Page 1

Dual, Low Noise, Low Offset

a

Instrumentation Operational Amplifier

FEATURES

Excellent Individual Amplifier Parameters

Low VOS, 80 V Max

Offset Voltage Match, 80 V Max

Offset Voltage Match vs. Temperature, 1 V/ⴗC Max

Stable V

vs. Time, 1 V/MO Max

OS

Low Voltage Noise, 3.9 nV/÷Hz Max

Fast, 2.8 V/s Typ

High Gain, 1.8 Million Typ

High Channel Separation, 154 dB Typ

GENERAL DESCRIPTION

The OP227 is the first dual amplifier to offer a combination of

low offset, low noise, high speed, and guaranteed amplifier matching

characteristics in one device. The OP227, with a VOS match of

25 mV typical, a TCVOS match of 0.3 mV/∞C typical and a 1/f corner

of only 2.7 Hz is an excellent choice for precision low noise designs.

These dc characteristics, coupled with a slew rate

typical and a small-signal bandwidth of 8 MHz typical,

of 2.8 V/ms

allow the

designer to achieve ac performance previously unattainable with

op amp based instrumentation designs.

When used in a three op amp instrumentation configuration, the

OP227 can achieve a CMRR in excess of 100 dB at 10 kHz. In

addition, this device has an open-loop gain of 1.5 M typical with

a 1 kW load. The OP227 also features an I

of ± 10 nA typical,

B

an IOS of 7 nA typical, and guaranteed matching of input currents

between amplifiers. These outstanding input current specifications

are realized through the use of a unique input current cancellation

circuit which typically holds IB and IOS to ± 20 nA and 15 nA

respectively over the full military temperature range.

Other sources of input referred errors, such as PSRR and CMRR,

are reduced by factors in excess of 120 dB for the individual

amplifiers. DC stability is assured by a long-term drift application

of 1.0 mV/month.

Matching between channels is provided on all critical parameters including offset voltage, tracking of offset voltage versus

temperature, noninverting bias current, CMRR, and power

supply rejection ratio. This unique dual amplifier allows the

elimination of external components for offset nulling and

frequency compensation.

PIN CONNECTIONS

–IN (A)

+IN (A)

V– (B)

OUT (B)

V+ (B)

1

2

3

A

4

5

6

7

NULL (A)

NULL (A)

NOTE

DEVICE MAY BE OPERATED EVEN IF INSERTION

1.

IS REVERSED; THIS IS DUE TO INHERENT SYMMETRY

OF PIN LOCATIONS OF AMPLIFIERS A AND B

V–(A) AND V–(B) ARE INTERNALLY CONNECTED VIA

2.

SUBSTRATE RESISTANCE

14

V+ (A)

13

OUT (A)

12

V– (A)

11

+IN (B)

B

10

–IN (B)

9

NULL (B)

8

NULL (B)

OP227

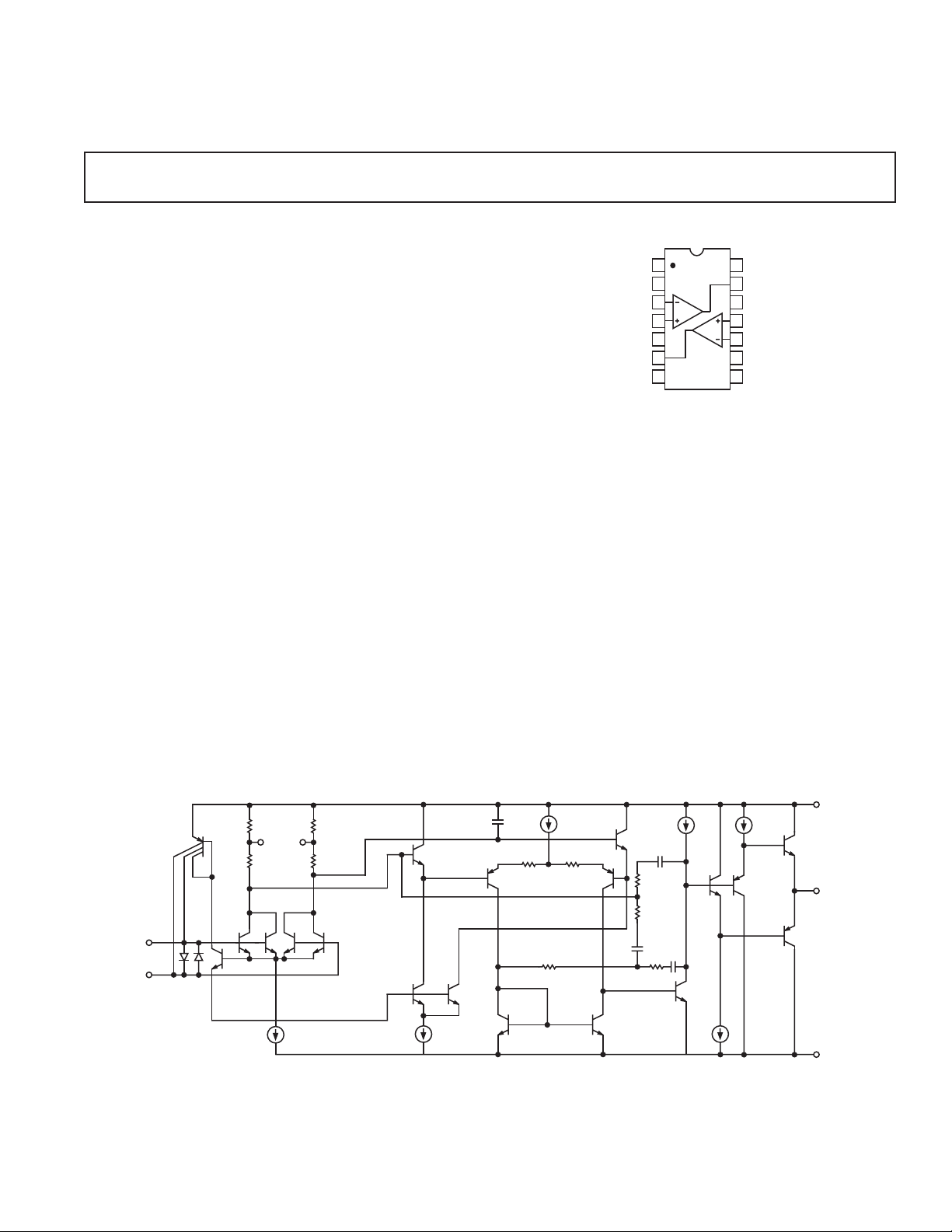

SIMPLIFIED SCHEMATIC

NON

INVERTING

INPUT (+)

INVERTING

INPUT (–)

Q6

Q3

*

R1 AND R2 ARE PREMATURELY ADJUSTED AT WAFER TEST FOR MINIMUM OFFSET VOLTAGE.

