Page 1

Dual 9 MHz Precision

8

7

6

5

V+

–IN B

+IN B

OUT B

1

2

3

4

–IN A

+IN A

V–

OUT A

+–

+–

OP285

a

FEATURES

Low Offset Voltage: 250 V

Low Noise: 6 nV/√ Hz

Low Distortion: 0.0006%

High Slew Rate: 22 V/s

Wide Bandwidth: 9 MHz

Low Supply Current: 5 mA

Low Offset Current: 2 nA

Unity-Gain Stable

SO-8 Package

APPLICATIONS

High Performance Audio

Active Filters

Fast Amplifiers

Integrators

GENERAL DESCRIPTION

The OP285 is a precision high-speed amplifier featuring the

Butler Amplifier front-end. This new front-end design combines the accuracy and low noise performance of bipolar

transistors with the speed of JFETs. This yields an amplifier

with high slew rates, low offset and good noise performance

at low supply currents. Bias currents are also low compared

to bipolar designs.

The OP285 offers the slew rate and low power of a JFET

amplifier combined with the precision, low noise and low

drift of a bipolar amplifier. Input offset voltage is laser-trimmed

and guaranteed less than 250 µV. This makes the OP285 useful

in dc-coupled or summing applications without the need for

special selections or the added noise of additional offset

adjustment circuitry. Slew rates of 22 V/µs and a bandwidth

of 9 MHz make the OP285 one of the most accurate medium

speed amplifiers available.

Operational Amplifier

OP285

PIN CONNECTIONS

8-Lead Narrow-Body SO (S-Suffix)

OUT A

1

–IN A

2

OP285

3

4

TOP VIEW

(Not to Scale)

+IN A

V–

8-Lead Epoxy DIP (P-Suffix)

The combination of low noise, speed and accuracy can be used

to build high speed instrumentation systems. Circuits such as

instrumentation amplifiers, ramp generators, bi-quad filters and

dc-coupled audio systems are all practical with the OP285. For

applications that require long term stability, the OP285 has a

guaranteed maximum long term drift specification.

The OP285 is specified over the XIND—extended industrial—

(–40°C to +85°C) temperature range. OP285s are available in

8-pin plastic DIP and SOIC-8 surface mount packages.

8

7

6

5

V+

OUT B

–IN B

+IN B

*

*Patents pending

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

Page 2

OP285–SPECIFICATIONS

(@ Vs = 15.0 V, TA = 25C, unless otherwise noted.)

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

OS

V

OS

B

I

B

OS

I

OS

CM

Common-Mode Rejection CMRR V

Large-Signal Voltage Gain A

VO

A

VO

A

VO

–40°C ≤ TA ≤ +85°C 600 µV

VCM = 0 V 100 350 nA

VCM = 0 V, –40°C ≤ TA ≤ +85°C 400 nA

VCM = 0 V 2 ±50 nA

VCM = 0 V, –40°C ≤ TA ≤ +85°C2±100 nA

–10.5 10.5 V

= ±10.5 V,

CM

–40°C ≤ T

≤ +85°C 80 106 dB

A

RL = 2 kΩ 250 V/mV

RL = 2 kΩ, –40°C ≤ TA ≤ +85°C 175 V/mV

RL = 600 Ω 200 V/mV

35 250 µV

Common-Mode Input Capacitance 7.5 pF

Differential Input Capacitance 3.7 pF

Long-Term Offset Voltage ∆V

Offset Voltage Drift ∆V

OS

/∆T1µV/°C

OS

Note 1 300 µV

OUTPUT CHARACTERISTICS

Output Voltage Swing V

O

V

O

RL = 2 kΩ –13.5 +13.9 +13.5 V

RL = 2 kΩ, –40°C ≤ TA ≤ +85°C –13 +13.9 +13 V

RL = 600 Ω, V

= ±18 V –16/+14 V

S

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

PSRR V

Supply Current I

SY

I

SY

= ±4.5 V to ±18 V 85 111 dB

S

= ±4.5 V to ±18 V,

S

–40°C ≤ T

≤ +85°C80 dB

A

VS = ±4.5 V to ±18 V, VO = 0 V,

= x, –40°C ≤ TA ≤ +85°C45mA

R

L

VS = ±22 V, VO, = 0 V, RL = x

–40°C ≤ T

≤ +85°C 5.5 mA

A

Supply Voltage Range VS ±4.5 ± 22 V

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 15 22 V/µs

L

Gain Bandwidth Product GBP 9 MHz

Phase Margin o 62 Degrees

Settling Time t

s

t

s

Distortion A

Voltage Noise Density e

Current Noise Density i

n

e

n

n

To 0.1%, 10 V Step 625 ns

To 0.01%, 10 V Step 750 ns

= 1, V

V

f = 1 kHz, R

= 8.5 V p-p,

OUT

= 2 kΩ –104 dB

L

f = 30 Hz 7 nV/√Hz

f = 1 kHz 6 nV/√Hz

f = 1 kHz 0.9 pA/√Hz

Headroom THD + Noise ≤ 0.01%,

RL = 2 kΩ, VS = ±18 V >12.9 dBu

NOTE

1

Long-term offset voltage is guaranteed by a 1,000 hour life test performed on three independent wafer lots at 125 °C, with an LTPD of 1.3.

Specifications subject to change without notice.

–2–

REV. A

Page 3

OP285

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±22 V

Input Voltage

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

2

. . . . . . . . . . . . . . . . . . . . . . ±7.5 V

Output Short-Circuit Duration to Gnd

Storage Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

OP285G . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

1

3

. . . . . . . . . Indefinite

Package Type

8-Pin Plastic DIP (P) 103 43 °C/W

8-Pin SOIC (S) 158 43 °C/W

NOTES

1

Absolute Maximum Ratings apply to packaged parts, unless otherwise noted.

