Page 1

OUT A

–IN A

+IN A

V–

V+

OUT B

–IN B

+IN B

1

2

3

4

5

6

7

8

OP220

Dual Micropower

+IN A

V–

+IN B

–IN B

–IN A

OUT A

V+

OUT B

1

2

3

4

5

6

7

8

a

FEATURES

Excellent TCV

Low Input Offset Voltage: 150 V Max

Low Supply Current: 100 A

Single-Supply Operation: 5 V to 30 V

Low Input Offset Voltage Drift: 0.75 V/ⴗC Max

High Open-Loop Gain: 2,000 V/mV

High PSRR: 3 V/V

Low Input Bias Current: 12 nA

Wide Common-Mode Voltage Range: V– to Within

1.5 V of V+

Pin Compatible with 1458, LM158, and LM2904

Available in Die Form

GENERAL DESCRIPTION

The OP220 is a monolithic dual operational amplifier that can

be used either in single or dual supply operation. The low offset

voltage and input offset voltage tracking as low as 1.0 mV/∞C,

make this the first micropower precision dual operational amplifier.

The excellent specifications of the individual amplifiers combined with the tight matching and temperature tracking between

channels provides high performance in instrumentation amplifier designs. The individual amplifiers feature extremely low

input offset voltage, low offset voltage drift, low noise voltage,

and low bias current. They are fully compensated and protected.

Matching between channels is provided on all critical parameters

including input offset voltage, tracking of offset voltage versus

temperature, noninverting bias currents, and common-mode

rejection ratios.

Match: 2 V/ⴗC Max

OS

Operational Amplifier

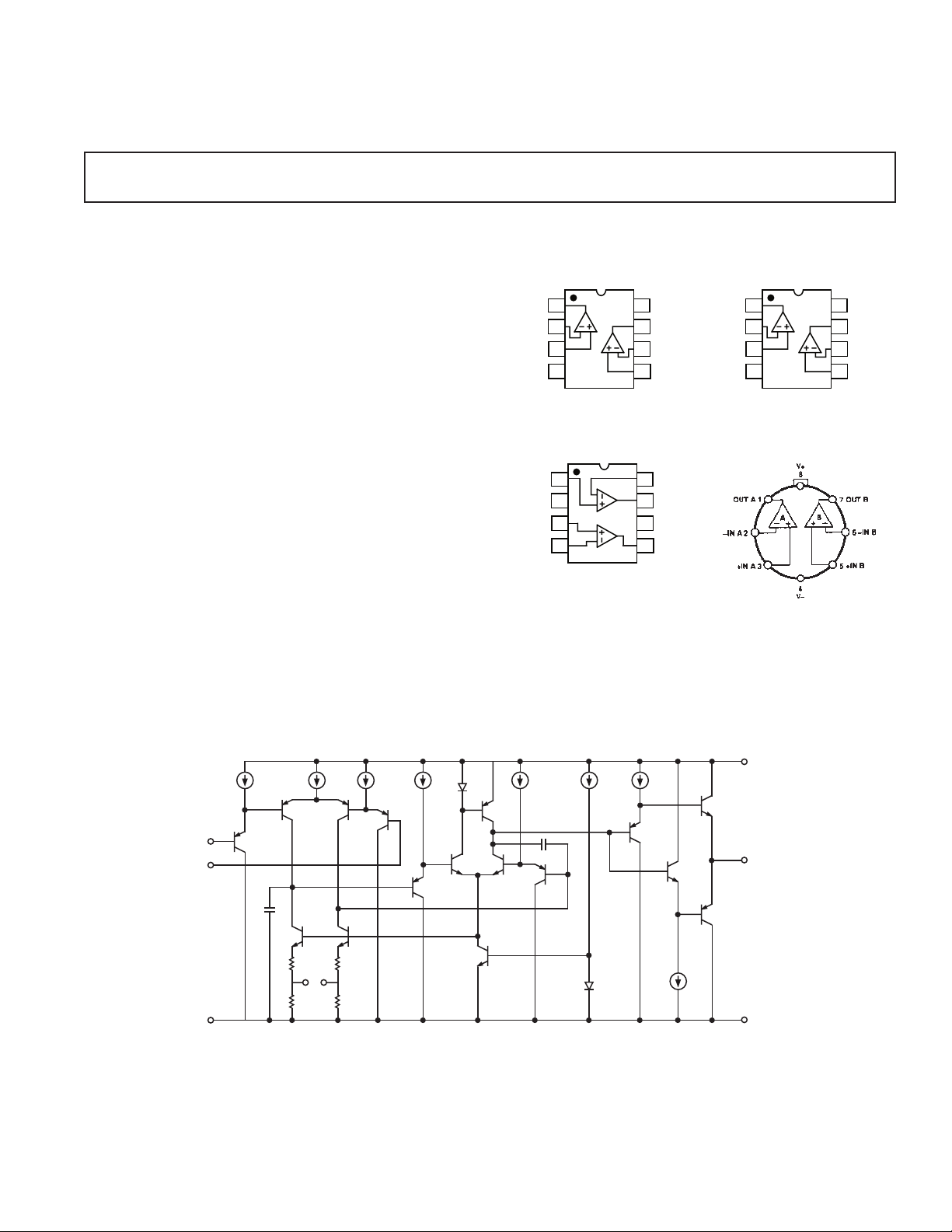

PIN CONFIGURATIONS

8-Lead Hermatic Dip

(Z-Suffix)

