Page 1

Precision Rail-to-Rail

A

T

2

O

www.BDTIC.com/ADI

Input and Output Operational Amplifiers

FEATURES

Single-supply operation

Wide bandwidth: 4 MHz

Low offset voltage: 65 μV

Unity-gain stable

High slew rate: 4.0 V/μs

Low noise: 3.9 nV/√Hz

APPLICATIONS

Battery-powered instrumentation

Power supply control and protection

Telecommunications

DAC output amplifier

ADC input buffer

GENERAL DESCRIPTION

The OP184/OP284/OP484 are single, dual, and quad single-supply,

4 MHz bandwidth amplifiers featuring rail-to-rail inputs and

outputs. They are guaranteed to operate from 3 V to 36 V (or

±1.5 V to ±18 V).

These amplifiers are superb for single-supply applications requiring

both ac and precision dc performance. The combination of wide

bandwidth, low noise, and precision makes the OP184/OP284/

OP484 useful in a wide variety of applications, including filters

and instrumentation.

Other applications for these amplifiers include portable telecommunications equipment, power supply control and protection,

and use as amplifiers or buffers for transducers with wide output

ranges. Sensors requiring a rail-to-rail input amplifier include

Hall effect, piezoelectric, and resistive transducers.

The ability to swing rail-to-rail at both the input and output

enables designers to build multistage filters in single-supply

systems and to maintain high signal-to-noise ratios.

The OP184/OP284/OP484 are specified over the hot extended

industrial temperature range of −40°C to +125°C. The single

OP184 is available in 8-lead SOIC surface mount packages. The

dual OP284 is available in 8-lead PDIP and SOIC surface mount

packages. The quad OP484 is available in 14-lead PDIP and

14-lead, narrow-body SOIC packages.

OP184/OP284/OP484

PIN CONFIGURATIONS

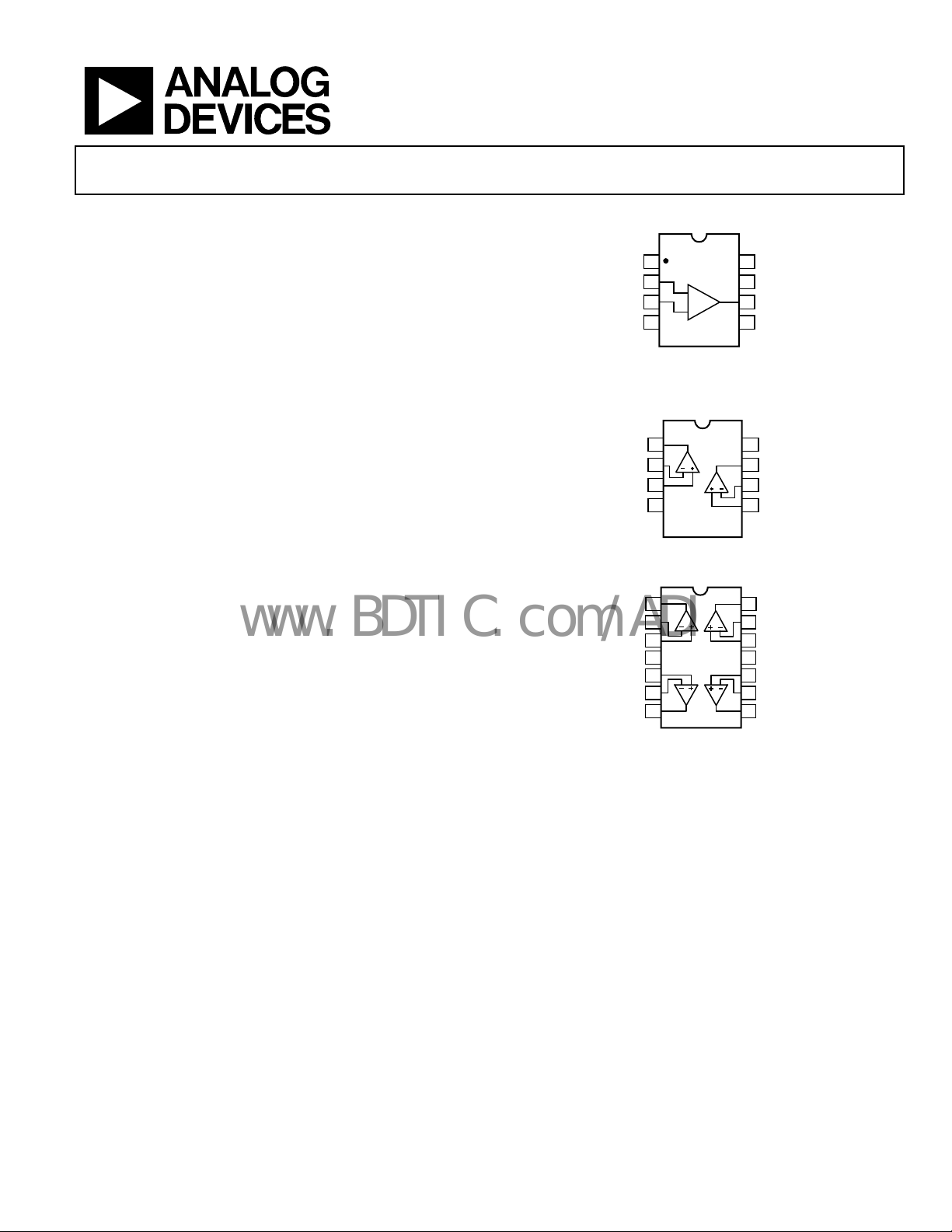

OP184

1

DNC

–IN A

2

–

3

+IN

V–

NOTES

1. NC = NO CONNEC

. DNC = DO NOT CO NNECT

4

(Not to Scale)

+

TOP VIEW

Figure 1. 8-Lead SOIC (S-Suffix)

OP284

1

UT A

2

–IN A

3

+IN A

4

V–

TOP VIEW

(Not to Scale)

Figure 2. 8-Lead PDIP (P-Suffix)

8-Lead SOIC (S-Suffix)

1

OUT A

2

–IN A

3

+IN A

V+

+IN B

–IN B

OUT B

4

TOP VIEW

(Not to Scale)

5

6

7

OP484

Figure 3. 14-Lead PDIP (P-Suffix)

14-Lead Narrow-Body SOIC (S-Suffix)

8

7

6

5

14

13

12

11

10

8

7

6

5

9

8

NC

V+

OUT A

DNC

V+

OUT B

–IN B

+IN B

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

00293-001

00293-002

00293-003

Rev. F

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©1996–2008 Analog Devices, Inc. All rights reserved.

Page 2

OP184/OP284/OP484

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Pin Configurations ........................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Electrical Characteristics ............................................................. 3

Absolute Maximum Ratings ............................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

Typical Performance Characteristics ............................................. 7

Applications Information .............................................................. 14

Functional Description .............................................................. 14

Input Overvoltage Protection ................................................... 14

REVISION HISTORY

9/08—Rev. E to Rev. F

Changes to General Description .................................................... 1

Changes to Figure 4 .......................................................................... 6

Changes to Low Dropout Regulator with Current Limiting .... 20

7/08—Rev. D to Rev. E

Changes to Figure 1 .......................................................................... 1

Changes to Figure 12 ........................................................................ 8

Changes to Figure 36 and Figure 37 ............................................. 12

Changes to Designing Low Noise Circuits in Single-Supply

Applications Section ....................................................................... 15

Updated Outline Dimensions ....................................................... 21

Changes to Ordering Guide .......................................................... 22

4/06—Rev. C to Rev. D

Changes to Table 1 ............................................................................ 3

Changes to Table 2 ............................................................................ 4

Changes to Table 3 ............................................................................ 5

Deleted Reference to 1993 System Applications Guide............... 15

Output Phase Reversal ............................................................... 15

Designing Low Noise Circuits in Single-Supply

Applications ................................................................................ 15

Overdrive Recovery ................................................................... 16

Single-Supply, 3 V Instrumentation Amplifier ...................... 16

2.5 V Reference from a 3 V Supply .......................................... 17

5 V Only, 12-Bit DAC Swings Rail-to-Rail ............................. 17

High-Side Current Monitor ...................................................... 18

Capacitive Load Drive Capability ............................................ 18

Low Dropout Regulator with Current Limiting ..................... 18

3 V, 50 Hz/60 Hz Active Notch Filter with False Ground ..... 20

Outline Dimensions ....................................................................... 21

Ordering Guide .......................................................................... 22

3/06—Rev. B to Rev. C

Changes to Figure 1 Caption........................................................... 1

Changes to Table 1 ............................................................................ 3

Changes to Table 2 ............................................................................ 4

Changes to Table 3 ............................................................................ 5

Changes to Table 4 ............................................................................ 6

Changes to Figure 5 through Figure 9 ........................................... 7

Changes to Functional Description Section ............................... 14

Deleted SPICE Macro Model ........................................................ 21

Updated Outline Dimensions ....................................................... 21

Changes to Ordering Guide .......................................................... 22

9/02—Rev. A to Rev. B

Changes to Pin Configurations ...................................................... 1

Changes to Specifications, Input Bias Current Maximum.......... 2

Changes to Ordering Guide ............................................................ 5

Updated Outline Dimensions ....................................................... 19

6/02—Rev. 0 to Rev. A

10/96—Revision 0: Initial Version

Rev. F | Page 2 of 24

Page 3

OP184/OP284/OP484

www.BDTIC.com/ADI

SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

VS = 5.0 V, VCM = 2.5 V, TA = 25°C, unless otherwise noted.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage, OP184/OP284E Grade1VOS 65 V

