Page 1

NCP81246

l

Three-Rail Controller

with Intel Proprietary

Interface for IMVP8 CPU

Applications

The NCP81246 contains a two-phase, and two single-phase buck

regulators optimized for Intel IMVP8 compatible CPUs.

The two-phase controller combines true differential voltage sensing,

differential inductor DCR current sensing, input voltage feed-forward,

and adaptive voltage positioning to provide accurately regulated

power for IMVP8 Rail2.

The two single-phase controllers can be used for Rail1, Rail3 and

Rail4 rails. Both make use of ON Semiconductor’s patented enhanced

RPM operation. RPM control maximizes transient response while

allowing for smooth transitions between discontinuous frequency

scaling operation and continuous mode full power operation. The

single-phase rails have an ultralow offset current monitor amplifier

with programmable offset compensation for ultra high accuracy

current monitoring.

The NCP81246 offers three internal MOSFET drivers with a single

external PWM signal.

Two-Phase Rail Features

• Dual Edge Modulation for Fastest Initial Response to Transient

Loading

• High Performance Operational Error Amplifier

• Digital Soft Start Ramp

• Dynamic Reference Injection

• Accurate Total Summing Current Amplifier(Patent #US6683441)

• Dual High Impedance Differential Voltage and Total Current Sense

Amplifiers

• Phase-to-Phase Dynamic Current Balancing

• True Differential Current Balancing Sense Amplifiers for Each Phase

• Adaptive Voltage Positioning (AVP)

• Switching Frequency Range of 300 kHz – 750 kHz

• Vin range 4.5 V to 25 V

• Start-Up into Pre-Charged Loads While Avoiding False OVP

• UltraSonic Operation

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

(Patent #US7057381)

onsemi.com

www.

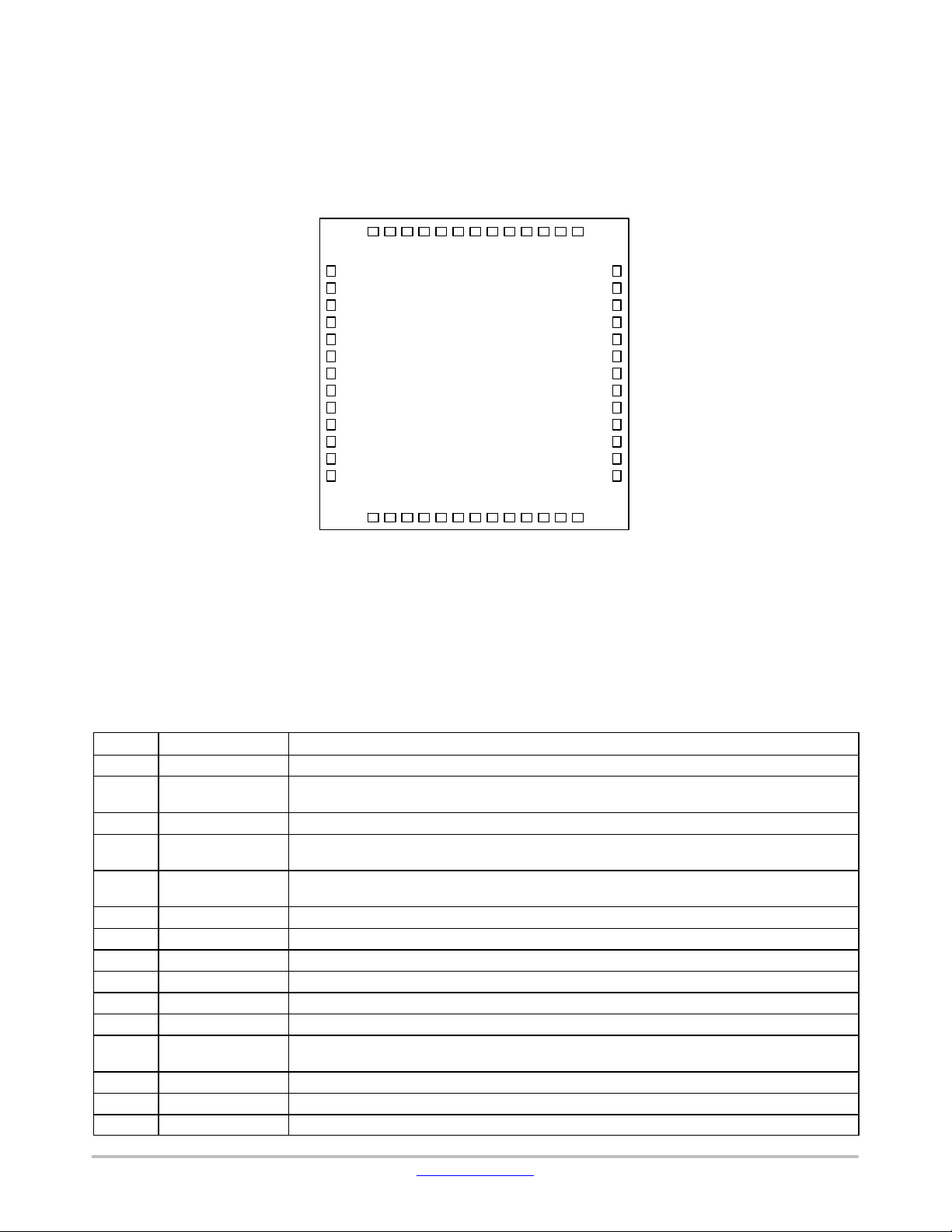

521

QFN52

MN SUFFIX

CASE 485BE

MARKING DIAGRAM

NCP81246

FAWLYYWW

G

NCP81246 = Specific Device Code

F = Wafer Fab

A = Assembly Site

WL = Lot ID

YY = Year

WW = Work Week

G = Pb-Free Package

ORDERING INFORMATION

Device Package Shipping

NCP81246MNTXG QFN52

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

5000 / Tape & Ree

†

Single-Phase Rail Features

• Enhanced RPM Control System

• Ultra Low Offset IOUT Monitor

• Dynamic VID Feed-Forward

• Programmable Droop Gain

• Zero Droop Capable

Semiconductor Components Industries, LLC, 2017

February, 2018 − Rev. 6

• Thermal Monitor

• UltraSonic Operation

• Adjustable Vboot

• Digitally Controlled Operating Frequency

1 Publication Order Number:

NCP81246/D

Page 2

SKT_SNS+

SKT_SNS*

Batt chrgr

NCP81246

+5 V

+5 V

VCC

VSP

VSN

COMP

ILIM

IOUT

TSENSE

V

PU

NTC

V

PU

VRHOT

V

PU

SDIO

ALERT

SCLK

PSYS

GND

PVCC

BST

HG

SW

CSP

CSN

LG

V

IN

VCC_Rail1

NTC

SKT_SNS+

SKT_SNS*

SKT_SNS+

SKT_SNS*

V

TSENSE

BST

HG

NCP81246

NTC

IOUT

VSP

VSN

DIFFOUT

FB

COMP

EN

V

VRRDY

IN

VRMP

VSP

VSN

COMP

IOUT

ILIM

SW

CSP1

BST

HG

SW

CSP2

CSREF

CSSUM

ILIM

CSCOMP

PWM

DRON

CSP

CSN

LG

LG

NTC

VRDV

BST

PWM

HG

SW

EN

VCC

LG

NCP81253

V

IN

IN

VCC_Rail2

V

IN

VCC_Rail3

NTC

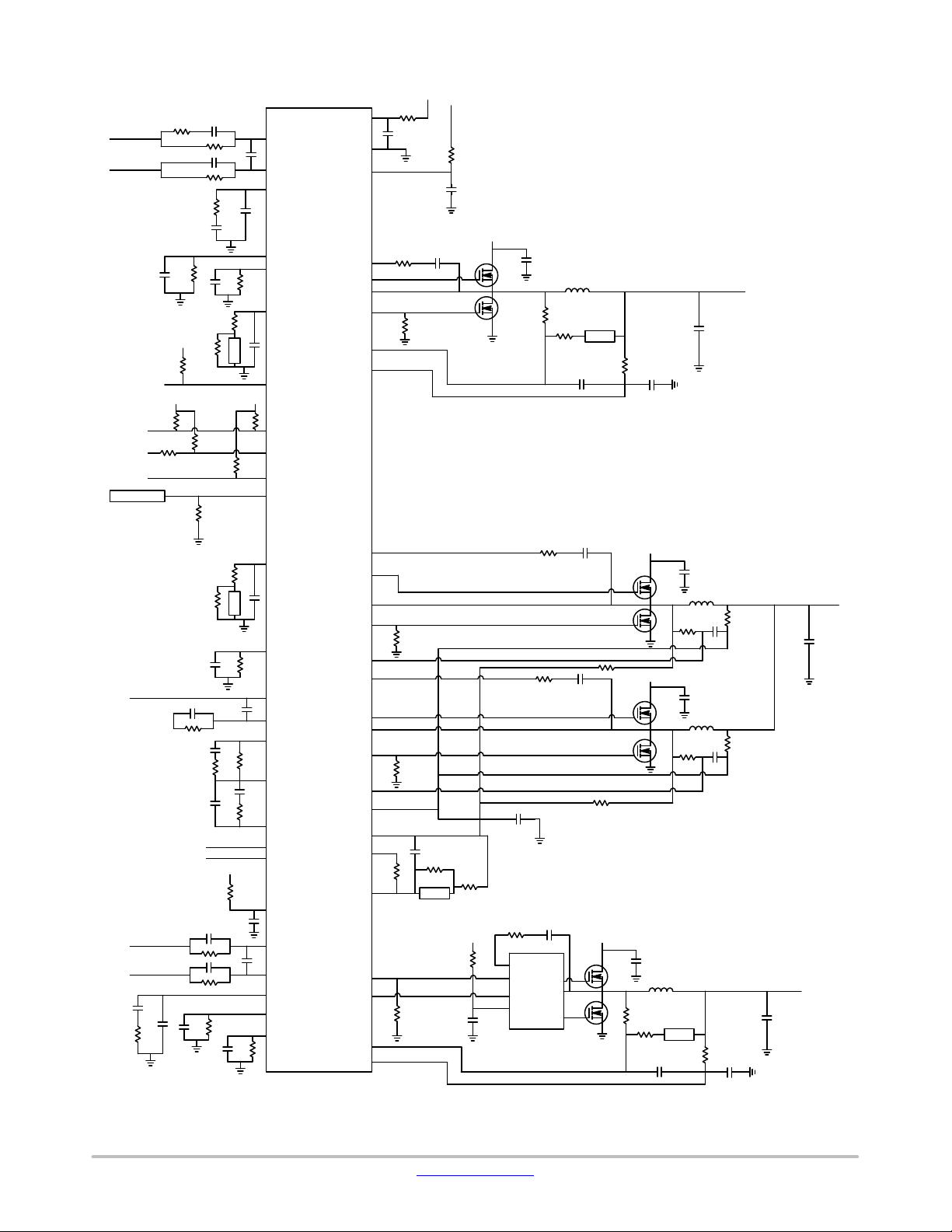

Figure 1. Application Schematic

www.onsemi.com

2

Page 3

NCP81246

VR_HOT#

SDIO

ALERT#

SCLK

VR_RDY

ROSC

ICCMAX_2PH

ICCMAX_1A

ICCMAX_1B

ADDR_VBOOT

TSENSE_2PH

TSENSE_1A

PSYS/TSENSE_1B

VRAMP

Thermal

Monitor

ENABLE

ENABLE

(VSP−VSN)

