Datasheet OR4E6-1BA352, OR4E6-2BM680, OR4E10-1BM680, OR4E2-1BA352, OR4E2-2BC352 Datasheet (AGERE)

...Page 1

Preliminary Data Sheet

December 2000

ORCA®

Series 4

Field-Programmable Gate Arrays

Programmable Features

■

High-performance platform design.

— 0.13 µm seven-level metal technology.

— Internal performance of >250 MHz

(four logic levels).

— I/O performance of >416 M H z for all user I/Os.

— Over 1.5 million usable system gates.

— Meets multiple I/O interface standards.

— 1.5 V operation (30% l e ss p o w er t han 1 .8 V op er -

ation) translates to greater performance.

— Embedded block RAM (EBR) for onboard stor-

age and buffer needs.

— Built-in system component s i n cl udi ng a n i nt ernal

system bus, eight PLLs, and microprocess or

interface.

■

Traditional I/O selections.

— LVTTL and LVCMOS (3.3 V, 2.5 V, and 1.8 V)

I/Os.

— Per pin-selectable I/O clamping diodes provide

3.3 V PCI compliance.

— Individually programmable drive capabilit y.

24 mA sink/12 mA sourc e, 12 mA si nk /6 mA

source, or 6 mA sink/3 mA source.

— Two slew rates supported (fast and slew-limited).

— Fast-capture input latch and input flip-flop (FF)/

latch for reduced input setup time and zero ho ld

time.

— Fast open-drain drive capability.

— Capability to register 3-state enable signal.

— Off-chip clock drive capability.

— Two-input function generator in output path.

■

New programmable high-speed I/O.

— Single-ended: GTL , GTL+, PECL, SSTL3/2

(class I & II), HSTL (Class I, III, IV), zero-bus

turn-around (

ZBT*

), and double data rate (DDR).

— Double-ended: LDVS, bused-LVDS, LVPECL.

— Customer defined: Ability to substitute arbitrary

standard-cell I/O to meet fast moving standards.

■

New capability to (de)multiplex I/O signals.

— New DDR on both input and output a t r ates up to

311 MHz (622 MHz effective rate).

— Used to implement emerging

RapidIO

†

back-

plane interface specification.

— New 2x and 4x downlink and uplink capability per

I/O (i.e., 104 MHz internal to 416 MHz I/O).

■

Enhanced twin-quad programmable function unit

(PFU).

— Eight 16-bit look-up tables (LUTs ) per PFU.

— Nine user registers pe r PF U, one following each

LUT and organized to allow two nibbles to act

independently, plus one extra for arithmetic

carry/borrow op eratio ns.

*

ZBT

is a trademark of Integrated Device Technologies Inc.

†

RapidIO

is a trademark of Motorola, Inc.

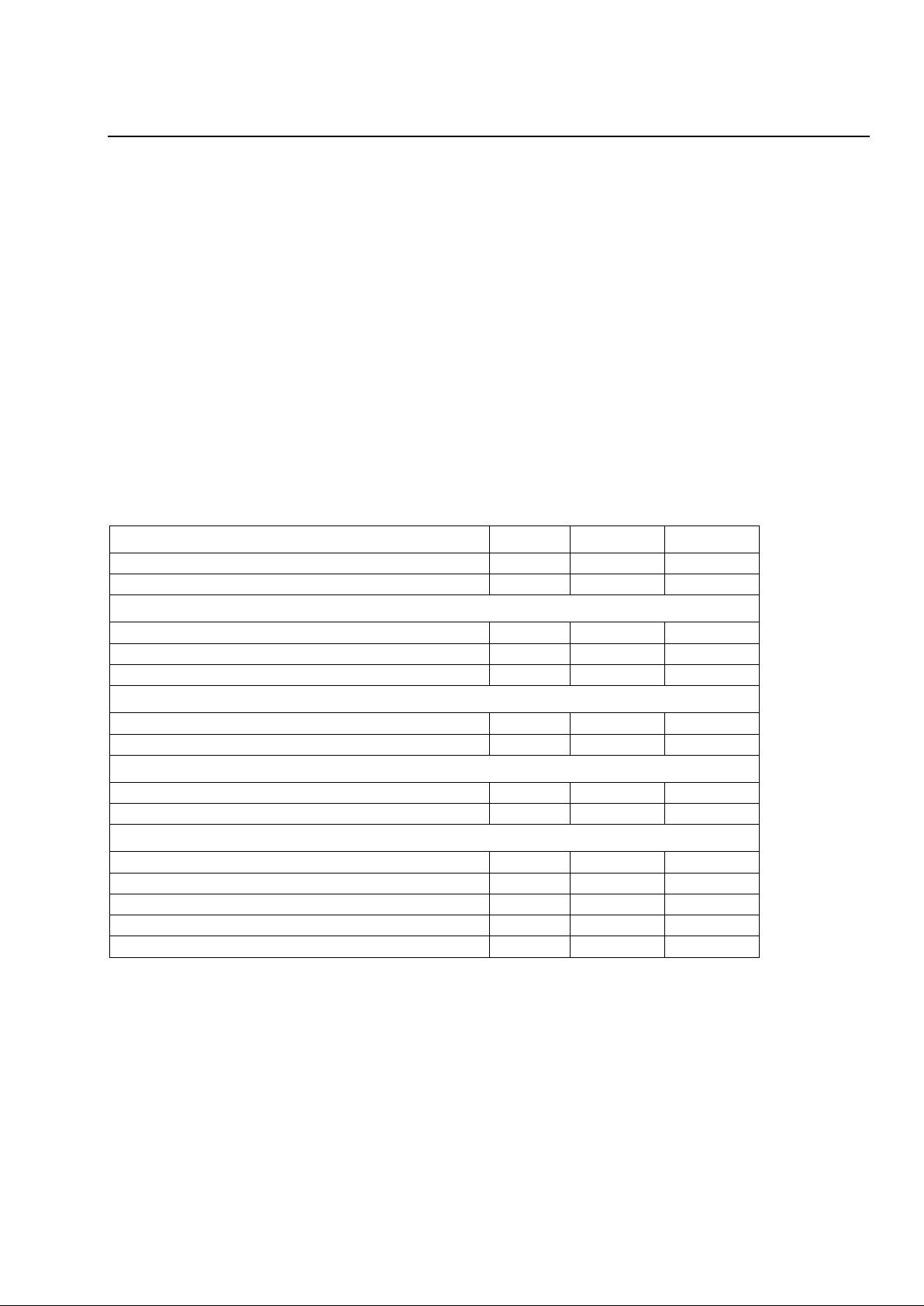

Table 1.

ORCA

Series 4—Available FPGA Logic

† The usable gate counts range from a logic-only gate count to a gate count assuming 20% of the PFUs/SLICs being used as RAMs. The

logic-only gate count includes each PFU/SLIC (counted as 108 gates/PFU), including 12 gates per LUT/FF pair (eight per PFU), and

12 gates per SLIC/FF pair (one per PFU). Each of the four PIO groups are counted as 16 gates (three FFs, fast-capture latch, output logic,

CLK, and I/O buffers). PFUs used as RAM are counted at four gates per bit, with each PFU capable of implementing a 32 x 4 RAM (or

512 gates) per PFU. Embedded block RAM (EBR) is counted as four gates per bit plus each block has an additional 25k gates. 7k gates

are used for each PLL and 50k gates for the embedded system bus and microprocessor interface logic. Both the EBR and PLLs are conservatively utilized in the gate count calculations.

Note: Devices are not pinout compatible with

ORCA

Series 2/3.

Device Columns Rows PFUs User I/O LUTs EBR

Blocks

EBR Bits (k)

Usable†

Gates (k)

OR4E2 26 24 624 400 4992 8 74 260—470

OR4E4 36 36 1296 576 10368 12 111 400—720

OR4E6 46 44 2024 720 16,192 16 148 530—970

OR4E10 60 56 3360 928 26,880 20 185 740—1350

OR4E14 70 66 4620 1088 36,960 24 222 930—1700

Page 2

Table of Contents

Contents Page Contents Page

2 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA

Series 4 FPGAs

Programmable Features............................................. 1

System Features ................................... ....... ...... ....... ..4

Product Description .....................................................6

Architecture Overview .............................................6

Programmable Logic Cells ..........................................7

Programmable Function Unit...................................8

Look-Up Table Operating Modes ..........................11

Supplemental Logic and Interconnect Cell ............21

PLC Latches/Flip-Flops .........................................25

Embedded Block RAM ..............................................27

EBR Features........................................................27

Routing Resources ...................................................31

Clock Distribution Network ........................................31

Primary Clock Nets................................................31

Secondary Clock and Control Nets .......................31

Edge Clock Nets....................................................31

Programmable Input/Output Cells.............................31

Programmable I/O .................................................31

Inputs.....................................................................34

Special Function Blocks ............................................38

Microprocessor Interface (MPI).................................48

Embedded System Bus (ESB) ..................................49

Phase-Locked Loops.................................................52

FPGA States of Operation.........................................55

Initialization............................................................56

Configuration .........................................................56

Start-Up .................................................................56

Reconfiguration .....................................................60

Partial Reconfiguration..........................................60

Other Configuration Options..................................60

Bit Stream Error Checking.....................................62

FPGA Configuration Modes.......................................62

Master Parallel Mode.............................................63

Master Serial Mode ...............................................64

Asynchronous Peripheral Mode ............................65

Microprocessor Interface Mode .............................66

Slave Serial Mode .................................................70

Slave Parallel Mode...............................................70

Daisy Chaining ......................................................71

Daisy-Chaining with Boundary Scan .....................72

Absolute Maximum Ratings.......................................72

Recommended Operating Conditions .......... ...... .......73

Electrical Characteristics...........................................73

Pin Information ..........................................................75

Pin Descriptions.....................................................75

Package Compatibility ...........................................78

Package Thermal Characteristics Summary ...........118

Θ

JA

......................................................................118

ψ

JC

......................................................................118

Θ

JC

......................................................................118

Θ

JB

......................................................................118

Package Thermal Characteristics............................119

Package Coplanarity ...............................................119

Package Parasitics..................................................119

Package Outline Diagrams......................................120

Terms and Definitions..........................................120

Package Outline Drawings......................................121

352-Pin PBGA .....................................................121

432-Pin EBGA .....................................................122

680-Pin PBGAM ..................................................123

Ordering Information................................................124

Figure Page

Figure 1. Series 4 Top-Level Diagram ........................7

Figure 2. PFU Ports.....................................................9

Figure 3. Simplified PFU Diagram.............................10

Figure 4. Simplified F4 and F5 Logic Modes.............12

Figure 5. Simplified F6 Logic Modes .........................13

Figure 6. MUX 4 x 1...................................................13

Figure 7. MUX 8 x 1...................................................14

Figure 8. Softwired LUT Topology Examples.............15

Figure 9. Ripple Mode ...............................................16

Figure 10. Counter Submode....................................17

Figure 11. Multiplier Submode...................................18

Figure 12. Memory Mode ..........................................19

Figure 13. Memory Mode Expansion

Example—128 x 8 RAM ........................................21

Figure 14. SLIC All Modes Diagram..........................22

Figure 15. Buffer Mode..............................................23

Figure 16. Buffer-Buffer-Decoder Mode ....................23

Figure 17. Buffer-Decoder-Buffer Mode ....................24

Figure 18. Buffer-Decoder-Decoder Mode ................24

Figure 19. Decoder Mode..........................................25

Figure 20. Latch/FF Set/Reset Configurations ..........26

Figure 21. EBR Read and Write Cycles

with Write Through ................................................29

Figure 22. Series 4 PIO Image from

ORCA Foundry.................. ...... ..............................33

Figure 23. ORCA High-Speed I/O Banks ..................36

Figure 24. PIO Shift Register.....................................38

Figure 25. Printed-Circuit Board with Boundary-

Scan Circuitry ........................................................39

Figure 26. Boundary-Scan Interface..........................40

Figure 27. ORCA Series Boundary-Scan

Circuitry Functional Diagram .................................43

Figure 28. TAP Controller State T ransition

Diagram.................................................................44

Figure 29. Boundary-Scan Cell .................................45

Figure 30. Instruction Regist er Scan Timing

Diagram.................................................................46

Figure 31. PLL_VF External Requirements...............53

Figure 32. PLL Naming Scheme ...............................54

Page 3

Lucent Technologies Inc. 3

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Contents Page Contents Page

Table of Contents

(continued)

Figure 33. FPGA States of Operation .......................55

Figure 34. Initialization/Configuration/Start-Up

Waveforms............................................................. 57

Figure 35. Start-Up Waveforms.................................59

Figure 36. Serial Configuration Data

Format—Autoincrement Mode ..............................60

Figure 37. Serial Configuration Data

Format—Expl ic it Mod e......... ....... ...... ....... ...... ....... 60

Figure 38. Master Parallel

Configuration Schematic ....................................... 63

Figure 39. Master Serial Configuration Schematic.... 65

Figure 40. Asynchronous Peripheral Configuration...66

Figure 41. PowerPC/MPI Configuration Schematic...67

Figure 42. Configuration Through MPI......................68

Figure 43. Readback Through MPI ...........................69

Figure 44. Slave Serial Configuration Schematic...... 70

Figure 45. Slave Parallel Configuration Schematic ...71

Figure 46. Daisy-Chain Configuration Schematic .....72

Figure 47. Package Parasitics................................. 120

Table Page

Table 1. ORCA Series 4—Available FPGA Logic.......1

Table 2. System Performance ....................................5

Table 3. Look-Up Table Operating Modes ................11

Table 4. Control Input Functionality..........................11

Table 5. Ripple Mode Equality Comparator

Functions and Outputs .......................................... 18

Table 6. SLIC Modes................................................22

Table 7. Configuration RAM Controlled Latch/

Flip-Flop Operation................................................25

Table 8. ORCA Series 4— Available

Embedded Block RAM .......................................... 27

Table 9. RAM Signals............................................... 28

Table 10. FIFO Signals ............................................29

Table 11. Constant Multiplier Signals .......................30

Table 12. 8 x 8 Multiplier Signals..............................30

Table 13. CAM Signals .............................................30

Table 14. Series 4 Programmable I/O Standards..... 32

Table 15. PIO Options ..............................................35

Table 16. PIO Register Control Signals....................35

Table 17. PIO Logic Options..................................... 36

Table 18. Compatible Mixed I/O Standards..............36

Table 19. LVDS I/O Specifications...........................37

Table 20. LVDS Termination Pin ............................. 37

Table 21. Dedicated Temperature Sensing..............39

Table 22. Boundary-Scan Instructions ..................... 40

Table 23. Series 4E Boundary-Scan

Vendor-ID Codes...................................................41

Table 24. TAP Controller Input/Outputs................... 43

Table 25. Readback Options .................................... 46

Table 26. MPC 860 to ORCA MPI Interconnection .. 48

Table 27. Embedded System Bus/MPI Registers..... 50

Table 28. Interrupt Register Space Assignments..... 50

Table 29. Status Register Space Assignments ........ 51

Table 30. Command Register Space Assignments.. 51

Table 31. PPLL Specifications.................................. 52

Table 32. DPLL DS-1/E-1 Specifications..................53

Table 33. Dedicated Pin Per Package...................... 53

Table 34. STS-3/STM-1 DPLL Specifications........... 54

Table 35. Phase-Lock Loops Index .......................... 54

Table 36A. Configuration Frame Format

and Contents......................................................... 61

Table 36B. Configuration Frame Format

and Contents for Embedded Block RAM...............61

Table 37. Configuration Frame Size ......................... 62

Table 38. Configuration Modes................................. 63

Table 39. Absolute Maximum Ratings...................... 73

Table 40. Recommended Operating Conditions....... 73

Table 41. Electrical Characteristics .......................... 73

Table 42. Pin Descriptions........................................75

Table 43. ORCA I/Os Summary ............................... 78

Table 44. 352-Pin PBGA Pinout ...............................79

Table 45. 432-Pin EBGA .......................................... 89

Table 46. 680-Pin PBGAM Pinout ............................99

Table 47. ORCA Series 4 FPGAs Plastic

Package Thermal Guidelines .............................. 119

Table 48. ORCA Series 4 FPGAs

Package Parasitics ..............................................119

Table 49. Series 4 Package Matrix

(Speed Grades).............................. ...... ....... ...... .. 124

Table 50. Package Options..................................... 124

Page 4

4 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Features

(continued)

— New register control in each PFU has two inde-

pendent programmable clocks, clock enables,

local set/reset, and data selects.

— New LUT structure allows flexible combinations of

LUT4, LUT5, new LUT6, 4-to-1 MUX, new

8-to-1 MUX, and ripple mode arithmetic functions

in the same PFU.

— 32 x 4 RAM per PFU, configurable as single- or

dual-port. Create large, fast RAM/ROM blocks

(128 x 8 in only eight PFUs) using the supplemental logic and interconnect cell (SLIC) decoders as

bank drivers.

— Softwired LUTs (SWL) allow fast cascading of up

to three levels of LUT logic in a single PFU

through fast internal routing which reduces routing

congestion and improves speed.

— Flexible fast access to PFU inputs from routing.

— Fast-carry logic and routing to all four adjacent

PFUs for nibble-, bytewide, or longer arithmetic

functions, with the option to register the PFU

carry-out.

■

Abundant high-speed buffered and nonbuffered routing resources provide 2x average speed improvements over previous architectures.

■

Hierarchical routing optimized for both local and global routing with dedicated routing resources. This

results in faster routing times with predictable and

efficient performance.

■

SLIC provides eight 3-statable buffers, up to 10-bit

decoder, and PAL

1

-like and-or-invert (AOI) in each

programmable logic cell.

■

New 200 MHz embedded quad-port RAM blocks, two

read ports, two write ports, and two sets of byte lane

enables. Each embedded RAM block can be configured as:

— One 512 x 18 (quad-port, two read/two write) with

optional built-in arbitration.

— One 256 x 36 (dual-port, one read/one write).

— One 1K x 9 (dual-port, one read/one write).

— Two 512 x 9 (dual-port, one read/one write for

each).

— Two RAMs with arbitrary number of words whose

sum is 512 or less by 18 (dual-port, one read/one

write).

— Supports joining of RAM blocks.

— Two 16 x 8-bit content addressable memory

(CAM) support.

