Page 1

PBD 3517/1

Stepper Motor

Drive Circuit

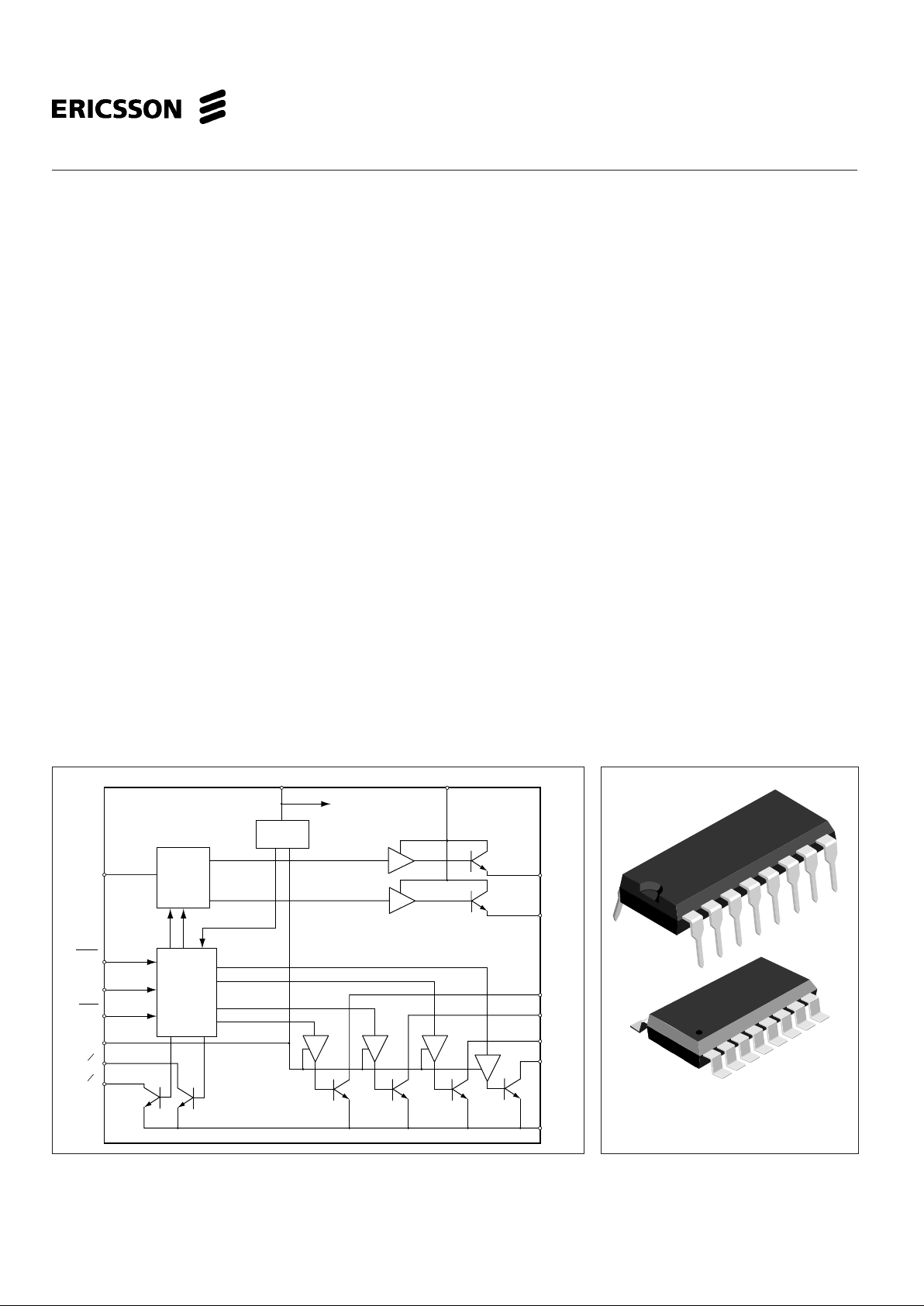

Figure 1. Block diagram.

February 1999

16-pin plastic DIP

16-pin SO (wide body)

RC

STEP

DIR

HSM

INH

O

A

OB

L

A

L

B

P

B2

P

B1

P

A2

P

A1

GND

V

CC

V

SS

PBD 3517/1

PQR

Mono

F - F

Phase

Logic

P

A

P

B

Description

PBD 3517/1 is a bipolar, monolithic, integrated circuit, intended to drive a stepper motor

in a unipolar, bilevel way.

One PBD 3517/1 and a minimum of external components form a complete control

and drive unit for LS-TTL- or microprocessor-controlled stepper motor system for

currents up to 500mA. The driver is suited for applications requiring least-posssible RFI.

Motor performance can be increased by operating in a bilevel drive mode. This

means that a high voltage pulse is applied to the motor winding at the beginning of a

step, in order to give a rapid rise of current.

