Page 1

5 mA, Rail-to-Rail

a

FEATURES

Low Supply Current: 5.5 mA max

Single-Supply Operation: 2.2 V to 12 V

Wide Bandwidth: 160 kHz

Wide Input Voltage Range

Rail-to-Rail Output Swing

No Phase Reversal

Output Short Circuit Current: 610 mA

APPLICATIONS

Portable Phones

Comparator

Battery Powered Instrumentation

Safety Monitoring

Remote Sensors

Low Voltage Strain Gauge Amplifiers

GENERAL DESCRIPTION

The OP186 is a single, low voltage, ultralow power singlesupply, amplifier featuring rail-to-rail outputs. Specifications are

guaranteed at +2.2 V, +2.7 V, and +5.0 V single supply as well

as ±5 V dual supplies.

Fabricated on Analog Device’s CBCMOS process, the OP186

features a bipolar input and an output that swings to within

millivolts of the supplies while continuing to sink or source

current all the way to the supplies.

Applications for these amplifiers include safety monitoring,

portable equipment, battery and power supply control, and as

signal conditioning and interface for transducers in very low

power systems.

The output’s ability to swing rail-to-rail and not increase supply

current when the output is driven to a supply enables the

OP186 to be used as a comparator in very low power systems.

The OP186 is specified over the extended industrial (–40°C to

+125°C) temperature range. The OP186 is available in the

SOT-23-5 package.

Output Operational Amplifier

OP186

FUNCTIONAL BLOCK DIAGRAM

5-Lead SOT-23

(RT Suffix)

OUT

+IN

V+

1

OP186

2

TOP VIEW

(Not to Scale)

