Page 1

Dual, Precision

O

0

www.BDTIC.com/ADI

JFET High Speed Operational Amplifier

FEATURES

Fast slew rate: 22 V/s typical

Settling time (0.01%): 1.2 µs maximum

Offset voltage: 300 µV maximum

High open-loop gain: 1000 V/mV minimum

Low total harmonic distortion: 0.002% typical

Improved replacement for AD712, LT1057, OP215, TL072,

and MC34

APPLICATIONS

Output amplifier for fast DACs

Signal processing

Instrumentation amplifiers

Fast sample-and-holds

Active filters

Low distortion audio amplifiers

Input buffer for ADCs

Servo controllers

082

OP249

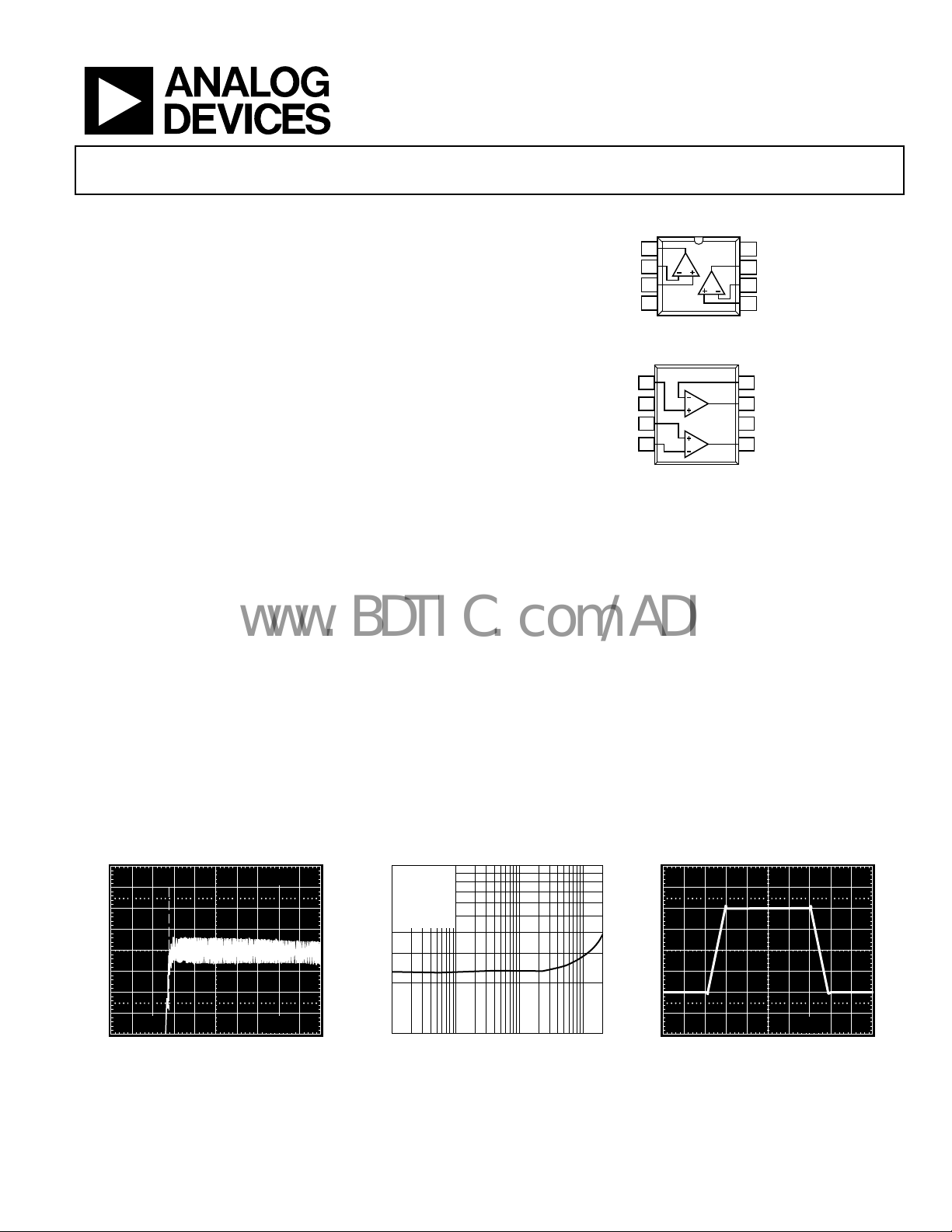

PIN CONFIGURATIONS

UT A

1

OP249

A

2

–IN A

+IN A

3

V–

4

B

Figure 1. 8-Lead CERDIP (Q-8) and

8-Lead

PDIP (N-8)

1

+IN A

+IN B

–IN B

2

V–

3

4

A

OP249

B

Figure 2. 8-Lead SOIC (R-8)

8

7

6

5

8

7

6

5

V+

OUT B

–IN B

+IN B

–IN A

OUT A

V+

OUT B

00296-001

00296-002

GENERAL DESCRIPTION

The OP249 is a high speed, precision dual JFET op amp, similar to

the popular single op amp, the OP42. The OP249 outperforms

available dual amplifiers by providing superior speed with

excellent dc performance. Ultrahigh open-loop gain (1 kV/mV

minimum), low offset voltage, and superb gain linearity makes

the OP249 the industry’s first true precision, dual high speed

amplifier.

With a slew rate of 22 V/μs typical and a fast settling time of less

n 1.2 μs maximum to 0.01%, the OP249 is an ideal choice for

tha

high speed bipolar DAC and ADC applications. The excellent

dc performance of the OP249 allows the full accuracy of high

resolution CMOS DACs to be realized.

