Page 1

Non-Linear High Speed Termination IC

n

n

r

PACNLT101

Features

• 16 channel, dual rail clamping action in

a single package

• Provides bus termination independent of line

impedance or loading conditions

• Uses CAMD’s patented EZterm™ technology

• 24-pin QSOP package saves board space and

eases layout in space critical areas.

• One IC replaces and outperforms up to 32 discrete

components.

• Enable pin included

Product Description

CAMD’s non-linear termination IC is specifically designed to minimize overshoot/undershoot disturbances

caused by impedance mismatch reflections and noise on

high-speed transmission lines.

Reflections on high-speed data lines lead to voltage

overshoot and undershoot disturbances, which may

result in data loss or improper system operation. Resistive terminations, when used to terminate these highspeed data lines, increase power consumption and

degrade output levels, resulting in reduced noise immunity. Clamping-type termination is the best overall

solution for applications in which these may be considerations.

This highly integrated non-linear termination IC provides

very effective termination performance for high-speed

data lines under variable loading conditions. The device

supports up to 16 terminated lines per package – each

of which are clamped to both ground and power supply

rail. A typical application may use 4 devices to replace

(and outperform) 64 conventional Schottky diode pairs;

thus providing significant reductions in component and

assembly costs, improvements in manufacturing efficiency and reliability, and savings in allocated board area

for space-critical designs.

Application

• High speed, low voltage buses

Pin Configuratio

Top View

NLT#1

NLT#2

NLT#3

GND

1

2

3

4

5NLT#4 20 NLT#15

6NLT#5 19 NLT#14

7NLT#6 18 NLT#13

8NLT#7 17 NLT#12

9GND 16 GND

10NLT#8 15 NLT#11

11NLT#9 14 Enable

12NLT#10 13 V

PACNLT101

24-Pin QSOP

24

23

22

21

V

DD

V

DD

NLT#16

GND

DD

Standard Part Ordering Informatio

Package Ordering Part Numbe

24 QSOP PACNLT101Q PACNLT101Q

©2001 California Micro Devices Corp. All rights reserved. EZterm™ is a trademark of California Micro Devices