IOUT_2ph

IOUT_1a

IOUT_1b

VR Ready

Logic

Intel pro-

prietary

interface

Interface

& Logic

MUX

DRVON

PS#

ADC

OCP

OVP

Data

Registers

ENABLE

PS#

Oscillator

& RAMP

Generators

VRMP

VSP VSN

OVP

OVP

DAC

DAC

Feed-Forward

Current

Sense

OVP

AMP

MAX

OVP

DRVON

DIFF

AMP

−

+

+

−

DAC

Error

AMP

1.3 V

1.3 V

Buffer

IOUT

S

VSP

VSN

S

CSCOMP

−

+

Over-Current

Programming

Over-Current

Comparators

CSREF

VSP_2PH

VSN_2PH

DIFFOUT_2PH

FB_2PH

COMP_2PH

CSCOMP_2PH

CSSUM_2PH

CSREF_2PH

ILIM_2PH

OCP

IOUT_2PH

Current

Monitor

DRVON

VCC

EN

PVCC

GND

UVLO&EN

Comparators

ENABLE

OVP

OCP

PS#

PWM

Generators

PVM2

PS#

Power

State

Gate

COMP

PVM1

Zero Current

Detection

Current Balance

Amplifiers

IPH2

IPH1

ADDR_VBOOT

Config

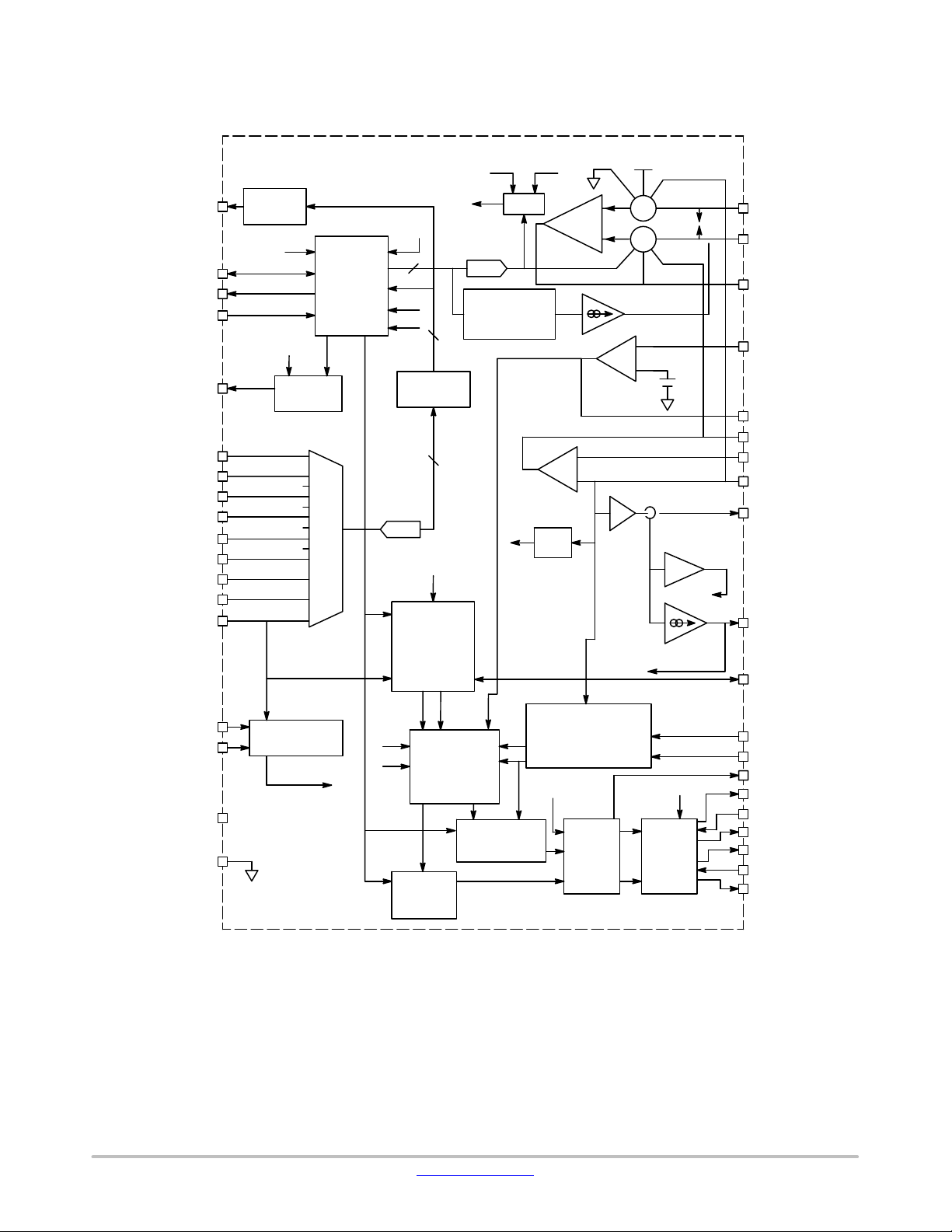

Figure 2. 2-Phase Rail Block Diagram

PVCC

Gate

Drivers

CSP2_2PH

CSP1_2PH

PWM

HG1

SW1

LG1

HG2

SW2

LG2

www.onsemi.com

3

Page 4

NCP81246

A

B

From Intel

proprietary

interface

Interface

VRMP

FREQ

DAC

DAC

Generator

DRVON

RAMP

DAC

Feed-Forward

COMP

PWM

Generator

RAMP

PWM

PS#

OVP

CURR

OCP

gm

Zero

Current

Detection

DAC Feed-Forward Current

DAC

OVP

OCP

+

AV = 1

OVP REF

OCP REF

IOUT

VSN

+

S

VSP

−

Droop

Current

+

Current

−

Sense AMP

Over-Current Programming

Over-Current

Comparators

Current

Monitor

ADDR_VBOOT

Config

Offset

Adjust

Gate

Driver

PVCC

Gate

Driver

PVCC

VSN_1x

VSP_1x

COMP_1x

CSP_1x

CSN_1x

ILIM_1x

IOUT_1x

HG3

SW3

LG3

PWM

HG2

SW2

LG2

1-Phase

Only

1-Phase

Only

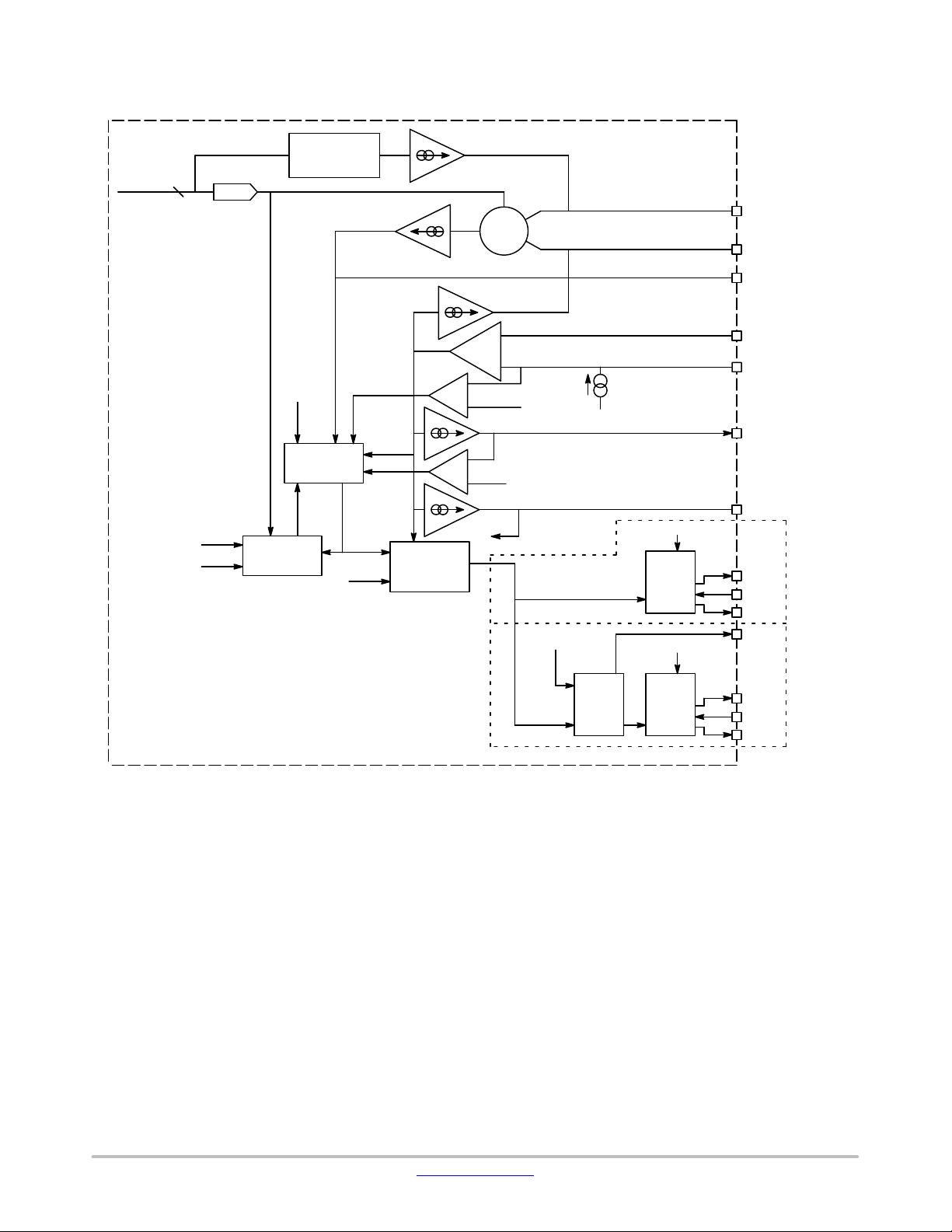

Figure 3. Single-Phase Block Diagram

www.onsemi.com

4

Page 5

IOUT_2ph

DIFFOUT_2ph/ICCMAX_2ph

FB_2ph

COMP_2ph

ILIM_2ph

CSCOMP_2ph

CSSUM_2ph

CSREF_2ph

CSP2_2ph

CSP1_2ph

TSENSE_2ph

VRMP

VCC

NCP81246

VSN_2ph

VSP_2ph

PSYS

VSP_1b

VSN_1b

COMP_1b

ILIM_1b

CSN_1b

CSP_1b

52515049484746454443424140

1

2

3

4

5

6

7

8

9

10

11

12

13

NCP81246

TAB: GROUND

(Not to Scale)