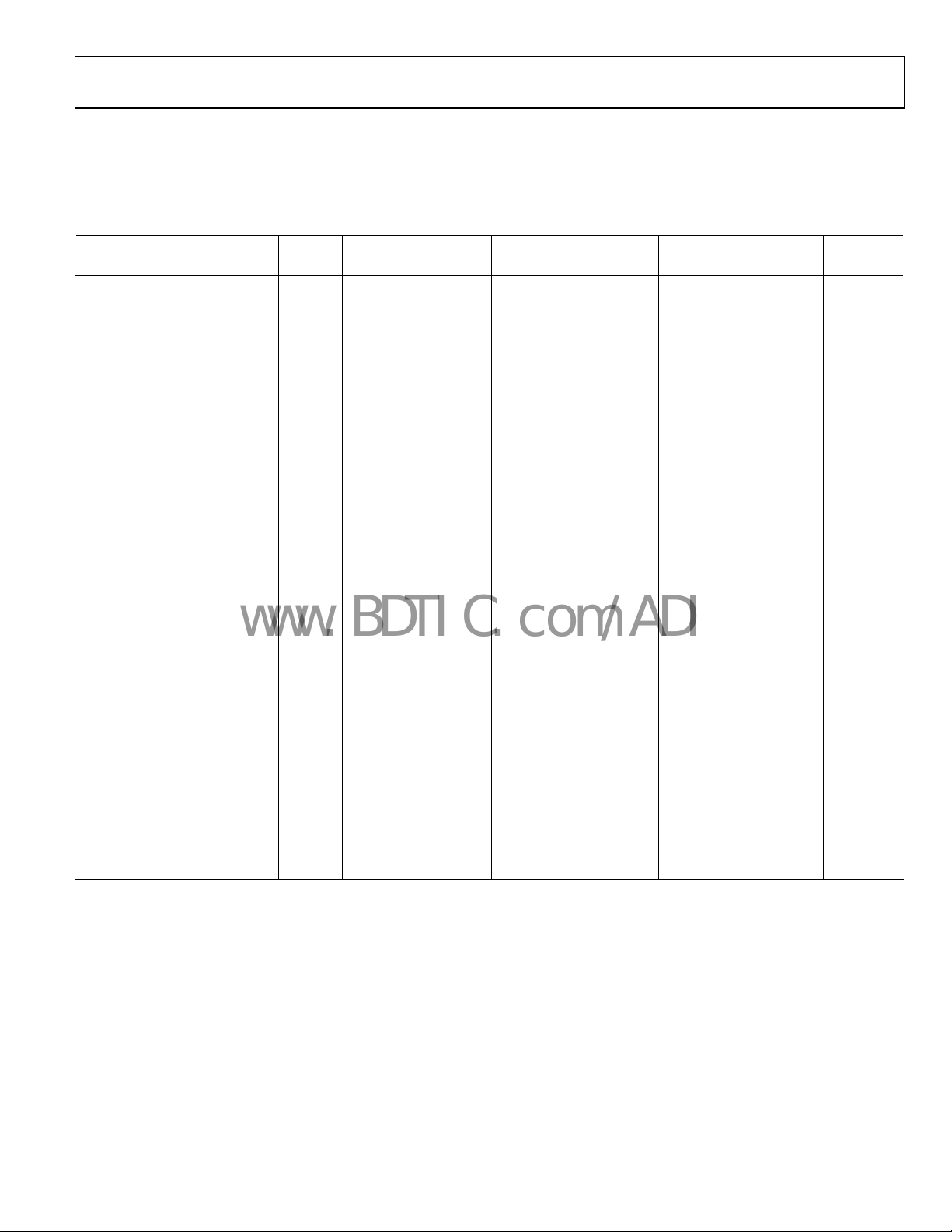

0.01

.001

TA = 25°C

= ±15V

V

S

= 10V p-p

V

O

= 10kΩ

R

L

= 1

A

V

20

100 1k 10k 20k

100

870ns

90

10

0%

500ns10mV

00296-003

Figure 3. Fast Settling (0.01%) Figure 4. Low Distortion, A

Symmetrical slew rate, even when driving large load, such as,

600 Ω o

r 200 pF of capacitance and ultralow distortion, make

the OP249 ideal for professional audio applications, active filters,

high speed integrators, servo systems, and buffer amplifiers.

The OP249 provides significant performance upgrades to the

TL072, AD712,

= 1, RL = 10 kΩ Figure 5. Excellent Output Drive, RL = 600 Ω

V

OP215, MC34082, and LT1057.

100

90

10

0%

00296-004

5V 1µs

00296-005

Rev. F

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

Page 2

OP249

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

Pin Configurations ........................................................................... 1

General Description......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Electrical Characteristics............................................................. 3

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

REVISION HISTORY

5/07—Rev. E to Rev. F

Updated Format..................................................................Universal

Changes to Table 1............................................................................ 3

Changes to Table 2............................................................................ 4

Changes to Table 3 and Table 4....................................................... 5

Changes to Table 5............................................................................ 6

Changes to Figure 31...................................................................... 11

Changes to Figure 37 and Figure 38............................................. 12

Deleted OP249 SPICE Macro-Model Section ............................ 14

Deleted Figure 18; Renumbered Sequentially ............................ 14

Deleted Table I ................................................................................ 15

Changes to Discussion on Driving ADCs Section..................... 17

Updated Outline Dimensions....................................................... 18

Changes to Ordering Guide.......................................................... 19

Typical Perf or m an c e Charac t e r istics ..............................................7

Applications Information.............................................................. 13

Open-Loop Gain Linearity ....................................................... 14

Offset Voltage Adjustment........................................................ 14

Settling Time............................................................................... 14

DAC Output Amplifier.............................................................. 15

Disscusion on Driving ADCs ................................................... 16

Outline Dimensions ....................................................................... 18

Ordering Guide .......................................................................... 19

9/01—Rev. D to Rev. E

E

dits to Features and Pin Connections ..........................................1

Edits to Electrical Characteristics .............................................. 2, 3

Edits to Absolute Maximum Ratings, Package Type, and

Ordering Guide..................................................................................4

Deleted Wafer Test Limits and Dice Characteristics Section ......5

Edits to Typical Performance Characteristics................................8

Edits to Macro-Model Figure........................................................ 15

Edits to Outline Dimensions......................................................... 17