R3

NULL

*

R1

Q1A Q1B Q2B Q2A

R4

R2

*

Q21

Q11 Q12

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

V+

C2

Q22

R23 R24

Q23 Q24

R5

Q27

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Q28

C1

R9

R12

C3

R11

Q20 Q19

C4

Q26

Q46

OUTPUT

Q45

V-

Page 2

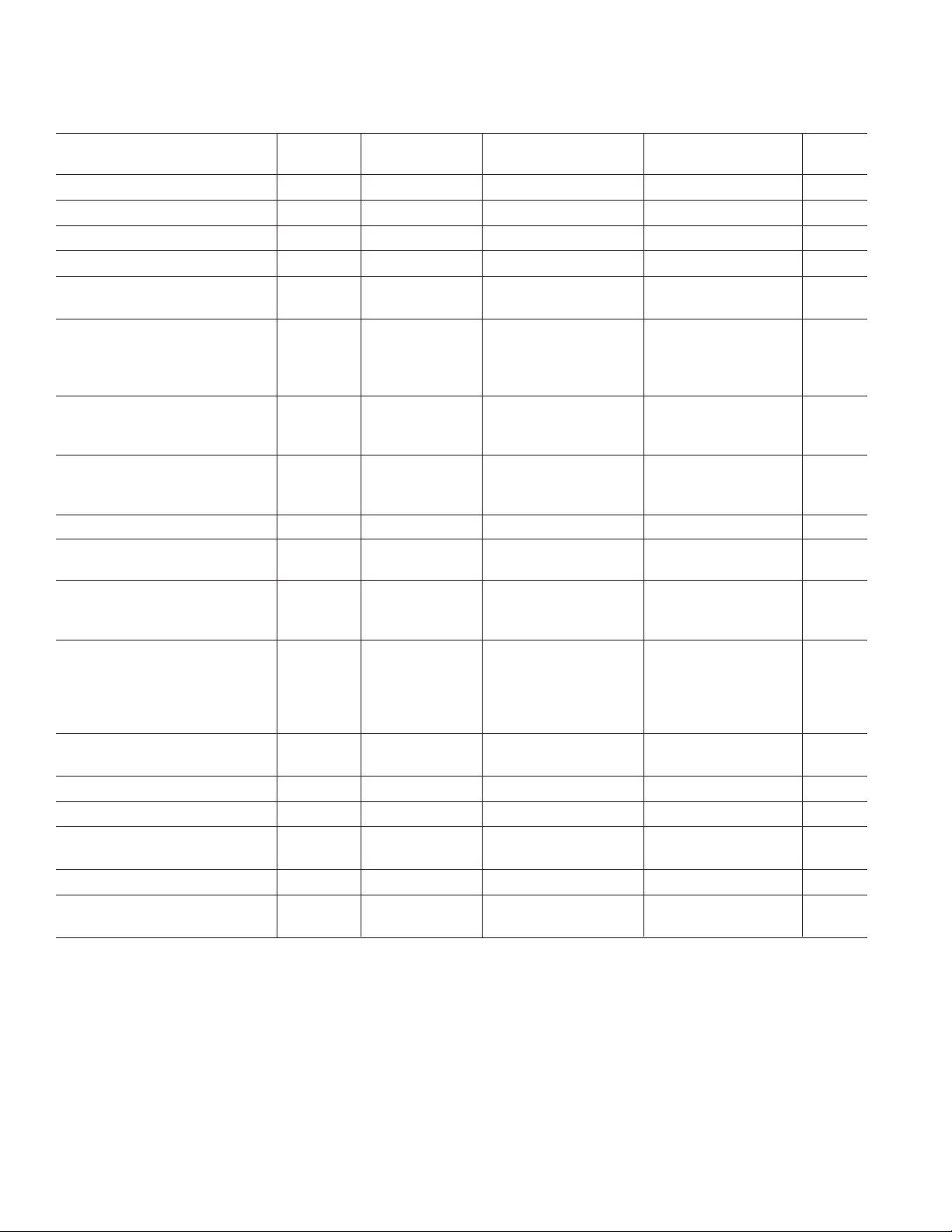

OP227–SPECIFICATIONS

Individual Amplifier Characteristics

(VS = ⴞ15 V, TA = 25ⴗC, unless otherwise noted.)

OP227E OP227G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

INPUT OFFSET VOLTAGE V

OS

LONG-TERM VOS STABILITY VOS/Time Notes 2,4 0.2 1.0 0.4 2.0 mV/M

INPUT OFFSET CURRENT I

INPUT BIAS CURRENT I

INPUT NOISE VOLTAGE e

OS

B

n p-p

Note 1 20 80 60 180 mV

O

735 1275nA

± 10 ± 40 ± 15 ± 80 nA

0.1 Hz to 10 Hz 0.08 0.20 0.09 0.28 mV p-p

Notes 3,5

INPUT NOISE VOLTAGE

DENSITY e

INPUT NOISE DENSITY i

n

fO = 10 Hz

f

= 30 Hz

O

fO = 1000 Hz

n

fO = 10 Hz

= 30 Hz

f

O

fO = 1000 Hz

3

3

3, 6

3, 6

3

3, 6

3.5 6.0 3.8 9.0 nV/Hz

3.1 4.7 3.3 5.9 nV/Hz

3.0 3.9 3.2 4.6 nV/Hz

1.7 4.5 1.7 pA/Hz

1.0 2.5 1.0 pA/Hz

0.4 0.7 0.4 0.7 pA/Hz

INPUT RESISTANCE

Differential Mode R

Common Mode R

IN

INCM

Note 7 1.3 6 0.7 4 MW

32GW

INPUT VOLTAGE RANGE IVR ± 11.0 ± 12.3 ± 11.0 ± 12.3 V

COMMON-MODE

REJECTION RATIO CMRR VCM = ± 11 V 114 126 100 120 dB

POWER SUPPLY

REJECTION RATIO PSRR VS = ± 4 V to

± 18 V 1 10 2 20 mV/V

LARGE-SIGNAL

VOLTAGE GAIN A

VO

RL ⱖ 2 kW,

V

= ± 10 V 1000 1800 700 1500 V/mV

O

ⱖ 600 kW,

R

L

VO = ± 10 V 800 1500 600 1500 V/mV

OUTPUT VOLTAGE SWING V

O

RL ⱖ 2 kW±12.0 ± 13.8 ± 11.5 ± 13.5 V

RL ⱖ 600 W±10.0 ± 11.5 ± 10.0 ± 11.5 V

SLEW RATE SR RL ⱖ 2 kW

4

1.7 2.8 1.7 2.8 V/ms

GAIN BANDWIDTH PROD. GBW Note 4 5 8 5 8 MHz

OPEN-LOOP OUTPUT

RESISTANCE R

POWER CONSUMPTION P

O

d

VO = 0, IO = 0 70 70 W

Each Amplifier 90 140 100 170 mW

OFFSET ADJUSTMENT

RANGE Rp = 10 kW±4 ± 4mV

NOTES

1

Input offset voltage measurements are performed by automated test equipment approximately 0.5 seconds after application of power. E Grade specifications are

guaranteed fully warmed up.