8-Lead SOIC

(S-Suffix)

OP220

8-Lead Plastic Dip

(P-Suffix)

OUT A

1

OP220

–IN A

2

+IN A

3

V–

4

8-Lead TO-99

(J-Suffix)

8

7

6

5

V+

OUT B

–IN B

+IN B

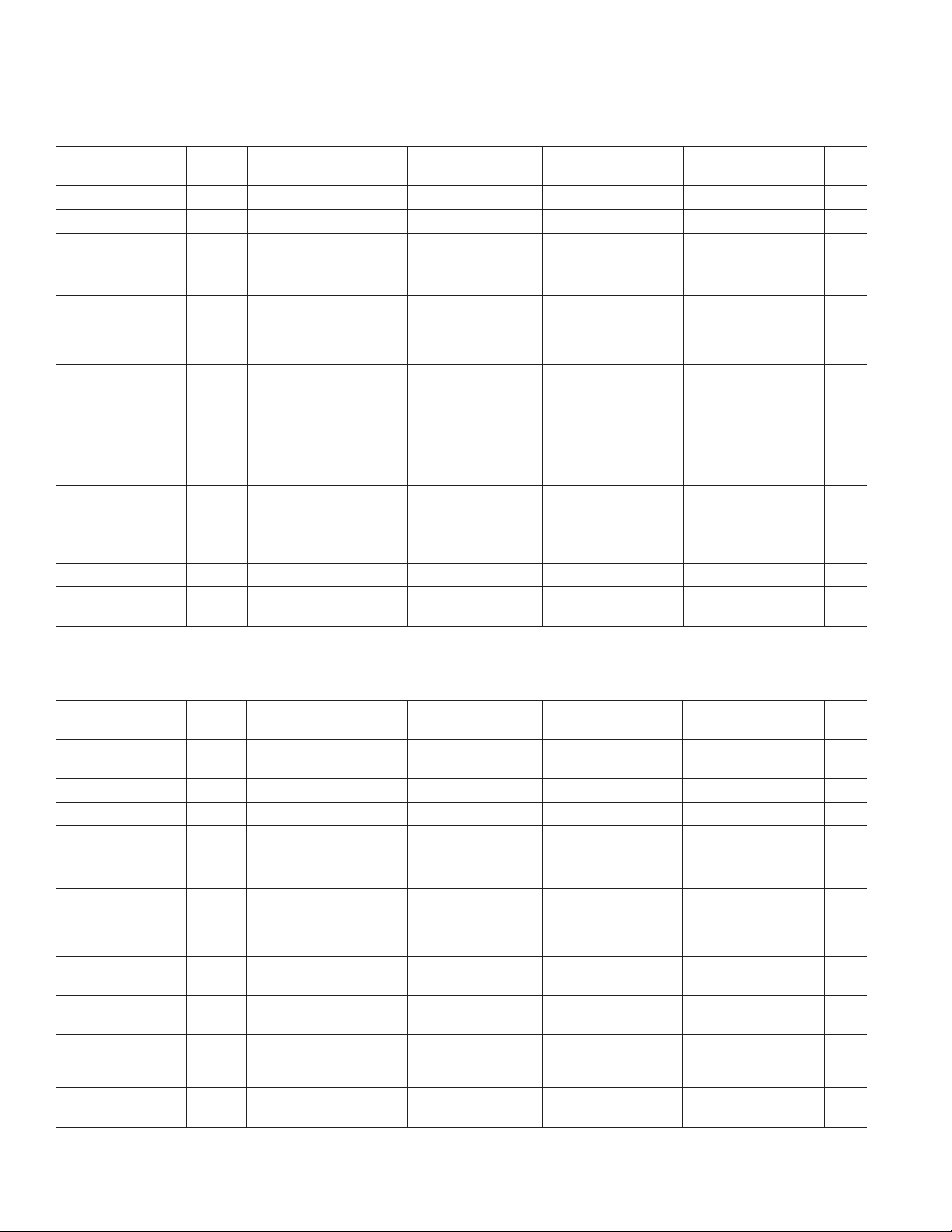

V+

Q11

Q27

Q28

OUTPUT

Q29

V–

Q3 Q4

–IN

+IN

Q1

Q5

NULL*

*ACESSIBLE IN CHIP FORM ONLY

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

Q2

Q7

Q6

Figure 1. Simplified Schematic

Q12

Q26

Q9

Q10

Q8

Q13

Q33

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

OP220–SPECIFICA TIONS

ELECTRICAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Unit

Input Offset Voltage V

Input Offset Current I

Input Bias Current I

Input Voltage Range IVR V+ = 5 V, V– = 0 V 0/3.5 0/3.5 0/3.5 V

Common-Mode CMRR V+ = 5 V, V– = 0 V 90 100 85 90 75 85 dB

Rejection Ratio 0 V £ VCM £ 3.5 V

Power Supply PSRR V

Rejection Ratio V– = 0 V, V+ = 5 V to 30 V 6 18 18 57 57 180 mV/V

Large-Signal A

Voltage Gain RL = 100 kW,

Output Voltage V

Swing RL = 10 kW

Slew Rate* SR RL =25 kW 0.05 0.05 0.05 V/ms

Bandwidth BW A

Supply Current I

(Both Amplifiers) VS = ± 15 V, No Load 140 170 150 190 205 220 mA

OS

OS

B

VO

O

SY

VS = ± 2.5 V to ± 15 V 120 150 250 300 500 750 mV

VCM = 0 0.15 1.5 0.2 2 0.2 3.5 nA

VCM = 0 12 201325 1430nA

VS = ± 15 V –15/+13.5 –15/+13.5 –15/+13.5 V

VS = ± 15 V 95 100 90 95 80 90 dB

–15 V £ VCM £ +13.5 V

= ± 2.5 V to ± 15 V, 3 10 10 32 32 100 mV/V

S

V+ = 5 V, V– = 0 V, 500 1,000 500 800 300 500 V/mV

1 V £ VO £ 3.5 V

VS = ± 15 V, RL = 25 kW 1,000 2,000 1,000 2,000 800 1,600 V/mV

VO = ± 10 V

V+ = 5 V, V– = 0 V 0.7/4 0.7/4 0.8/4 V

VS = ± 15 V, RL = 25 kW±14 ± 14 ± 14 V

= 1, RL =25 kW 200 200 200 kHz

VCL

VS = ± 2.5 V, No Load 100 115 115 125 125 135 mA

(@ VS = ⴞ2.5 V to ⴞ15 V, TA = 25ⴗC, unless otherwise noted.)

OP220A/E OP220F OP220C/G

*Sample tested.

(Vs = ⴞ2.5 V to ⴞ15 V, –55ⴗC £ TA £ +125ⴗC for OP220A/C, –25ⴗC £ TA £ +85ⴗC for OP220E/F,

ELECTRICAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Unit

Input Offset Voltage TCV

Drift*

Input Offset Voltage V

Input Offset Current I

Input Bias Current I

Input Voltage Range IVR V+ = 5 V, V– = 0 V 0/3.2 0/3.2 0/3.2 V

Common-Mode CMRR V+ = 5 V, V– = 0 V 86 90 80 85 70 80 dB

Rejection Ratio 0 V £ VCM £ 3.2 V

Power Supply PSRR VS = ± 2.5 V to ± 15 V, 6 18 18 57 57 180 mV/V

Rejection Ratio V– = 0 V, V+ = 5 V to 30 V 10 32 32 100 100 320 mV/V

Large-Signal A

Voltage Gain VO = ± 10 V

Output Voltage V

Swing RL = 20 kW

Supply Current I

(Both Amplifiers) VS = ± 15 V, No Load 190 250 200 280 275 330 mA

OS

OS

B

VO

O

SY

VS = ± 15 V 0.75 1.5 1.2 2 2 3 mV/∞C

OS

VCM = 0 0.5 2 0.6 2.5 0.6 5 nA

VCM = 0 12 251330 1440nA

VS = ± 15 V –15/+13.2 –15/+13.2 –15/+13.2 V

VS = ± 15 V 90 958590 7585 dB

–15 V £ VCM £ +13.2 V

VS = ± 15 V, RL = 50 kW 500 1,000 500 800 400 500 V/mV

V+ = 5 V, V– = 0 V 0.9/3.8 0.9/3.8 1.0/3.8 V

VS = ± 15 V, RL = 50 kW±13.6 ± 13.6 ± 13.6 V

VS = ± 2.5 V, No Load 135 170 155 185 170 210 mA

–40ⴗC £ TA £ +85ⴗC for OP220G unless otherwise noted.)

OP220A/E OP220F OP220C/G

200 300 400 500 1,000 1,300 mV

*Sample tested.

–2–

REV. A

Page 3

OP220

MATCHING CHARACTERISTICS

(@ VS = ⴞ15 V, TA = 25ⴗC, unless otherwise noted.)

OP220A/E OP220F OP220C/G

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Unit

Input Offset Voltage DV

OS

150 300 250 500 300 800 mV

Match

Average Noninverting I

+V

B

= 0 10 2015252030nA

CM

Bias Current

Noninverting Offset I

+VCM = 0 0.7 1.5 1 2 1.4 2.5 nA

OS

Current

Common-Mode DCMRR VCM = –15 V to +13.5 V 92 100 87 95 72 85 dB

Rejection Ratio Match

Power Supply DPSRR VS = ± 2.5 V to ± 15 V, 6 14 18 44 57 140 mV/V

Rejection Ratio Match

NOTES

1

DCMRR is 20 log10 VCM/DCME, where VCM is the voltage applied to both noninverting inputs and D CME is the difference in common-mode input-referred error.

