Page 1

Low Noise, Low Drift

a

Single-Supply Operational Amplifiers

FEATURES

Single- or Dual-Supply Operation

√

Low Noise: 4.7 nV/

Hz @ 1 kHz

Wide Bandwidth: 3.4 MHz

Low Offset Voltage: 100 V

Very Low Drift: 0.2 V/C

Unity Gain Stable

No Phase Reversal

APPLICATIONS

Digital Scales

Multimedia

Strain Gages

Battery-Powered Instrumentation

Temperature Transducer Amplifier

GENERAL DESCRIPTION

The OP113 family of single supply operational amplifiers

features both low noise and drift. It has been designed for

systems with internal calibration. Often these processor-based

systems are capable of calibrating corrections for offset and gain,

but they cannot correct for temperature drifts and noise. Optimized for these parameters, the OP113 family can be used to

take advantage of superior analog performance combined with

digital correction. Many systems using internal calibration operate from unipolar supplies, usually either 5 V or 12 V. The

OP113 family is designed to operate from single supplies from 4 V

to 36 V, and to maintain its low noise and precision performance.

The OP113 family is unity gain stable and has a typical gain

bandwidth product of 3.4 MHz. Slew rate is in excess of 1 V/µs.

Noise density is a very low 4.7 nV/√Hz, and noise in the 0.1 Hz to

10 Hz band is 120 nV p-p. Input offset voltage is guaranteed

and offset drift is guaranteed to be less than 0.8 µV/°C. Input

common-mode range includes the negative supply and to within

1 V of the positive supply over the full supply range. Phase reversal

protection is designed into the OP113 family for cases where

input voltage range is exceeded. Output voltage swings also include

the negative supply and go to within 1 V of the positive rail. The

output is capable of sinking and sourcing current throughout

its range and is specified with 600 Ω loads.

Digital scales and other strain gage applications benefit from the

very low noise and low drift of the OP113 family. Other applications include use as a buffer or amplifier for both A/D and D/A

sigma-delta converters. Often these converters have high resolutions requiring the lowest noise amplifier to utilize their full

potential. Many of these converters operate in either single supply

or low supply voltage systems, and attaining the greater signal

swing possible increases system performance.