2

Long term input offset voltage stability refers to the average trend line of VOS vs. time over extended periods after the first 30 days of operation. Excluding the initial

hour of operation, changes in VOS during the first 30 days are typically 2.5 mV. Refer to the Typical Performance Curve.

3

Sample tested.

4

Parameter is guaranteed by design.

5

See test circuit and frequency response curve for 0.1 Hz to 10 Hz tester.

6

See test circuit for current noise measurement.

7

Guaranteed by input bias current.

Specifications subject to change without notice.

–2–

REV. A

Page 3

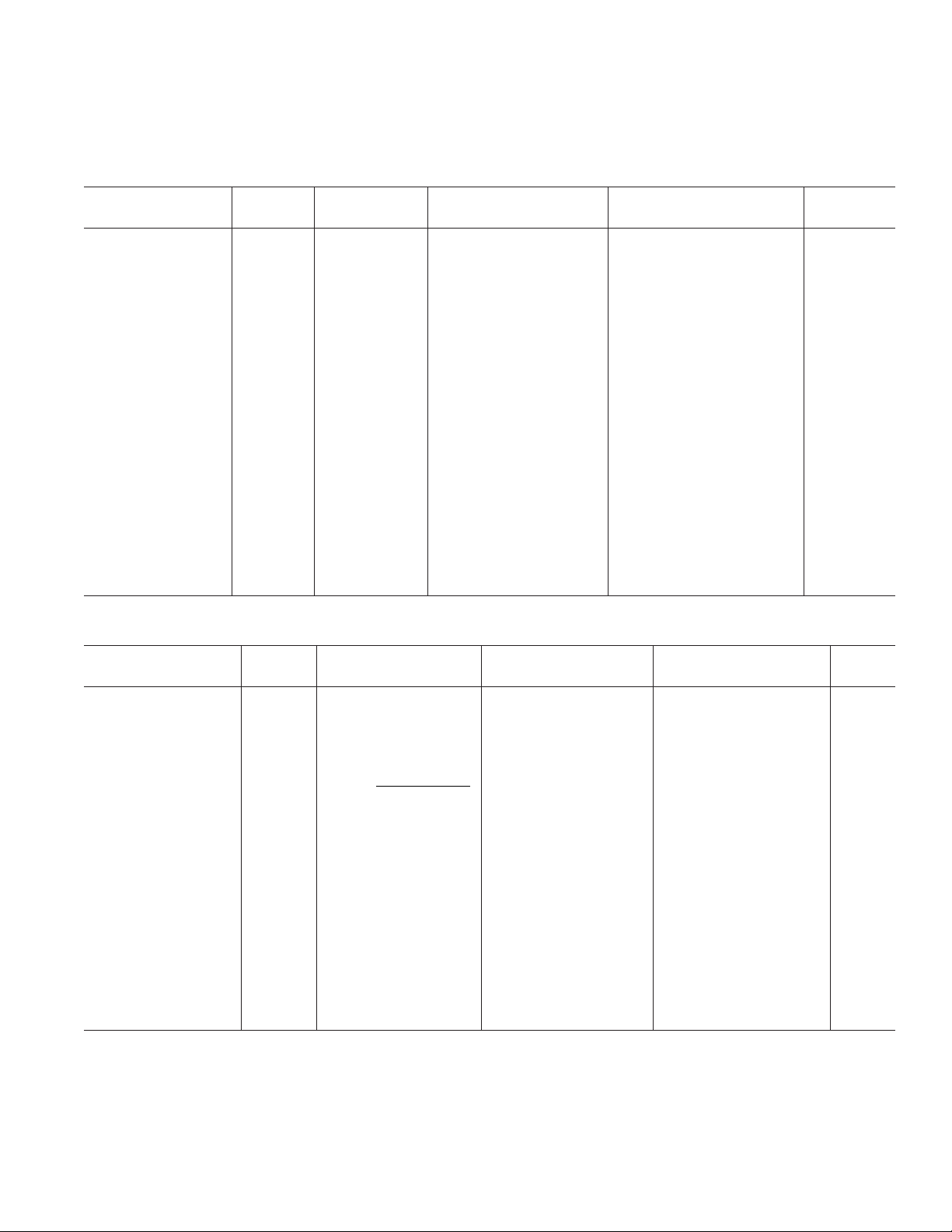

SPECIFICATIONS

OP227

Individual Amplifier Characteristics

(VS = ⴞ15 V, –25ⴗC £ TA £ +85ⴗC, unless otherwise noted.)

OP227E OP227G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

INPUT OFFSET

VOLTAGE V

OS

Note 1 40 140 85 280 mV

AVERAGE INPUT

OFFSET DRIFT TCV

TCV

OS

OSn

Note 2 0.5 1.0 0.5 1.8 mV/ⴗC

INPUT OFFSET

CURRENT I

OS

10 50 20 135 nA

INPUT BIAS

CURRENT I

B

± 14 ± 60 ± 25 ± 150 nA

INPUT VOLTAGE

RANGE IVR ± 10 ± 11.8 ± 10 ± 11.8 V

COMMON-MODE

REJECTION RATIO CMRR V

= ± 10 V 110 124 96 118 dB

CM

POWER SUPPLY

REJECTION RATIO PSRR V

= ± 4.5 V to

S

± 18 V 2 15 2 32 mV/V

LARGE-SIGNAL

VOLTAGE GAIN A

VO

RL ⱖ 2 kW,

V

= ± 10 V 750 1500 450 1000 V/mV

O

OUTPUT VOLTAGE

SWING V

O

RL ⱖ 2 kW±11.7 ± 13.6 ± 11.0 ± 13.3 V

Matching Characteristics

(VS = ± 15 V, TA = 25ⴗC, unless otherwise noted.)

