Page 1

Dual Bipolar/JFET, Audio

OP275

OUT A

–IN A

+IN A

V–

OUT B

–IN B

+IN B

V+

1

2

3

4

5

6

7

8

1

2

3

4

8

7

6

5

OP275

OUT B

–IN B

+IN B

V+OUT A

–IN A

+IN A

V–

a

FEATURES

Excellent Sonic Characteristics

Low Noise: 6 nV/√Hz

Low Distortion: 0.0006%

High Slew Rate: 22 V/s

Wide Bandwidth: 9 MHz

Low Supply Current: 5 mA

Low Offset Voltage: 1 mV

Low Offset Current: 2 nA

Unity Gain Stable

SOIC-8 Package

APPLICATIONS

High Performance Audio

Active Filters

Fast Amplifiers

Integrators

GENERAL DESCRIPTION

The OP275 is the first amplifier to feature the Butler Amplifier

front-end. This new front-end design combines both bipolar

and JFET transistors to attain amplifiers with the accuracy and

low noise performance of bipolar transistors, and the speed and

sound quality of JFETs. Total Harmonic Distortion plus Noise

equals that of previous audio amplifiers, but at much lower supply currents.

A very low l/f corner of below 6 Hz maintains a flat noise density

response. Whether noise is measured at either 30 Hz or 1 kHz,

it is only 6 nV/√

the OP275 its high slew rates to keep distortion low, even when

large output swings are required, and the 22 V/µs slew rate of

the OP275 is the fastest of any standard audio amplifier. Best of

all, this low noise and high speed are accomplished using less

than 5 mA of supply current, lower than any standard audio

amplifier.

Hz. The JFET portion of the input stage gives

Operational Amplifier

OP275*

PIN CONNECTIONS

8-Lead Narrow-Body SO 8-Lead Epoxy DIP

(S Suffix) (P Suffix)

Improved dc performance is also provided with bias and offset

currents greatly reduced over purely bipolar designs. Input offset voltage is guaranteed at 1 mV and is typically less than

200 µV. This allows the OP275 to be used in many dc coupled

or summing applications without the need for special selections

or the added noise of additional offset adjustment circuitry.

The output is capable of driving 600 Ω loads to 10 V rms while

maintaining low distortion. THD + Noise at 3 V rms is a low

0.0006%.

The OP275 is specified over the extended industrial (–40°C to

+85°C) temperature range. OP275s are available in both plastic

DIP and SOIC-8 packages. SOIC-8 packages are available in

2500 piece reels. Many audio amplifiers are not offered in

SOIC-8 surface mount packages for a variety of reasons; however, the OP275 was designed so that it would offer full performance in surface mount packaging.

*Protected by U.S. Patent No. 5,101,126.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

© Analog Devices, Inc., 1995

Page 2

OP275–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ VS = ⫾15.0 V, TA = +25ⴗC unless otherwise noted)

Parameter␣ Symbol Conditions Min Typ Max Units

AUDIO PERFORMANCE␣

THD + Noise V

Voltage Noise Density e

n

= 3 V rms,

IN

R

= 2 kΩ, f = 1 kHz 0.006 %

L

f = 30 Hz 7 nV/√Hz

f = 1 kHz 6 nV/√

Current Noise Density i

n

f = 1 kHz 1.5 pA/√Hz

Headroom THD + Noise ≤ 0.01%,

R

= 2 kΩ, VS = ±18 V >12.9 dBu

L

INPUT CHARACTERISTICS␣

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

OS

B

OS

CM

Common-Mode Rejection Ratio CMRR V

Large Signal Voltage Gain A

VO

–40°C ≤ T

≤ +85°C 1.25 mV

A

VCM = 0 V 100 350 nA

V

= 0 V, –40°C ≤ TA ≤ +85°C 100 400 nA

CM

VCM = 0 V 2 50 nA

= 0 V, –40°C ≤ TA ≤ +85°C 2 100 nA

V

CM

–10.5 +10.5 V

= ±10.5 V,

CM

–40°C ≤ T

R

= 2 kΩ 250 V/mV

L

R

= 2 kΩ, –40°C ≤ TA ≤ +85°C 175 V/mV

L

= 600 Ω 200 V/mV

R

L

≤ +85°C 80 106 dB

A

1mV

Offset Voltage Drift ∆VOS/∆T2µV/°C

Hz

OUTPUT CHARACTERISTICS␣

R

Output Voltage Swing V

O

= 2 kΩ –13.5 ±13.9 +13.5 V

L

= 2 kΩ, –40°C ≤ TA ≤ +85°C –13 ±13.9 +13 V

R

L

R

= 600 Ω, VS = ±18 V +14, –16 V

L

POWER SUPPLY␣

Power Supply Rejection Ratio PSRR V

Supply Current I

Supply Voltage Range V

SY

S

= ±4.5 V to ±18 V 85 111 dB

S

V

= ±4.5 V to ±18 V,

S

–40°C ≤ T

V

= ±4.5 V to ±18 V, V

S

R

= ∞, –40°C ≤ TA ≤ +85°C45mA

L

= ±22 V, V

V

S

–40°C ≤ T

≤ +85°C80 dB

A

= 0 V, R

O

≤ +85°C 5.5 mA

A

= 0 V,

O

= ∞,

L

±4.5 ±22 V

DYNAMIC PERFORMANCE␣

Slew Rate SR R

Full-Power Bandwidth BW

P

= 2 kΩ 15 22 V/µs

L

Gain Bandwidth Product GBP 9 MHz

Phase Margin ø

m

Overshoot Factor V

Specifications subject to change without notice.

= 100 mV, AV = +1,

IN

R

= 600 Ω, C

L

= 100 pF 10 %

L

62 Degrees

kHz

–2–

REV. A

Page 3

OP275

WARNING!