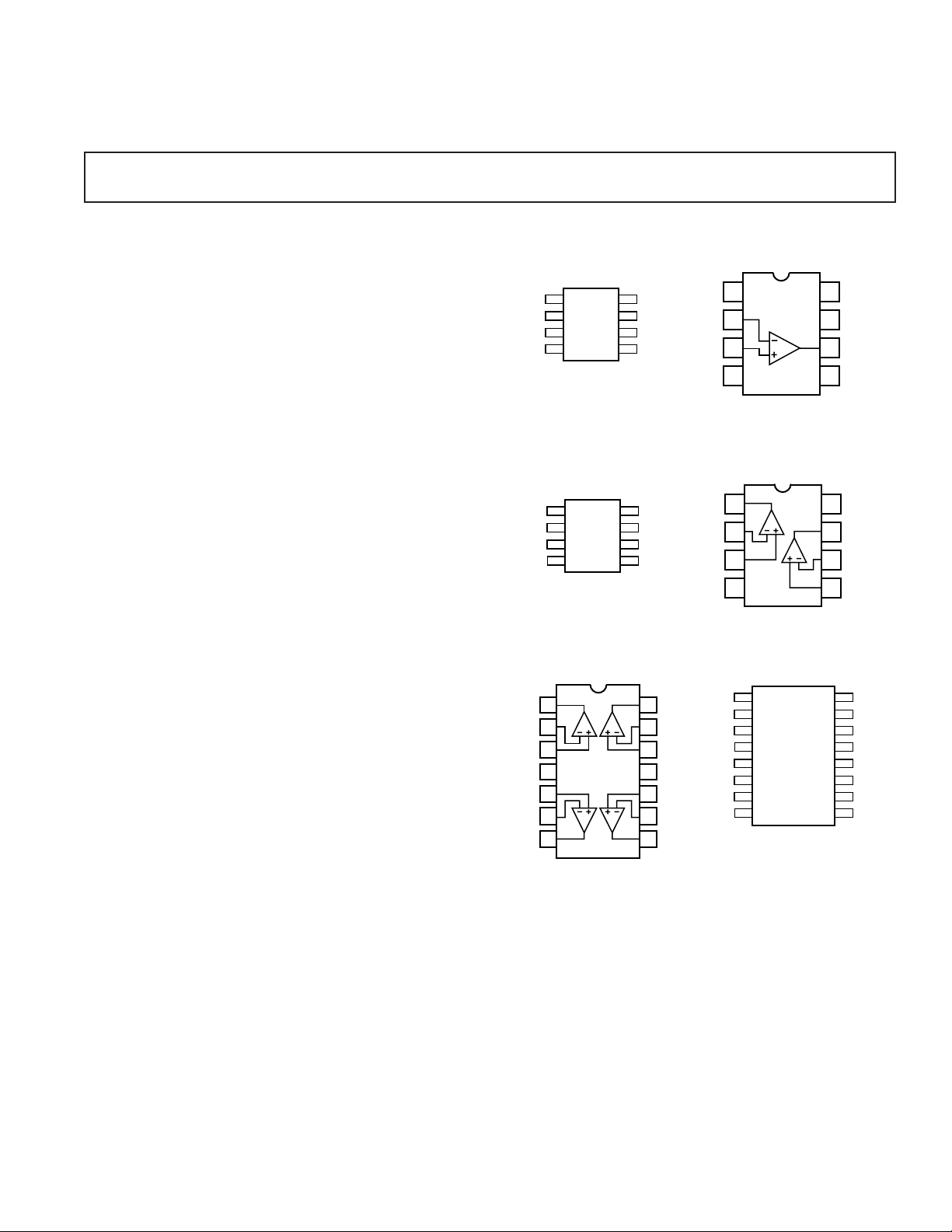

OP113/OP213/OP413

PIN CONNECTIONS

8-Lead Narrow-Body SO 8-Lead Plastic DIP

NULL

NULL

–IN A

+IN A

1

OP113

V–

4

NC = NO CONNECT

NC

8

V+

OUT A

NULL

5

8-Lead Narrow-Body SO

OUT A

–IN A

+IN A

1

8

V+

OP213

V–

4

OUT B

–IN B

5

+IN B

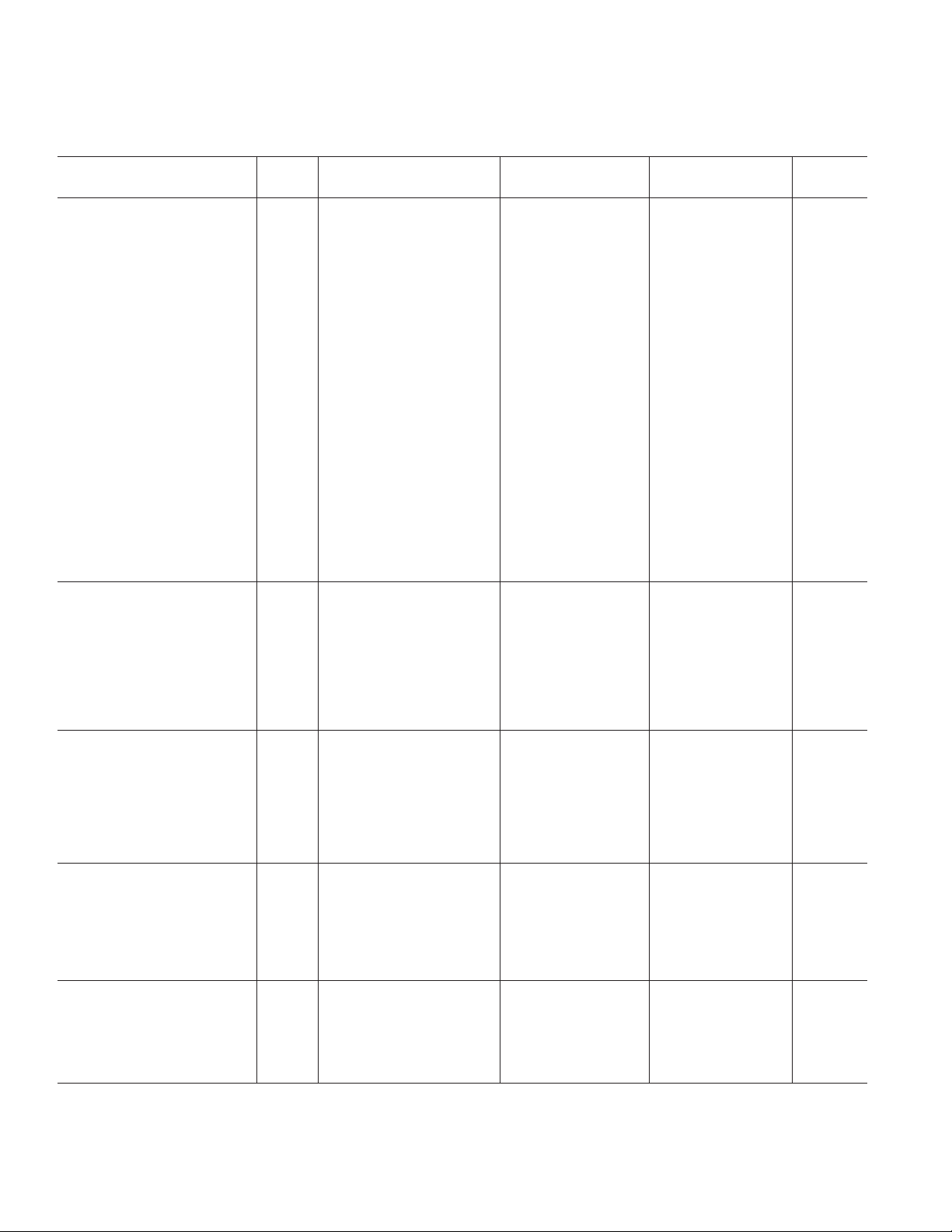

14-Lead Plastic DIP

1

OUT A

2

–IN A

+IN A

3

V+ V–

+IN B

–IN B

OUT B

OP413

4

5

6

7

14

13

12

11

10

9

8

OUT D

–IN D

+IN D

+IN C

–IN C

OUT C

1

–IN A

2

+IN A

3

V–

4

OP113

NC = NO CONNECT

8-Lead Plastic DIP

OUT A

1

–IN A

2

+IN A

3

V–

4

OP213

16-Lead Wide-Body SO

OUT A

–IN A

+IN A

+IN B

–IN B

OUT B

116

V+

NC

OP413

89

NC = NO CONNECT

The OP113 family is specified for single 5 V and dual ±15 V

operation over the XIND—extended industrial (–40°C to +85°C)

temperature range. They are available in plastic and SOIC

surface mount packages.

8

7

6

5

5

8

7

6

NC

V+

OUT A

NULL

V+

OUT B

–IN B

+IN B

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

NC

REV. D

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

OP113/OP213/OP413–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ VS = 15.0 V, TA = 25C unless otherwise noted.

E Grade F Grade

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP113 75 150 µV

–40°C ≤ T

≤ +85°C 125 225 µV

A

OP213 100 250 µV

–40°C ≤ T

≤ +85°C 150 325 µV

A

OP413 125 275 µV

Input Bias Current I

B

VCM = 0 V, 240 600 600 nA

–40°C ≤ T

–40°C ≤ T

Input Offset Current I

OS

VCM = 0 V

–40°C ≤ T

Input Voltage Range V

CM

Common-Mode Rejection CMR –15 V ≤ V

–15 V ≤ V

–40°C ≤ T

Large Signal Voltage Gain A

VO

OP113, OP213,

R

= 600 Ω,

L

–40°C ≤ T

OP413, R

–40°C ≤ T

= 2 kΩ,

R

L

Long-Term Offset Voltage

Offset Voltage Drift

2

1

V

OS

∆VOS/∆T Note 2 0.2 0.8 1.5 µV/°C

–40°C ≤ T

Note 1 150 300 µV

≤ +85°C 175 350 µV

A

≤ +85°C 700 700 nA

A

≤ +85°C5050nA

A

–15 +14 –15 +14 V

≤ +14 V 100 116 96 dB

CM

≤ +14 V,

CM

≤ +85°C 97 116 94 dB

A

≤ +85°C 1 2.4 1 V/µV

A

= 1 kΩ,

L

≤ +85°C 1 2.4 1 V/µV

A

≤ +85°C28 2 V/µV

A

OUTPUT

CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

Short Circuit Limit I

OH

OL

SC

RL = 2 kΩ 14 14 V

R

= 2 kΩ,

L

–40°C ≤ T

≤ +85°C 13.9 13.9 V

A

RL = 2 kΩ –14.5 –14.5 V

R

= 2 kΩ,

L

–40°C ≤ T

≤ +85°C –14.5 –14.5 V

A

±40 ±40 mA

POWER SUPPLY

Power Supply Rejection Ratio PSRR V

Supply Current/Amplifier I

Supply Voltage Range V

SY

S

= ±2 V to ±18 V 103 120 100 dB

S

= ±2 V to ±18 V

V

S

–40°C ≤ T

V

OUT

= ±18 V 3 3 mA

V

S

–40°C ≤ T

≤ +85°C 100 120 97 dB

A

= 0 V, RL = ∞,

≤ +85°C 3.8 3.8 mA

A

4 ±18 4 ±18 V

AUDIO PERFORMANCE

THD + Noise V

= 3 V rms, RL = 2 kΩ

IN

f = 1 kHz, 0.0009 0.0009 %

Voltage Noise Density e

n

f = 10 Hz 9 9 nV/√Hz

f = 1 kHz 4.7 4.7 nV/√Hz

Current Noise Density i

n

f = 1 kHz 0.4 0.4 pA/√Hz

Voltage Noise en p-p 0.1 Hz to 10 Hz 120 120 nV p-p

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 0.8 1.2 0.8 1.2 V/µs

L

Gain Bandwidth Product GBP 3.4 3.4 MHz

Channel Separation V

Settling Time t

NOTES

1

Long-term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at 125 °C, with an LTPD of 1.3.