OP227E OP227G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

INPUT OFFSET

VOLTAGE MATCH ⌬V

OS

25 80 55 300 mV

AVERAGE

NONINVERTING Bias

CURRENT I

+

B

II

I

+=

B

++ +

BA BB

2

± 10 ± 40 ± 15 ± 90 nA

NONINVERTING

OFFSET CURRENT IOS+I

+ = IB+A-I

OS

B+B

± 12 ± 60 ± 20 ± 130 nA

INVERTING OFFSET

CURRENT I

-I

OS

- = IB-A-IB-

OS

B

± 12 ± 60 ± 20 ± 130 nA

COMMON-MODE

REJECTION RATIO

MATCH ⌬CMRR V

= ± 11 V 110 123 97 117 dB

CM

POWER SUPPLY

REJECTION RATIO

MATCH ⌬PSRR V

= ± 4 V to

S

± 18 V 2 10 2 20 mV/V

CHANNEL

SEPARATION CS Note 1 126 154 126 154 dB

NOTES

1

Input Offset Voltage measurements are performed by automated equipment approximately 0.5 seconds after application of power.

2

The TCVOS performance is within the specifications unnulled or when nulled with RP = 8 kW to 20 kW, optimum performance is obtained with RP = 8 kW.

3

Sample tested.

Specifications subject to change without notice.

REV. A

–3–

Page 4

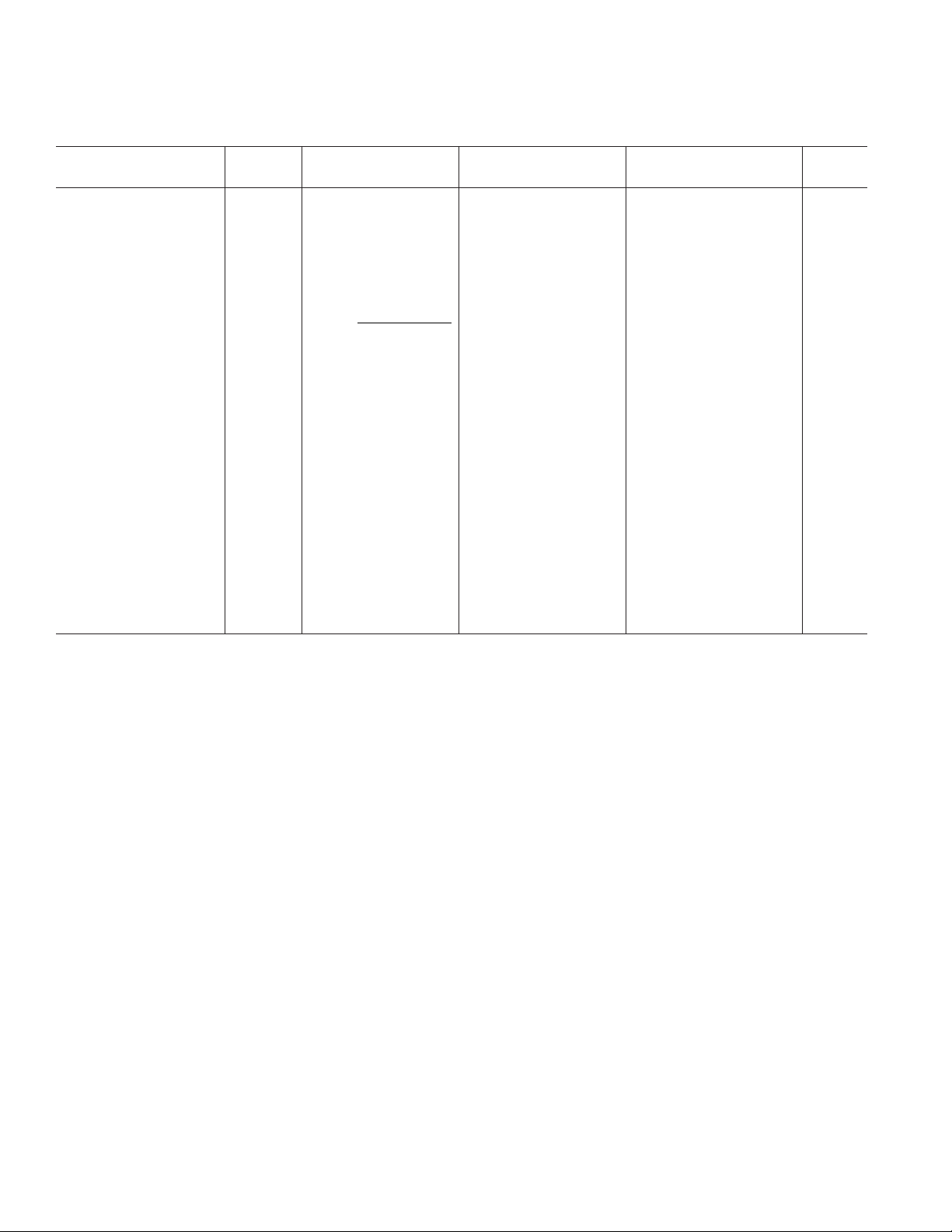

OP227–SPECIFICATIONS

Matching Characteristics

(VS = ⴞ15 V, TA = -25ⴗC to +85ⴗC, unless otherwise noted.)

OP227E OP227G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

INPUT OFFSET

VOLTAGE MATCH ⌬V

OS

40 140 90 400 mV

INPUT OFFSET

TRACKING TC⌬V

Nulled or Unnulled* 0.3 1.0 0.5 1.8 mV/ⴗC

OS

AVERAGE

NONINVERTING

BIAS CURRENT I

+

B

II

I

+=

B

++ +

BA BB

2

± 14 ± 60 ± 25 ± 170 nA

AVERAGE DRIFT OF

NONINVERTING BIAS

CURRENT TCI

+80180 pA/ⴗC

B

NONINVERTING

OFFSET CURRENT I

+I

OS

+ = IB+A–IB+

OS

B

± 20 ± 90 ± 35 ± 250 nA

AVERAGE DRIFT OF

NONINVERTING

OFFSET CURRENT TCI

+ 130 250 pA/ⴗC

OS

INVERTING OFFSET

CURRENT I

–I

OS

– = IB–A–IB–

OS

B

± 20 ± 90 ± 35 ± 250 nA

COMMON-MODE

REJECTION RATIO

MATCH ⌬CMRR V

= ± 10 V 106 120 90 112 dB

CM

POWER SUPPLY

REJECTION RATIO

MATCH ⌬PSRR V

= ± 4.5 V to ± 18 V 2 15 3 32 mV/V

S

NOTES

*Sample tested.