ESD SENSITIVE DEVICE

WAFER TEST LIMITS

(@ VS = ⴞ15.0 V, TA = +25ⴗC unless otherwise noted)

Parameter Symbol Conditions Limit Units

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range

1

OS

B

OS

V

CM

Common-Mode Rejection Ratio CMRR V

VCM = 0 V 350 nA max

VCM = 0 V 50 nA max

= ±10.5 V 80 dB min

CM

1mV max

±10.5 V min

Power Supply Rejection Ratio PSRR V = ±4.5 V to ±18 V 85 dB min

R

Large Signal Voltage Gain A

Output Voltage Range V

Supply Current I

NOTES

Electrical tests and wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed for standard

product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

1

Guaranteed by CMRR test.

Specifications subject to change without notice.

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±22 V

Input Voltage

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±22 V

2

. . . . . . . . . . . . . . . . . . . . . . . ±7.5 V

Output Short-Circuit Duration to GND

VO

O

SY

1

3

. . . . . . . . . Indefinite

Storage Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

= 2 kΩ 250 V/mV min

L

R

= 10 kΩ±13.5 V min

L

VO = 0 V, R

= ∞ 5 mA max

L

ORDERING GUIDE

Model Temperature Range Package Option

OP275GP –40°C to +85°C 8-Pin Plastic DIP

OP275GS –40°C to +85°C 8-Pin SOIC

OP275GSR –40°C to +85°C SO-8 Reel, 2500 pcs.

OP275GBC +25°C DICE

OP275G . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range

P, S Package . . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

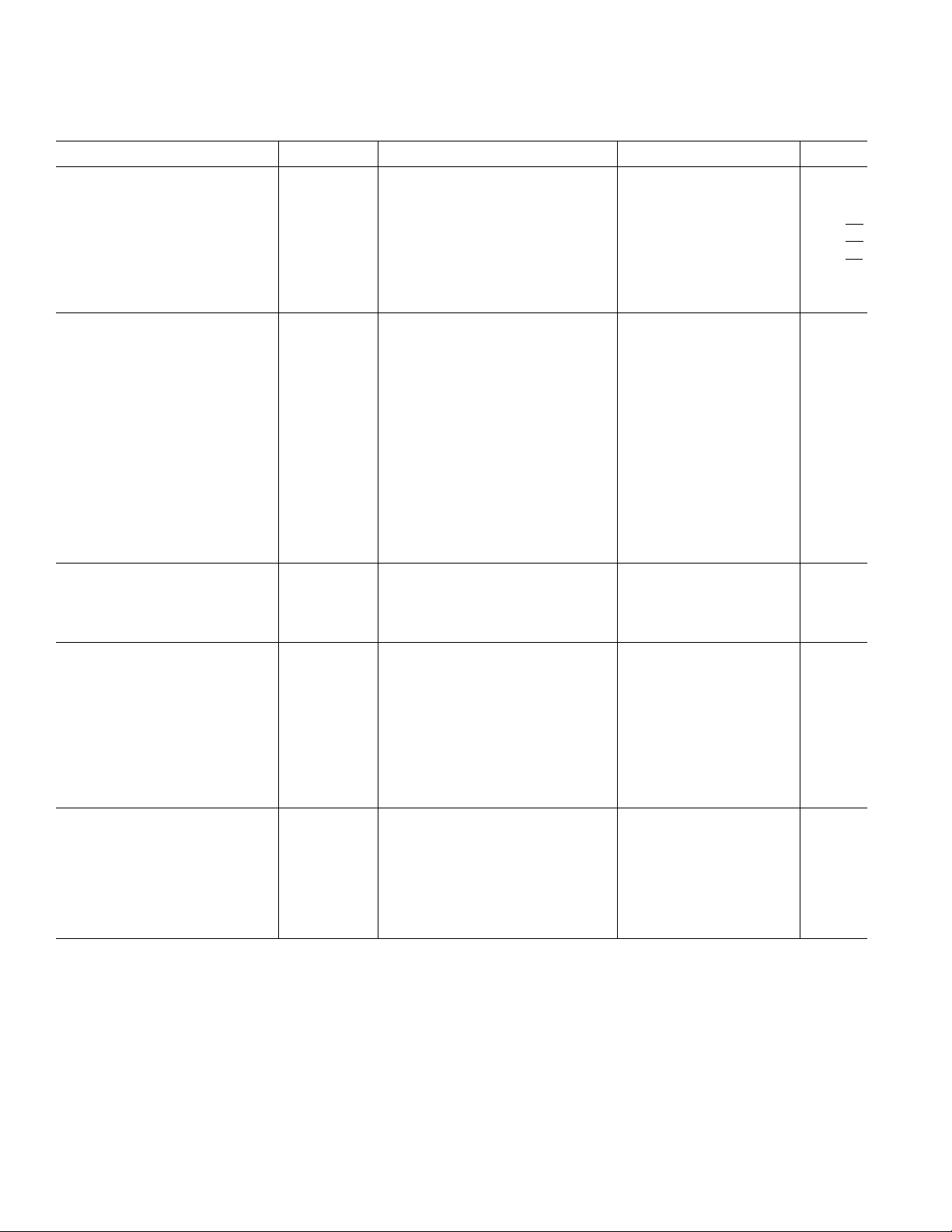

DICE CHARACTERISTICS

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300°C

Package Type θ

4

JA

θ

JC

Units

8-Pin Plastic DIP (P) 103 43 °C/W

8-Pin SOIC (S) 158 43 °C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

For supply voltages greater than ±22 V, the absolute maximum input voltage is

equal to the supply voltage.

3

Shorts to either supply may destroy the device. See data sheet for full details.

4

θJA is specified for the worst case conditions, i.e., θ

for cerdip, P-DIP, and LCC packages; θ

board for SOIC package.

