Datasheet P87C592EFA-02, P80C592FHA-00, P80C592FFA-00, P87C592EFL-02, P87C592EFA-A2 Datasheet (Philips)

Page 1

DATA SH EET

Product specification

Supersedes data of January 1995

File under Integrated Circuits, IC18

1996 Jun 27

INTEGRATED CIRCUITS

P8xC592

8-bit microcontroller

with on-chip CAN

Page 2

1996 Jun 27 2

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 BLOCK DIAGRAM

5 PINNING

6 FUNCTIONAL DESCRIPTION

7 MEMORY ORGANIZATION

7.1 Program Memory

7.2 Internal Data Memory

7.3 External Data Memory

8 I/O PORT STRUCTURE

9 PULSE WIDTH MODULATED OUTPUTS

(PWM)

9.1 Prescaler frequency control register (PWMP)

9.2 Pulse Width Register 0 (PWM0)

9.3 Pulse Width Register 1 (PWM1)

10 ANALOG-TO-DIGITAL CONVERTER (ADC)

10.1 ADC Control register (ADCON)

11 TIMERS/COUNTERS

11.1 Timer 0 and Timer 1

11.2 Timer T2 Capture and Compare Logic

11.3 Watchdog Timer (T3)

12 SERIAL I/O PORT: SIO0 (UART)

13 SERIAL I/O PORT: SIO1 (CAN)

13.1 On-chip CAN-controller

13.2 CAN Features

13.3 Interface between CPU and CAN

13.4 Hardware blocks of the CAN-controller

13.5 Control Segment and Message Buffer

description

13.6 CAN 2.0A Protocol description

14 INTERRUPT SYSTEM

14.1 Interrupt Enable and Priority Registers

14.2 Interrupt Vectors

14.3 Interrupt Priority

15 POWER REDUCTION MODES

15.1 Power Control Register (PCON)

15.2 CAN Sleep Mode

15.3 Idle Mode

15.4 Power-down Mode

16 OSCILLATOR CIRCUITRY

17 RESET CIRCUITRY

17.1 Power-on Reset

18 INSTRUCTION SET

18.1 Addressing Modes

18.2 Instruction Set

19 ABSOLUTE MAXIMUM RATINGS (note 1)

20 DC CHARACTERISTICS

21 AC CHARACTERISTICS

22 CAN APPLICATION INFORMATION

22.1 Latency time requirements

22.2 Connecting a P8xC592 to a bus line

(physical layer)

23 PACKAGE OUTLINES

24 SOLDERING

24.1 Introduction

24.2 Reflow soldering

24.3 Wave soldering

24.4 Repairing soldered joints

25 DEFINITIONS

26 LIFE SUPPORT APPLICATIONS

Page 3

1996 Jun 27 3

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

1 FEATURES

• 80C51 central processing unit (CPU)

• 16 kbytes on-chip ROM,

externally expandible to 64 kbytes

• 2 × 256 bytes on-chip RAM,

externally expandible to 64 kbytes

• Two standard 16-bit timers/counters

• One additional 16-bit timer/counter coupled to four

capture and three compare registers

• 10-bit ADC with 8 multiplexed analog inputs

• Two 8-bit resolution Pulse Width Modulated outputs

• 15 interrupt sources with 2 priority levels

(2 to 6 external interrupt sources possible)

• Five 8-bit I/O ports, plus one 8-bit input port shared

with analog inputs

• CAN-controller (CAN = Controller Area Network)

with DMA data transfer facility to internal RAM

• 1 Mbit/s CAN-controller with bus failure

management facility

•1⁄2AVDD reference voltage

• Full-duplex UART compatible with the standard 80C51

• On-chip Watchdog Timer (WDT)

• 1.2 to 16 MHz clock frequency.

2 GENERAL DESCRIPTION

The P8xC592 is a single-chip 8-bit high-performance

microcontroller with on-chip CAN-controller, derived from

the 80C51 microcontroller family.

It uses the powerful 80C51 instruction set.

