Page 1

DATA SH EET

Preliminary specification

Supersedes data of 1995 Oct 11

File under Integrated Circuits, IC18

1996 Jun 19

INTEGRATED CIRCUITS

P82C150

CAN Serial Linked I/O device

(SLIO) with digital and analog port

functions

Page 2

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

1996 Jun 19 2

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 BLOCK DIAGRAM

5 FUNCTIONAL DIAGRAM

6 PINNING INFORMATION

6.1 Pinning

6.2 Pin description

7 FUNCTIONAL DESCRIPTION

7.1 I/O functions

7.2 I/O registers

7.3 CAN functions

7.4 Initialization

7.5 P82C150 operation after RESET or change of

bus mode

8 LIMITING VALUES

9 DC CHARACTERISTICS

10 AC CHARACTERISTICS

11 APPLICATION INFORMATION

11.1 Maximum bus length

11.2 Start up sequence

11.3 External oscillator mode

11.4 Using digital I/O port functions

11.5 Using DPM

11.6 Using ADC

11.7 Using analog input port functions

11.8 CAN-bus system applications

12 PACKAGE OUTLINE

13 SOLDERING

13.1 Introduction

13.2 Reflow soldering

13.3 Wave soldering

13.4 Repairing soldered joints

14 DEFINITIONS

15 LIFE SUPPORT APPLICATIONS

Page 3

1996 Jun 19 3

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

1 FEATURES

• Single-chip I/O device with CAN protocol controller

• Meets CAN protocol specification version 2.0 A and B

(passive) with restricted bit timing

• Fully integrated clock oscillator (no crystal required)

• 16 configurable digital or analog I/O port pins

• Each of the port pins individually configurable via

CAN-bus: port direction, port mode and event capture

facilities for inputs (event driven or polling)

• Up to sixteen digital inputs; automatic transmission of a

CAN message on a change on inputs individually

selectable

• Up to sixteen 3-state outputs

• Up to two quasi-analog outputs with 10-bit accuracy

• 10-bit analog-to-digital converter with up to six

multiplexed analog input channels (for accuracy see

Section 11.6)

• Two general purpose comparators

• Bit rate from 20 kbit/s up to 125 kbit/s using internal

oscillator

• Automatic bit rate detection and calibration

• Up to sixteen P82C150 nodes for one CAN-bus system

• Four identifier bits programmable

• SLIO functions controlled by a single intelligent node

(‘host’)

• Sleep-mode with wake-up via CAN-bus

• Differential CAN-bus input comparator and CAN-bus

output driver

• Supply voltage: 5 V ±4%

• Operating temperature: two ranges −40 to +85 °C and

−40 to +125 °C.

2 GENERAL DESCRIPTION

The P82C150 is a single-chip 16-bit I/O device including a

Controller Area Network (CAN) protocol controller with

automatic bit rate detection and calibration. It features 16

configurable I/O port pins with programmable direction,

digital and analog modes.

The P82C150 provides a configurable event capture

facility supporting automatic transmission caused by a

change on the port input pins.

The clock oscillator requires no external components,

thus, the cost of the CAN link is reduced significantly.

The P82C150 is a very cost-effective way to increase the

I/O capability of a microcontroller based CAN node as well

as to reduce the amount and complexity of wiring.

Advanced safety is provided by the CAN protocol.

Applications:

• Body electronics and instrumentation in automotive

applications

• Sensor/actuator interface in automotive and general

industrial applications

• Extension of I/O capabilities of microcontroller based

CAN nodes.

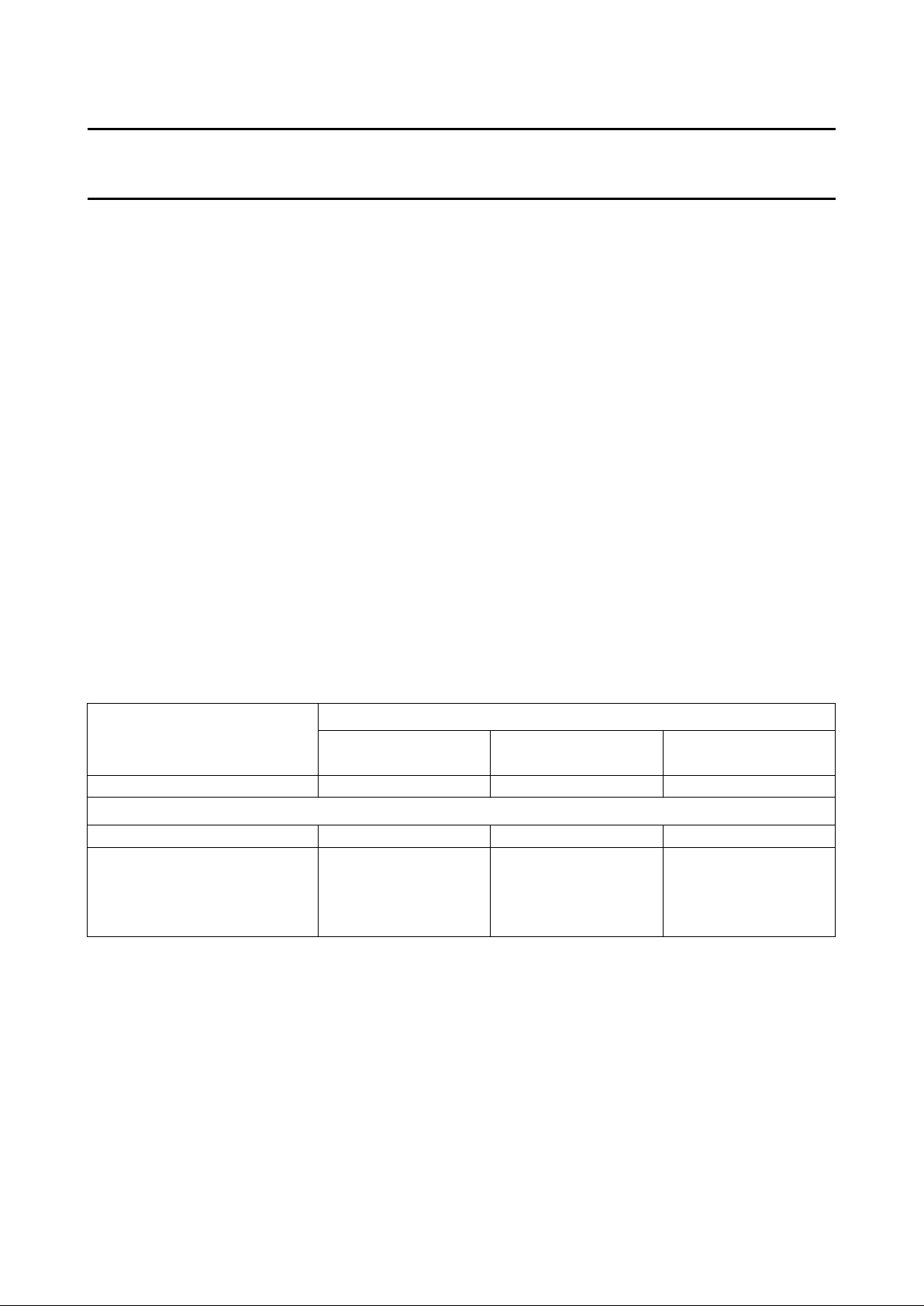

3 ORDERING INFORMATION

TYPE NUMBER

PACKAGE

TEMPERATURE

RANGE (°C)

