Page 1

Ultralow Power, Rail-to-Rail Output

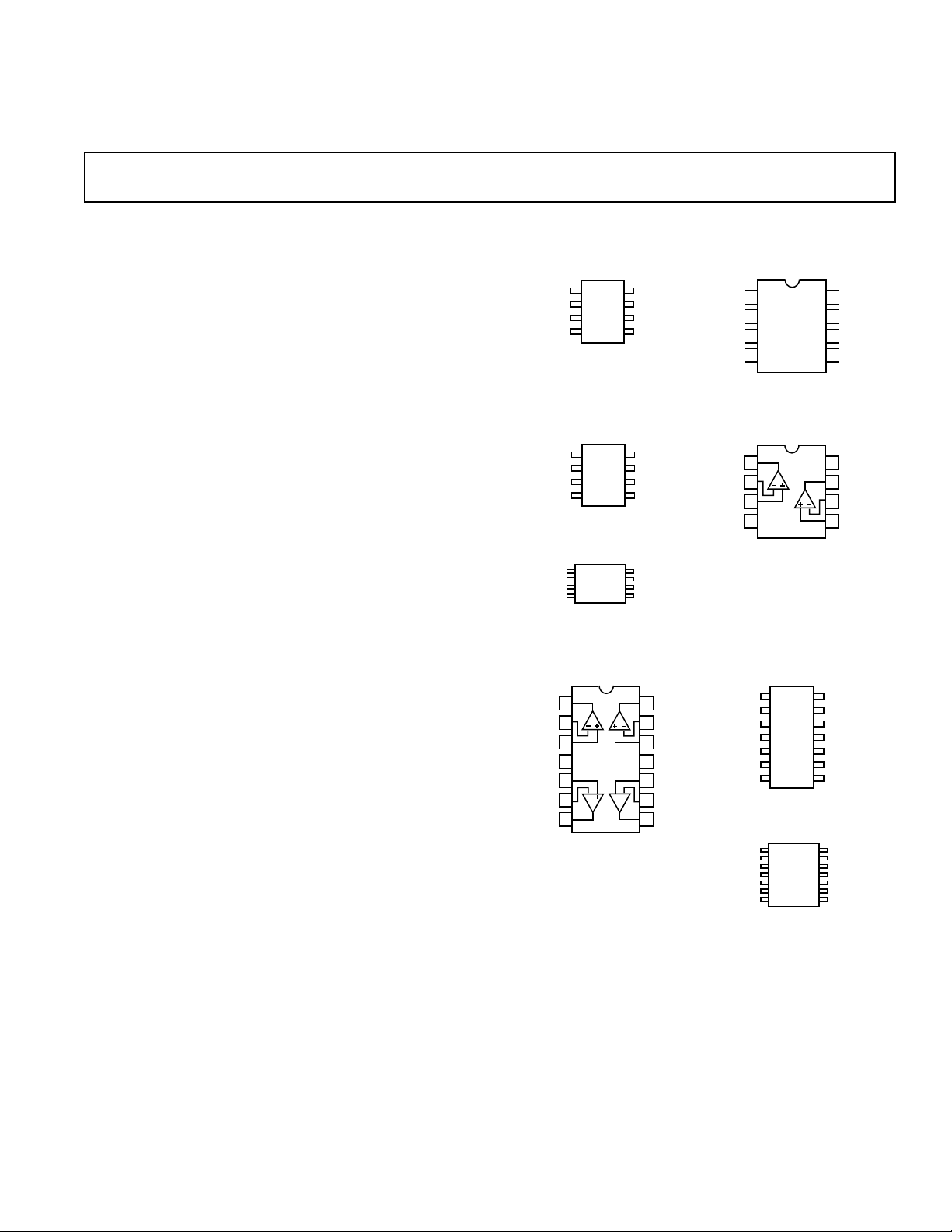

NC = NO CONNECT

8

7

6

5

1

2

3

4

NULL

V+

NULL

NC

OUT A

–IN A

+IN A

V–

OP181

NC = NO CONNECT

NULL

V+

NULL

NC

OUT A

–IN A

+IN A

V–

1

4

5

8

OP181

8

7

6

5

1

2

3

4

OP281

OUT A

V+

+IN B

–IN B

OUT B

–IN A

+IN A

V–

OUT A

V+

OUT B–IN A

+IN A

V–

+IN B

–IN B

1

4

5

8

OP281

14

13

12

11

10

9

8

1

2

3

4

7

6

5

OUT A

V–

+IN D

–IN D

OUT D

–IN A

+IN A

V+

OUT C

–IN C

+IN C

+IN B

–IN B

OUT B

OP481

1

7

8

14

OP481

a

FEATURES

Low Supply Current: 4 mA/Amplifier max

Single-Supply Operation: 2.7 V to 12 V

Wide Input Voltage Range

Rail-to-Rail Output Swing

Low Offset Voltage: 1.5 mV

No Phase Reversal

APPLICATIONS

Comparator

Battery Powered Instrumentation

Safety Monitoring

Remote Sensors

Low Voltage Strain Gage Amplifiers

GENERAL DESCRIPTION

The OP181, OP281 and OP481 are single, dual and quad

ultralow power, single-supply amplifiers featuring rail-to-rail

outputs. All operate from supplies as low as 2.0 V and are

specified at +3 V and +5 V single supply as well as ±5 V dual

supplies.

