Page 1

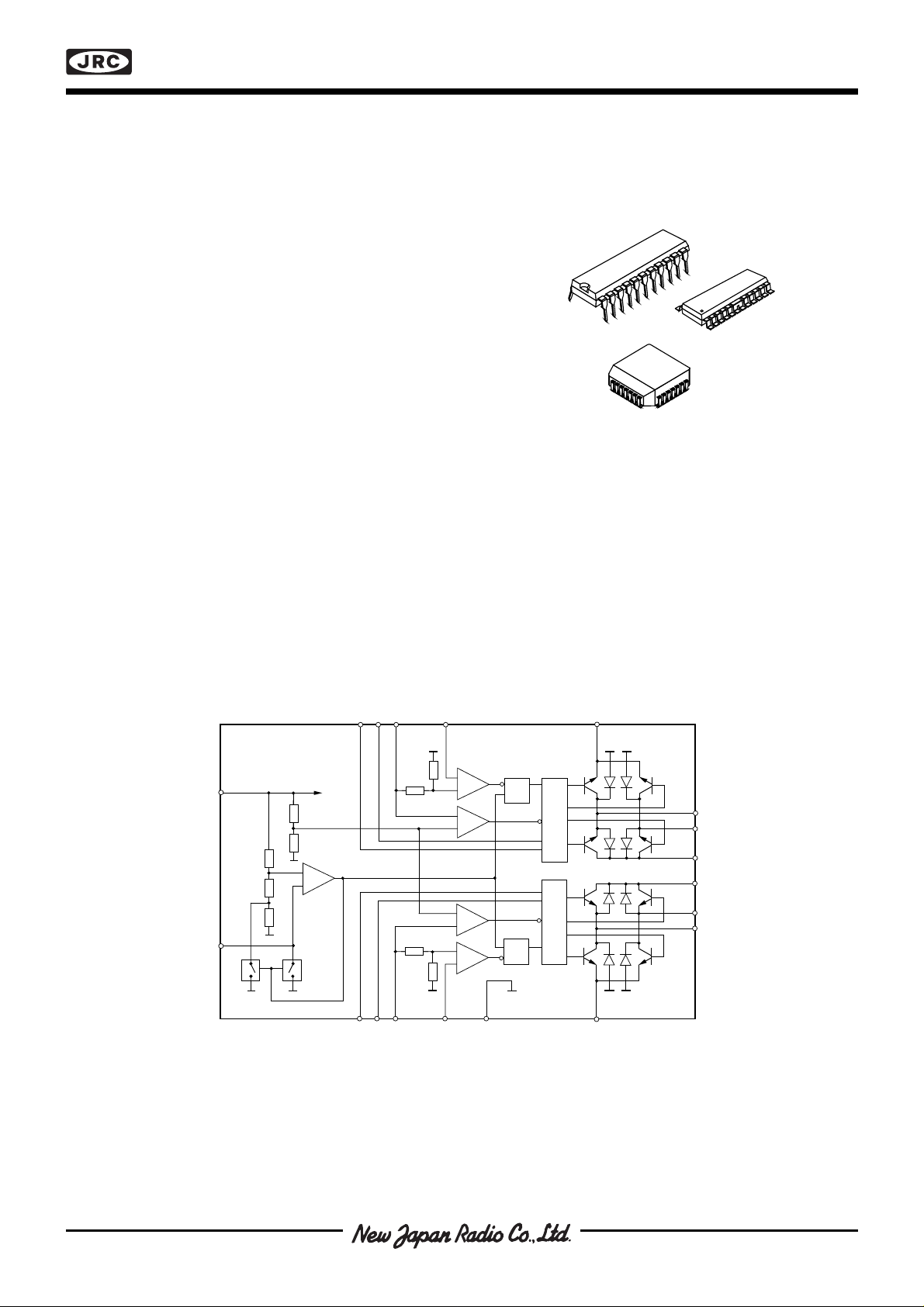

DUAL STEPPER MOTOR DRIVER

■ GENERAL DESCRIPTION ■ PACKAGE OUTLINE

The NJM3771 is a stepper motor driver, which circuit is

especially developed for use in microstepping applications in

conjunction with the matching dual DAC (Digital-to-Analog

Converter) NJU39610.