Rev. F | Page 2 of 20

Page 3

OP249

www.BDTIC.com/ADI

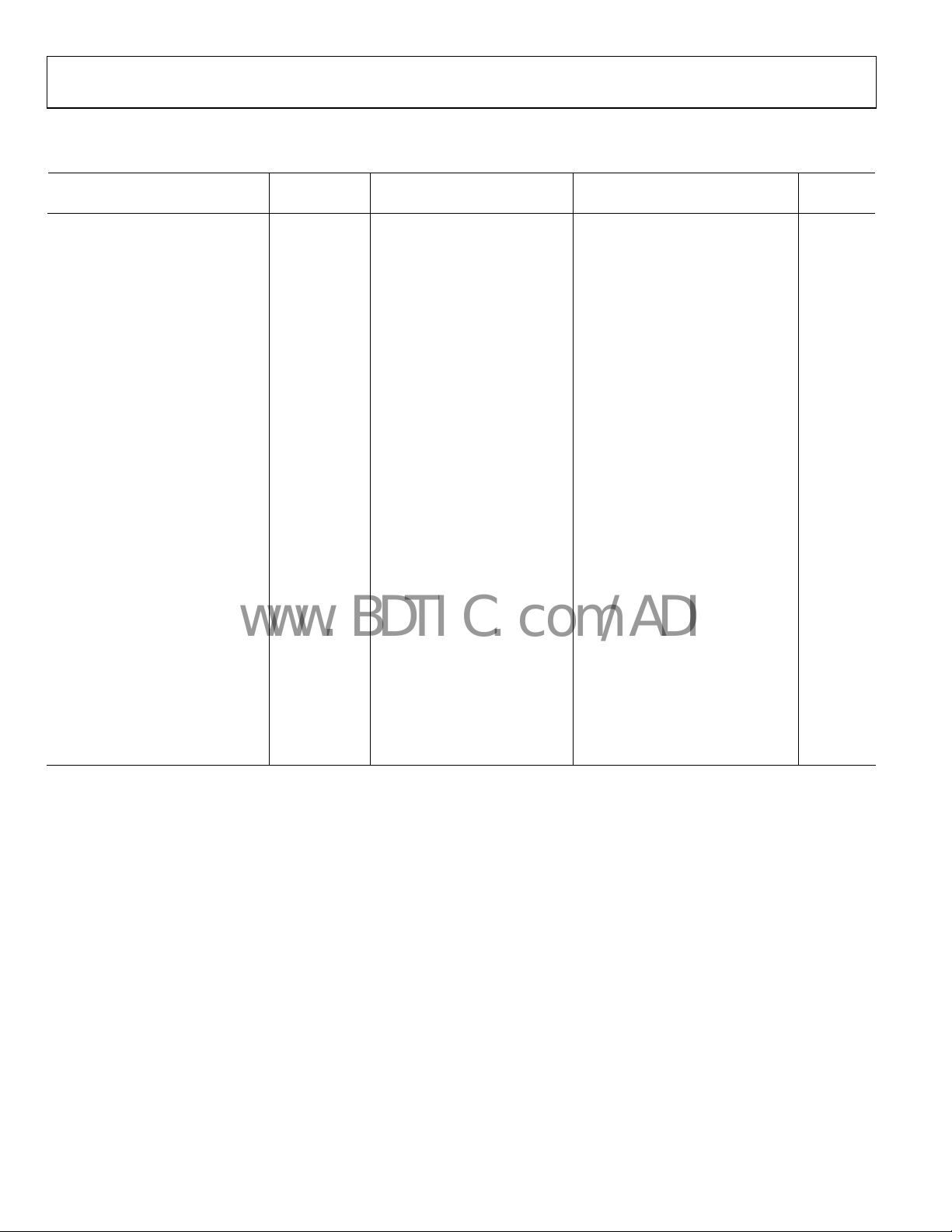

SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

VS = ±15 V, TA = 25°C, unless otherwise noted.

Table 1.

OP249A OP249F

Parameter Symbol Conditions

Min Typ Max Min Typ Max

Offset Voltage VOS 0.2 0.5 0.2 0.7 mV

Long Term Offset Voltage

1

VOS 0.8 1.0 mV

Offset Stability 1.5 1.5 µV/month

Input Bias Current IB VCM = 0 V, TA = 25°C 30 75 30 75 pA

Input Offset Current IOS VCM = 0 V, TA = 25°C 6 25 6 25 pA

Input Voltage Range

2

IVR 12.5 12.5 V

±11 ±11 V

−12.5 –12.5 V

Common-Mode Rejection CMR VCM = ±11 V 80 90 80 90 dB

Power-Supply Rejection Ratio PSRR VS = ± 4.5 V to ±18 V 12 31.6 12 50 µV/V

Large Signal Voltage Gain AVO VO = ±10 V, RL = 2 kΩ 1000 1400 500 1200 V/mV

Output Voltage Swing VO RL = 2 kΩ 12.5 12.5 V

±12.0 ±12.0 V

−12.5 –12.5 V

Short-Circuit Current Limit ISC

Output shorted to

ound

gr

36 36 mA

±20 ±50 ±20 ±50 mA

−33 –33 mA

Supply Current ISY No load, VO = 0 V 5.6 7.0 5.6 7.0 mA

Slew Rate SR RL = 2 kΩ, CL = 50 pF 18 22 18 22 V/µs

Gain Bandwidth Product

Settling Time tS 10 V step 0.01%

Phase Margin Θ

3

GBW 3.5 4.7 3.5 4.7 MHz

4

M

0 dB gain 55 55 Degrees

0.9 1.2 0.9 1.2 µs

Differential Input Impedance ZIN 1012||6 1012||6 Ω||pF

Open-Loop Output Resistance RO 35 35 Ω

Voltage Noise en p-p 0.1 Hz to 10 Hz 2 2 µV p-p

Voltage Noise Density en fO = 10 Hz 75 75 nV/√Hz

f

f

f

= 100 Hz 26 26 nV/√Hz

O

= 1 kHz 17 17 nV/√Hz

O

= 10 kHz 16 16 nV/√Hz

O

Current Noise Density in fO = 1 kHz 0.003 0.003 pA/√Hz

Voltage Supply Range VS ±4.5 ±15 ±18 ±4.5 ±15 ±18 V

1

Long-term offset voltage is guaranteed by a 1000 hour life test performed on three independent wafer lots at 125°C with LTPD of three.

2

Guaranteed by CMR test.

3

Guaranteed by design.

4

Settling time is sample tested.

Unit

Rev. F | Page 3 of 20

Page 4

OP249

www.BDTIC.com/ADI

VS = ±15 V, TA = 25°C, unless otherwise noted.

Table 2.

OP249G

Parameter Symbol Conditions

Min Typ Max

Offset Voltage VOS 0.4 2.0 mV

Input Bias Current IB VCM = 0 V, TA = 25°C 40 75 pA

Input Offset Current IOS VCM = 0 V TA = 25°C 10 25 pA

Input Voltage Range

1

IVR 12.5 V

±11 V

−12.0 V

Common-Mode Rejection CMR VCM = ±11 V 76 90 dB

Power Supply Rejection Ratio PSRR VS = ±4.5 V to ±18 V 12 50 µV/V

Large Signal Voltage Gain AVO VO = ±10 V; RL = 2 kΩ 500 1100 V/mV

Output Voltage Swing VO RL = 2 kΩ 12.5 V

±12.0 V

−12.5 V

Short-Circuit Current Limit ISC Output shorted to ground 36 mA

±20 ±50 mA

−33 mA

Supply Current ISY No load; VO = 0 V 5.6 7.0 mA

Slew Rate SR RL = 2 kΩ, CL = 50 pF 18 22 V/µs

Gain Bandwidth Product

2

GBW 4.7 MHz

Settling Time tS 10 V step 0.01% 0.9 1.2 µs

Phase Margin Θ

M

0 dB gain 55 Degree

Differential Input Impedance ZIN 1012||6 Ω||pF

Open-Loop Output Resistance RO 35 Ω

Voltage Noise en p-p 0.1 Hz to 10 Hz 2 V p-p

Voltage Noise Density en fO = 10 Hz 75 nV/√Hz

f

f

f

= 100 Hz 26 nV/√Hz

O

= 1 kHz 17 nV/√Hz

O

= 10 kHz 16 nV/√Hz

O

Current Noise Density in fO = 1 kHz 0.003 pA/√Hz

Voltage Supply Range VS ±4.5 ±15 ±18 V

1

Guaranteed by CMR test.