Fabricated on Analog Devices’ CBCMOS process, the OP181

family features a precision bipolar input and an output that

swings to within millivolts of the supplies and continues to sink

or source current all the way to the supplies.

Applications for these amplifiers include safety monitoring,

portable equipment, battery and power supply control, and

signal conditioning and interface for transducers in very low

power systems.

The output’s ability to swing rail-to-rail and not increase supply

current, when the output is driven to a supply voltage, enables

the OP181 family to be used as comparators in very low power

systems. This is enhanced by their fast saturation recovery time.

Propagation delays are 250 µs.

The OP181/OP281/OP481 are specified over the extended

industrial (–40°C to +85°C) temperature range. The OP181,

single, and OP281, dual, amplifiers are available in 8-pin plastic

DIPs and SO surface mount packages. The OP281 is also

available in 8-lead TSSOP. The OP481 quad is available in 14pin DIPs, narrow 14-pin SO and TSSOP packages.

Operational Amplifiers

OP181/OP281/OP481

PIN CONFIGURATIONS

8-Lead SO 8-Lead Epoxy DIP

(S Suffix) (P Suffix)

8-Lead SO 8-Lead Epoxy DIP

(S Suffix) (P Suffix)

8-Lead TSSOP

(RU Suffix)

1

8

OP281

4

5

14-Lead Epoxy DIP 14-Lead

(P Suffix) Narrow-Body SO

14-Lead TSSOP

NOTE: PIN ORIENTATION IS EQUIVALENT FOR

EACH PACKAGE VARIATION

(S Suffix)

(RU Suffix)

1

14

OP481

78

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.com

Fax: 617/326-8703 © Analog Devices, Inc., 1996

Page 2

OP181/OP281/OP481–SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

(@ VS = +3.0 V, VCM = 1.5 V, TA = +258C unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

OS

B

OS

Note 1 1.5 mV

–40°C ≤ T

≤ +85°C 2.5 mV

A

–40°C ≤ TA ≤ +85°C310nA

–40°C ≤ TA ≤ +85°C 0.1 7 nA

Input Voltage Range 0 2 V

Common-Mode Rejection Ratio CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

VO

/∆T10µV/°C

OS

/∆T 20 pA/°C

B

= 0 V to 2.0 V,

CM

–40°C ≤ T

R

= 1 MΩ, V

L

–40°C ≤ T

≤ +85°C6595 dB

A

= 0.3 V to 2.7 V 5 13 V/mV

O

≤ +85°C 2 V/mV

A

Offset Current Drift ∆IOS/∆T 2 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

Output Voltage Low V

Short Circuit Limit I

OH

OL

SC

R

= 100 kΩ to GND,

L

–40°C ≤ T

R

= 100 kΩ to V+,

L

–40°C ≤ T

≤ +85°C 2.925 2.96 V

A

≤ +85°C2575mV

A

±1.1 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= 2.7 V to 12 V

S

–40°C ≤ T

V

= 0 V 3 4 µA

O

≤ +85°C7695 dB

A

–40°C ≤ TA ≤ +85°C5µA

DYNAMIC PERFORMANCE

Slew Rate SR R

Turn On Time A

Turn On Time A

= 100 kΩ, C

L

= 1, V

V

= 20, V

V

= 1 40 µs

O

O

= 50 pF 25 V/ms

L

= 1 50 µs

Saturation Recovery Time 65 µs

Gain Bandwidth Product GBP 95 kHz

Phase Margin φo 70 Degrees

NOISE PERFORMANCE

Voltage Noise e

Voltage Noise Density e

Current Noise Density i

NOTES

1

VOS is tested under no load condition.

Specifications subject to change without notice.

p-p 0.1 Hz to 10 Hz 10 µV p-p

n

n

n

f = 1 kHz 75 nV/√Hz

<1 pA/√Hz

–2–

REV. 0

Page 3

OP181/OP281/OP481

ELECTRICAL SPECIFICATIONS

(@ VS = +5.0 V, VCM = 2.5 V, TA = +258C unless otherwise noted1)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

OS

B

OS

Note 1 0.1 1.5 mV

–40°C ≤ T

≤ +85°C 2.5 mV

A

–40°C ≤ TA ≤ +85°C310nA

–40°C ≤ TA ≤ +85°C 0.1 7 nA

Input Voltage Range 0 4 V

Common-Mode Rejection Ratio CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

VO

/∆T –40°C to +85°C10µV/°C

OS

/∆T20pA/°C

B

= 0 V to 4.0 V,

CM

–40°C ≤ T

R

= 1 MΩ , V

L

–40°C ≤ T

≤ +85°C6590 dB

A

= 0.5 V to 4.5 V 5 15 V/mV

O

≤ +85°C 2 V/mV

A

Offset Current Drift ∆IOS/∆T2pA/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

Output Voltage Low V

Short Circuit Limit I

OH

OL

SC

R

= 100 kΩ to GND,

L

–40°C ≤ T

R

= 100 kΩ to V+,

L

–40°C ≤ T

≤ +85°C 4.925 4.96 V

A

≤ +85°C2575mV

A

±3.5 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= 2.7 V to 12 V,

S

–40°C ≤ T

V

= 0 V 3.2 4 µA

O

≤ +85°C7695 dB

A

–40°C ≤ TA ≤ +85°C5µA

DYNAMIC PERFORMANCE

Slew Rate SR R

= 100 kΩ, C

L

= 50 pF 27 V/ms

L

Saturation Recovery Time 120 µs

Gain Bandwidth Product GBP 100 kHz

Phase Margin φo 74 Degrees

NOISE PERFORMANCE

Voltage Noise e

Voltage Noise Density e

Current Noise Density i

NOTES

1

VOS is tested under a no load condition.

