Page 1

MICROTECHNOLOGY

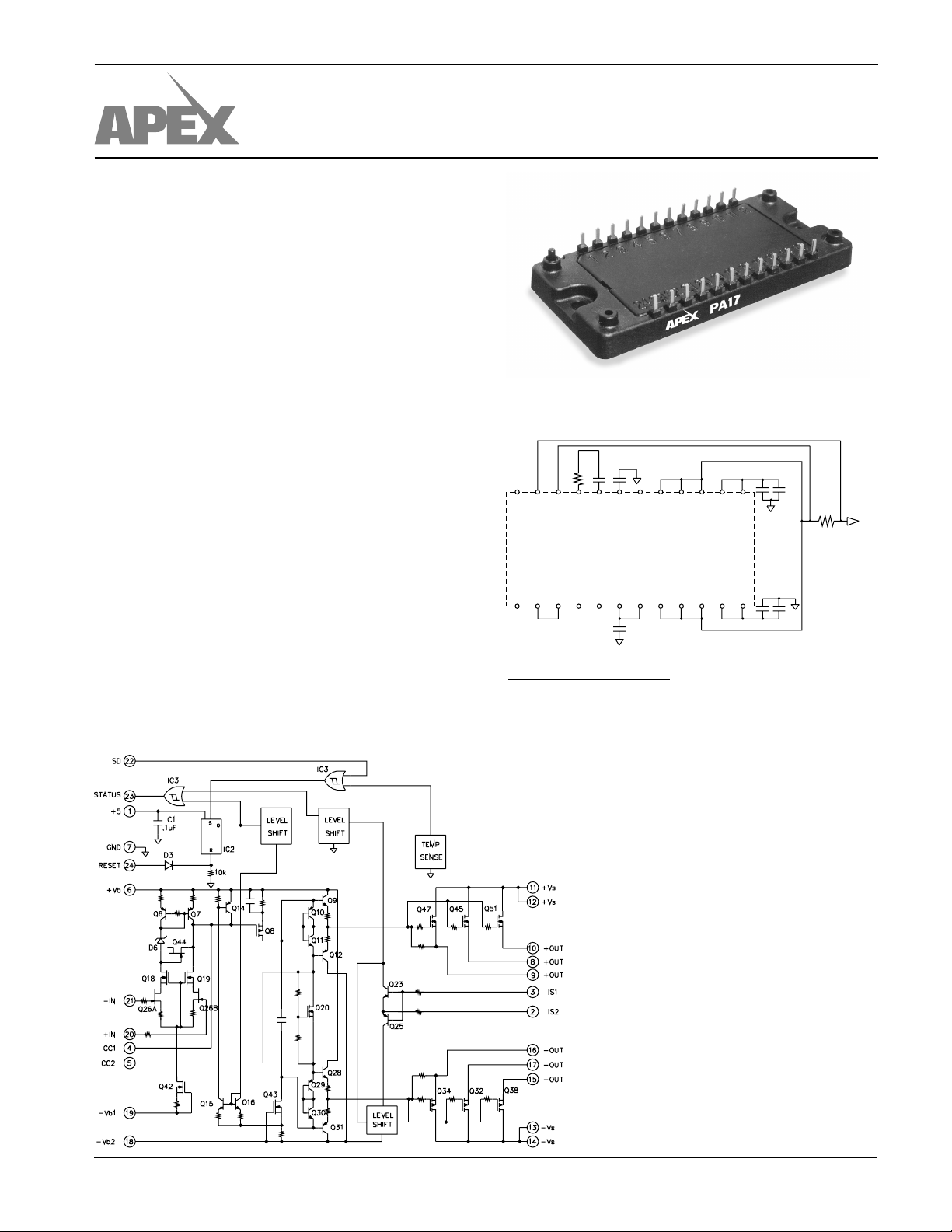

1 2 3 4 5 6 7 8 9 10 11 12

24 23 22 21 20 19 18 17 16 15 14 13

LOAD

+5V

IS2

IS1

CC1

CC2

+Vb

GND

+OUT

+OUT

+OUT

+Vs

+Vs

RESET

STATUS

SHT DN

-IN

+IN

-Vb2

-Vb1

– OUT

– OUT

– OUT

– Vs

– Vs

Rcl**

PIN SIDE VIEW

* BYPASSING OF SUPPLIES IS REQUIRED

** SEE TEXT FOR OTHER CURRENT

LIMIT CONNECTIONS

PHASE COMPENSATION

GAIN Rc Cc

1 100 470pF

>3 SHORT 220pF

>10 SHORT 100pF

100 SHORT 10pF

Rc

Cc

**

*

*

*

*

POWER OPERATIONAL AMPLIFIER

PA17

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

FEATURES

PRELIMINARY

• HIGH INTERNAL DISSIPATION — 850 WATTS

• HIGH VOLTAGE, HIGH CURRENT — 200V

50A CONTINUOUS, 100A PULSE

• HIGH SLEW RATE — 50V/µS

• 4 WIRE CURRENT LIMIT SENSING

• EXTERNAL SHUT DOWN CONTROL

• OPTIONAL BOOST VOLTAGE INPUTS

APPLICATIONS

• SEMI CONDUCTOR TESTING

• SONAR TRANSDUCER DRIVER

• LINEAR AND ROTARY MOTOR DRIVES

• YOKE/MAGNETIC FIELD EXCITATION

DESCRIPTION

The PA17 is a high voltage MOSFET power operational

amplifier that extends the performance limits of power amplifiers in slew rate and power bandwidth, while maintaining high

current and power dissipation ratings.

The PA17 is a highly flexible amplifier. The shutdown

feature allows ultra-low quiescent current for standby operation or load protection by disabling the entire amplifier. Boost

voltage inputs allow the small signal portion of the amplifier to

operate at a higher voltage than the high current output stage.

The amplifier is then biased to achieve close linear swings to

the supply rails at high currents for extra efficient operation.

External compensation tailors performance to user needs. A

four wire sense technique allows current limiting without the

need to consider internal or external milliohm parasitic resistance in the output line.