The NJM3771 contains a clock oscillator, which is common

for both driver channels; a set of comparators and flip-flops

imple menting the switching control; and two H-bridges with

internal recirculation diodes. Voltage supply requirements are

+5 V for logic and +10 to +45 V for the motor. Maximum

output current is 650 mA per channel.

NJM3771D2

NJM3771

NJM3771E3

■ FEATURES

• Dual chopper driver

• 650 mA output current per channel

• Selectable slow/fast current decay for improved high-

speed microstepping

• Specially matched to Dual DAC NJU39610

• Packages DIP22 / EMP24(Batwing) / PLCC28

■ BLOCK DIAGRAM

VR1CD

1

1

V

CC

RC

NJM3771

Phase

V

CC

+

–

NJM3771FM2

C

1

–

+

+

–

–

+

+

–

R

S

SRQ

Q

Logic

Logic

E

1

M

A1

M

B1

V

MM1

V

MM2

M

B2

M

A2

Figure 1. Block diagram

Phase

VR2CD

2

2

GNDC

2

E

2

Page 2

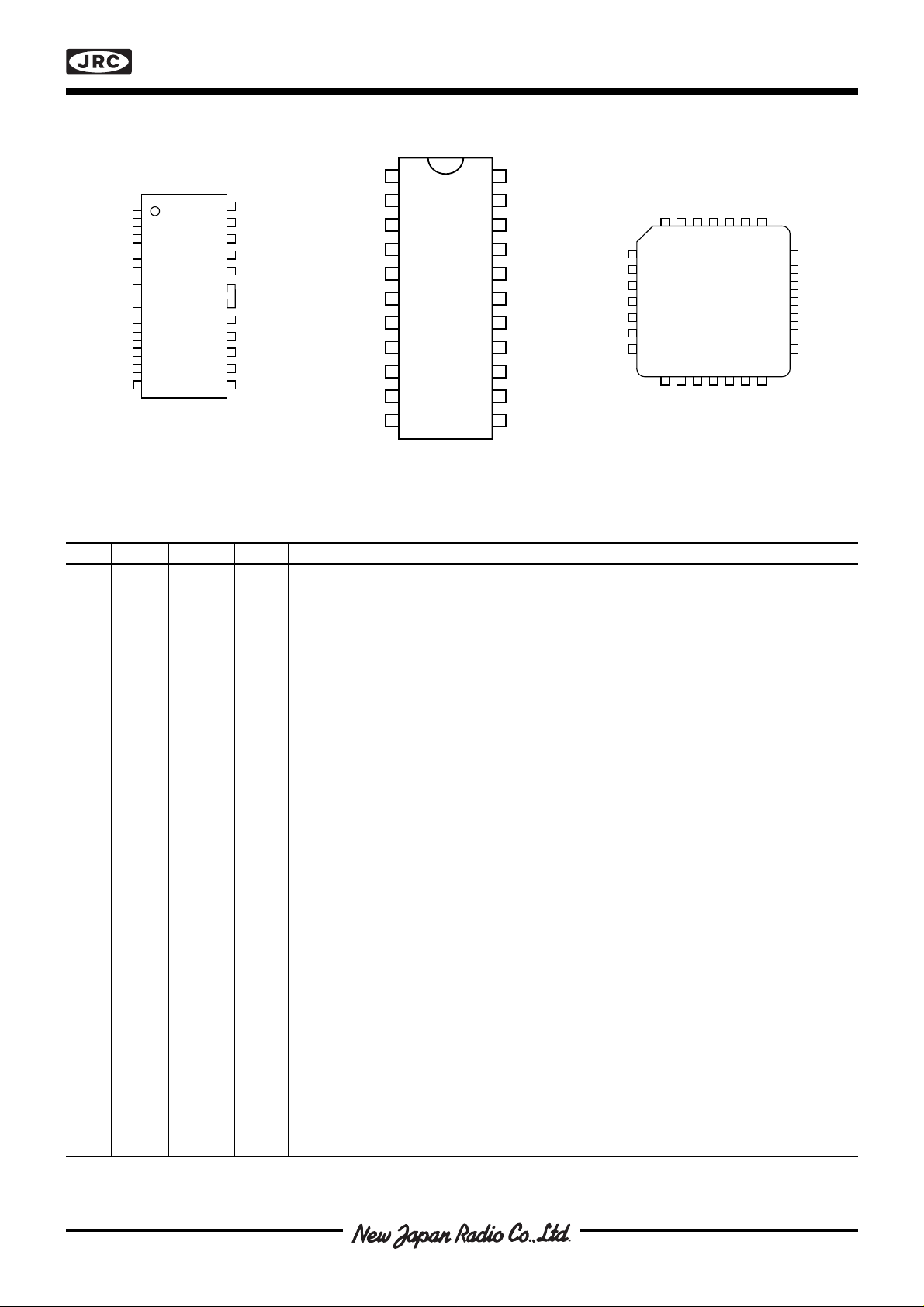

■ PIN CONFIGURATIONS

1

2

3

4

5

6

8

9

10

11

22

21

20

19

18

17

16

15

14

1312

GND

MA

1

MA

2

GND

NC

NJM

3771E3

MB

1

E

1

VMM

1

NC

MB

2

E

2

VMM

2

VR

2

CD

2

C

2

RC

23

24

GND

GND

Phase

2

7

VR

1

CD

1

C

1

V

CC

Phase

1

NJM3771

M

V

MM1

M

GND

GND

Phase

CD

V

V

E

C

CC

B1

A1

R1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

NJM

3771D2

22

21

20

19

18

17

16

15

14

13

12

M

B2

E

2

V

MM2

M

A2

GND

GND

Phase

CD

2

V

R2

C

2

RC

2

A2

M

GND

GND

GND

GND

GND

1

GND

432

5

V

MM2

E

6

2

M

7

B2

M

8

B1

NJM 3771FM2

GND

2

9

10

E

1

V

11

MM1

12131415161718

A1

M

GND

Phase