3/8/2001

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

Style Tape & Reel Part Marking

C1601100

1

Page 2

PACNLT101

gs

g

t

6

3V

T

0

0V

T

5V

T

0

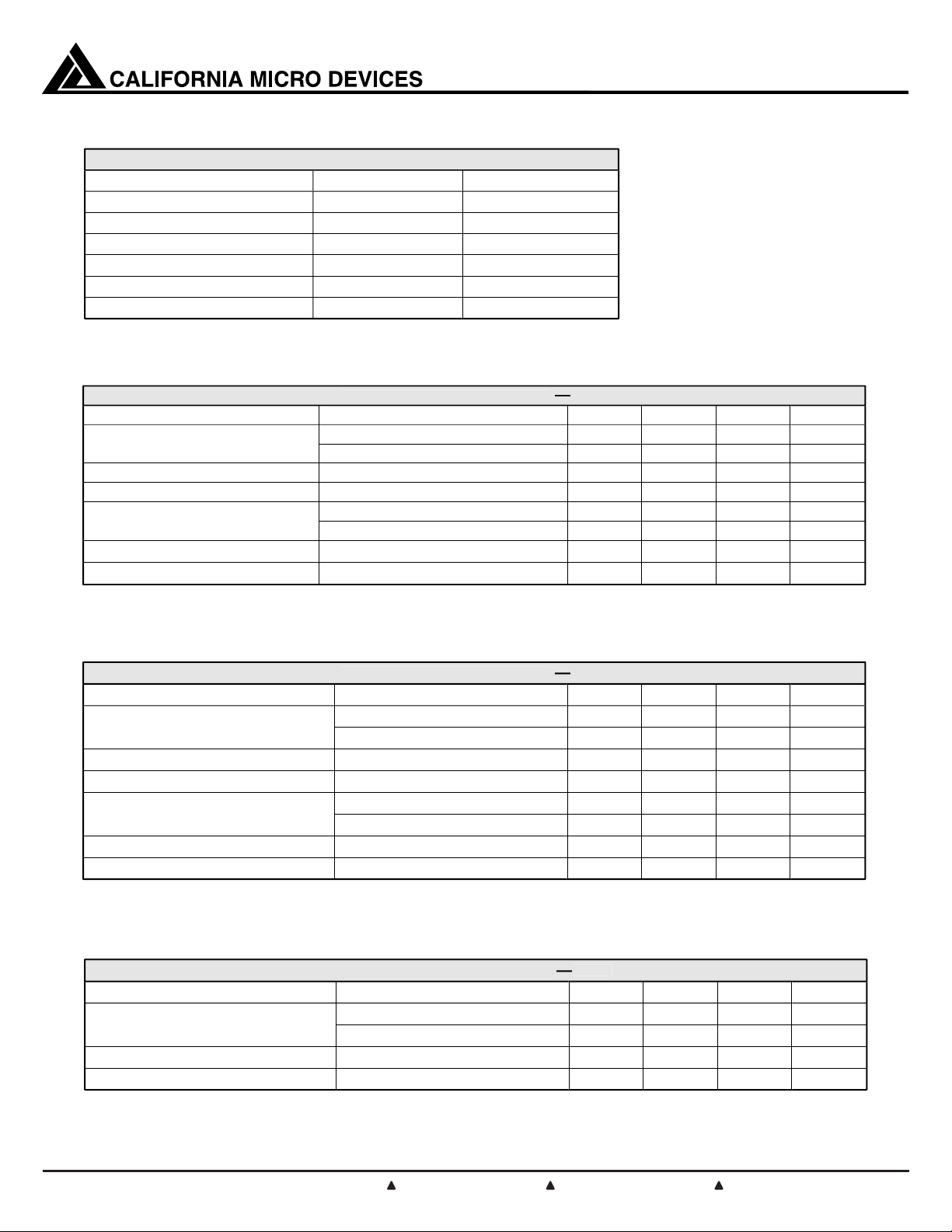

Absolute Maximum Ratin

Parameter Ratin

Maximum DC Voltage on any pin

Minimum DC Voltage on any pin –0.5 V

Continuous current per channel 72 mA

Operating Temperature (Ambient) –40 to 85

Storage Temperature (Ambient) –65 to 150

Power Dissipation @ T = 25

C 0.9 W

˚

.

Operating Characteristics - VDD = 3.3V, Enable = 3.3V, Temperature = –40°C to 85°C

Operating Characteristics

Parameter

Signal Voltage

below GND @ I = –50mA 510 750 mV

current all Channels floating 85 150 mA

V

DD

Enable pin (pin 14) current all Channels floating 10 15 mA

Input Capacitance* Signal voltage = V

Signal voltage = V

ESD protection MIL-STD-883, method 3015*

Response Time 400 ps

*These parameters are guaranteed by design and characterization.

ove V @ I = 50mA

onditions

3.4 pF

DD

3.0 pF

DD/2

ni

C

˚

C

˚

3.

1

kV

4

NI

Operating Characteristics - VDD = 2V, Enable = 2V, Temperature = –40°C to 85°C

Parameter

Signal Voltage

Operating Characteristics

onditions

ove V @ I = 20mA

2.

below GND @ I = –20mA 300 500 mV

current all Channels floating 25 42 mA

V

DD

Enable pin (pin 14) current all Channels floating 3.5 5.5 mA

Input Capacitance* Signal voltage = V

Signal voltage = V

3.5 pF

DD

3.2 pF

DD/2

ESD protection MIL-STD-883, method 3015* 4 kV

Response Time 400 ps

*These parameters are guaranteed by design and characterization.

Operating Characteristics - VDD = 2.5V, Enable = 2.5V, Temperature = 27°C

Parameter

Signal Voltage

Operating Characteristics

onditions

ove V @ I = 30mA 47

2.

below GND @ I = –30mA 375 mV

current all Channels floating 50 mA

V

DD

Enable pin current all Channels floating 6 mA

NI

NI

©2001 California Micro Devices Corp. All rights reserved. EZterm™ is a trademark of California Micro Devices

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

2

3/8/2001

Page 3

50

45

40

35

30

25

20

Current (mA)

15

10

5

0

0 100 200 300 400 500 600

VDD = 3.3V

VDD = 2.0V

PACNLT101

Voltage above V

Figure 1. DC I-V Curves for VDD = 2V and VDD = 3.3V

Application Information

Figure 2 shows one method of configuring the printed

circuit board such that all 16 terminated signals are

easily accessible. The decoupling capacitor should be a

high-frequency type, 0.1µF or larger, and placed as close

to the IC as possible. This will minimize

GND GND

16

Terminated

Signals

GND

(mV)

DD

the positive overshoot voltage and also reduce

EMI emissions. It should be noted that for optimum

performance the PACNLT101 termination should be

located as physically close to the receiving IC input as is

possible.