Key Features

• Complete driver and phase logic on

chip

• 2 x 350 mA continuous-output current

• Half- and full-step mode generation

• LS-TTL-compatible inputs

• Bilevel drive mode for high step rates

• Voltage-doubling drive possibilities

• Half-step position-indication output

• Minimal RFI

• 16-pin plastic DIP package or 16 pin

small outline wide body

PBD 3517/1

PBD 3517/1

1

Page 2

PBD 3517/1

2

Maximum Ratings

Parameter Pin No. Symbol Min Max Unit

Voltage

Logic supply 16 V

CC

07V

Second supply 15 V

SS

045V

Logic input 6, 7, 10, 11 VI -0.3 6 V

Current

Phase output 1, 2, 4, 5 I

P

0 500 mA

Second-level output 13, 14 I

L

-500 0 mA

Logic input 6, 7, 10, 11 I

I

-10 mA

The zero output 8, 9 I

Ο

6mA

Temperature

Operating junction temperature T

J

-40 +150 °C

Storage temperature T

S

-55 +150 °C

Power Dissipation (Package Data)

Power dissipation at TA = 25°C, DIP package. Note 2. P

D

1.6 W

Power dissipation, SO package. Note 3. P

D

1.3 W

Recommended Operating Conditions

Parameter Symbol Min Typ Max Unit

Logic supply voltage V

CC

4.75 5 5.25 V

Second-level supply voltage V

SS

10 40 V

Phase output current I

P

0 350 mA

Second-level output current I

L

-350 0 mA

Operating junction temperature T

J

-20 +125 °C

Set-up time t

s

400 ns

Step-pulse duration t

p

800 ns

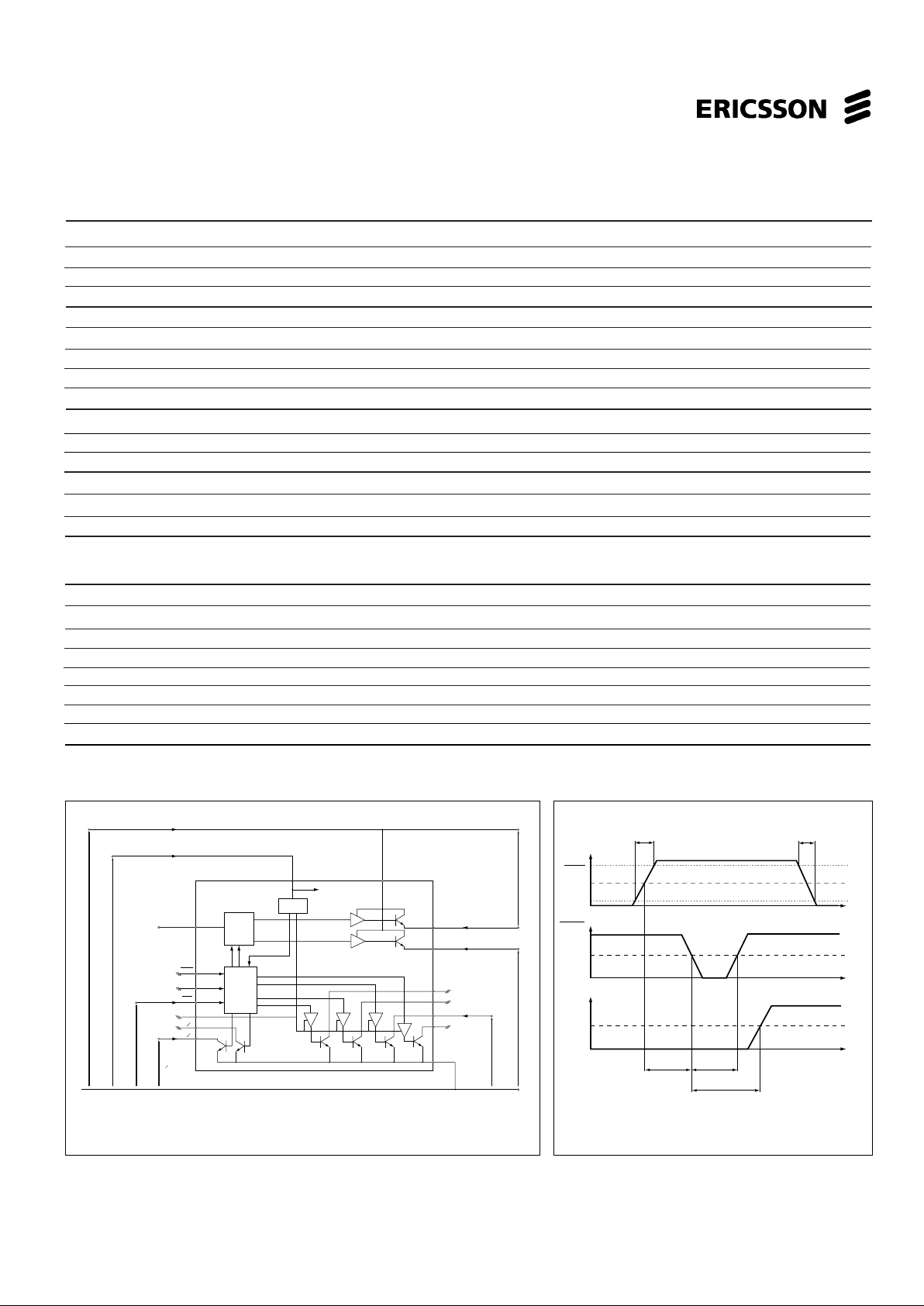

Figure 2. Definition of symbols.

HSM

or

DIR

V

I

STEP

I

P

t

