Page 1

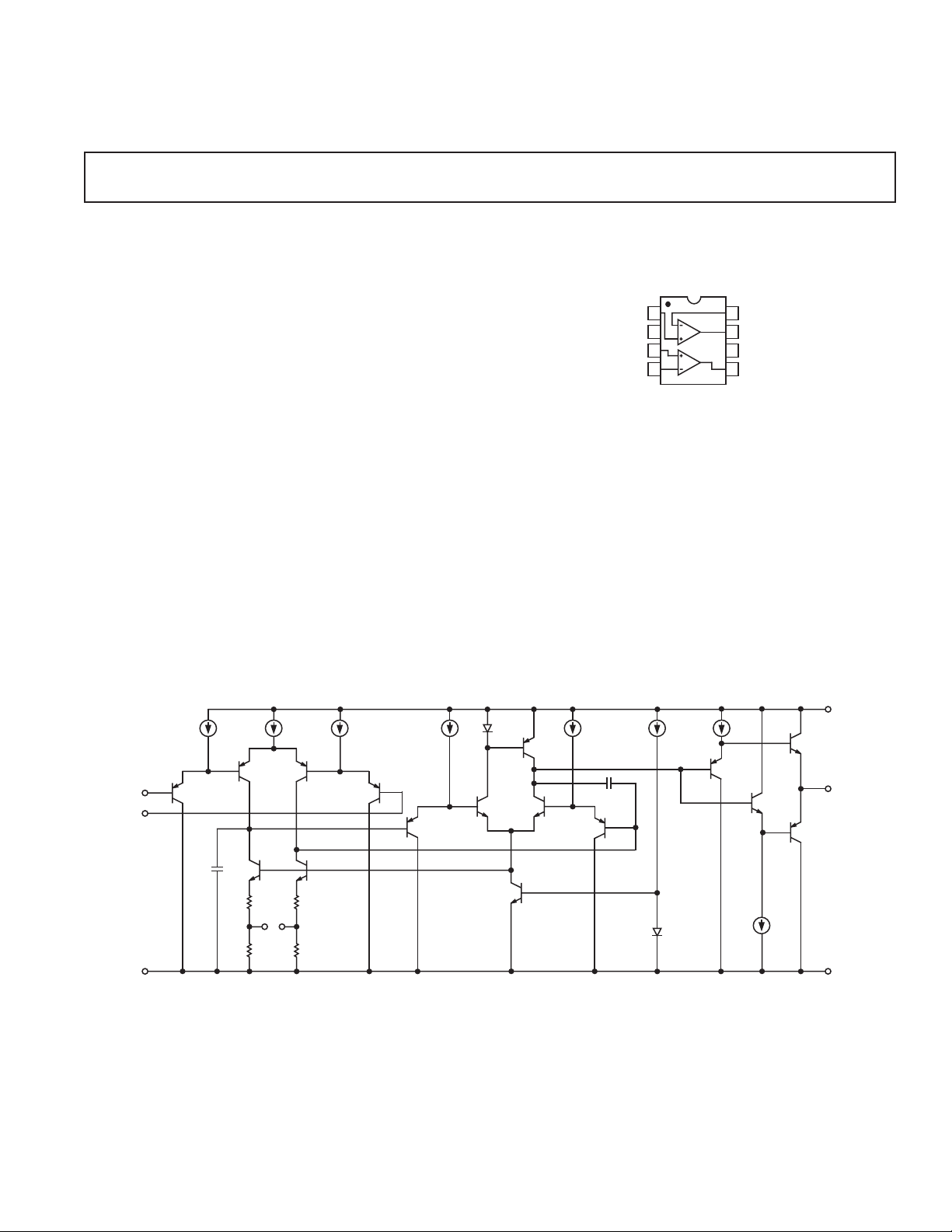

Dual Low Power Operational Amplifier,

8

7

6

5

1

2

3

4

NC = NO CONNECT

+IN A

V–

+IN B

–IN A

OUT A

V+

OUT B–IN B

a

FEATURES

Excellent TCV

Low Input Offset Voltage, 150 V Max

Low Supply Current, 550 A Max

Single Supply Operation, 5 V to 30 V

Low Input Offset Voltage Drift, 0.75 V/ⴗC

High Open-Loop Gain, 1500 V/mV Min

High PSRR, 3 V/V

Wide Common-Mode Voltage

Range, V– to within 1.5 V of V+

Pin Compatible with 1458, LM158, LM2904

Available in Die Form

GENERAL DESCRIPTION

The OP221 is a monolithic dual operational amplifier that can

be used either in single or dual supply operation. The wide

supply voltage range, wide input voltage range, and low supply

current drain of the OP221 make it well-suited for operation

from batteries or unregulated power supplies.

The excellent specifications of the individual amplifiers combined

with the tight matching and temperature tracking between channels

Match, 2 V/ⴗC Max

OS

Single or Dual Supply

OP221

PIN CONNECTIONS

8-Lead SOIC

(S-Suffix)

provide high performance in instrumentation amplifier designs.

The individual amplifiers feature very low input offset voltage,

low offset voltage drift, low noise voltage, and low bias current.

They are fully compensated and protected.

Matching between channels is provided on all critical parameters

including input offset voltage, tracking of offset voltage vs. temperature, non-inverting bias currents, and common-mode rejection.