— FIFO 512 x 18, 256 x 36, 1K x 9 or dual 512 x 9.

— Constant multiply (8 x 16 or 16 x 8).

— Dual-variable multiply (8 x 8).

■

Built-in testability.

— Full boundary- sc an (IEEE

2

1149.1 and Draft

1149.2 joint test access group (JTAG)).

— Programming and readback through boundary-

scan port compliant to IEEE Draft 1532:D1.7.

— TS_ALL testability function to 3-state all I/O pins.

— New temperature-sensing diode used to deter-

mine device junction temperature.

System Features

■

PCI local bus compliant.

■

Improved PowerPC3 860 and PowerPC II high-speed

(66 MHz) synchronous MPI interface can be used for

configuration, readback, device control, and device

status, as well as for a general-purpose interface to

the FPGA logic, RAMs, and embedded standard-cell

blocks. Glueless interface to synchronous PowerPC

processors with user-configurable address space

provided.

■

New embedded AMBA4 specification 2.0 AHB system bus (ARM

4

processor) facilitates communication

among the microprocessor interface, configuration

logic, EBR, FPGA logic, and embedded standard-cell

blocks. Embedded 32-bit internal system bus plus

4-bit parity interconn ec ts FPG A log ic, microp ro ce ssor interface (MPI), embedded RAM blocks, and

embedded standard-cell blocks with 100 MHz bus

performance. Included are built-in system regis te rs

that act as the control and status center for the

device.

■

New network phase-locked loops (PLLs) meet ITU-T

G.811 specifications and provide clock conditioning

for DS-1/E-1 and STS-3/STM-1 applications.

■

Flexible general-purpose programmable PLLs offer

clock multiply (up to 8x), divide (down to 1/8x), phase

shift, delay compensation, and duty cycle adjustment

combined. Improved built-in clock management with

programmable phase-locked loops (PPLLs) provide

optimum clock modification and conditioning for

phase, frequency , and duty cycle from 20 MHz up to

420 MHz. Each PPLL provides two separate clock

outputs.

1. PA L is a trademark of Advanced Micro Devices, Inc.

2. IEEE a is registered trademark of The Institute of Electrical and

Electronics Engineers, Inc.

3. PowerPC is a registered trademark of International Business

Machines, Corporation.

4. AMBA and ARM are trademarks of ARM Limited.

Page 5

Lucent Technologies Inc. 5

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

System Features

(continued)

■

Variable-size bused readback of configuration data capability with the built-in MPI and system bus.

■

Internal, 3-state, bidirectional buses with simple control provided by the SLIC.

■

Meets universal test and operations PHY interface for ATM (UTOPIA) Levels 1, 2, and 3. Also meets proposed

specifications for UTOPIA Level 4 for 10 Gbits/s interfaces.

■

New clock routing structures for global and local clocking significantly increases speed and reduces skew

(<200 ps for OR4E4).

■

New local clock routing structures allow creation of localized clock trees anywhere on the device.

■

New DDR, QDR, and ZBT memory interfaces support the latest high-speed memory interfaces.

■

New 2x/4x uplink and downlink I/O shift registers capabilities interface high-speed external I/Os to reduced internal logic speed.

■

ORCA Foundry 2000 development system software. Supported by industry-standard CAE tools for design entry,

synthesis, simulation, and timing analysis.

Table 2. System Performance

1. Implemented using 8 x 1 multiplier mode (unpipelined), register-to-register, two 8-bit inputs, one 16-bit output.

2. Implemented using two 32 x 4 RAMs and one 12-bit adder, one 8-bit input, one fixed operand, one 16-bit output.

3. Implemented using 8 x 1 multiplier mode (fully pipelined), two 8-bit inputs, one 16-bit output (seven of 15 PFUs

contain only pipelining registers).

4. Implemented using 32 x 4 RAM mode with read data on 3-state buffer to bidirectional read/write bus.

5. Implemented using 32 x 4 dual-port RAM mode.

6. Implemented in one partially occupied SLIC, with decoded output setup to CE in the same PLC.

7. Implemented in five partially occupied SLICs.

Function No. PFUs 2 Unit

16-bit loadable up/down counter 2 282 MHz

16-bit accumulator 2 282 MHz

8 x 8 Parallel Multiplier

Multiplier mode, unpipelined

1

11.5 72 MHz

ROM mode, unpipelined

2

8175MHz

Multiplier mode, pipelined

3

15 197 MHz

32 x 16 RAM (synchronous)

Single port, 3-state bus

4

4264MHz

Dual-port

5

4340MHz

128 x 8 RAM (synchronous)

Single port, 3-state bus

4

8264MHz

Dual-port, 3-state bus

5

8264MHz

Address Decode

8-bit internal, LUT-based 0.25 1.37 ns

8-bit internal, SLIC-based

6

00.73ns

32-bit internal, LUT-based 2 4.68 ns

32-bit internal, SLIC-based

7

02.08ns

36-bit Parity Check (internal) 2 4.68 ns

Page 6

6 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Product Description

Architecture Overview

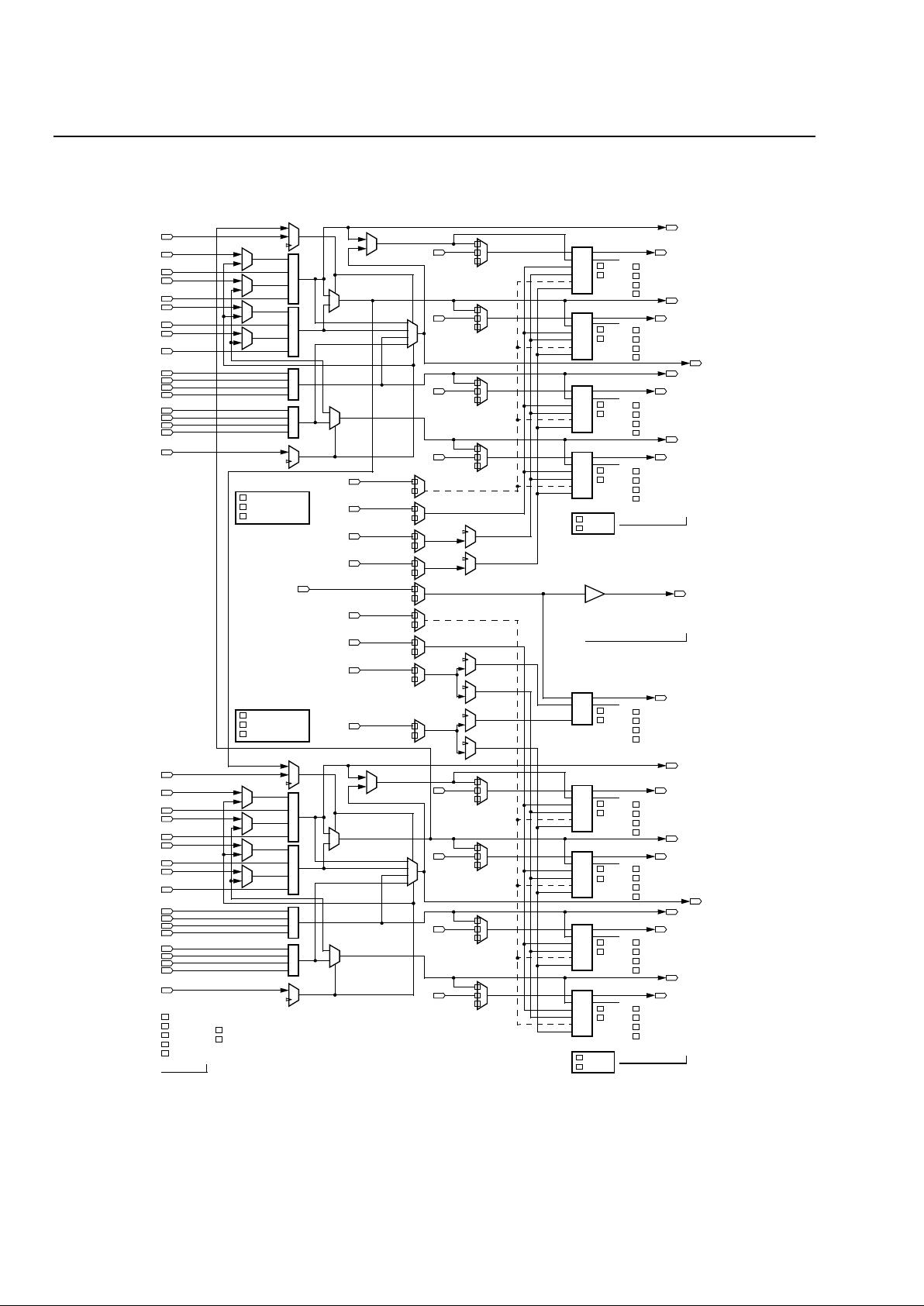

The ORCA Series 4 architecture is a new generation of

SRAM-based programmable devices from Lucent

Technologies Microelectronics Group. It includes

enhancements and innovations geared toward today’s

high-speed systems on a single chip. Designed with

networking applications in mind, the Series 4 family

incorporates system-level features that can further

reduce logic requirements and increase system speed.

ORCA Series 4 devices contain many new patented

enhancements and are offered in a variety of packages

and speed grades.

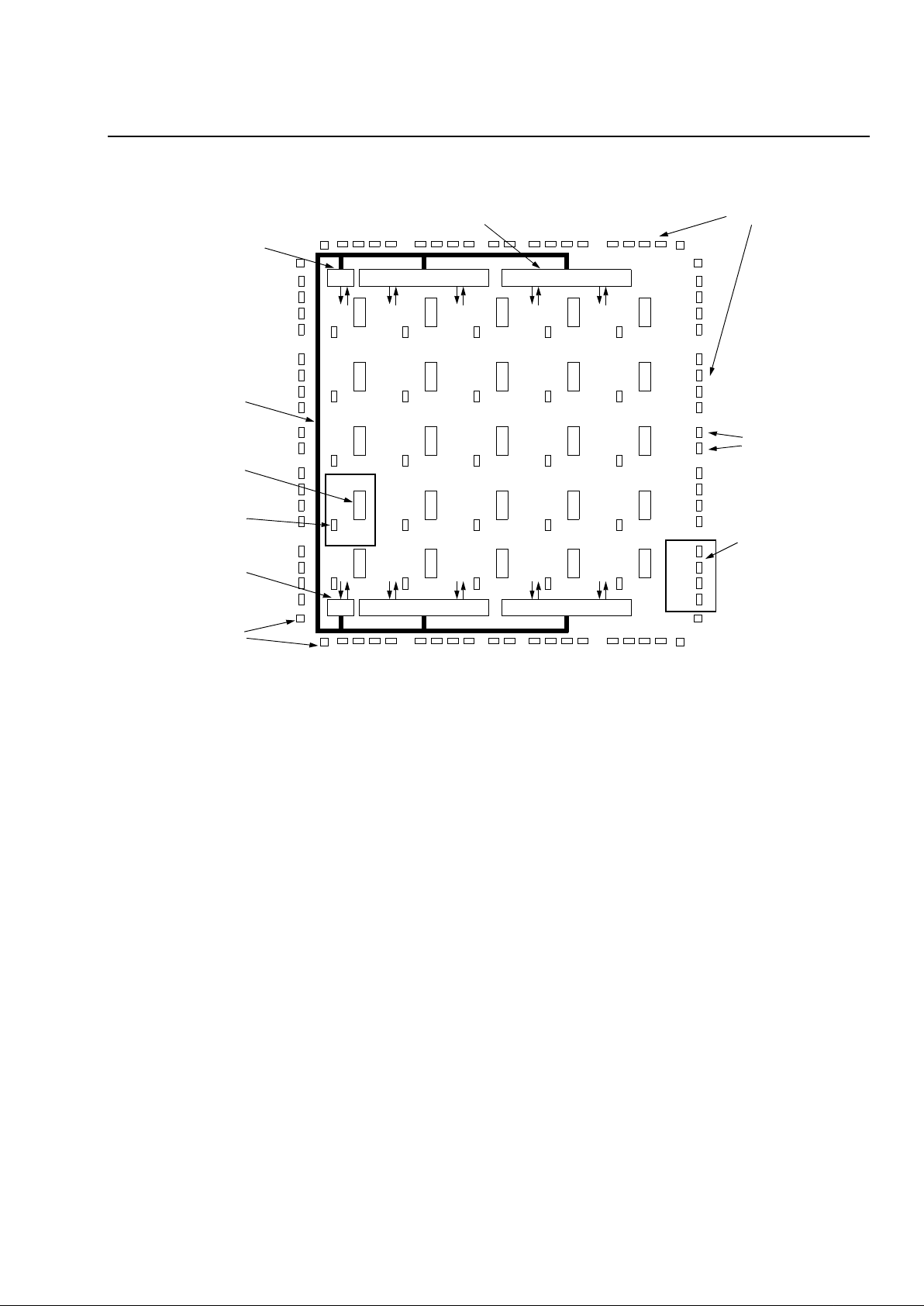

The hierarchical architecture of the logic, clocks, routing, RAM, and system-level blocks create a seamless

merge of FPGA and ASIC designs. Modular hardware

and software technologies enable system-on-chip integration with true plug-and-play design implementation.

The architecture consists of four basic elements: programmable logic cells (PLCs), programmable input/output cells (PIOs), embedded block RAMs (EBRs), and

system-level features. These elements are interconnected with a rich routing fabric of both global and local

wires. An array of PLCs and its associated resources

are surrounded by common interface blocks (CIBs) that

provide an abundant interface to the adjacent PIOs or

system blocks. Routing congestion around these critical blocks is eliminated by the use of the same routing

fabric implemented within the programmable logic core.

PICs provide the logical interface to the PIOs which

provide the boundary interface off and onto the device.

Also, the interquad routing blocks (hIQ, vIQ) separate

the quadrants of the PLC array and provide the global

routing and clocking elements. Each PLC contains a

PFU, SLIC, local routing resources, and configuration

RAM. Most of the FPGA logic is performed in the PFU,

but decoders, PAL-like functions, and 3-state buffering

can be performed in the SLIC. The PIOs provide device

inputs and outputs and can be used to register signals

and to perform input demultiplexing, output multiplexing, uplink and downlink functions, and other functions

on two output signals.

The Series 4 architecture integrates macrocell blocks

of memory known as EBR. The blocks run horizontally

across the PLC array and provide flexible memory

functionality. Large blocks of 512 x 18 quad-port RAM

complement the existing distributed PFU memory. The

RAM blocks can be used to implement RAM, ROM,

FIFO, multiplier , and CAM.

System-level functions such as a microprocessor interface, PLLs, embedded system bus elements (located in

the corners of the array), the routing resources, and

configuration RAM are also integrated elements of the

architecture.

Page 7

Preliminary Data Sheet

December 2000

Lucent Technologies Inc. 7

ORCA Series 4 FPGAs

Product Description

(continued)

5-7536 (F)a

Figure 1. Series 4 Top-Level Diagram

EMBEDDED

SYSTEM BUS

PIC

PLC

MICROPROCESSOR

INTERFACE (MPI)

PFU

SLIC

FPGA/SYSTEM

BUS INTERFACE

PLLs

EMBEDDED

BLOCK RAM

HIGH-SPEED I/Os

CLOCK PINS

PIO

Programmable Logic Cells

The PLCs are arranged in an array of rows and columns. The location of a PLC is indicated by its row and

column so that a PLC in the second row and the third

column is R2C3. The array of actual PLCs for every

device begins with R3C2 in all Series 4 generic

FPGAs.

The PLC consists of a PFU, SLIC, and routing

resources. Each PFU within a PLC contains eight

4-input (16-bit) LUTs, eight latches/FFs, and one additional FF that may be used independently or with arithmetic functions. The PFU is the main logic element of

the PLC, containing elements for both combinatorial

and sequential logic. Combinatorial logic is done in

LUTs located in the PFU. The PFU can be used in different modes to meet different logic requirements. The

LUTs twin-quad architecture provides a configurable

medium-/large-grain architecture that can be used to

implement from one to eight independent combinatorial

logic functions or a large number of complex logic functions using multiple LUTs. The flexibility of the LUT to

handle wide input functions, as well as multiple smaller

input functions, maximizes the gate count per PFU

while increasing system speed.

Page 8

8 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

The PFU is organized in a twin-quad fashion: two sets

of four LUTs and FFs that can be controlled independently. Each PFU has two independent programmable

clocks, clock enables, local set/reset, and data selects

with one available per set of quad FFs.

LUTs may also be combined for use in arithmetic functions using fast-carry chain logic in either 4-bit or 8-bit

modes. The carry-out of either mode may be registered

in the ninth FF for pipelining. Each PFU may also be

configured as a synchronous 32 x 4 single- or dual-port

RAM or ROM. The FFs (or latches) may obtain input

from LUT outputs or directly from invertible PFU inputs,

or they can be tied high or tied low . The FFs also have

programmable clock polarity, clock enables, and local

set/reset.

The LUTs can be programmed to operate in one of

three modes: combinatorial, ripple, or memory. In combinatorial mode, the LUTs can realize any 4-, 5-, or

6-input logic function and many multilevel logic functions using ORCA’s SWL connections. In ripple mode,

the high-speed carry logic is used for arithmetic functions, comparator functions, or enhanced data path

functions. In memory mode, the LUTs can be used as a

32 x 4 synchronous RAM or ROM, in either single- or

dual-port mode.

The SLIC is connected from PLC routing resources

and from the outputs of the PFU. It contains eight

3-state, bidirectional buffers and logic to perform up to

a 10-bit AND function for decoding, or an AND-OR with

optional INVERT to perform PAL-like functions. The

3-state drivers in the SLIC and their direct connections

from the PFU outputs make fast, true 3-state buses

possible within the FPGA.

