Page 1

nRF5340 DK Hardware

v0.11.0

User Guide

4406_638 / 2020-12-03

Page 2

Contents

Revision history. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Kit content. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Interface MCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 IF Boot/Reset button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Virtual COM port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.1 Dynamic HWFC handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 MSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Hardware description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Hardware drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.1 5 V power sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.2 VDD power sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.3 Interface MCU power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.4 nRF5340 power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3.5 nRF5340 SoC direct supply . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.1 USB detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.2 nRF only mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4.3 Signal switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.5 External memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6 Connector interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.1 Mapping of analog pins . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 Buttons and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.8 32.768 kHz crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.9 Debug input and trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.10 Debug output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.11 NFC antenna interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.12 Extra op-amp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.13 Solder bridge configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 Measuring current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 Preparing the DK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Using an oscilloscope for current profile measurement . . . . . . . . . . . . . . . . 32

5.3 Using an ampere meter for current measurement . . . . . . . . . . . . . . . . . . 33

6 RF measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Acronyms and abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Recommended reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4406_638

ii

Page 3

FCC regulatory notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Legal notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4406_638

iii

Page 4

Revision history

Date Description

2020-12-03 First release

4406_638

iv

Page 5

1

Introduction

The nRF5340 DK is a hardware development platform used to design and develop application firmware on

the nRF5340 System on Chip (SoC).

The key features of the Development Kit (DK) are:

• nRF5340 SoC

• Support for the following wireless protocols:

• Bluetooth® Low Energy

• NFC

• 802.15.4

• Thread

• Zigbee

• ANT

• 2.4 GHz proprietary

• Arduino Rev3 compatibility

• 2.4 GHz and NFC antennas

• SWF RF connector for direct RF measurements

• User-programmable LEDs (4) and buttons (4)

• SEGGER J-Link OB programmer/debugger

• Pins for measuring power consumption

• Drag-and-drop Mass Storage Device (MSD) programming

• 1.7-5.0 V power supply from USB, external Li-Po battery, or CR2032 coin cell battery

™

For access to firmware source code, hardware schematics, and layout files, see www.nordicsemi.com.

Note: The nRF5340 DK shall be powered by a PS1 class power supply (maximum power less than

15 W).

The nRF5340 DK is intended for use only by skilled persons.

Skilled person: Person with relevant education or experience to enable him or her to identify hazards and

to take appropriate actions to reduce the risks of injury to themselves and others.

4406_638

5

Page 6

2

Kit content

The nRF5340 DK includes hardware, preprogrammed firmware, documentation, hardware schematics, and

layout files.

The nRF5340 DK (PCA10095) comes with a Near Field Communication (NFC) antenna.

Figure 1: nRF5340 DK (PCA10095) and NFC antenna

Hardware files

The hardware design files including schematics, PCB layout files, bill of materials, and Gerber files for the

nRF5340 DK are available on the nRF5340 product page.

4406_638

6

Page 7

3

Interface MCU

The interface MCU on the nRF5340 DK runs SEGGER J-Link OB interface firmware and is used to program

and debug the firmware of the nRF5340 SoC.

Figure 2: Interface MCU

3.1 IF Boot/Reset button

The nRF5340 DK is equipped with an IF Boot/Reset button (SW5).

This button is connected to the interface MCU on the DK and has two functions:

• Resetting the nRF5340 SoC.

• Entering bootloader mode of the interface MCU.

The button is also used to enter the bootloader mode of the interface MCU. To enter the bootloader

mode, keep the reset button pressed while powering up the DK until LED5 starts to blink. You can power

up the DK either by disconnecting and reconnecting the USB cable or by toggling the power switch (SW8).

3.2 Virtual COM port

The onboard interface MCU features a Universal Asynchronous Receiver/Transmitter (UART) interface

through a virtual COM port.

The virtual COM port has the following features:

•

Flexible baud rate setting up to 1 Mbps.

• Dynamic Hardware Flow Control (HWFC) handling.

• Tri-stated UART lines when no terminal is connected.

The following table shows an overview of the UART connections on nRF5340 SoC and the interface MCU.

1

1

Baud rate 921 600 is not supported through the virtual COM port.

4406_638

7

Page 8

Interface MCU

GPIO nRF5340 nRF5340 UART

P0.19 RTS

P0.20 TXD

P0.21 CTS

P0.22 RXD

Table 1: Relationship of UART connections on nRF5340 and interface MCU

The UART signals are routed directly to the interface MCU. The UART pins connected to the interface MCU

are tri-stated when no terminal is connected to the virtual COM port on the computer.

Note: The terminal software used must send a Data Terminal Ready (DTR) signal to configure the

UART interface MCU pins.

The P0.19 (Request to Send (RTS)) and P0.21 (Clear to Send (CTS)) can be used freely when HWFC is

disabled on the SoC.

3.2.1 Dynamic HWFC handling

When the interface MCU receives a DTR signal from a terminal, it performs automatic HWFC detection.

Automatic HWFC detection is done by driving P0.21 (CTS) from the interface MCU and evaluating the state

of P0.19 (RTS) when the first data is sent or received. If the state of P0.19 (RTS) is high, HWFC is assumed

not to be used. If HWFC is not detected, both CTS and RTS can be used freely by the nRF application.

After a power-on reset of the interface MCU, all UART lines are tri-stated when no terminal is connected

to the virtual COM port. Due to the dynamic HWFC handling, if HWFC has been used and detected, P0.21

(CTS) will be driven by the interface MCU until a power-on reset has been performed or until a new DTR

signal is received and the detection is redone.

To ensure that the UART lines are not affected by the interface MCU, the solder bridges for these signals

can be cut and later resoldered if needed. This might be necessary if UART without HWFC is needed while

P0.19 (RTS) and P0.21 (CTS) are used for other purposes.

3.3 MSD

The interface MCU features an MSD. This makes the DK appear as an external drive on your computer.

This drive can be used for drag-and-drop programming. However, files cannot be stored on this drive. By

copying a HEX file to the drive, the interface MCU will program the file to the device.

Note:

• Windows might try to defragment the MSD part of the interface MCU. If this happens, the

interface MCU will disconnect and be unresponsive. To return to normal operation, the DK must

be power cycled.

• Your antivirus software might try to scan the MSD part of the interface MCU. Some antivirus

programs trigger a false positive alert in one of the files and quarantine the unit. If this happens,

the interface MCU will become unresponsive.

• If the computer is set up to boot from USB, it can try to boot from the DK if the DK is connected

during boot. This can be avoided by unplugging the DK before a computer restart, or changing

the boot sequence of the computer.

4406_638

8

Page 9

Interface MCU

You can also disable the MSD of the kit by using the msddisable command in J-Link Commander. To

enable, use the msdenable command. These commands take effect after a power cycle of the DK and

stay this way until changed again.

4406_638

9

Page 10

4

Hardware description

The nRF5340 DK (PCA10095) features an onboard programming and debugging solution.

In addition to radio communication, the SoC can communicate with a computer through USB and a virtual

COM port provided by the interface MCU.

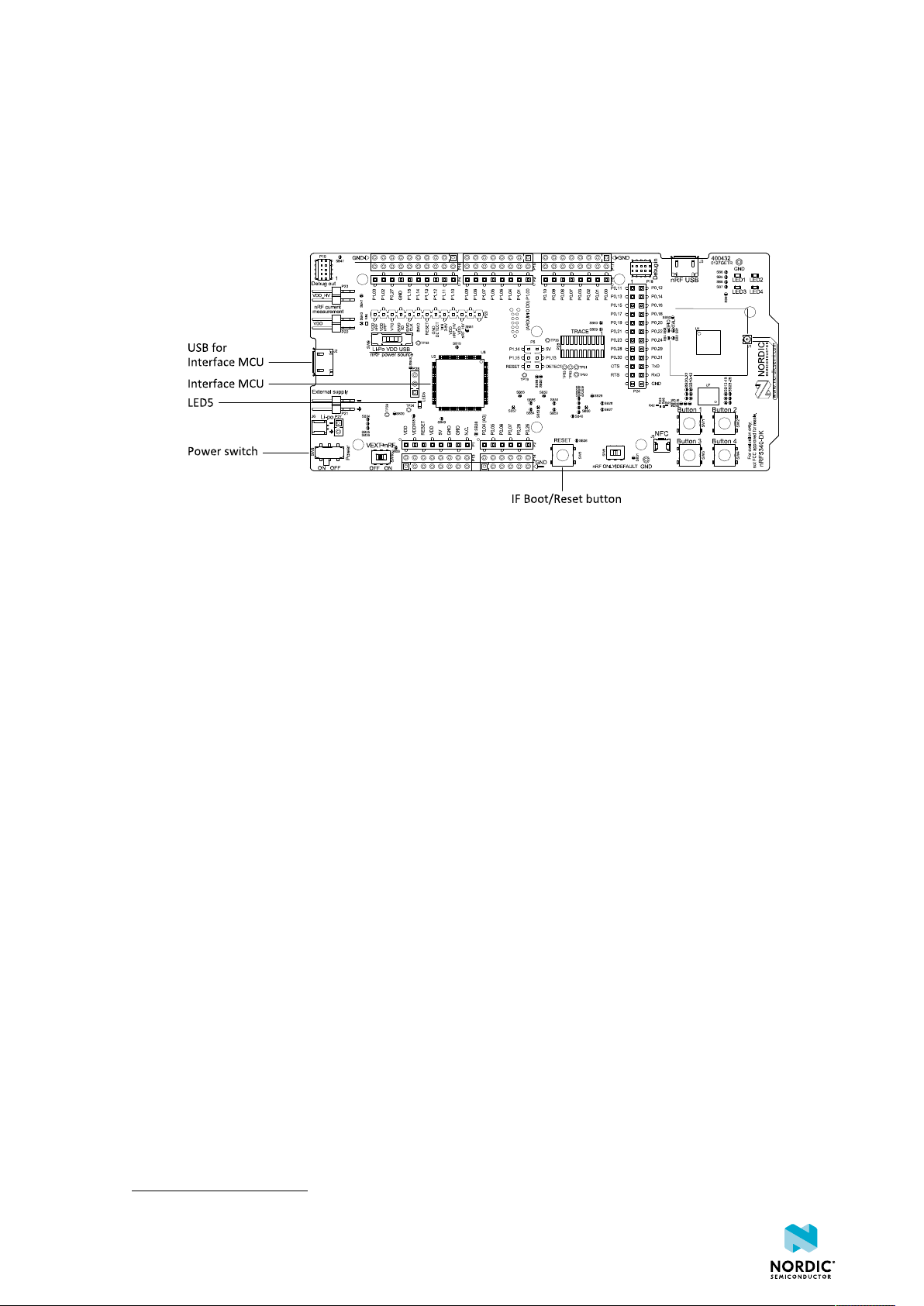

4.1 Hardware drawings

nRF5340 DK hardware drawings show both sides of the PCA10095.

Figure 3: nRF5340 DK (PCA10095) front view

Figure 4: nRF5340 DK (PCA10095) back view

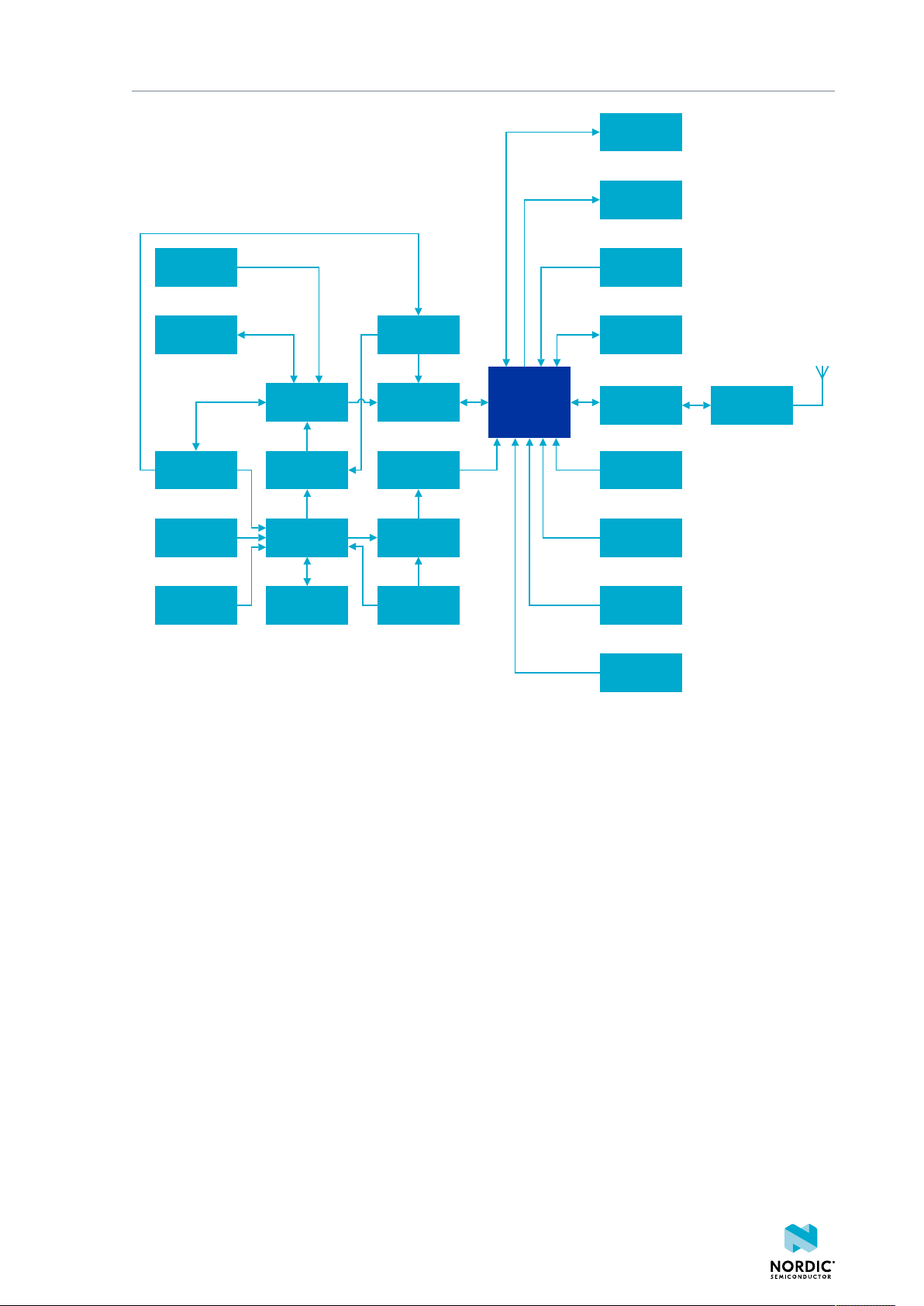

4.2 Block diagram

The nRF5340 DK block diagram shows the connections between the different blocks.