2

For supply voltages less than ± 7.5 V, the absolute maximum input voltage is

equal to the supply voltage.

3

Shorts to either supply may destroy the device. See data sheet for full details.

4

JA is specified for the worst case conditions, i.e., JA is specified for device in

socket for cerdip, P-DIP, and LCC packages; JA is specified for device soldered

in circuit board for SOIC package.

Lead Temperature Range (Soldering 60 Sec) . . . . . . . . 300°C

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

OP285GP* –40°C to +85°C 8-Pin Plastic DIP N-8

OP285GS –40°C to +85°C 8-Pin SOIC S0-8

OP285GSR –40°C to +85°C S0-8 Reel, 2500 pcs.

*Not for new designs. Obsolete April 2002.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP285 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

4

JA

WARNING!

JC

ESD SENSITIVE DEVICE

Unit

REV. A

–3–

Page 4

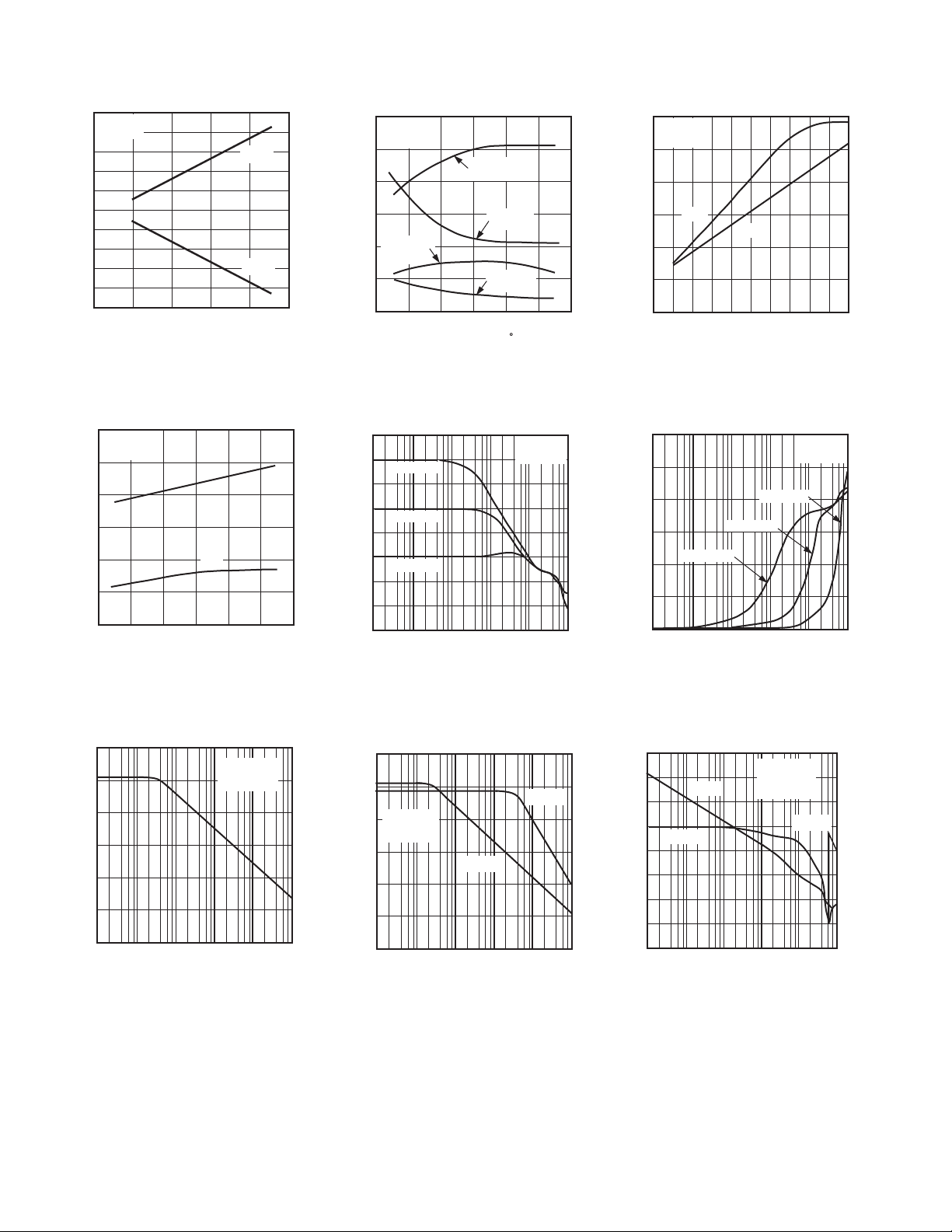

OP285

25

T

= 25C

A

20

= 2k

R

L

15

10

5

0

–5

–10

–15

OUTPUT VOLTAGE SWING – V

–20

–25

0 5 10 15 20 25

SUPPLY VOLTAGE – V

+VOM

–VOM

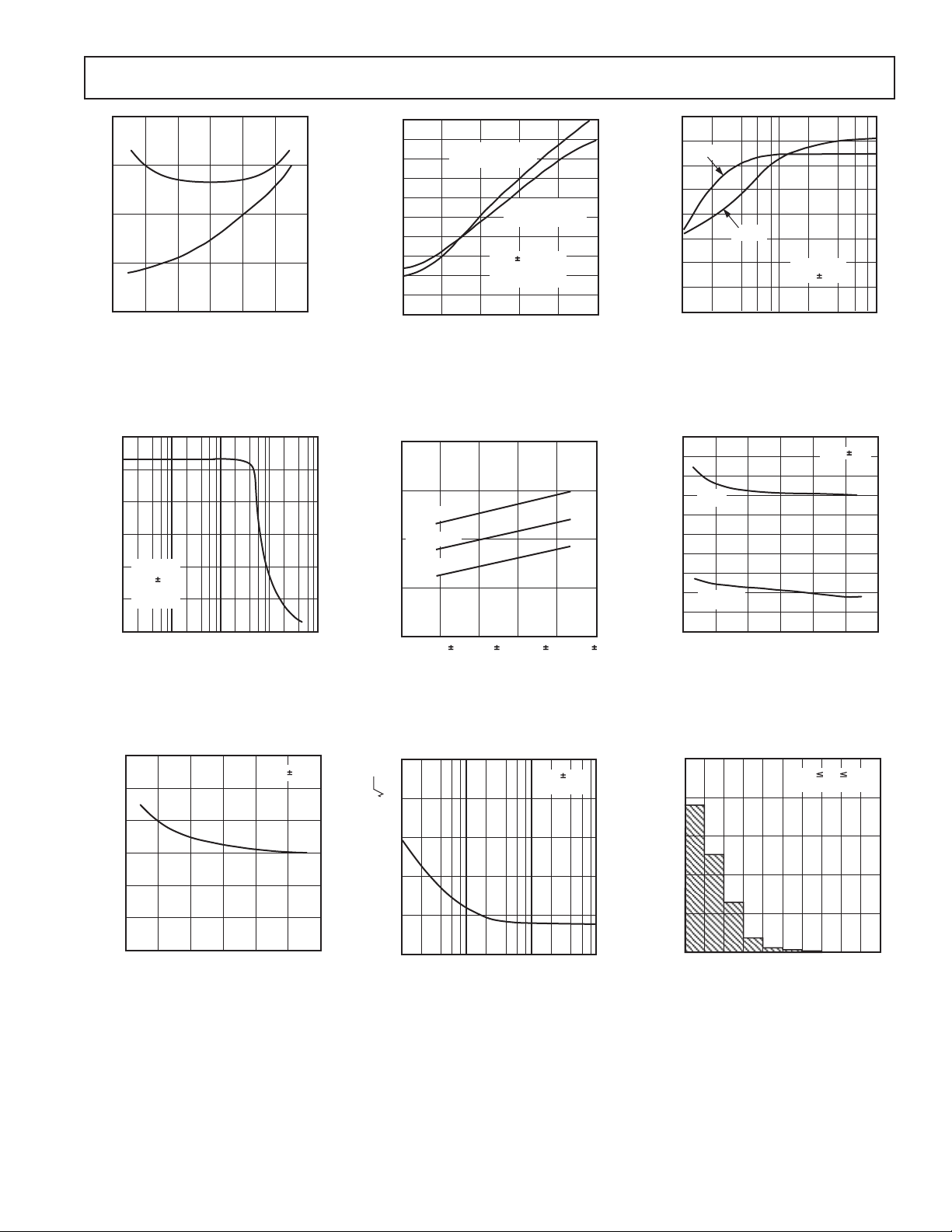

TPC 1. Output Voltage Swing vs.

