Page 1

15 MHz Rail-to-Rail

OP162

1

4

5

8

NULL

–IN A

+IN A

V–

NULL

V+

OUT A

NC

NC = NO CONNECT

OP262

1

4

5

8

OUT A

–IN A

+IN A

V–

V+

OUT B

–IN B

+IN B

14

13

12

11

10

9

8

1

2

3

4

7

6

5

OUT A

V–

+IN D

–IN D

OUT D

–IN A

+IN A

V+

OUT C

–IN C

+IN C

+IN B

–IN B

OUT B

OP462

1

7

8

14

OP462

OUT A

–IN A

+IN A

V+

+IN B

–IN B

OUT B

V–

+IN D

–IN D

OUT D

OUT C

–IN C

+IN C

OP462

1

78

14

OUT A

–IN A

+IN A

V+

+IN B

–IN B

OUT B

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

a

FEATURES

Wide Bandwidth: 15 MHz

Low Offset Voltage: 325 V max

Low Noise: 9.5 nV/√Hz @ 1 kHz

Single-Supply Operation: +2.7 V to +12 V

Rail-to-Rail Output Swing

Low TCV

High Slew Rate: 13 V/s

No Phase Inversion

Unity Gain Stable

APPLICATIONS

Portable Instrumentation

Sampling ADC Amplifier

Wireless LANs

Direct Access Arrangement

Office Automation

GENERAL DESCRIPTION

The OP162 (single), OP262 (dual), OP462 (quad) rail-to-rail

15 MHz amplifiers feature the extra speed new designs require,

with the benefits of precision and low power operation. With

their incredibly low offset voltage of 45 µV (typ) and low noise,

they are perfectly suited for precision filter applications and

instrumentation. The low supply current of 500 µA (typ) is

critical for portable or densely packed designs. In addition, the

rail-to-rail output swing provides greater dynamic range and

control than standard video amplifiers provide.

These products operate from single supplies as low as +2.7 V to

dual supplies of ±6 V. The fast settling times and wide output

swings recommend them for buffers to sampling A/D converters.

The output drive of 30 mA (sink and source) is needed for

many audio and display applications; more output current can

be supplied for limited durations.

The OP162 family is specified over the extended industrial

temperature range (–40°C to +125°C). The single OP162

and dual OP262 are available in 8-lead PDIP, SOIC and

TSSOP packages. The quad OP462 is available in 14-lead

PDIP, narrow-body SOIC and TSSOP packages.

: 1 V/ⴗC typ

OS

Operational Amplifiers

OP162/OP262/OP462

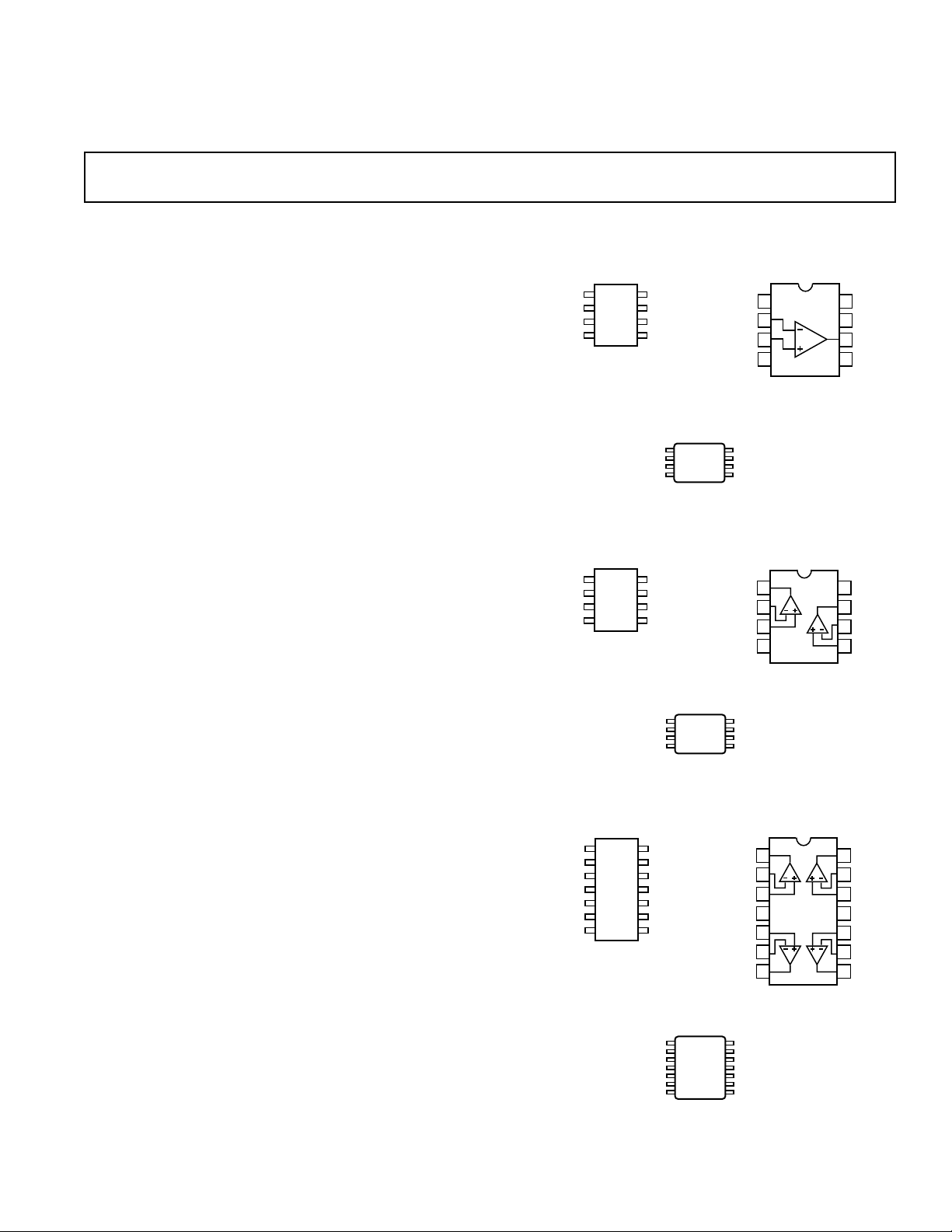

PIN CONFIGURATIONS

8-Lead Narrow-Body SO 8-Lead Plastic DIP

(S Suffix) (P Suffix)