SIMPLIFIED SCHEMATIC

Q3 Q4

–IN

+IN

Q1

Q5

*

NULL

*

ACCESSIBLE IN CHIP FORM ONLY

Q2

Q7

Q6

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

V+

Q11

Q12

Q26

Q9 Q10

Q4

Q13

Q33

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Q28

OUTPUT

Q27

Q29

V–

Page 2

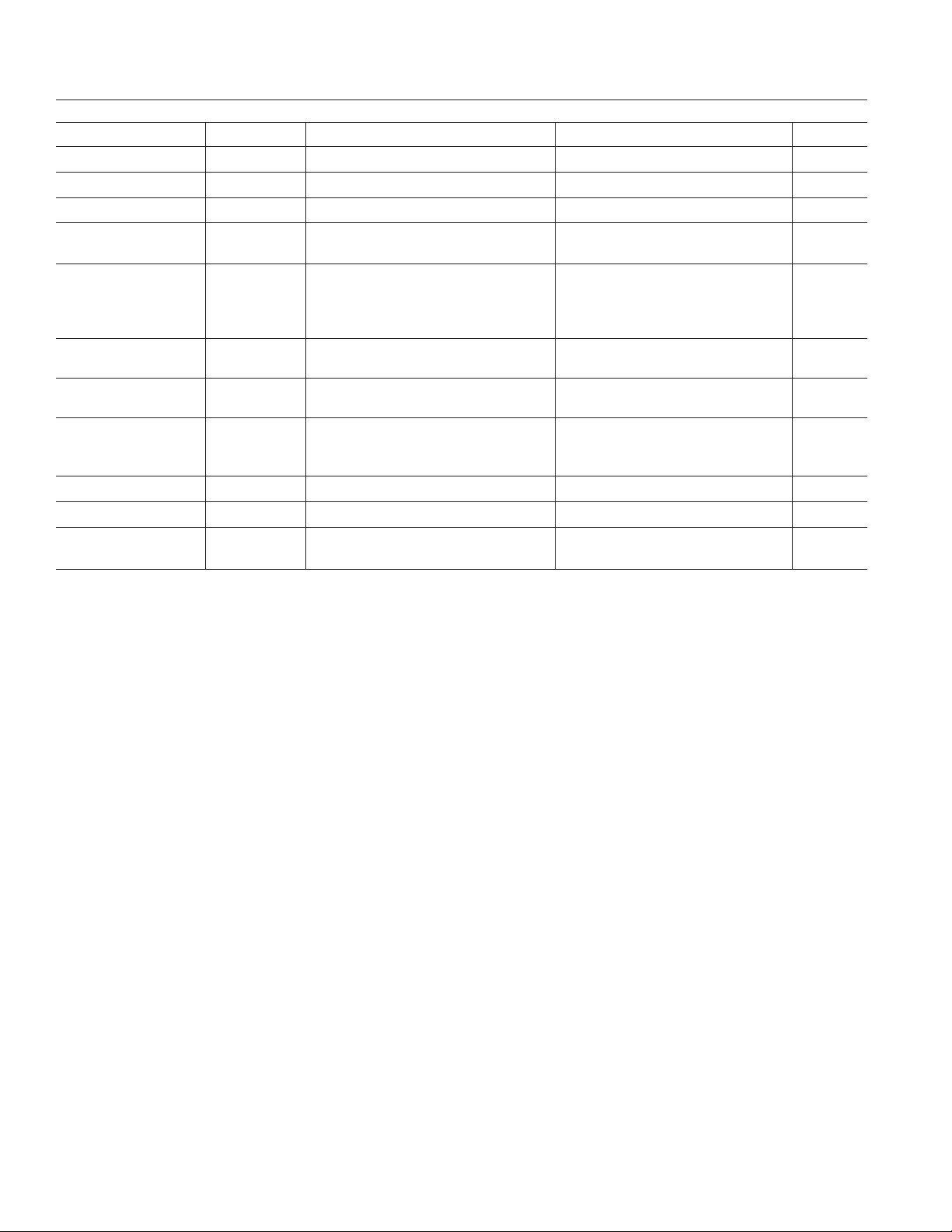

OP221–SPECIFICATIONS

(Electrical Characteristics at Vs = ⴞ2.5 V to ⴞ15 V, TA = 25ⴗC, unless otherwise noted.)

