Page 1

Precision, Micropower

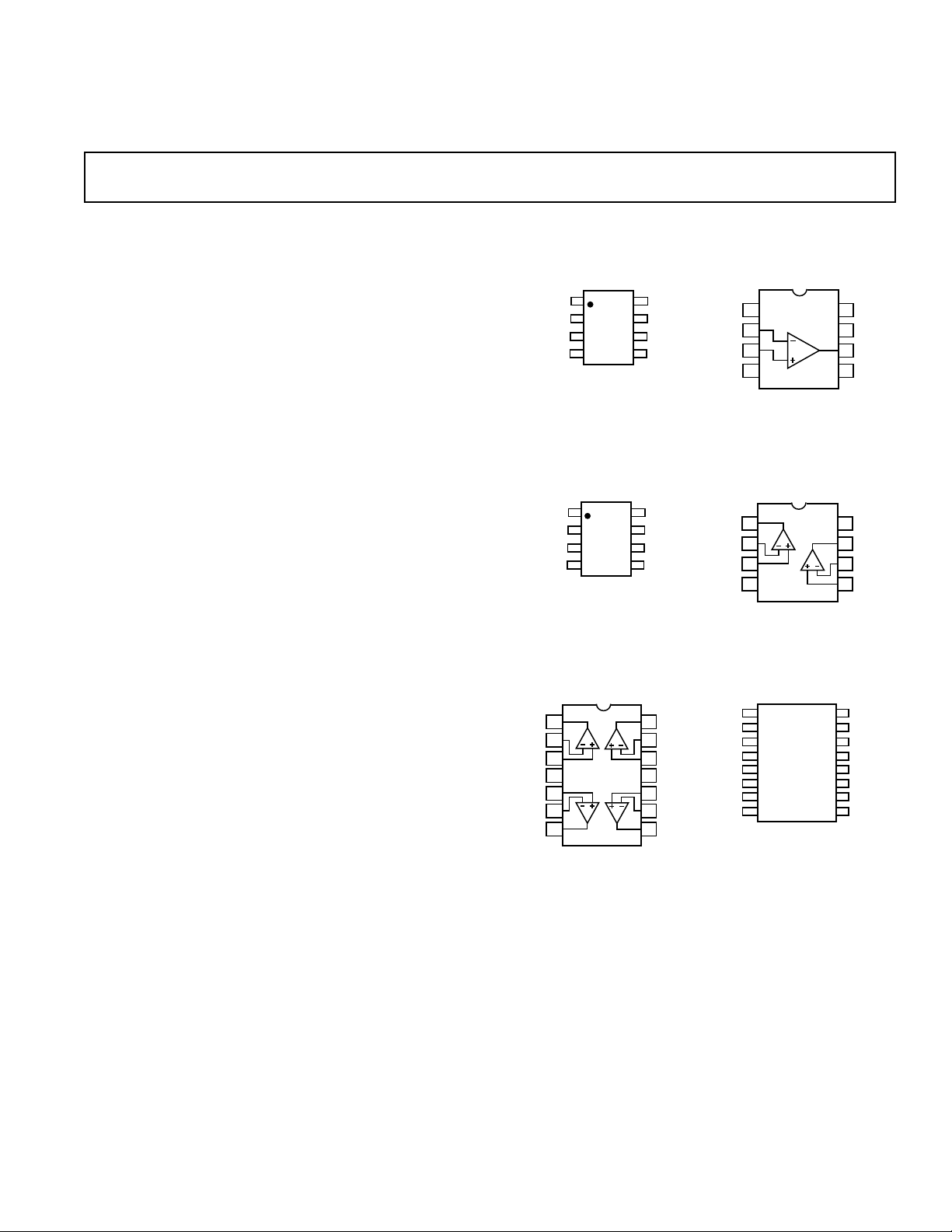

NC = NO CONNECT

1

2

3

4

8

7

6

5

OUT A

V+

NULL

NC

NULL

–IN A

+IN A

V–

OP193

OP193

OUT A

V+

NULL

NCNULL

–IN A

+IN A

V–

14

13

12

11

10

9

8

1

2

3

4

5

6

7

OP493

OUT A

–IN A

+IN A

V+

+IN B

–IN B

OUT B

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

OP493

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

NC

OUT A

–IN A

+IN A

V+

+IN B

–IN B

OUT B

NC

NC = NO CONNECT

a

FEATURES

Operates from +1.7 V to 618 V

Low Supply Current: 15 mA/Amplifier

Low Offset Voltage: 75 mV

Outputs Sink and Source: 68 mA

No Phase Reversal

Single or Dual Supply Operation

High Open-Loop Gain: 600 V/mV

Unity-Gain Stable

APPLICATIONS

Digital Scales

Strain Gages

Portable Medical Equipment

Battery Powered Instrumentation

Temperature Transducer Amplifier

GENERAL DESCRIPTION

The OP193 family of single-supply operational amplifiers features a combination of high precision, low supply current and

the ability to operate at low voltages. For high performance in

single supply systems the input and output ranges include

ground, and the outputs swing from the negative rail to within

600 mV of the positive supply. For low voltage operation the

OP193 family can operate down to 1.7 volts or ± 0.85 volts.

The combination of high accuracy and low power operation

make the OP193 family useful for battery powered equipment.

Its low current drain and low voltage operation allow it to continue performing long after other amplifiers have ceased functioning either because of battery drain or headroom.

The OP193 family is specified for single +2 volt through dual

±15 volt operation over the HOT (–40°C to +125°C) tempera-

ture range. They are available in plastic DIPs, plus SOIC surface mount packages.

Operational Amplifiers

OP193/OP293/OP493*

PIN CONFIGURATIONS

8-Lead SO

(S Suffix)

8-Lead SO

(S Suffix)

OUT A

–IN A

OP293

+IN A

V–

14-Lead Epoxy DIP

(P Suffix)

V+

OUT B

–IN B

+IN B

8-Lead Epoxy DIP

(P Suffix)

8-Lead Epoxy DIP

(P Suffix)

OUT A

–IN A

+IN A

V–

1

OP293

2

3

4

8

7

6

5

V+

OUT B

–IN B

+IN B

16-Lead Wide Body SOL

(S Suffix)