282726

GND

GND

2

CD

1

Phase

25

V

R2

C

24

2

RC

23

V

22

CC

C

21

1

20

V

R1

19

CD

1

Figure 2. Pin configurations

■ PIN DESCRIPTION

Refer to Figure 2

EMP DIP PLCC Symbol Description

218MB1Motor output B, channel 1. Motor current flows from MA1 to MB1 when Phase1 is HIGH.

3210E

4311V

5412MA1Motor output A, channel 1. Motor current flows from MA1 to MB1 when Phase1 is HIGH.

6,7, 5,6, 1-3,9, GND Ground and negative supply. Note: these pins are used thermally for heat-sinking.

18,19 17,18 13-17,28 Make sure that all ground pins are soldered onto a suitably large copper ground

8 7 18 Phase

9819CD

10 9 20 V

11 10 21 C

12 11 22 V

13 12 23 RC Clock oscillator RC pin. Connect a 15 kohm resistor to VCC and a 3300 pF capacitor to

14 13 24 C

15 14 25 V

16 15 26 CD2Current decay control, channel 2. A logic HIGH on this input results in

17 16 27 Phase

20 19 4 M

21 20 5 V

22 21 6 E

23 22 7 M

Common emitter, channel 1. This pin connects to a sensing resistor to ground.

1

Motor supply voltage, channel 1, 10 to 40 V. V

MM1

MM1

and V

should be connected together.

MM2

plane for efficient heat sinking.

Controls the direction of motor current at outputs MA1 and MB1. Motor current flows from M

1

to MB1 when Phase1 is HIGH.

Current decay control, channel 1. A logic HIGH on this input results in

1

a LOW results in

Reference voltage, channel 1. Controls the threshold voltage for the comparator and hence

R1

fast

current decay, see “Functional Description.”

slow

current decay,

the output current. Input resistance is typically 2.5 kohms, ±20%.

