Page 1

®

OPA128

Difet

®

Electrometer-Grade

OPERATIONAL AMPLIFIER

FEATURES

● ULTRA-LOW BIAS CURRENT: 75fA max

● LOW OFFSET: 500µV max

● LOW DRIFT: 5µV/

● HIGH OPEN-LOOP GAIN: 110dB min

● HIGH COMMON-MODE REJECTION:

90dB min

● IMPROVED REPLACEMENT FOR AD515

AND AD549

DESCRIPTION

The OPA128 is an ultra-low bias current monolithic

operational amplifier. Using advanced geometry

dielectrically-isolated FET (

lithic amplifier achieves a performance level exceeding even the best hybrid electrometer amplifiers.

Laser-trimmed thin-film resistors give outstanding voltage offset and drift performance.

A noise-free cascode and low-noise processing give

the OPA128 excellent low-level signal handling capabilities. Flicker noise is very low.

The OPA128 is an improved pin-for-pin replacement

for the AD515.

®

Difet

Burr-Brown Corp.

°C max

Difet

®

) inputs, this mono-

APPLICATIONS

● ELECTROMETER

● MASS SPECTROMETER

● CHROMATOGRAPH

● ION GAUGE

● PHOTODETECTOR

● RADIATION-HARD EQUIPMENT

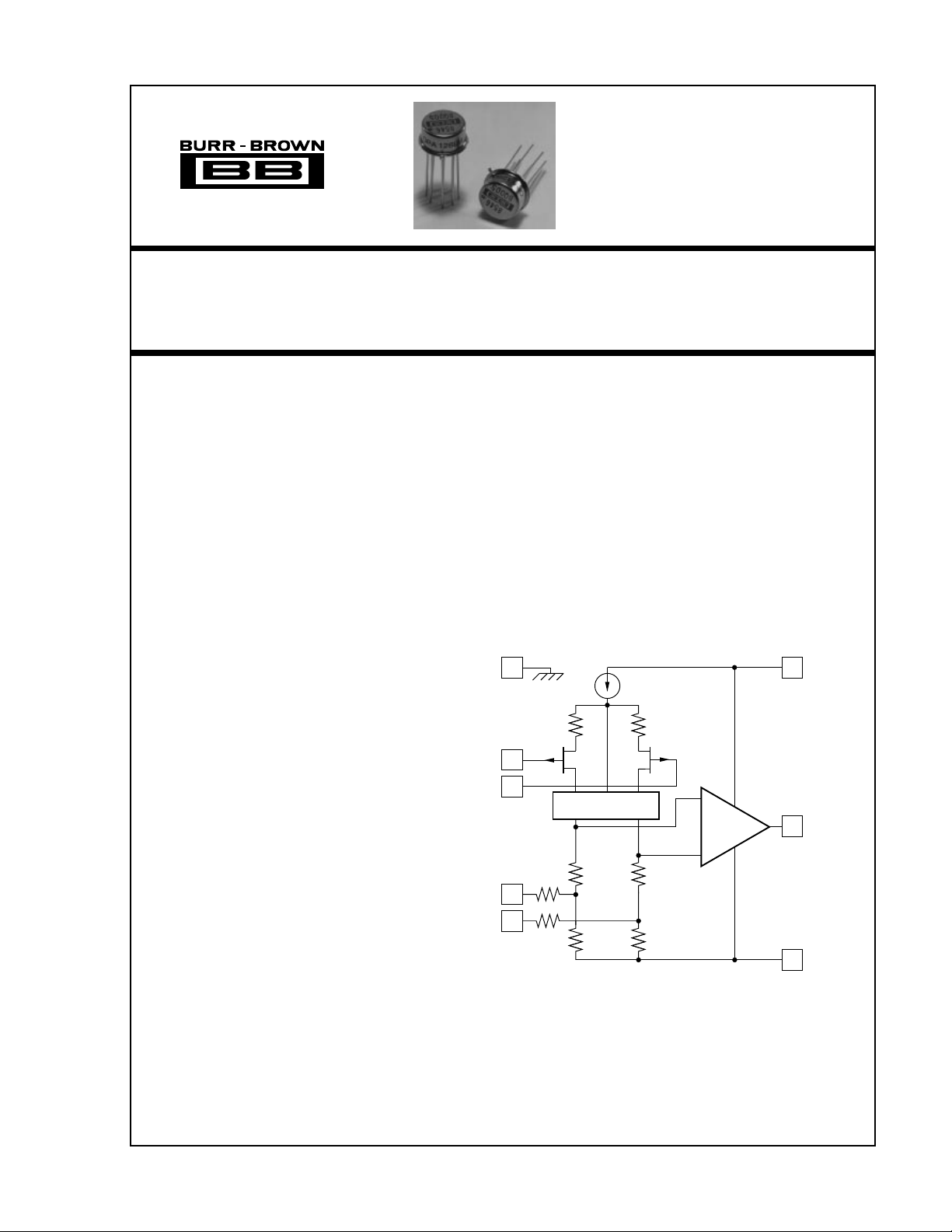

Case (Guard)

8

–In

2

3

+In

Trim

1

5

Trim

Noise-Free

Cascode

28kΩ

Ω1k

Ω1k

2kΩ 2kΩ

OPA128 Simplified Circuit

28kΩ

7

+V

CC

6

Output

4

–V

CC

International Airport Industrial Park • Mailing Address: PO Box 11400 • Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd. • Tucson, AZ 85706

Tel: (520) 746-1111 • Twx: 910-952-1111 • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