*Patent pending.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1996

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

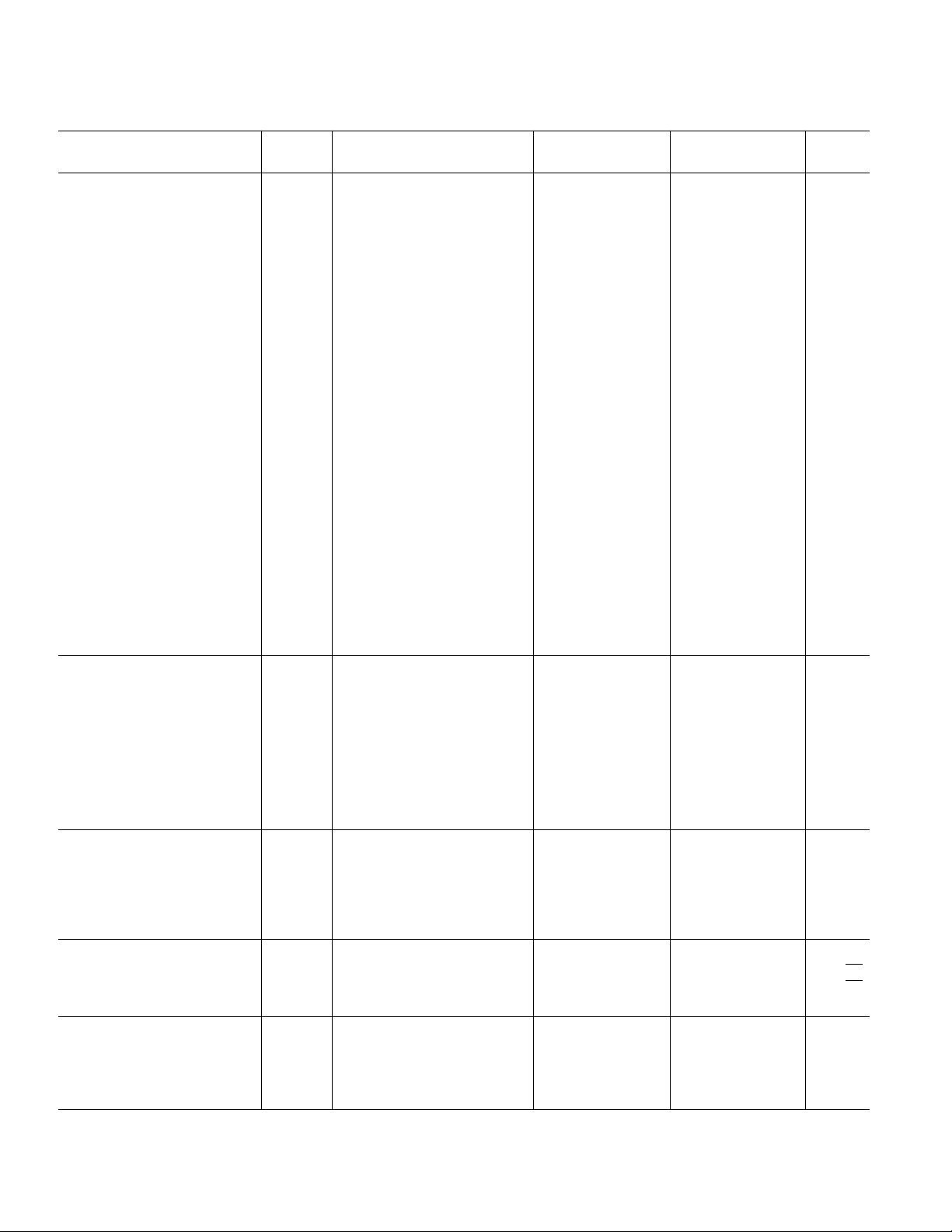

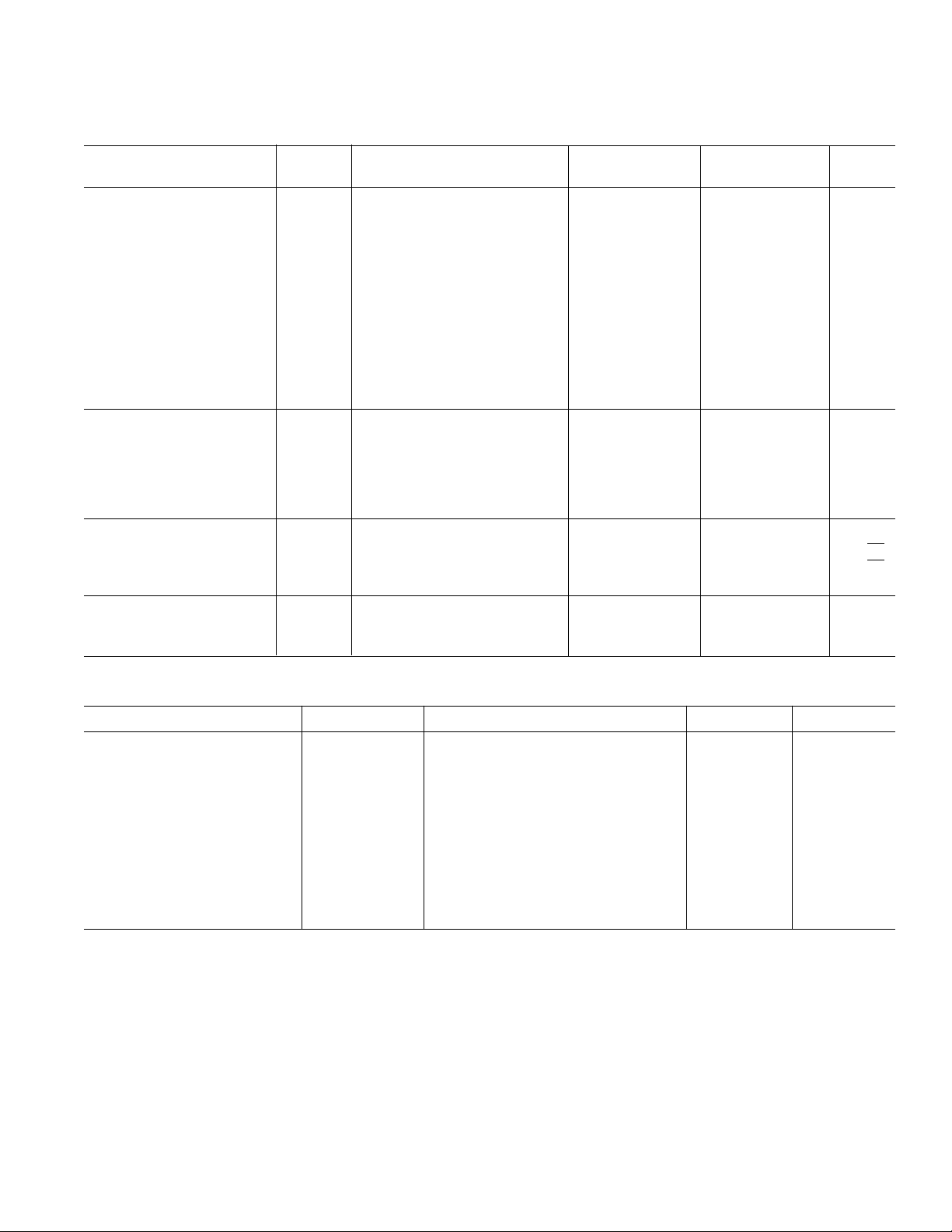

OP193/OP293/OP493–SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

(@ VS = 615.0 V, TA = +258C unless otherwise noted)

“E” Grade “F” Grade

Parameter Symbol Conditions Min Typ Max Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP193 75 150 µV

OP193, –40°C ≤ TA ≤ +125°C 175 250 µV

OP293 100 250 µV

OP293, –40°C ≤ T

≤ +125°C 200 350 µV

A

OP493 125 275 µV

Input Bias Current I

OP493, –40°C ≤ T

V

B

CM

= 0 V,

≤ +125°C 225 375 µV

A

–40°C ≤ TA ≤ +125°C1520nA

Input Offset Current I

OS

VCM = 0 V,

–40°C ≤ TA ≤ +125°C24nA

Input Voltage Range V

CM

–14.9 +13.5 –14.9 +13.5 V

Common-Mode Rejection CMRR –14.9 ≤ VCM ≤ +14 V 100 116 97 116 dB

–14.9 ≤ V

≤ +14 V,

CM

–40°C ≤ TA ≤ +125°C9794dB

Large Signal Voltage Gain A

VO

RL = 100 kΩ,

–10 V ≤ V

–40°C ≤ T

OUT

A

≤ +10 V 500 500 V/mV

≤ +85°C 300 300 V/mV

–40°C ≤ TA ≤ +125°C 300 300 V/mV

Large Signal Voltage Gain A

VO

RL = 10 kΩ,

–10 V ≤ V

OUT

–40°C ≤ T

≤ +10 V 350 350 V/mV

≤ +85°C 200 200 V/mV

A

–40°C ≤ TA ≤ +125°C 150 150 V/mV

Large Signal Voltage Gain A

VO

RL = 2 kΩ,

–10 V ≤ V

–40°C ≤ T

≤ +10 V 200 200 V/mV

OUT

≤ +85°C 125 125 V/mV

A

–40°C ≤ TA ≤ +125°C 100 100 V/mV

Long Term Offset Voltage V

OS

Note 1 150 300 µV

Offset Voltage Drift ∆VOS/∆T Note 2 0.2 1.75 µV/°C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

OH

IL = 1 mA +14.1 14.2 +14.1 14.2 V

I

= 1 mA,

L

–40°C ≤ TA ≤ +125°C +14.0 +14.0 V

I

= 5 mA +13.9 14.1 +13.9 14.1 V

Output Voltage Swing Low V

OL

L

IL = –1 mA –14.7 –14.6 -14.7 –14.6 V

I

= –1 mA,

L

–40°C ≤ TA ≤ +125°C –14.4 –14.4 V

I

= –5 mA 14.2 –14.1 14.2 –14.1 V

Short Circuit Current I

SC

L

±25 ±25 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

= ±1.5 V to ±18 V 100 120 97 120 dB

S

VS = ±1.5 V to ±18 V,

Supply Current/Amplifier I

–40°C ≤ T

SY

–40°C ≤ TA ≤ +125°C, RL = ∞

V

OUT

≤ +125°C9794dB

A

= 0 V, VS = ±18 V 30 30 µA

NOISE PERFORMANCE

Voltage Noise Density e

Current Noise Density i

n

n

f = 1 kHz 65 65 nV/√Hz

f = 1 kHz 0.05 0.05 pA/√Hz

Voltage Noise en p-p 0.1 Hz to 10 Hz 3 3 µV p-p

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 15 15 V/ms

L

Gain Bandwidth Product GBP 35 35 kHz

Channel Separation V

= 10 V p-p,

OUT

RL = 2 kΩ, f = 1 kHz 120 120 dB

NOTES

1

Long term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at +125°C, with an LTPD of 1.3.

