Page 1

OUT A

–IN A

+IN A

V–

V+

OUT B

–IN B

+IN B

1

2

3

4

5

6

7

8

OP295

OUT A

–IN A

+IN A

V–

V+

OUT B

–IN B

+IN B

1

2

3

4

5

6

7

8

OP295

C

D

Dual/Quad Rail-to-Rail

a

FEATURES

Rail-to-Rail Output Swing

Single-Supply Operation: 3 V to 36 V

Low Offset Voltage: 300 V

Gain Bandwidth Product: 75 kHz

High Open-Loop Gain: 1,000 V/mV

Unity-Gain Stable

Low Supply Current/Per Amplifier: 150 A max

APPLICATIONS

Battery-Operated Instrumentation

Servo Amplifiers

Actuator Drives

Sensor Conditioners

Power Supply Control

GENERAL DESCRIPTION

Rail-to-rail output swing combined with dc accuracy are the key

features of the OP495 quad and OP295 dual CBCMOS operational

amplifiers. By using a bipolar front end, lower noise and higher

accuracy than that of CMOS designs has been achieved. Both input

and output ranges include the negative supply, providing the user

“zero-in/zero-out” capability. For users of 3.3 V systems such as

lithium batteries, the OP295/OP495 is specified for 3 V operation.

Maximum offset voltage is specified at 300 mV for 5 V operation,

and the open-loop gain is a minimum of 1000 V/mV. This yields

performance that can be used to implement high accuracy systems,

even in single-supply designs.

The ability to swing rail-to-rail and supply 15 mA to the load makes

the OP295/OP495 an ideal driver for power transistors and “H”

bridges. This allows designs to achieve higher efficiencies and to

transfer more power to the load than previously possible without

the use of discrete components. For applications that require

Operational Amplifiers

OP295/OP495

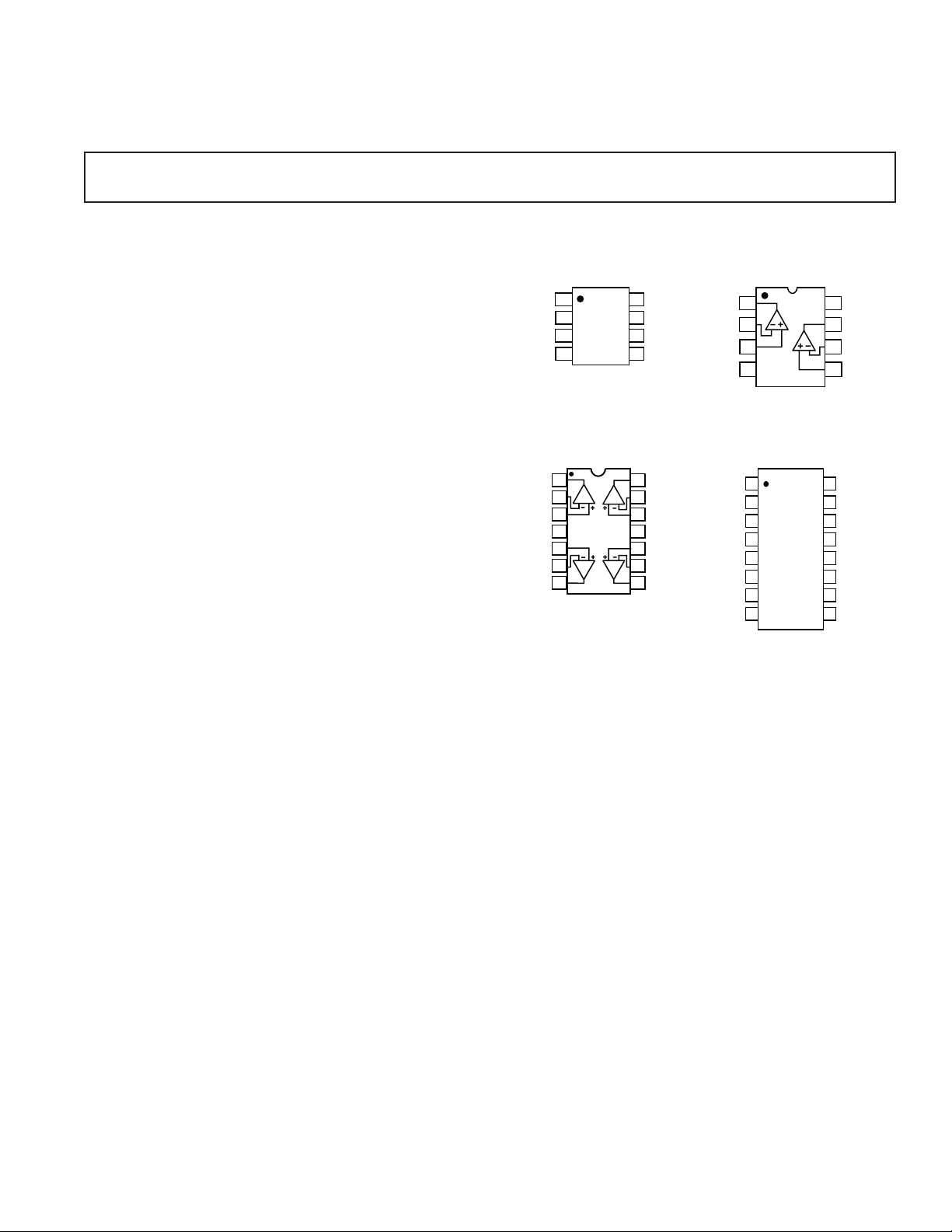

PIN CONNECTIONS

8-Lead Narrow-Body SO 8-Lead Epoxy DIP

(S Suffix) (P Suffix)

14-Lead Epoxy DIP 16-Lead SO (300 Mil)

(P Suffix) (S Suffix)

1

OUT A

2

–IN A

3

+IN A

4

V+

OP495

5

+IN B

6

–IN B

OUT B

7

driving inductive loads, such as transformers, increases in efficiency

are also possible. Stability while driving capacitive loads is another

benefit of this design over CMOS rail-to-rail amplifiers. This is

useful for driving coax cable or large FET transistors. The

OP295/OP495 is stable with loads in excess of 300 pF.