3

5

V–

4

–IN

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

Page 2

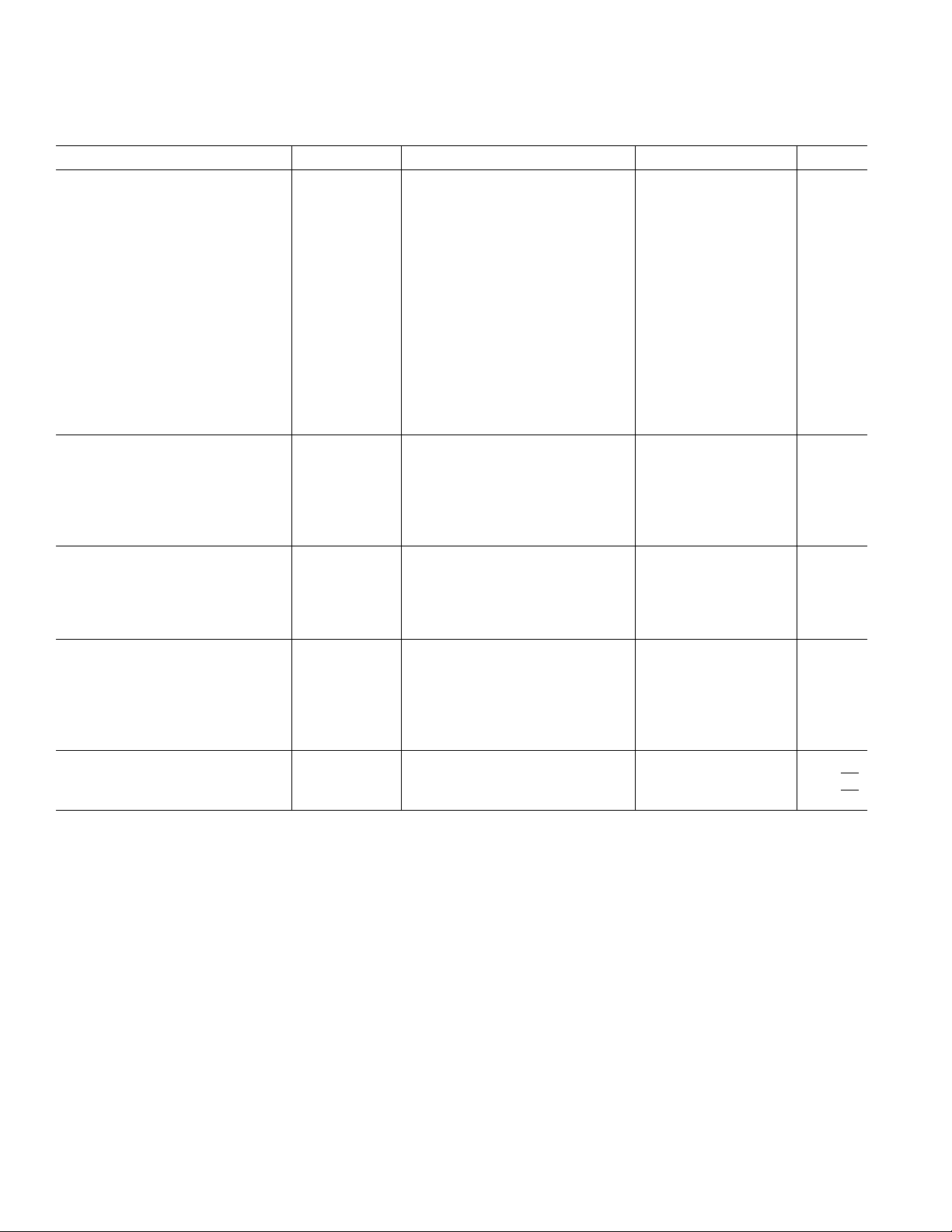

OP186–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(VS = +2.2 V, VCM = +1.1 V, TA = +258C unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS␣

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Common-Mode Rejection Ratio CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

1

OS

0°C ≤ T

B

0°C ≤ T

OS

0°C ≤ T

CM

CM

0°C ≤ T

VO

R

L

0°C ≤ T

/∆T 3.5 µV/°C

OS

/∆T 30 pA/°C

B

≤ +125°C6mV

A

≤ +125°C10nA

A

≤ +125°C5nA

A

0 1.2 V

= 0 V to 1.2 V 65 90 dB

≤ +125°C60 dB

A

= 1 MΩ , V

A

= 0.3 V to 1.9 V 5 18 V/mV

O

≤ +125°C 2 V/mV

0.8 5 mV

37 nA

0.1 2 nA

Offset Current Drift ∆IOS/∆T 3 pA/°C

OUTPUT CHARACTERISTICS

R

Output Voltage High V

OH

= 100 kΩ to GND 2.125 2.16 V

L

0°C to +125°C 2.1 V

R

Output Voltage Low V

OL

= 100 kΩ to V+ 25 60 mV

L

0°C to +125°C75mV

Short Circuit Limit I

SC

±500 µA

POWER SUPPLY␣

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= 2.2 V to 12 V 78 95 dB

S

0°C ≤ T

≤ +125°C76 dB

A

45 µA

0°C ≤ TA ≤ +125°C 5.5 µA

DYNAMIC PERFORMANCE␣

Slew Rate SR R

Turn-On Time A

= 100 kΩ, C

L

= 1, V

V

= 20, V

A

V

= 15 pF 60 V/ms

L

= 1 17 µs

O

= 1 35 µs

O

Gain Bandwidth Product GBP 150 kHz

Phase Margin Φo 60 Degrees

NOISE PERFORMANCE␣

Voltage Noise Density e

Current Noise Density i

NOTE

1

VOS is tested under a no load condition.

Specifications subject to change without notice.