2

DPSRR is

3

Sample tested.

Input Referred Differential Error

DV

1

2

S

.

(Vs = ⴞ15 V, –55ⴗC £ TA £ +125ⴗC for OP220A/C, –25ⴗC £ TA £ +85ⴗC for OP220E/F,

MATCHING CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Unit

Input Offset Voltage DV

Match

Input Offset Voltage TCDV

1

Tracking

Average Noninverting IB+V

Bias Current

Average Drift of TCIB+VCM = 0 15 2515303050pA/∞C

Noninverting

Bias Current

1

Noninverting Offset IOS+VCM = 0 0.7 2 1 2.5 2.5 5 nA

Current

Average Drift of TCIOS+VCM = 0 7 15 12 22.5 15 30 pA/∞C

Noninverting Offset

1

Current

Common-Mode DCMRR VCM = –15 V to +13 V 87 96 82 96 72 80 dB

Rejection Ratio Match

Power Supply DPSRR VS = ± 2.5 V to ± 15 V, 10 26 30 78 57 250 mV/V

Rejection Ratio Match

NOTES

1

Sample tested.

2

DCMRR is 20 log10 VCM/DCME, where VCM is the voltage applied to both noninverting inputs and D CME is the difference in common-mode input-referred error.

3

DPSRR is

Input Referred Differential Error

DV

OS

OS

= 0 10 2515302240nA

CM

2

3

S

.

–40ⴗC £ TA £ +85ⴗC for OP220G unless otherwise noted. Grades E, F are sample tested.)

OP220A/E OP220F OP220C/G

250 500 400 800 800 1,800 mV

12 1.5 3 1.5 5 mV/∞C

TYPICAL ELECTRICAL CHARACTERISTICS

(@ Vs = ⴞ15 V, TA = 25ⴗC, unless otherwise noted.)

OP220N

Parameter Symbol Conditions Typical Unit

Average Input Offset Voltage Drift TCV

Large-Signal Voltage Gain A

VO

REV. A

OS

RL = 25 kW 2000 V/mV

–3–

1.5 mV/∞C

Page 4

OP220–SPECIFICA TIONS

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

Differential Input Voltage . . . . . . . . . .30 V or Supply Voltage

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . Supply Voltage

Output Short-Circuit Duration Indefinite

Storage Temperature Range . . . . . . . . . . . . –65∞C to +150∞C

Junction Temperature (T

) . . . . . . . . . . . . . –65∞C to +150∞C

i

Operating Temperature Range

OP220A/OP220C . . . . . . . . . . . . . . . . . . –55∞C to +125∞C

OP220E/OP220F . . . . . . . . . . . . . . . . . . . . –25∞C to +85∞C

OP220G . . . . . . . . . . . . . . . . . . . . . . . . . . . –40∞C to +85∞C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . . 300∞C

NOTES

*Absolute Maximum Ratings apply to packaged parts, unless otherwise noted.