t

t

t

r

t

f

t

s

t

p

t

d

Figure 3. Timing diagram

.

RC 12

STEP 7

DIR 6

HSM 10

INH 11

O

A

9

OB 8

13 L

A

14 L

B

1 P

B2

2 P

B1

5 P

A2

4 P

A1

3 GND

V

CC

16

V

SS

15

PBD 3517/1

PQR

Mono

F - F

Phase

Logic

P

A

P

B

V

CC

V

SS

V

I

V

IH

V

IL

V

OCE Sat

V

LCE Sat

V

L

V

PCE Sat

V

P

IPI

PL

I

LL

I

L

IIIILI

IH

I

SS

I

CC

Page 3

PBD 3517/1

3

Electrical Characteristics

Electrical characteristics at TA = +25°C, VCC = +5.0 V, VMM = +40 V, VSS = +40 V unless otherwise specified.

Ref.

Parameter Symbol Fig. Conditions Min Typ Max Unit

Supply current I

CC

2 INH = LOW 45 60 mA

2 INH = HIGH 12 mA

Phase outputs

Saturation voltage V

PCE Sat

4IP = 350 mA 0.85 V

Leakage current I

PL

2VP = 0 V 500 µA

Turn on, turn off t

d

3 +70°C3µs

t

d

3 +125°C6µs

Second-level outputs

Saturation voltage V

LCE Sat

4IL = -350 mA 2.0 V

Leakage current I

LL

2VL = 0 V -500 µA

On time t

On

11 (note 4) 220 260 300 µs

Logic inputs

Voltage level, HIGH V

IH

2 2.0 V

Voltage level, LOW V

IL

2 0.8 V

Input current, low I

IL

2VI = 0.4 V -400 µA

Input current, high I

IH

2VI = 2.4 V 20 µA

Logic outputs

Saturation voltage V

ØCE Sat

5IØ = 1.6 mA 0.4 V

Notes

1. All voltages are with respect to ground. Current are positive into, negative out of specified terminal.

2 Derates at 12,8 mW/°C above +25°C.

3. Derates at 10.4 mW/°C above +25°C.

4. R

T

= 47 kΩ, CT = 10 nF.