2

Guaranteed by design.

Unit

Rev. F | Page 4 of 20

Page 5

OP249

www.BDTIC.com/ADI

VS = ±15 V, −40°C ≤ TA ≤ +85°C for F grade and −55°C ≤ TA ≤ +125°C for A grade, unless otherwise noted.

Table 3.

OP249A OP249F

Parameter Symbol Conditions

Offset Voltage VOS 0.12 1.0 0.5 1.1 mV

Offset Voltage Temperature Coefficient TCVOS 1 5 2.2 6 V/°C

Input Bias Current

Input Offset Current

Input Voltage Range

1

1

2

IB 4 20 0.3 4.0 nA

IOS 0.04 4 0.02 1.2 nA

IVR 12.5 12.5 V

±11 ±11 V

−12.5 −12.5 V

Common-Mode Rejection CMR VCM = ±11 V 76 110 80 90 dB

Power Supply Rejection Ratio PSRR VS = ±4.5 V to ±18 V 5 50 7 100 V/V

Large Signal Voltage Gain AVO RL = 2 kΩ; VO = ±10 V 500 1400 250 1200 V/mV

Output Voltage Swing VO RL = 2 kΩ 12.5 12.5 V

±12 ±12 V

−12.5 −12.5 V

Supply Current ISY No load, VO = 0 V 5.6 7.0 5.6 7.0 mA

1

TA = 85°C for F grade; TA = 125°C for A grade.

2

Guaranteed by CMR test.

V

= ±15 V, −40°C ≤ TA ≤ +85°C, unless otherwise noted.

S

Min Typ Max Min Typ Max

Unit

Table 4.

OP249G

Parameter Symbol Conditions

Min Typ Max

Unit

Offset Voltage VOS 1.0 3.6 mV

Offset Voltage Temperature Coefficient TCV

Input Bias Current

Input Offset Current

Input Voltage Range

1

1

2

IB 0.5 4.5 nA

IOS 0.04 1.5 nA

IVR 12.5 V

OS

6 25 µV/°C

±11 V

−12.5 V

Common-Mode Rejection CMR VCM = ±11 V 76 95 dB

Power Supply Rejection Ratio PSRR VS = ±4.5 V to ±18 V 10 100 µV/V

Large Signal Voltage Gain AVO RL = 2 kΩ; VO = ±10 V 250 1200 V/mV

Output Voltage Swing VO RL = 2 kΩ 12.5 V

±12.0 V

−12.5 V

Supply Current ISY No load, VO = 0 V 5.6 7.0 mA

1

TA = 85°C.

2

Guaranteed by CMR test.

Rev. F | Page 5 of 20

Page 6

OP249

www.BDTIC.com/ADI

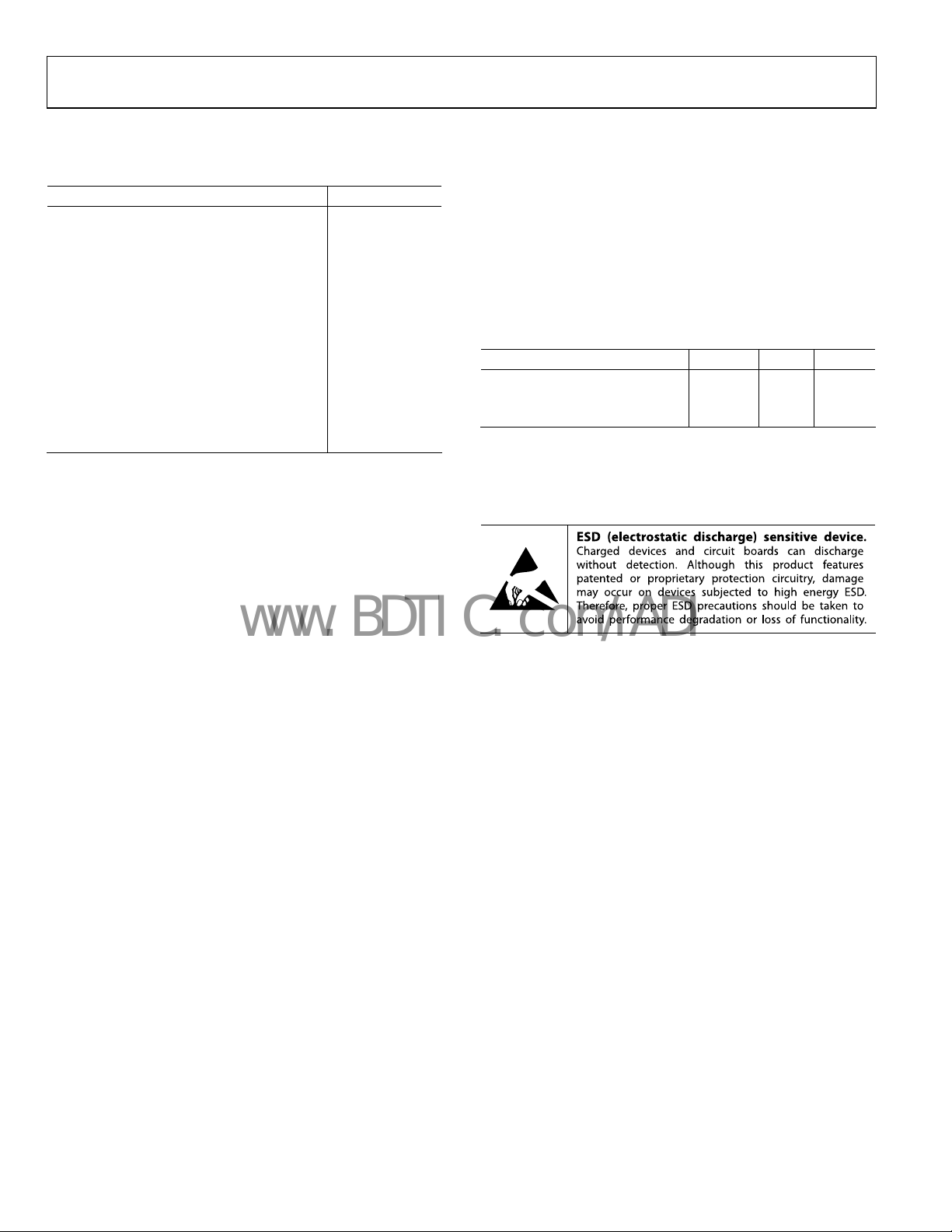

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter

Supply Voltage ±18 V

Input Voltage

Differential Input Voltage

Output Short-Circuit Duration Indefinite

Storage Temperature Range −65°C to +175°C

Operating Temperature Range

OP249A (Q) −55°C to +125°C

OP249F (Q) −40°C to +85°C

OP249G (N, R) −40°C to +85°C

Junction Temperature Range

OP249A (Q), OP249F (Q) −65°C to +175°C

OP249G (N, R) −65°C to +150°C

Lead Temperature (Soldering, 60 sec) 300°C

1

Absolute maximum ratings apply to packaged parts, unless otherwise noted.