©

1986 Burr-Brown Corporation PDS-653E Printed in U.S.A. May, 1995

Page 2

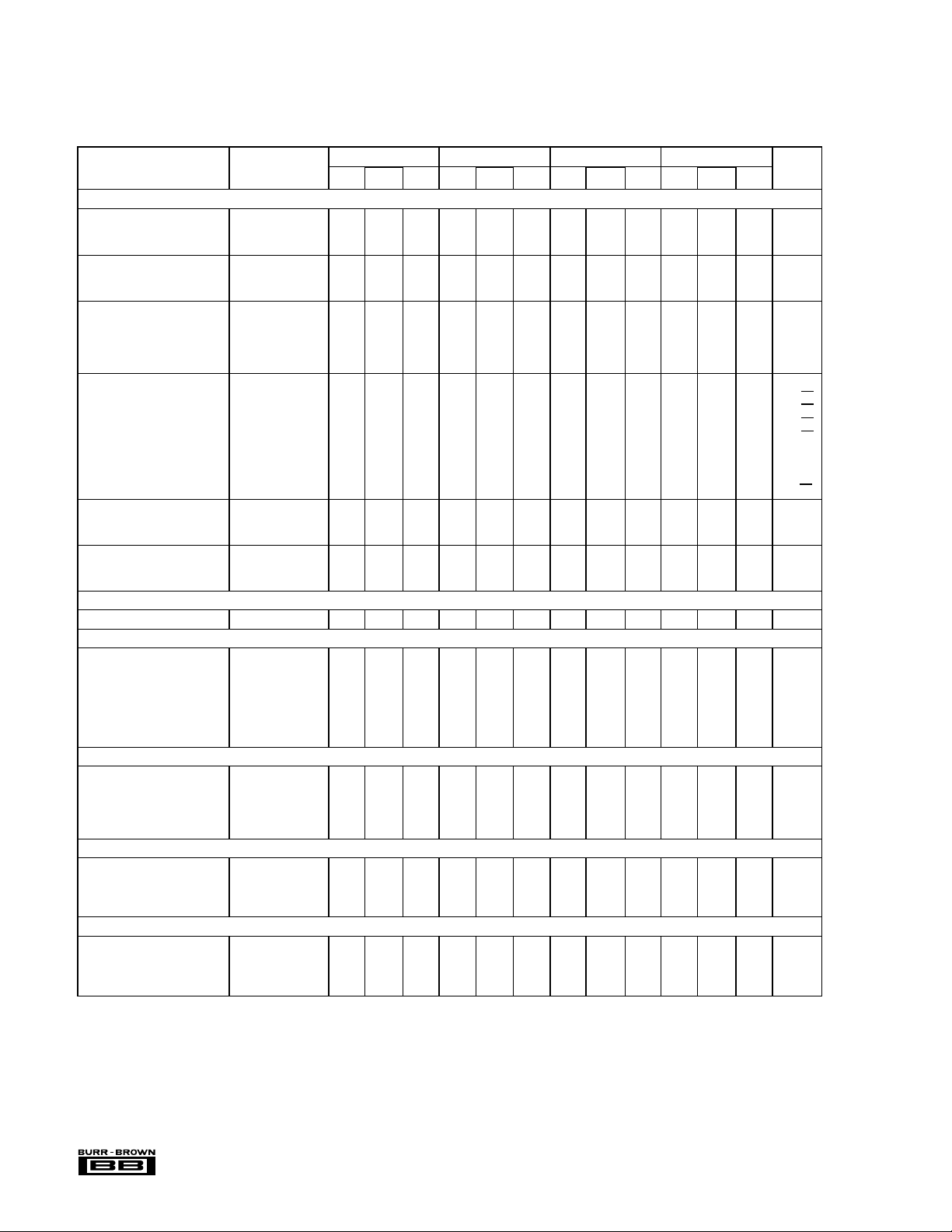

SPECIFICATIONS

ELECTRICAL

At V

= ±15VDC and TA = +25°C unless otherwise noted. Pin 8 connected to ground.

CC

OPA128JM OPA128KM OPA128LM OPA128SM

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

INPUT

BIAS CURRENT

Input Bias Current VCM = 0VDC,

OFFSET CURRENT

Input Offset Current VCM = 0VDC,

OFFSET VOLTAGE

Input Offset Voltage VCM = 0VDC ±260 ±1000 ±140 ±500 ±140 ±500 ±140 ±500 µV

Average Drift T

Supply Rejection 80 120 90 120 90 120 90 120 dB

NOISE

Voltage: f

f

f

f

f

f

Current: f

f

IMPEDANCE

Differential 10

Common-Mode 10

VOLTAGE RANGE

Common-Mode Input Range ±10 ±12 ±10 ±12 ±10 ±12 ±10 ±12 V

Common-Mode Rejection V

OPEN-LOOP GAIN, DC

Open-Loop Voltage Gain R

FREQUENCY RESPONSE

Unity Gain, Small Signal

Full Power Response 20Vp-p, R

Slew Rate V

Settling Time, 0.1% Gain = –1, R

0.01% 10V Step 10 10 10 10 µs

Overload Recovery,

50% Overdrive

RATED OUTPUT

Voltage Output R

Current Output V

Output Resistance DC, Open Loop 100 100 100 100 Ω

Load Capacitance Stability Gain = +1 1000 1000 1000 1000 pF

Short Circuit Current 10 34 55 10 34 55 10 34 55 10 34 55 mA

POWER SUPPLY

Rated Voltage ±15 ±15 ±15 ±15 VDC

Voltage Range,

Derated Performance ±5 ±18 ±5 ±18 ±5 ±18 ±5 ±18 VDC

Current, Quiescent I

TEMPERATURE RANGE

Specification Ambient Temp. 0 +70 0 +70 0 +70 –55 +125 °C

Operating Ambient Temp. –55 +125 –55 +125 –55 +125 –55 +125 °C

Storage Ambient Temp. –65 +150 –65 +150 –65 +150 –65 +150 °C

θ

Junction-Ambient 200 200 200 200 ° C/W

NOTES: (1) Offset voltage, offset current, and bias current are measured with the units fully warmed up. Bias current doubles approximately every 11°C. (2) Sample

tested. (3) Overload recovery is defined as the time required for the output to return from saturation to linear operation following the removal of a 50% input overdrive.