−40°C ≤ TA ≤ +125°C 165 V

Offset Voltage, OP184/OP284F Grade

−40°C ≤ TA ≤ +125°C 350 V

Offset Voltage, OP484E Grade

–40°C ≤ TA ≤ +125°C 175 V

Offset Voltage, OP484F Grade

–40°C ≤ TA ≤ +125°C 450 V

Input Bias Current IB 60 450 nA

–40°C ≤ TA ≤ +125°C 600 nA

Input Offset Current IOS 2 50 nA

–40°C ≤ TA ≤ +125°C 50 nA

Input Voltage Range 0 5 V

Common-Mode Rejection Ratio CMRR VCM = 0 V to 5 V 60 dB

V

Large Signal Voltage Gain AVO RL = 2 kΩ, 1 V ≤ VO ≤ 4 V 50 240 V/mV

R

Bias Current Drift ∆IB/∆T 150 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage High VOH IL = 1.0 mA 4.85 V

Output Voltage Low VOL IL = 1.0 mA 125 mV

Output Current I

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.0 V to 10 V, −40°C ≤ TA ≤ +125°C 76 dB

Supply Current/Amplifier ISY VO = 2.5 V, −40°C ≤ TA ≤ +125°C 1.45 mA

Supply Voltage Range VS 3 36 V

DYNAMIC PERFORMANCE

Slew Rate SR RL = 2 kΩ 1.65 2.4 V/µs

Settling Time tS To 0.01%, 1.0 V step 2.5 µs

Gain Bandwidth Product GBP 3.25 MHz

Phase Margin ΦM 45 Degrees

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 0.3 V p-p

Voltage Noise Density en f = 1 kHz 3.9 nV/√Hz

Current Noise Density in 0.4 pA/√Hz

1

Input offset voltage measurements are performed by automated test equipment approximately 0.5 seconds after application of power.

1

V

1

V

1

V

125 V

OS

75 V

OS

150 V

OS

= 1.0 V to 4.0 V, −40°C ≤ TA ≤ +125°C 86 dB

CM

= 2 kΩ, −40°C ≤ TA ≤ +125°C 25 V/mV

L

±6.5 mA

OUT

Rev. F | Page 3 of 24

Page 4

OP184/OP284/OP484

www.BDTIC.com/ADI

VS = 3.0 V, VCM = 1.5 V, TA = 25°C, unless otherwise noted.

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage, OP184/OP284E Grade

−40°C ≤ TA ≤ +125°C 165 V

Offset Voltage, OP184/OP284F Grade

−40°C ≤ TA ≤ +125°C 350 V

Offset Voltage, OP484E Grade

–40°C ≤ TA ≤ +125°C 200 V

Offset Voltage, OP484F Grade

–40°C ≤ TA ≤ +125°C 450 V

Input Bias Current IB 60 450 nA

−40°C ≤ TA ≤ +125°C 600 nA

Input Offset Current IOS −40°C ≤ TA ≤ +125°C 50 nA

Input Voltage Range 0 3 V

Common-Mode Rejection Ratio CMRR VCM = 0 V to 3 V 60 dB

V

OUTPUT CHARACTERISTICS

Output Voltage High VOH IL = 1.0 mA 2.85 V

Output Voltage Low VOL IL = 1.0 mA 125 mV

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = ±1.25 V to ±1.75 V 76 dB

Supply Current/Amplifier ISY VO = 1.5 V, −40°C ≤ TA ≤ +125°C 1.35 mA

DYNAMIC PERFORMANCE

Gain Bandwidth Product GBP 3 MHz

NOISE PERFORMANCE

Voltage Noise Density en f = 1 kHz 3.9 nV/√Hz

1

Input offset voltage measurements are performed by automated test equipment approximately 0.5 seconds after application of power.

1

V

1

V

1

V

1

V

65 V

OS

125 V

OS

100 V

OS

150 V

OS

= 0 V to 3 V, −40°C ≤ TA ≤ +125°C 56 dB

CM

Rev. F | Page 4 of 24

Page 5

OP184/OP284/OP484

www.BDTIC.com/ADI

VS = ±15.0 V, VCM = 0 V, TA = 25°C, unless otherwise noted.

Table 3.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage, OP184/OP284E Grade1VOS 100 V

−40°C ≤ TA ≤ +125°C 200 V

Offset Voltage, OP184/OP284F Grade

−40°C ≤ TA ≤ +125°C 375 V

Offset Voltage, OP484E Grade

−40°C ≤ TA ≤ +125°C 300 V

Offset Voltage, OP484F Grade

−40°C ≤ TA ≤ +125°C 500 V

Input Bias Current IB 80 450 nA

−40°C ≤ TA ≤ +125°C 575 nA

Input Offset Current IOS −40°C ≤ TA ≤ +125°C 50 nA

Input Voltage Range −15 +15 V

Common-Mode Rejection Ratio CMRR VCM = −14.0 V to +14.0 V, −40°C ≤ TA ≤ +125°C 86 90 dB

V

Large Signal Voltage Gain AVO R

R

Offset Voltage Drift E Grade ∆VOS/∆T 0.2 2.00 V/°C

Bias Current Drift ∆VB/∆T 150 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage High VOH IL = 1.0 mA 14.8 V

Output Voltage Low VOL IL = 1.0 mA −14.875 V

Output Current I

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = ±2.0 V to ±18 V, −40°C ≤ TA ≤ +125°C 90 dB

Supply Current/Amplifier ISY VO = 0 V, −40°C ≤ TA ≤ +125°C 2.0 mA

Supply Current/Amplifier ISY V

DYNAMIC PERFORMANCE

Slew Rate SR RL = 2 kΩ 2.4 4.0 V/µs

Full-Power Bandwidth BWp 1% distortion, RL = 2 kΩ, VO = 29 V p-p 35 kHz

Settling Time tS To 0.01%, 10 V step 4 µs

Gain Bandwidth Product GBP 4.25 MHz

Phase Margin ΦM 50 Degrees

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 0.3 µV p-p

Voltage Noise Density en f = 1 kHz 3.9 nV/√Hz

Current Noise Density in 0.4 pA/√Hz

1

Input offset voltage measurements are performed by automated test equipment approximately 0.5 seconds after application of power.

1

V

1

V

1

V

175 V

OS

150 V

OS

250 V

OS

= −15.0 V to +15.0 V 80 dB

CM

= 2 kΩ, −10 V ≤ VO ≤ 10 V 150 1000 V/mV

L

= 2 kΩ, −40 V ≤ TA ≤ +125°C 75 V/mV

L

±10 mA

OUT

= ±18 V, −40°C ≤ TA ≤ +125°C 2.25 mA

S

Rev. F | Page 5 of 24

Page 6

OP184/OP284/OP484

V

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

Supply Voltage ±18 V

Input Voltage ±18 V

Differential Input Voltage1 ±0.6 V

Output Short-Circuit Duration to GND Indefinite

Storage Temperature Range

P-Suffix, S-Suffix Packages −65°C to +150°C

Operating Temperature Range

OP184/OP284/OP484E/OP484F −40°C to +125°C

Junction Temperature Range

P-Suffix, S-Suffix Packages −65°C to +150°C

Lead Temperature

(Soldering 60 sec)

1

For input voltages greater than 0.6 V, the input current should be limited to

less than 5 mA to prevent degradation or destruction of the input devices.

300°C

THERMAL RESISTANCE

θJA is specified for the worst-case conditions; that is, θJA is specified

for a device in socket for PDIP. θ

in the circuit board for SOIC packages.

Table 5. Thermal Resistance

Package Type θJA θ

8-Lead PDIP (P-Suffix) 103 43 °C/W

8-Lead SOIC (S-Suffix) 158 43 °C/W

14-Lead PDIP (P-Suffix) 83 39 °C/W

14-Lead SOIC (S-Suffix) 92 27 °C/W

ESD CAUTION

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply to both DICE and packaged

parts, unless otherwise noted.