Specifications subject to change without notice.

–4–

REV. A

Page 5

OP227

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±22 V

Input Voltage

Output Short-Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage

Differential Input Current

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

. . . . . . . . . . . . . . . . . . . . . . . ±0.7 V

2

. . . . . . . . . . . . . . . . . . . . . ±25 mA

±22 V

Storage Temperature Range . . . . . . . . . . . . . –65∞C to +150∞C

Operating Temperature Range

OP227E, OP227G . . . . . . . . . . . . . . . . . . . . –25∞C to +85∞C

Lead Temperature (Soldering 60 sec) . . . . . . . . . . . . . . 300∞C

NOTES

1

For supply voltages less than ±22 V, the absolute maximum input voltage is equal

to the supply voltage.

2

The OP227 inputs are protected by back-to-back diodes. Current limiting resistors

are not used in order to achieve low noise. If differential input voltage exceeds ±0.7

V, the input current should be limited to 25 mA.

3

is specified for worst-case mounting conditions, i.e.,

JA

in socket for CERDIP package.

is specified for device

JA

THERMAL CHARACTERISTICS

Thermal Resistance

14-Lead CERDIP

3

= 106∞C/W

JA

= 16∞C/W

JC

ORDERING GUIDE

TA = 25ⴗCHermetic Operating

VOS MAX (V) DIP 14-Lead Temperature Range

80 OP227EY IND

180 OP227GY IND

For military processed devices, please refer to the Standard

Microcircuit Drawing (SMD) available at

www.dscc.dla.mil/programs/milspec/default.asp.

SMD Part Number ADI Equivalent

5962-8688701CA

*Not recommended for new design, obsolete April 2002.

*

OP227AYMDA

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP227 features propriety ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefor, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. A

–5–

Page 6

OP227

Hz

–Typical Performance Characteristics

BACK-TO-BACK

0.1F

47F

100k⍀

10⍀

D.U.T.

VOLTAGE GAIN

= 50,000

BACK-TO-BACK

2k⍀

5F

10F

TPC 1. Voltage Noise Test Circuit

(0.1 Hz to 10 Hz p-p)

10

9

8

7

6

5

4

3

2

VOLTA GE NOISE DENSITY – nV/ Hz

1

l/f CORNER

= 2.7Hz

1

10 100 1k

FREQUENCY – Hz

TA = 25ⴗC

VS = ⴞ15V

TPC 3. Voltage Noise Density vs.

Frequency

120

OP12

100k⍀

0.1F

24.3k⍀

BACK-TO-BACK

4.3k⍀

4.7F

2.35F

23.5F

SCOPE

R

IN

110k⍀

X 1

= 1M⍀

80

40

0

–40

–80

VOLTA G E NOISE – nV

–120

TPC 2. Low Frequency Noise

(Observation Must Be Limited to 10

Seconds to Ensure 0.1 Hz Cutoff)

100

741

l/f CORNER

10

l/f CORNER

2.7 Hz

VOLTA G E NOISE – nV/ Hz

INSTRUMENTATION

10

1

OP227

RANGE, TO DC

LOW NOISE

AUDIO

OP AMP

l/f CORNER

AUDIO RANGE

10 100 1k

FREQUENCY – Hz

TO 20 kHz

TPC 4. Comparison of Op Amp Voltage

Noise Spectra

1 SEC / DIV

100

90

10

0%

0.1Hz TO 10Hz PEAK-TO-PEAK NOISE

10

1

0.1

rms VOLTAGE NOISE – V

0.01

100

1k 10k 100k

BANDWIDTH – Hz

TPC 5. Input Wideband Noise vs. Bandwidth (0.1 Hz to Frequency Indicated)

T

A

V

S

= 25ⴗC

= ⴞ15V

100

T

= 25ⴗC

A

V

10

AT 10Hz

TOTAL NO ISE – nV/

AT 1kHZ

1

100

= ⴞ15V

S

RESISTOR NOISE ONLY

SOURCE RESISTANCE – ⍀

R1

R2

R

= 2R1

S

1k 10k

TPC 6. Total Noise vs. Source

Resistance

5

VS = ⴞ15V

4

3

2

VOLTA GE NOISE DENSITY – nV/ Hz

1

–50

AT 10Hz

AT 1kHz

–25 0 25 50 75 100 125

TEMPERATURE – ⴗC

TPC 7. Voltage Noise Density vs.

Temperature

–6–

10.0

1.0

l/f CORNER

CURRENT NOISE – pA/ Hz

= 140Hz

0.1

10

100 1k 10k

FREQUENCY – Hz

TPC 8. Current Noise Density vs.

Frequency

REV. A

Page 7

OP227

10

9

8

7

TA = +125ⴗC

6

5

4

(BOTH AMPLIFIERS ON)

SUPPLY CURRENT – mA

3

2

5

TA = +25ⴗC

TA = –55ⴗC

10 15 20 25 30 35 40 45

TOTA L SUPPLY VOLTAGE – V

TPC 9. Supply Current vs. Supply

Voltage

TA = 25ⴗC

V

S

= ⴞ15V

10

OP227G

5

CHANGE IN INPUT OFFSET VOLTAGE – V

0

01 5

TIME AFTER POWER ON – MINUTES

234

TPC 12. Warm-Up Drift

120

100

80

60

40

20

0

–20

–40

OFFSET VOLTAGE – V

–60

–80

–100

–55–35 –15 5 25 45 65 85 105125 145165

–75

TEMPERATURE – ⴗC

TPC 10. Offset Voltage Drift of

Representative Units

30

25

TA = 25ⴗC TA = 70ⴗC

20

15

VOLTA G E – V

10

5

ABSOLUTE CHANGE IN INPUT OFFSET

0

–20

DEVICE IMMERSED

IN 70ⴗ C OIL BATH

020406080100

TIME – Sec

VS = ⴞ15V

THERMAL

SHOCK

RESPONSE

BAND

TPC 13. Offset Voltage Change Due to

Thermal Shock

5

4

3

2

1

0

–1

–2

–3

–4

OFFSET VOLTAGE DRIFT WITH TIME – V

–5

2345678910

0

11112

0.2V/MO.

0.2V/MO.

0.2V/MO.

TIME – MONTHS

TPC 11. Offset Voltage Stability

with Time

50

VS = ⴞ15V

40

30

20

10

INPUT BIAS CURRENT – nA

0

–25 0 25 50 75 100 125 150

–50

TEMPERATURE – ⴗC

TPC 14. Input Bias Current vs.