1

NULL

–IN A

OP162

+IN A

4

V–

NC = NO CONNECT

8-Lead Narrow-Body SO 8-Lead Plastic DIP

(S Suffix) (P Suffix)

1

OUT A

OP262

+IN A

4

V–

14-Lead Narrow-Body SO 14-Lead Plastic DIP

(S Suffix) (P Suffix)

NULL

8

V+

OUT A

NC

5

8-Lead TSSOP

(RU Suffix)

8

V+

OUT B–IN A

–IN B

+IN B

5

8-Lead TSSOP

(RU Suffix)

NULL

–IN A

+IN A

V–

OUT A

–IN A

+IN A

V–

1

OP162

2

3

4

NC = NO CONNECT

1

OP262

2

3

4

8

7

6

5

8

7

6

5

NULL

V+

OUT A

NC

V+

OUT B

–IN B

+IN B

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

14-Lead TSSOP

(RU Suffix)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

Page 2

OP162/OP262/OP462–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ VS = +5.0 V, VCM = 0 V, TA = +25ⴗC, unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP162G, OP262G, OP462G, 45 325 µV

–40°C ≤ T

H Grade, –40°C ≤ T

D Grade, –40°C ≤ T

≤ +125°C 800 µV

A

≤ +125°C1mV

A

≤ +125°C 0.8 3 mV

A

5mV

Input Bias Current I

B

–40°C ≤ T

Input Offset Current I

OS

–40°C ≤ T

Input Voltage Range V

CM

Common-Mode Rejection CMRR 0 V ≤ V

–40°C ≤ T

Large Signal Voltage Gain A

Long-Term Offset Voltage V

Offset Voltage Drift ∆V

VO

OS

/∆T Note 2 1 µV/°C

OS

RL = 2 kΩ, 0.5 ≤ V

= 10 kΩ, 0.5 ≤ V

R

L

= 10 kΩ, –40°C ≤ TA ≤ +125°C 40 V/mV

R

L

G Grade

≤ +125°C 650 nA

A

≤ +125°C ±40 nA

A

0+4V

≤ +4.0 V,

CM

≤ +125°C 70 110 dB

A

1

≤ 4.5 V 30 V/mV

OUT

≤ 4.5 V 65 88 V/mV

OUT

360 600 nA

±2.5 ±25 nA

600 µV

Bias Current Drift ∆IB/∆T 250 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

Short Circuit Current I

Maximum Output Current I

OH

OL

SC

OUT

IL = 250 µA, –40°C ≤ TA ≤ +125°C 4.95 4.99 V

I

= 5 mA 4.85 4.94 V

L

IL = 250 µA, –40°C ≤ TA ≤ +125°C1450mV

I

= 5 mA 65 150 mV

L

Short to Ground ±80 mA

±30 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= +2.7 V to +7 V 120 dB

S

–40°C ≤ T

OP162, V

–40°C ≤ T

OP262, OP462, V

≤ +125°C90 dB

A

= 2.5 V 600 750 µA

OUT

≤ +125°C1mA

A

= 2.5 V 500 700 µA

OUT

–40°C ≤ TA ≤ +125°C 850 µA

DYNAMIC PERFORMANCE

Slew Rate SR 1 V < V

Settling Time t

S

To 0.1%, AV = –1, VO = 2 V Step 540 ns

< 4 V, RL = 10 kΩ 10 V/µs

OUT

Gain Bandwidth Product GBP 15 MHz

Phase Margin φ

m

61 Degrees

NOISE PERFORMANCE

Voltage Noise e

Voltage Noise Density e

Current Noise Density i

NOTES

1

Long-term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at +125 °C, with an LTPD of 1.3.

2

Offset voltage drift is the average of the –40°C to +25°C delta and the +25°C to +125°C delta.

Specifications subj]ect to change without notice.

p-p 0.1 Hz to 10 Hz 0.5 µV p-p

n

n

n

f = 1 kHz 9.5 nV/√Hz

f = 1 kHz 0.4 pA/√Hz

–2–

REV. C

Page 3

OP162/OP262/OP462–SPECIFICATIONS

OP162/OP262/OP462

ELECTRICAL CHARACTERISTICS

(@ VS = +3.0 V, VCM = 0 V, TA = +25ⴗC, unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP162G, OP262G, OP462G 50 325 µV

H Grade, –40°C ≤ T

D Grade, –40°C ≤ T

≤ +125°C1mV

A

≤ +125°C 0.8 3 mV

A

5mV

Input Bias Current I

Input Offset Current I

Input Voltage Range V

B

OS

CM

Common-Mode Rejection CMRR 0 V ≤ V

–40°C ≤ T

Large Signal Voltage Gain A

Long-Term Offset Voltage V

VO

OS

RL = 2 kΩ, 0.5 V ≤ V

= 10 kΩ, 0.5 V ≤ V

R

L

G Grade

0+2V

≤ +2.0 V,

CM

≤ +125°C 70 110 dB

A

1

≤ 2.5 V 20 V/mV

OUT

≤ 2.5 V 20 30 V/mV

OUT

360 600 nA

±2.5 ±25 nA

600 µV

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

OH

OL

IL = 250 µA 2.95 2.99 V

I

= 5 mA 2.85 2.93 V

L

IL = 250 µA1450mV

IL = 5 mA 66 150 mV

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

SY

= +2.7 V to +7 V,

S

–40°C ≤ T

OP162, V

–40°C ≤ T

≤ +125°C 60 110 dB

A

= 1.5 V 600 700 µA

OUT

≤ +125°C1mA

A

OP262, OP462, V

= 1.5 V 500 650 µA

OUT

–40°C ≤ TA ≤ +125°C 850 µA

DYNAMIC PERFORMANCE

Slew Rate SR R

Settling Time t

S

= 10 kΩ 10 V/µs

L

To 0.1%, AV = –1, VO = 2 V Step 575 ns

Gain Bandwidth Product GBP 15 MHz

Phase Margin φ

m

59 Degrees

NOISE PERFORMANCE

Voltage Noise e

Voltage Noise Density e

Current Noise Density i

NOTES

1

Long-term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at +125 °C, with an LTPD of 1.3.