(4) If it is possible for the input voltage to exceed the supply voltage, a series protection resistor should be added to limit input current to 0.5mA. The input devices

can withstand overload currents of 0.3mA indefinitely without damage.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

(1)

R

≥ 10kΩ±150 ±300 ±75 ±150 ±40 ±75 ±75 ±150 fA

(1)

(1)

L

R

≥ 10kΩ 65 30 30 30 fA

L

= T

to T

A

MIN

MAX

±20 ±10 ±5 ±10 µV/°C

±1 ±100 ±1 ±32 ±1 ±32 ±1 ±32 µV/V

= 10Hz 92 92 92 92 nV/√Hz

O

= 100Hz 78 78 78 78 nV/√Hz

O

= 1kHz 27 27 27 27 nV/√Hz

O

= 10kHz 15 15 15 15 nV/√Hz

O

= 10Hz to 10kHz 2.4 2.4 2.4 2.4 µVrms

B

= 0.1Hz to 10Hz 4 4 4 4 µVp-p

B

= 0.1Hz to 10Hz 4.2 3 2.3 3 fA, p-p

B

= 0.1Hz to 20kHz 0.22 0.16 0.12 0.16 fA/√Hz

O

13

|| 1 1013 || 1 1013 || 1 1013 || 1 Ω || pF

15

|| 2 1015 || 2 1015 || 2 1015 || 2 Ω || pF

(4)

= ±10VDC 80 118 90 118 90 118 90 118 dB

IN

≥ 2kΩ 94 128 110 128 110 128 110 128 dB

L

(2)

= 2kΩ 47 47 47 47 kHz

L

= ±10V, RL = 2kΩ 0.53131313V/µs

O

(3)