JA

is specified for device in socket

JA

is specified for device soldered in circuit

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the OP275 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. A

Die Size 0.070 × 0.108 in. (7,560 sq. mils)

Substrate is connected to V–

–3–

Page 4

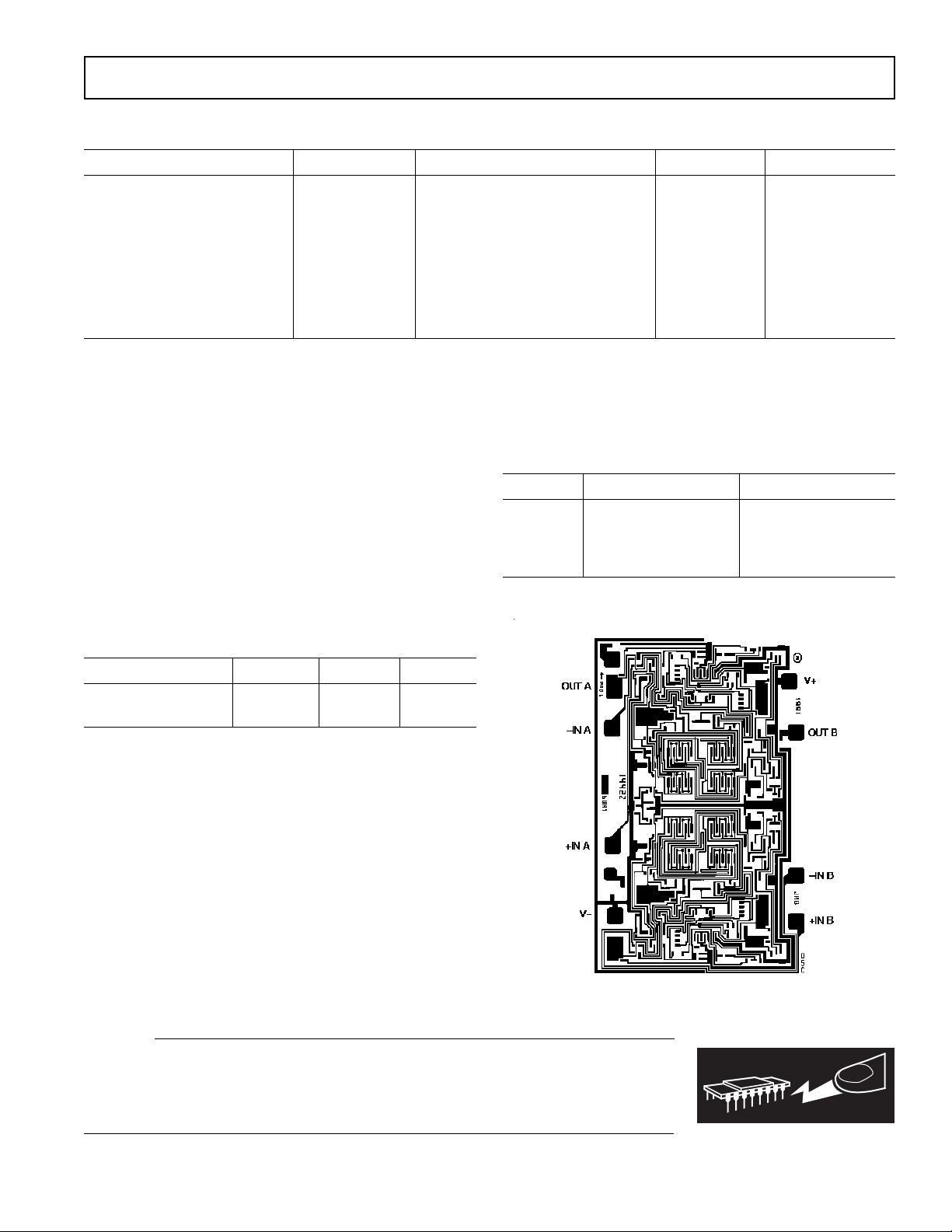

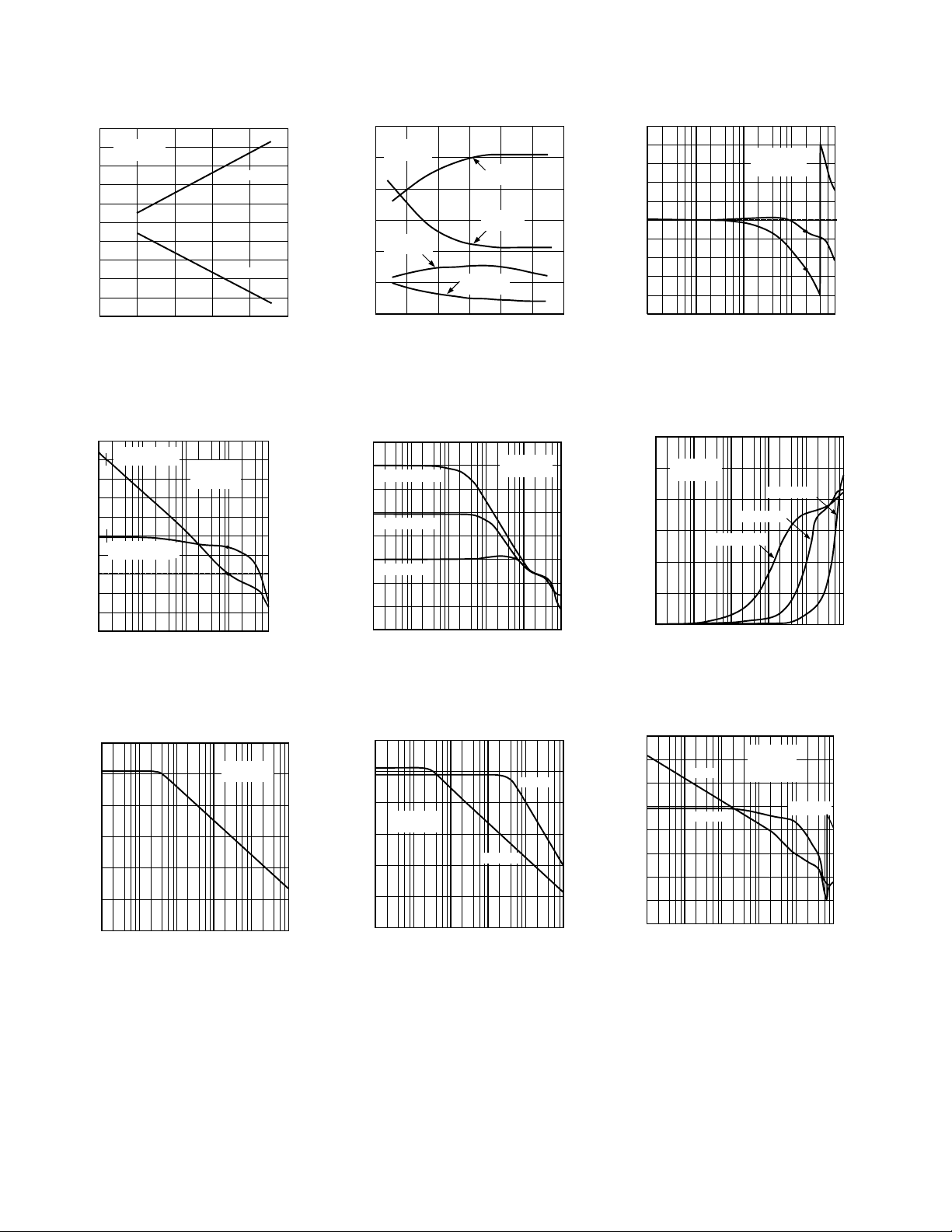

OP275–Typical Performance Curves

FREQUENCY – Hz

1M 10M

10k 100k

PHASE – Degrees

180

135

–180

90

45

0

–45

–90

–135

40

30

–40

20

10

0

–10

–20

–30

GAIN – dB

VS = ±15V

T

A

= +25°C

FREQUENCY – Hz

100

80

–60

1k 10k 100M

100k 1M 10M

60

40

20

0

–20

–40

0

PHASE – Degrees

45

90

135

180

225

270

VS = ±15V

R

L

= 2kΩ

T

A

= +25°C

OPEN-LOOP GAIN – dB

GAIN

PHASE

Øm= 58°

25

TA = +25°C

20

R

= 2kΩ

L

15

10

5

0

–5

–10

–15

OUTPUT VOLTAGE SWING – V

–20

–25

0 ±5 ±25

±10 ±15 ±20

SUPPLY VOLTAGE – V

+VOM

–VOM

Output Voltage Swing vs. Supply

Voltage

MARKER 15 309.059Hz

MAG (A/H) 60.115dB

60

50

40

30

20

MARKER 15 309.058Hz

PHASE (A/R 90.606Deg

10

GAIN – dB

0

–10

–20

10k 100k

VS = ±15V

TA = +25°C

135

90

45

0

–45

–90

1M 10M

FREQUENCY – Hz

OPEN-LOOP GAIN – V/mV

Open-Loop Gain vs. Temperature

PHASE – Degrees

1500

VS = ±15V

= ±10V

V

O

1250

1000

750

+GAIN

= 600Ω

R

L

500

250

0

–50 –25 100

50

40

A

30

20

A

10

0

A

–10

CLOSED-LOOP GAIN – dB

–20

–30

1k 10k 100M

0255075

TEMPERATURE – °C

= +100

VCL

= +10

VCL

= +1

VCL

100k 1M 10M

FREQUENCY – Hz

–GAIN

= 600Ω

R

L

+GAIN

R

L

–GAIN

= 2kΩ

R

L

= 2kΩ

VS = ±15V

= +25°C

T

A

Closed-Loop Gain and Phase, AV = +1

60

VS = ±15V

50

= +25°C

T