OP221G

Parameter Symbol Conditions Min Typ Max Unit

Input Offset Voltage V

OS

250 500 mV

Input Offset Current Ios VCM = 0 1.5 7 nA

Input Bias Current I

B

Input Voltage Range IVR V+ = 5 V, V– = 0 V

VCM = 0 70 120 nA

1

V

= ± 15 V –15/13.5

S

0/3.5

V

Common-Mode CMRR V+ = –5 V, V– = 0 V

Rejection Ratio 0 V £ V

= ± 15 V dB

V

S

–15 V £ V

Power Supply PSRR VS = ± 2.5 V to ± 15 V 32 100

Rejection Ratio V– = 0 V, V+ = 5 V to 30 V 57 180

£ 3.5 V 75 85

CM

£ 13.5 V 80 90

CM

mV/V

Large-Signal Avo VS = ±15 V, RL = 10 kW

Voltage Gain V

Output Voltage V

O

Swing R

= ±10 V 800 V/mV

O

V+ = 5 V, V– = 0 V 0.8/4 V

= 10 kW

L

VS = 15 V, RL = 10 kW±13.5

Slew Rate SR RL = 10 kW

2

0.2 0.3 V/mS

Bandwidth BW 600 kHz

Supply Current I

SY

(Both Amplifiers) VS = ± 15 V, No Load 850 900

VS = ± 2.5 V, No Load 550 650

mA

–2–

REV. C

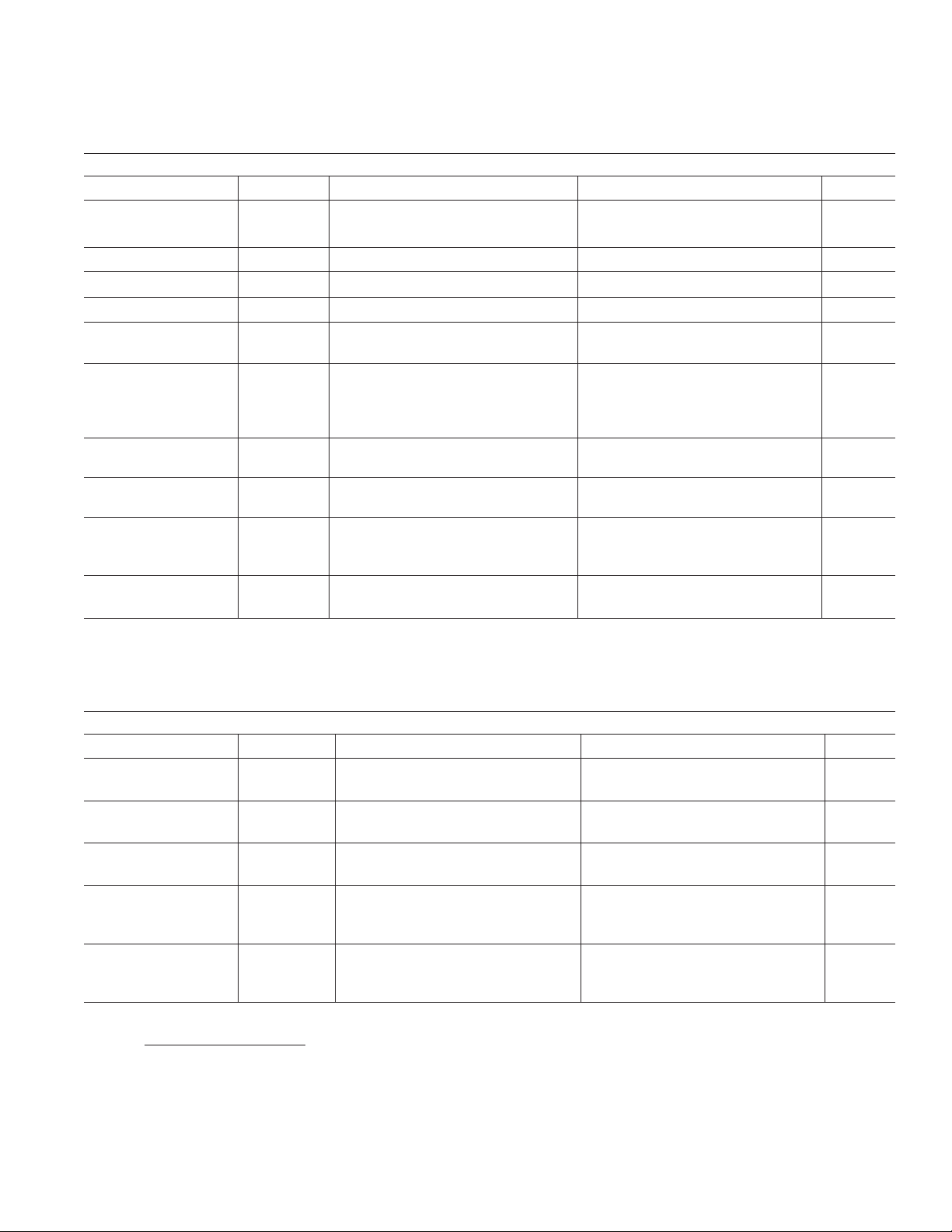

Page 3

OP221

SPECIFICATIONS