Comparator input channel 1. This input senses the instantaneous voltage across the

1

sensing resistor, filtered by an RC network. The threshold voltage for the comparator is

(0.450 / 2.5) • VR1, i.e. 450 mV at VR1 = 2.5 V.

Logic voltage supply, nominally +5 V.

CC

ground to obtain the nominal switching frequency of 26.5 kHz.

Comparator input channel 2. This input senses the instantaneous voltage across the

2

sensing resistor, filtered by an RC network. The threshold voltage for the comparator is

(0.450 / 2.5) • VR1, i.e. 450 mV at VR1 = 2.5 V.

Reference voltage, channel 2. Controls the threshold voltage for the comparator and hence

R2

the output current. Input resistance is typically 2.5 kohms, ±20%.

slow

current decay,

a LOW results in

Controls the direction of motor current at outputs MA2 and MB2. Motor current flows from M

2

fast

current decay, see “Functional Description.”

to MB2 when Phase2 is HIGH.

Motor output A, channel 2. Motor current flows from MA2 to MB2 when Phase2 is HIGH.

A2

Motor supply voltage, channel 2, 10 to 40 V. V

MM2

Common emitter, channel 2. This pin connects to a sensing resistor to ground.

2

Motor output B, channel 2. Motor current flows from MA2 to MB2 when Phase2 is HIGH.

B2

MM1

and V

should be connected together.