n

n

f = 1 kHz 80 nV/√Hz

<1 pA/√Hz

–2– REV. 0

Page 3

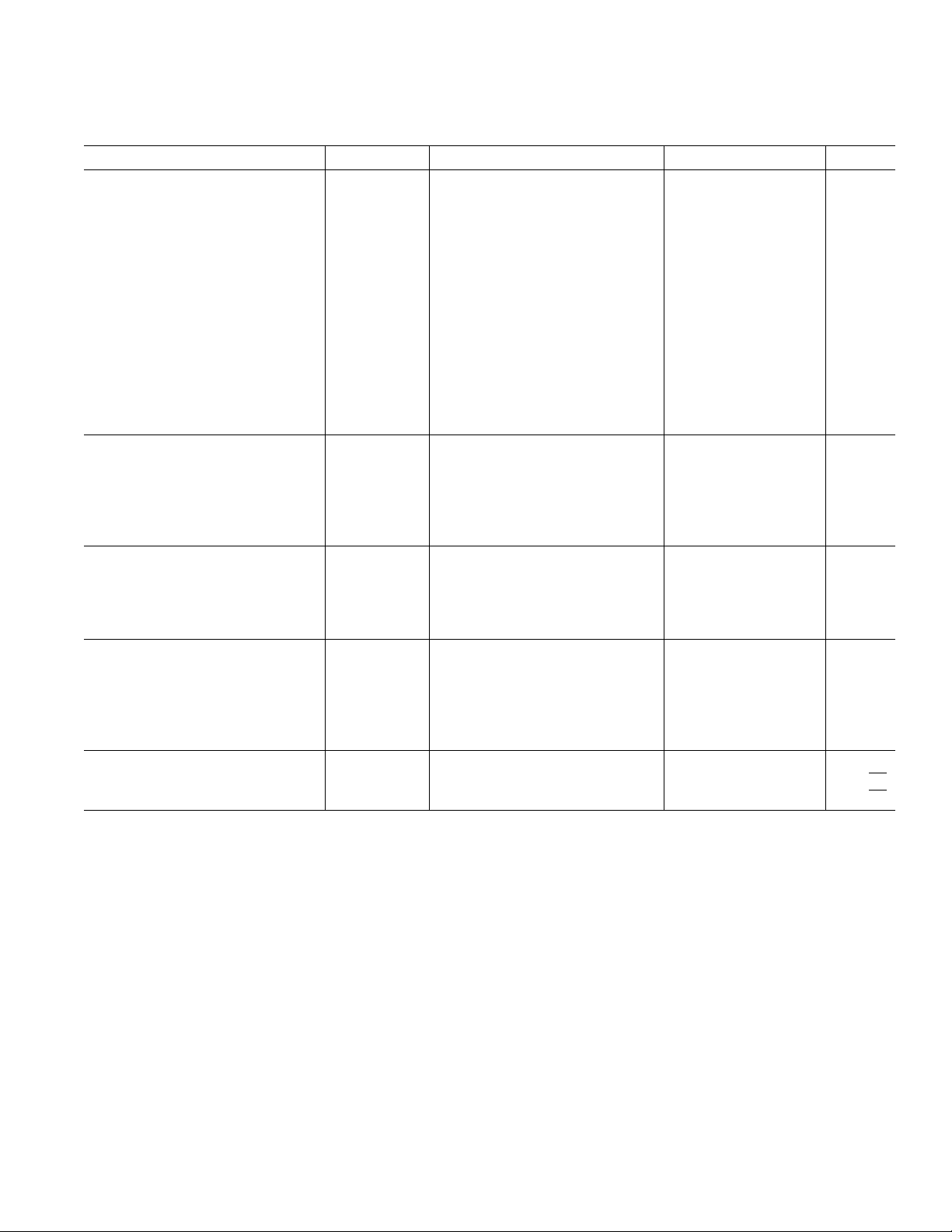

OP186

ELECTRICAL CHARACTERISTICS

(VS = +2.7 V, VCM = +1.35 V, TA = +258C unless otherwise noted)

1

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS␣

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Common-Mode Rejection Ratio CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

2

OS

–40°C ≤ T

B

–40°C ≤ T

OS

–40°C ≤ T

CM

CM

–40°C ≤ T

R

VO

= 1 MΩ, V

L

–40°C ≤ T

/∆T 3.5 µV/°C

OS

/∆T 30 pA/°C

B

≤ +125°C6mV

A

≤ +125°C10nA

A

≤ +125°C5nA

A

0 1.7 V

= 0 V to 1.7 V 65 90 dB

≤ +125°C60 dB

A

= 0.3 V to 2.4 V 5 22 V/mV

O

≤ +125°C 2 V/mV

A

0.6 5 mV

37 nA

0.1 2 nA

Offset Current Drift ∆IOS/∆T 3 pA/°C

OUTPUT CHARACTERISTICS

R

Output Voltage High V

OH

= 100 kΩ to GND 2.625 2.665 V

L

–40°C to +125°C 2.6 V

R

Output Voltage Low V

OL

= 100 kΩ to V+ 22 50 mV

L

–40°C to +125°C75mV

Short Circuit Limit I

SC

±0.8 mA

POWER SUPPLY␣

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= 2.7 V to 12 V 78 95 dB

S

–40°C ≤ T

≤ +125°C76 dB

A

4.2 5.5 µA

–40°C ≤ TA ≤ +125°C7µA

DYNAMIC PERFORMANCE␣

Slew Rate SR R

Turn-On Time A

=100 kΩ, C

L

= 1, V

V

= 20, V

A

V

= 15 pF 61 V/ms

L

= 1 17 µs

O

= 1 25 µs

O

Gain Bandwidth Product GBP 155 kHz

Phase Margin Φo 59 Degrees

NOISE PERFORMANCE␣

Voltage Noise Density e

Current Noise Density i

NOTES

1

+2.7 V specifications are guaranteed by +2.2 V and ±5 V testing.