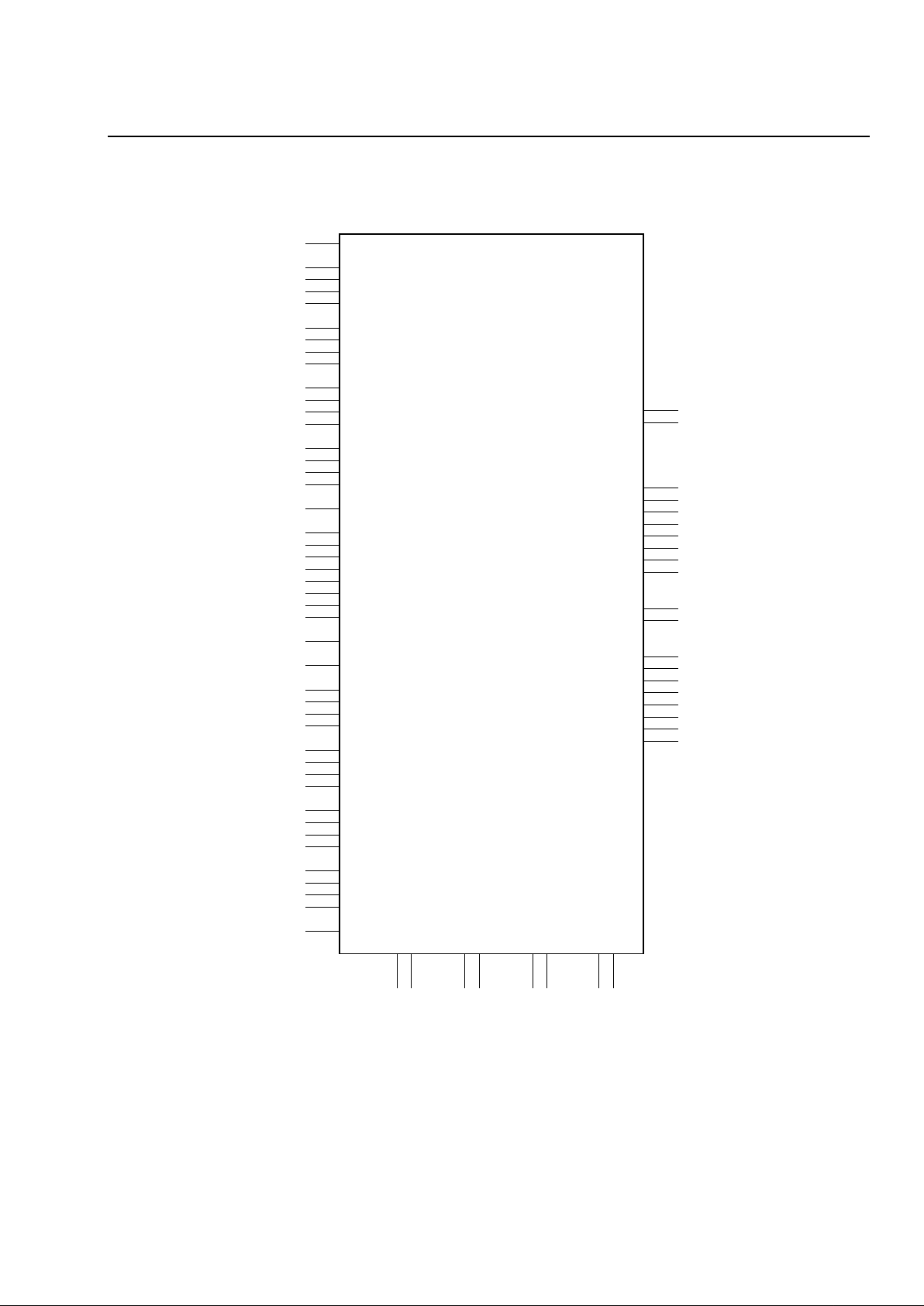

Programmable Function Unit

The PFUs are used for logic. Each PFU has 53 external inputs and 20 outputs and can operate in several

modes. The functionality of the inputs and outputs

depends on the operating mode.

The PFU uses 36 data input lines for the LUTs, eight

data input lines for the latches/FFs, eight control inputs

(CLK[1:0], CE[1:0], LSR[1:0], SEL[1:0]), and a carry

input (CIN) for fast arithmetic functions and generalpurpose data input for the ninth FF. There are eight

combinatorial data outputs (one from each LUT), eight

latched/registered outputs (one from each latch/FF), a

carry-out (COUT), and a registered carry-out (REGCOUT) that comes from the ninth FF. The carry-out signals are used principally for fast arithmetic functions.

There are also two dedicated F6 mode outputs which

are for the 6-input LUT function and 8-to-1 MUX.

Figure 2 and Figure 3 show high-level and detailed

views of the ports in the PFU, respectively. The eight

sets of LUT inputs are labeled as K0 through K7 with

each of the four inputs to each LUT having a suffix

of _x, where x is a number from 0 to 3.

There are four F5 inputs labeled A through D. These

are used for additional LUT inputs for 5- and 6-input

LUTs or as a selector for multiplexing two 4-input LUTs.

Four adjacent LUT4s can also be multiplexed together

with a 4-to-1 MUX to create a 6-input LUT. The eight

direct data inputs to the latches/FFs are labeled as

DIN[7:0]. Registered LUT outputs are shown as Q[7:0],

and combinatorial LUT outputs are labeled as F[7:0].

The PFU implements combinatorial logic in the LUTs

and sequential logic in the latches/FFs. The LUTs are

static random access memory (SRAM) and can be

used for read/write or ROM.

Each latch/FF can accept data from its associated LUT .

Alternatively, the latches/FFs can accept direct data

from DIN[7:0], eliminating the LUT delay if no combinatorial function is needed. Additionally , the CIN input can

be used as a direct data source for the ninth FF. The

LUT outputs can bypass the latches/FFs, which

reduces the delay out of the PFU. It is possible to use

the LUTs and latches/FFs more or less independently,

allowing, for instance, a comparator function in the

LUTs simultaneously with a shift register in the FFs.

Page 9

Lucent Technologies Inc. 9

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-5752(F)a

Figure 2. PFU Ports

The PFU can be configured to operate in four modes: logic mode, half-logic mode, ripple mode, and memory (RAM/

ROM) mode. In addition, ripple mode has four submodes and RAM mode can be used in either a single- or dualport memory fashion. These submodes of operation are discussed in the following sections.

F5D

K7_0

K7_1

K7_2

K7_3

K6_0

K6_1

K6_2

K6_3

K5_0

K5_1

K5_2

K5_3

K4_0

K4_1

K4_2

K4_3

F5C

DIN7

DIN6

DIN5

DIN4

DIN3

DIN2

DIN1

DIN0

CIN

F5B

K3_0

K3_1

K3_2

K3_3

K2_0

K2_1

K2_2

K2_3

K1_0

K1_1

K1_2

K1_3

K0_0

K0_1

K0_2

K0_3

F5A

PROGRAMMABLE

FUNCTION UNIT

(PFU)

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

COUT

REGCOUT

F7

F6

F5

F4

F3

F2

F1

F0

SEL[0:1]CE[0:1]CLK[0:1]LSR[0:1]

LUT603

LUT647

Page 10

10 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-9714(F)

Note: All multiplexers without select inputs are configuration selector multiplexers.

Figure 3. Simplified PFU Diagram

K3_0MUX

K7_0MUX

D0

D1

SD

SP

CK

LSR

REG7

RESET

SET

Q7

F7

0

DIN7

DIN7MUX

D0

D1

SD

SP

CK

LSR

REG6

RESET

SET

Q6

F6

0

DIN6

DIN6MUX

D0

D1

SD

SP

CK

LSR

REG5

RESET

SET

Q5

F5

0

DIN5

DIN5MUX

D0

D1

SD

SP

CK

LSR

REG4

RESET

SET

Q4

F4

0

DIN4

DIN4MUX

LUT647

0

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

FSDMUX

K7_2MUX

K6_0MUX

K6_2MUX

AMUX

H7H6MUX

K7

K6

K5

K4

FSCMUX

H5H4MUX

LUT6MUX

F5D

K7_0

K7_1

K7_2

K7_3

K6_0

K6_1

K6_2

K6_3

K5_0

K5_1

K5_2

K5_3

K4_0

K4_1

K4_2

F5C

K4_3

D0

D1

SD

SP

CK

LSR

REG3

RESET

SET

Q3

F3

0

DIN3

DIN3MUX

D0

D1

SD

SP

CK

LSR

REG2

RESET

SET

Q2

F2

0

DIN2

DIN2MUX

D0

D1

SD

SP

CK

LSR

REG1

RESET

SET

Q1

F1

0

DIN1

DIN1MUX

D0

D1

SD

SP

CK

LSR

REG0

RESET

SET

DEL0

DEL1

DEL2

Q0

F0

0

DIN0

DIN0MUX

LUT603

0

A

B

C

D

A

B

C

D

A

B

C

D

A

B

C

D

FSBMUX

K3_2MUX

K2_0MUX

K2_2MUX

BMUX

H3H2MUX

K3

K2

K1

K0

F5AMUX

H1H0MUX

LUT6MUX

F5B

K3_0

K3_1

K3_2

K3_3

K2_0

K2_1

K2_2

K2_3

K1_0

K1_1

K1_2

K1_3

K0_0

K0_1

K0_2

F5A

K0_3

0

CLK1

CLK1MUX

0

SEL1

SEL1MUX

1

CE1

CE1MUX

CE47MUX

0

LSR1

LSR1MUX

LSR47MUX

0

CIN

1

0

0

CLK0

CLK0MUX

0

SEL0

SEL0MUX

1

CE0

CE0MUX

CEBMUX

0

LSR0

LSR0MUX

CE03MUX

1

0

LSRBMUX

LSR03MUX

1

0

D0

SP

CK

LSR

REG8

RESET

SET

RECCOUT

COUT

SR1MODEATTR

SR1MODE

CE1_OVER_LSR1

LSR1_OVER_CE1

RSYNC1

SR0MODEATTR

SR0MODE

CE0_OVER_LSR0

LSR0_OVER_CE0

ASYNC0

REGMODE_TOP

FF

LATCH

REG 4 THROUGH 7

THIS IS ALWAYS A FLIPFLOP

REGMODE_BOT

FF

LATCH

REG 0 THROUGH 3

LOGIC

MLOGIC

RIPPLE

RAM

ROM

ENABLED

DISABLED

GSR

PFU MODES

CINMUX

0

0

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

DEL0

DEL1

DEL2

DEL3

Page 11

Lucent Technologies Inc. 11

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

Look-Up Table Operatin g Modes

The operating mode affects the functionality of the PFU input and output ports and internal PFU routing. For example, in some operating modes, the DIN[7:0] inputs are direct data inputs to the PFU latches/FFs. In memory mode,

the same DIN[7:0] inputs are used as a 4-bit write data input bus and a 4-bit write address input bus

into LUT memory.

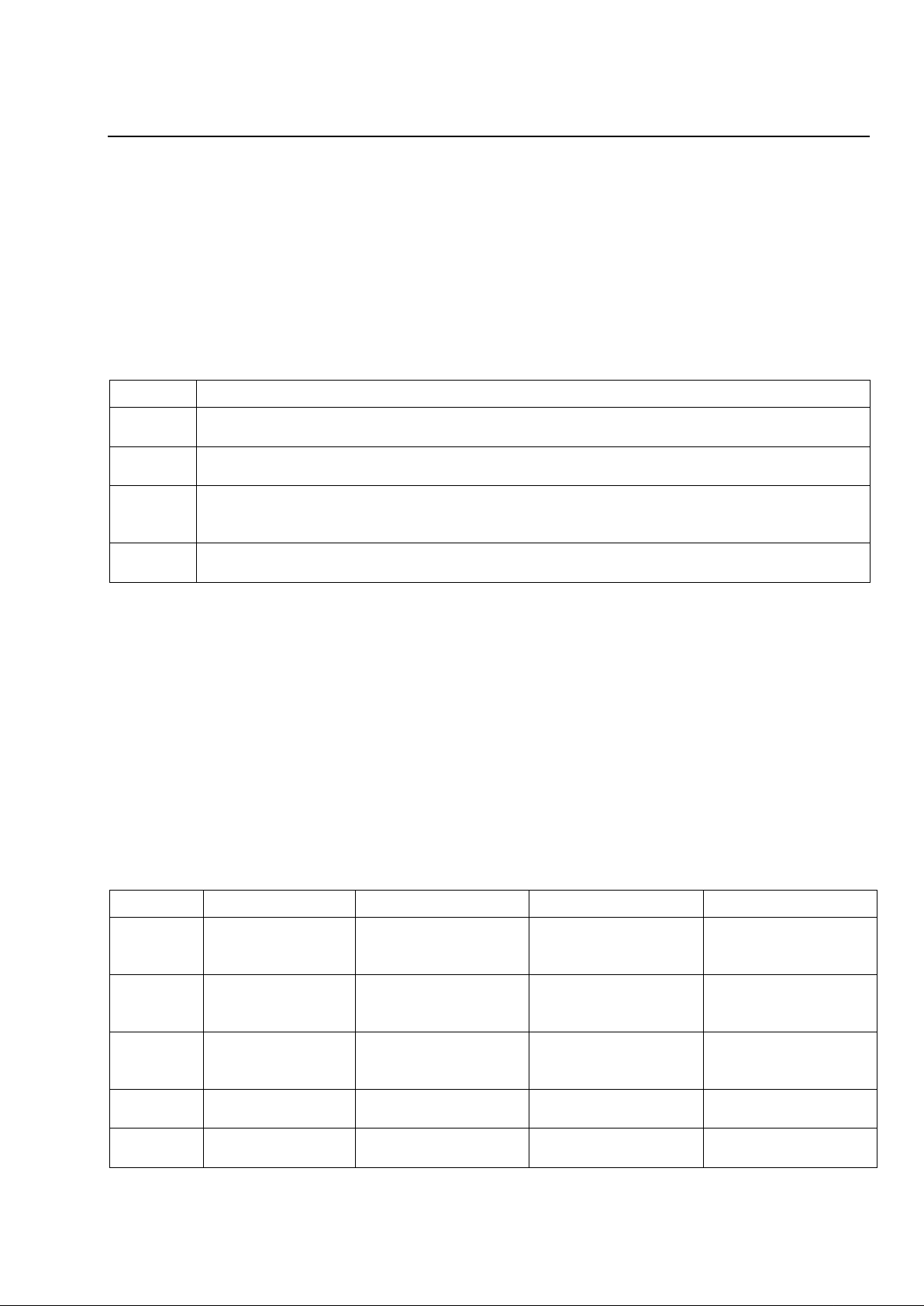

Table 3 lists the basic operating modes of the LUT. Figure 4—Figure 7 show block diagrams of the LUT operating

modes. The accompanying descriptions demonstrate each mode’s use for generating logic.

Table 3. Look-Up Table Operating Modes

PFU Control Inputs

Each PFU has eight routable control inputs and an active-low, asynchronous global set/reset (GSRN) signal that

affects all latches and FFs in the device. The eight control inputs are CLK[1:0], LSR[1:0], CE[1:0], and SEL[1:0],

and their functionality for each logic mode of the PFU is shown in Table 4. The clock signal to the PFU is CLK, CE

stands for clock enable, which is its primary function. LSR is the local set/reset signal that can be configured as synchronous or asynchronous. The selection of set or reset is made for each latch/FF and is not a function of the signal

itself. SEL is used to dynamically select between direct PFU input and LUT output data as the input to

the latches/FFs.

All of the control signals can be disabled and/or inverted via the configuration logic. A disabled clock enable

indicates that the clock is always enabled. A disabled LSR indicates that the latch/FF never sets/resets (except from

GSRN). A disabled SEL input indicates that DIN[7:0] PFU inputs or the LUT outputs are always input to the latches/

FFs.

Table 4. Control Input Functionality

Mode Function

Logic 4-, 5-, and 6-input LUTs; softwired LUTs; latches/FFs with direct input or LUT input; CIN as direct

input to ninth FF or as pass through to COUT.

Half Logic/

Half Ripple

Upper four LUTs and latches/FFs in logic mode; lower four LUTs and latches/FFs in ripple mode;

CIN and ninth FF for logic or ripple functions.

Ripple All LUTs combined to perform ripple-through data functions. Eight LUT registers available for

direct-in use or to register ripple output. Ninth FF dedicated to ripple out, if used. The submodes of

ripple mode are adder/subtractor, counter, multiplier, and comparator.

Memory All LUTs and latches/FFs used to create a 32x4 synchronous dual-port RAM. Can be used as

single-port or as ROM.