Supply Voltage

50

VS = 15V

VS = 15V

= 2k

R

R

= 2k

L

L

45

40

35

30

SLEW RATE – V/s

25

20

TEMPERATURE – C

–SR

+SR

0

100–25–50 755025

TPC 4. Slew Rate vs. Temperature

1500

VS = 15V

= 10V

V

O

1250

1000

750

500

OPEN-LOOP GAIN – V/MV

250

0

–50

R

+GAIN

= 600

L

–25

+GAIN

= 2k

R

L

–GAIN

= 2k

R

L

–GAIN

= 600

R

L

0

TEMPERATURE – C

755025

TPC 2. Open-Loop Gain

vs. Temperature

CLOSED-LOOP GAIN – dB

–10

–20

–30

50

40

A

= +100

VCL

30

20

A

= +10

VCL

10

0

1k

= +1

A

VCL

10k 100k 1M 10M 100M

FREQUENCY – Hz

VS = 15V

T

= +25C

A

TPC 5. Closed-Loop Gain

vs. Frequency

100

30

VS = 15V

R

= 2k

L

25

20

15

+SR

–SR

10

SLEW RATE – V/s

5

0

0

DIFFERENTIAL INPUT VOLTAGE – V

1.0

0.80.60.40.2

TPC 3. Slew Rate vs. Differential

Input Voltage

60

50

40

A

= +10

30

A

VCL

20

IMPEDANCE –

10

0

1k 10k 100k 1M 10M

100

VCL

= +100

FREQUENCY – Hz

VS = 15V

T

= 25C

A

A

= +1

VCL

TPC 6. Closed-Loop Output Imped

ance vs. Frequency

120

V

= 15V

S

T

= 25C

A

COMMON MODE REJECTION – dB

100

80

60

40

20

0

1k 10k 100k 1M 10M

100

FREQUENCY – Hz

TPC 7. Common-Mode Rejection

vs. Frequency

120

POWER SUPPLY REJECTION – dB

100

80

60

40

20

VS = 15V

T

= 25C

A

–PSRR

0

10

100 1k 10k 100k 1M

FREQUENCY – Hz

+PSRR

TPC 8. Power Supply Rejection

vs. Frequency

–4–

100

80

60

– dB

40

MIN

PHASE

20

0

OPEN-LOOP G

–20

–40

–60

1k

GAIN

10k 100k 1M 10M 100M

FREQUENCY – Hz

V

= 15V

S

R

= 2k

L

= 25C

T

A

= 58

0

N

TPC 9. Open-Loop Gain, Phase

vs. Frequency

REV. A

0

45

90

135

180

225

270

PHASE – Degrees

Page 5

Typical Performance Characteristics–OP285

11

10

9

8

GAIN BANDWIDTH PRODUCT – MHz

7

–50 100

–25 755025

TEMPERATURE – C

GBW

0

ø

M

65

60

55

50

40

TPC 10. Gain Bandwidth Product,

Phase Margin vs. Temperature

30

25

20

15

10

TA = 25C

= 15V

V

S

= +1

A

VCL

5

MAXIMUM OUTPUT SWING – V

= 2k

R

L

0

1k

10k 10M1M100k

FREQUENCY – Hz

TPC 13. Maximum Output Swing

vs. Frequency

100

PHASE MARGIN – Degrees

90

80

70

60

50

40

OVERSHOOT – %

30

20

10

0

0

A = +1

VCL

NEGATIVE EDGE

A = +1

VCL

POSITIVE EDGE

VS = 15V

= 2k

R

L

= 100mV p-p

V

IN

100

LOAD CAPACITANCE – pF

300

TPC 11. Small-Signal Overshoot vs.|

Load Capacitance

5.0

4.5

TA = +85C

4.0

TA = +25C

TA = –40C

3.5

SUPPLY CURRENT – mA

3.0

0

5

SUPPLY VOLTAGE – V

TPC 14. Supply Current vs.

Supply Voltage

16

14

–VOM

12

10

8

6

4

2

MAXIMUM OUTPUT SWING – Volts

0

500

400200

100 1k 10k

+VOM

TA = 25C

= 15V

V

S

LOAD RESISTANCE –

TPC 12. Maximum Output Voltage

vs. Load Resistance

120

110

100

90

SINK

80

70

60

50

40

SOURCE

30

ABSOLUTE OUTPUT CURRENT – mA

20

1510

25

–50

0

–25

TEMPERATURE – C

VS = 15V

7525 50

100

TPC 15. Short Circuit Current vs.

Temperature

300

VS = 15V

250

200

150

100

INPUT BIAS CURRENT – nA

50

0

–25

–50

0

TEMPERATURE – C

755025

TPC 16. Input Bias Current vs.

Temperature

REV. A

100

5

Hz

CURRENT NOISE DENSITY – pA/

4

3

2

1

10

100 100k1k

FREQUENCY – Hz

VS = 15V

= 25C

T

A

TPC 17. Current Noise Density vs.

Frequency

–5–

250

–40C TA +85C

TC V

402 OP AMPS

– V/ C

OS

200

150

UNITS

100

50

0

0

1

TPC 18. tC VOS Distribution

10

98765432

Page 6

OP285

250

TA= 25C

200

150

UNITS

100

50

–250

0

–

00

–150

–

2

–50

100

INPUT OFFSET – V

402 OP AMPS

0

15050

TPC 19. Input Offset (VOS)

Distribution

100

90

10

8

6

4

2

0

–2

STEP SIZE – V

–4

–6

–8

250

200100

–10

100

0

+0.1%

–0.1% –0.01%

SETTLING TIME – ns

+0.01%

800500 600300 400 700200

900

TPC 20. Settling Time vs. Step Size

50

45

40

35

30

SLEW RATE – V/S

25

20

0

–SR

+SR

100

CAPACITIVE LOAD – pF

TA = 25C

= 15V

V

S

400300200

TPC 21. Slew Rate vs.

500

Capacitive Load

100

90

100

90

10

0%

5V

200nS

TPC 22. Negative Slew Rate

=2 kΩ, VS = ±15 V, AV = +1

R

L

CH A: 80.0 V FS 10.0 V/DIV

MKR: 6.23 V/

0 Hz

Hz

2.5 KHz

BW: 15.0 MHzMKR: 1 000 Hz

TPC 25. OP285 Voltage Noise Density

vs. Frequency V

= ±15 V, AV = 1000

S

10

0%

5V

200nS

TPC 23. Positive Slew Rate

Ω

RL = 2 k

, VS = ±15 V, AV = +1

10

0%

50mV

100nS

TPC 24. Small Signal Response

=2 kΩ, VS = ±15 V, AV = +1

R

L

–6–

REV. A

Page 7

OP285

APPLICATIONS

Short-Circuit Protection

The OP285 has been designed with inherent short-circuit

protection to ground. An internal 30 Ω resistor, in series with

the output, limits the output current at room temperature to

+ = 40 mA and ISC- = –90 mA, typically, with ±15 V supplies.

I

SC

However, shorts to either supply may destroy the device when

excessive voltages or current are applied. If it is possible for a

user to short an output to a supply, for safe operation, the output current of the OP285 should be design-limited to ±30 mA,

as shown in Figure 1.

R

FB

R

–

A1

+

X

332

A1 = 1/2 OP285

FEEDBACK

V

OUT

Figure 1. Recommended Output Short-Circuit Protection

Input Over Current Protection

The maximum input differential voltage that can be applied

to the OP285 is determined by a pair of internal Zener diodes

connected across the inputs. They limit the maximum differential input voltage to ±7.5 V. This is to prevent emitter-base

junction breakdown from occurring in the input stage of the

OP285 when very large differential voltages are applied. However, in order to preserve the OP285’s low input noise

voltage, internal resistance in series with the inputs were not

used to limit the current in the clamp diodes. In small-signal

applications, this is not an issue; however, in industrial applications, where large differential voltages can be inadvertently

applied to the device, large transient currents can be made to

flow through these diodes. The diodes have been designed to

carry a current of ±8 mA; and, in applications where the

OP285’s differential voltage were to exceed ±7.5 V, the resistor values shown in Figure 2 safely limit the diode current to

±8 mA.