A

40

30

20

IMPEDANCE – Ω

10

0

100 1k 10M

A

VCL

FREQUENCY – Hz

A

= +1

VCL

A

= +10

VCL

= +100

10k 100k 1M

Open-Loop Gain, Phase vs. Frequency

120

100

80

60

40

20

COMMON-MODE REJECTION – dB

0

100 1k 10M10k 100k 1M

FREQUENCY – Hz

VS = ±15V

T

Common-Mode Rejection vs.

Frequency

= +25°C

A

Closed-Loop Gain vs. Frequency

120

100

80

VS = ±15V

= +25°C

T

A

60

40

20

POWER SUPPLY REJECTION – dB

0

10 100 1M

1k 10k 100k

FREQUENCY – Hz

+PSRR

–PSRR

Power Supply Rejection vs.

Frequency

–4–

Closed-Loop Output Impedance vs.

Frequency

Open-Loop Gain, Phase vs. Frequency

REV. A

Page 5

OP275

11

10

9

8

GAIN BANDWIDTH PRODUCT – MHz

7

–50 –25 100

TEMPERATURE – °C

Ø

m

GBW

0255075

Gain Bandwidth Product, Phase

Margin vs. Temperature

30

25

20

15

TA = +25°C

= ±15V

V

10

5

MAXIMUM OUTPUT SWING – V

0

S

= +1

A

VCL

= 2kΩ

R

L

1k 10k 10M

100k 1M

FREQUENCY – Hz

65

60

55

50

PHASE MARGIN – Degrees

40

100

OVERSHOOT – %

Small-Signal Overshoot vs. Load

Capacitance

5.0

4.5

4.0

3.5

SUPPLY CURRENT – mA

3.0

A

90

80

70

60

50

40

30

20

10

0

0 100 500

TA = +85°C

TA = +25°C

TA = –40°C

0 ±5 ±25

= +1

VCL

NEGATIVE EDGE

A

= +1

VCL

POSITIVE EDGE

VS = ±15V

= 2kΩ

R

L

V

= 100mV p-p

IN

200 300 400

LOAD CAPACITANCE – pF

±10 ±15

SUPPLY VOLTAGE – V

±20

16

14

–VOM

12

10

8

6

4

MAXIMUM OUTPUT SWING – V

2

0

100 1k 10k

+VOM

T

V

LOAD RESISTANCE – Ω

= +25°C

A

= ±15V

S

Maximum Output Voltage vs. Load

Resistance

120

110

100

90

80

70

60

50

40

30

ABSOLUTE OUTPUT CURRENT – mA

20

SINK

SOURCE

–50 –25 100

0255075

TEMPERATURE – °C

VS = ±15V

Maximum Output Swing vs.