2

Guaranteed specifications, based on characterization data.

Specifications subject to change without notice.

S

= 10 V p-p

OUT

R

= 2 kΩ, f = 1 kHz 105 105 dB

L

to 0.01%, 0 V to 10 V Step 9 9 µs

–2–

REV. D

Page 3

OP113/OP213/OP413

ELECTRICAL CHARACTERISTICS

(@ VS = 5.0 V, TA = 25C unless otherwise noted.)

E Grade F Grade

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage V

OS

OP113 125 175 µV

–40°C ≤ T

≤ +85°C 175 250 µV

A

OP213 150 300 µV

–40°C ≤ T

≤ +85°C 225 375 µV

A

OP413 175 325 µV

Input Bias Current I

B

VCM = 0 V, V

–40°C ≤ T

–40°C ≤ T

Input Offset Current I

OS

VCM = 0 V, V

–40°C ≤ T

Input Voltage Range V

CM

Common-Mode Rejection CMR 0 V ≤ V

0 V ≤ V

–40°C ≤ T

Large Signal Voltage Gain A

VO

OP113, OP213,

R

= 600 Ω, 2 kΩ

L

0.01 V ≤ V

OP413, R

Long-Term Offset Voltage

Offset Voltage Drift

2

1

V

OS

DVOS/DT Note 2 0.2 1.0 1.5 µV/°C

0.01 V ≤ V

Note 1 200 350 µV

≤ +85°C 250 400 µV

A

= 2 300 650 650 nA

OUT

≤ +85°C 750 750 nA

A

= 2

OUT

≤ +85°C5050nA

A

0+4 +4V

≤ 4 V 93 106 90 dB

CM

≤ 4 V,

CM

≤ +85°C90 87 dB

A

≤ 3.9 V 2 2 V/µV

OUT

= 600, 2 kΩ,

L

≤ 3.9 V 1 1 V/µV

OUT

OUTPUT

CHARACTERISTICS

Output Voltage Swing High V

Output Voltage Swing Low V

Short Circuit Limit I

OH

OL

SC

RL = 600 kΩ 4.0 4.0 V

R

= 100 kΩ, 4.1 4.1 V

L

–40°C ≤ T

= 600 Ω, 3.9 3.9 V

R

L

–40°C ≤ T

≤ +85°C

A

≤ +85°C

A

RL = 600 Ω,88mV

–40°C ≤ T

R

= 100 kΩ,88mV

L

–40°C ≤ T

≤ +85°C

A

≤ +85°C

A

±30 ±30 mA

POWER SUPPLY

Supply Current I

SY

I

SY

V

= 2.0 V, No Load 1.6 2.7 2.7 mA

OUT

–40°C ≤ TA ≤ +85°C 3.0 3.0 mA

AUDIO PERFORMANCE

THD + Noise V

Voltage Noise Density e

n

= 0 dBu, f = 1 kHz 0.001 0.001 %

OUT

f = 10 Hz 9 9 nV/√Hz

f = 1 kHz 4.7 4.7 nV/√Hz

Current Noise Density i

n

f = 1 kHz 0.45 0.45 pA/√Hz

Voltage Noise en p-p 0.1 Hz to 10 Hz 120 120 nV p-p

DYNAMIC PERFORMANCE

Slew Rate SR R

= 2 kΩ 0.6 0.9 0.6 V/µs

L

Gain Bandwidth Product GBP 3.5 3.5 MHz

Settling Time t

NOTES

1

Long-term offset voltage is guaranteed by a 1000 hour life test performed on three independent lots at 125 °C, with an LTPD of 1.3.

2

Guaranteed specifications, based on characterization data.

Specifications subject to change without notice.

S

to 0.01%, 2 V Step 5.8 5.8 µs

REV. D

–3–

Page 4

OP113/OP213/OP413

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . ±10 V

Output Short-Circuit Duration to GND . . . . . . . . . Indefinite

Storage Temperature Range

P, S Packages . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

OP113/OP213/OP413E, F . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range

P, S Packages . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering, 60 sec) . . . . . . . 300°C

Package Type

2

JA

JC

Unit

8-Lead Plastic DIP (P) 103 43 °C/W

8-Lead SOIC (S) 158 43 °C/W

Temperature Package Package

Model Range Description Options

OP113ES –40°C to +85°C 8-Lead SOIC SO-8

OP113FP* –40°C to +85°C 8-Lead Plastic DIP N-8

OP113FS –40°C to +85°C 8-Lead SOIC SO-8

OP213EP* –40°C to +85°C 8-Lead Plastic DIP N-8

OP213ES –40°C to +85°C 8-Lead SOIC SO-8

OP213FP –40°C to +85°C 8-Lead Plastic DIP N-8

OP213FS –40°C to +85°C 8-Lead SOIC SO-8

OP413ES –40°C to +85°C 16-Lead Wide SOIC R-16

OP413FP* –40°C to +85°C 14-Lead Plastic DIP N-14

OP413FS –40°C to +85°C 16-Lead Wide SOIC R-16

*Not for new designs; obsolete April 2002.

ORDERING GUIDE

14-Lead Plastic DIP (P) 83 39 °C/W

16-Lead SOIC (S) 92 27 °C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

θJA is specified for the worst-case conditions, i.e., θJA is specified for device in

socket for cerdip, P-DIP, and LCC packages; θJA is specified for device soldered in circuit board for SOIC package.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the OP113/OP213/OP413 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions

are recommended to avoid performance degradation or loss of functionality.