2

For supply voltages less than ±18 V, the absolute maximum input voltage is

equal to the supply voltage.

1

2

2

Rating

±18 V

36 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 6. Thermal Resistance

Package Type θ

8-Lead CERDIP (Q) 134 12 °C/W

8-Lead PDIP (N) 96 37 °C/W

8-Lead SOIC (R) 150 41 °C/W

1

θJA is specified for worst-case mounting conditions, that is, θJA is specified for

device in socket for CERDIP and PDIP packages; θJA is specified for device

soldered to printed circuit board for SOIC package.

1

JA

θ

JC

Unit

ESD CAUTION

Rev. F | Page 6 of 20

Page 7

OP249

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

120

100

TA = 25°C

V

= ±15V

S

= 2kΩ

R

L

120

100

TA = 25°C

= ±15V

V

S

80

60

40

OPEN-LOOP GAIN (dB)

20

0

–20

1k 10k 100k 1M 10M 100M

GAIN

PHASE

Θm = 55

FREQUENCY (Hz)

Figure 6. Open-Loop Gain, Phase vs. Frequency

65

VS = ±15V

60

Θm

55

GBW

PHASE MARGIN (° C)

50

0

45

90

135

180

225

10

8

6

4

80

60

PHASE (°C)

0296-006

40

POWER SUPPLY REJECTI ON (dB)

20

0

10 100 1k 10k 100k 1M

FREQUENCY (Hz)

+PSRR

–PSRR

00296-009

Figure 9. Power Supply Rejection vs. Frequency

28

VS = ±15V

= 2kΩ

R

L

= 50pF

C

26

L

24

–SR

22

20

SLEW RATE (V/µs)

GAIN BANDWIDT H PRODUCT (MHz)

18

+SR

45

–75 –50 –25 0 25 50 75 100 125

TEMPERATURE ( °C)

2

Figure 7. Phase Margin, Gain Bandwidth Product vs. Temperature

140

TA = 25°C

V

= ±15V

S

120

100

80

60

40

COMMON-MO DE REJECTIO N (dB)

20

0

100 1k 10k 100k 1M 10M

FREQUENCY (Hz)

Figure 8. Common-Mode Rejection vs. Frequency

16

–75 –50 –25 0 25 50 75 100 125

0296-007

TEMPERATURE ( °C)

00296-010

Figure 10. Slew Rate vs. Temperature

28

TA = 25°C

= ±15V

V

S

= 2kΩ

R

L

26

24

22

20

SLEW RATE (V/µs)

18

00296-008

16

0 0.2 0.4 0.6 0.8 1.0

DIFFERENTIAL INPUT VOLTAGE (V)

Figure 11. Slew Rate vs. Di

fferential Input Voltage

00296-011

Rev. F | Page 7 of 20

Page 8

OP249

www.BDTIC.com/ADI

35

TA = 25°C

= ±15V

V

S

30

25

NEGATIVE

20

POSITIVE

15

SLEW RATE (V/µs)

10

5

0 100 200 300 400 500

CAPACITIVE L OAD (pF)

Figure 12. Slew Rate vs. Capacitive Load

10

TA = 25°C

V

= ±15V

8

S

= 1

A

VCL

6

4

2

0

–2

–4

OUTPUT STEP SIZE (V)

–6

–8

–10

0 200 400 600 800 1000

0.1%

0.01%

0.01%

0.1%

SETTLING TIME (ns)

Figure 13. Step Size vs. Settling Time

100

TA = 25°C

V

= ±15V

S

80

60

00296-012

00296-013

0.01

0.001

20 100 1k 10k 20k

TA = 25°C

V

= ±15V

S

V

= 10V p-p

O

R

= 10kΩ

L

A

= 1

V

Figure 15. Distortion vs. Frequency

0.01

0.001

20 100 1k 10k 20k

TA = 25°C

= ±15V

V

S

= 10V p-p

V

O

= 2kΩ

R

L

= 1

A

V

Figure 16. Distortion vs. Frequency

0.01

TA = 25°C

= ±15V

V

S

= 10V p-p

V

O

= 600Ω

R

L

= 1

A

V

00296-015

00296-016

40

20

VOLTAGE NOISE DENSI TY (nV / Hz)

0

0 100 1k 10k

FREQUENCY (Hz)

00296-014

Figure 14. Voltage Noise Density vs. Frequency

Rev. F | Page 8 of 20

0.001

20 100 1k 10k 20k

Figure 17. Distortion vs. Frequency

00296-017

Page 9

OP249

www.BDTIC.com/ADI

0.1

0.01

20 100 1k 10k 20k

TA = 25°C

= ±15V

V

S

= 10V p-p

V

O

= 10kΩ

R

L

= 1

A

V

Figure 18. Distortion vs. Frequency

0.1

0.01

20 100 1k 10k 20k

TA = 25°C

= ±15V

V

S

= 10V p-p

V

O

= 2kΩ

R

L

= 10

A

V

Figure 19. Distortion vs. Frequency

0.1

TA = 25°C

= ±15V

V

S

= 10V p-p

V

O

= 600kΩ

R

L

= 10

A

V

500mV 1s

+1µV

–1µV

00296-018

BANDWIDTH (0.1Hz TO 10Hz)

= 25°C, VS = ±15V

T

A

00296-021

Figure 21. Low Frequency Noise

60

50

A

= 100

VCL

40

30

A

= 10

VCL

20

A

= 5

VCL

10

CLOSED-LOOP GAIN (dB)

0

A

= 1

VCL

–10

–20

00296-019

1k 10k 100k 1M 10M 100M

FREQUENCY (Hz)

TA = 25°C

= ±15V

V

S

00296-022

Figure 22. Closed-Loop Gain vs. Frequency

50

TA = 25°C

= ±15V

V

S

40

30

A

= 1

VCL

0.01

20 100 1k 10k 20k

00296-020

Figure 20. Distortion vs. Frequency

Rev. F | Page 9 of 20

20

IMPEDANCE (Ω)

10

0

100 1k 10k 100k 1M 10M

A

= 100

VCL

FREQUENCY (Hz)

Figure 23. Closed-Loop Outpu

A

= 10

VCL

t Impedance vs. Frequency

00296-023

Page 10

OP249

www.BDTIC.com/ADI

30

25

20

15

AD8512

AD712

1M 10M

OUTPUT VOLTAGE (V p-p)

10

5

0

1k

OP249

FREQUENCY (Hz)

Figure 24. Output Voltage vs. Frequency

90

VS = ±15V

= 2kΩ

R

80

L

= 100mV p-p

V

IN

70

60

50

40

OVERSHOOT (%)