2

VOS is tested under a no load condition.

Specifications subject to change without notice.

n

n

f = 1 kHz 80 nV/√Hz

<1 pA/√Hz

–3–REV. 0

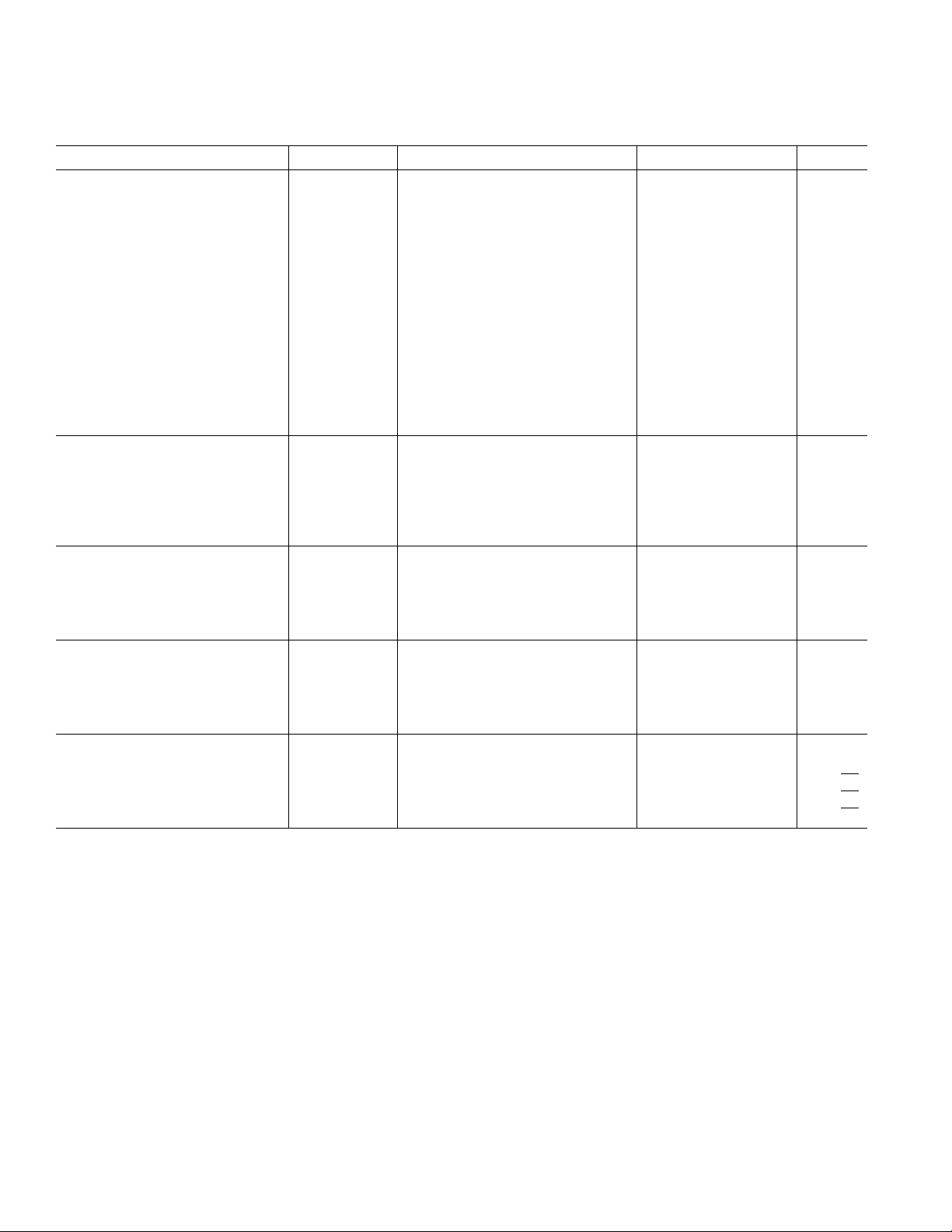

Page 4

OP186–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(VS = +5.0 V, VCM = +2.5 V, TA = +258C unless otherwise noted)

1

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Common-Mode Rejection Ratio CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