V

1

2

3

4

520

619

PACNLT101

718

817

916

10 15

11 14

12 13

24

23

22

21

GND

via

0.1µF

DD

Figure 2. Printed Circuit Board with Accessible Configuration for 16 Terminated Signals

©2001 California Micro Devices Corp. All rights reserved. EZterm™ is a trademark of California Micro Devices

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

3/8/2001

3

Page 4

V

CC

Non-Linear

Driver

7SZ04

Transmission

Line

Clamp

Termination

Receiver

74AC244

GND

Figure 3. Example Circuit: Single-Driver/Single Receiver

PACNLT101

Tek 136 Acqs

5GS/s

1V

Ch1

Figure 4. 74AC244 Termination Only

Tek 44 Acqs

5GS/s

∆: 2.50V

@: 0V

C1 Rise

1.14ns

C1 Fall

1ns

C1 Max

3.30V

C1 Min

–1.20V

1.24VM 10ns

∆: 2.50V

@: 0V

C1 Rise

1.18ns

1V

Figure 5. With PACNLT101 Termination

©2001 California Micro Devices Corp. All rights reserved. EZterm™ is a trademark of California Micro Devices

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

4

Ch1

C1 Fall

1ns

C1 Max

2.82V

C1 Min

–500mV

1.24 VM 10ns

3/8/2001

Page 5

Enable pin

PACNLT101

In normal use the Enable pin is connected to VDD.

If the Enable pin is set to 0V or disconnected (high

impedance), then the PACNLT101 will be disabled. The

supply current will drop to almost zero and the clamping

performance will be worsened.

The Enable pin can also be used to vary the supply

current and clamping voltage. As the current into the

Enable pin is increased the supply current will increase

and the clamping voltage will be reduced. The minimum

clamping voltage will occur when the Enable pin voltage

equals the supply voltage. (The Enable pin voltage

PACNLT101

Enable

Figure 6. Resistor In Series with the Enable Pin

100

90

80

70

60

50

(mA)

40

DD

I

30

20

10

0

0 100 220 470 1000 2200

Value of External Resistor R1 (Ω)

cannot exceed the supply voltage.)

Users who cannot tolerate the supply current quoted in

the Operating Characteristics can connect a resistor in

series with the Enable pin to reduce the supply current,

at the cost of increasing the clamping voltage. See

Figure 6.

The controller IC sets the powerdown pin to 0V to

powerdown the PACNLT101, and sets the powerdown

pin to V

to power up the PACNLT101. The system

DD

designer can vary the value of R1 to optimize the tradeoff between power consumption and clamping voltage.

See Figure 7, 8, 9, and 10.

R1

Controller

Powerdown

800

750

700

650

for 50mA (mV)

DD

600

Clamping Voltage

550

above V

500

0 100 220 470 1000 2200

Value of External Resistor R1 (Ω)

Figure 7. IDD vs R1 @ VDD = 3.3V

30

25

20

15

(mA)

DD

I

10

5

0

0 100 220 470 1000 2200 4700 10000 100000

Value of External Resistor R1 (Ω)

Figure 9. I

©2001 California Micro Devices Corp. All rights reserved. EZterm™ is a trademark of California Micro Devices

215 Topaz Street, Milpitas, California 95035 Tel: (408) 263-3214 Fax: (408) 263-7846 www.calmicro.com

3/8/2001

vs R1 @ VDD = 2V Figure 10. Clamping Voltage vs R1 @ VDD = 2V

DD

Figure 8. Clamping Voltage vs R1 @ VDD = 3.3V

650

600

550

500

for 20mA (mV)

450

DD

400

Clamping Voltage

above V

350

300

0 100 220 470 1000 2200 4700 10000 100000

Value of External Resistor R1 (Ω)

5

Loading...

Loading...