Temperature

50

VS = ⴞ15V

40

30

20

10

INPUT OFFSET CURRENT – nA

0

–50 –25 0 25 50 75 100 125

–75

TEMPERATURE – ⴗC

TPC 15. Input Offset Current vs.

Temperature

REV. A

130

110

90

70

50

30

OPEN-LOOP GAIN – dB

10

–10

1

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY – Hz

TPC 16. Open-Loop Gain vs. Frequency

–7–

70

⌽M

60

GBW

50

PHASE MARGIN – DEG

4

3

SLEW

2

SLEW RATE – V/s

–50 –25 0 25 50 75 100 125

–75

TEMERATURE – ⴗC

VS = ⴞ15V

10

9

8

7

8

TPC 17. Slew Rate, Gain Bandwidth

Product, Phase Margin vs. Temperature

GAINBANDWIDTH PRODUCT – MHz

Page 8

OP227

25

20

15

10

5

GAIN – dB

0

–5

10

1M

GAIN

PHASE

MARGIN

= 70ⴗ

10M 100M

FREQUENCY – Hz

TA = 25ⴗC

V

S

= ⴞ15V

80

100

120

140

160

180

200

220

TPC 18. Gain, Phase Shift vs.

Frequency

28

24

20

16

12

8

4

PEAK-TO-PEAK OUTPUT VOLTAGE – V

0

1k

10k 100k 1M 10M

FREQUENCY – Hz

TA = 25ⴗC

V

S

= ⴞ15V

TPC 21. Maximum Undistorted Output

vs. Frequency

2.5

2.0

TA = 25ⴗC

1.5

1.0

PHASE SHIFT – DEG

OPEN-LOOP GAIN – V/V

0.5

0.0

0

10 20 30 40 50

TOTA L SUPPLY VOLTAGE – V

= 2k⍀

R

L

RL = 1k⍀

TPC 19. Open-Loop Gain vs. Supply

Voltage

100

80

60

40

PERCENT OVERSHOOT

20

0

0

500 1000 1500 2000 2500

CAPACITIVE LOAD – pF

VS = 615V

VIN = 100mV

AV = +1

TPC 22. Small-Signal Overshoot vs.

Capacitive Load

18

16

14

POSITIVE

12

10

8

6

4

OUTPUT SWING – V

2

0

–2

SWING

TS = 25ⴗC

VS = ⴞ15V

100

NEGATIVE

SWING

LOAD RESISTANCE – ⍀

1k 10k

TPC 20. Output Swing vs. Resistive

Load

60

50

40

30

20

SHORT-CIRCUIT CURRENT – mA

20

01 5

lSC(–)

lSC(+)

TIME FROM OUTPUT SHORTED TO

234

GROUND – MINUTES

T

A

= ⴞ15V

V

S

= ⴞ25ⴗ

TPC 23. Short-Circuit Current vs. Time

100

90

10

0%

= +1, CL= 15pF

A

VCL

V

= ⴞ15V

S

T

= 25ⴗC

A

20mV

+50mV

0V

–50mV

TPC 24. Small-Signal Transient

Response

500ns

100

90

10

0%

A

VCL

V

S

T

A

= +1

= ⴞ15V

= 25ⴗC

2V

+5V

0V

–5V

TPC 25. Large-Signal Transient

Response

2s

140

120

100

⌬CMMR – dB

80

60

1k

10k 100k 1M 10M

FREQUENCY – Hz

TPC 26. Matching Characteristic

CMRR Match vs. Frequency

–8–

REV. A

Page 9

OP227

16

COMMON-MODE RANGE – V

–12

–16

12

8

4

0

–4

–8

TA = +25ⴗC

0

TA = –55ⴗC

TA = –55ⴗC

TA = +125ⴗC

ⴞ5 ⴞ10 ⴞ15

SUPPLY VOLTAGE – V

TA = +125ⴗC

TA = +25ⴗC

ⴞ20

TPC 27. Common-Mode Input Range

vs. Supply Voltage

100

80

60

40

20

0

–20

–40

–60

–80

OFFSET VOLTAGE MATCH – V

–100

–120

–75

–55–35 –15 5 25 45 65 85 105125145 165

TEMPERATURE – ⴗC

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

OPEN-LOOP VOLTAGE GAIN – V/V

0.6

0.4

100

1k 10k 100k

LOAD RESISTANCE – ⍀

TA = 25ⴗC

VS = ⴞ15V

TPC 28. Open-Loop Voltage Gain vs.

Load Resistance

40

30

20

10

NONINVERTING BIAS CURRENT – ⴞnA

0

–35 –15 5 25 45 65 85 105 125

–55

TEMPERATURE – ⴗC

140

120

100

PSSR – dB

PSRR (+)

80

⌬

PSRR (–)

60

PSRR AND

40

20

1

10 100 1k 10k 100k 1M

FREQUENCY – Hz

⌬ PSRR (–)

⌬ PSRR (+)

TPC 29. PSRR and ⌬PSRR vs.

Frequency

50

40

30

20

OFFSET CURRENT – ⴞnA

10

–35 –15 5 25 45 6585105125

–55

TEMPERATURE – ⴗC

TPC 30. Matching Characteristic:

Drift of Offset Voltage Match of

Representative Units

125

120

115

⌬ CMRR – dB

110

105

–55

–35 –15

525456585105 125

TEMPERATURE – ⴗC

TPC 33. Matching Characteristic:

CMRR Match vs. Temperature

TPC 31. Matching Characteristic:

Average Noninverting Bias Current

vs. Temperature

180

140

120

100

80

CHANNEL SEPARATION – dB

60

100

1k 10k 100k 1M 10M

FREQUENCY – Hz

TPC 34. Channel Separation vs.

Frequency

TPC 32. Matching Characteristic:

Average Offset Current vs. Temperature (Inverting or Noninverting)

REV. A

–9–

Page 10

OP227

BASIC CONNECTIONS

V+(A)

10k⍀

21 14

3

(–)

INPUTS

(+)

(+)

INPUTS

(–)

A

4

OP227

11

B

10

98 7

10k⍀

V+(A)

13

OUT (A)

12

V–(A)

5

V–(B)

6

OUT (B)

Figure 1. Offset Nulling Circuit

APPLICATIONS INFORMATION

Noise Measurements

To measure the 80 nV peak-to-peak noise specification of the

OP227 in the 0.1 Hz to 10 Hz range, the following precautions

must be observed:

•The device must be warmed up for at least five minutes. As

shown in the warm-up drift curve, the offset voltage typically

changes 4 mV due to increasing chip temperature after power-up.

In the 10-second measurement interval, these temperatureinduced effects can exceed tens-of-nanovolts.