2

Offset voltage drift is the average of the –40°C to +25°C delta and the +25 °C to +125 °C delta.

Specifications subject to change without notice.

–2–

REV. A

Page 3

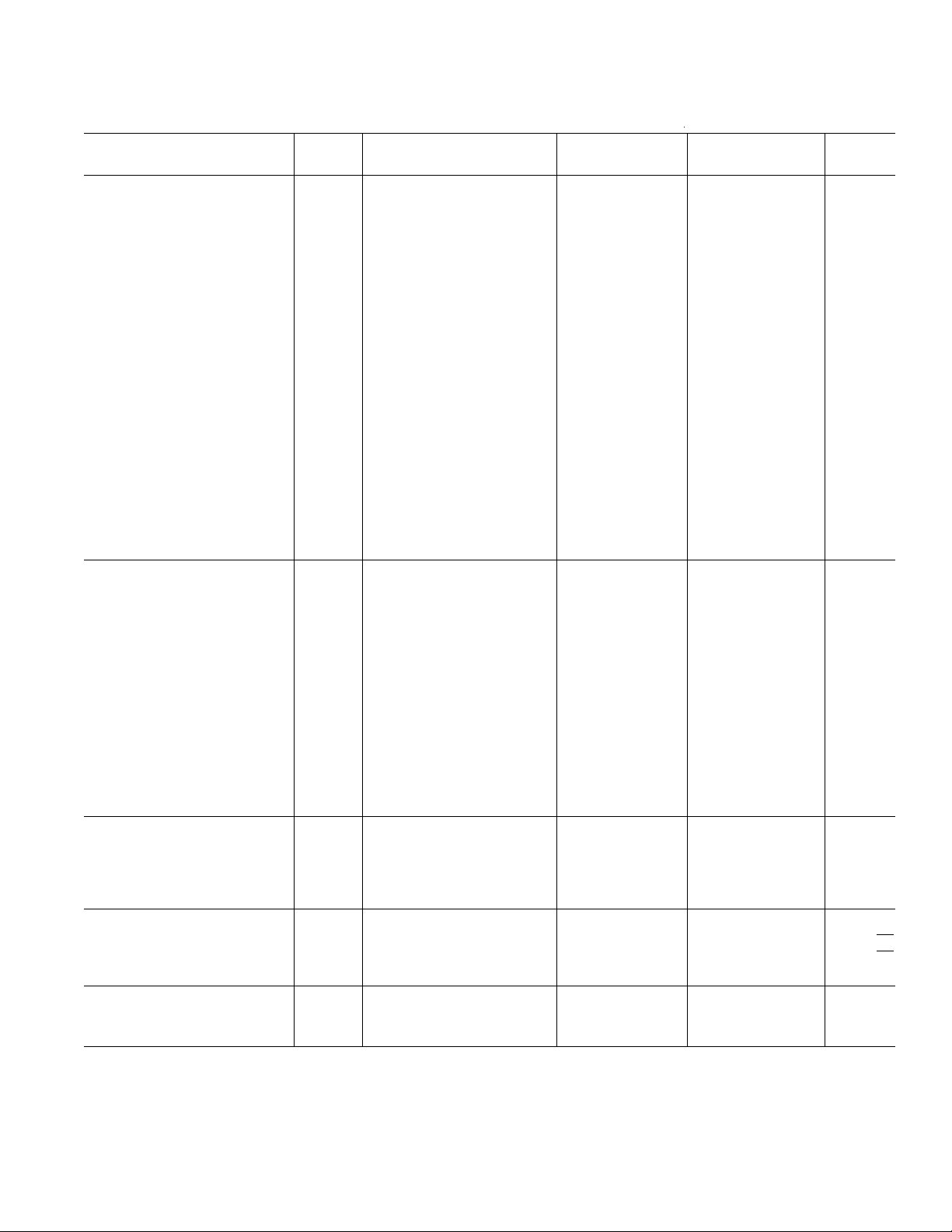

OP193/OP293/OP493

ELECTRICAL SPECIFICATIONS

(@ VS = +5.0 V, VCM = 0.1 V, TA = +258C unless otherwise noted)

“E” Grade “F” Grade

Parameter Symbol Conditions Min Typ Max Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP193 75 150 µV

OP193, –40°C ≤ T

≤ +125°C 175 250 µV

A

OP293 100 250 µV

OP293, –40°C ≤ T

≤ +125°C 200 350 µV

A

OP493 125 275 µV

OP493, –40°C ≤ T

Input Bias Current I

Input Offset Current I

Input Voltage Range V

B

OS

CM

–40°C ≤ TA ≤ +125°C1520nA

–40°C ≤ TA ≤ +125°C24nA

Common-Mode Rejection CMRR 0.1 ≤ V

≤ +4 V 100 116 96 116 dB

CM

≤ +125°C 225 375 µV

A

0404V

0.1 ≤ VCM ≤ +4 V,

Large Signal Voltage Gain A

VO

–40°C ≤ T

RL = 100 kΩ,

0.03 ≤ V

≤ +125°C92 92 dB

A

≤ +4.0 V 200 200 V/mV

OUT

–40°C ≤ TA ≤ +85°C 125 125 V/mV

Large Signal Voltage Gain A

VO

–40°C ≤ T

RL = 10 kΩ,

0.03 ≤ V

≤ +125°C 130 130 V/mV

A

≤ +4.0 V 75 75 V/mV

OUT

–40°C ≤ TA ≤ +85°C 50 50 V/mV

Long Term Offset Voltage V

OS

–40°C ≤ T

Note 1 150 300 µV

≤ +125°C 70 70 V/mV

A

Offset Voltage Drift ∆VOS/∆T Note 2 0.2 1.25 µV/°C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

OH

IL = 100 µA 4.4 4.4 V

IL = 1 mA +4.1 4.4 +4.1 4.4 V

I

= 1 mA,

L

–40°C ≤ TA ≤ +125°C +4.0 +4.0 V

I

= 5 mA +4.0 4.4 +4.0 4.4 V

Output Voltage Swing Low V

OL

L

IL = –100 µA 140 160 140 160 mV

I

= –100 µA,

L

–40°C ≤ TA ≤ +125°C 220 220 mV

No Load 5 5 mV

I

= –1 mA 280 400 280 400 mV

L

I

= –1 mA,

L

–40°C ≤ TA ≤ +125°C 500 500 mV

I

= –5 mA 700 900 700 900 mV

Short Circuit Current I

SC

L

±8 ±8mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

= ±1.7 V to ±6.0 V 100 120 97 120 dB

S

VS = ±1.5 V to ±18 V,

Supply Current/Amplifier I

–40°C ≤ T

SY

VCM = 2.5 V, RL = ∞ 14.5 14.5 µA

≤ +125°C94 90 dB

A

NOISE PERFORMANCE

Voltage Noise Density e

Current Noise Density i

n

n

f = 1 kHz 65 65 nV/√Hz

f = 1 kHz 0.05 0.05 pA/√Hz

Voltage Noise en p-p 0.1 Hz to 10 Hz 3 3 µV p-p

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 12 12 V/ms

L

Gain Bandwidth Product GBP 35 35 kHz

NOTES

1

Long term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at +125°C, with an LTPD of 1.3.

2

Offset voltage drift is the average of the –40°C to +25°C delta and the +25 °C to +125 °C delta.

Specifications subject to change without notice.