Frequency

300

250

200

150

100

INPUT BIAS CURRENT – nA

50

0

–50 –25 100

TEMPERATURE – °C

VS = ±15V

0255075

Input Bias Current vs. Temperature

Supply Current vs. Supply Voltage

5

Hz

4

3

2

1

CURRENT NOISE DENSITY – pA/

10 100 100k1k

FREQUENCY – Hz

V

= ±15V

S

T = +25°C

A

Current Noise Density vs. Frequency

Short Circuit Current vs. Temperature

500

400

BASED ON 920 OP AMPS

300

UNITS

200

100

0

01 10

234 567 8 9

VS = ±15V

–40°C to +85°C

TCVOS – µV/°C

TCVOS Distribution

REV. A

–5–

Page 6

OP275–Typical Performance Curves

200

BASED ON 920 OP AMPS

160

120

UNITS

80

40

0

–300–200

–400

–500

INPUT OFFSET VOLTAGE – µV

–100

0 100 200

VS = ±15V

TA = +25°C

300

Input Offset (VOS) Distribution

40

VS = ±15V

35

R

= 2kΩ

L

30

= +25°C

T

A

25

20

15

SLEW RATE – V/µs

10

5

0

0.2.4.6.81.0

DIFFERENTIAL INPUT VOLTAGE – V

400

500

10

8

6

4

2

0

–2

STEP SIZE – V

–4

–6

–8

–10

0 100 900

+0.1%

–0.1%

200 300 400 500 600 700 800

SETTLING TIME – ns

+0.01%

–0.01%

Settling Time vs. Step Size

50

45

40

35

30

SLEW RATE – V/µs

25

20

0 100 500

–SR

+SR

CAPACITIVE LOAD – pF

Slew Rate vs. Capacitive Load

50

VS = ±15V

45

= 2kΩ

R

L

40

35

30

SLEW RATE – V/µs

25

20

–50 –25 100

TEMPERATURE – °C

–SR

+SR

0255075

TA = +25°C

= ±15V

V

S

200 300 400

Slew Rate vs. Differential Input Voltage

100

90

10

0%

5V

200ns

Negative Slew Rate

= 2 kΩ, VS = ±15 V, AV = +1

R

L

100

90

10

0%

50mV

100ns

Slew Rate vs. Temperature

100

90

10

0%

5V

200ns

Positive Slew Rate

= 2 kΩ, VS = ±15 V, AV = +1

R

L

CH A: 80.0 µV FS 10.0 µV/DIV

MKR: 6.23 nV/√Hz

2.5 kHz0 Hz

BW: 15.0 MHzMKR: 1 000 Hz

Small Signal Response

= 2 kΩ, VS = ±15 V, AV = +1

R

L

–6–

Voltage Noise Density vs. Frequency

= ±15 V

V

S

REV. A

Page 7

OP275

SUPPLY VOLTAGE – V

0.0001

0.001

THD – %

0

±17 ±22±18 ±19 ±20 ±21

0.01

0.1

RL = 600Ω

V

OUT

= 10 Vrms @ 1kHz

APPLICATIONS

Short Circuit Protection

The OP275 has been designed with inherent short circuit pro-

tection to ground. An internal 30 Ω resistor, in series with the

output, limits the output current at room temperature to I

= 40 mA and I

– = –90 mA, typically, with ±15 V supplies.

SC

SC

+

However, shorts to either supply may destroy the device when

excessive voltages or currents are applied. If it is possible for a

user to short an output to a supply, for safe operation, the out-

put current of the OP275 should be design-limited to ±30 mA,

as shown in Figure 1.

Total Harmonic Distortion

Total Harmonic Distortion + Noise (THD + N) of the OP275

is well below 0.001% with any load down to 600 Ω. However,

this is dependent upon the peak output swing. In Figure 2 it is

seen that the THD + Noise with 3 V rms output is below

0.001%. In the following Figure 3, THD + Noise is below

0.001% for the 10 kΩ and 2 kΩ loads but increases to above

0.1% for the 600␣ Ω load condition. This is a result of the output

swing capability of the OP275. Notice the results in Figure 4,

showing THD vs. V

(V rms). This figure shows that the THD

IN

+ Noise remains very low until the output reaches 9.5 volts rms.

This performance is similar to competitive products.

R

FB

0.010

VS = ±18V

= 600Ω

R

L

0.001

THD + NOISE – %

0.0001

0.5 1 10

OUTPUT SWING – V rms

Figure 4. Headroom, THD + Noise vs. Output Amplitude

(V rms); R

= 600 Ω, V

LOAD

= ±18 V

SUP

The output of the OP275 is designed to maintain low harmonic

distortion while driving 600 Ω loads. However, driving 600 Ω

loads with very high output swings results in higher distortion if

clipping occurs. A common example of this is in attempting to

drive 10 V rms into any load with ±15 volt supplies. Clipping

will occur and distortion will be very high.

To attain low harmonic distortion with large output swings,

supply voltages may be increased. Figure 5 shows the perfor-

mance of the OP275 driving 600␣ Ω loads with supply voltages

varying from ±18 volts to ±20 volts. Notice that with ±18 volt

supplies the distortion is fairly high, while with ±20 volt supplies

it is a very low 0.0007%.