–4–

REV. D

Page 5

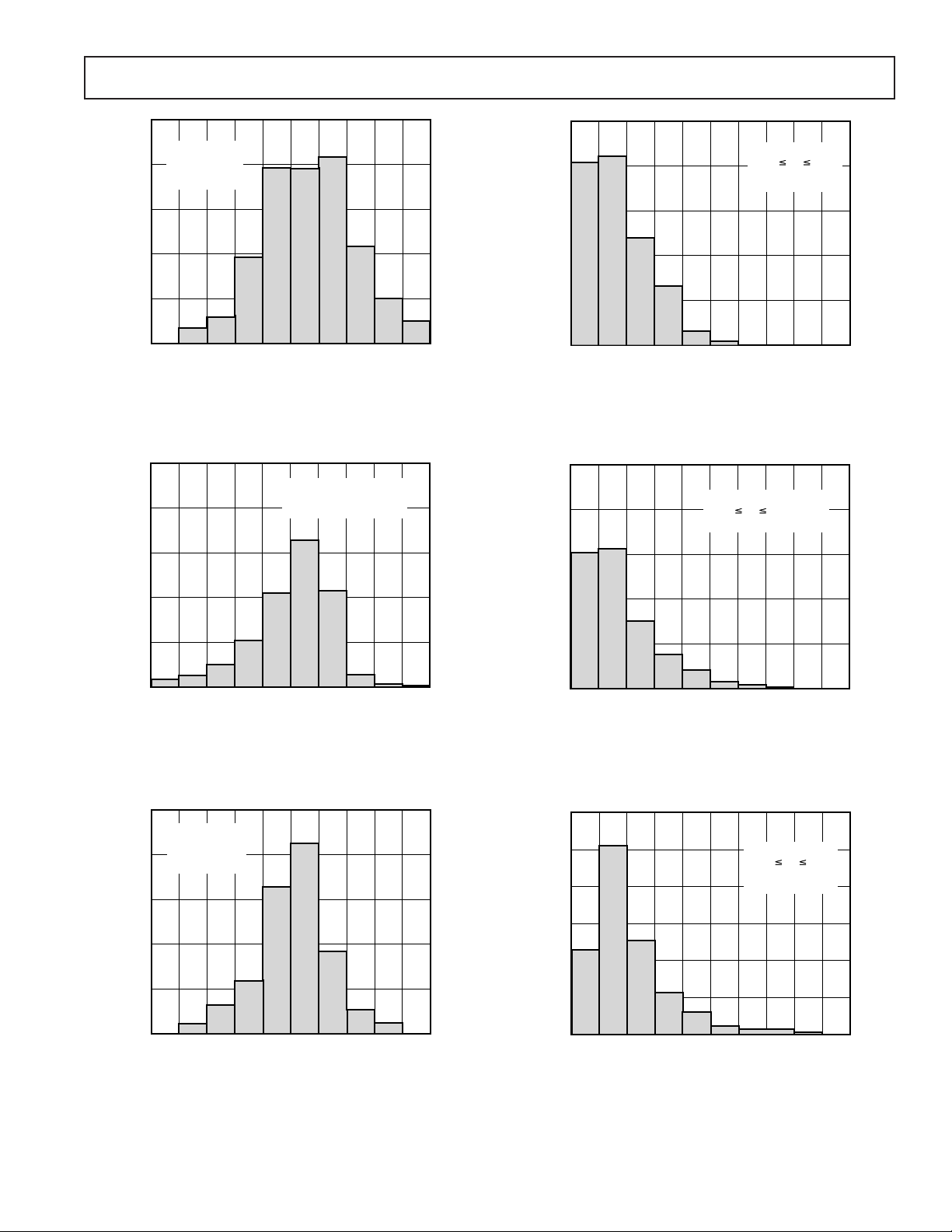

Typical Performance Characteristics–

TCVOS – V

UNITS

600

0

1.0

300

100

0.1

200

0

500

400

0.90.70.60.5 0.80.40.30.2

VS = 15V

–40

C T

A

+85C

1220 OP AMPS

PLASTIC PKG

OP113/OP213/OP413

100

VS = 15V

= 25C

T

A

80

400 OP AMPS

PLASTIC PKG

60

UNITS

40

20

0

–40

–50

INPUT OFFSET VOLTAGE, V

– V

OS

403020100–10–20–30

TPC 1a. OP113 Input Offset (VOS) Distribution

±

15 V

@

500

VS = 15V

= 25C

T

400

300

A

896 (PLASTIC) OP AMPS

150

VS = 15V

–40

120

90

UNITS

60

C TA +85C

400 OP AMPS

PLASTIC PKG

30

50

0

0.1

0

TCVOS – V

1.0

0.90.80.70.60.50.40.30.2

TPC 2a. OP113 Temperature Drift (TCVOS)

Distribution @

500

400

300

±

15 V

VS = 15V

–40

C TA +85C

896 (PLASTIC) OP AMPS

UNITS

200

100

0

–80

–100

INPUT OFFSET VOLTAGE, VOS – V

806040200–20–40–60

TPC 1b. OP213 Input Offset (VOS) Distribution

@

±

15 V

500

VS = 15V

= 25C

T

A

400

1220 OP AMPS

PLASTIC PKG

300

UNITS

200

100

0

–60

–40

INPUT OFFSET VOLTAGE, VOS – V

120100806040200–20

100

140

UNITS

200

100

0

0.1

0

TCVOS – V

TPC 2b. OP213 Temperature Drift (TCVOS)

±

Distribution @

15 V

1.0

0.90.80.70.60.50.40.30.2

TPC 1c. OP413 Input Offset (VOS) Distribution

@

±

15 V

REV. D

–5–

TPC 2c. OP413 Temperature Drift (TCVOS)