IOUT_1b

VR_RDYENPWM/ADDR_VBOOT

39

DRON

38

SCLK

37

ALERT#

36

SDIO

35

VR_HOT#

34

IOUT_1a

33

CSP_1a

32

CSN_1a

31

ILIM_1a

30

COMP_1a

29

VSN_1a

28

VSP_1a

27

TSENSE_1a

14151617181920212223242526

HG1

BST1

SW1

LG1/ROSC

PVCC

HG2

SW2

BST2

LG2/ICCMAX_1a

LG3/ICCMAX_1b

SW3

HG3

BST3

Figure 4. Pin Configuration

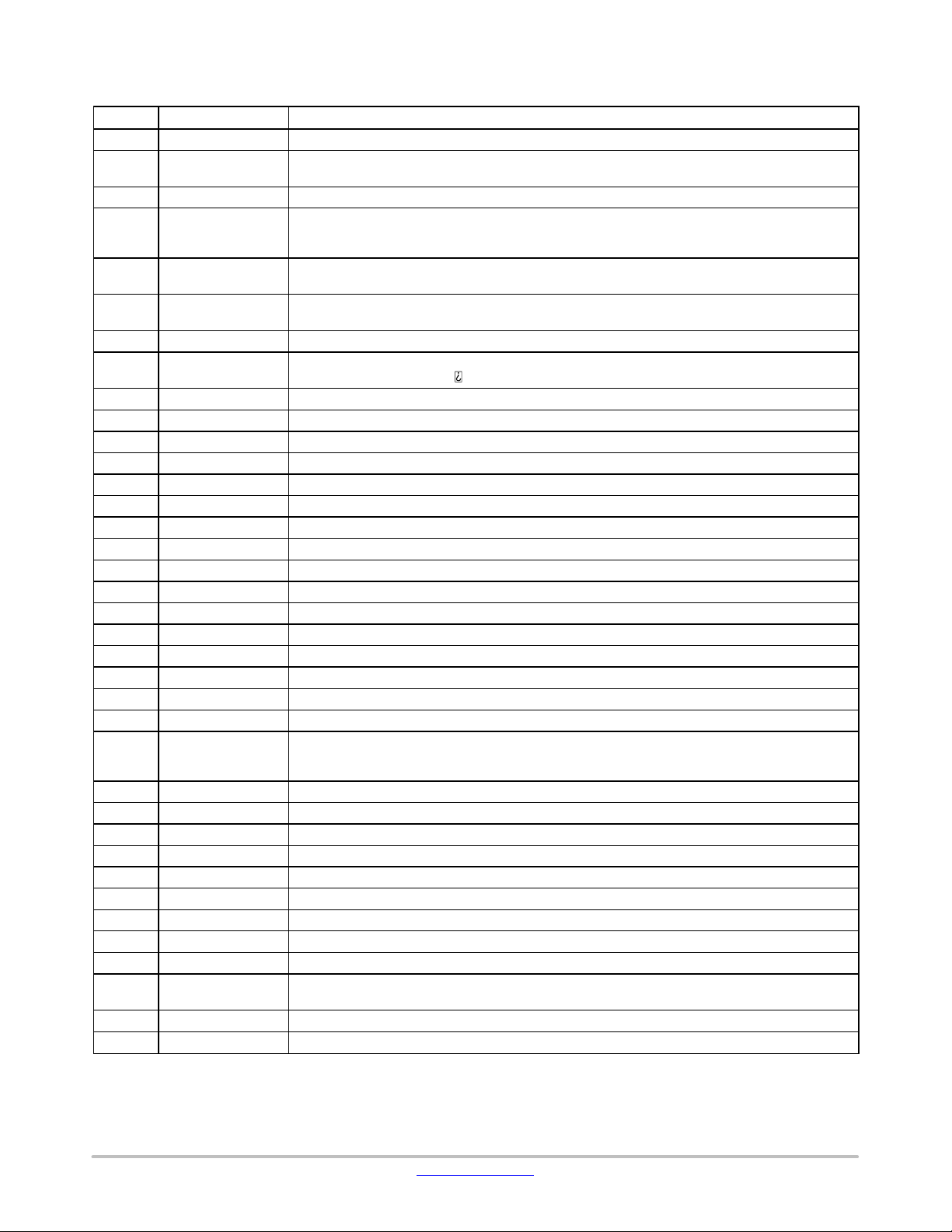

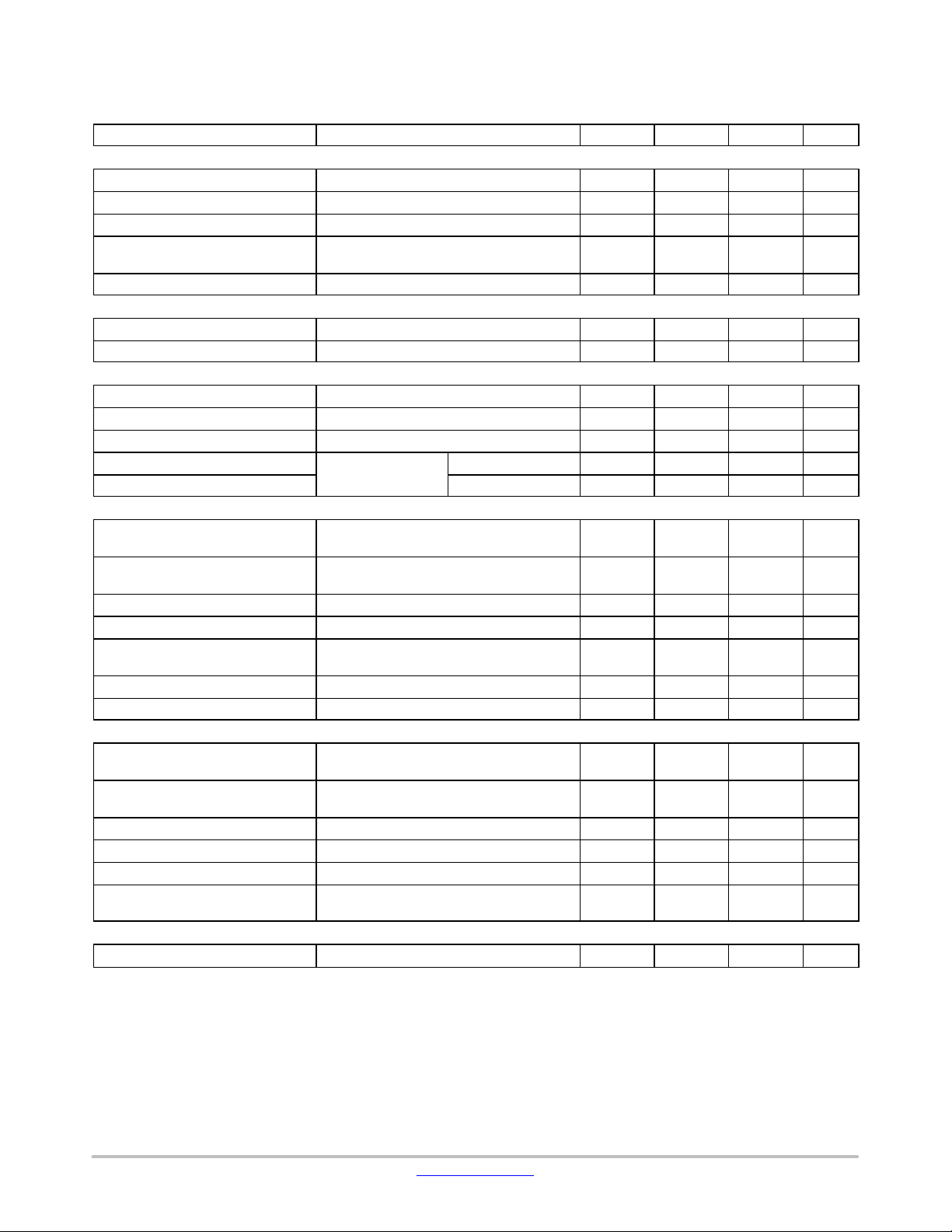

Table 1. NCP81246 PIN DESCRIPTIONS

Pin No.

1 IOUT_2ph A resistor to ground programs IOUT gain for the two-phase regulator.

2 DIFFOUT_2ph/

3 FB_2ph Error amplifier voltage feedback for two-phase regulator.

4 COMP_2ph Output of the error amplifier and the inverting inputs of the PWM comparators for two-phase

5 ILIM_2ph Over-current threshold setting − programmed with a resistor to CSCOMP_2ph for two-phase

6 CSCOMP_2ph Output of total-current-sense amplifier for two-phase regulator.

7 CSSUM_2ph Inverting input of total-current-sense amplifier for two-phase regulator.

8 CSREF_2ph Total-current-sense amplifier reference voltage input for two-phase regulator.

9 CSP2_2ph Non-inverting input to current-balance amplifier for Phase 2 of the two-phase regulator.

10 CSP1_2ph Non-inverting input to current-balance amplifier for Phase 1 of the two-phase regulator.

11 TSENSE_2ph Temperature sense input for the two-phase regulator.

12 VRMP Feed-forward input of Vin for the ramp-slope compensation. The current fed into this pin is used to

13 VCC Power for the internal control circuits. A decoupling capacitor is connected from this pin to ground.

14 BST1 High-side bootstrap supply for Phase 1 of the two-phase regulator.

15 HG1 High-side FET gate driver output for Phase 1 of the two-phase regulator.

Symbol Description

ICCMAX_2ph

Output of the two-phase regulator’s differential remote sense amplifier.

During start-up, the two-phase regulator’s ICCMAX is programmed with a pull-down on this pin.

regulator.

regulator.

control the ramp of the PWM slopes.

www.onsemi.com

5

Page 6

NCP81246

Table 1. NCP81246 PIN DESCRIPTIONS (continued)

Pin No. DescriptionSymbol

16 SW1 Current return for high-side FET gate driver for Phase 1 of the two-phase regulator.

17 LG1/ROSC Low-side FET gate driver output for Phase 1 of the two-phase regulator.

18 PVCC Power supply for all three internal FET gate drivers.

19 LG2/ICCMAX_1a Low-side FET gate driver output for Phase 2 of the two-phase regulator, or output of single-phase

20 SW2 Current return for high-side FET gate driver for Phase 2 of the two-phase regulator, or for

21 HG2 High-side FET gate driver output for Phase 2 of the two-phase regulator, or for single-phase

22 BST2 High-side bootstrap supply for Phase 2 of the two-phase regulator, or for single-phase regulator 1b.

23 LG3/ICCMAX_1b Low-side FET gate driver output for single-phase regulator 1a.

24 SW3 Current return for high-side FET gate driver for single-phase regulator 1a.

25 HG3 High-side FET gate driver output for single-phase regulator 1a.

26 BST3 High-side bootstrap supply for single-phase regulator 1a.

27 TSENSE_1a Temperature sense input for the single-phase regulators.

28 VSP_1a Differential Output Voltage Sense Positive for single-phase regulator 1a.

29 VSN_1a Differential Output Voltage Sense Negative for single-phase regulator 1a.

30 COMP_1a Compensation for single-phase regulator 1a.

31 ILIM_1a A resistor to ground programs the current-limit for single-phase regulator 1a.

32 CSN_1a Differential current sense negative for single-phase regulator 1a.

33 CSP_1a Differential current sense positive for single-phase regulator 1a.

34 IOUT_1a A resistor to ground programs IOUT gain for single-phase regulator 1a.

35 VR_HOT# Thermal logic output for over temperature.

36 SDIO Serial VID data interface

37 ALERT# Serial VID ALERT#

38 SCLK Serial VID clock

39 DRON Bi-directional FET driver enable

40 PWM/

ADDR_VBOOT

41 EN Enable. High enables all three rails.

42 VR_RDY VR_RDY indicates all three rails are ready to accept Intel proprietary interface commands.

43 IOUT_1b A resistor to ground programs IOUT gain for single-phase regulator 1b.

44 CSP_1b Differential current sense positive for single-phase regulator 1b.

45 CSN_1b Differential current sense negative for single-phase regulator 1b.

46 ILIM_1b A resistor to ground programs the current-limit for single-phase regulator 1b.

47 COMP_1b Compensation for single-phase regulator 1b.

48 VSN_1b Differential Output Voltage Sense Negative for single-phase regulator 1b.

49 VSP_1b Differential Output Voltage Sense Positive for single-phase regulator 1b.

50 PSYS/TSENSE_1b System power signal input. Resistor to ground for scaling /

51 VSP_2ph Differential Output Voltage Sense Positive for the two-phase regulator.

52 VSN−2ph Differential Output Voltage Sense Negative for the two-phase regulator.

During start-up ROSC is programmed with a pull-down resistor on this line.

regulator 1b.