909

909

–

A1

+

A1 = 1/2

Figure 2. OP285 Input Over Current Protection

Output Voltage Phase Reversal

Since the OP285’s input stage combines bipolar transistors

for low noise and p-channel JFETs for high speed performance,

the output voltage of the OP285 may exhibit phase reversal if

either of its inputs exceed its negative common-mode input

voltage. This might occur in very severe industrial applications

where a sensor or system fault might apply very large voltages on

the inputs of the OP285. Even though the input voltage range of

the OP285 is ±10.5 V, an input voltage of approximately –13.5 V

will cause output voltage phase reversal. In inverting amplifier

configurations, the OP285’s internal 7.5 V input clamping

diodes will prevent phase reversal; however, they will not prevent

this effect from occurring in noninverting applications. For these

applications, the fix is a simple one and is illustrated in Figure 3.

A 3.92 kΩ resistor in series with the noninverting input of the

OP285 cures the problem.

RFB*

V

IN

RS

3.92k

IS OPTIONAL

*R

FB

–

+

RL

2k

V

OUT

Figure 3. Output Voltage Phase Reversal Fix

Overload or Overdrive Recovery

Overload or overdrive recovery time of an operational amplifier

is the time required for the output voltage to recover to a rated

output voltage from a saturated condition. This recovery time is

important in applications where the amplifier must recover quickly

after a large abnormal transient event. The circuit shown in Figure

4 was used to evaluate the OP285’s overload recovery time. The

OP285 takes approximately 1.2 µs to recover to V

R2

= –10 V.

OUT

1

RL

2.43k

and approximately 1.5 µs to recover to V

V

IN

4V p-p

@100 Hz

R1

1k

R

909

A1 = 1/2 OP285

S

10k

2

A1

3

OUT

V

OUT

= +10 V

Figure 4. Overload Recovery Time Test Circuit

Driving the Analog Input of an A/D Converter

Settling characteristics of operational amplifiers also include the

amplifier’s ability to recover, i.e., settle, from a transient output

current load condition. When driving the input of an A/D

converter, especially successive-approximation converters, the

amplifier must maintain a constant output voltage under

dynamically changing load current conditions. In these types of

converters, the comparison point is usually diode clamped, but

it may deviate several hundred millivolts resulting in high

frequency modulation of the A/D input current. Amplifiers that

exhibit high closed-loop output impedances and/or low unity-gain

crossover frequencies recover very slowly from output load

current transients. This slow recovery leads to linearity errors or

missing codes because of errors in the instantaneous input voltage.

Therefore, the amplifier chosen for this type of application should

exhibit low output impedance and high unity-gain bandwidth so

that its output has had a chance to settle to its nominal value

before the converter makes its comparison.

The circuit in Figure 5 illustrates a settling measurement circuit

for evaluating the recovery time of an amplifier from an output

load current transient. The amplifier is configured as a follower

with a very high speed current generator connected to its output.

In this test, a 1 mA transient current was used. As shown in

Figure 6, the OP285 exhibits an extremely fast recovery time of

139 ns to 0.01%. Because of its high gain-bandwidth product,

high open-loop gain, and low output impedance, the OP285 is

ideally suited to drive high speed A/D converters.

REV. A

–7–

Page 8

OP285

+15V

+

2

3

8

1

4

V

IN

V

OUT

–15V

10F

0.1F

R

L

15k

0.1F

10F

+

–

1/2

OP285

+15V

0.1F

8

3

+

1

1/2

OP285

2

–

4

–15V

300pF

15V

TTL

INPUT

1N4148

15V

*NOTE

DECOUPLE CLOSE

TOGETHER ON GROUND PLAN

WITH SHORT LEAD LENGTHS.

1.5k

1.8k

0.1F

2N2907

220

0.1F

*

1k

2N3904

1k

0.01F

10F

V

REF

(–1V)

I

OUT

+

0.47F

+ 7A13 PLUG-IN

– 7A13 PLUG-IN

|V

|

REF

1k

Figure 5. Transient Output Load Current Test Fixture

Measuring Settling Time

The design of OP285 combines high slew rate and wide gainbandwidth product to produce a fast-settling (ts < l µs) amplifier

for 8- and 12-bit applications. The test circuit designed to measure

the settling time of the OP285 is shown in Figure 7. This test

method has advantages over false-sum node techniques in that

the actual output of the amplifier is measured, instead of an

error voltage at the sum node. Common-mode settling effects

are exercised in this circuit in addition to the slew rate and

bandwidth effects measured by the false-sum-node method. Of

course, a reasonably flat-top pulse is required as the stimulus.

The output waveform of the OP285 under test is clamped by

Schottky diodes and buffered by the JFET source follower.

The signal is amplified by a factor of ten by the OP260 and

then Schottky-clamped at the output to prevent overloading

the oscilloscope’s input amplifier. The OP41 is configured as

a fast integrator which provides overall dc offset nulling.

High Speed Operation

As with most high speed amplifiers, care should be taken with

supply decoupling, lead dress, and component placement. Recommended circuit configurations for inverting and noninverting

applications are shown in Figures 8 and Figure 9.