Specifications subject to change without notice.

p-p 0.1 Hz to 10 Hz 0.5 µV p-p

n

n

n

f = 1 kHz 9.5 nV/√Hz

f = 1 kHz 0.4 pA/√Hz

REV. C

–3–

Page 4

OP162/OP262/OP462–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ VS = ⴞ5.0 V, VCM = 0 V, TA = +25ⴗC, unless otherwise noted)

Parameter Symbol Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP162G, OP262G, OP462G 25 325 µV

–40°C ≤ T

H Grade, –40°C ≤ T

D Grade, –40°C ≤ T

≤ +125°C 800 µV

A

≤ +125°C1mV

A

≤ +125°C 0.8 3 mV

A

5mV

Input Bias Current I

B

–40°C ≤ T

Input Offset Current I

OS

–40°C ≤ T

Input Voltage Range V

CM

Common-Mode Rejection CMRR –4.9 V ≤ V

–40°C ≤ T

Large Signal Voltage Gain A

Long-Term Offset Voltage V

Offset Voltage Drift ∆V

VO

OS

/∆T Note 2 1 µV/°C

OS

RL = 2 kΩ, –4.5 V ≤ V

= 10 kΩ, –4.5 V ≤ V

R

L

–40°C ≤ T

G Grade

1

≤ +125°C 650 nA

A

≤ +125°C ±40 nA

A

–5 +4 V

≤ +4.0 V,

CM

≤ +125°C 70 110 dB

A

≤ +125°C 25 V/mV

A

≤ 4.5 V 35 V/mV

OUT

≤ 4.5 V 75 120 V/mV

OUT

260 500 nA

±2.5 ±25 nA

600 µV

Bias Current Drift ∆IB/∆T 250 pA/°C

OUTPUT CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

Short Circuit Current I

Maximum Output Current I

OH

OL

SC

OUT

IL = 250 µA, –40°C ≤ TA ≤ +125°C 4.95 4.99 V

I

= 5 mA 4.85 4.94 V

L

IL = 250 µA, –40°C ≤ TA ≤ +125°C –4.99 –4.95 V

I

= 5 mA –4.94 –4.85 V

L

Short to Ground ±80 mA

±30 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

Supply Voltage Range V

SY

S

= ±1.35 V to ±6 V,

S

–40°C ≤ T

OP162, V

–40°C ≤ T

≤ +125°C 60 110 dB

A

= 0 V 650 800 µA

OUT

≤ +125°C 1.15 mA

A

OP262, OP462, V

–40°C ≤ T

≤ +125°C1mA

A

= 0 V 550 775 µA

OUT

+3.0 (±1.5) +12 (± 6) V

DYNAMIC PERFORMANCE

Slew Rate SR –4 V < V

Settling Time t

S

To 0.1%, AV = –1, VO = 2 V Step 475 ns

< 4 V, RL = 10 kΩ 13 V/µs

OUT

Gain Bandwidth Product GBP 15 MHz

Phase Margin φ

m

64 Degrees

NOISE PERFORMANCE

Voltage Noise e

Voltage Noise Density e

Current Noise Density i

NOTES

1

Long-term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at +125 °C, with an LTPD of 1.3.

2

Offset voltage drift is the average of the –40°C to +25°C delta and the +25°C to +125°C delta.

Specifications subject to change without notice.

p-p 0.1 Hz to 10 Hz 0.5 µV p-p

n

n

n

f = 1 kHz 9.5 nV/√Hz

f = 1 kHz 0.4 pA/√Hz

–4–

REV. C

Page 5

OP162/OP262/OP462

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±6 V

Input Voltage

Differential Input Voltage

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 6 V

2

. . . . . . . . . . . . . . . . . . . . . ±0.6 V

Internal Power Dissipation

Plastic DIP (P) . . . . . . . . . . . . . . . Observe Derating Curves

SOIC (S) . . . . . . . . . . . . . . . . . . . Observe Derating Curves

TSSOP (RU) . . . . . . . . . . . . . . . . Observe Derating Curves

Output Short-Circuit Duration . . . . Observe Derating Curves

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range . . . . . . . . . . –40°C to +125°C

Junction Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 10 sec) . . . . . . . +300°C

Package Type

3

JA

JC

Units

8-Lead Plastic DIP (P) 103 43 °C/W

8-Lead SOIC (S) 158 43 °C/W

8-Lead TSSOP (RU) 240 43 °C/W

14-Lead Plastic DIP (P) 83 36 °C/W

14-Lead SOIC (S) 120 36 °C/W

14-Lead TSSOP (RU) 180 35 °C/W

NOTES

1

For supply voltages greater than 6 volts, the input voltage is limited to less than or

equal to the supply voltage.

2

For differential input voltages greater than 0.6 volts the input current should be

limited to less than 5 mA to prevent degradation or destruction of the input devices.

3

θJA is specified for the worst case conditions, i.e., θ

for P-DIP package; θ

TSSOP packages.

is specified for device soldered in circuit board for SOIC and

JA

is specified for device in socket

JA

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

OP162GP –40°C to +125°C 8-Lead Plastic DIP N-8

OP162GS –40°C to +125°C 8-Lead SOIC SO-8

OP162HRU –40°C to +125°C 8-Lead TSSOP RU-8

OP262DRU –40°C to +125°C 8-Lead TSSOP RU-8

OP262GP –40°C to +125°C 8-Lead Plastic DIP N-8

OP262GS –40°C to +125°C 8-Lead SOIC SO-8

OP262HRU –40°C to +125°C 8-Lead TSSOP RU-8

OP462DRU –40°C to +125°C 14-Lead TSSOP RU-14

OP462DS –40°C to +125°C 14-Lead SOIC SO-14

OP462GP –40°C to +125°C 14-Lead Plastic DIP N-14

OP462GS –40°C to +125°C 14-Lead SOIC SO-14

OP462HRU –40°C to +125°C 14-Lead TSSOP RU-14

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the OP162/OP262/OP462 features proprietary ESD protection circuitry, permanent

damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper

ESD precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

REV. C

–5–

Page 6

OP162/OP262/OP462–Typical Characteristics

250

VS = 5V

T

= 25ⴗC

200

150

100

QUANTITY – Amplifiers

50

0

–200 –140 16 0100–20 40–80

INPUT OFFSET VOLTAGE – V

A

COUNT =

720 OP AMPS

Figure 1. OP462 Input Offset Voltage

Distribution

125

V

100

75

50

25

INPUT OFFSET VOLTAGE –

0

–25 0 25 75 100 12550

–75 –50 150

TEMPERATURE – ⴗC

VS = 5V

Figure 4. OP462 Input Offset Voltage

vs. Temperature

100

VS = 5V

T

= 25ⴗC

80

60

40

QUANTITY – Amplifiers

20

0

0.2 0.3 1.31.10.7 0.90.5 1.5

INPUT OFFSET DRIFT, TCVOS – V/ⴗC

A

COUNT =

360 OP AMPS

Figure 2. OP462 Input Offset Voltage

Drift (TCV

–100

–200

–300

–400

INPUT BIAS CURRENT – nA

–500

)

OS

0

VS = 5V

–50 –25 150

0 25 50 75 100 125

TEMPERATURE – ⴗC

Figure 5. OP462 Input Bias Current

vs. Temperature

420

VS = 5V

340

260

180

INPUT BIAS CURRENT – nA

100

0 0.5

1.0 1.5 2.0 2.5 3.0 3.5 4.0

COMMON-MODE VOLTAGE – Volts

Figure 3. OP462 Input Bias Current

vs. Common-Mode Voltage

15

VS = 5V

10

5

INPUT OFFSET CURRENT – nA

0

–25 0 25 75 100 12550

–75 –50 150

TEMPERATURE – ⴗC

Figure 6. OP462 Input Offset Current

vs. Temperature

5.12

VS = 5V

5.06

I

= 250A

5.00

4.94

4.88

OUTPUT HIGH VOLTAGE – Volts

4.82

–75 –50 150

–25 0 25 75 100 12550

OUT

I

= 5mA

OUT

TEMPERATURE – ⴗC

Figure 7. OP462 Output High Voltage

vs. Temperature

0.100

0.080

0.060

0.040

0.020

OUTPUT LOW VOLTAGE – mV

0.000

–25 0 25 75 100 12550

–75 –50 150

TEMPERATURE – ⴗC

I

I

OUT

OUT

VS = 5V

= 5mA

= 250A

Figure 8. OP462 Output Low Voltage

vs. Temperature

100

RL = 10k⍀

80

60

40

20

OPEN-LOOP GAIN – V/mV

0

–75 –50 150

RL = 2k⍀

RL = 600⍀

–25 0 25 75 100 12550

TEMPERATURE – ⴗC

VS = 5V

Figure 9. OP462 Open-Loop Gain

vs. Temperature

–6–

REV. C

Page 7

OP162/OP262/OP462

100

80

60

40

OUTPUT VOLTAGE – mV

20

0

VS = 10V

01 7

LOAD CURRENT – mA

VS = 3V

23456

Figure 10. Output Low Voltage to

Supply Rail vs. Load Current

50

40

30

20

10

GAIN – dB

0

–10

–20

–30

100k 1M 100M

GAIN

FREQUENCY – Hz

VS = 5V

= 25ⴗC

T

A

10M

PHASE

45

90

135

180

225

270

Figure 13. Open-Loop Gain and

Phase vs. Frequency (No Load)

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

SUPPLY CURRENT – mA

0.2

0.1

0

–75 –50 150

VS = 5V

–25 0 25 75 100 12550

TEMPERATURE – ⴗC

VS = 10V

VS = 3V

Figure 11. Supply Current/Amplifier

vs. Temperature

60

VS = 5V

T

= +25ⴗC

A

R

L

C

L

1M 10M

PHASE SHIFT – dB

40

20

0

–20

CLOSED-LOOP GAIN – dB

–40

10k 100k 100M

FREQUENCY – Hz

Figure 14. Closed-Loop Gain vs.

Frequency

= 830⍀

5pF

0.7

0.6

0.5

SUPPLY CURRENT – mA

0.4

02 1246810

SUPPLY VOLTAGE – Volts

TA = 25ⴗC

Figure 12. OP462 Supply Current/

Amplifier vs. Supply Voltage

5

4

3

VS = 5V

2

A

= 1

VCL

R

= 10k⍀

L

C

= 15pF

L

1

= 25°C

T

A

MAXIMUM OUTPUT SWING – V p-p

DISTORTION < 1%

0

10k 100k 10M

FREQUENCY – Hz

1M

Figure 15. Maximum Output Swing

vs. Frequency

4

3

VS = 5V

2

= 25ⴗC

T

A

1

0

–1

STEP SIZE – Volts

–2

–3

–4

0 200 1000

0.1% 0.01%

0.1% 0.01%

400 600 800

SETTLING TIME – ns

Figure 16. Settling Time vs. Step Size

60

50

VS = 5V

T

= 25ⴗC

A

40

V

= ⴞ50mV

IN

R

= 10k⍀

L

30

20

OVERSHOOT – %

10

0

10 100 1000

+OS

–OS

CAPACITANCE – pF

Figure 17. Small-Signal Overshoot

vs. Capacitance

70

60

50

40

30

20

NOISE DENSITY – nV/ Hz

10

0

110 1k100

FREQUENCY – Hz

VS = 5V

T

= 25ⴗC

A

Figure 18. Voltage Noise Density vs.

Frequency

REV. C

–7–

Page 8

OP162/OP262/OP462–Typical Characteristics

7

6

5

4

3

2

NOISE DENSITY – pA/ Hz

1

0

110 1k

FREQUENCY – Hz

VS = 5V

T

100

= 25ⴗC

A

Figure 19. Current Noise Density vs.

Frequency

90

80

70

60

50

PSRR – dB

40

30

20

1k 10k 10M

FREQUENCY – Hz

VS = 5V

T

= 25ⴗC

A

–PSRR+PSRR

100k 1M

Figure 22. PSRR vs. Frequency

300

250

200

150

A

= 10

VCL

100

OUTPUT IMPEDANCE – ⍀

50

0

100k 1M 10M

FREQUENCY – Hz

VS = 5V

T

= 25ⴗC

A

A

= 1

VCL

Figure 20. Output Impedance vs.