±

Distribution @

15 V

Page 6

OP113/OP213/OP413

1000

800

VCM = 0V

1007550250–25

INPUT BIAS CURRENT – nA

600

400

200

0

–75

–50

VS = 5.0V

V

CM

VS = 15V

V

= 0V

CM

TEMPERATURE – C

= 2.5V

TPC 3. OP113 Input Bias Current vs. Temperature

5.0

4.5

4.0

3.5

POSITIVE OUTPUT SWING – Volts

3.0

–75

+SWING

R

= 2k

L

+SWING

R

= 600

L

–50

TEMPERATURE – C

–SWING

R

= 2k

L

–SWING

R

L

VS = 5.0V

= 600

75 10050250–25

125

125

1.5

1.0

2.0

0.5

0

NEGATIVE OUTPUT SWING – mV

500

400

300

VS = 15V

200

INPUT BIAS CURRENT – nA

100

0

–50

–75

0–25

TEMPERATURE – C

VS = 5.0V

125

100755025

TPC 6. OP213 Input Bias Current vs. Temperature

15.0

14.5

14.0

13.5

13.0

12.5

–13.5

–14.0

POSITIVE OUTPUT SWING – Volts

–14.5

–15.0

–75

VS = 15V

–50

–SWING

R

= 600

L

+SWING

R

= 2k

L

+SWING

= 600

R

L

TEMPERATURE – C

–SWING

R

= 2k

L

1007550250–25

125

TPC 4. Output Swing vs. Temperature and RL @ 5 V

60

VS = 15V

40

= 25C

T

A

20

0

–20

–40

–60

–80

CHANNEL SEPARATION – dB

–100

–120

10 100 10M1M100k10k1k

105

FREQUENCY – Hz

TPC 5. Channel Separation

TPC 7. Output Swing vs. Temperature and RL @ ±15 V

20

18

16

14

12

10

8

6

OPEN-LOOP GAIN – V/V

4

2

0

–50

–75

RL = 2k

RL = 600

0–25

TEMPERATURE – C

VS = 5.0V

= 3.9V

V

O

100755025

125

TPC 8. Open-Loop Gain vs. Temperature @ 5 V

–6–

REV. D

Page 7

OP113/OP213/OP413

100

40

–20

10k 10M1M100k1k

20

0

60

80

FREQUENCY – Hz

OPEN-LOOP GAIN – dB

90

225

135

180

45

0

PHASE – Degrees

TA= 25C

V

S

= 15V

GAIN

PHASE

m = 72

12.5

VS = 15V

V

= 10V

D

1007550250–25

10.0

OPEN-LOOP GAIN – V/V

7.5

5.0

2.5

RL = 2k

RL = 1k

RL = 600

0

–75

TEMPERATURE – C

TPC 9. OP413 Open-Loop Gain vs. Temperature

100

OPEN-LOOP GAIN – dB

V+ = 5V

V– = 0V

T

= 25C

80

60

40

20

A

GAIN

PHASE

m = 57

0

10

9

8

–50

RL = 2k

RL = 600

0–25

TEMPERATURE – C

7

6

5

4

3

OPEN LOOP GAIN – V/V

2

1

0

125–50

–75

VS = 15V

V

= 10V

O

100755025

125

TPC 12. OP213 Open-Loop Gain vs. Temperature

0

45

90

135

PHASE – Degrees

180

–20

10k 10M1M100k1k

FREQUENCY – Hz

TPC 10. Open-Loop Gain, Phase vs. Frequency @ 5 V

50

V+ = 5V

40

AV = 100

30

20

AV = 10

10

0

CLOSED-LOOP GAIN – dB

AV = 1

–10

–20

10k 10M1M100k1k

FREQUENCY – Hz

V– = 0V

T

= 25C

A

TPC 11. Closed-Loop Gain vs. Frequency @ 5 V

225

TPC 13. Open-Loop Gain, Phase vs. Frequency @ ±15 V

50

TA= 25C

= 15V

V

S

CLOSED-LOOP GAIN – dB

–10

–20

40

AV = 100

30

20

AV = 10

10

0

AV = 1

10k 10M1M100k1k

FREQUENCY – Hz

TPC 14. Closed-Loop Gain vs. Frequency @ ±15 V

REV. D

–7–

Page 8

OP113/OP213/OP413

70

65

60

55

PHASE MARGIN – Degrees

50

–75

V+ = 5V

V– = 0V

–50

GBW

m

75 10050250–25

TEMPERATURE – C

125

5

4

3

2

GAIN-BANDWIDTH PRODUCT – MHz

1

TPC 15. Gain Bandwidth Product and Phase Margin vs.

Temperature @ 5 V

30

25

20

TA = 25C

= 15V

V

S

70

65

60

55

PHASE MARGIN – Degrees

50

–75

VS = 15V

–50

GBW

m

TEMPERATURE – C

75 10050250–25

125

5

4

3

2

1

TPC 18. Gain Bandwidth Product and Phase Margin vs.

Temperature @

3.0

2.5

2.0

±

15 V

TA = 25C

= 15V

V

S

GAIN-BANDWIDTH PRODUCT – MHz

15

10

5

VOLTAGE NOISE DENSITY – nV/ Hz

0

110 1k100

FREQUENCY – Hz

TPC 16. Voltage Noise Density vs. Frequency

COMMON-MODE REJECTION – dB

140

120

100

80

60

40

20

0

1k 1M100k10k100

FREQUENCY – Hz

V+ = 5V

V– = 0V

T

= 25C

A

TPC 17. Common-Mode Rejection vs. Frequency @ 5 V

1.5

1.0

0.5

CURRENT NOISE DENSITY – pA/ Hz

0

110 1k100

FREQUENCY – Hz

TPC 19. Current Noise Density vs. Frequency

140

120

100

80

60

40

COMMON-MODE REJECTION – dB

20

0

1k 1M100k10k100

FREQUENCY – Hz

TA= 25C

= 15V

V

S

TPC 20. Common-Mode Rejection vs. Frequency @ ±15 V

–8–

REV. D

Page 9

OP113/OP213/OP413

20

0

500

6

2

100

4

0

12

8

10

14

16

18

400300200

LOAD CAPACITANCE – pF

OVERSHOOT – %

VS = 15V

R

L

= 2k

V

IN

= 100mV p-p

T

A

= 25C

A

VCL

= 1

POSITIVE

EDGE

NEGATIVE

EDGE

140

120

100

80

60

40

POWER SUPPLY REJECTION – dB

20

0

–PSRR

1k 1M100k10k100

FREQUENCY – Hz

+PSRR

TA = 25C

= 15V

V

S

TPC 21. Power Supply Rejection vs. Frequency @ ±15 V

6

VS = 5V

= 2k

R

5

4

L

T

A

A

VCL

= 25C

= 1

40

30

20

IMPEDANCE –

10

0

1k 1M100k10k100

AV = 100

AV = 10

FREQUENCY – Hz

TA = 25C

= 15V

V

S

AV = 1

TPC 24. Closed-Loop Output Impedance vs. Frequency

@

±

15 V

30

25

20

VS = 15V

R

= 2k

L

= 25C

T

A

= 1

A

VOL

3

2

MAXIMUM OUTPUT SWING – Volts

1

0

TPC 22. Maximum Output Swing vs. Frequency @ 5 V

50

45

40

35

30

25

20

OVERSHOOT – %

15

10

REV. D

5

0

0

TPC 23. Small Signal Overshoot vs. Load

Capacitance @ 5 V

VS = 5V

= 2k

R

L

V

= 100mV p-p

IN

= 25C

T

A

= 1

A

VCL

100

10k 10M1M100k1k

FREQUENCY – Hz

NEGATIVE

EDGE

LOAD CAPACITANCE – pF

POSITIVE

EDGE

TPC 25. Maximum Output Swing vs. Frequency @ ±15 V

400300200

500

–9–

15

10

MAXIMUM OUTPUT SWING – Volts

5

0

10k 10M1M100k1k

FREQUENCY – Hz

TPC 26. Small Signal Overshoot vs. Load

±

Capacitance @

15 V

Page 10

OP113/OP213/OP413

2.0

VS = 5, 0

V

4.0V

OUT

TEMPERATURE – C

+SLEW RATE

0.5V

1.5

1.0

SLEW RATE – V/s

0.5

0

–75

–50

TPC 27. Slew Rate vs. Temperature @ 5 V

V

(0.5 V

100

90

OUT

4.0 V)

–SLEW RATE

75 10050250–25

1s

125

2.0

VS = 15V

V

1.5

1.0

SLEW RATE – V/s

0.5

0

–75

–50

TPC 30. Slew Rate vs. Temperature @ ±15 V

(–10 V

100

90

OUT

= 10V

≤

V

TEMPERATURE – C

≤ +10.0 V)

OUT

+SLEW RATE

–SLEW RATE

75 10050250–25

1s

125

10

0%

20mV

TPC 28. Input Voltage Noise @ ±15 V (20 nV/div)

909

100

0.1Hz–10Hz

= 1000

A

V

AV = 100

t

OUT

TPC 29. Noise Test Diagram

10

0%

20mV

TPC 31. Input Voltage Noise @ 5 V (20 nV/div)

5

4

VS = 18V

3

2

SUPPLY CURRENT – mA

1

0

–75

–50

0–25

TEMPERATURE – C

VS = 15V

VS = 5.0V

100755025

125

TPC 32. Supply Current vs. Temperature

–10–

REV. D

Page 11

OP113/OP213/OP413

16

2

136711 12

4

14

15

9

1

3

AD588BD

8

10

3

2

8

1

R5

1k

A2

2N2219A

+10.000V

+15V

–15V

10F

1/2

OP213

+10.000V

6

5

4

7

A1

R3

17.2k

0.1%

R4

500

CMRR TRIM

10-TURN

T.C. LESS THAN 50ppm/C

OUTPUT

0 10V

FS

–15V

350

LOAD

CELL

100mV

F.S.