4406_638

10

Page 11

GPIO

LEDs

Hardware description

IF Boot/Reset

Debug out

Interface

MCU

IF MCU USB Analog switch

Battery

External

supply

Power supply

circuitry

Power switch

nRF only

mode switch

Analog switch

Current

measurement

nRf power

source switch

Li-ion

nRF5340

Buttons

External

memory

Matching

network

Osc

16 MHz

Osc

32.768 kHZ

Debug in

USB

RF connector

Figure 5: Block diagram

4.3 Power supply

The nRF5340 DK has multiple power options.

The power options are the following:

• USB connector J2 for the interface MCU (5 V)

• USB connector J3 for the nRF5340 SoC (5 V)

• Lithium polymer (Li-Po) battery connectors J6 or P27 (2.5–5.0 V)

• VIN 3–5 pin on P20 (3.0–5.0 V)

• External supply on P21 (1.7–3.6 V)

• Coin cell battery

4406_638

11

Page 12

Figure 6: Power supply options (front)

Hardware description

Figure 7: Power supply options (back)

4.3.1 5 V power sources

The nRF5340 DK has a 5 V boost regulator.

It gives a stable 5 V output from the following sources:

• USB connector J2 for the interface MCU

• USB connector J3 for the nRF5340 SoC

• Li-Po polymer battery connectors (J6 or P27)

• VIN 3–5 V pin on P20

Each source has a reverse protection diode to prevent current flowing in the wrong direction if multiple

sources are connected at the same time.

Figure 8: 5 V regulator and protecting diodes

4.3.2 VDD power sources

The main supply (VDD) can be sourced from the 5 V domain, external power supply, and coin cell battery.

4406_638

12

Page 13

Hardware description

For the 5 V domain, there are two regulators, one fixed 3 V buck regulator and one voltage follower

regulator that follows the VDD_nRF voltage. The coin cell battery and external power supply are not

regulated.

• 5 V domain:

• Fixed 3 V buck regulator

• VDD_nRF voltage follower

• External power supply

• Coin cell battery

For more information about power sources, see nRF5340 power source on page 15.

The power sources are routed through a set of load switches, which is controlled by logic to prioritize the

power sources in the correct manner.

If the high voltage regulator of the nRF5340 is used, the DK will be supplied from the VDD_nRF voltage

follower regardless of the state of the other power sources.

4406_638

13

Page 14

SB34

SB35

SB36

1

2

P21

Pin List 1x2, Angled

VBAT

VEXT

Q8A

TSM250N02DCQ RFG

R68

1M0

VSUPPLY

VEXT_EN

VREG_EN

VSUPPLY

VREG_EN_INV

R74

1M0

VSUPPLY

Q8B

TSM250N02DCQ RFG

VEXT_EN_INV

VREG

V5V

R65

820k

R66

470k

C68

100nF

VSUPPLY

C69

100nF

VSUPPLY

VREG_EN_INV

SW10

CAS-220TA

VDD

VSRC_NRF

GND

VCC

U24

74LVC1G08

GND

VCC

U18

74LVC1G11

GND

VCC

U16

74LVC1G08

VSUPPLY_EN

C70

100nF

VSUPPLY

R73

10M

TP27

TP26

TP29

SB58

VSUPPLY

VSUPPLY

VBAT_EN

VEXT_EN_INV

VREG_EN_INV

Q10A

PMCPB5530

Q10B

PMCPB5530

R72

1M0

R71

100k

VSUPPLY

VSUPPLY

VEXT_EN_INV

VREG_EN_INV

C71

100nF

VSUPPLY

GND

VCC

U21

74LVC1G11

+

Bat1

Bat Holder CR2032

VIN

A2

VOUT

A1

CTRL

B2

GND

B1

U13

TCK106AG

VIN

A2

VOUT

A1

CTRL

B2

GND

B1

U17

TCK106AG

VIN

A2

VOUT

A1

CTRL

B2

GND

B1

U23

TCK106AG

Hardware description

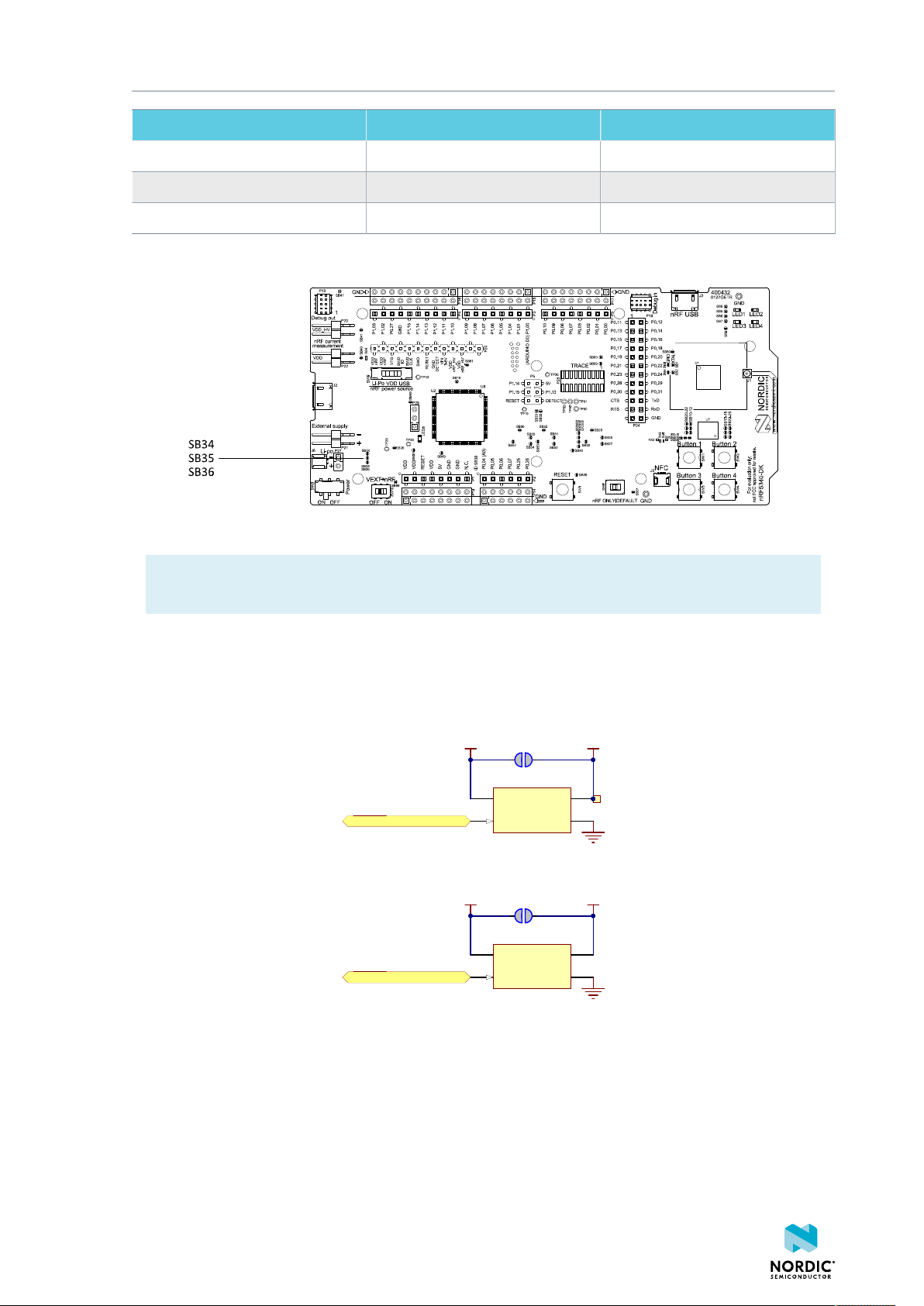

The power switches work in the way that the body diode of the internal transistor powers the VSUPPLY

net, which supplies the gates controlling the enable signal of the switches. If 5 V is present, the switches

for external supply and battery are disabled. If external supply is present, the switch for the battery is

disabled.

The power switches can be bypassed by shorting one or more solder bridges.

Figure 9: Power supply circuitry

4406_638

14

Page 15

Power source Power switch bypass Voltage level

SB37

VDD_IMCUVDD

SB48

VDD_IMCU_3VVREG

IF_OFF

IF_OFF

TP35

VINA2VOUT

A1

CTRLB2GND

B1

U19

TCK106AG

VINA2VOUT

A1

CTRLB2GND

B1

U22

TCK106AG

Regulator SB34 3.0 V

Coin cell battery SB35 Battery

External supply SB36 1.7 V–3.6 V

Table 2: Power switch bypass solder bridges

Hardware description

Figure 10: Power switch bypass solder bridges

Note: Connect only one power source at a time. Shorting the solder bridges removes the reverse

voltage protection.

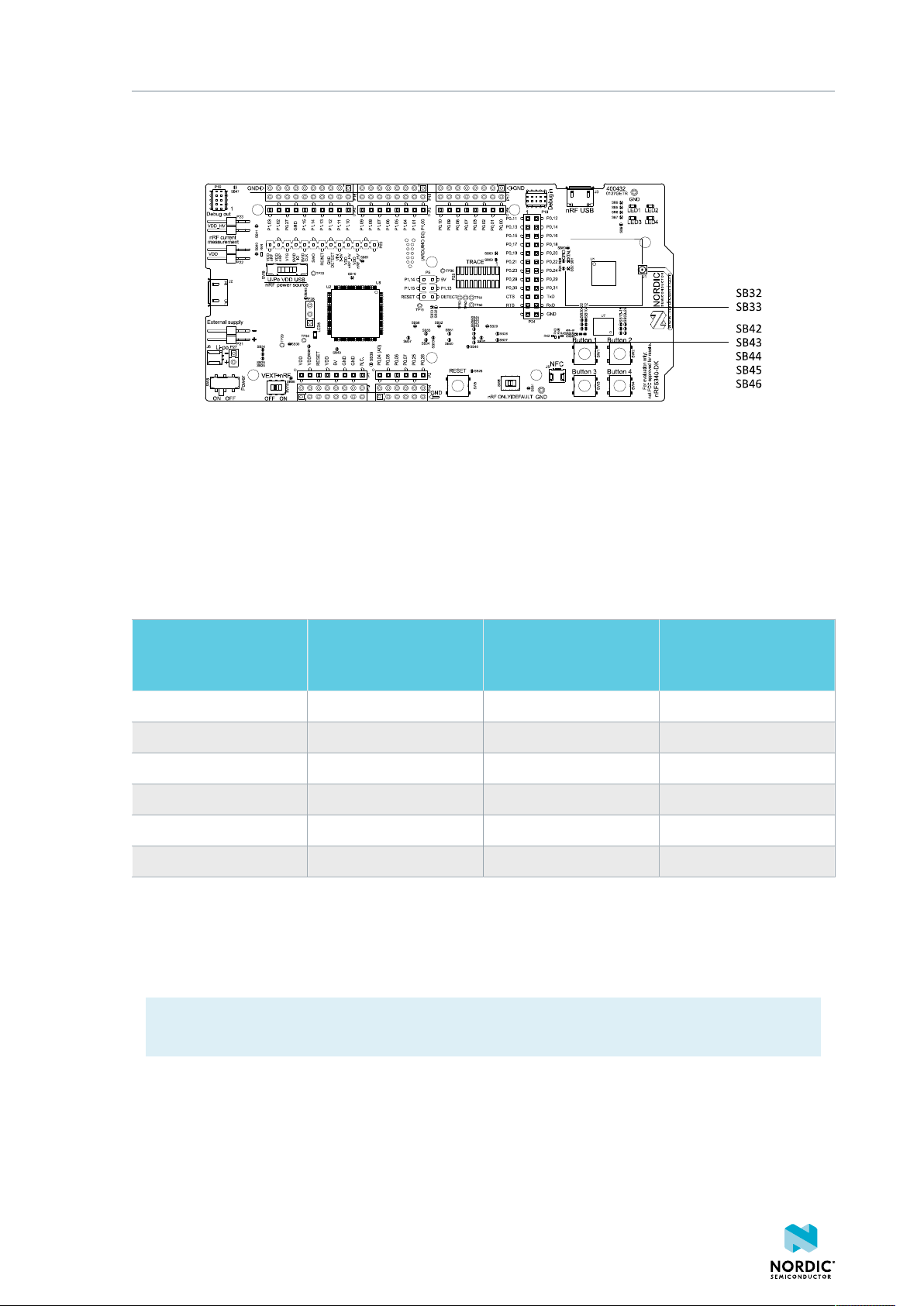

4.3.3 Interface MCU power

The power for the interface MCU is routed through two load switches, one for the VDD supply and one for

the USB supply. This makes it possible to disconnect the interface MCU from the power domain when not

in use.