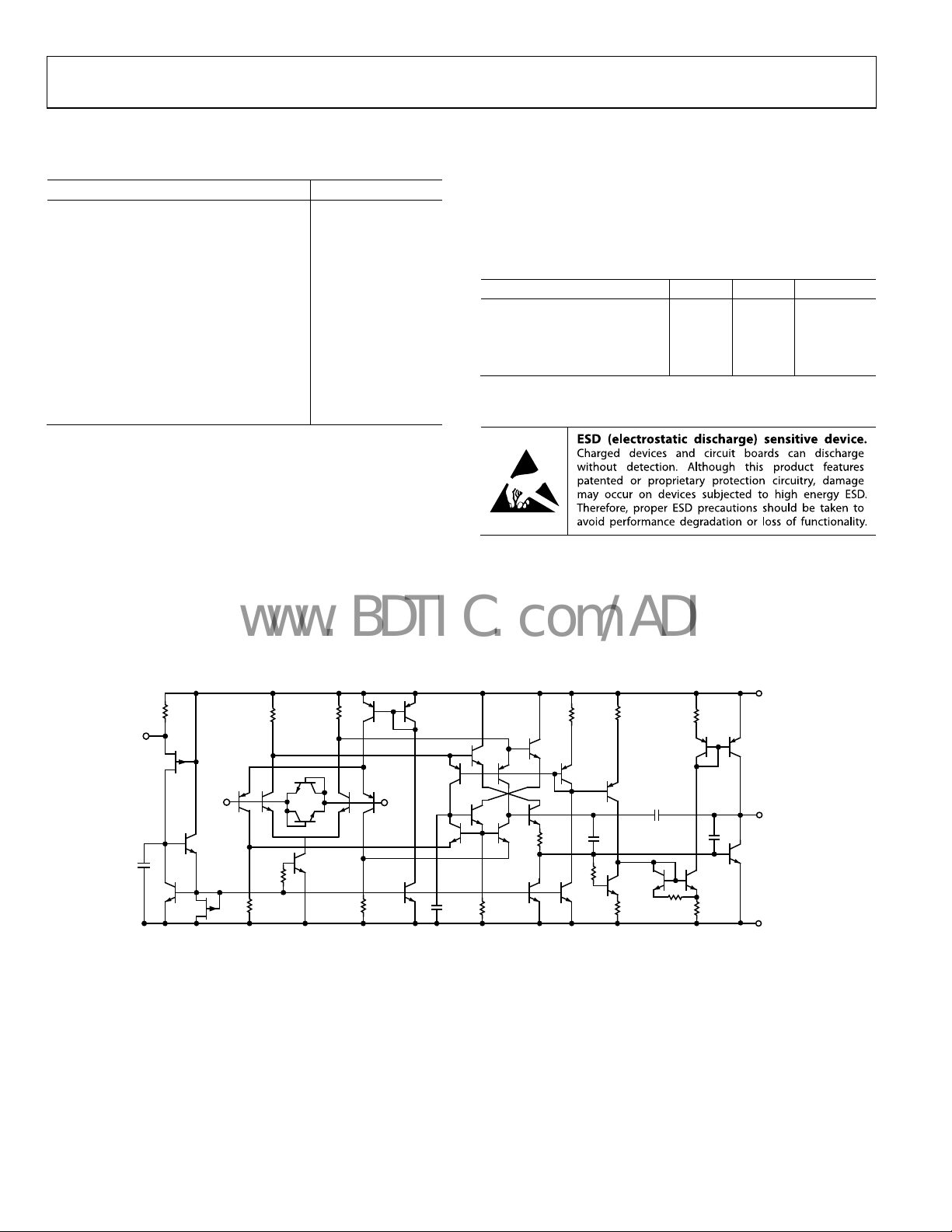

RB1

TP

JB1

–IN +IN

QB2

N+CB1

P+M

QB1

JB2

Q1

R3

Q3

RB2

R1

QL1

QB3

QL2

R4

QB6

Q4

QB5

Q11

Q2

QB4

R2

Q7

Q9

Q5

CC1

Figure 4. Simplified Schematic

Q12

Q8

Q10

Q6

QB7

R5

is specified for a device soldered

JA

Unit

JC

CC

RB3

QB9

R6

R7

QB8

RB4

QB10

CC2

FFC

Q14

Q13

R8

R11

Q15

C

R10

Q17

Q18

OUT

V

EE

00293-004

O

Q16

R9

Rev. F | Page 6 of 24

Page 7

OP184/OP284/OP484

–

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

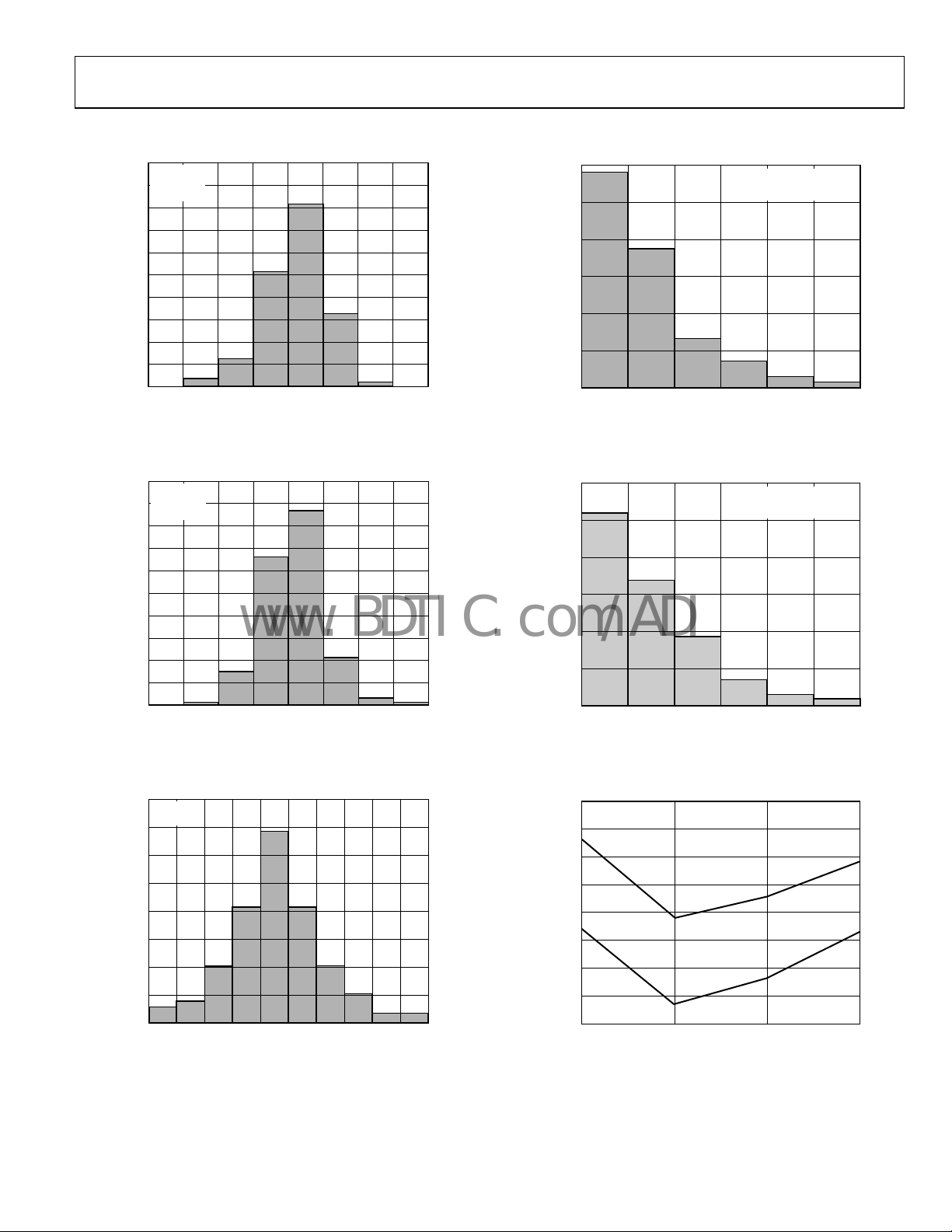

300

VS= 3V

T

= 25°C

A

270

V

= 1.5V

CM

240

210

180

150

QUANTITY

120

90

60

30

0

–100 –75 –50 –25 0 25 50 75 100

INPUT OFFSET VOLTAGE (µV )

Figure 5. Input Offset Voltage Distribution

00293-005

300

250

200

150

QUANTITY

100

50

0

0 0.250.500.751.001.251.

OFFSET VO LTAGE DRIFT , TCVOS (µV/°C)

VS = 5V

–40°C ≤ T

≤ +125°C

A

Figure 8. Input Offset Voltage Drift Distribution

00293-008

50

300

VS= 5V

= 25°C

T

A

270

V

= 2.5V

CM

240

210

180

150

QUANTITY

120

90

60

30

0

–100 –75 –50 –25 0 25 50 75 100

INPUT OFFSET VOLTAGE (µV)

Figure 6. Input Offset Voltage Distribution

200

VS= ±15V

T

= 25°C

A

175

150

125

100

QUANTITY

75

300

250

200

150

QUANTITY

100

50

00293-006

0

0 0.250.500.751.001.251.

OFFSET VO LTAGE DRIFT , TCVOS (µV/°C)

VS = ±15V

–40°C ≤ T

≤ +125°C

A

00293-009

50

Figure 9. Input Offset Voltage Drift Distribution

–45

–50

–55

–60

–65

40

= +5V

V

S

= VS/2

V

CM

50

25

0

–125 –100 –75 –50 –25 0 25 10050 75 125

INPUT OFFSET VOLTAGE (µV)

00293-007

Figure 7. Input Offset Voltage Distribution

Rev. F | Page 7 of 24

–70

INPUT BIAS CURRENT (nA)

–75

–80

–40 25 85 125

V

= ±15V

S

TEMPERATURE (°C)