∑

For similar reasons, the device must be well shielded from air

currents. Shielding minimizes thermocouple effects.

∑

Sudden motion in the vicinity of the device can also “feedthrough”

∑

The test time to measure 0.1 Hz to 10 Hz noise should not

to increase the observed noise.

exceed 10-seconds. As shown in the noise-tester frequencyresponse curve, the 0.1 Hz corner is defined by only one zero

to eliminate noise contributions from the frequency band

below 0.1 Hz.

∑

A noise-voltage-density test is recommended when measuring

noise on a large number of units. A 10 Hz noise-voltagedensity measurement will correlate well with a 0.1 Hz to 10 Hz

peak-to-peak noise reading, since both results are determined

by the white noise and the location of the 1/f corner frequency.

Instrumentation Amplifier Applications of the OP227

The excellent input characteristics of the OP227 make it ideal

for use in instrumentation amplifier configurations where low

level differential signals are to be amplified. The low noise, low

input offsets, low drift, and high gain, combined with excellent

CMR provide the characteristics needed for high performance

instrumentation amplifiers. In addition, CMR versus frequency

is very good due to the wide gain bandwidth of these op amps.

The circuit of Figure 2 is recommended for applications where

the common-mode input range is relatively low and differential

gain will be in the range of 10 to 1000. This two op amp

instrumentation amplifier features independent adjustment of

common-mode rejection and differential gain. Input impedance is very high since both inputs are applied to non-inverting

op amp inputs.

R0

R2R1

R4

A2

R4R3R3

V

d

]

+

–

( )

R4

V

O

R2

V

CM

R1

V

– 1/2V

CM

VCM + 1/2V

VO =

d

d

R4

1

1+

[ ( )

R3

2

A1

R2R1R3

+

V1

R3

R2 + R3

+

R0

R4

Figure 2. Two Op Amp Instrumentation Amplifier Configuration

The output voltage VO, assuming ideal op amps, is given in

Figure 2. the input voltages are represented as a common-mode

input, V

, plus a differential input, Vd. The ratio R3/R4 is

CM

made equal to the ratio R2/R1 to reject the common mode input

. The differential signal VO is then amplified according to:

V

CM

Ê

R

V

=++

O

R

RRRR

4

1

Á

3

Ë

3423 342

ˆ

+

V where

,

˜

R

O

d

¯

RRR

=

R

1

Note that gain can be independently varied by adjusting RO.

From considerations of dynamic range, resistor tempco matching, and matching of amplifier response, it is generally best to

make R1, R2, R3, and R4 approximately equal. Designing R1,

R2, R3, and R4 as R

allows the output equation to be further

N

simplified:

V

=+

O

Ê

Á

Ë

ˆ

R

N

V where R R R R R

,

˜

dN

R

¯

O

= ===21

123 4

–10–

REV. A

Page 11

OP227

Dynamic range is limited by A1 as well as A2. The output of A1

is:

Ê

V

12=+

Á

Ë

ˆ

R

N

VV

˜

R

¯

O

+–

dCM1

If the instrumentation amplifier was designed for a gain of 10

and maximum V

of ± 1 V, then RN/RO would need to be four

d

and VO would be a maximum of ± 10 V. Amplifier A1 would have

a maximum output of ± 5 V plus 2 VCM, thus a limit of ± 10 V

on the output of A1 would imply a limit of ± 2.5 V on V

nominal value of 10 kW for R

A range of 20 W to 2.5 kW for R

is suitable for most applications.

N

will then provide a gain range

O

CM

. A

of 10 to 1000. The current through RO is Vd/RO, so the amplifiers

must supply ± 10 mV/20 W (or ± 0.5 mA) when the gain is at the

maximum value of 1000 and V

is at ± 10 mV.

d

Rejecting common-mode inputs is important in accurately

amplifying low level differential signals. Two factors determine

the CMR in this instrumentation amplifier configuration (assuming

infinite gain):

∑

CMR of the op amps

∑

Matching of the resistor network ratios (R3/R4 = R2/R1)

In this instrumentation amplifier configuration error due to CMR

effect is directly proportional to the CMR match of the op

For the OP227, this DCMR is a minimum of 97 dB for the

amps.

“G”

and 110 dB for the “E” grades. A DCMR value of 100 dB and a

common-mode input range of ± 2.5 V indicates a peak inputreferred error of only ± 25 mV. Resistor matching is the other

factor affecting CMR. Defining A

as the differential gain of the

d

instrumentation amplifier and assuming that R1, R2, R3, and R4

are approximately equal (RN will be the nominal value), then CMR

for this instrumentation amplifier configuration will be approximately A

divided by 4⌬R/RN. CMR at differential gain of 100

d

would be 88 dB with resistor matching of 0.01%. Trimming R1

to make the ratio R3/R4 equal to R2/R1 will raise the CMR

until limited by linearity and resistor stability considerations.

The high open-loop gain of the OP227 is very important to

achieving high accuracy in the two op amp instrumentation

amplifier configuration. Gain error can be approximated by:

A

Gain Error

1

A

d

+

1

A

O

2

AA

2

OO

d

11

<,

1

where Ad is the instrumentation amplifier differential gain and

is the open loop gain of op amp A2. This analysis assumes

A

O2

equal values of R1, R2, R3, and R4. For example, consider an

OP227 with A

of 700 V/mV. Id the differential gain Ad were

O2

set to 700, then the gain error would be 1/1.001, which is

approximately 0.1%.

Another effect of finite op amp gain is undesired feedthrough of

common-mode input. Defining A

as the open-loop gain of op

O1

amp A1, then the common-mode error (CME) at the output

due to this effect would be approximately:

A

REV. A

CME

2

1

+

d

,

AAA

d

2

O

1

V

CM

1

O

–11–

For Ad/A01 < 1, this simplifies to (2Ad/A01) 3 VCM. If the op amp

gain is 700 V/mV, V

is 2.5 V, and Ad is set to 700, then the

CM

error at the output due to this effect will be approximately 5 mV.

A compete instrumentation amplifier designed for a gain of 100

is shown in Figure 3. It has provision for trimming of input

voltage, CMR, and gain. Performance is excellent due to

offset

the high

fiers combined

gain, high CMR, and low noise of the individual ampli-

with the tight matching characteristics of the

OP227 dual.