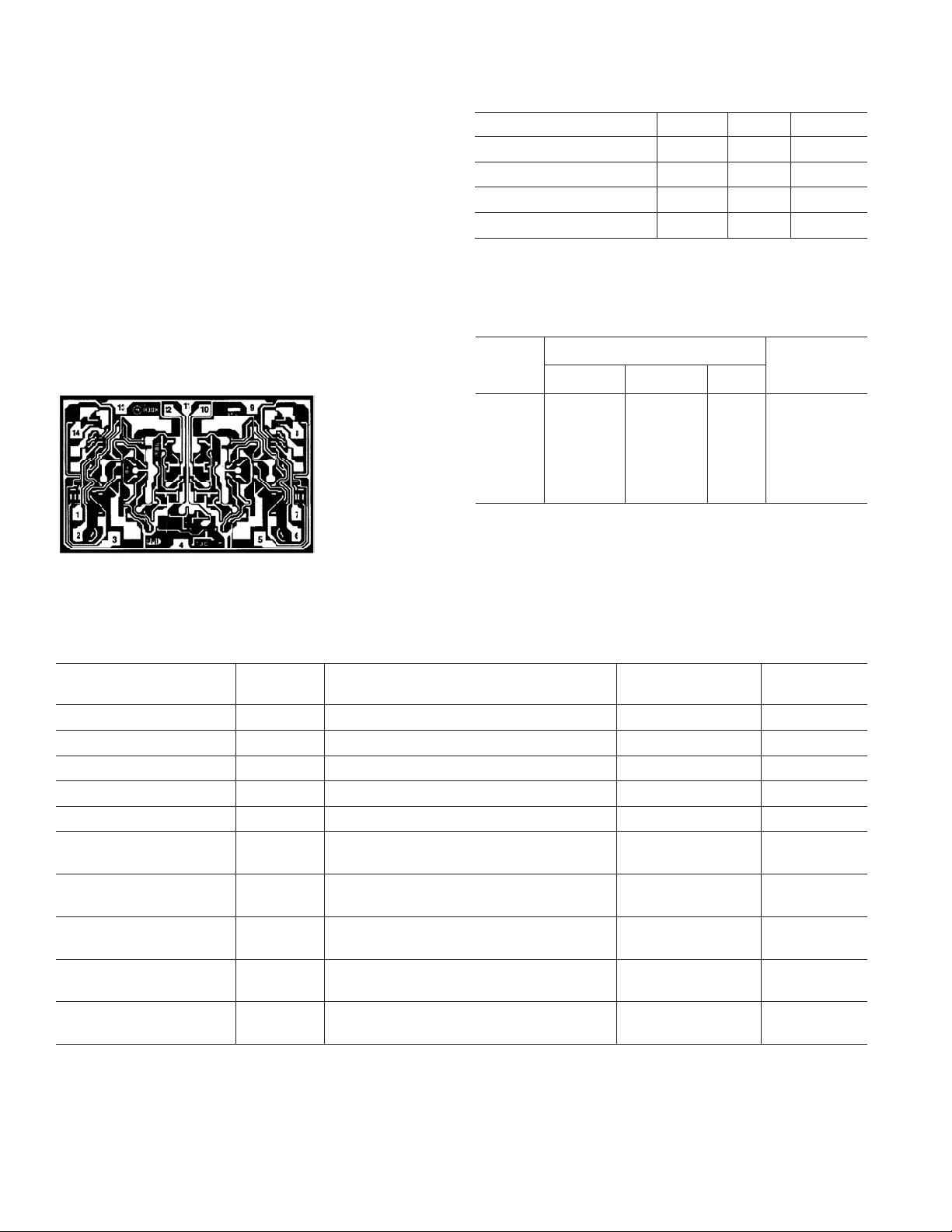

DIE CHARACTERISTICS

1. INVERTING INPUT (A)

2. NONINVERTING INPUT (A)

3. BALANCE (A)

4. V–

5. BALANCE (B)

6. NONINVERTING INPUT (B)

7. INVERTING INPUT (B)

8. BALANCE (B)

9. V+

10. OUT (B)

11. V+

12. OUT (A)

13. V+

DIE SIZE 0.097 INCH ⴛ 0.063 INCH, 6111 SQ. MILS

(2.464 mm ⴛ 1.600 mm, 3.94 SQ. mm)

NOTE : ALL V+ PADS ARE INTERNALL CONNECTED

14. BALANCE (A)

Package Type

*

JA

JC

Unit

8-Lead Hermetic DIP (Q) 148 16 ∞C/W

8-Lead Plastic DIP (N) 103 43 ∞C/W

8-Lead SOL (RN) 158 43 ∞C/W

TO-99 (H) 150 18 ∞C/W

*

is specified for worst-case mounting conditions, i.e., JA is specified for device

JA

in socket for CERDIP and PDIP packages; JA is specified for device soldered to

printed circuit board for SO packages.

ORDERING GUIDE

TA = 25∞C Package Options Operating

MAX Temperature

V

OS

(mV) CERDIP Plastic TO-99 Range

150 OP220AZ* MIL

150 OP220EZ* IND

300 OP220FZ* IND

750 OP220CJ* MIL

750 OP220GZ* OP220GP* XIND

750 OP220GS XIND

For military processed devices, please refer to the Mil Standard

Data Sheet

OP220AJ/883*.

*Not for new design. Obsolete April 2002.

WAFER TEST LIMITS

(@ VS = ⴞ2.5 V, to ⴞ15 V, TA = 25ⴗC, unless otherwise noted.)

OP220N

Parameter Symbol Conditions Limit Unit

Input Offset Voltage V

Input Offset Voltage Match ⌬V

Input Offset Current I

Input Bias Current I

OS

B

OS

OS

VCM = 0 2 nA Max

VCM = 0 25 nA Max

200 mV Max

300 mV Max

Input Voltage Range IVR VS = ± 15 V –15/13.5 V Min

Common-Mode CMRR V– = 0 V, V+ = 5 V, 0 V £ V

£ 3.5 V 88 dB Min

CM

Rejection Ratio –15 V £ VCM £ 13.5 V, VS = ± 15 V 93

Power Supply PSRR V

= ± 2.5 V to ± 15 V 12.5 mV/V Max

S

Rejection Ratio V– = 0 V, V+ = 5 V to 30 V 22.5

Large-Signal A

VO

RL = 25 kW, VS = ± 15 V 1000 V/mV Min

Voltage Gain VO = ± 10 V

Output Voltage Swing V

O

V+ = 5 V, V– = 0 V, RL = 10 kW 0.7/4 V Min

VS = ± 15 V, RL = 25 kW±14

Supply Current I

SY

VS = ± 2.5 V, No Load 125 mA Max

(Both Amplifiers) VS = ± 15 V, No Load 190

NOTE

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packing is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on die lot qualification through sample lot assembly and testing.