30

20

10

0

0 100 200 300 400 500

A

= 1

VCL

NEGATIVE EDGE

LOAD CAPACITANCE (pF)

A

= 1

VCL

POSITIVE EDGE

A

= 5

VCL

Figure 25. Small Overshoot vs. Load Capacitance

16

TA = 25°C

V

= ±15V

S

14

12

10

8

6

4

MAXIMUM OUTPUT SWING (V)

2

0

100 1k 10k

+V

= |–V

OHM

OHM

LOAD RESISTANCE (Ω)

|

Figure 26. Maximum Output Voltage Swing vs. Load Resistance

20

TA = 25°C

= 2kΩ

R

L

15

10

5

0

–5

–10

OUTPUT VOLTAGE SWING (V)

–15

00296-024

–20

0 ±5 ±10 ±15 ±20

SUPPLY VOLTAGE (V)

00296-027

Figure 27. Output Voltage Swing vs. Supply Voltage

6.0

VS = ±15V

NO LOA D

5.8

5.6

SUPPLY CURRENT (mA)

5.4

00296-025

5.2

–75 –50 –25 0 25 50 75 100 125

TEMPERATURE (° C)

00296-028

Figure 28. Supply Current vs. Temperature

6.0

5.8

5.6

5.4

SUPPLY CURRENT (mA)

5.2

00296-026

5.0

TA = +125°C

TA = –55°C

0 5 10 15 20

SUPPLY VOLTAGE (V)

TA = +25°C

00296-029

Figure 29. Supply Current vs. Supply Voltage

Rev. F | Page 10 of 20

Page 11

OP249

www.BDTIC.com/ADI

180

TA = 25°C

V

= ±15V

160

S

415 × OP249

(830 OP AMPS)

140

120

100

UNITS

80

60

40

20

0

–1000 –800 –600 –400 –200 0 200 400 600 800 1000

(µV)

V

OS

Figure 30. V

Distribution (N-8)

OS

00296-030

10k

VS = ±15V

= 0V

V

CM

1k

100

10

INPUT BIAS CURRENT (pA)

1

–75 –50 –25 0 25 50 75 100 125

TEMPERATURE (° C)

Figure 33. Input Bias Current vs. Temperature

00296-033

300

270

240

210

180

150

UNITS

120

90

60

30

0

024681012141618202224

(µV/°C)

TCV

OS

Figure 31. TCV

Distribution (N-8)

OS

VS = ±15V

–40°C TO +85°C

(830 OP AMPS)

50

VS = ±15V

40

30

20

OFFSET VOLTAGE (µV)

10

4

10

TA = 25°C

V

= ±15V

S

3

10

2

10

BIAS CURRENT (pA)

1

10

00296-031

0

10

–15 –10 –5 0 5 10 15

COMMON-MODE VOLTAGE (V)

00296-034

Figure 34. Bias Current vs. Common-Mode Voltage

50

TA = 25°C

= ±15V

V

S

40

30

20

INPUT BIAS CURRENT (pA)

10

0

01234

TIME AFT ER POWER APPLIED (M inutes)

00296-032

5

Figure 32. Offset Voltage Warm-Up Drift

Rev. F | Page 11 of 20

0

02468

TIME AFTER POWE R APPLIED (M inutes)

Figure 35. Bias Current Warm-Up Drift

00296-035

10

Page 12

OP249

www.BDTIC.com/ADI

80

TA = 25°C

= 0V

V

CM

60

40

20

INPUT OFFSET CURRENT ( pA)

0

–75 –50 –25 0 25 50 75 100 125

TEMPERATURE (° C)

Figure 36. Input Offset Current vs. Temperature

12000

VS = ±15V

10000

8000

6000

4000

OPEN-LOOP GAIN (V/mV)

2000

RL = 10kΩ

RL = 2kΩ

00296-036

80

SOURCE

60

40

20

SHORT-CIRCUIT OUTPUT CURRENT (mA)

0

–75 –50 –25 0 25 50 75 100 125

Figure 38. Short-Circuit Output Cu

SINK

TEMPERATURE ( °C)

rrent vs. Junction Temperature

VS = ±15V

00296-038

0

–75 –50 –25 0 25 50 75 100 125

TEMPERATURE ( °C)

00296-037

Figure 37. Open-Loop Gain vs. Temperature

Rev. F | Page 12 of 20

Page 13

OP249

V

www.BDTIC.com/ADI

APPLICATIONS INFORMATION

+

+IN

V

–IN

Figure 39. Simplified Schematic (1/2 OP249)

2

1/2

+18V

8

1/2

4

–18V

1

5kΩ

7

5kΩ

0296-040

+3V

+3V

OP249

3

6

OP249

5

Figure 40. Burn-In Circuit

The OP249 represents a reliable JFET amplifier design,

featuring an excellent combination of dc precision and high

speed. A rugged output stage provides the ability to drive a

600 Ω load and still maintain a clean ac response. The OP249

features a large signal response that is more linear and symmetric

than previously available JFET input amplifiers.

mpares the large signal response of the OP249 to other

co

Figure 41

industry-standard dual JFET amplifiers.

Typically, the slewing performance of the JFET amplifier is

pecified as a number of V/μs. There is no discussion on the

s

quality, that is, linearity and symmetry of the slewing response.

OUT

V–

100

90

10

0%

1µs5V

A) OP249

100

90

0296-039

10

0%

1µs5V

B) LT1057

100

90

10

0%

1µs5V

C) AD712

00296-041

Figure 41. Large-Signal Transient Response,

= 1, VIN = 20 V p-p, ZL = 2 kΩ//200 pF, VS = ±15 V

A

V

The OP249 was carefully designed to provide symmetrically

matched slew characteristics in both the negative and positive

directions, even when driving a large output load.

The slewing limitation of the amplifier determines the

max

imum frequency at which a sinusoidal output can be

obtained without significant distortion. However, it is important

to note that the nonsymmetric slewing typical of previously

available JFET amplifiers adds a higher series of harmonic

energy content to the resulting response—and an additional

dc output component. Examples of potential problems of

nonsymmetric slewing behavior can be in audio amplifier

applications, where a natural low distortion sound quality is

desired and in servo or signal processing systems where a net

dc offset cannot be tolerated. The linear and symmetric slewing

feature of the OP249 makes it an ideal choice for applications

that exceed the full power bandwidth range of the amplifier.

Rev. F | Page 13 of 20

Page 14

OP249

5

V

www.BDTIC.com/ADI

100

90

10

0%

50mV 1µs

00296-042

Figure 42. Small-Signal Transient Response,

= 1, ZL = 2 kΩ||100 pF, No Compensation, VS = ±15 V

A

V

As with most JFET input amplifiers, the output of the OP249

can undergo phase inversion if either input exceeds the specified

input voltage range. Phase inversion does not damage the

amplifier, nor does it cause an internal latch-up condition.