␣

2

OS

–40°C ≤ T

B

–40°C ≤ T

OS

–40°C ≤ T

CM

CM

–40°C ≤ T

R

VO

= 1 MΩ, V

L

–40°C ≤ T

/∆T –40°C ≤ TA ≤ +125°C 3.3 µV/°C

OS

/∆T 25 pA/°C

B

≤ +125°C6mV

A

≤ +125°C10nA

A

≤ +125°C5nA

A

04V

= 0 V to 4.0 V 65 90 dB

≤ +125°C60 dB

A

= 0.5 V to 4.5 V 5 40 V/mV

O

≤ +125°C 2 V/mV

A

0.6 5 mV

37 nA

0.1 2 nA

Offset Current Drift ∆IOS/∆T 3 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

Output Voltage Low V

Short Circuit Limit I

OH

OL

SC

R

= 100 kΩ to GND 4.925 4.965 V

L

–40°C ≤ T

R

= 100 kΩ to V+ 20 50 mV

L

–40°C ≤ T

≤ +125°C 4.9 V

A

≤ +125°C75mV

A

±3.5 mA

POWER SUPPLY␣

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= 2.7 V to 12 V 78 95 dB

S

–40°C ≤ T

≤ +125°C76 dB

A

4.7 6 µA

–40°C ≤ TA ≤ +125°C 7.5 µA

DYNAMIC PERFORMANCE␣

Slew Rate SR R

= 100 kΩ, C

L

= 15 pF 62 V/ms

L

Gain Bandwidth Product GBP 155 kHz

Phase Margin Φo 59 Degrees

Saturation Recovery Time 60 µs

NOISE PERFORMANCE␣

Voltage Noise e

Voltage Noise Density e

p-p 0.1 Hz to 10 Hz 6 µV p-p

n

n

f = 1 kHz 80 nV/√Hz

f = 10 kHz 70 nV/√

Current Noise Density i

NOTES

1

+5 V specifications are guaranteed by +2.2 V and ± 5 V testing.

2

VOS is tested under a no load condition.

Specifications subject to change without notice.

n

<1 pA/√Hz

Hz

–4– REV. 0

Page 5

OP186

ELECTRICAL CHARACTERISTICS

(VS = 65.0 V, TA = +258C unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS␣

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

Common-Mode Rejection CMRR V

Large Signal Voltage Gain A

Offset Voltage Drift ∆V

Bias Current Drift ∆I

1

OS

–40°C ≤ T

B

–40°C ≤ T

OS

–40°C ≤ T

CM

CM

–40°C ≤ T

R

VO

= 1 MΩ, VO = ±4.0 V, 50 250 V/mV

L

–40°C ≤ T

/∆T3µV/°C

OS

/∆T 25 pA/°C

B

≤ +125°C6mV

A

≤ +125°C10nA

A

≤ +125°C5nA

A

–5 +4 V

= –5.0 V to +4.0 V 65 90 dB

≤ +125°C60 dB

A

≤ +125°C 10 V/mV

A

0.6 5 mV

37 nA

0.1 2 nA

Offset Current Drift ∆IOS/∆T 3 pA/°C

OUTPUT CHARACTERISTICS␣

R

Output Voltage Swing V

O

= 100 kΩ to GND ±4.95 ±4.98 V

L

–40°C to +125°C ±4.90 V

Short Circuit Limit I

SC

±10 mA

POWER SUPPLY␣

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= ±1.35 V to ± 6 V 78 95 dB

S

–40°C ≤ T

V

= 0 V 5.2 7 µA

O

≤ +125°C76 dB

A

–40°C ≤ TA ≤ +125°C8µA

DYNAMIC PERFORMANCE␣

Slew Rate ±SR R

= 100 kΩ, C

L

= 15 pF 62 V/ms

L

Gain Bandwidth Product GBP 170 kHz

Phase Margin Φo 58 Degrees

NOISE PERFORMANCE␣

Voltage Noise e

Voltage Noise Density e

p-p 0.1 Hz to 10 Hz 6 µV p-p

n

n

f = 1 kHz 80 nV/√Hz

f = 10 kHz 70 nV/√

Current Noise Density i

NOTE

1

VOS is tested under a no load condition.