NS

50NS

TTL CTRL

(5V/ DIV)

10V

V

OUT

(2MV/ DIV)

A1 1,2 V T 138.9

100

90

10

0%

5V

2MV

Figure 6. OP285’s Output Load Current Recovery Time

16–20V

– +

0.1F

V+

DUT

+ –

16–20V

5V

V–

0.1F

R

L

1k

D1 D2

1N4148

Figure 7. OP285’s Settling Time Test Fixture

–15V

15k

+15V

2N4416

2N2222A

1/2 OP260AJ

R

F

2k

R

G

222

SCHOTTKY DIODES D1–D4 ARE

HEWLETT-PACKARD HP5082-2835

IC1 IS 1/2 OP260AJ

IC2 IS PMI OP41EJ

Figure 8. Unity Gain Follower

1k

D3

10k

10k

750

D4

1F

IC2

OUTPUT

(TO SCOPE)

–8–

REV. A

Page 9

+15V

10F

+

0.1F

10pF

4.99k

V

IN

2.49k

2

–

OP285

3

+

4.99k

1/2

–15V

8

4

0.1F

10F

V

1

OUT

2k

+

Figure 9. Unity-Gain Inverter

In inverting and noninverting applications, the feedback resistance forms a pole with the source resistance and capacitance

(R

and CS) and the OP285’s input capacitance (CIN), as

S

shown in Figure 10. With R

and RF in the kilohm range, this

S

pole can create excess phase shift and even oscillation. A small

capacitor, C

setting R

, in parallel with RFB eliminates this problem. By

FB

(CS + CIN) = RFBCFB, the effect of the feedback pole

S

is completely removed.

C

FB

R

FB

V

R

S

C

S

C

IN

OUT

OP285

R3

2k

2

A2

3

R1

2k

V

3

IN

1

A1

2

2k

R4

2k

R5

2k

R2

A1 = 1/2OP285

A2, A3 = 1/2 OP285

GAIN = SET R2, R4, R5 = R1 AND R, R7, R8 = R2

2k

6

A3

5

Figure 11. High-Speed, Low-Noise Differential Line Driver

Low Phase Error Amplifier

The simple amplifier configuration of Figure 12 uses the OP285

and resistors to reduce phase error substantially over a wide

frequency range when compared to conventional amplifier designs.

This technique relies on the matched frequency characteristics

of the two amplifiers in the OP285. Each amplifier in the circuit

has the same feedback network which produces a circuit gain of

10. Since the two amplifiers are set to the same gain and are

matched due to the monolithic construction of the OP285, they

will exhibit identical frequency response. Recall from feedback

theory that a pole of a feedback network becomes a zero in the

loop gain response. By using this technique, the dominant pole

of the amplifier in the feedback loop compensates for the dominant pole of the main amplifier,

R9

1

50

R11

R7

2k

R6

R10

7

50

R8

2k

1k

10k

R12

1k

P1

V

O2

V

O1

– VO1 = V

V

O2

IN

Figure 10. Compensating the Feedback Pole

High-Speed, Low-Noise Differential Line Driver

The circuit of Figure 11 is a unique line driver widely used in

industrial applications. With ±18 V supplies, the line driver can

deliver a differential signal of 30 V p-p into a 2.5 kΩ load. The

high slew rate and wide bandwidth of the OP285 combine to

yield a full power bandwidth of 130 kHz while the low noise

front end produces a referred-to-input noise voltage spectral

density of 10 nV/√Hz. The design is a transformerless, balanced

transmission system where output common-mode rejection of

noise is of paramount importance. Like the transformer-based

design, either output can be shorted to ground for unbalanced

line driver applications without changing the circuit gain of 1.

Other circuit gains can be set according to the equation in the

diagram. This allows the design to be easily set to noninverting,

inverting, or differential operation.

REV. A

–9–

R2

R3

499

4.99k

2

A1

3

6

A2

5

A1, A2 = 1/2 OP285

1

R5

549

R4

4.99

7

V

OUT

V

IN

R1

549

Figure 12. Cancellation of A2’s Dominant Pole by A1

Page 10

OP285

thereby reducing phase error dramatically. This is shown in

Figure 13 where the 10x composite amplifier’s phase response

exhibits less than 1.5° phase shift through 500 kHz. On the other

hand, the single gain stage amplifier exhibits 25° of phase shift

over the same frequency range. An additional benefit of the low

phase error configuration is constant group delay, by virtue of

constant phase shift at all frequencies below 500 kHz. Although

this technique is valid for minimum circuit gains of 10, actual

closed-loop magnitude response must be optimized for the

amplifier chosen.

LOW PHASE ERROR

0

–5

–10

–15

–20

–25

PHASE – Degrees

–30

–35

–40

–45

SINGLE STAGE

AMPLIFIER RESPONSE

10k 100k 10M1M

START 10,000.000Hz STOP 10,000,000.000Hz

AMPLIFIER RESPONSE

Figure 13. Phase Error Comparison

A Low Noise, High Speed Instrumentation Amplifier

A high speed, low noise instrumentation amplifier, constructed

with a single OP285, is illustrated in Figure 15. The circuit exhibits

less than 1.2 µV p-p noise (RTI) in the 0.1 Hz to 10 Hz band

and an input noise voltage spectral density of 9 nV/√Hz (1 kHz)

at a gain of 1000. The gain of the amplifier is easily set by R

G

according to the formula:

V

OUT

V

IN G

k

9982. Ω

=+

R

The advantages of a two op amp instrumentation amplifier

based on a dual op amp is that the errors in the individual amplifiers tend to cancel one another. For example, the circuit’s

input offset voltage is determined by the input offset voltage

matching of the OP285, which is typically less than 250 µV.