The OP295 and OP495 are specified over the extended industrial

(–40∞C to +125∞C) temperature range. OP295s are available in

8-lead plastic DIP plus SO-8 surface-mount packages. OP495s are

available in 14-lead plastic and SO-16 surface-mount packages.

Contact your local sales office for MIL-STD-883 data sheet.

14

OUT

13

–IN D

12

+IN D

11

V–

10

+IN C

9

–IN C

8

OUT

1

OUT A

–IN A

2

3

+IN A

4

V+

5

+IN B

6

–IN B

7

OUT B

8

NC

NC = NO CONNECT

OP495

TOP VIEW

(Not to Scale)

16

15

14

13

12

11

10

9

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

NC

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

that may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

OP295/OP495–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Common-Mode Rejection Ratio CMRR 0 V £ VCM £ 4.0 V, –40∞C £ TA £ +125∞C90110 dB

Large Signal Voltage Gain A

Offset Voltage Drift DVOS/DT 15 mV/∞C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

Output Current I

POWER SUPPLY

Power Supply Rejection Ratio PSRR ± 1.5 V £ VS £ ± 15 V 90 110 dB

Supply Current Per Amplifier I

DYNAMIC PERFORMANCE

Skew Rate SR RL = 10 kW 0.03 V/ms

Gain Bandwidth Product GBP 75 kHz

Phase Margin q

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 1.5 mV p-p

Voltage Noise Density e

Current Noise Density i

Specifications subject to change without notice.

OS

B

OS

CM

VO

OH

OL

OUT

SY

O

n

n

(@ VS = 5.0 V, VCM = 2.5 V, TA = 25ⴗC unless otherwise noted.)

–40∞C £ TA £ +125∞C 800 mV

–40∞C £ TA £ +125∞C30nA

–40∞C £ TA £ +125∞C ±5nA

0 4.0 V

RL = 10 kW, 0.005 £ V

RL = 10 kW, –40∞C £ TA £ +125∞C 500 V/mV

£ 4.0 V 1,000 10,000 V/mV

OUT

RL = 100 kW to GND 4.98 5.0 V

RL = 10 kW to GND 4.90 4.94 V

I

= 1 mA, –40∞C £ TA £ +125∞C 4.7 V

OUT

RL = 100 kW to GND 0.7 2 mV

RL = 10 kW to GND 0.7 2 mV

I

= 1 mA, –40∞C £ TA £ +125∞C90mV

OUT

±11 ±18 mA

±1.5 V £ VS £ ± 15 V,

–40∞C £ TA £ +125∞C85dB

V

= 2.5 V, RL = •, –40∞C £ TA £ +125∞C 150 mA

OUT

f = 1 kHz 51 nV/÷Hz

f = 1 kHz <0.1 pA/÷Hz

30 300 mV

820 nA

±1 ±3nA

86 Degrees

ELECTRICAL CHARACTERISTICS

(@ VS = 3.0 V, VCM = 1.5 V, TA = 25ⴗC unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Common-Mode Rejection Ratio CMRR 0 V £ VCM £ 2.0 V, –40∞C £ TA £ +125∞C90110 dB

Large Voltage Gain A

Offset Voltage Drift DVOS/DT 1 mV/∞C

OS

B

OS

CM

VO

RL = 10 kW 750 V/mV

0 2.0 V

30 500 mV

820 nA

±1 ±3nA

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

OH

OL

RL = 10 kW to GND 2.9 V

RL = 10 kW to GND 0.7 2 mV

POWER SUPPLY

Power Supply Rejection Ratio PSRR ± 1.5 V £ VS £ ± 15 V 90 110 dB

±1.5 V £ VS £ ± 15 V,

–40∞C £ TA £ +125∞C85dB

Supply Current Per Amplifier I

SY

V

= 1.5 V, RL = •, –40∞C £ TA £ +125∞C 150 mA

OUT

DYNAMIC PERFORMANCE

Slew Rate SR RL = 10 kW 0.03 V/ms

Gain Bandwidth Product GBP 75 kHz

Phase Margin q

O

85 Degrees

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 1.6 mV p-p

Voltage Noise Density e

Current Noise Density i

Specifications subject to change without notice.

n

n

f = 1 kHz 53 nV/÷Hz

f = 1 kHz <0.1 pA/÷Hz

–2–

REV. C

Page 3

OP295/OP495

ELECTRICAL CHARACTERISTICS

(@ VS = ±15.0 V, TA = 25ⴗC unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

OS

–40∞C £ T

B

VCM = 0 V 7 20 nA

£ +125∞C 800 mV

A

30 300 mV

VCM = 0 V, –40∞C £ TA £ +125∞C30nA

Input Offset Current I

Input Voltage Range V

OS

CM

Common-Mode Rejection Ratio CMRR –15.0 V £ V

Large Signal Voltage Gain A

VO

VCM = 0 V ±1 ± 3nA

= 0 V, –40∞C £ TA £ +125∞C ±5nA

V

CM

–15 13.5 V

£ +13.5 V, –40∞C £ TA £ +125∞C90 110 dB

CM

RL = 10 kW 1,000 4,000 V/mV

Offset Voltage Drift DVOS/DT 1 mV/∞C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

OH

RL = 100 kW to GND 14.95 V

RL = 10 kW to GND 14.80 V

Output Voltage Swing Low V

Output Current I

OL

OUT

RL = 100 kW to GND –14.95 V

R

= 10 kW to GND –14.85 V

L

±15 ±25 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = ± 1.5 V to ± 15 V 90 110 dB

VS = ±1.5 V to ±15 V, –40∞C £ TA £ +125∞C85 dB

Supply Current I

SY

VO = 0 V, RL = •, VS = ±18 V,

–40∞C £ TA £ +125∞C 175 mA

Supply Voltage Range V

S

3 (±1.5) 36 (± 18) V

DYNAMIC PERFORMANCE

Slew Rate SR RL = 10 kW 0.03 V/ms

Gain Bandwidth Product GBP 85 kHz

Phase Margin q

O

83 Degrees

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 1.25 mV p-p

Voltage Noise Density e

Current Noise Density i

Specifications subject to change without notice.

n

n

f =1 kHz 45 nV/÷Hz

f = 1 kHz <0.1 pA/÷Hz

REV. C

–3–

Page 4

OP295/OP495

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±18 V

Input Voltage

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

2

. . . . . . . . . . . . . . . . . . . . . . . . . 36 V

1

Output Short-Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Storage Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . . –65∞C to +150∞C

Operating Temperature Range

OP295G, OP495G . . . . . . . . . . . . . . . . . . . –40∞C to +125∞C

Junction Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . . –65∞C to +150∞C

Lead Temperature Range (Soldering, 60 Sec) . . . . . . . . 300∞C

NOTES

1

Absolute maximum ratings apply to packaged parts, unless otherwise noted.