These switches are controlled by the presence of a USB connected to the interface MCU USB connector

(J2), and the state of the nRF only switch (SW6). See Operating modes on page 17 for more

information.

Figure 11: Interface MCU power switch

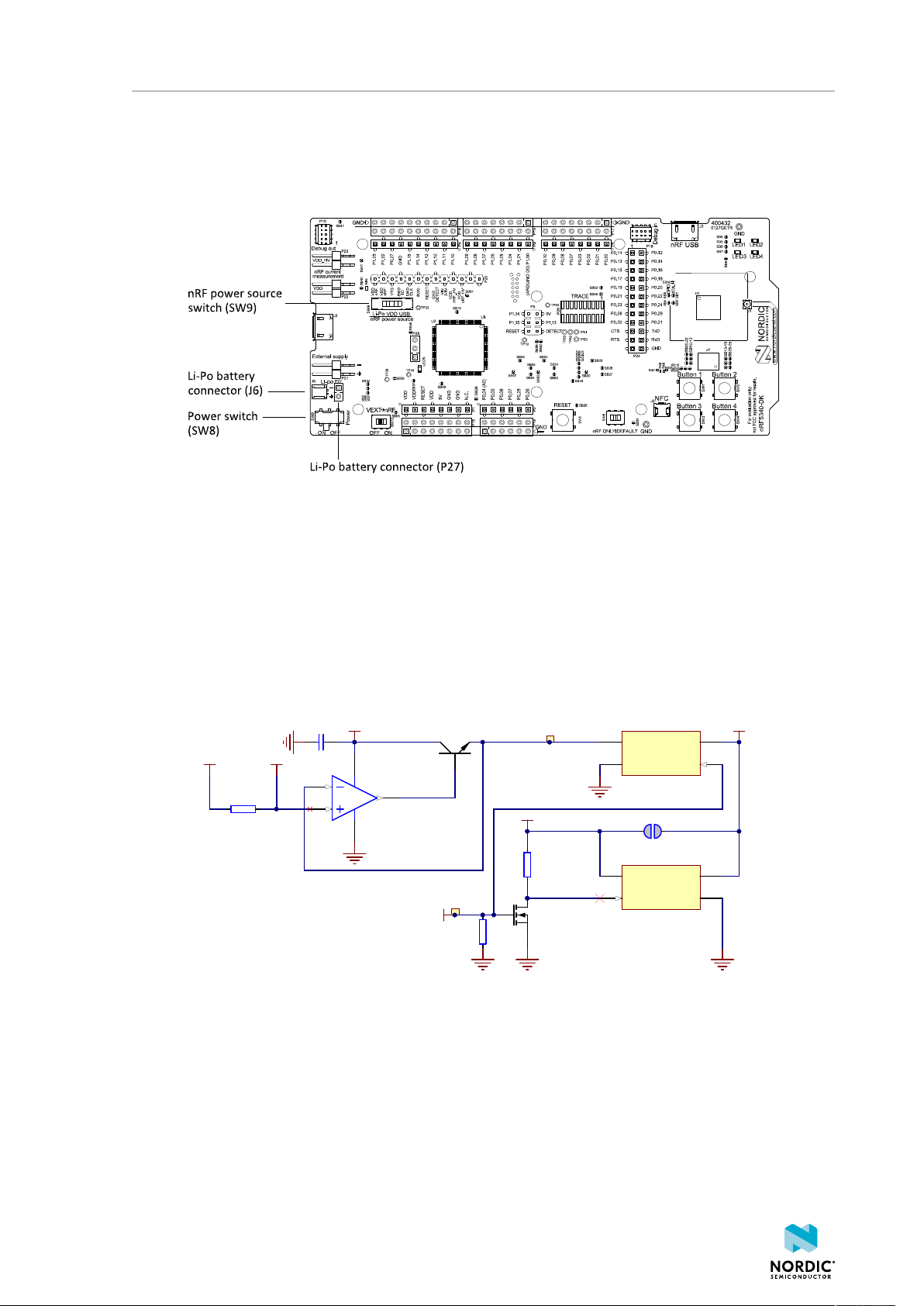

4.3.4 nRF5340 power source

The nRF5340 DK has a power source switch (SW9) for selecting between three power sources for the

nRF5340 SoC.

4406_638

15

Page 16

The three positions of the switch are the following:

VDD_nRF_SENSE

C65

100nF

V5V

3

2

1

A

84

V- V+

U9A

TS27L2IPT

VSENSE_SW_OUT

R70

10M

Q9

RV2C010UNT2L

R69

1M0

VDD_nRF_SENSE

VSUPPLY

Q7

FCX690BTA

SB39

VSUPPLY_EN

TP33

TP34

VIO_REF

R77

10k

VINA2VOUT

A1

CTRLB2GND

B1

U14

TCK106AG

VIN

A2

VOUT

A1

CTRL

B2

GND

B1

U12

TCK106AG

• VDD (default)

• Li-Po

• USB

Figure 12: nRF5340 DK power source switch

Hardware description

The nRF5340 SoC has a high voltage buck regulator that can support up to 5 V input. In the VDD position,

the SoC is powered either from the onboard buck regulator, coin cell battery, or external supply (P21).

In the Li-Po position, the high voltage regulator of the SoC is supplied directly from the Li-Po battery

connectors (J6 or P27). In the USB position, the USB high voltage regulator gets power from the nRF5340

USB connector (J3).

When the high voltage regulator is used, the VDD_nRF voltage can be set by the firmware of the SoC.

To make sure the rest of the DK has the same voltage level, the VDD of the DK is sourced by a regulator

following the VDD_nRF voltage when the high voltage regulator is used.

Figure 13: VDD_nRF voltage follower and switch

To make sure that the nRF5340 SoC is not powered when the nRF power switch (SW8) is OFF, two load

switches are used, one for the high voltage regulator (U15) and one for the USB supply (U20). These

switches are controlled by VDD.

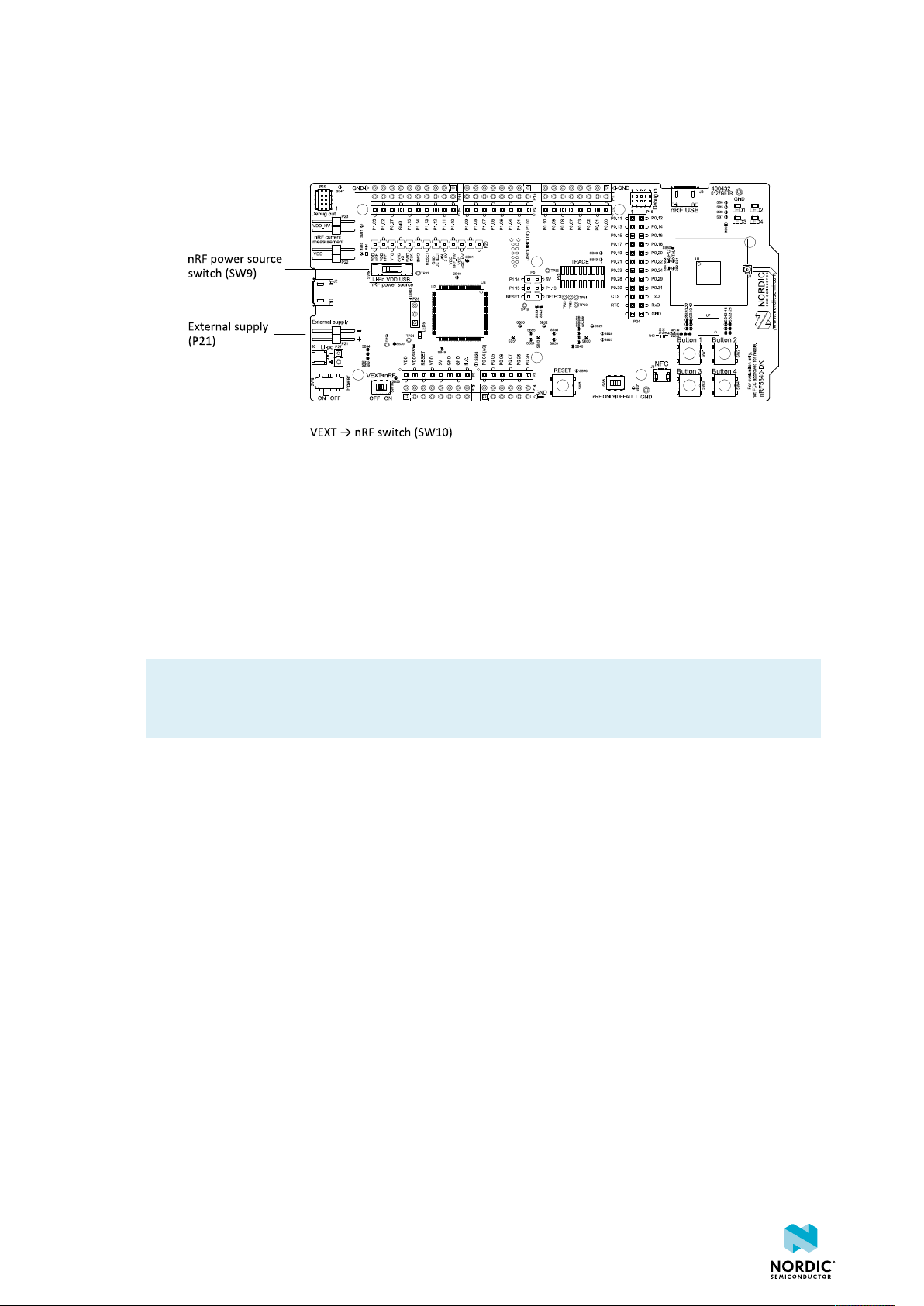

4.3.5 nRF5340 SoC direct supply

It is possible to power the SoC directly from a source without powering the rest of the DK from the same

source.

4406_638

16

Page 17

Hardware description

This is done by connecting the external source to the external supply connector (P21) and sliding the

VEXT->nRF switch (SW10) to the ON position. The nRF power source switch (SW9) must be in the VDD

position, and the allowed voltage range is 1.7–3.6 V.

Figure 14: VEXT->nRF switch (SW10)

Since it is only the nRF5340 SoC that is supplied from this source, it is recommended that the VDD domain

is supplied from a different source to prevent the pins of the SoC to be connected to unpowered devices.

To avoid voltage differences on the DK, the External supply is also connected to the input of the voltage

follower when the VEXT->nRF switch (SW10) is in the ON position. The voltage follower circuit requires 5 V

to be present on the DK, see 5 V power sources on page 12.

The voltage follower can be disconnected from the External supply by cutting SB58. To prevent leakage

due to voltage differences, the DK should be set in the nRF only mode, see nRF only mode on page 18.

Note: To reduce trace length and parasitic components, the external memory is connected to the

SoC directly instead of using analog switches. It is recommended to cut solder bridges to avoid

leakage, see External memory on page 20.

4.4 Operating modes

The nRF5340 DK has various modes of operation.