Frequency

20mV

100

90

10

0%

VS = 5V

= 100k⍀

A

V

= 0.5V p-p

e

n

2s

Figure 23. 0.1 Hz to 10 Hz Noise

90

80

70

60

50

CMRR – dB

40

30

20

1k 10k 10M

FREQUENCY – Hz

VS = 5V

T

= 25ⴗC

A

100k 1M

Figure 21. CMRR vs. Frequency

2V

100

90

10

0%

2V

VIN = 12V p-p

= ⴞ5V

V

S

= 1

A

V

20s

Figure 24. No Phase Reversal; [VIN =

12 V p-p, V

= ±5 V, AV = 1]

S

100

90

10

0%

20mV

VS = 5V

= 1

A

V

= 25ⴗC

T

A

= 100pF

C

L

200ns

Figure 25. Small Signal Transient

Response

VS = 5V

= 1

A

V

100

90

= 25ⴗC

T

A

= 100pF

C

L

10

0%

500mV

100s

Figure 26. Large Signal Transient

Response

–8–

REV. C

Page 9

OP162/OP262/OP462

APPLICATIONS SECTION

Functional Description

The OPx62 family is fabricated using Analog Devices’ high

speed complementary bipolar process, also called XFCB. The

process includes trench isolating each transistor to lower parasitic capacitances thereby allowing high speed performance.

This high speed process has been implemented without trading

off the excellent transistor matching and overall dc performance

characteristic of Analog Devices’ complementary bipolar process. This makes the OPx62 family an excellent choice as an

extremely fast and accurate low voltage op amp.

Figure 27 shows a simplified equivalent schematic for the OP162.

A PNP differential pair is used at the input of the device. The

cross connecting of the emitters is used to lower the transconductance of the input stage, which improves the slew rate of the

device. Lowering the transconductance through cross connecting the emitters has another advantage in that it provides a

lower noise factor than if emitter degeneration resistors were

used. The input stage can function with the base voltages taken

all the way to the negative power supply, or up to within 1 V of

the positive power supply.

V

CC

+IN

V

–IN

V

EE

OUT

Figure 27. Simplified Schematic

Two complementary transistors in a common-emitter configuration are used for the output stage. This allows the output of the

device to swing to within 50 mV of either supply rail at load

currents less than 1 mA. As load current increases, the maximum voltage swing of the output will decrease. This is due to

the collector-to-emitter saturation voltages of the output transistors increasing. The gain of the output stage, and consequently

the open-loop gain of the amplifier, is dependent on the load

resistance connected at the output. And because the dominant

pole frequency is inversely proportional to the open-loop gain,

the unity-gain bandwidth of the device is not affected by the

load resistance. This is typically the case in rail-to-rail output

devices.

Offset Adjustment

Because the OP162/OP262/OP462 has such an exceptionally

low typical offset voltage, adjustment to correct offset voltage

may not be needed. However, the OP162 does have pinouts

where a nulling resistor can be attached. Figure 28 shows how

the OP162 offset voltage can be adjusted by connecting a potentiometer between Pins 1 and 8, and connecting the wiper to

VCC. It is important to avoid accidentally connecting the wiper

to V

, as this will damage the device. The recommended value

EE

for the potentiometer is 20 kΩ.

+5V

20k⍀

1

8

3

2

OP162

–5V

7

6

4

V

OS

Figure 28. Schematic Showing Offset Adjustment

Rail-to-Rail Output

The OP162/OP262/OP462 has a wide output voltage range that

extends to within 60 mV of each supply rail with a load current

of 5 mA. Decreasing the load current will extend the output

voltage range even closer to the supply rails. The commonmode input range extends from ground to within 1 V of the

positive supply. It is recommended that there be some minimal

amount of gain when a rail-to-rail output swing is desired. The

minimum gain required is based on the supply voltage and can

be found as:

V

=

VS–1

S

A

V,min

where VS is the positive supply voltage. With a single supply

voltage of +5 V, the minimum gain to achieve rail-to-rail output

should be 1.25.

Output Short-Circuit Protection

To achieve a wide bandwidth and high slew rate, the output of

the OP162/OP262/OP462 is not short-circuit protected. Shorting the output directly to ground or to a supply rail may destroy

the device. The typical maximum safe output current is ±30 mA.

Steps should be taken to ensure the output of the device will not

be forced to source or sink more than 30 mA.

In applications where some output current protection is needed,

but not at the expense of reduced output voltage headroom, a

low value resistor in series with the output can be used. This is

shown in Figure 29. The resistor is connected within the feedback loop of the amplifier so that if V

and V

swings up to +5 V, the output current will not exceed

IN

is shorted to ground

OUT

30 mA.

For single +5 V supply applications, resistors less than 169 Ω

are not recommended.

+5V

V

IN

OPx62

169⍀

V

OUT

Figure 29. Output Short-Circuit Protection

REV. C

–9–

Page 10

OP162/OP262/OP462

Input Overvoltage Protection

The input voltage should be limited to ±6 V or damage to the

device can occur. Electrostatic protection diodes placed in the

input stage of the device help protect the amplifier from static

discharge. Diodes are connected between each input as well as

from each input to both supply pins as shown in the simplified

equivalent circuit in Figure 27. If an input voltage exceeds

either supply voltage by more than 0.6 V, or if the differential

input voltage is greater than 0.6 V, these diodes begin to energize and overvoltage damage could occur. The input current

should be limited to less than 5 mA to prevent degradation or

destruction of the device.

This can be done by placing an external resistor in series with

the input that could be overdriven. The size of the resistor can

be calculated by dividing the maximum input voltage by 5 mA.

For example, if the differential input voltage could reach 5 V,

the external resistor should be 5 V/5 mA = 1 kΩ. In practice,

this resistance should be placed in series with both inputs to

balance any offset voltages created by the input bias current.

Output Phase Reversal

The OP162/OP262/OP462 is immune to phase reversal as long

as the input voltage is limited to ±6 V. Figure 24 shows a photo

of the output of the device with the input voltage driven beyond

the supply voltages. Although the device’s output will not

change phase, large currents due to input overvoltage could

result, damaging the device. In applications where the possibility

of an input voltage exceeding the supply voltage exists, overvoltage protection should be used, as described in the previous

section.