R1

17.2k

0.1%

R2

301

0.1%

1/2

OP213

APPLICATIONS

The OP113, OP213, and OP413 form a new family of high

performance amplifiers that feature precision performance in

standard dual supply configurations and, more importantly,

maintain precision performance when a single power supply is

used. In addition to accurate dc specifications, it is the lowest

noise single supply amplifier available with only 4.7 nV/√Hz

typical noise density.

Single supply applications have special requirements due to the

generally reduced dynamic range of the output signal. Single

supply applications are often operated at voltages of 5 V or 12 V,

compared to dual supply applications with supplies of ±12 V or

± 15 V. This results in reduced output swings. Where a dual

supply application may often have 20 V of signal output swing,

single supply applications are limited to, at most, the supply range

and, more commonly, several volts below the supply. In order to

attain the greatest swing, the single supply output stage must

swing closer to the supply rails than in dual supply applications.

The OP113 family has a new patented output stage that allows

the output to swing closer to ground, or the negative supply,

than previous bipolar output stages. Previous op amps had

outputs that could swing to within about ten millivolts of the

negative supply in single supply applications. However, the

OP113 family combines both a bipolar and a CMOS device in

the output stage, enabling it to swing to within a few hundred

microvolts of ground.

When operating with reduced supply voltages, the input range is

also reduced. This reduction in signal range results in reduced

signal-to-noise ratio, for any given amplifier. There are only two

ways to improve this: increase the signal range or reduce the

noise. The OP113 family addresses both of these parameters.

Input signal range is from the negative supply to within one

volt of the positive supply over the full supply range. Competitive parts have input ranges that are a half a volt to five

volts less than this. Noise has also been optimized in the OP113

family. At 4.7 nV/√Hz, it is less than one fourth that of competitive devices.

Phase Reversal

The OP113 family is protected against phase reversal as long

as both of the inputs are within the supply ranges. However, if

there is a possibility of either input going below the negative

supply (or ground in the single supply case), the inputs should

be protected with a series resistor to limit input current to 2 mA.

OP113 Offset Adjust

The OP113 has the facility for external offset adjustment,

using the industry standard arrangement. Pins 1 and 5 are used

in conjunction with a potentiometer of 10 kΩ total resistance,

of approximately 3.3 µV/°C

OS

connected with the wiper to V– (or ground in single supply

applications). The total adjustment range is about ±2 mV using

this configuration.

Adjusting the offset to zero has minimal effect on offset drift

(assuming the potentiometer has a tempco of less than 1000 ppm/

°C). Adjustment away from zero, however, (like all bipolar

amplifiers) will result in a TCV

for every millivolt of induced offset.

It is therefore not generally recommended that this trim be

used to compensate for system errors originating outside of the

OP113. The initial offset of the OP113 is low enough that external

trimming is almost never required but, if necessary, the 2 mV trim

REV. D

range may be somewhat excessive. Reducing the trimming

potentiometer to a 2 kΩ value will give a more reasonable range

of ±400 µV.

Figure 1. Precision Load Cell Scale Amplifier

APPLICATION CIRCUITS

A High Precision Industrial Load-Cell Scale Amplifier

The OP113 family makes an excellent amplifier for conditioning

a load-cell bridge. Its low noise greatly improves the signal resolution, allowing the load cell to operate with a smaller output

range, thus reducing its nonlinearity. Figure 1 shows one half of

the OP113 family used to generate a very stable 10.000 V bridge

excitation voltage while the second amplifier provides a differential

gain. R4 should be trimmed for maximum common-mode rejection.

A Low Voltage Single Supply, Strain-Gage Amplifier

The true zero swing capability of the OP113 family allows the

amplifier in Figure 2 to amplify the strain-gage bridge accurately

even with no signal input while being powered by a single 5 V

supply. A stable 4.000 V bridge voltage is made possible by the

rail-to-rail OP295 amplifier, whose output can swing to within a

millivolt of either rail. This high voltage swing greatly increases

the bridge output signal without a corresponding increase in

bridge input.

5V

2

IN

6

OUT

GND

5

6

4

REF43

5V

8

1/2

OP295

4

100k

OUTPUT

0V 3.5V

7

R4

350

35mV

FS

2N2222A

4.000V

3

2

R1

100k

1

12.0k

1/2

OP213

R8

8

1/2

OP295

4

1

R2

20k

R5

2.10k

R

= 2,127.4

G

3

2

27.4

2.500V

R7

20.0k

R3

20k

R6

Figure 2. Single Supply Strain-Gage Amplifier

–11–

Page 12

OP113/OP213/OP413

A High Accuracy Linearized RTD Thermometer Amplifier

Zero suppressing the bridge facilitates simple linearization of the

RTD by feeding back a small amount of the output signal to the

RTD (Resistor Temperature Device). In Figure 3, the left leg of

the bridge is servoed to a virtual ground voltage by amplifier

A1, while the right leg of the bridge is also servoed to zero volt

by amplifier A2. This eliminates any error resulting from commonmode voltage change in the amplifier. A 3-wire RTD is used to

balance the wire resistance on both legs of the bridge, thereby

reducing temperature mismatch errors. The 5.000 V bridge

excitation is derived from the extremely stable AD588 reference

device with 1.5 ppm/°C drift performance.

Linearization of the RTD is done by feeding a fraction of the

output voltage back to the RTD in the form of a current. With

just the right amount of positive feedback, the amplifier output

will be linearly proportional to the temperature of the RTD.

+15V–15V

2

16

10F

100

RTD

11

12

13

4

6

AD588BD

7

14

15

1

R3

3

50

10

8

9

R

R

R

R1

8.25k

W1

W2

W3

RG FULL SCALE ADJUST

R2

8.25k

R4

100

2

3

1

A1

1/2

R5

4.02k

6

A2

5

+15V

8

4

–15V

R7

100

7

1/2

OP213

R8

49.9k

V

(10mV/C)

OUT

–1.50V = –150C

+5.00V = +500C

R9

5k

LINEARITY

ADJUST

@1/2 FS

OP213

Figure 3. Ultraprecision RTD Amplifier

To calibrate the circuit, first immerse the RTD in a zero-degree

ice bath or substitute an exact 100 Ω resistor in place of the

RTD. Adjust the ZERO ADJUST potentiometer for a 0.000 V

output, then set R9 LINEARITY ADJUST potentiometer to

the middle of its adjustment range. Substitute a 280.9 Ω resistor

(equivalent to 500°C) in place of the RTD, and adjust the

FULL-SCALE ADJUST potentiometer for a full-scale voltage

of 5.000 V.

To calibrate out the nonlinearity, substitute a 194.07 Ω resistor

(equivalent to 250°C) in place of the RTD, then adjust the

LINEARITY ADJUST potentiometer for a 2.500 V output.

Check and readjust the full-scale and half-scale as needed.