Figure 10. Bias Current vs. Temperature

00293-010

Page 8

OP184/OP284/OP484

www.BDTIC.com/ADI

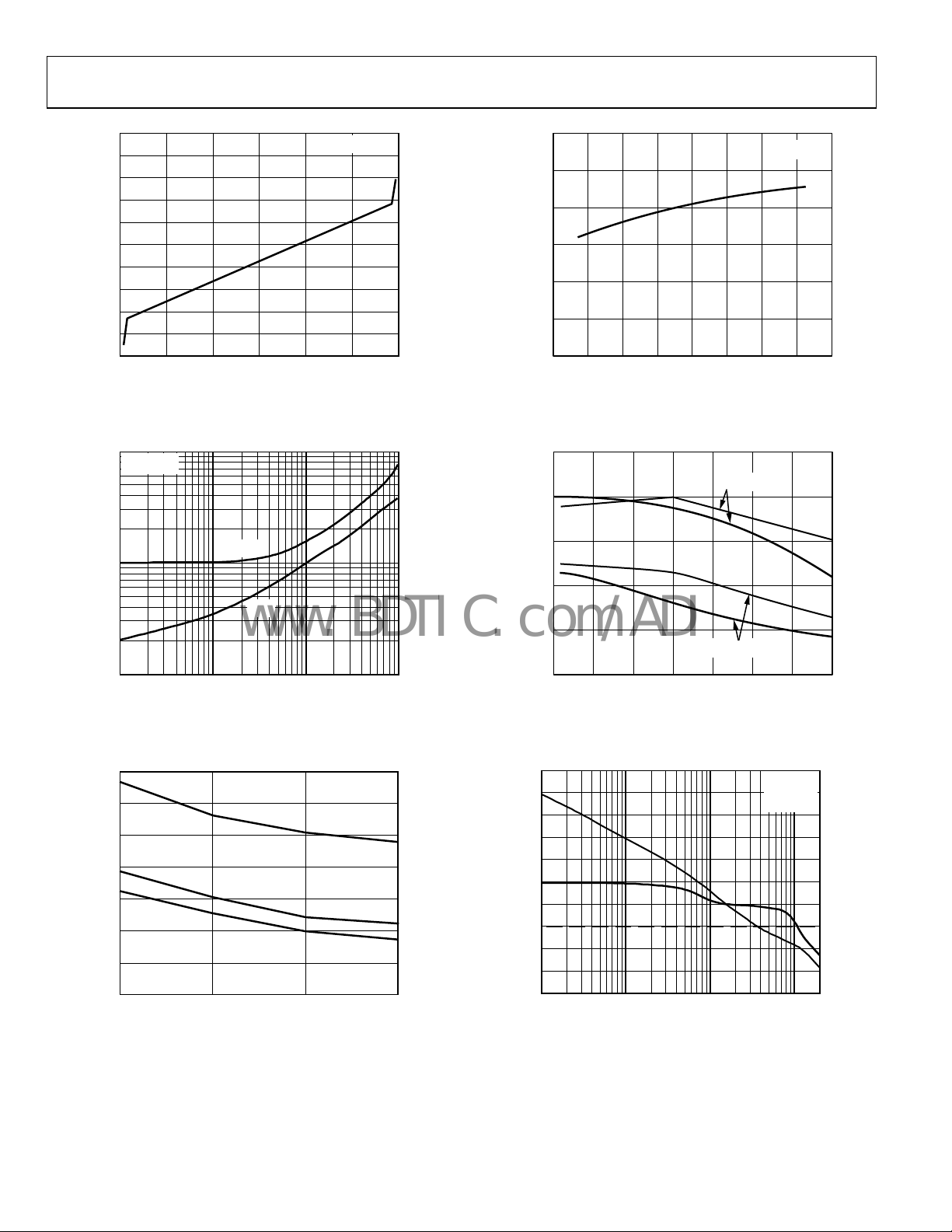

500

400

300

200

100

0

–100

–200

INPUT BIAS CURRENT (nA)

–300

–400

–500

–15 –10 –5 0 5 10 15

COMMON-MODE VOLTAGE (V)

Figure 11. Input Bias Current vs. Common-Mode Voltage

VS = ±15V

00293-011

1.50

1.25

1.00

0.75

0.50

0.25

SUPPLY CURRENT/ PER AMPLIF IER (mA)

0

0 ±2. 5 ±5. 0 ±7. 5 ±10.0 ±12.5 ±15.0 ±17.5 ±20.0

SUPPLY VOLTAGE (V)

Figure 14. Supply Current vs. Supply Voltage

TA = 25°C

00293-014

1000

VS = ±15V

100

OUTPUT VOLTAGE (mV)

10

0.01 0.1 1 10

SOURCE

SINK

LOAD CURRENT (mA)

Figure 12. Output Voltage to Supply Rail vs. Load Current

1.2

1.1

1.0

0.9

0.8

0.7

SUPPLY CURRENT/ AMPLIFIER (mA)

0.6

0.5

–40 25 85 125

TEMPERATURE (°C)

VS = ±15V

V

= +5V

S

= +3V

V

S

Figure 13. Supply Current vs. Temperature

50

40

30

–I

SC

20

+I

SC

10

SHORT-CIRCUIT CURRENT (mA)

00293-012

0

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

VS = ±15V

+I

SC

–I

SC

VS = +5V, VCM = +2.5V

00293-015

Figure 15. Short-Circuit Current vs. Temperature

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN (dB)

–10

–20

00293-013

–30

10k 100k 1M 10M

FREQUENCY (Hz)

VS = 5V

T

= 25°C

A

NO LOAD

0

45

90

135

180

225

270

PHASE SHIFT (Degrees)

00293-016

Figure 16. Open-Loop Gain and Phase vs. Frequency (No Load)

Rev. F | Page 8 of 24

Page 9

OP184/OP284/OP484

www.BDTIC.com/ADI

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN (dB)

–10

–20

–30

10k 100k 1M 10M

FREQUENCY (Hz)

VS = 3V

T

= 25°C

A

NO LOAD

Figure 17. Open-Loop Gain and Phase vs. Frequency (No Load)

0

45

90

135

180

225

270

PHASE SHIFT (Degrees)

00293-017

60

50

40

30

20

10

0

–10

CLOSED-LOOP GAIN (dB)

–20

–30

–40

10 1k 100k 10M100 10k 1M

FREQUENCY (Hz)

Figure 20. Closed-Loop Gain vs. Frequency (2 kΩ Load)

VS = 5V

R

= 2kΩ

L

T

= 25°C

A

00293-020

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN (dB)

–10

–20

–30

10k 100k 1M 10M

FREQUENCY (Hz)

VS = ±15V

T

= 25°C

A

NO LOAD

Figure 18. Open-Loop Gain and Phase vs. Frequency (No Load)

2500

2000

1500

1000

OPEN-LOOP GAIN (V/mV)

500

0

–50 1251007550250–25

V

= +5V

S

+1V < V

R

= 2kΩ

L

O

VS = ±15V

–10V < V

R

= 2kΩ

L

< +10V

TEMPERATURE (°C)

< +10V

O

Figure 19. Open-Loop Gain vs. Temperature

0

45

90

135

180

225

270

60

50

40

30

20

10

0

PHASE SHIFT (Degrees)

00293-018

–10

CLOSED-LOOP GAIN (dB)

–20

–30

–40

10 1k 100k 10M100 10k 1M

FREQUENCY (Hz)

VS = ±15V

R

= 2kΩ

L

T

= 25°C

A

00293-020

Figure 21. Closed-Loop Gain vs. Frequency (2 kΩ Load)

60

50

40

30

20

10

0

–10

CLOSED-LOOP GAIN (dB)

–20

–30

00293-019

–40

10 1k 100k 10M100 10k 1M

FREQUENCY (Hz)

VS = 3V

R

= 2kΩ

L

T

= 25°C

A

00293-020

Figure 22. Closed-Loop Gain vs. Frequency (2 kΩ Load)

Rev. F | Page 9 of 24

Page 10

OP184/OP284/OP484

www.BDTIC.com/ADI

300

VS = 5V

T

= 25°C

270

A

240

210

180

150

120

90

OUTPUT IM PEDANCE (Ω)

60

30

0

10 1k 100k 10M100 10k 1M

AV = +100

FREQUENCY (Hz)

Figure 23. Output Impedance vs. Frequency

A

= +10

V

A

= +1

V

00293-023

5

4

3

2

1

VS = 5V

MAXIMUM OUTPUT SWING (V p-p)

V

= 0.5V TO 4.5V

IN

R

= 2kΩ

L

T

= 25°C

A

0

1k 100k 10M10k 1M

FREQUENCY (Hz)

Figure 26. Maximum Output Swing vs. Frequency

00293-026

300

VS = 15V

T

= 25°C

270

A

240

210

180

150

120

90

OUTPUT IM PEDANCE (Ω)

60

30

0

10 1k 100k 10M100 10k 1M

AV = +100

FREQUENCY (Hz)

Figure 24. Output Impedance vs. Frequency

300

VS = 3V

T

= 25°C

270

A

240

210

180

150

120

90

OUTPUT IM PEDANCE (Ω)

60

30

0

10 1k 100k 10M100 10k 1M

AV = +100

FREQUENCY (Hz)

Figure 25. Output Impedance vs. Frequency

A

A

V

= +10

V

= +10

A

V

A

V

= +1

= +1

6

5

4

3

2

MAXIMUM OUTPUT SWING (V p-p)

1

00293-024

0

1k 100k 10M10k 1M

FREQUENCY (Hz)

VS = 15V

V

= ±14V

IN

R

= 2kΩ

L

T

= 25°C

A

00293-027

Figure 27. Maximum Output Swing vs. Frequency

180

TA = 25°C

160

140

120

100

V

= +3V

S

VS = ±15V

= +5V

V

S

00293-028

80

60

CMRR (dB)

40

20

0

00293-025

–20

10 100k 10M1k100 10k 1M

FREQUENCY (Hz)

Figure 28. CMRR vs. Frequency

Rev. F | Page 10 of 24

Page 11

OP184/OP284/OP484

www.BDTIC.com/ADI

160

TA = 25°C

140

120

100

80

60

PSRR (dB)

40

20

0

–20

–40

10 100k 10M1k100 10k 1M

FREQUENCY (Hz)

VS = ±15V

Figure 29. PSRR vs. Frequency

V

= +3V

S

V

= +5V

S

00293-029

30

25

20

15

10

NOISE DENSIT Y (nV / Hz)

5

0

110100

FREQUENCY (Hz)

±2.5V ≤ VS ≤ ±15V

T

Figure 32. Voltage Noise Density vs. Frequency

= 25°C

A

00293-032

1000

80

VS = ±2.5V

T

= 25°C, A

A

70

V

= ±50mV

IN

60

50

40

30

OVERSHOOT (%)

20

10

0

10 1000100

= 1

VCL

CAPACITIVE L OAD (pF)

–OS

+OS

Figure 30. Small Signal Overshoot vs. Capacitive Load

7

VS = ±15V

R

VS = ±5V

R

= 2kΩ

L

= 2kΩ

L

6

5

4

3

SLEW RATE (V/µs)