(Electrical Characteristics at VS = ⴞ2.5 V to ⴞ15 V, –40ⴗC £ TA £ +85ⴗC, unless otherwise noted.)

OP221G

Parameter Symbol Conditions Min Typ Max Unit

Average Input TCV

Offset Voltage Drift

1

Input Offset Voltage V

Input Offset Current I

Input Bias Current I

OS

B

OS

OS

VCM = 0 2 10 nA

VCM = 0 80 140 nA

Input Voltage Range IVR V+ = 5 V, V– = 0 V

V

= ± 15 V –15/13.2

S

2

0/3.2

23 mV/∞C

400 700 mV

V

Common-Mode CMRR V+ = –5 V, V– = 0 V

Rejection Ratio 0 V £ V

V

= ±15 V dB

S

–15 V £ V

Power Supply PSRR VS = ± 2.5 V to ± 15 V 57 180

Rejection Ratio V– = 0 V, V+ = 5 V to 30 V 100 320

Large-Signal A

VO

Voltage Gain V

Output Voltage V

O

Swing R

VS = ±15 V, RL = 10 kW

O

V+ = 5 V, V– = 0 V 0.9/3.7

L

£ 3.5 V 70 80

CM

£ 13.5 V 75 85

CM

= ±10 V 600

= 10 kW V

mV/V

V/mV

VS = 15 V, RL = 10 kW 13.2

Supply Current I

SY

VS = ± 2.5 V, No Load 600 750 mA

(Both Amplifiers) VS = ± 15 V, No Load 950 1000

NOTES

1

Sample tested.