2

For supply voltages less than ± 18 V, the absolute maximum input voltage is

equal to the supply voltage.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

OP295GP –40∞C to +125∞C 8-Lead Plastic DIP N-8

OP295GS –40∞C to +125∞C 8-Lead SOIC SO-8

OP495GP –40∞C to +125∞C 14-Lead Plastic DIP N-14

OP495GS –40∞C to +125∞C 16-Lead SOL R-16

Package Type JA*

JC

Unit

8-Lead Plastic DIP (P) 103 43 ∞C/W

8-Lead SOIC (S) 158 43 ∞C/W

14-Lead Plastic DIP (P) 83 39 ∞C/W

16-Lead SO (S) 98 30 ∞C/W

*qJA is specified for the worst case conditions, i.e., qJA is specified for device in

socket for cerdip, P-DIP, and LCC packages; qJA is specified for device soldered

in circuit board for SOIC package.

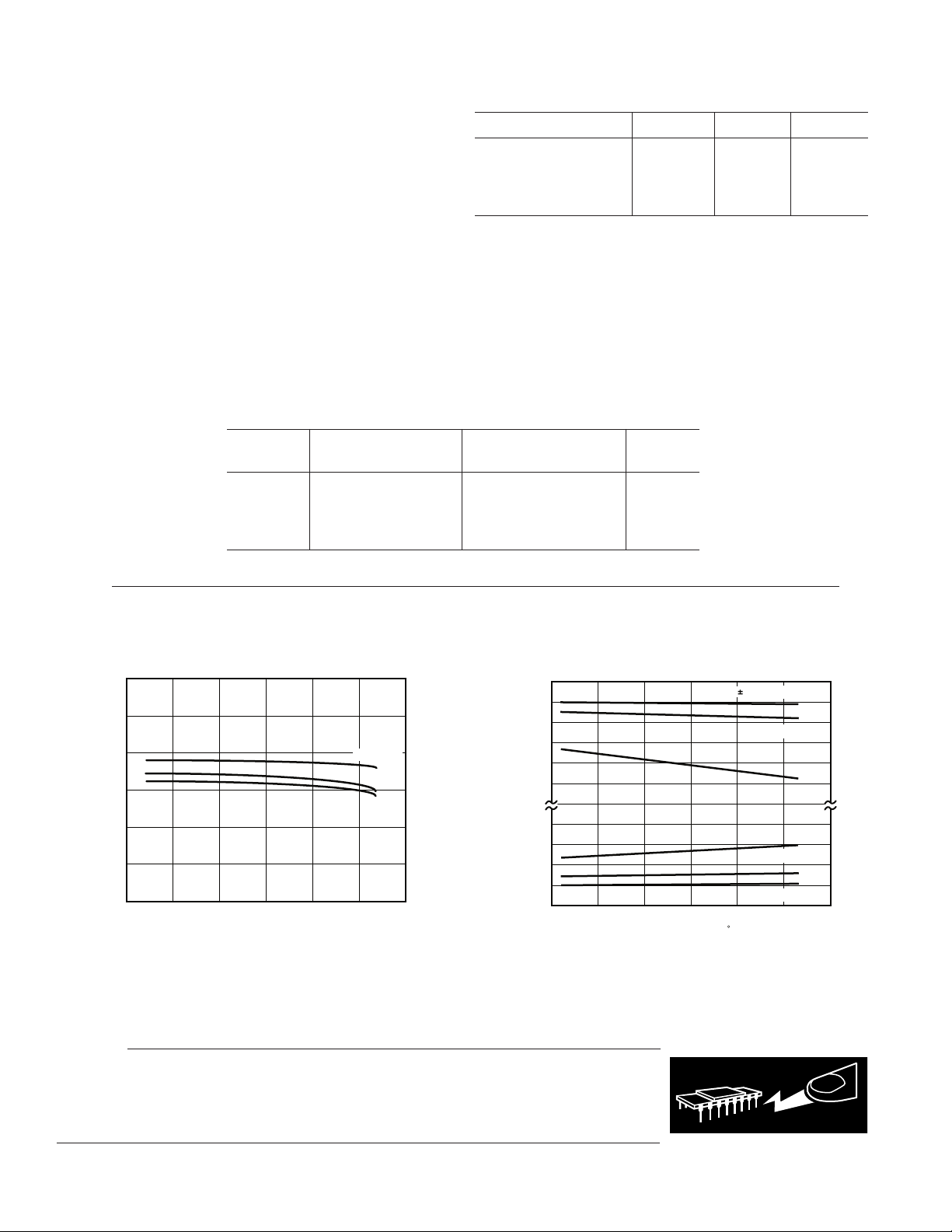

Typical Performance Characteristics

140

120

100

80

60

SUPPLY CURRENT – A

40

20

–50

–25

TEMPERATURE – ⴗC

VS = 36V

VS = 5V

V

= 3V

S

7550250

100

TPC 1. Supply Current Per Amplifier vs. Temperature

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP295/OP495 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