Mode CLK[1:0] LSR[1:0] CE[1:0] SEL[1:0]

Logic CLK to all latches/

FFs

LSR to all latches/FFs,

enabled per nibble and

for ninth FF

CE to all latches/FFs,

selectable per nibble

and for ninth FF

Select between LUT

input and direct input for

eight latches/FFs

Half Logic/

Half Ripple

CLK to all latches/

FFs

LSR to all latches/FF,

enabled per nibble and

for ninth FF

CE to all latches/FFs,

selectable per nibble

and for ninth FF

Select between LUT

input and direct input for

eight latches/FFs

Ripple CLK to all latches/

FFs

LSR to all latches/FFs,

enabled per nibble and

for ninth FF

CE to all latches/FFs,

selectable per nibble

and for ninth FF

Select between LUT

input and direct input for

eight latches/FFs

Memory

(RAM)

CLK to RAM LSR0 port enable 2 CE1 RAM write enable

CE0 Port enable 1

Not used

Memory

(ROM)

Optional for

synchronous outputs

Not used Not used Not used

Page 12

12 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

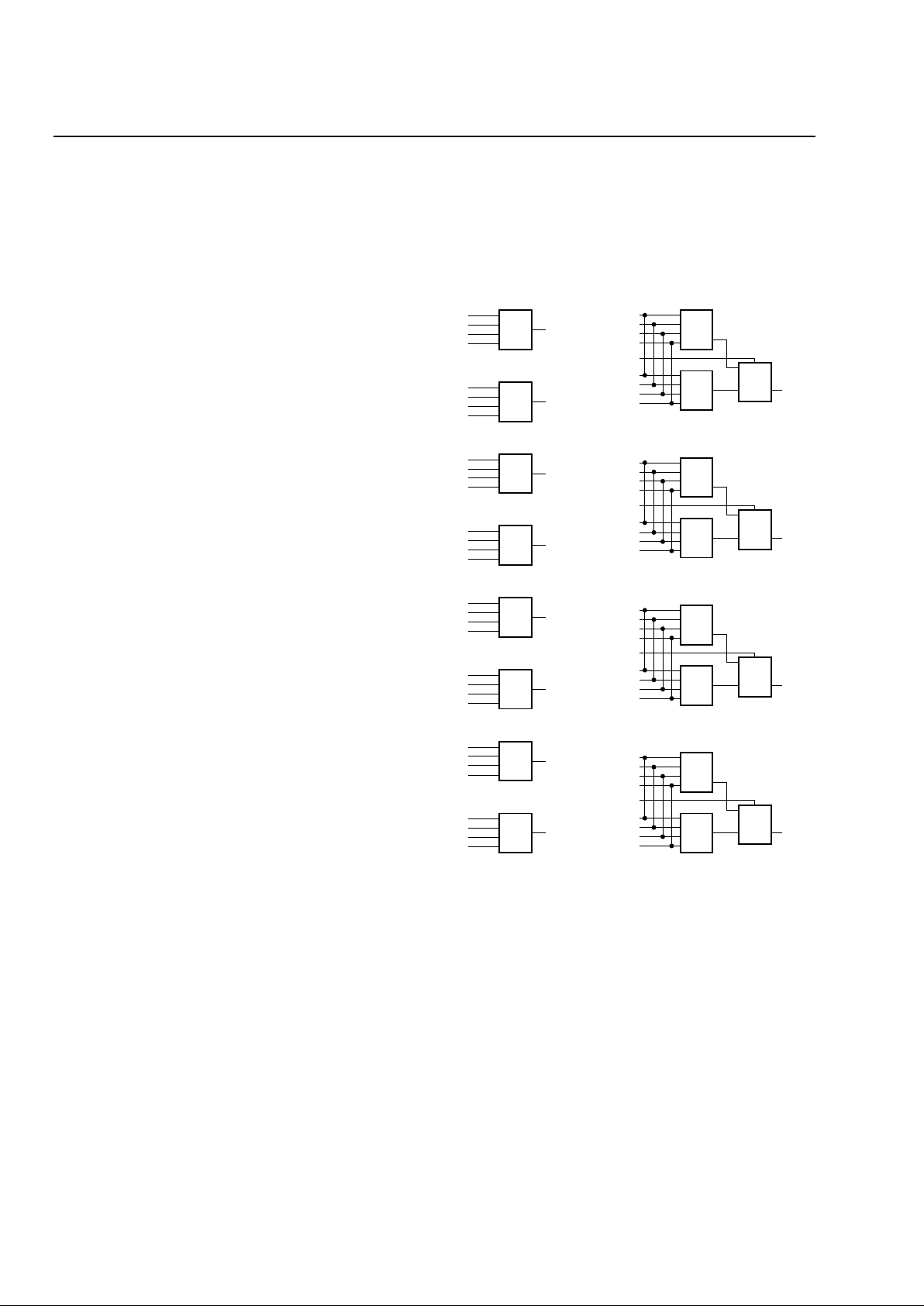

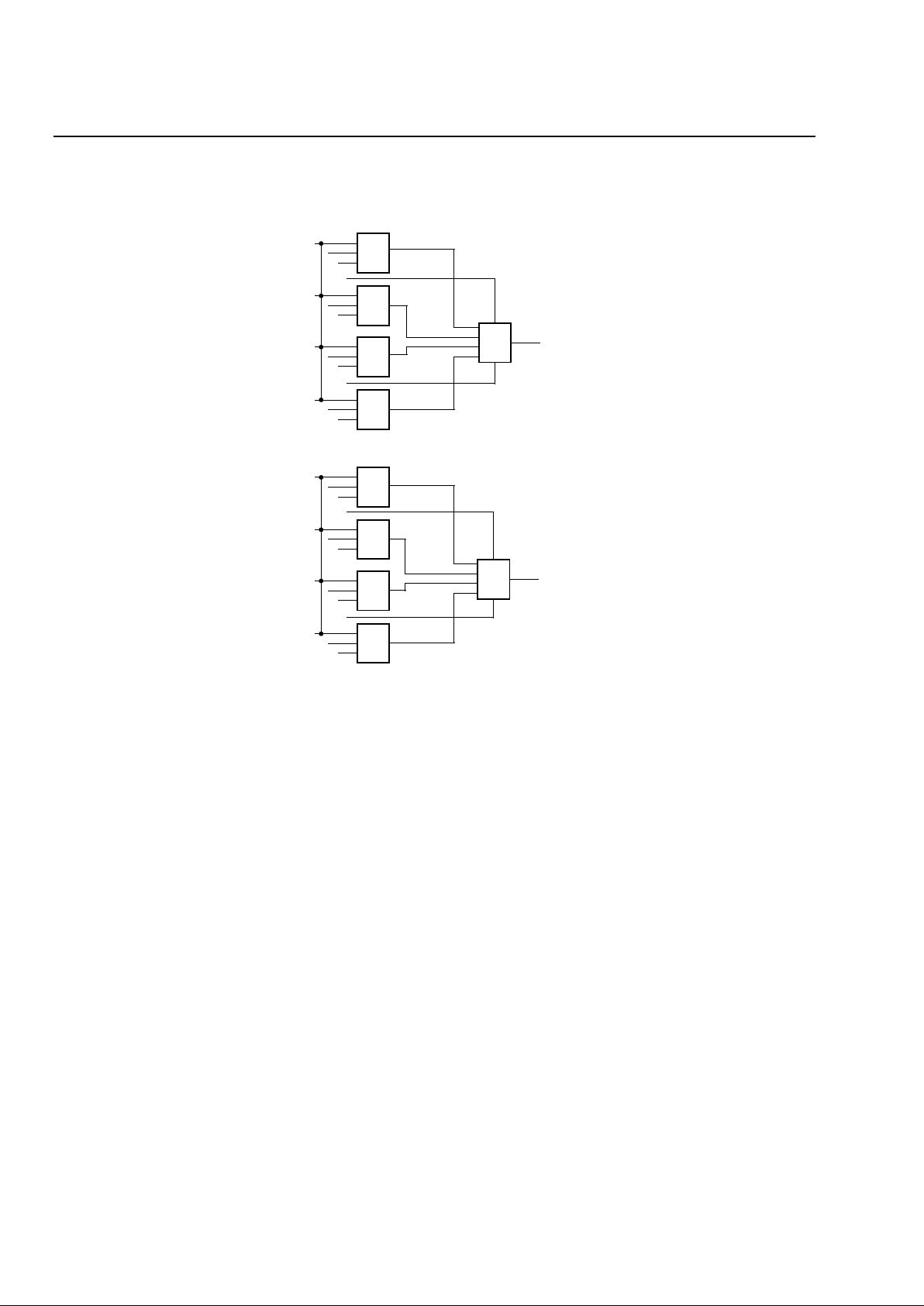

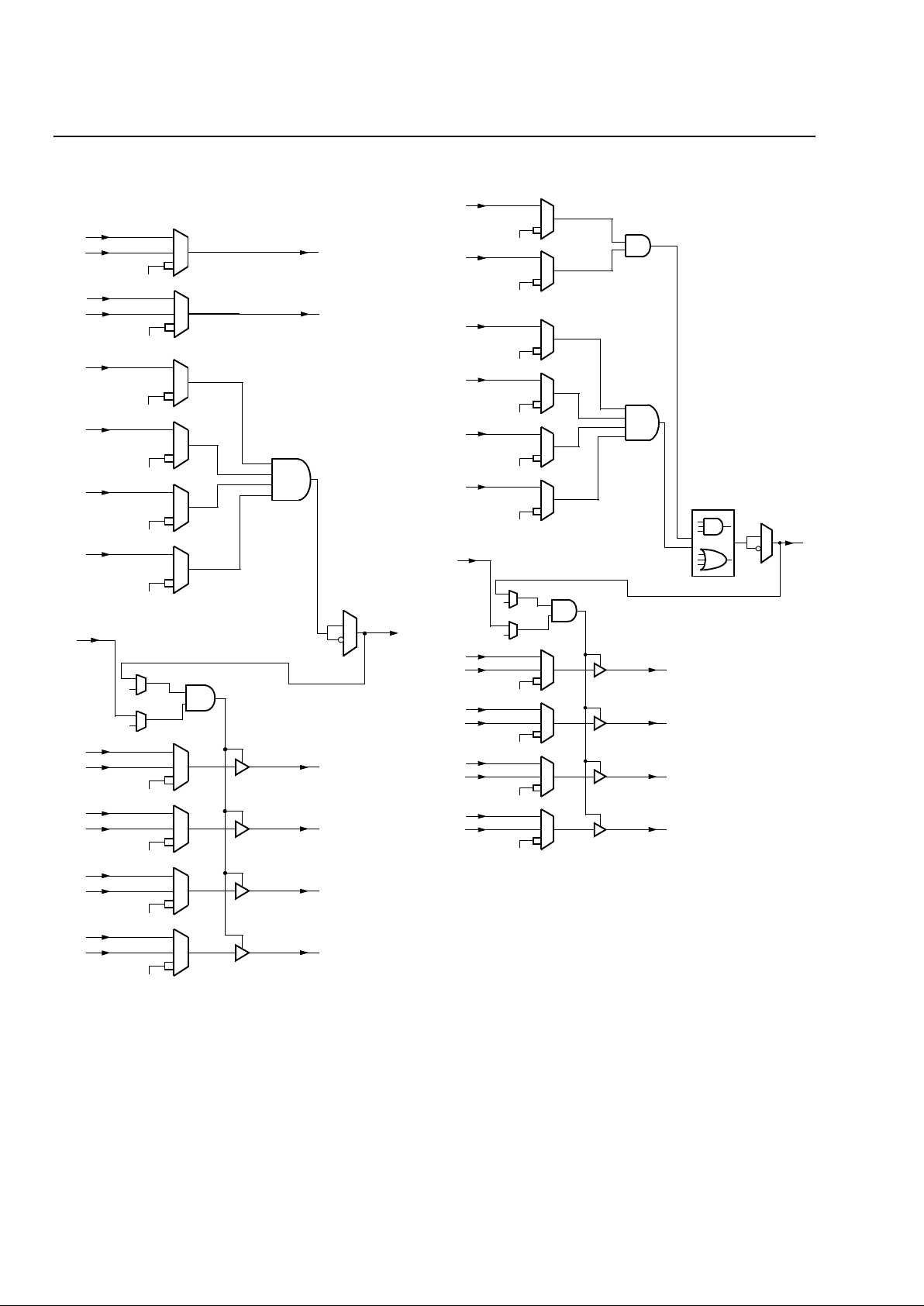

Logic Mode

The PFU diagram of Figure 3 represents the logic

mode of operation. In logic mode, the eight LUTs are

used individually or in flexible groups to implement user

logic functions. The latches/FFs may be used in conjunction with the LUTs or separately with the direct

PFU data inputs. There are three basic submodes of

LUT operation in PFU logic mode: F4 mode, F5 mode,

and the F6 mode. Combinations of the submodes are

possible in each PFU.

F4 mode, shown simplified in Figure 4, illustrates the

uses of the basic 4-input LUTs in the PFU. The output

of an F4 LUT can be passed out of the PFU, captured

at the LUTs associated latch/FF, or multiplexed with the

adjacent F4 LUT output using one of the F5[A:D] inputs

to the PFU (not shown). Only adjacent LUT pairs (K

0

and K

1

, K2 and K3, K4 and K5, K6 and K7) can be multiplexed, and the output always goes to the even-numbered output of the pair.

The F5 submode of the LUT operation, shown simplified in Figure 4, indicates the use of 5-input LUTs to

implement logic. 5-input LUTs are created from two

4-input LUTs and a multiplexer. The F5 LUT is the

same as the multiplexing of two F4 LUTs described

previously with the constraint that the inputs to both F4

LUTs be the same. The F5[A:D] input is then used as

the fifth LUT input. The equations for the two F4 LUTs

will differ by the assumed value for the F5[A:D] input,

one F4 LUT assuming that the F5[A:D] input is zero,

and the other assuming it is a one. The selection of the

appropriate F4 LUT output in the F5 MUX by the

F5[A:D] signal creates a 5-input LUT.

Two 6-input LUTs are created by shorting together the

inputs of four 4-input LUTs (K0:3 and K4:7) which are

multiplexed together. The F5 inputs of the adjacent F4

LUTs derive the fifth and sixth inputs of the F6 mode as

shown in Figure 5. The F6 outputs, LUT603 and

LUT647, are dedicated to the F6 mode or can be used

as the outputs of MUX8x1. MUX8x1 modes as shown

in Figure 7 are created by programming adjacent

4-input LUTs to 2x1 MUXs and multiplexing down to

create MUX8x1. Other functions can be implemented

from the configuration shown in Figure 5 where the four

LUT4s drive the 4x1 MUX in each half of the PFU if the

LUT4 inputs are not tied to the same inputs. Both F6

mode and MUX8x1 are available in the upper and

lower PFU nibbles.

Any combination of F4 and F5 LUTs is allowed per

PFU using the eight 16-bit LUTs. Examples are eight

F4 LUTs, four F5 LUTs, a combination of four F4 plus

two F5 LUTs, a combination of two F4, one F5, plus

one F6, or a combination of one F5, one MUX21 of two

LUT4s, and one MUX41 of four LUT4s.

5-9733(F)

Figure 4. Simplified F4 and F5 Logic Modes

K7_0

K7_1

K7_2

F5D

LUT4

LUT4

2x1

MUX

F6

K7_3

K6_0

K6_1

K6_2

K6_3

K5_0

K5_1

K5_2

F5C

LUT4

LUT4

2x1

MUX

F4

K5_3

K4_0

K4_1

K4_2

K4_3

K3_0

K3_1

K3_2

F5B

LUT4

LUT4

2x1

MUX

F2

K3_3

K2_0

K2_1

K2_2

K2_3

K1_0

K1_1

K1_2

F5A

LUT4

LUT4

2x1

MUX

F0

K1_3

K0_0

K0_1

K0_2

K0_3

K7 F7

K6 F6

K5 F5

K4 F4

K3 F3

K2 F2

K1 F1

K0 F0

Page 13

Lucent Technologies Inc. 13

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-9734(F)a

Figure 5. Simplified F6 Logic Modes

5-9735(F)