Power Dissipation

The maximum power that can be safely dissipated by the

OP162/OP262/OP462 is limited by the associated rise in junction temperature. The maximum safe junction temperature is

150°C, and should not be exceeded or device performance

could suffer. If this maximum is momentarily exceeded, proper

circuit operation will be restored as soon as the die temperature

is reduced. Leaving the device in an “overheated” condition for

an extended period can result in permanent damage to the device.

To calculate the internal junction temperature of the OPx62,

the following formula can be used:

T

= P

J

× θJA + T

DISS

A

where: TJ = OPx62 junction temperature;

P

= OPx62 power dissipation;

DISS

θ

= OPx62 package thermal resistance, junction-to-

JA

ambient; and

T

= Ambient temperature of the circuit.

A

The power dissipated by the device can be calculated as:

P

where: I

= I

DISS

is the OPx62 output load current;

LOAD

V

is the OPx62 supply voltage; and

S

V

is the OPx62 output voltage.

OUT

LOAD

× (VS – V

OUT

)

Figures 30 and 31 provide a convenient way to see if the device

is being overheated. The maximum safe power dissipation can

be found graphically, based on the package type and the ambient temperature around the package. By using the previous

equation, it is a simple matter to see if P

exceeds the device’s

DISS

power derating curve. To ensure proper operation, it is important to observe the recommended derating curves shown in

Figures 30 and 31.

2.0

1.5

1.0

0.5

MAXIMUM POWER DISSIPATION – Watts

8-PIN DIP

PACKAGE

8-PIN SOIC

PACKAGE

8-PIN TSSOP

PACKAGE

0

–40 120–20 0 20 40 60 80 100

AMBIENT TEMPERATURE – ⴗC

Figure 30. Maximum Power Dissipation vs. Temperature

for 8-Pin Package Types

2.0

14-PIN DIP

PACKAGE

1.5

14-PIN SOIC

PACKAGE

1.0

14-PIN TSSOP

PACKAGE

0.5

MAXIMUM POWER DISSIPATION – Watts

0

–40 120–20 0 20 40 60 80 100

AMBIENT TEMPERATURE – ⴗC

Figure 31. Maximum Power Dissipation vs. Temperature

for 14-Pin Package Types

Unused Amplifiers

It is recommended that any unused amplifiers in a dual or a

quad package be configured as a unity gain follower with a 1 kΩ

feedback resistor connected from the inverting input to the

output and the noninverting input tied to the ground plane.

Power On Settling Time

The time it takes for the output of an op amp to settle after a

supply voltage is delivered can be an important consideration in

some power-up sensitive applications. An example of this

would be in an A/D converter where the time until valid data

can be produced after power-up is important.

The OPx62 family has a rapid settling time after power-up.

Figure 32 shows the OP462 output settling times for a single

supply voltage of V

= +5 V. The test circuit in Figure 33 was

S

used to find the power on settling times for the device.

–10–

REV. C

Page 11

OP162/OP262/OP462

2V

100

90

10

0%

50mV

Figure 32. Oscilloscope Photo of VS and V

+1

0 TO +5V

SQUARE

+

–

OP462

VS = 5V

A

= 1

V

= 10k⍀

R

L

500ns

10k⍀

OUT

V

OUT

Figure 33. Test Circuit for Power On Settling Time

Capacitive Load Drive

The OP162/OP262/OP462 is a high speed, extremely accurate

device and can tolerate some capacitive loading at its output.

As load capacitance increases, however, the unity-gain bandwidth of the device will decrease. There will also be an increase

in overshoot and settling time for the output. Figure 35 shows

an example of this with the device configured for unity gain and

driving a 10 kΩ resistor and 300 pF capacitor placed in parallel.

By connecting a series R-C network, commonly called a “snubber” network, from the output of the device to ground, this

ringing can be eliminated and overshoot can be significantly

reduced. Figure 34 shows how to set up the snubber network,

and Figure 36 shows the improvement in output response with

the network added.

+5V

OPx62

V

IN

R

X

C

X

V

OUT

C

L

Figure 34. Snubber Network Compensation for Capacitive

Loads

VS = 5V

A

= 1

1s

V

C

L

R

L

= 300pF

= 10k⍀

100

90

10

0%

50mV

Figure 35. A Photo of a Ringing Square Wave

VS = 5V

= 1

A

100

90

10

0%

50mV 1s

V

= 300pF

C

L

= 10k⍀

R

L

WITH SNUBBER:

R

= 140⍀

X

= 10nF

C

X

Figure 36. A Photo of a Nice Square Wave at the Output

The network operates in parallel with the load capacitor, CL,

and provides compensation for the added phase lag. The actual

values of the network resistor and capacitor are determined

empirically to minimize overshoot while maximizing unity-gain

bandwidth. Table I shows a few sample snubber networks for

large load capacitors:

Table I. Snubber Networks for Large Capacitive Loads

C

LOAD

R

X

C

X

<300 pF 140 Ω 10 nF

500 pF 100 Ω 10 nF

1 nF 80 Ω 10 nF

10 nF 10 Ω 47 nF

Obviously, higher load capacitance will also reduce the unitygain bandwidth of the device. Figure 37 shows a plot of unitygain bandwidth versus capacitive load. The snubber network

will not provide any increase in bandwidth, but it will substantially reduce ringing and overshoot, as shown in the difference

between Figures 35 and 36.

10

9

8

7

6

5

4

BANDWIDTH – MHz

3

2

1

0

10pF 10nF100pF 1nF

Figure 37. Unity Gain Bandwidth vs. C

C

LOAD

LOAD

Total Harmonic Distortion and Crosstalk

The OPx62 device family offers low total harmonic distortion.

This makes it an excellent device choice for audio applications.

Figure 38 shows a graph of THD plus noise figures at 0.001%

for the OP462.

Figure 39 shows a graph of the worst case crosstalk between two

amplifiers in the OP462 device. A 1 V rms signal is applied to

one amplifier while measuring the output of an adjacent amplifier. Both amplifiers are configured for unity gain and supplied

with ±2.5 V.