15.2

15.0

14.8

14.6

14.4

14.2

–14.4

–14.6

–14.8

–15.0

–15.2

– OUTPUT SWING – V + OUTPUT SWING – V

–50

–25

TEMPERATURE –

TPC 2. Output Voltage Swing vs. Temperature

VS = 15V

C

R

= 100k⍀

L

RL = 10k⍀

R

= 2k⍀

L

RL = 2k⍀

RL = 10k⍀

RL = 100k⍀

7550250

100

–4–

REV. C

Page 5

OP295/OP495

500

0

300

150

50

–50

100

–100

300

200

250

350

400

450

250200150100500

INPUT OFFSET VOLTAGE – V

UNITS

VS = 5V

T

A

= 25ⴗC

BASED ON 1200 OP AMPS

500

0

3.2

150

50

0.4

100

0

300

200

250

350

400

450

2.82.42.01.61.20.8

T

C

– VOS – V/ⴗC

UNITS

VS = 5V

–40ⴗ

TA +85ⴗC

BASED ON 1200 OP AMPS

3.10

VS = 3V

3.00

2.90

2.80

2.70

OUTPUT VOLTAGE SWING – V

2.60

2.50

–50

–25

TEMPERATURE – ⴗC

RL = 100k⍀

RL = 10k⍀

RL = 2k⍀

7550250

TPC 3. Output Voltage Swing vs. Temperature

200

BASED ON 600 OP AMPS

175

150

125

100

UNITS

75

VS = 5V

T

= 25ⴗC

A

100

5.10

VS = 5V

5.00

4.90

4.80

4.70

OUTPUT VOLTAGE SWING – V

4.60

4.50

–50

–25

TEMPERATURE – ⴗC

RL = 100k⍀

RL = 10k⍀

RL = 2k⍀

7550250

100

TPC 6. Output Voltage Swing vs. Temperature

50

25

0

–200–250

TPC 4. OP295 Input Offset (VOS) Distribution

250

BASED ON 600 OP AMPS

225

200

175

150

125

UNITS

100

75

50

25

0

0

TPC 5. OP295 TC–VOS Distribution

REV. C

INPUT OFFSET VOLTAGE – V

0.4

T

– VOS – V/ⴗC

C

VS = 5V

–40ⴗ

200150100500–50–100–150

TA +85ⴗC

2.82.42.01.61.20.8

250

TPC 7. OP495 Input Offset (VOS) Distribution

3.2

TPC 8. OP495 TC–VOS Distribution

–5–

Page 6

OP295/OP495

20

VS = 5V

16

12

8

INPUT BIAS CURRENT – nA

4

0

–50

–25

TEMPERATURE – ⴗC

7550250

TPC 9. Input Bias Current vs. Temperature

40

35

30

25

20

15

OUTPUT CURRENT – mA

10

5

SINK

SOURCE

VS = 15V

SOURCE

SINK

VS = 5V

100

100

VS = 15V

V

= 10V

O

50

RL = 100k⍀

RL = 10k⍀

RL = 2k⍀

75

10

OPEN-LOOP GAIN – V/V

1

–50 25

–25

0

TEMPERATURE – ⴗC

TPC 11. Open-Loop Gain vs. Temperature

12

VS = 5V

VO = 4V

10

8

RL = 100k⍀

6

4

OPEN-LOOP GAIN – V/V

2

RL = 10k⍀

RL = 2k⍀

100

0

–25–50

TEMPERATURE – ⴗC

7550250

TPC 10. Output Current vs. Temperature

VS = 5V

= 25ⴗC

T

A

1V

100mV

10mV

OUTPUT VOLTAGE TO RAIL

1mV

100V

1A10A

TPC 13. Output Voltage to Supply Rail vs. Load Current

100

SOURCE

SINK

100A

LOAD CURRENT

0

–50

–25

TEMPERATURE – ⴗC

7550250

TPC 12. Open-Loop Gain vs. Temperature

10mA1mA

100

REV. C–6–

Page 7

OP295/OP495

APPLICATIONS

Rail-to-Rail Application Information

The OP295/OP495 has a wide common-mode input range extending

from ground to within about 800 mV of the positive supply.

There is a tendency to use the OP295/OP495 in buffer applications

where the input voltage could exceed the common-mode input

range. This may initially appear to work because of the high input

range and rail-to-rail output range. But above the common-mode

input range the amplifier is, of course, highly nonlinear. For this

reason it is always required that there be some minimal amount

of gain when rail-to-rail output swing is desired. Based on the

input common-mode range, this gain should be at least 1.2.

Low Drop-Out Reference

The OP295/OP495 can be used to gain up a 2.5 V or other low

voltage reference to 4.5 V for use with high resolution A/D converters that operate from 5 V only supplies. The circuit in Figure 1 will

supply up to 10 mA. Its no-load drop-out voltage is only 20 mV.

This circuit will supply over 3.5 mA with a 5 V supply.

16k⍀

5V

2

REF43

4

20k⍀

6

0.001F

1/2

OP295/

OP495

5V

10⍀

V = 4.5V

OUT

1F TO

10 F

Figure 1. 4.5 V, Low Drop-Out Reference

Low Noise, Single-Supply Preamplifier

Most single-supply op amps are designed to draw low supply

current, at the expense of having higher voltage noise. This

tradeoff may be necessary because the system must be powered

by a battery. However, this condition is worsened because all

circuit resistances tend to be higher; as a result, in addition to

the op amp’s voltage noise, Johnson noise (resistor thermal noise)

is also a significant contributor to the total noise of the system.

The choice of monolithic op amps that combine the characteristics of low noise and single-supply operation is rather limited.

Most single-supply op amps have noise on the order of 30 nV/÷

to 60 nV/÷

5 nV/÷

Hz and single-supply amplifiers with noise below

Hz do not exist.

Hz

In order to achieve both low noise and low supply voltage operation, discrete designs may provide the best solution. The circuit

on Figure 2 uses the OP295/OP495 rail-to-rail amplifier and a

matched PNP transistor pair—the MAT03—to achieve zero-in/

zero-out single-supply operation with an input voltage noise of

3.1 nV/÷

Hz at 100 Hz. R5 and R6 set the gain of 1,000, making

this circuit ideal for maximizing dynamic range when amplifying

low level signals in single-supply applications. The OP295/OP495

provides rail-to-rail output swings, allowing this circuit to operate with 0 V to 5 V outputs. Only half of the OP295/OP495 is

used, leaving the other uncommitted op amp for use elsewhere.