2

Guaranteed by CMRR test limits.

Matching Characteristics at Vs = ⴞ15 V, TA = 25ⴗC, unless otherwise noted.

OP221G

Parameter Symbol Conditions Min Typ Max Unit

Input Offset

Voltage Match DV

OS

250 600 mV

Average Noninverting

Bias Current IB+ 120 nA

Noninverting Input I

+410nA

OS

Offset Current

Common-Mode

Rejection Ratio DCMRR V

1

Match

= –15 V to 13.5 V 72 dB

CM

Power Supply

Rejection Ratio DPSRR V

2

Match

NOTES

1

DCMRR is 20 log10 VCM/DCME, where V

2

DPSRR is: Input-Referred Differential Error

DV

S

is the voltage applied to both noninverting inputs and DCME is the difference in common-mode input-referred error.

CM

= ± 2.5 V to ± 15 V 140 mV/V

S

REV. C

–3–

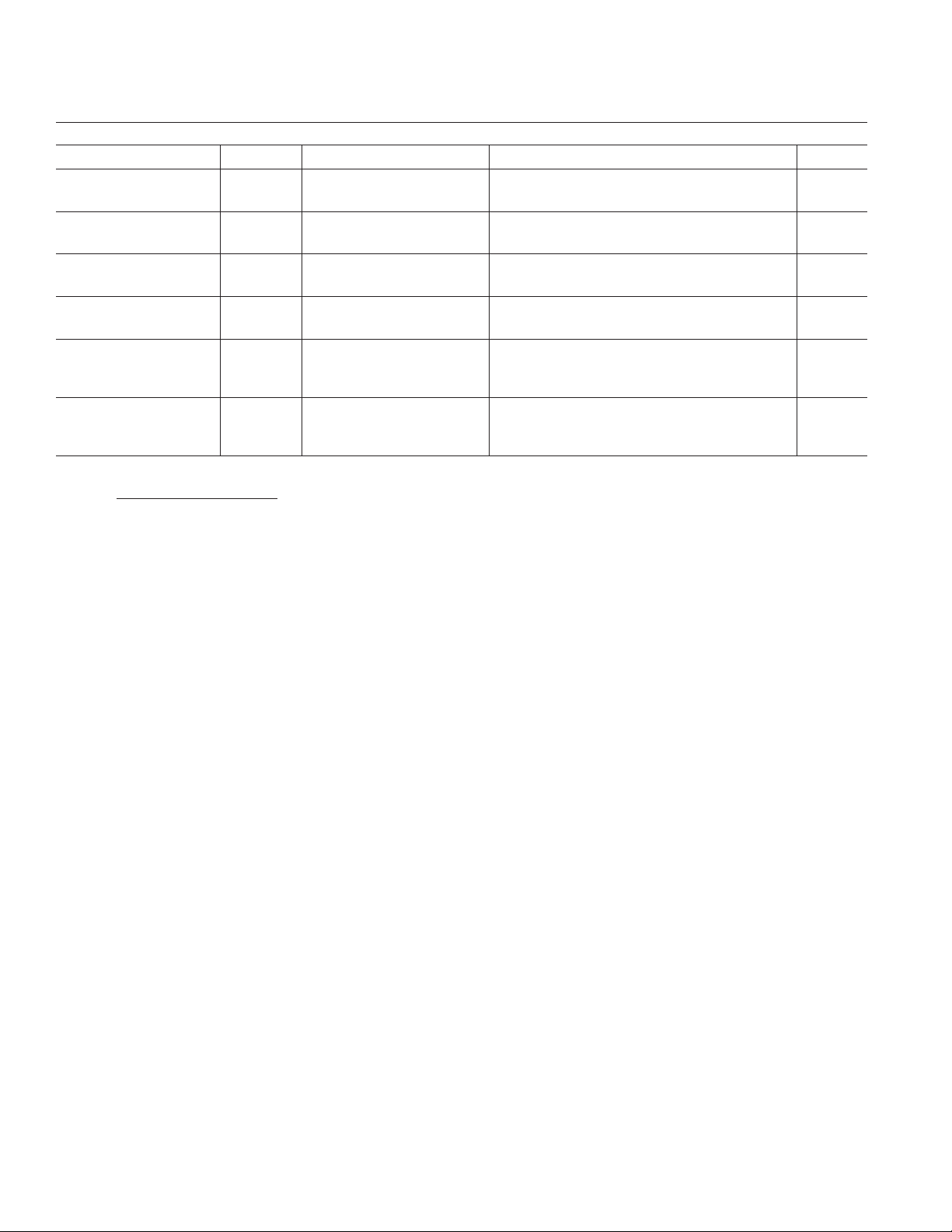

Page 4

(Matching Characteristics at Vs = ⴞ15 V, –40ⴗC £ TA £ +85ⴗC for OP221G, unless other-

OP221–SPECIFICATIONS

.

wise noted. G is sample tested.)

OP221G

Parameter Symbol Conditions Min Typ Max Unit

Input Offset

Voltage Match DV

Average Noninverting I

B

OS

+V

= 0 140 nA

CM

400 800 mV

Bias Current

Input Offset ICDV

OS

35mV∞C

Voltage Tracking

Noninverting Input I

+V

OS

= 0 6 12 nA

CM

Offset Current

Common-Mode

Rejection Ratio DCMRR V

1

Match

= –15 V to 13.2 V 72 80 dB

CM

Power Supply

Rejection Ratio DPSRR 140 mV/V

2

Match

NOTES

1

DCMRR is 20 log10 VCM/DCME, where V

2

DPSRR is: Input-Referred Differential Error

DV

S

is the voltage applied to both noninverting inputs and DCME is the difference in common-mode input-referred error.

CM

–4–

REV. C

Page 5

OP221

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS (Note 1)

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

Differential Input Voltage . . . . . . . . . .30 V or Supply Voltage