Figure 6. MUX 4x1

K7_0

K7_1

K7_2

K7_3

K6_0

K6_1

K6_2

K6_3

K5_0

K5_1

K5_2

K5_3

K4_0

K4_1

K4_2

K4_3

F5D

F5C

LUT4

LUT4

LUT4

LUT4

4x1

MUX

K3_0

K3_1

K3_2

K3_3

K2_0

K2_1

K2_2

K2_3

K1_0

K1_1

K1_2

K1_3

K0_0

K0_1

K0_2

K0_3

F5B

F5A

LUT4

LUT4

LUT4

LUT4

LUT603

4x1

MUX

LUT647

K7_0

K7_1

K7_2

F5D

LUT4

LUT4

2x1

MUX

K6_0

K6_1

K6_2

F4

K5_0

K5_1

K5_2

F5C

LUT4

LUT4

2x1

MUX

K4_0

K4_1

K4_2

F3

K3_0

K3_1

K3_2

F5B

LUT4

LUT4

2x1

MUX

K2_0

K2_1

K2_2

F2

K1_0

K1_1

K1_2

F5A

LUT4

LUT4

2x1

MUX

K0_0

K0_1

K0_2

F0

Page 14

14 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-9736(F)a

Figure 7. MUX 8x1

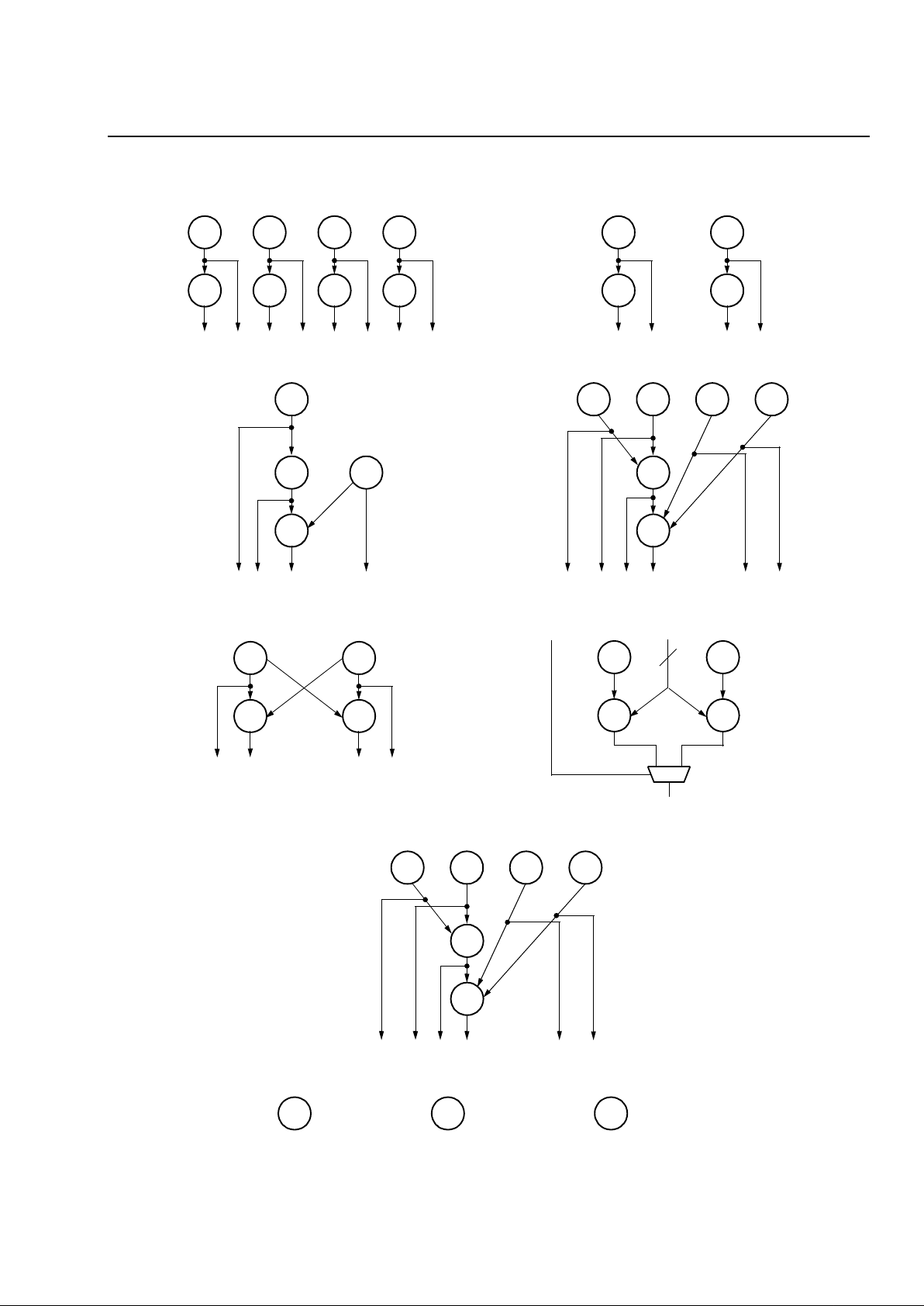

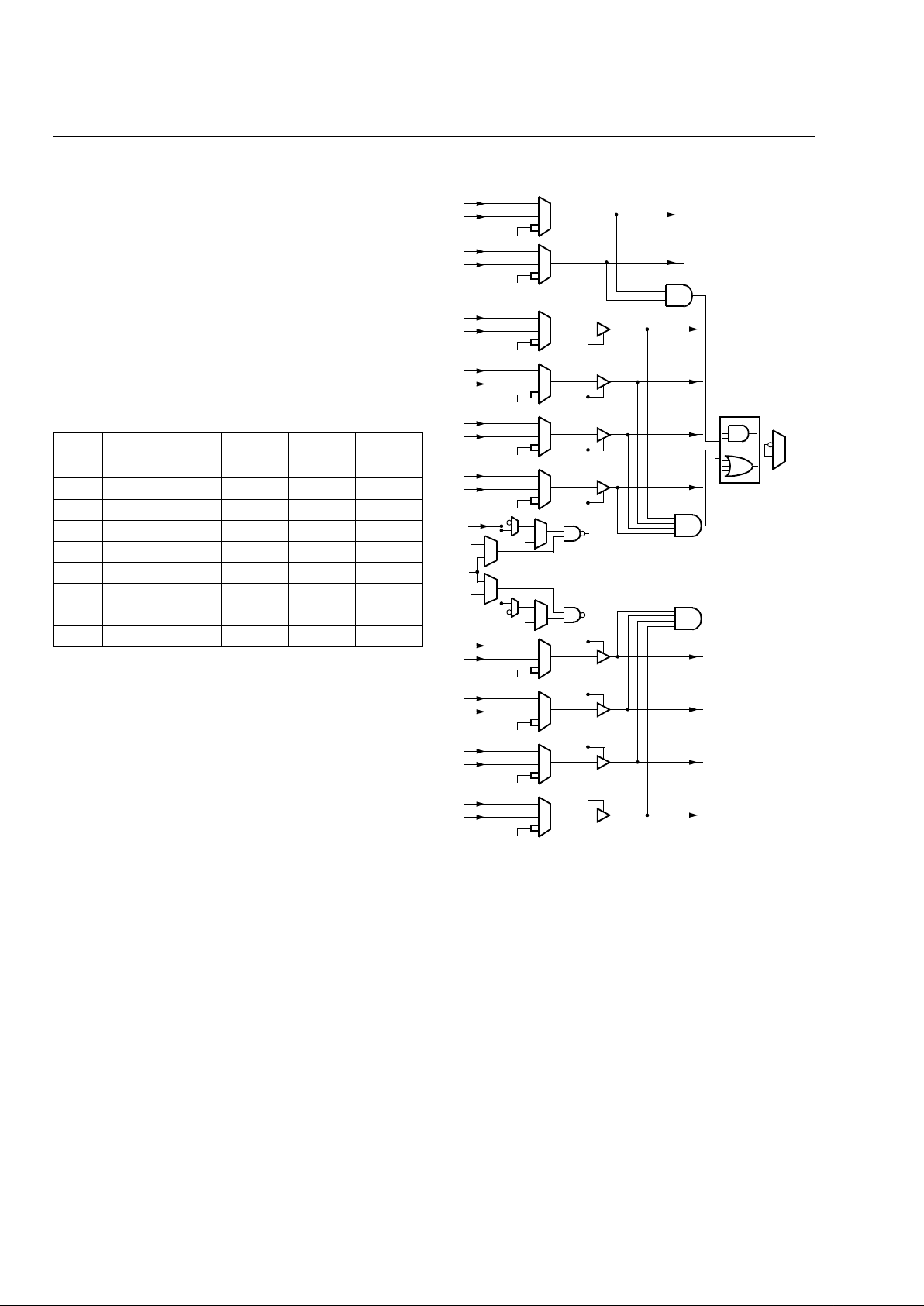

Softwired LUT capability uses F4, F5, and F6 LUTs, along with MUX21 and MUX41 blocks together with internal

PFU feedback routing, to generate complex logic functions up to three LUT levels deep. Multiplexers can be independently configured to route certain LUT outputs to the input of other LUTs. In this manner, very complex logic

functions, some of up to 22 inputs, can be implemented in a single PFU at greatly enhanced speeds.

It is important to note that an LUT output that is fed back for softwired use is still available to be registered or output

from the PFU. This means, for instance, that a logic equation that is needed by itself and as a term in a larger equation need only be generated once, and PLC routing resources will not be required to use it in the larger equation.

K7_0

K7_1

K7_2

F5D

LUT4

LUT4

K6_0

K6_1

K6_2

LUT4

LUT4

K5_0

K5_1

K5_2

K4_0

K4_1

K4_2

F5C

LUT4

K3_0

K3_1

K3_2

F5B

LUT4

LUT4

K2_0

K2_1

K2_2

LUT4

LUT4

K1_0

K1_1

K1_2

K0_0

K0_1

K0_2

F5A

LUT4

MUX8x1

4x1

MUX

4x1

MUX

[LUT647]

MUX8x1

[LUT603]

Page 15

Lucent Technologies Inc. 15

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

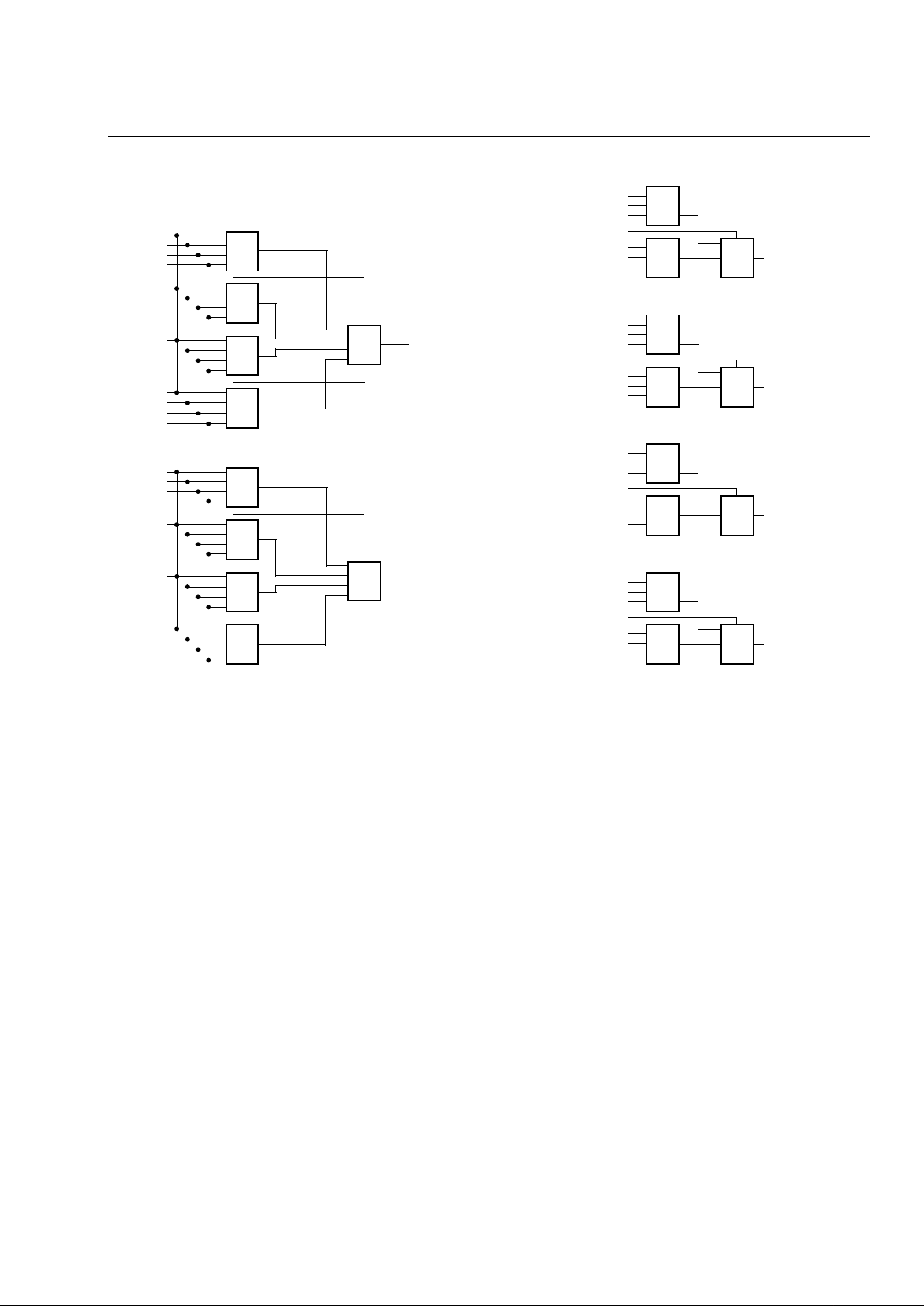

5-5753 (F)

5-5754 (F)

Figure 8. Softwired LUT Topology Examples

F4

F4

F4

F4

F4

F4

F4

F4

FOUR 7-INPUT FUNCTIONS IN ONE PFU

F5

F5

F5

F5

TWO 9-INPUT FUNCTIONS IN ONE PFU

F5

F5

F5

F5

ONE 17-INPUT FUNCTION IN ONE PFU

F5

F5

F4

ONE 21-INPUT FUNCTION IN ONE PFU

F4 F4 F4

F4

F4

F4

F4

TWO 10-INPUT FUNCTIONS IN ONE PFU

F4

F4

F4

F4

3

ONE OF TWO 21-INPUT FUNCTIONS IN ONE PFU

ONE 22-INPUT FUNCTION IN ONE PFU

F5

F6

F4F4 F4 F4

F4 F54-INPUT LUT 5-INPUT LUT F6

6-INPUT LUT

Page 16

16 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

Half-Logic Mode

Series 4 FPGAs are based upon a twin-quad architecture in the PFUs. The bytewide nature (eight LUTs,

eight latches/FFs) may just as easily be viewed as two

nibbles (two sets of four LUTs, four latches/FFs). The

two nibbles of the PFU are organized so that any nibblewide feature (excluding some softwired LUT topologies) can be swapped with any other nibblewide f eature

in another PFU. This provides for very flexible use of

logic and for extremely flexible routing. The half-logic

mode of the PFU takes advantage of the twin-quad

architecture and allows half of a PFU, K

[7:4]

and associated latches/FFs, to be used in logic mode while the

other half of the PFU, K

[3:0]

and associated

latches/FFs, is used in ripple mode. In half-logic mode,

the ninth FF may be used as a general-purpose FF or

as a register in the ripple mode carry chain.

Ripple Mode

The PFU LUTs can be combined to do bytewide ripple

functions with high-speed carry logic. Each LUT has a

dedicated carry-out net to route the carry to/from any

adjacent LUT. Using the internal carry circuits, fast

arithmetic, counter, and comparison functions can be

implemented in one PFU. Similarly, each PFU has

carry-in (CIN, FCIN) and carry-out (COUT, FCOUT)

ports for fast-carry routing between adjacent PFUs.

The ripple mode is generally used in operations on two

data buses. A single PFU can support an 8-bit ripple

function. Data buses of 4 bits and less can use the

nibblewide ripple chain that is available in half-logic

mode. This nibblewide ripple chain is also useful for

longer ripple chains where the length modulo 8 is four

or less. For example, a 12-bit adder (12 modulo 8 = 4)

can be implemented in one PFU in ripple mode (8 bits)

and one PFU in half-logic mode (4 bits), freeing half of

a PFU for general logic mode functions.

Each LUT has two operands and a ripple (generally

carry) input, and provides a result and ripple (generally

carry) output. A single bit is rippled from the previous

LUT and is used as input into the current LUT. For LUT

K

0

, the ripple input is from the PFU CIN or FCIN port.

The CIN/FCIN data can come from either the fast-carry

routing (FCIN) or the PFU input (CIN), or it can be tied

to logic 1 or logic 0.

In the following discussions, the notations LUT K

7/K3

and F[7:0]/F[3:0]

are used to denote the LUT that provides the carry-out and the data outputs for full PFU

ripple operation (K

7

, F[7:0]) and half-logic ripple

operation (K

3

, F[3:0]), respectively. The ripple mode

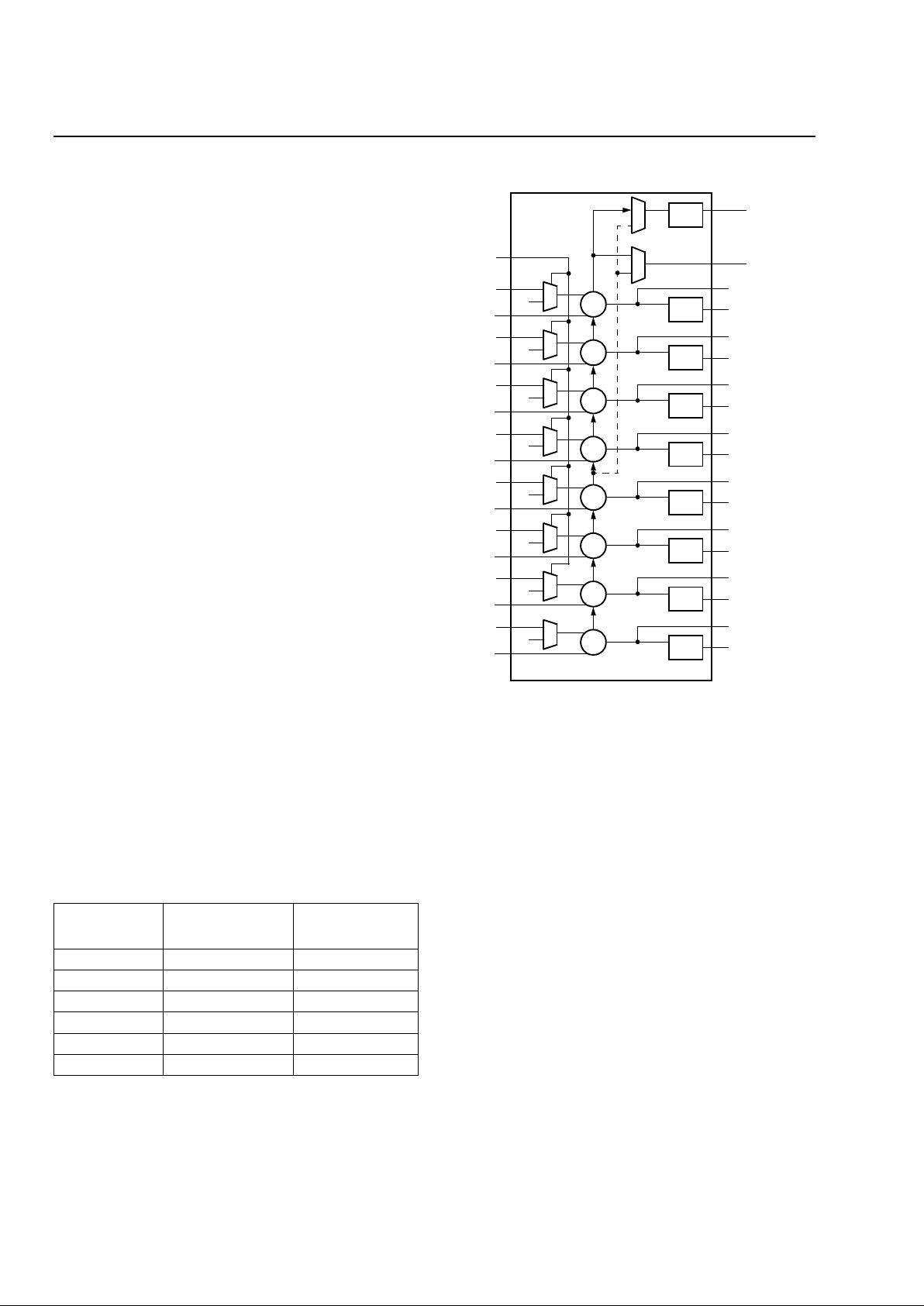

diagram (Figure 9) shows full PFU ripple operation,

with half-logic ripple connections shown as dashed

lines.

The result output and ripple output are calculated by

using generate/propagate circuitry. In ripple mode, the

two operands are input into K

Z

[1] and KZ[0] of each

LUT. The result bits, one per LUT , are F[7:0]/F[3:0]

(see

Figure 9). The ripple output from LUT K

7/K3

can be

routed on dedicated carry circuitry into any of four adjacent PLCs, and it can be placed on the PFU COUT/

FCOUT outputs. This allows the PLCs to be cascaded

in the ripple mode so that nibblewide ripple functions

can be expanded easily to any length.

Result outputs and the carry-out may optionally be registered within the PFU. The capability to register the

ripple results, including the carry output, provides for

improved counter performance and simplified pipelining in arithmetic functions.

5-5755(F).

Figure 9. Ripple Mode

F7

K

7

[1]

K

7

[0]

K7

DQ

C

C

DQ

Q7

REGOUT

COUT

F6

K

6

[1]

K

6

[0]

K6

DQ

Q6

F4

K

4

[1]

K

4

[0]

K4

DQ

Q4

F3

K

3

[1]

K

3

[0]

K3

DQ

Q3

F2

K

2

[1]

K

2

[0]

K2

DQ

Q2

F1

K

1

[1]

K

1

[0]

K1

DQ

Q1

F5

K

5

[1]

K

5

[0]

K5

DQ

Q5

F0

K

0

[1]

K

0

[0]

K0

DQ

Q0

IN/FCIN

FCOUT

Page 17

Lucent Technologies Inc. 17

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

The ripple mode can be used in one of four submodes.