0.1F

R1LED

Q2

2N3906

35

V

IN

2

R2

27k⍀

Q1 Q2

MAT-03

R7

510⍀

C1

R3

1500pF

R8

100⍀

6

71

2

3

R4

10F

R5

10k⍀

8

1

4

OP295/OP495

10⍀

C2

10F

R6

V

OUT

Figure 2. Low Noise Single-Supply Preamplifier

The input noise is controlled by the MAT03 transistor pair and

the collector current level. Increasing the collector current reduces

the voltage noise. This particular circuit was tested with 1.85 mA

and 0.5 mA of current. Under these two cases, the input voltage

noise was 3.1 nV/÷

Hz and 10 nV/÷Hz, respectively. The high

collector currents do lead to a tradeoff in supply current, bias

current, and current noise. All of these parameters will increase

with increasing collector current. For example, typically the

MAT03 has an h

= 165. This leads to bias currents of 11 mA

FE

and 3 mA, respectively. Based on the high bias currents, this circuit

is best suited for applications with low source impedance such

as magnetic pickups or low impedance strain gages. Furthermore,

a high source impedance will degrade the noise performance.

For example, a 1 kW resistor generates 4 nV/÷

Hz of broadband

noise, which is already greater than the noise of the preamp.

The collector current is set by R1 in combination with the LED

and Q2. The LED is a 1.6 V Zener diode that has a temperature

coefficient close to that of Q2’s base-emitter junction, which

provides a constant 1.0 V drop across R1. With R1 equal to 270 W,

the tail current is 3.7 mA and the collector current is half that, or

1.85 mA. The value of R1 can be altered to adjust the collector current. Whenever R1 is changed, R3 and R4 should also be adjusted.

To maintain a common-mode input range that includes ground,

the collectors of the Q1 and Q2 should not go above 0.5 V—otherwise

they could saturate. Thus, R3 and R4 must be small enough to

prevent this condition. Their values and the overall performance

for two different values of R1 are summarized in Table I. Lastly,

the potentiometer, R8, is needed to adjust the offset voltage to

null it to zero. Similar performance can be obtained using an OP90

as the output amplifier with a savings of about 185 mA of supply

current. However, the output swing will not include the positive

rail, and the bandwidth will reduce to approximately 250 Hz.

REV. C

–7–

Page 8

OP295/OP495

Table I. Single-Supply Low Noise Preamp Performance

IC = 1.85 mA IC = 0.5 mA

R1 270 W 1.0 kW

R3, R4 200 W 910 W

@ 100 Hz 3.15 nV/÷Hz 8.6 nV/÷Hz

e

n

e

@ 10 Hz 4.2 nV/÷Hz 10.2 nV/÷Hz

n

I

SY

I

B

4.0 mA 1.3 mA

11 mA3 mA

Bandwidth 1 kHz 1 kHz

Closed-Loop Gain 1,000 1,000

Driving Heavy Loads

The OP295/OP495 is well suited to drive loads by using a

power transistor, Darlington or FET to increase the current to

the load. The ability to swing to either rail can assure that the

device is turned on hard. This results in more power to the load

and an increase in efficiency over using standard op amps with

their limited output swing. Driving power FETs is also possible

with the OP295/OP495 because of its ability to drive capacitive

loads of several hundred picofarads without oscillating.

Without the addition of external transistors, the OP295/OP495

can drive loads in excess of ±15 mA with ± 15 V or +30 V

supplies. This drive capability is somewhat decreased at lower

supply voltages. At ±5 V supplies, the drive current is ±11 mA.

Driving motors or actuators in two directions in a single-supply

application is often accomplished using an “H” bridge. The principle is demonstrated in Figure 3a. From a single 5 V supply this

driver is capable of driving loads from 0.8 V to 4.2 V in both directions. Figure 3b shows the voltages at the inverting and noninverting

outputs of the driver. There is a small crossover glitch that is frequency

dependent and would not cause problems unless this was a low

distortion application such as audio. If this is used to drive inductive loads, be sure to add diode clamps to protect the bridge from

inductive kickback.

5V

2N2222

VIN 2.5V

0

5k⍀

10k⍀

2N2222

OUTPUTS

Direct Access Arrangement

OP295/OP495 can be used in a single-supply Direct Access

Arrangement (DAA) as is shown in Figure 4. This figure shows

a portion of a typical DM capable of operating from a single 5 V

supply and it may also work on 3 V supplies with minor modifications. Amplifiers A2 and A3 are configured so that the transmit

signal TXA is inverted by A2 and is not inverted by A3. This arrangement drives the transformer differentially so that the drive to the

transformer is effectively doubled over a single amplifier arrangement. This application takes advantage of the OP295/OP495’s

ability to drive capacitive loads, and to save power in single-supply

applications.

390pF

37.4k⍀

0.1F

RXA

0.0047F

OP295/

A1

3.3k⍀

A2

OP295/

OP495

20k⍀

20k⍀

475⍀

OP495

22.1k⍀

0.1F

TXA

2.5V REF

20k⍀

OP295/

OP495

750pF

20k⍀

20k⍀

A3

0.033F

1:1

Figure 4. Direct Access Arrangement

A Single-Supply Instrumentation Amplifier

The OP295/OP495 can be configured as a single-supply instrumentation amplifier as in Figure 5. For our example, V

V +

equal to

common-mode voltage range includes ground and the output

and VO is measured with respect to V

2

REF

is set

REF

. The input

swings to both rails.

1.67V

10k⍀ 10k⍀

2N2907

2N2907

Figure 3a. “H” Bridge

100

90

10

0%

2V

2V

1ms

Figure 3b. “H” Bridge Outputs

1/2

V+

OP295/

5

8

V

IN

R1

100k⍀

V

REF

1/2

OP295/

OP495

3

2

1

R2

20k⍀ 20k⍀ 100k⍀

VO = 5 +

R

G

200k⍀

R

G

R3

VIN + V

4

6

R4

REF

OP495

V

7

O

Figure 5. Single-Supply Instrumentation Amplifier

Resistor RG sets the gain of the instrumentation amplifier. Minimum gain is 6 (with no R

). All resistors should be matched in

G

absolute value as well as temperature coefficient to maximize

–8–

REV. C

Page 9

OP295/OP495

common-mode rejection performance and minimize drift. This

instrumentation amplifier can operate from a supply voltage as

low as 3 V.