L

Gain = –1 5 5 5 5 µs

= 2kΩ±10 ±13 ±10 ±13 ±10 ±13 ±10 ±13 V

L

= ±10VDC ±5 ±10 ±5 ±10 ±5 ±10 ±5 ±10 mA

O

= 0mADC 0.9 1.5 0.9 1.5 0.9 1.5 0.9 1.5 mA

O

0.5 1 0.5 1 0.5 1 0.5 1 MHz

= 2kΩ 5555µs

®

OPA128

2

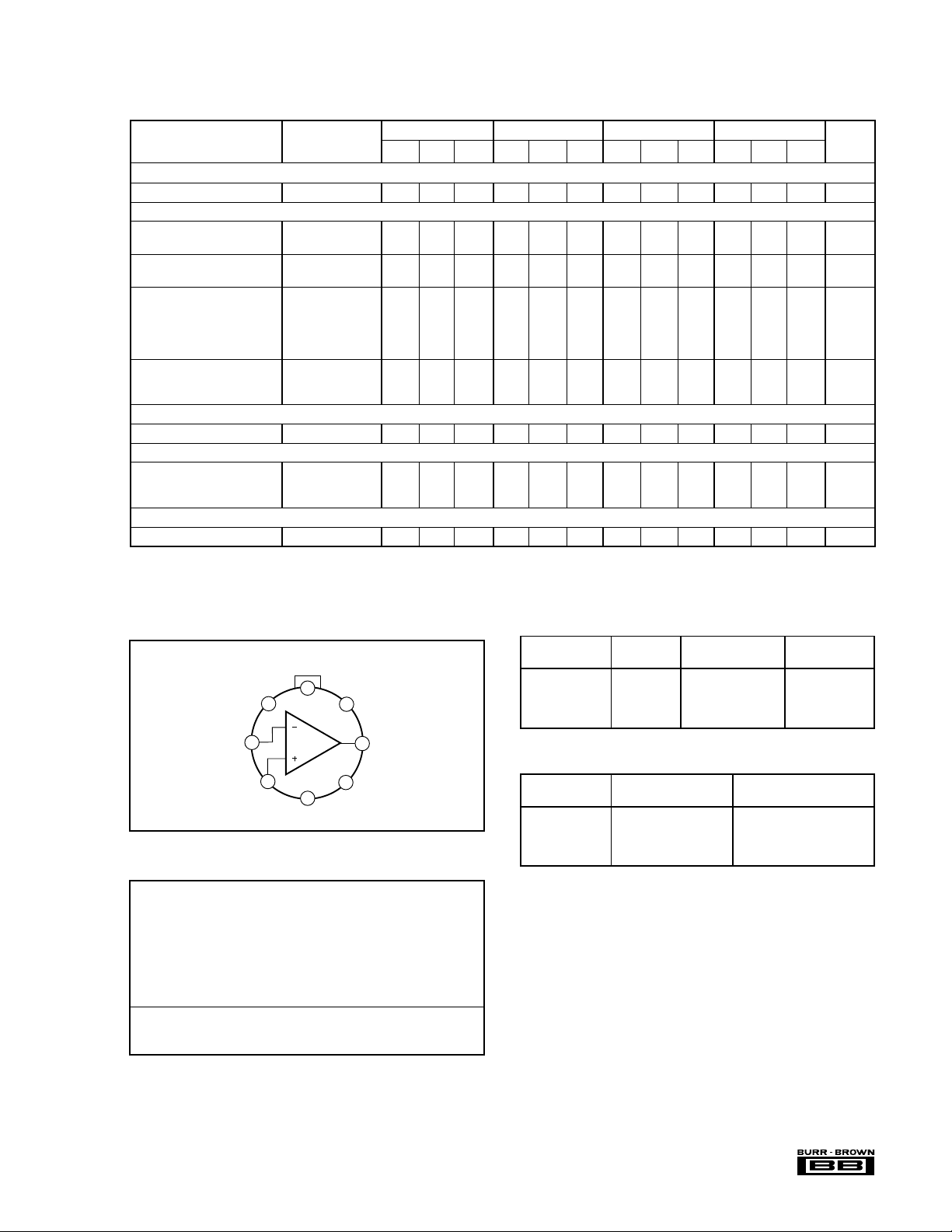

Page 3

®

ELECTRICAL (FULL TEMPERATURE RANGE SPECIFICATIONS)

At V

= ±15VDC and TA = T

CC

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

TEMPERATURE RANGE

Specification Range Ambient Temp. 0 +70 0 +70 0 +70 –55 +125 °C

INPUT

BIAS CURRENT

(1)

Input Bias Current VCM = 0VDC ±2.5 ±8 ±1.3 ±4 ±0.7 ±2 ±43 ±170 pA

OFFSET CURRENT

Input Offset Current VCM = 0VDC 1.1 0.6 0.6 18 pA

OFFSET VOLTAGE

Input Offset Voltage VCM = 0VDC ±2.2mV ±1mV ±750 ±1.5mV µV

Average Drift ±20 ±10 ±5 ±10 µV/°C

Supply Rejection 74 114 80 114 80 114 80 106 dB

VOLTAGE RANGE

Common-Mode Input Range ±10 ±11 ±10 ±11 ±10 ±11 ±10 ±11 V

Commmon-Mode Rejection V

OPEN-LOOP GAIN, DC

Open-Loop Voltage Gain R

RATED OUTPUT

Voltage Output R

Current Output V

Short Circuit Current V