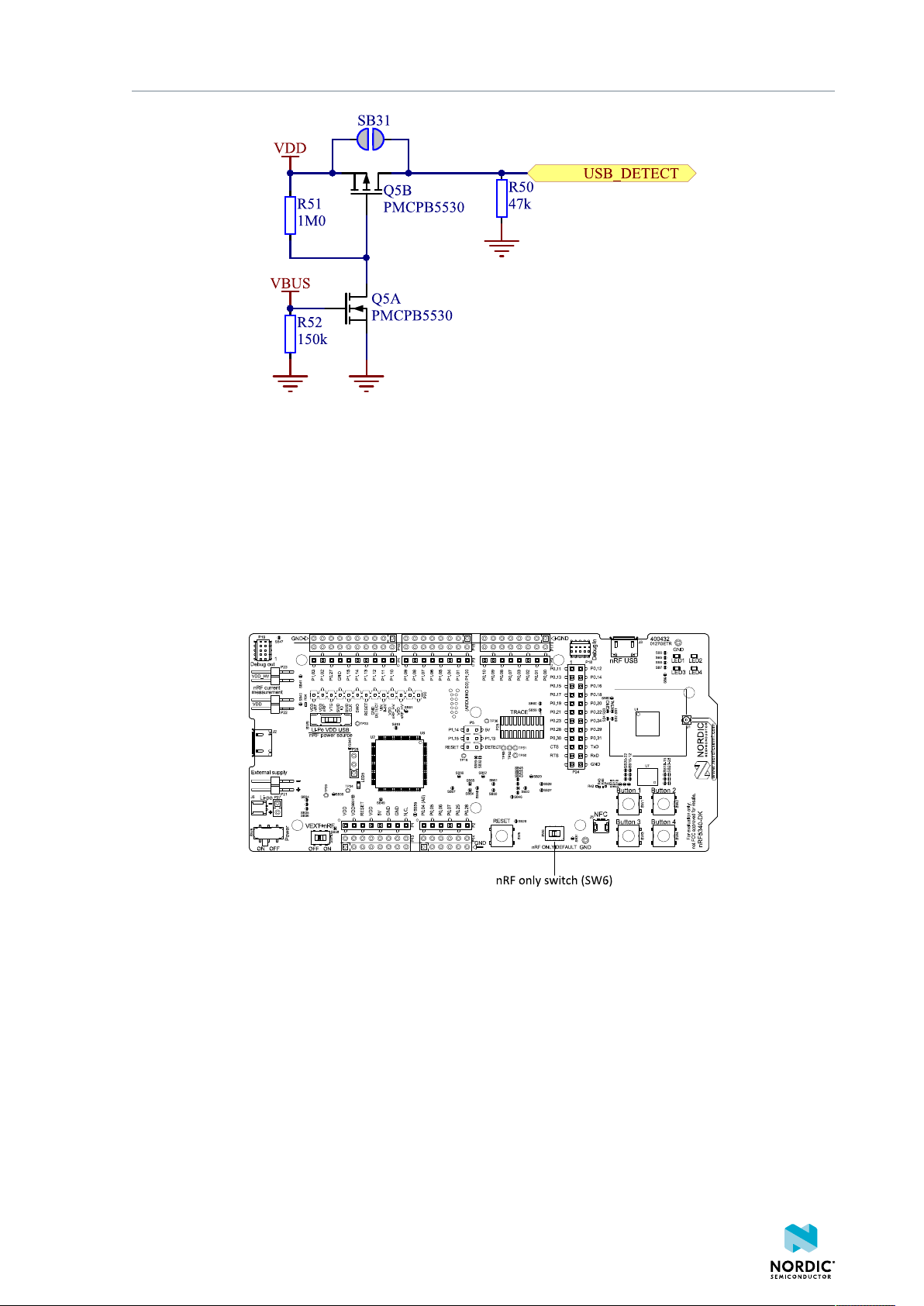

4.4.1 USB detect

To detect when USB for the interface MCU is connected, there is a circuit sensing the VBUS of USB

connector J2.

When the USB cable is connected, the VDD is propagated to the USB_DETECT signal.

4406_638

17

Page 18

Hardware description

Figure 15: USB detect

4.4.2 nRF only mode

The nRF only mode disconnects the power supply, external memory, and LEDs of the interface MCU. It also

disconnects the signal lines between the nRF5340 SoC and the interface MCU using analog switches.

This is done to isolate the chip on the DK as much as possible, and can be of use when measuring currents

on low-power applications.

The power supply of the external memory can be changed to maintain operation in the nRF only mode.

See External memory on page 20.

Figure 16: nRF ONLY switch (SW6)

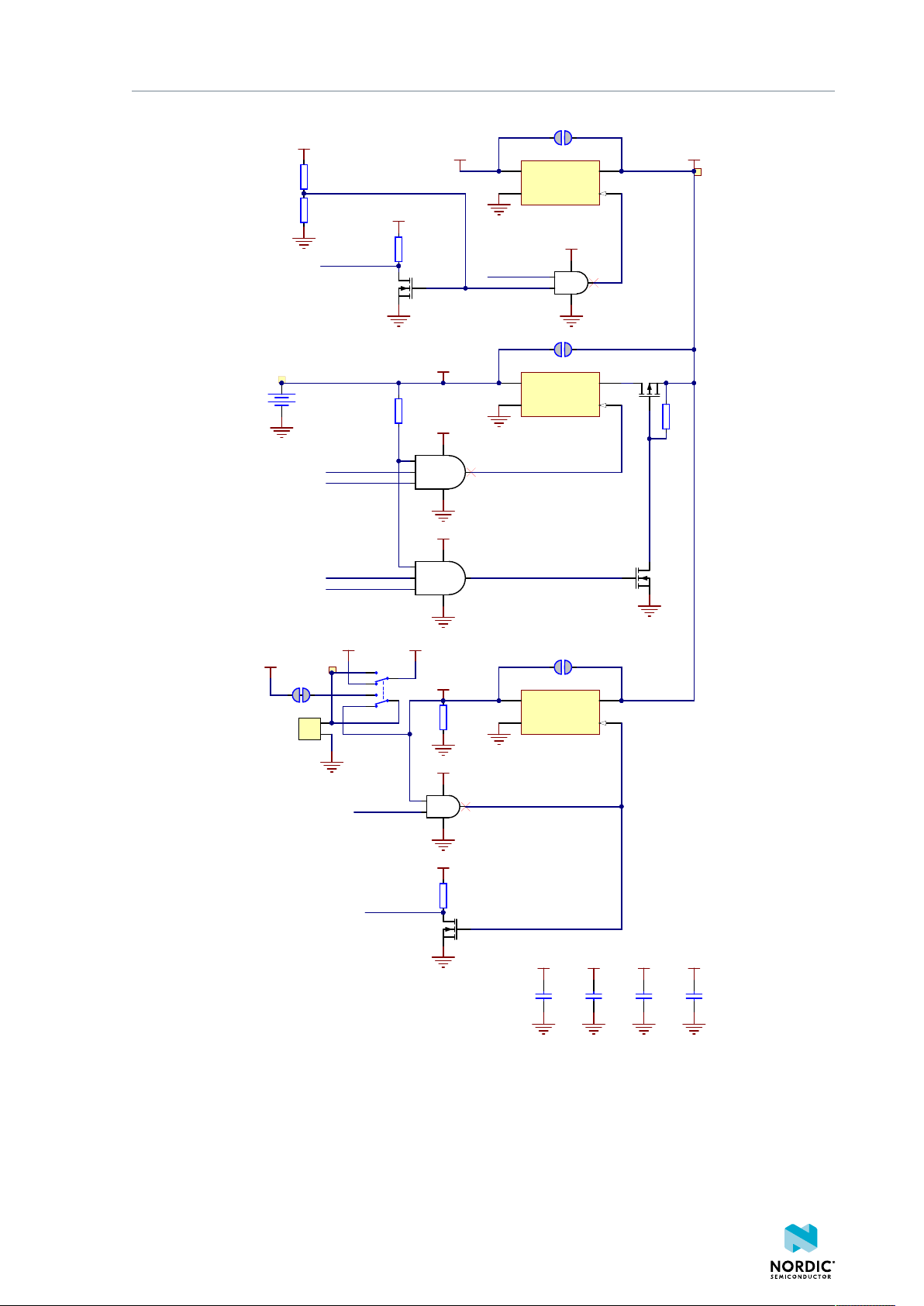

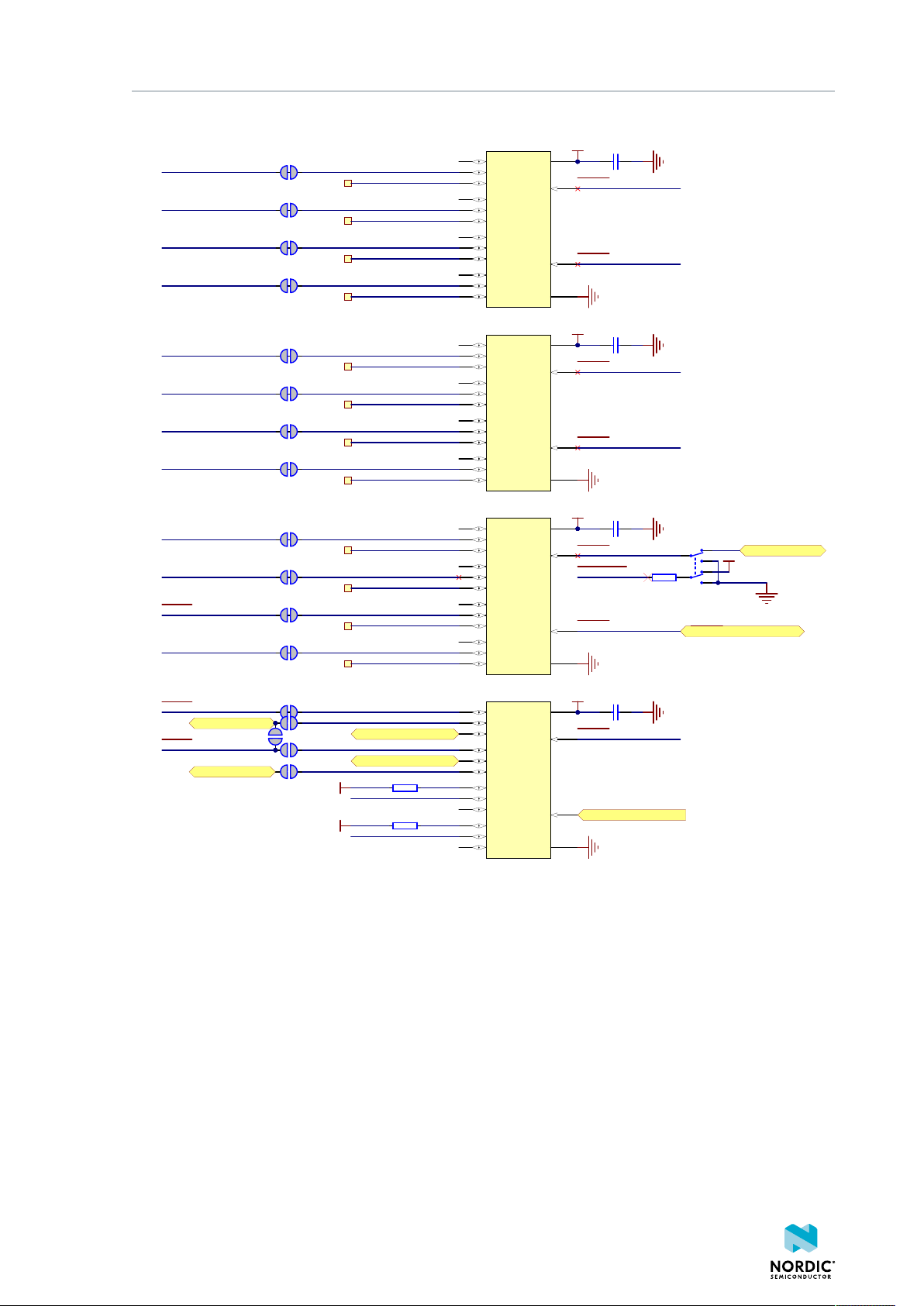

4.4.3 Signal switches

On the nRF5340 DK, there are multiple analog switches that are used to connect and disconnect signals

based on different scenarios.

4406_638

18

Page 19

Hardware description

TP3

TP2

TP4

TP1

TP5

TP6

TP7

SB54

SB55

SB51

SB53

SB50

SB52

SB57

SB56

NC1

1

IN 1-2

2

NO2

3

COM2

4

NC2

5

GND

6

NO3

7

COM3

8

NC3

9

IN 3-4

10

NO4

11

COM4

12

NC4

13

VCC

14

NO1

15

COM1

16

U5

FSA2466UMX

C42

100nF

VDD

NC1

1

IN 1-2

2

NO2

3

COM2

4

NC2

5

GND

6

NO3

7

COM3

8

NC3

9

IN 3-4

10

NO4

11

COM4

12

NC4

13

VCC

14

NO1

15

COM1

16

U3

FSA2466UMX

NC1

1

IN 1-2

2

NO2

3

COM2

4

NC2

5

GND

6

NO3

7

COM3

8

NC3

9

IN 3-4

10

NO4

11

COM4

12

NC4

13

VCC

14

NO1

15

COM1

16

U6

FSA2466UMX

C41

100nF

C45

100nF

IF_OFF

IF_OFF

IF_OFF

VDD

VDD

TP8

IMCU_BOOT

USB_DETECT

IF_OFF

VDD

SB46

RESET_PIN

SB45

IMCU_BOOT

SB42

SB43

RESET_PIN

SB44

nRF_ONLY

BOOT/RESET

IF_OFF

R48 4k7

R49 4k7

SHIELD_DETECT

VDD

VDD

IF_OFF

R44

10k

SW6

CAS-220TA

RESET

RESET

RESET

SWDCLK

SWDIO

P0.11/TRACEDATA0

SWD3_RESET

SWD3_SWDCLK

SWD3_SWDIO

SWD3_SWO

VCOM2_CTS

VCOM2_RTS

VCOM2_RxD

VCOM2_TxD

P1.03

P1.02

UART_1_CTS

UART_1_RTS

UART_1_RxD

UART_1_TxD

TP54

TP57

TP56

TP55

SB28

SB30

SB27

SB29

NC1

1

IN 1-2

2

NO2

3

COM2

4

NC2

5

GND

6

NO3

7

COM3

8

NC3

9

IN 3-4

10

NO4

11

COM4

12

NC4

13

VCC

14

NO1

15

COM1

16

U25

FSA2466UMX

C24

100nF

VDD

IF_OFF

IF_OFF

UART_2_CTS

UART_2_RTS

UART_2_RxD

UART_2_TxD

VCOM0_CTS

VCOM0_RTS

VCOM0_RxD

VCOM0_TxD

The USB and SW6 control the signal switches by using USB_DETECT as an input to SW6. Therefore, the

interface MCU can be disconnected either by unplugging the USB cable from J2 or by toggling the nRF

ONLY switch SW6.