EXTERNAL CONNECTIONS

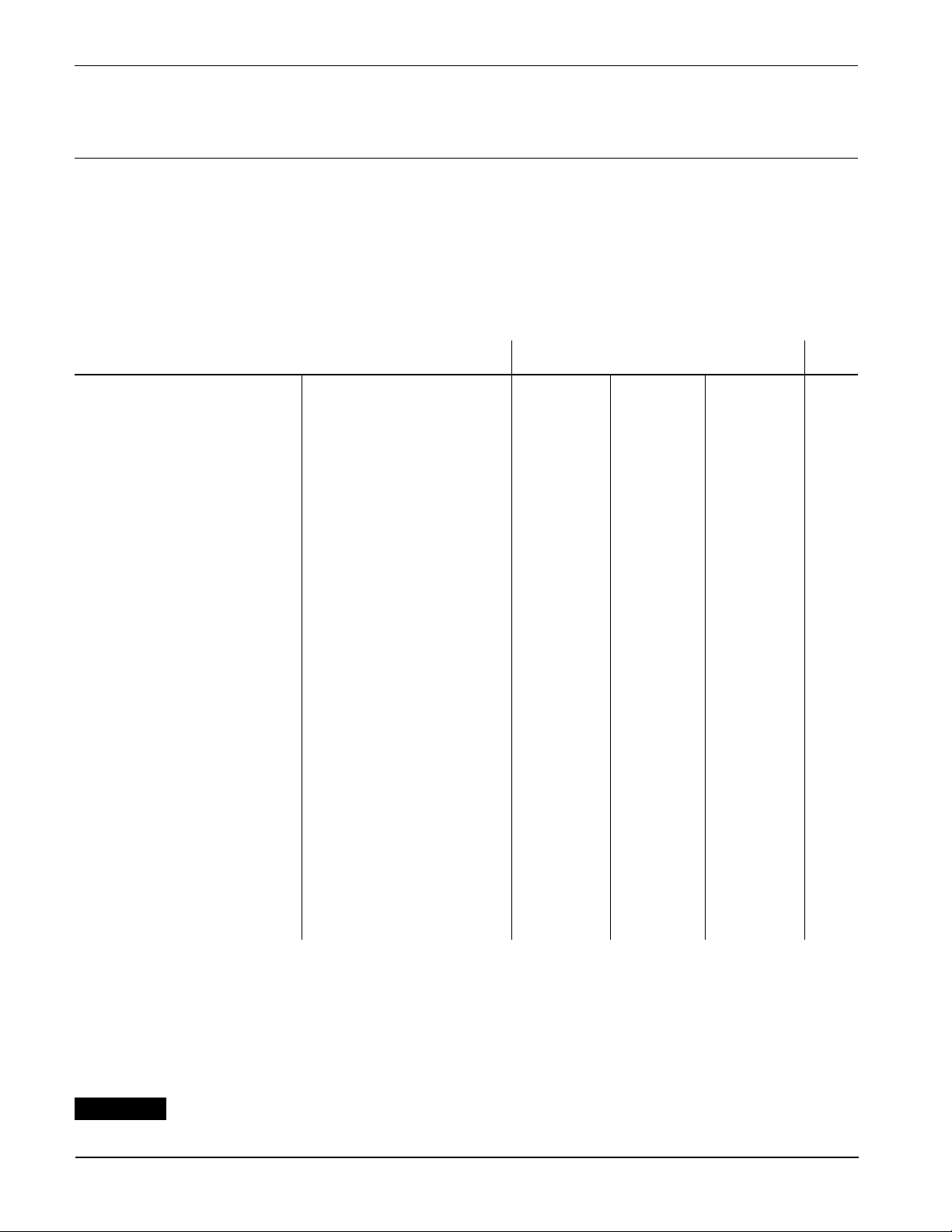

EQUIVALENT SCHEMATIC

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

Page 2

PA17

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

SUPPLY VOLTAGE, +VS to –V

BOOST VOLTAGE ±VS±20V

S

200V

OUTPUT CURRENT, within SOA 100A

POWER DISSIPATION, internal 850W

INPUT VOLTAGE, differential ±20V

INPUT VOLTAGE, common mode ±V

TEMPERATURE, pin solder - 10s 300°C

TEMPERATURE, junction

2

B

150°C

TEMPERATURE, storage –65 to +150°C

OPERATING TEMPERATURE RANGE, case –25 to +85°C

SPECIFICATIONS

PARAMETER TEST CONDITIONS

INPUT

OFFSET VOLTAGE, initial 510mV

OFFSET VOLTAGE, vs. temperature Full temperature range 30 50 µV/°C

OFFSET VOLTAGE, vs. supply 15 µV/V

BIAS CURRENT, initial 10 50 pA

BIAS CURRENT, vs. supply .01 pA/V

OFFSET CURRENT, initial 10 50 pA

INPUT IMPEDANCE, DC 10

INPUT CAPACITANCE 4pF

COMMON MODE VOLTAGE RANGE Full temperature range ±VB 10 V

COMMON MODE REJECTION, DC Full temp. range, VCM = ±20V 86 98 dB

INPUT NOISE 100kHz BW, RS = 1KΩ 10 µVrms

GAIN

OPEN LOOP, @ 15Hz Full temperature range, CC = 100pF 94 102 dB

GAIN BANDWIDTH PRODUCT IO = 10A 2 MHz

POWER BANDWIDTH RL = 4.5Ω, VO = 180V p-p 90 kHz

1

MIN TYP MAX UNITS

11

Ω

±

PHASE MARGIN Full temperature range 60 °

OUTPUT

VOLTAGE SWING