The first of these is

adder-subtractor submode

. In

this submode, each LUT generates three separate outputs. One of the three outputs selects whether the

carry-in is to be propagated to the carry-out of the current LUT or if the carry-out needs to be generated. If

the carry-out needs to be generated, this is provided by

the second LUT output. The result of this selection is

placed on the carry-out signal, which is connected to

the next LUT carry-in or the COUT/FCOUT signal, if it

is the last LUT (K

7/K3

). Both of these outputs can be

any equation created from K

Z

[1] and KZ[0], but in this

case, they have been set to the propagate and generate functions.

The third LUT output cre ates th e result b it f or each LU T

output connected to F[7:0]/F[3:0]. If an adder/subtractor is needed, the control signal to select addition or

subtraction is input on F5A/F5C inputs. These inputs

generate the controller input AS. When AS = 0, this

function performs the adder, A + B. When AS = 1, the

function performs the subtractor, A – B. The result bit is

created in one-half of the LUT from a single bit from

each input bus K

Z

[1:0], along with the ripple input bit.

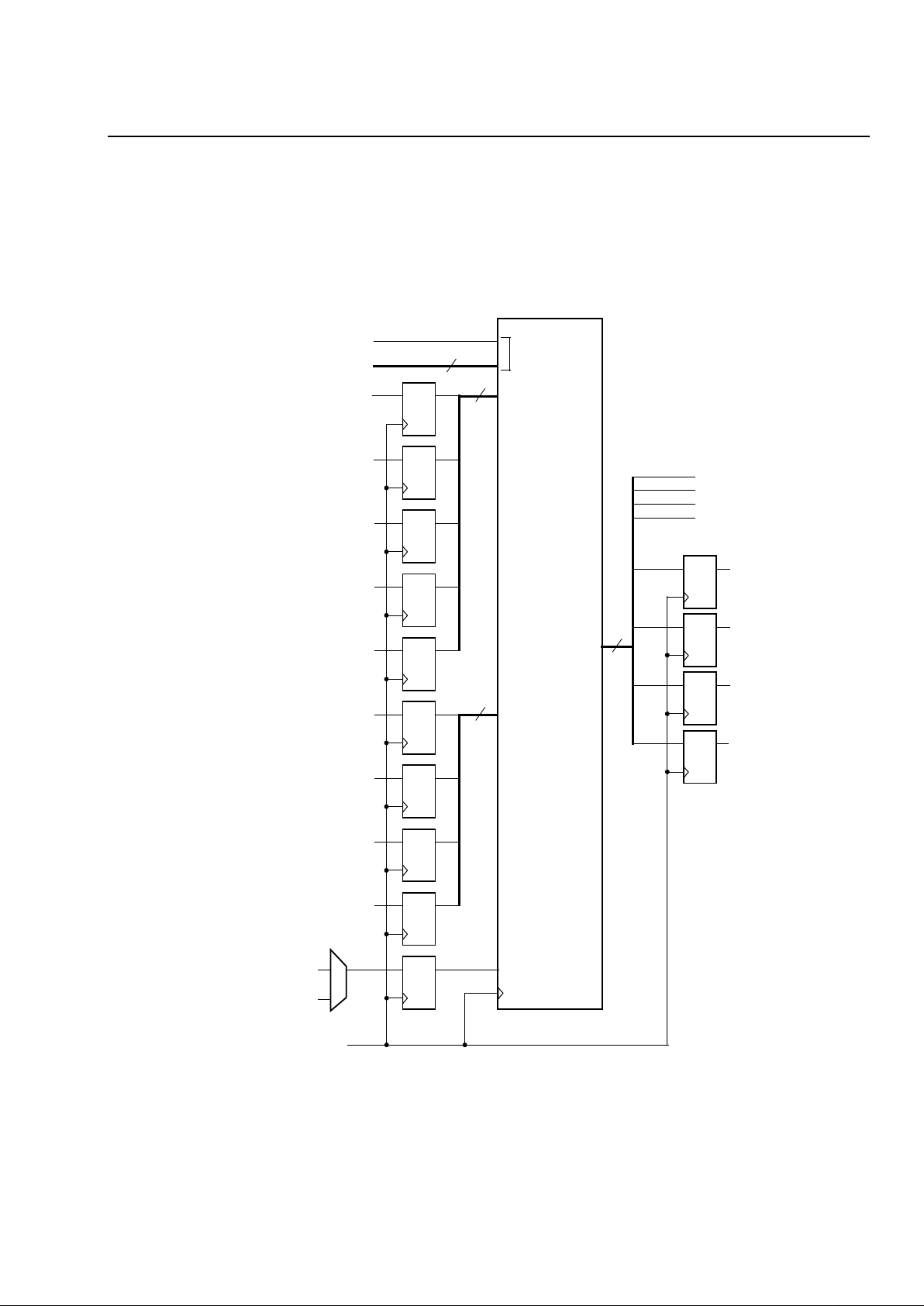

The second submode is the

counter submode

(see

Figure 10) . T he present count, wh ic h m ay be initia l ized

via the PFU DIN inputs to the latches/FFs, is supplied

to input K

Z

[0], and then output F[7:0]/F[3:0] will either

be incremented by one for an up counter or decremented by one for a down counter. If an up/down

counter is needed, the control signal to select the direction (up or down) is input on F5A and F5C. When

F5[A:C], respectively per nibble, is a logic 1, this indicates a down counter and a logic 0 indicates an up

counter.

5-5756(F)

Figure 10. Counter Submode

F7

K

7

[0]

K7

DQ

C

C

DQ

Q7

REGCOUT

COUT

F6

K

6

[0]

K6

DQ

Q6

F4

K

4

[0]

K4

DQ

Q4

F3

K

3

[0]

K3

DQ

Q3

F2

K

2

[0]

K2

DQ

Q2

F1

K

1

[0]

K1

DQ

Q1

F5

K

5

[0]

K5

DQ

Q5

F0

K

0

[0]

K0

DQ

Q0

CIN/FCIN

FCOUT

Page 18

18 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

In the third submode,

multiplier submode

, a single

PFU can affect an 8x1 bit (4x1 for half-ripple mode)

multiply and sum with a partial product (see Figure 11).

The multiplier bit is input at F5[A:C], respectively per

nibble, and the multiplicand bits are input at K

Z

[1],

where K

7

[1] is the most significant bit (MSB). KZ[0] contains the partial product (or other input to be summed)

from a previous stage. If F5[A:C] is logical 1, the multiplicand is added to the partial product. If F5[A:C] is logical 0, 0 is added to the partial product, which is the

same as passing the partial product. CIN/FCIN can

bring the carry-in from the less significant PFUs if the

multiplicand is wider than 8 bits, and COUT/FCOUT

holds any carry-out from the multiplication, which may

then be used as part of the product or routed to another

PFU in multiplier mode for multiplicand width expansion.

Ripple mode’s fourth submode features

equality

comparators

. The functions that are explicitly available

are A

≥

B, A

≠

B, and A ≤ B, where the value for A is

input on K

Z

[0], and the value for B is input on KZ[1]. A

value of 1 on the carry-out signals valid argument. For

example, a carry-out equal to 1 in AB submode indicates that the value on K

Z

[0] is greater than or equal to

the value on K

Z

[1]. Conversely, the functions A ≤ B,

A + B, and A > B are available using the same functions

but with a 0 output expected. For example, A

>

B with a

0 output i ndicates A

≤

B. Table 5 shows each function

and the output expected.

If larger than 8 bits, the carry-out signal can be cas-

caded using fast-carry logic to the carry-in of any adjacent PFU. The use of this submode could be shown

using Figure 9, except that the CIN/FCIN input for the

least significant PFU is controlled via configuration.

Table 5. Ripple Mode Equality Comparator

Functions and Outputs

5-5757(F)

Key: C = configuration data.

Note: F5[A:C] shorted together.

Figure 11. Multiplier Submode

Equality

Function

ORCA Foundry

Submode

True, if

Carry-Out Is:

A

≥

BA ≥ B1

A

≤

BA ≤ B1

A

≠

BA

≠

B1

A < B A > B 0

A > B A < B 0

A = B A ≠ B0

K7[1]

K7[0]

+

D

Q

C

C

DQ

1

00

K7

F5[A:C]

K4[1]

K4[0]

+

D

Q

1

00

K4

K3[1]

K3[0]

+

D

Q

1

00

K3

K2[1]

K2[0]

+

D

Q

1

00

K2

K1[1]

K1[0]

+

D

Q

1

00

K1

K6[1]

K6[0]

+

D

Q

1

00

K6

K5[1]

K5[0]

+

D

Q

1

00

K5

K0[1]

K0[0]

+

D

Q

1

00

K0

Q0

F0

Q1

F1

Q2

F2

Q3

F3

Q4

F4

Q5

F5

Q6

F6

Q7

F7

COUT

REGCOUT

Page 19

Lucent Technologies Inc. 19

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

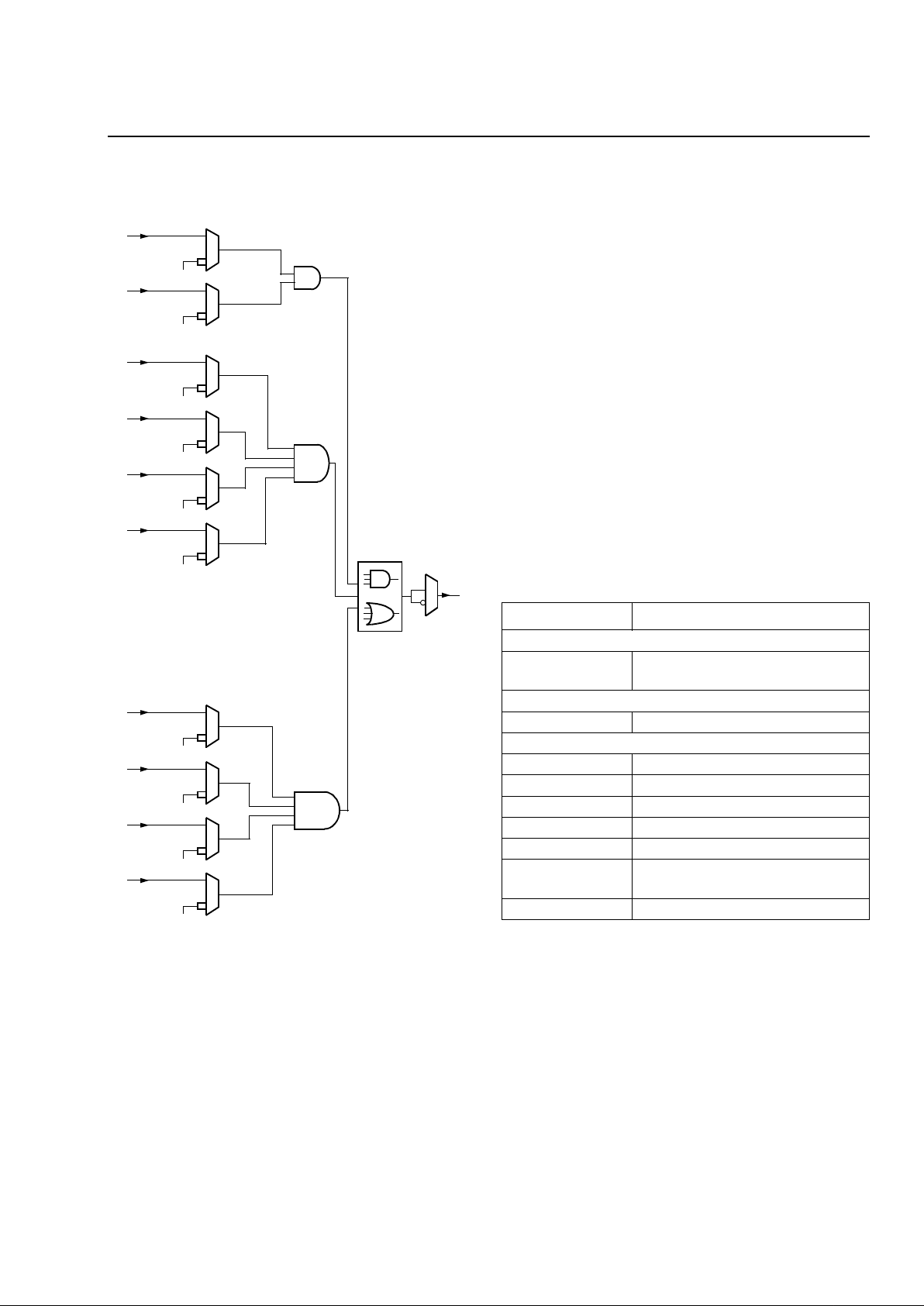

Memory Mode

The Series 4 PFU can be used to implement a 32 x 4 (128-bit) synchronous, dual-port RAM. A block diagram of a

PFU in memory mode is shown in Figure 12. This RAM can also be configured to work as a single-port memory

and because initial values can be loaded into the RAM during configuration, it can also be used as a ROM.

5-5969(F)a

1. CLK[0:1] are commonly connected in memory mode.

2. CE1 = write enable = wren; wren = 0 (no write enable); wren = 1 (write enabled).

CE0 = write port enable 0; CE0 = 0, wren = 0; CE0 = 1, wren = CE1.

LSR0 = write port enable 1; LSR0 = 0, wren = CE0; LSR0 = 1, wren = CE1.

Figure 12. Memory Mode

Q6

Q4

Q2

Q0

D5Q

CIN(WA1)

KZ[3:0]

4

F5[A:D]

D Q

DIN7(WA3)

D Q

DIN5(WA2)

D Q

DIN3(WA1)

D Q

DIN1(WA0)

D Q

DIN6(WD3)

D Q

DIN4(WD2)

D Q

DIN2(WD1)

D Q

DIN0(WD0)

D Q

CE0, LSR0

S/E

CLK[0:1]

4

WRITE

WRITE

READ

READ

4

F6

F4

F2

F0

D Q

D Q

D Q

D Q

WRITE

RAM CLOCK

ADDRESS[4:0]

ADDRESS[4:0]

DATA[3:0]

DATA[3:0]

ENABLE

(SEE NOTE 2.)

CE1

Page 20

20 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

The PFU memory mode uses all LUTs and latches/FFs

including the ninth FF in its implementation as shown in

Figure 12. The read address is input at the K

Z

[3:0] and

F5[A:D] inputs where K

Z

[0] is the LSB and F5[A:D] is

the MSB, and the write address is input on CIN (MSB)

and DIN[7, 5, 3, 1], with DIN[1] being the LSB. Write

data is input on DIN[6, 4, 2, 0], where DIN[6] is the

MSB, and read data is available combinatorially on

F[6, 4, 2, 0] and registered on Q[6, 4, 2, 0] with F[6] and

Q[6] being the MSB. The write enable controlling ports

are input on CE0, CE1, and LSR0. CE1 is the activehigh write enable (CE1 = 1, RAM is write enabled). The

first write port is enabled by CE0. The second write

port is enabled with LSR0. The PFU CLK (CLK0) signal

is used to synchronously write the data. The polarities

of the clock, write enable, and port enables are all programmable. Write-port enables may be disabled if they

are not to be used.

Data is written to the write data, write address, and

write enable registers on the active edge of the clock,

but data is not written into the RAM until the next clock

edge one-half cycle later. The read port is actually

asynchronous, providing the user with read data very

quickly after setting the read address, but timing is also

provided so that the read port may be treated as fully

synchronous for write then read applications. If the

read and write address lines are tied together (maintaining MSB to MSB, etc.), then the dual-port RAM

operates as a synchronous single-port RAM. If the

write enable is disabled, and an initial memory contents

are provided at configuration time, the memory acts as

a ROM (the write data and write address ports and

write port enables are not used).

Wider memories can be created by operating two or

more memory mode PFUs in parallel, all with the same

address and control signals, but each with a different

nibble of data. To increase memory word depth above

32, two or more PLCs can be used. Figure 10 shows a

128 x 8 dual-port RAM that is implemented in eight

PLCs. This figure demonstrates data path width expansion by placing two memories in parallel to achieve an

8-bit data path. Depth expansion is applied to achieve

128 words deep using the 32-word deep PFU memories. In addition to the PFU in each PLC, the SLIC

(described in the next section) in each PLC is used for

read address decodes and 3-state drivers. The 128 x 8

RAM shown could be made to operate as a single-port

RAM by tying (bit-for-bit) the read and write addresses.

To achieve depth expansion, one or two of the write

address bits (generally the MSBs) are routed to the

write port enables as in Figure 10. For 2 bits, the bits

select which 32-word bank of RAM of the four available

from a decode of two WPE inputs is to be written. Similarly, 2 bits of the read address are decoded in the

SLIC and are used to control the 3-state buffers

through which the read data passes. The write data

bus is common, with separate nibbles for width expansion, across all PLCs, and the read data bus is common (again, with separate nibbles) to all PLCs at the

output of the 3-state buffers.

Figure 13 also shows the capability to provide a read

enable for RAMs/ROMs using the SLIC cell. The read

enable will 3-state the read data bus when inactive,

allowing the write data and read data buses to be tied

together if desired.