MM2

A1

A2

Page 3

NJM3771

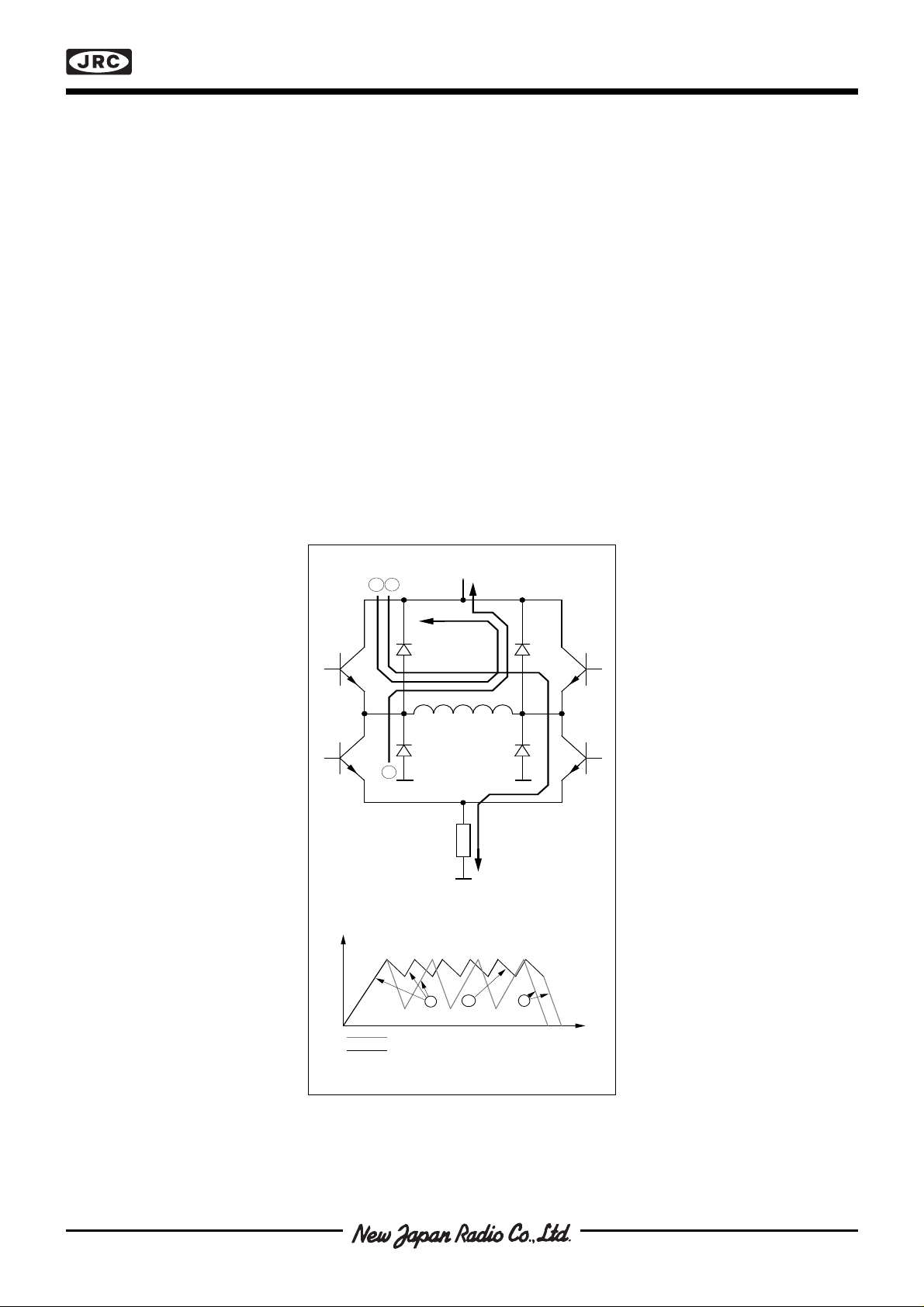

■ FUNCTIONAL DESCRIPTION

Each channel of the NJM3771 consists of the following sections: an H-bridge output stage, capable of driving up

to 650 mA continuous motor current (or 500 mA, both channels driven), a logic section that controls the output

transistors, an S-R flip-flop, and two comparators. The oscillator is common to both channels.

Constant current control is achieved by switching the current to the windings. This is done by sensing the (peak)

voltage across a current-sensing resistor, RS, effectively connected in series with the motor winding, and feeding

that voltage back to a comparator. When the motor current reaches a threshold level, determined by the voltage at

the reference input, VR, the comparator resets the flip-flop, which turns off the output transistors. The current

decreases until the clock oscillator triggers the flip-flop, which turns on the output transistors again, and the cycle is

repeated.

The current-decay rate during the turn-off portion of the switching cycle, can be selected fast or slow by the CD

input.

In slow current-decay mode, only one of the lower transistors in the H-bridge (those closest to the negative

supply) is switched on and off, while one of the upper transistors is held constantly on. During turn-off, the current

recirculates through the upper transistor (which one depends on current direction) and the corresponding freewheeling diode connected to VMM, see figure 3.

In fast current decay mode, both the upper and lower transistors are switched. During the off-time, the freewheeling current is opposed by the supply voltage, causing a rapid discharge of energy in the winding.

Fast current decay may be required in half- and microstepping applications when rapid changes of motor current

are necessary. Slow current decay, however, gives less current ripple, and should always be selected, if possible,

to minimize core losses and switching noise.

Motor Current

1

2

3

R

s

1

32

FAST Current Decay

SLOW Current Decay

Time

Figure 3. Output stage with current paths

during turn -on, turn-off and phase shift

Page 4

NJM3771

50 %

V

CH

t

on

t

off

V

E

| V – V |

MA MB

t

d

t

t

f =

s

tont

off

+

D =

t

t

on

off

+

1

t

on

■ ABSOLUTE MAXIMUM RATINGS

Parameter Pin no. (DIP) Symbol Min Max Unit

Voltage

Logic supply 11 V

Motor supply 3, 20 V

Logic inputs 7, 8, 15, 16 V

Comparator inputs 10, 13 V

Reference inputs 9, 14 V

CC

MM

I

C

R

Current

Motor output current 1, 4, 19, 22 I

Logic inputs 7, 8, 15, 16 I

Analog inputs 10, 13 I

Oscillator charging current 12 I

M

I

A

RC

Temperature

Operating junction temperature T

Storage temperature** T

J

S

** Circuit only. The packaging can handle max 60°C

■ RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Unit

Logic supply voltage V

Motor supply voltage V

Motor output current *** I

Junction temperature **** T

Rise time logic inputs t

Fall time logic inputs t

Oscillator timing resistor R

CC

MM

M

J

r

f

T

4.75 5 5.25 V

10 - 40 V

-650 - 650 mA

-20 - +125 °C

--2µs

--2µs

2 15 20 kohm

07V

045V

-0.3 6 V

-0.3 V

CC

V

-0.3 7.5 V

-700 +700 mA

-10 - mA

-10 - mA

-5mA

-40 +150 °C

-55 +150 °C

*** In microstepping mode, “sine/cosine” drive where I

= 650 • cos(q) and I2 = 650 • sin(q) mA, otherwise 500 mA/channel both

1

channels fully on.