VOLTAGE SWING

CURRENT, peak

5

5

5

IO = 50A ±VS 8.8 ±VS 7.5 V

±VB=±Vs ± 10V, IO = 50A ±VS 6.8 ±VS 5.5 V

±

±

100 A

±

±

SETTLING TIME to .1% 2.5 µs

SLEW RATE Cc= 100pF 40 50 V/µs

CAPACITIVE LOAD AV = +1 10 nF

POWER SUPPLY

VOLTAGE Full temperature range ±15 ±75 ±100 V

CURRENT, quiescent, boost supply 30 mA

CURRENT, quiescent, total 120 mA

CURRENT, quiescent, total, shutdown Full temperature range 22 mA

THERMAL

RESISTANCE, AC, junction to case

3

Full temperature range, F>60Hz .1 °C/W

RESISTANCE, DC, junction to case Full temperature range, F<60Hz .15 °C/W

RESISTANCE4, junction to air Full temperature range 10 °C/W

TEMPERATURE RANGE, case Meets full range specification –25 85 °C

NOTES 1. Unless otherwise noted: TC = 25°C. DC input specifications are ± value given. Power supply voltage is typical rating.

±VB= ±VS, Cc = 470pF, Rc=100Ω.

2. Long term operation at the maximum junction temperature will result in reduced product life. Derate internal power dissipation

to achieve high MTTF. For guidance, refer to the heatsink data sheet.

3. Rating applies if the output current alternates between both output transistors at a rate faster than 60 Hz.

4. The PA17 must be used with a heatsink or the quiescent power may drive the unit to junction temperatures higher than 150°C.

