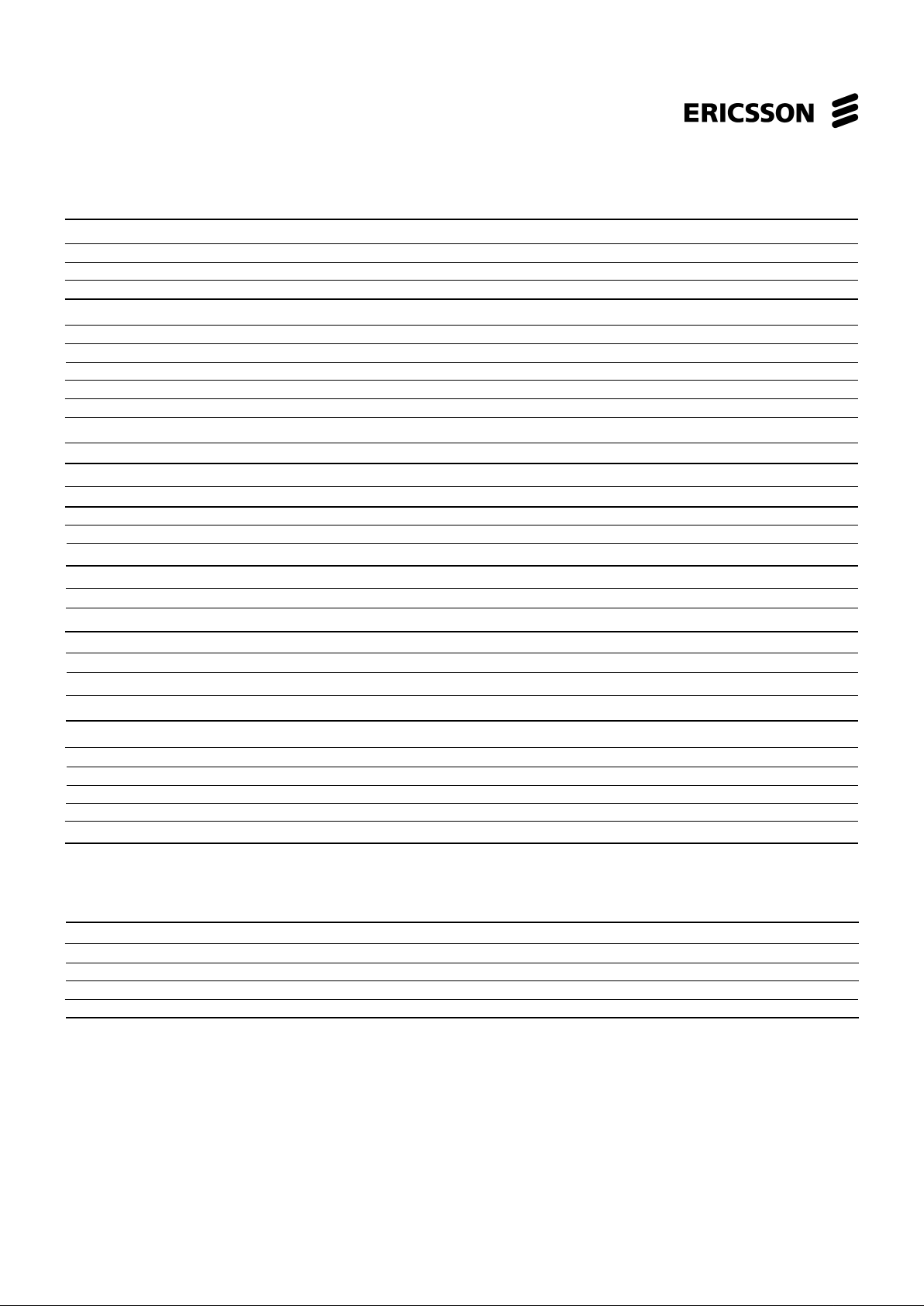

Figure 2. Overload level, V

TRO

, two-wire

port

1

<< RL, RL= 600 Ω

ωC

RT = 120 kΩ, RRX = 120 kΩ

PBL 386 61/2

TIPX

RINGX

RSN

VTX

R

T

R

RX

E

RX

R

L

V

TRO

I

LDC

C

PBL 386 61/2

TIPX

RINGX RSN

VTX

R

T

R

RX

V

TX

R

LT

C

V

TR

R

LR

E

Lo

Figure 3. Longitudinal to metallic (B

LME

)

and Longitudinal to four-wire (B

LFE

)

balance

1

<< 150 Ω, R

LR

= RLT = RL /2= 300Ω

ωC

RT = 120 kΩ, RRX = 120 kΩ

Page 4

PBL 386 61/2

4

Preliminary

Parameter fig Conditions Min Typ Max Unit

Four-wire to longitudinal balance, B

FLE

4 active state

E

RX

B

FLE

= 20 • Log

V

Lo

0.2 kHz < f < 3.4 kHz 40 dB

Two-wire return loss, r |Z

TR

+ ZL|

r = 20 • Log

|Z

TR

- ZL|

0.2 kHz < f < 0.5 kHz 25 dB

0.5 kHz < f < 1.0 kHz 27 dB

1.0 kHz < f < 3.4 kHz, Note 3 23 dB

TIPX idle voltage, V

Ti

active, IL = 0 - 1.5 V

RINGX idle voltage, V

Ri

active, IL = 0 V

Bat+

2.7 V

V

TR

active, IL = 0 V

Bat

+4.2 V

Four-wire transmit port (VTX)

Overload level, I

LDC

≥ 10 mA 5 Load impedance > 20 kΩ, 1.55 V

Peak

On hook I

LDC

≤ 5 mA 1% THD, Note 4 0.7 V

Peak

Output offset voltage, ∆V

TX

-60 60 mV

Output impedance, z

TX

0.2 kHz < f < 3.4 kHz 5 20 Ω

Four-wire receive port (RSN)