Supply decoupling should be used to overcome inductance and

r

esistance associated with supply lines to the amplifier. A 0.1 μF

and a 10 μF capacitor should be placed between each supply pin

and ground.

OPEN-LOOP GAIN LINEARITY

The OP249 has both an extremely high open-loop gain of

1 kV/mV minimum and constant gain linearity, which enhances its

dc precision and provides superb accuracy in high closed-loop

gain applications. Figure 43 illustrates the typical open-loop

ga

in linearity—high gain accuracy is assured, even when

driving a 600 Ω load.

OFFSET VOLTAGE ADJUSTMENT

The inherent low offset voltage of the OP249 makes offset

adjustments unnecessary in most applications. However, where

a lower offset error is required, balancing can be performed

with simple external circuitry, as shown in Figure 44 and Figure 45.

VERTICAL 50µV/DIV

INPUT VARIAT ION

R4

0kΩ

+V

V

R5

–V

IN

R1

200kΩ

R3

31Ω

1/2

OP249

R2

VOS ADJUST RANGE = ±V

V

OUT

R2

R1

00296-044

Figure 44. Offset Adjustment for Inverting Amplifier Configuration

+

50kΩ

V

R1

200kΩ

R3

–V

IN

33Ω

R4

R2

Figure 45. Offset Adjustment for Non

R5

1/2

OP249

V

ADJUST RANGE = ±V

OS

V

OUT

GAIN = = 1 +

V

IN

R5

1 +

IF R2 << R4

=

R4

R5

R4 + R2

V

OUT

R2

R1

inverting Amplifier Configuration

00296-045

In Figure 44, the offset adjustment is made by supplying a small

voltage at the noninverting input of the amplifier. Resistors R1

and R2 attenuate the potentiometer voltage, providing a ±2.5 mV

(with V

= ±15 V) adjustment range, referred to the input.

S

Figure 45 shows the offset adjustment for the noninverting

a

mplifier configuration, also providing a ±2.5 mV adjustment

range. As shown in the equations in

eater than R2, a resulting closed-loop gain error must be

gr

Figure 45, if R4 is not much

accounted for.

SETTLING TIME

The settling time is the time between when the input signal begins

to change and when the output permanently enters a prescribed

error band. The error bands on the output are 5 mV and 0.5 mV,

respectively, for 0.1% and 0.01% accuracy.

Figure 46 shows the settling time of the OP249, which is typically

870 n

s. Moreover, problems in settling response, such as thermal

tails and long-term ringing, are nonexistent.

870ns

HORIZONT AL 5V/DIV

OUTPUT CHARGE

00296-043

Figure 43. Open-Loop Gain Linearity; Variation in Open-Loop Gain Results in

rrors in High Closed-Loop Gain Circuits; R

E

= 600 Ω, VS = ±15 V

L

Rev. F | Page 14 of 20

100

90

10

0%

500ns10mV

Figure 46. Settling Characteristics of the OP249 to 0.01%

00296-046

Page 15

OP249

V

www.BDTIC.com/ADI

DAC OUTPUT AMPLIFIER

Unity-gain stability, a low offset voltage of 300 μV typical, and a

fast settling time of 870 ns to 0.01%, makes the OP249 an ideal

amplifier for fast DACs.

For CMOS DAC applications, the low offset voltage of the

P249 results in excellent linearity performance. CMOS DACs,

O

such as the PM7545, typically have a code-dependent output

resistance variation between 11 kΩ and 33 kΩ. The change in

output resistance, in conjunction with the 11 kΩ feedback resistor,

results in a noise gain change, which causes variations in the

offset error, increasing linearity errors. The OP249 features

low offset voltage error, minimizing this effect and maintaining

12-bit linearity performance over the full-scale range of the

converter.

DD

0.1µF

18 20

V

DD

REFERENCE

OR V

IN

Figure 47. Fast Settling and Low Offset Error of the OP249 Enhances CMOS DAC Performance—Unipolar Operation

REFERENCE

OR V

IN

500Ω

19

Figure 48. Fast Settling and Low Offset Error of the OP249 Enhances CMOS DAC Performance—Bipolar Operation

19

500Ω

V

DD

0.1µF

18 20

V

DD

V

PM7545

REF

DB11 TO DB

12

DATA INPUT

V

PM7545

REF

DB11 TO DB

12

DATA INPUT

R

FB

OUT

AGND

DGND

0

3

0

75Ω

1

R

FB

DGND

3

1

2

Because the DAC output capacitance appears at the inputs of

he op amp, it is essential that the amplifier be adequately

t

compensated. Compensation increases the phase margin and

ensures an optimal overall settling response. The required lead

compensation is achieved with Capacitor C in

75Ω

C

+15V

1

OUT

1

23

AGND

C

+15V

33pF

2

1/2

OP249

3

R4

20kΩ

1%

8

33pF

2

0.1µF

1

1/2

OP249

4

–15V

8

R3

10kΩ

1%

0.1µF

1

0.1µF

5

1/2

OP249

6

–15V

10kΩ

4

1%

R5

V

OUT

7

0.1µF

00296-047

V

OUT

00296-048

Figure 48.

Rev. F | Page 15 of 20

Page 16

OP249

V

T

*

www.BDTIC.com/ADI

100

90

10

0%

500mV 1µs

RESPONSE IS GROSSLY UNDERDAMPED,

AND EXHIBITS RI NGING

A

4µs

C = 5pF

Figure 49. Effect of Altering Compensation from Circuit in Figure 47—PM7545 CMOS DAC with 1/2 OP249, Unipolar Operation;

Crit

ically Damped Response Is Obtained with C ≈ 33 pF

Figure 49 illustrates the effect of altering the compensation on

the output response of the circuit in Figure 47. Compensation is

r

equired to address the combined effect of the output capacitance

of the DAC, the input capacitance of the op amp, and any stray

capacitance. Slight adjustments to the compensation capacitor

may be required to optimize settling response for any given

application.

The settling time of the combination of the current output DAC

a

nd the op amp can be approximated by

()( )

+=

SSS

22

AMPtDACtTOTALt

The actual overall settling time is affected by the noise gain of

t

he amplifier, the applied compensation, and the equivalent

input capacitance at the input of the amplifier.

DISSCUSION ON DRIVING ADCs

Settling characteristics of op amps also include the ability of the

amplifier to recover, that is, settle, from a transient current output

load condition. An example of this includes an op amp driving

the input from a SAR-type ADC. Although the comparison

point of the converter is usually diode clamped, the input swing

of plus-and-minus a diode drop still gives rise to a significant

modulation of input current. If the closed-loop output impedance

is low enough and bandwidth of the amplifier is sufficiently

large, the output settles before the converter makes a comparison

decision, which prevents linearity errors or missing codes.