During start-up, regulator 1a’s ICCMAX is programmed with a pull-down on this pin.

single-phase regulator 1b.

regulator 1b.

During start-up, regulator 1b

PWM output for phase 2 of the two-phase regulator or single-phase regulator 1b.

During start-up, a resistor to ground programs Intel proprietary interface address and VBOOT

options for all three rails.

Temperature sense input for the single-phase regulators.

s ICCMAX is programmed with a pull-down on this pin.

www.onsemi.com

6

Page 7

NCP81246

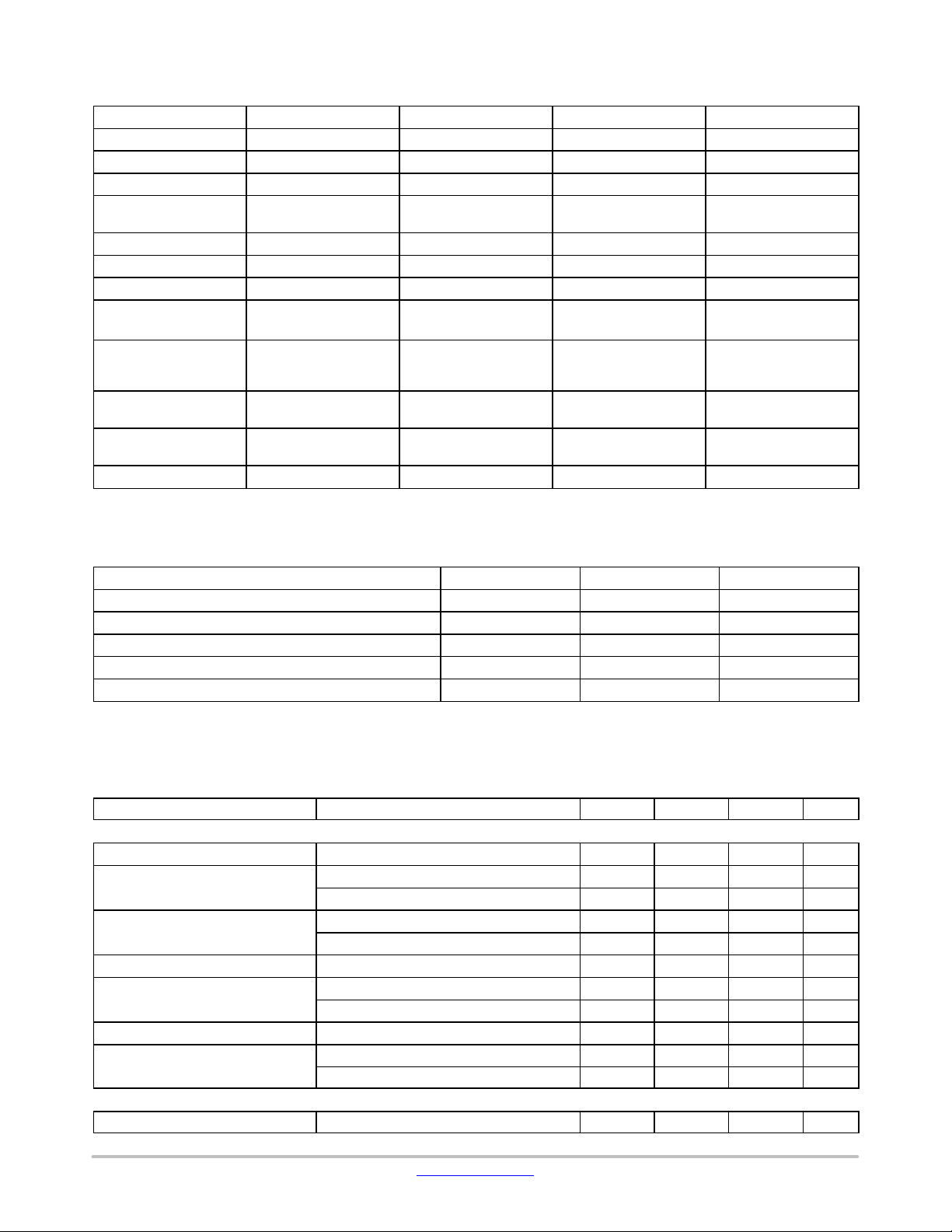

Table 2. ABSOLUTE MAXIMUM RATINGS

Pin Symbol

COMP_2ph VCC + 0.3 V −0.3 V 2mA 2mA

CSCOMP_2ph VCC + 0.3 V −0.3 V 2mA 2mA

VSN_2ph GND + 0.3 V GND – 0.3 V 1mA 1mA

DIFFOUT_2ph /

IccMax_2ph

VCC 6.5 V −0.3 V 100 mA 100 mA

PVCC 6.5 V −0.3 V 100 mA 100 mA

VRMP 25 V −0.3 V 100 mA 100 mA

SW_x 35 V

BST_x 35 V wrt / GND

40 V ≤ 50 ns wrt / GND

LG_x / ICCMAX_x VCC + 0.3 V −0.3 V

HG_x BST + 0.3 V −0.3 V wrt / SW

All Other Pins VCC + 0.3 V −0.3 V 100 mA 100 mA

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

*All signals referenced to GND unless noted otherwise.

V

MAX

V

MIN

I

SOURCE

I

SINK

VCC + 0.3 V −0.3 V 2mA 2mA

−5 V 100 mA 100 mA

40 V ≤ 50 ns

−0.3 V wrt / SW 100 mA 100 mA

6.5 V wrt / SW

100 mA 100 mA

−2 V ≤ 200 ns

100 mA 100 mA

−2 V ≤ 200 ns wrt /SW

Table 3. THERMAL INFORMATION

Description

Thermal Characteristic QFN Package (Note 1)

Operating Junction Temperature Range (Note 2) T

Operating Ambient Temperature Range −40 to +100

Maximum Storage Temperature Range T

Moisture Sensitivity Level QFN Package MSL 1

*The maximum package power dissipation must be observed.

1. JESD 51−5 (1S2P Direct-Attach Method) with 0 LFM

2. JESD 51−7 (1S2P Direct-Attach Method) with 0 LFM

Symbol Value Unit

R

q

JA

J

68

−40 to +125

_C/W

_C

_C

STG

− 40 to +150

_C

Table 4. ELECTRICAL CHARACTERISTICS − GENERAL

(Unless otherwise stated: −40°C<TA< 100°C; 4.75 V < VCC< 5.25 V; C

Parameter

Test Conditions Min Typ Max Unit

BIAS SUPPLY

VCC Voltage Range

VCC Quiescent Current

4.75 − 5.25 V

EN = High − 26 − mA

EN = Low − 20 −

VCC UVLO

VCC Rising − − 4.5 V

VCC Falling 4 − − V

PVCC Voltage Range 4.75 − 5.25 V

PVCC Quiescent Current

EN = Low (Shutdown) − − 1

EN = High, No Switching − − 1.5 mA

VRAMP Voltage Range 5 − 20 V

VRAMP UVLO

VRAMP Rising − − 4.25 V

VRAMP Falling 3 − − V

ENABLE INPUT

Upper Threshold 0.8 − − V

VCC

= 0.1 mF)

mA

mA

www.onsemi.com

7

Page 8

NCP81246

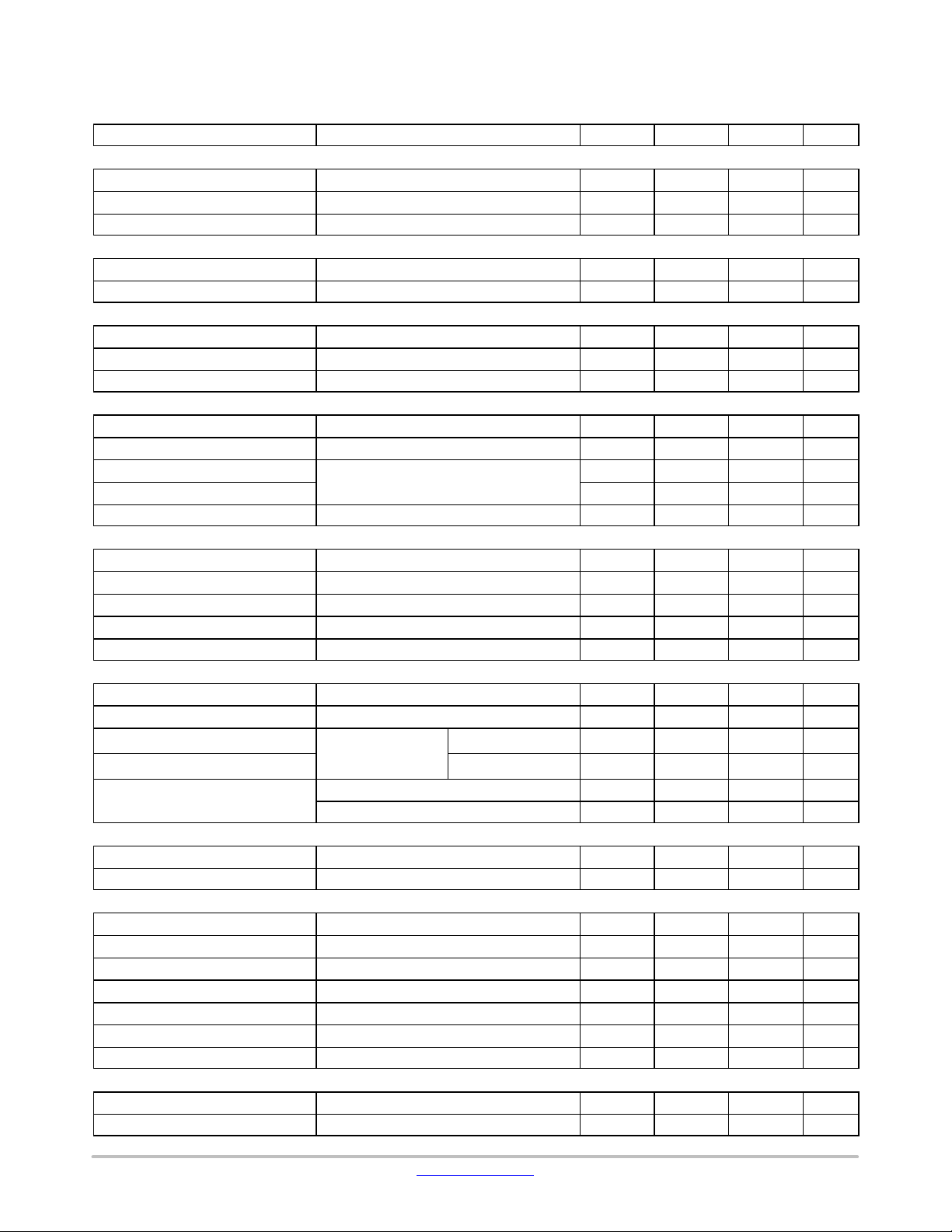

Table 4. ELECTRICAL CHARACTERISTICS − GENERAL (continued)