REV. A

–3–

Page 4

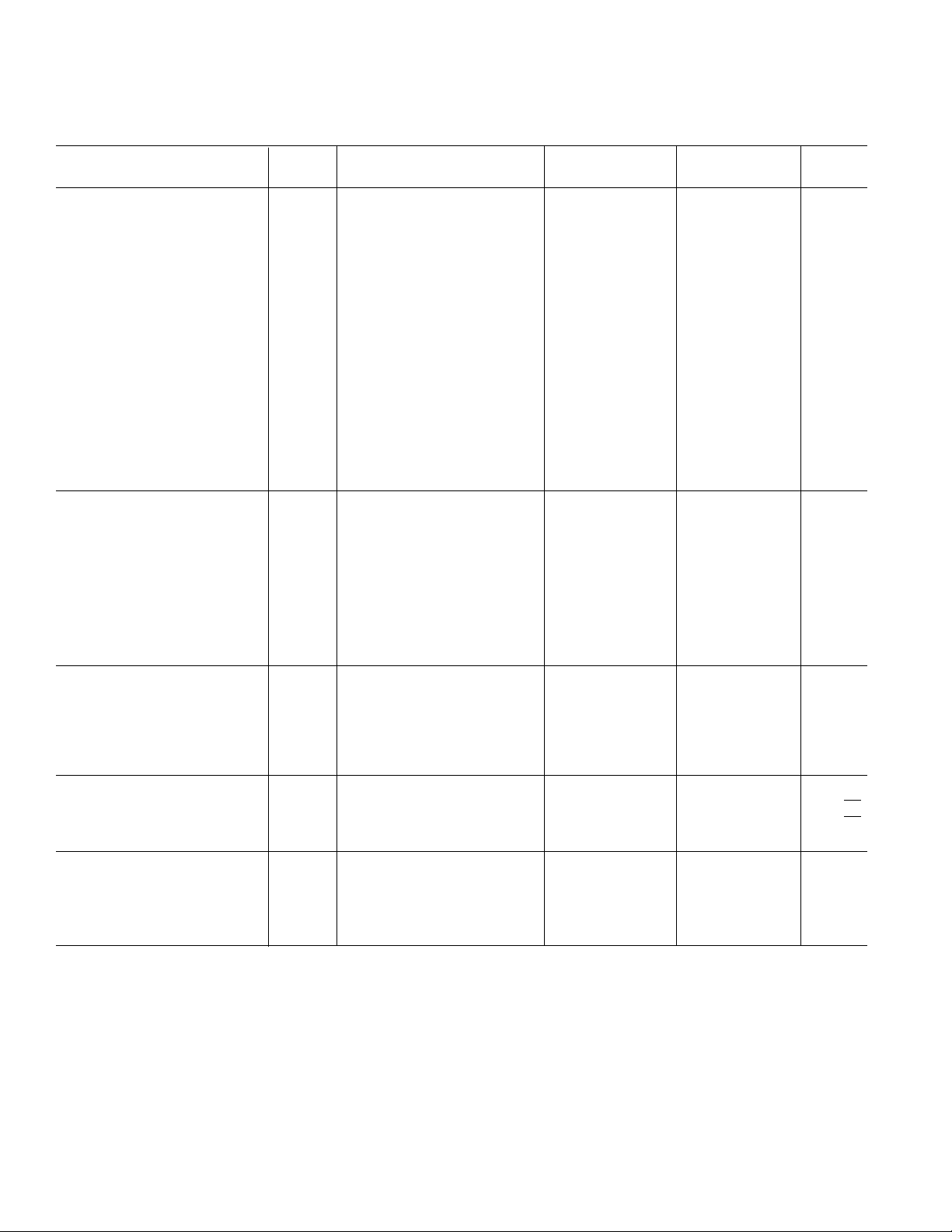

OP193/OP293/OP493

ELECTRICAL SPECIFICATIONS

(@ VS = +3.0 V, VCM = 0.1 V, TA = +258C unless otherwise noted)

“E” Grade “F” Grade

Parameter Symbol Conditions Min Typ Max Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP193 75 150 µV

OP193, –40°C ≤ T

≤ +125°C 175 250 µV

A

OP293 100 250 µV

OP293, –40°C ≤ T

≤ +125°C 200 350 µV

A

OP493 125 275 µV

OP493, –40°C ≤ T

Input Bias Current I

Input Offset Current I

Input Voltage Range V

B

OS

CM

–40°C ≤ TA ≤ +125°C1520nA

–40°C ≤ TA ≤ +125°C24nA

Common-Mode Rejection CMRR 0.1 ≤ V

≤ +2 V 97 116 94 116 dB

CM

≤ +125°C 225 375 µV

A

0202V

0.1 ≤ VCM ≤ +2 V,

Large Signal Voltage Gain A

VO

–40°C ≤ T

RL = 100 kΩ, 0.03 ≤ V

–40°C ≤ T

≤ +125°C9087dB

A

≤ +85°C 75 75 V/mV

A

≤ 2 V 100 100 V/mV

OUT

–40°C ≤ TA ≤ +125°C 100 100 V/mV

Long Term Offset Voltage V

OS

Note 1 150 300 µV

Offset Voltage Drift ∆VOS/∆T Note 2 0.2 1.25 µV/°C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

OH

IL = 1 mA +2.1 2.14 +2.1 2.14 V

IL = 1 mA,

–40°C ≤ T

≤ +125°C 1.9 1.9 V

A

IL = 5 mA +1.9 2.1 +1.9 2.1 V

Output Voltage Swing Low V

OL

IL = –1 mA 280 400 280 400 mV

IL = –1 mA

–40°C ≤ T

≤ +125°C 500 500 mV

A

IL = –5 mA 700 900 700 900 mV

Short Circuit Current I

SC

±8 ±8mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

= +1.7 V to +6 V, 100 97

S

–40°C ≤ TA ≤ +125°C9490dB

Supply Current/Amplifier I

SY

VCM = 1.5 V, RL = ∞ 14.5 22 14.5 22 µA

–40°C ≤ TA ≤ +125°C2222µA

Supply Voltage Range V

S

+2 ±18 +2 ±18 V

NOISE PERFORMANCE

Voltage Noise Density e

Current Noise Density i

n

n

f = 1 kHz 65 65 nV/√Hz

f = 1 kHz 0.05 0.05 pA/√Hz

Voltage Noise en p-p 0.1 Hz to 10 Hz 3 3 µV p-p

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 10 10 V/ms

L

Gain Bandwidth Product GBP 25 25 kHz

Channel Separation V

= 10 V p-p,

OUT

RL = 2 kΩ, f = 1 kHz 120 120 dB

NOTES

1

Long term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at +125°C, with an LTPD of 1.3.

2

Offset voltage drift is the average of the –40°C to +25°C delta and the +25 °C to +125 °C delta.

Specifications subject to change without notice.

–4–

REV. A

Page 5

OP193/OP293/OP493

ELECTRICAL SPECIFICATIONS

(@ VS = +2.0 V, VCM = 0.1 V, TA = +258C unless otherwise noted)

“E” Grade “F” Grade

Parameter Symbol Conditions Min Typ Max Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP193 75 150 µV

OP193, –40°C ≤ T

≤ +125°C 175 250 µV

A

OP293 100 250 µV

OP293, –40°C ≤ T

≤ +125°C 175 350 µV

A

OP493 125 275 µV

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Large Signal Voltage Gain A

B

OS

CM

VO

OP493, –40°C ≤ T

–40°C ≤ TA ≤ +125°C1520nA

–40°C ≤ TA ≤ +125°C24nA

RL = 100 kΩ, 0.03 ≤ V

≤ +125°C 225 375 µV

A

0101V

≤ 1 V 60 60 V/mV

OUT

–40°C ≤ TA ≤ +125°C 70 70 V/mV

Long Term Offset Voltage V

OS

Note 1 150 300 µV

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

Supply Voltage Range V

SY

S

= +1.7 V to +6 V, 100 97

S

–40°C ≤ T

≤ +125°C9490dB

A

VCM = 1.0 V, RL = ∞ 13.2 20 13.2 20 µA

–40°C ≤ T

≤ +125°C2525µA

A

+2 ±18 +2 ±18 V

NOISE PERFORMANCE

Voltage Noise Density e

Current Noise Density i

n

n

f = 1 kHz 65 65 nV/√Hz

f = 1 kHz 0.05 0.05 pA/√Hz

Voltage Noise en p-p 0.1 Hz to 10 Hz 3 3 µV p-p

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 10 10 V/ms

L

Gain Bandwidth Product GBP 25 25 kHz

W AFER TEST LIMITS

(@ VS = +5.0 V, VCM = 0.1 V, V

= 2 V, TA = +258C unless otherwise noted)

OUT

Parameter Symbol Conditions Limit Units

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range

1

OS

B

OS

V

CM

Common-Mode Rejection CMRR 0 ≤ V

Power Supply Rejection Ratio PSRR V

Large Signal Voltage Gain A

Output Voltage Swing High V

Output Voltage Swing Low V

Supply Current/Amplifier I

NOTES

Electrical tests and wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed for standard

product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

1

Guaranteed by CMRR test.

Specifications subject to change without notice.