Specifications subject to change without notice.

p-p 0.1 Hz to 10 Hz 10 µV p-p

n

n

n

f = 1 kHz 75 nV/√Hz

<1 pA/√Hz

REV. 0

–3–

Page 4

OP181/OP281/OP481–SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

(@ VS = ±5 V, TA = +258C unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

OS

B

OS

Note 1 0.1 1.5 mV

–40°C ≤ T

≤ +85°C 2.5 mV

A

–40°C ≤ TA ≤ +85°C310nA

–40°C ≤ TA ≤ +85°C 0.1 7 nA

Input Voltage Range –5 +4 V

Common-Mode Rejection CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

VO

/∆T –40°C to +85°C10µV/°C

OS

/∆T 20 pA/°C

B

= –5.0 V to +4.0 V,

CM

–40°C ≤ T

R

= 1 MΩ, VO = ±4.0 V, 5 13 V/mV

L

–40°C ≤ T

≤ +85°C6595dB

A

≤ +85°C 2 V/mV

A

Offset Current Drift ∆IOS/∆T 2 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage Swing V

Short Circuit Limit I

O

SC

R

= 100 kΩ to GND,

L

–40°C ≤ T

≤ +85°C ±4.925 ±4.98 V

A

12 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= ±1.35 V to ±6V,

S

–40°C ≤ T

V

= 0 V 3.3 5 µA

O

≤ +85°C7695dB

A

–40°C ≤ TA ≤ +85°C6µA

DYNAMIC PERFORMANCE

Slew Rate ±SR R

= 100 kΩ, C

L

= 50 pF 28 V/ms

L

Gain Bandwidth Product GBP 105 kHz

Phase Margin φo 75 Degrees

NOISE PERFORMANCE

Voltage Noise e

Voltage Noise Density e

Voltage Noise Density e

Current Noise Density i

NOTES

1

VOS is tested under no load condition.

Specifications subject to change without notice.

p-p 0.1 Hz to 10 Hz 10 µV p-p

n

n

n

n

f = 1 kHz 85 nV/√Hz

f = 10 kHz 75 nV/√Hz

<1 pA/√Hz

–4–

REV. 0

Page 5

OP181/OP281/OP481

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +16 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . Gnd to V

+ 10 V

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . ±3.5 V

Output Short-Circuit Duration to Gnd . . . . . . . . . . Indefinite

Storage Temperature Range

P, S, RU Package . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

OP181/OP281/OP481G . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range

P, S, RU Package . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300°C

Package Type uJA* u

JC

Units

8-Pin Plastic DIP (P) 103 43 °C/W

8-Pin SOIC (S) 158 43 °C/W

8-Pin TSSOP (RU) 240 43 °C/W

14-Pin Plastic DIP (P) 76 33 °C/W

14-Pin SOIC (S) 120 36 °C/W

14-Pin TSSOP (RU) 240 43 °C/W

*θJA is specified for the worst case conditions, i.e., θJA is specified for device in socket

for P-DIP packages; θJA is specified for device soldered in circuit board for TSSOP

and SOIC packages.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

OP181GP –40°C to +85°C 8-Pin Plastic DIP N-8

OP181GS –40°C to +85°C 8-Pin SOIC SO-8

OP281GP –40°C to +85°C 8-Pin Plastic DIP N-8

OP281GS –40°C to +85°C 8-Pin SOIC SO-8

OP281GRU –40°C to +85°C 8-Pin TSSOP RU-8

OP481GP –40°C to +85°C 14-Pin Plastic DIP N-14

OP481GS –40°C to +85°C 14-Pin SOIC SO-14

OP481GRU –40°C to +85°C 14-Pin TSSOP RU-14

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP181/OP281/OP481 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality.

REV. 0

–5–

Page 6

OP181/OP281/OP481–Typical Characteristics

45

VS = +2.7V

40

T

= +258C

A

35

30

25

20

15

QUANTITY – Amplifiers

10

5

0

–1.0 –0.8 –0.6 –0.4 –0.2 0 0.2 0.4 0.6 0.8 1.0

INPUT OFFSET VOLTAGE – mV

Figure 1. Input Offset Voltage

Distribution

0

–0.5

VS = +5V

–1.0

–1.5

–2.0

–2.5

–3.0

–3.5

INPUT BIAS CURRENT – nA

–4.0

–4.5

–5.0

–40

–20020406080

TEMPERATURE – 8C

100 120

50

VS = +5V

45

T

= +258C

A

40

35

30

25

20

15

QUANTITY – Amplifiers

10

5

0

–1.0 –0.8 –0.6 –0.4 –0.2 0 0.2 0.4 0.6 0.8 1.0

INPUT OFFSET VOLTAGE – mV

Figure 2. Input Offset Voltage

Distribution

1.0

VS = +5V

0.5

T

= +258C

A

0.0

–0.5

–1.0

–1.5

–2.0

–2.5

INPUT BIAS CURRENT – nA

–3.0

–3.5

0.0

0.5 1.0 1.5 2.0 2.5 3.0

COMMON-MODE VOLTAGE – Volts

3.5 4.0

4.5 5.0

2000

1800

VS = +5V

1600

1400

1200

1000

800

600

400

INPUT OFFSET VOLTAGE – µV

200

0

–40

–20020406080

TEMPERATURE – 8C

100 120

Figure 3. Input Offset Voltage vs.