(Unless otherwise stated: −40°C<TA< 100°C; 4.75 V < VCC < 5.25 V; C

Parameter UnitMaxTypMinTest Conditions

ENABLE INPUT

Lower Threshold

Enable Delay Time − − 2.5 ms

Enable High Input Leakage Current − − 0.5

PHASE DETECTION

CSP Pin Threshold Voltage

Phase Detect Timer − 1.75 − ms

DAC SLEW RATE

Soft Start Slew Rate

Slew Rate Slow − 15 −

Slew Rate Fast − 30 −

DRVON

Output High Voltage 3 − − V

Output Low Voltage − − 0.1 V

Rise Time

Fall Time − 2.5 − ns

Internal Pull-Down Resistance EN = Low − 69.5 −

T

SENSE

Bias Current −40°C to 100°C 115 120 125

Alert# Assert Threshold − 485 − mV

Alert# De-Assert Threshold − 513 − mV

VR_Hot Assert Threshold − 466 − mV

VR_Hot De-Assert Threshold − 490 − mV

VR_Rdy OUTPUT

Output Low Saturation Voltage

Output Leakage Current When High VR_RDY = 5 V −1 − 1

Rise Time 1kW Pull-Up to

Fall Time

VR_Rdy Delay Falling

VR_Hot#

Output Low Saturation Voltage

Output Leakage Current When High VR_HOT = 5 V −1 − 1

ADC

Linear Input Voltage Range

Differential Non-Linearity (DNL) 8-Bits − − 1 LSB

Total Unadjusted Error (TUE) −1 − 1 %

Conversion Time − 10 −

Conversion Rate − 33 − kHz

Power Supply Sensitivity − ±1 − %

Round Robin − 90 −

IccMax

Bias Current 9.7 10 10.3

Full scale input voltage − 2.0 − V

− − 0.3 V

− − 4.5 V

− 15 −

CL (PCB) = 20 pF

DVo = 10% to 90%

IVR_RDY = −4 mA − − 0.3 V

3.3V

C

= 45 pF

TOT

Due to OVP − 0.3 −

Due to OCP − 50 −

IVR_HOT = −4 mA − − 0.3 V

0 − 2 V

DVo = 10% to 90%

DVo = 90% to 10%

VCC

= 0.1 mF)

mV/ms

mV/ms

mV/ms

− 100 − ns

− 110 − ns

− 20 − ns

mA

kW

mA

mA

ms

ms

mA

ms

ms

mA

www.onsemi.com

8

Page 9

NCP81246

Table 4. ELECTRICAL CHARACTERISTICS − GENERAL (continued)

(Unless otherwise stated: −40°C<TA< 100°C; 4.75 V < VCC < 5.25 V; C

Parameter UnitMaxTypMinTest Conditions

OVP and UVP

Absolute Over Voltage Threshold

Over Voltage Threshold Above DAC VSP−VSN−VID Rising 360 400 440 mV

Over Voltage Delay VSP−VSN Rising to PWM Low − 25 − ns

Under Voltage Threshold Below

DAC

Under Voltage Delay − 5 −

OSCILLATOR

Switching Frequency Range 300 − 750 kHz

Switching Frequency Accuracy − ±10 − %

PWM OUTPUT

Output High Voltage

Output Mid Voltage No Load, Power State 2 1.9 2 2.1 V

Output Low Voltage

Rise Time

Fall Time

HIGH-SIDE MOSFET DRIVER

Pull-Up Resistance, Sourcing

Current

Pull-Down Resistance, Sinking

Current

HG Rise Time PVCC = 5 V, CL = 3 nF, BST−SW = 5 V 6 12 27 ns

HG Fall Time PVCC = 5 V, CL = 3 nF, BST−SW = 5 V 6 11 15 ns

HG Turn ON Propagation Delay

tpdhDRVH

SW Pull-Down Resistance SW to GND − 2 −

HG Pull-Down Resistance HG to SW, BST − SW = 0 V − 292 −

LOW-SIDE MOSFET DRIVER

Pull-Up Resistance, Sourcing

Current

Pull-Down Resistance, Sinking

Current

LGx Rise Time 3 nF Load 6 18 27 ns

LGx Fall Time 3 nF Load 6 12 25 ns

Dead-Time − − −

LGx Turn-On Propagation Delay

tpdhDRVL

BOOST RECTIFIER

RON

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

3. Based on design or characterisation data, not in production test.

During Soft Start − 2.0 − V

VSP−VSN−VID Falling − 300 − mV

Sourcing 500 mA

Sinking 500 mA

CL (PCB) = 50 pF

BST = PVCC − 1.4 2.5

BST = PVCC − 0.9 2

CL = 3 nF 13 16 21 ns

− 1.6 3.5

− 0.5 1.5

C

= 3 nF − 14 20 ns

LOAD

EN = Low or EN = High and DRVL = HIGH 5 13 22

DVo = 10% to 90%

DVo = 90% to 10%

VCC

= 0.1 mF)

ms

VCC−0.2 − − V

− − 0.7 V

− 5 − ns

− 5 − ns

W

W

kW

kW

W

W

W

www.onsemi.com

9

Page 10

NCP81246

Table 5. ELECTRICAL CHARACTERISTICS − 2-PHASE RAIL SPECIFIC

(Unless otherwise stated: −40°C<T

Parameter

DIFFERENTIAL SUMMING AMP

Input Bias Current

VSP Input Voltage Range −0.3 − 3 V

VSN Input Voltage Range −0.3 − 0.3 V

−3dB Bandwidth

Closed Loop DC Gain VSP − VSN = 0.5 V to 1.3 V − 1 − V/V

ERROR AMPLIFIER

Input Bias Current

Open Loop DC Gain

Open Loop Unity Gain Bandwidth

Slew Rate

Maximum Output Voltage I

Minimum Output Voltage I

CURRENT SUMMING AMPLIFIER

Input Bias Current CSSUM = CSREF = 1.0 V −8 − 8

Offset Voltage (Vos) (Note 4) −2.5 − 2.5 mV

Open Loop Gain − 80 − dB

Open Loop Unity Gain Bandwidth

Maximum Output Voltage I

Minimum Output Voltage I

CURRENT BALANCE AMPLIFIERS

Input Bias Current CSP1/2 = CSREF = 1.2 V −50 − 50 nA

Common Mode Input Voltage Range CSP1/2 = CSREF 0 − 2.3 V

Differential Mode Input Voltage

Range

Input Offset Voltage Matching CSP1/2 = CSREF = 1.2 V

Current Sense Amplifier Gain 0 V < CSP1/2 − CSREF < 0.1 V 5.7 6 6.3 V/V

Multiphase Current Sense Gain

Matching

−3dB Bandwidth − 6 − MHz

OVER−CURRENT PROTECTION

I

Threshold Current

LIM

(Delayed OCP Shutdown)

I

Threshold Current

LIM

(Immediate OCP Shutdown)

Shutdown Delay Immediate − 300 − ns

Shutdown Delay Delayed − 50 −

I

Output Voltage Offset

LIM

< 100°C; 4.75 V < VCC < 5.25 V; C

A

VCC

= 0.1 mF)

Test Conditions Min Typ Max Unit

VSP = VSN = 1.3 V −25 − 25 nA

CL = 20 pF, RL = 10 kW

− 22.5 − MHz

@1.3 V −400 − 400 nA

CL = 20 pF, RL = 10 kW

CL = 20 pF, RL = 10 kW

DVIN = 100 mV, G = −10 V/V

= 1.5 V to 2.5 V, CL = 20 pF,

DV

OUT

= 10 kW

R

L

= 2.0 mA 4 − − V

SOURCE

= 2.0 mA − − 0.9 V

SINK

CL = 20 pF, RL = 10 kW

= 2.0 mA 3.5 − − V

SOURCE

= 0.5 mA − − 0.1 V

SINK

− 80 − dB

− 20 − MHz

− 5 −

− 10 − MHz

CSREF = 1.2 V −100 − 100 mV

−1.6 − 1.6 mV

Measured from Average.

CSP1/2 = CSREF = 10 mV to 30 mV −3.5 − 3.5 %

PS0 8.5 10 11.5

PS1, PS2, PS3 − 6.67 −

PS0 13 15 17

PS1, PS2, PS3 − 10 −

I

sourcing 15 mA

LIM

Measured relative to CSREF

−1.5 − 1.5 mV

V/ms

mA

mA

mA

mA

mA

ms

www.onsemi.com

10

Page 11

NCP81246

Table 5. ELECTRICAL CHARACTERISTICS − 2-PHASE RAIL SPECIFIC (continued)

(Unless otherwise stated: −40°C<TA< 100°C; 4.75 V < VCC < 5.25 V; C

Parameter UnitMaxTypMinTest Conditions

Iout OUTPUT

Output Offset Current

Output Source Current

Current Gain

V

= 5 V − − 0.25

ILIM

I

Source Current = 20 mA

LIM

I

/ I

, R

IOUT

ILIM

DAC = 0.8 V, 1.25 V, 1.52 V

= 20 kW R

ILIM

MODULATORS

0% Duty Cycle Comp Voltage for PWM Held Low − 1.3 − V

Comp Voltage for PWM Held High

100% Duty Cycle

VRAMP = 12 V

PWM Ramp Duty Cycle Matching Comp = 2 V, PWM TON Matching − ±3 − %

PWM Phase Angle Error − ±15 − °

Ramp Feed Forward Voltage Range 5 − 20 V

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

4. Based on design or characterisation data, not in production test.

Table 6. ELECTRICAL CHARACTERISTICS − SINGLE PHASE RAIL SPECIFIC

(Unless otherwise stated: −40°C<TA< 100°C; 4.75 V < VCC < 5.25 V; C

Parameter Test Conditions Min Typ Max Unit

ERROR AMPLIFIER

Input Bias Current −25 − 25 nA

VSP Input Voltage Range −0.3 − 3 V

VSN Input Voltage Range −0.3 − 0.3 V

gm 1.3 1.6 2.0 mS

Output Offset −15 − 15

Open Loop Gain

Source Current

Sink Current

−3dB Bandwidth

CURRENT SENSE AMPLIFIER

Input Bias Current CSP = CSN = 1.2 V −50 − 50 nA

Common Mode Input Voltage Range CSP = CSN 0 − 2.3 V

Common Mode Rejection CSP = CSN = 0.5 V to 1.2 V 60 80 − dB

Differential Mode Input Voltage

Range

Gain I

Gain VSP and I

Output 0V ≤ CSP−CSN ≤ 0.1 V 0.96 1 1.04 mS

OUT

Outputs 0V ≤ CSP−CSN ≤ 0.1 V 0.96 1 1.04 mS

LIM

−3dB Bandwidth − 6 − MHz

OVER-CURRENT PROTECTION

Output Offset Current V

Maximum Output Current 0V ≤ V

Maximum Output Voltage

Activation Threshold Voltage 1.28 1.3 1.32 V

Activation Delay − 250 − ns

I

OUT

Output Offset Current 0V ≤ V

ZL = (1 nF +1 kW) || 10 pF

DVIN = −200 mV

DVIN = 200 mV

ZL = (1 nF +1 kW) || 10 pF

CSN = 1.2 V −100 − 100 mV

= 1.3 V −1.5 − 1.5

ILIM

≤ 1.3 V 130 − −

ILIM

I

= 100 mA

ILIM

≤ 2.0 V −250 − 250 nA

IOUT

IOUT

VCC

= 5 kW

VCC

= 0.1 mF)