FEEDBACK

X

R

A1

332Ω

A1 = 1/2 OP275

V

OUT

Figure 1. Recommended Output Short Circuit Protection

0.010

RL = 600Ω, 2k, 10k

VS = ±15V

= 3V rms

V

IN

= +1

A

V

THD + NOISE – %

0.001

0.0005

20 100 1k 10k 20k

Figure 2. THD + Noise vs. Frequency vs. R

1

0.1

0.010

THD + NOISE – %

0.001

0.0001

20 100 1k 10k 20k

Figure 3. THD + Noise vs. R

±

18 V Supplies

FREQUENCY – Hz

600Ω

2k

FREQUENCY – Hz

LOAD

AV = +1

VS = ±18V

= 10V rms

V

IN

80kHz FILTER

10k

; VIN =10 V rms,

LOAD

Figure 5. THD + Noise vs. Supply Voltage

Noise

The voltage noise density of the OP275 is below 7 nV/√Hz from

30 Hz. This enables low noise designs to have good performance throughout the full audio range. Figure 6 shows a typical

OP275 with a 1/f corner at 2.24 Hz.

CH A: 80.0 µV FS 10.0 µV/DIV

0 Hz

MKR: 45.6 µV/√Hz

10 Hz

BW: 0.145 HzMKR: 2.24 Hz

Figure 6. 1/f Noise Corner, VS = ±15 V, AV = 1000

REV. A

–7–

Page 8

OP275

Noise Testing

For audio applications the noise density is usually the most important noise parameter. For characterization the OP275 is

tested using an Audio Precision, System One. The input signal

to the Audio Precision must be amplified enough to measure it

accurately. For the OP275 the noise is gained by approximately

1020 using the circuit shown in Figure 7. Any readings on the

Audio Precision must then be divided by the gain. In implementing this test fixture, good supply bypassing is essential.

100Ω

909Ω

100Ω

A

OP275

B

909Ω

OP37

100Ω

909Ω

OP37

OUTPUT

4.42kΩ

490Ω

Figure 7. Noise Test Fixture

Input Overcurrent Protection

The maximum input differential voltage that can be applied to

the OP275 is determined by a pair of internal Zener diodes connected across its inputs. They limit the maximum differential in-

put voltage to ±7.5 V. This is to prevent emitter-base junction

breakdown from occurring in the input stage of the OP275

when very large differential voltages are applied. However, in order to preserve the OP275’s low input noise voltage, internal resistances in series with the inputs were not used to limit the

current in the clamp diodes. In small signal applications, this is

not an issue; however, in applications where large differential

voltages can be inadvertently applied to the device, large transient currents can flow through these diodes. Although these di-

odes have been designed to carry a current of ±5 mA, external

resistors as shown in Figure 8 should be used in the event that

the OP275’s differential voltage were to exceed ±7.5 V.

1.4kΩ

2

–

6

1.4kΩ

OP275

3

+

Figure 8. Input Overcurrent Protection

Output Voltage Phase Reversal

Since the OP275’s input stage combines bipolar transistors for

low noise and p-channel JFETs for high speed performance, the

output voltage of the OP275 may exhibit phase reversal if either

of its inputs exceed its negative common-mode input voltage.

This might occur in very severe industrial applications where a

sensor, or system, fault might apply very large voltages on the

inputs of the OP275. Even though the input voltage range of the

OP275 is ±10.5 V, an input voltage of approximately –13.5 V

will cause output voltage phase reversal. In inverting amplifier

configurations, the OP275’s internal 7.5 V input clamping diodes will prevent phase reversal; however, they will not prevent

this effect from occurring in noninverting applications. For these

applications, the fix is a simple one and is illustrated in Figure 9.

A 3.92 kΩ resistor in series with the noninverting input of the

OP275 cures the problem.

R

FB*

V

V

IN

R

3.92kΩ

IS OPTIONAL

*R

FB

S

R

2kΩ

L

OUT

Figure 9. Output Voltage Phase Reversal Fix

Overload, or Overdrive, Recovery

Overload, or overdrive, recovery time of an operational amplifier

is the time required for the output voltage to recover to a rated

output voltage from a saturated condition. This recovery time is

important in applications where the amplifier must recover

quickly after a large abnormal transient event. The circuit

shown in Figure 10 was used to evaluate the OP275’s overload

recovery time. The OP275 takes approximately 1.2 µs to recover

to V

= +10 V and approximately 1.5 µs to recover to V

OUT

OUT

=

–10 V.

R2

10kΩ

2

3

A1

1

R

2.43kΩ

V

OUT

L

V

IN

4V p-p

@100Hz

R1

1kΩ

R

S

909Ω

A1 = 1/2 OP275

Figure 10.␣ Overload Recovery Time Test Circuit

Measuring Settling Time

The design of OP275 combines high slew rate and wide gainbandwidth product to produce a fast-settling (t

< 1 µs) ampli-

S

fier for 8- and 12-bit applications. The test circuit designed to

measure the settling time of the OP275 is shown in Figure 11.

This test method has advantages over false-sum node techniques in that the actual output of the amplifier is measured, instead of an error voltage at the sum node. Common-mode

settling effects are exercised in this circuit in addition to the slew

rate and bandwidth effects measured by the false-sum-node

method. Of course, a reasonably flat-top pulse is required as the

stimulus.

The output waveform of the OP275 under test is clamped by

Schottky diodes and buffered by the JFET source follower. The

signal is amplified by a factor of ten by the OP260 and then

Schottky-clamped at the output to prevent overloading the

oscilloscope’s input amplifier. The OP41 is configured as a fast

integrator which provides overall dc offset nulling.

High Speed Operation

As with most high speed amplifiers, care should be taken with

supply decoupling, lead dress, and component placement. Recommended circuit configurations for inverting and noninverting

applications are shown in Figures 12 and Figure 13.