****See operating temperature chapter.

C

VR1CD

Phase

1

NJM 3771

V

I

CC

CC

11

15 kΩ

R

T

I

RC

RC

12

3 300 pF

V

CC

C

T

I I I

I IH IL

I

V

I

V

IH

V

V

IL

V

A

A

R

7

V

CC

+

–

16

Phase

2

15 14

1

1

10

98

–

R

+

S

+

–

–

+

SRQ

+

–

5, 6, 17, 18

13

VR2CD

2

GNDC

2

I

C

I

A

820 pF

1 kΩ

C

C

V

CH

V

C

Figure 4. Definitions of symbols Figure 5. Definition of terms

E

1

2

Q

Logic

Logic

21

E

2

R

C

R

S

M

4

A1

M

1

B1

V

3

MM1

I

V

20

M

22

M

19

V

E

MM

MM2

B2

I I

M OL

A2

V

V

MM

M

V

MA

Page 5

NJM3771

■ ELECTRICAL CHARACTERISTICS

Electrical characteristics over recommended operating conditions, unless otherwise noted. -20°C < TJ < +125°C

Parameter Symbol Conditions Min Typ Max Unit

General

Supply current I

Total power dissipation P

CC

VMM = 40 V, IM1= 450 mA, IM2= 0 mA. 1.4 1.6 W

D

Notes 2, 3.

V

= 40 V, IM1 = IM2 = 318 mA. 1.6 1.8 W

MM

Notes 2, 3.

Turn-off delay t

Ta = +25°C, dVC/dt ≥ 50 mV/µs. - 1.0 1.5 µs

d

Note 3.

Logic Inputs

Logic HIGH input voltage V

Logic LOW input voltage V

Logic HIGH input current I

Logic LOW input current I

IH

IL

VI = 2.4 V - - 20 µA

IH

VI = 0.4 V -0.4 - - mA

IL

Reference Inputs

Input resistance R

Input current I

Turn-off voltage V

Ta = +25°C - 5 - kohm

R

Ta = +25°C, VR = 2.5 V. 0.5 1.0 mA

R

TO

Comparator Inputs

Threshold voltage V

| V

- V

CH1

| mismatch V

CH2

Input current I

CH,diff

RC = 1 kohms, VR = 2.5 V 430 450 470 mV

CH

RC = 1 kohms - 1 - mV

C

Motor Outputs

Lower transistor saturation voltage I

= 500 mA - 1.00 1.20 V

M

Lower transistor leakage current VMM = 41 V, VE = VR = 0 V, VC = V

Lower diode forward voltage drop I

Upper transistor saturation voltage I

Upper transistor leakage current V

Upper diode forward voltage drop I

= 500 mA - 1.10 1.25 V

M

= 500 mA - 1.20 1.35 V

M

= 41 V, VE = VR = 0 V, VC = V

MM

= 500 mA - 1.00 1.25 V

M

Chopper Oscillator

Chopping frequency f

CT = 3300 pF, RT = 15 kohms 25.0 26.5 28.0 kHz

s

CC

CC

-3850mA

2.0 - - V

- - 0.6 V

20 29 38 mV

-10 - 1 µA

- - 300 µA

- - 300 µA

■ THERMAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Unit

Thermal resistance Rth

Rth

Rth

Rth

Rth

Rth

Notes

1. All voltages are with respect to ground. Currents are positive into, negative out of specified terminal.

2. All ground pins soldered onto a 20 cm

3. Not covered by final test program.

4. Switching duty cycle D = 30%, f

= 26.5 kHz

S

DIP package. - 11 - °C/W

J-GND

DIP package. Note 2. - 40 - °C/W

J-A

PLCC package. - 9 - °C/W

J-GND

PLCC package. Note 2. - 35 - °C/W

J-A

EMP package. - 13 - °C/W

J-GND

EMP package. Note 2. - 42 - °C/W

J-A

2

PCB copper area with free air convection.