–4–

REV. A

Page 5

INPUT OFFSET VOLTAGE – V

TEMPERATURE – ⴗC

14

0

–100 150

INPUT BIAS CURRENT – nA

–50 0 50 100

12

10

8

6

4

2

VS = 15V

–100

150

100

–50

Typical Performance Characteristics–

VS = 15V

50

0

OP220

–150

–50 125–25

0255075100

TEMPERATURE – ⴗC

TPC 1. Normalized Offset Voltage vs. Temperature

80

TA = 25ⴗC

60

40

20

0

–20

⌬ INPUT OFFSET VOLTAGE – V

–40

–60

0

4 8 12 16

POWER SUPPLY VOLTAGE – V

20

TPC 2. Input Offset Voltage vs. Power Supply Voltage

110

VS = 15V

100

90

80

70

60

50

40

OPEN-LOOP GAIN – dB

30

20

10

0

–75 125–50

–25 0 25 50 75 100

10Hz

100Hz

1kHz

TEMPERATURE – ⴗC

TPC 3. Open-Loop Gain vs. Temperature

TPC 4. Input Bias Current vs. Temperature

700

VS = 15V

600

500

400

300

200

INPUT OFFSET CURRENT – pA

100

0

–100 150

–50 0 50 100

TEMPERATURE – ⴗC

TPC 5. Input Offset Current vs. Temperature

200

180

160

140

120

100

SUPPLY CURRENT – A

80

60

0

TA = 125ⴗC

TA = 25ⴗC

TA = –55ⴗC

7.5 10.0 12.5

5.02.5 15.0

SUPPL Y V OL T A GE – V

TPC 6. Supply Current vs. Supply Voltage

17.5

REV. A

–5–

Page 6

OP220

k

k

FREQUENCY – Hz

160

0

0.01 1M0.1

OPEN-LOOP GAIN – dB

1101001k10k 100k

140

80

60

40

20

120

100

TA = 25ⴗC

V

S

= 15V

GAIN

PHASE

⌽m = 53ⴗ

0

45

90

135

180

PHASE SHIFT – Degrees

120

100

80

60

CMRR – dB

40

20

TA = 25ⴗC

V

= 15V

S

0

0.01 1

130

120

110

100

90

80

PSRR – dB

70

60

50

40

1100

17

15

10

5

PEAK OUTPUT VOLTAGE – V

0

110010

TPC 9. Maximum Output Voltage vs. Load Resistance

0.1

110100

FREQUENCY – Hz

TPC 7. CMRR vs. Frequency

–PSRR

10

100 1k 10k

FREQUENCY – Hz

TPC 8. PSRR vs. Frequency

TA = 25ⴗC

V

LOAD RESISTANCE – k⍀

+PSRR

VS = 15V

= 5V

S

TPC 10. Open-Loop Voltage Gain and Phase vs. Frequency

36

T

A

V

S

= 25ⴗC

= 15V

TA = 25ⴗC

32

= 15V

V

S

28

24

20

16

12

8

PEAK-TO-PEAK AMPLITUDE – V

4

0

100 1M1k

10k 100k

FREQUENCY – Hz

TPC 11. Maximum Output Swing vs. Frequency

0.09

0.08

0.07

0.06

sec

0.05

0.04

0.03

SLEW RATE – V/

0.02

0.01

0

–75 150–50 –25 0 25 50 75 100 125

TPC 12. Slew Rate vs. Temperature

VS = 15V

VS = 5V

TEMERATURE – ⴗC

–6–

REV. A

Page 7

OP220

k

k

1,000

100

VOLTAGE NOISE DENSITY – nV/ Hz

10

0.1 1

110100

FREQUENCY – Hz

TPC 13. Voltage Noise Density vs. Frequency

10

Hz

1

0.1

CURRENT NOISE DENSITY – pA/

0.01

0.1 1

110100

FREQUENCY – Hz

TPC 14. Noise Density vs. Frequency

REV. A

–7–

Page 8

OP220

T

25k⍀

2s

OUTPU

100pF

INPUT

100

90

10

0%

50mV

20mV

OP220

Figure 2. Small-Signal Transient Response

2V

100

90

200s

R0

GAIN

R1 R2

V

– 1/2 V

CM

D

–

V

D

+ 1/2 V

È

4

Í

3

Î

1

+

D

12213

RRR

Ê

Á

Ë

V

CM

R

V

=+ +

ODCM

R

If then,

1234 21

=== =+

RRRR V

1/2

OP220

4

R

A1

R3

RR

ˆ

+

˜

¯

OD

ADJ

V1

23043342

+

R

Ê

Á

Ë

R4

A2

1/2

OP220

˘

RRRRR

Ê

+-

V

˙

˚

1

R

0

R

Á

Ë

ˆ

V

˜

¯

V

R

O

ˆ

V

˜

¯

1

Figure 4. Two Op Amp Instrumentation Amplifier

Configuration

The input voltages are represented as a common-mode input

plus a differential input VD. The ratio R3/R4 is made equal

V

CM

to the ratio R2/R, to reject the common-mode input V

differential signal V

is then amplified according to:

D

CM

. The

10

0%

5V

INPUT

OUTPUT

C

L

100pF

10k⍀

OP220

40k⍀

R

L

25k⍀

Figure 3. Large-Signal Transient Response

INSTRUMENTATION AMPLIFIER APPLICATIONS OF

THE OP220

Two Op Amp Configuration

The excellent input characteristics of the OP220 make it ideal for

use in instrumentation amplifier configurations where low-level

differential signals are to be amplified. The low-noise, low input

offsets, low drift, and high gain combined with excellent CMRR

provide the characteristics needed for high-performance instrumentation amplifiers. In addition, the power supply current

drain is very low.

The circuit of Figure 4 is recommended for applications where

the common-mode input range is relatively low and differential

gain will be in the range of 10 to 1,000. This two op amp instrumentation amplifier features independent adjustment of common-mode

rejection and differential gain. Input impedance is very high since

both inputs are applied to noninverting op amp inputs.

Ê

R

V

4

=++

O

R

3

3423 342

RRRR

1

Á

Ë

ˆ

+

R

O

˜

¯

V

D

,where

RRR

=

R

1

Note that gain can be independently varied by adjusting RO.

From considerations of dynamic range, resistor tempco matching, and matching of amplifier response, it is generally best to

make RX, R2, R3, and R4 approximately equal. Designating

R1, R2, R3, and R4 as RN allows the output equation to be

further simplified:

V

=+

O

Ê

Á

Ë

ˆ

R

N

VRRRRR

˜

DN

R

¯

O

=== =21 1 2 3 4,where

Dynamic range is limited by A1 as well as A2; the output of A1 is:

V

11 2=- +

Ê

Á

Ë

ˆ

R

N

VV

˜

DCM

R

¯

O

+

If the instrumentation amplifier were designed for a gain of 10

and maximum V

would be a maximum of ± 10 V. Amplifier A1 would

and V

O

have a maximum output of ± 5 V plus 2 V

± 10 V on the output of A1 would imply a limit of ±2.5 V on V

A nominal value of 100 kW for R

tions. A range of 200 W to 25 kW for R

range of 10 to 1,000. The current through R

of ± 1 V, then RN/RO would need to be four

D

, thus a limit of

CM

is suitable for most applica-

N

will then provide a gain

O

is VD/RO, so the

O

CM

.

amplifiers must supply ± 10 mV/200 W when the gain is at the

maximum value of 1,000 and V

is at ± 10 mV.

D

Rejecting common-mode inputs is most important in accurately

amplifying low-level differential signals. Two factors determine

the CMR of this instrumentation amplifier configuration (assuming

infinite gain):

1. CMRR of the op amps

2. Matching of the resistor network (R3/R4 = R2/R1)

–8–

REV. A

Page 9

OP220

V

R

R

V

V

V

R

R

V

V

VVV

R

R

V

VAV

O

D

CM

O

D

CM

O

O

D

ODD

11

21

2

21

21

2

211

21

=- +

Ê

Ë

Á

ˆ

¯

˜

+

=+

Ê

Ë

Á

ˆ

¯

˜

+

=-=+

Ê

Ë

Á

ˆ

¯

˜

=

In this instrumentation amplifier configuration, error due to

CMRR effect is directly proportional to the differential CMRR

of the op amps. For the OP220A/E, this combined CMRR is a

minimum of 98 dB. A combined CMRR value of 100 dB and

common-mode input range of ± 2.5 V indicates a peak inputreferred error of only ± 25 mV.

Resistor matching is the other factor affecting CMRR. Defining

Ad as the differential gain of the instrumentation amplifier and

assuming that R1, R2, R3 and R4 are approximately equal (R

N

will be the nominal value), then CMRR will be approximately

divided by 4DR/RN. CMRR at differential gain of 100 would

A

D

be 88 dB with resistor matching of 0.1%. Trimming R1 to make

the ratio R3/R4 equal to R2/R1 will directly raise the CMRR

until it is limited by linearity and resistor stability considerations.

The high open-loop gain of the OP220 is very important in

achieving high accuracy in the two-op-amp instrumentation

amplifier configuration. Gain error can be approximated by:

GainError =

1

A

+

1

A

A

D

<

,

AA

2

D

01 02

02

1

where AD is the instrumentation amplifier differential gain and

A

is the open-loop gain of op amp A2. This analysis assumes

02

equal values of R1, R2, R3, and R4. For example, consider an

OP220 with A

of 700 V/mV. If the differential gain AD were

02

set to 700, the gain error would be 1/1.001 which is approximately 0.1%.

Another effect of finite op amp gain is undesired feedthrough of

common-mode input. Defining A

as the open-loop gain of op

01

amp A1, then the common-mode error (CME) at the output

due to this effect will be approximately:

THREE OP AMP CONFIGURATION

A three op amp instrumentation amplifier configuration using

the OP220 and OP777 is recommended for applications requiring

high accuracy over a wide gain range. This circuit provides

excellent CMR over a wide input range. As with the two op amp

instrumentation amplifier circuits, tight matching of the two op

amps provides a real boost in performance.