2

1

0

–50 –25 0 25 50 75 100 125

+SLEW RATE

–SLEW RATE

+SLEW RATE

–SLEW RATE

TEMPERATURE ( °C)

Figure 31. Slew Rate vs. Temperature

10

8

6

4

2

CURRENT NOISE DENSITY (pA/ Hz)

00293-030

0

110100

FREQUENCY (Hz)

±2.5V ≤ VS ≤ ±15V

T

= 25°C

A

00293-033

1000

Figure 33. Current Noise Density vs. Frequency

5

4

3

2

1

0

–1

STEP SIZE (V)

–2

–3

–4

00293-031

–5

0.1% 0.01%

0654321

SETTLING TIME (µs)

VS = 5V

T

= 25°C

A

00293-034

Figure 34. Step Size vs. Settling Time

Rev. F | Page 11 of 24

Page 12

OP184/OP284/OP484

www.BDTIC.com/ADI

STEP SIZE (V)

10

8

6

4

2

0.1% 0.01%

0

–2

–4

–6

–8

–10

0654321

Figure 35. Step Size vs. Settling Time

SETTLING TIME (µs)

VS = ±15V

T

= 25°C

A

00293-035

160

140

120

100

80

60

40

20

CHANNEL SEPARATIO N (dB)

0

–20

–40

100 10M1M100k10k1k

V

S

FREQUENCY (Hz)

Figure 38. Channel Separation vs. Frequency

TA = 25°C

V

= ±15V

S

= +3V

00293-038

0.3

VS = ±2.5V

A

= 10M

V

0.2

0.1

0

NOISE (µV )

–0.1

–0.2

–0.3

–5 –4 –3 –2 –1 0 1 2 3 4 5

TIME

Figure 36. 0.1 Hz to 10 Hz Noise

0.3

VS = ±15V

= 10M

A

V

0.2

0.1

0

NOISE (µV )

–0.1

–0.2

–0.3

–5 –4 –3 –2 –1 0 1 2 3 4 5

TIME

Figure 37. 0.1 Hz to 10 Hz Noise

VS = 5V

A

= +1

V

R

= OPEN

1µs

L

C

= 300pF

L

T

= 25°C

A

0293-039

100

90

400mV

10

0V

0%

100mV

00293-036

Figure 39. Small Signal Transient Response

VS = 5V

A

= +1

V

R

= 2kΩ

1µs

L

C

= 300pF

L

T

= 25°C

A

0293-040

100

90

400mV

10

0V

0%

100mV

00293-037

Figure 40. Small Signal Transient Response

Rev. F | Page 12 of 24

Page 13

OP184/OP284/OP484

+

V

–

V

+

V

–

V

www.BDTIC.com/ADI

0.1

VO = ±0.75V

AV = +1000

V

S

R

0.01

THD+N (%)

VO = ±2.5V

= ±1.5V

V

0.001

0.0005

20 1k 20k100 10k

O

FREQUENCY (Hz)

L

Figure 43. Total Harmonic Distortion + Noise vs. Frequency

= ±2.5V

= 2kΩ

00293-043

200m

200m

100

90

0V

10

0%

100mV

Figure 41. Small Signal Transient Response

VS = ±1.5V

A

V

NO LOAD

T

A

500ns

= +1

= 25°C

0293-041

200m

200m

VS = ±0.75V

A

= +1

V

100

90

0V

10

0%

100mV

NO LOAD

T

= 25°C

A

1µs

0293-042

Figure 42. Small Signal Transient Response

Rev. F | Page 13 of 24

Page 14

OP184/OP284/OP484

V

V

S

www.BDTIC.com/ADI

APPLICATIONS INFORMATION

FUNCTIONAL DESCRIPTION

The OP184/OP284/OP484 are precision single-supply, rail-to-rail

operational amplifiers. Intended for the portable instrumentation

marketplace, the OPx84 family of devices combine the attributes

of precision, wide bandwidth, and low noise to make them a superb

choice in single-supply applications that require both ac and

precision dc performance. Other low supply voltage applications for which the OP284 is well suited are active filters,

audio microphone preamplifiers, power supply control, and

telecommunications. To combine all of these attributes with

rail-to-rail input/output operation, novel circuit design techniques

are used.

+

To achieve rail-to-rail output, the OP284 output stage design

employs a unique topology for both sourcing and sinking current.

This circuit topology is illustrated in Figure 45. The output stage

is voltage-driven from the second gain stage. The signal path

through the output stage is inverting; that is, for positive input

signals, Q1 provides the base current drive to Q6 so that it conducts

(sinks) current. For negative input signals, the signal path via

Q1Q2D1Q4Q3 provides the base current drive for Q5 to

conduct (source) current. Both amplifiers provide output current

until they are forced into saturation, which occurs at approximately 20 mV from the negative supply rail and 100 mV from

the positive supply rail.

+

+IN x

R1

4kΩ

Q3 2Q1Q

R3

3kΩ

Figure 44. OP284 Equivalent Input Circuit

I1

D1

D2

V–

Q4

I2

R4

3kΩ

R2

4kΩ

–

V

–IN x

–

V

01

02

00293-044

For example, Figure 44 illustrates a simplified equivalent circuit

for the input stage of the OP184/OP284/OP484. It comprises

an NPN differential pair, Q1Q2, and a PNP differential pair,

Q3Q4, operating concurrently. Diode Network D1Diode

Network D2 serves to clamp the applied differential input

voltage to the OP284, thereby protecting the input transistors

against avalanche damage. Input stage voltage gains are kept low

for input rail-to-rail operation. The two pairs of differential

output voltages are connected to the second stage of the OP284,

which is a compound folded cascade gain stage. It is also in the

second gain stage, where the two pairs of differential output

voltages are combined into a single-ended, output signal voltage

used to drive the output stage. A key issue in the input stage is

the behavior of the input bias currents over the input commonmode voltage range. Input bias currents in the OP284 are the

arithmetic sum of the base currents in Q1Q3 and in Q2Q4.

As a result of this design approach, the input bias currents in

the OP284 not only exhibit different amplitudes; they also

exhibit different polarities. This effect is best illustrated by

Figure 10. It is, therefore, of paramount importance that the

effective source impedances connected to the OP284 inputs

be balanced for optimum dc and ac performance.

R4

Q4

Q5

V

OUT

Q6

R6R3

00293-045

Q3

R5

INPUT FROM

ECOND GAIN

STAGE

Q1

I1

Figure 45. OP284 Equivalent Output Circuit

I2

R1

R2

Q2

V–

D1

Thus, the saturation voltage of the output transistors sets the

limit on the OP284 maximum output voltage swing. Output

short-circuit current limiting is determined by the maximum

signal current into the base of Q1 from the second gain stage.

Under output short-circuit conditions, this input current level

is approximately 100 A. With transistor current gains around 200,

the short-circuit current limits are typically 20 mA. The output

stage also exhibits voltage gain. This is accomplished by the use

of common-emitter amplifiers, and, as a result, the voltage gain

of the output stage (thus, the open-loop gain of the device)

exhibits a dependence to the total load resistance at the output

of the OP284.

INPUT OVERVOLTAGE PROTECTION

As with any semiconductor device, if conditions exist where the

applied input voltages to the device exceed either supply voltage,

the input overvoltage I-V characteristic of the device must be

considered. When an overvoltage occurs, the amplifier could be

damaged, depending on the magnitude of the applied voltage

and the magnitude of the fault current. Figure 46 illustrates the

overvoltage I-V characteristic of the OP284. This graph was

generated with the supply pins connected to GND and a curve

tracer’s collector output drive connected to the input.

Rev. F | Page 14 of 24

Page 15

OP184/OP284/OP484

V

[

www.BDTIC.com/ADI

5

4

3

2

1

0

–1

–2

INPUT CURRENT (mA)

–3

–4

–5

–5–4–3–2–1012345

Figure 46. Input Overvoltage I-V Characteristics of the OP284

INPUT VOLTAGE (V)

00293-046

As shown in Figure 46, internal p-n junctions to the OP284

energize and permit current flow from the inputs to the supplies

when the input is 1.8 V more positive and 0.6 V more negative

than the respective supply rails. As illustrated in the simplified

equivalent circuit shown in Figure 44, the OP284 does not have

any internal current limiting resistors; thus, fault currents can

quickly rise to damaging levels.

This input current is not inherently damaging to the device,

provided that it is limited to 5 mA or less. For the OP284, once

the input exceeds the negative supply by 0.6 V, the input current

quickly exceeds 5 mA. If this condition continues to exist, an

external series resistor should be added at the expense of additional thermal noise. Figure 47 illustrates a typical noninverting

configuration for an overvoltage-protected amplifier where the

series resistance, R

R−=

S

, is chosen such that

S

IN

VV

()

MAX

SUPPLY

mA5

For example, a 1 k resistor protects the OP284 against input

signals up to 5 V above and below the supplies. For other configurations where both inputs are used, each input should be protected

against abuse with a series resistor. Again, to ensure optimum

dc and ac performance, it is recommended that source impedance

levels be balanced.

R2

IN

R1

Figure 47. Resistance in Series with Input Limits Overvoltage Currents

to Safe Values

1/2

OP284

V

OUT

00293-047

OUTPUT PHASE REVERSAL

Some operational amplifiers designed for single-supply operation

exhibit an output voltage phase reversal when their inputs are

driven beyond their useful common-mode range. Typically, for

single-supply bipolar op amps, the negative supply determines

the lower limit of their common-mode range. With these devices,

external clamping diodes, with the anode connected to ground

and the cathode to the inputs, prevent input signal excursions

from exceeding the negative supply of the device (that is, GND),

preventing a condition that causes the output voltage to change

phase. JFET-input amplifiers can also exhibit phase reversal;

and, if so, a series input resistor is usually required to prevent it.