Once calibrated, the amplifier outputs a 10 mV/°C temperature

coefficient with an accuracy better than ±0.5°C over an RTD

measurement range of –150°C to +500°C. Indeed the amplifier

can be calibrated to a higher temperature range, up to 850°C.

A High Accuracy Thermocouple Amplifier

Figure 4 shows a popular K-type thermocouple amplifier with

cold-junction compensation. Operating from a single 12 V supply,

the OP113 family’s low noise allows temperature measurement

to better than 0.02°C resolution from 0°C to 1000°C range.

The cold-junction error is corrected by using an inexpensive silicon

diode as a temperature measuring device. It should be placed as

close to the two terminating junctions as physically possible. An

aluminum block might serve well as an isothermal system.

1N4148

D1

R4

5.000V

R1

10.7k

R2

2.74k

200

R3

53.6

R9

124k

R5

40.2k

R8

453

R6

2

OP213

3

12V

1/2

10F

0.1F

8

4

+

1

0V TO 10.00V

(0C TO 1000C)

12V

0.1F

K-TYPE

THERMOCOUPLE

40.7V/C

2 6

REF02EZ

4

––

++

5.62k

Figure 4. Accurate K-Type Thermocouple Amplifier

R6 should be adjusted for a zero-volt output with the thermocouple measuring tip immersed in a zero-degree ice bath. When

calibrating, be sure to adjust R6 initially to cause the output to

swing in the positive direction first. Then back off in the negative direction until the output just stops changing.

An Ultralow Noise, Single Supply Instrumentation Amplifier

Extremely low noise instrumentation amplifiers can be built

using the OP113 family. Such an amplifier that operates off a

single supply is shown in Figure 5. Resistors R1–R5 should be

of high precision and low drift type to maximize CMRR performance. Although the two inputs are capable of operating to zero

volt, the gain of –100 configuration will limit the amplifier input

common mode to not less than 0.33 V.

5V TO 36V

+

V

IN

–

*R1

10k

*ALL RESISTORS 0.1%, 25ppm/C

1/2

OP213

10k

*R2

(200 + 12.7)

*R3

10k

*R

G

1/2

OP213

*R4

10k

GAIN = + 6

20k

R

V

OUT

G

Figure 5. Ultralow Noise, Single Supply Instrumentation

Amplifier

–12–

REV. D

Page 13

OP113/OP213/OP413

Supply Splitter Circuit

The OP113 family has excellent frequency response characteristic that makes it an ideal pseudo-ground reference generator as

shown in Figure 6. The OP113 family serves as a voltage follower

buffer. In addition, it drives a large capacitor that serves as a charge

reservoir to minimize transient load changes, as well as a low

impedance output device at high frequencies. The circuit easily

supplies 25 mA load current with good settling characteristics.

+ = 5V 12V

V

S

R3

2.5k

C1

8

1/2

OP113

4

0.1F

R4

100

1

+

C2

1F

VS+

2

OUTPUT

5k

5k

R1

2

3

R2

Figure 6. False Ground Generator

Low Noise Voltage Reference

Few reference devices combine low noise and high output drive

capabilities. Figure 7 shows the OP113 family used as a two-pole

active filter that band limits the noise of the 2.500 V reference.

Total noise measures 3 µV p-p.

5V

5V

2

IN

OUT

REF43

GND

4

–

10F

+

10k

10k

6

+

C2

10F

2

3

8

1/2

OP113

4

1

3V p-p NOISE

OUTPUT

2.500V

Figure 7. Low Noise Voltage Reference

5 V Only Stereo DAC for Multimedia

The OP113 family’s low noise and single supply capability are

ideally suited for stereo DAC audio reproduction or sound

synthesis applications such as multimedia systems. Figure 8

shows an 18-bit stereo DAC output setup that is powered from a

single 5 V supply. The low noise preserves the 18-bit dynamic

range of the AD1868. For DACs that operate on dual supplies,

the OP113 family can also be powered from the same supplies.

5V SUPPLY

L

DL

18-BIT

DAC

18-BIT

SERIAL

REG.

18-BIT

SERIAL

REG.

18-BIT

DAC

AD1868

1

V

LL

2

3

4

CK

DR

5

LR

6

DGND

7

8

VBR

VBL

16

15

7.68k

7.68k

9.76k

9.76k

14

VOL

V

REF

AGND

V

REF

VOR

330pF

13

12

11

10

9

V

S

330pF

OP213

7.68k

7.68k

6

OP213

5

1/2

1/2

8

100pF

100pF

220F

1

+

220F

7

+

LEFT

CHANNEL

–

OUTPUT

47k

RIGHT

CHANNEL

–

OUTPUT

47k

Figure 8. 5 V Only 18-Bit Stereo DAC

SoundPort is a registered trademark of Analog Devices, Inc.

REV. D

–13–

Page 14

OP113/OP213/OP413

Low Voltage Headphone Amplifiers

Figure 9 shows a stereo headphone output amplifier for the

AD1849 16-bit SoundPort

®

Stereo Codec device. The pseudoreference voltage is derived from the common-mode voltage

generated internally by the AD1849, thus providing a convenient bias for the headphone output amplifiers.

OPTIONAL

GAIN

LOUT1L

AD1849

CMOUT

LOUT1R

1k

V

REF

10F

31

V

19

29

REF

10k

10k

10F

L VOLUME

CONTROL

R VOLUME

CONTROL

1k

OPTIONAL

GAIN

V

REF

5k

5V

1/2

OP213

5V

1/2

OP213

1/2

OP213

5k

16

16

220F

+

47k

220F

+

47k

HEADPHONE

LEFT

HEADPHONE

RIGHT

Figure 9. Headphone Output Amplifier for Multimedia

Sound Codec

Low Noise Microphone Amplifier for Multimedia

The OP113 family is ideally suited as a low noise microphone

preamp for low voltage audio applications. Figure 10 shows a

gain of 100 stereo preamp for the AD1849 16-bit SoundPort

Stereo Codec chip. The common-mode output buffer serves as

a “phantom power” driver for the microphones.

10k

5V

LEFT

ELECTRET

CONDENSER

MIC

INPUT

RIGHT

ELECTRET

CONDENSER

MIC

INPUT

20

20

10F

OP213

10F

1/2

50

5V

1/2

10k

50

OP213

10010k

100

1/2

OP213

10k

17

MINL

AD1849

19

CMOUT

15

MINR

Precision Voltage Comparator

With its PNP inputs and zero volt common-mode capability, the

OP113 family can make useful voltage comparators. There is

only a slight penalty in speed in comparison to IC comparators.

However, the significant advantage is its voltage accuracy. For

example, V

can be a few hundred microvolts or less, combined

OS

with CMRR and PSRR exceeding 100 dB, while operating on 5 V

supply. Standard comparators like the 111/311 family operate

on 5 V, but not with common-mode at ground, nor with offset

below 3 mV. Indeed, no commercially available single supply

comparator has a V

less than 200 µV.