POWER SUPPLY

Current, Quiescent I = 0mADC 0.9 1.8 0.9 1.8 0.9 1.8 0.9 2 mA

NOTES: (1) Offset voltage, offset current, and bias current are measured with the units fully warmed up. (2) If it is possible for the input voltage to exceed the supply

voltage, a series protection resistor should be added to limit input current to 0.5mA. The input devices can withstand overload currents of 0.3mA indefinitely without

damage.

and T

MIN

unless otherwise noted.

MAX

OPA128JM OPA128KM OPA128LM OPA128SM

(1)

(1)

±2 ±200 ±2 ±100 ±2 ±100 ±5 ±100 µV/V

(2)

= ±10VDC 74 112 80 112 80 112 74 104 dB

IN

≥ 2kΩ 90 125 104 125 104 125 90 122 dB

L

= 2k±10 ±10 ±10 ±10 V

L

= ±10VDC ±5 ±5 ±5 ±5mA

O

= 0VDC 10 22 10 22 10 22 10 18 mA

O

CONNECTION DIAGRAM

Top View

Substrate and Case

Offset

Trim

2

–In

+In

1

3

8

OPA128

4

–V

CC

7

5

+V

CC

6

Offset

Trim

Output

ABSOLUTE MAXIMUM RATINGS

Supply ...........................................................................................±18VDC