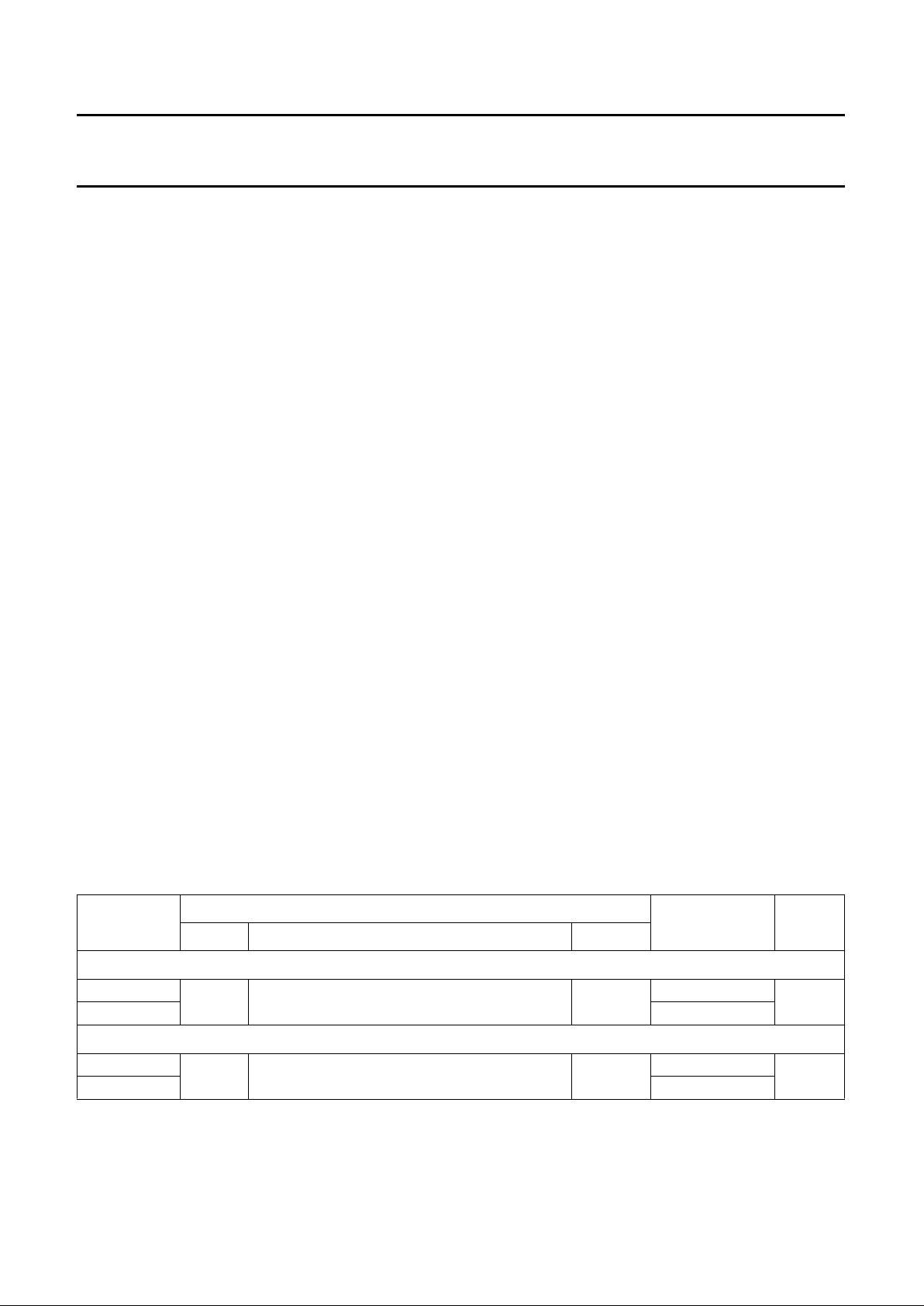

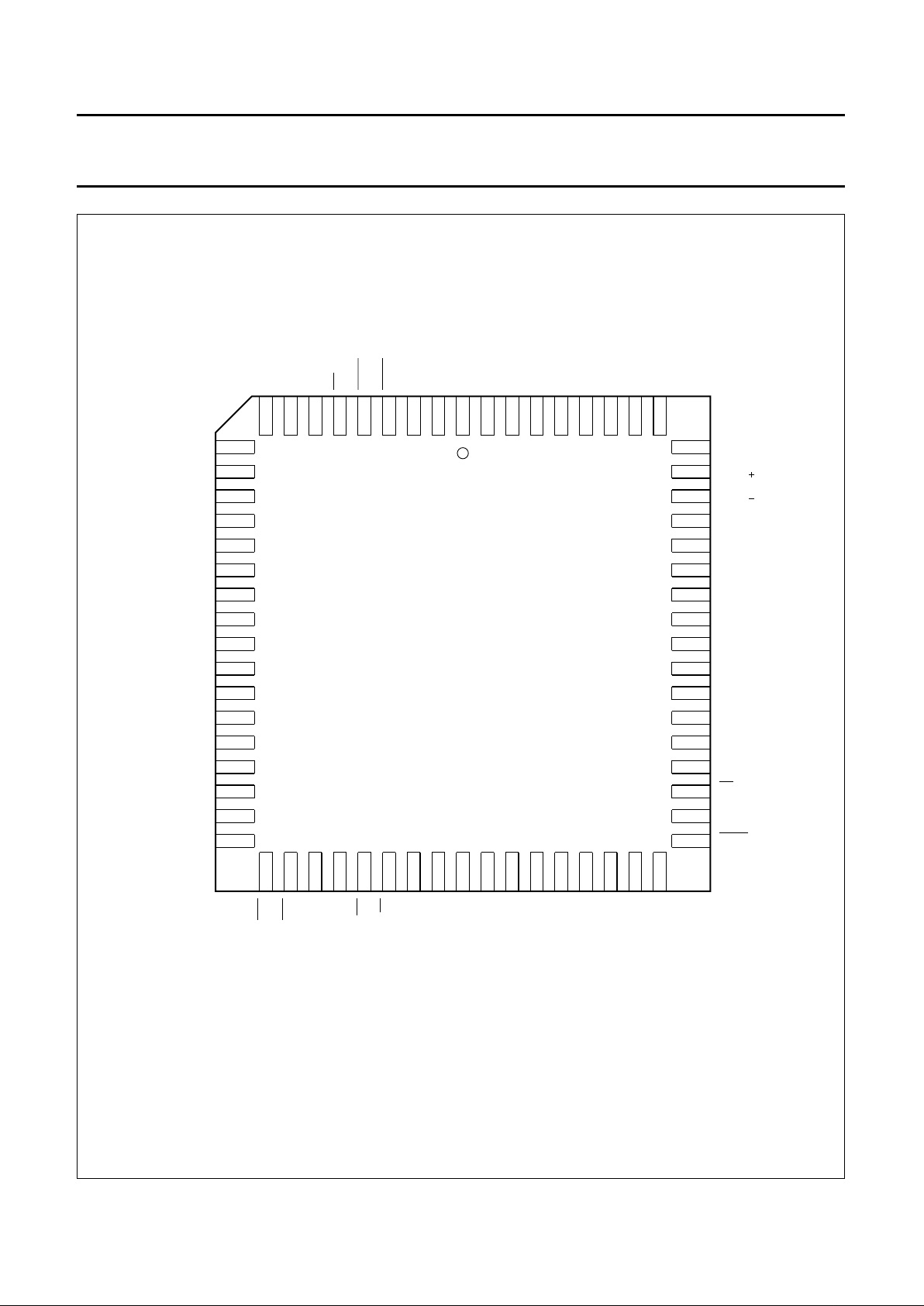

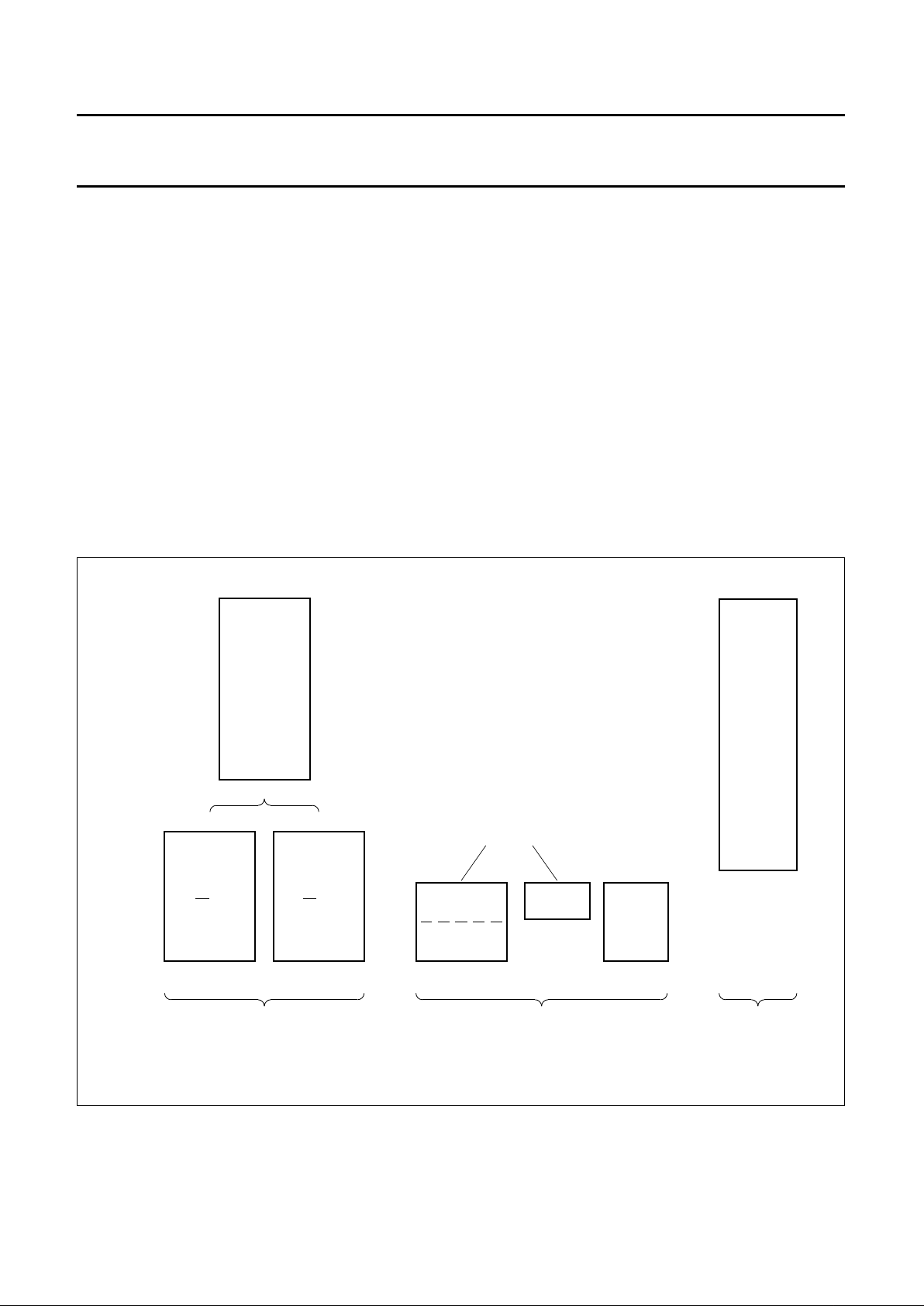

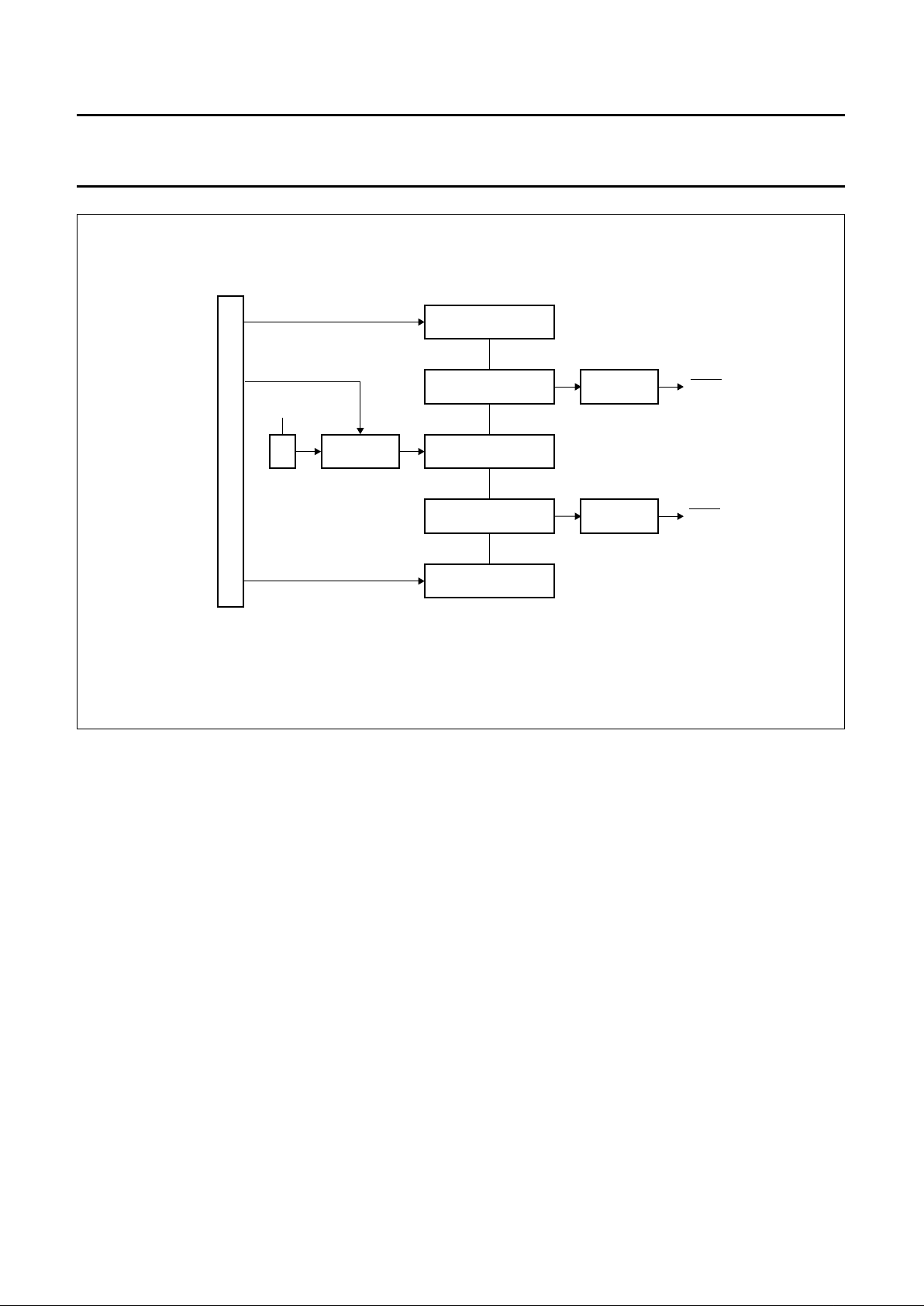

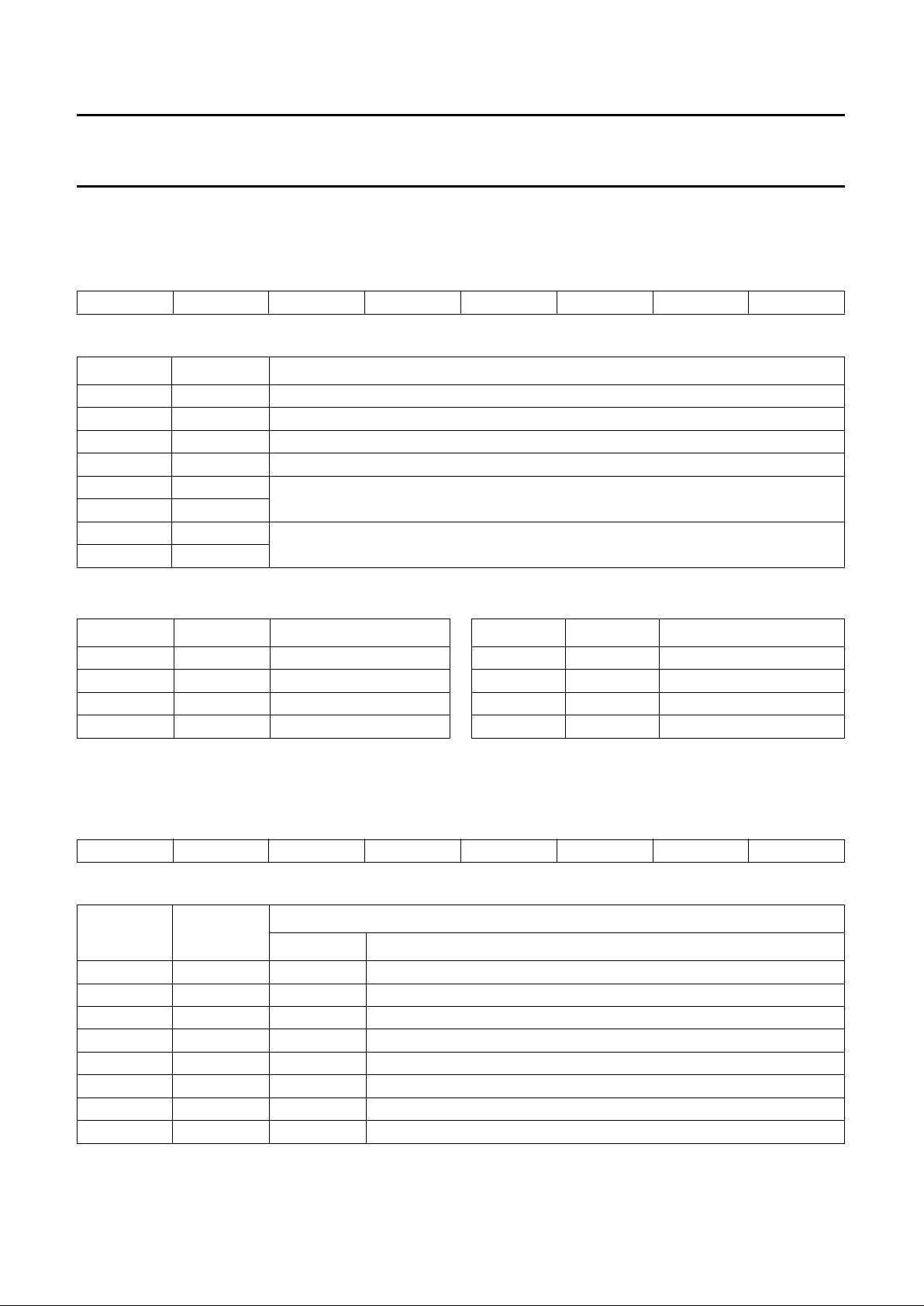

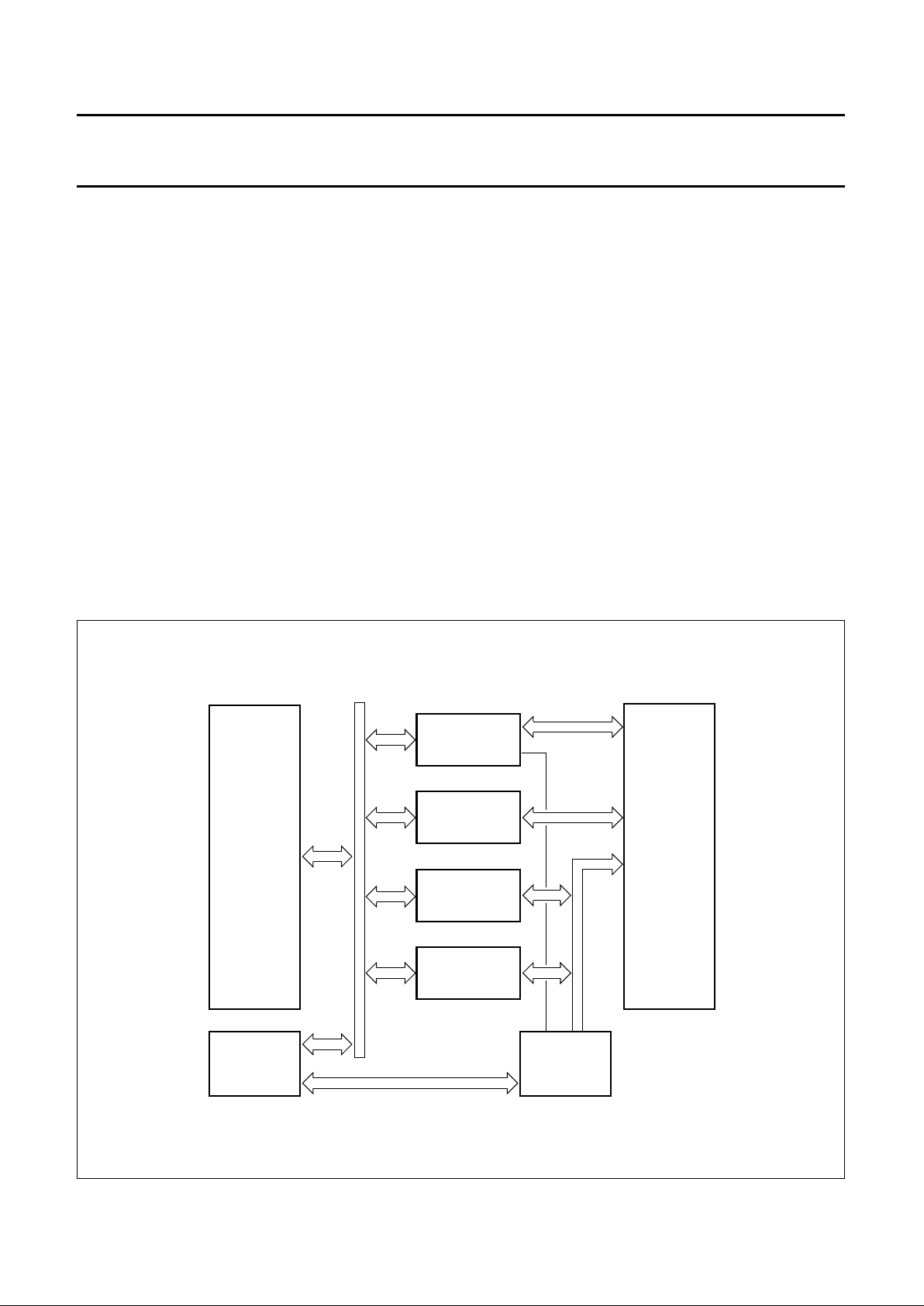

Figure 1 shows a block diagram of the P8xC592.

The P8xC592 is manufactured in an advanced CMOS

process, and is designed for use in automotive and

general industrial applications. In addition to the 80C51

standard features, the device provides a number of

dedicated hardware functions for these applications.

Two versions of the P8xC592 will be offered:

• P80C592 (without ROM)

• P83C592 (with ROM).

Hereafter these versions will be referred to as P8xC592.

The temperature range includes (max. f

CLK

= 16 MHz):

•−40 to +85 °C version, for general applications

•−40 to +125 °C version for automotive applications.

The P8xC592 combines the functions of the P8xC552

(microcontroller) and the PCA82C200 (Philips

CAN-controller) with the following enhanced features:

• 16 kbytes Program Memory

• 2 × 256 bytes Data Memory

• DMA between CAN Transmit/Receive Buffer and

internal RAM.

The main differences between P8xC592 and P8xC552

are:

• 16 kbytes programmable ROM (P8xC552 has 8 kbytes)

• Additional 256 bytes RAM

• A CAN-controller instead of the I2C-serial interface.

3 ORDERING INFORMATION

TYPE

NUMBER

PACKAGE

TEMPERATURE

RANGE (°C)

FREQ.

(MHz)

NAME DESCRIPTION VERSION

Without ROM

P80C592FFA

PLCC68 plastic leaded chip carrier; 68 leads SOT188-2

−40 to +85

1.2 to 16

P80C592FHA −40 to +125

With ROM

P83C592FFA

PLCC68 plastic leaded chip carrier; 68 leads SOT188-2

−40 to +85

1.2 to 16

P83C592FHA −40 to +125

Page 4

1996 Jun 27 4

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

4 BLOCK DIAGRAM

handbook, full pagewidth

handbook, full pagewidth

MGA146

RD

WR

PSEN

XTAL2

XTAL1

A8 to A15

AD0 to AD7

ADC0 to ADC7

EA

CTX1

CTX0CRX0

CRX1

STADC

AV

ref

AV

SS

AV

DD

RST EWCMSR0 to CMSR5

CMT0, CMT1

RT2

T2

P4P5RXDTXDP3P2P1P0

T0

T1 INT0 INT1

V

DD

V

SS

CV

SS

THREE

16-BIT

COMPARATORS

WITH

REGISTERS

PARALLEL

I/O PORTS

&

EXT. BUS

SERIAL

UART

PORT

8-BIT

I/O

PORTS

FOUR

16-BIT

CAPTURE

LATCHES

T2

16-BIT

TIMER/

EVENT

COUNTER

16

16

COMPARATOR

OUTPUT

SELECTION

T3

WATCHDOG

TIMER

T0, T1

TWO 16 - BIT

TIMER/

EVENT

COUNTERS

80C51

core

excluding

ROM/RAM

CPU

PROGRAM

MEMORY

AUXILIARY

MEMORY

DATA

MEMORY

DUAL

PWM

CAN

ADC

DMA - BUS

INTERNAL BUS

P8xC592

REF

16K x 8

ROM

PWM0

PWM1

1/2AV

DD

256 x 8

RAM

256 x 8

RAM

CT0I/INT2 to

CT3I/INT5

(4)

(4) (4) (2) (2) (2) (5)

(6)

(7)

(4)(4)(4)(4) (2) (2)

(4)

(1)

(3)

Fig.1 Block diagram.

(1) Alternative function of Port 0.

(2) Alternative function of Port 1.

(3) Alternative function of Port 2.

(4) Alternative function of Port 3.

(5) Alternative function of Port 4.

(6) Alternative function of Port 5.

(7) Not present in P80C592.