The signal controls a set of switches (U3, U5, U6) that break the connection between the nRF5340 and the

interface MCU, and control the power for the interface MCU. For more information, see Interface MCU

power on page 15.

Switches U3 and U5 break the connection of the UART lines and SWD/RESET lines. In addition, the

signal controls the routing of the RESET signal depending on user preference when the interface MCU is

connected/disconnected.

• When the interface MCU is connected, shorting SB46 will connect the RESET pin in the Arduino

interface to the BOOT input of the interface MCU.

• Shorting SB43 will connect the RESET pin in the Arduino interface to the IF Boot/Reset button.

4406_638

Figure 17: Signal switches

19

Page 20

Hardware description

When a shield is connected, there are two analog switches connecting the pull-up resistors to the I2C bus

lines (SDA and SCL). This function is using one ground pin on the Arduino shield to control the switch. This

feature can be disabled by cutting SB33. To permanently enable pull-up resistors, short SB32.

Figure 18: Solder bridges: Shield detect and reset behavior

4.5 External memory

The nRF5340 DK has a 64 Mb external flash memory. The memory is a multi-I/O memory supporting both

regular SPI and Quad SPI.

The memory is connected to the chip using the following GPIOs:

GPIO Flash memory pin Solder bridge for

memory use (default:

shorted)

P0.18 CS SB13 SB23

P0.17 SCLK SB11 SB21

P0.13 SIO_0/SI SB12 SB22

P0.14 SIO_1/SO SB14 SB24

P0.15 SIO_2/WP SB15 SB25

P0.16 SIO_3/HOLD SB10 SB20

Table 3: Flash memory GPIO usage and connecting solder bridges

To use the GPIOs for a purpose other than the onboard external memory and have them available on the

P24 connector, six solder bridges (SB10–SB15) must be cut and six solder bridges (SB20–SB25) must be

shorted. See the following figure for details.

Solder bridge for GPIO

use (default: open)

Note: If debugging the QSPI communication is needed, the SB20–SB25 can be shorted without

cutting SB10–SB15, but the pins should not be driven externally.

4406_638

20

Page 21

Hardware description

Figure 19: Configuring GPIOs for external memory

By default, the power supply of the external memory is coming from the VDD domain and it is controlled

by the nRF only switch (SW6). In the nRF only mode, there are two optional power sources for keeping

the external memory powered, VDD and VDD_nRF. If VDD_nRF is selected, the power consumption of the

external memory will be added to the nRF5340 current measured on P22 or P23. See the following table

for configuration:

Power source Solder bridge Default state

VDD_PER SB16 Shorted

VDD SB17 Open

VDD_nRF SB18 Open

Table 4: Flash memory power source configuration

4.6 Connector interface

Access to the nRF5340 GPIOs is available from connectors P2, P3, P4, P5, P6, and P24.

The P1 connector provides access to ground and power on the nRF5340 DK.

4406_638

21

Page 22

Hardware description

Figure 20: nRF5340 DK connectors

Some of the signals are also available on connectors P7, P8, P9, P10, P11, and P12, which are on the

bottom side of the DK. By mounting pin lists on the connector footprints, the nRF5340 DK can be used as a

shield for Arduino motherboards2 or other boards that follow the Arduino standard.

For easy access to GPIO, power, and ground, the signals can also be found on the through-hole connectors

P13–P17.

Note:

Some pins have default settings:

• P0.00 and P0.01 are used for the 32.768 kHz crystal and are not available on the connectors. For

more information, see 32.768 kHz crystal on page 24.

• P0.19, P0.20, P0.21, and P0.22 are used by the UART connected to the interface MCU. For more

information, see Virtual COM port on page 7.

• P0.02 and P0.03 are by default used by NFC1 and NFC2. For more information, see NFC antenna

interface on page 27.

• P0.08–P0.09 and P0.23–P0.24 are by default connected to the buttons and P0.28–P0.31 are

connected to the LEDs. For more information, see Buttons and LEDs on page 23.

• P0.13–P0.18 are by default connected to the external memory. For more information, see

External memory on page 20.

When the nRF5340 DK is used as a shield together with an Arduino standard motherboard, the Arduino

signals are routed as shown in the following figure.

2

Only 3.3 V Arduino boards.

4406_638

22

Page 23

Hardware description

Figure 21: Arduino signals routing on the nRF5340 DK

4.6.1 Mapping of analog pins

The table shows the mapping between GPIO pins, analog inputs, and the corresponding Arduino analog

input naming.

GPIO Analog input Arduino naming

P0.04 AIN0 A0

P0.05 AIN1 A1

P0.06 AIN2 A2

P0.07 AIN3 A3

P0.25 AIN4 A4

P0.26 AIN5 A5

Table 5: Mapping of analog pins

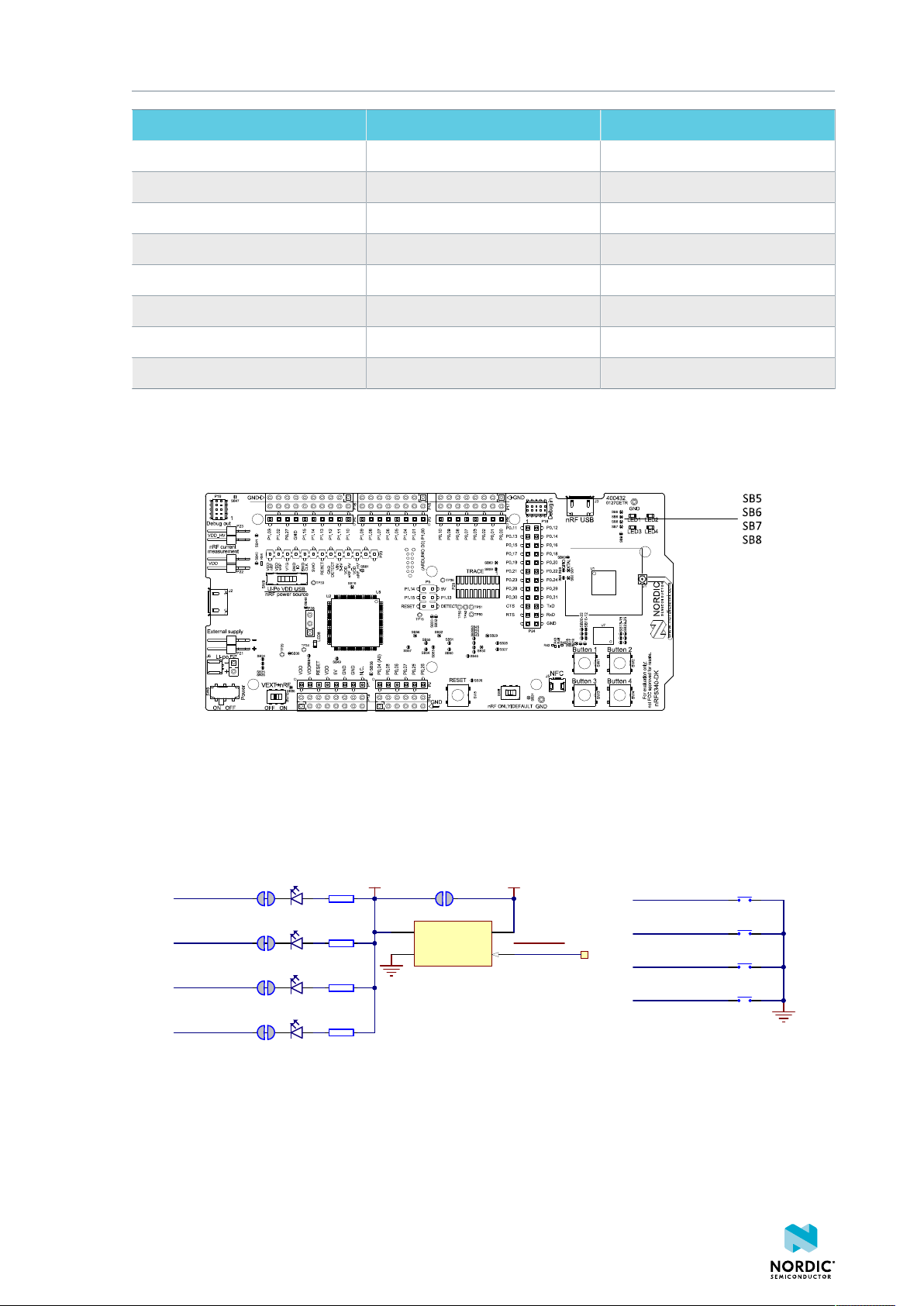

4.7 Buttons and LEDs

The four buttons and four LEDs on the nRF5340 DK are connected to dedicated GPIOs on the nRF5340 SoC.

4406_638

23

Page 24

Hardware description

R3

220R

R2

220R

SB6

VDD_PER

R4

220R

SB7

R5

220R

SB8

SB5

LED1

L0603G

LED2

L0603G

LED3

L0603G

LED4

L0603G

SB9

VDD

nRF_ONLY

TP22

P0.28/AIN7

P0.30

P0.31

P0.29

VIN

A2

VOUT

A1

CTRL

B2

GND

B1

U4

TCK106AG

SW1

PB SW

SW2

PB SW

SW3

PB SW

SW4

PB SW

P0.23

P0.24

P0.08/TRACEDATA3

P0.09/TRACEDATA2

Part GPIO Solder bridge

Button 1 P0.23 -

Button 2 P0.24 -

Button 3 P0.08 -

Button 4 P0.09 -

LED 1 P0.28 SB5

LED 2 P0.29 SB6

LED 3 P0.30 SB7

LED 4 P0.31 SB8

Table 6: Button and LED connection

If P0.28–P0.31 are needed elsewhere, the LEDs can be disconnected by cutting the short on SB5–SB8. See

Figure 22: Disconnecting the LEDs on page 24 for more information.

Figure 22: Disconnecting the LEDs

The buttons are active low, meaning that the input will be connected to ground when the button is

activated. The buttons have no external pull-up resistor, and therefore, to use the buttons, the P0.08,

P0.09, P0.23, P0.24 pins must be configured as input with an internal pull-up resistor.

The LEDs are active low, meaning that writing a logical zero (0) to the output pin will illuminate the LED.

Figure 23: Button and LED configuration

4.8 32.768 kHz crystal

The nRF5340 SoC can use an optional 32.768 kHz crystal (X2) for higher accuracy and lower average power

consumption.

4406_638

24

Page 25

Hardware description

On the nRF5340 DK, P0.00 and P0.01 are used for the 32.768 kHz crystal by default and are not available

as GPIO on the connectors.

Note: When using ANT/ANT+™, the 32.768 kHz crystal (X2) is required for correct operation.

If P0.00 and P0.01 are needed as normal I/Os, the 32.768 kHz crystal can be disconnected and the

GPIO routed to the connectors. Cut the shorting track on SB1 and SB2, and solder SB3 and SB4. See the

following figure for reference.

Figure 24: Configuring P0.00 and P0.01

Figure 25: 32.768 kHz crystal and SB1–SB4

4.9 Debug input and trace

The Debug in connector (P18) makes it possible to connect external debuggers for debugging when the

interface MCU USB cable is not connected or the DK is in nRF only mode.

Figure 26: Debug input and trace connectors

For trace, a footprint for a 20-pin connector is available (P25). If trace functionality is required, it is

possible to mount a 2×10 pin 1.27 mm pitch surface-mount pin header.

4406_638

25

Page 26

Hardware description

GPIO Trace Default use

P0.12 TRACECLK

P0.11 TRACEDATA[0]

P0.10 TRACEDATA[1]

P0.09 TRACEDATA[2] Button 4

P0.08 TRACEDATA[3] Button 3

Table 7: Default and Trace GPIOs

The reference voltage for the debug input and trace is by default connected to VDD_nRF'. This can be

connected to the VDD by cutting SB60 and soldering SB59.