The OP284 is free from reasonable input voltage range restrictions,

provided that input voltages no greater than the supply voltages

are applied. Although device output does not change phase, large

currents can flow through the input protection diodes, as shown

in Figure 46. Therefore, the technique recommended in the Input

Overvoltage Protection section should be applied to those applications where the likelihood of input voltages exceeding the

supply voltages is high.

DESIGNING LOW NOISE CIRCUITS IN SINGLESUPPLY APPLICATIONS

In single-supply applications, devices like the OP284 extend the

dynamic range of the application through the use of rail-to-rail

operation. In fact, the OPx84 family is the first of its kind to

combine single-supply, rail-to-rail operation, and low noise in

one device. It is the first device in the industry to exhibit an input

noise voltage spectral density of less than 4 nV/√Hz at 1 kHz.

It was also designed specifically for low-noise, single-supply

applications, and as such, some discussion on circuit noise

concepts in single-supply applications is appropriate.

Referring to the op amp noise model circuit configuration

illustrated in Figure 48, the expression for an amplifier’s total

equivalent input noise voltage for a source resistance level, R

is given by

2

nT

nR

Ri

SnOA

22

]

)()()(2

eee

+×+= , units in

nOA

V

Hz

where:

R

= 2R is the effective, or equivalent, circuit source resistance.

S

(e

)2 is the source resistance thermal noise voltage power (4kTR).

nR

k is the Boltzmann’s constant = 1.38 × 10

–23

J/K.

T is the ambient temperature in Kelvins of the circuit = 273.15 +

(°C).

T

A

(i

)2 is the op amp equivalent input noise current spectral power

nOA

(1 Hz bandwidth).

)2 is the op amp equivalent input noise voltage spectral power

(e

nOA

(1 Hz bandwidth).

e

e

nR

R

NOISELESS

R

NOISELESS

Figure 48. Op Amp Noise Circuit Model Used to Determine Total Circuit

Equivalent Input Noise Voltage and Noise Figure

e

nOA

i

nOA

nR

i

nOA

IDEAL

NOISELESS

OP AMP

= 2R

R

S

,

S

00293-048

Rev. F | Page 15 of 24

Page 16

OP184/OP284/OP484

www.BDTIC.com/ADI

As a design aid, Figure 49 shows the total equivalent input noise

of the OP284 and the total thermal noise of a resistor for comparison. Note that for source resistance less than 1 k, the

equivalent input noise voltage of the OP284 is dominant.

100

FREQUENCY = 1kHz

= 25°C

T

A

OP284 TOT AL

10

EQUIVALENT THERMAL NOISE (nV/ Hz)

1

100 1k 100k

Figure 49. OP284 Equivalent Thermal Noise vs. Total Source Resistance

EQUIVALENT NOISE

RESISTOR THERMAL

NOISE ONLY

10k

TOTAL SO URCE RESISTANCE, RS (Ω)

00293-049

Because circuit SNR is the critical parameter in the final analysis,

the noise behavior of a circuit is often expressed in terms of its

noise figure, NF. The noise figure is defined as the ratio of a

circuit’s output signal-to-noise to its input signal-to-noise.

An expression of a circuit NF in dB, and in terms of the

operational amplifier voltage and current noise parameters

defined previously, is given by

NF

1log10dB

+=

⎢

⎢

⎣

()

⎡

2

⎛

()

⎜

⎜

⎝

()

()

e

nRS

2

⎤

⎞

Rie

×+

SnOAnOA

⎟

2

⎥

⎟

⎥

⎠

⎦

where:

NF (dB) is the noise figure of the circuit, expressed in decibels.

(e

)2 is the OP284 noise voltage spectral power (1 Hz bandwidth).

nOA

)2 is the OP284 noise current spectral power (1 Hz bandwidth).

(i

nOA

(e

)2 is the source resistance thermal noise voltage power =

nRS

).

(4kTR

S

R

is the effective, or equivalent, source resistance presented to

S

the amplifier.

Calculation of the circuit noise figure is straightforward because

the signal level in the application is not required to determine it.

However, many designers using NF calculations as the basis for

achieving optimum SNR believe that a low noise figure is equal to

low total noise. In fact, the opposite is true, as shown in Figure 50.

The noise figure of the OP284 is expressed as a function of the

source resistance level. Note that the lowest noise figure for the

OP284 occurs at a source resistance level of 10 k. However,

Figure 49 shows that this source resistance level and the OP284

generate approximately 14 nV/√Hz of total equivalent circuit

noise. Signal levels in the application invariably increase to

maximize circuit SNR, which is not an option in low voltage,

single-supply applications.

10

9

8

7

6

5

4

NOISE FI GURE (dB)

3

2

1

0

100

Figure 50. OP284 Noise Figure vs. Source Resistance

TOTAL S OURCE RESIST ANCE, RS (Ω)

FREQUENCY = 1kHz

T

= 25°C

A

10k 100k1k

00293-050

Therefore, to achieve optimum circuit SNR in single-supply

applications, it is recommended that an operational amplifier

with the lowest equivalent input noise voltage be chosen, along

with source resistance levels that are consistent with maintaining

low total circuit noise.

OVERDRIVE RECOVERY

The overdrive recovery time of an operational amplifier is the

time required for the output voltage to recover to its linear region

from a saturated condition. The recovery time is important in

applications where the amplifier must recover quickly after a

large transient event. The circuit shown in Figure 51 was used

to evaluate the OP284 overload recovery time. The OP284

takes approximately 2 µs to recover from positive saturation

and approximately 1 µs to recover from negative saturation.

R1

10kΩ

R3

9kΩ

V

IN

10V STEP

Figure 51. Output Overload Recovery Test Circuit

2

1/2

OP284

3

R2

10kΩ

+5V

–5V

8

1

V

OUT

4

00293-051

SINGLE-SUPPLY, 3 V INSTRUMENTATION AMPLIFIER

The low noise, wide bandwidth, and rail-to-rail input/output

operation of the OP284 make it ideal for low supply voltage

applications such as in the two op amp instrumentation amplifier

shown in Figure 52. The circuit uses the classic two op amp

instrumentation amplifier topology with four resistors to set the

gain. The transfer equation of the circuit is identical to that of a

noninverting amplifier. Resistor R2 and Resistor R3 should be

closely matched to each other, as well as to Resistors (R1 + P1)

and Resistor R4 to ensure good common-mode rejection

performance.

Rev. F | Page 16 of 24

Page 17

OP184/OP284/OP484

V

V

A

T

F

www.BDTIC.com/ADI

Resistor networks should be used in this circuit for R2 and R3

because they exhibit the necessary relative tolerance matching for

good performance. Matched networks also exhibit tight relative

resistor temperature coefficients for good circuit temperature

stability. Trimming Potentiometer P1 is used for optimum dc

CMR adjustment, and C1 is used to optimize ac CMR. With the

circuit values as shown, Circuit CMR is better than 80 dB over the

frequency range of 20 Hz to 20 kHz. Circuit referred-to-input

(RTI) noise in the 0.1 Hz to 10 Hz band is an impressively low

0.45 V p-p. Resistor RP1 and Resistor RP2 serve to protect the

OP284 inputs against input overvoltage abuse. Capacitor C2 can

be included to the limit circuit bandwidth and, therefore, wide

bandwidth noise in sensitive applications. The value of this

capacitor should be adjusted, depending on the required closedloop bandwidth of the circuit. The R4 to C2 time constant creates

a pole at a frequency equal to

()

3CRdBf

1

=

π

242

2.5 V REFERENCE FROM A 3 V SUPPLY

In many single-supply applications, the need for a 2.5 V reference

often arises. Many commercially available monolithic 2.5 V

references require at least a minimum operating supply of 4 V.

The problem is exacerbated when the minimum operating

supply voltage is 3 V. The circuit illustrated in Figure 53 is an

example of a 2.5 V reference that operates from a single 3 V

supply. The circuit takes advantage of the OP284 rail-to-rail

input/output voltage ranges to amplify an AD589 1.235 V

output to 2.5 V.

RP1

1kΩ

+

V

IN

AC CMRR

5pF TO 40p

–

TRIM

RP2

1kΩ

3

A1

2

1.1kΩ

C1

R1

9.53kΩ

P1

500Ω

A1, A2 = 1/2 OP 284

GAIN = 1 +

SET R2 = R3

1

R2

R1 + P1 = R4

R3

1.1kΩ

R4

R3

Figure 52. Single Supply, 3 V Low Noise Instrumentation Amplifier

The low TCVOS of the OP284 at 1.5 V/°C helps maintain an

output voltage temperature coefficient that is dominated by

the temperature coefficients of R2 and R3. In this circuit with

100 ppm/°C TCR resistors, the output voltage exhibits a temperature coefficient of 200 ppm/°C. Lower tempco resistors are

recommended for more accurate performance over temperature.

3V

5

8

7

A2

6

4

R4

10kΩ

C2

V

OU

00293-052

One measure of the performance of a voltage reference is its

capacity to recover from sudden changes in load current. While

sourcing a steady-state load current of 1 mA, this circuit recovers

to 0.01% of the programmed output voltage in 1.5 s for a total

change in load current of ±1 mA.