= 0.1 mF)

mA

− 200 −

mA

9.5 10 10.5 A/A

− 2.6 − V

mA

− 73 − dB

− 200 −

− 200 −

mA

mA

− 20 − MHz

mA

mA

1.4 − − V

www.onsemi.com

11

Page 12

NCP81246

Table 6. ELECTRICAL CHARACTERISTICS − SINGLE PHASE RAIL SPECIFIC (continued)

(Unless otherwise stated: −40°C<TA< 100°C; 4.75 V < VCC < 5.25 V; C

Parameter UnitMaxTypMinTest Conditions

I

OUT

Maximum Output Current 0V ≤ V

Maximum Output Voltage

I

IOUT

≤ 2.0 V 130 − −

IOUT

= 100 mA

DROOP

Output Offset Current 1A

Output Offset Current 1B 0V ≤ V

Maximum Output Current 0V ≤ V

Maximum Output Voltage

0V ≤ V

I

DROOP

≤ 1.8 V −1800 − 1800 nA

DROOP

≤ 1.8 V −900 − 900 nA

DROOP

≤ 1.8 V 130 − −

DROOP

= 100 mA

ZCD COMPARATOR

Offset Accuracy

Referred to CSP − CSN − ±1.5 − mV

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

VCC

= 0.1 mF)

mA

2.1 − − V

mA

1.8 − − V

DRVL

DRVH−SW

SW

t

fDRVL

t

pdhDRVH

t

rDRVH

V

TH

V

TH

NOTE: Timing is referenced to the 10% and the 90% points, unless otherwise stated.

Figure 5. Driver Timing Diagram

t

fDRVH

1 V

t

pdhDRVL

t

rDRVL

www.onsemi.com

12

Page 13

NCP81246

Table 7. STATE TRUTH TABLE

Error AMP

State

POR

0 < VCC < UVLO

Disabled

EN < Threshold

UVLO > Threshold

Start-Up Delay &

Calibration

EN > Threshold

UVLO > Threshold

DRON Fault

EN > Threshold

UVLO > Threshold

DRON < Threshold

Soft Start

EN > Threshold

UVLO > Threshold

DRON > High

Normal Operation

EN > Threshold

UVLO > Threshold

DRON > High

Over Voltage Low N/A DAC+OVP High

Over Current Low Operational Last DAC Code Low

Vout = 0 V Low: if Reg34h: bit 0 = 0;

VR_RDY Pin

N/A N/A N/A Resistive Pull

Low Low Disabled Low

Low Low Disabled Low

Low Low Disabled Resistive Pull

High Operational Active/No Latch High

High Operational Active/Latching High N/A

High: if Reg34h: bit 0 = 1;

Comp Pin

Clamped at

0.9 V

OVP & UVP DRON Pin

Disabled High, PWM

Down

Up

Outputs in Low

State

Method

of Reset

Driver Must

Release

DRON

to High

www.onsemi.com

13

Page 14

NCP81246

Controller

POR

VCC < UVLO

OVP

VCC > UVLO

Drive Off

OCP

Condition

Disable

EN = 0 EN = 1

Calibrate

2.5 ms and CAL DONE

Phase

Detect

VCCP > UVLO and DRON HIGH

0V

BOOT

Soft Start

Ramp

DAC = VID

Non-0 V

Soft Start

BOOT

Ramp

DAC = V

BOOT

VS > OVP

Normal

VR_RDY

VS > UVP VS < UVP

UVP

Figure 6. State Diagram

www.onsemi.com

14

Page 15

NCP81246

GENERAL

Configuration

The NCP81246 is a three-rail IMVP8 controller, with

three internal drivers. The NCP81246 is configured with the

Table 8 shows the available configurations, and the

pull-down resistor required on Pin 40 (PWM/

ADDR_VBOOT) to configure them.

two-phase, dual-edge controller providing V_Rail2.

Table 8. CONFIGURATIONS

2ph Ph1 Ph2 1ph A 1ph B

Addr

V

BOOT

(V)

D

RV1DRV2

PWM T

SENSE

R

(kW)

10 1 0 x x 2ph 0 0 x 1a 2 1 x N/A

16.2 1 1.2 x x 2ph 0 1.2 x 1a 2 1 x N/A

22.1 1 0 x x 2ph 0 0 x 1a 2 1.05 x N/A

28.7 1 0 x x 2ph 0 0 x 1a 2 0.95 x N/A

35.7 1 0 x x 2ph 0 0 x 1a 2 1 x N/A

43.2 1 1.2 x x 2ph 0 1.2 x 1a 2 1 x N/A

51.1 1 0 x x 2ph 0 0 x 1a 2 1.05 x N/A

61.9 1 0 x x 2ph 0 0 x 1a 2 0.95 x N/A

71.5 1 0 x x 2ph 2 1 x N/A

82.5 1 1.2 x x 2ph 2 1 x N/A

95.3 1 0 x x 2ph 2 1.05 x N/A

110 1 0 x x 2ph 2 0.95 x N/A

127 1 0 x x 2ph 3 0 x 1a 0 0 x 1b

143 1 1.2 x x 2ph 3 1.2 x 1a 0 1.2 x 1b

165 1 0 x x 2ph 3 0 x 1a 0 0 x 1b

187 1 0 x x 2ph 3 0 x 1a 0 0 x 1b

Addr

V

BOOT

(V)

D

RV3TSENSE

(P

(P

(P

(P

SYS

SYS

SYS

SYS

V

Addr

)

)

)

)

BOOT

D

(V)

0 0 x 1a

0 1.2 x 1a

0 0 x 1a

0 0 x 1a

RV2

PWM T

SENSE

(P

SYS

(P

(P

(P

(P

(P

(P

(P

SYS

SYS

SYS

SYS

SYS

SYS

SYS

))

)

)

)

)

)

)

)

Switching Frequency Fsw

FSW is programmed on start-up with a pull-down on the

LG1 pin.

Table 9. SWITCHING FREQUENCY

Resistor Rail1/Rail2 Rail3

6.81 kW

14 kW

21.5 kW

28.7 kW

750 kHz 750 kHz

600 kHz 600 kHz

450 kHz 600 kHz

300 kHz 450 kHz

Serial VID Interface (Intel proprietary interface)

For Intel proprietary interface communication details please contact Intel, Inc.

www.onsemi.com

15

Page 16

NCP81246

Ultra-Sonic Mode

Ultra-Sonic Mode forces a minimum switching frequency

above audible range when a rail is in DCM mode.

Two-Phase Rail Voltage Compensation

The remote Sense Amplifier output is applied to a Type III

compensation network formed by the error amplifier and

external tuning components. The non-inverting input of the

error amplifier is connected to the same reference voltage

used to bias the Remote sense amplifier output.

Two-Phase Rail Remote Sense Amplifier

A high performance high input impedance true

differential amplifier is provided to accurately sense the

output voltage of the regulator. The VSP and VSN inputs

should be connected to the regulator’s output voltage sense

points. The remote sense amplifier takes the difference of

the output voltage with the DAC voltage and adds the droop

voltage to

R

IN1

C

IN

V

R

IN2

BIAS

V

DIFFOUT

ǒ

+

V

VSP

ǒ

)

V

DROOP

* V

VSN

* V

Ǔ)ǒ

CSREF

1.3 V * V

Ǔ

DAC

Ǔ

)

(eq. 1)

This signal then goes through a standard error

compensation network and into the inverting input of the

error amplifier. The non-inverting input of the error

amplifier is connected to the same 1.3 V reference used for

the differential sense amplifier output bias.

Two-Phase Rail High Performance Voltage Error

Amplifier

A high performance error amplifier is provided for high

bandwidth transient performance. A standard type III

compensation circuit is normally used to compensate the

system.

C

R

−

+

F

F

COMP

ERROR AMP

C

F1

Figure 7. Standard Type III Compensation Circuit

www.onsemi.com

16

Page 17

NCP81246

Differential Current Feedback Amplifiers

Each phase of the two-phase rail has a low offset

differential amplifier to sense that phase current for current

balance and per phase OCP protection during soft-start.

The inputs to the CSNx and CSPx pins are high impedance

inputs. It is recommended that any external filter resistor

RCSN does not exceed 10 kW to avoid offset issues with

leakage current. It is also recommended that the voltage

SWNx

DCR LPHASE

Figure 8.

Two-Phase Rail Total Current Sense Amplifier

The NCP81246 uses a patented approach to sum the phase

currents into a single temperature compensated total current

signal. This signal is then used to generate the output voltage

droop, total current limit, and the output current monitoring

functions. The total current signal is floating with respect to

CSREF. The current signal is the difference between

CSCOMP and CSREF. The Rref(n) resistors sum the signals

sense element be no less than 0.5 mW for accurate current

balance. Fine tuning of this time constant is generally not

required. The individual phase current is summed into the

PWM comparator feedback this way current is balanced via

a current mode control approach.

L

CCSNRCSN

CSPx

12

CSNx

VOUT

R

CSN

PHASE

+

C

@ DCR

CSN

(eq. 2)

from the output side of the inductors to create a low

impedance virtual ground. The amplifier actively filters and

gains up the voltage applied across the inductors to recover

the voltage drop across the inductor series resistance (DCR).

Rth is placed near an inductor to sense the temperature of the

inductor. This allows the filter time constant and gain to be

a function of the Rth NTC resistor and compensate for the

change in the DCR with temperature.

R

CSN1

CSN2

SWN1

SWN2

REF1

10 W

R

REF2

10 W

R

R

PH1

PH2

The DC gain equation for the current sensing:

V

CSCOMP*CSREF

+*

Figure 9.

R

)

CS2

C

REF

1 nF

CSREF

CSSUM

R

CS1

R

CS1

R

PH

−

+

C

CS1

C

CS2

R

CS2

165 kW 75 kW

@R

TH

)R

TH

ǒ

@

I

OUT

Total

CSCOMP

R

R

220 kW

Ǔ

@ DCR

CS1

TH

(eq. 3)

www.onsemi.com

17

Page 18

NCP81246

Set the gain by adjusting the value of the RPH resistors.

The DC gain should be set to the output voltage droop. If the

voltage from CSCOMP to CSREF is less than 100 mV at

ICCMAX then it is recommend increasing the gain of the

CSCOMP amp. This is required to provide a good current

signal to offset voltage ratio for the ILIMIT pin. When no

droop is needed, the gain of the amplifier should be set to

provide ~100 mV across the current limit programming

resistor at full load. The NTC should be placed near the

closest inductor . The output voltage droop should be set with

the droop filter divider.

The pole frequency in the CSCOMP filter should be set

equal to the zero from the output inductor. This allows the

circuit to recover the inductor DCR voltage drop current

signal. C

CS1

and C

are in parallel to allow for fine tuning

CS2

of the time constant using commonly available values. It is

best to fine tune this filter during transient testing.