REV. C

–11–

Page 12

OP162/OP262/OP462

0.010

VS = ⴞ2.5V

A

= 1

V

= 1.0V rms

V

IN

= 10k⍀

R

L

BANDWIDTH:

<10Hz TO 22kHz

0.001

THD+N – %

0.0001

20 10k100 1k

FREQUENCY – Hz

20k

Figure 38. THD+N vs. Frequency Graph

–40

AV = 1

–50

= 1.0V rms

V

IN

(0dBV)

= 10k⍀

R

L

= ⴞ2.5V

V

S

20 10k100 1k

FREQUENCY – Hz

20k

–100

XTALK – dBV

–110

–120

–130

–140

–60

–70

–80

–90

Figure 39. Crosstalk vs. Frequency Graph

PCB Layout Considerations

Because the OP162/OP262/OP462 can provide gain at high

frequency, careful attention to board layout and component

selection is recommended. As with any high speed application,

a good ground plane is essential to achieve the optimum performance. This can significantly reduce the undesirable effects of

ground loops and I×R losses by providing a low impedance reference point. Best results are obtained with a multilayer board

design with one layer assigned to ground plane.

Chip capacitors should be used for supply bypassing, with one

end of the capacitor connected to the ground plane and the

other end connected within 1/8 inch of each power pin. An

additional large tantalum electrolytic capacitor (4.7 µF–10 µF)

should be connected in parallel. This capacitor does not need to

be placed as close to the supply pins, as it is to provide current

for fast large-signal changes at the device’s output.

APPLICATION CIRCUITS

Single Supply Stereo Headphone Driver

Figure 40 shows a stereo headphone output amplifier that can

be run from a single +5 V supply. The reference voltage is

derived by dividing the supply voltage down with two 100 kΩ

resistors. A 10 µF capacitor prevents power supply noise from

contaminating the audio signal and establishes an ac ground for

the volume control potentiometers.

The audio signal is ac coupled to each noninverting input

through a 10 µF capacitor. The gain of the amplifier is controlled by the feedback resistors and is: (R2/R1) + 1. For this

example, the gain is 6. By removing R1 altogether, the amplifier

would have unity gain. A 169 Ω resistor is placed at the output

in the feedback network to short-circuit protect the output of

the device. This would prevent any damage to the device from

occurring if the headphone output became shorted. A 270 µF

capacitor is used at the output to couple the amplifier to the

headphone. This value is much larger than that used for the

input because of the low impedance of headphones, which can

range from 32 Ω to 600 Ω or more.

LEFT IN

RIGHT IN

5V

10F

10k⍀

100k⍀

10k⍀

10F

R1 = 10k⍀

10F

L VOLUME

CONTROL

R VOLUME

CONTROL

R1 = 10k⍀

OP262-A

100k⍀

10F

OP262-B

10F

R2

= 50k⍀

5V

5V

R2 = 50k⍀

169⍀

169⍀

270F

47k⍀

270F

47k⍀

HEADPHONE

LEFT

HEADPHONE

RIGHT

Figure 40. Headphone Output Amplifier

Instrumentation Amplifier

Because of its high speed, low offset voltages and low noise

characteristics, the OP162/OP262/OP462 can be used in a wide

variety of high speed applications, including a precision instrumentation amplifier. Figure 41 shows an example of such an

application.

–V

IN

+V

IN

OP462-A

R

G

OP462-B

1k⍀

1k⍀

10k⍀

10k⍀

2k⍀

2k⍀

2k⍀

OP462-COP462-D

1.9k⍀

200⍀

10 TURN

(OPTIONAL)

OUTPUT

Figure 41. A High Speed Instrumentation Amplifier

–12–

REV. C

Page 13

OP162/OP262/OP462

The differential gain of the circuit is determined by RG, where:

= 1 +

2

R

G

A

DIFF

with the RG resistor value in kΩ. Removing RG will set the circuit gain to unity.

The fourth op amp, OP462-D, is optional and is used to improve CMRR by reducing any input capacitance to the amplifier. By shielding the input signal leads and driving the shield

with the common-mode voltage, input capacitance is eliminated

at common-mode voltages. This voltage is derived from the

midpoint of the outputs of OP462-A and OP462-B by using two

10 kΩ resistors followed by OP462-D as a unity gain buffer.

It is important to use 1% or better tolerance components for the

2 kΩ resistors, as the common-mode rejection is dependent on

their ratios being exact. A potentiometer should also be connected in series with the OP462-C noninverting input resistor to

ground to optimize common-mode rejection.

The circuit in Figure 41 was implemented to test its settling

time. The instrumentation amp was powered with ±5 V, so the

input step voltage went from –5 V to +4 V to keep the OP462

within its input range. Therefore, the 0.05% settling range is

when the output is within 4.5 mV. Figure 42 shows the positive

slope settling time to be 1.8 µs, and Figure 43 shows a settling

time of 3.9 µs for the negative slope.

5mV

100

90

10

0%

2V

1s

Figure 42. Positive Slope Settling Time

5mV

5mV

100

100

90

90

2V

Direct Access Arrangement

Figure 44 shows a schematic for a +5 V single supply transmit/

receive telephone line interface for 600 Ω transmission systems.

It allows full duplex transmission of signals on a transformer

coupled 600 Ω line. Amplifier A1 provides gain that can be

adjusted to meet the modem output drive requirements. Both

A1 and A2 are configured so as to apply the largest possible

differential signal to the transformer. The largest signal available

on a single +5 V supply is approximately 4.0 V p-p into a 600 Ω

transmission system. Amplifier A3 is configured as a difference

amplifier to extract the receive information from the transmission line for amplification by A4. A3 also prevents the transmit

signal from interfering with the receive signal. The gain of A4

can be adjusted in the same manner as A1’s to meet the modem’s

input signal requirements. Standard resistor values permit the

use of SIP (Single In-line Package) format resistor arrays. Couple

this with the OP462 14-lead SOIC or TSSOP package and this

circuit can offer a compact solution.