3

R1

17.4kΩ

+

AD589

–

R3

100kΩ

RESISTO RS = 1%, 100p pm/°C

POTENTI OMETE R = 10 TURN, 100ppm/°C

Figure 53. 2.5 V Reference That Operates on a Single 3 V Supply

3V

8

3

1/2

OP284

2

4

R2

100kΩP15kΩ

0.1µF

1

2.5V

REF

00293-053

5 V ONLY, 12-BIT DAC SWINGS RAIL-TO-RAIL

The OP284 is ideal for use with a CMOS DAC to generate a

digitally controlled voltage with a wide output range. Figure 54

shows a DAC8043 used in conjunction with the AD589 to generate a voltage output from 0 V to 1.23 V. The DAC is actually

operating in voltage switching mode, where the reference is

connected to the current output, I

taken from the V

pin. This topology is inherently noninverting,

REF

as opposed to the classic current output mode, which is inverting

and not usable in single-supply applications.

5

R1

17.8kΩ

1.23V

D589

I

OUT

8

V

DD

DAC8043

GND CLK SR1 LD

4

R

V

REF

765

DIGITAL

CONTROL

R2

R3

32.4Ω

232Ω

1%

1%

Figure 54. 5 V Only, 12-Bit DAC Swings Rail-to-Rail

In this application, the OP284 serves two functions. First, it

buffers the high output impedance of the DAC V

is on the order of 10 k. The op amp provides a low impedance

output to drive any following circuitry.

Second, the op amp amplifies the output signal to provide a railto-rail output swing. In this particular case, the gain is set to 4.1

so that the circuit generates a 5 V output when the DAC output

is at full scale. If other output voltage ranges are needed, such as

0 V ≤ V

≤ 4.095 V, the gain can be easily changed by adjusting

OUT

the values of R2 and R3.

, and the output voltage is

OUT

2

RB

13

5V

3

8

1/2

R4

100kΩ

1%

1

4

OP284

2

V

=

OUT

pin, which

REF

D

4096

(5V)

00293-054

Rev. F | Page 17 of 24

Page 18

OP184/OP284/OP484

S

www.BDTIC.com/ADI

50mV

5V

1/2

OP284

50mV

0.1µF

V

R

S

50Ω

C

S

100nF

is determined; 10 F is a good

S

DLY 5.49µs

B

W

C

1nF

L

2µs

OUT

00293-056

0293-057

HIGH-SIDE CURRENT MONITOR

In the design of power supply control circuits, a great deal of design

effort is focused on ensuring the long-term reliability of a pass

transistor over a wide range of load current conditions. As a result,

monitoring and limiting device power dissipation is of prime

importance in these designs. The circuit shown in Figure 55 is

an example of a 3 V, single-supply, high-side current monitor that

can be incorporated into the design of a voltage regulator with

fold-back current limiting or a high current power supply with

crowbar protection. This design uses an OP284 rail-to-rail input

voltage range to sense the voltage drop across a 0.1 current shunt.

A P-channel MOSFET, used as the feedback element in the circuit,

converts the differential input voltage of the op amp into a current.

This current is applied to R2 to generate a voltage that is a linear

representation of the load current. The transfer equation for the

current monitor is given by

R

Monitor Output =

⎛

R2 ×

×

⎜

⎝

SENSE

R1

⎞

I

⎟

L

⎠

For the element values shown, the transfer characteristic of the

monitor output is 2.5 V/A.

R

SENSE

100Ω

M1

0.1Ω

R1

S

D

R2

2.49kΩ

3

2

G

MONITOR

OUTPUT

3V

SI9433

Figure 55. High-Side Load Current Monitor

3V

8

1/2

OP284

4

I

L

0.1µF

3V

1

0293-055

CAPACITIVE LOAD DRIVE CAPABILITY

The OP284 exhibits excellent capacitive load driving capabilities.

It can drive up to 1 nF, as shown in Figure 30. Even though the

device is stable, a capacitive load does not come without penalty in

bandwidth. The bandwidth is reduced to less than 1 MHz for loads

greater than 2 nF. A snubber network on the output does not

increase the bandwidth, but it does significantly reduce the amount

of overshoot for a given capacitive load.

A snubber consists of a series R-C network (R

Figure 56, connected from the output of the device to ground.

This network operates in parallel with the load capacitor, C

provide the necessary phase lag compensation. The value of the

resistor and capacitor is best determined empirically.

, CS), as shown in

S

, to

L

V

IN

100mV p-p

Figure 56. Snubber Network Compensates for Capacitive Load

The first step is to determine the value of Resistor RS. A good

starting value is 100 (typically, the optimum value is less than

100 ). This value is reduced until the small-signal transient

response is optimized. Next, C

starting point. This value is reduced to the smallest value for

acceptable performance (typically, 1 F). For the case of a 10 nF

load capacitor on the OP284, the optimal snubber network is

a 20 in series with 1 F. The benefit is immediately apparent,

as shown in the scope photo in Figure 57. The top trace was taken

with a 1 nF load, and the bottom trace was taken with the 50 ,

100 nF snubber network in place. The amount of overshoot and

ringing is dramatically reduced. Table 6 shows a few sample

snubber networks for large load capacitors.

100

ONLY

NUBBER

CIRCUIT

90

10

IN

0%

1nF LOAD

Figure 57. Overshoot and Ringing Are Reduced by Adding a Snubber

Network in Parallel with the 1 nF Load

Table 6. Snubber Networks for Large Capacitive Loads

Load Capacitance (CL) Snubber Network (RS, CS)

1 nF 50 Ω, 100 nF

10 nF 20 Ω, 1 µF

100 nF 5 Ω, 10 µF

Rev. F | Page 18 of 24

Page 19

OP184/OP284/OP484

www.BDTIC.com/ADI

LOW DROPOUT REGULATOR WITH CURRENT LIMITING

Many circuits require stable, regulated voltages relatively close

in potential to an unregulated input source. This low dropout

type of regulator is readily implemented with a rail-to-rail output

op amp, such as the OP284, because the wide output swing allows

easy drive to a low saturation voltage pass device. Furthermore,

it is particularly useful when the op amp also employs a rail-torail input feature because this factor allows it to perform highside current sensing for positive rail current limiting. Typical

examples are voltages developed from 3 V to 9 V range system

sources or anywhere that low dropout performance is required

for power efficiency. This 4.5 V example works from 5 V nominal

sources with worst-case levels down to 4.6 V or less. Figure 58

shows such a regulator set up, using an OP284 plus a low R

P-channel MOSFET pass device. Part of the low dropout performance of this circuit is provided by Q1, which has a rating of 0.11

with a gate drive voltage of only 2.7 V. This relatively low gate

drive threshold allows operation of the regulator on supplies as

low as 3 V without compromising overall performance.

The main voltage control loop operation of the circuit is

provided by U1B, half of the OP284. This voltage control

amplifier amplifies the 2.5 V reference voltage produced by

Three Terminal U2, a REF192. The regulated output voltage,

V

, is then

OUT

R2

⎞

⎛

VV

⎜

OUTOUT

2

⎝

+=

⎟

31R

⎠

DS(ON)

For this example, because V

a U1B gain of 1.8 times, R3 and R2 are chosen for a ratio of 1.2:1 or

10.0 k:8.06 k (using closest 1% values). Note that for the lowest

V

dc error, R2||R3 should be maintained equal to R1 (as in

OUT

this example), and the R2 to R3 resistors should be stable, close

tolerance metal film types. The table in Figure 58 summarizes

R1 to R3 values for some popular voltages. However, note that,

in general, the output can be anywhere between V

12 V maximum rating of Q1.

While the low voltage saturation characteristic of Q1 is a key part

of the low dropout, another component is a low current sense comparison threshold with good dc accuracy. Here, this is provided by

Current Sense Amplifier U1A, which is provided by a 20 mV

reference from the 1.235 V, AD589 Reference Diode D2, and the

,

R7 to R8 divider. When the product of the output current and the

R

value match this voltage threshold, the current control loop is

S

activated, and U1A drives the Q1 gate through D1. This causes the

overall circuit operation to enter current mode control with a

current limit, I

I

LIMIT

⎛

⎜

=

⎜

⎝

, defined as

LIMIT

V

D2R

()

R

S

⎞

⎟

⎟

⎠

OUT

R7

⎛

⎜

+

7

⎝

of 4.5 V with V

⎞

⎟

R8R

⎠

= 2.5 V requires

OUT2

and the

OUT2

C4

U1A

OP284

8

1

4

R1

4.53kΩ

0.1µF

V

OUT2

2.5V

D1

1N4148

C1

0.01µF

6

5

R3

10kΩ

7

U1B

OP284

V

OUT

5.0V 4.99 10.0 10.0

4.5V 4.53 8.08 10.0

3.3V 2.43 3.24 10.0

3.0V 1.69 2.00 10.0

Q1

SI9433DY

R5

22.1kΩ

R4

2.21kΩ

R2

8.06kΩ

OUTPUT TABLE

R1kΩ R2kΩ R3kΩ

V

OUT

4.5V @ 350mA

(SEE TABLE)

C6

10µF

V

OUT

=

COMMON

00293-058

+V

S

VS > V

+ 0.1V

OUT

C2

0.1µF

V

C

OPTIONAL

ON/OFF CONTROL I NPUT

CMOS HI (OR OPEN) = ON

LO = OFF

VIN COMMON

AD589

R

S

0.05Ω

R11

1kΩ

U2

REF192

6

R10

1kΩ

R6

4.99kΩ

3

2

C5

0.01µF

C2

1µF

R7

4.99kΩ

D2

R8

301kΩ

R9

27.4kΩ

D3

1N4148

2

3

4

Figure 58. Low Dropout Regulator with Current Limiting

Rev. F | Page 19 of 24

Page 20

OP184/OP284/OP484

www.BDTIC.com/ADI

Obviously, it is desirable to keep this comparison voltage small

because it becomes a significant portion of the overall dropout

voltage. Here, the 20 mV reference is higher than the typical

offset of the OP284 but is still reasonably low as a percentage

of V

(<0.5%). In adapting the limiter for other I

OUT

Sense Resistor R

should be adjusted along with R7 to R8, to

S

LIMIT

levels,

maintain this threshold voltage between 20 mV and 50 mV.