5. Parameter guaranteed but not tested.

CAUTION

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

The PA17 is constructed from MOSFET transistors. ESD handling procedures must be observed.

Page 3

OPERATING CONSIDERATIONS

PA17

GENERAL

Please read Application Note 1 "General Operating Considerations" which covers stability, supplies, heat sinking, mounting, current limit, SOA interpretation, and specification interpretation. Visit www.apexmicrotech.com for design tools that

help automate tasks such as calculations for stability, internal

power dissipation, current limit; heat sink selection; Apex’s

complete Application Notes library; Technical Seminar Workbook; and Evaluation Kits.

CURRENT LIMIT

The positive and negative outputs of the PA17 must be

connected together by the user. However, the fact that multiple

pins share the output current allows for some unusual current

limit schemes not found in amplifiers with a single output pin.

Three pins each in the positive and negative outputs share

the output current of the PA17. Pins 8 and 10 of the positive

output and pins 15 and 17 of the negative output each carry

approximately 25% of the output current. Pin 9 of the positive

output and pin 16 of the negative output carry the remaining

50% of the output current .

For the current limit to operate correctly pin 3 (IS1) must be

connected to the amplifier output side and pin 2 (IS2) connected to the load side of the current limit resistor Rcl, as

shown in Figure 1. But Rcl may be connected to sample only

a fraction of the output current. With this method the current

limit resistor consumes less power and only slightly lowers the

overall accuracy of the current limit set point. Figure 1, shows

a circuit that samples only 25% of the output current. Only

those pins necessary to illustrate the current limit function are

shown in Figure 1.

FIGURE 1.

In addition, the current limit of the PA17 operates differently

than other Apex linear power amplifiers in that the output

current is not clamped at the current limit set point. Instead,

when an over-current condition is detected the PA17 sets

STATUS (pin 23) high. This flag can alert external circuitry to

do a variety of things to deal with this fault condition. For

example, when STATUS is connected directly to SD (pin 22)

the output stage of the PA17 is disabled until RESET (pin 24)

is toggled high (Figure 1). Another possibility would be to

connect STATUS to the SD pin via a RC circuit to delay the

shutdown of the output stage (Figure 2). This technique would

be useful if a short-term overload is normally expected that

does not exceed the safe operating area of the PA17. In still

another variation STATUS could trigger an external timer that

would periodically reset the PA17 until the fault is cleared.

STATUS, SHUTDOWN AND RESET FUNCTIONS

The 5V logic section of the PA17 provides control and

monitoring functions. The PA17 is protected from thermal

overloads by directly measuring the temperature of the output

transistors. When a thermal overload is detected the output

stage is latched off and the STATUS output goes high, indicating an alarm condition. A high on the RESET pin resets the

output stage. A high on the SHUTDOWN pin will also latch the

output stage off and forces the STATUS pin high. The SHUTDOWN pin can be used to put the PA17 in a standby mode to

lower the quiescent current and standby power dissipation. A

thermal overload immediately latches off the output stage and

cannot be delayed by external circuitry.

BOOST OPERATION

With the V

amplifier are operated at higher supply voltages than the

amplifier’s high current output stage. +V

–V

(pins 18, 19) are connected to the small signal circuitry

BOOST

of the amplifier. +V

connected to the high current output stage. An additional 10V

on the V

BOOST

to drive the output transistors into saturation and improve the

output voltage swing for extra efficient operation when required. When close swings to the supply rails is not required

the +V

BOOST

the –V

BOOST

at a voltage lower than the V

feature the small signal stages of the

BOOST

(pin 6) and

BOOST

(pins 11,12) and –VS (pins 13, 14) are

S

pins is sufficient to allow the small signal stages

and +VS pins must be strapped together as well as

and –VS pins. The boost voltage pins must not be

pins.

S

COMPENSATION

The external compensation components CC and RC are

connected to pins 4 and 5. Unity gain stability can be achieved

at any compensation capacitance greater than 330 pF with at

least 60 degrees of phase margin. At higher gains more phase

shift can be tolerated in most designs and the compensation

capacitance can accordingly be reduced, resulting in higher

bandwidth and slew rate. Use the typical operating curves as

a guide to select C

FIGURE 2.

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

PA17U REV 3 JUNE 2000 © 2000 Apex Microtechnology Corp.

and RC for the application.

C

Loading...

Loading...