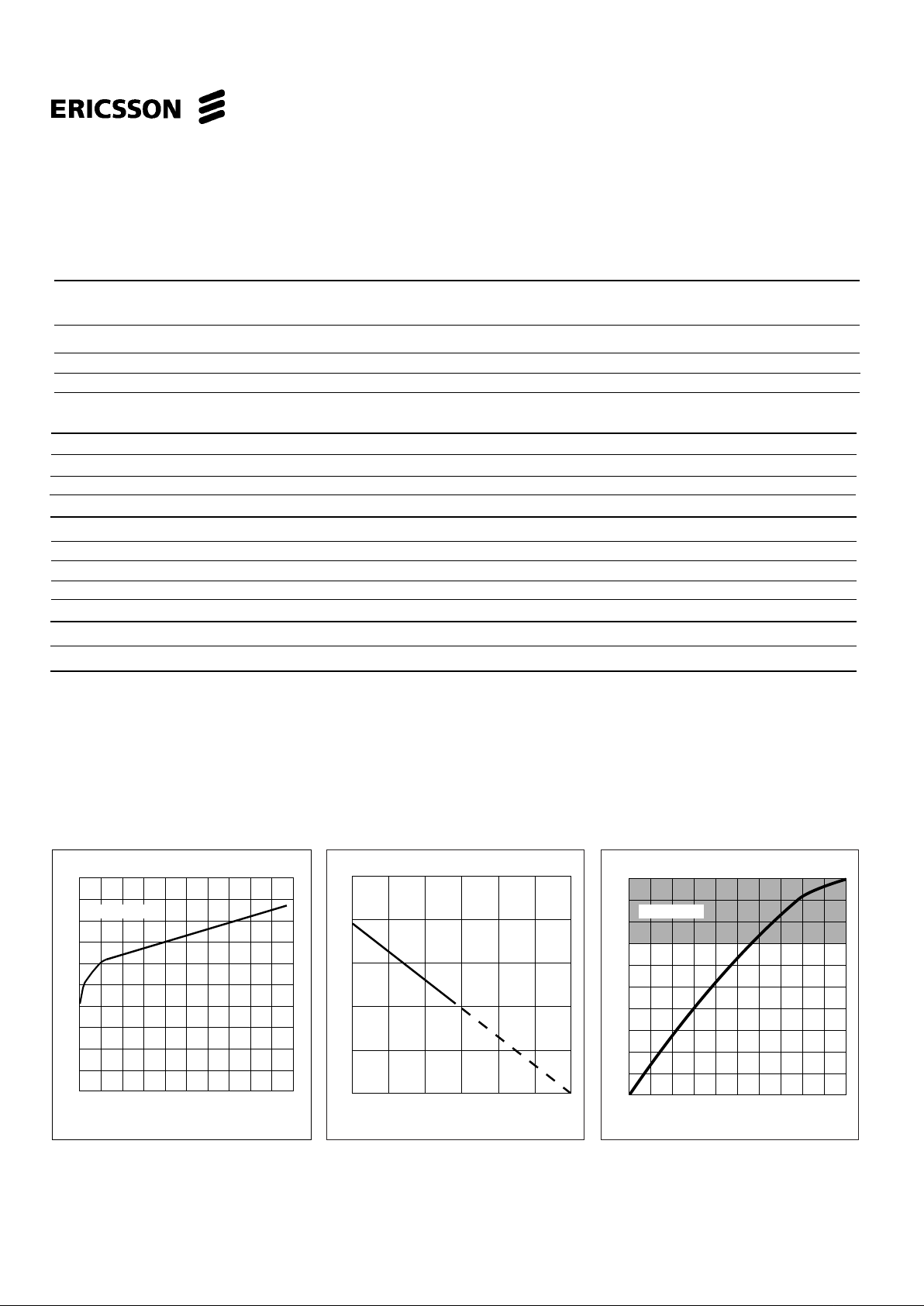

Figure 5. Typical second level saturation

voltage vs output current.

Figure 4. Typical phase output saturation

voltage vs. output current.

Figure

2.5

2.0

1.5

1.0

0,5

0

0 0.1 0.2 0.50.40.3

V

LCE

sat [V]

I

L

[A]

TA= +25° C

2.5

2.0

1.5

1.0

0,5

0

0 50 100 150

Allowable power dissipation [W]

Ambient temrature [°C]

0.5

0.4

0.3

0.2

0.1

0

0 0.2 0.4 1.00.80.6

Output Current [A]

Output Voltage [V]

TA= +25° C

Page 4

PBD 3517/1

4

Diagrams

How to use the diagrams:

1. What is the maximum motor current

in the application?

• The ambient temperature sets the

maximum allowable power

dissipation in the IC, which

relates to the motor currents and

the duty cycle of the bilevel

function. For PBD 3517/1, without

any measures taken to reduce

the chip temperature via

heatsinks, the power dissipation

vs. temperature follows the curve

in figure 4.

• Figures 9 and 10 give the

relationship between motor

currents and their dissipations.

The sum of these power dissipations must never exceed the

previously-established value, or

life expectancy will be drastically

shortened.

• When no bilevel or voltage

doubling is utilized, the maximum

motor current can be found

directly in figure 9.

2. How to choose timing components.

• Figure 7 shows the relationship

between C

T

, RT, and tOn. Care

must be taken to keep the tOn time

short, otherwise the current in the

winding will rise to a value many

times the rated current, causing

an overheated IC or motor.

3. What is the maximum t

On

pulse-width

at a given frequency?

• Figure 8 shows the relationship

between duty cycle, pulse width,

and step frequency. Check

specifications for the valid

operating area.

4. Figures 4, 5 and 6 show typical

saturation voltages vs. output current

levels for different output transistors.

5. Shaded areas represent operating

conditions outside the safe operating

area.

Figure 7. Typical IØ vs. V

ØCE Sat

. “Zero

output” saturation.

Figure 8. Typical t

On

vs. CT/RT. Output

pulse width vs. capacitance/resistance.

Figure 9. Typical tOn vs. fs/dc. Output pulse

width vs. step frequency/duty cycle

.

Figure 10. Typical PDP vs. IP. Power

dissipation without second-level supply

(includes 2 active outputs = FULL STEP)

.

Figure 11. Typical PDI vs. II. Power

dissipation in the bilevel pulse when

raising to the II value. One active output.

Figure 12 . Motor Current 1p.