Page 5

1996 Jun 27 5

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

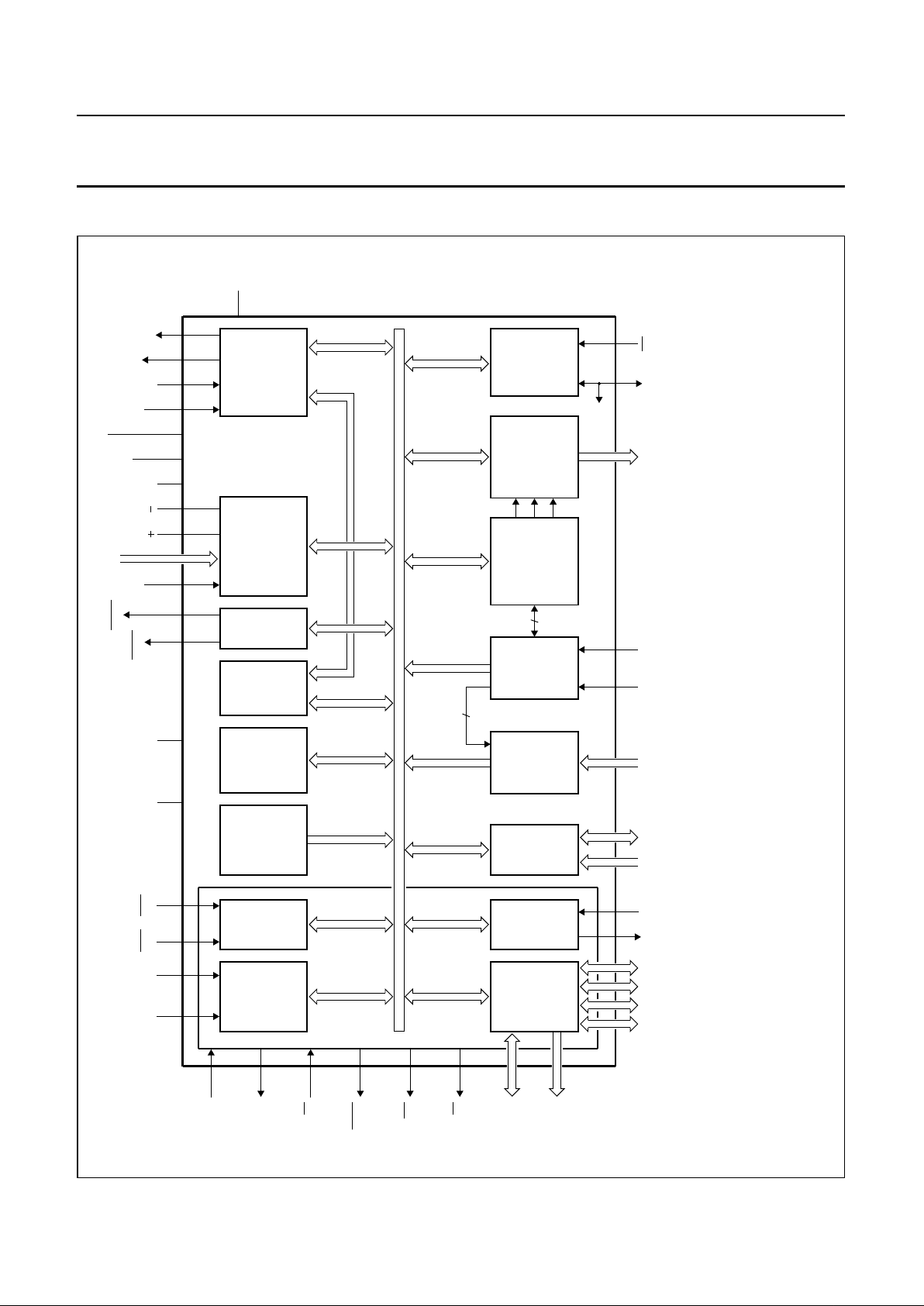

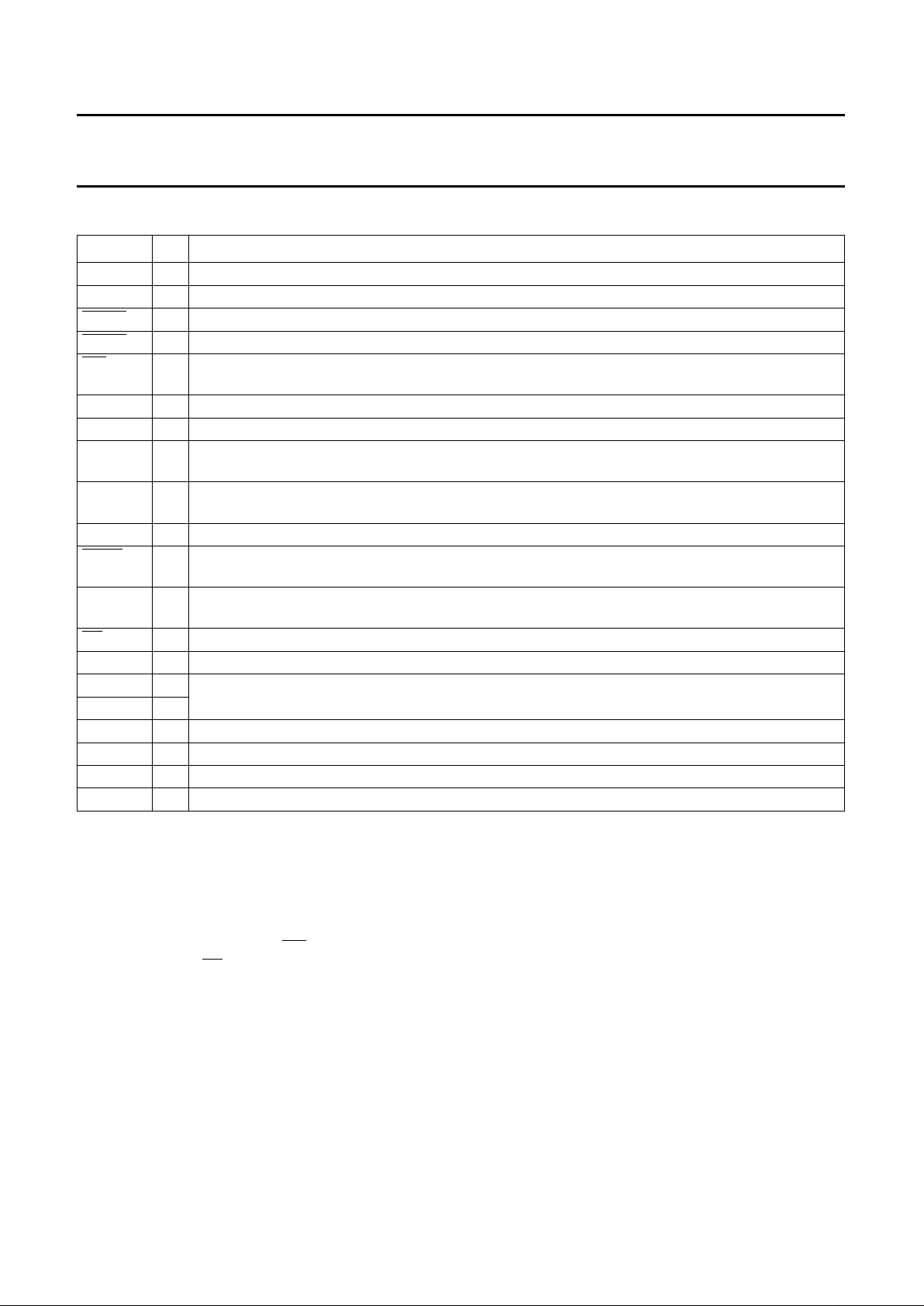

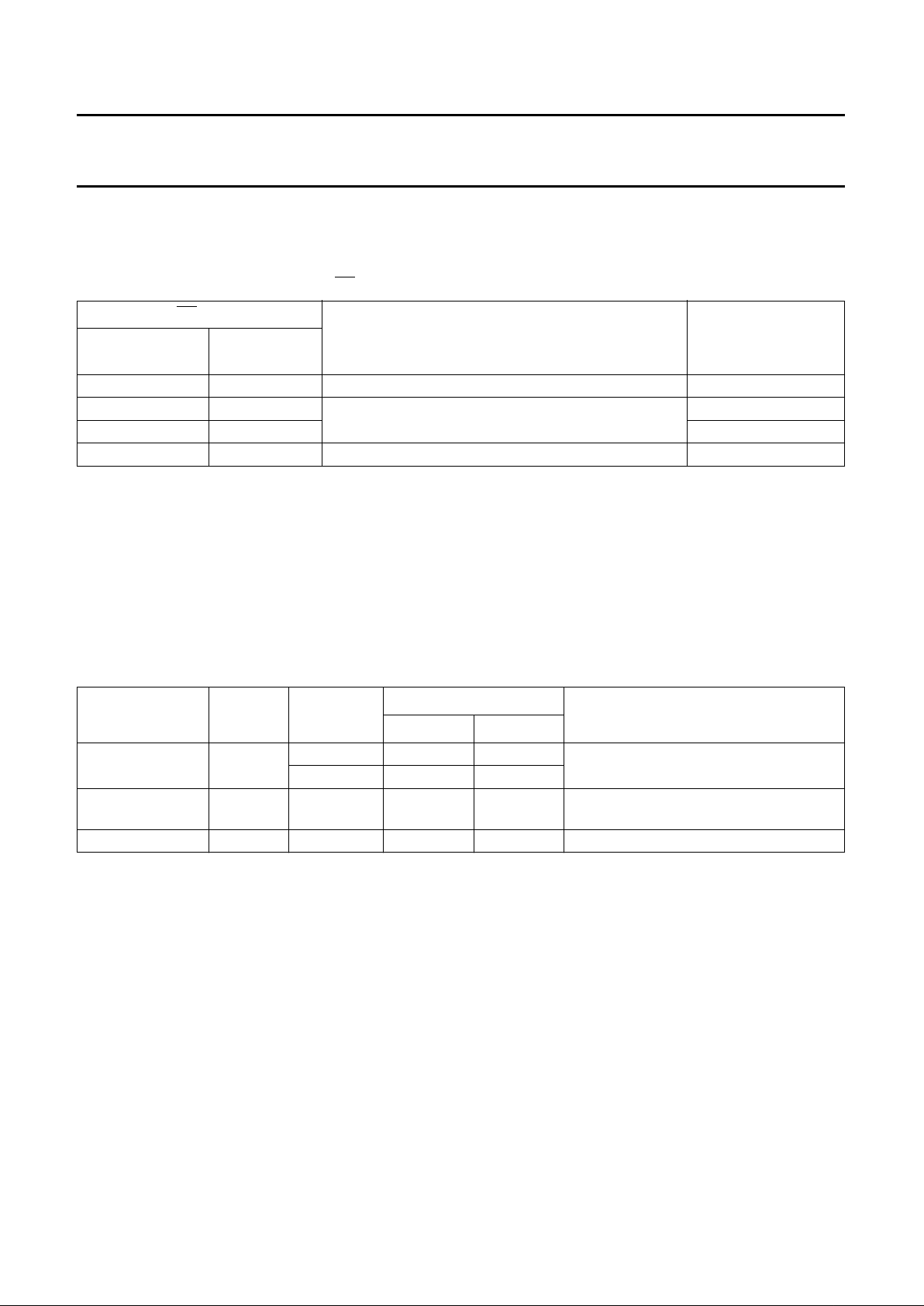

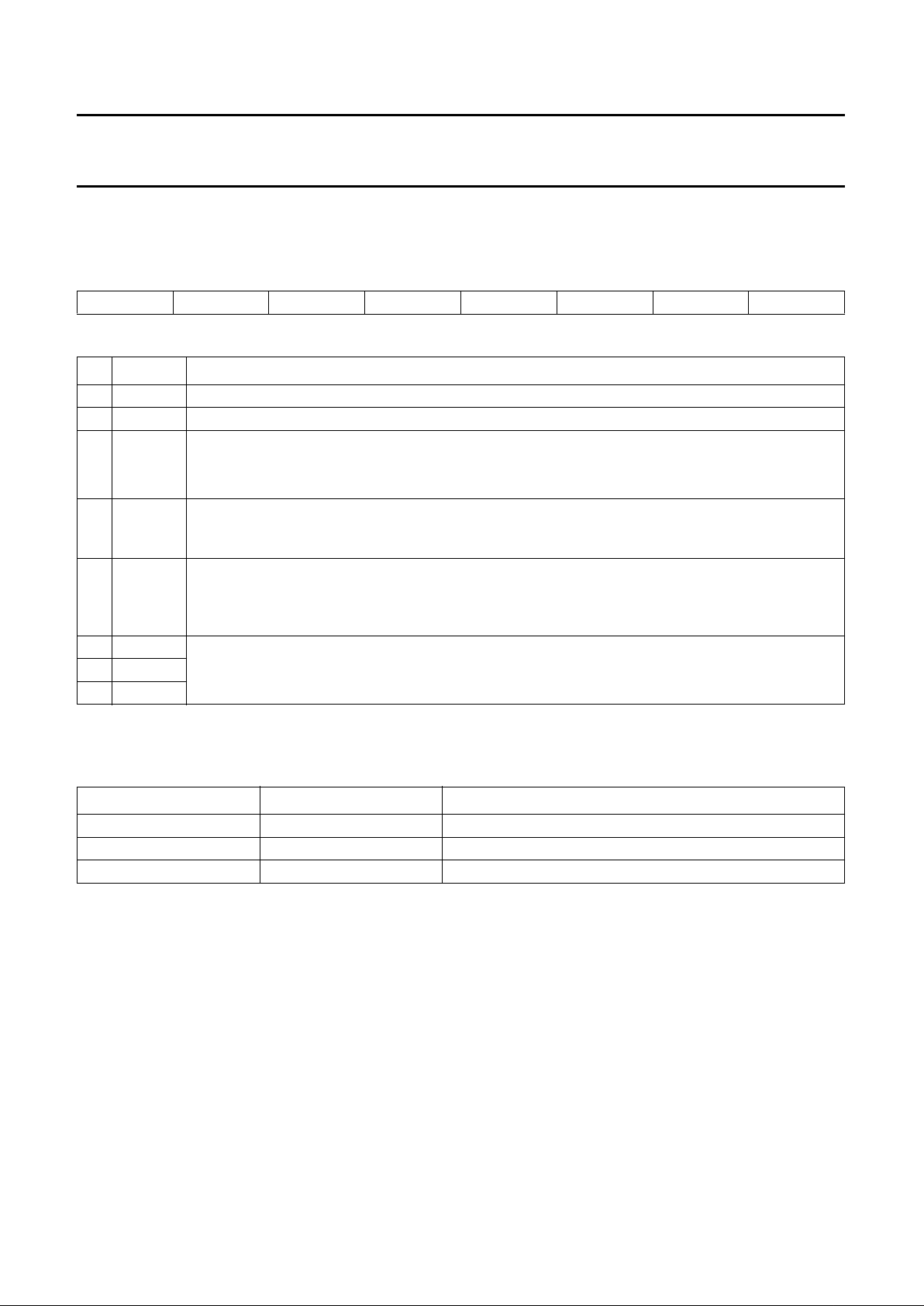

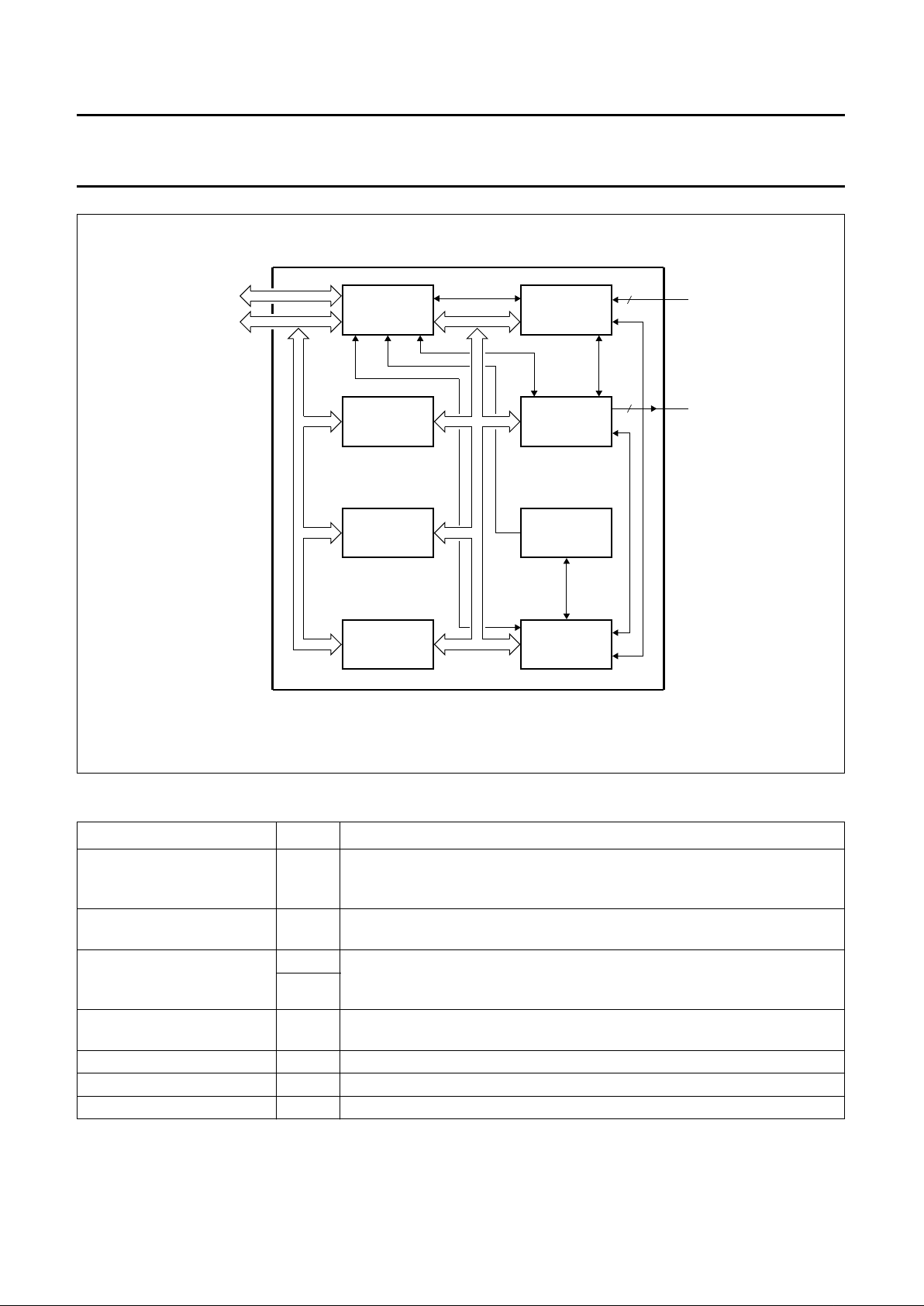

5 PINNING

Fig.2 Pin functions.

handbook, full pagewidth

MGA147 - 2

P8xC592

0

1

2

3

4

5

6

7

PORT 0

CV

SS

SS

V

DD

V

0

1

2

3

4

5

6

7

PORT 1

0

1

2

3

4

5

6

7

PORT 3

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

LOW ORDER

ADDRESS

AND

DATA BUS

alternative function

0

1

2

3

4

5

6

7

PORT 2

A8

A9

A10

A11

A12

A13

A14

A15

HIGH ORDER

ADDRESS

BUS

CT0I/INT2

CT1I/INT3

CT2I/INT4

CT3I/INT5

T2

RT2

CTX0

CTX1

0

1

2

3

4

5

6

7

PORT 5

0

1

2

3

4

5

6

7

PORT 4

RST

EW

alternative function

ADC0

CMSR0

ADC1

ADC2

ADC3

ADC4

ADC5

ADC6

ADC7

CMSR1

CMSR2

CMSR3

CMSR4

CMSR5

CMT0

CMT1

AV

SS

AV

ref+

AV

ref –

STADC

DD

AV

PSEN

CRX0

CRX1

PWM0

PWM1

XTAL1

XTAL2

RXD/DATA

TXD/CLOCK

T0

T1

RD

WR

INT1

INT0

ALE

EA

REF

Page 6

1996 Jun 27 6

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

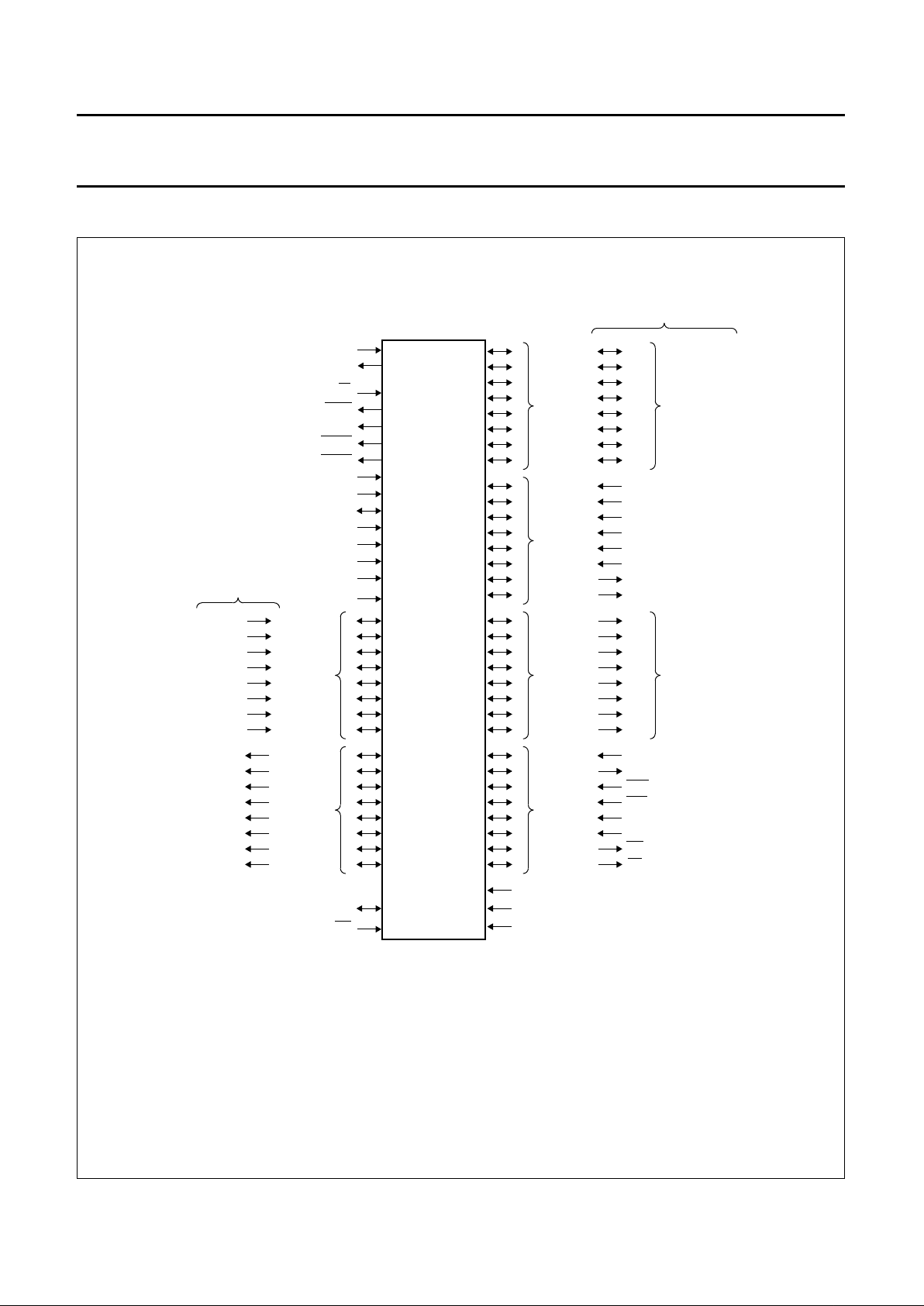

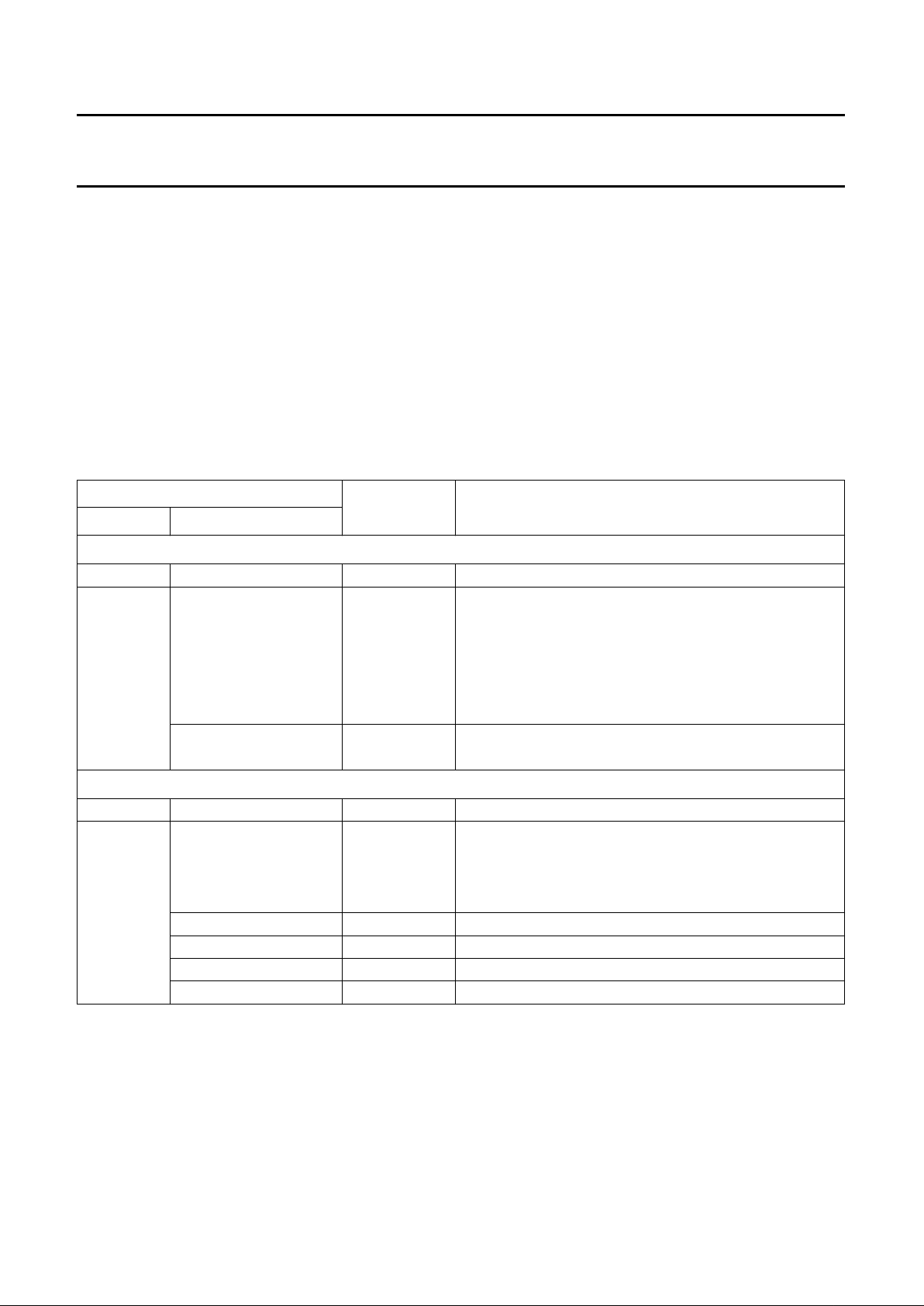

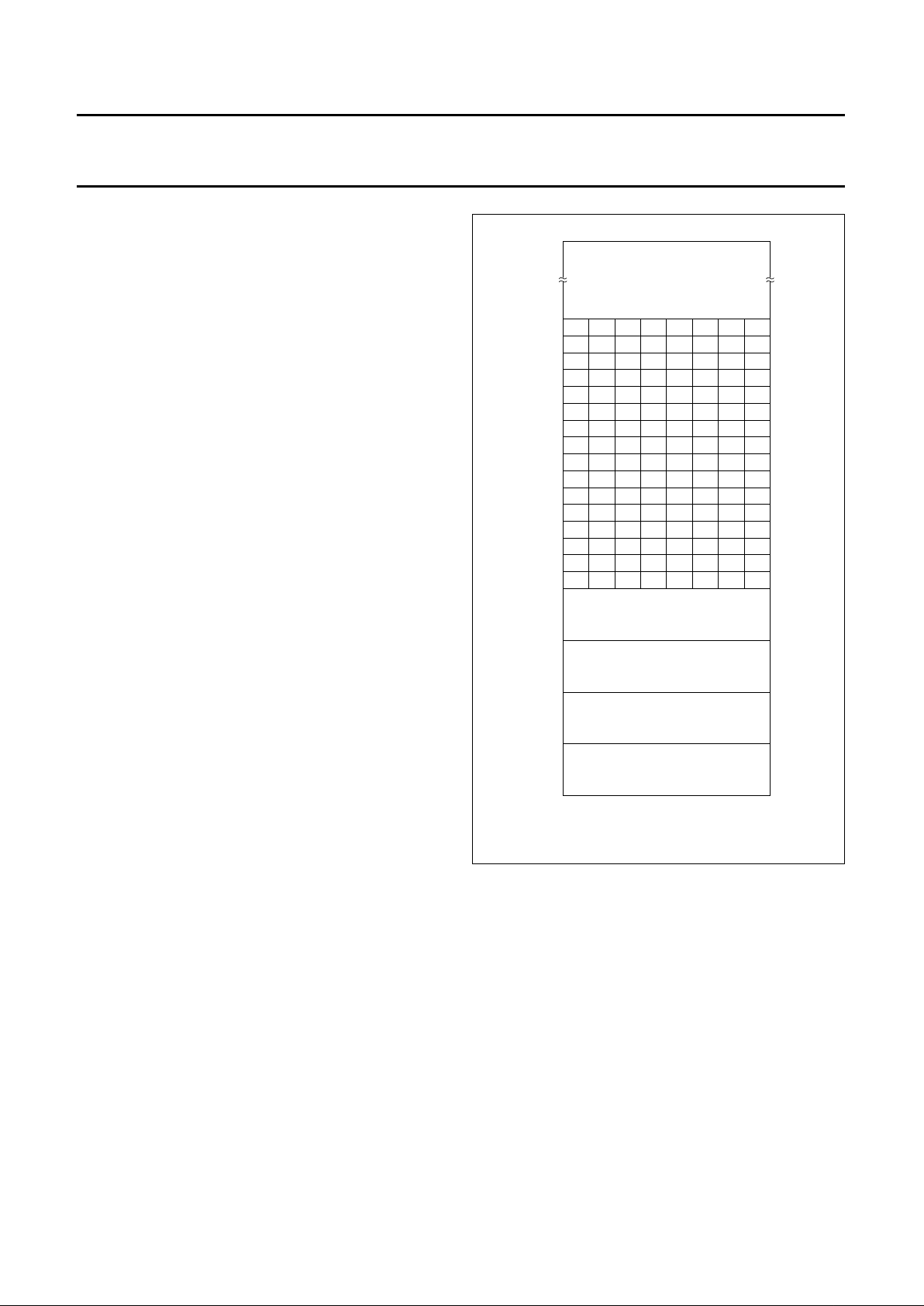

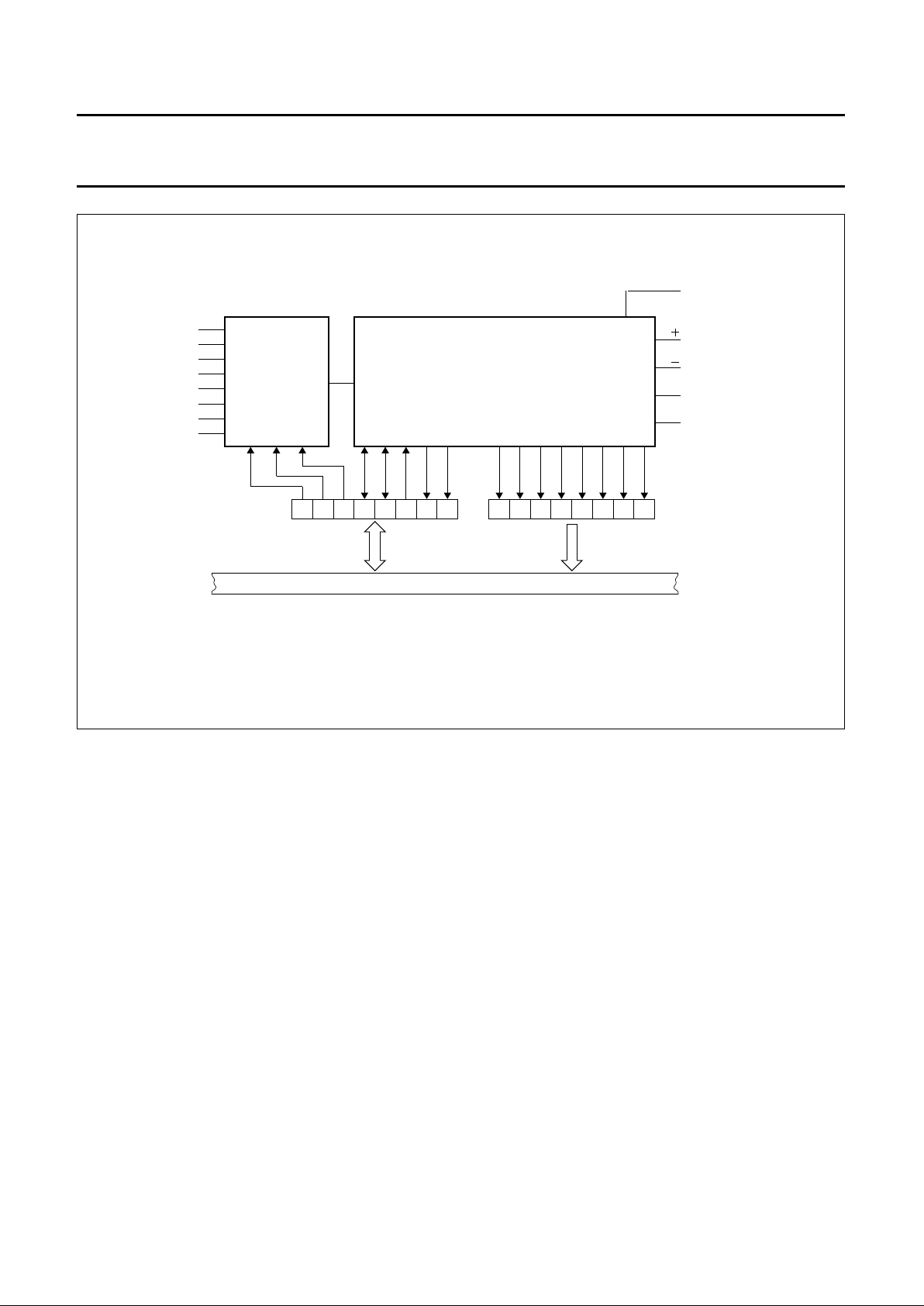

Fig.3 Pin configuration PLCC68/SOT188-2 version (P8xC592FFA; FHA;).