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . Supply Voltage

Output Short-Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Storage Temperature Range . . . . . . . . . . . . –65∞C to +150∞C

Operating Temperature Range

OP221G . . . . . . . . . . . . . . . . . . . . . . . . . . . . –40∞C to +85∞C

Lead Temperature (Soldering 60 sec) . . . . . . . . . . . . . . 300∞C

Junction Temperature (T

) . . . . . . . . . . . . . –65∞C to +150∞C

J

Package Type JA (Note 2)

JC

Unit

8-Lead SOIC(S) 158 43 ∞C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

is specified for device soldered to printed circuit board for SOIC package.

JA

ORDERING GUIDE

TA = +25ⴗC Operating Package

V

MAX Plastic Temperature Options

OS

(V) 8-Lead Range

150

150

300

500

500

500 OP221GS XIND RN-8

Figure 1. Dice Characteristics

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP221 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. C

–5–

Page 6

OP221–Typical Perfomance Characteristics

140

120

100

dc

10Hz

80

60

10 0H z

1kHz

140

120

100

dc

10Hz

80

60

10 0Hz

1kHz

140

120

100

T

= 25ⴗC

A

RL = 15k⍀

80

60

40

OPEN-LOOP GAIN – dB

VS = ⴞ15V

20

0

–25 0 25 50 75 100 125

–50

TEMPERATURE – ⴗC

TPC 1. Open-Loop Gain at ±15 V vs.

Temperature

120

100

80

60

40

OPEN-LOOP GAIN – dB

20

0

0.1

VS = ⴞ5V

110100 1k 10k 100k 1M 10M

FREQUENCY – Hz

VS = ⴞ15V

TPC 4. Open-Loop Gain at ±15 V vs.

Frequency

40

OPEN-LOOP GAIN – dB

VS = ⴞ15V

20

0

–25 0 25 50 75 100 125

–50

TEMPERATURE – ⴗC

TPC 2. Open-Loop Gain at ± 5 V vs.

Temperature

70

60

50

40

30

20

10

CLOSED-LOOP GAIN – dB

0

–10

110

100

1k 10k 100k 1M 10M

FREQUENCY – Hz

TPC 5. Closed-Loop Gain vs.