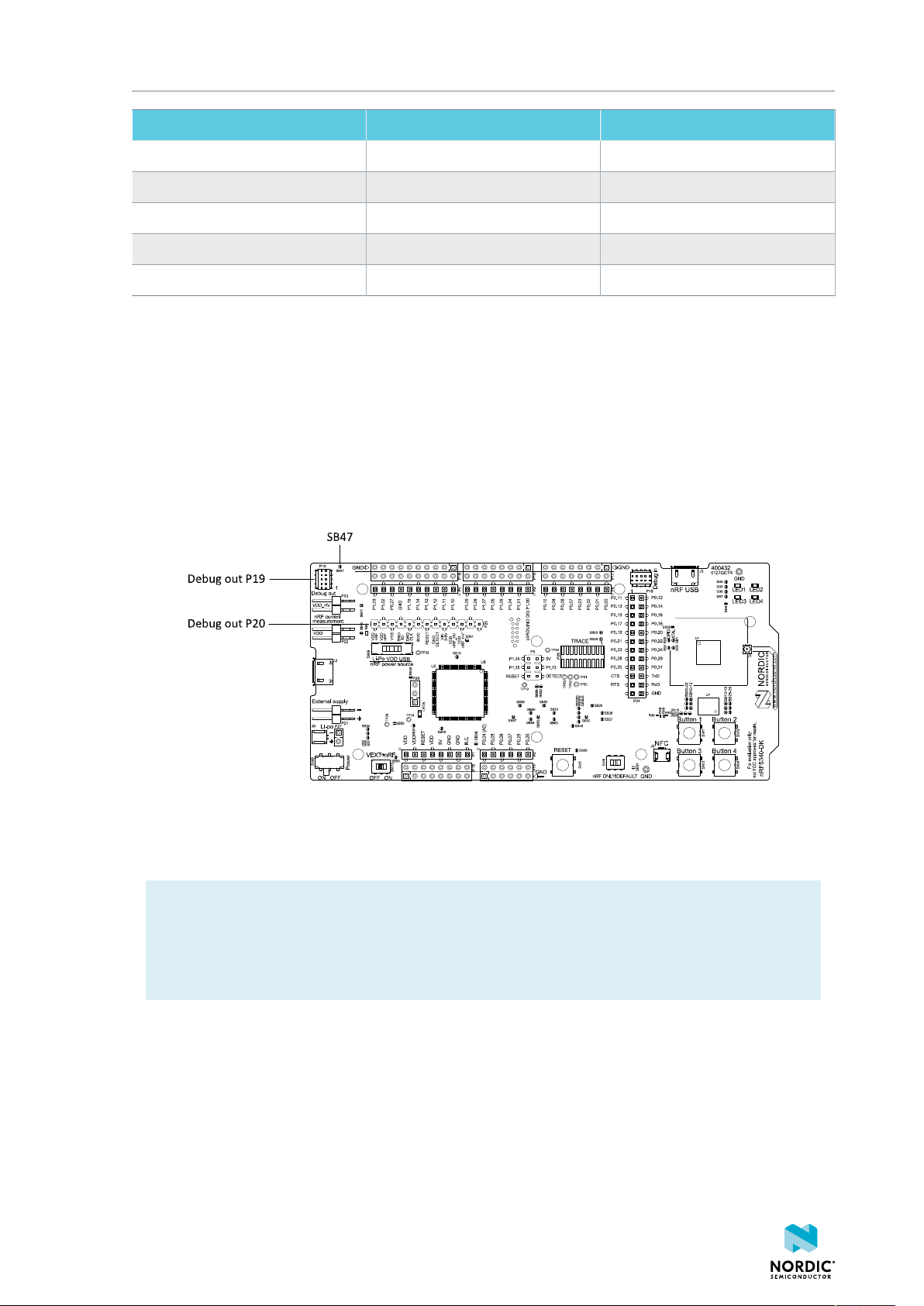

4.10 Debug output

The nRF5340 DK supports programming and debugging external boards with nRF51 Series , nRF52 Series,

or nRF53 Series SoCs. To debug an external board with SEGGER J-Link OB IF, connect to the Debug out

connector (P19) with a 10-pin cable.

Figure 27: Debug output connector

When the external board is powered, the interface MCU will detect the supply voltage of the board and

program/debug the target chip on the external board instead of the onboard nRF5340 SoC.

Note: The voltage supported by external debugging/programming is VDD voltage. Normally, this

is 3 V when running from USB, but if the onboard nRF5340 SoC is supplied from either USB or LiIon, the nRF power source switch (SW9) is in either Li-Po or USB position, and VDD can be set by

the nRF5340 firmware. Make sure the voltage level of the external board matches the VDD of the

nRF5340 DK.

You can also use P20 as a debug out connection to program shield-mounted targets. For both P19 and

P20, the interface MCU will detect the supply voltage on the mounted shield and program/debug the

target.

If the interface MCU detects target power on both P19 and P20, it will by default program/debug the

target connected to P19.

If it is inconvenient to have a separate power supply on the external board, the nRF5340 DK can supply

power through the Debug out connector (P19). To enable this, short solder bridge SB47. While SB47 is

shorted, it is not possible to program the onboard nRF5340 SoC even if the external board is unplugged.

4406_638

26

Page 27

Hardware description

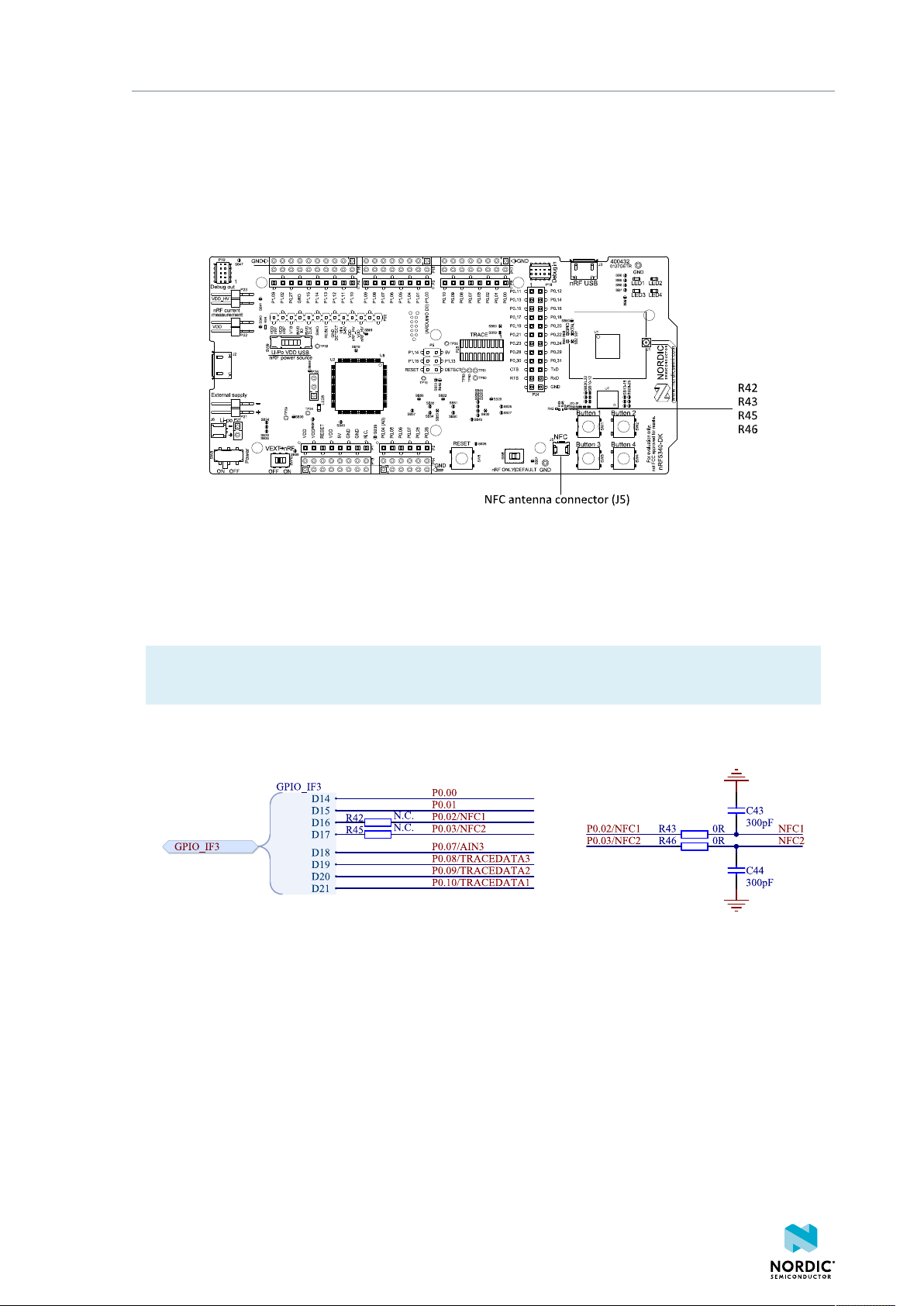

4.11 NFC antenna interface

The nRF5340 DK supports an NFC tag.

NFC-A listen mode operation is supported on the nRF5340 SoC. The NFC antenna input is available on

connector J5 on the nRF5340 DK.

Figure 28: NFC antenna connector

NFC uses two pins, W1 (NFC1) and AA1 (NFC2), to connect the antenna. These pins are shared with GPIOs

(P0.02 and P0.03) and the PROTECT field in the NFCPINS register in UICR defines the usage of these pins

and their protection level against abnormal voltages. The content of the NFCPINS register is reloaded at

every reset.

Note: The NFC pins are enabled by default. NFC can be disabled and GPIOs enabled by setting the

CONFIG_NFCT_PINS_AS_GPIOS to y. See Configuring your application for instructions.

Pins W1 and AA1 are by default configured to use the NFC antenna, but if they are needed as normal

GPIOs, R43 and R46 must be NC and R42 and R45 must be shorted by 0R.

Figure 29: NFC input

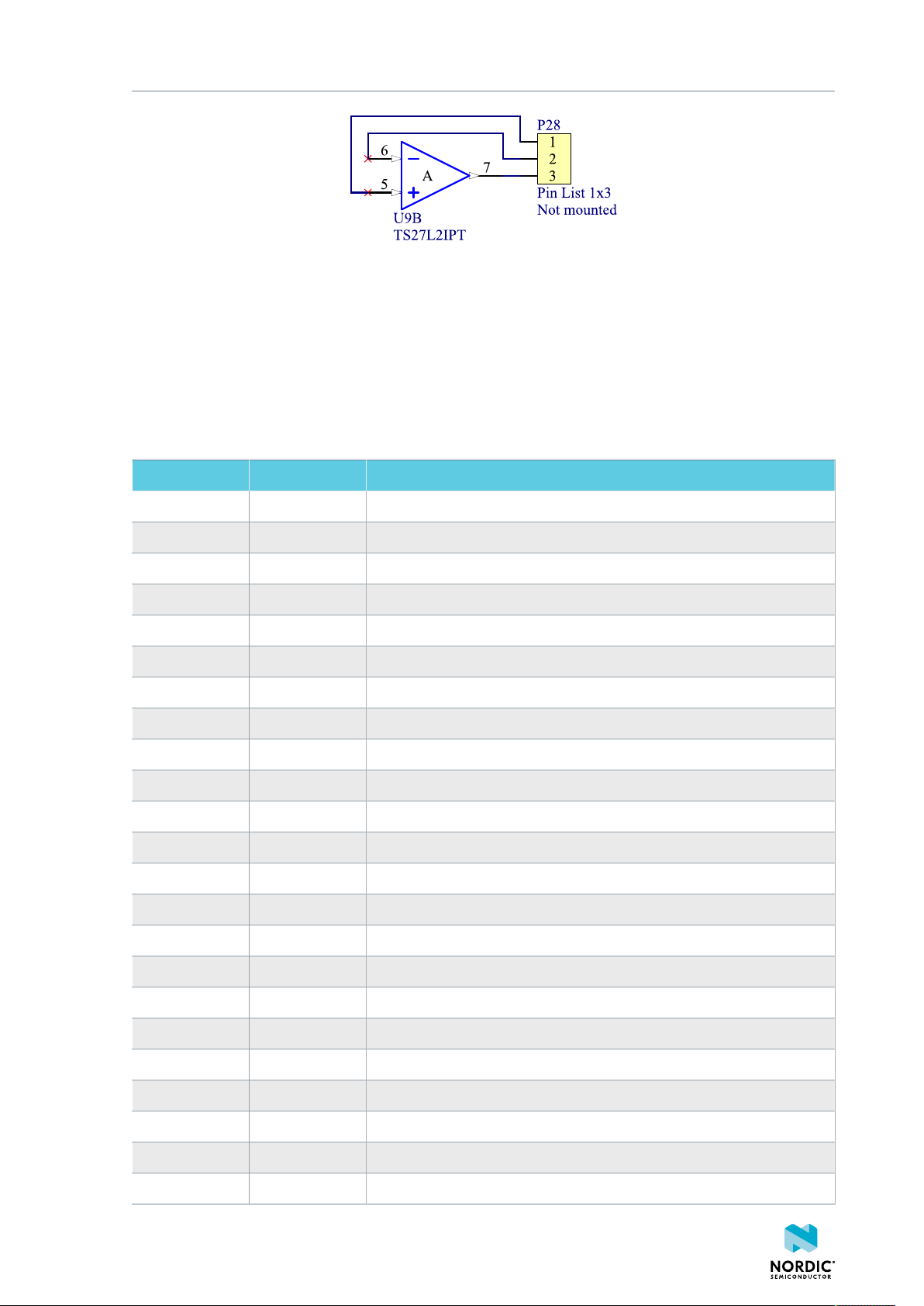

4.12 Extra op-amp

The voltage follower for the power supply uses a dual package op-amp.