andbook, full pagewidth

P4.3/CMSR3

P4.4/CMSR4

P4.5/CMSR5

P4.6/CMT0

P4.7/CMT1

RST

P1.0/CT0I/INT2

P1.1/CT1I/INT3

P1.2/CT2I/INT4

P1.3/CT3I/INT5

P1.4/T2

P1.5/RT2

CV

SS

P1.6/CTX0

P1.7/CTX1

P3.0/RXD

P3.1/TXD

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

9

8

7

6

5

4

3

2

1

68

67

66

65

64

63

62

61

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

P4.2/CMSR2

P4.1/CMSR1

P4.0/CMSR0

EW

PWM1

PWM0

STADC

V

DD

P5.0/ADC0

P5.1/ADC1

P5.2/ADC2

P5.3/ADC3

P5.4/ADC4

P5.5/ADC5

P5.6/ADC6

P5.7/ADC7

AV

DD

P8xC592

MGA148 - 1

AV

SS

CRX0

CRX1

REF

P0.0/AD00

P0.1/AD01

P0.2/AD02

P0.3/AD03

P0.4/AD04

P0.5/AD05

P0.6/AD06

P0.7/AD07

ALE

PSEN

AV

ref

AV

ref

EA

P3.7/RD

XTAL1

P2.3/A11

P3.2/INT0

P3.3/INT1

P3.4/T0

P3.5/T1

P3.6/WR

XTAL2

P2.0/A08

P2.1/A09

P2.2/A10

P2.4/A12

P2.5/A13

P2.6/A14

P2.7/A15

V

SS

Page 7

1996 Jun 27 7

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

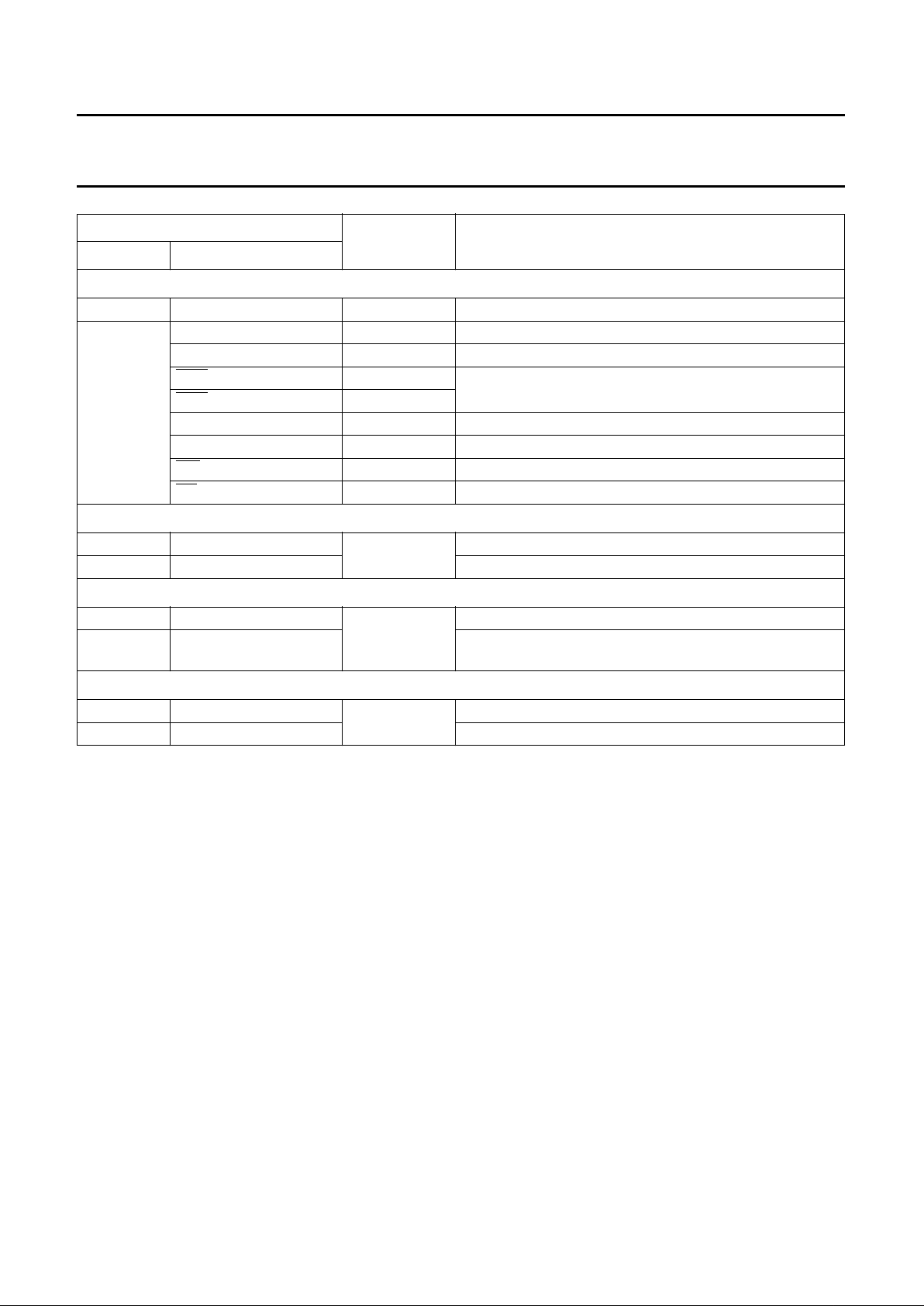

Table 1 Pin description for single function pins (SOT188-2; see note 1)

Notes

1. To avoid a ‘latch up’ effect at power-on: VSS− 0.5 V < ‘voltage on any pin at any time’ < VDD+ 0.5 V.

2. Triggered by a rising edge. ADC operation can also be started by software.

3. RST also provides a reset pulse as output when timer T3 overflows or after a CAN wake-up from Power-down.

4. ALE is activated every six oscillator periods. During an external data memory access one ALE pulse is skipped.

5. See Section 7.1, Table 3 for EA operation. For P83Cxxx microcontrollers specified with the option ‘ROM-code

protection’, the EA pin is latched during reset and is ‘don't care’ after reset, regardless of whether the ROM-code

protection is selected or not.

SYMBOL PIN DESCRIPTION

V

DD

2 Power supply, digital part (+5 V). For normal operation and power reduced modes.

STADC 3 Start ADC operation. Input starting analog-to-digital conversion (note 2). This pin must not float.

PWM0 4 Pulse width modulation output 0.

PMW1 5 Pulse width modulation output 1.

EW 6 Enable Watchdog Timer (WDT): enable for T3 Watchdog Timer and disable Power-down mode.

This pin must not float.

RST 15 Reset: input to reset the P8xC592 (note 3).

CV

SS

22 CAN ground potential for the CAN transmitter outputs.

XTAL2 33 Crystal pin 2: output of the inverting amplifier that forms the oscillator.

When an external clock oscillator is used this pin is left open-circuit.

XTAL1 34 Crystal pin 1: input to the inverting amplifier that forms the oscillator, and input to the internal clock

generator. Receives the external clock oscillator signal, when an external oscillator is used.

V

SS

35 Ground, digital part.

PSEN 44 Program Store Enable: Read strobe to external Program Memory (active LOW).

Drive: 8 × LSTTL inputs.

ALE 45 Address Latch Enable: latches the Low-byte of the address during accesses to external memory

(note 4). Drive: 8 × LSTTL inputs; handles CMOS inputs without an external pull-up.

EA 46 External Access input. See note 5.

REF 55

1

⁄2AVDD reference voltage output respectively input (note 6).

CRX1 56 Inputs from the CAN-bus line to the differential input comparator of the on-chip CAN-controller

(note 7).

CRX0 57

AV

REF−

58 Low-end of ADC (analog-to-digital) conversion reference resistor.

AV

REF+

59 High-end of ADC (analog-to-digital) conversion reference resistor (note 8).

AV

SS

60 Ground, analog part. For ADC, CAN receiver and reference voltage.

AV

DD

61 Power supply, analog part (+5 V). For ADC, CAN receiver and reference voltage.

Page 8

1996 Jun 27 8

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

6. Pin 55, REF:

a) Selection of input resp. output dependent of CAN Control Register bit 5 (CR.5; see Section 13.5.3 Table 32).

b) If the internal reference is used, then REF should be connected to AVSS via a capacitor with a value of ≥10 nF.

c) After an external reset (RST = HIGH) the internal1⁄2AVDD source is activated and, REF is a reference output.

d) If the CAN-controller is in the reset state, e.g. after an external reset, then the1⁄2AVDD source is switched off

during Power-down mode.

7. CAN-bus line:

a) CRX0 level > CRX1 level is interpreted as a logic 1 (recessive).

b) CRX0 level < CRX1 level is interpreted as a logic 0 (dominant).

8. The level of AV

REF+

must be higher than that of AV

REF−

.

Table 2 Pin description for pins with alternative functions (SOT188-2 and NO330; see note 1)

SYMBOL

PIN DESCRIPTION

DEFAULT ALTERNATIVE

Port 4

P4.0 to P4.7 7 to 14 8-bit quasi-bidirectional I/O port.

CMSR0 7 Compare and Set/Reset outputs for Timer T2.

CMSR1 8

CMSR2 9

CMSR3 10

CMSR4 11

CMSR5 12

CMT0 13 Compare and toggle outputs for Timer T2.

CMT1 14

Port 1

P1.0 to P1.7 16 to 21, 23, 24 8-bit quasi-bidirectional I/O port.

CT0I/INT2 16 Capture timer inputs for Timer T2,

or

External interrupt inputs.

CT1I/INT3 17

CT2I/INT4 18

CT3I/INT5 19

T2 20 T2 event input (rising edge triggered).

RT2 21 T2 timer reset input (rising edge triggered).

CTX0 23 CAN transmitter output 0 (note 2).

CTX1 24 CAN transmitter output 1 (note 2).

Page 9

1996 Jun 27 9

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Notes

1. To avoid a ‘latch up’ effect at power-on: VSS− 0.5 V < ‘voltage on any pin at any time’ < VDD+ 0.5 V.

2. If the CAN-controller is in the reset state (e.g. after a power-up reset; CAN Control Register bit CR.0; see

Section 13.5.3 Table 32), the CAN transmitter outputs are floating and the pins P1.6 and P1.7 can be used as

open-drain port pins. After a power-up reset the port data is HIGH, leaving the pins P1.6 and P1.7 floating.

Port 3

P3.0 to P3.7 25 to 32 8-bit quasi-bidirectional I/O port.

RXD 25 Serial Input Port.

TXD 26 Serial Output Port.

INT0 27 External interrupt inputs.

INT1 28

T0 29 Timer 0 external input.

T1 30 Timer 1 external input.

WR 31 External Data Memory Write strobe.

RD 32 External Data Memory Read strobe.

Port 2 (Sink/source: 1 × TTL = 4 × LSTTL inputs)

P2.0 to P2.7 36 to 43 8-bit quasi-bidirectional I/O port.

A08 to A15 High-order address byte for external memory.

Port 0 (Sink/source: 8 × LSTTL inputs)

P0.7 to P0.0 47 to 54 8-bit open drain bidirectional I/O port.

AD7 to AD0 Multiplexed Low-order address and

Data bus for external memory.

Port 5

P5.7 to P5.0 62 to 68, 1 8-bit input port.

ADC7 to ADC0 8 input channels to ADC.

SYMBOL

PIN DESCRIPTION

DEFAULT ALTERNATIVE

Page 10

1996 Jun 27 10

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

6 FUNCTIONAL DESCRIPTION

The P8xC592 functions will be described as shown in the

following overview:

• Memory organization

• I/O Port structure

• Pulse Width Modulated outputs

• Analog-to-digital Converter

• Timers/Counters

• Serial I/O Ports

• Interrupt system

• Power reduction modes

• Oscillator circuitry

• Reset circuitry

• Instruction Set.

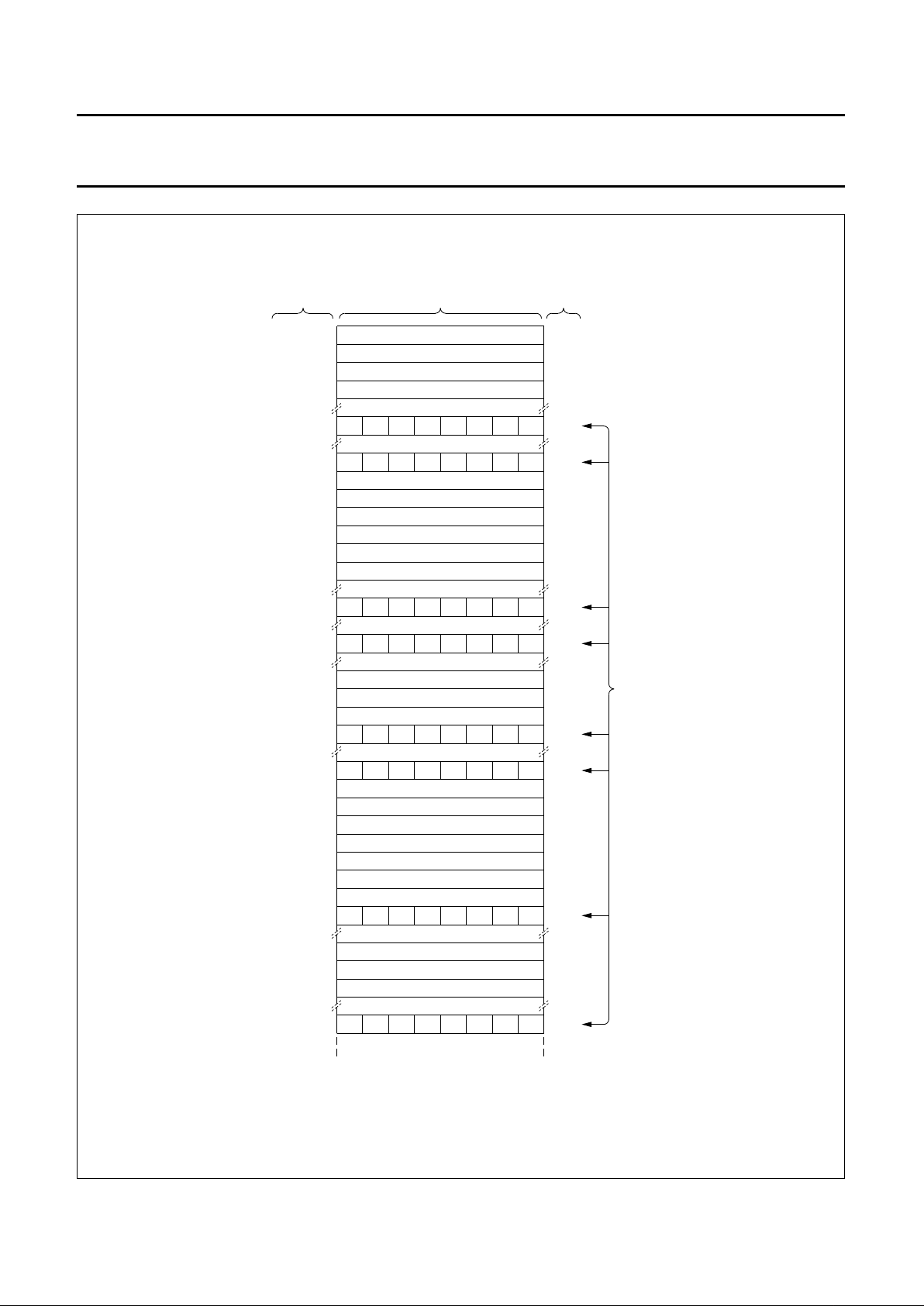

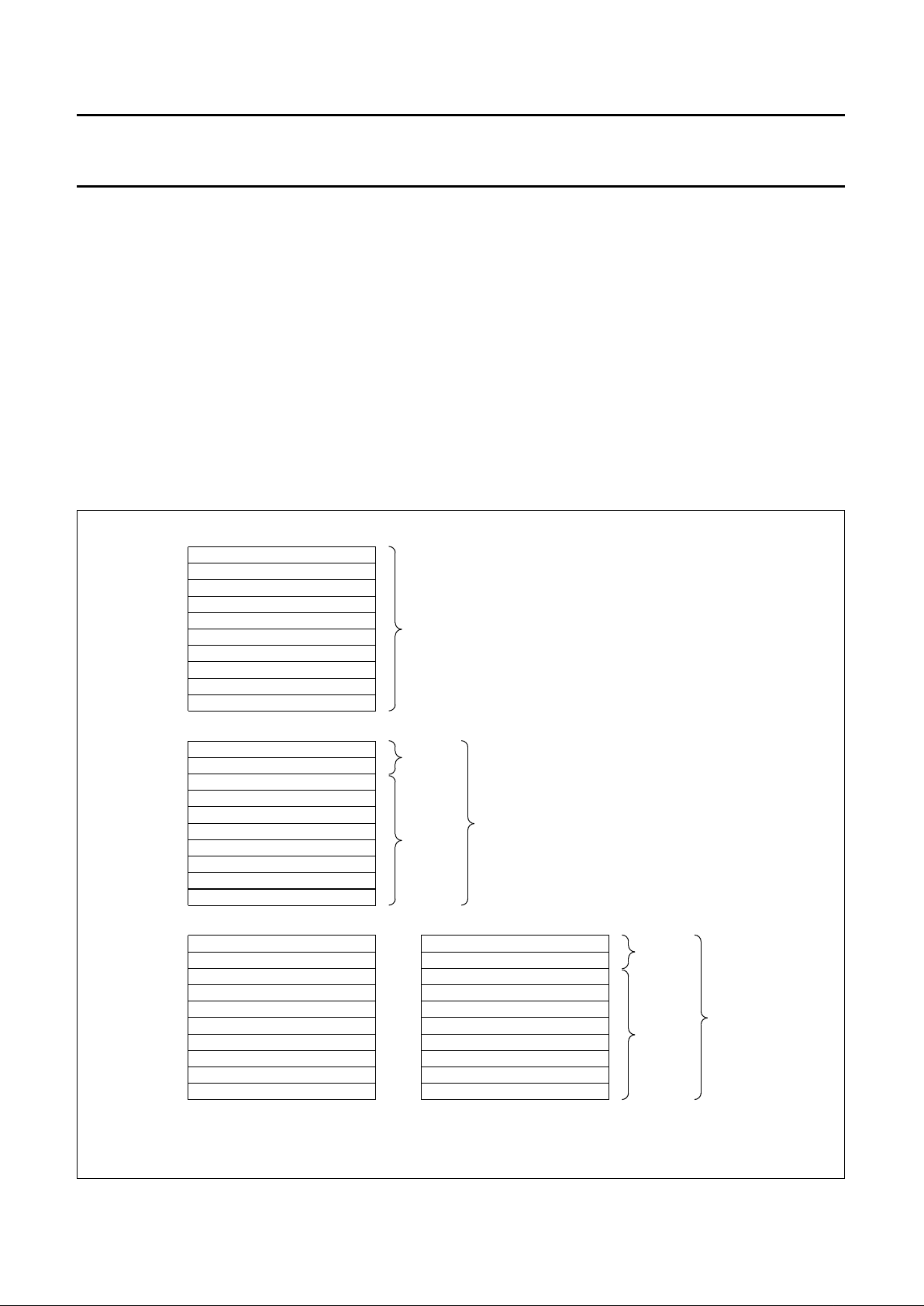

7 MEMORY ORGANIZATION

The Central Processing Unit (CPU) manipulates operands

in three memory spaces (see Fig.4) as follows:

• 16 kbytes internal resp. 64 kbytes external Program

Memory

• 512 bytes internal Data Memory MAIN- and AUXILIARY

RAM

• up to 64 kbytes external Data Memory

(with 256 bytes residing in the internal AUXILIARY

RAM).

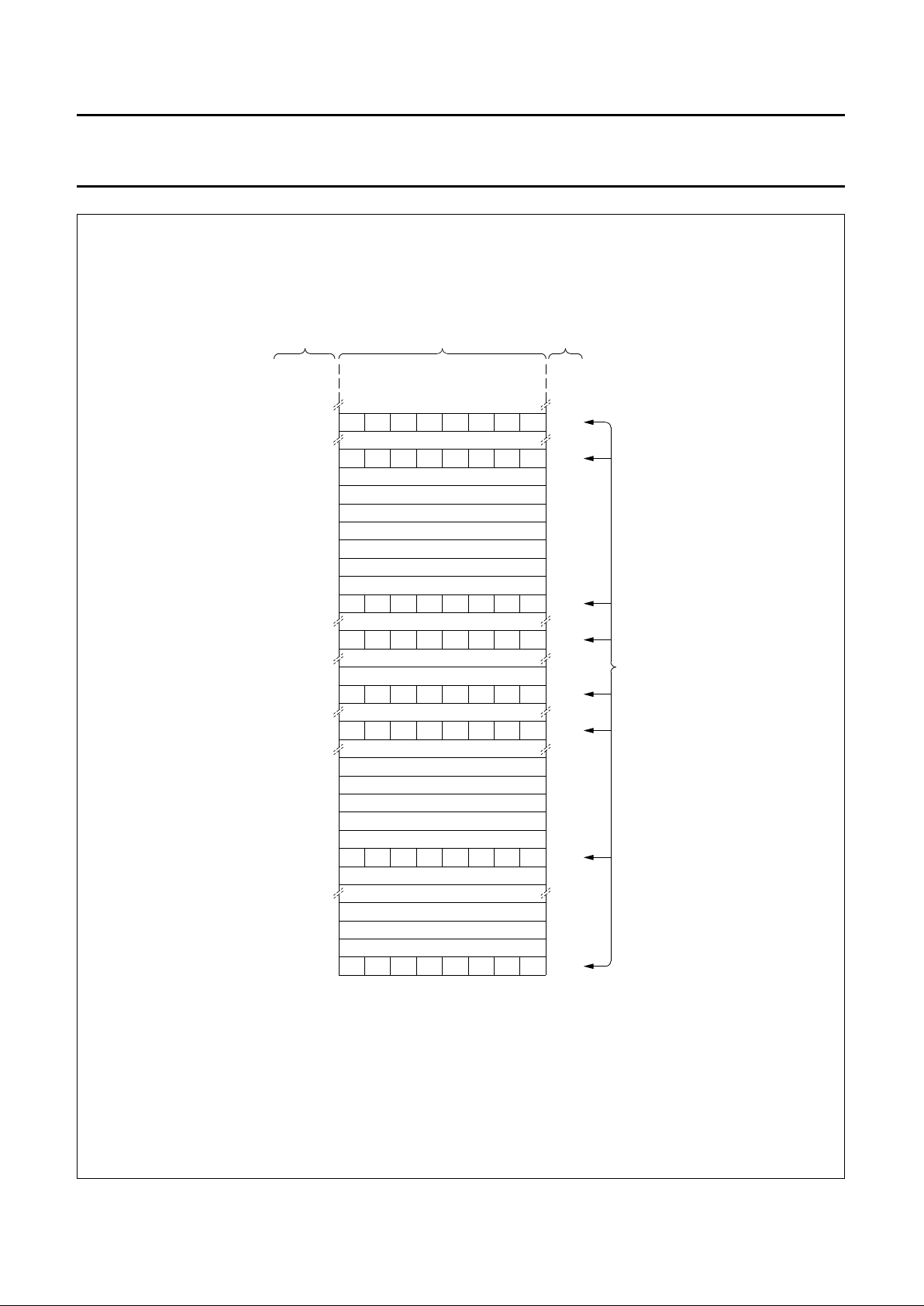

handbook, full pagewidth

MGA149

INDIRECT ONLY

DIRECT AND

INDIRECT

AUXILIARY

RAM

SFRs

255

127

0

EXTERNAL

(EA = 0)

INTERNAL

(EA = 1)

MAIN RAM

INTERNAL DATA MEMORY

EXTERNAL

DATA MEMORY

PROGRAM MEMORY

EXTERNAL

64K

64K

16384

16383

0

OVERLAPPED SPACE

256

Fig.4 Memory map.

