Page 1

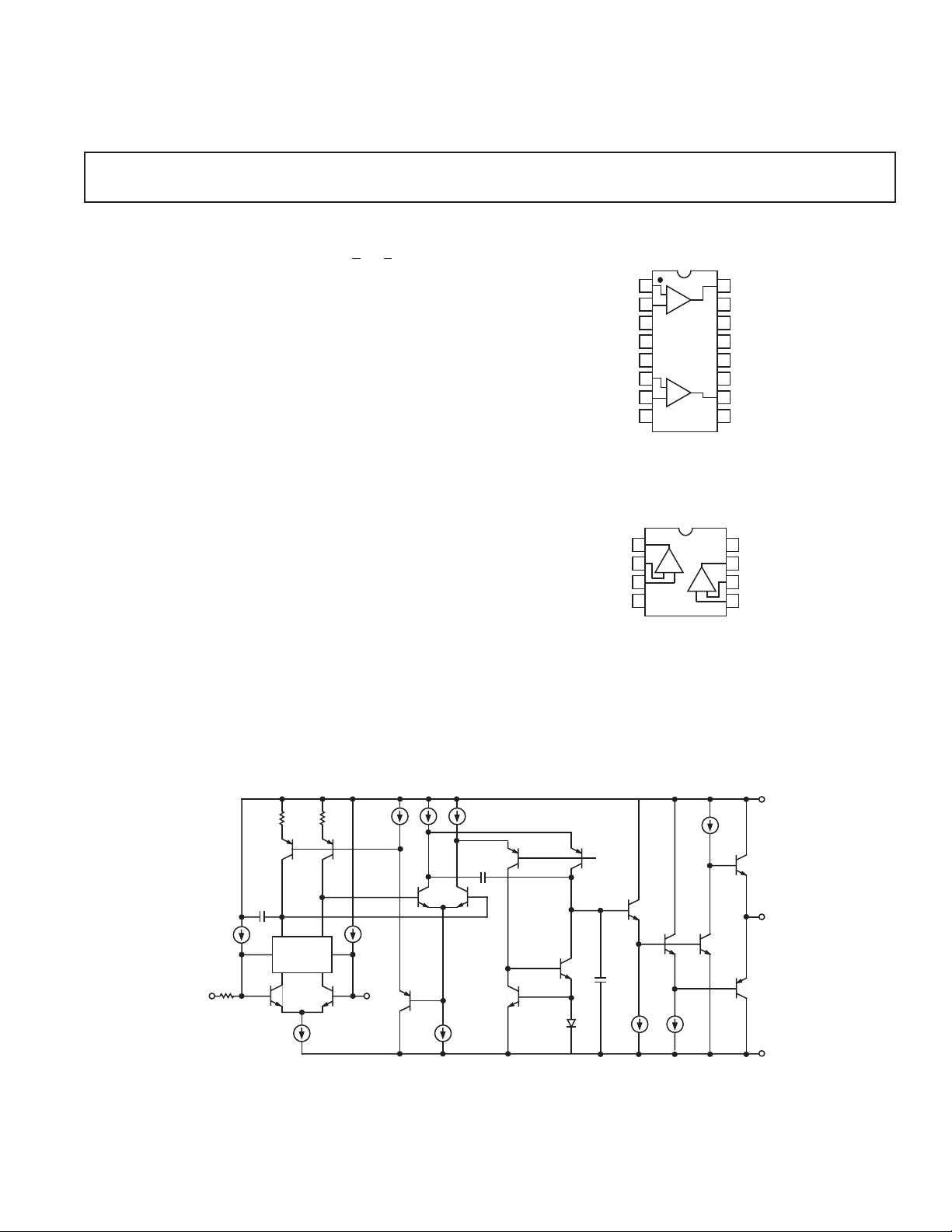

Dual Low Offset, Low Power

8

7

6

5

V+

–IN B

+IN B

OUT B

1

2

3

4

–IN A

+IN A

V–

OUT A

+–

+–

A

B

a

FEATURES

Low Input Offset Voltage: 75 V Max

<

<

T

+125C:

Low Offset Voltage Drift, Over –55C

0.5 V/C Max

Low Supply Current (Per Amplifier): 725 A Max

High Open-Loop Gain: 5000 V/mV Min

Low Input Bias Current: 2 nA Max

Low Noise Voltage Density: 11 nV/√Hz at 1 kHz

Stable with Large Capacitive Loads: 10 nF Typ

Pin Compatible to OP221, MC1458, and LT1013 with

Improved Performance

Available in Die Form

GENERAL DESCRIPTION

The OP200 is the first monolithic dual operational amplifier to

offer OP77 type precision performance. Available in the industrystandard 8-lead pinout, the OP200 combines precision performance

with the space and cost savings offered by a dual amplifier.