NAME DESCRIPTION VERSION

P82C150 AFT

SO28 plastic small outline package; 28 leads; body width 7.5 mm SOT136-1

−40 to +85

P82C150 AHT −40 to +125

Page 4

1996 Jun 19 4

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

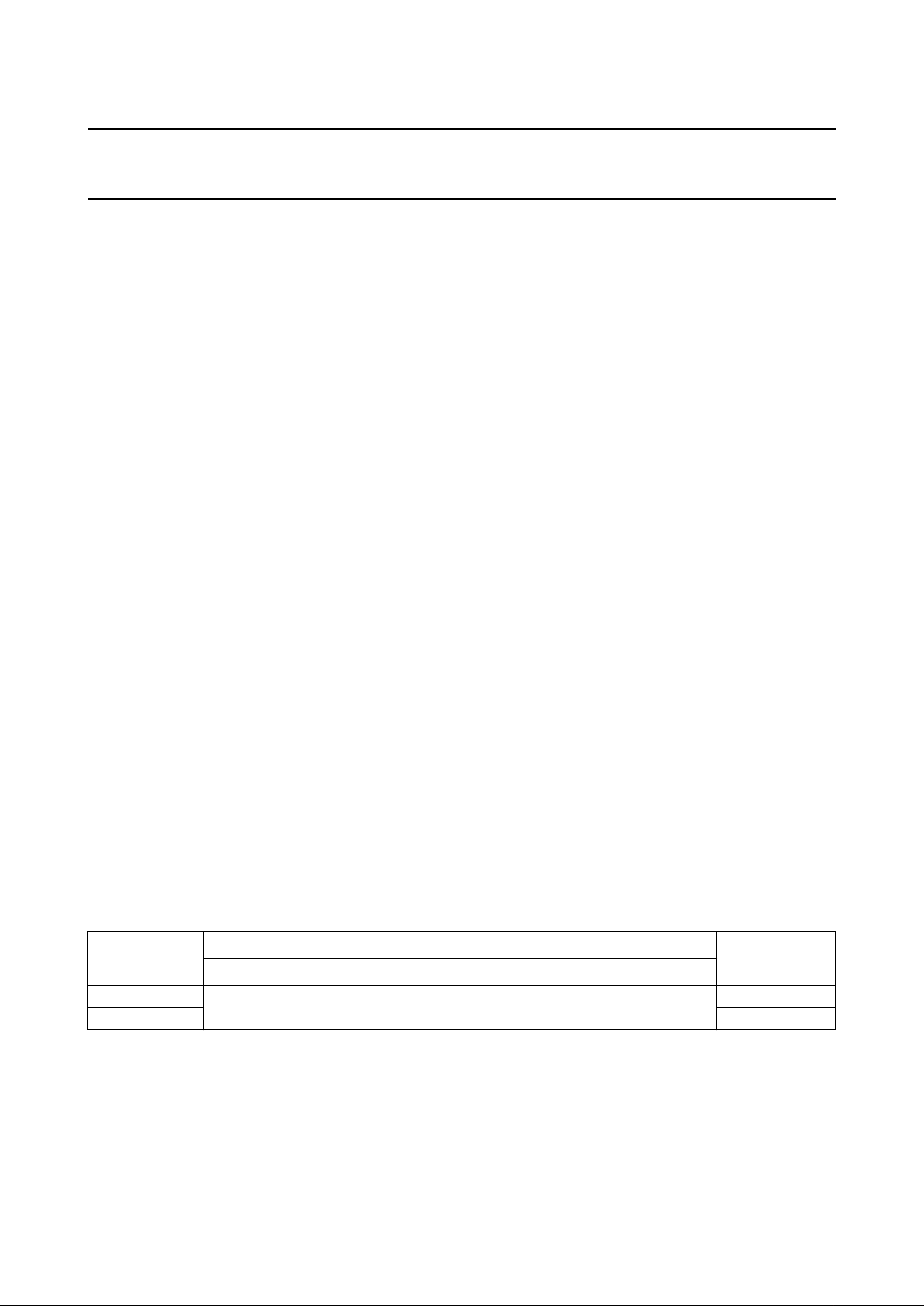

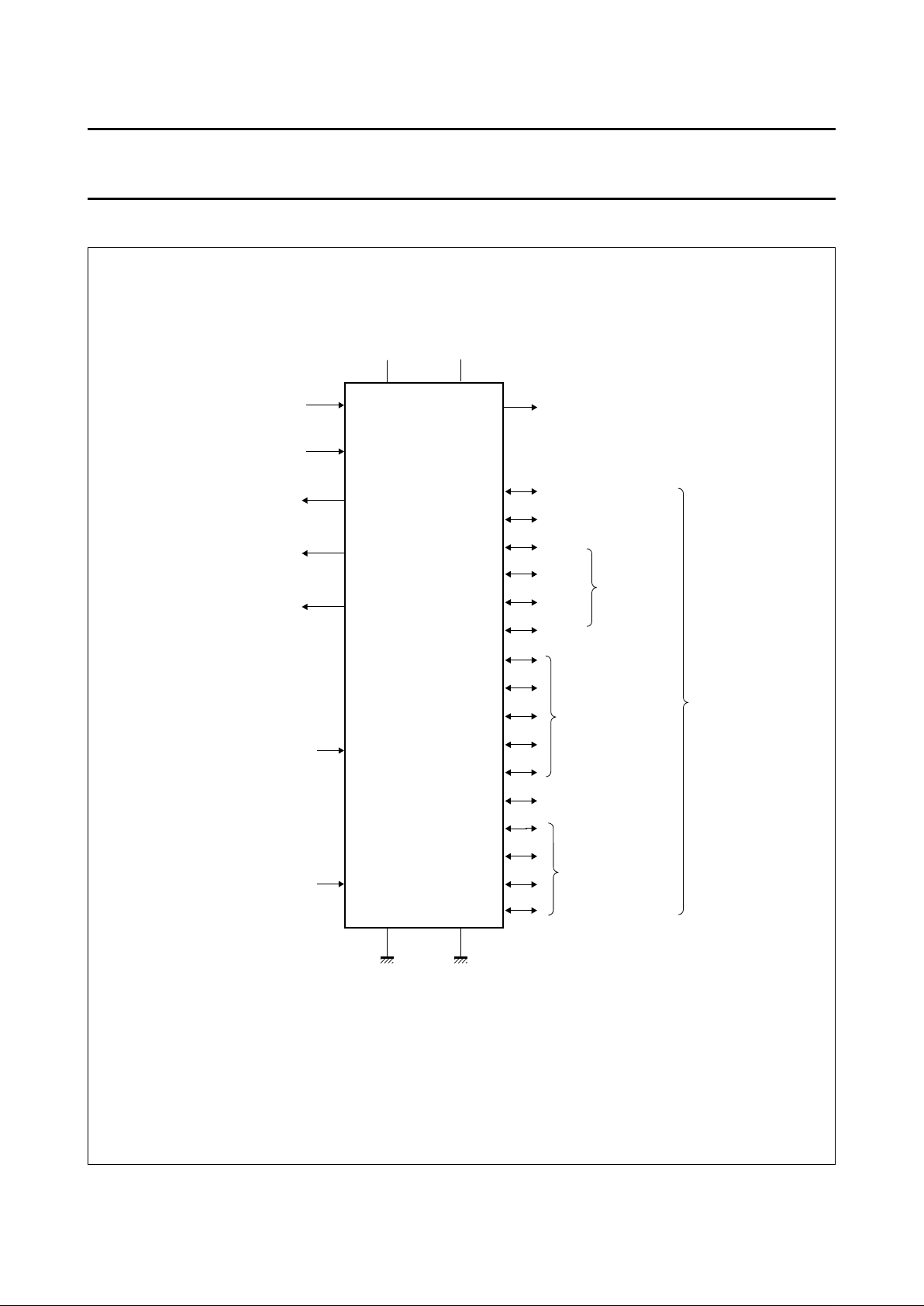

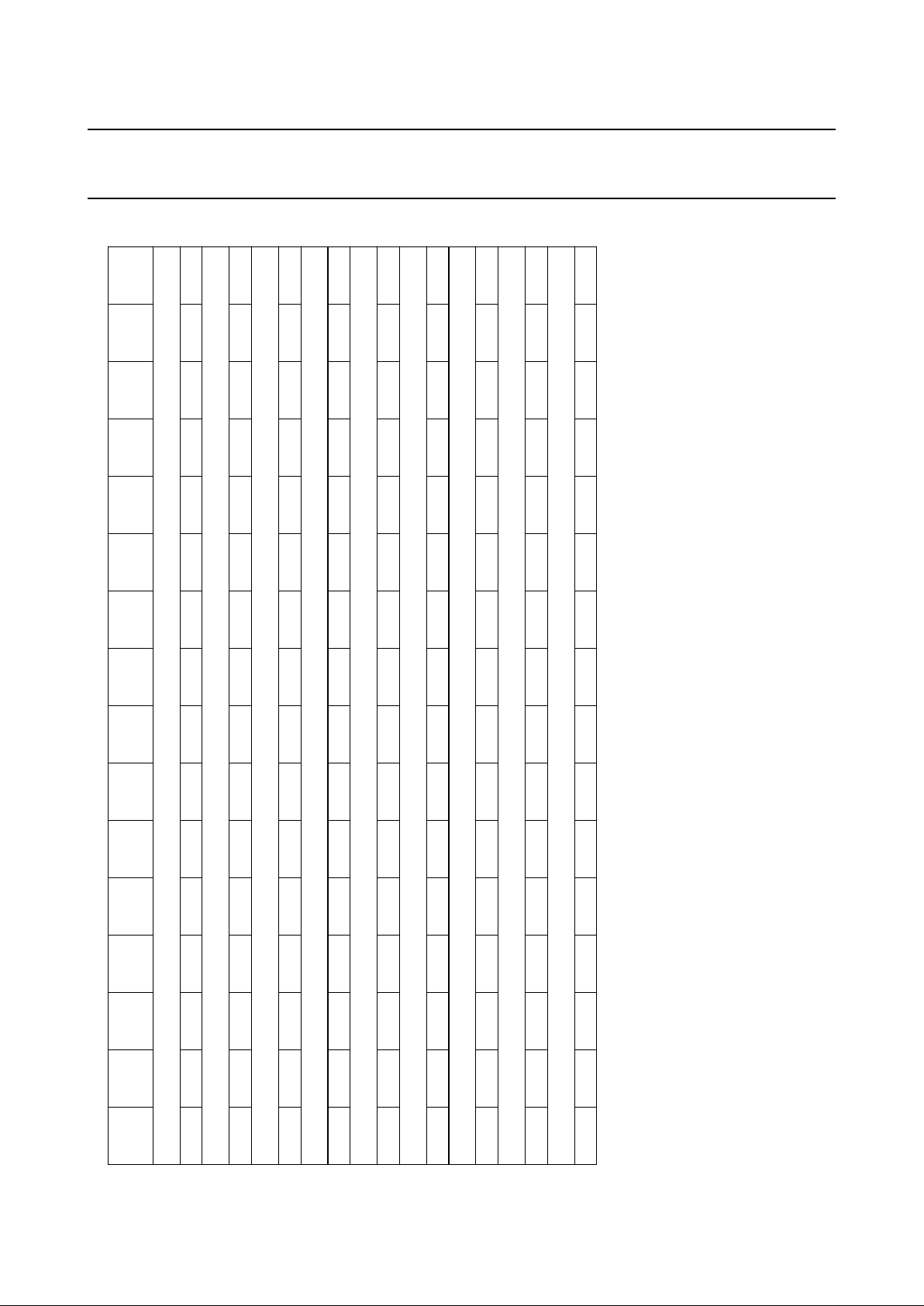

4 BLOCK DIAGRAM

Fig.1 Block diagram.

handbook, full pagewidth

P82C150

ERROR

MANAGEMENT

LOGIC

RXO

21

RX1

22

19

18

BIT STREAM

PROCESSOR

input

comparator

TRANSMIT/

RECEIVE

LOGIC

PORT

LOGIC

IDENTIFIER

LATCH

23

4

20

OSCILLATOR

AND

CALIBRATOR

clock

8

REF

AV

DD

V

DD

+5 V

+5 V

9 to 16

5, 6, 7

1, 2, 3

P8 to P15

P5 to P7

P2 to P4

P0/CLK, P1

AV

SS

MHA064

CAN-bus

CAN-bus

17

P16

XMOD

25

26TX1

TX0

RST

16 I/O

port pins

1

/2 AV

DD

+

REFERENCE

VOLTAGE

27, 28

bus mode

bus mode

I/O

REGISTERS

24

V

SS

Page 5

1996 Jun 19 5

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

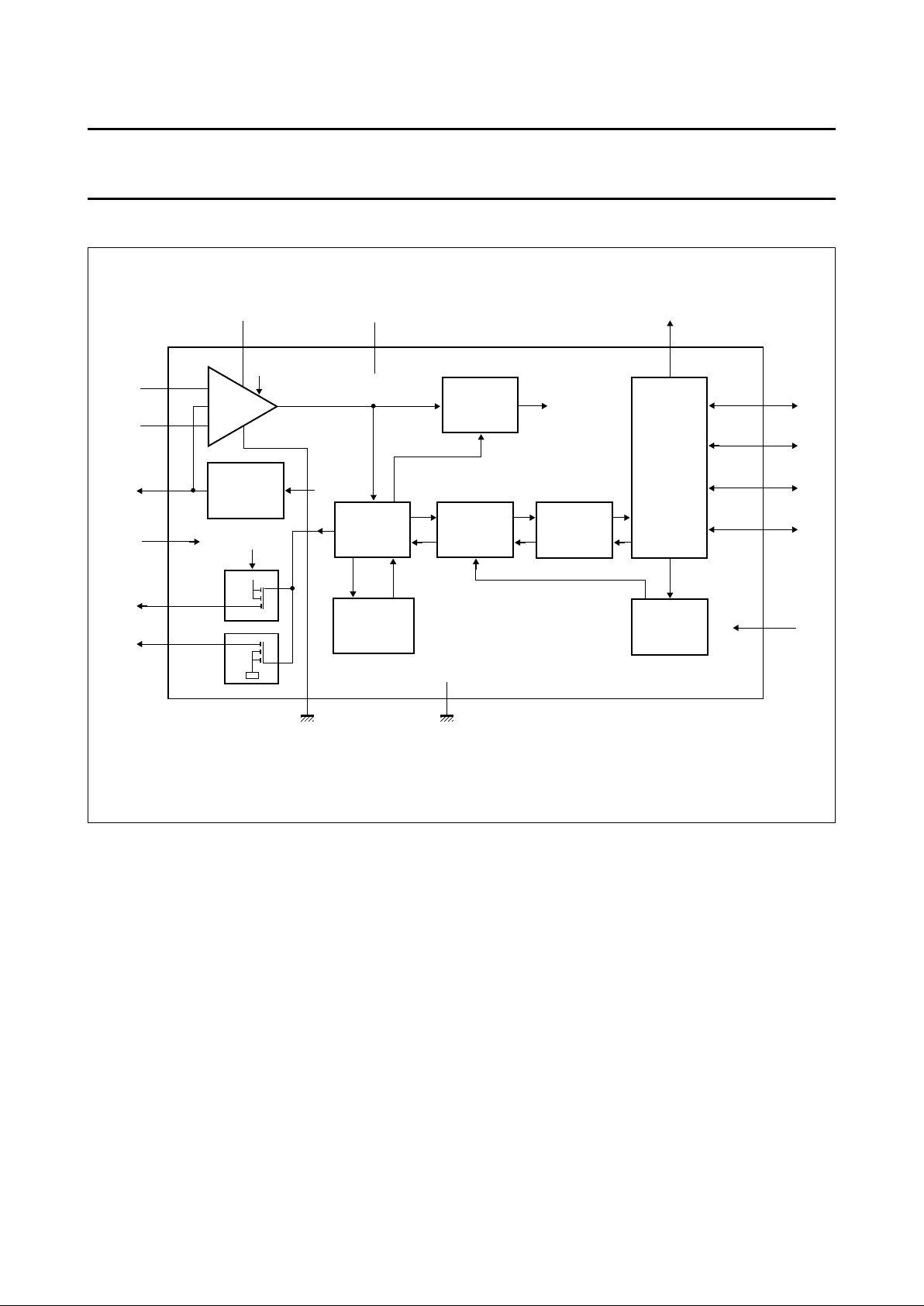

5 FUNCTIONAL DIAGRAM

Fig.2 Functional diagram.