A Single-Supply RTD Thermometer Amplifier

This RTD amplifier takes advantage of the rail-to-rail swing of

the OP295/OP495 to achieve a high bridge voltage in spite of a

low 5 V supply. The OP295/OP495 amplifier servos a constant

200 mA current to the bridge. The return current drops across

the parallel resistors 6.19 kW and the 2.55 MW, developing a

voltage that is servoed to 1.235 V, which is established by the

AD589 bandgap reference. The 3-wire RTD provides an equal

line resistance drop in both 100 W legs of the bridge, thus improving

the accuracy.

The AMP04 amplifies the differential bridge signal and converts it

to a single-ended output. The gain is set by the series resistance of

the 332 W resistor plus the 50 W potentiometer. The gain scales the

output to produce a 4.5 V full scale. The 0.22 mF capacitor to the

output provides a 7 Hz low-pass filter to keep noise at a minimum.

ZERO ADJ

10-TURNS

26.7k⍀

2.55M⍀

1%

0.5%

100⍀

RTD

200⍀

100⍀

0.5%

6.19k⍀

1%

26.7k⍀

0.5%

2

AD589

1

3

7

3

2

1/2

OP295/

OP495

1.235

37.4k⍀

5V

1

AMP04

4

8

5

5V

50⍀

332⍀

0.22F

6

4.5V = 450ⴗC

0V = 0ⴗC

V

O

To calibrate, immerse the thermocouple measuring junction in a

0∞C ice bath, adjust the 500 W Zero Adjust pot to zero volts out.

Then immerse the thermocouple in a 250∞C temperature bath

or oven and adjust the Scale Adjust pot for an output voltage of

2.50 V, which is equivalent to 250∞C. Within this temperature

range, the K-type thermocouple is quite accurate and produces

a fairly linear transfer characteristic. Accuracy of ±3∞C is achievable without linearization.

Even if the battery voltage is allowed to decay to as low as 7 V, the

rail-to-rail swing allows temperature measurements to 700∞C.

However, linearization may be necessary for temperatures above

250∞C where the thermocouple becomes rather nonlinear. The

circuit draws just under 500 mA supply current from a 9 V battery.

A 5 V Only, 12-Bit DAC That Swings 0 V to 4.095 V

Figure 8 shows a complete voltage output DAC with wide output

voltage swing operating off a single 5 V supply. The serial input

12-bit D/A converter is configured as a voltage output device with

the 1.235 V reference feeding the current output pin (I

DAC. The V

which is normally the input now becomes the output.

REF

OUT

) of the

The output voltage from the DAC is the binary weighted voltage

of the reference, which is gained up by the output amplifier such

that the DAC has a 1 mV per bit transfer function.

5V 5V

1.23V

R1

17.8k⍀

3

AD589

I

OUT

V

DAC8043

GND CLK SRI

8

DD

4765

2

R

FB

1

V

REF

LD

5V

D

V

= (4.096V)

O

8

3

2

4

OP295/

4096

1

OP495

Figure 6. Low Power RTD Amplifier

A Cold Junction Compensated, Battery-Powered

Thermocouple Amplifier

The OP295/OP495’s 150 mA quiescent current per amplifier

consumption makes it useful for battery-powered temperature

measuring instruments. The K-type thermocouple terminates

into an isothermal block where the terminated junctions’ ambient temperatures can be continuously monitored and corrected

by summing an equal but opposite thermal EMF to the amplifier, thereby canceling the error introduced by the cold junctions.

1.235V

24.9k⍀

ISOTHERMAL

ALUMEL

AL

CR

CHROMEL

K-TYPE

THERMOCOUPLE

40.7V/ ⴗC

BLOCK

1N914

COLD

JUNCTIONS

AD589

7.15k⍀

1%

1.5M⍀1%24.9k⍀

1%

475⍀

1%

24.3k⍀

1%

4.99k⍀

1%

500⍀

10-TURN

ZERO

ADJUST

2.1k⍀

1%

9V

2

3

1.33M⍀

8

4

SCALE

ADJUST

20k⍀

1

OP295/

OP495

V

O

5V = 500ⴗC

0V = 0ⴗC

Figure 7. Battery-Powered, Cold-Junction Compensated

Thermocouple Amplifier

DIGITAL

CONTROL

TOTA L POWER DISSIPATION = 1.6mW

R2

41.2k⍀

R3

5k⍀

R4

100k⍀

Figure 8. A 5 V 12-Bit DAC with 0 V to 4.095 Output Swing

4 mA to 20 mA Current Loop Transmitter

Figure 9 shows a self powered 4 mA to 20 mA current loop

transmitter. The entire circuit floats up from the single-supply

(12 V to 36 V) return. The supply current carries the signal within

the 4 mA to 20 mA range. Thus the 4 mA establishes the baseline

current budget with which the circuit must operate. This circuit

consumes only 1.4 mA maximum quiescent current, making 2.6 mA

of current available to power additional signal conditioning circuitry

or to power a bridge circuit.

SPAN ADJ

V

IN

0 + 3V

10k⍀

10-TURN

182k⍀

1%

100k⍀

10-TURN

1.21M

1%

HP

5082-2800

NULL ADJ

3

2

220pF

100k⍀

1%

62

REF02

GND

4

5V

8

4

1/2

100⍀

220⍀

1

2N1711

OP295/

OP495

100⍀

1%

4mA

TO

20mA

12V

TO

36V

R

L

100⍀

REV. C

Figure 9. 4 mA to 20 mA Current Loop Transmitter

–9–

Page 10

OP295/OP495

O

A 3 V Low-Dropout Linear Voltage Regulator

Figure 10 shows a simple 3 V voltage regulator design. The

regulator can deliver 50 mA load current while allowing a 0.2 V

dropout voltage. The OP295/OP495’s rail-to-rail output swing

handily drives the MJE350 pass transistor without requiring special

drive circuitry. At no load, its output can swing less than the pass

transistor’s base-emitter voltage, turning the device nearly off. At

full load, and at low emitter-collector voltages, the transistor beta

tends to decrease. The additional base current is easily handled

by the OP295/OP495 output.