Receive summing node (RSN) dc voltage I

RSN

= 0 mA GND +25 mV

Receive summing node (RSN) impedance 0.2 kHz < f < 3.4 kHz 10 50 Ω

Receive summing node (RSN) 0.3 kHz < f < 3.4 kHz

current (I

RSN

) to metallic loop current (IL) 400 ratio

gain,α

RSN

Frequency response

Two-wire to four-wire, g

2-4

6 relative to 0 dBm, 1.0 kHz. ERX = 0 V

0.3 kHz < f < 3.4 kHz -0.15 0.15 dB

f = 8.0 kHz, 12 kHz, 16 kHz -0.5 -0.1 0 dB

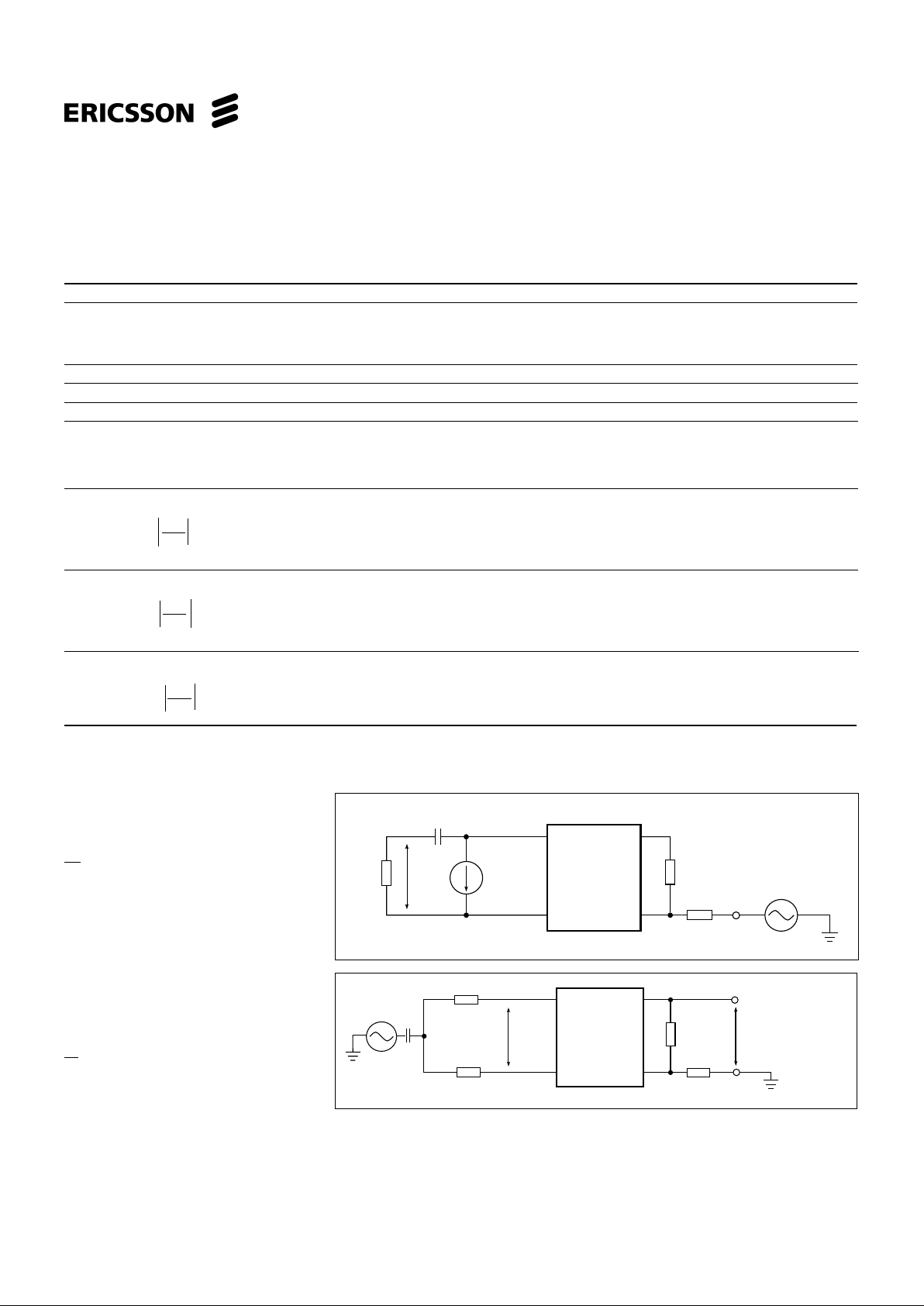

Figure 4. Metallic to longitudinal and

four-wire to longitudinal balance

1

<< 150 Ω, R

LT

= RLR = RL /2 =300Ω

ωC

RT = 120 kΩ, RRX = 120 kΩ

Figure 5. Overload level, V

TXO

, four-wire

transmit port

1

<< R

L

, RL = 600 Ω

ωC

R

T

= 120 kΩ, RRX = 120 kΩ

Ref

PBL 386 61/2

TIPX

RINGX RSN

VTX

R

T

R

RX

E

RX

R

LT

C

V

TR

R

LR

V

Lo

PBL 386 61/2

TIPX

RINGX RSN

VTX

R

T

R

RX

R

L

I

LDC

C

E

L

V

TXO

Page 5

PBL 386 61/2

5

Preliminary

Four-wire to two-wire, g

4-2

6 relative to 0 dBm, 1.0 kHz. EL = 0 V

0.3 kHz < f < 3.4 kHz -0.15 0.15 dB

f = 8 kHz, 12 kHz, -1.0 -0.2 0 dB

16 kHz -1.0 -0.3 0 dB

Four-wire to four-wire, g

4-4

6 relative to 0 dBm, 1.0 kHz. EL = 0 V

0.3 kHz < f < 3.4 kHz -0.15 0.15 dB

Insertion loss

Two-wire to four-wire, G

2-4

6 0 dBm, 1.0 kHz, Note 5

V

TX

G

2-4

= 20 • Log ,ERX = 0

V

TR

-6.22 -6.02 -5.82 dB

Four-wire to two-wire, G

4-2

6 0 dBm, 1.0 kHz, Notes 5, 6

V

TR

G

4-2

= 20 • Log ,EL = 0

E

RX

-0.2 0.2 dB

Gain tracking

Two-wire to four-wire R

LDC

≤ 2kΩ 6 Ref. -10 dBm, 1.0 kHz, Note 7

-40 dBm to +3 dBm -0.1 0.1 dB

-55 dBm to -40 dBm -0.2 0.2 dB

Four-wire to two-wire R

LDC

≤ 2kΩ 6 Ref. -10 dBm, 1.0 kHz, Note 7

-40 dBm to +3 dBm -0.1 0.1 dB

-55 dBm to -40 dBm -0.2 0.2 dB

Noise

Idle channel noise at two-wire C-message weighting 7 12 dBrnC

(TIPX-RINGX) Psophometrical weighting -85 -78 dBmp

Note 8

Harmonic distortion

Two-wire to four-wire 6 0 dBm, 1.0 kHz test signal -50 dB

Four-wire to two-wire 0.3 kHz < f < 3.4 kHz -50 dB

Battery feed characteristics

Constant loop current, I

LConst

12 I

LProg

=

500

R

LC

18 < I

LProg

< 65 mA 0.92 I

LProgILProg

1.08 I

LProg

mA

Ref

Parameter fig Conditions Min Typ Max Unit

Figure 6.

Frequency response, insertion loss,

gain tracking.