handbook, full pagewidth

P82C150

REF

RX0

RX1

TX0

P15

P13

P14

P12

P11

P10

P9

P8

P7

P6

P5

P4

P3

P2

P1

P0/CLK

RST (reset)

XMOD

CAN-bus inputs

analog-to-digital

comparator input

comparator

inputs

16-bit

digital I/O

MHA066

TX1

P16

CAN-bus outputs

ADC feedback output

multiplexed analog-

to-digital signal

analog

input

DPM1

output

analog inputs,

analog switches

DPM2

output

identifier

programming

reference

voltage output

VSS

AVSS

VDD

AVDD

Page 6

1996 Jun 19 6

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

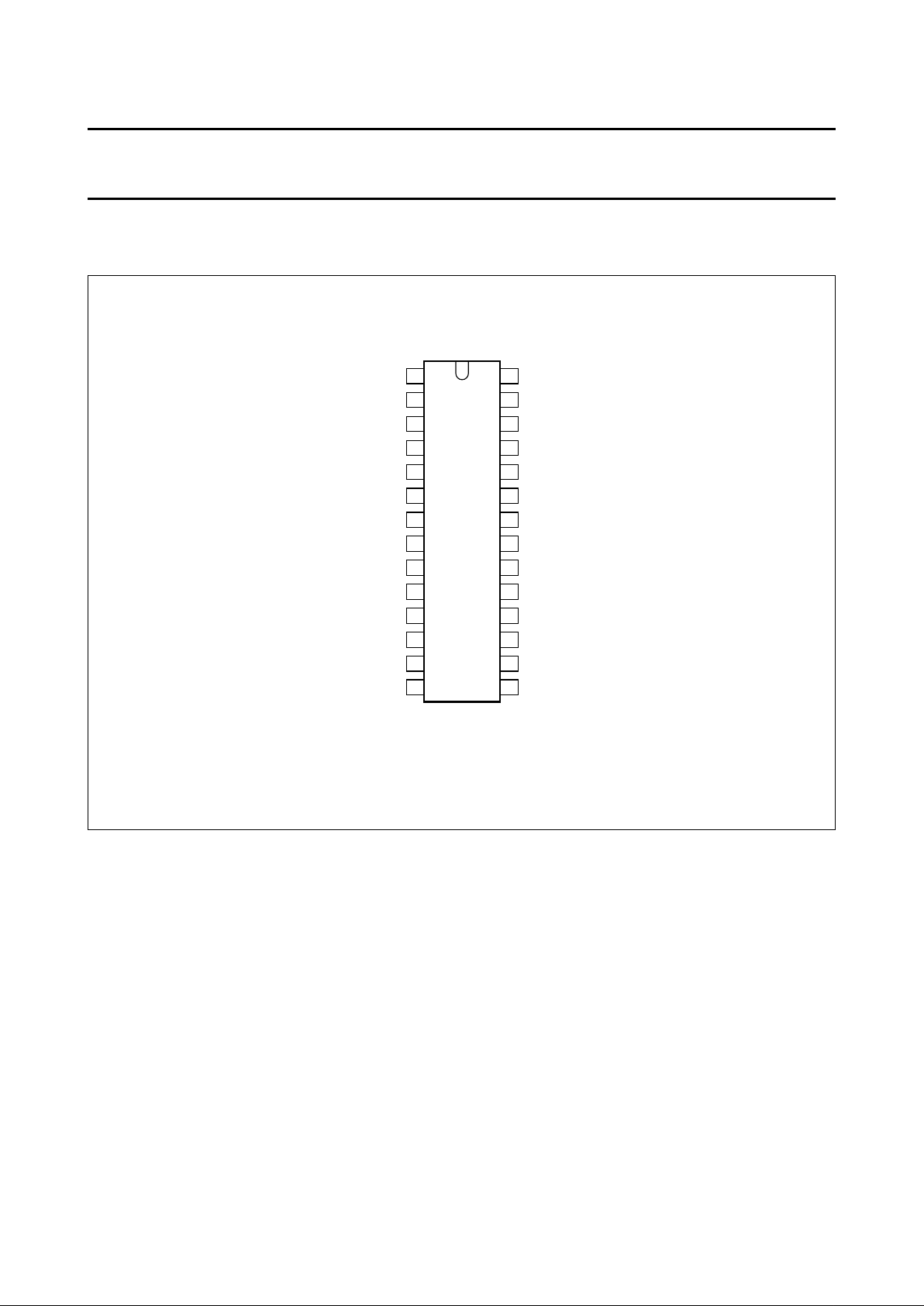

6 PINNING INFORMATION

6.1 Pinning

Fig.3 Pin configuration.

handbook, halfpage

26

27

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

P82C150

14

28

25

MHA065

P2

P3

P4

V

SS

XMOD

P6

P5

P7

V

DD

P8

P9

P10

P11

P12

P13

P1

P0/CLK

TX1

AV

SS

TX0

RST

RX1

RX0

AV

DD

REF

P16

P15

P14

Page 7

1996 Jun 19 7

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

6.2 Pin description

Table 1 Pin description for P82C150; SO28; see note 1

Note

1. In this documentation the port pins are referred to by their symbols, not by their pin number. For example P15 means

I/O Port 15 at pin 16.

SYMBOL PIN DESCRIPTION

P2 1 I/O Ports P2 to P3; Identifier programming input.

P3 2

P4 3 I/O Port 4; DPM2 output.

V

SS

4 Ground, digital part (0 V; logic circuits and CAN-bus driver).

P5 5 I/O Ports P5 to P6; analog input.

P6 6

P7 7 I/O Port 7; analog input or analog-to-digital comparator 1 output.

V

DD

8 Power supply, digital part (+5 V; logic circuits and CAN-bus driver).

P8 9 I/O Port 8; analog input or comparator 3 output.

P9 10 I/O Port 9; analog input or comparator 2 output.

P10 11 I/O Port 10; comparator 3 inverting input or DPM1 output.

P11 12 I/O Port 11; comparator 3 non-inverting input.

P12 13 I/O Port 12; comparator 2 inverting input.

P13 14 I/O Port 13; comparator 2 non-inverting input.

P14 15 I/O Port 14; multiplexed analog signal.

P15 16 I/O Port 15; analog-to-digital comparator input.

P16 17 Feedback output of analog-to-digital converter.

AV

DD

18 Power supply, analog part (+5 V; CAN input, oscillator and reference).

REF 19 Reference voltage output (

1

⁄2× AVDD).

AV

SS

20 Ground, analog part (0 V; CAN input, oscillator, reference).

RX0 21 CAN-bus input.

RX1 22

RST 23 External reset input (active-HIGH) for internal oscillator mode; pulled to +5 V for external

oscillator mode (see Section 11.3).

XMOD 24 Connected to GND for internal oscillator mode; external reset input (active-LOW) for

external oscillator mode (see Section 11.3).

TX0 25 Open-drain CAN-bus output: dominant = LOW; recessive = floating.

TX1 26 Open-drain CAN-bus output: dominant = HIGH; recessive or at bus mode 2 floating.

P0/CLK 27 I/O Port P0, Identifier programming input in internal oscillator mode; clock input in external

oscillator mode (see Section 11.3).

P1 28 I/O Port P1; identifier programming input.

Page 8

1996 Jun 19 8

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7 FUNCTIONAL DESCRIPTION

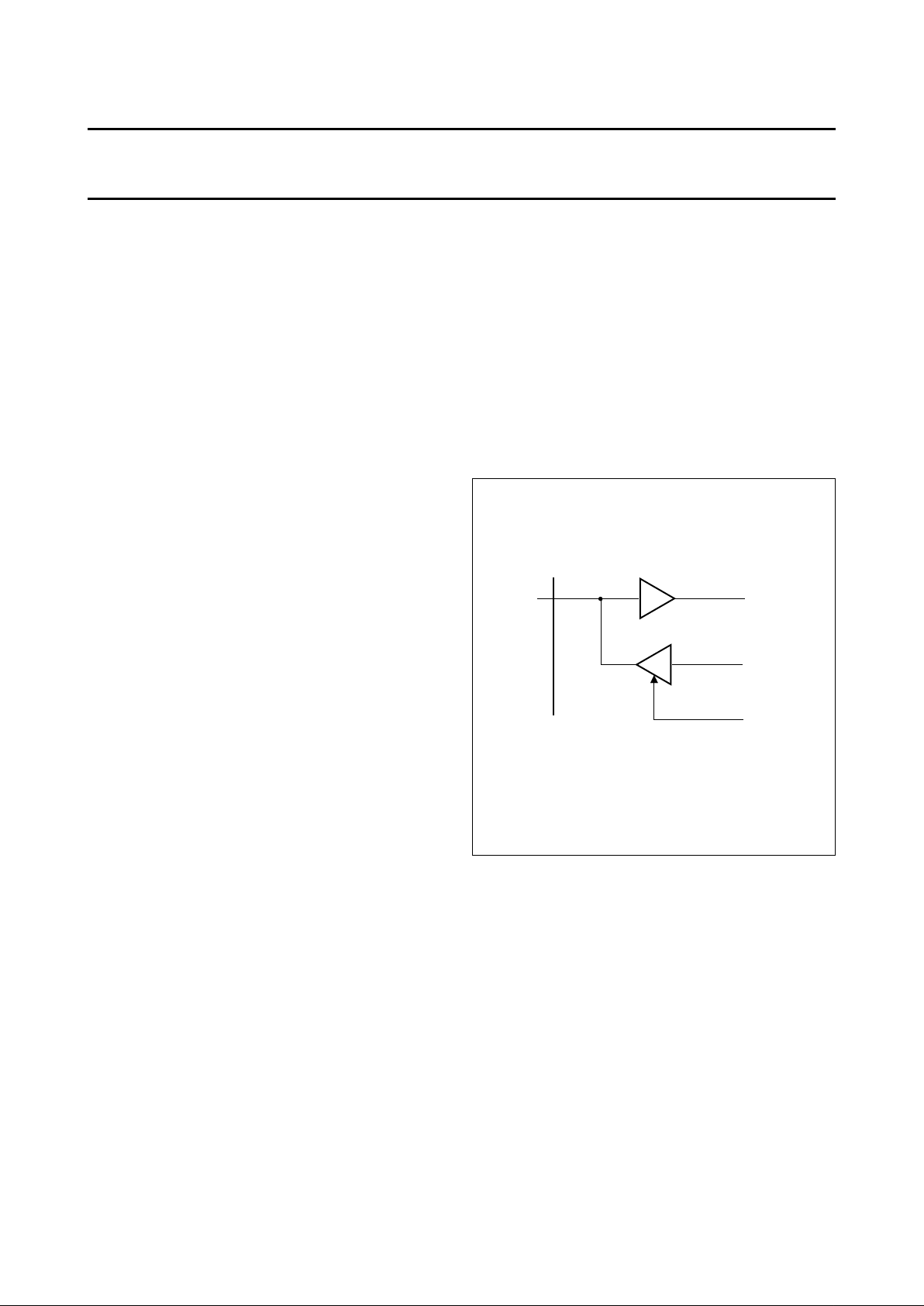

7.1 I/O functions

The P82C150 provides 16 port pins (P15 to P0) which are

individually configurable via CAN-bus. Besides the digital

I/O functions some of these port pins provide analog I/O

functions.