Page 11

1996 Jun 27 11

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

7.1 Program Memory

The Program Memory of the P8xC592 consists of 16 kbytes ROM on-chip, externally expandible up to 64 kbytes.

Table 3 Instruction fetch controlled by

EA

Notes

1. This implementation prevents reading of the internal program code by switching from external Program Memory

during a MOVC instruction.

2. By setting a security bit the internal Program Memory content is protected, which means it cannot be read out.

If the security bit has been set to LOW there are no restrictions for the MOVC instruction.

7.2 Internal Data Memory

The internal Data Memory is physically built-up and accessible as shown in Table 4 (see Fig.5).

Table 4 Internal Data Memory size and address mode

Notes

1. MAIN RAM can be addressed directly and indirectly as in the 80C51.

2. AUXILIARY RAM (0 to 255):

a) Is indirectly addressable in the same way as the external Data Memory with MOVX instructions.

b) Access will not affect the ports P0, P2, P3.6 and P3.7 during internal program execution.

3. SFRs = Special Function Registers.

PIN EA (note 1)

INSTRUCTIONS FETCHED FROM:

ADDRESS

LOCATION

DURING RESET

LATCHED TO:

AFTER RESET

H − internal Program Memory (note 2) 0000H → 3FFFH

H − external Program Memory 4000H → FFFFH

L − 0000H → FFFFH

− ‘don’t care’ −−

INTERNAL

DATA MEMORY

SIZE LOCATION

ADDRESS MODE

POINTERS

DIRECT INDIRECT

MAIN RAM

(note 1)

256 bytes 0 to 127 X X address pointers are R0 and R1 of the

selected register bank

128 to 255 − X

AUXILIARY RAM

(note 2)

256 bytes 0 to 255 − X address pointers are R0 and R1 of the

selected register bank and the DPTR

SFRs (note 3) 128 bytes 128 to 255 X −−

Page 12

1996 Jun 27 12

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

7.2.1 MAIN RAM

Four 8-bit register banks occupy the lower RAM area,

• BANK 0: location 0 to 7

• BANK 1: location 8 to 15

• BANK 2: location 16 to 23

• BANK 4: location 24 to 31.

Only one of these banks may be enabled at the same time.

The next 16 bytes, locations 32 through 45, contains

128 directly addressable bit locations.

The stack can be located anywhere in the internal MAIN

RAM address space. The stack depth is only limited by the

internal RAM space available. All registers except the

program counter and the four 8-bit register banks reside in

the SFR address space.

MGA152

7F 7E 7D 7C 7B 7A 79 78

77 76 75 74 73 72 71 70

6F 6E 6D 6C 6B 6A 69 68

67 66 65 64 63 62 61 60

5F 5E 5D 5C 5B 5A 59 58

57 56 55 54 53 52 51 50

4F 4E 4D 4C 4B 4A 49 48

47 46 45 44 43 42 41 40

3F 3E 3D 3C 3B 3A 39 38

37 36 35 34 33 32 31 30

2F 2E 2D 2C 2B 2A 29 28

27 26 25 24 23 22 21 20

1F 1E 1D 1C 1B 1A 19 18

17 16 15 14 13 12 11 10

0F 0E 0D 0C 0B 0A 09 08

07 06 05 04 03 02 01 00

18H

17H

10H

0FH

08H

07H

00H

24

23

31

16

15

8

7

0

BANK 0

BANK 1

BANK 2

BANK 3

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

(MSB) (LSB)

127

7FH

2FH

2EH

2DH

2CH

2BH

2AH

29H

28H

27H

26H

25H

24H

23H

22H

21H

20H

1FH

Fig.5 Internal MAIN RAM bit addresses.

7.3 External Data Memory

An access to external Data Memory locations higher than

255 will be performed with the MOVX @DPTR instructions

in the same way as in the 80C51 structure,

i.e. with P0 and P2 as data/address bus and P3.6 and P3.7

as Write and Read strobe signals.

Note that these external Data Memory locations cannot be

accessed with R0 or R1 as address pointer.

Page 13

1996 Jun 27 13

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Fig.6 Special Function Register memory map (a).

handbook, full pagewidth

MGA150

FEFF FD FC FB FA F9 F8

F6F7 F5 F4 F3 F2 F1 F0

EEEF ED EC EB EA E9 E8

E6E7 E5 E4 E3 E2 E1 E0

DEDF DD DC DB DA D9 D8

D6D7 D5 D4 D3 D2 D1 D0

CECF CD CC CB CA C9 C8

C6C7 C5 C4 C3 C2 C1 C0

BIT ADDRESS

REGISTER

MNEMONIC

FFH

DIRECT

BYTE

ADDRESS (HEX)

FEH

FDH

FCH

F8H

F0H

EFH

EEH

EDH

ECH

EBH

EAH

E8H

E0H

DBH

DAH

D9H

D8H

D0H

CFH

CEH

CDH

CCH

CBH

CAH

C9H

C8H

C6H

C5H

C4H

C0H

SFRs containing

directly addressable

bits

T3

PWMP

PWM1

PWM0

IP1

B

RTE

STE

# TMH2

# TML2

CTCON

TM2CON

IEN1

ACC

CANADR

CANDAT

CANCON

CANSTA

PSW

# CTH3

# CTH2

# CTH1

# CTH0

CMH2

CMH1

CMH0

TM2IR

# ADCH

ADCON

# P5

P4

# denotes read-only registers

Page 14

1996 Jun 27 14

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Fig.7 Special Function Register memory map (b).

handbook, full pagewidth

MGA151

BEBF BD BC BB BA B9 B8

B6B7 B5 B4 B3 B2 B1 B0

AEAF AD AC AB AA A9 A8

A6A7 A5 A4 A3 A2 A1 A0

9E9F 9D 9C 9B 9A 99 98

9697 95 94 93 92 91 90

8E8F 8D 8C 8B 8A 89 88

8687 85 84 83 82 81 80

BIT ADDRESS

REGISTER

MNEMONIC

DIRECT

BYTE

ADDRESS (HEX)

B8H

B0H

AFH

AEH

ADH

ACH

ABH

AAH

A8H

A0H

99H

98H

90H

8DH

8CH

8BH

8AH

89H

88H

87H

83H

82H

81H

80H

SFRs containing

directly addressable

bits

IP0

P3

# CTL3

P2

S0BUF

S0CON

P1

TH1

TH0

TL1

TL0

TMOD

PCON

DPH

DPL

SP

P0

# denotes read-only registers

# CTL2

# CTL1

# CTL0

CML2

CML1

CML0

IEN0

TCON

A9H

Page 15

1996 Jun 27 15

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

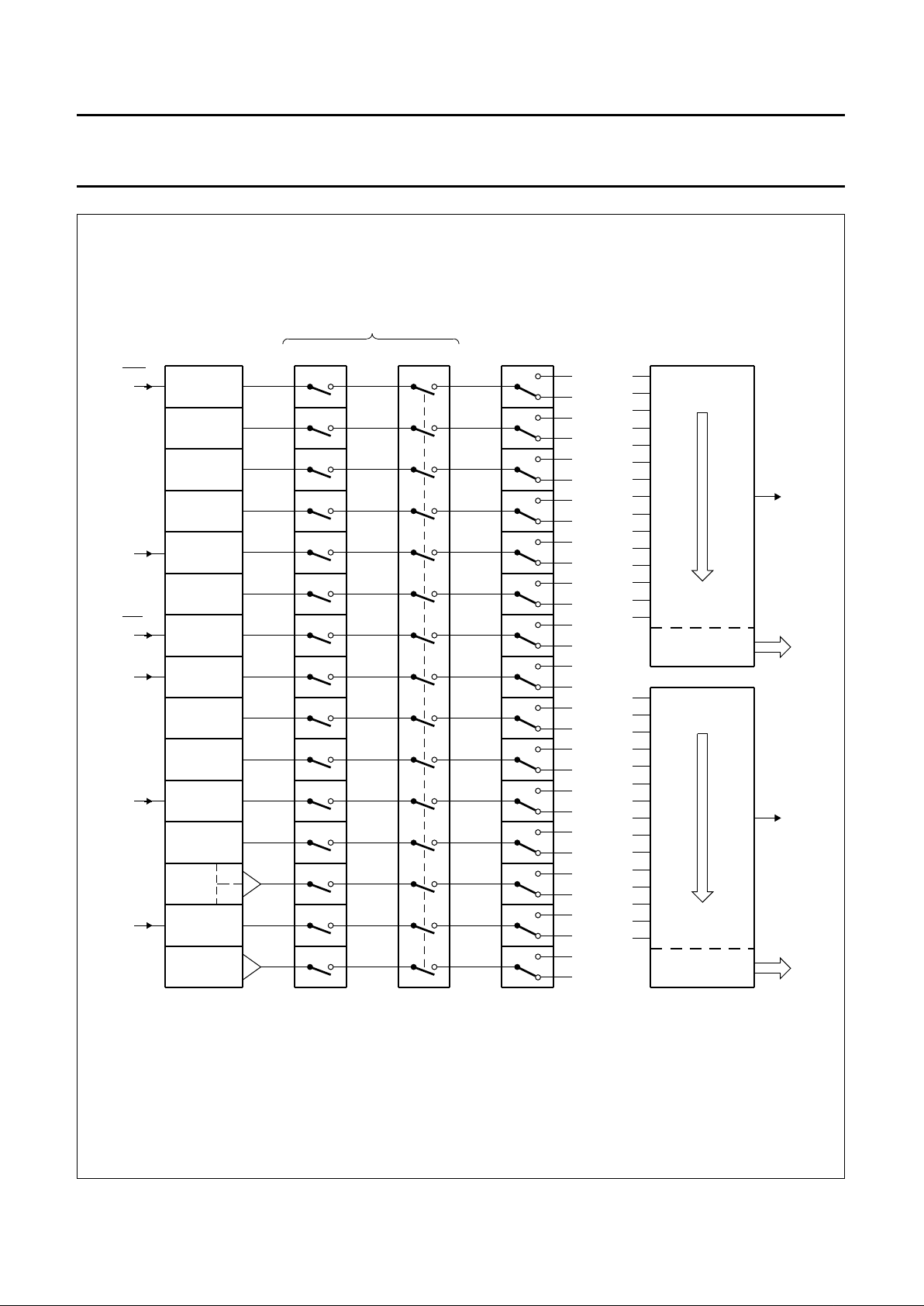

8 I/O PORT STRUCTURE

The P8xC592 has six 8-bit parallel ports: Port 0 to Port 5. In addition to the standard 8-bit parallel ports, the I/O facilities

also include a number of special I/O lines. The use of a Port 1, Port 3 or Port 4 pins as an alternative function is carried

out automatically provided the associated SFR bit is set HIGH.

Table 5 Default Port functions

Table 6 Alternative Port functions

PORT TYPE FUNCTION REMARKS

Port 0 I/O The same as in the 80C51 Except for the additional functions of P1.6 and

P1.7.

Port 1 I/O

Port 2 I/O

Port 3 I/O

Port 4 I/O Parallel l/O port Parallel I/O function is identical to Port1, 2 and 3.

Port 5 I Parallel input port with an input function only May be used as normal inputs if the ADC function

is inoperative.

PORT TYPE FUNCTION REMARKS

Port 0 I/O Multiplexed Low-order address and

Data bus for external memory (AD7 to AD0)

Provides the multiplexed Low-order address and

data bus used for expanding the P8xC592 with

standard memories and peripherals.

Port 1 I/O Capture timer inputs for Timer T2

(CT0I to CT3I), or

External interrupt request inputs

(INT2 to INT5)

External interrupt request inputs, if capture

information is not utilized.

T2 event input (T2) External counter input.

T2 timer reset input (RT2) External counter reset input.

CAN transmitter output 0 (CTX0) CTX0 and CTX1 outputs of the CAN interface

(note 1).

CAN transmitter output 1 (CTX1)

Port 2 I/O High-order address byte for external memory

(A08 to A15)

Port 2 provides the High-order address bus when

the P8xC592 is expanded with external Program

Memory and/or external Data Memory.

Port 3 I/O Serial Input Port (RXD) Receiver input of serial port SIO0 (UART).

Serial Output Port (TXD) Transmitter output of serial port SIO0 (UART).

External interrupt (

INT0) External interrupt request inputs.

External interrupt (

INT1)

Timer 0 external input (T0) Counter inputs.

Timer 1 external input (T1)

External data memory Write strobe (

WR) Control signal to write to external Data Memory.

External data memory Read strobe (

RD) Control signal to read from external Data Memory.

Port 4 I/O Compare and Set/Reset outputs

(CMSR0 to CMSR5)

Can be configured to provide signals indicating a

match between Timer counter T2 and its compare

registers.

Compare and toggle outputs (CMT0, CMT1)

Port 5 I Input channels to ADC (ADC7 to ADC0) Port 5 may be used in conjunction with the ADC

interface (note 2).

Page 16

1996 Jun 27 16

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Notes to the alternative Port functions

1. Port lines P1.6 and P1.7 may be selected as CTX0 and CTX1 outputs of the serial port SIO1 (CAN).

After reset P1.6 and P1.7 may be used as normal I/O ports, if the CAN interface is not used.

2. Unused analog inputs can be used as digital inputs. As Port 5 lines may be used as inputs to the ADC, these digital

inputs have an inherent hysteresis to prevent the input logic from drawing too much current from the power lines

when driven by analog signals.

Channel-to-channel crosstalk should be taken into consideration when both digital and analog signals are

simultaneously input to Port 5 (see Chapter 20).

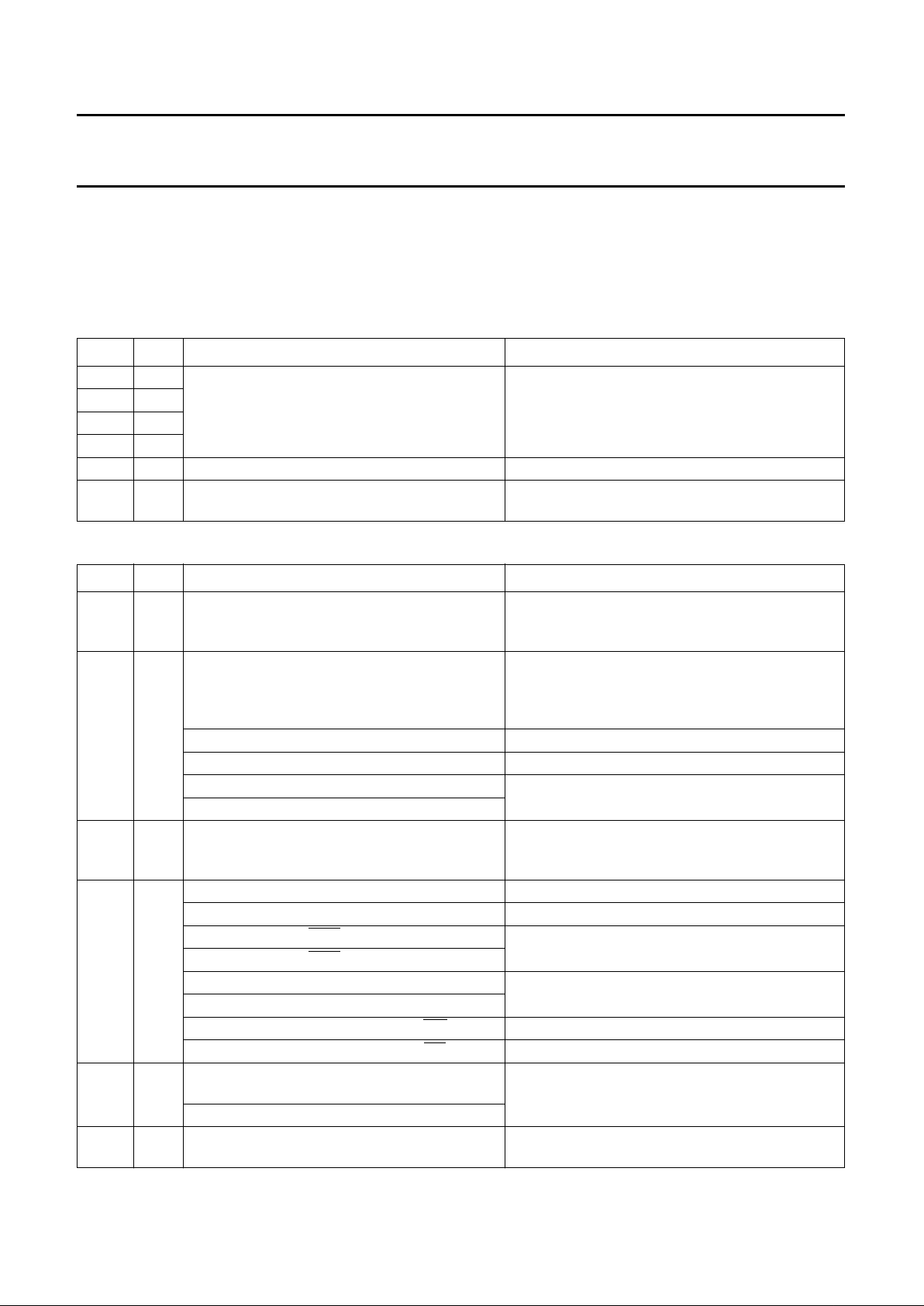

Fig.8 I/O buffers in the P8xC592 (P1.0 to P1.5, Ports 2, 3, and 4).