+

V

IN

–

AC CMRR TRIM

C1

5pF–40pF

DC CMRR TRIM

3

A1

2

4.99

R1

4.99k

P1

500

1

R2

R3

4.99k

R

G

5

7

A2

6

R4

4.99k

A1, A2 = 1/2 OP285

9.98k

GAIN =

R

GAIN

2

10

100

1000

Q

()

R

G

OPEN

1.24k

102

10

V

OUT

+2

For a more detailed treatment on the design of low phase error

amplifiers, see Application Note AN-107.

Fast Current Pump

A fast, 30 mA current source, illustrated in Figure 14, takes

advantage of the OP285’s speed and high output current drive.

This is a variation of the Howland current source where a second amplifier, A2, is used to increase load current accuracy and

output voltage compliance. With supply voltages of ±15 V, the

output voltage compliance of the current pump is ±8 V. To

keep the output resistance in the MΩ range requires that 0.1%

or better resistors be used in the circuit. The gain of the current

pump can be easily changed according to the equations shown

in the diagram.

R1

V

V

2k

IN1

R3

2k

IN2

A1, A2 = 1/2 OP285

R2

GAIN = , R4 = R2, R3 = R1

R1

R2

2k

2

A1

3

R4

2k

R5

50

1

V

– V

V

IN1

5

7

A2

6

IN2

I

=

OUT

I

= (MAX) = 30mA

OUT

R5

IN

=

R5

Figure 14. A Fast Current Pump

Figure 15. A High-Speed Instrumentation Amplifier

Common-mode rejection of the circuit is limited by the matching

of resistors R1 to R4. For good common-mode rejection, these

resistors ought to be matched to better than 1%. The circuit was

constructed with 1% resistors and included potentiometer P1

for trimming the CMRR and a capacitor C1 for trimming the

CMRR. With these two trims, the circuit’s common-mode

rejection was better than 95 dB at 60 Hz and better than 65 dB

at 10 kHz. For the best common-mode rejection performance,

use a matched (better than 0.1%) thin-film resistor network for

R1 through R4 and use the variable capacitor to optimize the

circuit’s CMR.

The instrumentation amplifier exhibits very wide small- and

large-signal bandwidths regardless of the gain setting, as shown

in the table. Because of its low noise, wide gain-bandwidth

product, and high slew rate, the OP285 is ideally suited for high

speed signal conditioning applications.

Circuit R

Gain () V

G

OUT

Circuit Bandwidth

= 100 mV p-p V

= 20 V p-p

OUT

2 Open 5 MHz 780 kHz

10 1.24 k 1 MHz 460 kHz

100 102 90 kHz 85 kHz

1000 10 10 kHz 10 kHz

–10–

REV. A

Page 11

OP285

R1

95.3k

2

A1

V

3

IN

C1

2200pF

1

1

A2

R2

787

C2

2200pF

R3

1.82k

2

2200pF

C3

3

5

6

R6

4.12k

A3

7

2200pF

5

C4

100k

6

R7

R9

1k

A4

1k

7

V

OUT

R8

R4

1.87k

R5

1.82k

Figure 16. A 3-Pole, 40 kHz Low-Pass Filter

A 3-Pole, 40 kHz Low-Pass Filter

The closely matched and uniform ac characteristics of the OP285

make it ideal for use in GIC (Generalized Impedance Converter)

and FDNR (Frequency Dependent Negative Resistor) filter applications. The circuit in Figure 16 illustrates a linear-phase,

3-pole, 40 kHz low-pass filter using an OP285 as an inductance

simulator (gyrator). The circuit uses one OP285 (A2 and A3)

for the FDNR and one OP285 (Al and A4) as an input buffer

and bias current source for A3. Amplifier A4 is configured in a

gain of 2 to set the pass band magnitude response to 0 dB. The

benefits of this filter topology over classical approaches are

that the op amp used in the FDNR is not in the signal path and

that the filter’s performance is relatively insensitive to component variations. Also, the configuration is such that large signal

levels can be handled without overloading any of the filter’s

internal nodes. As shown in Figure 17, the OP285’s symmetric

slew rate and low distortion produce a clean, well-behaved

transient response.

100

90

V

OUT

10V p-p

10kHz

A1, A4 = 1/2 OP285

A2, A3 = 1/2 OP285

Driving Capacitive Loads

The OP285 was designed to drive both resistive loads to 600 Ω

and capacitive loads of over 1000 pF and maintain stability. While

there is a degradation in bandwidth when driving capacitive loads,

the designer need not worry about device stability. The graph in

Figure 18 shows the 0 dB bandwidth of the OP285 with capacitive

loads from 10 pF to 1000 pF.