7.1.1 D

IGITAL INPUT FUNCTIONS

Input levels HIGH and LOW on the port pins (P15 to P0)

can be read in two ways by the host node:

• Polling: a Remote Frame is sent to the P82C150 to be

answered by a Data Frame containing the Data Input

Register contents.

• Event capture: in case of edge-triggered mode, the

P82C150 sends the same Data Frame caused by the

event of a rising and/or falling edge on the

corresponding port pins (see Table 3).

7.1.2 D

IGITAL OUTPUT FUNCTIONS

The Data Output Register is set via a CAN message.

Its content is only output when the corresponding bits of

the Output Enable Register are set to logic 1s.

7.1.3 A

NALOG INPUT/OUTPUT FUNCTIONS

• Up to six multiplexed analog input signals for

analog-to-digital conversion or general purpose

• Up to two quasi-analog output channels (DPM;

Distributed Pulse Modulation)

• Two input comparators, for example for window

comparator applications

• A separate analog-to-digital input comparator with

feedback output.

Analog-to-digital converted digital results are obtained by

reading the Analog-to-Digital Conversion (ADC) Register.

Analog functions of each port pin are individually

controlled by the Analog Configuration Register.

Writing the I/O registers is done serially via CAN-bus by

Data Frames. The first data byte contains the register

address, and the second and third data bytes represent

the register contents. If a read only register is addressed,

the contents of the second and third data bytes are

ignored.

It is recommended to set unused port pins to HIGH

(100 kΩ resistor to V

DD

).

Fig.4 I/O port pins.

handbook, halfpage

Px

MHA068

DIx

DOx

OEx

3-state buffer

P82C150

Page 9

1996 Jun 19 9

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.2 I/O registers

Table 2 I/O register map

15

(MSB)

1413121110987654321

0

(LSB)

ADDRESS 0: DATA INPUT

DI15 DI14 DI13 DI12 DI11 DI10 DI9 DI8 DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

ADDRESS 1: POSITIVE EDGE

PE15 PE14 PE13 PE12 PE11 PE10 PE9 PE8 PE7 PE6 PE5 PE4 PE3 PE2 PE1 PE0

ADDRESS 2: NEGATIVE EDGE

NE15 NE14 NE13 NE12 NE11 NE10 NE9 NE8 NE7 NE6 NE5 NE4 NE3 NE2 NE1 NE0

ADDRESS 3: DATA OUTPUT

DO15 DO14 DO13 DO12 DO11 DO10 DO9 DO8 DO7 DO6 DO5 DO4 DO3 DO2 DO1 DO0

ADDRESS 4: OUTPUT ENABLE

OE15 OE14 OE13 OE12 OE11 OE10 OE9 OE8 OE7 OE6 OE5 OE4 OE3 OE2 OE1 OE0

ADDRESS 5: ANALOG CONFIGURATION

ADC OC3 OC2 OC1 0 M3 M2 M1 SW3 SW2 SW1 0 0 0 0 0

ADDRESS 6: DPM1

DP9DP8DP7DP6DP5DP4DP3DP2DP1DP0000000

A

DDRESS 7: DPM2

DQ9DQ8DQ7DQ6DQ5DQ4DQ3DQ2DQ1DQ0000000

A

DDRESS 8: ANALOG-TO-DIGITAL CONVERSION (ADC)

AD9 AD8 AD7 AD6 AD5 AD4 AD3 AD2 AD1 AD0 0 0 0 0 0 0

Page 10

1996 Jun 19 10

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.2.1 DATA INPUT REGISTER (ADDRESS 0)

This read only register contains the states of port pins

P15 to P0 which are transmitted on request, or

automatically by change of one of the input levels,

provided that the respective input is configured to event

capture mode (see Table 3). When an edge is detected

the port state is loaded into the transmit buffer after the

Control Field of the triggered message is sent. Therefore a

delay for input settling is provided. If between edge

detection and transmission of the data input register

another input signal change at the input port occurs, the

corresponding data input register bit is overwritten by the

current input port value. Additionally the register content is

sent automatically after wake-up or bus mode change,

once the bit time has been calibrated (part of the ‘sign-on’

message).

7.2.2 P

OSITIVE EDGE REGISTER (ADDRESS 1)

This write only register contains configuration information

per port pin for the event capture facility.

The corresponding PE-bit (see Table 3) has to be set to

logic 1 to enable capturing of the rising edge.

7.2.3 N

EGATIVE EDGE REGISTER (ADDRESS 2)

This write only register contains configuration information

per port pin for the event capture facility.

The corresponding NE-bit (see Table 3) has to be set to

logic 1 to enable capturing of the falling edge.

The combination of PE and NE functions is possible.

7.2.4 D

ATA OUTPUT REGISTER (ADDRESS 3)

This write only register contains the output data for the port

pins. The output drivers are bitwise enabled by OE

(see Section 7.2.5). New data for the output port register

are processed and written to the output ports directly after

the corresponding CAN message to the P82C150 is

successfully checked and becomes valid.

7.2.5 O

UTPUT ENABLE REGISTER (ADDRESS 4)

This write only register controls the output drivers of the

port pins. The corresponding Output Enable Register bit

has to be set to logic 1 to enable an output driver. If set to

logic 0, the corresponding output driver is disabled

(floating; see Fig.7).

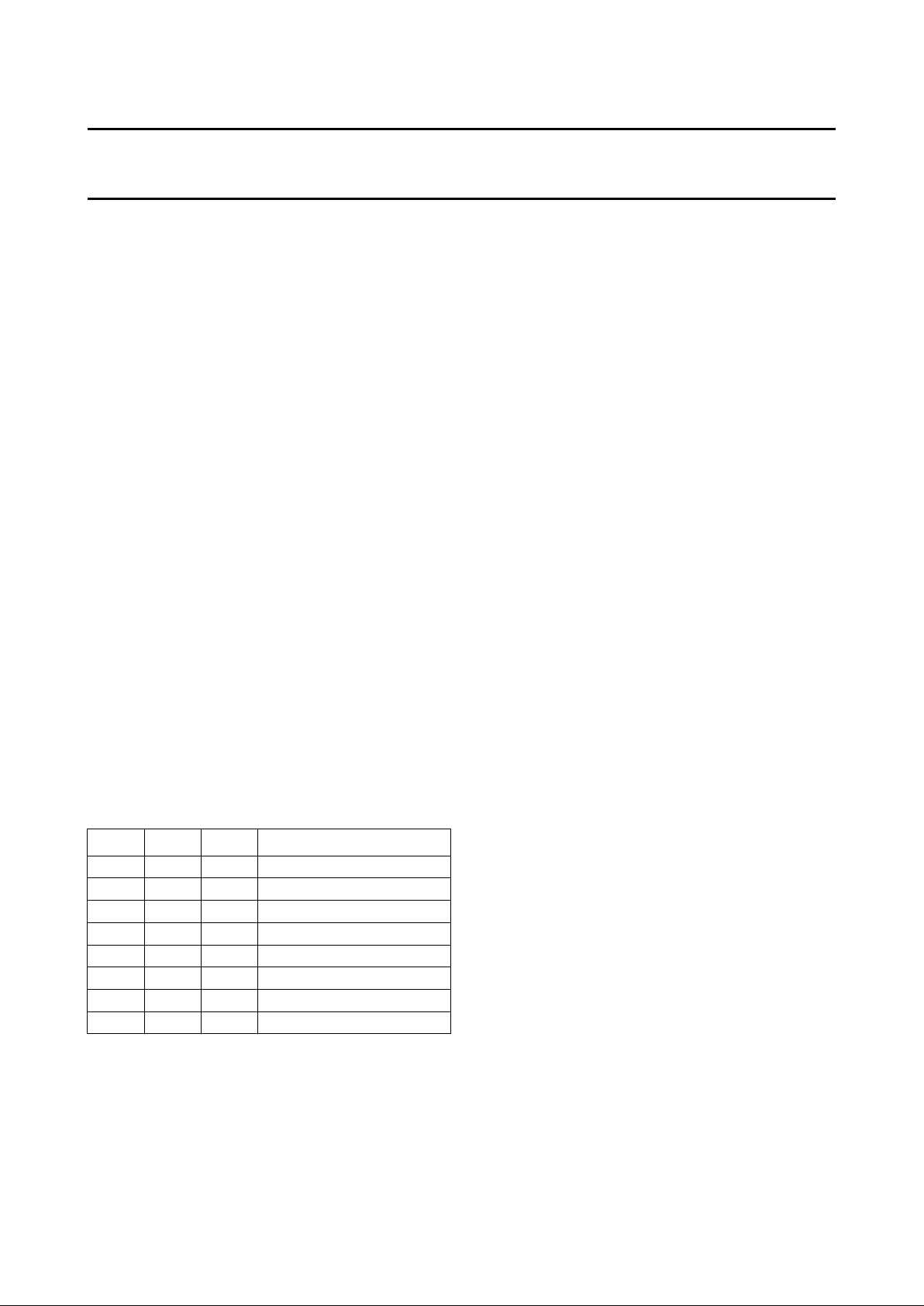

Table 3 Programming of the I/O registers to event capture on edge or to digital output

X = don’ t care; n=0to15.

FUNCTION

REGISTER CONTENTS OF PARTICULAR PORT PIN

POSITIVE EDGE

(BITS PEn)

NEGATIVE EDGE

(BITS NEn)

OUTPUT ENABLE

(BITS OEn)

Digital output X X 1

Digital input

Polling X X X

Event capture on edge

Rising 1 0 X

Falling 0 1 X

Rising and Falling 1 1 X

Page 11

1996 Jun 19 11

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.2.6 ANALOG CONFIGURATION REGISTER (ADDRESS 5)

This read/write register contains the bits ADC, OC3 to

OC1, M3 to M1 and SW3 to SW1 (see Fig.7).