handbook, full pagewidth

MGA153

p1

p2

p3

input data

read port pin

2 oscillator

periods

n

strong pull-up

I/O PIN

PORT

1, 2, 3 or 4

+5 V

I1

Q

from port latch

INPUT

BUFFER

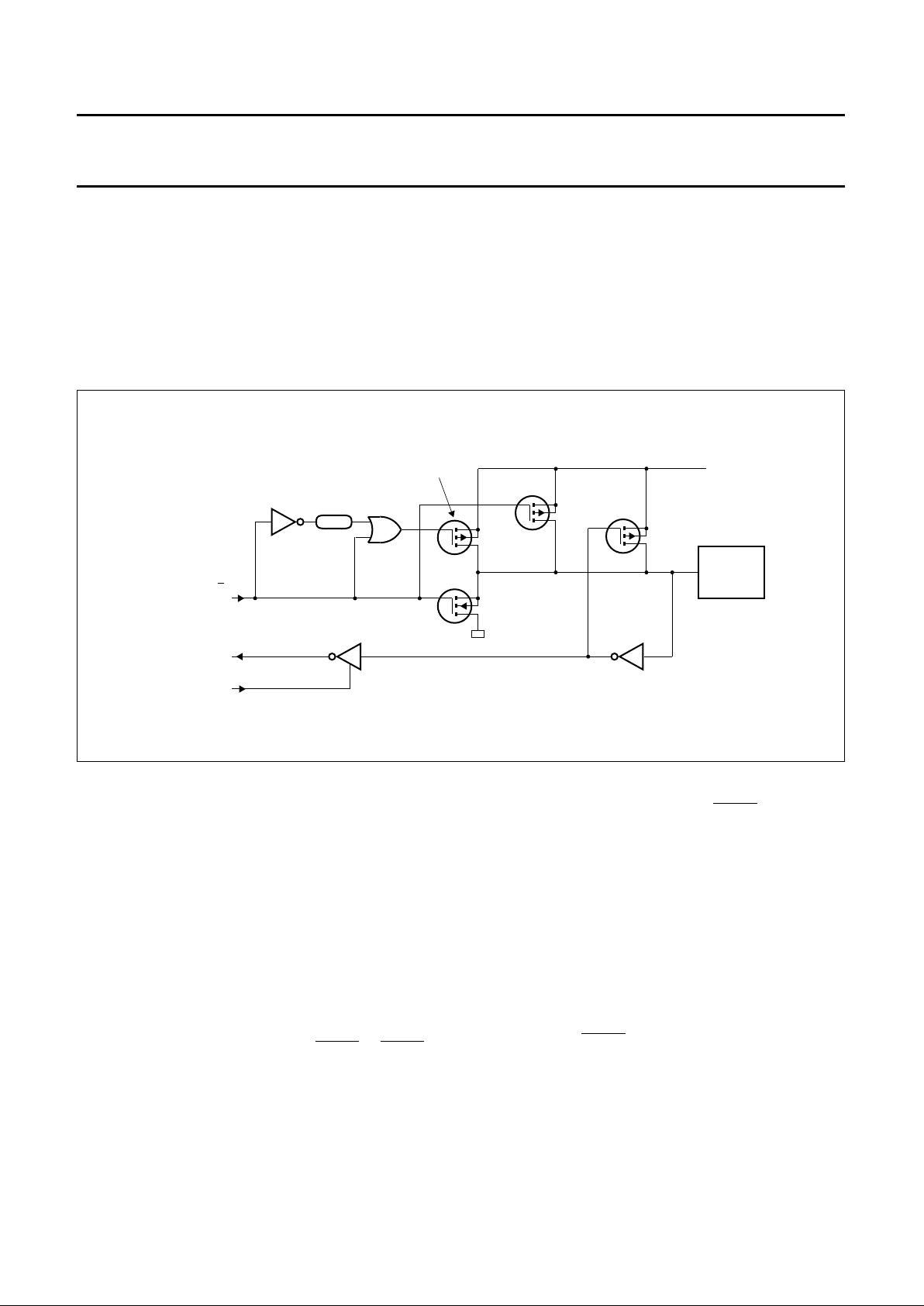

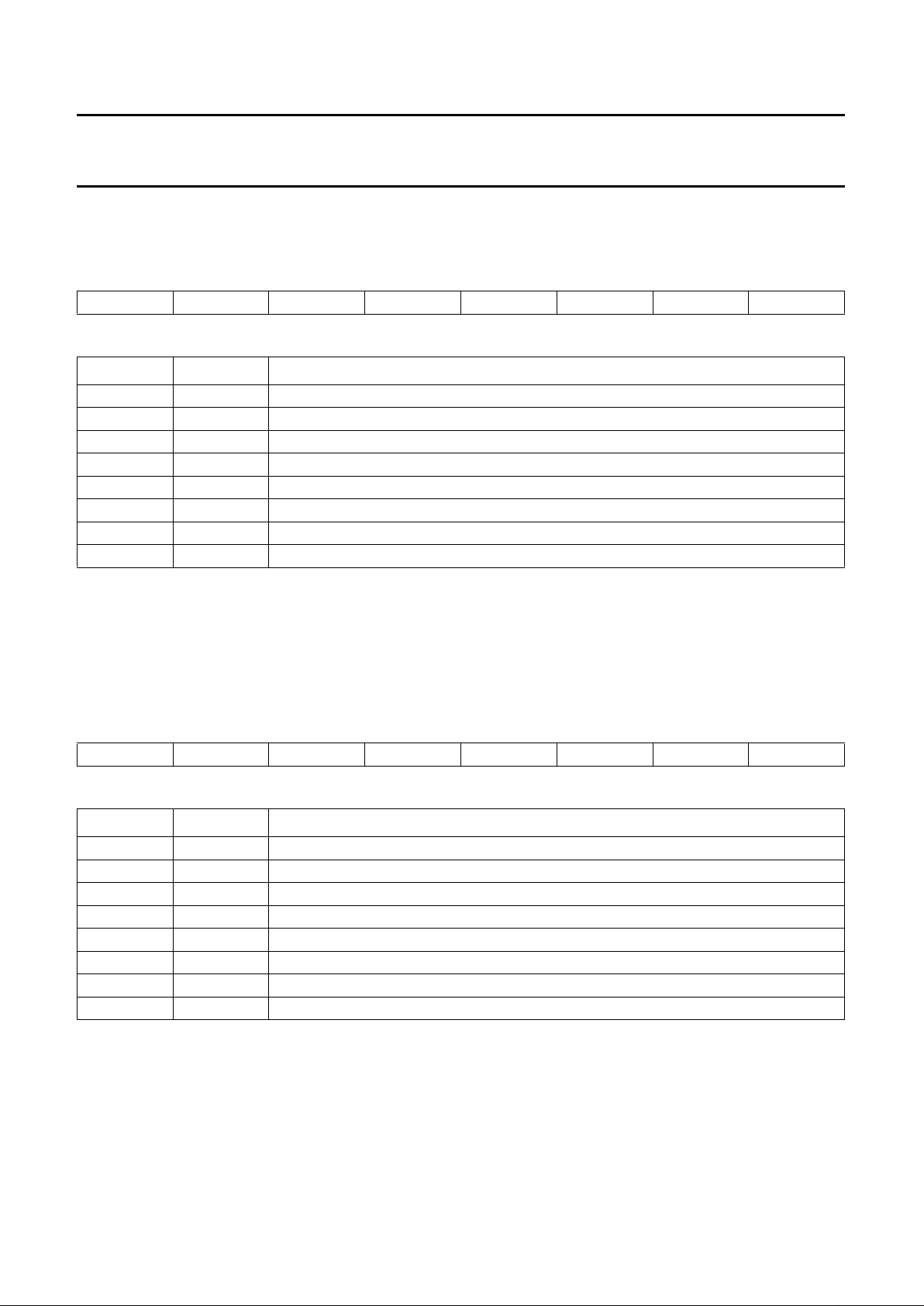

9 PULSE WIDTH MODULATED OUTPUTS (PWM)

Two Pulse Width Modulated (PWM) output channels are

available with the P8xC592. These channels provide

output pulses of programmable length and interval.

The repetition frequency is defined by an 8-bit prescaler

PWMP which generates the clock for the counter.

Both the prescaler and counter are common to both PWM

channels. The 8-bit counter counts modulo 255 i.e. from

0 to 254 inclusive. The value of the 8-bit counter is

compared to the contents of two registers:

PWM0 and PWM1.

Provided the contents of either of these registers is greater

than the counter value, the output of PWM0 or PWM1 is

set LOW. If the contents of these register are equal to, or

less than the counter value, the output will be HIGH. The

pulse-width-ratio is therefore defined by the contents of the

register PWM0 and PWM1. The pulse-width-ratio is in the

range of 0 to

255

⁄

255

and may be programmed in

increments of1⁄

255

.

The repetition frequency f

PWM

, at the PWMn outputs is

given by:

When using an oscillator frequency of 16 MHz, for

example, the above formula would give a repetition

frequency range of 123 Hz to 31.4 kHz.

By loading the PWM registers with either 00H or FFH, the

PWM outputs can be retained at a constant HIGH or LOW

level respectively. When loading FFH to the PWM

registers, the 8-bit counter will never actually reach this

(FFH) value.

Both output pins

PWMn are driven by push-pull drivers,

and are not shared with any other function.

f

PWM

f

CLK

2 PWMP 1+()× 255×

--------------------------------------------------------------

=

Page 17

1996 Jun 27 17

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

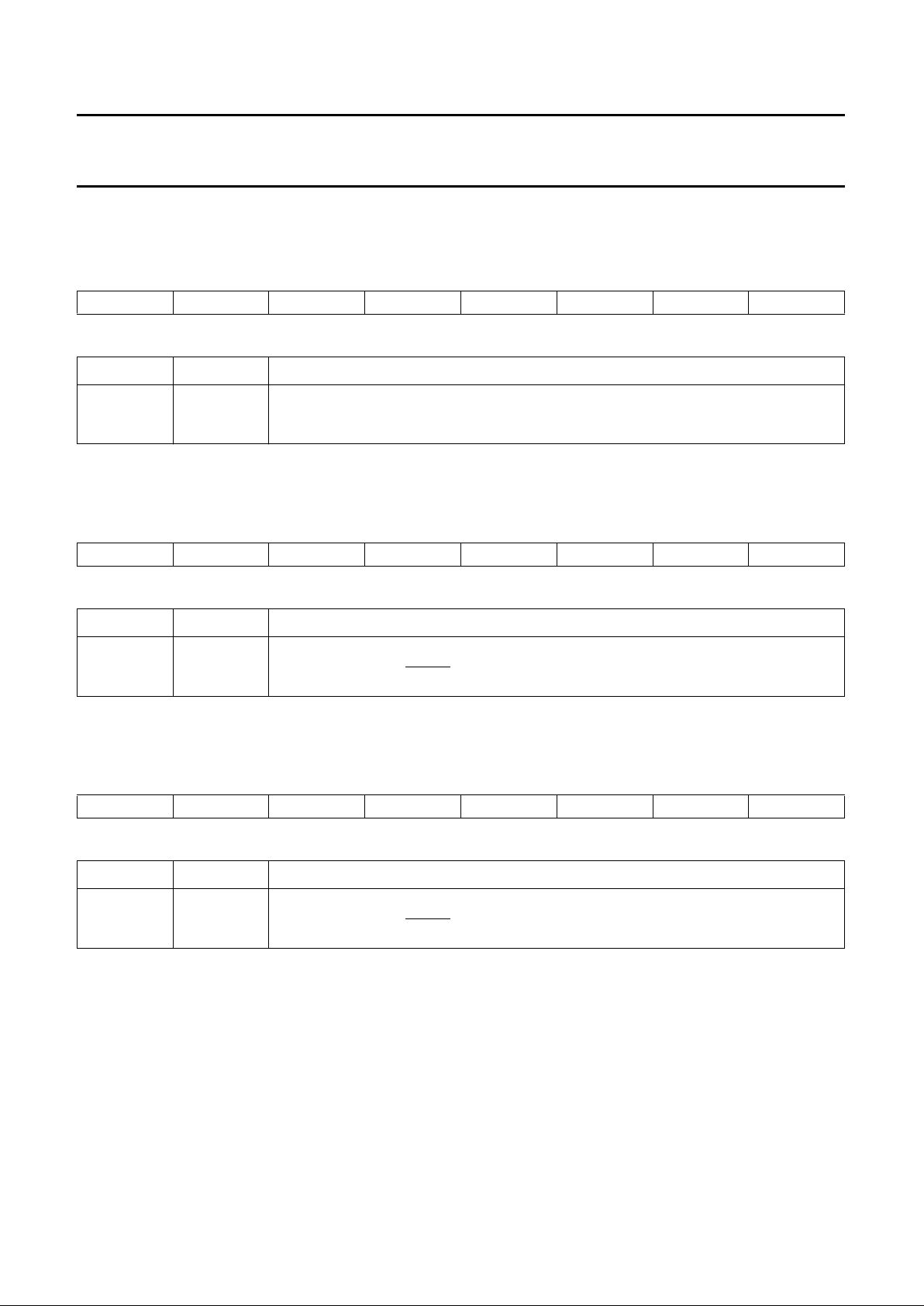

9.1 Prescaler frequency control register (PWMP)

Table 7 Prescaler frequency control register (address FEH)

Table 8 Description of PWMP bits

9.2 Pulse Width Register 0 (PWM0)

Table 9 Pulse Width Register (address FCH)

Table 10 Description of PWM0 bits

9.3 Pulse Width Register 1 (PWM1)

Table 11 Pulse width register (address FDH)

Table 12 Description of PWM1 bits

76543210

PWMP.7 PWMP.6 PWMP.5 PWMP.4 PWMP.3 PWMP.2 PWMP.1 PWMP.0

BIT SYMBOL FUNCTION

7

to

0

PWMP.7

to

PWMP.0

Prescaler division factor.

The Prescaler division factor = (PWMP) + 1.

76543210

PWM0.7 PWM0.6 PWM0.5 PWM0.4 PWM0.3 PWM0.2 PWM0.1 PWM0.0

BIT SYMBOL FUNCTION

7

to

0

PWM0.7

to

PWM0.0

Pulse width ratio.

76543210

PWM1.7 PWM1.6 PWM1.5 PWM1.4 PWM1.3 PWM1.2 PWM1.1 PWM1.0

BIT SYMBOL FUNCTION

7

to

0

PWM1.7

to

PWM1.0

Pulse width ratio.

LOW/HIGH ratio of PWMn signals

PWMn()

255 PWMn()–

----------------------------------------- -

=

LOW/HIGH ratio of PWMn signals

PWMn()

255 PWMn()–

----------------------------------------- -

=

Page 18

1996 Jun 27 18

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Fig.9 Functional diagram of Pulse Width Modulated outputs.

handbook, full pagewidth

MGA154

I

N

T

E

R

N

A

L

B

U

S

f

clk

PWMP

PWM1

PRESCALER

8-BIT COUNTER1/2

PWM0

8-BIT COMPARATOR

8-BIT COMPARATOR

OUTPUT

BUFFER

PWM1

OUTPUT

BUFFER

PWM0

10 ANALOG-TO-DIGITAL CONVERTER (ADC)

The analog input circuitry consists of an 8-input analog

multiplexer and an ADC with 10-bit resolution. The analog

reference voltage and analog power supplies are

connected via separate input pins. The conversion takes

50 machine cycles i.e. 37.5 µs at 16 MHz oscillator

frequency. The input voltage swing is from 0 V to AVDD.

The ADC is controlled using the ADCON control register.

Register bits ADCON.0 to ADCON.2 select the input

channels of the analog multiplexer (see Fig.10).

The completion of the 10-bit analog-to-digital conversion is

flagged by ADCI in the ADCON register and the result is

stored in the SFR ADCH (upper 8-bits) and the 2 lower bits

(ADC.1 and ADC.0) in register ADCON.

An analog-to-digital conversion in progress is unaffected

by an external or software ADC start. The result of a

completed conversion remains unchanged provided

ADCI = HIGH. While ADCI or ADCS are HIGH, a new ADC

START will be blocked and consequently lost. An

analog-to-digital conversion already in progress is aborted

when the Idle or Power-down mode is entered.

The result of a completed conversion (ADCI = HIGH)

remains unaffected during the Idle mode.

The LOW-to-HIGH transition of STADC is recognized at

the end of a machine cycle and the conversion

commences at the beginning of the next cycle. When a

conversion is initiated by software, the conversion starts at

the beginning of the machine cycle following the

instruction that sets ADCS.

The next two machine cycles are used to initiate the

converter. At the end of this first cycle, the ADCS status

flag is set to HIGH while the conversion is in progress.

Sampling of the analog input commences at the end of the

second cycle.

During the next eight machine cycles, the voltage at the

previously selected pin of Port 5 is sampled and this input

voltage should be stable in order to obtain a useful sample.

In any case, the input voltage slew rate must be less than

10 V/ms (5 V conversion range) in order to prevent an

undefined result. The conversion takes four machine

cycles per bit.

Page 19

1996 Jun 27 19

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

10.1 ADC Control register (ADCON)

Table 13 ADC Control register (address C5H)

Table 14 Description of the ADCON bits

Table 15 ADCI and ADCS operating modes

If ADCI is cleared by software while ADCS is set at the same time a new analog-to-digital conversion with the same

channel-number may be started. It is recommended to reset ADCI before ADCS is set.

Note

1. Start of a new conversion requires ADCI = 0.

76543210

ADC.1 ADC.0 ADEX ADCI ADCS AADR2 AADR1 AADR0

BIT SYMBOL FUNCTION

7 ADC.1 Bit 1 of ADC converted value.

6 ADC.0 Bit 0 of ADC converted value.

5 ADEX Enable external start of conversion by STADC. If ADEX is:

LOW, then conversion cannot be started externally by STADC (only by software by setting ADCS)

HIGH, then conversion can be started externally by a rising edge on STADC or externally.

4 ADCI ADC interrupt flag. This flag is set when an analog-to-digital conversion result is ready to be read.

If enabled, an interrupt is invoked. The flag must be cleared by software.

It cannot be set by software (see Table 15).

3 ADCS ADC start and status. Setting this bit starts an analog-to-digital conversion. It may be set by

software or by the external signal STADC. The ADC logic ensures that this signal is HIGH while the

ADC is busy. On completion of the conversion, ADCS is reset at the same time the interrupt flag

ADCI is set. ADCS can not be reset by software (see Table 15).

2 AADR2 Analog input select. This binary coded address selects one of the eight analog port pins of P5 to be

input to the converter. It can only be changed when ADCI and ADCS are both LOW. AADR2 is the

MSB. (e.g. 100B selects the analog input channel ADC4)

1 AADR1

0 AADR0

ADCI ADCS OPERATION

0 0 ADC not busy, a conversion can be started.

0 1 ADC busy, start of a new conversion is blocked.

1 X (don’t care) Conversion completed; see note 1.

Page 20

1996 Jun 27 20

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

andbook, full pagewidth

MGA155

ADC0

ANALOG INPUT

MULTIPLEXER

10-BIT A/D

CONVERTER

ADCON

1234567012345670

STADC

analog reference

supply (analog part)

ground (analog part)

ADCH

INTERNAL BUS

ADC1

ADC2

ADC3

ADC4

ADC5

ADC6

ADC7

Fig.10 Functional diagram of analog input.

Page 21

1996 Jun 27 21

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

11 TIMERS/COUNTERS

The P8xC592 contains:

• Three 16-bit timer/event counters:

Timer 0, Timer 1 and Timer T2

• One 8-bit timer, T3 (Watchdog WDT).

11.1 Timer 0 and Timer 1

Timer 0 and Timer 1 may be programmed to carry out the

following functions:

• Measure time intervals and pulse durations

• Count events

• Generate interrupt requests.

Timer 0 and Timer 1 can be programmed independently to

operate in 3 modes:

Mode 0 8-bit timer or 8-bit counter each with divide-by-32

prescaler.

Mode 1 16-bit timer-interval or event counter.

Mode 2 8-bit timer-interval or event counter with

automatic reload upon overflow.

Timer 0 can be programmed to operate in an additional

mode as follows:

Mode 3 one 8-bit time-interval or event counter and one

8-bit timer-interval counter.

When Timer 0 is in Mode 3, Timer 1 can be programmed

to operate in Modes 0, 1 or 2 but cannot set an interrupt

flag or generate an interrupt. However, the overflow from

Timer 1 can be used to pulse the Serial Port baud-rate

generator.

The frequency handling range of these counters with a

16 MHz crystal is as follows:

• In the timer function, the timer is incremented at a

frequency of 1.33 MHz (

1

⁄12 of the oscillator frequency)

• 0 Hz to an upper limit of 0.66 MHz (1⁄24 of the oscillator

frequency) when programmed for external inputs.

Both internal and external inputs can be gated to the

counter by a second external source for directly measuring

pulse durations. When configured as a counter, the

register is incremented on every falling edge on the

corresponding input pin, T0 or T1.

The earliest moment, when the incremented register value

can be read is during the second machine cycle following

the machine cycle within which the incrementing pulse

occurred.The counters are started and stopped under

software control. Each one sets its interrupt request flag

when it overflows from all HIGHs to all LOWs

(or automatic reload value), with the exception of Mode 3

as previously described.

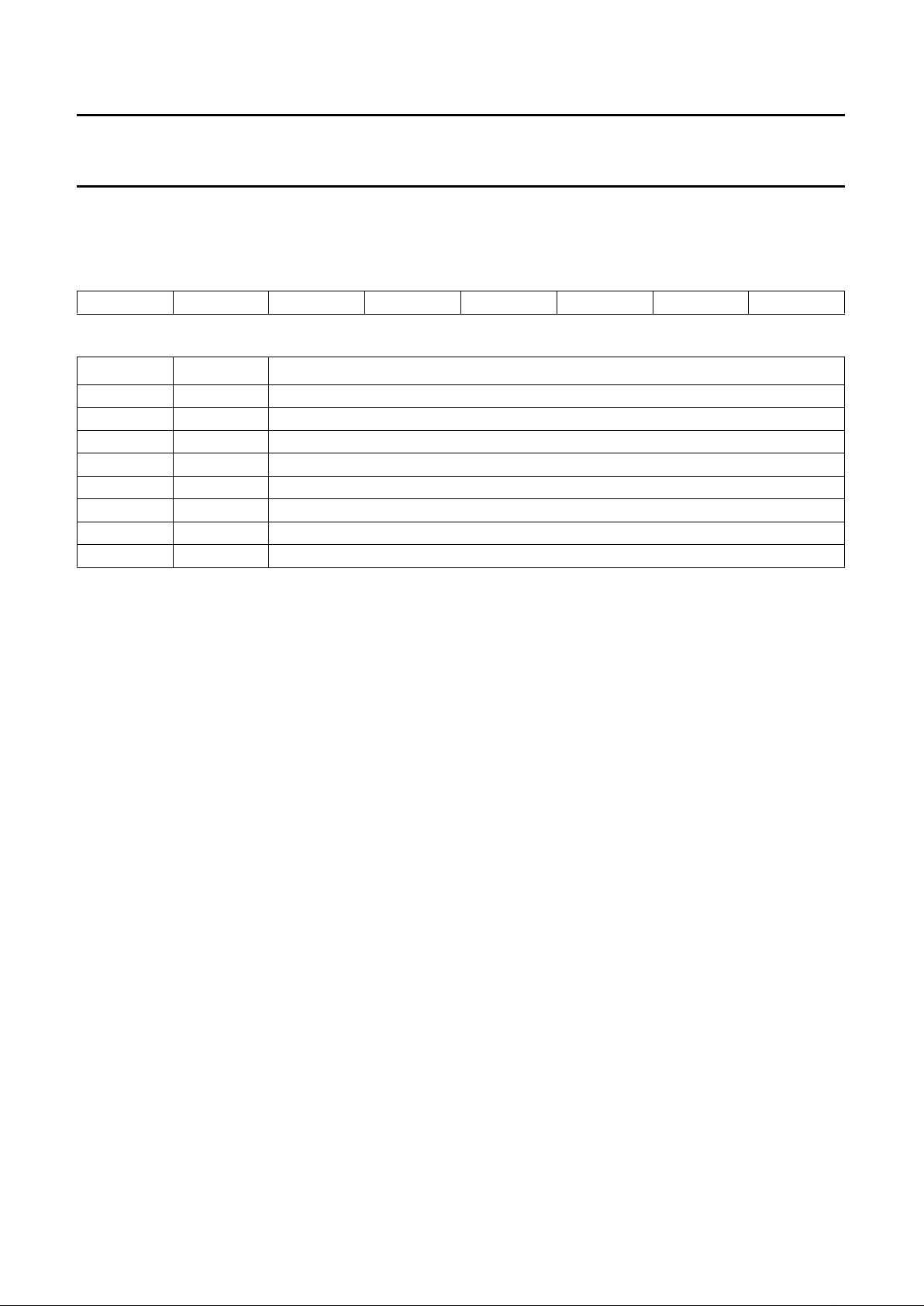

11.2 Timer T2 Capture and Compare Logic

Timer T2 is a 16-bit timer/counter which has capture and

compare facilities (see Fig.11).

The 16-bit timer/counter is clocked via a prescaler with a

programmable division factor of 1, 2, 4 or 8. The input of

the prescaler is clocked with

1

⁄12 of the oscillator

frequency, or by an external source connected to the T2

input, or it is switched off. The maximum repetition rate of

the external clock source is1⁄12f

CLK

, twice that of Timer 0

and Timer 1. The prescaler is incremented on a rising

edge. It is cleared if its division factor or its input source is

changed, or if the timer/counter is reset.

T2 is readable ‘on the fly’, without any extra read latches;

this means that software precautions have to be taken

against misinterpretation at overflow from least to most

significant byte while T2 is being read. T2 is not loadable

and is reset by the RST signal or at the positive edge of the

input signal RT2, if enabled. In the Idle mode the

timer/counter and prescaler are reset and halted.