Performance of the circuit is excellent. For the 4.5 V output

version, the measured dc output change for a 225 mA load

change was on the order of a few microvolts, while the dropout

voltage at this same current level was about 30 mV. The current

limit, as shown in Figure 58, is 400 mA, allowing the circuit to

be used at levels up to 300 mA or more. While the Q1 device can

actually support currents of several amperes, a practical current

rating takes into account the 2.5 W, 25°C dissipation of the the

8-lead SOIC device. Because a short-circuit current of 400 mA

at an input level of 5 V causes a 2 W dissipation in Q1, other input

conditions must be considered carefully in terms of potential

overheating of Q1. Of course, if higher powered devices are used

for Q1, this circuit can support outputs of tens of amperes as

well as the higher V

levels already noted.

OUT

The circuit shown can either be used as a standard low dropout

regulator, or it can be used with on/off control. By driving Pin 3

of U2 with the optional logic control signal, V

, the output is

C

switched between on and off. Note that when the output is off

in this circuit, it is still active (that is, not an open circuit). This

is because the off state simply reduces the voltage input to R1,

leaving the U1A/U1B amplifiers and Q1 still active.

When the on/off control is used, Resistor R10 should be used

with U2 to speed on/off switching and to allow the output of the

circuit to settle to a nominal zero voltage. Component D3 and

Component R11 also aid in speeding up the on/off transition by

providing a dynamic discharge path for C2. Off/on transition

time is less than 1 ms, while the on/off transition is longer, but

less than 10 ms.

3 V, 50 HZ/60 HZ ACTIVE NOTCH FILTER WITH FALSE GROUND

To process signals in a single-supply system, it is often best to use

a false ground biasing scheme. A circuit that uses this approach is

shown in Figure 59. In this circuit, a false ground circuit biases

an active notch filter used to reject 50 Hz/60 Hz power line

interference in portable patient monitoring equipment.

Notch filters are commonly used to reject power line frequency

interference that often obscures low frequency physiological

signals, such as heart rates, blood pressure readings, EEGs, and

EKGs. This notch filter effectively squelches 60 Hz pickup at a

Filter Q of 0.75. Substituting 3.16 k resistors for the 2.67 k

resistor in the twin-T section (R1 through R5) configures the

active filter to reject 50 Hz interference.

3V

R1

2.67kΩ

4

2

A1

IN

1µF

3

11

R6

10kΩ

3V

R9

20kΩ

C4

R10

20kΩ

V

C1

1µF

1

R3

2.67kΩ

C3

2µF

(1µF × 2)

R11

10kΩ

C5

0.03µF

9

10

8

A3

A1, A2, A3 = OP484

R12

150Ω

Figure 59. A 3 V Single-Supply, 50Hz to 60 Hz Active Notch Filter

with False Ground

R2

2.67kΩ

C2

1µF

R4

2.67kΩ

R5

1.33kΩ

(2.68kΩ ÷ 2)

NOTE: F OR 50Hz APPL ICATI ONS

5

A2

6

R7

1kΩ

R8

1kΩ

Q = 0.75

CHANGE R1, R2, R3, AND R4 TO 3.1kΩ

AND R5 TO 1.58kΩ (3.16kΩ ÷ 2).

C6

1µF

1.5V

7

V

O

Amplifier A3 is the heart of the false ground bias circuit. It buffers

the voltage developed at R9 and R10 and is the reference for the

active notch filter. Because the OP484 exhibits a rail-to-rail input

common-mode range, R9 and R10 are chosen to split the 3 V

supply symmetrically. An in-the-loop compensation scheme is

used around the OP484 that allows the op amp to drive C6, a

1 F capacitor, without oscillation. C6 maintains a low impedance

ac ground over the operating frequency range of the filter.

The filter section uses an OP484 in a Twin-T configuration whose

frequency selectivity is very sensitive to the relative matching of

the capacitors and resistors in the twin-T section. Mylar is the

material of choice for the capacitors, and the relative matching

of the capacitors and resistors determines the pass band symmetry

of the filter. Using 1% resistors and 5% capacitors produces satisfactory results.

00293-059

Rev. F | Page 20 of 24

Page 21

OP184/OP284/OP484

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.400 (10.16)

0.365 (9.27)

0.355 (9.02)

0.150 (3.81)

0.130 (3.30)

0.115 (2.92)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

0.210

(5.33)

0.150 (3.81)

0.130 (3.30)

0.110 (2.79)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

8

1

PIN 1

0.100 (2.54)

0.210

(5.33)

MAX

0.070 (1.78)

0.060 (1.52)

0.045 (1.14)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

CORNER LEADS MAY BE CONFIGURED AS WHOLE OR HALF LEADS.

Figure 60. 8-Lead Plastic Dual In-Line Package [PDIP]

0.775 (19.69)

0.750 (19.05)

0.735 (18.67)

14

1

PIN 1

0.100 (2.54)

MAX

0.070 (1.78)

0.050 (1.27)

0.045 (1.14)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

CORNER LEADS MAY BE CONFIGURED AS WHOLE OR HALF LEADS.

Figure 61. 14-Lead Plastic Dual In-Line Package [PDIP]

5

0.280 (7.11)

0.250 (6.35)

0.240 (6.10)

4

BSC

0.005 (0.13)

MIN

COMPLIANT TO JEDEC STANDARDS MS-001-BA

0.015

(0.38)

MIN

SEATING

PLANE

0.060 (1.52)

0.015 (0.38)

GAUGE

PLANE

MAX

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.430 (10.92)

(N-8)

P-Suffix

Dimensions shown in inches and (millimeters)

8

0.280 (7.11)

0.250 (6.35)

0.240 (6.10)

7

BSC

0.015

(0.38)

MIN

SEATING

PLANE

0.005 (0.13)

MIN

COMPLIANT TO JEDEC STANDARDS MS-001-AA

0.060 (1.52)

MAX

0.015 (0.38)

GAUGE

PLANE

0.430 (10.92)

(N-14)

P-Suffix

Dimensions shown in inches and (millimeters)

MAX

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

MAX

0.195 (4.95)

0.130 (3.30)

0.115 (2.92)

0.014 (0.36)

0.010 (0.25)

0.008 (0.20)

0.195 (4.95)

0.130 (3.30)

0.115 (2.92)

0.014 (0.36)

0.010 (0.25)

0.008 (0.20)

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

85

1.27 (0.0500)

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012-AA

BSC

6.20 (0.2440)

5.80 (0.2284)

41

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

8°

1.27 (0.0500)

0°

0.40 (0.0157)

Figure 62. 8-Lead Standard Small Outline Package [SOIC_N]

Narrow Body

(R-8)

S-Suffix

Dimensions shown in millimeters and (inches)

8.75 (0.3445)

8.55 (0.3366)

4.00 (0.1575)

3.80 (0.1496)

0.25 (0.0098)

0.10 (0.0039)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

14

1

1.27 (0.0500)

BSC

0.51 (0.0201)

0.31 (0.0122)

COMPLIANT TO JEDEC STANDARDS MS-012-AB

8

6.20 (0.2441)

7

5.80 (0.2283)

SEATING

PLANE

1.75 (0.0689)

1.35 (0.0531)

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0197)

0.25 (0.0098)

8°

0°

1.27 (0.0500)

0.40 (0.0157)

Figure 63. 14-Lead Standard Small Outline Package [SOIC_N]

Narrow Body

(R-14)

S-Suffix

Dimensions shown in millimeters and (inches)

× 45°

× 45°

Rev. F | Page 21 of 24

Page 22

OP184/OP284/OP484

www.BDTIC.com/ADI

ORDERING GUIDE

Model Temperature Range Package Description Package Option

OP184ES −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184ES-REEL −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184ES-REEL7 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184ESZ

OP184ESZ-REEL1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184ESZ-REEL71 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184FS −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184FS-REEL −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184FS–REEL7 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184FSZ1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184FSZ-REEL1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP184FSZ-REEL71 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284EP −40°C to +125°C 8-Lead PDIP P-Suffix (N-8)

OP284EPZ1 −40°C to +125°C 8-Lead PDIP P-Suffix (N-8)

OP284ES −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284ES-REEL −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284ES-REEL7 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284ESZ1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284ESZ-REEL1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284ESZ-REEL71 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284FS −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284FS-REEL −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284FS-REEL7 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284FSZ1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284FSZ-REEL1 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284FSZ-REEL71 −40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

OP284GBC Die

OP484ES −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484ES-REEL −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484ESZ1 −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484ESZ-REEL1 −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484FP −40°C to +125°C 14-Lead PDIP P-Suffix (N-14)

OP484FPZ1 −40°C to +125°C 14-Lead PDIP P-Suffix (N-14)

OP484FS −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484FS-REEL −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484FS-REEL7 −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484FSZ1 −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484FSZ-REEL1 −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

OP484FSZ-REEL71 −40°C to +125°C 14-Lead SOIC_N S-Suffix (R-14)

1

Z = RoHS Compliant part.

1

−40°C to +125°C 8-Lead SOIC_N S-Suffix (R-8)

Rev. F | Page 22 of 24

Page 23

OP184/OP284/OP484

www.BDTIC.com/ADI

NOTES

Rev. F | Page 23 of 24

Page 24

OP184/OP284/OP484

www.BDTIC.com/ADI

NOTES

©1996–2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D00293-0-9/08(F)

Rev. F | Page 24 of 24

Loading...

Loading...