DCR @ 25 C

F

+

Z

2 @ p @ L

Two-Phase Rail Programming the Current Limit

°

Phase

(eq. 4)

The current limit thresholds are programmed with

a resistor between the ILIMIT and CSCOMP pins.

The ILIMIT pin mirrors the voltage at the CSREF pin and

mirrors the sink current internally to IOUT (reduced by the

IOUT Current Gain) and the current limit comparators.

The 100% current limit trips if the ILIMIT sink current

exceeds 10 mA for 50 ms. The 150% current limit trips with

minimal delay if the ILIMIT sink current exceeds 15 mA. Set

the value of the current limit resistor based on the

CSCOMP-CSREF voltage as shown below.

R

@R

TH

CS2

CS1

)

R

)R

TH

CS1

R

PH

@

10 m

ǒ

I

OUT

Total

@ DCR

Ǔ

(eq. 5)

R

LIMIT

R

+

or

R

LIMIT

CSCOMP*CSREF @ ILIMIT

+

10 m

(eq. 6)

V

Two-Phase Rail Programming DAC Feed-Forward

Filter

The DAC feed-forward implementation is realized by

having a filter on the VSN pin. Programming R

gain of the DAC feed-forward and C

provides the time

VSN

VSN

sets the

constant to cancel the time constant of the system per the

following equations. C

and R

is the output impedance of the system.

OUT

is the total output capacitance

OUT

VSN

C67

510 pF

12

VSS_SENSE

R68

2.1 kW

12

Figure 10.

+ C

R

VSN

@ R

OUT

R

OUT

@ 453.6 @ 10

@ C

OUT

R

VSN

OUT

+

C

VSN

6

(eq. 7)

(eq. 8)

Two-Phase Rail Programming DROOP

The signals CSCOMP and CSREF are differentially

summed with the output voltage feedback to add precision

voltage droop to the output voltage.

CSREF

CSSUM56

−

+

CSCOMP

7

Figure 11.

Droop + DCR @

R

R

Two-Phase Rail Programming IOUT

CS

PH

DROOP

(eq. 9)

The IOUT pin sources a current in proportion to the

ILIMIT sink current. The voltage on the IOUT pin is

monitored by the internal A/D converter and should be

scaled with an external resistor to ground such that a load

equal to ICC_MAX generates a 2 V signal on I

OUT

A pull-up resistor from 5 V VCC can be used to offset the

I

signal positive if needed.

OUT

@ DCR

(eq. 10)

Ǔ

R

+

IOUT

10 @

R

CS2

2.0 V @ R

R

@R

CS1

)

R

)R

CS1

R

PH

TH

TH

LIMIT

ǒ

@

I

OUT

ICC_MAX

.

www.onsemi.com

18

Page 19

NCP81246

Programming ICC_MAX

A resistor to ground on the IMAX pin programs these

registers at the time the part is enabled. 10 mA is sourced

from these pins to generate a voltage on the program resistor .

The resistor value should be no less than 2 kW.

Design Note:

Since ICC_MAX is multi-functioned with

LG, it is crucial that the LS FET is not turned on during

ICC_MAX programming. Source current and maximum

Table 10. ICCMAX_1PH

Resistor 00h (IA) Resistor Other 02h/03h

6.8 kW

11 kW

14.1 kW

17.2 kW

22.6 kW

26.5 kW

29.5 kW

32.8 kW

36 kW

23

24

25

28

29

30

34

35

36

resistor value must not produce a voltage at the FET gate that

will turn it on. Keeping the voltage less than 400 mV should

be safe.

IccMax_2ph:

R

IccMax2ph

IccMax

+

2ph

127

) 32

@ 200 kW

(eq. 11)

IccMax_1ph: See Table 10 below.

5kW

7.8 kW

11 kW

14.1 kW

17.2 kW

20.3 kW

23.4 kW

3

4

5

6

7

8

9

IccMax_2ph

VSP

VSN

COMPFBDIFFOUT

−

EA

+

+

−

−

+

R

D

Detect

on

R

OSC

Detect

Figure 12.

www.onsemi.com

19

Page 20

NCP81246

Programming TSENSE

Temperature sense inputs are provided. A precision

current is sourced out the output of the TSENSE pin to

generate a voltage on the temperature sense network.

The voltage on the temperature sense input is sampled by the

C

FILTER

0.1 mF

internal A/D converter. A 100k NTC similar to the VISHAY

ERT−J1VS104JA should be used. See the specification

table for the thermal sensing voltage thresholds and source

current.

TSENSE

R

COMP1

0.0 W

AGND AGND

Figure 13.

Precision Oscillator

A programmable precision oscillator is provided.

The clock oscillator serves as the master clock to the ramp

generator circuit. This oscillator is programmed during

start-up by a resistor to ground on the LG1/ROSC pin.

The oscillator generates triangle ramps that are 0.5~2.5 V

in amplitude depending on the VRMP pin voltage to provide

input voltage feed forward compensation.

Programming the Ramp Feed-Forward Circuit

The ramp generator circuit provides the ramp used by the

PWM comparators. The ramp generator provides voltage

R

COMP2

8.2 kW

R

TNC

100 kW

feed-forward control by varying the ramp magnitude with

respect to the VRMP pin voltage. The VRMP pin also has

a UVLO function. The VRMP UVLO is only active after the

controller is enabled. The VRMP pin is high impedance

input when the controller is disabled.

The PWM ramp is changed according to the following,

V

RAMPpk+pk

+ 0.1 @ V

pp

VRMP

(eq. 12)

V

IN

Comp_IL

Duty

Figure 14.

Two-Phase Rail PWM Comparators

The non-inverting input of the comparator for each phase

is connected to the summed output of the error amplifier

(COMP) and each phase current (I

⋅ DCR ⋅ Phase Balance

L

www.onsemi.com

V

RAMP_PP

Gain Factor). The inverting input is connected to the

oscillator ramp voltage with a 1.3 V offset. The operating

input voltage range of the comparators is from 0 V to 3.0 V

and the output of the comparator generates the PWM output.

20

Page 21

NCP81246

During steady state operation, the duty cycle is centered

on the valley of the sawtooth ramp waveform. The steady

state duty cycle is still calculated by approximately

V

OUT/VIN

Two-Phase Rail Phase Detection Sequence

.

During start-up, the number of operational phases and

their phase relationship is determined by the internal

circuitry monitoring the CSP outputs. Normally, this rail

operates as a two-phase VCC_Rail2 PWM controller. If

CSP2_2ph is pulled high to VCC, the two-phase rail

operates as a single-phase rail.

Disable Single-Phase Rail

If the NCP81246 is to provide fewer than three rails, one

or both of the single-phase rails can be disabled by pulling

up their respective CSP pin. The main rail cannot be

disabled.

Single-Phase Rails

The architecture of the two single-phase rails makes use

of a digitally enhanced, high performance, current mode

RPM control method that provides excellent transient

response while minimizing transient aliasing. The average

operating frequency is digitally stabilized to remove

frequency drift under all continuous mode operating

conditions. At light load the single-phase rails automatically

transition into DCM operation to save power.

Single-Phase Rail Remote Sense Error Amplifier

A high performance, high input impedance, true

differential transconductance amplifier is provided to

accurately sense the regulator output voltage and provide

high bandwidth transient performance. The VSP and VSN

inputs should be connected to the regulator’s output voltage

sense points through filter networks describe in the Droop

Compensation and DAC Feedforward Compensation

sections. The remote sense error amplifier outputs a current

proportional to the difference between the output voltage

and the DAC voltage:

I

COMP

+ gm @ǒV

DAC

ǒ

*

V

VSP

* V

VSN

Ǔ

Ǔ

(eq. 13)

This current is applied to a standard Type II compensation

network.

Single-Phase Rail Voltage Compensation

The Remote Sense Amplifier outputs a current that is

applied to a Type II compensation network formed by

external tuning components CLF, RZ and CHF.

DAC

gm

Figure 15.

Single-Phase Rail – Differential Current Feedback

Amplifier

Each single-phase controller has a low offset, differential

amplifier to sense output inductor current. An external

lowpass filter can be used to superimpose a reconstruction

of the AC inductor current onto the DC current signal sensed

across the inductor. The lowpass filter time constant should

match the inductor L/DCR time constant by setting the filter

pole frequency equal to the zero of the output inductor. This

makes the filter AC output mimic the product of AC inductor

current and DCR, with the same gain as the filter DC output.

It is best to perform fine tuning of the filter pole during

transient testing.

+

VSN

+

S

VSP

−

F

+

P

2 @ p @

VSN

VSP

COMP

R

ǒ

R

F

Z

PHSP

PHSP

+

@

CHF

DCR @ 25 C

2 @ p @ L

1

ǒ

RTH)R

)RTH)R

Phase

CSSP

CSSP

R

CLF

°

Z

Ǔ

Ǔ

@ C

CSSP

Forming the lowpass filter with an NTC thermistor (RTH)

placed near the output inductor, compensates both the DC

gain and the filter time constant for the inductor DCR change

with temperature. The values of R

PHSP

and R

CSSP

(eq. 14)

(eq. 15)

are set

www.onsemi.com

21

Page 22

NCP81246

based on the effect of temperature on both the thermistor and

inductor. The CSP and CSN pins are high impedance inputs,

but it is recommended that the lowpass filter resistance not

exceed 10kW in order to avoid offset due to leakage current.

It is also recommended that the voltage sense element

(inductor DCR) be no less than 0.5 mW for sufficient current

accuracy. Recommended values for the external filter

components are:

R

R

R

= 7.68 kW

PHSP

= 14.3 kW

CSSP

= 100 kW, Beta = 4300

TH

C

CSSP

L

+

R

PHSP

R

PHSP

PHASE

ǒ

@

RTH)R

)RTH)R

CSSP

CSSP

Ǔ

@ DCR

(eq. 16)

Using 2 parallel capacitors in the lowpass filter allows fine

tuning of the pole frequency using commonly available

capacitor values.

+

A

= 1

V

−

COMP

PWM

Generator

CURR

The DC gain equation for the current sense amplifier

output is:

V

CURR

+

R

PHSP

CSSP

) RTH) R

CSSP

@ I

OUT

@ DCR

(eq. 17)

R

) R

TH

To improve the noise immunity of the current feedback

amplifier, i t i s recommended to use an RC low pass filter (R

and CF in Figure 16) on the CSN pin of the amplifier placed

as close as possible to the controller. The bandwidth of this

filter shou l d b e ~ 5 M H z with R

< 20 W. To mitigate against

F

noise due to excessive ringing that may be present on the

inductor side of R

, it is recommended to use a capacitor

PHSP

in parallel with the inductor. The value of the capacitor

should be chosen such that:

R

R

R

PHSP

CSSP

t

TH

1

To Inductor

(eq. 18)

Ǹ

CSP

CSN

L C

C

F

tt

2 p Ringing Frequency

C

CSSP

R

F

F

RAMP PWM

Figure 16.

The amplifier output signal is combined with the COMP

and RAMP signals at the PWM comparator inputs to

produce the Ramp Pulse Modulation (RPM) PWM signal.