1

<< R

L

, RL = 600 Ω

ωC

RT = 120 kΩ, RRX = 120 kΩ

PBL 386 61/2

TIPX

RINGX RSN

VTX

R

T

R

RX

E

RX

R

L

V

TR

I

LDC

C

E

L

V

TX

Page 6

PBL 386 61/2

6

Preliminary

Loop current detector

Programmable threshold, I

DET

I

LTh

=

500 0.9•I

LThILTh

1.1•I

LTh

mA

R

LD

Ring trip comparator

Offset voltage, ∆V

DTDR

Source resistance, RS = 0 Ω -20 0 20 mV

Input bias current, I

B

IB = (IDT + IDR)/2 -50 -20 200 nA

Input common mode range, V

DT

, V

DR

V

Bat

+1 -1 V

Ring relay driver

Saturation voltage, V

OL

IOL = 50 mA 0.5 V

Off state leakage current, I

Lk

V

OH

= 12 V 100 µA

Digital inputs (C1, C2, C3)

Input low voltage, V

IL

0 0.5 V

Input high voltage, V

IH

2.5 V

CC

V

Input low current, I

IL

VIL = 0.5 -200 µA

Input high current, I

IH

VIH = 2.5 V 200 µA

Detector output (DET)

Output low current, I

OL

VOL < 0.6V 0.5 1 mA

Internal pull-up resistor 10 kΩ

Power dissipation (V

Bat

= -48V, V

Bat2

= -32V)

P

1

Open circuit state, C1, C2, C3 = 0, 0, 0 14 mW

P

2

@ VEE = -5V Active state, C1, C2, C3 = 0, 1, 0 39 mW

P

3

@ VEE = -48V Longitudinal current = 0 mA, IL = 0 mA 44 mW

P

4

@ VEE = -5V RL = 300Ω (off-hook) 710 mW

P

5

@ VEE = -5V RL = 800Ω (off-hook) 340 mW

Power supply currents (V

Bat

= -48V)

V

CC

current, I

CC

Open circuit state 0.8 mA

V

EE

current, I

EE

C1, C2, C3 = 0, 0, 0 -0.1 mA

V

Bat

current, I

Bat

-0.2 mA

V

CC

current, I

CC

Active state 2.0 mA

V

EE

current, I

EE

C1, C2, C3 = 0, 1, 0 0.1 mA

V

Bat

current, I

Bat

On-hook, Long Current = 0 mA, IL = 0 mA -0.7 mA

Power supply rejection ratios

V

CC

to 2- or 4-wire port Active State 28.5 35 dB

V

EE

to 2- or 4-wire port C1, C2, C3 = 0, 1, 0 28.5 55 dB

V

Bat

to 2- or 4-wire port 50 Hz < f< 3400 Hz, Vn = 100mV 28.5 40 dB

V

Bat2

to 2- or 4-wire port 28.5 60 dB

Temperature guard

Junction threshold temperature, T

JG

140 °C

Parameter fig Conditions Min Typ Max Unit

Ref

Page 7

PBL 386 61/2

7

Preliminary

Notes

1. The overload level is automatically expanded when the

signal level > 3.1 V

Peak

and is specified at the two-wire port

with the signal source at the four-wire receive port.

2. The two-wire impedance is programmable by selection of

external component values according to:

Z

TR

= ZT/|G

2-4S αRSN

| where:

ZTR= impedance between the TIPX and RINGX

terminals

ZT= programming network between the VTX and RSN

terminals

G

2-4S

= transmit gain, nominally = -0.5

α

RSN

= receive current gain, nominally = 400 (current

defined as positive flowing into the receivesumming node, RSN, and when flowing from tip to ring).

3. Higher return loss values can be achieved by adding a

reactive component to R

T

, the two-wire terminating

impedance programming resistance, e.g. by dividing R

T

into two equal halves and connecting a capacitor from the

common point to ground.

4. The overload level is automatically expanded as needed up

to 3.1 V

Peak

when the signal level >1.55 V

Peak

and is

specified at the four-wire transmit port, V

TX

, with the signal

source at the two-wire port. Note that the gain from the

two-wire port to the four-wire transmit port is G

2-4S

= -0.5.

5. Secondary protection resistors R

F

impact the insertion loss

as explained in the text, section Transmission. The

specified insertion loss is for R

F

= 0.

6. The specified insertion loss tolerance does not include

errors caused by external components.

7. The level is specified at the four-wire receive port and

referenced to a 600 Ω programmed two-wire impedance

level.

8. The two-wire idle noise is specified with the four-wire

receive port grounded (ERX = 0; see figure 6).

The four-wire idle noise at VTX is the two-wire value -6 dB

and is specified with the two-wire port terminated in 600 Ω

(R

L

). The noise specification is referenced to a 600 Ω

programmed two-wire impedance level at VTX. The fourwire receive port is grounded (E

RX

= 0).

Page 8

PBL 386 61/2

8

Preliminary

Pin Description

Refer to figure 7.

PLCC Symbol Description

1 VBAT Battery supply voltage. Negative with respect to BGND.

2 VBAT2 An optional second battery voltage, connected in series with a diode, or an external powerhandling resistor

connects to this pin.

3 AOV Adaptive Overhead Voltage. If the pin is left open then the overhead voltage is set internally to 3.1 V

Peak

in

off-hook and 1.4 V

Peak

in on-hook. The overhead voltage will adapt to signals > 3.1 V

Peak

. If the pin is

connected to AGND then no internal overhead voltage is set. The overhead voltage adapts to 0.6 V

Peak

<

signals < 6.2 V

Peak

.

4 PSG Programmable Saturation Guard. The resistive part of the DC feed characteristic is programmed by a

resistor connected from this pin to VBAT.

5 LP Low Pass saturation guard filter capacitor connected here to filter out noise and improve PSRR. Other end

of C

LP

connects to VBAT.

6 DT Input to the ring trip comparator. With DR more positive than DT the detector output, DET, is at logic level

low, indicating off-hook condition. The ring trip network connects to this input.

7 DR Input to the ring trip comparator. With DR more positive than DT the detector output, DET, is at logic level

low, indicating off-hook condition. The ring trip network connects to this input.

8 VEE -5V to VBAT power supply.

9 REF A 15 kΩ resistor should be connected between this pin and AGND.

10 NU Not Used. Must be left open.

11 PLC Prog. Line Current, the constant current part of the DC feed characteristic is programmed by a resistor

connected from this pin to AGND.

12 PLD Programmable Loop Detector threshold. The loop detection threshold is programmed by a resistor

connected from this pin to AGND.

13 VCC +5 V power supply.

14 NU Not Used. Pin must be connected to AGND.

15 C2 C1 and C2 are digital inputs Controlling the SLIC operating states. Refer to

16 C1 section operating states for details.

17 NC No Connect. Must be left open.

18 DET Detector output. Active low when indicating loop or ring trip detection, active high when indicating ground

key detection

19 RSN Receive Summing Node. 400 times the current flowing into this pin equals the metallic (transversal) current

flowing from RINGX to TIPX. Programming networks for two-wire impedance and receive gain connect to

the receive summing node.

20 AGND Analog Ground, should be tied together with BGND.

21 VTX Transmit vf output. The ac voltage difference between TIPX and RINGX, the ac metallic voltage, is

reproduced as an unbalanced GND referenced signal at VTX with a gain of -0.5. The two-wire impedance

programming network connects between VTX and RSN.

22 RRLY Ring Relay driver output.

23 TS Tip Sense should be connected to TIPX.

24 NC No Connect. Must be left open.

25 HP High Pass connection for ac/dc separation capacitor C

HP

. Other end of CHP connects to RINGX (pin 26).

26 RINGX The TIPX and RINGX pins connect to the tip and ring leads of the two-wire interface via overvoltage

protection components and ring relay (and optional test relay).

27 BGND Battery Ground, should be tied together with AGND.

28 TIPX The TIPX and RINGX pins connect to the tip and ring leads of the two-wire interface via overvoltage

protection components and ring relay (and optional test relay).

}

Page 9

PBL 386 61/2

9

Preliminary

SLIC Operating States

Figure 7. Pin configuration 28 pin PLCC package, top view.