The OP200 features an extremely low input offset voltage of less

than 75 µV with a drift below 0.5 µV/°C, guaranteed over the full

military temperature range. Open-loop gain of the OP200 exceeds

5,000,000 into a 10 kΩ load; input bias current is under 2 nA;

CMR is over 120 dB and PSRR below 1.8 µV/V. On-chip

Zener zap trimming is used to achieve the extremely low input

offset voltage of the OP200 and eliminates the need for offset

pulling.

Power consumption of the OP200 is very low, with each amplifier

drawing less than 725 µA of supply current. The total current

drawn by the dual OP200 is less than one-half that of a single

OP07, yet the OP200 offers significant improvements over this

industry-standard op amp. The voltage noise density of the OP200,

11 nV/√Hz at 1 kHz, is half that of most competitive devices.

A

Operational Amplifier

OP200

PIN CONNECTIONS

16-Lead SOIC

1

–IN A

2

+IN A

3

NC

4

V–

5

NC

6

+IN B

7

–IN B

8

NC

NC = NO CONNECT

8-Lead PDIP (P-Suffix)

8-Lead CERDIP (Z-Suffix)

The OP200 is pin compatible with the OP221, LM158,

MC1458/1558, and LT1013.

The OP200 is an ideal choice for applications requiring multiple

precision op amps and where low power consumption is critical.

For a quad precision op amp, see the OP400.

–

+

+

–

(S-Suffix)

16

OUT A

15

NC

14

NC

13

V+

12

NC

11

NC

10

OUT B

9

NC

V+

BIAS

OUT

VOLTAGE

LIMITING

NETWORK

+IN –IN

V–

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

Figure 1. Simplified Schematic (One of two amplifiers is shown.)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

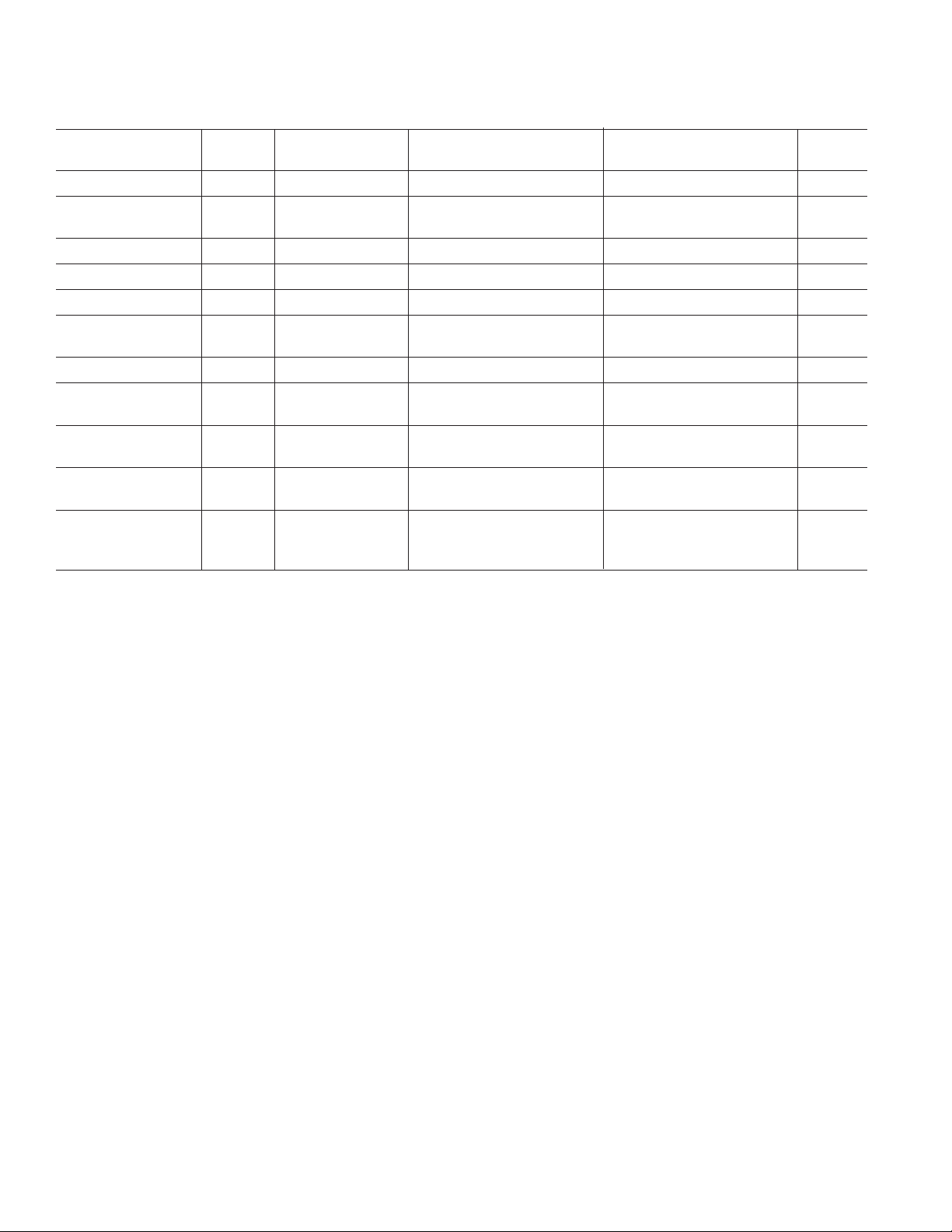

OP200–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(VS = ±15 V, TA = 25C, unless otherwise noted.)