The extra op-amp has been routed out to a connector (P28, not mounted) so that it is accessible for the

user.

For more information on the power supply, see Power supply on page 11.

4406_638

27

Page 28

Hardware description

Figure 30: Extra op-amp

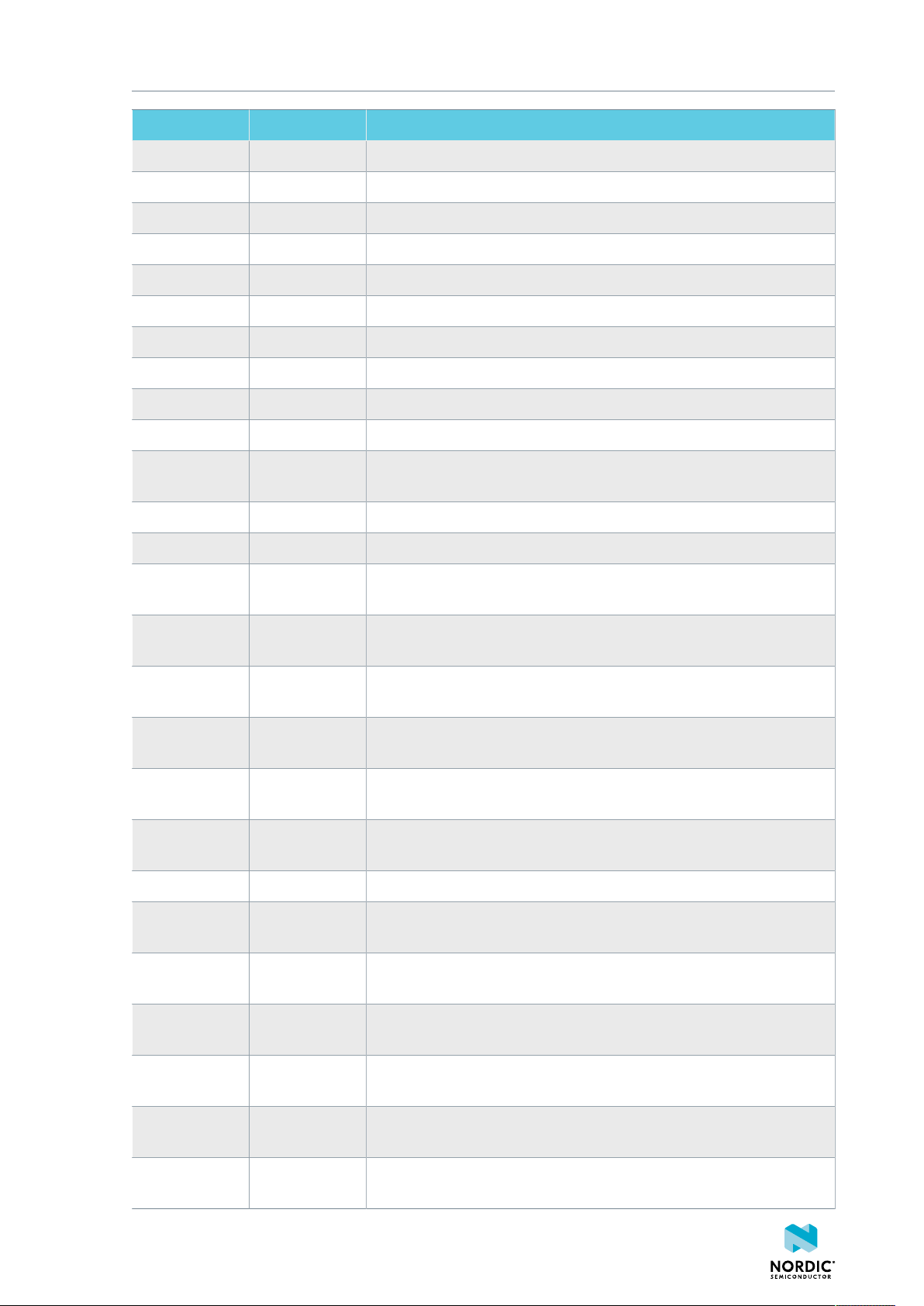

4.13 Solder bridge configuration

The nRF5340 DK has a range of solder bridges for enabling or disabling functionality on the DK. Changes to

these are not needed for normal use of the DK.

The following table is a complete overview of the solder bridges on the nRF5340 DK.

Solderbridge Default Function

SB1 Closed Cut to disconnect the 32.768 kHz on P0.01

SB2 Closed Cut to disconnect the 32.768 kHz on P0.00

SB3 Open Short to enable P0.01 as normal GPIO

SB4 Open Short to enable P0.00 as normal GPIO

SB5 Closed Cut to disconnect LED1

SB6 Closed Cut to disconnect LED2

SB7 Closed Cut to disconnect LED3

SB8 Closed Cut to disconnect LED4

SB9 Open Short to bypass peripheral power switch

SB10 Closed Cut to disconnect the QSPI memory from P0.16

SB11 Closed Cut to disconnect the QSPI memory from P0.17

SB12 Closed Cut to disconnect the QSPI memory from P0.13

SB13 Closed Cut to disconnect the QSPI memory from P0.18

SB14 Closed Cut to disconnect the QSPI memory from P0.14

SB15 Closed Cut to disconnect the QSPI memory from P0.15

SB16 Closed Cut to disconnect QSPI memory power supply from VDD_PER

SB17 Open Short to connect QSPI memory power supply to VDD

SB18 Open Short to connect QSPI memory power supply to VDD_nRF

SB20 Open Short to enable P0.16 as a normal GPIO

SB21 Open Short to enable P0.17 as a normal GPIO

SB22 Open Short to enable P0.13 as a normal GPIO

SB23 Open Short to enable P0.18 as a normal GPIO

SB24 Open Short to enable P0.14 as a normal GPIO

4406_638

28

Page 29

Hardware description

Solderbridge Default Function

SB25 Open Short to enable P0.15 as a normal GPIO

SB26 Closed Cut to disable the rgw pull-up resistor of the BOOT/RESET line

SB31 Open Short to bypass the USB detect switch

SB32 Open Short to permanently enable the I2C pull-up resistors

SB33 Closed Cut to permanently disable the I2C pull-up resistors

SB34 Open Short to bypass the power switch on the USB power

SB35 Open Short to bypass the power switch on the coin cell battery power

SB36 Open Short to bypass the power switch on the external supply power

SB37 Open Short to bypass the interface MCU power switch

SB38 Closed Cut to disable VDD power to the Arduino interface

SB39 Open Short to bypass the power switch for regulator, coin cell, or external

supply

SB40 Closed Cut for current measurements of the VDD_nRF

SB41 Closed Cut for current measurements of the VDD_nRF_HV

SB42 Closed Cut to disconnect IF Boot/Reset button from nRF5340 reset pin when

the interface MCU is disconnected

SB43 Open Short to connect IF Boot/Reset button to RESET pin on the Arduino

interface

SB44 Open Short to connect the RESET pin on the Arduino interface to the

nRF5340 reset pin

SB45 Open Short to connect the RESET pin on the Arduino interface to the

interface nRF5340 reset pin when the interface MCU is disconnected

SB46 Open Short to connect the RESET pin on the Arduino interface to the

interface MCU Boot when the interface MCU is disconnected

SB47 Open Short to enable power supply of the external device when using the

debug out connector

SB48 Open Short to bypass the interface MCU USB power switch

SB50 Closed Cut to disconnect the nRF5340 CTS line from the signal switch and

interface MCU

SB51 Closed Cut to disconnect the nRF5340 RTS line from the signal switch and

interface MCU

SB52 Closed Cut to disconnect the nRF5340 RxD line from the signal switch and

the interface MCU

SB53 Closed Cut to disconnect the nRF5340 TxD line from the signal switch and

interface MCU

SB54 Closed Cut to disconnect the nRF5340 SWDIO line from the signal switch and

interface MCU

SB55 Closed Cut to disconnect the nRF5340 SWDCLK line from the signal switch

and interface MCU

4406_638

29

Page 30

Hardware description

Solderbridge Default Function

SB56 Closed Cut to disconnect the nRF5340 RESET line from the signal switch and

interface MCU

SB57 Closed Cut to disconnect the nRF5340 SWO line from the signal switch and

the interface MCU

SB58 Closed Cut to disconnect voltage follower from external supply when SW10

is in ON position

SB59 Open Solder to connect debug in and trace reference voltage to VDD

SB60 Closed Cut to disconnect debug in and trace reference voltage from

VDD_nRF'

SB80 Open Short to bypass the power switch for the VBUS of nRF5340

SB81 Open Short to bypass the power switch for VDD_HV of nRF5340

Table 8: Solder bridge configuration

4406_638

30

Page 31

5

Measuring current

The current drawn by the nRF5340 SoC can be monitored on the nRF5340 DK.

Current can be measured using various test instruments. Examples of test equipment are the following:

• Power analyzer

• Oscilloscope

• Ampere meter

• Power Profiler Kit

Power analyzer and Power Profiler Kit measurements are not described in this document. For more

information on Power Profiler Kit, see Power Profiler Kit User Guide.

For measuring instructions, see Using an oscilloscope for current profile measurement on page 32 and

Using an ampere meter for current measurement on page 33.

The nRF5340 SoC has two possible power supplies, VDD (1.7–3.6 V) and VDDH (2.5–5.5 V). The nRF5340

DK is prepared for measuring current on both domains. Only the VDD domain current measurement

is described here, but the approach is the same with the VDDH supply. See the following table for the

corresponding components.

Component VDD VDDH

Measurement connector P22 P23

Solder bridge SB40 SB41

Series resistor R64 R67

Table 9: Components for current measurement on VDD and VDDH

Note: When measuring the current consumption:

• It is not recommended to use a USB connector to power the DK during current measurements

due to potential noise from the USB power supply. However, when measuring current on

an application using the USB interface of the nRF5340 SoC, the USB must be connected. It is

recommended to power the DK from a coin cell battery, external power supply on connector

P21 (1.7–3.6 V), or through the Li-Po connector J6 or P27 (2.5–5.0 V).

• The current measurements will become unreliable when a serial terminal is connected to the

virtual COM port.

• After programming the nRF5340 SoC, the USB for the interface MCU must be disconnected.

For more information on current measurement, see the tutorial Current measurement guide:

Introduction.

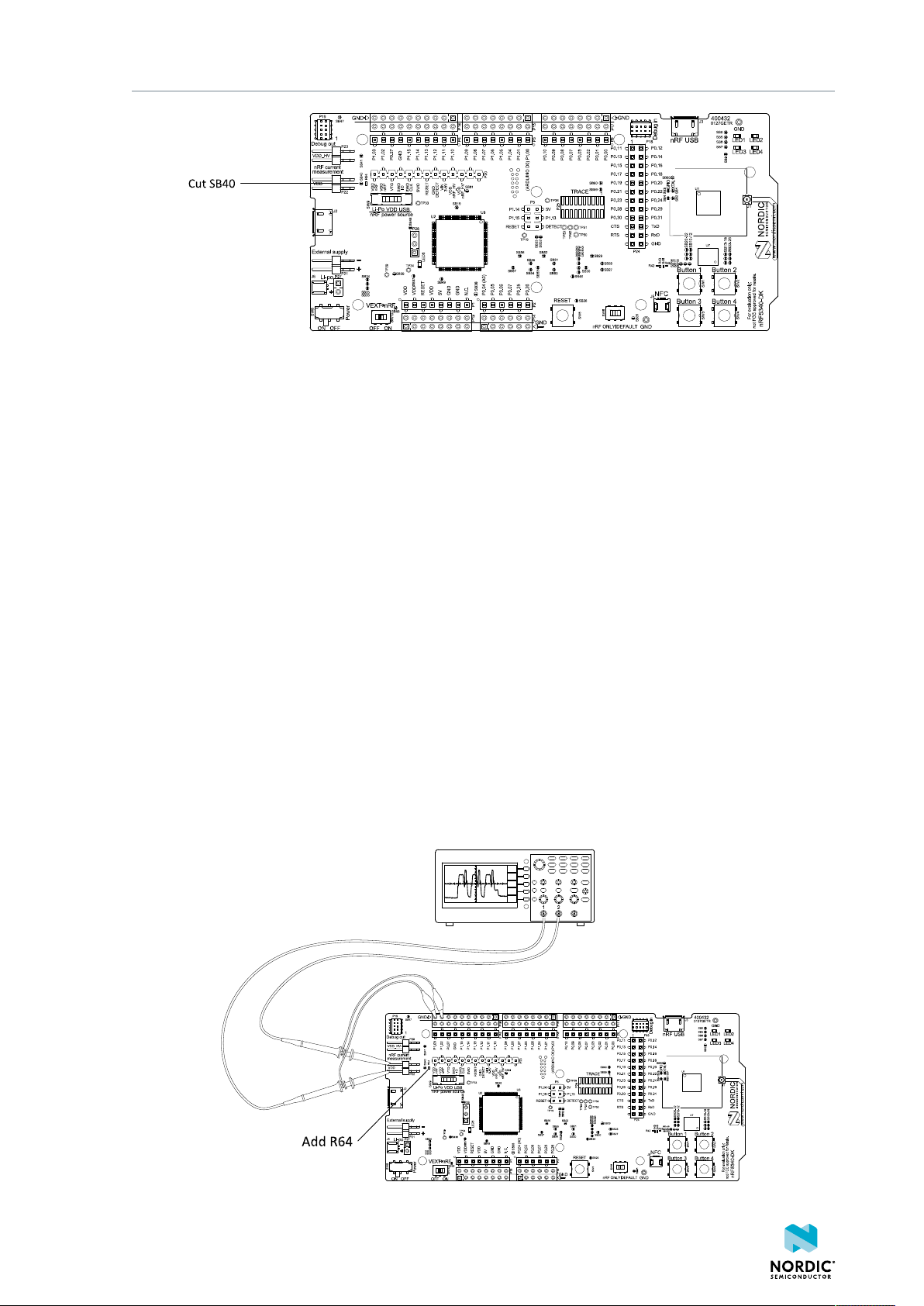

5.1 Preparing the DK

To measure current, you must first prepare the DK.