Specifications subject to change without notice.

n

<1 pA/√Hz

Hz

–5–REV. 0

Page 6

OP186

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +16 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . GND to V

Differential Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . ±3.5 V

Output Short-Circuit Duration to GND . . . . . . . . . Indefinite

Storage Temperature Range

RT Package . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

OP186G . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +125°C

Junction Temperature Range

RT Package . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . +300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

2

For supplies less than ±5 V the differential input voltage is limited to the supplies.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the OP186 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

1

Package Type u

+ 10 V

S

5-Lead SOT-23 (RT) 230 140 °C/W

NOTE

1

θJA is specified for worst case conditions, i.e., θ

for SOT packages.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

OP186GRT –40°C to +125°C 5-Lead SOT-23 RT-5

1

JA

u

JC

is specified for device in socket

JA

Units

–6– REV. 0

Page 7

45

0

5

V

S

= +5V

T

A

= +258C

40

35

30

25

20

15

10

INPUT OFFSET VOLTAGE – mV

22 21.5 21 20.5

0 0.5 1 1.5 2

QUANTITY – A

INPUT BIAS CURRENT – nA

TEMPERATURE – 8C

240

27

26

25

24

23

22

21

0

220

0 20 40 60 80 100 120 140

VS = 65V

VS = +2.2V

INPUT OFFSET CURRENT – nA

TEMPERATURE – 8C

–40

–0.3

–0.2

–0.1

0

0.1

0.2

0.3

0.4

–20

0 20 40 60 80 100 120 140

VS = +2.7V, +5V

Typical Performance Characteristics–

OP186

45

40

35

30

25

20

QUANTITY – A

15

10

5

0

22

21.5 21 20.5

INPUT OFFSET VOLTAGE – mV

VS = +2.2V

T

= +258C

A

0 0.5 1 1.5 2

Figure 1. Input Offset Voltage

Distribution

45

40

35

30

25

20

QUANTITY – A

15

10

5

0

22 21.5 21 20.5

INPUT OFFSET VOLTAGE – mV

VS = 65V

T

= +258C

A

0 0.5 1 1.5 2

Figure 4. Input Offset Voltage

Distribution

45

V

= +2.7V

40

35

30

25

20

QUANTITY – A

15

10

5

0

22 21.5 21 20.5

INPUT OFFSET VOLTAGE – mV

0 0.5 1 1.5 2

S

T

= +258C

A

Figure 2. Input Offset Voltage

Distribution

350

300

250

200

150

100

INPUT OFFSET VOLTAGE – mV

250

2100

50

0

240

VS = +2.7V

0 20 40 60 80 100 120 140

220

TEMPERATURE – 8C

VS = +2.2V

VS = 65V

Figure 5. Input Offset Voltage vs.

Temperature

Figure 3. Input Offset Voltage

Distribution

Figure 6. Input Bias Current vs.

Temperature

0

21

22

23

24

25

INPUT BIAS CURRENT – nA

26

27

240

Figure 7. Input Bias Current vs.

Temperature

VS = 65.5V

0 20 40 60 80 100 120 140

220

TEMPERATURE – 8C

VS = +2.7V

1.0

VS = +5V

0.5

T

= +258C

A

0

20.5

21.0

21.5

22.0

22.5

INPUT BIAS CURRENT – nA

23.0

23.5

24.0

0 0.5

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

COMMON-MODE VOLTAGE – Volts

Figure 8. Input Bias Current vs.

Common-Mode Voltage

–7–REV. 0

Figure 9. Input Offset Current vs.