VO

OH

OL

SY

VS = ±15 V, V

V

= +2 V, V

S

= 0 V ±75 µV max

OUT

= 1.0 V ±75 µV max

OUT

VCM = 1.0 V 20 nA max

VCM = 1.0 V 4 nA max

0 to 4 V min

≤ 4 V 96 dB min

CM

= ±1.5 V to ±18 V 100 dB min

S

RL = 100 kΩ 100 V/mV min

IL = 1 mA 4.1 V min

IL = –1 mA 400 mV max

VO = 0 V, RL = ∞, VS = ±18 V 25 µA max

REV. A

–5–

Page 6

OP193/OP293/OP493

2

1

3

4

6

5

7

2

1

34

6

5

8

7

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Input Voltage

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

2

. . . . . . . . . . . . . . . . . . . . . . . ±18 V

Output Short-Circuit Duration to Gnd . . . . . . . . . . Indefinite

Storage Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

OP193/OP293/OP493E, F . . . . . . . . . . . . –40°C to +125°C

Junction Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300°C

Package Type θ

8-Pin Plastic DIP (P) 103 43 °C/W

8-Pin SOIC (S) 158 43 °C/W

14-Pin Plastic DIP (P) 83 39 °C/W

16-Pin SOL (S) 92 27 °C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

For supply voltages less than ± 18 V, the input voltage is limited to the supply

voltage.

3

θJA is specified for the worst case conditions, i.e., θJA is specified for device in socket

for P-DIP, and θ

package.

is specified for device soldered in circuit board for SOIC

JA

1

3

JA

θ

JC

Units

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

OP193EP –40°C to +125°C 8-Pin Plastic DIP N-8

OP193ES –40°C to +125°C 8-Pin SOIC SO-8

OP193ES-REEL –40°C to +125°C 8-Pin SOIC SO-8

OP193ES-REEL7 –40°C to +125°C 8-Pin SOIC SO-8

OP193FP –40°C to +125°C 8-Pin Plastic DIP N-8

OP193FS –40°C to +125°C 8-Pin SOIC SO-8

OP193FS-REEL –40°C to +125°C 8-Pin SOIC SO-8

OP193FS-REEL7 –40°C to +125°C 8-Pin SOIC SO-8

OP193GBC +25°C DICE

OP293EP –40°C to +125°C 8-Pin Plastic DIP N-8

OP293ES –40°C to +125°C 8-Pin SOIC SO-8

OP293ES-REEL –40°C to +125°C 8-Pin SOIC SO-8

OP293ES-REEL7 –40°C to +125°C 8-Pin SOIC SO-8

OP293FP –40°C to +125°C 8-Pin Plastic DIP N-8

OP293FS –40°C to +125°C 8-Pin SOIC SO-8

OP293FS-REEL –40°C to +125°C 8-Pin SOIC SO-8

OP293FS-REEL7 –40°C to +125°C 8-Pin SOIC SO-8

OP293GBC +25°C DICE

OP493EP –40°C to +125°C 14-Pin Plastic DIP N-14

OP493ES –40°C to +125°C 16-Pin SOL SOL-16

OP493ES-REEL –40°C to +125°C 16-Pin SOL SOL-16

OP493FP –40°C to +125°C 14-Pin Plastic DIP N-14

OP493FS –40°C to +125°C 16-Pin SOL SOL-16

OP493FS-REEL –40°C to +125°C 16-Pin SOL SOL-16

OP493GBC +25°C DICE

DICE CHARACTERISTICS

1

8

7

OP193 Die Size 0.070 × 0.055 Inch, 3,850 Sq. Mils Substrate

(Die Backside) Is Connected to V– Transistor Count, 55

2

34

OP493 Die Size 0.106 × 0.143 Inch, 15,158 Sq. Mils Substrate

6

5

(Die Backside) Is Connected to V– Transistor Count, 215

OP293 Die Size 0.072 × 0.110 Inch, 7,920 Sq. Mils Substrate

(Die Backside) Is Connected to V– Transistor Count, 105

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the OP193/OP293/OP493 feature proprietary ESD protection circuitry, permanent

damage may occur on devices subjected to high energy electrostatic discharges. Therefore,

proper ESD precautions are recommended to avoid performance degradation or loss of

functionality.

–6–

WARNING!

ESD SENSITIVE DEVICE

REV. A

Page 7

T ypical Performance Characteristics–OP193/OP293/OP493

100

80

40

10 100 1k 10k

FREQUENCY – Hz

60

20

0

PSRR – dB

+PSRR

5V ≤ VS ≤ 30V

TA = +25°C

–PSRR

120

SHORT CIRCUIT CURRENT – mA

| –ISC

|

VS = ±15V

75

20

–50

0

10

TEMPERATURE – °C

30

–25 1250 25 50 100

40

+ISC

V

S

= ±15V

| –ISC

|

VS = +5V

+ISC

V

S

= +5V

200

VS = ±15V

= +25°C

T

160

120

80

40

NUMBER OF AMPLIFIERS

0

A

450 x PDIPS

OFFSET – µV

756030150–15–30–45–60–75

45

Figure 1. OP193 Offset Distribution,

V

= ±15 V

S

150

VS = ±15V

120

90

60

30

NUMBER OF AMPLIFIERS

–40°C ≤ T

450 x PDIPS

≤ +125°C

A

200

160

120

80

40

NUMBER OF AMPLIFIERS

0

–75

–45 6045–30 0 30

OFFSET – µV

VS = +3V

V

CM

= +25°C

T

A

450 x PDIPS

15–15–60

= 0.1V

75

Figure 2. OP193 Offset Distribution,

= +3 V

V

S

1

VS = +5V

0

–1

–2

–3

INPUT BIAS CURRENT – nA

–40°C

+125°C

+25°C

150

120

90

60

30

NUMBER OF AMPLIFIERS

0

0

0.2 0.80.4

TCV

OS

VS = +3V

V

= 0.1V

CM

–40°C ≤ T

450 x PDIPS

0.6

– µV/°C

≤ +125°C

A

1.0

Figure 3. OP193 TCVOS Distribution,

= +3 V

V

S

0

0

0.2 0.80.4

Figure 4. OP193 TCVOS Distribution,

= ±15 V

V

S

120

100

80

60

CMRR – dB

40

20

0

10 100 1k 10k

VS = +5V

FREQUENCY – Hz

Figure 7. CMRR vs. Frequency

REV. A

TCV

VS = ±15V

– µV/°C

OS

0.6

TA = +25°C

1.0

–4

0

1234

COMMON MODE VOLTAGE – Volts

5

Figure 5. Input Bias Current vs.

Common-Mode Voltage

25

20

15

10

SLEW RATE – V/ms

+SR = –SR

= ±15V

V

S

+SR = –SR

= +5V

V

S

5

0

–50

0 25 50 100

–25 125

TEMPERATURE – °C

75

Figure 8. Slew Rate vs. Temperature

–7–

Figure 6. PSRR vs. Frequency

Figure 9. Short Circuit Current vs.

Temperature

Page 8

OP193/OP293/OP493–Typical Performance Characteristics

0

–0.5

–0.10

–0.15

–0.20

INPUT OFFSET CURRENT – nA

–0.25

–50

VS = +2V

= 0.1V

V

CM

VS = ±15V

–25 1250 25 50 100

TEMPERATURE – °C

75

Figure 10. Input Offset Current vs.

Temperature

1000

5V ≤ VS ≤ 30V

= +25°C

T

A

100

10

0

–1

–2

–3

VS = +2V

INPUT BIAS CURRENT – nA

–4

V

CM

–5

–50

–25 1250 25 50 100

VS = ±15V

= 0.1V

75

TEMPERATURE – °C

Figure 11. Input Bias Current vs.

Temperature

1000

Hz

100

10

5V ≤ VS ≤ 30V

= +25°C

T

A

25

20

15

10

SUPPLY CURRENT – µA

5

0

–50

–25 1250 25 50 100

VS = ±18V

VS = +2V

V

CM

TEMPERATURE – °C

75

= +1V

Figure 12. Supply Current vs.

Temperature

10000

1000

100

DELTA

FROM V

DELTA

10

FROM V

CC

EE

5V ≤ VS ≤ 30V

TA = +25°C

VOLTAGE NOISE DENSITY – nV/√ Hz

1

0.1 1 10 100 1k

FREQUENCY – Hz

Figure 13. Voltage Noise Density vs.