Page 21

Preliminary Data Sheet

December 2000

Lucent Technologies Inc. 21

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-5749(F)

Figure 13. Memory Mode Expansion Example—128 x 8 RAM

RD[7:0]

WE

WA[6:0]

RA[6:0]

CLK

WA RA

WPE 1

WPE 2

WE

WD[7:4]

5 5

4

PLC

8

WD[7:0]

8

7

7

WA RA

WPE 1

WPE 2

WE

RD[3:0]

WD[3:0]

5 5

4

PLC

RD[7:4]

WA RA

WPE 1

WPE 2

WE

WD[7:4]

5 5

4

PLC

WA RA

WPE 1

WPE 2

WE

RD[3:0]

WD[3:0]

5 5

4

PLC

RD[7:4]

RE

RE

4

RE

4

RE

4

RE

4

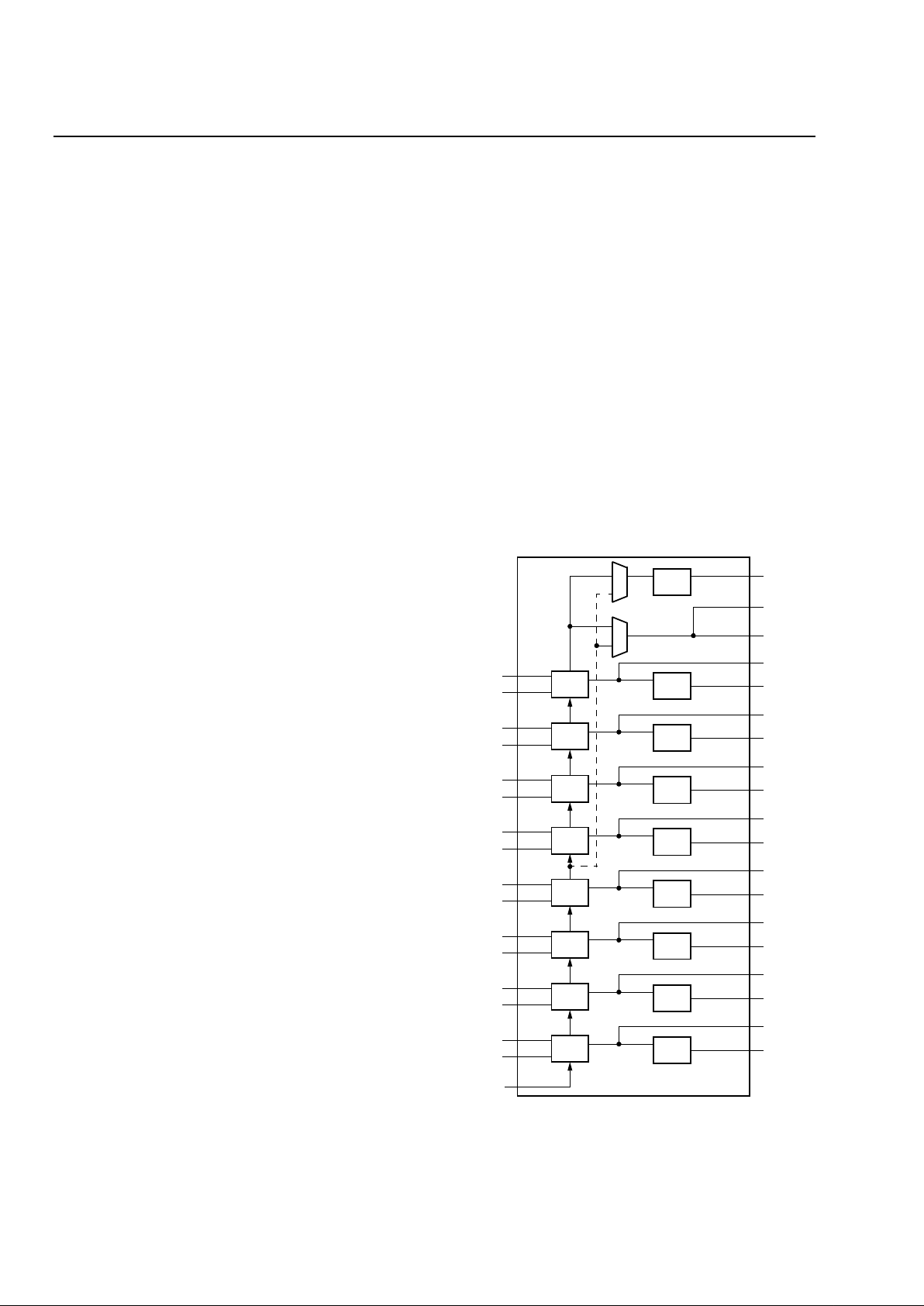

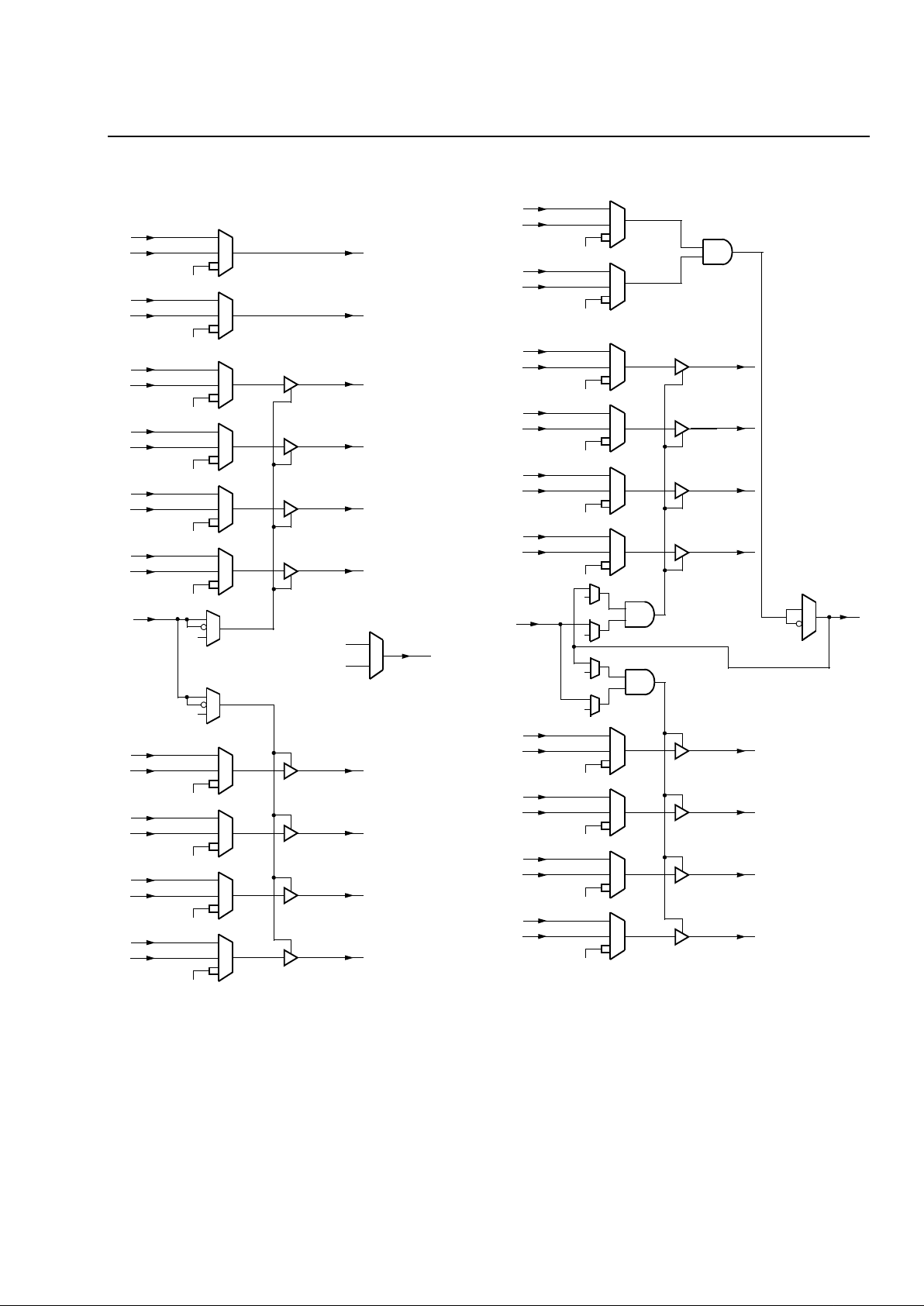

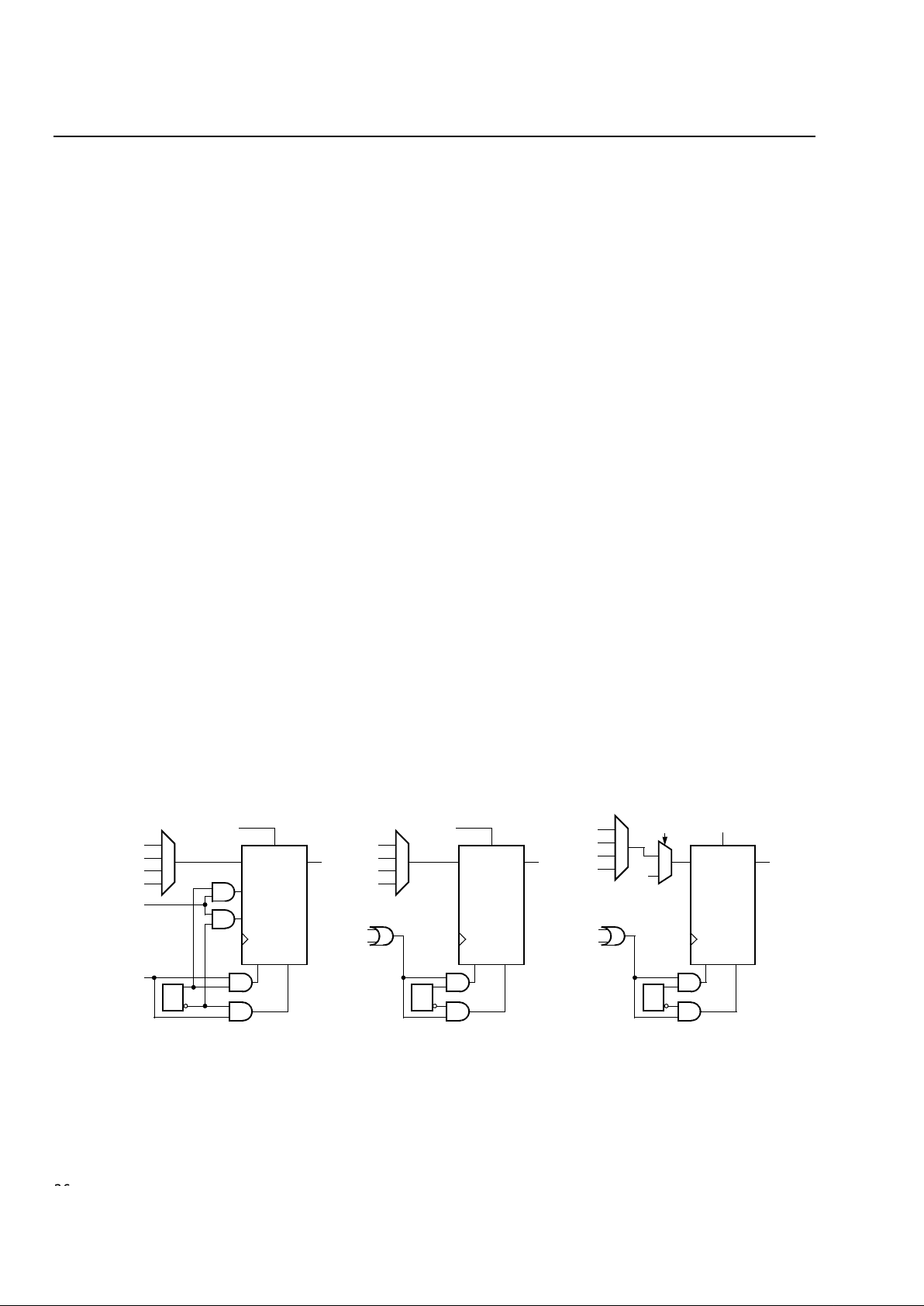

Supplemental Logic and Interconnect Cell

Each PLC contains a SLIC embedded within the PLC

routing, outside of the PFU. As its name indicates, the

SLIC performs both logic and interconnect (routing)

functions. Its main features are 3-statable, bidirectional

buffers, and a PAL-like decoder capability. Figure 14

shows a diagram of a SLIC with all of its features

shown. All modes of the SLIC are not available at one

time.

The ten SLIC inputs can be sourced directly from the

PFU or from the general routing fabric. SI[0:9] inputs

can come from the horizontal or vertical routing, and

I[0:9} comes from the PFU outputs O[9:0]. These

inputs can also be tied to a logical 1 or 0 constant. The

inputs are twin-quad in nature and are segregated into

two groups of four nibbles and a third group of two

inputs for control. Each input nibble groups also have

3-state capability; however, the third pair does not.

There is one 3-state control (TRI) for each SLIC, with

the capability to invert or disable the 3-state control for

each group of four BIDIs. Separate 3-state control for

each nibblewide group is achievable by using the

SLICs decoder (DEC) output, driven by the group of

two BIDIs, to control the 3-state of one BIDI nibble

while using the TRI signal to control the 3-state of the

other BIDI nibble. Figure 15

shows the SLIC in buffer

mode with available 3-state control from the TRI and

DEC signals. If the entire SLIC is acting in a buffer

capacity, the DEC output may be used to generate a

constant logic 1 (V

HI

) or logic 0 (VLO) signal for general

use.

The SLIC may also be used to generate PAL-like AND-

OR with optional INVERT (AOI) functions or a decoder

of up to 10 bits. Each group of buffers can feed into an

AND gate (4-input AND for the nibble groups and

2-input AND for the other two buffers). These AND

gates then feed into a 3-input gate that can be configured as either an AND gate or an OR gate. The output

of the 3-input gate is invertible and is output at the DEC

output of the SLIC. Figure 19 shows the SLIC in full

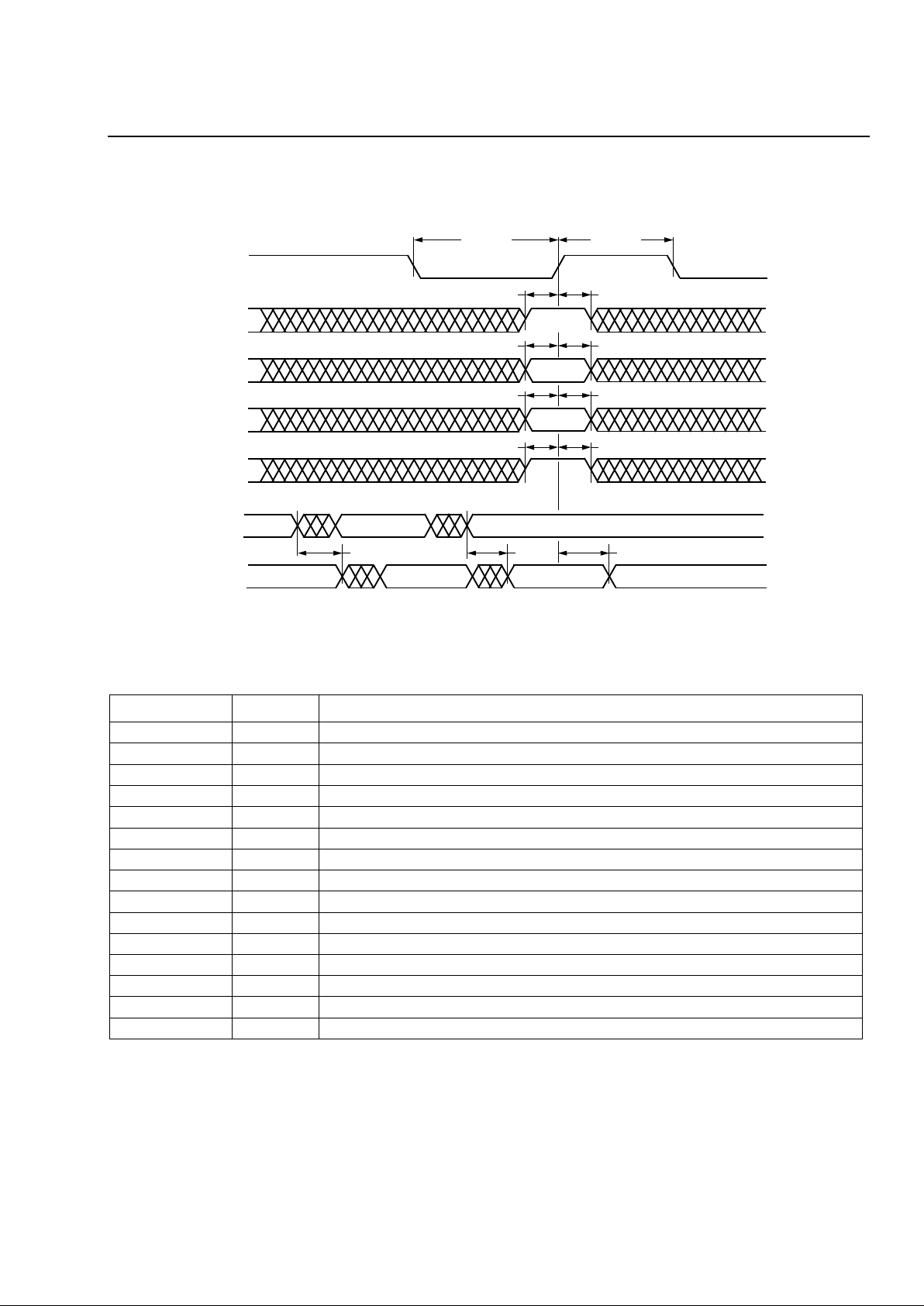

decoder mode.

The functionality of the SLIC is parsed by the two

nibblewide groups and the 2-bit buffer group. Each of

these groups may operate independently as BIDI buffers (with or without 3-state capability for the nibblewide

groups) or as a PAL/decoder.

Page 22

22 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

As discussed in the Memory Mode section on page 19,

if the SLIC is placed into one of the modes where it

contains both buffers and a decode or AOI function

(e.g., BUF_BUF_DEC mode), the DEC output can be

gated with the 3-state input signal. This allows up to a

6-input decode (e.g., BUF_DEC_DEC mode) plus the

3-state input to control the enable/disable of up to four

buffers per SLIC. Figure 15—Figure 19 show several

configurations of the SLIC, while Table 6 shows all of

the possible modes.