OP200A/E OP200G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

Input Offset Voltage V

OS

25 75 80 200 µV

Long-Term Input

Voltage Stability 0.1 0.1 µV/mo

Input Offset Current I

Input Bias Current I

Input Noise Voltage e

Input Noise e

OS

B

n p-p

n

V

= 0 V 0.05 1.0 0.05 3.5 nA

CM

V

= 0 V 0.1 2.0 0.1 5.0 nA

CM

0.1 Hz to 10 Hz 0.5 0.5 µV

p-p

fO = 10 Hz 22 36 22 nV/√Hz

Voltage Density* fO = 1000 Hz 11 18 11

Input Noise Current in

p-p

0.1 Hz to 10 Hz 15 15 pA

p-p

Input Noise

Current Density i

n

fO = 10 Hz 0.4 0.4 pA/√Hz

Input Resistance

Differential Mode R

IN

10 10 MΩ

Input Resistance

Common Mode R

Large Signal A

INCM

VO

Voltage Gain R

VO – ±10 V

= 10 kΩ 5000 12000 3000 7000

L

125 125 GΩ

RL = 2 kΩ 2000 3700 1500 3200 M/mV

*Sample tested.

Specifications subject to change without notice.

–2–

REV. B

Page 3

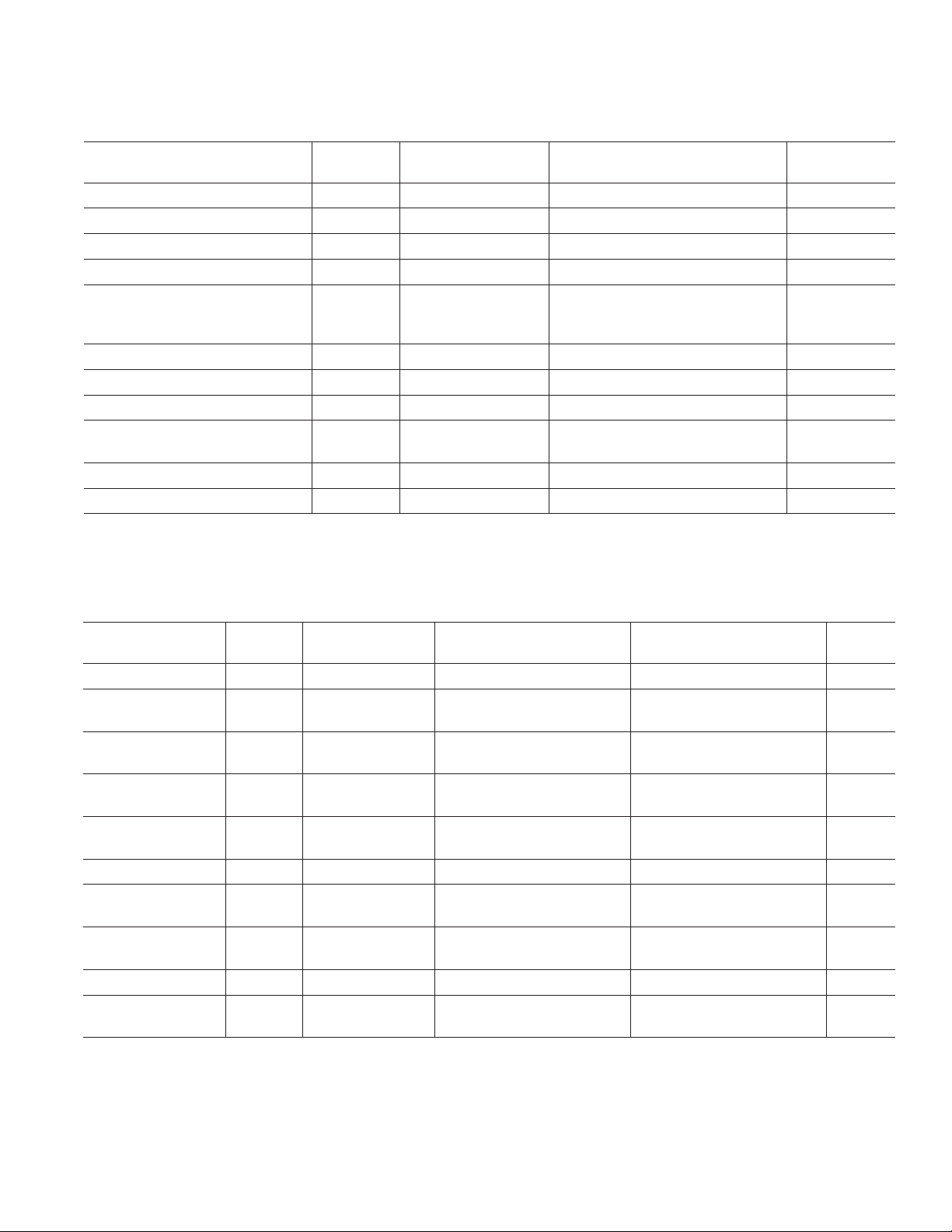

OP200

ELECTRICAL CHARACTERISTICS

(VS = 15 V, –55C ≤ TA ≤ +125C for OP200A, unless otherwise noted.)

OP200A

Parameter Symbol Conditions Min Typ Max Unit

Input Offset Voltage V

OS

Average Input Offset Voltage Drift TCV

Input Offset Current I

Input Bias Current I

Large Signal Voltage Gain A

OS

B

VO

OS

VCM = 0 V 0.15 2.5 nA

VCM = 0 V 0.9 5.0 nA

VO = 10 V

= 10 Ω 3000 9000 V/mV

R

L