Temperature

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

INPUT OFFSET CURRENT – nA

–0.3

–0.4

–40

–20 0 20 40 60 80

TEMPERATURE – 8C

VS = +5V

100 120

Figure 4. Input Bias Current vs.

Temperature

10,000

VS = +3V

TA = +258C

1,000

100

10

1.0

OUTPUT VOLTAGE – mV

0.1

1 1000

SOURCE

SINK

10 100

LOAD CURRENT – µA

Figure 7. Output Voltage to Supply

Rail vs. Load Current

Figure 5. Input Bias Current vs.

Common-Mode Voltage

1,000

VS = +5V

TA = +258C

100

10

1.0

OUTPUT VOLTAGE – mV

0.1

1 1000

SOURCE

SINK

10 100

LOAD CURRENT – µA

Figure 8. Output Voltage to Supply

Rail vs. Load Current

Figure 6. Input Offset Current vs.

Temperature

1,000

VS = ±5V

TA = +258C

100

10

1.0

OUTPUT VOLTAGE – mV

0.1

1 1000

SOURCE

SINK

10 100

LOAD CURRENT – µA

Figure 9. Output Voltage to Supply

Rail vs. Load Current

–6–

REV. 0

Page 7

OP181/OP281/OP481

FREQUENCY – Hz

OPEN-LOOP GAIN – dB

70

60

–30

100 1k 1M

10k 100k

20

50

40

30

10

0

–10

–20

VS = +2.7V

T

A

= +258C

R

L

= 100kΩ

90

0

45

135

180

225

270

PHASE SHIFT – Degrees

FREQUENCY – Hz

VS = +5V

T

A

= +258C

MARKER @ 67nV/√Hz

02k4k6k8k10k

50nV/√Hz/Div

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN – dB

–10

–20

–30

100 1k 1M

FREQUENCY – Hz

VS = +5V

T

A

R

L

10k 100k

= +258C

= 100kΩ

0

45

90

135

180

225

270

Figure 10. Open-Loop Gain and Phase

vs. Frequency

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN – dB

–10

–20

–30

100 1k 1M

VS = ±5V

T

= +258C

A

R

= 100kΩ TO GROUND

L

10k 100k

FREQUENCY – Hz

0

45

90

135

180

225

270

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN – dB

–10

PHASE SHIFT – Degrees

–20

–30

100 1k 1M

FREQUENCY – Hz

VS = +3V

T

A

R

L

10k 100k

= +258C

= 100kΩ

Figure 11. Open-Loop Gain and Phase

vs. Frequency

60

50

40

30

20

10

0

–10

CLOSED-LOOP GAIN – dB

PHASE SHIFT – Degrees

–20

–30

–40

10 100 1M1k 10k 100k

FREQUENCY – Hz

VS = +5V

= +258C

T

A

= INFINITE

R

L

0

45

90

135

180

225

PHASE SHIFT – Degrees

270

Figure 12. Open-Loop Gain and Phase

vs. Frequency

Figure 13. Open-Loop Gain and Phase

vs. Frequency

90

VS = ±5V

80

70

60

50

40

30

CMRR – dB

20

10

–10

VS = +5V

VS = +3V

0

1k 10k 10M100k 1M

FREQUENCY – Hz

Figure 16. CMRR vs. Frequency

REV. 0

TA = +258C

Figure 14. Closed-Loop Gain vs.

Frequency

160

140

120

100

80

60

40

PSRR – dB

20

0

–20

–40

10 100 1M1k 10k 100k

VS = ±5V, +5V, +3V, +2.7V

T

= +258C

A

R

= INFINITE

L

FREQUENCY – Hz

Figure 17. PSRR vs. Frequency

–7–

Figure 15. Voltage Noise Density vs.

Frequency

50

VS = +5V

45

V

= ±50mV

IN

R

= 100kΩ

L

40

T

= +258C

A

35

30

25

20

15

10

SMALL SIGNAL OVERSHOOT – %

5

0

10 100 1000

CAPACITANCE – pF

–OS

+OS

Figure 18. Small Signal Overshoot vs.