Frequency

2500

2000

1500

1000

VOLTAGE GAIN – V/mV

500

VS = ±15V

–10V ≤ V

VS = +5V

0.03V ≤ V

0

–50

–25 1250 25 50 100

≤ +10V

OUT

≤ 4V

OUT

TEMPERATURE – °C

75

Figure 16. Voltage Gain (RL = 100 kΩ)

vs. Temperature

CURRENT NOISE DENSITY – pA/√

1

0.1 1 10 100 1k

FREQUENCY – Hz

Figure 14. Current Noise Density vs.

Frequency

1000

800

600

400

200

VOLTAGE GAIN – V/mV

0

–50

–25 1250 25 50 100

VS = ±15V

–10V ≤ V

VS = +5V

0.03V ≤ V

TEMPERATURE – °C

OUT

≤ 4V

OUT

≤ +10V

75

Figure 17. Voltage Gain (RL = 10 kΩ)

vs. Temperature

DELTA FROM SUPPLY RAIL – mV

1

0.1 1 10 100 1000 10000

LOAD CURRENT – µA

Figure 15. Delta Output Swing from

Either Rail vs. Current Load

60

TA = +25°C

= +5V

V

40

20

GAIN – dB

0

–20

10 100 1k 10k 100k

FREQUENCY – Hz

S

Figure 18. Closed-Loop Gain vs.

Frequency, V

= 5 V

S

–8–

REV. A

Page 9

OP193/OP293/OP493

GAIN – dB

60

40

100 1k 10k 100k 1M

0

–20

VS = +5V

FREQUENCY – Hz

20

PHASE

–40

GAIN

PHASE – Degrees

90

0

–45

45

–90

Q4

Q1

Q5

Q3

Q2

OUTPUT

I

1

I

2

I

3

FROM

INPUT

STAGE

V+

V–

60

40

20

GAIN – dB

0

–20

10 100 1k 10k 100k

Figure 19. Closed-Loop Gain vs.

Frequency, V

60

40

20

0

GAIN – dB

–20

–40

100 1k 10k 100k 1M

Figure 22. Open Loop, Gain and

Phase vs. Frequency

FUNCTIONAL DESCRIPTION

The OP193 family of operational amplifiers are single-supply,

micropower, precision amplifiers whose input and output ranges

both include ground. Input offset voltage (V

maximum, while the output will deliver ± 5 mA to a load. Supply current is only 17 µA.

A simplified schematic of the input stage is shown in Figure 23.

Input transistors Q1 and Q2 are PNP devices, which permit the

inputs to operate down to ground potential. The input transistors have resistors in series with the base terminals to protect the

junctions from over voltage conditions. The second stage is an

NPN cascode which is buffered by an emitter follower before

driving the final PNP gain stage.

The OP193 includes connections to taps on the input load resistors, which can be used to null the input offset voltage, V

The OP293 and OP493 have two additional transistors, Q7 and

Q8. The behavior of these transistors is discussed in the Output

Phase Reversal section of this data sheet.

The output stage, shown in Figure 24, is a noninverting NPN

“totem-pole” configuration. Current is sourced to the load by

emitter follower Q1, while Q2 provides current sink capability.

When Q2 saturates, the output is pulled to within 5 mV of

ground without an external pull-down resistor. The totem-pole

output stage will supply a minimum of 5 mA to an external

load, even when operating from a single 3.0 V power supply.

By operating as an emitter follower, Q1 offers a high impedance

load to the final PNP collector of the input stage. Base drive to

Q2 is derived by monitoring Q1’s collector current. Transistor

REV. A

FREQUENCY – Hz

= ±15 V

S

PHASE

GAIN

FREQUENCY – Hz

TA = +25°C

V

= ±15V

S

VS = ±15V

90

45

0

PHASE – Degrees

–45

–90

OS

60

VS = +5V TA = +25°C

A

= 1

V

50

50mV ≤ V

LOADS TO GND

40

30

20

OVERSHOOT – %

10

0

10 100 1000 10000

≤ 150mV

IN

+OS

=

∞

R

L

–OS

RL =

CAPACITIVE LOAD – pF

∞

+OS = | –OS

RL = 50kΩ

+OS = | –OS

RL = 10kΩ

Figure 20. Small Signal Overshoot

vs. Capacitive Load

+INPUT

2k

2k

–INPUT

OP293,

OP493

ONLY

) is only 75 µV

Figure 23. OP193/OP293/OP493 Equivalent Input Circuit

.

OS

Figure 24. OP193/OP293/OP493 Equivalent Output Circuit

Q5 tracks the collector current of Q1. When Q1 is on, Q5 keeps

Q4 off, and current source I1 keeps Q2 turned off. When Q1 is

driven to cutoff (i.e., the output must move toward V–), Q5

allows Q4 to turn on. Q4’s collector current then provides the

base drive for Q3 and Q2, and the output low voltage swing is

set by Q2’s V

–9–

|

|

Figure 21. Open Loop, Gain and

Phase vs. Frequency

I

1

Q1 Q2

Q7

R1

A

R1

B

NULLING

TERMINALS

(OP193 ONLY)

which is about 5 mV.

CE,SAT

Q8

R2

A

R2

B

Q3

V+

I

2

I3I

4

Q5

Q6

Q4

TO

I5I

OUTPUT

STAGE

6

V–

D1

Page 10

OP193/OP293/OP493

LITHIUM SULPHUR DIOXIDE

CELL VOLTAGE – Volts

50000

2

1

HOURS

3

1000 70002000 3000 4000 6000

4

0

OP493 OP293

OP193

6

5

7

4

1

2

3

V–

V+

OP193

100kΩ

Driving Capacitive Loads

OP193 family amplifiers are unconditionally stable with capacitive loads less than 200 pF. However, the small signal, unitygain overshoot will improve if a resistive load is added. For

example, transient overshoot is 20% when driving a 1000pF/

10 kΩ load. When driving large capacitive loads in unity-gain

configurations, an in-the-loop compensation technique is recommended as illustrated in Figure 28.

Input Overvoltage Protection

As previously mentioned, the OP193 family of op amps use a

PNP input stage with protection resistors in series with the

inverting and noninverting inputs. The high breakdown of the

PNP transistors, coupled with the protection resistors, provides

a large amount of input protection from over voltage conditions.

The inputs can therefore be taken 20 V beyond either supply

without damaging the amplifier.

Output Phase Reversal—OP193

The OP193’s input PNP collector-base junction can be forwardbiased if the inputs are brought more than one diode drop

(0.7 V) below ground. When this happens to the noninverting

input, Q4 of the cascode stage turns on and the output goes

high. If the positive input signal can go below ground, phase

reversal can be prevented by clamping the input to the negative

supply (i.e., GND) with a diode. The reverse leakage of the

diode will, of course, add to the input bias current of the amplifier. If input bias current is not critical, a 1N914 will add less

than 10 nA of leakage. However, its leakage current will double

for every 10°C increase in ambient temperature. For critical

applications, the collector-base junction of a 2N3906 transistor

will only add about 10 pA of additional bias current. To limit

the current through the diode under fault conditions, a 1 kΩ

resistor is recommended in series with the input. (The OP193’s

internal current limiting resistors will not protect the external

diode).

Output Phase Reversal—OP293 and OP493

The OP293 and OP493 include lateral PNP transistors Q7 and

Q8 to protect against phase reversal. If an input is brought more

than one diode drop (≈0.7 V) below ground, Q7 and Q8 combine to level shift the entire cascode stage, including the bias to

Q3 and Q4, simultaneously. In this case Q4 will not saturate

and the output remains low.

The OP293 and OP493 do not exhibit output phase reversal for

inputs up to –5 V below V– at +25°C. The phase reversal limit

at +125°C is about –3 V. If the inputs can be driven below these

levels, an external clamp diode, as discussed in the previous section, should be added.

Battery Powered Applications

OP193 series op amps can be operated on a minimum supply

voltage of +1.7 V, and draw only 13 µA of supply current per

amplifier from a 2.0 V supply. In many battery-powered circuits, OP193 devices can be continuously operated for thousands of hours before requiring battery replacement, thus

reducing equipment downtime and operating cost.

High performance portable equipment and instruments frequently use lithium cells because of their long shelf life, light

weight, and high energy density relative to older primary cells.