Page 6

NJM3771

■ APPLICATIONS INFORMATION

Current control

The output current to the motor winding is mainly determined by the voltage at the reference input and the value of

the sensing resistor, RS.

Chopping frequency, winding inductance, and supply voltage will affect the current level, but to much less extent.

Fast current decay setting will produce somewhat lower (average) current than slow current decay. The peak

current through the sensing resistor (and motor winding) can be expressed as:

I

= 0.18 • (VR / RS)[A]

M,peak

i.e., with a recommended value of 1 ohm for the sensing resistor, RS, a 2.5 V reference voltage will produce an

output current of approximately 450 mA. To improve noise immunity on the VR input, the control range may be

increased to

5 volts if RS is correspondingly changed to 2 ohms.

To

P

+2.5V

+

10 µF

V

MM

V (+5 V)

CC

0.1 µF 0.1 µF

11 3 20

Phase

CD

V

R1

Phase

CD

V

R2

RC

V

1

1

2

2

5, 6,

17, 18

+5 V

7

8

9

16

15

14

12

15 kΩ

3 300 pF

GND

(V )

CC MM

VV

CC

MM1 MM2

NJM3771

11

2

10

1 kΩ 1 kΩ

820 pF 820 pF

1.0 Ω 1.0 Ω

4

M

A1

M

1

B1

19

M

A2

22

M

B2

ECECGND

2

13

2

21

STEPPER

MOTOR

Pin numbers refer

to DIP package.

R

S

R

S

GND (V

)

Figure 6. Typical stepper motor application with NJM3771

V (+5 V)

CC

+

0.1 µF 0.1 µF

14

D0

7

D7

NJU 39610

15

A0

16

A1

6

WR

17

CS

22

RESET

1

VV

Ref

GND

(V )

CC MM

5

V

DD

SS

18

Sign

Sign

3

1

4

CD

1

2

DA

1

20

2

19

CD

2

21

DA

2

+5 V

7

8

9

16

15

14

15 kΩ

3 300 pF

Phase

CD

V

Phase

CD

V

RC

12

11 3 20

V

CC

1

1

R1

R2

2

5, 6,

17, 18

NJM 3771

2

VV

MM1 MM2

11

10

1 kΩ 1 kΩ

820 pF 820 pF

1.0 Ω 1.0 Ω

2

2

13

R

S

M

A1

M

B1

M

A2

M

B2

ECECGND

2

21

R

10 µF

4

1

19

22

STEPPER

Pin numbers refer

to DIP package.

S

GND (V

MOTOR

V

MM

)

Figure 7. Microstepping system with NJU39610 and NJM3771

Page 7

NJM3771

External components

The voltage across the sensing resistor is fed back to the comparator via a low-pass filter section, to prevent

erroneous switching due to switching transients. The recommended filter component values, 1 kohm and 820 pF,

are suitable for a wide range of motors and operational conditions.

Since the low-pass filtering action introduces a small delay of the signal to the comparator, peak voltage across

the sensing resistor, and hence the peak motor current, will reach a slightly higher level than the threshold, VC, set

by the reference voltage

(VC = 450 mV @VR = 2.5 V).

The time constant of the low-pass filter may therefore be reduced to minimize the delay and optimize low-current

performance, especially if a low (12 V) supply voltage is used. Increasing the time constant may result in unstable

switching.

The frequency of the clock oscillator is set by the R-C combination at pin RC. The recommended values give a

nominal frequency of 26.5 kHz. A lower frequency will result in higher current ripple and may cause audible noise

from the motor, while increasing the frequency results in higher switching losses and possibly increased iron losses

in the motor.