Load Capacitance

Page 8

OP181/OP281/OP481

TEMPERATURE – 8C

SUPPLY CURRENT/AMPLIFIER – µA

4.0

1.5

0

–40

–20 0 20 40 60 80 100 120

3.5

2.0

1.0

0.5

3.0

2.5

VS = +3V

10

0%

100

90

0mV

A2

100µs

50mV

VS = ±2.5V

AV = 1

RL = 100kΩ

CL = 50pF

TA = +258C

10

0%

100

90

0.50V

A2

100µs

500mV

VS = +2.7V

AV = 1

RL = 100kΩ

CL = 50pF

TA = +258C

5

4

VS = +5V

V

= 4Vp–p

IN

3

R

= INFINITE

L

T

= +258C

A

2

1

MAXIMUM OUTPUT SWING – Vp-p

0

10 100 100k

1k 10k

FREQUENCY – Hz

Figure 19. Maximum Output Swing

vs. Frequency

4.5

VS = +5V

4.0

3.5

3.0

2.5

2.0

1.5

1.0

SUPPLY CURRENT/AMPLIFIER – µA

0.5

0

–20 0 20 40 60 80 100 120

–40

TEMPERATURE – 8C

3

2

1

MAXIMUM OUTPUT SWING – Vp-p

0

10 100 100k

FREQUENCY – Hz

VS = +3V

V

= 2Vp–p

IN

R

= INFINITE

L

T

= +258C

A

1k 10k

Figure 20. Maximum Output Swing

vs. Frequency

3.50

TA = +258C

3.25

3.00

2.75

2.50

2.25

2.00

1.75

1.50

1.25

1.00

0.75

0.50

SUPPLY CURRENT/AMPLIFIER – µA

0.25

0.00

0.0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

SUPPLY VOLTAGE – ±Volts

4.55.0 5.5 6.0

Figure 21. Supply Current/Amplifier

vs. Temperature

Figure 22. Supply Current/Amplifier

vs. Temperature

A2

0mV

100

90

10

0%

50mV

Figure 25. Small Signal Transient

Response

100µs

VS = ±1.35V

AV = 1

RL = 100kΩ

CL = 50pF

TA = +258C

Figure 23. Supply Current/Amplifier

vs. Supply Voltage

100µs1V

VS = +5V

AV = 1

RL = 100kΩ

CL = 50pF

TA = +258C

A2

2.50V

100

90

10

0%

Figure 26. Large Signal Transient

Response

–8–

Figure 24. Small Signal Transient

Response

Figure 27. Large Signal Transient

Response

REV. 0

Page 9

OP181/OP281/OP481

10

0%

100

90

0.00V

A2

50µs

500mV

VS = 61.35V

RL = ∞

500mV

VIN = 61Vp-p

AT 2kHz

120

A2

2.50V

100

90

VS = +5V

TA = +258C

90

75

60

45

30

105

10

0%

1V

1V

200µs

15

0

CHANNEL SEPARATION – dB

–15

–30

100 1k 1M10k 100k

FREQUENCY – Hz

=

V

+5V

S

=

T

+258C

A

=

R

∞

L

Figure 28. No Phase Reversal

Figure 29. Channel Separation vs.

Frequency

0.00V

500mV

VS = 62.5V

CIRCUIT = A

A2

100

90

10

0%

1V

VOL

100µs

RL = ∞

TA = +258C

Figure 31. Saturation Recovery Time

Figure 30. Saturation Recovery Time

REV. 0

–9–

Page 10

OP181/OP281/OP481

6

5

7

4

1

2

3

+5V

OP181

V

OUT

20kΩ

POT.

V

EE

= –5V

APPLICATIONS

THEORY OF OPERATION

The OPx81 family of op amps is comprised of extremely low

powered, rail-to-rail output amplifiers, requiring less than 4 µA

of quiescent current per amplifier. Many other competitors’

devices may be advertised as low supply current amplifiers but

draw significantly more current as the outputs of these devices

are driven to a supply rail. The OPx81’s supply current remains

under 4 µA even with the output driven to either supply rail.

Supply currents should meet the specification as long as the inputs

and outputs remain within the range of the power supplies.

Figure 32 shows a simplified schematic of the OP181. A bipolar

differential pair is used in the input stage. PNP transistors are

used to allow the input stage to remain linear with the commonmode range extending to ground. This is an important consideration for single supply applications. The bipolar front end also

contributes less noise than a MOS front end with only nanoamps of bias currents. The output of the op amp consists of a

pair of CMOS transistors in a common source configuration.

This setup allows the output of the amplifier to swing to within

millivolts of either supply rail. The headroom required by the

output stage is limited by the amount of current being driven

into the load. The lower the output current, the closer the

output can go to either supply rail. Figures 7, 8 and 9 show the

output voltage headroom versus load current. This behavior is

typical of rail-to-rail output amplifiers.

where: VEE is the negative power supply for the amplifier, and

V

is the lowest input voltage excursion expected

IN, MIN

For example, an OP181 is to be used with a single supply voltage of 5 V where the input signal could possibly go as low as

–1.0 V. Because the amplifier is powered from a single supply,

V

is ground, so the necessary series resistance should be 2 kΩ.

EE

Input Offset Voltage Nulling

The OPx81 family of op amps was designed for low offset

voltages less than 1 mV. The single OP181 does provide two

offset adjust terminals, should the user require greater precision.

In general, these terminals should be used only to zero amplifier

offsets and should not be used to adjust system offset voltages.

A 20 kΩ potentiometer connected to the offset adjust terminals,

with the wiper connected to V

, can be used to reduce the

EE

offset voltage of the amplifier. The OP181 should be connected

in the unity-gain configuration (as shown in Figure 33) or in a

gain configuration. The potentiometer should be adjusted until

V

is minimized. The wiper of the potentiometer must be

OUT

connected to V

; connecting it to the positive supply rail could

EE

damage the device.

V

CC

+IN

–IN

V

EE

OUT

Figure 32. Simplified Schematic of the OP181

Input Overvoltage Protection

The input stage to the OPx81 family of op amps consists of a

PNP differential pair. If the base voltage of either of these input

transistors drops to more than 0.6 V below the negative supply,

the input ESD protection diodes will become forward biased,

and large currents will begin to flow. In addition to possibly

damaging the device, this will create a phase reversal effect at

the output. To prevent these effects from happening, the input

current should be limited to less than 0.5 mA.