TA= +25° C

10

8

6

4

2

0

0 0.2 0.4 1.00.80.6

Output Current [A]

Output Voltage [V]

1

10

-1

10

-6

0.01 0.1 1 100010010

Output Pulse Width [s]

Ct Capacitance [nF]

10

-2

10

-3

10

-4

10

-5

TA= +25° C

Rt = 10M

Rt = 100k

Rt = 10k

Rt = 1k

1

10

-1

10

-6

0.001 0.01 0.1 100101

Output Pulse Width [s]

fs Step frequency [kHz]

10

-2

10

-3

10

-4

10

-5

TA= +25° C

50%

25%

Dutycykle

100%

0.1%

1%

10%

0.5

0.4

0.3

0.2

0.1

0

0 0.2 0.4 1.00.80.6

Output Current [A]

Power Dissipation [W]

TA= +25° C

(II = 0)

-0.5

-0.4

-0.3

-0.2

-0.1

0

0 0.2 0.4 1.00.80.6

Output Current [A]

Power Dissipation [W]

TA= +25° C

(Ip = 0)

10% 50% 100%

350

Motor Current [mA]

t

ON

Time

Normal

Bilevel

Bilevel without

time limit

Page 5

PBD 3517/1

5

Pin Description

DIP SO-pack. Symbol Description

11 PB2Phase output 2, phase B. Open collector output capable of sinking max 500 mA.

22 P

B1

Phase output 1, phase B. Open collector output capable of sinking max 500 mA.

3 3 GND Ground and negative supply for both V

CC

and VSS.

44 P

A1

Phase output 1, phase A.

55 P

A2

Phase output 2, phase A.

6 6 DIR Direction input. Determines in which rotational direction steps will be taken.

7 7 STEP Stepping pulse. One step is generated for each negative edge of the step signal.

8 8 ØB Zero current half step position indication output for phase B.

9 9 ØA Zero current half step position indication output for phase A.

10 10 HSM Half-step mode. Determines whether the motor will be operated in half or full-step

mot. When pulled low, one step pulse will correspond to a half step of the motor.

11 11 INH A high level on the inhibit input turns all phase output off.

12 12 RC Bilevel pulse timing pin. Pulse time is approximately t

on

= 0.55 • RT • C

T

13 13 LA Second level (bilevel) output, phase A.

14 14 LB Second level (bilevel) output, Phase B.

15 15 V

SS

Second level supply voltage, +10 to +40 V.

16 16 V

CC

Logic supply voltage, nominally +5 V.

Figure 13. Pin configuration.

B2

B1

GND

A1

A2

DIR

STEP

B

V

V

L

L

R

INH

HSM

Ø

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

P

P

P

P

A

C

A

B

SS

CC

Ø

B2

B1

GND

A1

A2

DIR

STEP

B

V

V

L

L

R

INH

HSM

Ø

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

P

P

P

P

A

C

A

B

SS

CC

Ø

PBD

3517/1N

PBD

3517/1SO

Page 6

PBD 3517/1

6

determined by VSS voltage and motor

data, the L/R time-constant.

In a low-voltage system, where high

motor performance is needed, it is also

possible to double the motor voltage by

adding a few external components, see

figure 14.

The time the circuit applies the higher

voltage to the motor is controlled by a

monostable flip-flop and determined by

the timing components RT and CT.

The circuit can also drive a motor in

traditional unipolar way.

An inhibit input (INH) is used to switch

off the current completely.

Logic inputs

All inputs are LS-TTL compatible. If any

of the logic inputs are left open, the

circuit will accept it as a HIGH level. PBD

3517/1 contains all phase logic

necessary to control the motor in a

proper way.

Functional Description

The circuit, PBD 3517/1, is a high

perform-ance motor driver, intended to

drive a stepper motor in a unipolar, bilevel

way. Bilevel means that during the first

time after a phase shift, the voltage

across the motor is increased to a second

voltage supply, VSS, in order to obtain a

more-rapid rise of current, see figure 11.

The current starts to rise toward a

value which is many times greater than

the rated winding current. This compensates for the loss in drive current and loss

of torque due to the back emf of the

motor.

After a short time, tOn, set by the

monostable, the bilevel output is switched

off and the winding current flows from the

VMM supply, which is chosen for rated

winding current. How long this time must

be to give any increase in performance is

STEP — Stepping pulse

One step is generated for each negative

edge of the STEP signal. In half-step

mode, two pulses will be required to move

one full step. Notice the set up time, t

s

, of

DIR and HSM signals. These signals

must be latched during the negative edge

of STEP, see timing diagram, figure 3.

DIR — Direction

DIR determines in which direction steps

will be taken. Actual direction depends on

motor and motor connections. DIR can be

changed at any time, but not simultaneously with STEP, see timing diagram,

figure 3.

HSM determines whether the motor will

be controlled in full-step or half-step

mode. When pulled low, a step-pulse will

correspond to a half step of the motor.

HSM can be changed at any time, but not

simultaneously with STEP, see timing

diagram, figure 3.

Figure 15. Voltage

doubling with

external

transistors.

Figure 14.

Typical

application.