T2 is connected to four 16-bit Capture Registers: CT0,

CT1, CT2 and CT3. A rising or falling edge on the inputs

CT0I, CT1I, CT2I or CT3I (alternative function of Port 1)

results in loading the contents of T2 into the respective

Capture Registers and an interrupt request.

Using the Capture Register CTCON, these inputs may

invoke capture and interrupt request on a positive edge, a

negative edge or on both edges. If neither a positive nor a

negative edge is selected for capture input, no capture or

interrupt request can be generated by this input.

The contents of the Compare Registers CM0, CM1 and

CM2 are continually compared with the counter value of

Timer T2. When a match occurs, an interrupt may be

invoked. A match of CM0 sets the bits 0 to 5 of Port 4, a

CM1 match resets these bits and a CM2 match toggles bits

6 and 7 of Port 4, provided these functions are enabled by

the STE/RTE registers. A match of CM0 and CM1 at the

same time results in resetting bits 0 to 5 of Port 4. CM0,

CM1 and CM2 are reset by the RST signal.

Port 4 can be read and written by software without

affecting the toggle, set and reset signals. At a byte

overflow of the least significant byte, or at a 16-bit overflow

of the timer/counter, an interrupt sharing the same

interrupt vector is requested. Either one or both of these

overflows can be programmed to request an interrupt.

All interrupt flags must be reset by software.

Page 22

1996 Jun 27 22

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

handbook, full pagewidth

MGA156

STE

R

RTE

I/O port 4

= set

= reset

= toggle

= toggle status

S

R

T

TG

T2 SFR address: TML2 = lower 8 bits

TMH2 = higher 8 bits

INT

COMP

CM0 (S)

INT

COMP

CM1 (R)

INT

COMP

CM2 (T)

CT3I INT

CTI3

CT3

off

f

CLK

T2

RT2

T2ER

external reset

enable

PRESCALER

1/12

T2 COUNTER

8-bit overflow interrupt

16-bit overflow interrupt

CT2I INT

CTI2

CT2

CT1I INT

CTI1

CT1

CT0I INT

CTI0

CT0

R

R

R

R

R

T

T

P4.0

P4.1

P4.2

P4.3

P4.4

P4.5

P4.6

P4.7

S

S

S

S

S

S

TG

TG

Fig.11 Block diagram of Timer T2 configuration.

Page 23

1996 Jun 27 23

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

11.2.1 COUNTER CONTROL REGISTER (TM2CON)

Table 16 Counter Control register (address EAH)

Table 17 Description of the TM2CON bits

76543210

T2IS1 T2IS0 T2ER T2B0 T2P1 T2P0 T2MS1 T2MS0

BIT SYMBOL FUNCTION

7 T2IS1 Timer 2 16-bit overflow interrupt select.

6 T2IS0 Timer 2 byte overflow interrupt select.

5 T2ER Timer 2 external reset enable.

4 T2B0 Timer 2 byte overflow interrupt flag.

3 T2P1 Timer 2 prescaler select (see Table 18).

2 T2P0

1 T2MS1 Timer 2 mode select (see Table 19).

0 T2MS0

Table 18 Timer 2 prescaler select

T2P1 T2P0 T2 CLOCK

0 0 Clock source

01

1

⁄

2

Clock source

10

1

⁄

4

Clock source

11

1

⁄

8

Clock source

Table 19 Timer 2 mode select

T2MS1 T2MS0 MODE

0 0 Timer T2 is halted

0 1 T2 clock source =

1

⁄12f

CLK

.

1 0 Test mode; do not use

1 1 T2 clock source = pin T2

11.2.2 CAPTURE CONTROL REGISTER (CTCON)

Table 20 Capture Control register (address EBH)

Table 21 Description of the CTCON bits

76543210

CTN3 CTP3 CTN2 CTP2 CTN1 CTP1 CTN0 CTP0

BIT SYMBOL

FUNCTION

CAPTURE INTERRUPT ON

7 CTN3 CT3I negative edge

6 CTP3 CT3I positive edge

5 CTN2 CT2I negative edge

4 CTP2 CT2I positive edge

3 CTN1 CT1I negative edge

2 CTP1 CT1I positive edge

1 CTN0 CT0I negative edge

0 CTP0 CT0I positive edge

Page 24

1996 Jun 27 24

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

11.2.3 TIMER INTERRUPT FLAG REGISTER (TM2IR)

Table 22 Timer Interrupt Flag register (address C8H)

Table 23 Description of the TM2IR bits (see notes 1 and 2)

Notes

1. Interrupt Enable IEN1 is used to enable/disable Timer 2 interrupts (see Section 14.1.2).

2. Interrupt Priority Register IP1 is used to determine the Timer 2 interrupt priority (see Section 14.1.4).

11.2.4 S

ET ENABLE REGISTER (STE)

Table 24 Set Enable register (address EEH)

Table 25 Description of the STE bits (see notes 1 and 2)

Notes

1. If STE.n is LOW then P4.n is not affected by a match of CM0 and T2 (n = 0, 1, 2, 3, 4, 5).

2. STE.6 and STE.7 are read only.

76543210

T2OV CMI2 CMI1 CMI0 CTI3 CTI2 CTI1 CTI0

BIT SYMBOL FUNCTION

7 T2OV T2: 16-bit overflow interrupt flag

6 CMI2 CM2: interrupt flag

5 CMI1 CM1: interrupt flag

4 CMI0 CM0: interrupt flag

3 CTI3 CT3: interrupt flag

2 CTI2 CT2: interrupt flag

1 CTI1 CT1: interrupt flag

0 CTI0 CT0: interrupt flag

76543210

TG47 TG46 SP45 SP44 SP43 SP42 SP41 SP40

BIT SYMBOL FUNCTION

7 TG47 if HIGH then P4.7 is reset on the next toggle, if LOW P4.7 is set on the next toggle

6 TG46 if HIGH then P4.6 is reset on the next toggle, if LOW P4.6 is set on the next toggle

5 SP45 if HIGH then P4.5 is set on a match of CM0 and T2

4 SP44 if HIGH then P4.4 is set on a match of CM0 and T2

3 SP43 if HIGH then P4.3 is set on a match of CM0 and T2

2 SP42 if HIGH then P4.2 is set on a match of CM0 and T2

1 SP41 if HIGH then P4.1 is set on a match of CM0 and T2

0 SP40 if HIGH then P4.0 is set on a match of CM0 and T2

Page 25

1996 Jun 27 25

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

11.2.5 RESET/TOGGLE ENABLE REGISTER (RTE)

Table 26 Reset/Toggle Enable register (address EFH)

Table 27 Description of the RTE bits (note 1)

Note

1. If RTE.n is LOW then P4.n is not affected by a match of CM1 and T2 or CM2 and T2.

For more information, refer to the 8051-based

“8-bit Microcontrollers Data Handbook IC20”

.

76543210

TP47 TP46 RP45 RP44 RP43 RP42 RP41 RP40

BIT SYMBOL FUNCTION

7 TP47 if HIGH then P4.7 toggles on a match of CM2 and T2

6 TP46 if HIGH then P4.6 toggles on a match of CM2 and T2

5 RP45 if HIGH then P4.5 is reset on a match of CM1 and T2

4 RP44 if HIGH then P4.4 is reset on a match of CM1 and T2

3 RP43 if HIGH then P4.3 is reset on a match of CM1 and T2

2 RP42 if HIGH then P4.2 is reset on a match of CM1 and T2

1 RP41 if HIGH then P4.1 is reset on a match of CM1 and T2

0 RP40 if HIGH then P4.0 is reset on a match of CM1 and T2

Page 26

1996 Jun 27 26

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

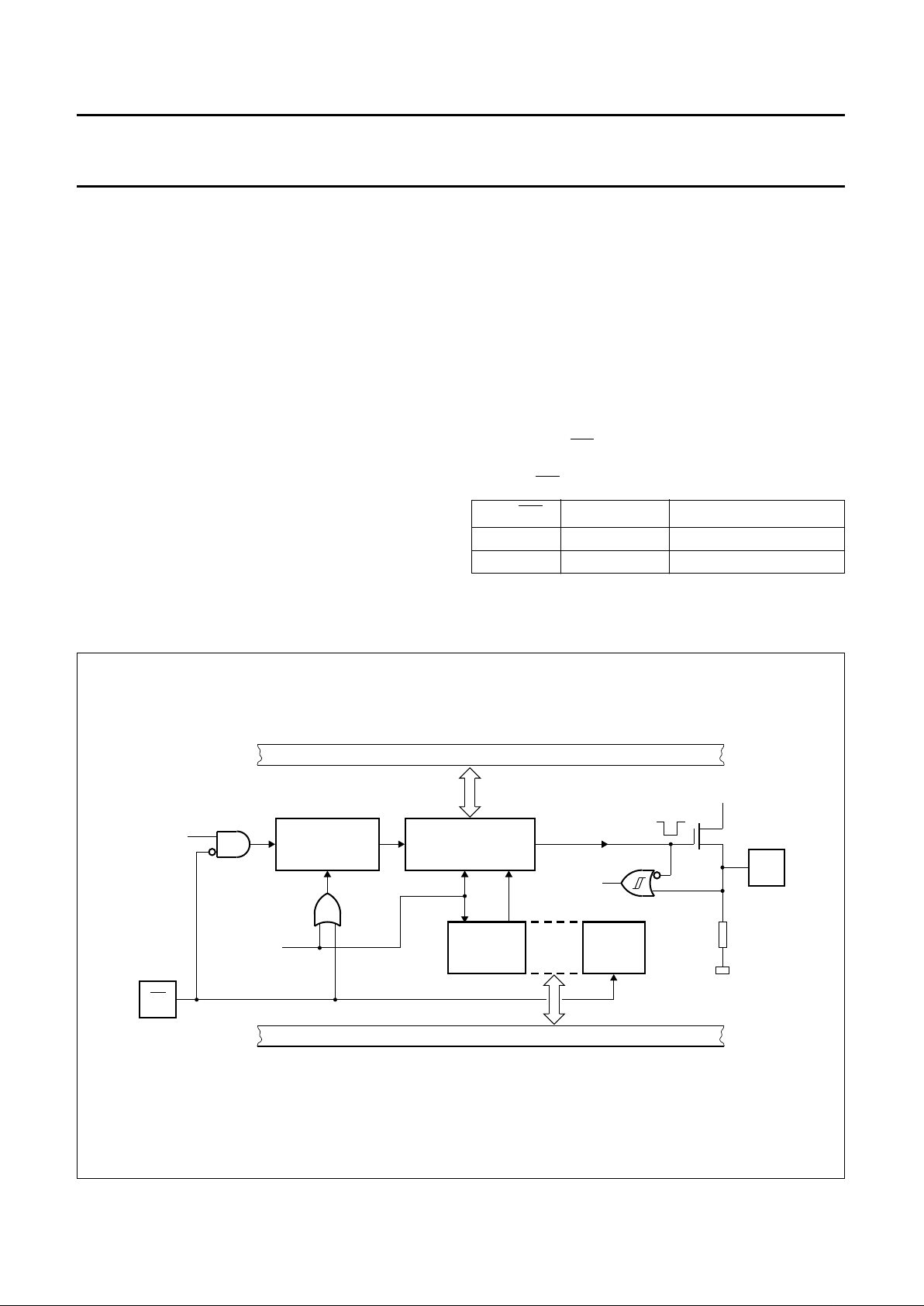

11.3 Watchdog Timer (T3)

In addition to Timer T2 and the standard timers (Timer 0

and Timer 1), a Watchdog Timer (WDT) comprising an

11-bit prescaler and an 8-bit timer (T3) is also provided

(see Fig.12).

The timer T3 is incremented every 1.5 ms, derived from

the oscillator frequency of 16 MHz by the following

formula:

When a timer T3 overflow occurs, the microcontroller is

reset and a reset-output-pulse is generated at pin RST.

This short output pulse (3 machine cycles) may be

suppressed if the RST pin is connected to a capacitor.

To prevent a system reset (by an overflow of the WDT), the

user program has to reload T3 within periods that are

shorter than the programmed Watchdog time interval.

If the processor suffers a hardware/software malfunction,

the software will fail to reload the timer. This failure will

produce a reset upon overflow thus preventing the

processor running out of control.

f

timer

f

CLK

12 2048×

------------------------- -

=

The Watchdog Timer can only be reloaded if the condition

flag WLE = PCON.4 has been previously set by software.

At the moment the counter is loaded the condition flag is

automatically cleared.

The timer interval between the timer's reloading and the

occurrence of a reset depends on the reloaded value. For

example, this may range from 1.5 ms to 0.375 s when

using an oscillator frequency of 16 MHz.

In the Idle state the Watchdog Timer and reset circuitry

remain active.

The Watchdog Timer (WDT) is controlled by the Enable

Watchdog pin (

EW) (see Table 28).

Table 28

EW controlling WDT and Power-down mode

PIN EW WDT POWER-DOWN MODE

LOW enabled disabled

HIGH disabled enabled

Fig.12 Functional diagram of T3 Watchdog Timer.

andbook, full pagewidth

MGA157

INTERNAL BUS

1/12 f

CLK

write

T3

PRESCALER

11-BIT

TIMER T3 (8-BIT)

LOADCLEAR

overflow

internal

reset

LOADEN

EW

LOADEN

PCON.4

PCON.1

CLEAR

WLE PD

R

RST

RST

P

V

DD

INTERNAL BUS

Page 27

1996 Jun 27 27

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

12 SERIAL I/O PORT: SIO0 (UART)

The Serial Port SIO0 is a full duplex (UART) serial I/O port

i.e. it can transmit and receive simultaneously. This Serial

Port is also receive-buffered. It can commence reception

of a second byte before the previously received byte has

been read from the receive register. However, if the first

byte has still not been read by the time reception of the

second byte is complete, one of these (first or second)

bytes will be lost. The SIO0 receive and transmit registers

are both accessed via the S0BUF SFR. Writing to S0BUF

loads the transmit register, and reading S0BUF accesses

to a physically separate receive register. SIO0 can operate

in 4 modes:

Mode 0 Serial data is transmitted and received through

RXD. TXD outputs the shift clock. 8 data bits are

transmitted/received (LSB first). The baud rate is

fixed at1⁄12 of the oscillator frequency.

Mode 1 10 bits are transmitted via TXD or received

through RXD: a start bit (0), 8 data bits (LSB first),

and a stop bit (1). On receive, the stop bit is put

into RB8 of the S0CON SFR. The baud rate is

variable.

Mode 2 11 bits are transmitted through TXD or received

through RXD: a start bit (0), 8 data bits (LSB first),

a programmable 9th data bit, and a stop bit (1).

On transmit, the 9th data bit (TB8 in S0CON) can

be assigned the value of 0 or 1. With nominal

software, TB8 can be the parity bit (P in PSW).

During a receive, the 9th data bit is stored in RB8

(S0CON), and the stop bit is ignored. The baud

rate is programmable to either1⁄32 or1⁄64 of the

oscillator frequency.

Mode 3 11 bits are transmitted through TXD or received

through RXD: a start bit (0), 8 data bits (LSB first),

a programmable 9th data bit, and a stop bit (1).

Mode 3 is the same as Mode 2 except for the

baud rate which is variable in Mode 3.

In all four modes, transmission is initiated by any

instruction that writes to the S0BUF SFR.

Reception is initiated in Mode 0 when RI = 0 and REN = 1.

In the other three modes, reception is initiated by the

incoming start bit provided that REN = 1.

Modes 2 and 3 are provided for multiprocessor

communications. In these modes, 9 data bits are received

with the 9th bit written to RB8 (S0CON). The 9th bit is

followed by the stop bit. The port can be programmed so

that with receiving the stop bit, the Serial Port interrupt will

be activated if, and only if RB8 = 1.

This feature is enabled by setting bit SM2 in S0CON. This

feature may be used in multiprocessor systems.

For more information about how to use the UART in

combination with the registers S0CON, PCON, IE, SBUF

and the Timer register, refer to the 8051-based

“8-bit Microcontrollers Data Handbook IC20”

.

13 SERIAL I/O PORT: SIO1 (CAN)

SIO1 (CAN) provides the CAN (Controller Area Network)

serial-bus data communication interface. SIO1 (CAN)

replaces the SIO1 (I

2

C) serial interface as provided in the

microcontroller derivative P8xC552.

13.1 On-chip CAN-controller

CAN is the definition of a high performance

communication protocol for serial data communication.

The P8xC592 on-chip CAN-controller is a full

implementation of the CAN 2.0A protocol. With the

P8xC592 powerful local networks can be built, both for

automotive and general industrial environments. This

results in a much reduced wiring harness and enhanced

diagnostic and supervisory capabilities.

13.2 CAN Features

• Multi-master architecture

• Bus access priority determined by the message

identifier

• 2032 message identifier (2

11

standard frame CAN 2.0A)

• Guaranteed latency time for high priority messages

• Powerful error handling capability

• Data length from 0 up to 8 bytes

• Multicast and broadcast message facility

• Non destructive bit-wise arbitration

• Non-return-to-zero (NRZ) coding/decoding with

bit-stuffing

• Programmable transfer rate (up to 1 Mbit/s)

• Programmable output driver configuration

• Suitable for use in a wide range of networks including

the SAE's network classes A, B and C

• DMA providing high-speed on-chip data exchange

• Bus failure management facility

•1⁄2AVDD reference voltage.

Page 28

1996 Jun 27 28

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

13.3 Interface between CPU and CAN

The internal interface between the P8xC592's CPU and

on-chip CAN-controller is achieved via the following four

SFRs (see Fig.13):

• CANADR, to point to a register of the CAN-controller

• CANDAT, to read or write data

• CANCON, to read interrupt flags and to write commands

• CANSTA, to read status information and to write DMA

pointer.

Additionally, the DMA-logic allows a high-speed data

exchange between the CAN-controller and the CPU's

on-chip MAIN RAM. For more information, see

Section 13.5.15 “Handling of the CPU-CAN interface”.

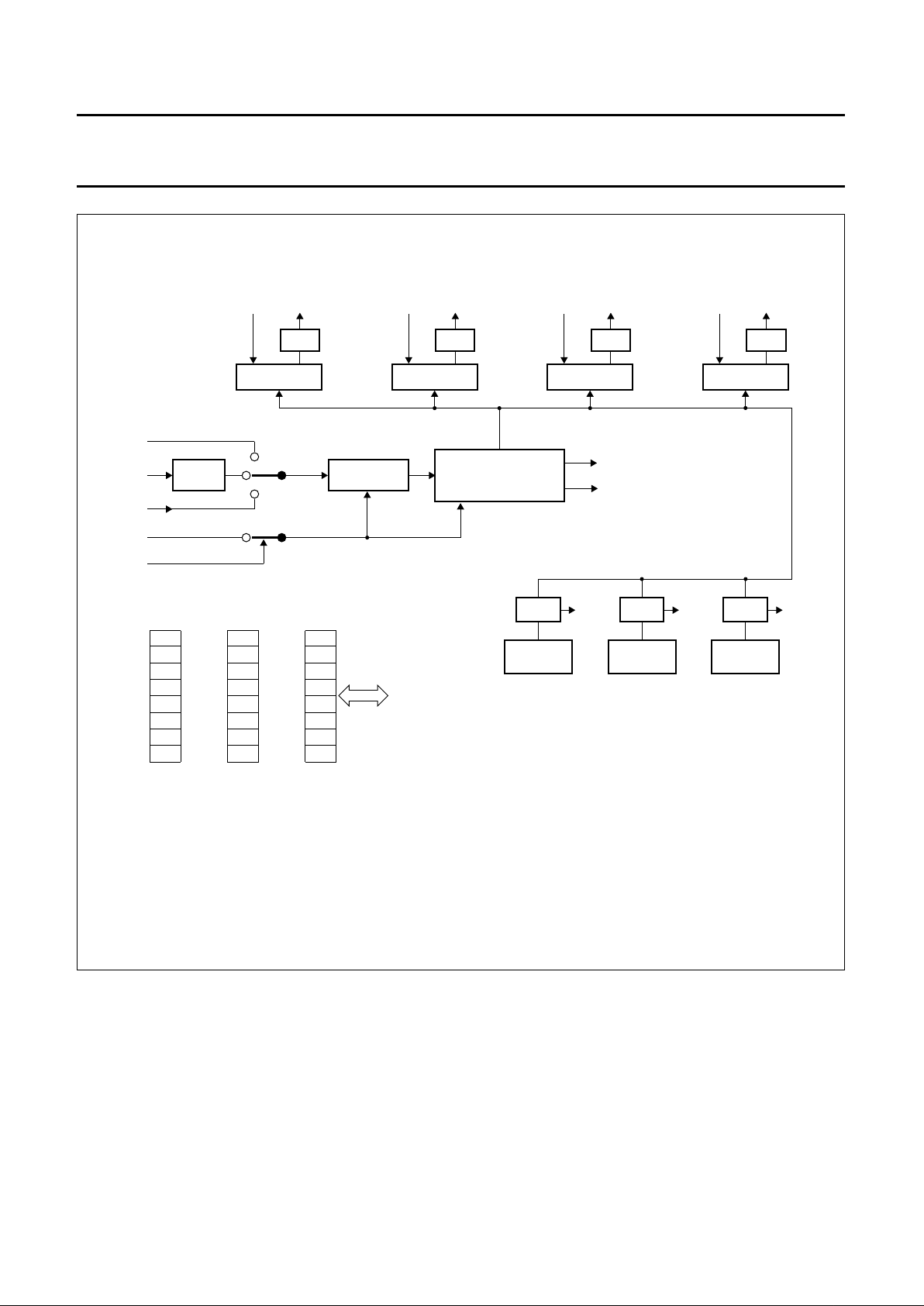

13.4 Hardware blocks of the CAN-controller

The P8xC592 CAN-controller contains all necessary

hardware for high performance serial network

communications (see Fig.14 and Table 29).

It controls the communication flow through the area

network using the CAN-protocol. The CAN-controller

meets the following automotive requirements:

• Short message length

• Bus access priority, determined by the message

identifier

• Powerful error handling capability

• Configuration flexibility to allow area network expansion

• Guaranteed latency time for urgent messages;

– The latency time defines the period between the

initiation (Transmission Request) and the start of the

transmission on the bus. The latency time strongly

depends on a large variety of bus-related conditions.