Internal Power Dissipation

Differential Input Voltage...............................................................±36VDC

Input Voltage Range ..................................................................... ±18VDC

Storage Temperature Range .......................................... –65°C to +150°C

Operating Temperature Range ....................................... –55°C to +125°C

Lead Temperature (soldering, 10s)................................................ +300°C

Output Short Circuit Duration

Junction Temperature .................................................................... +175°C

NOTES: (1) Packages must be derated based on

200°C/W. (2) Short circuit may be to power supply common only. Rating

applies to +25°C ambient. Observe dissipation limit and T

(1)

..........................................................500mW

(2)

................................................ Continuous

θ

= 150°C/W or

CA

.

J

ORDERING INFORMATION

MODEL PACKAGE RANGE max (fA)

OPA128JM TO-99 0°C to +70°C ±300

OPA128KM TO-99 0°C to +70°C ±150

OPA128LM TO-99 0°C to +70°C ±75

OPA128SM TO-99 –55°C to +125°C ±150

TEMPERATURE BIAS CURRENT,

PACKAGE INFORMATION

MODEL PACKAGE NUMBER

PACKAGE DRAWING

OPA128JM TO-99 001

OPA128KM TO-99 001

OPA128LM TO-99 001

OPA128SM TO-99 001

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix D of Burr-Brown IC Data Book.

θ

=

JA

(1)

3

OPA128

Page 4

DICE INFORMATION

OPA128 DIE TOPOGRAPHY

PAD FUNCTION

1 Offset Trim

2 –In

3 +In

4–V

5 Offset Trim

6 Output

7+V

8 Substrate

NC No Connection

Substrate Bias: Isolated, normally connected to common.

CC

CC

MECHANICAL INFORMATION

MILS (0.001") MILLIMETERS

Die Size 96 x 71 ±5 2.44 x 1.80 ±0.13

Die Thickness 20 ±3 0.51 ±0.08

Min. Pad Size 4 x 4 0.10 x 0.10

Backing None

TYPICAL PERFORMANCE CURVES

TA = +25°C, ±15VDC, unless otherwise noted.

140

120

100

80

60

Voltage Gain (dB)

40

20

0

120

110

100

OPEN-LOOP FREQUENCY RESPONSE

Gain

Ø

Phase

Margin

∼

≈ 90°

∼

11k10 100 10k 100k 1M 10M

Frequency (Hz)

COMMON-MODE REJECTION

vs INPUT COMMON-MODE VOLTAGE

–45

–90

–135

Phase Shift (Degrees)

–180

140

120

100

Power Supply Rejection (dB)

140

120

100

80

POWER SUPPLY REJECTION vs FREQUENCY

80

60

40

20

0

11k10 100 10k 100k 1M 10M

–PSRR

Frequency (Hz)

COMMON-MODE REJECTION

vs FREQUENCY

+PSRR

90

80

Common-Mode Rejection (dB)

70

–15

–10 –5 0 5 10 15

Common-Mode Voltage (V)

®

OPA128

60

40

20

Common-Mode Rejection (dB)

0

11k10 100 10k 100k 1M 10M

4

Frequency (Hz)

Page 5

®

TYPICAL PERFORMANCE CURVES (CONT)

0 5 10 20

Supply Voltage (±V

CC

)

0

3

2

1

Gain-Bandwidth (MHz)

GAIN-BANDWIDTH AND SLEW RATE

vs SUPPLY VOLTAGE

15

Slew Rate (V/µs)

0

6

4

2

– Slew

+ Slew

100

–75 –50 –25 0 25 50 125

Ambient Temperature (°C)

140

130

120

110

PSR, CMR, Voltage Gain (dB)

OPEN-LOOP GAIN, PSR, AND CMR vs TEMPERATURE

75

100

PSR

CMR

A

OL

At TA = +25°C, +15VDC unless otherwise noted.