RC 12

STEP 7

DIR 6

HSM 10

INH 11

O

A

9

OB 8

13 L

A

14 L

B

1 P

B2

2 P

B1

5 P

A2

4 P

A1

3 GND

V

CC

16

V

SS

15

PBD 3517/1

PQR

Mono

F - F

Phase

Logic

P

A

P

B

STEP

CW / CCW

HALF / FULL STEP

NORMAL /INHIBIT

(Optional Sensor)

GND

V

CC

CMOS, TTL-LS

Input / Output-Device

V

SS

+ 5V

GND (V

CC

)

V

MM

R9 R8

R

T

C

T

C3C4C

5

+++

R11 R10

D2 D1

MOTOR

D3-D6

D3-D6 are

UF 4001 or

BYV 27

trr < 100 ns

GND (VMM,VSS)

D3

+

RC 12

STEP 7

DIR 6

HSM 10

INH 11

O

A

9

OB 8

13 L

A

14 L

B

1 P

B2

2 P

B1

5 P

A2

4 P

A1

3 GND

V

CC

16

V

SS

15

PBD 3517/1

PQR

Mono

F - F

Phase

Logic

P

A

P

B

STEP

CW / CCW

HALF / FULL STEP

NORMAL /INHIBIT

(Optional Sensor)

GND

V

CC

CMOS, TTL-LS

Input / Output-Device

V

MM

+ 5V

GND (V

CC

)

R9 R8

R

T

C

T

C3C

4

++

R10

D1

1/2 MOTOR

GND (V

MM,VSS

)

R1

R2

Q1

Q3

C1

R12 R13

R4

R5

Q5

Q6

Equal to

Phase A

Page 7

PBD 3517/1

7

Purpose of external components

For figures 14 and 15. Note that “Larger than …” is normally the vice versa of “Smaller

than … .”

Component Purpose Value Larger than value Smaller than value

D1, D2 Passes low power to

motor and prevents

high power from

shorting through low

power supply

If = 1A

1N4001, UF4001

Increases price Decreases max

current capability

D3 … D6 Inductive current

supressor

Increases price Decreases current

turn-off capability

trr = 100nS

e.g. BYV27

UF4001

RGPP10G

RGPP30D

Slows down turnoff time. Voltage

at anode might

exceed voltage

breakdown

Speeds up turn-

off time.

R1 Base drive current

limitter

R = 20ohm

2

Slows down Q1’s

turn-on and Q4’s

turn-off time.

Speeds up Q1’s

turn-on and Q4’s

turn-off time.

R2, R3 Base discharge resistor R = 240ohm

2

Slows down Q1’s

turn-off and Q4’s

turn-on time.

Speeds up Q1’s

turn-off and Q4’s

turn-on time.

R4 … R7 External transistor base

driver

Vmm - Vbe - V

ce

R =

P > (I4)2 • R4

Check hfe.

Decreases ext.

transistor IC max.

Lowers 3517

power dissipation.

Increases ext.

transistor IC max.

Increases 3517

power dissipation.

R8, R9 ØA, ØB pull-up

resistors

R = 5ohm @ pull-up

voltage = 5V.

Increases noise

sensitivity, worse

logic-level

definition

Increases noise

immunity, better

logic-level

definition.

Less stress on ØA,

ØB output

transistors

Stress on ØA, ØB

output

transistors.

R10, R11 Limit max. motor

current. Resistors may

be omitted. (Check

motor specifications

first.)

Vmm -V

Motor

-V

CESat

R =

I

Motor max

Decreases motor

current.

Increases motor

current.

R12 … R15 External transistor base

discharge.

V

be

R =

ª 15

W

I

12

P > Vbe • I

12

Slows down

external transistor

turn-off time.

Lowers 3517

power dissipation

Speeds up

external transistor

turn-off time.

Increases 3517

power dissipation

RT, CT Sets LA and LB on time

when triggered by

STEP.

R = 47kohm, C = 10nf

P < 250mW

Increases on time. Decreases on time.

C1, C2 Stores the doubling

voltage.

C = 100µF

VC ≥ 45V

Increases effective

on-time during

voltage doubling

Decreases

effective on-time

during voltage

doubling.

C3 … C5 Filtering of supply-

voltage ripple and takeup of energy feedback

from D3 … D6

C µF Increases price,

better filtering,

decreases risk of

IC breakdown

Decreases price,

more compact

solution.

V

Rated

>Vmm,Vss or VccIncreases price Risk for capacitor

breakdown.

Q1, Q2 Activation transistor of

voltage doubling.

IC as motor requires. Increases price. Decreases max I

m

during voltage

doubling.

Q3, Q4 Charging of voltage

doubling capacitor

Q5 … Q8 Motor current drive

transistor. PNP power trans.

Increases max

current capability.

Decreases max

current capability.