45 125 µV

0.2 0.5 µV/°C

RL = 2 kΩ 1000 2700 V/mV

Input Voltage Range* IVR ±12 ±12.5 V

Common-Mode Rejection CMR VCM = ±12 V 115 130 dB

Power Supply Rejection Ratio PSRR VS = +3 V to +18 V 0.2 3.2 µV/V

Output Voltage Swing V

O

RL = 10 kΩ±12 ±12.4 V

RL = 2 kΩ±11 ±12 V

Supply Current Per Amplifier I

SY

No Load 600 775 µA

Capacitive Load Stability AV = 1 8 nF

*Guaranteed by CMR test.

Specifications subject to change without notice.

ELECTRICAL CHARACTERISTICS

(VS = 15 V, TA = 25C, unless otherwise noted.)

OP200A/E OP200G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

Input Voltage Range1IVR ±12 ±13 ±12 ±13 V

Common-Mode

Rejection CMR VCM = ±12 V 120 135 110 130 dB

Power Supply V

= ±3 V

S

Rejection Ratio PSRR to ± 18 V 0.4 1.8 0.6 5.6 µV/V

Output Voltage V

O

RL= 10 kΩ±12 ±12.6 ±12 ±12.6 V

Swing RL = 2 kΩ±11 ±12.2 ±11 ±12.2 V

Supply Current

Per Amplifier I

SY

No Load 570 725 570 725 µA

Slew Rate SR 0.1 0.15 0.1 0.15 V/µS

Gain Bandwidth

Product GBWP AV = 1 500 500 kHz

Channel Separation

2

VO = 20 V p-p

CS fO = 10 Hz 123 145 123 145 dB

Input Capacitance C

IN

Capacitive Load A

V

= 1

3.2 3.2 pF

Stability No Oscillations 10 10 nF

NOTES

1

Guaranteed by CMR test.

2

Guaranteed but not 100% tested.

Specifications subject to change without notice.