• ADC bit (analog-to-digital conversion start bit; write only

bit). The P82C150 starts an analog-to-digital conversion

cycle at ADC = 1 ended with the transmission of a

message containing the result. After that, the ADC bit is

reset automatically.

• OC3 to OC1 bits (comparator output data; read only

bits). The bits OC3 to OC1 represent the logical output

level of the analog comparators at input port pins P10,

P11, P12, P13 and P15. The P82C150 sends back the

logical output value of these comparators after having

received a Data Frame (see Section 7.3.3) addressing

the Analog Configuration Register. The comparator

outputs can be monitored at the output port pins P8, P9

and P7.

• M3 to M1 bits (multiplexer control bits; write only bits).

The logical value of the comparators is monitored on

port pins P8, P9 and P7 (see Fig.7) by setting M3 to M1

to logic 1, provided that these pins are configured as

outputs (OE = 1). Additionally the register content is

sent automatically when the corresponding port bits in

the Positive Edge Register and/or Negative Edge

Register and the corresponding bits in the Output

Enable Register are set.

• SW3 to SW1 (analog switch control bits; write only bits).

One of the analog switches S1 to S6 can be closed by

setting the switch bits to the corresponding value

(see Fig.7 and Table 4).

Table 4 Analog switch selection by SW3, SW2, SW1.

Note

1. Evidently if P14 is driven, it may not be connected to

any other driven pin via the internal analog switches

(avoid short-circuit!).

SW3 SW2 SW1 SWITCH STATE

0 0 0 no switch closed (S0); note 1

0 0 1 S1 closed

0 1 0 S2 closed

0 1 1 S3 closed

1 0 0 S4 closed

1 0 1 S5 closed

1 1 0 S6 closed

1 1 1 reserved

7.2.7 DPM1 REGISTER (ADDRESS 6)

This write only register contains data for a quasi-analog

output signal on port pin P10, which is generated by

Distributed Pulse Modulation (DPM; see Fig.9).

The Output Enable bit must be set for this functions

(OE10 = 1). The DPM1 output signal is inverted by setting

DO10 = 1. The number of output pulses during a DPM

period is given by the DPM1 Register value. These pulses

have 4 × t

CLK

length and are distributed over the DPM

period. An analog voltage is provided after smoothing the

output signal by an external RC combination.

7.2.8 DPM2 R

EGISTER (ADDRESS 7)

This write only register contains data for a quasi-analog

output signal on port pin P4. The function of the DPM2

corresponds to the definition of DPM1.

7.2.9 A

NALOG-TO-DIGITAL CONVERSION (ADC)

R

EGISTER (ADDRESS 8)

This read only register contains the result of the

analog-to-digital converted level of that I/O pin which was

selected by the SW bits. The conversion is started by

ADC-bit set to logic 1 (see Section 7.2.6), or by

transmitting a Data Frame addressing the ADC Register.

Page 12

1996 Jun 19 12

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

Fig.5 Analog configuration of I/O port pins; R1, R2 and C1 are used to implement the analog-to-digital converter.

k, full pagewidth

15

3

P82C150

7

6

5

9

10

16

17

R1

R2

C1

1

/4f

CLK

ADC

REGISTER

OC1

S0

S2

S3

S4

S5

S6

P13

13

12

11

DPM1

DPM2

OC2

OC3

M3

M2

M1

MHA067

P16

P15

P14

P7

P6

P5

P8

P9

14

P12

P11

P10

P4

S1

SW3 to SW1

= 1

= 1

1

/2 V

DD

DO7

DO8

DO9

DO4

DO10

OE7

OE8

OE9

OE10

OE4

+

−

+

−

+

−

Page 13

1996 Jun 19 13

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

Fig.6 DPM output pulses at DO10(4) = 0; output pulses are inverted at DO10(4) = 1.

handbook, full pagewidth

L

H

L

H

L

H

L

H

L

H

L

H

L

H

t

DPM

= 1024 x 4 t

CLK

4 t

CLK

DPM = 0

DPM = 1

DPM = 2

DPM = 3

DPM = 512

DPM = 513

DPM = 1023

MHA081

Distributed Pulse Modulation (DPM) is a special pulse count modulation.

Page 14

1996 Jun 19 14

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.3 CAN functions

The P82C150 meets the CAN protocol specification

version 2.0 A and B (passive) with restricted bit timing

because of the on-chip RC-oscillator and the automatic bit

rate detection.

In a system with P82C150 nodes there must be at least

one conventional crystal-driven CAN controller (host node)

which is compatible to the CAN specification V1.2 or later

to control P82C150 nodes. Host nodes compatible to CAN

specification V1.1 can also be used provided that the

P82C150 nodes are powered by a high-accuracy power

supply or they are in external oscillator mode (refer to

Section 11.3).

Each time a P82C150 node receives a Data Frame, it

initiates the transmission of a Data Frame containing four

bits status information, the register address (previously

received) and the current contents of the addressed

register (exception: see Section 7.3.3.1). This enables the

host node to verify that the addressed register has

correctly been written in case of writeable registers, and to

read the contents in case of readable registers.

7.3.1 CAN IDENTIFIER

Data and Remote Frames to be processed by the

P82C150 are of Standard Format with 11 Identifier bits

ID.10 to ID.0. Frames with extended Identifier (CAN

specification version 2.0 B) are ignored.

The way of identifier programming is based on two facts:

• Each P82C150 operates with only two Identifiers

distinguished by the LSB (see Tables 5, 6 and 7).

The identifier with the higher priority is used for Data

Frame reception. An extra Identifier is used for

calibration purposes.

• There can be maximum sixteen P82C150 circuits in one

network.

Table 5 Message types and format

Note

1. DLC = Data Length Code; DIR = LSB of Identifier (see Section 7.3.1).

Table 6 Standard Format Identifier bits ID.10 to ID.0

1 = recessive; 0 = dominant

Table 7 Description of the Standard Format Identifier bits

FRAME TRANSMISSION BY 82C150 RECEPTION AT 82C150

Data Frame yes (DLC = 3; DIR = 1) yes (DLC = 3; DIR = 0; calibration message

with DLC = 2 to 8 allowed, see Section 7.3.10)

Remote Frame no yes (DLC = 3; DIR = 1)

Error Frame yes yes

Overload Frame yes (only as a response) yes

IDENTIFIER

ID.10 ID.9 ID.8 ID.7 ID.6 ID.5 ID.4 ID.3 ID.2 ID.1 ID.0

0 1 P3 1 0 P2 P1 P0 1 0 DIR RTR

BIT SYMBOL DESCRIPTION

ID.8 P3 Programmable identifier bits read from Port pins P3 to P0 during reset. The input levels

on P3 to P0, for example set by resistors to V

SS

or to VDD, are latched in the Identifier

latch with the falling edge of the RST input signal. They represent the variable part of

the Identifier, while the remaining bits are fixed (mask-programmed), P3 to P0 can be

used as I/O ports after reset.

ID.5 to ID.3 P2 to P0

ID.0 DIR DIR = 1 for transmission of Data Frames to the host. It must be set to a logic 1 in

Remote Frames and to a logic 0 in Data Frames received from the host.

RTR Remote Transmission Request bit.

Page 15

1996 Jun 19 15

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.3.2 TRANSMISSION OF DATA FRAMES

Data Frames transmitted by the P82C150 contain three

data bytes (see Fig.7). The first data byte contains the

status information and the register address A3 to A0 (see

Tables 8 and 9), the other two data bytes contain the

content of the addressed I/O Register.

After each successful message transmission, the

P82C150 delays the transmission of a possibly further

pending message for three bit times. The reason is to give

other CAN controllers - with a lower identifier priority - the

possibility to transmit a message in case of faulty contact

at one of the edge-triggered port pins.

7.3.3 R

ECEPTION OF DATA FRAMES AND REMOTE

FRAMES

Received Data Frames have the same format as

transmitted ones, only the DIR-bit (ID.0) in the Arbitration

Field is different. The status bits RSTD, EW, BM1 and BM0

are ignored during reception.

The P82C150 confirms each reception of a Data Frame by

transmitting a Data Frame containing the (new) contents of

the addressed I/O Register.

7.3.3.1 Exceptions to the rule

1. Analog Configuration Register: If a P82C150 receives

a Data Frame addressing the Analog Configuration

Register and the ADC bit is set to logic 1, it will

respond with two messages. The first message returns

the contents of the Analog Configuration Register. The

control instructions are executed (e.g. next analog

input channel selected), and an analog-to-digital

conversion cycle is started after a set-up time. After

finishing the analog-to-digital conversion cycle, the

second message is transmitted containing the result

(ADC Register).

2. ADC Register: On receiving a Data Frame addressing

the ADC Register, the P82C150 starts an

analog-to-digital conversion cycle. It automatically

returns the result of the conversion (ADC Register) by

transmitting a respective Data Frame after finishing

the analog-to-digital conversion cycle.

3. At normal operation, the calibration messages are

confirmed by returning a dominant bit in the

acknowledge slot. There is no particular confirmation

message returned by the P82C150. Only after

entering the calibrated state (start-up), a Data Frame

(‘sign-on’ message) containing the Data Input Register

contents is transmitted indicating to the host node, that

the P82C150 is now ready for transmission.

7.3.3.2 Remote Frame

Received Remote Frames must have the Data Length

Code DLC = 3 (Remote Frames with DLC≠ 3 are ignored).

It is answered by a Data Frame containing the contents of

the Data Input Register.

Page 16

1996 Jun 19 16

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

Table 8 Data Frame Byte 1

Table 9 Description of Data Frame Byte 1 bits

STATUS REGISTER ADDRESS

RSTD EW BM1 BM0 A3 A2 A1 A0

SYMBOL DESCRIPTION

Status

RSTD It is logic 1 in the first message (‘sign-on’ message) after the successful detection of the bit rate

(bit time calibrated).

EW Logic 1, if the error warning limit (32) is reached. In the “sign-on” message EW is always logic 1. The

EW status bit is set when the Receive Error Counter or the Transmit Error Counter have exceeded the

Error Warning Limit of 32, also temporarily, since the last successful transmission of a message.

BM1 Bus mode status bits.

BM0

Register address

A3 to A0 Register address bits.

Fig.7 P82C150 Data Frame.

handbook, full pagewidth

MHA071

0 0 1 P3 1 0 P2 P1 P0 1 0 DIR RTR

ID0ID10

SOF

Identifier

0 0 0 0 1 1 RSTD EW BM1 BM0 A3 A2 A1 A0

reserved Data Length Code P82C150 status register address

X X X X X X X X X X X X X X X X

I/O Register data(15 to 8) I/O Register data(7 to 0)

CONTROL FIELD

ARBITRATION FIELD

BYTE 1

BYTE 2 BYTE 3

SOF: Start Of Frame.

RTR: Remote Transmission Request.

P3 toP0: equals programmed identifier bits.

Page 17

1996 Jun 19 17

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.3.4 CAN-BUS MODES

The P82C150 can pass through four CAN-bus modes

under certain conditions (see Fig.8). In the bus modes

0 to 2 (see Table 10) the P82C150 is operating with

different input comparator configurations. Bus mode 3 is

the power reduced Sleep Mode.