Frequency

40

OPEN-LOOP GAIN – dB

20

0

0

ⴞ5 ⴞ10 ⴞ15

SUPPLY VOLTAGE – V

TPC 3. Open-Loop Gain at vs.

Supply Voltage

25

PHASE

TA = 25ⴗC

= ⴞ15V

V

S

20

15

10

VOLTA G E GAIN – dB

–5

–10

⵰m = 42ⴗ

5

GAIN

0

100k 1M 10M

FREQUENCY – Hz

TPC 6. Gain and Phase Shift vs.

Frequency

80

100

120

140

160

180

PHASE SHIFT – Degrees

200

220

55

50

45

Degrees

40

PHASE MARGIN –

0.35

SLEW RATE

0.30

0.25

V/sec

SLEW RATE –

0.20

–25 0 25 50 75 100 125

–50

PHASE MARGIN

GAIN BANDWIDTH

TEMPERATURE – ⴗC

VS = ⴞ15V

TPC 7. Phase Margin, Gain Bandwidth,

and Slew Rate vs. Temperature

850k

800k

750k

700k

650k

120

100

80

60

PSRR – dB

GAIN BANDWIDTH – Hz

40

20

0

T

A

V

= ⴞ15V

S

10

–PSRR

= 25ⴗC

100 1k 10k 100k

FREQUENCY – Hz

TPC 8. PSRR vs. Frequency

+PSRR

120

100

80

60

CMRR – Hz

40

20

0

1

10 100

FREQUENCY – Hz

TA = 25ⴗC

V

S

1k 10k 100k

TPC 9. CMRR vs. Frequency

= ⴞ15V

–6–

REV. C

Page 7

30

28

24

20

16

12

8

PEAK-TO-PEAK AMPLITUTDE – V

4

0

1K 1M

10k 100k

FREQUENCY – Hz

TA = 25ⴗC

V

= ⴞ15V

S

R

= 10k⍀

L

TPC 10. Maximum Output Swing

vs. Frequency

16

TA = 25ⴗC

14

V

= ⴞ15V

S

12

10

MAXIMUM OUTPUT – V

POSITIVE

8

6

4

2

0

100 100k

LOAD RESISTANCE – ⍀

NEGATIVE

1k 10k

TPC 11. Maximum Output Voltage

vs. Load Resistance

OP221

TA = 25ⴗC

2.0

V

= ⴞ2.5V

S

1.0

MAXIMUM OUTPUT – V

0

100 100k1k 10k

LOAD RESISTANCE – ⍀

TPC 12. Maximum Output Voltage

vs. Load Resistance

NEGATIVE

POSITIVE

100

80

70

60

50

40

30

20

VOLTAGE NOISE – nV/ Hz

10

11k10 100

FREQUENCY – Hz

TPC 13. Voltage Noise Density vs.

Frequency

10

1.0

CURRENT NOISE – pA Hz

0.1

11k

10 100

FREQUENCY – Hz

TPC 13. Current Noise Density vs.

Frequency

REV. C

–7–

Page 8

OP221

Figure 2a. Noninverting Step Response

Figure 2b. Noninverting Step Response

INPUT

OUTPUT

10k⍀

Figure 3a. Inverting Step Response

Figure 3b. Inverting Step Response

10k⍀

INPUT

10k⍀

OUTPUT

Figure 4. Noninverting Test Circuit

–8–

Figure 5. Inverting Test Circuit

REV. C

Page 9

OP221

SPECIAL NOTES ON THE APPLICATION OF DUAL

MATCHED OPERATIONAL AMPLIFIERS

Advantages of Dual Monolithic Operational Amplifiers

Dual matched operational amplifiers provide the engineer with a

powerful tool for designing instrumentation amplifiers and many

other differential-input circuits. These designs are based on the

principle that careful matching between two operational amplifiers

can minimize the effect of dc errors in the individual amplifiers.