The amplifier servos the output to a constant voltage, which

feeds a portion of the signal to the error amplifier.

Higher output current, to 100 mA, is achievable at a higher

dropout voltage of 3.8 V.

I

< 50mA

1.235V

L

44.2k⍀

1%

30.9k⍀

1%

OP295/

OP495

V

100F

1/2

V

5V TO 3.2V

MJE 350

IN

43k⍀

1

1000pF

8

4

AD589

3

2

Figure 10. 3 V Low Dropout Voltage Regulator

Figure 11 shows the regulator’s recovery characteristic when its

output underwent a 20 mA to 50 mA step current change.

If the output current greater than 1 amp persists, the current limit

loop forces a reduction of current to the load, which causes a

corresponding drop in output voltage. As the output voltage

drops, the current limit threshold also drops fractionally, resulting

in a decreasing output current as the output voltage decreases,

to the limit of less than 0.2 A at 1 V output. This “fold-back”

effect reduces the power dissipation considerably during a short

circuit condition, thus making the power supply far more forgiving

in terms of the thermal design requirements. Small heat sinking

on the power MOSFET can be tolerated.

The OP295’s rail-to-rail swing exacts higher gate drive to the

power MOSFET, providing a fuller enhancement to the transistor.

The regulator exhibits 0.2 V dropout at 500 mA of load current.

At 1 amp output, the dropout voltage is typically 5.6 V.

R

5

6

3

124k⍀

2

0.1⍀

1/4W

210k⍀

1%

45.3k⍀

1%

1%

IRF9531

SD

6V

G

1N4148

8

7

A2

1/2

OP295/

5%

OP495

0.01F

1/2

OP295/

A1

1

4

100k⍀

OP495

2

REF43

4

6

2.500V

SENSE

(NORM) = 0.5A

I

O

(MAX) = 1A

I

O

205k⍀

1%

45.3k⍀

1%

124k⍀

1%

5V V

O

2V

100

50mA

20mA

OUTPUT

90

10

0%

20mV

1ms

STEP

CURRENT

CONTROL

WAVEFORM

Figure 11. Output Step Load Current Recovery

Low-Dropout, 500 mA Voltage Regulator with Fold-Back

Current Limiting

Adding a second amplifier in the regulation loop as shown in

Figure 12 provides an output current monitor as well as foldback current limiting protection.

Amplifier A1 provides error amplification for the normal voltage

regulation loop. As long as the output current is less than 1 A,

amplifier A2’s output swings to ground, reverse biasing the diode and effectively taking itself out of the circuit. However, as

the output current exceeds 1 amp, the voltage that develops

across the 0.1 W sense resistor forces the amplifier A2’s output

to go high, forward-biasing the diode, which in turn closes the

current limit loop. At this point A2’s lower output resistance

dominates the drive to the power MOSFET transistor, thereby

effectively removing the A1 voltage regulation loop from the circuit.

Figure 12. Low Dropout, 500 mA Voltage Regulator with

Fold-Back Current Limiting

Square Wave Oscillator

The circuit in Figure 13 is a square wave oscillator (note the

positive feedback). The rail-to-rail swing of the OP295/OP495

helps maintain a constant oscillation frequency even if the supply

voltage varies considerably. Consider a battery powered system

where the voltages are not regulated and drop over time. The

rail-to-rail swing ensures that the noninverting input sees the full

V+/2, rather than only a fraction of it.

The constant frequency comes from the fact that the 58.7 kW

feedback sets up Schmitt Trigger threshold levels that are directly

proportional to the supply voltage, as are the RC charge voltage

levels. As a result, the RC charge time, and therefore, the frequency,

remains constant independent of supply voltage. The slew rate

of the amplifier limits oscillation frequency to a maximum of

about 800 Hz at a 5 V supply.

Single-Supply Differential Speaker Driver

Connected as a differential speaker driver, the OP295/OP495

can deliver a minimum of 10 mA to the load. With a 600 W

load, the OP295/OP495 can swing close to 5 V peak-to-peak

across the load.

–10–

REV. C

Page 11

OP295/OP495

V+

100k⍀

100k⍀

58.7k⍀

C

8

3

1

1/2

4

2

OP295/

OP495

R

FREQ OUT

F

=

OSC

1

< 350Hz @ V+ = 5V

RC

Figure 13. Square Wave Oscillator Has Stable Frequency

Regardless of Supply Changes

90.9k⍀90.9k⍀

V

IN

20k⍀ 20k⍀

V+

10k⍀

2.2F

10k⍀

1/4

OP295/

OP495

100k⍀

V+

1/4

OP295/

OP495

1/4

OP295/

OP495

SPEAKER

Figure 14. Single-Supply Differential Speaker Driver

High Accuracy, Single-Supply, Low Power Comparator

The OP295/OP495 makes an accurate open-loop comparator.

With a single 5 V supply, the offset error is less than 300 mV. Figure

15 shows the OP295/OP495’s response time when operating

open-loop with 4 mV overdrive. It exhibits a 4 ms response time at

the rising edge and a 1.5 ms response time at the falling edge.

1V

100

90

INPUT

(5mV OVERDRIVE

@ OP-295 INPUT)