BIAS AND OFFSET CURRENT

100pA

10pA

1pA

100

10

Bias and Offset Current (fA)

1

–50 –25 0 25 50 75 125

GAIN-BANDWIDTH AND SLEW RATE

4

3

2

1

Gain-Bandwidth (MHz)

vs TEMPERATURE

SM

Ambient Temperature (°C)

vs TEMPERATURE

I

B

BIAS AND OFFSET CURRENT

10

1

I

OS

0.1

Normalized Bias and Offset Current

0.01

100

4

3

2

Slew Rate (V/µs)

1

vs INPUT COMMON-MODE VOLTAGE

–15 –10 –5 0 5 10 15

Common-Mode Voltage (V)

0

–75 –50 –25 0 25 50 125

Ambient Temperature (°C)

2

1.5

1

Supply Current (mA)

0.5

0

–75 –50 –25 0 25 50 125

SUPPLY CURRENT vs TEMPERATURE

Ambient Temperature (°C)

0

100

75

75

100

5

OPA128

Page 6

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, +15VDC unless otherwise noted.

LARGE SIGNAL TRANSIENT RESPONSE

10

0

Output Voltage (V)

–10

5V

05025

Time (µs)

COMMON-MODE INPUT RANGE

vs SUPPLY VOLTAGE

15

10

5

Common-Mode Voltage (±V)

0

0 5 10 20

Supply Voltage (±V

5µs

5µs

15

)

CC

SMALL SIGNAL TRANSIENT RESPONSE

80

40

0

Output Voltage (mV)

–40

–80

100pA

10pA

1pA

100

Bias Current (fA)

10

20mV 1µs

0108642

Time (µs)

BIAS CURRENT

vs ADDITIONAL POWER DISSIPATION

KM

1

0 50 100 150 200 250 350

Additional Power Dissipation (mW)

300

1k

100

Voltage Density (nV/ Hz)

10

INPUT VOLTAGE NOISE SPECTRAL DENSITY

1 10 100 1k 10k 100k

Frequency (Hz)

®

OPA128

30

20

10

Output Voltage (Vp-p)

0

FULL-POWER OUTPUT vs FREQUENCY

1k 10k 1M

Frequency (Hz)

100k

6

Page 7

®

APPLICATIONS INFORMATION

OFFSET VOLTAGE ADJUSTMENT

The OPA128 offset voltage is laser-trimmed and will require

no further trim for most applications. As with most amplifiers, externally trimming the remaining offset can change

drift performance by about 0.3µV/°C for each 100µV of

adjusted effort. Note that the trim (Figure 1) is similar to

operational amplifiers such as HA-5180 and AD515. The

OPA128 can replace many other amplifiers by leaving the

external null circuit unconnected.

+V

CC

The amplifier case should be connected to any input shield or

guard via pin 8. This insures that the amplifier itself is fully

surrounded by guard potential, minimizing both leakage and

noise pickup (see Figure 2).

In

Non-Inverting

2

3

8

OPA128

Out

6

In

Buffer

2

OPA128

3

8

Out

6

7

2

6

1

(1)

NOTE: (1) 10kΩ to 1MΩ

Trim Potentiometer

(100kΩ Recommended)

±10mV Typical

Trim Range

3

OPA128

5

4

–V

CC

FIGURE 1. Offset Voltage Trim.

INPUT PROTECTION

Conventional monolithic FET operational amplifiers’ inputs

must be protected against destructive currents that can flow

when input FET gate-to-substrate isolation diodes are for-

®

ward-biased. Most BIFET

the loss of –V

.

CC

amplifiers can be destroyed by

Because of its dielectric isolation, no special protection is

needed on the OPA128. Of course, the differential and

common-mode voltage limits should be observed.

Static damage can cause subtle changes in amplifier input

characteristics without necessarily destroying the device. In

precision operational amplifiers (both bipolar and FET types),

this may cause a noticeable degradation of offset voltage and

drift.

Static protection is recommended when handling any precision IC operational amplifier.