Reference to the circuit shown in Figure 6, a differential-in,

differential-out amplifier, shows how the reductions in error can

be accomplished. Assuming the resistors used are ideally matched,

the gain of each side will be identical. If the offset voltages of

each amplifier are perfectly matched, then the net differential

voltage at the amplifier’s output will be zero. Note that the output

offset error of this amplifier is not a function of the offset voltage

of the individual amplifiers, but only a function of the difference

(degree of matching) between the amplifiers’ offset voltages. This

error-cancellation principle holds for a considerable number of

input referred error parameters—offset voltage, offset voltage

drift, inverting and noninverting bias currents, common mode

and power supply rejection ratios. Note also that the impedances

of each input, both common-mode and differential-mode, are

high and tightly matched, an important feature not practical with

single operation amplifier circuits.

R3

R1

+

INPUT

–

SIDE

‘A’

OP221

R2

SIDE

‘R’

R4

+

OUTPUT

–

Figure 6. Differential-In, Differential-Out Amplifier

INSTRUMENTATION AMPLIFIER APPLICATIONS

Two-Op Amp Configuration

The two-op amp circuit (Figure 7) is recommended where the

common-mode input voltage range is relatively limited; the

common-mode and differential voltage both appear at V1. The

high open-loop gain of the OP221 is very important in achieving

good CMRR in this configuration. Finite open-loop gain of A1

(Ao1) causes undesired feedthrough of the common-mode input.

For Ad/Ao, << 1, the common-mode error (CME) at the output due to this effect is approximately (2 Ad/Ao1) x VCM. This

circuit features independent adjustment of CMRR and differential gain.

Three-Op Amp Configuration

The three-op amp circuit (Figure 8) has increased commonmode voltage range because the common-mode voltage is not

amplified as it is in Figure 7. The CMR of this amplifier is directly

proportional to the match of the CMR of the input op amps. CMRR

can be raised even further by trimming the output stage resistors.

R0

GAIN

ADJ

R1

V

– 1/2V

CM

D

–

V

d

+

V

+ 1/2V

CM

D

R4

1 +

V

=

O

R3

R2

V1

R3

R2 + R3

R0

AD = 2 1+

R4

OP221

A2

Vd +

1/2

OP221

A1

1

R3

R2

+

2

R1

+

R4

IF R1 = R2 = R3 = R4, THEN VO = 2 1 +

1/2

R1

R0

– ADVD

V

O

R4

R2

R3

–

R3

VCM

R1

R4

R1

V

D

R0

Figure 7. Two-Op Amp Circuit

R1

V

– 1/2V

CM

–

V

d

+ 1/2V

V

CM

A1

D

OP221

R0

R1

V+

A2

–

D

OP221

V–

1/2

1/2

VO = 2 1 +

R2

V1

R2

V2

R2

2R1

R2

V+

OP221

A3

V–

V

D

R0

V

O

Figure 8. Three-Op Amp Circuit

REV. C

–9–

Page 10

OP221

OUTLINE DIMENSIONS

8-Lead Standard Small Outline Package [SOIC]

Narrow Body

(RN-8)

Dimensions shown in millimeters and (inches)

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

85

6.20 (0.2440)

5.80 (0.2284)

41

1.27 (0.0500)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

BSC

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012AA

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.33 (0.0130)

0.25 (0.0098)

0.19 (0.0075)

0.50 (0.0196)

0.25 (0.0099)

8ⴗ

0ⴗ

1.27 (0.0500)

0.41 (0.0160)

ⴛ 45ⴗ

–10–

REV. C

Page 11

OP221

Revision History

Location Page

10/02—Data Sheet changed from REV. B to REV. C.

Deleted 8-Lead CERDIP Package (Q-8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Universal

Edits to SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6/02—Data Sheet changed from REV. A to REV. B.

Edits to 8-Lead SOIC Package (R-8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

09/01—Data Sheet changed from REV. 0 to REV. A.

Edits to PIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Global deletion of references to OP221B and OP221C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 3, 4

Edits to WAFER TEST LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edits to PACKAGE TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

REV. C

–11–

Page 12

C00324–0–10/02(C)

–12–

PRINTED IN U.S.A.

Loading...

Loading...