R1

V

– 1/2 V

CM

D

–

R0 A3

V

D

+ 1/2 V

V

CM

+

D

1/2

OP220

1/2

OP220

A1

R1

V+

A2

V–

V

O

R2

V1

R2

V2

= VD 1 +

V–

R2

2R1

R0

R2

V+

OP777

V

O

Figure 5. Three Op Amp Instrumentation Amplifier Using

OP220 and OP777

A simplified schematic is shown in Figure 2. The input stage

(A1 and A2) serves to amplify the differential input V

amplifying the common-mode voltage V

. The output stage

CM

without

D

then rejects the common-mode input. With ideal op amps and

no resistor matching errors, the outputs of each amplifier will be:

For AD/A01, < 1, this simplifies to (2 AD/A01) ⫻ VCM. If the op

amp gain is 700 V/mV, V

the error at the output due to this effect will be approximately 5 mV.

The OP220 offers a unique combination of excellent dc performance, wide input range, and low supply current drain that is

particularly attractive for instrumentation amplifier design.

REV. A

A

1

CME

D

=

A

+21

A

is 2.5 V, and AD is set to 700, then

CM

V

CM

A

D

01

01

The differential gain AD is 1 + 2R1/RO and the common-mode

input V

is rejected.

CM

This three op amp instrumentation amplifier configuration using an

OP220 at the input and an OP777 at the output provides excellent

performance over a wide gain range with very low power consumption. A gain range of 1 to 2,000 is practical and CMR of over

120 dB is readily achievable.

–9–

Page 10

OP220

OUTLINE DIMENSIONS

8-Lead Ceramic DIP – Glass Hermatic Seal [CERDIP]

(Q-8)

Dimensions shown in inches and (millimeters)

0.005 (0.13)

PIN 1

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCH; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.055 (1.40)

MIN

0.100 (2.54) BSC

0.405 (10.29) MAX

MAX

85

1

4

0.070 (1.78)

0.030 (0.76)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150 (3.81)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15

0

0.015 (0.38)

0.008 (0.20)

8-Lead Plastic Dual-in-Line Package [PDIP]

(N-8)

Dimensions shown in inches and (millimeters)

8-Lead Standard Small Outline Package [SOIC]

Narrow Body

(RN-8)

Dimensions shown in millimeters and (inches)

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

85

1.27 (0.0500)

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012AA

BSC

6.20 (0.2440)

5.80 (0.2284)

41

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.33 (0.0130)

0.25 (0.0098)

0.19 (0.0075)

0.50 (0.0196)

0.25 (0.0099)

8ⴗ

0ⴗ

1.27 (0.0500)

0.41 (0.0160)

8-Lead Metal Can [TO-99]

(H-08)

Dimensions shown in inches and (millimeters)

ⴛ 45ⴗ

0.375 (9.53)

0.365 (9.27)

0.355 (9.02)

8

1

0.100 (2.54)

0.180

(4.57)

MAX

0.150 (3.81)

0.130 (3.30)

0.110 (2.79)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES)

COMPLIANT TO JEDEC STANDARDS MO-095AA

BSC

5

4

0.295 (7.49)

0.285 (7.24)

0.275 (6.98)

0.015

(0.38)

MIN

SEATING

PLANE

0.060 (1.52)

0.050 (1.27)

0.045 (1.14)

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.150 (3.81)

0.135 (3.43)

0.120 (3.05)

0.015 (0.38)

0.010 (0.25)

0.008 (0.20)

REFERENCE PLANE

0.5000 (12.70)

0.1850 (4.70)

0.1650 (4.19)

0.3700 (9.40)

0.3350 (8.51)

0.3350 (8.51)

0.3050 (7.75)

0.0400 (1.02) MAX

0.0400 (1.02)

0.0100 (0.25)

COMPLIANT TO JEDEC STANDARDS MO-002AK

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

MIN

0.2500 (6.35) MIN

0.0500 (1.27) MAX

0.2000

(5.08)

BSC

0.0190 (0.48)

0.0160 (0.41)

0.0210 (0.53)

0.0160 (0.41)

BASE & SEATING PLANE

0.1000 (2.54) BSC

4

3

2

0.1000

(2.54)

BSC

5

1

0.0340 (0.86)

0.0280 (0.71)

0.1600 (4.06)

0.1400 (3.56)

6

7

8

45 BSC

0.0450 (1.14)

0.0270 (0.69)

–10–

REV. A

Page 11

OP220

Revision History

Location Page

10/02—Data Sheet changed from REV. 0 to REV. A.

Edits to TYPICAL ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to WAFER TEST LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Change to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

REV. A

–11–

Page 12

C00323–0–10/02(A)

–12–

PRINTED IN U.S.A.

Loading...

Loading...