REV. B

–3–

Page 4

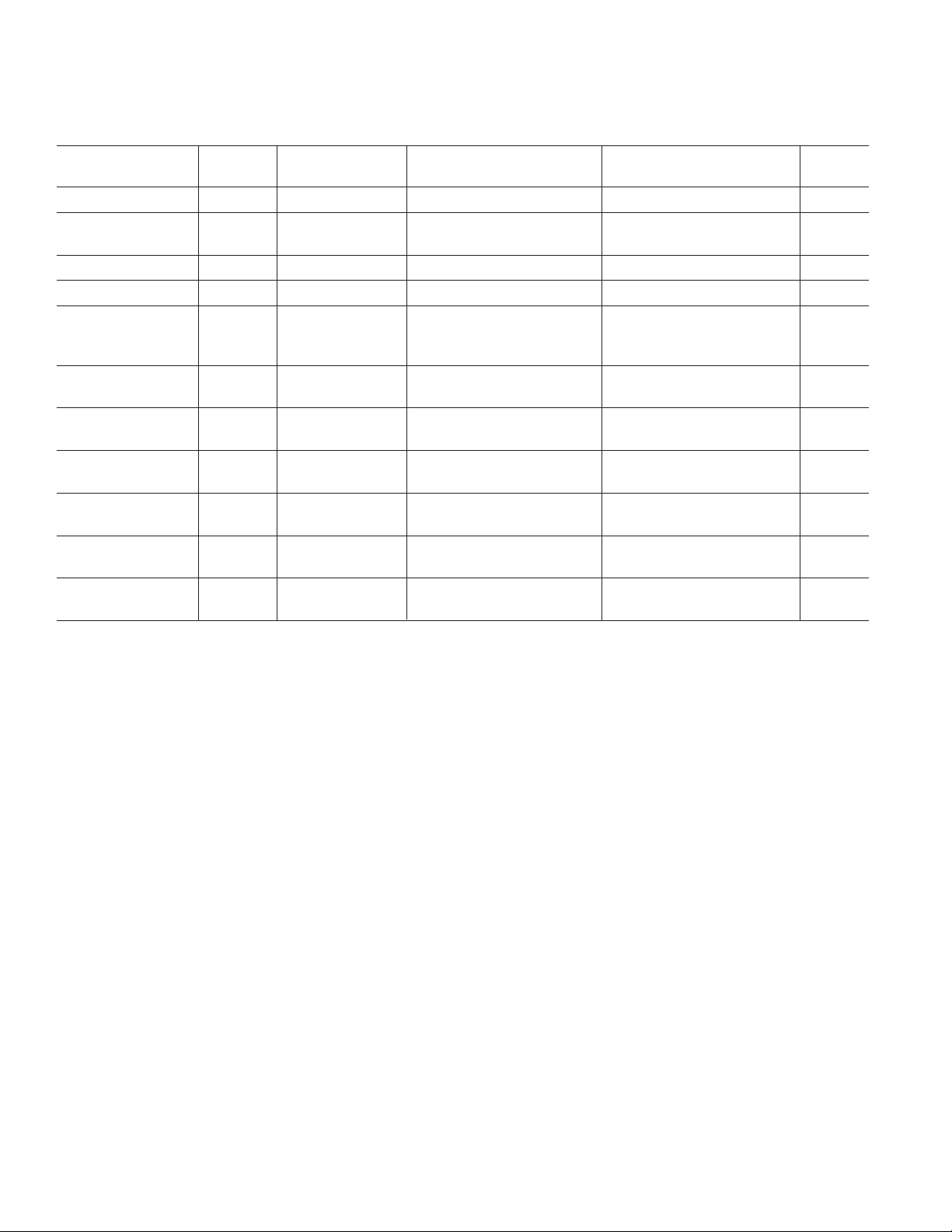

OP200–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(VS = ±15 V, –40C ≤ TA ≤ +85C, unless otherwise noted.)

OP200E OP200G

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

Input Offset Voltage V

OS

35 100 110 300 µV

Average Input Offset

Voltage Drift TCV

Input Offset Current I

Input Bias Current I

OS

B

OS

VCM = 0 V 0.08 2.5 0.1 6.0 nA

VCM = 0 V 0 3 5.0 0.5 10.0 nA

0.2 0.5 0.6 2.0 µV/°C

Large-Signal VO = ±10 V

Voltage Gain A

VO

RL= 10 kΩ 3000 10000 2000 5000 V/mV

RL = 2 kΩ 1500 3200 1000 2500 V/mV

Input Voltage

Range* IVR ± 12 ± 12.5 ± 12 ± 12.5 V

Common-Mode

Rejection CMR VCM = ±12 V 115 130 105 130 dB

Power Supply PSRR V

= ±3 V 0.15 3.2 0.3 10.0 µV/V

S

Rejection Ratio to ±18 V

Output Voltage V

O

RL = 10 kΩ±12 ±12.4 ±12 ±12.4 V

Swing RL = 2 kΩ±11 ±12 ± 11 ± 12.2 V

Supply Current

Per Amplifier I

SY

Capacitive Load A

No Load 600 775 600 775 µA

= 1 10 10 nF

V

Stability No Oscillations 10 10 nF

*Guaranteed by CMR test.

Specifications subject to change without notice.

–4–

REV. B

Page 5

OP200

1/2

OP200

50k

50

1/2

OP200

CHANNEL SEPARATION = 20 LOG

V2/1000

V

1

20Vp-p @ 10Hz

V

1

V

2

Figure 2. Channel Separation Test Circuit

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±20 V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . ±30 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . Supply Voltage

Output Short-Circuit Duration . . . . . . . . . . . . . . Continuous

Storage Temperature Range

P, S, Z-Package . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . 300°C

Junction Temperature (T

) . . . . . . . . . . . . . –65°C to +150°C

J

Operating Temperature Range

OP200A . . . . . . . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

OP200E . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

OP200G . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Package Type

2

JA

JC

Unit

8-Lead CERDIP (Z) 148 16 °C/W

8-Lead Plastic DIP (P) 96 37 °C/W

16-Lead SOIC (S) 92 27 °C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

is specified for worst-case mounting conditions, i.e., JA is specified for

JA

device in socket for CERDIP and PDIP packages; JA is specified for device

soldered to printed circuit board for SOIC package.