B

4µs

100

90

10

0%

500mV 1µs

FAST RISE T IME CHARACTERI STICS, BUT AT EXPENSE

OF SLIG HT PEAKING I N RESPONSE

C = 15pF

00296-049

Figure 50 shows a settling measurement circuit for evaluating

r

ecovery from an output current transient. An output disturbing

current generator provides the transient change in output load

current of 1 mA.

+15

0.1µF

8

3

1/2

4

–15V

300pF

1.5kΩ

1

0.1µF

2N2907

220Ω

*

1kΩ

0.01µF

*

1kΩ

ΔI

OUT

2N3904

10µF

+

0.47µF

V

REF

ance Test Fixture

=

OP249

2

+15V

TL INPUT

DECOUPLE CLO SE TOG ETHER ON G ROUND

PLANE WITH SHORT LEAD LENGTHS.

+15V

1N4148

1.8kΩ

0.1µF

Figure 50. Transient Output Imped

7A13 PLUG-I N

7A13 PLUG-I N

|

|V

REF

1kΩ

00296-050

Rev. F | Page 16 of 20

Page 17

OP249

V

V

–15V

www.BDTIC.com/ADI

As seen in Figure 51, the OP249 has an extremely fast recovery

of 247 ns (to 0.01%) for a 1 mA load transient. The performance

makes it an ideal amplifier for data acquisition systems.

The combination of high speed and excellent dc performance of

th

e OP249 makes it an ideal amplifier for 12-bit data acquisition

systems. Examining the circuit in

P249 provides a stable −5 V reference voltage for the V

O

Figure 53, one amplifier in the

input of

REF

the ADC912. The other amplifier in the OP249 performs high

speed buffering of the input of the ADC.

By examining the worst-case transient voltage error at the A

IN

node of the ADC, it is shown that the OP249 recovers in less

than 100 ns (see

wide bandwid

100

90

Figure 52). The fast recovery is due to both the

th and low dc output impedance of the OP249.

247.4ns

5mV

100

90

10

0%

100ns

Figure 52. Worst-Case Transient Voltage at Analog In Occurs at

the Ha

lf-Scale Point of the ADC; the OP249 Buffers the

ADC Input from Figure 53 and Recovers in <100 ns

00296-052

10

0%

100ns2V2mV

00296-051

Figure 51. Transient Recovery Time of the OP249 from

a 1

mA Load Transient to 0.01%

A

2

IN

V

–5V

REFIN

10µF|| 0.1µF

+5

24 23

ADC912A

AGND

DGND HBEN

10µF||0 .1µF10µF||0.1µF

CLK IN

BUSY

RD

CS

20

17

22

2119123

00296-053

+15

0.1µF

ANALOG

INPUT

+15V

0.1µF

2

V

IN

REF02

V

OUT

GND

4

6

3

OP249

2

0.1µF

5

1/2

OP249

6

1/2

–15V

8

1

4

0.1µF

1

10Ω

1

Figure 53. OP249 Dual Amplifiers Provide Both Stable −5 V Reference Input and Buffers Input to ADC912A

Rev. F | Page 17 of 20

Page 18

OP249

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.400 (10.16)

0.365 (9.27)

0.355 (9.02)

0.210 (5.33)

MAX

0.150 (3.81)

0.130 (3.30)

0.115 (2.92)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

8

1

0.070 (1.78)

0.060 (1.52)

0.045 (1.14)

0.100 (2.54)

BSC

5

4

0.280 (7. 11)

0.250 (6.35)

0.240 (6.10)

0.015

(0.38)

MIN

SEATING

PLANE

0.005 (0.13)

MIN

0.060 (1.52)

MAX

0.015 (0.38)

GAUGE

PLANE

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.430 (10.92)

MAX

0.195 (4.95)

0.130 (3.30)

0.115 (2.92)

0.014 (0.36)

0.010 (0.25)

0.008 (0.20)

CONTROLLING DIMENSIONSARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ON LY AND ARE NOT APPRO PRIATE FOR USE IN DESIGN.

CORNER LEADS MAY BE CONFIGURED AS WHOLE OR HALF LEADS.

COMPLIANT TO JEDEC STANDARDS MS-001

070606-A

Figure 54. 8-Lead Plastic Dual In-Line Package [PDIP]

Nar

row Body

(N-8)

Dimensions shown in inches and (millimeters)

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLL ING DIMENSI ONS ARE IN MILLIMETERS; INCH DI MENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRI ATE FOR USE IN DES IGN.

85

1

1.27 (0.0500)

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012-A A

BSC

6.20 (0.2441)

5.80 (0.2284)

4

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

8°

0°

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

1.27 (0.0500)

0.40 (0.0157)

45°

012407-A

Figure 55. 8-Lead Standard Small Outline Package [SOIC_N]

Nar

row Body

(R-8)

Dimensions shown in millimeters and (inches)

Rev. F | Page 18 of 20

Page 19

OP249

www.BDTIC.com/ADI

0.005 (0.13)

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

0.055 (1.40)

MIN

14

0.100 (2.54) BSC

0.405 (10.29) MAX

MAX

0.070 (1.78)

0.030 (0.76)

58

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150 (3.81)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15°

0°

0.015 (0.38)

0.008 (0.20)

Figure 56. 8-Lead Ceramic Dual In-Line Package [CERDIP]

(Q-8)

Dim

ensions shown in inches and (millimeters)

ORDERING GUIDE

Model Temperature Range Package Description Package Option

OP249AZ −55°C to +125°C 8-Lead CERDIP Q-8

OP249FZ −40°C to +85°C 8-Lead CERDIP Q-8

OP249GP −40°C to +85°C 8-Lead PDIP N-8

OP249GPZ

OP249GS −40°C to +85°C 8-Lead SOIC_N R-8

OP249GS-REEL −40°C to +85°C 8-Lead SOIC_N R-8

OP249GS-REEL7 −40°C to +85°C 8-Lead SOIC_N R-8

OP249GSZ

OP249GSZ-REEL

OP249GSZ-REEL7

1

Z = RoHS Compliant Part.

For Military processed devices, see the standard microcircuit drawings (SMD) available at www.dscc.dla.mil/programs/milspec/default.asp.

1

1

1

1

−40°C to +85°C 8-Lead PDIP N-8

−40°C to +85°C 8-Lead SOIC_N R-8

−40°C to +85°C 8-Lead SOIC_N R-8

−40°C to +85°C 8-Lead SOIC_N R-8

Table 7.

SMD Part Number Analog Devices, Inc. Equivalent

5962-9151901M2A OP249ARCMDA

5962-9151901MPA OP249AZMDA

Rev. F | Page 19 of 20

Page 20

OP249

www.BDTIC.com/ADI

NOTES

©2007 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D00296-0-5/07(F)

Rev. F | Page 20 of 20

Loading...

Loading...