GUARDING AND SHIELDING

As in any situation where high impedances are involved,

careful shielding is required to reduce “hum” pickup in input

leads. If large feedback resistors are used, they should also be

shielded along with the external input circuitry. Leakage

currents across printed circuit boards can easily exceed the

bias current of the OPA128. To avoid leakage problems, it is

recommended that the signal input lead of the OPA128 be

wired to a Teflon standoff. If the input is to be soldered

directly into a printed circuit board, utmost care must be used

in planning the board layout. A “guard” pattern should

completely surround the high impedance input leads and

should be connected to a low impedance point which is at the

signal input potential.

Inverting

In

2

OPA128

3

Out

6

8

BOARD LAYOUT

FOR INPUT GUARDING

Guard top and bottom of board.

Alternate: use Teflon

for sensitive input pins.

Teflon® E.I. Du Pont de Nemours & Co.

TO-99 Bottom View

5

4

3

2

1

®

standoff

6

7

8

FIGURE 2. Connection of Input Guard.

Triboelectric charge (static electricity generated by friction)

can be a troublesome noise source from cables connected to

the input of an electrometer amplifier. Special low-noise cable

will minimize this effect but the optimum solution is to mount

the signal source directly at the electrometer input with short,

rigid, wiring to preclude microphonic noise generation.

TESTING

Accurately testing the OPA128 is extremely difficult due to its

high level of performance. Ordinary test equipment may not

be able to resolve the amplifier’s extremely low bias current.

Inaccurate bias current measurements can be due to:

1. Test socket leakage

2. Unclean package

3. Humidity or dew point condensation

4. Circuit contamination from fingerprints or anti-static

treatment chemicals

5. Test ambient temperature

6. Load power dissipation

BIFET® National Semiconductor Corp.

7

OPA128

Page 8

500Ω 9.5kΩ

Guard

pH Probe

R

≈ 500MΩ

S

50mV Output

100kΩ

FIGURE 3. High Impedance (10

–In

+15V

8

2

OPA128

3

5

1

–15V

15

Ω) Amplifier.

3

2

7

6

4

Offset Trim

OPA128

R

F

Ω10k

1VDC

Output

6

FIGURE 4. Piezoelectric Transducer Charge Amplifier.

≈ 100fA

I

B

Gain = 100

CMRR ≈ 118dB

R

≈ 1015Ω

IN

2

Q∆

100pF

Ω25k Ω25k

C

10pF

F

R

2

3

11

11

F

8

OPA128

e= –∆Q/C

O

Ω10

Low Frequency Cutoff =

Rπ

1/(2

5

Ω10

6

FCF

Output

e

O

F

) = 0.16Hz

R

G

Ω202

+In

R

F

Ω10k

2

OPA128

3

6

Differential Voltage Gain = 1 + 2R

Ω25k

3

Ω25k

1

F/RG

FIGURE 5. FET Input Instrumentation Amplifier for Biomedical Applications.

1N914

10kΩ

(1)

6

1N914

NOTE: (1) Reverse polarity

for negative peak detection.

1MΩ

(1)

(1)

2N4117A

Input

10pF≈

2

OPA606

3

Burr-Brown

INA105

Differential

Amplifier

2

3

1000µF

Polystyrene

8

OPA128

6

Output

6

Output

100µV/s≈Droop

FIGURE 6. Low-Droop Positive Peak Detector.

®

OPA128

8

Page 9

®

<1pF to prevent gain peaking.

10

Ω

10

Silicon Detector Corp.

SD-020-11-21-011

0.01µF

+15V

Guard

2

3

1010Ω

+5V

Biased

Current

Transducer

0.1µF

8

7

OPA128

0.1µF

4

–15V

Circuit must be well shielded.

+15V

1000MΩ

2

Current

6

Output

5 x 10

9

V/W

Input

3

OPA128

18kΩ

6

8

VO = –1V/nA

2kΩ

Output

FIGURE 8. Current-to-Voltage Converter.FIGURE 7. Sensitive Photodiode Amplifier.

109Ω

2

OPA128

3

6

8

3

4

5

10

11

12

INA101HP

1

Output

14

5

6

7

REF101

4 1

8

FIGURE 9. Biased Current-to-Voltage Converter.

VO = 1mV/pA

+5V

9

OPA128

Loading...

Loading...