10k100

1/2

OP200

(nV/ Hz) = 2 e

e

OUT

1/2

OP200

(nV/ Hz) 101

OUT

TO SPECTRUM

e

OUT

ANALYZER

Figure 3. Noise Test Schematic

ORDERING GUIDE

Package

T

= 25C Operating

A

Max CERDIP Temperature

V

OS

(V) 8-Lead Plastic Range

75 OP200AZ MIL

75 OP200EZ XIND

200 OP200GP XIND

200 OP200GS XIND

200 OP200GS-REEL XIND

For military processed devices, please refer to the Standard

Microcircuit Drawing (SMD) available at

www.dscc.dla.mil/programs/milspec/default.asp

SMD Part Number ADI Equivalent

5962-8859301M2A OP200ARCMDA

5962-8859301MPA OP200AZMDA

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP200 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. B

–5–

Page 6

OP200

–Typical Performance Characteristics

TA = 25C

VS = 15V

2

1

CHANGE IN OFFSET VOLTAGE – V

5

0

12345

TIME – Minutes

TPC 1. Warm-Up Drift

300

VS = 15V

250

200

150

100

50

INPUT OFFSET CURRENT – pA

0

–75

–50 –25 0 25 50 75 100 125

TEMPERATURE – C

TPC 4. Input Offset Current vs.

Temperature

60

VS = 15V

50

40

30

20

10

INPUT OFFSET VOLTAGE – V

0

–75

–50 –25 0 25 50 75 100 125

TEMPERATURE – C

TPC 2. Input Offset Voltage

vs. Temperature

1.0

TA = 25C

VS = 15V

0.8

0.6

0.4

0.2

INPUT BIAS CURRENT – nA

0

–15

–10 –5 0 5 10 15

COMON-MODE VOLTAGE – V

TPC 5. Input Bias Current vs.

Common-Mode Voltage

3

VS = 15V

2

1

0

–1

INPUT BIAS CURRENT – nA

–2

–3

–50 –25 0 25 50 75 100 125

–75

TEMPERATURE – C

TPC 3. Input Bias Current vs.

Temperature

140

120

100

80

60

40

20

COMMON-MODE REJECTION – dB

0

1

10 100 1k 10k 100k

FREQUENCY – Hz

TA = 25C

= 15V

V

S

TPC 6. Common-Mode Rejection

vs. Frequency

VOLTAGE NOISE DENSITY – nV/ Hz

100

10

1 10010

FREQUENCY – Hz

TA = 25C

V

= 15V

S

TPC 7. Voltage Noise Density

vs. Frequency

1000

CURRENT NOISE DENSITY – fA/ Hz

1k

100

1

10 1k100

FREQUENCY – Hz

TPC 8. Current Noise Density

TA = 25C

V

= 15V

S

TPC 9. 0.1 to 10 Hz Noise

vs. Frequency

–6–

REV. B

Page 7

OP200

0.1

20

0

FREQUENCY – Hz

POWER SUPPLY REJECTION – nA

NEGATIVE

SUPPLY

110100 1k 10k 100k

40

60

80

100

POSITIVE

SUPPLY

120

140

TA = 25C

1.18

TWO AMPLIFIERS

= 25C

T

A

1.16

1.14

1.12

1.10

1.08

TOTAL SUPPLY CURRENT – mA

1.06

2 6 10 14 16

SUPPLY VOLTAGE – V

TPC 10. Total Supply Current

vs. Supply Voltage

0.7

0.6

0.5

0.4

0.3

0.2

POWER SUPPLY REJECTION – V/V

0.1

–75

–50 –25 0 25 50 75 100 125

TEMPERATURE – C

TPC 13. Power Supply Rejection

vs. Temperature

1.16

TWO AMPLIFIERS

VS = 15V

1.15

1.14

1.13

1.12

TOTAL SUPPLY CURRENT – mA

1.11

–75

–50 –25 0 25 50 75 100 125

TEMPERATURE – C

TPC 11. Total Supply Current

vs. Temperature

6000

5000

4000

3000

2000

OPEN-LOOP GAIN – V/mV

1000

0

–75

–50 –25 0 25 50 75 100 125

TEMPERATURE – C

VS = 15V

RL = 2k

TPC 14. Open-Loop Gain vs.