P1

TX GAIN

TO TELEPHONE

LINE

1:1

Z

O

600⍀

T1

MIDCOM

671-8005

A1, A2 = 1/2 AD8532

A3, A4 = 1/2 AD8532

6.2V

6.2V

10k⍀

R11

R3

360⍀

R9

10k⍀

R12

10k⍀

2

3

ADJUST

R5

10k⍀

R6

10k⍀

R10

10k⍀

A3

2k⍀

1

7

1

9.09k⍀

A1

A2

R13

10k⍀

R2

2

3

6

5

10k⍀

R14

14.3k⍀

6

A4

5

R1

C1

0.1F

5V DC

10F

P2

RX GAIN

ADJUST

2k⍀

7

C2

0.1F

TRANSMIT

R7

10k⍀

R8

10k⍀

RECEIVE

TXA

RXA

Figure 44. A Single-Supply Direct Access Arrangement for

Modems

REV. C

10

10

0%

0%

1µs

1s

Figure 43. Negative Slope Settling Time

–13–

Page 14

OP162/OP262/OP462

Spice Macro-Model

* OP162/OP262/OP462 SPICE Macro-model

* 7/96, Ver. 1

* Troy Murphy / ADSC

*

* Copyright 1996 by Analog Devices

*

* Refer to “README.DOC” file for License Statement. Use of this model

* indicates your acceptance of the terms and provisions in the License

* Statement

*

* Node Assignments

* noninverting input

* | inverting input

* | | positive supply

* | | | negative supply

* | | | | output

*|| | | |

*|| | | |

.SUBCKT OP162 1 2 99 50 45

*

*INPUT STAGE

*

Q1 5 7 3 PIX 5

Q2 6 2 4 PIX 5

Ios 1 2 1.25E-9

I1 99 15 85E-6

EOS 7 1 POLY(1) (14, 20) 45E-6 1

RC1 5 50 3.035E+3

RC2 6 50 3.035E+3

RE1 3 15 607

RE2 4 15 607

C1 5 6 600E-15

D1 3 8 DX

D2 4 9 DX

V1 99 8 DC 1

V2 99 9 DC 1

*

* 1st GAIN STAGE

*

EREF 98 0 (20, 0) 1

G1 98 10 (5, 6) 10.5

R1 10 98 1

C2 10 98 3.3E-9

*

* COMMON-MODE STAGE WITH ZERO AT 4kHz

*

ECM 13 98 POLY (2) (1, 98) (2, 98) 0 0.5 0.5

R2 13 14 1E+6

R3 14 98 70

C3 13 14 80E-12

*

* POLE AT 1.5MHz, ZERO AT 3MHz

*

G2 21 98 (10, 98) .588E-6

R4 21 98 1.7E6

R5 21 22 1.7E6

C4 22 98 31.21E-15

*

* POLE AT 6MHz, ZERO AT 3MHz

*

E1 23 98 (21, 98) 2

R6 23 24 53E+3

R7 24 98 53E+3

C5 23 24 1E-12

*

* SECOND GAIN STAGE

*

G3 25 98 (24, 98) 40E-6

R8 25 98 1.65E+6

D3 25 99 DX

D4 50 25 DX

*

* OUTPUT STAGE

*

GSY 99 50 POLY (1) (99, 50) 277.5E-6 7.5E-6

R9 99 20 100E3

R10 20 50 100E3

Q3 45 41 99 POUT 4

Q4 45 43 50 NOUT 2

EB1 99 40 POLY (1) (98, 25) 0.70366 1

EB2 42 50 POLY (1) (25, 98) 0.73419 1

RB1 40 41 500

RB2 42 43 500

CF 45 25 11E-12

D5 46 99 DX

D6 47 43 DX

V3 46 41 0.7

V4 47 50 0.7

.

MODEL PIX PNP (Bf=117.7)

.MODEL POUT PNP (BF=119, IS=2.782E-17, VAF=28, KF=3E-7)

.MODEL NOUT NPN (BF=110, IS=1.786E-17, VAF=90, KF=3E-7)

.MODEL DX D()

.ENDS

–14–

REV. C

Page 15

OUTLINE DIMENSIONS

14

17

8

0.795 (20.19)

0.725 (18.42)

0.280 (7.11)

0.240 (6.10)

PIN 1

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

SEATING

PLANE

0.022 (0.558)

0.014 (0.356)

0.060 (1.52)

0.015 (0.38)

0.210 (5.33)

MAX

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

0.100

(2.54)

BSC

0.160 (4.06)

0.115 (2.93)

14 8

7

1

0.201 (5.10)

0.193 (4.90)

0.256 (6.50)

0.246 (6.25)

0.177 (4.50)

0.169 (4.30)

PIN 1

SEATING

PLANE

0.006 (0.15)

0.002 (0.05)

0.0118 (0.30)

0.0075 (0.19)

0.0256

(0.65)

BSC

0.0433

(1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.028 (0.70)

0.020 (0.50)

8°

0°

Dimensions shown in inches and (mm).

OP162/OP262/OP462

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

8-Lead Plastic DIP

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.070 (1.77)

0.045 (1.15)

8-Lead SOIC

0.1968 (5.00)

0.1890 (4.80)

8

5

41

PIN 1

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

(N-8)

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

(SO-8)

0.2440 (6.20)

0.2284 (5.80)

0.0098 (0.25)

0.0075 (0.19)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

0.195 (4.95)

0.115 (2.93)

x 45°

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

14-Lead Plastic DIP

(N-14)

14-Lead Narrow Body SOIC

(SO-14)

0.3444 (8.75)

0.3367 (8.55)

14 8

PIN 1

0.0500

0.0192 (0.49)

(1.27)

0.0138 (0.35)

BSC

0.2440 (6.20)

71

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0099 (0.25)

0.0075 (0.19)

8°

0°

0.0196 (0.50)

0.0099 (0.25)

0.0500 (1.27)

0.0160 (0.41)

C2131b–0–4/00 (rev. C)

x 45°

0.177 (4.50)

PIN 1

REV. C

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

0.122 (3.10)

0.114 (2.90)

8

0.169 (4.30)

1

0.0256 (0.65)

BSC

0.0118 (0.30)

0.0075 (0.19)

8-Lead TSSOP

(RU-8)

5

0.256 (6.50)

0.246 (6.25)

4

0.0433

(1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

8°

0°

14-Lead TSSOP

(RU-14)

PRINTED IN U.S.A.

0.028 (0.70)

0.020 (0.50)

–15–

Loading...

Loading...