The bus modes support:

• Communication on two balanced wires (differential

system)

• Communication on one wire in a two-wire differential

system

• Sleep Mode with wake-up via either a dominant signal

on RX0 or RX1 input

• Connection of a second transmission medium

(redundancy)

There are two possibilities for condition 1 to switch to the

next mode (see Fig.8):

• Overflow of the bit counter when 8192 is reached since

the last calibration message

• Overflow of the Transmit Error Counter (>255; bus-off

limit reached).

When the bus mode changes, all I/O Registers are cleared

and outputs become floating (OE bits cleared). That

means the I/O ports return to a fail-safe state whenever the

P82C150 looses connection to its host controller. This is a

kind of network watchdog function. The status bits are set

to the following values after a bus mode change:

• RSTD = 1

• EW = 0

• BM

new

=BM

old

+1.

The programmed Identifier bits remain unchanged.

After reset the P82C150 changes directly into bus mode 3

(Sleep Mode). During Sleep Mode, the internal RC

oscillator is stopped, and all the output drivers are disabled

(I/O Register contents cleared). A P82C150 in Sleep Mode

can be woken up via CAN-bus lines (dominant level on

RX0 or RX1) or by a reset condition.

Fig.8 CAN-bus modes and switch-over conditions.

olumns

DIFFERENTIAL

MODE

Inputs: RX0, RX1

Outputs: TX0, TX1

'0'

ONE-WIRE

RX1 MODE

Input: RX1

Outputs: TX0, TX1

'1'

'2'

SLEEP

MODE

Inputs: RX0, RX1

Outputs: no

'3'

ONE-WIRE

RX0 MODE

Input: RX0

Output: TX0

Condition 1

Condition 1

Condition 1

Condition 2

MHA070

end of

RESET

Condition 1:

bit counter overflow (>8191) or Transmit Error Counter overflow (>255).

Condition 2:

dominant bit detected on RX0 and RX1.

Table 10 Can-bus modes

Note

1. Output TX1 is disabled in bus mode 2 to tolerate short-circuit between the CAN-bus wires CAN_H and CAN_L.

BUS MODE

BITS RECEPTION LEVEL TRANSMISSION

BM1 BM0 RECESSIVE DOMINANT TX1 TX0

0 = Differential 0 0 RX0 > RX1 RX0 < RX1 enabled enabled

1 = One-wire RX1 0 1 RX1 < REF RX1 > REF enabled enabled

2 = One-wire RX0 1 0 RX0 > REF RX0 < REF disabled enabled

3 = Sleep 1 1 RX0 > REF

and

RX1 < REF

RX0 < REF

or

RX1 > REF

disabled disabled

Page 18

1996 Jun 19 18

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.3.5 BIT TIMING

The Nominal Bit Time of the P82C150 is subdivided into 10

Time Quanta. The Synchronization Time Segment

(SYNC_SEG) and the Propagation Time Segment

(PROP_SEG) are each one Time Quantum long. The

Phase Buffer Segment 1 (PHASE_SEG1) and the Phase

Buffer Segment 2 (PHASE_SEG2) are each four Time

Quanta long. The Resynchronization Jump Width (SJW) is

four Time Quanta long.

The sample point is located at the end of the Phase Buffer

Segment 1. The Nominal Bit Time is internally adjusted to

that bit timing which is provided by the crystal driven host

(calibration message).

The usable bus length at a given bit rate is reduced in

comparison to other CAN controllers with programmable

bit timing because the Propagation Time Segment is fixed

to

1

⁄10 length of the Nominal Bit Time. The bit segmentation

of the crystal driven host should be programmed like the

fixed bit segmentation of the P82C150, e.g. one bit time

segment is1⁄10 length of the Nominal Bit Time (refer also

to Table 15 for bit time programming).

Table 11 Bit time subdivision

1 BIT TIME

BT1 BT2 BT3 BT4 BT5 BT6 BT7 BT8 BT9 BT10

SYNC_SEG PROP_SEG

PHASE_SEG1 PHASE_SEG2

7.3.6 CAN-BUS TRANSCEIVER

The transceiver of the P82C150 consists of the

configurable input comparator and of complementary

open-drain driver outputs. The reference voltage REF is

an additional output.

7.3.6.1 CAN-bus input comparator (RX0, RX1)

The input comparator monitors the transient voltage on

RX1 and RX0.

The result of the input comparator is logic 1 if the voltage

levels of the CAN-bus lines are regarded as recessive, and

logic 0 if they are regarded as dominant.

The recessive state and the dominant state are not

equivalent and may not be mixed-up.

The input comparator is configurable depending on the

four CAN-bus modes (see Table 10), supporting

battery-powered applications (Sleep Mode) and tolerance

against bus wiring failures.

7.3.6.2 CAN-bus output drivers (TX0, TX1)

The output driver function is shown in Table 12. The output

driver TX1 is disabled in bus mode 2 to tolerate a

short-circuit between the CAN-bus lines in a two-wire

differential CAN physical layer.

Table 12 CAN-bus driver output function

CAN OUTPUT RECESSIVE

DOMINANT

RESET STATE, BUS-OFF AND

SLEEP MODE (MODE 3)

MODES 0 AND 1 MODE 2

TX0 floating LOW LOW floating

TX1 floating HIGH floating floating

Page 19

1996 Jun 19 19

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.3.7 TRANSMIT AND RECEIVE LOGIC

The transmit and receive logic stores the destuffed bit

stream which was received or is about to be transmitted.

The incoming Identifier is compared with that of the

P82C150. The content of the message is transferred to the

port logic in case of matching.

At transmission, the message about to be sent is put

together: the Identifier, the status information, the register

address and the content of the addressed register from the

port logic.

7.3.8 B

IT STREAM PROCESSOR AND ERROR

MANAGEMENT LOGIC

The Bit Stream Processor (BSP) is a sequencer to control

the data stream between the transmit/receive logic

(parallel data) and the on-chip CAN transceiver (serial

data). Reception/transmission, bit stuffing/destuffing,

arbitration and error detection, according to CAN protocol

specification version 2.0 A and B (passive), are performed.

Further, automatic re-transmission of corrupted messages

is handled by means of continuously comparing the output

bit stream with the input bit stream. Moreover, the Bit

Stream Processor provides control information to calibrate

the internal bit time.

The Error Management Logic is responsible for the

complete CAN-inherent error management.

7.3.9 O

SCILLATOR AND CALIBRATION

The P82C150 contains an on-chip RC-oscillator. The bit

time is automatically calibrated by messages being

received via CAN-bus. During start-up (after wake-up or

reset) any message is used to calibrate the bit time until

the calibration is sufficient to receive messages correctly.

From this time on, the bit time is calibrated and fine-tuned

by calibration messages with a special Identifier

transmitted by the crystal-controlled host.

Only P82C150 nodes being calibrated by calibration

messages can transmit messages. The first message is

transmitted directly after entering the calibrated state

(‘sign-on’ message). Since the P82C150 is not able to

transmit as long as the bit time is not calibrated, it cannot

wake-up other CAN nodes via the bus line. Hence to keep

the network alive, the calibration message must be

transmitted regularly by a crystal-controlled (host) node

with a maximum repetition period of 8192 bit (bit length

measured by the 82C150). It is recommended to select a

repetition period between 3800 and maximum 8000 bit

times.

7.3.10 C

ALIBRATION MESSAGE

The calibration message has to meet the following

requirements

• Transmitted by a crystal-controlled node (host node)

• Identifier: 000 1010 1010 (1 = recessive; 0 = dominant)

• RTR bit: 0

• Allowed control field: DLC=2to8

• The first recessive to dominant transition after the

control field must be followed by another recessive to

dominant transition in a distance of exactly 32 bit (stuff

bits included).

Example of a suitable calibration message (there are

others using different data bytes; see Table 13):

• Data length code: 0010

• 1st data byte: 1010 1010 (AAH)

• 2nd data byte: 0000 0100 (04H).

Table 13 Example of a suitable calibration message

The two important 1/0 transitions are marked by underlines; see note 1.

Note

1. I = stuff bit (recessive); the total length is 67 bit from start-of-frame to end-of-intermission.

SOF ARBITRATION FIELD

CONTROL

FIELD

DATA BYTE 1 DATA BYTE 2 CRC FIELD

0 000 1010 1010 0 000I010

1010 1010 0000I 0100 000I0 1011 1000 00I0

Page 20

1996 Jun 19 20

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.4 Initialization

7.4.1 I

DENTIFIER PROGRAMMING

Most of the P82C150 identifier bits are fixed. Four bits are

programmable via port pins P3 to P0. All output drivers are

disabled at reset, also P3 to P0. Thus the outputs are

floating unless the input level is defined by external

components to define identifier bits. They are latched at

the end of reset, and P3 to P0 can be used as port pins.

It is not allowed, according to the CAN protocol

specification, that multiple bus nodes transmit the same

identifier bit combination. Therefore a P82C150 must have

one of the 16 possible identifier bit combinations, one that

is not yet occupied.

7.4.2 R

ESET FUNCTION

RST = HIGH disables all output drivers P16 to P0, TX0

and TX1. All I/O Registers are automatically cleared and

set to logic 0. The bit time is set greater than 50 µs.

If a particular clock period is necessary, e.g. for a

dedicated DPM output frequency, this can be achieved by

feeding an external clock signal into P0. RST and TEST

must be permanently HIGH for this special mode. A reset

is then performed as usual (RST = HIGH; TEST = LOW).

Table 14 Situation after RESET

7.4.3 B

IT TIME CALIBRATION

The P82C150 must receive at least three messages to

calibrate its bit time after reset or change of bus mode.

The first message is used to detect the bit time length

(rough calibration) between two consecutive falling edges

at the output of the CAN input comparator. Therefore the

bit stream should contain a sequence of ‘1010’.

STATUS BITS IDENTIFIER BITS

RSTD = 1 ID.8 equals P3

EW = 1 ID.5 equals P2

BM1 = 0 ID.4 equals P1

BM0 = 0 ID.3 equals P0

After rough calibration the P82C150 can receive any valid

CAN message correctly and executes respective

commands without giving an acknowledge. With another

valid CAN message and additionally with one valid

calibration message the P82C150 is fully calibrated and

sends its ‘sign-on’ message. As long as the P82C150 is

fully calibrated the P82C150 acts as an active CAN node.

The P82C150 treats any CAN message (including the

calibration message) as a valid message, when these

messages are terminated by an error passive frame

because of a missing acknowledge. This situation may

occur whenever a host node works together with

P82C150’s and the host node doesn’t receive an

acknowledge as long as the P82C150’s are not fully

calibrated.

7.4.3.1 Sign-on message

This special Data Frame is transmitted once by the

P82C150 after entering the calibrated state. It indicates to

the host node that the P82C150 is ready for transmission.

The sign-on message returns the contents of the Data

Input Register, and can be recognized by the host mode by

checking the RSTD status bit:

• Sign-on message RSTD = 1

• Other Data Frames RSTD = 0

Note that in the sign-on message the EW bit is logic 1.

Nevertheless the P82C150 status with the error counters

are set to logic 0.