Temperature

TPC 12. Power Supply Rejection

vs. Frequency

140

120

100

80

60

40

OPEN-LOOP GAIN – dB

20

0

–20

10 100 1k 10k 100k

FREQUENCY – Hz

GAIN

TA = 25C

= 15V

V

S

PHASE

TPC 15. Open-Loop Gain and

Phase Shift vs. Frequency

0

90

135

PHASE SHIFT – Degrees

180

1M

140

120

100

AV = 1000

80

AV = 100

60

GAIN – dB

AV = 10

40

AV = 1

20

0

10 100 1k 10k 100k

TPC 16. Closed-Loop Gain

vs. Frequency

REV. B

FREQUENCY – Hz

TA = 25C

= 15V

V

S

1M

30

25

20

15

10

5

OUTPUT SWING – V p-p AT 1% Distortion

0

10 100 1k 10k

FREQUENCY – Hz

TA = 25C

= 15V

V

S

TPC 17. Maximum Output Swing

vs. Frequency

–7–

100k

1

0.1

DISTORTION – %

0.01

0.001

FREQUENCY – Hz

AV = 100

AV = 10

AV = 1

TA = 25C

VS = 15V

V

= 10V p-p

OUT

RL = 2k

TPC 18. Total Harmonic Distortion

vs. Frequency

10k1k100

Page 8

OP200

50

TA = 25C

45

V

40

35

30

25

20

OVERSHOOT – %

15

10

5

0

0

= 15V

S

FALLING

RISING

0.5 1.0 1.5

CAPACITIVE LOAD – nF

1.0 1.5 3.0

TPC 19. Overshoot vs.

Capacitive Load

29

28

27

26

25

24

SOURCING

23

SHORT-CIRCUIT CURRENT – mA

22

01 345

SINKING

2

TIME – Minutes

TPC 20. Short-Circuit

Current vs. Time

TA = 25C

VS = 15V

150

140

130

120

110

CHANNEL SEPARATION – dB

100

90

10 100 1k 10k

FREQUENCY – Hz

TPC 21. Channel Separation

vs. Frequency

100k

TPC 22. Large Signal

Transient Response

TPC 23. Small Signal

Transient Response

APPLICATIONS INFORMATION

The OP200 is inherently stable at all gains and is capable of

driving large capacitive loads without oscillating. Nonetheless,

good supply decoupling is highly recommended. Proper supply

decoupling reduces problems caused by supply line noise and

improves the capacitive load driving capability of the OP200.

APPLICATIONS

Dual Low-Power Instrumentation Amplifier

A dual instrumentation amplifier that consumes less than 33 mW

of power per channel is shown in Figure 4. The linearity of the

instrumentation amplifier exceeds 16 bits in gains of 5 to 200

and is better than 14 bits in gains from 200 to 1000. CMRR is

above 115 dB (gain = 1000). Offset voltage drift is typically

0.2 µV/°C over the military temperature range, which is comparable to the best monolithic instrumentation amplifiers. The

bandwidth of the low power instrumentation amplifier is a function of gain and is shown below:

Gain Bandwidth

5 150 kHz

10 67 kHz

100 7.5 kHz

1000 500 Hz

TPC 24. Small Signal Transient

LOAD

3

2

40000

R

+15V

1/2

OP200AZ

–15V

VIN + V

G

= 1 nF

8

4

20k

REF

1

V

OUT

V

IN

V

REF

5

1/2

OP200AZ

6

20k 5k

Response C

7

5k

R

G

V

= 5 +

OUT

Figure 4. Dual Low Power Instrumentation Amplifier

The output signal is specified with respect to the reference

input, which is normally connected to analog ground. The

reference input can be used to offset the output from –10 V

to +10 V if required.

–8–

REV. B

Page 9

OP200

Precision Absolute Value Amplifier

The circuit in Figure 5 is a precision absolute value amplifier

with an input impedance of 10 MΩ. The high gain and low

of the OP200 ensure accurate operation with microvolt

TCV

OS

input signals. In this circuit, the input always appears as a

common-mode signal to the op amps. The CMR of the OP200

exceeds 120 dB, yielding an error of less than 2 ppm.

+15

C2

0.1pF

R1

1k

C1

OP200AZ

2

1/2

–15

8

4

30pF

C2

0.1pF

3

V

IN

D1

1N4148

1

D1

1N4148

6

5

R2

2k

R3

1k

1/2

OP200AZ

7

0V < V

OUT

V

OUT

< 10V

Figure 5. Precision Absolute Value Amplifier

Precision Current Pump

Maximum output current of the precision current pump shown

in Figure 6 is ±10 mA. Voltage compliance is ±10 V with ±15 V

supplies. Output impedance of the current transmitter exceeds

3 MΩ with linearity better than 16 bits.

=

2

3

100

10k

1/2

OP200EZ

R4

1k

V

IN

R3

= 10mA/V

1

7

OP200EZ

R5

100

+15

8

1/2

4

–15

I

OUT

5

6

R1

10k

V

R2

IN

10k

V

IN

I

=

OUT

RS

Figure 6. Precision Current Pump

Dual 12-Bit Voltage Output DAC

The dual output DAC shown in Figure 7 is capable of providing

untrimmed 12-bit accurate operation over the entire military

temperature range. Offset voltage, bias current, and gain errors

of the OP200 contribute less than 1/10 of an LSB error at 12

bits over the military temperature range.