If = 1A

V

mm

P = R1

)

R1 + R

2

(

V

mm

P = R1

)

R1 + R

2

(

V

be

I4 -

)

R12

(

(VCC)

2

P =

R

(V

mm

- Vf -VCE) • C1

IC =

(

- 0.55 • RT • C

T

1

f

Step

)

IC as motor requires.

10≥

INH — Inhibit

A HIGH level on the INH input,turns off all

phase outputs to reduce current

consumption.

Reset

An internal Power-On Reset circuit

connected to Vcc resets the phase logic

and inhibits the outputs during power up,

to prevent false stepping.

Output Stages

The output stage consists of four opencollector transistors. The second highvoltage supply contains Darlington

transistors.

Phase Outputs

The phase outputs are connected directly

to the motor as shown in figure 14.

Bilevel Technique

The bilevel pulse generator consists of

two monostables with a common RC

network.

The internal phase logic generates a

trigger pulse every time the phase

changes state. The pulse triggers its own

monostable which turns on the output

transistors for a precise period of time:

t

On

= 0.55 • CT • RT.

See pulse diagrams, figures 16 through

20.

Bipolar Phase Logic Output

The ØA and ØB outputs are generated

from the phase logic and inform an

external device if the A phase or the B

phase current is internally inhibited.

These outputs are intended to support if it

is legal to correctly go from a half-step

mode to a full-step mode without loosing

positional information.

The PBD 3517/1 can act as a controller

IC for 2 driver ICs, the PBL 3770A. Use

PA1 and PB1 for phase control, and ØA and

ØB for I0 and I1 control of current turn-off.

Applications Information

Logic inputs

If any of the logic inputs are left open, the

circuit will treat it as a high-level input.

Unused inputs should be connected to

proper voltage levels in order to get the

highest noise immunity.

Phase outputs

Page 8

PBD 3517/1

8

Phase outputs use a current-sinking

method to drive the windings in a unipolar

way. A common resistor in the center tap

will limit the maximum motor current.

Fast free-wheeling diodes must be

used to protect output transistors from

inductive spikes. Alternative solutions are

shown in figures 21 through 25 on pages

6 - 10.

Series diodes in VMM supply, prevent

VSS voltage from shorting through the V

MM

power supply. However, these may be

omitted if no bilevel is used. The VSS pin

must not be connected to a lower voltage

than VMM, but can be left unconnected.

Zero outputs

Ø

A

and ØB, “zero A” and “zero B,” are

open-collector outputs, which go high

when the corresponding phase output is

inhibited by the half-step-mode circuitry. A

pull-up resistor should be used and

connected to a suitable supply voltage (5

kohms for 5V logic). See “Bipolar phase

logic output.”

Interference

To avoid interference problems, a good

idea is to route separate ground leads to

each power supply, where the only

common point is at the 3517/1’s GND pin.

Decoupling of V

SS

and VMM will improve

performance. A 5 kohm pull-up resistor at

logic inputs will improve level definitions,

especially when driven by open-collector

outputs.

Input and Output Signals for

Different Drive Modes

The pulse diagrams, figures 16 through

20, show the necessary input signals and

the resulting output signals for each drive

mode.

On the left side are the input and output

signals, the next column shows the state

of each signal at the cursor position

marked “C.”

STEP is shown with a 50% duty cycle,

but can, of course, be with any duty cycle,

as long as pulse time (tp) is within

specifications.

PA and PB are displayed with low level,

showing current sinking.

LA and LB are displayed with high level,

showing current sourcing.

Figure 16. Full-step mode, forward. 4-step sequence. Gray-code +90° phase shift.

Figure 17. Full-step mode, reverse. 4-step sequence. Gray-code -90° phase shift.

Figure 20. Half-step mode, inhibit.

Figure 18. Half-step mode, forward. 8-step sequence.

DIR

INH

HSM

STEP

OB

LB

PB1

PB2

PA1

PA2

LA

OA

H

L

H

P

L

P

P

P

P

P

P

L

DIR

INH

HSM

STEP

OB

LB

PB1

PB2

PA1

PA2

LA

OA

H

L

L

P

P

P

P

P

P

P

P

P

C

DIR

INH

HSM

STEP

OB

LB

PB1

PB2

PA1

PA2

LA

OA

L

L

L

P

P

P

P

P

P

P

P

P

C

DIR

INH

HSM

STEP

OB

LB

PB1

PB2

PA1

PA2

LA

OA

L

H

L

P

P

P

H

H

H

H

P

P

C

Figure 19. Half-step mode, reverse. 8-step sequence.

DIR

INH

HSM

STEP

OB

LB

PB1

PB2

PA1

PA2

LA

OA

H

L

H

P

L

P

P

P

P

P

P

L

Page 9

PBD 3517/1

9

V

Z

R

R

Ext

i

Figure 24. Power return turn-off circuit. Figure 25. Power return turn-off circuit for

bilevel .

Figure 22. Resistance turn-off circuit.