Single-Phase Rail – Loadline Programming (DROOP)

An output loadline is a power supply characteristic

wherein the regulated (DC) output voltage decreases by

a voltage V

, proportional to load current. This

DROOP

characteristic can reduce the output capacitance required to

+

S

gm

A

V

= 1

VSN

+

VSP

−

+

Current

−

Sense AMP

VSN

VSP

CSP

CSN

maintain output voltage within limits during load transients

faster than those to which the regulation loop can respond.

In the NCP81246, a loadline is produced by adding a signal

proportional to output load current (V

DROOP

) to the output

voltage feedback signal – thereby satisfying the voltage

regulator at an output voltage reduced proportional to load

current. V

is developed across a resistance between

DROOP

the VSP pin and the output voltage sense point.

C

SNSSP

R

DRPSP

R

DRPSPCDRPSP

C

CSSP

To VCC_SENSE

R

PHSP

R

CSSP

t

R

TH

To Inductor

Figure 17.

www.onsemi.com

22

Page 23

NCP81246

DROOP

+ R

V

The loadline is programmed by choosing R

that the ratio of voltage produced across R

current is equal to the desired loadline.

R

R

DRPSP

Loadline

+

gm @ DCR

@

PHSP

RTH) R

) RTH) R

CSSP

CSSP

Single-Phase Rail − Programming the DAC

Feed-Forward Filter

The DAC feed-forward implementation for the

single-phase rail is the same as for the 2-phase rail.

The NCP81246 outputs a pulse of current from the VSN pin

DRPSP

DRPSP

@ gm @

DRPSP

to output

(eq. 20)

such

R

PHSP

R

) R

TH

CSSP

) RTH) R

CSSP

@ I

OUT

@ DCR

upon each increment of the internal DAC following a DVID

UP command. A parallel RC network inserted into the path

from VSN to the output voltage return sense point,

VSS_SENSE, causes these current pulses to temporarily

decrease the voltage between VSP and VSN. This causes the

output voltage during DVID to be regulated slightly higher,

in order to compensate for the response of the Droop

function to the inductor current flowing into the charging

output capacitors. R

feed-forward and C

FFSP

sets the gain of the DAC

FFSP

provides the time constant to cancel

the time constant of the system per the following equations.

is the total output capacitance of the system.

C

OUT

(eq. 19)

DAC Feed-Forward Current

DAC

+

S

From Intel

proprietary

interface

Interface

DAC

Feed-Forward

DAC

gm

Figure 18.

R

FFSP

Loadline @ C

+

1.35 @ 10

*9

OUT

(W)

Single-Phase Rail – Programming the Current Limit

The current limit threshold is programmed with a resistor

(R

) from the ILIM pin to ground. The current limit

ILIMSP

latches the single-phase rail off immediately if the ILIM pin

voltage exceeds the ILIM Threshold. Set the value of the

+

V

= 1

Current

−

Sense AMP

A

+

−

CSP

CSN

C

VSN

VSP

C

FFSP

VSN

VSP

+

R

200

FFSP

(nF)

R

FFSP

FFSP

To VCC_SENSE

C

SNSSP

current limit resistor based on the equation shown below.

A capacitor must be placed in parallel with the

programming resistor to avoid false trips due to the effect of

the output ripple current.

R

PHSP

R

C

CSSP

CSSP

t

R

TH

To Inductor

(eq. 21)

gm

OCP

Over-Current

Programming

Over-Current

Comparators

OCP REF

R

ILIMSP

ILIM

R

ILIMSP

Figure 19.

+

gm @

R

R

PHSP

)R

TH

CSSP

)RTH)R

1.3 V

CSSP

@ I

OUT

LIMIT

(eq. 22)

@ DCR

www.onsemi.com

23

Page 24

NCP81246

Single-Phase Rail – Programming IOUT

The IOUT pin sources a current in proportion to the

ILIMIT sink current. The voltage on the IOUT pin is

monitored by the internal A/D converter and should be

+

V

= 1

R

IOUTSP

−

Current

Sense AMP

Current

Monitor

+

gm @

Figure 20.

R

R

PHSP

A

gm

IOUT

CSP

CSN

IOUT

)R

TH

)RTH)R

scaled with an external resistor to ground such that a load

equal to ICCMAX generates a 2 V signal on IOUT.

A pull-up resistor from 5 V VCC can be used to offset the

IOUT signal positive if needed.

R

PHSP

R

C

2V

CSSP

CSSP

R

IOUTSP

@ IccMax @ DCR

CSSP

CSSP

t

R

TH

To Inductor

(eq. 23)

Single-Phase Rail PWM Comparators

The non-inverting input of each comparator (one for each

phase) is connected to the summation of the output of the

error amplifier (COMP) and each phase current

(IL⋅ DCR ⋅ Phase Current Gain Factor). The inverting input

is connected to the triangle ramp voltage of that phase.

The output of the comparator generates the PWM output.

A PWM pulse starts when the error amp signal (COMP

voltage) rises above the trigger threshold plus gained-up

inductor current, and stops when the artificial ramp plus

gained-up inductor current crosses the COMP voltage. Both

edges of the PWM signals are modulated. During a transient

event, the duty cycle can increase rapidly as the COMP

voltage increases with respect to the ramps, to provide

a highly linear and proportional response to the step load.

www.onsemi.com

24

Page 25

NCP81246

PROTECTION FEATURES

Under Voltage Lockouts

There are several under voltage monitors in the system.

Hysteresis is incorporated within the comparators.

The NCP81246 monitors the 5 V VCC supply as well as the

VRMP pin. The gate drivers monitor both the gate driver

VCC and the BST voltage. When the voltage on the gate

driver is insufficient it will pull DRON low and prevents the

controller from being enabled. The gate driver will hold

DRON low for a minimum period of time to allow the

controller to hold off it’s start-up sequence. In this case the

PWM is set to the MID state to begin soft start.

DAC

Figure 21. Gate Driver UVLO Restart

Soft Start

Soft start is implemented internally. A digital counter

steps the DAC up from zero to the target voltage based on the

predetermined SetVID_SLOW rate in the spec table.

The PWM signal will start out open with a test current to

collect data on Intel proprietary interface address and

V

. After the configuration data is collected, if the

BOOT

PWM Driver Disabled

Internal Test

Current Applied

MID State

until First PWM Pulse

or DAC Reaches Target

If DRON is Pulled Low

the Controller will Hold

Off its Start-Up

Gate Driver Pulls DRON Low during

Driver UVLO and Calibration

controller is enabled, the internal and external PWMs will be

set to 2.0 V MID state to indicate that the drivers should be

in diode mode. DRON will then be asserted. As the DAC

ramps the PWM outputs will begin to fire. Each phase will

move out of the MID state when the first PWM pulse is

produced. When a controller is disabled the PWM signal

will return to the MID state.

PWM Returns to MID State

when Controller is Disabled

PWMx

DRON

VCC

Figure 22. Soft Start

www.onsemi.com

25

Page 26

NCP81246

Over Current Latch-Off Protection

Each of the NCP81246 rails compares a programmable

current-limit set point to the voltage from the output of its

current-summing amplifier. The level of current limit is set

with the resistor from the ILIM pin to CSCOMP (two-phase)

or to ground (single-phase rails).

Two-Phase Rail Over Current

The current through the external resistor connected

between ILIM and CSCOMP is then compared to the

internal current-limit threshold. If the current generated

through this resistor into the ILIM pin (I

) exceeds the

LIM

internal current-limit threshold, an internal latch-off counter

starts, and the controller shuts down if the fault is not

removed after 50 ms (immediately shut down for 150% of

current-limit threshold) after which the outputs will remain

disabled until the V

voltage or EN is toggled.

CC

The voltage swing of CSCOMP cannot go below ground.

This limits the voltage drop across the DCR through the

current balance circuitry. An inherent per-phase current

limit protects individual phases if one or more phases stop

functioning because of a faulty component.

The over-current limit is programmed by a resistor on the

ILIM pin. The resistor value can be calculated by the

following equations.

Equation related to the NCP81246:

R

@ DCR @

I

LIM

+

R

ILIM

CS

R

PH

I

CL

(eq. 24)

Where ICL =10 mA

CSSUM

CSREF

R

CS

−

+

ILIM

R

LIM

CSCOMP

R

PH

R

PH

Figure 23.

Under Voltage Monitor

The output voltage is monitored at the output of the

differential amplifier for UVLO. If the output falls more

than 300 mV below the DAC−DROOP voltage the UVLO

comparator will trip sending the VR_RDY signal low.

Over Voltage Protection

The output voltage is also monitored at the output of the

differential amplifier for OVP. During normal operation, if

the output voltage exceeds the DAC voltage by 400 mV, th e

VR_RDY flag goes low, and the output voltage will be

ramped down to 0 V. At the same time, the high side gate

drivers are all t u r n e d o ff and the low side gate drivers are all

turned on. The part will stay in this mode until the V

CC

voltage or EN is toggled.

UVLO Rising

DRON

2.0 V

OVP Threshold

DAC

V

CC

DAC + ~400 mV

Figure 24. OVP Threshold Behavior

www.onsemi.com

26

Page 27

NCP81246

OVP Threshold

DRON

PWM

V

OUT

DAC

OVP Threshold

2.0 V

Figure 25. OVP Behavior at Start-Up

DAC

VSP_VSN

OVP

Triggered

Latch Off

PWM

Figure 26. OVP during Normal Operation Mode

During start-up, the OVP threshold is set to 2.0 V. This allows the controller to start up without false triggering the OVP.

Intel is a registered trademark of Intel Corporation in the U.S. and/or other countries.

www.onsemi.com

27

Page 28

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

521

SCALE 2:1

40

(A3)

A1

27

A B

E

K

DETAIL A

52X

L

b

52X

0.05 C

52X

0.63

A

LOCATION

NOTE 4

DETAIL C

D

PIN ONE

0.10 C

TOP VIEW

C

0.10

0.10 C

DETAIL B

0.08 C

SIDE VIEW

D2

14

E2

1

52

e

BOTTOM VIEW

SOLDERING FOOTPRINT*

6.40

4.80

QFN52 6x6, 0.4P

CASE 485BE

L1

ALTERNATE TERMINAL

SEATING

C

PLANE

A0.07 B

C

NOTE 3

ISSUE B

L

DETAIL A

CONSTRUCTIONS

MOLD CMPDEXPOSED Cu

DETAIL B

ALTERNATE

CONSTRUCTION

L2

DETAIL C

8 PLACES

DATE 23 JUN 2010

NOTES:

1. DIMENSIONING AND TOLERANCING PER

L

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSIONS: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.30mm FROM TERMINAL TIP

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

MILLIMETERS

DIM MIN MAX

A 0.80 1.00

A1 0.00 0.05

A3 0.20 REF

b 0.15 0.25

D 6.00 BSC

D2 4.60 4.80

E 6.00 BSC

e 0.40 BSC

K 0.30 REF

L 0.25 0.45

L1 0.00 0.15

L2 0.15 REF

4.80E2 4.60

GENERIC

MARKING DIAGRAM*

L2

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

XXXXXXXXX

XXXXXXXXX

AWLYYWWG

XXX = Specific Device Code

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

4.80

PKG

OUTLINE

0.40

PITCH

0.25

DIMENSIONS: MILLIMETERS

52X

6.40

DETAIL D

0.11

DETAIL D

8 PLACES

0.49

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON47515E

QFN52, 6x6, 0.4MM PITCH

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 29

onsemi, , and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

Loading...

Loading...