State C3 C2 C1 SLIC operating state Active detector

0 0 0 0 Open circuit Detector is set high

1 0 0 1 Ringing state Ring trip detector (active low)

2 0 1 0 Active state Loop detector (active low)

3 0 1 1 Not applicable 4 1 0 0 Not applicable 5 1 0 1 Not applicable 6 1 1 0 Not applicable 7 1 1 1 Not applicable -

Table 1. SLIC operating states.

* Pins must be left open.

LP

DR

VEE

REF

PLC

HP

NC*

TS

RRLY

VTX

AGND

RSN

PSG

AOV

VBAT2

VBAT

TIPX

BGND

RINGX

VCC

NU

C2

C1

NC*

5

6

7

8

9

10

11

25

24

23

22

21

20

19

4

3

2

1

28

27

26

12

13

14

15

16

17

18DET

PLD

NU

DT

Page 10

PBL 386 61/2

10

Preliminary

Figure 9. Simplified ac transmission circuit.

Functional Description and Applications

Information Transmission

PBL 386 61/2

+

-

+

-

VTX

RSN

I

L

/α

TIPX

RINGX

+

-

E

L

+

-

TIP

RING

R

F

R

F

Z

TR

Z

T

V

TX

V

RX

Z

RX

I

L

I

L

R

HP

+

-

Z

L

V

TR

G

RSN

2-4S

General

A simplified ac model of the transmission

circuits is shown in figure 9. Circuit analysis

yields:

V

TR

=

V

TX

- I

L

• 2R

F

(1)

G

2-4S

VTX + VRX = I

L

(2)

Z

T

ZRX α

RSN

VTR = IL • ZL - E

L

(3)

where:

V

TX

is a ground referenced version

of the ac metallic voltage

between the TIPX and RINGX

terminals.

VTRis the ac metallic voltage

between tip and ring.

ELis the line open circuit ac metallic

voltage.

ILis the ac metallic current.

RFis a fuse resistor.

G

2-4S

is the SLIC two-wire to four-

wire gain (transmit direction) with

a nominal value of -0.5.

ZLis the line impedance.

ZTdetermines the SLIC TIPX to

RINGX impedance for signal in

the 0 - 20kHz frequency range.

ZRXcontrols four- to two-wire gain.

V

RX

is the analogue ground referenced

receive signal.

α

RSN

is the receive summing node

current to metallic loop current

gain. The nominal value of

α

RSN

= 400

Two-Wire Impedance

To calculate ZTR, the impedance presented

to the two-wire line by the SLIC including

the fuse resistor RF, let VRX = 0.

From (1) and (2):

Z

TR

=

Z

T

- 2R

F

α

RSN

• G

2-4S

Thus with ZTR, G

2-4S

, α

RSN

, and RF known:

Z

T

= α

RSN

• G

2-4S

• (2RF - |ZTR|)

Two-Wire to Four-Wire Gain

From (1) and (2) with VRX = 0:

G

2-4

=

VTX = ZT/α

RSN

VTR ZT

- 2R

F

α

RSN

• G

2-4S

Four-Wire to Two-Wire Gain

From (1), (2) and (3) with EL = 0:

G

4-2

=

VTX = ZT • Z

L

VTR ZRX ZT

- G

2-4S

• ( ZL + 2RF)

α

RSN

In applications where

2RF - ZT/(α

RSN

• G

2-4S

) is chosen to be

equal to ZL, the expression for G

4-2

simpli-

fies to:

G

4-2

= -

ZT • 1

ZRX 2 • G

2-4S

Four-Wire to Four-Wire Gain

From (1), (2) and (3) with EL = 0:

G

4-4

=

V

TX

= ZT • G

2-4S

• ( ZL + 2RF)

VRX ZRX ZT

- G

2-4S

• ( ZL + 2RF)

α

RSN

Page 11

PBL 386 61/2

11

Preliminary

Figure 10. Hybrid function.

V

T

Combination

CODEC/Filter

R

TX

R

FB

Z

B

Z

RX

Z

T

VTX

RSN

V

RX

PBL

386 61/2

Hybrid Function

The hybrid function can easily be implemented utilizing the uncommitted amplifier

in conventional CODEC/filter combinations.

Please, refer to figure 10. Via impedance

Z

B

a current proportional to VRX is injected

into the summing node of the combination

CODEC/filter amplifier. As can be seen

from the expression for the four-wire to

four-wire gain a voltage proportional to V

RX

is returned to VTX. This voltage is converted

by RTX to a current flowing into the same

summing node. These currents can be

made to cancel by letting:

VTX + VRX

= 0 (E

L

= 0)

R

TX

Z

B

The four-wire to four-wire gain, G

4-4

, includes the required phase shift and thus

the balance network ZB can be calculated

from:

Z

B

= - RTX •

VRX

=

V

TX

ZT

- G

2-4S

• ( ZL + 2RF)

- R

TX

•

ZRX

•

α

RSN

ZT G

2-4S

• ( ZL + 2RF)

When choosing RTX, make sure the

output load of the VTX terminal (R

TX

//R

T

in figure 12) is > 20 kΩ.

If calculation of the Z

B

formula above

yields a balance network containing an

inductor, an alternate method is recommended. Contact Ericsson Microelectronics for assistance.

The PBL 386 61/2 SLIC may also be

used together with programmable CODEC/

filters. The programmable CODEC/filter

allows for system controller adjustment of

hybrid balance to accommodate different

line impedances without change of hardware. In addition, the transmit and receive

gain may be adjusted. Please, refer to the

programmable CODEC/filter data sheets

for design information.

Longitudinal Impedance

A feed back loop counteracts longitudinal

voltages at the two-wire port by injecting

longitudinal currents in opposing phase.

Thus longitudinal disturbances will appear as longitudinal currents and the TIPX

and RINGX terminals will experience very

small longitudinal voltage excursions, leaving metallic voltages well within the SLIC

common mode range.

The SLIC longitudinal impedance per wire,

Z

LoT

and Z

LoR

, appears as typically 20 Ω to

longitudinal disturbances. It should be noted that longitudinal currents may exceed

the dc loop current without disturbing the vf

transmission.

Capacitors CTC and C

RC

If RFI filtering is needed, the capacitors

designated CTC and CRC in figure 12, connected between TIPX and ground as well

as between RINGX and ground, may be

mounted.

CTC and CRC work as RFI filters in conjunction with suitable series impedances

(i.e. resistances, inductances). Resistors

R

F1

and RF2 may be sufficient, but series

inductances can be added to form a second order filter. Current-compensated inductors are suitable since they suppress

common-mode signals with minimum influence on return loss. Recommended values

for CTC and CRC are below 1 nF. Lower

values impose smaller degradation on return loss and longitudinal balance, but also

attenuate radio frequencies to a smaller

extent. The influence on the impedance

loop must also be taken into consideration

when programming the CODEC. CTC and

CRC contribute to a metallic impedance of

1/(π

•f•C

TC

) = 1/(π•f•CRC), a TIPX to ground

impedance of 1/(2

•π•f•C

TC

) and a RINGX to

ground impedance of 1/(2•π•f•CRC).