CMR

10k⍀

0.1%

50⍀

9.95k⍀

3

– 1/2V

V

CM

d

GAIN

V

– 1/2V

CM

d

4

2.5k⍀

191⍀

10

11

OFFSET

10k⍀

21 14

OP227

10k⍀, 0.1%

10k⍀, 0.1%

ADJUST

V+

13

12

7

6

5

V–

V+

V

V–

= 100V

O

d

Figure 3. Two Op Amp Instrumentation Amplifier Using

OP227 Dual

A three op amp instrumentation amplifier configuration using

the OP227 and OP27 is recommended for applications requiring high accuracy over a wide gain range. This circuit provides

excellent CMR over a wide frequency range. As with the two op

amp instrumentation amplifier circuits, the tight matching of the

two op amps within the OP227 package provides a real boost in

performance. Also, the low noise, low offset, and high gain of

the individual op amps minimize errors.

A simplified schematic is shown in Figure 4. The input stage

(A1 and A2) serves to amplify the differential input V

amplifying the common-mode voltage V

. The output stage

CM

without

d

then rejects the common-mode input. With ideal op amps and

no resistor matching errors, the outputs of each amplifier will

be:

Ê

V

1

=+

–

Á

1

Ë

Ê

V

=+

–

Á

2

Ë

==+

VVV

O

21

=

VAV

Odd

1

–

R

21

R

O

21

R

R

O

ˆ

V

d

V

+

˜

¯

ˆ

˜

¯

Ê

Á

Ë

1

V

2

d

2

+

V

21

R

R

O

CM

CM

ˆ

˜

¯

V

d

Page 12

OP227

The differential gain Ad is 1 + 2R1/R0 and the common-mode

input V

is rejected.

CM

While output error due to input offsets and noise are easily

determined, the effects of finite gain and common-mode rejection are more subtle. CMR of the complete instrumentation

amplifier is directly proportioned to the match in CMR of the

input op amps. This match varies from 97 dB to 110 dB minimum for the OP227. Using 100 dB, then the output response to

a common-mode input V

VAV

[]

would be:

CM

=¥10

O

CM

dCM

5–

CMRR of the instrumentation amplifier, which is defined as

20 log10A

, is simply equal to the ⌬CMRR of the OP227.

d/ACM

While this ⌬CMRR is already high, overall CMRR of the

complete amplifier can be raised by trimming the output stage

resistor network.

Finite gain of the input op amps causes a scale factor error and a

small degradation in CMR. Designating the open-loop gain of

op amp A

as AO1, and op amp A2 as AO2, then the following

1

equation approximates output:

ˆ

˜

¯

Ê

AV

Á

dd

Á

Ë

V

O

++

1

1

Ê

R

1011

Á

RA A

Ë

12

OO

Ê

R

21011

+

RA A

–

Á

Ë

12

OO

ˆ

ˆ

V

˜

˜

CM

˜

¯

¯

This can be simplified by defining AO as the nominal open-loop

gain and ⌬A0 as the differential open-loop gain. Then:

Ê

1

+

1

R

101

RA

V

O

O

AV

Á

dd

Ë

+

R

21

R

0

A

D

O

2

A

O

ˆ

V

˜

CM

¯

The high open-loop gain of each amplifier within the OP227

(700,000 minimum at 25∞C in R

accuracy even at high values of A

≥ 2 kW) assures good gain

L

. The effect of finite open-

d

loop gain on CMR can be approximated by:

2

A

CMRR

O

A

D

O

If ⌬AO/AO were 6% and AO were 600,000, then the CMRR due to

finite gain of the input op amps would be approximately 140 dB.

R1

2R1

= (1 +

) Vd

R0

R2

OP27

A3

R2

V

O

V

– 1/2V

CM

VCM + 1/2V

V

1/2

OP227

A1

d

R0

R1

1/2

OP227

A2

d

O

R2

V1

R2

V2

Figure 4. Three Op Amp Instrumentation Amplifier Using

OP227 and OP27

The unity-gain output stage contributes negligible error to the

overall amplifier. However, matching of the four resistor R2

network is critical to achieving high CMR. Consider a worstcase situation where each R2 resistor had an error of ± ⌬R2. If

the resistor ratio is high on one side and low on the other, then

the common-mode gain will be 2⌬R2/2⌬R2. Since the output

stage gain is unity, CMRR will then be R2/2⌬R2. It is common

practice to maximize overall CMRR for the total instrumentation amplifier circuit.

–12–

REV. A

Page 13

OP227

High Speed Precision Rectifier

The low offsets and excellent load driving capability of the OP27

are key advantages in this precision rectifier circuit. The summing

impedances can be as low as 1 kW which helps to reduce the

effects of stray capacitance.

For positive inputs, D2 conducts and D1 is biased OFF. Amplifiers A1 and A2 act as a follower with output-to-output feedback

and the R1 resistors are not critical. For negative inputs, D1

conducts and D2 is biased OFF. A1 acts as a follower and A2

serves as a precision inverter. In this mode, matching of the two

R1 resistors is critical to gain accuracy.

C

1

30pF

A1 A2

V

1

A1, A2: OP27

Figure 5. High Speed Precision Rectifier

Typical component values are 30 pF for C1 and 2 kW for R3.

The drop across D1 must be less than the drop across the FET

diode D2. A 1N914 for D1 and a 2N4393 for the JFET were

used successfully.

The circuit provides full-wave rectification for inputs of up to

± 10 V and up to 20 kHz in frequency. To assure frequency stability,

be sure to decouple the power supply inputs and minimize any

capactive loading. An OP227, which is two OP27 amplifiers in a

single package, can be used to improve packaging density.

D

1

1N914

R

*

1

1k⍀

2N4393

R

2k⍀

*

D

2

3

MATCHED

R

1k⍀

*

2

V

O

REV. A

–13–

Page 14

OP227

OUTLINE DIMENSIONS

14-Lead Ceramic Dip – Glass Hermetic Seal [CERDIP]

(Q-14)

Dimensions shown in inches and (millimeters)

0.005 (0.13) MIN

PIN 1

0.200 (5.08)

0.200 (5.08)

0.125 (3.18)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.785 (19.94) MAX

MAX

0.023 (0.58)

0.014 (0.36)

0.098 (2.49) MAX

14

17

0.100 (2.54) BSC

8

0.070 (1.78)

0.030 (0.76)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

SEATING

PLANE

0.150

(3.81)

MIN

0.320 (8.13)

0.290 (7.37)

15

0

0.015 (0.38)

0.008 (0.20)

–14–

REV. A

Page 15

OP227

Revision History

Location Page

10/02—Data Sheet changed from REV. 0 to REV. A.

Edits to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

OP227A and OP227F deleted from Individual Amplifier Characteristics section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OP227A and OP227F deleted from Matching Characteristics section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

REV. A

–15–

Page 16

C02685–0–10/02(A)

–16–

PRINTED IN U.S.A.

Loading...

Loading...