Temperature

Page 8

OP186

g

LOAD CURRENT – mA

10

0.1

1

100

1k

1 100010 100

VS = 65V

T

A

= +258C

SOURCE

SINK

OUTPUT VOLTAGE – mV

FREQUENCY – Hz

100

–30

–20

–10

0

10

20

30

40

50

60

70

1k 10k 100k

1M

270

225

180

135

90

45

0

VS = 65V

T

A

= +258C

RL = 100kV

OPEN-LOOP GAIN – dB

PHASE SHIFT – Degrees

GAIN

PHASE

PSRR – dB

FREQUENCY – Hz

0

10 100 1k 10k 100k 1M

20

40

60

80

100

120

+2.7V # VS # +5V

TA = +258C

R

L

= `

1k

VS = +2.7V

T

= +258C

A

100

10

1

OUTPUT VOLTAGE – mV

0.1

1 100010 100

SOURCE

SINK

LOAD CURRENT – mA

Figure 10. Output Voltage to Supply

Rail vs. Load Current

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN – dB

210

220

230

100

GAIN

PHASE

1k 10k 100k

FREQUENCY – Hz

VS = +2.2V

T

= +258C

A

R

= 100kV

L

0

45

90

135

180

225

270

1M

1k

VS = +5V

T

= +258C

A

100

10

1

OUTPUT VOLTAGE – mV

0.1

1 100010 100

SOURCE

LOAD CURRENT – mA

SINK

Figure 11. Output Voltage to Supply

Rail vs. Load Current

70

60

50

40

30

20

10

0

OPEN-LOOP GAIN – dB

–10

PHASE SHIFT – Degrees

–20

–30

100

1k 10k 100k

GAIN

PHASE

FREQUENCY – Hz

VS = +5V

T

= +258C

A

R

= 100kV

L

1M

Figure 12. Output Voltage to Supply

Rail vs. Load Current

0

45

rees

90

135

180

225

PHASE SHIFT – De

270

Figure 13. Open-Loop Gain and

Phase vs. Frequency

50

40

30

20

10

0

–10

CLOSED-LOOP GAIN – dB

–20

–30

10

Figure 16. Closed-Loop Gain vs.

Frequency

FREQUENCY – Hz

VS = +5V

T

= +258C

A

R

=

L

100k10k1k100 1M

Figure 14. Open-Loop Gain and

Phase vs. Frequency

120

+2.7V

100

80

60

CMRR – dB

40

20

1k

# VS # +5V

10k

FREQUENCY – HZ

100k

T

= +258C

A

1M 10M

Figure 17. CMRR vs. Frequency

–8– REV. 0

Figure 15. Open-Loop Gain and

Phase vs. Frequency

Figure 18. PSRR vs. Frequency

Page 9

OP186

FREQUENCY – Hz

5

10

2

100 1k 10k 100k

3

0

1

4

VS = +5V

V

IN

= 4V p-p

A

VCL

= +1

R

L

=

T

A

= +258C

MAXIMUM OUTPUT SWING – V p-p

COMMON MODE VOLTAGE – V

2

0 0.5

2.25

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

VS = +5V

R

L

=

T

A

= +258C

2.5

2.75

3

3.25

3.5

3.75

4

4.25

4.5

SUPPLY CURRENT – mA

65

VS = +5V

60

VIN = 100mV p-p

55

A

= +1

VCL

50

RL = 100kV

45

T

= +258C

A

40

35

30

25

20

15

10

SMALL SIGNAL OVERSHOOT – %

5

0

10 1000100

CAPACITANCE – pF

+OS

2OS

Figure 19. Small Signal Overshoot

vs. Load Capacitance

6.5

6

5.5

VS = 65V

VS = 65V

5

VS = +5V

4.5

4

INPUT BIAS CURRENT – nA

3.5

VS = +2.7V

3

–20

–40

VS = +2.2V

0 20 40 60 80 100 120 140

TEMPERATURE – 8C

Figure 22. Bias Current vs.

Temperature

3

2

VS = +2.7V

= 2V p-p

V

IN

= +1

A

1

VCL

=

R

L

= +258C

T

A

MAXIMUM OUTPUT SWING – V p-p

0

10

100 1k 10k 100k

FREQUENCY – Hz

Figure 20. Maximum Output Swing

vs. Frequency

6

TA = +258C

5.5

5

4.5

4

3.5

3

2.5

2

1.5

SUPPLY CURRENT – mA

1

0.5

0

0 0.5

2.5

1 1.5 2

SUPPLY VOLTAGE – 6V

3 3.5 4 4.5 5 5.5 6

Figure 23. Supply Current vs. Supply

Voltage

Figure 21. Maximum Output Swing

vs. Frequency

Figure 24. Supply Current vs.

Common-Mode Voltage

500mV 100ms

Figure 25. Large Signal Transient

Response

VS = +2.7V

AV = +1

R

L

CL = 50pF

T

A

= 100kV

= +258C

VS = +5V

A

= +1

V

RL = 100kV

CL = 50pF

T

= +258C

A

1.0V 100ms

Figure 26. Large Signal Transient

Response

–9–REV. 0

VS = 61.35V

AV = +1

R

= 100kV

L

CL = 50pF

T

= +258C

A

50mV 100ms

Figure 27. Small Signal Transient

Response

Page 10

OP186

500mV 100ms

VS = 61.35V

A

VOL

= CIRCUIT

V

IN

= 61V p-p

R

L

=

T

A

= +258C

VS = 62.5V

AV = +1

R

= 100kV

L

CL = 50pF

T

= +258C

50mV 100ms

A

VS = +5V

T

= +258C

A

1.0V 200ms

Figure 28. Small Signal Transient

Figure 29. No Phase Reversal

Response

1.0V

VS = –2.5V

= CIRCUIT

A

VOL

= –1V p-p

V

IN

=

R

L

= +258C

T

A

100ms

Figure 31. Saturation Recovery Time

APPLICATIONS

The OP186 is very similar in design to the OP181. Please see the

OP181/OP281/OP481 data sheet for applications information.