OS

Figure 11 shows the OP113 family response to a 10 mV overdrive signal when operating in open loop. The top trace shows

the output rising edge has a 15 µs propagation delay, while the

bottom trace shows a 7 µs delay on the output falling edge. This

ac response is quite acceptable in many applications.

10mV OVERDRIVE

+2.5V

0V

–2.5V

t

=

t

= 5ms

r

f

100

90

10

0%

25k

100

2V

2V

5V

1/2

OP113

5s

Figure 11. Precision Comparator

The low noise and 250 µV (maximum) offset voltage enhance the

overall dc accuracy of this type of comparator. Note that zero

crossing detectors and similar ground referred comparisons can be

implemented even if the input swings to –0.3 V below ground.

Figure 10. Low Noise Stereo Microphone Amplifier for

Multimedia Sound Codec

SoundPort is a registered trademark of Analog Devices, Inc.

–14–

REV. D

Page 15

+IN

9V 9V

–IN

Figure 12. OP213 Simplified Schematic

*OP113 Family SPICE Macro-Model

*

*Copyright 1992 by Analog Devices, Inc.

*

*Node Assignments

*

* Noninverting Input

* Inverting Input

* Positive Supply

* Negative Supply

* Output

*

.SUBCKT OP113 Family 3 2 7 4 6

*

* INPUT STAGE

R3 4 19 1.5E3

R4 4 20 1.5E3

C1 19 20 5.31E–12

I1 7 18 106E–6

IOS 2 3 25E–09

EOS 12 5 POLY(1) 51 4 25E–06 1

Q1 19 3 18 PNP1

Q2 20 12 18 PNP1

CIN 3 2 3E–12

D1 3 1 DY

D2 2 1 DY

EN 5 2 22 0 1

GN1 0 2 25 0 1E–5

GN2 0 3 28 0 1E–5

*

* VOLTAGE NOISE SOURCE WITH FLICKER NOISE

DN1 21 22 DEN

DN2 22 23 DEN

VN1 21 0 DC 2

VN2 0 23 DC 2

*

* CURRENT NOISE SOURCE WITH FLICKER NOISE

DN3 24 25 DIN

DN4 25 26 DIN

VN3 24 0 DC 2

VN4 0 26 DC 2

*

OUT

OP113/OP213/OP413

* SECOND CURRENT NOISE SOURCE

DN5 27 28 DIN

DN6 28 29 DIN

VN5 27 0 DC 2

VN6 0 29 DC 2

*

* GAIN STAGE & DOMINANT POLE AT .2000E+01 HZ

G2 34 36 19 20 2.65E–04

R7 34 36 39E+06

V3 35 4 DC 6

D4 36 35 DX

VB2 34 4 1.6

*

* SUPPLY/2 GENERATOR

ISY 7 4 0.2E–3

R10 7 60 40E+3

R11 60 4 40E+3

C3 60 0 1E–9

*

* CMRR STAGE & POLE AT 6 kHZ

ECM 50 4 POLY(2) 3 BΠ60 2 60 0 1.6 0 1.6

CCM 50 51 26.5E–12

RCM1 50 51 1E6

RCM2 51 4 1

*

*

OUTPUT STAGE

R12 37 36 1E3

R13 38 36 500

C4 37 6 20E–12

C5 38 39 20E–12

M1 39 36 4 4 MN L=9E–6 W=1000E–6 AD=15E–9 AS=15E–9

M2 45 36 4 4 MN L=9E–6 W=1000E–6 AD=15E–9 AS=15E–9

D5 39 47 DX

D6 47 45 DX

Q3 39 40 41 QPA 8

VB 7 40 DC 0.861

R14 7 41 375

Q4 41 7 43 QNA 1

R17 7 43 15

Q5 43 39 6 QNA 20

Q6 46 45 6 QPA 20

R18 46 4 15

Q7 36 46 4 QNA 1

M3 6 36 4 4 MN L = 9E–6 W=2000E–6 AD=30E–9 AS=30E–9

*

* NONLINEAR MODELS USED

*

.MODEL DX D (IS=1E–15)

.MODEL DY D (IS=1E–15 BV=7)

.MODEL PNP1 PNP (BF=220)

.MODEL DEN D(IS=1E–12 RS=1016 KF=3.278E–15 AF=1)

.MODEL DIN D(IS=1E–12 RS=100019 KF=4.173E–15 AF=1)

.MODEL QNA NPN(IS=1.19E–16 BF=253 VAF=193 VAR=15 RB=2.0E3

+ IRB=7.73E–6 RBM=132.8 RE=4 RC=209 CJE=2.1E–13 VJE=0.573

+ MJE=0.364 CJC=1.64E–13 VJC=0.534 MJC=0.5 CJS=1.37E–12

+ VJS=0.59 MJS=0.5 TF=0.43E–9 PTF=30)

.MODEL QPA PNP(IS=5.21E–17 BF=131 VAF=62 VAR= 15 RB=1.52E3

+ IRB=1.67E–5 RBM=368.5 RE=6.31 RC=354.4 CJE=1.1E–13

+ VJE=0.745 MJE=0.33 CJC=2.37E–13 VJC=0.762 MJC=0.4

+ CJS=7.11E–13 VJS=0.45 MJS=0.412 TF=1.0E–9 PTF=30)

.MODEL MN NMOS(LEVEL=3 VTO=1.3 RS=0.3 RD=0.3 TOX=8.5E–8

+ LD=1.48E–6 WD=1E–6 NSUB=1.53E16 UO=650 DELTA=10 VMAX=2E5

+ XJ=1.75E–6 KAPPA=0.8 ETA=0.066 THETA=0.01 TPG=1 CJ=2.9E–4

+ PB=0.837 MJ=0.407 CJSW=0.5E–9 MJSW=0.33)

*

.ENDS OP113 Family

REV. D

–15–

Page 16

OP113/OP213/OP413

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

8-Lead Plastic DIP

(N-8)

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

8-Lead Narrow-Body Plastic DIP

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

PIN 1

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

0.195 (4.95)

0.115 (2.93)

x 45°

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.92)

0.0118 (0.30)

0.0040 (0.10)

14-Lead Plastic DIP

(N-14)

0.795 (20.19)

0.725 (18.41)

14

17

PIN 1

0.022 (0.558)

0.014 (0.36)

0.100

(2.54)

BSC

8

0.070 (1.77)

0.045 (1.15)

16-Lead Wide Body SOIC

(R-16)

0.4133 (10.50)

0.3977 (10.00)

16 9

81

PIN 1

0.0500

(1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.0192 (0.49)

0.0138 (0.35)

SEATING

PLANE

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

0.0125 (0.32)

0.0091 (0.23)

0.325 (8.25)

0.300 (7.62)

0.015 (0.38)

0.008 (0.20)

0.0291 (0.74)

0.0098 (0.25)

8

0

0.195 (4.95)

0.115 (2.93)

C00286–0–1/02(D)

x 45

0.0500 (1.27)

0.0157 (0.40)

Revision History

Location Page

9/01—Data Sheet changed from REV. C to REV. D.

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

–16–

REV. D

PRINTED IN U.S.A.

Loading...

Loading...