Figure 23. Zener diode turn-off circuit.

Figure 21. Diode turn-off circuit.

7. To change actual motor rotation

direction, exchange motor connections at PA1 and PA2 (or PB1 and PB2).

8. Half-stepping. in the half-step mode,

the power input to the motor alternates between one or two phase

windings. In half-step mode, motor

resonances are reduced. In a twophase motor, the electrical phase

shift between the windings is 90

degrees. The torque developed is the

vector sum of the two windings

energized. Therefore, when only one

winding is energized, which is the

case in half-step mode for every

second step, the torque of the motor

is reduced by approximately 30%.

This causes a torque ripple.

9. Ramping. Every drive system has

inertia which must be considered in

the drive scheme. The rotor and load

inertia plays a big role at higher

speeds. Unlike the DC motor, the

stepper motor is a synchronous

motor and does not change speed

due to load variations. Examination of

typical stepper motors’ torque versus

speed curves indicates a sharp

torque drop-off for the start-stop

without error curve. The reason for

this is that the torque requirements

increase by the cube of the speed

change. As it can be seen, for good

motor performance, controlled

acceleration and deceleration should

be considered.

User Hints

1. Never disconnect ICs or PC-boards

when power is supplied.

2. If second supply is not used, disconnect and leave open V

SS

, LA, LB, and

RC. Preferably replace the V

MM

supply diodes (D1, D2) with a straight

connection.

3. Remember that excessive voltages

might be generated by the motor,

even though clamping diodes are

used.

4. Choice of motor. Choose a motor

that is rated for the current you need

to establish desired torque. A high

supply voltage will gain better

stepping performance. If the motor is

not specified for the V

MM

voltage, a

current limiting resistor will be

necessary to connect in series with

center tap. This changes the L/R

time constant.

5. Never use L

A

or LB for continuous

output at high currents. L

A

and LB ontime can be altered by changing the

RC net. An alternative is to trigger

the mono-flip-flop by taking a STEP

and then externally pulling the RC

pin (12) low (0V) for the desired ontime.

6. Avoid V

MM

and VSS power supplies

with serial diodes (without filter

capacitor) and/or common ground

with V

CC

. The common place for

ground should be as close as

possible to the IC’s ground pin (pin

3).

V

1

V

2

C

S

0V

Power supply

Page 10

PBD 3517/1

10

Zener diode T O C (figure 23)

Relatively high VZ gives:

— Relatively fast current decay

— Energy lost mainly in V

Z

— Potential cooling problems

Power return T O C for unipolar drive

(figure 24)

Relatively high V

Z

gives:

— Relatively fast current decay

— Energy returned to power supply

— Only small energy losses

— Winding leakage flux must be

considered

— Potential cooling problems

Power return to T O C for bilevel drive

(figure 25)

— Very fast current decay

— Energy returned to power supply

— Only small energy losses

— Winding leakage flux must be

considered

Common Fault Conditions

•VMM supply not connected, or V

MM

supply not connected through diodes.

• The inhibit input not pulled low or

floating. Inhibit is active high.

• A bipolar motor without a center tap is

used. Exchange motor for unipolar

version. Connect according to figure

14.

• External transistors connected without

proper base-current supply resistor.

• Insufficient filtering capacitors used.

• Current restrictions exceeded.

•L

A

and LB used for continuous output at

high currents. Use the RC network to

set a proper duty cycle according to

specifications, see figures 6 through

11.

• A common ground wire is used for all

three power supplies. If possible, use

separate ground leads for each supply

to minimize power interference.

Ericsson Components AB

SE-164 81 Kista-Stockholm, Sweden

Telephone: +46 8 757 50 00

Specifications subject to change without

notice.

1522-PBD 3517/1 Uen Rev. C

© Ericsson Components AB 1999

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties

which may result from its use. No license is granted

by implication or otherwise under any patent or patent

rights of Ericsson Components. These products are

sold only according to Ericsson Components' general

conditions of sale, unless otherwise confirmed in

writing.

Drive Circuits

If high performance is to be achieved from

a stepper motor, the phase must be

energized rapidly when turned on and

also de-energize rapidly when turned off.

In other words, the phase current must

increase/decrease rapidly at phase shift.

Phase Turn-off

Considerations

When the winding current is turned off the

induced high voltage spike will damage

the drive circuits if not properly suppressed. Different turn-off circuits

are used; e. g. :

Diode turn-off circuit (figure 21)

— Slow current decay

— Energy lost mainly in winding

resistance

— Potential cooling problems.

Resistance T O C (figure 22)

— Somewhat faster current decay

— Energy lost mainly in R-Ext

— Potential cooling problems

Ordering Information

Package Part No.

DIP Tube PBD 3517/1NS

SO Tube PBD 3517/1SOS

SO Tape & Reel PBD 3517/1SOT

Loading...

Loading...