10V

REFERENCE

VOLTAGE

PINS 6(MSB) – 17(LSB)

CONTROL

4

DAC DATA BUS

22

18

19

DAC

20

5V

21

V

DD

R

A

FB

I

OUT

RFBB

I

OUT

AGND

3

A

2

23

B

24

1

2

–

1/2

OP200AZ

3

6

–

1/2

OP200AZ

5

DAC-8222EW

DAC A

A

V

REF

DAC8212AV

DAC B

B

V

REF

DAC8212AV

DAC A/DAC B

CS

WR

1/2

1/2

DGND

5

Figure 7. Dual 12-Bit Voltage Output DAC

8

1

4

7

OUTA

–15V

OUTB

REV. B

–9–

Page 10

OP200

Dual Precision Voltage Reference

A dual OP200 and a REF43, a 2.5 V reference, can be used to

build a ±2.5 V precision voltage reference. Maximum output

current from each reference is ±10 mA with load regulation

under 25 µV/mA. Line regulation is better than 15 µV/V and

output voltage drift is under 20 µV/°C. Output voltage noise

from 0.1 Hz to 10 Hz is typically 75 µV p-p. R1 and D1 ensure

correct start-up.

Programmable High Resolution Window Comparator

The programmable window comparator shown in Figure 9 is

easily capable of 12-bit accuracy over the full military temperature range. A dual CMOS 12-bit DAC, the DAC8212, is used

in the voltage switching mode to set the upper and lower thresholds (DAC A and DAC B, respectively).

V

IN

21

V

DD

10V

REFERENCE

PINS 6(MSB) – 17(LSB)

CONTROL

SIGNALS

2

DAC DATA BUS

24

18

DAC

19

20

I

OUT

I

OUT

DAC A/DAC B

CS

WR

A

B

DAC A

1/2

DAC8212AV

DAC B

1/2

DAC8212AV

DGND

5

AGND

R

A

4

REF

R

B

22

REF

1

R1

10k

–15V

R2

10k

3

2

4

5

+5V

R2

1/2

OP200AZ

10k

8

1/2

OP200AZ

4

–5V

7

2

3

R1

22k

2

REF43A

4

6

D1

1N914

6

5

Figure 8. Dual Precision Voltage Reference

15V

8

+

1/2

OP200AZ

–

+

1/2

OP200AZ

1

D1

R3

1N4148

10k

D2

1N4148

7

OUTB

R4

10k

5V

Q1

2N2222

–

R4

5k

TTL OUT

R3

10k

–2.5V

–2.5V

Figure 9. Programmable High Resolution Window Comparator

–10–

REV. B

Page 11

OUTLINE DIMENSIONS

SEATING

PLANE

0.180

(4.57)

MAX

0.150 (3.81)

0.130 (3.30)

0.110 (2.79)

0.060 (1.52)

0.050 (1.27)

0.045 (1.14)

8

1

4

5

0.295 (7.49)

0.285 (7.24)

0.275 (6.98)

0.100 (2.54)

BSC

0.375 (9.53)

0.365 (9.27)

0.355 (9.02)

0.150 (3.81)

0.135 (3.43)

0.120 (3.05)

0.015 (0.38)

0.010 (0.25)

0.008 (0.20)

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

COMPLIANT TO JEDEC STANDARDS MO-095AA

0.015

(0.38)

MIN

OP200

8-Lead Ceramic Dual In-Line Package [CERDIP]

(Q-8)

Z-Suffix

Dimensions shown in inches and (millimeters)

0.005 (0.13)

PIN 1

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.055 (1.40)

MIN

0.100 (2.54) BSC

0.405 (10.29) MAX

MAX

85

1

4

0.070 (1.78)

0.030 (0.76)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150 (3.81)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15

0

0.015 (0.38)

0.008 (0.20)

8-Lead Plastic Dual In-Line Package [PDIP]

(N-8)

P-Suffix

Dimensions shown in inches and (millimeters)

REV. B

0.30 (0.0118)

0.10 (0.0039)

COPLANARITY

16-Lead Standard Small Outline Package [SOIC]

Wide Body

(RW-16)

S-Suffix

Dimensions shown in millimeters and (inches)

10.50 (0.4134)

10.10 (0.3976)

16

1

1.27 (0.0500)

BSC

0.51 (0.0201)

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.31 (0.0122)

COMPLIANT TO JEDEC STANDARDS MS-013AA

9

7.60 (0.2992)

7.40 (0.2913)

8

2.65 (0.1043)

2.35 (0.0925)

SEATING

PLANE

10.65 (0.4193)

10.00 (0.3937)

0.33 (0.0130)

0.20 (0.0079)

0.75 (0.0295)

0.25 (0.0098)

8

0

1.27 (0.0500)

0.40 (0.0157)

–11–

45

Page 12

OP200

Revision History

Location Page

2/04—Data Sheet changed from REV. A to REV. B.

OP200F deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Universal

Changes to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Changes to Figure 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4/02—Data Sheet changed from REV. 0 to REV. A.

Edits to FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to PIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Edits to PACKAGE TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

C00322–0–2/04(B)

–12–

REV. B

Loading...

Loading...