–8–

REV. A

Page 9

0.1µF

+15V

16–20V

–+

0.1µF

0.1µF

+

16–20V

±5V

10µF

+

+15V

R

V+

DUT

V–

–

1kΩ

1N4148

L

D1 D2

–15V

15kΩ

2N4416

2N2222A

1/2 OP260AJ

R

F

2kΩ

R

G

222Ω

SCHOTTKY DIODES D1–D4 ARE

HEWLETT-PACKARD HP5082-2835

IC1 IS 1/2 OP260AJ

IC2 IS PMI OP41EJ

Figure 11.␣ OP275’s Settling Time Test Fixture

1kΩ

10kΩ

750Ω

D3

10kΩ

D4

1µF

IC2

OUTPUT

(TO SCOPE)

C

FB

R

FB

OP275

2

8

1/2

–15V

1

4

0.1µF

OP275

10µF

+

3

V

IN

R

2kΩ

V

OUT

L

Figure 12. Unity Gain Follower

+15V

10µF

+

V

IN

2.49kΩ

4.99kΩ

0.1µF

2

3

0.1µF

1/2

OP275

–15V

8

4

10µF

10pF

4.99kΩ

1

+

2kΩ

V

OUT

Figure 13. Unity Gain Inverter

In inverting and noninverting applications, the feedback resistance forms a pole with the source resistance and capacitance

and CS) and the OP275’s input capacitance (CIN), as shown

(R

S

in Figure 14. With R

and RF in the kilohm range, this pole can

S

create excess phase shift and even oscillation. A small capacitor,

, in parallel and RFB eliminates this problem. By setting R

C

FB

S

(CS + CIN) = RFBCFB, the effect of the feedback pole is completely removed.

R

S

C

S

C

IN

V

OUT

Figure 14. Compensating the Feedback Pole

Attention to Source Impedances Minimizes Distortion

Since the OP275 is a very low distortion amplifier, careful attention should be given to source impedances seen by both inputs.

As with many FET-type amplifiers, the p-channel JFETs in the

OP275’s input stage exhibit a gate-to-source capacitance that

varies with the applied input voltage. In an inverting configuration, the inverting input is held at a virtual ground and, as such,

does not vary with input voltage. Thus, since the gate-to-source

voltage is constant, there is no distortion due to input capacitance modulation. In noninverting applications, however, the

gate-to-source voltage is not constant. The resulting capacitance

modulation can cause distortion above 1 kHz if the input im-

pedance is > 2 kΩ and unbalanced.

Figure 15 shows some guidelines for maximizing the distortion

performance of the OP275 in noninverting applications. The

best way to prevent unwanted distortion is to ensure that the

parallel combination of the feedback and gain setting resistors

(R

and R

F

) is less than 2 kΩ. Keeping the values of these resis-

G

tors small has the added benefits of reducing the thermal noise

R

G

R

V

IN

S*

R

F

0P275

* RS = RG//RF IF RG//RF > 2kΩ

FOR MINIMUM DISTORTION

V

OUT

Figure 15. Balanced Input Impedance to Minimize

Distortion in Noninverting Amplifier Circuits

REV. A

–9–

Page 10

OP275

of the circuit and dc offset errors. If the parallel combination of

R

and R

F

is larger than 2␣ kΩ, then an additional resistor, R

G

,

S

should be used in series with the noninverting input. The value

is determined by the parallel combination of RF and RG to

of R

S

maintain the low distortion performance of the OP275.

Driving Capacitive Loads

The OP275 was designed to drive both resistive loads to 600 Ω

and capacitive loads of over 1000 pF and maintain stability.

While there is a degradation in bandwidth when driving capacitive loads, the designer need not worry about device stability.

The graph in Figure 16 shows the 0 dB bandwidth of the OP275

with capacitive loads from 10 pF to 1000 pF.

10

9

8

7

6

5

4

BANDWIDTH – MHz

3

2

1

0

0 200 400 600 800 1000

Figure 16. Bandwidth vs. C

– pF

C

LOAD

LOAD

High Speed, Low Noise Differential Line Driver

The circuit of Figure 17 is a unique line driver widely used in

industrial applications. With ±18 V supplies, the line driver can

deliver a differential signal of 30 V p-p into a 2.5 kΩ load. The

high slew rate and wide bandwidth of the OP275 combine to

yield a full power bandwidth of 130 kHz while the low noise

front end produces a referred-to-input noise voltage spectral

density of 10 nV/√

3

V

IN

2

A1 = 1/2 OP275

A2, A3 = 1/2 OP275

R3

GAIN =

R1

SET R2, R4, R5 = R1 AND R6, R7, R8 = R3

Hz.

R3

2k

2

A2

3

R1

2k

1

A1

R2

2k

R4

2k

R5

2k

R6

2k

6

A3

5

R9

50

1

R11

10k

R12

1k

P1

1k

R7

2k

R10

50

7

R8

2k

V

O2

V

O1

– VO1 = V

V

O2

IN

Figure 17. High Speed, Low Noise Differential Line Driver

importance. Like the transformer based design, either output

can be shorted to ground for unbalanced line driver applications

without changing the circuit gain of 1. Other circuit gains can be

set according to the equation in the diagram. This allows the

design to be easily set to noninverting, inverting, or differential

operation.

A 3-Pole, 40 kHz Low-Pass Filter

The closely matched and uniform ac characteristics of the

OP275 make it ideal for use in GIC (Generalized Impedance

Converter) and FDNR (Frequency-Dependent Negative Resistor) filter applications. The circuit in Figure 18 illustrates a linear-phase, 3-pole, 40 kHz low-pass filter using an OP275 as an

inductance simulator (gyrator). The circuit uses one OP275 (A2

and A3) for the FDNR and one OP275 (A1 and A4) as an input

buffer and bias current source for A3. Amplifier A4 is configured in a gain of 2 to set the pass band magnitude response to

0 dB. The benefits of this filter topology over classical approaches are that the op amp used in the FDNR is not in the

signal path and that the filter’s performance is relatively insensitive to component variations. Also, the configuration is such that

large signal levels can be handled without overloading any of the

the filter’s internal nodes. As shown in Figure 19, the OP275’s

symmetric slew rate and low distortion produce a clean, wellbehaved transient response.