AC - DC Separation Capacitor, C

HP

The high pass filter capacitor connected

between terminals HP and RINGX provides the separation of the ac and dc

signals. CHP positions the low end frequency response break point of the ac loop in the

SLIC. Refer to table 1 for recommended

value of CHP.

Example: A CHP value of 68 nF will

position the low end frequency response

3dB break point of the ac loop at 13 Hz (f

3dB

)

according to f

3dB

= 1/(2•π•R

HP•CHP

) where

RHP = 180 kΩ.

Page 12

PBL 386 61/2

12

Preliminary

Figure 11. The AOV funktion when the AOV-pin is left open. (Observe, burst

undersampled).

High-Pass Transmit Filter

When CODEC/filter with a singel 5 V power

supply is used, it is necessary to separate

the different signal reference voltages between the SLIC and the CODEC/filter. In

the transmit direction this can be done by

connecting a capacitor between the VTX

output of the SLIC and the CODEC/filter

input. This capacitor will also form, together with RTX and/or the input impedance of

the CODEC/filter, a high-pass RC filter. It is

recommended to position the 3 dB break

point of this filter between 30 and 80 Hz to

get a fast enough response for the dc steps

that may occur with DTMF signaling.

Capacitor C

LP

The capacitor CLP, which connects between

the terminals LP and VBAT, positions the

high end frequency break point of the low

pass filter in the dc loop in the SLIC. C

LP

together with CHP and ZT (see section TwoWire Impedance) forms the total two wire

output impedance of the SLIC. The choice

of these programming components influence the power supply rejection ratio

(PSRR) from VBAT to the two wire side in

the low frequency range.

R

Feed

R

SG

C

LP

C

HP

[Ω][kΩ] [nF] [nF]

2•25 4.02 330 68

2•50 23.7 330 68

2•200 147 100 33

2•400 301 47 33

2•800 619 22 33

Table 1. RSG, CLP and CHP values for

different feeding characteristics.

Table 1 suggest values of CLP and CHP for

different feeding characteristics.

For values outside table 1, please contact Ericsson Microelectronics for assistance.

Adaptive Overhead Voltage, AOV

The Adaptive Overhead Voltage feature

minimises the power dissipation and at the

same time provides a flexible solution for

differing system requirements and possible future changes concerning voice, metering and other signal levels. This is done

by using an overhead voltage which automatically adapts to the signal level (voice +

metering). With the AOV-pin left open, the

PBL 386 61/2 will behave as a SLIC with

fixed overhead voltage for signals in the 0

- 20kHz frequency range and with an ampli-

tude less than 3.1V

Peak

11

. For signal ampli-

tudes between 3.1V

Peak

and 6.2V

Peak

, the

AOV-function will expand the overhead

voltage making it possible for the signal, Vt,

to propagate through the SLIC without distortion (see figure 11). The expansion of

the overhead voltage occurs instantaneously. When the signal amplitude decreases, the overhead voltage returns to its initial

value with a time constant of approximately

one second.

If the AOV-pin is connected to AGND, the

overhead voltage will automatically be adjusted for signal levels between 0.6 V

Peak

and 6.2 V

Peak

.

AOV In the Constant Current Region

When the overhead voltage is automatically increased, the apparent battery (V

App

,

reference F in figure 13), will be reduced by

the signal amplitude minus 3.1 V

Peak

(11)

, (Vt

- 3.1

(11)

).

In the constant current region this change

will not affect the line current as long as

VTR < V

App

- (I

LConst

• R

Feed

) - (Vt-3.1

(11)

),

(references A-C in figure 13).

AOV In the Resistive Loop Feed Region

The saturation guard will be activated when

the SLIC is working in the resistive loop

feed region, i.e.

V

TR

> V

App

- (I

LConst

• R

Feed

) - (Vt - 3.1

(11)

)

(references D in figure 13).

If the signal amplitude is greater than

3.1V

Peak

11

the line current, IL, will be re-

duced corresponding to the formula

∆I

L

= | (Vt - 3.1

(11)

)/(RL + R

Feed

) |.

This reduction of line current will introduce a transversal signal into the two-wire

which under some circumstances may be

audible (e g when sending metering signals > 3.1 V

Peak

without any speech signal

burying the transversal signal generated

from the linecurrent reduction).

The sum of all signals should not exceed

6.2 V

Peak

.

Line Feed

If VTR < V

App

- (I

LConst

• R

Feed

), the PBL 386 61/

2 SLIC will emulate constant current feed

(references A-C in figure 13).

For VTR > V

App

- (I

LConst

• R

Feed

) the PBL 386

61/2 SLIC will emulate resistive loop feed

programmable between 2•25 Ω12 and 2•900

Ω (references D in figure 13). The current

limitation region is adjustable between

0 mA and 65 mA13.

When the line current is approaching

open loop conditions, the overhead voltage is reduced. To ensure maximum open

loop voltage, even with telephone line leakage, this occurs at a line current of approximately 5 mA (references E in figure 13).

After the overhead voltage reduction, the

line voltage is kept nearly constant with a

steep slope corresponding to 2 • 25 Ω(ref-

erence G in figure 13).

The open loop voltage, V

TRMax

, measured

between the TIPX and RINGX terminals is

tracking the battery voltage V

Bat

(referenc-

es H in figure 13). V

TRMax

is programmable

by connecting the AOV-pin to AGND or by

Page 13

PBL 386 61/2

13

Preliminary

leaving the AOV-pin open.

V

TRMax

is defined as the battery voltage on

the VBat terminal minus the Battery Over

Head voltage, V

BOH

, according to the equa-

tion

V

TRMax

(at IL = 0 mA) = |V

Bat

| - V

BOH

Refer to table 2 for typical V

BOH

values.

V

BOH

(typ) [V]

AOV-PIN NC 4.2

AOV-PIN to AGND 3.2

Table 2. The battery overhead voltages

at open loop conditions.

Resistive Loop Feed Region

The resistive loop feed (reference D in

figure 13) is programmed by connecting a

resistor R

SG

, between terminals PSG and

VBAT according to the equation

R

Feed

=

R

SG

+ 40 + 2R

F

400

Constant Current Region

The current limit (reference C in figure 13)

is adjusted by connecting a resistor, R

LC

,

between terminal PLC and ground according to the equation:

RLC =

500

14

I

LProg

Battery Switch (VBAT2)

To reduce short loop power dissipation, a

second lower battery voltage may be connected to the device through an external

diode at terminal VBAT2. The SLIC automatically switches between the two battery

supply voltages without need for external

control. The silent battery switching occurs

when the line voltage passes the value

|V

Bat2

| - 40•IL - 6

15

Connect the terminal VBAT2 to the sec-

ond power supply via the diode DB2 in figure

12.

An optional diode DBB connected between

terminal VBAT and the VB2 power supply,

see figure 12, will make sure that the SLIC

continues to work on the second battery

even if the first battery voltage disappears.

If the V

B2

voltage is not available, an

optional external power management resistor, R

PM

, may be connected between the

VBAT2-pin and the VBAT-pin to move power dissipation outside the chip.

Calculation of the external power management resistor to locate the maximum

power dissipation outside the SLIC is according to:

RPM =

|V

Bat

| - 3

I

LProg

Metering Applications

It is very easy to use PBL 386 61/2 in

metering applications; simply connect a

suitable resistor (RM) in series with a capacitor (CM) between pin RSN and the

metering source. Capacitor C

M

decouples

all DC-voltages that may be superimposed

on the metering signal. Choose 1/(2πRMCM)

≥ 5kHz to suppress low frequency disturbances from the metering puls generator.