10

9

8

7

6

5

4

BANDWIDTH – MHz

3

2

1

0

0

200 400 600 800 1000

Figure 18. Bandwidth vs. C

C

LOAD

– pF

LOAD

10

0%

SCALE: VERTICAL – 2V/ DIV

HORIZONTAL – 10S/ DIV

Figure 17. Low-Pass Filter Transient Response

REV. A

–11–

Page 12

OP285

OP285 SPICE Model

* Node assignments

* noninverting input

* inverting input

* positive supply

* negative supply

* output

*

*

.SUBCKT OP285 1 2 99 50 34

*

* INPUT STAGE & POLE AT 100 MHZ

*

R3 5 51 2.188

R4 6 51 2.188

CIN 1 2 1.5E-12

C2 5 6 364E-12

I1 97 4 100E-3

IOS 1 2 1E-9

EOS 9 3 POLY(1) 26 28 35E-6 1

Q1 5 2 7 QX

Q2 6 9 8 QX

R5 7 4 1.672

R6 8 4 1.672

D1 2 36 DZ

D2 1 36 DZ

EN 3 1 100 1

GN1 0 2 13 0 1

GN20 1 16 0 1

*

EREF 98 0 28 0 1

EP 97 0 99 0 l

EM 510 50 0 1

*

* VOLTAGE NOISE SOURCE

*

DN1 35 10 DEN

DN2 10 11 DEN

VN1 35 0 DC 2

VN2 0 11 DC 2

*

* CURRENT NOISE SOURCE

*

DN3 12 13 DIN

DN4 13 14 DIN

VN3 12 0 DC 2

VN4 0 14 DC 2

CN1 13 0 7.53E-3

*

* CURRENT NOISE SOURCE

*

DN5 15 16 DIN

DN6 16 17 DIN

VN5 15 0 DC 2

VN6 0 17 DC2

CN2 16 0 7.53E-3

*

* GAIN STAGE & DOMINANT POLE AT 32 HZ *

R7 18 98 1.09E6

C3 18 98 4.55E-9

G1 98 18 5 6 4.57E-1

V2 97 19 1.4

V3 20 51 1.4

D3 18 19 DX

D4 20 18 DX

*

* POLE/ZERO PAIR AT 1.5MHz/2.7MHz

*

R8 21 98 1E3

R9 21 22 1.25E3

C4 22 98 47.2E-12

G2 98 21 18 28 1E-3

*

* POLE AT 100 MHZ

*

R10 23 98 1

C5 23 98 1.59E-9

G3 98 23 21 28 1

*

* POLE AT 100 MHZ

*

R11 24 98 l

C6 24 98 1.59E-9

G4 98 24 23 28 1

*

* COMMON-MODE GAIN NETWORK WITH ZERO AT

1 kHZ *

R12 25 26 1E6

C7 25 26 1.59E-12

R13 26 98 1

E2 25 98 POLY(2) 1 98 2 98 0 2.506 2.506

*

* POLE AT 100 MHZ

*

R14 27 98 1

C8 27 98 1.59E-9

G5 98 27 24 28 1

*

* OUTPUT STAGE

*

Rl5 28 99 100E3

R16 28 50 100E3

C9 28 50 1 E-6

ISY 99 50 1.85E-3

R17 29 99 100

R18 29 50 100

L2 29 34 1E-9

G6 32 50 27 29 10E-3

G7 33 50 29 27 10E-3

G8 29 99 99 27 10E-3

G9 50 29 27 50 10E-3

V4 30 29 1.3

V5 29 31 3.8

F1 29 0 V4 1

F2 0 29 V5 1

D5 27 30 DX

D6 31 27 DX

D7 99 32 DX

D8 99 33 DX

D9 50 32 DY

D10 50 33 DY

*

* MODELS USED

*

.MODEL QX PNP(BF = 5E5)

.MODEL DX D(IS = lE-12)

.MODEL DY D(IS = lE-15 BV = 50)

.MODEL DZ D(IS = lE-15 BV = 7.0)

.MODEL DEN D(IS = lE-12 RS = 4.35K KF = 1.95E-15

AF = l) .MODEL DIN D(IS = lE-12 RS = 77.3E-6

KF = 3.38E-15 AF = 1) .ENDS OP-285

–12–

REV. A

Page 13

–IN

+IN

OP285

97

E

I1

4

R5

2

C

IN

I

OS

1

7

Q1

D1

36

D2

E

N

56

R3

R6

8

Q2

E

OS

3

C2

R4

Figure 19a. Spice Diagram

P

9

E

M

35

V

D

N1

N1

10

D

N2

V

N2

11

12

V

D

N3

N3

13

C

N1

D

V

N4

N4

14

15

V

D

N5

N5

16

D

V

N6

N6

17

C

N2

G1

97

V2

19

D3

21

R9

C3

R7

51

G2

D4

20

V3

R8

G3

C4

23

G4

C5

R10

24

C6

R11

E2

C7

R12

26

R13

25

Figure 19b. Spice Diagram

99

32 33

G6

G7

D8

G8

V4

F1

V5

F2

D10

G3

R17

L2

29

34

OUTPUT

R18

D7

R15

I

SY

28

27

G5

98

R14

C8

R16

C9

50

D5

30

D6

31

D9

REV. A

Figure 19c. Spice Diagram

–13–

Page 14

OP285

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead PDIP Package

(N-8)

0.200 (5.05)

0.125 (3.18)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

0.210

(5.33)

MAX

8

1

0.430 (10.92)

0.348 (8.84)

0.022 (0.558)

0.014 (0.356)

8

1

0.1968 (5.00)

0.1890 (4.80)

5

0.280 (7.11)

0.240 (6.10)

4

0.070 (1.77)

0.045 (1.15)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

0.100

(2.54)

BSC

PLANE

0 - 15

8-Lead SOIC Package

(R-8)

5

0.1574 (4.00)

0.1497 (3.80)

4

0.2440 (6.20)

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0196 (0.50)

0.0099 (0.25)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0500 (1.27)

0.0160 (0.41)

× 45

0

- 8

0.0500

(1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

SEATING

PLANE

–14–

0.0098 (0.25)

0.0075 (0.19)

SEE DETAIL

ABOVE

REV. A

Page 15

OP285

Revision History

Location Page

Data Sheet changed from REV. 0 to REV. A.

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Deleted WAFER TEST LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Deleted DICE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

REV. A

–15–

Page 16

(A)

C00306–0–1/02

–16–

PRINTED IN U.S.A.

Loading...

Loading...