In the case of a message being transmitted on the

bus and one distortion, the latency time can be up to

149 bit times (worst case). For more information see

Chapter 22 “CAN application information”.

handbook, full pagewidth

CANADR

DBH

CANDAT

DAH

CANCON

D9H

CANSTA

D8H

ADDRESS

DATA

CAN

CONTROLLER

MAIN

RAM

CPU

DMA

LOGIC

internal

bus

4 special function

registers

MGA158

DMA bus

Fig.13 Interface between CPU and CAN-controller.

Page 29

1996 Jun 27 29

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Table 29 Hardware blocks of the CAN-controller (see Fig.14)

NAME BLOCK DESCRIPTION

Interface Management Logic IML Interprets commands from the CPU, allocates the message buffers

(TBF, RBF0 and RBF1) and provides interrupts and status information to the

microcontroller.

Transmit Buffer TBF 10 bytes memory into which the CPU writes messages which are to be

transmitted over the CAN network.

Receive Buffers (0 and 1) RBF0 RBF0 and RBF1 are each 10 bytes memories which are alternatively used to

store messages received from the CAN network.

The CPU can process one message while another is being received.

RBF1

Bit Stream Processor BSP Is a sequencer, controlling the data stream between the Transmit Buffer,

Receive Buffers (parallel data) and the CAN-bus (serial data).

Bit Timing Logic BTL Synchronizes the CAN-controller to the bitstream on the CAN-bus.

Transceiver Control Logic TCL Controls the output driver.

Error Management Logic EML Performs the error confinement according to the CAN-protocol.

Fig.14 Block diagram of the P8xC592 on-chip CAN-controller.

handbook, full pagewidth

MGA159

INTERFACE

MANAGEMENT

LOGIC

TRANSCEIVER

LOGIC

TRANSMIT

BUFFER

BIT TIMING

LOGIC

2

2

ON - CHIP

CAN

CONTROLLER

RECEIVE

BUFFER 0

RECEIVE

BUFFER 1

BIT STREAM

PROCESSOR

ERROR

MANAGEMENT

LOGIC

address

data

CRX0

and

CRX1

CTX0

and

CTX1

Page 30

1996 Jun 27 30

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

13.5 Control Segment and Message Buffer

description

The CAN-controller appears to the CPU as a

memory-mapped peripheral, guaranteeing the

independent operation of both parts.

13.5.1 A

DDRESS ALLOCATION

The address area of the CAN-controller consists of the

Control Segment and the message buffers. The Control

Segment is programmed during an initialization down-load

in order to configure communication parameters (e.g. bit

timing). The communication over the CAN-bus is also

controlled via this segment by the CPU. A message which

is to be transmitted, must be written to the Transmit Buffer.

After a successful reception the CPU may read the

message from the Receive Buffer and then release it for

further use.

13.5.2 CONTROL SEGMENT LAYOUT

The exchange of status, control and command signals

between the CPU and the CAN-controller is performed in

the control segment. The layout of this segment is shown

in Fig.15. After an initial down-load, the contents of the

registers Acceptance Code, Acceptance Mask,

Bus Timing 0, Bus Timing 1 and Output Control should not

be changed. These registers may only be accessed when

the Reset Request bit in the Control Register is set HIGH

(see Tables 30, 31 and 32).

handbook, full pagewidth

ADDRESS

0

control segment

MGA160 - 1

CONTROL

descriptor

data field

transmit buffer

descriptor

data field

receive buffer 0 or 1

1 COMMAND

2 STATUS

3 INTERRUPT

4 ACCEPTANCE CODE

5 ACCEPTANCE MASK

6 BUS TIMING 0

7 BUS TIMING 1

8 OUTPUT CONTROL

9 TEST

10 IDENTIFIER,

11 RTR BIT, DATA LENGTH CODE

12 BYTE 1

13 BYTE 2

14 BYTE 3

15 BYTE 4

16 BYTE 5

17 BYTE 6

18 BYTE 7

19 BYTE 8

2014H

15H

16H

11H

12H

13H

17H

18H

19H

1AH

1BH

1CH

1DH

IDENTIFIER,

21 RTR BIT, DATA LENGTH CODE

22 BYTE 1

23 BYTE 2

24 BYTE 3

25 BYTE 4

26 BYTE 5

27 BYTE 6

28 BYTE 7

29 BYTE 8

IDENTIFIER,

RTR BIT, DATA LENGTH CODE

BYTE 1

BYTE 2

BYTE 3

BYTE 4

BYTE 5

BYTE 6

BYTE 7

BYTE 8

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0CH

0DH

0EH

0FH

10H

0BH

Fig.15 CAN-controller internal address allocation.

Page 31

1996 Jun 27 31

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Table 30 CPU/CAN Register map

BIT

76543210

Control Segment

ADDRESS 0: CONTROL REGISTER

TM S RA OIE EIE TIE RIE RR

ADDRESS 1: COMMAND REGISTER

RX0A RX1A WUM SLP COS RRB AT TR

ADDRESS 2: STATUS REGISTER

BS ES TS RS TCS TBS DO RBS

ADDRESS 3: INTERRUPT REGISTER

Reserved Reserved Reserved WUI OI EI TI RI

ADDRESS 4: ACCEPTANCE CODE REGISTER

AC.7 AC.6 AC.5 AC.4 AC.3 AC.2 AC.1 AC.0

ADDRESS 5: ACCEPTANCE MASK REGISTER

AM.7 AM.6 AM.5 AM.4 AM.3 AM.2 AM.1 AM.0

ADDRESS 6: BUS TIMING REGISTER 0

SJW.1 SJW.0 BRP.5 BRP.4 BRP.3 BRP.2 BRP.1 BRP.0

ADDRESS 7: BUS TIMING REGISTER 1

SAM TSEG2.2 TSEG2.1 TESG2.0 TSEG1.3 TSEG1.2 TSEG1.1 TSEG1.0

ADDRESS 8: OUTPUT CONTROL REGISTER

OCTP1 OCTN1 OCPOL1 OCTP0 OCTN0 OCPOL0 OCMODE1 OCMODE0

ADDRESS 9: TEST REGISTER (note 1)

Reserved Reserved Map Internal

Register

Connect RX

Buffer 0

CPU

Connect TX

Buffer CPU

Access

Internal Bus

Normal

RAM

Connect

Float Output

Driver

Page 32

1996 Jun 27 32

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Note

1. The Test Register is used for production testing only.

13.5.3 C

ONTROL REGISTER (CR)

The contents of the Control Register are used to change the behaviour of the CAN-controller. Control bits may be set or

reset by the CPU which uses the Control Register as a read/write memory.

Table 31 Control Register (address 0)

Table 32 Description of the CR bits

Transmit Buffer

ADDRESS 10: IDENTIFIER

ID.10 ID.9 ID.8 ID.7 ID.6 ID.5 ID.4 ID.3

ADDRESS 11: RTR, DATA LENGTH CODE

ID.2 ID.1 ID.0 RTR DLC.3 DLC.2 DLC.1 DLC.0

ADDRESS 12 TO 19: BYTES 1 TO 8

Data Data Data Data Data Data Data Data

Receive Buffer 0 and 1

ADDRESS 20: IDENTIFIER

ID.10 ID.9 ID.8 ID.7 ID.6 ID.5 ID.4 ID.3

ADDRESS 21: RTR, DATA LENGTH CODE

ID.2 ID.1 ID.0 RTR DLC.3 DLC.2 DLC.1 DLC.0

ADDRESS 22 TO 29: BYTES 1 TO 8

Data Data Data Data Data Data Data Data

76543210

TM S RA OIE EIE TIE RIE RR

BIT SYMBOL FUNCTION

7TM Test Mode (note 1).If the value of TM is:

HIGH (enabled), then the CAN-controller enters Test Mode (normal operations

impossible).

LOW (disabled), then the CAN-controller is in normal operating mode.

6S Sync (note 2). If the value of S is:

HIGH (2 edges), then bus-line transitions from recessive-to-dominant and vice-versa

are used for resynchronization (see Sections 13.5.20 and 13.6).

LOW (1 edge), then the only transitions from recessive-to-dominant are used for

resynchronization.

BIT

76543210

Page 33

1996 Jun 27 33

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Notes to the description of the CR bits

1. The test mode is intended for factory testing and not for customer use.

2. A modification of the bits Reference Active and Sync is only possible with Reset Request = HIGH (present). It is

allowed to set these bits while Reset Request is changed from a HIGH level to a LOW level. After an external reset

(pin RST = HIGH) the Reference Active bit is set HIGH (output), the Sync bit is undefined.

3. During an external reset (RST = HIGH) or when the Bus Status bit is set HIGH (Bus-OFF), the IML forces the

Reset Request HIGH (present). After the Reset Request bit is set LOW (absent) the CAN-controller will wait for:

a) One occurrence of the Bus-Free signal (11 recessive bits, see Section 13.6.9.6), if the preceding reset (Reset

Request = HIGH) has been caused by an external reset or a CPU initiated reset.

b) 128 occurrences of Bus-Free, if the preceding reset (Reset Request = HIGH) has been caused by a

CAN-controller initiated Bus-OFF, before re-entering the Bus-On mode, see Section 13.6.9.

c) When Reset Request is set HIGH (present), for whatever reason, the Control, Command, Status and Interrupt

bits are affected, see Table 40. The registers at addresses 4 to 8 are only accessible when the Reset Request is

set HIGH (present).

5RA Reference Active (notes 2). If the value of RA is:

HIGH (output), then the pin REF is an1⁄2AVDD reference output.

LOW (input), then a reference voltage may be input.

4 OIE Overrun Interrupt Enable. If the value of OIE is:

HIGH (enabled) and the Data Overrun bit is set (see Section 13.5.5) then the CPU

receives an Overrun Interrupt signal.

LOW (disabled), then the CPU receives no Overrun Interrupt signal from the

CAN-controller.

3 EIE Error Interrupt Enable. If the value of EIE is:

HIGH (enabled) and the Error or Bus Status change (see Section 13.5.5) then the CPU

receives an Error Interrupt signal.

LOW (disabled), then the CPU receives no Error Interrupt signal.

2 TIE Transmit Interrupt Enable. If the value of TIE is:

HIGH (enabled) and when a message has been successfully transmitted or the

Transmit Buffer is accessible again, (e.g. after an Abort Transmission command), then

the CAN-controller transmits a Transmit Interrupt signal to the CPU.

LOW (disabled), then there is no transmission of the Transmit Interrupt signal by the

CAN-controller to the CPU.

1 RIE Receive Interrupt Enable. If the value of RIE is:

HIGH (enabled) and when a message has been received without errors, then the

CAN-controller transmits a Receive Interrupt signal to the CPU.

LOW (disabled), then there is no transmission of the Receive Interrupt signal by the

CAN-controller to the CPU.

0RR Reset Request (note 3). If the value of RR is:

HIGH (present), then detection of a Reset Request results in the CAN-controller

aborting the current transmission/reception of a message entering the reset state

synchronously to the system clock (t

SCL

, see Section 13.5.9).

LOW (absent), on the HIGH-to-LOW transition of the Reset Request bit, the

CAN-controller returns to its normal operating state.

BIT SYMBOL FUNCTION

Page 34

1996 Jun 27 34

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

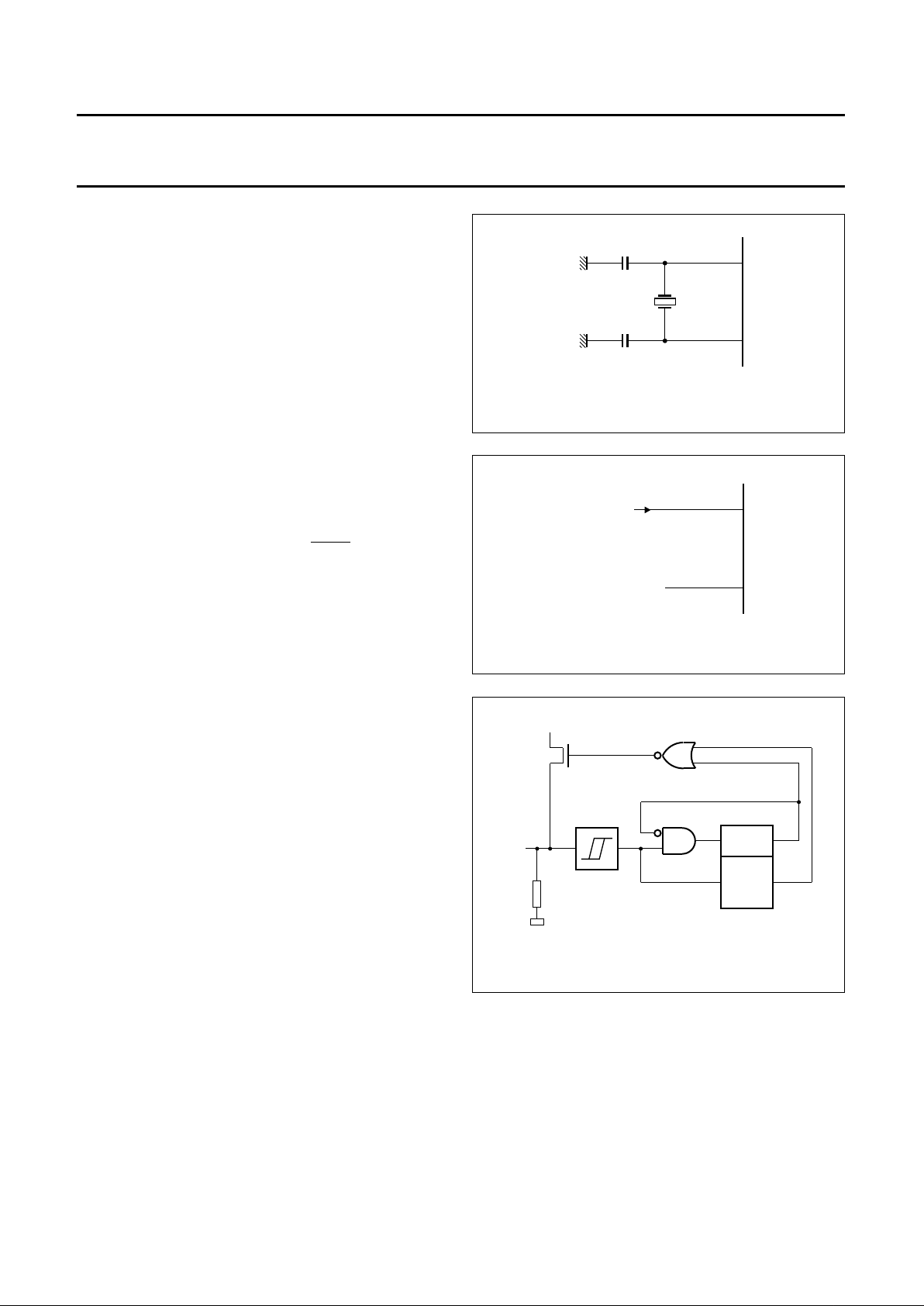

handbook, full pagewidth

MGA161

single-ended

wake-up

WAKE-UP

(bus active signal)

COMP OUT

RX0 ACTIVE

RX1 ACTIVE

1/2 AV - VOLTAGE

WAKE-UP MODE

1

0

S2

RX0

RX1

1

0

S1

0

1

S0

differential

wake-up

P8xC592

REF

CRX0

CRX1

REFERENCE ACTIVE

DD

Fig.16 Configurable CAN receiver.

Page 35

1996 Jun 27 35

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

13.5.4 COMMAND REGISTER (CMR)

A command bit initiates an action within the transfer layer of the CAN-controller. The Command Register appears to the

CPU as a read/write memory, except for the bits CMR.0 (TR) to CMR.3 (COS), which return a HIGH if being read.

Table 33 Command Register (address 1)

Table 34 Description of the CMR bits

76543210

RX0A RX1A WUM SLP COS RRB AT TR

BIT SYMBOL FUNCTION

7 RX0A RX0 Active. See Table 35; note 1.

6 RX1A RX1 Active. See Table 35; note 1.

5 WUM Wake-up Mode (note 2). If the value of WUM is:

HIGH (single ended), then the difference of the RX signals to the internal reference voltage

1

⁄2AV

DD

is used for wake up.

LOW (differential), then the differential signal between RX0 and RX1 is used for wake up.

4 SLP Sleep (note 3). If the value of SLP is:

HIGH (sleep), then the CAN-controller enters sleep mode if no CAN interrupt is pending and there

is no bus activity.

LOW (wake up), then the CAN-controller functions normally.

3 COS Clear Overrun Status (note 4). If the value of COS is:

HIGH (clear), then the Data Overrun status bit is set to LOW (see Table 37).

LOW (no action), then there is no action.

2 RRB Release Receive Buffer (note 5). If the value of RRB is:

HIGH (released), then the Receive Buffer attached to the CPU is released.

LOW (no action), then there is no action.

1AT Abort Transmission (note 6). If the value of AT is:

HIGH (present) and if not already in progress, a pending Transmission Request is cancelled.

LOW (absent), then there is no action.

0TR Transmission Request (note 7). If the value of TR is:

HIGH (present), then a message shall be transmitted.

LOW (absent), then there is no action.

Page 36

1996 Jun 27 36

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Notes to the description of the CMR bits

1. The RX0/RX1 Active bits, if being read, reflect the status of the respective switches (see Fig.16). It is recommended

to change the switches only during the reset state (Reset Request = HIGH).

2. The Wake-Up Mode bit should be set at the same time as the Sleep bit. The differential wake up mode is useful if

both bus wires are fully functioning; it minimizes the amount of wake ups due to noise. The single ended wake up

mode is recommended if a wake up must be possible even if one bus wire is already or may become disturbed

(see Fig.16).

3. The CAN-controller will enter sleep mode, if the Sleep bit is set HIGH (sleep) there is no bus activity and no interrupt

is pending. The CAN-controller will wake up after the Sleep bit is set LOW (wake up) or when there is bus activity.

On wake up, a Wake-Up Interrupt (see Section 13.5.6) is generated (see also Chapter 15). A CAN-controller which

is sleeping and then awaken by bus activity will not be able to receive this message until it detects a Bus-Free signal

(see Section 13.6.9.6). The Sleep bit, if read, reflects the status of the CAN-controller.

4. This command bit is used to acknowledge the Data Overrun condition signalled by the Data Overrun status bit.

Command is given only after releasing both receive buffers. The stored messages have to be rejected. The

command bit is set simultaneously with setting of the Release Receive Buffer command bit the second time.

5. After reading the contents of the Receive Buffer (RBF0 or RBF1) the CPU must release this buffer by setting Release

Receive Buffer bit HIGH (released). This may result in another message becoming immediately available.

To prevent the RRB command being executed only once, the minimum wait time between two successive RRB

commands is 3 system clock cycles (t

SCL

, see Section 13.5.9).

6. The Abort Transmission bit is used when the CPU requires the suspension of the previously requested transmission,

e.g. to transmit an urgent message. A transmission already in progress is not stopped. In order to see if the original

message had been either transmitted successfully or aborted, the Transmission Complete Status bit should be

checked. This should be done after the Transmit Buffer Access bit has been set HIGH (released) or a Transmit

Interrupt has been generated (see Section 13.5.6).

7. If the Transmission Request bit was set HIGH in a previous command, it cannot be cancelled by setting the

Transmission Request bit LOW (absent). Cancellation of the requested transmission may be performed by setting

the Abort Transmission bit HIGH (present).

Table 35 Combination of bits RX0A and RX1A (see Fig.16)

CONTROL

RX0 RX1

RX0A RX1A

1 1 CRX0 CRX1

1 0 CRX0

1

⁄2AV

DD

01

1

⁄

2

AV

DD

CRX1

0 0 No action

Page 37

1996 Jun 27 37

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

13.5.5 STATUS REGISTER (SR)

The contents of the Status Register reflects the status of the CAN-controller. The Status Register appears to the CPU

as a read only memory.

Table 36 Status Register (address 2)

Table 37 Description of the SR bits

76543210

BS ES TS RS TCS TBS DO RBS

BIT SYMBOL FUNCTION

7BS Bus Status (note 1). If the value of BS is:

HIGH (Bus-OFF), then the CAN-controller is not involved in bus activities.

LOW (Bus-ON), then the CAN-controller is involved in bus activities.

6ES Error Status. If the value of ES is:

HIGH (error), then at least one of the Error Counters (see Section 13.6.10) has reached the

CPU Warning limit.

LOW (ok), then both Error Counters have not reached the warning limit.

5TS Transmit Status (note 2). If the value of TS is:

HIGH (transmit), then the CAN-controller is transmitting a message.

LOW (idle), then no message is transmitted.

4RS Receive Status (note 2). If the value of RS is:

HIGH (receive), then the CAN-controller is receiving a message.

LOW (idle), then no message is received.

3 TCS Transmission Complete Status (note 3). If the value of TCS is:

HIGH (complete), then last requested transmission has been successfully completed.

LOW (incomplete), then previously requested transmission is not yet completed.

2 TBS Transmit Buffer Access (note 3). If the value of TBS is:

HIGH (released), then the CPU may write a message into the TBF.

LOW (locked), then the CPU cannot access the Transmit Buffer. A message is either waiting for

transmission or is in the process of being transmitted.

1DO Data Overrun (note 4). If the value of DO is:

HIGH (overrun), then both Receive Buffers are full and the first byte of another message should be

stored.

LOW (absent), then no data overrun has occurred since the Clear Overrun command was given.

0 RBS Receive Buffer Status (note 5). If the value of RBS is

HIGH (full), then this bit is set when a new message is available.

LOW (empty), then no message has become available since the last Release Receive Buffer

command bit was set.

Page 38

1996 Jun 27 38

Philips Semiconductors Product specification

8-bit microcontroller with on-chip CAN P8xC592

Notes to the description of the SR bits

1. When the Bus Status bit is set HIGH (Bus-OFF), the CAN-controller will set the Reset Request bit HIGH (present).

It will stay in this state until the CPU sets the Reset Request bit LOW (absent). Once this is completed the

CAN-controller will wait the minimum protocol-defined time (128 occurrences of the Bus-Free signal) before setting