The metering signal gain can be calculated

from the equation:

G

4-2Metering

=

V

TR

=

V

Meter

Z

T • ZLM

ZM ZT

- G

2-4S

• (ZLM + 2RF)

α

RSN

where

V

Meter

is the voltage of the signal at the

metering generator,

Z

LM

is the line impedance seen by the

12 or 16 kHz metering signal,

G

2-4S

is the transmit gain through the SLIC,

i e -0.5.

In metering applications with resistive

line feeding characteristic and very strict

requirements (as mentioned earlier in chapter “AOV in resistive loop feed region“), the

metering signal level should not exceed 2.2

V

RMS

16

, since a reduction of the line current

will generate a transversal, and sometimes

audible, signal (which is not the case in the

constant current region).

Analog Temperature Guard

The widely varying environmental conditions in which SLICs operate may lead to

the chip temperature limitations being exceeded. The PBL 386 61/2 SLIC reduces

the dc line current and the longitudinal

current limit when the chip temperature

reaches approximately 145°C and increases it again automatically when the temperature drops.

The detector output, DET, is forced to a

logic low level when the temperature guard

is active.

Loop Monitoring Functions

The loop current and ring trip detectors

report their status through a common output, DET. The status of the detector pin,

DET, is selected via the two bit control

interface C1 and C2. Please refer to section Control Inputs for a description of the

control interface.

Loop Current Detector

The loop current detector indicates that the

telephone is off hook and that DC current is

flowing in the loop by putting the output pin

DET, to a logic low level when selected.

The loop current detector threshold value,

I

LTh

, where the loop current detector chang-

es state, is programmable with the R

LD

resistor. RLD connects between pin PLD

and ground and is calculated according to:

RLD =

500

I

LTh

The current detector is internally filtered

and is not influenced by the ac signal at the

two wire side.

Ring Trip Detector

Ring trip detection is accomplished by connecting an external network to a comparator in the SLIC with inputs DT and DR. The

ringing source can be balanced or unbalanced e g superimposed on the battery

voltage or ground. The unbalanced ringing

source may be applied to either the ring

lead or the tip lead with return via the other

wire. A ring relay driven by the SLIC ring

relay driver connects the ringing source to

Page 14

PBL 386 61/2

14

Preliminary

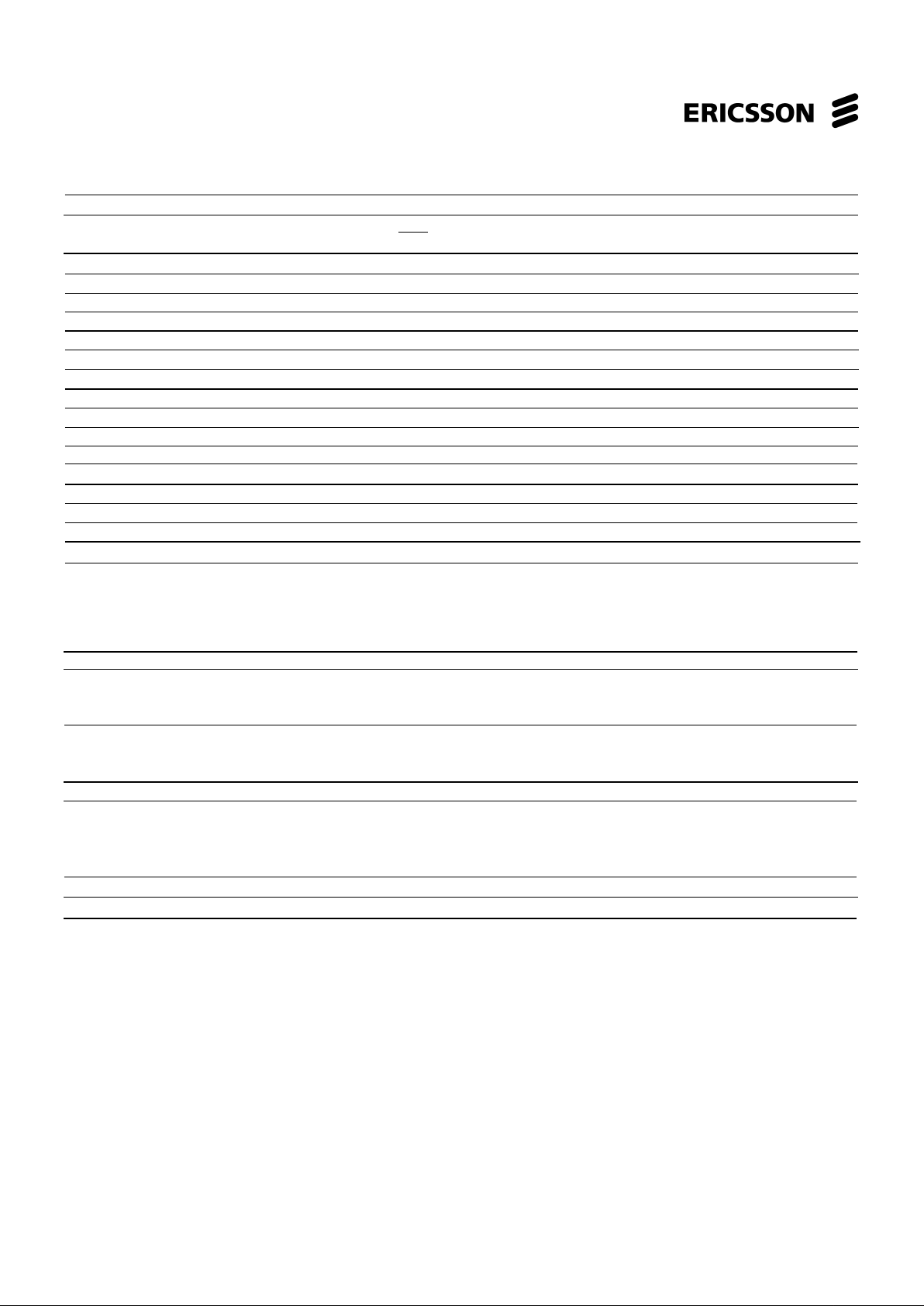

RESISTORS: (Values according to IEC-63 E96

series)

R

SG

= 23.7 kΩ 1% 1/10 W

R

LD

= 49.9 kΩ 1% 1/10 W

R

LC

= 18.7 kΩ 1% 1/10 W

R

REF

= 15 kΩ 1% 1/10 W

R

T

= 105 kΩ 1% 1/10 W

R

TX

= 32.4kΩ 1% 1/10 W

R

B

= 57.6kΩ 1% 1/10 W

R

RX

= 105kΩ 1% 1/10 W

R

FB

Depending on CODEC / filter

R

1

= 604 kΩ 1% 1/10 W

R

2

= 604 kΩ 1% 1/10 W

R

3

= 249 kΩ 1% 1/10 W

R

4

= 280 kΩ 1% 1/10 W

R

RT

= 332 Ω 5% 2 W

R

RF

= 332 Ω 5% 2 W

RF1, R

F2

= Line resistor, 40 Ω 1%

CAPACITORS:(Values according to IEC-63 E6

series)