Page 21

1996 Jun 19 21

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

7.5 P82C150 operation after RESET or change of bus mode

Figure 9 illustrates the calibration procedure of the P82C150 after Power-on-reset or after a bus mode change.

ndbook, full pagewidth

P82C150 receives calibration

message within 8192 bit times after

wake-up or bus mode change

P82C150 is fine calibrated

and I/O register cleared

bus mode change e.g. due to

missing reception of a calibration

message within 8192 bit times

end of

Power-on-reset

ID bits from P0-P3 latched

I/O registers cleared

P82C150 receives 1st message

(any message)

P82C150 receives 2nd message

(any message), acknowledge not

required but no active error flag allowed

P82C150 waits until bus-off recovery

sequence finished

P82C150 sends 'sign-on' message

P82C150 is roughly calibrated and has

started bus-off recovery sequence

(counting 129 blocks of 11 recessive bits)

Rough calibration verified

P82C150 is on bus and ready to

send after bus-of f sequence finished

Communication with host node possible

MHA080

Fig.9 SLIO operation flow after reset and bus mode change.

Page 22

1996 Jun 19 22

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

8 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

DD

supply voltage on VDD pin −0.5 +6.5 V

V

I

DC input voltage on any pin

(RX0, RX1, TX0, TX1 excluded)

−0.5 VDD+ 0.5 V

I

I

RX1 and RX0 input current −±2mA

I

REF

reference output current −±2mA

I

O

port output current at port enabled (pins P0 to P15) −±5mA

port output current at analog switch enabled

(OE-bits = 0; pins P5 to P9, P13, P14)

− 7.5 mA

TX0 and TX1 output current − 30 mA

P

Otot

total power dissipation (port outputs together) − 200 mW

T

amb

operating ambient temperature range: −40 +125 °C

T

stg

storage temperature range −65 +150 °C

P

tot

total power dissipation − 1W

Page 23

1996 Jun 19 23

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

9 DC CHARACTERISTICS

V

DD

=5V±4%; VSS=0V; T

amb

= −40 to +85 °C and T

amb

= −40 to +125 °C; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

Supply

V

DD

supply voltage note 1 4.8 5.2 V

I

DD

operating supply current V

RST=VDD

; all port inputs

connected via 1 MΩ to GND

− 22 mA

I

DD(SM)

supply current Sleep mode Ports P15, P13 and P11

connected to VDD;

Ports P12 and P10

connected to VSS;

all other port inputs

connected via 1 MΩ to GND

1mA

CAN Input comparators RX0 and RX1

V

DIF

differential input voltage 0.3AVDD<VI< 0.7AVDD;

note 2

±100 − mV

V

HYST

input voltage hysteresis 8 60 mV

I

I

input current 0.45 V < VI<VDD− 0.45 V −±400 nA

CAN output driver TX0 and TX1; port pins P0 to P16 unloaded

V

OLT

TX0 output voltage LOW;

note 3

I

OLT

= 1.5 mA − 0.1 V

I

OLT

= 10 mA 1.0 V

V

OHT

TX1 output voltage HIGH;

note 4

I

OHT

= −1.5 mA VDD− 0.1 − V

I

OHT

= −10 mA VDD− 1.0 V

Reference voltage REF

V

REF

reference output voltage IO< ±75 µA 0.5AVDD− 0.25 0.5AVDD+ 0.25 V

Control inputs RST, XMOD and digital port inputs P0/CLK, P1 to P15

V

IL

input voltage LOW − 0.2V

DD

V

V

IH

input voltage HIGH 0.7V

DD

− V

V

HYST

input voltage hysteresis note 2 0.5 − V

I

IL1

input leakage current 0.45 V < VI< VDD− 0.45 V ±10 µA

Digital port outputs P0/CLK, P1 to P16; OE bits set

V

OL

output voltage LOW IOL= 4mA (sink) − 1.0 V

V

OH

output voltage HIGH IOH= −4mA (source) VDD− 1.0 − V

OC2 comparator P12, P13 and OC3 comparator P10, P11

V

DIF1

differential input voltage 1.5 V < VI<(AVDD− 1.5 V);

note 2

±20 − mV

Page 24

1996 Jun 19 24

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

Notes to the DC characteristics:

1. Alteration of VDD between two calibration messages should not exceed 0.2 V to avoid failures during CAN

message transfer. If CAN devices according to CAN specification V1.0 or V1.1 (like the 82C200 V0 or V1) are in the

same network with the 82C150, then this alteration of VDD should be limited to 0.1V for the 82C150.

2. These values are characterized but not 100% production tested.

3. The TX0 output pin is an open drain pull-down driver (no pull-up driver included).

4. The TX1 output pin is an open drain pull-up driver (no pull-down driver included).

10 AC CHARACTERISTICS

V

DD

=5V±4%; VSS=0V; CL= 100 pF (output pins); T

amb

= −40 to +85 °C and T

amb

= −40 to +125 °C; unless

otherwise specified.

Notes

1. Other bit time values are possible with the external oscillator mode (refer to Chapter 11.3).

2. These values are characterized but not 100% production tested.

OC1 comparator input P15

V

i sw

input switch-over voltage 1.5 V < VI<(AVDD− 1.5 V);

note 2

lower threshold 0.5V

DD

− 0.02 V

upper threshold − 0.5V

DD

+ 0.02 V

I

LI2

input leakage current 0.45 V < VI<VDD− 0.45 V −±400 nA

C

IA

analog input capacitance note 2 − 20 pF

Analog switches; ION = ±4mA

R

ON

On resistance between P5 to P9, P13 and

P14; note 2

20 200 Ω

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

f

CLK_INT

system clock frequency on-chip internal oscillator 4 10 MHz

t

bit

bit time on CAN-bus note 1 8 50 µs

t

RST1

min. RST pulse width after power on note 2 150 − ms

t

RST2

min. RST pulse width during operation note 2 1 −µs

t

hold

ID hold time after end of reset note 2 100 − ns

t

d

total signal delay of CAN input comparator and

CAN output driver

0.3AVDD<VI< 0.7AVDD;

note 2

− 100 ns

t

rep

max. time without recalibration message − 8000 bit

Analog-to-digital comparator input P15

t

cyc

analog-to-digital conversion cycle time 0.4 1.1 ms

t

init

initialization time of analog-to-digital conversion 0.4 2.1 ms

OC2 comparator P12, P13 and OC3 comparator P10, P11

t

resp

response time V

DIF1

= ±100 mV; note 2 1 µs

DPM1 and DPM2 outputs

t

DPM

repetition time of DPM cycle 0.4 1.1 ms

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

Page 25

1996 Jun 19 25

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

11 APPLICATION INFORMATION

11.1 Maximum bus length

The bit timing parameters refer to using a P8xCE598 or

P8xC592 microcontroller with on-chip CAN interface as a

host node (see Fig.20).

11.1.1 ASSUMPTIONS

• The total in/out delay of external transceiver circuit is

less than 180 ns (e.g. PCA82C250 CAN transceiver;

see Fig.20).

• The propagation delay on the transmission medium is

5.0 ns/m.

Table 15 Maximum bus length for CAN-bus systems with P82C150 nodes.

Notes

1. t

prop

is the maximum propagation delay between two CAN-bus nodes (delays of on- and off-chip transceiver circuits

included).

2. BTR0 and BTR1 (hex values) are particular configuration registers referring to bit timing.

BIT RATE

(kbit/s)

t

prop

(1)

(µs)

INDICATION

FOR MAXIMUM

BUS LENGTH

(m)

BIT TIMING (P8xCE598/P8xC592)

f

CLK

(MHz)

BTR0

(2)

BTR1

(2)

125 0.8 25 15 C5H 34H

100 1 45 16 C7H 34H

50 2 145 16 CFH 34H

20 5 445 16 E7H 34H

11.2 Start up sequence

The following start-up sequence, illustrated by

Figures 10 and 11, shows a simple example how

P82C150 nodes can be controlled from a host node. This

application example works with different system

configurations:

• One conventional crystal-controlled CAN node and one

or more P82C150 nodes.

• More than one conventional crystal-controlled CAN

node and one or more P82C150 nodes.

Fig.10 General start-up procedure for CAN-bus

systems with P82C150 nodes.

handbook, halfpage

Power-on

MHA077

Initialization of host node's CAN controller

Wait until all P82C150 nodes are assumed

to have finished Power-on-reset

Periodic calibration

(transmit calibration message with a

repetition period of maximum 8000 bit times)

Start-up bit time calibration procedure

(1)

(1) See Fig.11.

Page 26

1996 Jun 19 26

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

Fig.11 P82C150 start-up bit time calibration procedure for host node (P8xC592, P8xCE598 or P82C200).

handbook, full pagewidth

if

if

Load calibration message

into transmit buf fer

j := 18

else

else

then

else

j : = j −1

if j = 0

Wait for reception of sign-on message

from P82C150 nodes

from now onwards transmit calibration message

periodically with a recommended repetition

period between 3800 and 8000 bit times

then

then

MHA079

'0'

Set bit 'Transmission Request' (CMR.0) in Command Register

Set bit 'Abort Transmission' (CMR.1) in Command Register

'Transmit Status' = 0

(1)

'Transmit Status' = 1

(1)

(1) Bit SR.5 in Status Register.

Page 27

1996 Jun 19 27

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

11.3 External oscillator mode

In this mode the P82C150 operates with an external clock

instead with the on-chip RC-oscillator. Figure 14 shows

the application with an external clock.

In this mode the P82C150 can achieve bit rates below

20 kbit/s and above 125 kbit/s. The DPM pulse width is

4 × t

CLK

of the external clock. The corresponding CAN

identifier bit at Port P0 is set to a logic 0. Therefore only

eight P82C150 based CAN nodes operate within the same

network in external oscillator mode.

11.3.1 N

OTE

The external oscillator mode is not the normal operation

mode.

11.4 Using digital I/O port functions

Figures 12 and 13, show the principle application for

digital input and output.

11.5 Using DPM

The simplest way to generate an analog voltage using the

P82C150 is to apply an external low pass filter at one of

the DPM (Distributed Pulse Modulation) outputs. The

simplest implementation concept is a RC-filter of the first

order (refer to Fig.15). Regarding the selection of the time

constant (edge frequency) of this filter, a trade-off between

minimizing of the ripple voltage for maximum accuracy and

minimum of the settling time has to be considered.

Fig.12 Example for digital input application.

P82C150

+5 V

P0 to P15

digital

input

MHA072

Fig.13 Example for digital output application.

P82C150

digital

output

P0 to P15

MHA073

Fig.14 P82C150 in external oscillator mode.

handbook, halfpage

P82C150

reset

MHA078

clock

P0/CLK

XMOD

RST

+5 V

Fig.15 Example for DPM application.

P82C150

analog

output

DPM1(2)

P10(P4)

V

t

V

t

MHA074

If the output is loaded by a resistive load, this will decrease the

accuracy due to the voltage drop across the series resistor. In these

cases a low value for the series resistor should be chosen.

The repetition time of one DPM cycle can be derived from:

t

CYC

4096

f

OSC

------------ -=

Page 28

1996 Jun 19 28

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

11.6 Using ADC

The application in Fig.16 can be used for analog-to-digital

conversion for only one analog input signal. The

evaluation of ADC were done with the values

R1 = R2 = 100 kΩ and C = 3.3 nF; under these conditions

the ADC may reach an accuracy of 7 to 8 bit (depends on

application). The external components should be

connected close to the port pins P15 and P16 with short

wiring to avoid disturbances at the analog input

port pin P15.

Using the on-chip multiplex function the P82C150 provides

up to six input port pins to convert analog input signals to

digital values (see Fig.17).