R1

95.3kΩ

2

A1

3

V

IN

1

A2

C1

2200pF

1

R2

R6

787Ω

4.12kΩ

A3

2200pF

7

C4

100kΩ

A1, A4 = 1/2 OP275

A2, A3 = 1/2 OP275

C2

2200pF

1.82kΩ

2

2200pF

1.87kΩ

1.82kΩ

C3

3

5

6

R3

R4

R5

5

7

A4

6

R7

R8

R9

1kΩ

1kΩ

V

OUT

Figure 18. A 3-Pole, 40 kHz Low-Pass Filter

100

90

V

OUT

10Vp-p

10kHz

10

0%

SCALE: VERTICAL–2V/ DIV

HORIZONTAL–10µs/ DIV

The design is a transformerless, balanced transmission system

where output common-mode rejection of noise is of paramount

–10–

Figure 19. Low-Pass Filter Transient Response

REV. A

Page 11

OP275

OP275 SPICE Model

*

* Node assignments

* noninverting input

* inverting input

* positive supply

* negative supply

* output

*

*

.SUBCKT OP275 1 2 99 50 34

*

* INPUT STAGE & POLE AT 100 MHz

*

R3 5 51 2.188

R4 6 51 2.188

CIN 1 2 3.7E-12

CM1 1 98 7.5E-12

CM2 2 98 7.5E-12

C2 5 6 364E-12

I1 97 4 100E-3

IOS 1 2 1E-9

EOS 9 3 POLY(1) 26 28 0.5E-3 1

Q1 5 2 7 QX

Q2 6 9 8 QX

R5 7 4 1.672

R6 8 4 1.672

D1 2 36 DZ

D2 1 36 DZ

EN 3 1 10 0 1

GN1 0 2 13 0 1E-3

GN2 0 1 16 0 1E-3

*

EREF 98 0 28 0 1

EP 97 0 99 0 1

EM 51 0 50 0 1

*

* VOLTAGE NOISE SOURCE

*

DN1 35 10 DEN

DN2 10 11 DEN

VN1 35 0 DC 2

VN2 0 11 DC 2

*

* CURRENT NOISE SOURCE

*

DN3 12 13 DIN

DN4 13 14 DIN

VN3 12 0 DC 2

VN4 0 14 DC 2

*

* CURRENT NOISE SOURCE

*

DN5 15 16 DIN

DN6 16 17 DIN

VN5 15 0 DC 2

VN6 0 17 DC 2

*

* GAIN STAGE & DOMINANT POLE AT 32 Hz

*

R7 18 98 1.09E6

C3 18 98 4.55E-9

G1 98 18 5 6 4.57E-1

V2 97 19 1.35

V3 20 51 1.35

D3 18 19 DX

D4 20 18 DX

*

* POLE/ZERO PAIR AT 1.5 MHz/2.7 MHz

*

R8 21 98 1E-3

R9 21 22 1.25E-3

C4 22 98 47.2E-12

G2 98 21 18 28 1E-3

*

* POLE AT 100 MHz

*

R10 23 98 1

C5 23 98 1.59E-9

G3 98 23 21 28 1

*

* POLE AT 100 MHz

*

R11 24 98 1

C6 24 98 1.59E-9

G4 98 24 23 28 1

*

* COMMON-MODE GAIN NETWORK WITH ZERO AT

1 kHz

*

R12 25 26 1E6

C7 25 26 1.5915E-12

R13 26 98 1

E2 25 98 POLY(2) 1 98 2 98 0 2.50 2.50

*

* POLE AT 100 MHz

*

R14 27 98 1

C8 27 98 1.59E-9

G5 98 27 24 28 1

*

* OUTPUT STAGE

*

R15 28 99 100E3

R16 28 50 100E3

C9 28 50 1E-6

ISY 99 50 1.85E-3

R17 29 99 100

R18 29 50 100

L2 29 34 1E-9

G6 32 50 27 29 10E-3

G7 33 50 29 27 10E-3

G8 29 99 99 27 10E-3

G9 50 29 27 50 10E-3

V4 30 29 1.3

V5 29 31 3.8

F1 29 0 V4 1

F2 0 29 V5 1

D5 27 30 DX

D6 31 27 DX

D7 99 32 DX

D8 99 33 DX

D9 50 32 DY

D10 50 33 DY

*

* MODELS USED

*

.MODEL QX PNP(BF=5E5)

.MODEL DX D(IS=1E-12)

.MODEL DY D(IS=1E-15 BV=50)

.MODEL DZ D(IS=1E-15 BV=7.0)

.MODEL DEN D(IS=1E-12 RS=4.35K KF=1.95E-15 AF=1)

.MODEL DIN D(IS=1E-12 RS=268 KF=1.08E-15 AF=1)

.ENDS

REV. A

–11–

Page 12

OP275

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

0.2440 (6.20)

0.2284 (5.80)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

8-Lead Narrow-Body SOIC

(S Suffix)

0.1968 (5.00)

0.1890 (4.80)

85

0.1574 (4.00)

0.1497 (3.80)

41

0.0688 (1.75)

PIN 1

0.0500

(1.27)

BSC

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

x 45°

0.0500 (1.27)

0.0160 (0.41)

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

8-Lead Epoxy DIP

(P Suffix)

0.430 (10.92)

0.348 (8.84)

8

5

0.280 (7.11)

14

PIN 1

0.100

(2.54)

BSC

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

C1652a–2–7/95

0.325 (8.25)

0.300 (7.62)

0.195 (4.95)

0.115 (2.93)

0.015 (0.381)

0.008 (0.204)

–12–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...