C

B

= 100 nF 100 V 20%

C

B2

= 150 nF 100 V 20%

C

VCC

= 100 nF 10 V 20%

C

VEE

= 100 nF 10 V* 20%

C

TC

= optional

C

RC

= optional

C

HP

= 68 nF 100 V 20%

C

LP

= 330 nF 100 V 20%

C

GG

= 220 nF 100 V 20%

C

1

= 330 nF 63 V 10%

C

2

= 330 nF 63 V 10%

*100V if VEE pin connected to VBAT, VBAT2

DIODES:

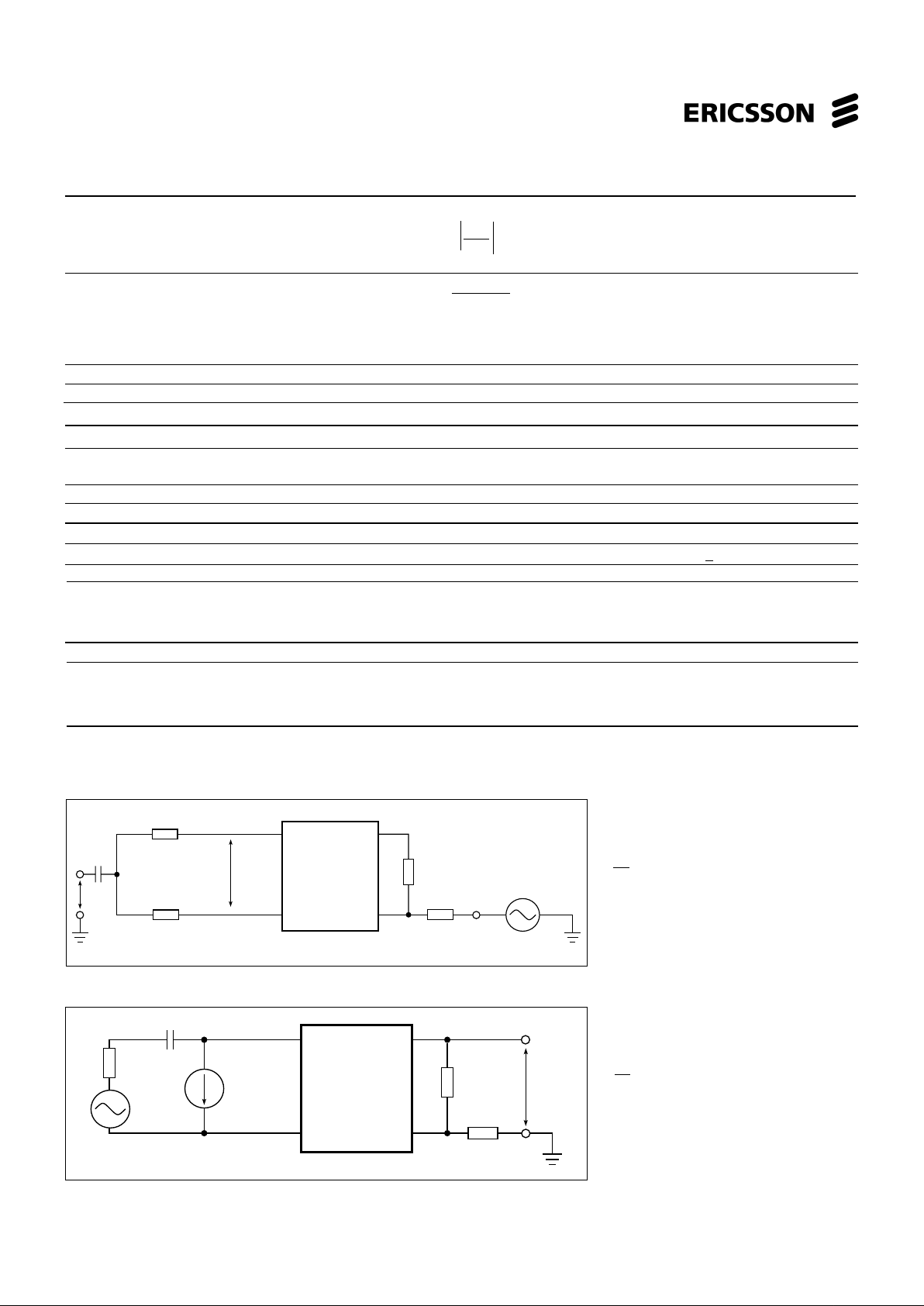

Figure 12. Single-channel subscriber line interface with PBL 386 61/2 and combination CODEC/filter

D

B

= 1N4448

D

B2

= 1N4448

D

BB

= 1N4448 (optional)

OVP:

Secondary protection (eg Power Innovations TISP

PBL1 or PBL2). The ground terminals of the

secondary protection should be connected to the

common ground on the Printed Board Assembly

with a track as short and wide as possible,

preferably a groundplane.

C

VCC

CODEC/

Filter

SYSTEM CONTROL

INTERFACE

D

B2

C

RC

C

LP

C

HP

TIP

RING

OVP

+12 V /+5V

C

1

R

4

E

RG

R

RT

R

T

KR

VB

VB2

VCC

VCC

C

GG

C

2

R

3

C

TC

D

B

VEE

VEE

BGND

TIPX

VBAT

VBAT2

C1

C2

C3

VCC

AOV

PSG

LP

DR

PLD

PLC

NC

REF

TS

NC

HP

RINGX

AGND

RSN

DET

NC

RRLY VTX

DT VEE

R

FB

R

RX

R

B

R

LD

R

LC

R

REF

R

F1

R

F2

R

1

R

2

R

SG

D

BB

C

B2

PBL 386 61/2

VB

R

TX

VBAT<VEE<-5 V

out

-

+

out

C

VEE

R

RF

+5 V

C

B

tip and ring.

The ring trip function is based on a polarity change at the comparator input when

the line goes off-hook. In the on-hook state

no dc current flows through the loop and

the voltage at comparator input DT is more

positive than the voltage at input DR. When

the line goes off-hook, while the ring relay

is energized, dc current flows and the comparator input voltage reverses polarity.

Figure 12 gives an example of a ring trip

detection network. This network is applicable, when the ring voltage superimposed

on the battery voltage is injected on the ring

lead of the two-wire port. The dc voltage

across sense resistor RRT is monitored by

the ring trip comparator input DT and DR

via the filter network R1, R2, R3, R4, C1 and

C2. DT is more positive than DR, with the

line on-hook (no dc current). The DET

output will report logic level high, i.e. the

detector is not tripped. When the line goes

off-hook, while ringing, a dc current will flow

through the loop including sense resistor

RRT and will cause the input DT to become

more negative than input DR. This changes the output on the DET pin to logic level

low, i.e. tripped detector condition. The

system controller (or line card processor)

responds by de-energizing the ring relay

via the SLIC, i.e. ring trip.

Complete filtering of the 20 Hz ac component at terminals DT and DR is not necessary. A toggling DET output can be examined by a software routine to determine the

duty cycle. Off-hook condition is indicated

when the DET output is at logic level low for

more than half the time.