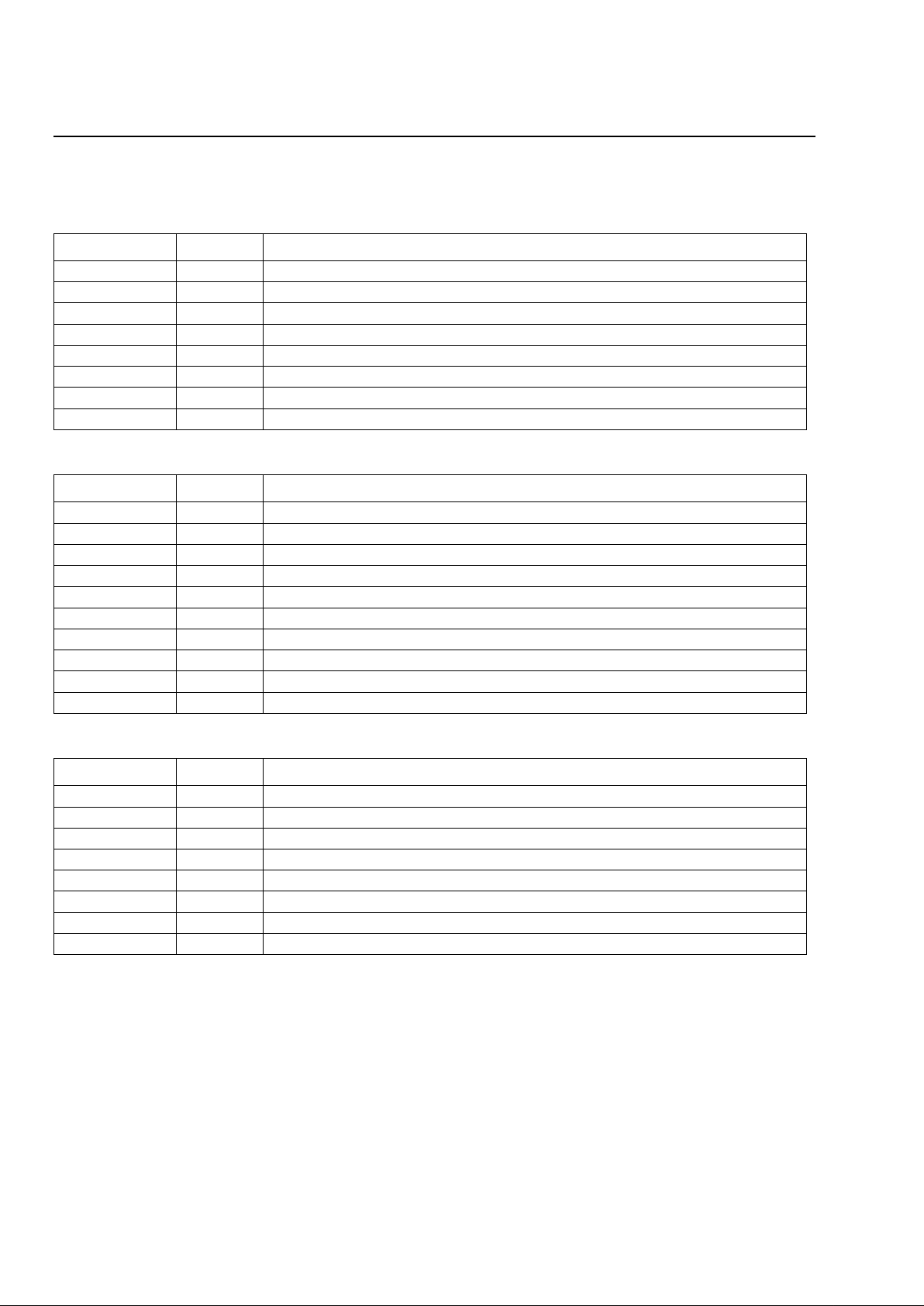

Table 6. SLIC Modes

5-5744(F).a.

Figure 14. SLIC All Modes Diagram

Mode

No.

Mode BUF

[3:0]

BUF

[7:4]

BUF

[9:8]

1 BUFFER Buffer Buffer Buffer

2 BUF_BUF_DEC Buffer Buffer Decoder

3 BUF_DEC_BUF Buffer Decoder Buffer

4

BUF_DEC_DEC

Buffer Decoder Decoder

5 DEC_BUF_BUF Decoder Buffer Buffer

6

DEC_BUF_DEC

Decoder Buffer Decoder

7

DEC_DEC_BUF

Decoder Decoder Buffer

8 DECODER Decoder Decoder Decoder

SIN9

I9

SOUT09

DEC

DEC

0/1

0/1

TRI

0/1

0/1

SOUT08

SOUT07

SOUT06

SOUT05

SOUT04

SOUT03

SOUT02

SOUT01

SOUT00

LOGIC 1 OR 0

SIN8

I8

LOGIC 1 OR 0

SIN7

I7

LOGIC 1 OR 0

SIN6

I6

LOGIC 1 OR 0

SIN5

I5

LOGIC 1 OR 0

SIN4

I4

LOGIC 1 OR 0

SIN3

I3

LOGIC 1 OR 0

SIN2

I2

LOGIC 1 OR 0

SIN1

I1

LOGIC 1 OR 0

SIN0

I0

LOGIC 1 OR 0

Page 23

Lucent Technologies Inc. 23

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

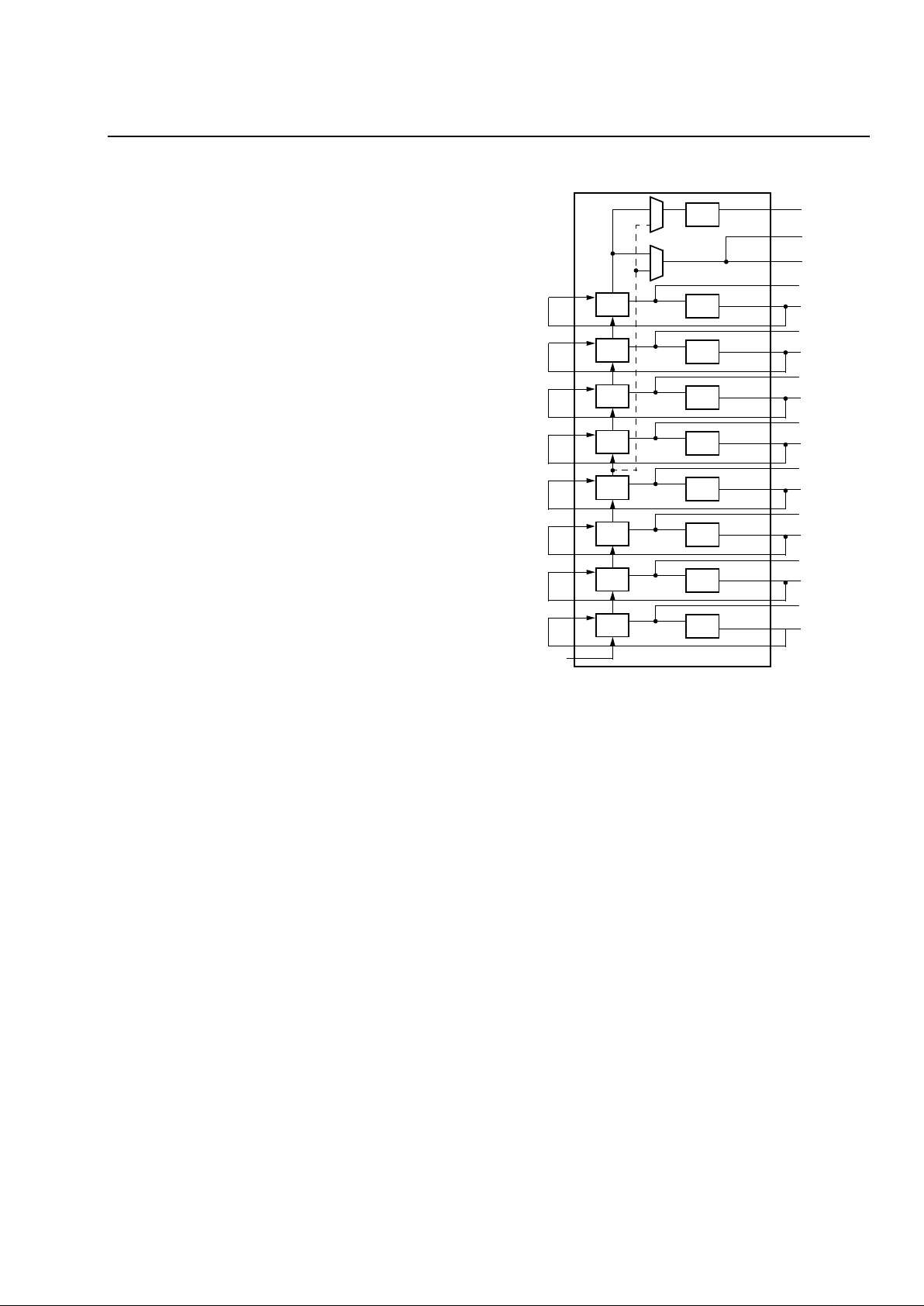

5-5745(F).a

Figure 15. Buffer Mode

5-5746(F).a

Figure 16. Buffer-Buffer-Decoder Mode

SOUT08

TRI

0/1

0/1

1

0

DEC

THIS CAN BE USED TO GENERATE

A V

HI

OR VLO.

SIN8

I8

LOGIC 1 OR 0

SOUT09

SIN9

I9

LOGIC 1 OR 0

SOUT07

SIN7

I7

LOGIC 1 OR 0

SOUT06

SIN6

I6

LOGIC 1 OR 0

SOUT05

SIN5

I5

LOGIC 1 OR 0

SOUT04

SIN4

I4

LOGIC 1 OR 0

SOUT03

SIN3

I3

LOGIC 1 OR 0

SOUT02

SIN2

I2

LOGIC 1 OR 0

SOUT01

SIN1

I1

LOGIC 1 OR 0

SOUT00

SIN0

I0

LOGIC 1 OR 0

TRI

DEC

1

1

1

1

SOUT07

SIN7

I7

LOGIC 1 OR 0

SOUT06

SIN6

I6

LOGIC 1 OR 0

SOUT05

SIN5

I5

LOGIC 1 OR 0

SOUT04

SIN4

I4

LOGIC 1 OR 0

SIN9

I9

LOGIC 1 OR 0

SIN8

I8

LOGIC 1 OR 0

SOUT03

SIN3

I3

LOGIC 1 OR 0

SOUT02

SIN2

I2

LOGIC 1 OR 0

SOUT01

SIN1

I1

LOGIC 1 OR 0

SOUT00

SIN0

I0

LOGIC 1 OR 0

Page 24

24 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-5747(F).a

Figure 17. Buffer-Decoder-Buffer Mode

5-5750(F).a

Figure 18. Buffer-Decoder-Decoder Mode

TRI

DEC

1

1

SOUT08

SIN8

I8

LOGIC 1 OR 0

SOUT09

SIN9

I9

LOGIC 1 OR 0

SIN7

LOGIC 1 OR 0

SIN6

LOGIC 1 OR 0

SIN5

LOGIC 1 OR 0

SIN4

LOGIC 1 OR 0

SOUT03

SIN3

I3

LOGIC 1 OR 0

SOUT02

SIN2

I2

LOGIC 1 OR 0

SOUT01

SIN1

I1

LOGIC 1 OR 0

SOUT00

SIN0

I0

LOGIC 1 OR 0

IF LOW, THEN 3-STATE BUFFERS ARE HIGH Z.

DEC

TRI

1

1

SIN7

LOGIC 1 OR 0

SIN6

LOGIC 1 OR 0

SIN5

LOGIC 1 OR 0

SIN4

LOGIC 1 OR 0

SOUT03

SIN3

I3

LOGIC 1 OR 0

SOUT02

SIN2

I2

LOGIC 1 OR 0

SOUT01

SIN1

I1

LOGIC 1 OR 0

SOUT00

SIN0

I0

LOGIC 1 OR 0

SIN9

LOGIC 1 OR 0

SIN8

LOGIC 1 OR 0

Page 25

Lucent Technologies Inc. 25

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

5-5748(F)

Figure 19. Decoder Mode

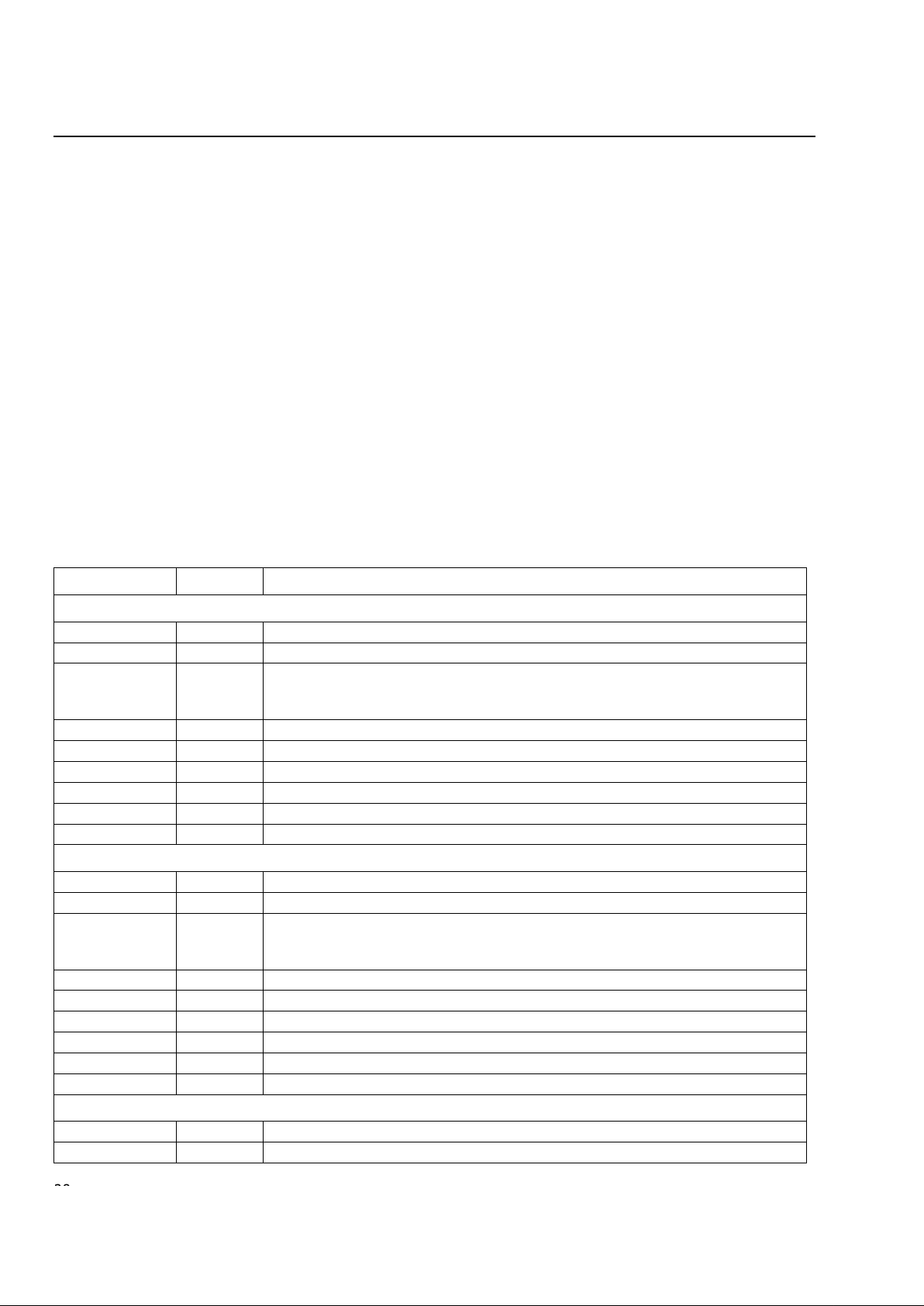

PLC Latches/Flip-Flops

The eight general-purpose latches/FFs in the PFU can

be used in a variety of configurations. In some cases,

the configuration options apply to all eight latches/FFs

in the PFU and some apply to the latches/FFs on a nibblewide basis where the ninth FF is considered independently. For other options, each latch/FF is

independently programmable. In addition, the ninth FF

can be used for a variety of functions.

Table 7 summarizes these latch/FF options. The

latches/FFs can be configured as either positive- or

negative-level sensitive latches, or positive or negative

edge-triggered FFs (the ninth register can only be a

FF). All latches/FFs in a given nibble of a PFU share

the same clock, and the clock to these latches/FFs can

be inverted. The input into each latch/FF is from either

the corresponding LUT output (F[7:0]) or the direct data

input (DIN[7:0]). The latch/FF input can also be tied to

logic 1 or to logic 0, which is the default.

Table 7. Configuration RAM Controlled Latch/

Flip-Flop Operation

* Not available for FF[8].

Each PFU has two independent programmable clocks,

clock enable CE[1:0], local set/reset LSR[1:0], and

front-end data selects SEL[1:0]. When CE is disabled,

each latch/FF retains its previous value when clocked.

The clock enable, LSR, and SEL inputs can be inverted

to be active-low.

DEC

SIN7

LOGIC 1 OR 0

SIN6

LOGIC 1 OR 0

SIN5

LOGIC 1 OR 0

SIN4

LOGIC 1 OR 0

SIN9

LOGIC 1 OR 0

SIN8

LOGIC 1 OR 0

SIN3

LOGIC 1 OR 0

SIN1

LOGIC 1 OR 0

SIN2

LOGIC 1 OR 0

SIN0

LOGIC 1 OR 0

Function Options

Common to All Latches/FFs in PFU

Enable GSRN GSRN enabled or has no effect on

PFU latches/FFs.

Set Individually in Each Latch/FF in PFU

Set/Reset Mode Set or reset.

By Group (Latch/FF[3:0], Latch/FF[7:4], and FF[8])

Clock Enable CE or none.

LSR Control LSR or none.

Clock Polarity Noninverted or inverted.

Latch/FF Mode Latch or FF.

LSR Operation Asynchronous or synchronous.

Front-end Select* Direct (DIN[7:0]) or from LUT

(F[7:0]).

LSR Priority Either LSR or CE has priority.

Page 26

2626 Lucent Technologies Inc.

Preliminary Data Sheet

December 2000

ORCA Series 4 FPGAs

Programmable Logic Cells

(continued)

The set/reset operation of the latch/FF is controlled by

two parameters: reset mode and set/reset value. When

the GSRN and local set/reset (LSR) signals are not

asserted, the latch/FF operates normally. The reset

mode is used to select a synchronous or asynchronous

LSR operation. If synchronous, LSR has the option to

be enabled only if clock enable (CE) is active or for LSR

to have priority over the clock enable input, thereby setting/resetting the FF independent of the state of the