Design of the OP186 was based on the OP181. The major difference is that the trim structures have been removed. This

results in the offset of the OP186 being higher than the OP181.

There are no other major changes to the circuit. Other performance differences, such as the higher bandwidth and slightly

higher supply current, also result from the removal of the trim

resistors.

Figure 30. Saturation Recovery Time

–10– REV. 0

Page 11

OP186

SPICE MODEL

* OP186 SPICE Macro-model Typical Values

* 2/98, Ver. 1

* TAM / ADSC

*

* Copyright 1998 by Analog Devices

*

* Refer to “README.DOC” file for License State-

* ment. Use of this

* model indicates your acceptance of the terms

* and provisions in

* the License Statement.

*

* Node Assignments

* noninverting input

* | inverting input

* | | positive supply

* | | | negative supply

* | | | | output

*|| | ||

*|| | ||

.SUBCKT OP186 1 2 99 50 45

*

* INPUT STAGE

*

Q1 4 1 3 PIX

Q2 6 7 5 PIX

RC1 4 50 100E3

RC2 6 50 100E3

RE1 3 8 6.452E3

RE2 5 8 6.452E3

C1 4 6 50E-15

I1 99 8 1E-6

EOS 7 2 POLY(2) (12,98) (73,98) 800E-6 1 1

IOS 1 2 50E-12

V1 99 9 0.9

V2 99 10 0.9

D1 3 9 DX

D2 5 10 DX

*

* CMRR 90dB, ZERO AT 1kHz

*

ECM1 11 98 POLY(2) (1,98) (2,98) 0 .5 .5

RCM1 11 12 1.59E6

CCM1 11 12 100E-12

RCM2 12 98 50

*

* PSRR=100dB, ZERO AT 200Hz

*

RPS1 70 0 1E6

RPS2 71 0 1E6

CPS1 99 70 1E-5

CPS2 50 71 1E-5

EPSY 98 72 POLY(2) (70,0) (0,71) 0 1 1

RPS3 72 73 1.59E6

CPS3 72 73 500E-12

RPS4 73 98 15.9

*

* INTERNAL VOLTAGE REFERENCE

*

EREF 98 0 POLY(2) (99,0) (50,0) 0 .5 .5

GSY 99 50 POLY(1) (99,50) 2E-6 .1E-6

*

* POLE AT 600kHz; ZERO AT 900kHz

*

G1 98 20 (4,6) 11.3E-6

R1 20 98 88.46E3

R2 20 21 176.8E3

C2 21 98 1E-12

*

* GAIN STAGE

*

G4 98 30 (20,98) 19.54E-6

R7 30 98 111.6E6

CF 45 30 32E-12

D3 30 31 DX

D4 32 30 DX

V3 99 31 0.6

V4 32 50 0.6

*

* OUTPUT STAGE

*

M1 45 46 99 99 POX L=2u W=100u

M2 45 47 50 50 NOX L=2u W=98u

EG1 99 46 POLY(1) (98,30) 0.82 1

EG2 47 50 POLY(1) (30,98) 0.79 1

*

* MODELS

*

.MODEL POX PMOS (LEVEL=2, KP=10E-6,

+ VTO=-0.75, LAMBDA=0.01)

.MODEL NOX NMOS (LEVEL=2, KP=17E-6,

+ VTO=0.75, LAMBDA=0.01)

.MODEL PIX PNP (BF=185,KF=1.6E-12,AF=1)

.MODEL DX D(IS=1E-14)

.ENDS OP186

–11–REV. 0

Page 12

OP186

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

5-Lead SOT-23

(RT Suffix)

0.1181 (3.00)

0.1102 (2.80)

0.0669 (1.70)

0.0590 (1.50)

0.0512 (1.30)

0.0354 (0.90)

0.0059 (0.15)

0.0019 (0.05)

PIN 1

1 3

2

0.0748 (1.90)

BSC

0.0197 (0.50)

0.0138 (0.35)

4 5

0.1181 (3.00)

0.1024 (2.60)

0.0374 (0.95) BSC

0.0571 (1.45)

0.0374 (0.95)

SEATING

PLANE

108

08

C3330–8–4/98

0.0079 (0.20)

0.0031 (0.08)

0.0217 (0.55)

0.0138 (0.35)

–12–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...