The sensing resistor, RS, should be selected for maximum motor current. The relationship between peak motor

current, reference voltage and the value of RS is described under “Current control” above. Be sure not to exceed

the maximum output current which is 650 mA per channel (or 500 mA per channel, both channels fully on, see

“Recommended Operating Conditions”).

Motor selection

The NJM3771 is designed for bipolar motors, i.e., motors that have only one winding per phase. A unipolar motor,

having windings with a center tap, can also be used, see figure 8.

The chopping principle in the NJM3771 is based on a constant frequency and a varying duty cycle. This

scheme imposes certain restrictions on motor selection. Unstable chopping can occur if the chopping duty cycle

exceeds approximately 50%. To avoid this, it is necessary to choose a motor with a low winding resistance. Low

winding resistance means less inductance and will therefore enable higher stepping rates, however it also means

less torque capability. A compromise has to be made.

Choose a motor with the lowest possible winding resistance that still gives the required torque and use as high

supply voltage as possible without exceeding the maximum recommended 40 V. Check that the chopping duty

cycle does not exceed 50% at maximum current.

Since the NJM3771 produces a regulated, constant output current it is not necessary to use a motor that is rated

at the same voltage as the actual supply voltage. Only rated current needs to be considered. Typical motors to be

used together with the NJM3771 have voltage ratings of 5 to 12 V, while the supply voltage usually ranges from 24

to 40 V.

Best for high speed

NJM3771

Figure 8. Connection of unipolar motors

Best for high torque

NJM3771

Page 8

NJM3771

General

Phase inputs

A logic HIGH on a Phase input gives positive current flowing out from MA into MB. A logic LOW gives a current in

the opposite direction.

Slow/fast current decay

A logic HIGH on the CD input gives slow current decay, a logic LOW gives fast current decay.

Heat sinking

Soldering the four center pins onto a free PCB copper area of 20 cm2 (approx. 1.8" x 1.8", copper foil thickness =

35 µm) permits the circuit to operate with a maximum of 320 mA output current, both channels driving, at ambient

temperatures up to +70°C. Consult figures 9 and 14 in order to determine the necessary copper area for heat

sinking if higher currents are required.

Thermal shutdown

The circuit is equipped with a thermal shutdown function that reduces the output current at chip temperatures

above +160°C.

Thermal resistance [°C/W]

80

70

60

50

24-pin EMP

40

30

20

5101520

PCB copper foil area [cm ]

PLCC package

DIP package

30 3525

2

Figure 9. Thermal Resistance vs. PC Board copper area and suggested layout

22-pin

DIP

28-pin

PLCC

Page 9

■ TYPICAL CHARACTERISTICS

Vd (V)

°C

1.0

Tj = 25

V

CE Sat

1.2

(V)

Vd (V)

1.0

NJM3771

°C

Tj = 25

.8

.6

.4

.2

0

0 .10 .20 .30 .40 .50 .60

Tj = 125

IM (A)

°C

Figure 10. Typical upper diode

voltage drop vs. recirculating current

V

(V)

CE Sat

1.0

.8

.6

.4

.2

0 .10 .20 .30 .40 .50 .60

Tj = 25

°C

Tj = 125

IM (A)

°C

1.0

.8

.6

.4

.2

°C

Tj = 25

°C

Tj = 125

0 .10 .20 .30 .40 .50 .60

IM (A)

Figure 11. Typical source saturation

voltage vs. output current

.8

Tj = 125

.6

.4

.2

0

0 .10 .20 .30 .40 .50 .60

Figure 12. Typical lower diode

voltage drop vs. recirculating current

PD (W)

3.0

2.0

VMM = 36V

VMM = 14V

1.0

0

0 .10 .20 .30 .40 .50 .60

Max allow power is

IM (A)

°C

IM (A)

Figure 13 Typical sink saturation

voltage vs. output current

Figure 14. Power dissipation vs. motor current,

both channels driven, Ta = 25°C

The specifications on this databook are only

given for information , without any guarantee

as regards either mistakes or omissions.

The application circuits in this databook are

described only to show representative

usages of the product and not intended for

the guarantee or permission of any right

including the industrial rights.

Loading...

Loading...