This can be done quite easily by placing a resistor in series with

the input to the device. The size of the resistor should be proportional to the lowest possible input signal excursion and can

be found using the following formula:

V

EE−VIN, MIN

R =

0.5×10

−3

Figure 33. Offset Voltage Nulling Circuit

Input Common-Mode Voltage Range

The OPx81 is rated with an input common-mode voltage range

from V

to 1 volt under VCC. However, the op amp can still

EE

operate even with a common-mode voltage that is slightly less

than V

. Figure 34 shows an OP181 configured as a difference

EE

amplifier with a single supply voltage of +3 V. Negative dc

voltages are applied at both input terminals creating a commonmode voltage that is less than ground. A 400 mV p-p input

signal is then applied to the noninverting input. Figure 35 shows

a picture of the input and output waves. Notice how the output

of the amplifier also drops slightly negative without distortion.

100kΩ

100kΩ

+3V

OP181

V

OUT

–0.27V

100kΩ

100kΩ

VIN = 1kHz AT

400mV p-p

–0.1V

Figure 34. OP181 Configured as a Difference Amplifier

Operating at V

–10–

CM

< 0 V

REV. 0

Page 11

OP181/OP281/OP481

6

7

4

2

3

OP181

10kΩ

0.022µF

V

REF

+1.5V TO +6V1µF

1µF

1MΩ

+3V TO +12V

100Ω

1MΩ

0.2ms

100

90

V

OUT

0V

V

IN

10

0%

0.1V

100

90

10

0%

Figure 35. Input and Output Signals with VCM < 0 V

Overdrive Recovery Time

The amount of time it takes for an amplifier to recover from

saturation can be an important consideration when using an

amplifier as a comparator or when outputs can be driven to the

supplies. The overdrive recovery time for the OP181 is 50 µs

with the amplifier running from a 3 volt supply and increases

to 100 µs with a 10 volt supply. Figure 36 shows the result of

the OP181 running from a 3 V supply with its output being

overdriven.

0.2ms

V

IN

100

SCALE 0.1V

SCALE 1V

90

0V

V

OUT

10

0%

0V

0.1V

VS = +3V

AV = +100

Figure 36. Output of the Op Amp Recovering from

Saturation

Capacitive Loading

Most low supply current amplifiers have difficulty driving

capacitive loads due to the higher currents required from the

output stage for such loads. Higher capacitance at the output

will increase the amount of overshoot and ringing in the

amplifier’s step response and could even affect the stability of

the device. However, through careful design of the output stage

and its high phase margin, the OPx81 family can tolerate some

degree of capacitive loading. Figure 37 shows the step response

of an OP181 with a 10 nF capacitor connected at the output.

Notice that the overshoot of the output does not exceed more

than 10% with such a load, even with a supply voltage of only

+3 V.

Figure 37. Ringing and Overshoot of the Output of the

Amplifier

A Micropower Reference Voltage Generator

Many single supply circuits are configured with the circuit

biased to 1/2 of the supply voltage. In these cases, a falseground reference can be created by using a voltage divider

buffered by an amplifier. Figure 38 shows the schematic for

such a circuit.

The two 1 MΩ resistors generate the reference voltage while

drawing only 1.5 µA of current from a 3 V supply. A capacitor

connected from the inverting terminal to the output of the op

amp provides compensation to allow for a bypass capacitor to be

connected at the reference output. This bypass capacitor helps

establish an ac ground for the reference output. The entire

reference generator draws less than 5 µA from a 3 V supply

source.

Figure 38. A Micropower Bias Voltage Generator

A Window Comparator

The extremely low power supply current demands of the OPx81

family make it ideal for use in long life battery powered applications such as a monitoring system. Figure 39 shows a circuit

that uses the OP281 as a window comparator.

REV. 0

–11–

Page 12

OP181/OP281/OP481

5.1kΩ

5.1kΩ

+3V

V

OUT

Q1

+3V

R1

R2

V

IN

2kΩ

+3V

R3

R4

+3V

V

H

A1

D1

10kΩ

OP281-A

+3V

A2

V

L

D2

OP281-B

Figure 39. Using the OP281 as a Window Comparator

The threshold limits for the window are set by VH and VL,

provided that V

> VL. The output of A1 will stay at the

H

negative rail, in this case ground, as long as the input voltage is

less than V

long the input voltage is higher than V

between V

. Similarly, the output of A2 will stay at ground as

H

and VH, the outputs of both op amps will be 0 V.

L

. As long as VIN remains

L

With no current flowing in either D1 or D2, the base of Q1 will

stay at ground, putting the transistor in cutoff and forcing V

OUT

to the positive supply rail. If the input voltage rises above VH,

the output of A2 stays at ground, but the output of A1 will go to

the positive rail, and D1 will conduct current. This creates a

base voltage that will turn on Q1 and drive V

condition occurs if V

falls below VL with A2’s output going

IN

high, and D2 conducting current. Therefore, V

if the input voltage is between V

and VH, and V

L

low. The same

OUT

will be high

OUT

will be low

OUT

if the input voltage moves outside of that range.

The R1 and R2 voltage divider sets the upper window voltage,

and the R3 and R4 voltage divider sets the lower voltage for the

window. For the window comparator to function properly, V

H

must be a greater voltage than VL.

VH=

VL=

R2

R1+R2

R4

R3 + R4

The 2 kΩ resistor connects the input voltage to the input terminals to the op amps. This protects the OP281 from possible

excess current flowing into the input stages of the devices. D1

and D2 are small-signal switching diodes (1N4446 or equivalent), and Q1 is a 2N2222 or equivalent NPN transistor.