Most lithium cells have a nominal output voltage of 3 V and are

noted for a flat discharge characteristic. The low supply voltage

requirement of the OP193, combined with the flat discharge

characteristic of the lithium cell, indicates that the OP193 can

be operated over the entire useful life of the cell. Figure 25

shows the typical discharge characteristic of a 1 AH lithium cell

powering the OP193, OP293, and OP493, with each amplifier,

in turn, driving 2.1 Volts into a 100 kΩ load.

Figure 25. Lithium Sulfur Dioxide Cell Discharge Characteristic with OP193 Family and 100 k

Ω

Loads

Input Offset Voltage Nulling

The OP193 provides two offset nulling terminals that can be

used to adjust the OP193’s internal V

. In general, operational

OS

amplifier terminals should never be used to adjust system offset

voltages. The offset null circuit of Figure 26 provides about

±7 mV of offset adjustment range. A 100 kΩ resistor placed in

series with the wiper arm of the offset null potentiometer, as

shown in Figure 27, reduces the offset adjustment range to

400 µV and is recommended for applications requiring high null

resolution. Offset nulling does not adversely affect TCV

OS

performance, providing that the trimming potentiometer temperature coefficient does not exceed ±100 ppm/°C.

Figure 26. Offset Nulling Circuit

–10–

REV. A

Page 11

6

7

2

3

C1

1000pF

OP193

V

BE2

4

R2

1.5MΩ

Q1

V

OUT

(1.23V @ 25°C)

5

R1

240kΩ

V+

(+2.5V TO +36V)

Q2

1

2

3

7

6

5

V

BE1

MAT-01AH

∆V

BE

R3 68kΩ

R5 20kΩ

OUTPUT

ADJUST

R4

130kΩ

V1

6

7

2

3

OP193

4

R2

100kΩ

V

OUT =

100mV/mA(I

TEST

)

5

V+

1

R2

9.9kΩ

R3

100kΩ

R5

100Ω

R1

1Ω

TO CIRCUIT

UNDER TEST

I

TEST

V+

7

2

OP193

3

1

6

4

5

100kΩ

100kΩ

V–

Figure 27. High Resolution Offset Nulling Circuit

A Micropower False-Ground Generator

Some single supply circuits work best when inputs are biased

above ground, typically at 1/2 of the supply voltage. In these

cases a false ground can be created by using a voltage divider

buffered by an amplifier. One such circuit is shown in Figure 28.

This circuit will generate a false-ground reference at 1/2 of the

supply voltage, while drawing only about 27 µA from a 5 V sup-

ply. The circuit includes compensation to allow for a 1 µF by-

pass capacitor at the false-ground output. The benefit of a large

capacitor is that not only does the false ground present a very

low dc resistance to the load, but its ac impedance is low as well.

The OP193 can both sink and source more than 5 mA, which

improves recovery time from transients in the load current.

+5V OR +12V

10kΩ

0.022µF

240kΩ

7

240kΩ

1µF

2

3

OP193

4

100Ω

6

+2.5V OR +6V

1µF

Figure 28. A Micropower False-Ground Generator

A Battery Powered Voltage Reference

The circuit of Figure 29 is a battery-powered voltage reference

that draws only 17 µA of supply current. At this level, two AA

alkaline cells can power this reference for more than 18 months.

At an output voltage of 1.23 V @ 25°C, drift of the reference is

only 5.5 µV/°C over the industrial temperature range. Load

regulation is 85 µV/mA with line regulation at 120 µV/V.

Design of the reference is based on the Brokaw bandgap core

technique. Scaling of resistors R1 and R2 produces unequal currents in Q1 and Q2. The resulting ∆V

perature-proportional voltage (PTAT) which, in turn, produces

across R3 creates a tem-

BE

a larger temperature-proportional voltage across R4 and R5, V1.

The temperature coefficient of V1 cancels (first order) the

complementary to absolute temperature (CTAT) coefficient of

V

BE1

tempco is at a minimum. Bandgap references can have start-up

problems. With no current in R1 and R2, the OP193 is beyond

its positive input range limit and has an undefined output state.

Shorting Pin 5 (an offset adjust pin) to ground forces the output

high under these circumstances and insures reliable startup

. When adjusted to 1.23 V @ +25°C, output voltage

without significantly degrading the OP193’s offset drift.

REV. A

OP193/OP293/OP493

Figure 29. A Battery Powered Voltage Reference

A Single-Supply Current Monitor

Current monitoring essentially consists of amplifying the voltage

drop across a resistor placed in series with the current to be

measured. The difficulty is that only small voltage drops can be

tolerated, and with low precision op amps this greatly limits the

overall resolution. The single-supply current monitor of Figure

30 has a resolution of 10 µA and is capable of monitoring 30

mA of current. This range can be adjusted by changing the current sense resistor R1. When measuring total system current, it

may be necessary to include the supply current of the current

monitor, which bypasses the current sense resistor, in the final

result. This current can be measured and calibrated (together

with the residual offset) by adjustment of the offset trim potentiometer, R2. This produces a deliberate temperature dependent

offset. However, the supply current of the OP193 is also proportional to temperature, and the two effects tend to track. Current

in R4 and R5, which also bypasses R1, can be adjusted via a

gain trim.

Figure 30. Single-Supply Current Monitor

–11–

Page 12

OP193/OP293/OP493

+5V

V+

V–

+5V

V+

V–

V

OUT

+IN

1/2 OP293

A2

R4

1.98M

R3

20k

R2

1.98M

R1

20k

–IN

1/2 OP293

A1

+5V

10k

Q1

Q2

VN2222

I

OUT

+

V

TEMP

× R6 + R7

()

R2×R10

– V

SET

R2 + R6 + R7

R2 × R10

∆I

OUT

∆T

=

∆V

TEMP

∆T

(R6 + R7)

R2× R10

A Single-Supply Instrumentation Amplifier

Designing a true single-supply instrumentation amplifier with

zero-input and zero-output operation requires special care. The

traditional configuration, shown in Figure 31, depends upon

amplifier A1’s output being at 0 V when the applied commonmode input voltage is at 0 V. Any error at the output is multiplied by the gain of A2. In addition, current flows through

resistor R3 as A2’s output voltage increases. A1’s output must

remain at 0 V while sinking the current through R3, or a gain

error will result. With a maximum output voltage of 4 V, the

current through R3 is only 2 µA, but this will still produce an

appreciable error.

–IN

+IN

R1

20k

R2

1.98M

+5V

A1

1/2 OP293

R3

V+

V–

I

SINK

20k

R4

1.98M

+5V

V+

A2

1/2 OP293

V–

V

OUT

Figure 31. A Conventional Instrumentation Amplifier

One solution to this problem is to use a pull-down resistor. For

example, if R3 = 20 kΩ, then the pull-down resistor must be

less than 400 Ω. However, the pull-down resistor appears as a

fixed load when a common-mode voltage is applied. With a 4 V

common-mode voltage, the additional load current will be 10 mA,

which is unacceptable in a low power application.

Figure 32 shows a better solution. A1’s sink current is provided

by a pair of N-channel FET transistors, configured as a current

mirror. With the values shown, sink current of Q2 is about

340 µA. Thus, with a common-mode voltage of 4 V, the addi-

tional load current is limited to 340 µA versus 10 mA with a

400 Ω resistor.

REF-43BZ

V

TEMP

R3

100kΩ

R2

1kΩ

R5

5kΩ

V

2

IN

V

6

OUT

3

V

TEMP

GND

R1 10kΩ

4

ALL RESISTORS 1/4W, 5% UNLESS OTHERWISE NOTED

2

8

1

4

1/2 OP293

3

Figure 33. Temperature to 4–20 mA Transmitter

Figure 32. An Improved Single-Supply, 0 VIN, 0 V

OUT

Instrumentation Amplifier

A Low-Power, Temperature to 4–20 mA Transmitter

A simple temperature to 4–20 mA transmitter is shown in Figure 33. After calibration, this transmitter is accurate to ± 0.5°C

over the –50°C to +150°C temperature range. The transmitter

operates from +8 V to +40 V with supply rejection better than

3 ppm/V. One half of the OP293 is used to buffer the V

TEMP

pin, while the other half regulates the output current to satisfy

the current summation at its noninverting input:

The change in output current with temperature is the derivative

of the transfer function:

R4

20kΩ

ZERO

TRIM

1N4002

SPAN TRIM

R6

3kΩ

R7

5kΩ

6

1/2 OP293

V

SET

5

7

R9

100kΩ

1%, 1/2 W

R8

1kΩ

R10

100Ω

2N1711

I

OUT

R

LOAD

V+

+8V TO +40V

–12–

REV. A

Page 13

From the formulas, it can be seen that if the span trim is ad-

8

4

1/2 OP293

1

2

3

R3

100kΩ

V

CONTROL

R4

200kΩ

TRIANGLE

OUT

A1

+5V

R1

200kΩ

R2

200kΩ

1/2 OP293

6

5

7

A2

SQUARE

OUT

+5V

R6

200kΩ

R7

200kΩ

S3

S4

S1

1 IN/OUT

2 OUT/IN

CONT 12

OUT/IN 10

3 OUT/IN

S2

CONT 13

4 IN/OUT

6 CONT

5 CONT

7

V

SS

IN/OUT 8

IN/OUT 11

OUT/IN 9

V

DD

14

+5V

+5V

CD4066

R8

200kΩ

+5V

R5

200kΩ

C1

75nF

justed before the zero trim, the two trims are not interactive,

which greatly simplifies the calibration procedure.