OUTPUT

10

0%

2V

5ms

Figure 15. Open-Loop Comparator Response Time with

5 mV Overdrive

OP295/OP495 SPICE MODEL Macro-Model

* Node Assignments

* Noninverting Input

* Inverting Input

* Positive Supply

* Negative Supply

* Output

*

*

.SUBCKT OP295 1 2 99 50 20

*

* INPUT STAGE

*

I1 99 4 2E-6

R1 1 6 5E3

R2 2 5 5E3

CIN 1 2 2E-12

IOS 1 2 0.5E-9

D1 5 3 DZ

D2 6 3 DZ

EOS 7 6 POLY (1) (31,39) 30E-6 0.024

Q1 8 5 4 QP

Q2 9 74QP

R3 8 50 25.8E3

R4 9 50 25.8E3

*

* GAIN STAGE

*

R7 10 98 270E6

G1 98 10 POLY (1) (9,8) –4.26712E-9 27.8E-6

EREF 98 0 (39, 0) 1

R5 99 39 100E3

R6 39 50 100E3

*

* COMMON MODE STAGE

*

ECM 30 98 POLY(2) (1,39) (2,39) 0 0.5 0.5

R12 30 31 1E6

R13 31 98 100

*

* OUTPUT STAGE

*

I2 18 50 1.59E-6

V2 99 12 DC 2.2763

Q4 10 14 50 QNA 1.0

R11 14 50 33

M3 15 10 13 13 MN L=9E-6 W=102E-6 AD=15E-10 AD=15E-10

M4 13 10 50 50 MN L=9E-6 W=50E-6 AD=75E-11 AS=75E-11

D8 10 22 DX

V3 22 50 DC 6

M2 20 10 14 14 MN L=9E-6 W=2000E-6 AD=30E-9 AS=30E-9

Q5 17 17 99 QPA 1.0

Q6 18 17 99 QPA 4.0

R8 18 99 2.2E6

Q7 18 19 99 QPA 1.0

R9 99 19 8

C2 18 99 20E-12

M6 15 12 17 99 MP L=9E-6 W=27E-6 AD=405E-12 AS=405E-12

M1 20 18 19 99 MP L=9E-6 W=2000E-6 AD=30E-9 AS=30E-9

D4 21 18 DX

V4 99 21 DC 6

R10 10 11 6E3

C3 11 20 50E-12

.MODEL QNA NPN (IS=1.19E-16 BF=253 NF=0.99 VAF=193 IKF=2.76E-3

+ ISE=2.57E-13 NE=5 BR=0.4 NR=0.988 VAR=15 IKR=1.465E-4

+ ISC=6.9E-16 NC=0.99 RB=2.0E3 IRB=7.73E-6 RBM=132.8 RE=4

RC=209

+ CJE=2.1E-13 VJE=0.573 MJE=0.364 FC=0.5 CJC=1.64E-13 VJC=0.534

MJC=0.5

+ CJS=1.37E-12 VJS=0.59 MJS=0.5 TF=0.43E-9 PTF=30)

.MODEL QPA PNP (IS=5.21E-17 BF=131 NF=0.99 VAF=62 IKF=8.35E-4

+ ISE=1.09E-14 NE=2.61 BR=0.5 NR=0.984 VAR=15 IKR=3.96E-5

+ ISC=7.58E-16 NC=0.985 RB=1.52E3 IRB=1.67E-5 RBM=368.5 RE=6.31

RC=354.4

+ CJE=1.1E-13 VJE=0.745 MJE=0.33 FC=0.5 CJC=2.37E-13 VJC=0.762

MJC=0.4

+ CJS =7.11E-13 VJS=0.45 MJS=0.412 TF=1.0E-9 PTF=30)

.MODEL MN NMOS (LEVEL=3 VTO=1.3 RS=0.3 RD=0.3

+ TOX=8.5E-8 LD=1.48E-6 NSUB=1.53E16 UO=650 DELTA=10 VMAX=2E5

+ XJ=1.75E-6 KAPPA=0.8 ETA=0.066 THETA=0.01 TPG=1 CJ=2.9E-4

PB=0.837

+ MJ=0.407 CJSW=0.5E-9 MJSW=0.33)

.MODEL MP PMOS (LEVEL=3 VTO=–1.1 RS=0.7 RD=0.7

+ TOX=9.5E-8 LD=1.4E-6 NSUB=2.4E15 UO=650 DELTA=5.6 VMAX=1E5

+ XJ=1.75E-6 KAPPA=1.7 ETA=0.71 THETA=5.9E-3 TPG=–1 CJ=1.55E-4

PB=0.56

+ MJ=0.442 CJSW=0.4E-9 MJSW=0.33)

.MODEL DX D(IS=1E-15)

.MODEL DZ D (IS=1E-15, BV=7)

.MODEL QP PNP (BF=125)

.ENDS

REV. C

–11–

Page 12

OP295/OP495

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm)

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

PIN 1

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

8-Lead Plastic DIP

0.430 (10.92)

0.348 (8.84)

8

14

0.100 (2.54)

BSC

0.022 (0.558)

0.014 (0.356)

0.070 (1.77)

0.045 (1.15)

14-Lead Plastic DIP

0.795 (20.19)

0.725 (18.42)

14

17

0.100 (2.54)

BSC

0.022 (0.558)

0.014 (0.356)

(P Suffix)

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

(P Suffix)

8

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

0.195 (4.95)

0.115 (2.93)

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

16

1

PIN 1

0.1968 (5.00)

0.1890 (4.80)

85

0.0500 (1.27)

PLANE

0.4133 (10.50)

0.3977 (10.00)

0.050 (1.27)

BSC

8-Lead Narrow-Body SO

(S Suffix)

0.2440 (6.20)

0.2284 (5.80)

41

BSC

0.0192 (0.49)

0.0138 (0.35)

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0075 (0.19)

16-Lead Wide-Body SO

(S Suffix)

9

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

8

0.3937 (10.00)

0.1043 (2.65)

0.0926 (2.35)

0.0196 (0.50)

0.0099 (0.25)

8ⴗ

0.0500 (1.27)

0ⴗ

0.0160 (0.41)

0.0291 (0.74)

0.0098 (0.25)

ⴛ 45ⴗ

C00331–0–4/02(C)

ⴛ 45ⴗ

0.0118 (0.30)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

SEATING

PLANE

0.0125 (0.32)

0.0091 (0.23)

8ⴗ

0ⴗ

0.0500 (1.27)

0.0157 (0.40)

Revision History

Location Page

03/02—Data Sheet changed from REV. B to REV. C.

Figure changes to PIN CONNECTIONS ..................................................................................................................................... 1

Deletion of OP295GBC and OP495GBC from ORDERING GUIDE .......................................................................................... 3

Deletion of WAFER TEST LIMITS table .................................................................................................................................... 3

Changes to ABSOLUTE MAXIMUM RATINGS........................................................................................................................ 4

Deletion of DICE CHARACTERISTICS .................................................................................................................................... 4

PRINTED IN U.S.A.

–12–

REV. C

Loading...

Loading...