A Low-Side Current Monitor

In the design of power supply control circuits, a great deal of

design effort is focused on ensuring a pass transistor’s long-term

reliability over a wide range of load current conditions. As a

result, monitoring and limiting device power dissipation is of

prime importance in these designs. Figure 40 shows an example

of a +5 V, single-supply current monitor that can be incorporated into the design of a voltage regulator with fold-back

current limiting or a high current power supply with crowbar

protection. The design capitalizes on the OP181’s commonmode range that extends to ground. Current is monitored in the

power supply return path where a 0.1 Ω shunt resistor, R

SENSE

,

creates a very small voltage drop. The voltage at the inverting

terminal becomes equal to the voltage at the noninverting

terminal through the feedback of Q1, which is a 2N2222 or

equivalent NPN transistor. This makes the voltage drop across

R1 equal to the voltage drop across R

. Therefore, the

SENSE

current through Q1 becomes directly proportional to the current

through R

, and the output voltage is given by:

SENSE

V

OUT

= VEE−

R2

× R

R1

SENSE

× I

L

The voltage drop across R2 increases with IL increasing, so

V

decreases with higher supply current being sensed. For

OUT

the element values shown, the V

–2.5 V/A, decreasing from V

V

OUT

+5V

Q1

R2

2.49kΩ

R1

100Ω

0.1Ω

R

SENSE

EE

transfer characteristic is

OUT

.

+5V

OP181

RETURN TO

GROUND

Figure 40. A Low-Side Load Current Monitor

Low Voltage Half-Wave and Full-Wave Rectifiers

Because of its quick overdrive recovery time, an OP281 can be

configured as a full-wave rectifier for low frequency (<500 Hz)

applications. Figure 41 shows the schematic.

R1 = 100kΩ R2 = 100kΩ

+3V

A2

OP281-B

FULL-WAVE

RECTIFIED

OUTPUT

HALF-WAVE

RECTIFIED

OUTPUT

VIN = 2V p-p

+3V

2kΩ

A1

OP281-A

Figure 41. Single Supply Full- and Half-Wave Rectifiers

Using an OP281

100

90

10

0%

SCALE 0.1V/DIV

SCALE 0.1ms/DIV

Figure 42. Full-Wave Rectified Signal

–12–

REV. 0

Page 13

OP181/OP281/OP481

Amplifier A1 is used as a voltage follower that will only track the

input voltage when it is greater than 0 V. This provides a halfwave rectification of the input signal to the noninverting

terminal of amplifier A2. When A1’s output is following the

input, the inverting terminal of A2 will also follow the input

from the virtual ground between the inverting and noninverting

terminals of A2. With no potential difference across R1, no

current flows through either R1 or R2, therefore the output of

A2 will also follow the input. Now, when the input voltage goes

below 0 V, the noninverting terminal of A2 becomes 0 V. This

makes A2 work as an inverting amplifier with a gain of 1 and

provides a full-wave rectified version of the input signal. A 2 kΩ

resistor in series with A1’s noninverting input protects the

device when the input signal becomes less than ground.

A Battery Powered Telephone Headset Amplifier

Figure 43 shows how the OP281 can be used as a two-way

amplifier in a telephone headset. One side of the OP281 can be

used as an amplifier for the microphone, while the other side

can be used to drive the speaker. A typical telephone headset

uses a 600 Ω speaker and an electret microphone that requires a

supply voltage and a biasing resistor.

0.1µF

11kΩ 300kΩ

+3V

2.2kΩ

INPUT

+3V

1MΩ 1MΩ

ELECTRET

MIC

1µF

1µF

10kΩ

POT.

1µF

1µF

+3V

1MΩ

1MΩ

50kΩ10kΩ

+3V

+3V

20kΩ

OP281-B

20kΩ

1µF

OP281-A

+3V

Q1

Q2

SPEAKER

MIC OUT

1µF

600Ω

Figure 43. A Battery Powered Telephone Headset

Two-Way Amplifier

The OP281-A op amp provides about 29 dB of gain for audio

signals coming from the microphone. The gain is set by the

300 kΩ and 11 kΩ resistors. The gain bandwidth product of the

amplifier is 95 kHz, which, for the set gain of 28, yields a –3 dB

rolloff at 3.4 kHz. This is acceptable since telephone audio is

band limited for 300 kHz to 3 kHz signals. If higher gain is

required for the microphone, an additional gain stage should be

used, as adding any more gain to the OP281 would limit the

audio bandwidth. A 2.2 kΩ resistor is used to bias the electret

microphone. This resistor value may vary depending on the

specifications on the microphone being used. The output of the

microphone is ac coupled to the noninverting terminal of the op

amp. Two 1 MΩ resistors are used to provide the dc offset for

single supply use.

The OP281-B amplifier can provide up to 15 dB of gain for the

headset speaker. Incoming audio signals are ac coupled to a

10 kΩ potentiometer that is used to adjust the volume. Again,

two 1 MΩ resistors provide the dc offset with a 1 µF capacitor

establishing an ac ground for the volume control potentiometer.

Because the OP281 is a rail-to-rail output amplifier, it would

have difficulty driving a 600 Ω speaker directly. Here, a class AB

buffer is used to isolate the load from the amplifier and also

provide the necessary current drive to the speaker. By placing

the buffer in the feedback loop of the op amp, crossover

distortion can be minimized. Q1 and Q2 should have minimum

betas of 100. The 600 Ω speaker is ac coupled to the emitters to

prevent any quiescent current from flowing in the speaker. The

1 µF coupling capacitor makes an equivalent high pass filter

cutoff at 265 Hz with a 600 Ω load attached. Again, this does

not pose a problem, as it is outside the frequency range for

telephone audio signals.