The suggested configurations actually split the power domains for the nRF5340 SoC and the rest of the DK.

4406_638

31

Page 32

Measuring current

Figure 31: Preparing the DK for current measurements

• To put P22 in series with the load, cut the PCB track shorting solder bridge SB40.

• To restore normal kit function after measurement, solder SB40 or apply a jumper on P22.

• To reprogram the nRF5340 SoC while the DK is prepared for current measurements, remove

measurement devices from P22, and then connect the USB cable.

5.2 Using an oscilloscope for current profile measurement

An oscilloscope can be used to measure both the average current over a given time interval and capture

the current profile.

Make sure you have prepared the DK as described in section Preparing the DK on page 31.

1. Mount a 10 Ω resistor on the footprint for R64.

2. Connect an oscilloscope in differential mode or similar with two probes on the pins of the P22

connector as shown in the following figure.

3. Calculate or plot the instantaneous current from the voltage drop across the 10 Ω resistor by taking the

difference of the voltages measured on the two probes. The voltage drop will be proportional to the

current. The 10 Ω resistor will cause a 10 mV drop for each 1 mA drawn by the circuit being measured.

The plotted voltage drop can be used to calculate the current at a given point in time. The current can

then be averaged or integrated to analyze current and energy consumption over a period.

4406_638

Figure 32: Current measurement with an oscilloscope

32

Page 33

Measuring current

Some tips to reduce noise:

• Use probes with 1× attenuation

• Enable averaging mode to reduce random noise

• Enable high resolution function if available

Use a minimum of 200 kSa/s (one sample every 5 µs) to get the correct average current measurement.

5.3 Using an ampere meter for current measurement

The average current drawn by the nRF5340 SoC can be measured using an ampere meter. This method

monitors the current in series with the nRF device.

Make sure you have prepared the DK as described in section Preparing the DK on page 31.

Connect an ampere meter between the pins of connector P22 as shown in the following figure.

Figure 33: Current measurement with an ampere meter

Note: An ampere meter will measure the average current drawn by the nRF5340 SoC if:

• The SoC is in a state where it draws a constant current, or, the activity on the device changing

load current, like BLE connection events, is repeated continuously and has a short cycle time

(less than 100 ms) so that the ampere meter will average whole load cycles and not parts of the

cycle.

• The dynamic range of the ampere meter is wide enough to give accurate measurements from 1

µA to 15 mA.

We recommend that you use a true RMS ampere meter.

4406_638

33

Page 34

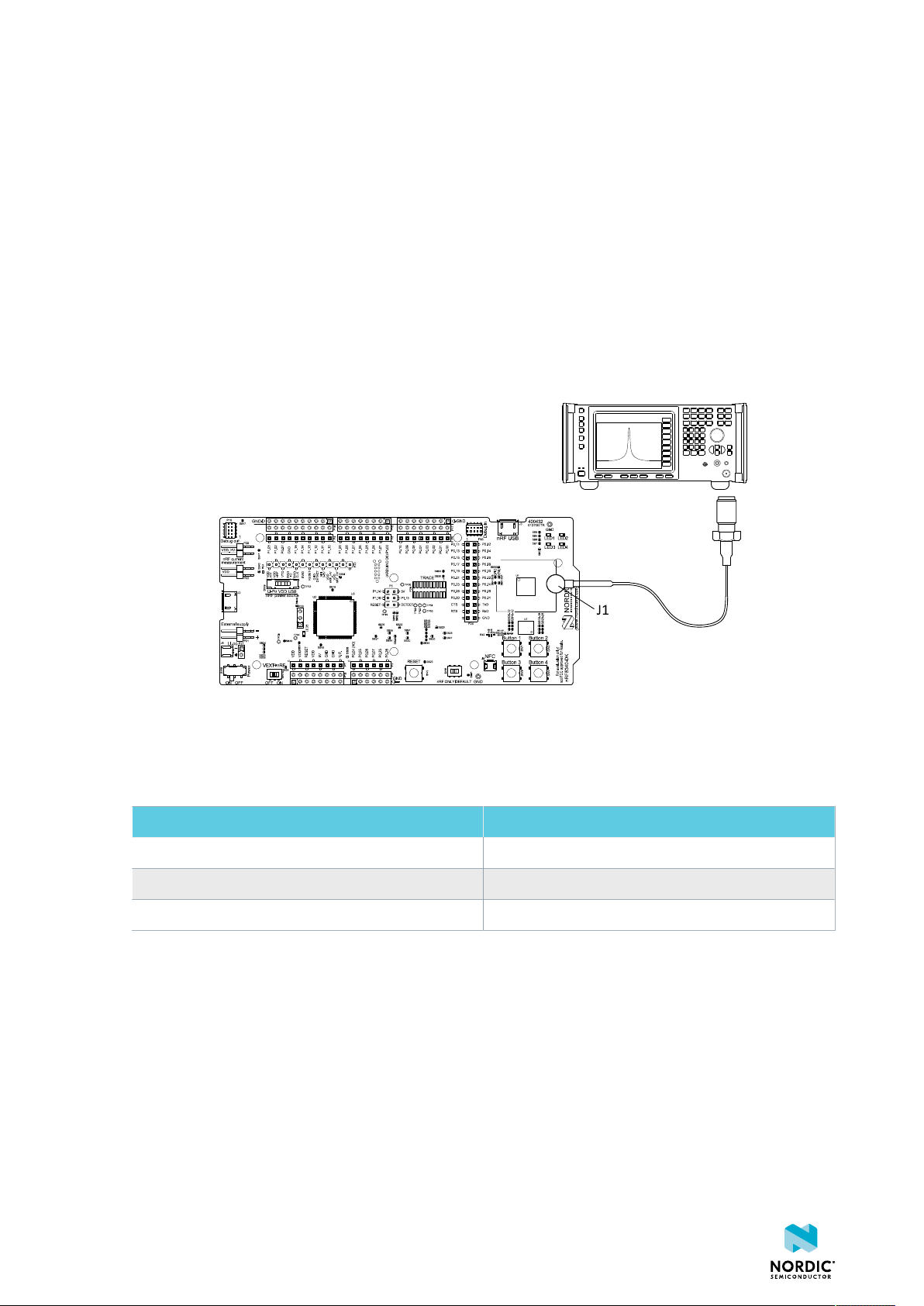

6

RF measurements

The nRF5340 DK is equipped with a small coaxial connector (J1) for conducting measurements of the RF

signal using a spectrum analyzer.

The connector is of SWF type (Murata part no. MM8130-2600) with an internal switch. By default, when

no cable is attached, the RF signal is routed to the onboard trace antenna.

A test probe is available (Murata part no. MXHS83QE3000) with a standard SMA connection on the other

end for connecting instruments (the test probe is not included with the kit). When connecting the test

probe, the internal switch in the SWF connector will disconnect the onboard antenna and connect the RF

signal from the nRF5340 SoC to the test probe.

Figure 34: Connecting a spectrum analyzer

The connector and test probe will add loss to the RF signal, which should be taken into account when

measuring. See the following table for more information.

Frequency (MHz) Loss (dB)

2440 1.0

4880 1.7

7320 2.6

Table 10: Typical loss in connector and test probe

4406_638

34

Page 35

Glossary

Clear to Send (CTS)

In flow control, the receiving end is ready and telling the far end to start sending.

Data Terminal Ready (DTR)

A control signal in RS-232 serial communications transmitted from data terminal equipment, such as

a computer, to data communications equipment.

Development Kit (DK)

A development platform used for application development.

Hardware Flow Control (HWFC)

A handshaking mechanism used to prevent an overflow of bytes in modems. It is utilizing two

dedicated pins on the RS-232 connector, Request to Send and Clear to Send.

Integrated Development Environment (IDE)

A software application that provides facilities for software development.

Mass Storage Device (MSD)

Any storage device that makes it possible to store and port large amounts of data in a permanent

and machine-readable fashion.

Near Field Communication (NFC)

A standards-based short-range wireless connectivity technology that enables two electronic devices

to establish communication by bringing them close to each other.

NFC-A Listen Mode

Initial mode of an NFC Forum Device when it does not generate a carrier. The device listens for the

remote field of another device. See Near Field Communication (NFC) on page 35.

Operational Amplifier (op-amp)

A high-gain voltage amplifier that has a differential input and, usually, a single output.

Receive Data (RXD)

A signal line in a serial interface that receives data from another device.

Request to Send (RTS)

In flow control, the transmitting end is ready and requesting the far end for a permission to transfer

data.

Root Mean Square (RMS)

An RMS meter calculates the equivalent direct current (DC) value of an alternating current (AC)

waveform. A true-RMS meter can accurately measure both pure waves and the more complex

nonsinusoidal waves.

SubMiniature Version A (SMA) Connector

A semi-precision coaxial RF connector for coaxial cables with a screw-type coupling mechanism.

4406_638

35

Page 36

System on Chip (SoC)

A microchip that integrates all the necessary electronic circuits and components of a computer or

other electronic systems on a single integrated circuit.

Transmit Data (TXD)

A signal line in a serial interface that transmits data to another device.

Universal Asynchronous Receiver/Transmitter (UART)

A hardware device for asynchronous serial communication between devices.

4406_638

36

Page 37

Acronyms and abbreviations

These acronyms and abbreviations are used in this document.

CTS

Clear to Send

DK

Development Kit

DTR

Data Terminal Ready

HWFC

Hardware Flow Control

IDE

Integrated Development Environment

MSD

Mass Storage Device

NFC

Near Field Communication

op-amp

Operational Amplifier

RMS

Root Mean Square

RTS

Request to Send

RXD

Receive Data

SMA

SubMiniature version A

SoC

System on Chip

TXD

Transmit Data

UART

Universal Asynchronous Receiver/Transmitter

4406_638

37

Page 38

Recommended reading

In addition to the information in this document, you may need to consult other documents.

Nordic documentation

• nRF5340 Product Specification

• nRF5340 Compatibility Matrix

• nRF5340 Errata

• nRF Connect SDK

4406_638

38

Page 39

FCC regulatory notice

The following regulatory notices apply to the nRF5340 DK.

This kit has not been authorized under the rules of the FCC and is designed to allow:

• Product developers to evaluate electronic components, circuitry, or software associated with the kit to

determine whether to incorporate such items in a finished product.

• Software developers to write software applications for use with the end product.

This kit is not a finished product and when assembled may not be resold or otherwise marketed unless all

required FCC equipment authorizations are first obtained. Operation is subject to the condition that this

product not cause harmful interference to licensed radio stations and that this product accept harmful

interference. Unless the assembled kit is designed to operate under part 15, part 18 or part 95 of 47 CFR

Chapter I - FCC, the operator of the kit must operate under the authority of an FCC license holder or must

secure an experimental authorization under part 5 of the latter chapter.

4406_638

39

Page 40

Legal notices

By using this documentation you agree to our terms and conditions of use. Nordic Semiconductor may

change these terms and conditions at any time without notice.

Liability disclaimer

Nordic Semiconductor ASA reserves the right to make changes without further notice to the product to

improve reliability, function, or design. Nordic Semiconductor ASA does not assume any liability arising out

of the application or use of any product or circuits described herein.

Nordic Semiconductor ASA does not give any representations or warranties, expressed or implied, as to

the accuracy or completeness of such information and shall have no liability for the consequences of use

of such information. If there are any discrepancies, ambiguities or conflicts in Nordic Semiconductor’s

documentation, the Product Specification prevails.

Nordic Semiconductor ASA reserves the right to make corrections, enhancements, and other changes to

this document without notice.

Life support applications

Nordic Semiconductor products are not designed for use in life support appliances, devices, or systems

where malfunction of these products can reasonably be expected to result in personal injury.

Nordic Semiconductor ASA customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Nordic Semiconductor ASA for any damages resulting from

such improper use or sale.

RoHS and REACH statement

Complete hazardous substance reports, material composition reports and latest version of Nordic's REACH

statement can be found on our website www.nordicsemi.com.

Trademarks

All trademarks, service marks, trade names, product names, and logos appearing in this documentation

are the property of their respective owners.

Copyright notice

©

2020 Nordic Semiconductor ASA. All rights are reserved. Reproduction in whole or in part is prohibited

without the prior written permission of the copyright holder.

4406_638

40

Loading...

Loading...