Page 15

PBL 386 61/2

15

Preliminary

Detector Output (DET)

The PBL 386 61/2 SLIC incorporates a

detector output driver designed as open

collector (npn) with a current sinking capability of min 3 mA, and a 5 kΩ pull-up

resistor. The emitter of the drive transistor

is connected to AGND. A LED can be

connected in series with a resistor (≈1 kΩ)

at the DET output to visualize, for example

loop status.

Relay driver

The PBL 386 61/2 SLIC incorporates a ring

relay driver designed as open collector

(npn) with a current sinking capability of 50

mA.The emitter of the drive transistor is

connected to BGND. The relay driver has

an internal zener diode clamp to protect the

SLIC from inductive kick-back voltages. No

external clamp is needed.

Control Inputs

The PBL 386 61/2 SLIC has two digital

control inputs, C1 and C2.

A decoder in the SLIC interprets the control input condition and sets up the commanded operating state.

C1 and C2 are internal pull-up inputs.

Open Circuit State

In the Open Circuit State the TIPX and

RINGX line drive amplifiers as well as other

circuit blocks are powered down. This causes the SLIC to present a high impedance to

the line. Power dissipation is at a minimum

and no detectors are active.

Ringing State

In the ringing state the SLIC will behave as

in the active state with the exception

that the ring relay driver and the ring trip

detector are activated. The ring trip detector will indicate off hook with a logic low

level at the detector output.

Active State

TIPX is the terminal closest to ground and

sources loop current while RINGX is the

more negative terminal and sinks loop current. The loop current or the ground key

detector is activated. The loop current detector indicates off hook with a logic low

level and the ground key detector indicates

active ground key with a logic high level

present at the detector output.

Overvoltage Protection

PBL 386 61/2 must be protected against

overvoltages on the telephone line. The

overvoltages could be caused for instance

by lightning, ac power contact and induction. Refer to Maximum Ratings, TIPX and

RINGX terminals, for maximum continuous and transient voltages.

Secondary Protection

The circuit shown in figure 12 utilizes series

resistors together with a programmable

overvoltage protector (e g Power Innovations TISP PBL1 or PBL2), serving as a

secondary protection.

The TISP PBLx is a dual forward-conducting buffered p-gate overvoltage protector. The protector gate references the

protection (clamping) voltage to negative

supply voltage (i.e. the battery voltage, VB).

As the protection voltage will track the

negative supply voltage the overvoltage

stress on the SLIC is minimised.

Positive overvoltages are clamped to

ground by a diode. Negative overvoltages

are initially clamped close to the SLIC negative supply rail voltage and the protector

will crowbar into a low voltage on-state

condition, by firing an internal thyristor.

A gate decoupling capacitor, C

GG

, is needed to carry enough charge to supply a high

enough current to quickly turn on the thyristor in the protector. CGG should be placed

close to the overvoltage protection device.

Without the capacitor even the low inductance in the track to the VB supply will limit

the current and delay the activation of the

thyristor clamp.

The programmed line current, I

LProg

, must

be less than 55 mA when using the TISP

PBL1 to ensure that the TISP holding current is not exceeded. For higher programmed line currents, the TISP PBL2 is

recommended.

The fuse resistors R

F

serve the dual purposes of being non- destructive energy

dissipators, when transients are clamped

and of being fuses, when the line is exposed to a power cross.

Note that it is always important to use

resistors not sensitive to temperature in

series with PTC´s since the PTC acts as a

capacitance for transients. Otherwise the

SLIC is not protected properly.

Page 16

PBL 386 61/2

16

Preliminary

Figure 13. Battery feed characteristics (without the protection resistors on the line).

A: IL (@ VTR = 0) = I

LConst ILConst

(typ) = I

LProg

=

500

R

LC

(14)

B, C: IL = I

LConst

VTR = V

BatVirt

- R

Feed

• (I

LProg

- 5•10-3)

D: R

Feed

=

R

SG

+ 40

400

E: IL ≈ 5 mA

F: Apparent battery V

App

(@IL = 0) = V

BatVirt

+ 5•10

-3

• R

Feed

G: R

FeedG

= 2 • 25 Ω

H: V

TRMax

= |V

Bat

| - V

BOH

J: Virtual battery V

BatVirt

(@ IL = 5 mA) = |V

Bat

| - 6.8

(17)

C

D

B

E

G

F

F

J

H

C

D

A

VTR [V]

I

L

[mA]

DC characteristics

B

Power-up Sequence

No special power-up sequence is necessary except that ground has to be present

before all other power supply voltages.

The digital inputs C1 and C2 are internal

pull-up terminals.

Printed Circuit Board Layout

Care in Printed Circuit Board (PCB) layout

is essential for proper function;

The components connecting to the RSN

input should be placed in close proximity to

that pin, such that no interference is injected into the RSN pin. Ground plane surrounding the RSN pin is advisable.

Analog ground (AGND) should be con-

nected to battery ground (BGND) on the

PCB in one point.

R

LC

and R

REF

should be connected to

AGND with short leads. Pin LP, pin PSG

and pin AOV are sensitive to leakage currents. Pin AOV should be surrounded by a

guardring connected to AGND.

RSG and CLP connections to VBAT should

be short and very close to each other.

CB and CB2 must be connected with short

wide leads.

Page 17

PBL 386 61/2

17

Preliminary

Notes

Note 11

.

3.1 V

Peak

if AOV-pin is left open and 0.6 V

Peak

if AOV-pin is connected to AGND.

Note 12

.

R

Feed

lower than 2x50Ω will reduce noise

and PSRR performance in resistive loop

region (reference D in figure 13). Better

PSRR performance can be achieved by

increasing CLP and CHP.

Note 13.

If the momentary value of the current in

TIPX-pin or RINGX-pin exceeds 85mA

harmonic distortion specification can be

derated.

Note 14.

The accurate equation for RLC is:

R

LC

=

500 - 10.4

• In (I

LProg

• 32)

I

LProg

I

LProg

Note 15.

6.0V when AOV-pin is not connected, 3.9V

when AOV-pin is connected to AGND.

Note 16.

2.2V

RMS

if AOV-pin is left open and 0.4V

RMS

if AOV-pin is connected to AGND.

Note 17.

6.8V when AOV-pin is left open, 4.2V when

AOV-pin is connected to AGND.

Page 18

PBL 386 61/2

18

Preliminary

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties

which may result from its use. No license is granted by

implication or otherwise under any patent or patent

rights of Ericsson Microelectronics AB. These products

are sold only according to Ericsson Microelectronics

general conditions of sale, unless otherwise confirmed

in writing.

Specifications subject to change without

notice.

1522-PBL 386 61/2 Uen Rev.2A

© Ericsson Microelectronics AB, 2000

This product is an original Ericsson product

protected by US, European and other

patents.

Ericsson Microelectronics AB

SE-164 81 Kista-Stockholm, Sweden

Telephone: +46 8 757 50 00

Ordering Information

Package Temp. Range Part No.

28pin PLCC Tube 0 °C - + 70 °C PBL 386 61/2QNS

28pin PLCC Tape & Reel 0 °C - + 70 °C PBL 386 61/2QNT

Loading...

Loading...