The circuit in Figure 43 draws around 250 µA of current. The

class AB buffer has a quiescent current of 140 µA while roughly

100 µA is drawn by the microphone itself. A CR2032 3 V

lithium battery has a life expectancy of 160 mA hours, which

means this circuit could run continuously for 640 hours on a

single battery.

SPICE Macro-Model

* OP181 SPICE Macro-model

* 9/96, Ver. 1

*

* Copyright 1996 by Analog Devices

*

* Refer to “README.DOC” file for License Statement. Use of this

* model indicates your acceptance of the terms and provisions in

* the License Statement.

*

* Node Assignments

* noninverting input

* | inverting input

* | | positive supply

* | | | negative supply

* | | | | output

*|| | | |

*|| | | |

.SUBCKT OP181 1 2 99 50 45

*

* INPUT STAGE

*

Q1 413PIX

Q2 675PIX

I1 99 8 1.28E-6

EOS 7 2 POLY(1) (12, 98) 80E-6 1

IOS 1 2 1E-10

RC1 4 50 500E3

RC2 6 50 500E3

RE1 3 8 108

RE2 5 8 108

V1 99 13 DC .9

V2 99 14 DC .9

D1 3 13 DX

D2 5 14 DX

*

* CMRR76dB, ZERO AT 1kHz

*

REV. 0

–13–

Page 14

OP181/OP281/OP481

ECM1 11 98 POLY(2) (1, 98) (2, 98) 0 .5 .5

R1 11 12 1.59E6

C1 11 12 100E-12

R2 12 98 283

*

* POLE AT 900kHz

*

EREF 98 0 (90, 0) 1

G1 98 20 (4, 6) 1E-6

R3 20 98 1E6

C2 20 98 177E-15

*

* POLE AT 500kHz

*

E2 21 98 (20, 98) 1

R4 21 22 1E6

C3 22 98 320E-15

*

* GAIN STAGE

*

CF 45 40 8. 5E-12

R5 40 98 65. 65E6

G3 98 40 (22, 98) 4.08E-7

D3 40 41 DX

D4 42 40 DX

V3 99 41 DC 0.5

V4 42 50 DC 0.5

*

* OUTPUT STAGE

*

ISY 99 50 1.375E-6

RS1 99 90 10E6

RS2 90 50 10E6

M1 45 46 99 99 POX L=1.5u W=300u

M2 45 47 50 50 NOX L=1.5u W=300u

EG1 99 46 POLY(1) (98, 40) 0.77 1

EG2 47 50 POLY(1) (40, 98) 0.77 1

*

* MODELS

*

.MODEL POX PMOS (LEVEL=2, KP=25E-6, VTO=-0.75, LAMBDA=0.01)

.MODEL NOX NMOS (LEVEL=2, KP=25E-6, VTO=0.75, LAMBDA=0.01)

.MODEL PIX PNP (BF=200)

.MODEL DX D(IS=1E-14)

.ENDS

–14–

REV. 0

Page 15

14 8

7

1

0.201 (5.10)

0.193 (4.90)

0.256 (6.50)

0.246 (6.25)

0.177 (4.50)

0.169 (4.30)

PIN 1

SEATING

PLANE

0.006 (0.15)

0.002 (0.05)

0.0118 (0.30)

0.0075 (0.19)

0.0256

(0.65)

BSC

0.0433

(1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.028 (0.70)

0.020 (0.50)

8°

0°

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

OP181/OP281/OP481

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

8-Lead Plastic DIP

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.070 (1.77)

0.045 (1.15)

8-Lead SOIC

0.1968 (5.00)

0.1890 (4.80)

8

5

41

PIN 1

0.0688 (1.75)

0.0532 (1.35)

(N-8)

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

(SO-8)

0.2440 (6.20)

0.2284 (5.80)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0196 (0.50)

0.0099 (0.25)

0.195 (4.95)

0.115 (2.93)

x 45°

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

14-Lead Plastic DIP

(N-14)

0.795 (20.19)

0.725 (18.42)

14

17

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

8

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

14-Lead Narrow Body SOIC

(SO-14)

0.3444 (8.75)

0.3367 (8.55)

14 8

71

PIN 1

0.0688 (1.75)

0.0532 (1.35)

0.130

(3.30)

MIN

SEATING

PLANE

0.2440 (6.20)

0.2284 (5.80)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0196 (0.50)

0.0099 (0.25)

0.195 (4.95)

0.115 (2.93)

x 45°

SEATING

PLANE

0.177 (4.50)

PIN 1

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

0.0500

(1.27)

BSC

0.122 (3.10)

0.114 (2.90)

8

0.169 (4.30)

1

0.0256 (0.65)

BSC

0.0118 (0.30)

0.0075 (0.19)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

8-Lead TSSOP

(RU-8)

5

0.256 (6.50)

0.246 (6.25)

4

0.0433

(1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

8°

0°

8°

0°

0.0500 (1.27)

0.0160 (0.41)

0.028 (0.70)

0.020 (0.50)

SEATING

PLANE

0.0500

0.0192 (0.49)

(1.27)

0.0138 (0.35)

BSC

14-Lead TSSOP

0.0099 (0.25)

0.0075 (0.19)

(RU-14)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

REV. 0

–15–

Page 16

C2195–12–10/96

–16–

PRINTED IN U.S.A.

Loading...

Loading...