Calibration of the transmitter is simple. First, the slope of the

output current versus temperature is calibrated by adjusting the

span trim, R7. A couple of iterations may be required to be sure

the slope is correct.

Once the span trim has been completed, the zero trim can be

made. Remember that adjusting the zero trim will not affect the

gain.

The zero trim can be set at any known temperature by adjusting

R5 until the output current equals:

OP193/OP293/OP493

I

OUT

=

∆I

∆T

OPERATING

FS

(T

AMBIENT−TMIN

)+ 4 mA

Table I shows the values of R6 required for various temperature

ranges.

Table I. R6 Values vs. Temperature

Temp Range R6

0°C to +70°C 10 kΩ

–40°C to +85°C 6.2 kΩ

–55°C to +150°C3 kΩ

A Micropower Voltage Controlled Oscillator

An OP293 in combination with an inexpensive quad CMOS

analog switch forms the precision VCO of Figure 34. This circuit provides triangle and square wave outputs and draws only

50 µA from a single 5 V supply. A1 acts as an integrator; S1

switches the charging current symmetrically to yield positive and

negative ramps. The integrator is bounded by A2 which acts as

a Schmitt trigger with a precise hysteresis of 1.67 volts, set by

resistors R5, R6, and R7, and associated CMOS switches. The

resulting output of A1 is a triangle wave with upper and lower

levels of 3.33 and 1.67 volts. The output of A2 is a square wave

with almost rail-to-rail swing. With the components shown, frequency of operation is given by the equation:

but this can easily be changed by varying C1. The circuit operates well up to 500 Hz.

f

OUT

= V

CONTROL

(Volts) × 10 Hz/V

Figure 34. Micropower Voltage Controlled Oscillator

A Micropower, Single-Supply Quad Voltage Output 8-Bit

DAC

The circuit of Figure 35 uses the DAC8408 CMOS quad 8-bit

DAC and the OP493 to form a single-supply quad voltage output DAC with a supply drain of only 140 µA. The DAC8408 is

used in the voltage switching mode and each DAC has an output resistance (≈10 kΩ) independent of the digital input code.

The output amplifiers act as buffers to avoid loading the DACs.

The 100 kΩ resistors ensure that the OP493 outputs will swing

to within 1/2 LSB of ground, i.e.:

1

1.23V

×

2

256

= 3mV

REV. A

–13–

Page 14

OP193/OP293/OP493

+5V

3.6k

25

4

5

6

AD589

1.23V

I

OUT

I

OUT

I

OUT

I

OUT

1A

2A/2B

1B

1C

+5V

1

V

DD

DAC A

1/4

DAC8408

DAC B

1/4

DAC8408

DAC C

1/4

DAC8408

+5V

A Single-Supply Micropower Quad Programmable-Gain

Amplifier

4

The combination of the quad OP493 and the DAC8408 quad

8-bit CMOS DAC creates a quad programmable gain amplifier

with a quiescent supply drain of only 140 µA (Figure 36). The

digital code present at the DAC, which is easily set by a micro-

2

A

V

A

2

REF

V

B

8

REF

3

6

5

1/4 OP493

B

1/4 OP493

V

OUT

1

11

R1

100kΩ

V

OUT

7

R2

100kΩ

processor, determines the ratio between the fixed DAC feedback

A

resistor and the resistance that the DAC feedback ladder presents to the op amp feedback loop. The gain of each amplifier is:

V

V

OUT

IN

256

=

n

where n equals the decimal equivalent of the 8-bit digital code

B

present at the DAC.

If the digital code present at the DAC consists of all zeros, the

feedback loop will be open causing the op amp to saturate. The

10 MΩ resistors placed in parallel with the DAC feedback loop

eliminates this problem with a very small reduction in gain accuracy. The 2.5 V reference biases the amplifiers to the center of

13

C

C

V

27

REF

12

1/4 OP493

V

OUT

14

R3

100kΩ

the linear region providing maximum output swing.

C

I

2C/2D

OUT

24

DAC D

I

OUT

23

1/4

1D

DAC8408

D

V

REF

9

D

1/4 OP493

10

21

8

OP493

DAC DATA BUS

PINS 9(LSB)–16(MSB)

DAC8408ET

DGND

28

A/B

R/W

DS1

DS2

17

18

DIGITAL

CONTROL

19

SIGNALS

20

Figure 35. Micropower Single-Supply Quad VoltageOutput 8-Bit DAC

V

R4

100kΩ

OUT

D

–14–

REV. A

Page 15

VINA

VINB

VINC

VIND

DIGITAL

CONTROL

SIGNALS

C1

0.1µF

C2

0.1µF

C3

0.1µF

C4

0.1µF

OP193/OP293/OP493

1

V

DD

RFBA

3

DAC A

1/4

DAC8408

RFBB

7

DAC B

1/4

DAC8408

RFBC

26

DAC C

1/4

DAC8408

RFBD

22

DAC D

1/4

DAC8408

DAC DATA BUS

PINS 9(LSB)–16(MSB)

I

I

OUT

I

OUT

V

V

I

V

I

V

OUT

I

REF

OUT

REF

OUT

REF

REF

OUT

1A

2A/2B

C

1C

2C/2D

D

1D

A

2

R1

10MΩ

4

5

B

8

R2

1B

10MΩ

6

27

R3

10MΩ

25

24

21

R4

10MΩ

23

2

3

6

5

9

10

13

12

A

1/4 OP493

B

1/4 OP493

C

1/4 OP493

D

1/4 OP493

4

OP493

17

A/B

18

R/W

19

DS1

20

DS2

DAC8408ET

DGND

28

1

11

7

8

14

+5V

V

OUT

V

OUT

V

OUT

V

OUT

+2.5V

REFERENCE

VOLTAGE

A

B

C

D

REV. A

Figure 36. Single-Supply Micropower Quad Programmable-Gain Amplifier

–15–

Page 16

OP193/OP293/OP493

PIN 1

0.280 (7.11)

0.240 (6.10)

4

5

8

1

SEATING

PLANE

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.430 (10.92)

0.348 (8.84)

0.022 (0.558)

0.014 (0.356)

0.070 (1.77)

0.045 (1.15)

0.100

(2.54)

BSC

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

PIN 1

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

1

16

9

8

0.0192 (0.49)

0.0138 (0.35)

0.0500 (1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.4133 (10.50)

0.3977 (10.00)

0.0118 (0.30)

0.0040 (0.10)

0.0125 (0.32)

0.0091 (0.23)

0.0500 (1.27)

0.0157 (0.40)

8

°

0

°

0.0291 (0.74)

0.0098 (0.25)

x 45

°

8-Lead SO

(S Suffix)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Epoxy DIP

(P Suffix)

0.0098 (0.25)

0.0040 (0.10)

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

PIN 1

14

1

0.022 (0.558)

0.014 (0.356)

8

1

0.1968 (5.00)

0.1890 (4.80)

0.0500

(1.27)

BSC

5

4

0.0192 (0.49)

0.0138 (0.35)

0.1574 (4.00)

0.1497 (3.80)

0.2440 (6.20)

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0075 (0.19)

14-Lead Epoxy DIP

(P Suffix)

8

7

0.795 (20.19)

0.725 (18.42)

0.070 (1.77)

0.100

(2.54)

0.045 (1.15)

BSC

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.0196 (0.50)

0.0099 (0.25)

8

°

0

°

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

x 45

0.0500 (1.27)

0.0160 (0.41)

0.195 (4.95)

0.115 (2.93)

°

C1994–18–1/95

16-Lead Wide Body SOL

(S Suffix)

–16–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...