The period for one ADC cycle is identical to the length of

one DPM cycle.

11.7 Using analog input port functions

Figure 18 shows the wide range of analog input

applications:

• Comparison of two analog input signals.

• Comparison of one analog input signal against a fixed

threshold.

• Window comparator including monitoring the

comparator outputs at the port pins P8 and P9;

additional automatically generated messages, when the

corresponding port bits in the Negative Edge and/or

Positive Edge register are set.

• Local control two-step system.

Fig.16 ADC implementation.

handbook, halfpage

P82C150

P16

R1

R2

C

P15

one analog input signal

for A/D conversion

MHA076

Fig.17 Two multiplexed analog input signals

switched for analog-to-digital conversion

(maximum 6 signals; see Fig.5).

handbook, halfpage

P82C150

feedback

P15

P16

P14analog signal

P5

P6

V

t

V

t

MHA075

SW3 to

SW1

Page 29

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

1996 Jun 19 29

Fig.18 Examples of comparator applications.

book, full pagewidth

MHA082

P82C150

V

t

V

t

P11 (P13)

P10 (P12)

P82C150

V

t

P11 (P13)

P10 (P12)

M3 (M2)

+5 V

threshold

comparator

P8 (P9)

output enabled and edge-triggered mode (PE and/or NE set)

V

comparison between two

analog input signals

message transmission

when analog input signal

exceeds upper respectively

lower threshold voltage

(window comparator)

P82C150

V

t

P13

P12

+5 V

upper

threshold

sensor

signal

P8

V

t

V

t

P9

P11

P10

comparators

M3

lower

threshold

M2

message transmission

when analog input signal

exceeds threshold voltage

P82C150

t

P11 (P13)

P10 (P12)

M3 (M2)

+5 V

threshold

comparator

P8 (P9)

output enabled

V

t

to actuator

local two-step control

system

sensor

signal

output enabled and edge-triggered

mode (PE and/or NE set)

output enabled and edge-triggered

mode (PE and/or NE set)

OC3 (OC2)

OE8 (OE9)

DO8 (DO9)

DO8

OE8

DO9

OE9

DI9

DI8

OE8 (OE9)

DO8 (DO9)

DI8 (DI9)

DI8 (DI9)

Page 30

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

1996 Jun 19 30

Fig.19 Examples of TOPFET applications with P82C150.

handbook, full pagewidth

P82C150

RX0 RX1

TX0

TX1

REF

+5 V

RST

V

SS

V

DD

BUK105-50S

LOAD

P

w

D

S

I

linear

control

with

status

feedback

BUK101-50GS

V

bat

LOAD

D

S

I

on/off

control

KM110BH/21-90

angle

measurement

+5 V

V

o

V

S

GND

+5 V

10 kΩ

P

V

(digital out)

(analog in)

P

y

P

x

P

z

(digital in)

(digital out)

(DPM)

V

bat

PF

MHA083

Page 31

1996 Jun 19 31

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

11.8 CAN-bus system applications

handbook, full pagewidth

P8xC592 / P8xCE598

CAN-CONTROLLER

MHA069

CRX0

P82C150

PCA82C250

CRX1

R

ext

= 0

CTX0

Px,y

XTAL1

XTAL2

RX0

RX1

6.8 kΩ3.6 kΩ560 Ω

124 Ω

TX0

+5 V+5 V

TX1

RxD

CANH

CAN BUS

LINE

CANL

Rs

TxD

V

ref

TOPFET

(1)

TOPFET

M

motor

lamp analog

digital

sensor

124 Ω

PCA82C250

RxD

CANH CANL

Rs

TxD

V

ref

Fig.20 P82C150 system application using CAN transceiver PCA82C250 (ISO/DIS 11898 standard).

(1) TOPFET =temperature and Overload-Protected Field-Effect-Transistor

Page 32

1996 Jun 19 32

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

12 PACKAGE OUTLINE

UNIT

A

max.

A

1

A2A

3

b

p

cD

(1)E(1) (1)

eHELLpQ

Z

ywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

inches

2.65

0.30

0.10

2.45

2.25

0.49

0.36

0.32

0.23

18.1

17.7

7.6

7.4

1.27

10.65

10.00

1.1

1.0

0.9

0.4

8

0

o

o

0.25 0.1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

1.1

0.4

SOT136-1

91-08-13

95-01-24

X

14

28

w M

θ

A

A

1

A

2

b

p

D

H

E

L

p

Q

detail X

E

Z

c

L

v M

A

e

15

1

(A )

3

A

y

0.25

075E06 MS-013AE

pin 1 index

0.10

0.012

0.004

0.096

0.089

0.019

0.014

0.013

0.009

0.71

0.69

0.30

0.29

0.050

1.4

0.055

0.42

0.39

0.043

0.039

0.035

0.016

0.01

0.25

0.01

0.004

0.043

0.016

0.01

0 5 10 mm

scale

SO28: plastic small outline package; 28 leads; body width 7.5 mm

SOT136-1

Page 33

1996 Jun 19 33

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

13 SOLDERING

13.1 Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

cases reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook

” (order code 9398 652 90011).

13.2 Reflow soldering

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from 215 to

250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

13.3 Wave soldering

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

13.4 Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds at between 270 and

320 °C

Page 34

1996 Jun 19 34

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

14 DEFINITIONS

15 LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Page 35

Philips Semiconductors Preliminary specification

CAN Serial Linked I/O device (SLIO) with

digital and analog port functions

P82C150

1996 Jun 19 35

NOTES

Page 36

Internet: http://www.semiconductors.philips.com/ps/

(1) ADDRESS CONTENT SOURCE June 20, 1996

Philips Semiconductors – a worldwide company

© Philips Electronics N.V. 1996 SCA49

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Netherlands: Postbus 90050, 5600PB EINDHOVEN, Bldg.VB,

Tel. +3140 2783749, Fax. +31 40 27 88399

New Zealand: 2 WagenerPlace, C.P.O. Box1041, AUCKLAND,

Tel. +649 8494160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud0612, OSLO,

Tel. +4722 748000, Fax. +47 22 74 8341

Philippines: Philips Semiconductors Philippines Inc.,

106 ValeroSt. SalcedoVillage, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel.+63 2816 6380, Fax. +63 2 817 3474

Poland: Ul. Lukiska10, PL 04-123WARSZAWA,

Tel. +4822 6122831, Fax. +48 22 612 2327

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva35A, 119048 MOSCOW,

Tel. +7095 9265361, Fax. +7 095 564 8323

Singapore: Lorong 1, ToaPayoh, SINGAPORE 1231,

Tel. +65350 2538,Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 MainRoad Martindale,

2092 JOHANNESBURG, P.O.Box 7430 Johannesburg2000,

Tel. +2711 4705911, Fax. +27 11 470 5494

South America: Rua doRocio 220- 5th floor, Suite 51,

CEP: 04552-903-SÃOPAULO-SP, Brazil, P.O. Box7383 (01064-970),

Tel. +5511 8212333, Fax. +55 11 829 1849

Spain: Balmes 22, 08007BARCELONA,

Tel. +343 3016312, Fax. +34 3 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485STOCKHOLM,

Tel. +468 6322000, Fax. +46 8 632 2745

Switzerland: Allmendstrasse 140, CH-8027ZÜRICH,

Tel. +411 4882686, Fax. +41 1 481 7730

Taiwan: PHILIPS TAIWAN Ltd., 23-30F, 66,

Chung HsiaoWest Road,Sec. 1, P.O. Box 22978,

TAIPEI 100,Tel. +8862 382 4443, Fax. +886 2 382 4444

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-BangnaRoad Prakanong, BANGKOK10260,

Tel. +662 7454090, Fax. +66 2 398 0793

Turkey: Talatpasa Cad. No. 5, 80640GÜLTEPE/ISTANBUL,

Tel. +90212 2792770, Fax. +90 212 282 6707

Ukraine: PHILIPS UKRAINE, 2A AkademikaKoroleva str., Office165,

252148 KIEV, Tel.+380 44476 0297/1642, Fax. +380 44 476 6991

United Kingdom: Philips Semiconductors Ltd., 276 BathRoad, Hayes,

MIDDLESEX UB35BX, Tel. +44181 730 5000, Fax. +44 181 754 8421

United States: 811 EastArques Avenue, SUNNYVALE, CA94088-3409,

Tel. +1800 2347381, Fax. +1 708 296 8556

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica5/v, 11000 BEOGRAD,

Tel. +38111 825344, Fax.+381 11 635 777

For all other countries apply to: Philips Semiconductors, Marketing &Sales Communications,

Building BE-p, P.O.Box 218, 5600MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

Argentina: see South America

Australia: 34 Waterloo Road, NORTH RYDE, NSW 2113,

Tel. +612 8054455, Fax. +61 2 805 4466

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box213,

Tel. +431 60101, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r.1211, Volodarski Str.6,

220050 MINSK, Tel.+375 172200 733, Fax. +375 172 200 773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15thfloor,

51 JamesBourchier Blvd., 1407SOFIA,

Tel. +3592 689211, Fax. +359 2 689 102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1800 2347381, Fax. +1 708 296 8556

China/Hong Kong: 501 HongKong Industrial Technology Centre,

72 TatChee Avenue, Kowloon Tong, HONG KONG,

Tel. +8522319 7888,Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Prags Boulevard80, PB 1919, DK-2300COPENHAGEN S,

Tel. +4532 882636, Fax. +45 31 57 1949

Finland: Sinikalliontie 3, FIN-02630ESPOO,

Tel. +358615 800,Fax. +358 615 80920

France: 4 Ruedu Port-aux-Vins, BP317, 92156SURESNES Cedex,

Tel. +331 4099 6161, Fax. +33 1 40 99 6427

Germany: Hammerbrookstraße 69, D-20097HAMBURG,

Tel. +4940 2352 60, Fax. +49 40 23 536 300

Greece: No. 15,25th MarchStreet, GR 17778 TAVROS,

Tel. +301 4894339/911, Fax. +30 1 4814 240

Hungary: see Austria

India: Philips INDIA Ltd, Shivsagar Estate, A Block, Dr. Annie Besant Rd.

Worli, MUMBAI 400018, Tel. +9122 4938 541, Fax. +91 22 4938 722

Indonesia: see Singapore

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +3531 7640000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7Kehilat SalonikiSt, TEL AVIV 61180,

Tel. +9723 6450444, Fax. +972 3 648 1007

Italy: PHILIPS SEMICONDUCTORS, Piazza IVNovembre 3,

20124 MILANO, Tel.+39 26752 2531, Fax. +39 2 6752 2557

Japan: Philips Bldg13-37, Kohnan 2-chome, Minato-ku, TOKYO108,

Tel. +813 37405130, Fax. +81 3 3740 5077

Korea: Philips House, 260-199Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +822 7091412, Fax. +82 2 709 1415

Malaysia: No. 76Jalan Universiti, 46200PETALING JAYA, SELANGOR,

Tel. +60 3750 5214,Fax. +60 3 757 4880

Mexico: 5900 GatewayEast, Suite 200, ELPASO, TEXAS 79905,

Tel. +1800 2347381, Fax. +1 708 296 8556

Middle East: see Italy

Printed in The Netherlands 617021/1200/02/pp36 Date of release: 1996 Jun 19 Document order number: 9397 750 00918

Loading...

Loading...